Page 1

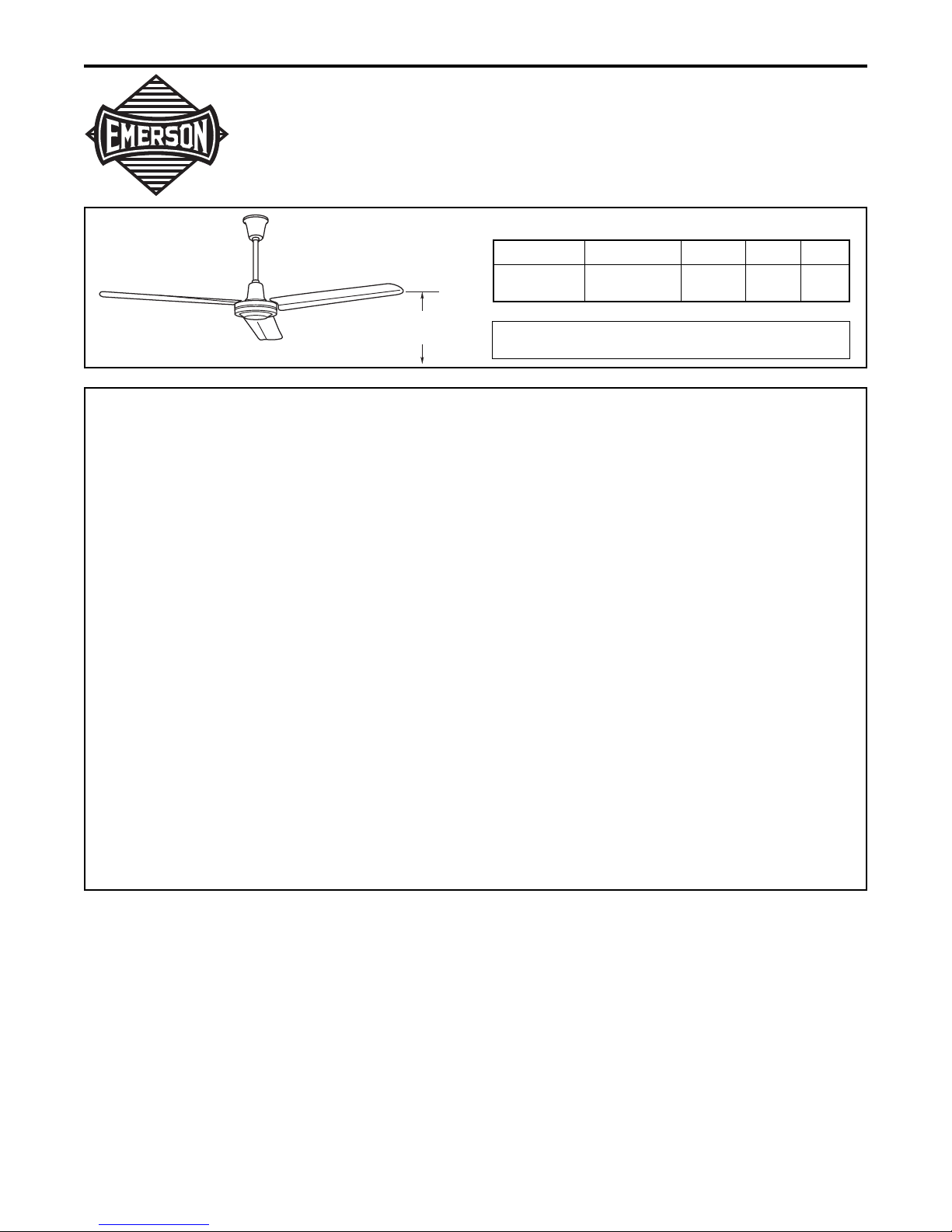

HEAT F AN

®

48" Model Number:

HF948W 0 (White)

1. Unpack the items carefully to avoid damage to any of the

components.

2. Make certain you receive the following parts:

a.Motor subassembly

b.Blades (3 ea.)

c. Upper canopy

d.Lower canopy

e.J-hook bag assembly containing:

1. J-hook (2 ea.) 3. Lock washers (2 ea.)

2. Flat washers (2 ea.) 4. Hex nuts (2 ea.)

f. 24" Hanger pipe assembly

g. 8” Hanger pipe

h.Bag of parts containing:

1.Wire connectors (3 ea.)

2.Cable clamps (2 ea.)

3.M6 x 1/2" Hex head screws (6 ea.)

4.M6 Spring washers (6 ea.)

5.Blade gaskets (3 ea.)

6.Clevis pin

7.Hairpin clip

8.5/16-18 x 1/4” Setscrews (2 ea.)

9.Allen wrench

NOTE: Intermixing blades between fans can cause

excessive wobble. Keep blades in sets of three.

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. READ YOUR OWNER'S MANUAL CAREFULLY AND KEEP IT FOR FUTURE REFERENCE.

2. USE THIS UNIT ONLY IN THE MANNER INTENDED BY THE MANUFACTURER. IF YOU HAVE ANY QUESTIONS,

CONTACT THE MANUFACTURER.

3. BEFORE SERVICING OR CLEANING UNIT, SWITCH POWER OFF AT SERVICE PANEL AND LOCK SERVICE PANEL

DISCONNECTING MEANS TO PREVENT POWER FROM BEING SWITCHED ON ACCIDENTALLY. WHEN THE

SERVICE DISCONNECTING MEANS CANNOT BE LOCKED, SECURELY FASTEN A WARNING DEVICE, SUCH AS A

TAG TO THE SERVICE PANEL.

4. SUITABLE FOR USE WITH SOLID-STATE SPEED CONTROLS.

5. DO NOT BEND THE BLADE BRACKETS WHEN INSTALLING THE BLADES, BALANCING THE BLADES, OR

CLEANING THE FAN. DO NOT INSERT FOREIGN OBJECTS IN BETWEEN THE ROTATING BLADES.

RULES FOR SAFE INSTALLATION

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. BE SURE POWER IS TURNED OFF AT THE SERVICE PANEL BEFORE WIRING.

2. INSTALLATION WORK AND ELECTRICAL WIRING MUST BE DONE BY QUALIFIED PERSON(S) IN ACCORDANCE

WITH ALL APPLICABLE CODES AND STANDARDS, INCLUDING FIRE-RATED CONSTRUCTION.

3. ALL WIRING MUST SATISFY NATIONAL AND LOCAL ELECTRICAL CODES. THE HEAT FAN MUST BE GROUNDED

AS A PRECAUTION AGAINST POSSIBLE ELECTRICAL SHOCK.

4. THE FAN MUST BE MOUNTED WITH THE FAN BLADES AT LEAST 10 FEET FROM THE FLOOR TO PREVENT

ACCIDENTAL CONTACT WITH THE FAN BLADES.

5. SUITABLE FOR USE WITH SOLID-STATE SPEED CONTROLS.

6. ALWAYS PROPERLY CONNECT THE SECONDARY SUPPORT CABLE INCLUDED WITH THIS FAN (FOLLOW

"INSTALLATION" SECTION CAREFULLY).

7. THE SUPPORT BEAM OR JOIST MUST BE SECURE AND CAPABLE OF SUPPORTING AT LEAST 50 POUNDS.

Part No. F40BP71650001 Form No. BP7165-1

Net Weight: 18.0 Lbs.

®

Checking Contents of Package

SPECIFICATIONS

Model No. Power Amps Watts RPM

HF948W 0

60Hz 0.70 85 315

120V

50Hz 0.47 54 270

10' MIN.

TO FLOOR

Page 2

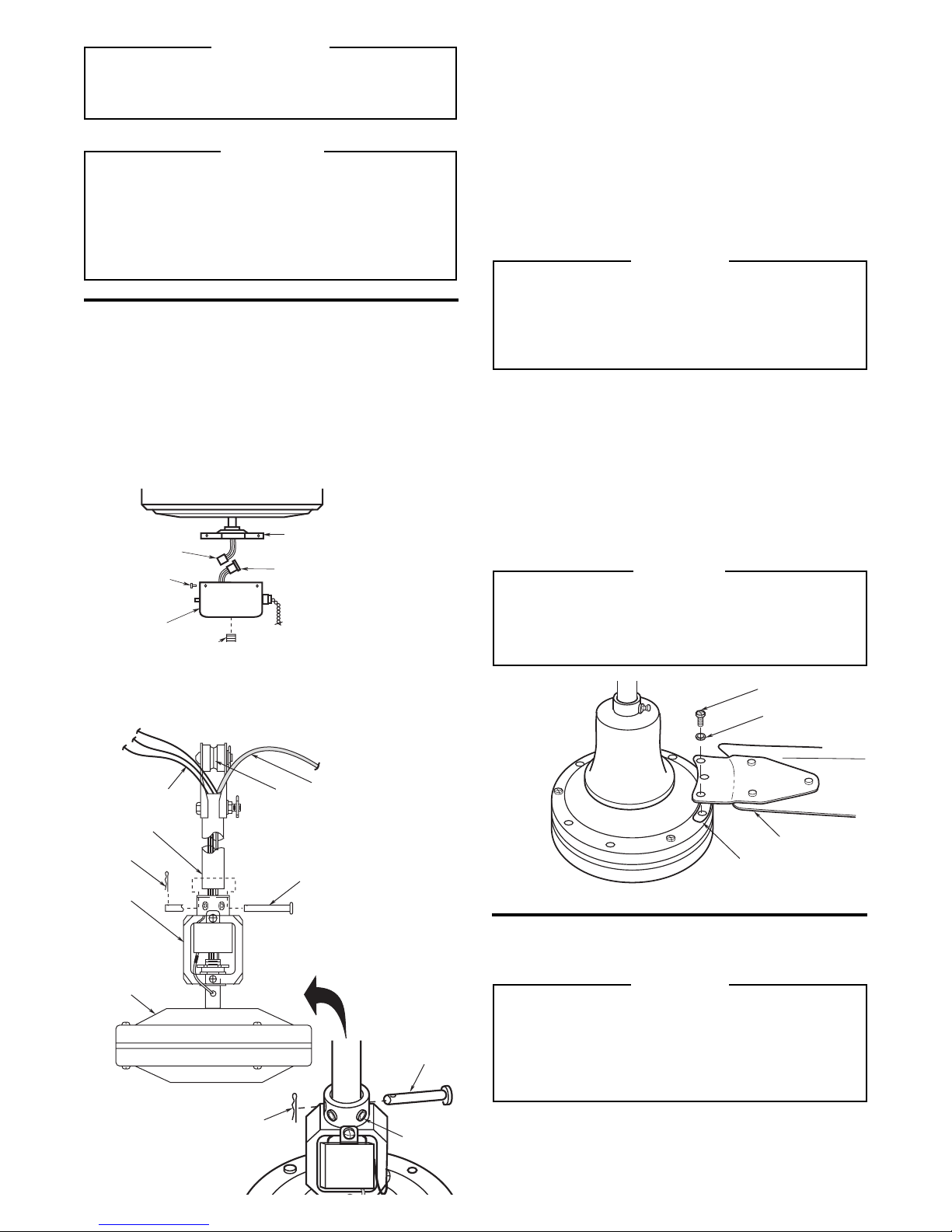

Fan Assembly Instructions

1. Put the upper canopy and lower canopy on the hanger

pipe assembly, facing in the proper direction. (See

Figure 1.)

NOTE: The fan is supplied with a 8” and a 22” hanger

pipe. If you are going to use the 8” pipe, first remove

the hanger assembly from the 22” pipe and install it on

the 8” pipe. Be sure that the nut is securely tightened

and the hairpin clip properly installed.

2. Pass the motor wires and safety cable through the

hanger pipe assembly and seat the hanger pipe in the

motor yoke. (See Figure 2.)

3. Align the clevis pin holes in the hanger pipe with the

holes in the motor yoke. Install the clevis pin and secure

with the hairpin clip (Figure 2). The clevis pin must go

through the holes in the motor yoke and the holes in the

hanger pipe. Push the straight leg of the hairpin clip

through the hole near the end of the clevis pin until the

curved portion of the hairpin clip snaps around the clevis

pin. The hairpin clip must be properly installed to prevent

the clevis pin from working loose. Pull on the rubber

grommet to make sure the clevis pin is properly installed.

4. Install and securely tighten the two 5/16-18 setscrews in

the motor yoke against the hanger pipe using the allen

wrench supplied. (Figure 2.)

5. Slide the lower canopy down the hanger pipe and

securely tighten the set-screw against the hanger pipe.

(See Figure 3.)

CAUTION: Blades come in balanced sets of three. Do

not mix blades if installing more than one fan.

NOTE: Install the blade gaskets between the blades and

the motor. (See Figure 3.)

6. Install the three blades onto the motor using spring

washers, M6 x 1/2" screws and blade gaskets supplied.

Securely tighten the six blade screws.

Hanging Your Heat Fan

Figure 3

Figure 2

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

PERSONAL INJURY:

a. The fan must be hung with at least 10 foot of

clearance from floor to blades. (See Figure 4.)

b. Your support beam or joist must be secure and

capable of withstanding a load of at least 50 pounds.

WARNING

IT IS CRITICAL THAT THE CLEVIS PIN IN THE MOTOR

YOKE IS INSTALLED CORRECTLY AND THE

SETSCREWS ARE SECURELY TIGHTENED. FAILURE

TO INSTALL PIN CORRECTLY OR TO TIGHTEN

SETSCREWS COULD RESULT IN FAN WOBBLE OR

FAN FALLING.

WARNING

TO REDUCE THE RISK OF PERSONAL INJURY, DO NOT

BEND THE BLADE FLANGES WHEN INSTALLING THE

BLADES, BALANCING THE BLADES, OR CLEANING

THE FAN. DO NOT INSERT FOREIGN OBJECTS

BETWEEN ROTATING FAN BLADES.

WARNING

Figure 1

2

CANOPIES NOT

SHOWN FOR

CLARITY

WARNING

DO NOT INSTALL OR USE FAN IF ANY PART IS

DAMAGED OR MISSING. CALL TOLL-FREE:

1-800-654-3545

WARNING

THIS PRODUCT IS DESIGNED TO USE ONLY THOSE

PARTS SUPPLIED WITH THIS PRODUCT AND/OR ANY

ACCESSORIES DESIGNATED SPECIFICALLY FOR USE

WITH THIS PRODUCT BY EMERSON ELECTRIC.

SUBSTITUTION OF PARTS OR ACCESSORIES NOT

DESIGNATED FOR USE WITH THIS PRODUCT BY

EMERSON ELECTRIC COULD RESULT IN PERSONAL

INJURY OR PROPERTY DAMAGE.

(4) MOTOR

CONNECTOR

(3) SCREWS

(1) SWITCH

CUP

(2) COVER PLATE

(5) SWITCH CUP

CONNECTOR

MOTOR WIRE (3)

HANGER PIPE

ASSEMBLY

HAIRPIN

CLIP

MOTOR

YOKE

MOTOR

RUBBER

GROMMET

HAIRPIN

CLIP

SAFETY

CABLE (1)

CLEVIS

PIN

CLEVIS

PIN

5/16-18

SETSCREW (2)

M6 x 1/2" SCREW

(2 PER BLADE)

SPRING WASHER

(2 PER BLADE)

BLADE

BLADE GASKET

Page 3

1. Attach the appropriate J-hook to the building structure

member.

On Steel Beam - Locate and drill a 13/32” diameter hole

in the beam. (See Figure 5.) Use a flat washer, lock

washer and nut on both sides of the beam. Position the

J-hook so that the hook extends 2-1/2” out of outlet box.

Securely tighten both nuts.

CAUTION: If pilot hole is used with the wood thread

hook, the pilot hole should be drilled no larger than the

minor diameter of the screw threads on the hook (1/4”

max.). Do not put a lubricant on the J-hook. At least

1-1/2” of the screw threads should be secured into the

structural wood joist. When the threaded bolt hook is

used, be careful to securely tighten with supplied

lockwashers and nuts.

On Wood Joist - Locate and drill a pilot hole in the wood

joist. Install the screw-type J-hook so that hook extends

2-1/2” below the outlet box. (See Figure 6.)

2. Lift the fan onto the J-hook and position as shown in

Figure 7. Make sure the motor wires and safety cable at

the top of the hanger pipe are positioned behind J-hook

as illustrated in Figure 7.

CAUTION: The safety cable must not be placed between

the rubber roller and the hook, but rather as illustrated

in Figure 7.

3. This fan is equipped with the new required "secondary

support" cable. This cable must be affixed to the building

structure and securely clamped in such a manner to

support the weight of the fan in the event the mounting

hook or other parts fail. After wrapping cable around or to

a structural member that will support 300 pounds, secure

cable with supplied cable clamps as illustrated in Figure 8.

NOTE: Leave approximately 3" but no more than 5" of

slack on this safety cable to allow for possible fan

movement. Do not exceed more than 5" total slack.

CAUTION: It is important to note the proper installation

position of the cable clamps as illustrated in Figure 8.

To obtain maximum holding power, install U-bolt

section of clip on dead or short end of cable and saddle

on long end of cable. Improper installation reduces the

efficiency of the connection by as much as 40 percent.

Wiring Your Heat Fan

NOTE: If you feel that you do not have enough electrical

wiring knowledge or experience, have your fan installed

by a licensed electrician.

1. Connect the green grounding wire from the fan motor to

the green grounding wire from the supply source.

Securely connect wires with wire connectors supplied.

(See Figure 9.)

CAUTION: Use larger U.L. listed wire connectors if

supply source wires are larger than #12 AWG.

2. Securely connect the fan motor white wire to the supply

white (neutral) wire using a wire connector supplied

(Figure 9). Securely connect the fan motor black wire to

the supply black (hot) wire using wire connector

supplied. After connections have been made, turn leads

upward and carefully push leads into the outlet box, with

the white and green leads on one side of the outlet box

and the black leads on the other side of the outlet box.

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

3

STEEL

BEAM

WOOD JOIST

CHECK TO SEE THAT ALL CONNECTIONS ARE TIGHT,

INCLUDING GROUND, AND THAT NO BARE WIRE IS

VISIBLE AT THE WIRE CONNECTORS, EXCEPT FOR

THE GROUND.

CAUTION: DO NOT OPERATE FAN UNTIL BLADES ARE

IN PLACE. NOISE AND FAN DAMAGE COULD RESULT.

WARNING

WARNING

TO AVOID POSSIBLE ELECTRICAL SHOCK, BE SURE

ELECTRICITY IS TURNED OFF AT THE MAIN SERVICE

BOX BEFORE WIRING.

NOTE: IF YOU ARE NOT SURE IF THE OUTLET BOX IS

GROUNDED, CONTACT A LICENSED ELECTRICIAN

FOR ADVICE, AS IT MUST BE GROUNDED FOR SAFE

OPERATION.

READ AND FOLLOW INSTRUCTIONS CAREFULLY.

FAILURE TO COMPLY WITH INSTRUCTIONS COULD

RESULT IN THE RISK OF FIRE, FAN FALLING AND

INJURY TO PERSONS.

WARNING

(1) SWITCH

Figure 4

HOUSING

BLUE WIRE

(6) WIRE CONNECTORS

BLACK WIRE

(2) SWITCH

HOUSING COVER

(4) CENTER

SCREW

(3) SCREWS

WHITE WIRES

OUTLET

BOX

LOCK WASHER

FLAT WASHER

2-1/2"

NUT

OUTLET

BOX

1-1/2"

2-1/2"

TO

FAN

TO SUPPORT

STRUCTURE

CABLE

CLAMPS

BLACK SUPPLY

(HOT)

WHITE SUPPLY

(NEUTRAL)

GROUND WIRE

GREEN WIRE (GROUND)

FROM FAN

WIRE CONNECTORS (3)

WHITE FAN WIRE

BLACK FAN WIRE

SAFETY

CABLE

CABLE

CLAMPS

Page 4

Repair Parts List

1

2

3A

4

5

9

10

16

12

11

15

13

6

14

7

8

3B

SUITABLE FOR USE WITH EMERSON SOLID STATE

SPEED CONTROL.

3. Slide the upper canopy up the rod within 1/4" of the

ceiling or beam and securely tighten the setscrew.

4. If a remote speed control is to be used refer to the

instructions included with that control for proper

installation and wiring.

5. Restore power.

6. After completing installation, test run fan in normal

operation manner. Inspect for any possible shake or

wobble which may be caused by binding as a result of

"tight cable". if this should happen, shut off power supply

and re-check instructions to correct problem.

NOTE: When any solid state motor speed control is

used, a humming noise may be present in the fan on

low speed. This hum in no way affects the operation of

the fan and is acceptable in most industrial

installations.

Maintenance

LUBRICATION - All bearings are permanently lubricated

and do not require further lubrication.

CLEANING - This fan may be wiped off with a damp cloth.

Do not allow the motor to get wet. Do not use solvents or

harsh detergents.

TO AVOID POSSIBLE ELECTRICAL SHOCK, BE SURE

ELECTRICITY IS TURNED OFF AT THE MAIN SERVICE

BOX BEFORE SERVICING.

WARNING

DO NOT USE WATER WHEN CLEARING YOUR CEILING

FAN. IT COULD DAMAGE THE MOTOR OR THE

BLADES AND CREATE THE POSSIBILITY OF AN

ELECTRICAL SHOCK.

WARNING

LIMITED WARRANTY

All products covered by this Owner’s Manual are warranted against defects in workmanship and

materials for one year from date of sale, except for motor which is warranted against defects in

workmanship and materials for two years. This warranty does not apply to damage from accident,

misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate

voltage; nor to equipment improperly installed or wired or maintained in violation of this Owner’s

Manual. This warranty is valid only in the fifty states of the United States. No other written or oral

warranty applies. No employee, agent, dealer or other person is authorized to give any warranties

on behalf of Emerson Electric Co.

The customer shall be responsible for all costs incurred in the removal or reinstallation and

shipping of the product for repairs. Within the limitations of this warranty, inoperative units should

be returned, freight prepaid, to the nearest Emerson authorized service center, or the Emerson

Electric Co. Service Center, and we will repair or replace, at our option, at no charge to you with

return freight paid by Emerson. It is agreed that such repair or replacement is the exclusive

remedy available from Emerson Electric Co. and that EMERSON IS NOT RESPONSIBLE FOR

DAMAGES OF ANY KIND, INCLUDING INCIDENTAL AND CONSEQUENTIAL DAMAGE. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the

above exclusion or limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

For the address of your nearest authorized service center, call toll-free 1-800-654-3545.

Merchandise returned to the factory must be accompanied by a return authorization and service

identification tag, both available from Air Comfort Products, Division of Emerson Electric Co.,

8100 W. Florissant, St. Louis, MO 63136. When requesting return authorization include all model

numbers shown on the product.

WARNING

THIS PRODUCT IS DESIGNED TO USE ONLY THOSE

PARTS SUPPLIED WITH THIS PRODUCT AND/OR ANY

ACCESSORIES DESIGNATED SPECIFICALLY FOR USE

WITH THIS PRODUCT BY EMERSON ELECTRIC.

SUBSTITUTION OF PARTS OR ACCESSORIES NOT

DESIGNATED FOR USE WITH THIS PRODUCT BY

EMERSON ELECTRIC COULD RESULT IN PERSONAL

INJURY OR PROPERTY DAMAGE.

Before discarding packaging material, be certain all parts have

been removed.

HOW TO ORDER REPAIR PARTS

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

• PART NUMBER • NAME OF ITEM

• PART DESCRIPTION • MODEL NUMBER

The model number of your Fan will be found on a label attached to the

top of the motor.

For repair parts, phone 1-800-654-3545.

Printed in Taiwan 07/98

Part No. F40BP71650001 Form No. BP7165-1

EMERSON

Air Comfort Products

DIVISION OF EMERSON ELECTRIC CO.

8100 W. Florissant, St. Louis, MO 63136

8100 W. Florissant, St. Louis, MO 63136

Key

No. Description HF948W 0

1 J-Hook Bag Assembly 761385

J-Hooks (2 ea.) —

Hardware (2 ea.) —

2 Hanger Assembly 761339

3A Hanger Nipple, 22” 761387

3B Hanger Nipple, 8” 761387-2

4 Upper Canopy 761335

5 Lower Canopy 761336

6 Blades (set of 3) 761412

7 Capacitor 761337

Bag Assembly, containing: 761384

8 5/16-18 x 1/4” Setscrews (2 ea.) —

9 Hairpin Clip —

10 Clevis Pin —

11 Safety Wire Clamp (2 ea.) —

12 Screw, M6 x 1/2” (6 ea.) —

13 Spring Washer, M6 (6 ea.) —

14 Blade Gasket (3 ea.) —

15 Wire Connector (3 ea.) —

16 Allen Wrench —

— Owner's Manual (Not Shown) BP7165-1

Loading...

Loading...