Emerson K-BALL F110, K-BALL F120, K-BALL F130, K-BALL F133, K-BALL F138 Operating And Safety Instructions Manual

...Page 1

K-BALL PED - BALL VALVES

OPERATING AND SAFETY INSTRUCTIONS

Before installation these instructions must be fully read and understood

CONTENTS

1 - Protection / Storing

2 - Installation / Operation

3 - Maintenance

This sheet applies to the following products:

F110-F120-F130-F133-F138-F150-F170F180-F190.

These products have been designed,

manufactured and tested under the supervision

of a certified Quality Assurance system in

accordance with Module H (categories I, II and

III) of Annex 3 of European Directive 97/23/CE

concerning pressure equipment.

The products are designed to guarantee your

safety during the installation, operation and

maintenance under the condition of applying

the following recommendations, of respecting

the conditions of use defined in the technical

data sheets of the products and not being in an

exceptional situation. The products covered by

this document are standard valves in manual

version or actuated version. For the other

products, a complementary instruction sheet

will be attached if required.

It is imperative that these instruction sheets

accompany the products to their final

destination. The control of the distribution of

these documents, translated into the language

(*) where the end-user is located, is under your

responsibility.

(*) This only applies to European countries.

1 - PROTECTION / STORING

Protection

Except for particular customer specification at

the time in the order, the valves are delivered

in conformity with Emerson packaging

procedures. The package ensures the

protection of the product against the shocks

in the conditions of road and railway transport

and of storage in clean and dry premises.

The protection caps mounted on the valves,

in order to protect the seats and discs from

ulterior damages, must not be removed

before the moment of the installation of the

valve on the line. For storing or transporting

in conditions different from those mentioned

above, it belongs to the customer to condition

the product in an adapted way to protect it or to

specify it in the order.

Storing

The storing must be done separate from the

ground in a dry location, and indoor.

In the case the valves are delivered with

watertight package with a desiccative product

(provided for a long storing time before

installation), the desiccative product bags must

be replaced for any storing period exceeding 6

months. The package must be kept watertight

again.

Emerson.com/FinalControl VCOSI-01684-EN 16/07

© 2017 Emerson. All Rights Reserved.

Page 2

K-BALL PED - BALL VALVES

OPERATING AND SAFETY INSTRUCTIONS

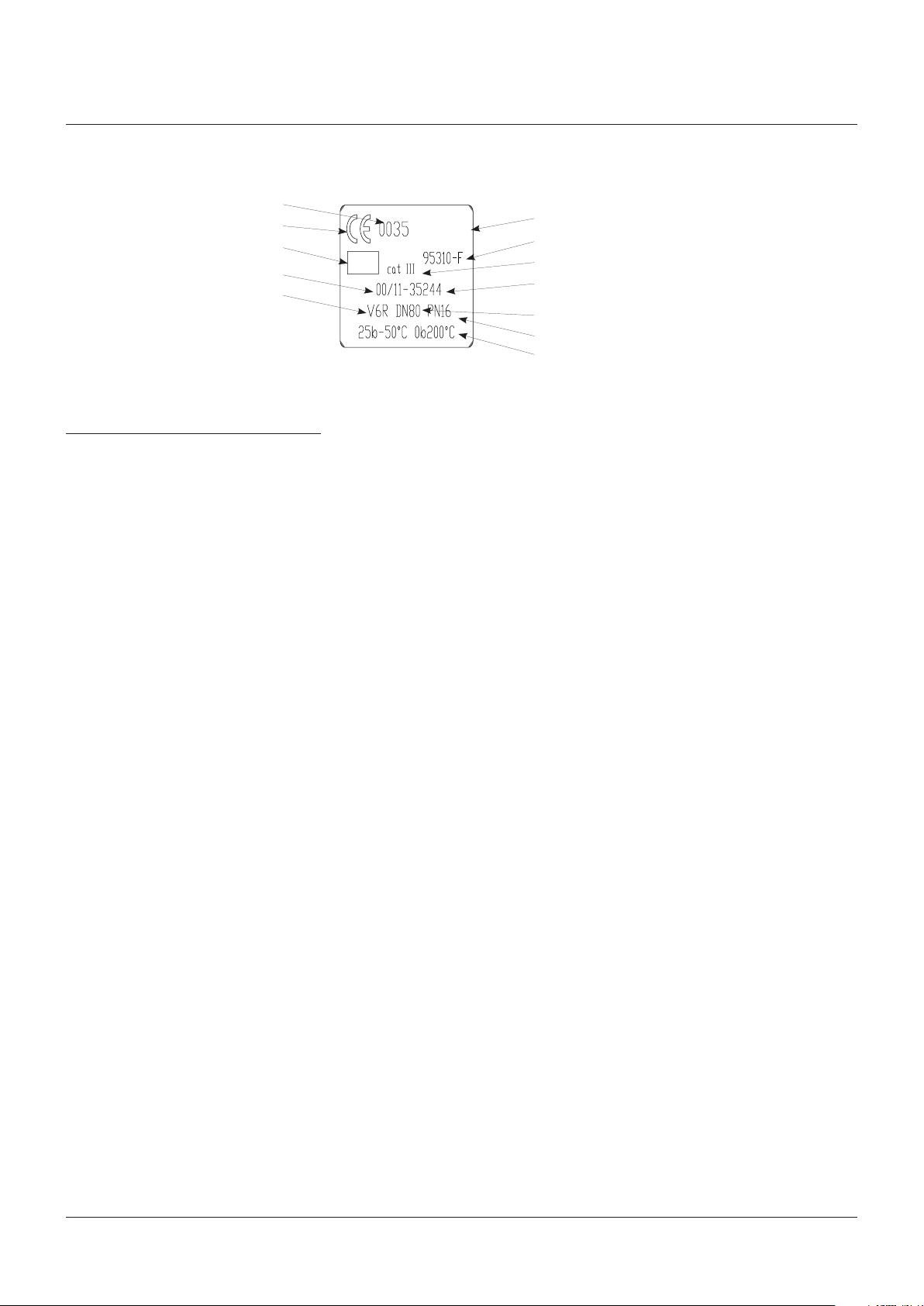

EXPLANATION OF THE MARKINGS ON THE VALVE IDENTIFICATION PLATE.

Number of the notified body

EC mark

Valve type

Date of manufacture: year/month

Valve code

2 - INSTALLATION / OPERATION

WARNING

For safety reasons, it is important to respect

the following precautions before beginning the

installation of the valve:

1. Installation and maintenance of valves and

actuators must be carried out by personnel

trained in all the appropriate mechanical,

electrical and pneumatic aspects required by

such an operation.

2. Any person intervening on the installation of

the valve, even for a simple adjustment must

use equipment and clothes adapted in function

of the process on which the valve is installed.

3. The installer must check that the pressure

and temperature limits of the valve, indicated

on the identification plate (see use curve on

the technical sheet) are appropriate to the

operation conditions of the installation.

4. If the valve is to be used in a “fire-safe”

situation, the user must ensure that the

valve has been designed for such a use (see

technical documents).

5. The installer must ensure that the materials

from which the valve is made are suitable

for the operation for which they are to be

used (see the corrosion/fluid/concentration/

temperature combination).

6. The line must be depressurized before any

intervention. The line must be drained, rinsed

(and decontaminated in the case of noxious

fluid) before installation of the valve.

7. If the user should carry out any alterations to

our product, he will be responsible for ensuring

that those changes do not compromise the

safety or the operation of the valve.

8. Physical access to the closure (disc, ball,

plug, etc.) is not authorized unless it is

absolutely certain that this cannot be operated

unintentionally.

9. The valves under pressure can be subject to

a cavity overpressure at the body level when

the valve is in closed position. This is due to

some fluids, which can be subject to rapidly

provoking overpressure. In this case, the

Manufacturer’s brand

Manufacturer’s postal code

xxx

Valve category

Manufacturing

identification number

Valve diameter

Nominal pressure

Pressure limitations /

max./min. temperature

installation necessitates an adapted means

to relieve the excessive inner pressures. For

more information, contact Emerson (Emerson.

com/FinalControl).

Installation

1. Ensure that connecting ends in the line are

clean, undamaged and correctly lined up

(axially and radially).

2. Remove the protective covers from the valve

ends.

3. The valve can be gripped by the handle,

provided that it is correctly fitted along the

operating axis.

4. An arrow on the body indicates the direction

of flow for valves that are designed to be

used only one-way.

5. Place the valve between the connecting

parts in such a way that it can be easily

accessed for operation before assembly.

6. Where there are flange connections, nuts

and bolts must be tightened as specified

and according to the appropriate standards.

7. For the welded assemblies, the piping

must be cleaned and freed of all slurries

before the valve is operated (risk of abrasive

particles, sand, welding particles, etc. in the

pipings that could damage the seats and

ball disks).

2

Page 3

K-BALL PED - BALL VALVES

OPERATING AND SAFETY INSTRUCTIONS

Operation

All the manually operated valves are closed

by clockwise rotation except if a different

specification is mentioned in the customer

order.

The closed position is indicated either by the

position of the lever, or by an arrow, positioned

at 90° from the axis of the valve and pipeline

bore.

The particular operation conditions (seism,

strong moment of reaction within the

installation, or water hammer superior to 1,5

times the nominal pressure of the valve) must

be the object of a specific prior request to our

engineering department.

3 - MAINTENANCE

Servicing

No servicing is required except from periodical

inspections to ensure proper operation.

Any indication of leak of the packinggland must be immediately repaired by

depressurizing the valve and by gradually and

regularly tightening the gland.

If no further adjustment is possible, or if a leak

at the level of the seat or of the body seal is

detected, the valve will require a full revision.

The dismounting of the valve must be done

after the depressurizing of the line and of

the valve (**) by respecting the maintenance

instructions. Only the original parts must be

used.

(**) Open and then close the valve. Leaving the

valve in closed position, secures the handling

of the valve in the case of possible retentions of

dangerous products within the body.

If the valve is actuated, the user must without

fail disconnect the power source before

dismantling to avoid any possible danger from

the closure moving. Instructions available upon

request.

A maintenance instruction leaflet will be

provided on request.

Spare Parts

The valves are identified by a supplier letter

symbol, a heat number and a material

designation marked on the side of the body and

an identification plate. These elements must

be mentioned for any assistance, for the spare

parts or the repair orders.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

K-Ball is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

3

Loading...

Loading...