Page 1

KD2 & KD20 Disc Coupling

Installation and Alignment

Instructions

FORM 15-111

APRIL, 2002

KOP-FLEX, INC., P.O. BOX 1696, BALTIMORE MARYLAND 21203, 410-768-2000

KOP-FLEX CANADA, LTD., 19 METEOR DRIVE, REXDALE, ONTARIO, CANADA M9W-1A3, 416-675-7144

!

WARNING

High voltage and rotating parts may cause

serious or fatal injury.

Turn off power to install or service.

Operate with guards in place.

Read and follow all instructions in this manual.

Because of the possible danger to person(s) or property from accidents which may result from the improper use or unapproved modification of the

product, this product must be installed, maintained, and operated in accordance with the procedures, standards and engineering information

specified in the product brochures and illustrations. To assure safe operation, this product should be inspected in accordance with the instructions

described in this form. Proper guards and other suitable safety devices or procedures as may be desirable, or as may be specified in safety codes,

should be installed by the user. Guards and other safety equipment are not provided, nor are they the responsibility of Emerson Power Transmission.

1.0 General Instructions

Prior to installation, inspect the coupling for any signs of damage that may

have occured during shipment. Check that all parts are on hand and are as

ordered.

ONLY BOLTS AND NUTS SUPPLIED BY

KOP-FLEX ARE TO BE USED.

Components should be cradled or supported during handling to avoid damage and should be wrapped for protection. Flanges and pilot surfaces should

be kept free of nicks and burrs.

Read all of the installation instructions and review the procedure before

the actual coupling installation.

2.0 Installation of Coupling Hubs - Keyed Mounting

2.1 Check the hub bore and shaft for nicks and burrs, dress if necessary.

Make sure that the bore and shaft are clean.

2.2 For tapered bores, check the fit of the bore to the shaft.

2.3 Keys must be precisely fitted to the keyways in the shaft and hub.

Each key should have a tight fit on the sides with a slight clearance on

top. To maintain dynamic balance, the keys should fill the keyways

exactly and not be too short or too long.

2.4 Clean the hub bore and shaft. For straight bores, proceed to step 2.6.

For taper bores, mount the hub handtight on the shaft and lightly rap

it with a soft mallet to establish the initial line-to-line fit. This is the

START position. With a depth gauge, measure the amount the hub

overhangs the shaft end and record this value. See Figure 1.

DEPTH GAUGE

Figure 1. Measuring Hub Overhang

2.5 Taper Bores Only: A recommended method to measure the hub advance is to install a split collar on the shaft, away from the hub by the

amount of the specified advance. Use feeler gauges for accurate spacing. See Figure 2. The amount of hub draw is dependent upon the

desired interference and taper angle as specified by the machine manufacturer or as given on the coupling drawing. See Figure 3.

Advance (in.)

2.6 Heat the hub to expand the bore; DO NOT allow the hub temperature

2.7 Place the hub in the proper position on the shaft. Hold the hub in

Figure 2. Using Split Collar to Set Advance

.070

.060

.050

.040

.030

.020

.010

.000

.0000 .0005 .0010 .0015 .0020 .0025 .0030 .0035 .0040

Figure 3. Hub Advance vs. Interference Chart

to exceed 600°F (300°C). DO NOT apply an open flame to any par t

of the coupling, an oven is recommended.

place as it cools. For taper bores, verify the hub advance (see Figures 1 and 2) and install the shaft retaining nut. Remove the split

collar from the shaft

®

Emerson Power Transmission

FEELER GAUGES

SPLIT COLLAR

Diametral Taper Rate

1/2"/ft

Interference (in.)

To avoid the risk of explosion, fire, or damage to

the coupling and equipment, and/or injury to personnel, do not use an open flame or oil bath to

expand the hub. If heat is used at any time for installation, DO NOT allow the hub temperature to

exceed 600°F (300°C).

5/8"/ft

3/4"/ft

1"/ft

1 1/4"/ft

1 1/2"/ft

.

™

Page 2

3.0 Alignment

Note: Exact values and procedures for aligning equipment are normally

specified by the equipment manufacturers. Good initial alignment to

the minimum possible values will promote optimum machinery performance and eliminate potential operating problems. After securely

tightening the foundation bolts, the hub separation and alignment

should be rechecked and adjusted if necessary.

The coupling alignment should be checked periodically. Even

when a coupling is well aligned at installation, subsequent settling of

foundations, shifting of equipment, etc., may cause the alignment to

deteriorate.

Offset and Angular Alignment

3.1 Reverse dial indication or optical methods of alignment (such as laser) are recommended. A cold alignment and a hot check (with corrections if necessary) are required. The hub flange OD can be used to

mount the alignment equipment. The hub flange OD is machined to

be concentric to the coupling bore and can be used as the reference

diameter.

3.2 The maximum recommended operating misalignment is:

0.10 degrees per disc pack

(0.0035 in/in TIR equivalent parallel offset)

Important: Total misalignment is the combination of equipment parallel offset

Note that improving the alignment below these values will promote

optimum machinery performance.

and angular misalignment.

Axial Alignment

3.3 Align the hubs until they are at the correct hub separation. The hub

separation is measured from the two flange faces, not from the pilot

face.

Hub Separation = Center Assembly Length

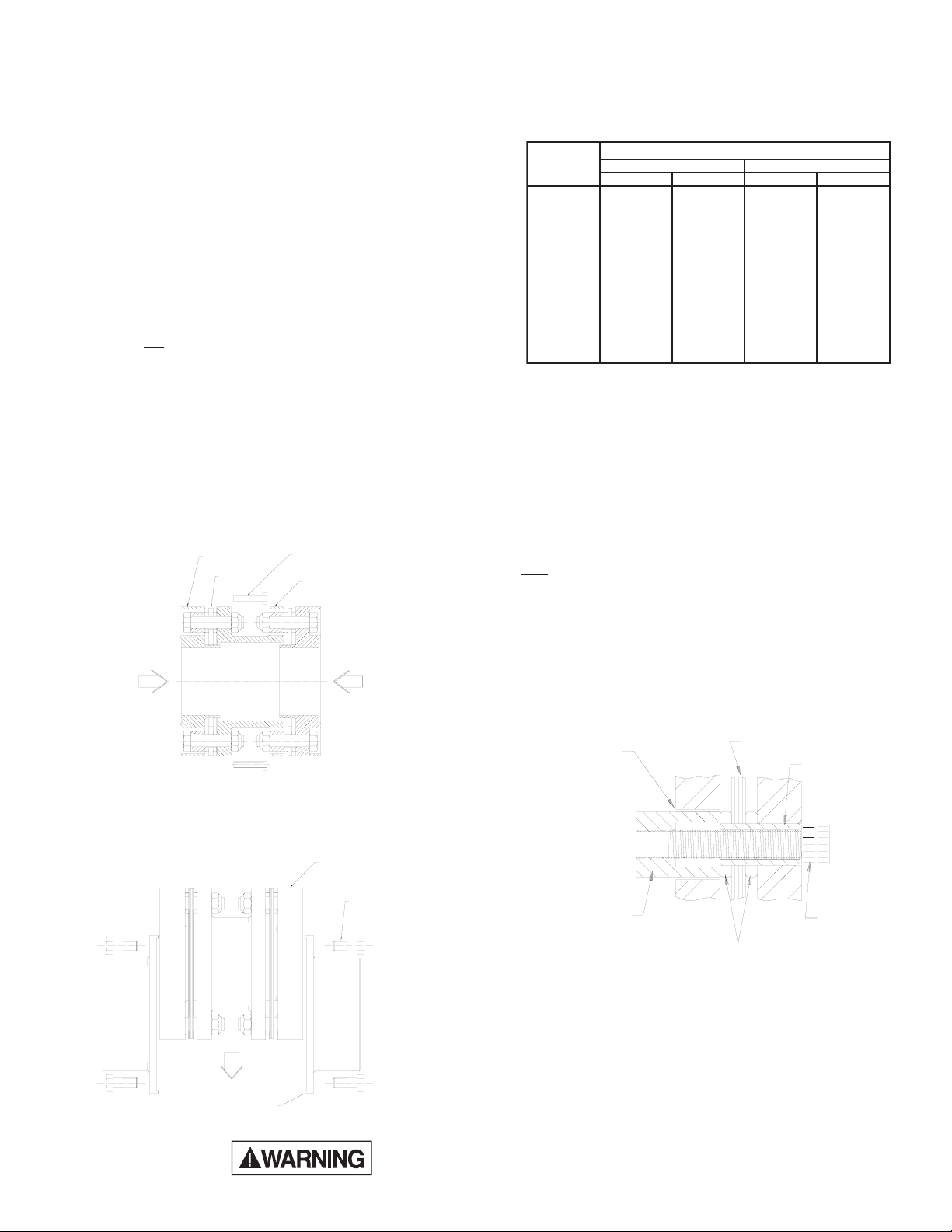

4.0 Final Assembly

(KD2 and KD20)

4.1 After correctly installing both hubs, use the separate collapsing screws

to pull the adapter rings toward the center of the pre-assembled center section. This is made up of the spacer, two disc packs, and two

adapter rings.

ADAPTER RING

DISC PACK

COLLAPSING BOLT

SPACER

4.4 Put the center assembly (spacer and rings) between the rigid hubs,

engage the pilot, and install the hub bolts in one hub flange.

4.5 Release all the collapsing bolts, and install the hub flange bolts on the

second rigid hub flange.

4.6 Torque the hub flange bolts to the value specified in Table 1.

gnilpuoC

eziS

301801---351801----

402,30203040507

452,35203040507

403,30357001011051

453,35357001051002

404,304051002072073

454,354051002072073

405----034085

455----046078

406----046078

507----02110051

508----07410002

509----07410002

2DK02DK

bl-tfm-Nbl-tfm-N

)deliOylthgiL(euqroTgninethgiT

Table 1. Flange Bolt Tightening Torques.

5.0 Removal

5.1 Disassemble the coupling in the reverse order as per the applicable

assembly procedure.

5.2 KEYED HUBS - Install a puller on the hub using the tapped holes

provided in the hub face. Pull the hub off the shaft.

6.0 Disc Pack Replacement

The terminology used to identify parts and the order of assembly may differ

from one coupling style to another. Follow the instructions which match the

coupling style being installed.

KD2 - For KD20 skip to 6.7

6.1 Remove the center assembly in reverse order as per the applicable

assembly procedure. Remove disc pack bolts and nuts.

6.2 Insert the disc pack removal socket into one of the clearance holes in

the spacer flange or ring (Figure 6). Install the removal cap screw and

turn it until it cannot be tightened any more.

Note: The removal socket is supplied as part of the “parts kit”.

Figure 4. Collapsing center section

4.2 For each side of the center section, insert the collapsing bolts through

the spacer clearance holes into tapped holes in the ring (see Figure 4).

4.3 Tighten them evenly and collapse the disc packs equally, only enough

to allow the center assembly to drop into place (see Figure 5).

CENTER ASSEMBLY

HUB BOLTS

O.D. PILOT

Figure 5. Installing center section.

Disconnect all power before adjusting units

CLEARANCE HOLE

REMOVAL SOCKET

DISC PACK

BUSHING

REMOVAL SCREW

WASHER

Figure 6. Bolt Disc Pack to Adapter.

6.3 Remove the tool and repeat step 6.2 on all bushings to free the disc

pack from the ring and spacer.

The Emerson logo is a trademark and a service mark of Emerson Electric Co.

© Emerson Power Transmission Manufacturing, L. P. or affiliates 2002. All Rights Reserved.

Page 3

DISC PACK NUT

ADAPTER RING

SPACING WASHER

DISC PACK

DISC PACK BOLT

SPACER

6.4 Line up the bushings of the new disc pack with the reamed holes in

the ring, lightly tap on the bushings to start them into the holes. Insert

3 disc pack bolts and nuts with the

hole, tighten them evenly to pull the bushing into the ring flange (see

Figure 7).

DISK PACK NUT

SPACER

bolt heads in the ring counterbore

DISK PACK

BUSHING

ADAPTER RING

DISK PACK BOLT

Figure 7. Bolt Disc Pack to Adapter Ring.

6.5 Line up the bushings with the spacer reamed holes, lightly tap the

bushings to start them in the holes. Install and tighten 3 disc pack

bolts and nuts

with bolt heads in the ring (see Figure 8).

DISK PACK BOLT

ADAPTER RING

DISC PACK

BUSHING

SPACER

KD20

6.7 Remove the center assembly in reverse order as per the applicable

assembly procedure.

6.8 Unbolt the adapter ring from the disc pack. Unbolt the disc pack from

the spacer.

6.9 Clean and deburr all of the coupling parts.

6.10 Line up the new disc pack between the adapter ring and the spacer.

Insert the disc pack bolt into the counterbored hole in the adapter

ring, and through the disc pack.

6.11 Make sure that the spacer is properly indexed for the large clearance holes to receive the bolt ends. Place the spacing washer and

disc pack nut on the bolt. Repeat for the other bolts (see Figure 9).

Figure 9. Bolt Disc Pack to Adapter Ring.

6.12 Place a spacing washer over a disc pack bolt. Insert the bolt through

the large hole in the adapter ring and through the disc pack bushing

and reamed hole in the spacer. Place the disc pack nut on the bolt.

Repeat for the other bolts (see Figure 10).

ADAPTER RING

SPACING WASHER

DISC PACK

DISC PACK NUT

DISC PACK NUT

Figure 8. Bolt Disc Pack to Spacer.

6.6 Torque all disc pack fasteners evenly and in successive steps to the

value specified in Table 2.

)deliOylthgiL(euqroTgninethgiT

gnilpuoC

eziS

301801---3510304----

402,30205075557

452,352570015557

403,303021061511061

453,353091062571042

404,304092093082083

454,354023034082083

405----024075

455----0370001

406----02010041

507----00810542

508----00320013

509----00320013

2DK02DK

bl-tfm-Nbl-tfm-N

Table 2. Disc Pack Bolt Tightening Torques.

SPACER

DISC PACK BOLT

Figure 10. Bolt Disc Pack to Spacer.

6.13 Torque all disc pack fasteners evenly in successive steps to the

value specified in Table 2.

7.0 Dynamic Balance

Balanced parts will be marked with the letter “B.” The couplings may be

component balanced (hubs and center assembly) with no match marks, or

assembly balanced as a complete coupling with match marks of the hub to

ring connections. If the coupling is supplied with match marks, it must be

assembled with the match marks in line.

Note: For balanced couplings, disconnecting the disc packs from the cen-

ter assemblies disturbs the balance of the coupling. When disc packs

are replaced in balanced couplings, the couplings must be balanced

before placing back in operation.

8.0 Finish Boring and Keyways

Coupling hubs are often furnished with a “rough stock bore.” This rough

bore is not necessarily concentric to other hub diameters. To prepare for

boring, set-up and indicate the hub as shown in Figure 11.

Disconnect all power before adjusting units

© Emerson Power Transmission Manufacturing, L. P. or affiliates 2002. All Rights Reserved.

Page 4

9.0 Bore Sizing and Recommended Fit

The finish bore size should be based on the actual measured shaft dimension, regardless of whether straight or taper shaft. For keyed shafts, a light

interference fit based on a nominal interference rate of 0.0005 inch per inch

of shaft diameter is suggested, or refer to published AGMA standards. Do

not exceed an interference fit of 0.001 inch/inch of shaft diameter. If other

than a light interference fit is desired, consult the published AGMA boring

and keyway standards.

For Straight Bores, the rigid hub diameter should be chucked in the boring lathe and dial indicated as shown of Figure 11. For Taper Bores, chuck

and indicate as shown on Figure 11. Machine the counterbore and SKIM A

REFERENCE DIAMETER on the hub body. Then chuck the hub as shown

on Figure 12, and indicate using the reference diameter before final boring.

Run-outs should be as near zero as possible. It is essential that the finished bore be concentric with the two indicating surfaces.

Figure 11

5 YEAR WARRANTY REGISTRATION CARD

10.0 Keyways

Keyways should be cut to give a tight fit on the sides and slight clearance

over the key. Keyways should not have sharp corners. Refer to published

AGMA standards for specific dimensioning of coupling bores and keyways.

11.0 General Recommendations

11.1 KOP-FLEX KD2 and KD20 disc couplings are designed to operate for

extended periods without the need for lubrication or maintenance. Visual

inspection of the disc packs is sufficient to assess the operational condition

of the coupling.

11.2 All machinery should be monitored to detect unusual or changing vi-

bration levels. KOP-FLEX KD2 and KD20 couplings, under normal conditions, have no wearing parts and will retain their original balance quality.

Any change in vibration levels should be investigated and remedial action

should be taken immediately.

REFERENCE

DIAMETER

Figure 12

Name (Last, First)

Title:

Company Name:

Location:

Phone:

APPLICATION DATA

Coupling Type:

HP:

RPM:

Application:

Shaft Size(s): Driving: Driven:

Distance Between Shaft Ends

Plant Identification Pump # Motor #

Send Warranty Card To: Attention Marketing Department

KOP-FLEX, Inc.

Mail to: P. O. Box 1696 or Fax to: 410-787-8424

Baltimore, MD 21203-1696

Important Safety Instructions

Before start-up . . . for reasons of safety and to extend shaft coupling life,

follow these requirements.

1. Coupling guards protect personnel.

ALL COUPLINGS MUST BE COVERED WITH A GUARD AS PER OSHA REQUIREMENTS.

2. Recheck alignment after all foundation bolts and mechanical connections are tightened.

3. Make sure all fasteners are properly installed and tightened.

4. Take the time to double check your work.

5. Only authorized KOP-FLEX replacement parts are to be used.

6. Call KOP-FLEX for any clarification or questions.

© Emerson Power Transmission Manufacturing, L. P. or affiliates 2002. All Rights Reserved.

®

Emerson Power Transmission

P. O. Box 1696

Baltimore, MD 21203-1696

www.emerson-ept.com

Loading...

Loading...