Page 1

EV3200 Door Control Inverter

User Manual

Version V1.4

Revision date April 21, 2008

BOM

31011543

Emerson Network Power provides customers with technical support. Users may contact the nearest

Emerson local sales office or service center.

Copyright © 2007 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

Customer Service Hotline: +86 755 86010537, 400-887-6510

Complaint Hotline: +86 755 86010800

E-mail: support@emersonnetwork.com.cn

Page 2

Contents

Chapter 1 Safety Information ..............................................................................................................................................1

1.1 Warnings, Cautions & Notes................................................................................................................................. 1

1.2 Electrical Safety - General Warning ...................................................................................................................... 1

1.3 System Design And Safety Of Personnel .............................................................................................................1

1.4 Motor..................................................................................................................................................................... 1

1.5 Adjusting Parameters............................................................................................................................................ 1

1.6 Electrical Installation ............................................................................................................................................. 1

1.6.1 Electric Shock Risk.................................................................................................................................... 1

1.6.2 Isolation Device ......................................................................................................................................... 1

1.6.3 STOP Function .......................................................................................................................................... 2

1.6.4 Stored Charge ........................................................................................................................................... 2

1.6.5 Equipment Supplied By Plug And Socket .................................................................................................. 2

1.6.6 Earthing Requirement................................................................................................................................ 2

1.6.7 Capacitor And Varistors............................................................................................................................. 2

1.7 Disposing Of Unwanted Inverter ........................................................................................................................... 2

Chapter 2 Product Specifications ........................................................................................................................................ 3

2.1 Model Description ................................................................................................................................................. 3

2.2 Nameplate ............................................................................................................................................................ 3

2.3 Models .................................................................................................................................................................. 3

2.4 Installation Size..................................................................................................................................................... 4

2.5 Specifications........................................................................................................................................................ 4

Chapter 3 Electrical Installation........................................................................................................................................... 6

3.1 Wiring Of Power Terminals ................................................................................................................................... 6

3.1.1 Introduction To Power Terminals............................................................................................................... 6

3.1.2 Connection Of Power Terminals................................................................................................................ 7

3.2 Control Terminals.................................................................................................................................................. 8

3.3 User Relay Output Terminals................................................................................................................................ 8

3.4 PG Terminals Of Synchronous Motor ................................................................................................................... 9

3.5 Wiring Diagram Of Inverter ................................................................................................................................... 9

3.6 EMC.................................................................................................................................................................... 10

Chapter 4 Operation.......................................................................................................................................................... 12

4.1 Operation ............................................................................................................................................................ 12

4.1.1 Operation Keypad.................................................................................................................................... 12

4.1.2 Description Of Inverter Operating Status ................................................................................................. 12

4.1.3 Description Of Inverter Operating Mode .................................................................................................. 12

4.1.4 Parameter Classification.......................................................................................................................... 13

4.1.5 Parameter Setting Method....................................................................................................................... 13

Page 3

4.1.6 Display Of Parameters............................................................................................................................. 13

4.2 Basic Applications............................................................................................................................................... 13

4.2.1 Motor Tuning ........................................................................................................................................... 13

4.2.2 Basic Operating Modes ...........................................................................................................................14

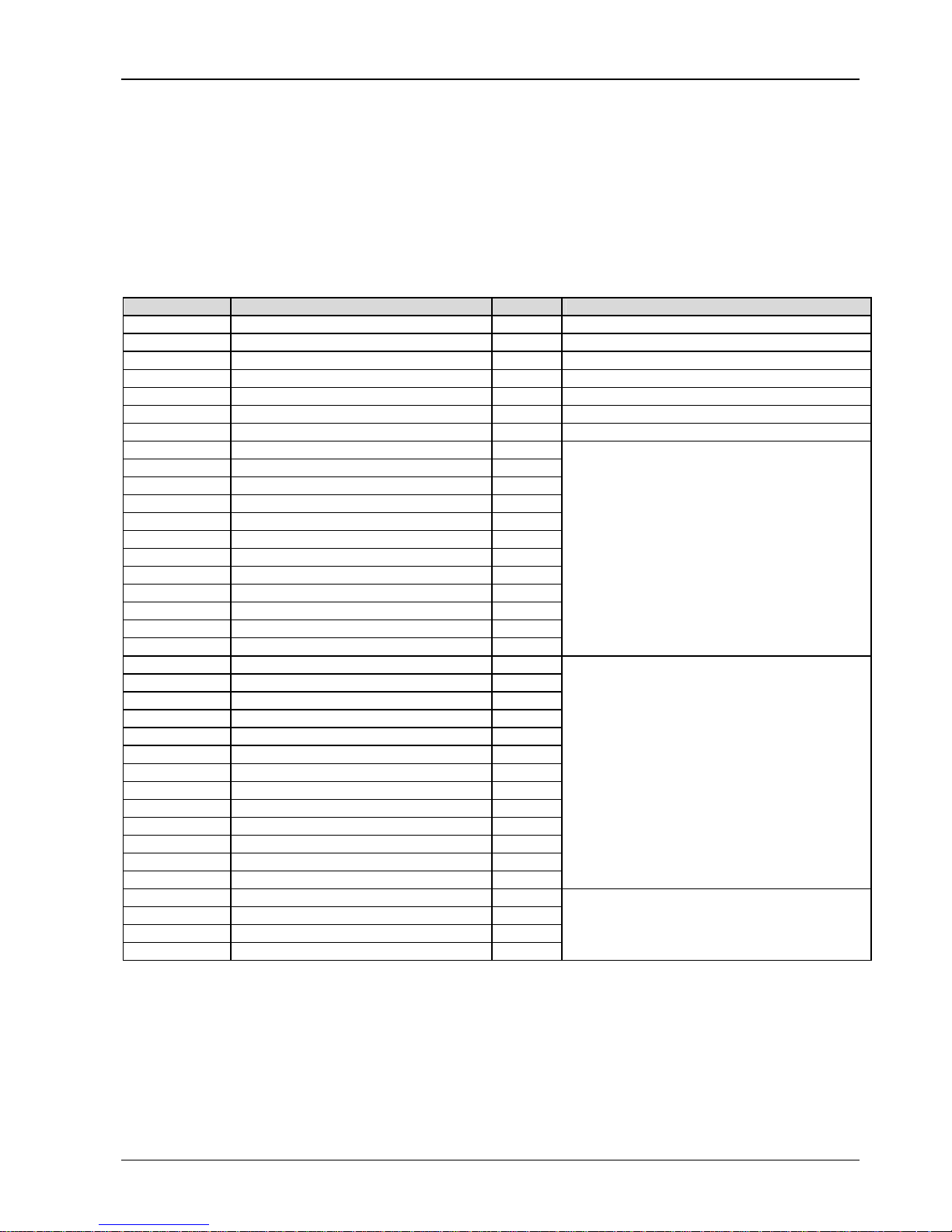

Chapter 5 Parameter Table............................................................................................................................................... 15

5.1 Basic Operation Parameters F0.......................................................................................................................... 15

5.2 OD Operation Parameters F1 ............................................................................................................................. 15

5.3 CD Operation Parameters F2 ............................................................................................................................. 16

5.4 Enhanced Function Parameters F3 .................................................................................................................... 16

5.5 Door Width Self-learning Parameters F4 ............................................................................................................ 17

5.6 Multi-function Input Terminal Parameters F5 ...................................................................................................... 18

5.7 Motor Parameters F6 .......................................................................................................................................... 18

5.8 Vector Control Parameters F7 ............................................................................................................................ 19

5.9 Communication Parameters F8 (Reserved)........................................................................................................ 19

5.10 Monitoring And Recording Parameters F9........................................................................................................ 20

Chapter 6 Parameter Description...................................................................................................................................... 22

6.1 Basic Operation Parameters F0.......................................................................................................................... 22

6.2 OD Operation Parameters F1 ............................................................................................................................. 23

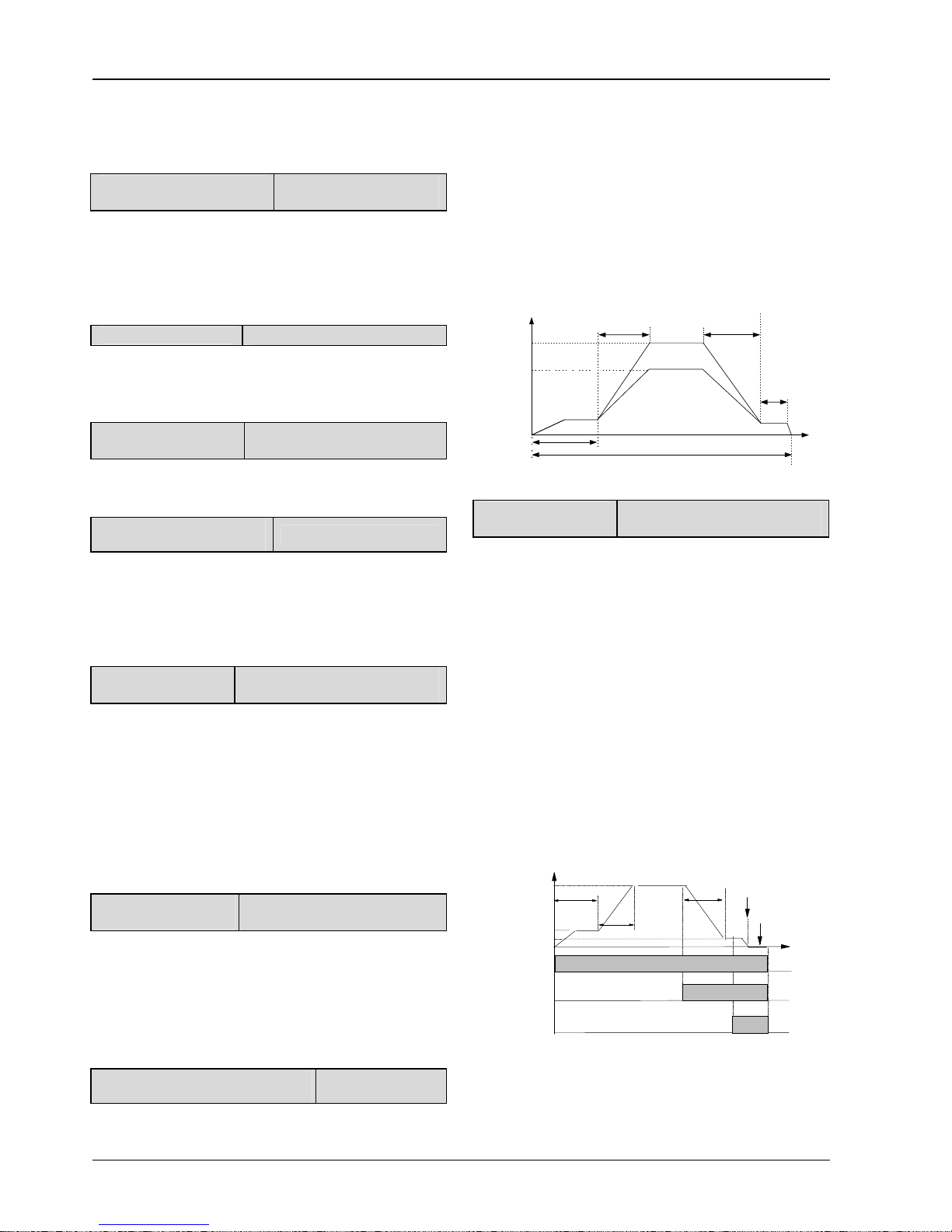

6.2.1 OD Operation Curve For Speed Control.................................................................................................. 23

6.2.2 OD Operation Curve For Distance Control .............................................................................................. 24

6.3 CD Operation Parameters F2 ............................................................................................................................. 25

6.3.1 CD Operation Curve For Speed Control .................................................................................................. 25

6.3.2 CD Operation Curve For Distance Control ..............................................................................................26

6.4 Enhanced Function Parameters F3 .................................................................................................................... 27

6.5 Door Width Self-learning Parameters F4 ............................................................................................................ 29

6.6 Multi-function Input Terminal Parameters F5 ...................................................................................................... 31

6.7 Motor Parameters F6 .......................................................................................................................................... 33

6.8 Vector Control Parameters F7 ............................................................................................................................ 33

6.9 Communication Parameters F8 (Reserved)........................................................................................................ 35

6.10 Monitoring And Recording Parameters F9........................................................................................................ 36

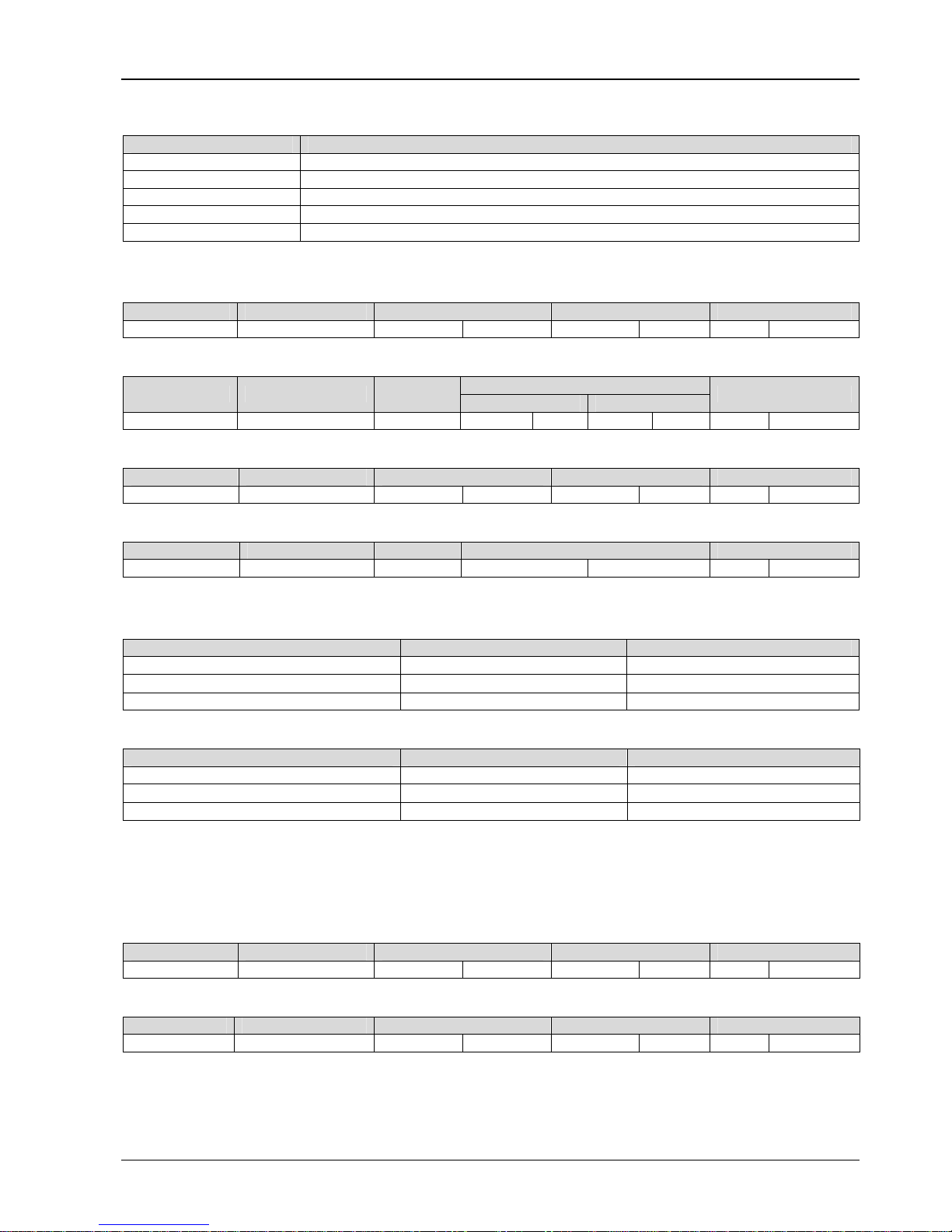

Chapter 7 Application Guidance........................................................................................................................................ 38

7.1 Motor Type Setup ...............................................................................................................................................38

7.2 Speed Control..................................................................................................................................................... 39

7.2.1 System Wiring Diagram........................................................................................................................... 39

7.2.2 Testing Procedures ................................................................................................................................. 39

7.2.3 Parameter Settings.................................................................................................................................. 40

7.3 Distance Control 1 ..............................................................................................................................................40

7.3.1 System Wiring Diagram........................................................................................................................... 40

7.3.2 Testing Procedures ................................................................................................................................. 41

7.3.3 Parameter Settings.................................................................................................................................. 42

Page 4

7.4 Distance Control 2 ..............................................................................................................................................43

7.5 Distance Control 3 ..............................................................................................................................................43

7.5.1 System Wiring Diagram........................................................................................................................... 43

7.5.2 Testing Procedures ................................................................................................................................. 43

7.5.3 Parameter Settings.................................................................................................................................. 44

Chapter 8 Troubleshooting................................................................................................................................................ 45

Chapter 9 Maintenance ..................................................................................................................................................... 47

9.1 Daily Maintenance ..............................................................................................................................................47

9.2 Periodical Maintenance....................................................................................................................................... 48

9.3 Replacing Weary Parts ....................................................................................................................................... 48

9.4 Storage ............................................................................................................................................................... 49

9.5 Warranty ............................................................................................................................................................. 49

Appendix 1 EMI Filter And AC Input Reactor .................................................................................................................... 50

Appendix 2 Modbus Communication Protocol................................................................................................................... 51

Appendix 3 EU Declaration Of Conformity ........................................................................................................................ 56

Page 5

Chapter 1 Safety Information 1

EV3200 Door Control Inverter User Manual

Chapter 1 Safety Information

This chapter provides safety information of the inverter.

1.1 Warnings, Cautions & Notes

A

Warning

contains information, which is essential

for avoiding a safety hazard.

A

Caution

contains information, which is

necessary for avoiding a risk of damage to the

product or other equipment.

A

Note

contains information, which helps to ensure

correct operation of the product.

1.2 Electrical Safety - General

Warning

The voltages used in the EV3200 door control inverter (for

short, controller) can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all

times when working with or adjacent to the inverter.

Specific warnings are given at the relevant places in this

guide.

1.3 System Design And Safety Of

Personnel

The inverter is intended as a component for inverter system.

If installed incorrectly, the inverter may present a safety

hazard. The inverter uses high voltages and currents,

carries a high level of stored electrical energy, and is used

to control equipment that can cause injury.

System design, installation, commissioning and

maintenance must be carried out by personnel who have

the necessary training and experience. They must read this

safety information and this guide carefully.

The supply must be disconnected by an approved electrical

isolation device before gaining access to the electrical

connections.

Careful consideration must be given to the function of the

inverter which might result in a hazard, either through its

intended behavior or through incorrect operation due to a

fault. In any application where a malfunction of the inverter

or its control system could lead to or allow damage, loss or

injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for

example, an over-speed protection device in case of failure

of the speed control, or a fail-safe mechanical brake in case

of loss of motor braking.

1.4 Motor

Ensure the motor is installed in accordance with the

manufacturer's recommendations.

Ensure the motor shaft is not exposed.

If it is intended to use the capability of an inverter to run a

motor at speeds above its designed maximum, it is strongly

recommended that the manufacturer be consulted first.

Low speeds may cause the motor to overheat because the

cooling fan becomes less effective. The motor should be

fitted with a protection thermistor. If necessary, an electric

force vent fan should be used.

It is essential that the correct value is entered into F6.03,

motor rated current. This affects the thermal protection of

the motor.

1.5 Adjusting Parameters

Some parameters have a profound effect on the operation

of the inverter. They must not be altered without careful

consideration of the impact on the controlled system.

Measures must be taken to prevent unwanted changes due

to error or tampering.

1.6 Electrical Installation

1.6.1 Electric Shock Risk

The voltages present in the following locations can cause

severe electric shock and may be lethal:

AC supply cables and connections

DC and brake cables, and connections

Output cables and connections

Many internal parts of the inverter, and external option

units

Unless otherwise indicated, control terminals are single

insulated and must not be touched.

1.6.2 Isolation Device

The AC supply must be disconnected from the inverter

using an approved isolation device before any cover is

removed from the inverter or before any servicing work is

performed.

Page 6

2 Chapter 1 Safety Information

EV3200 Door Control Inverter User Manual

1.6.3 STOP Function

The STOP function does not remove dangerous voltages

from the inverter, the motor or any external option units.

1.6.4 Stored Charge

The inverter contains capacitors that remain charged to a

potentially lethal voltage after the AC supply has been

disconnected. If the inverter has been energized, the AC

supply must be isolated at least ten minutes before work

may continue.

Normally, the capacitors are discharged by an internal

resistor. Under certain, unusual fault conditions, it is

possible that the capacitors may fail to discharge, or be

prevented from being discharged by a voltage applied to the

output terminals. If the inverter has failed in a manner that

causes the display to go blank immediately, it is possible the

capacitors will not be discharged. In this case, consult

Emerson Network Power Co., Ltd. or their authorized

distributor.

1.6.5 Equipment Supplied By Plug And Socket

Special attention must be given if the inverter is installed in

equipment which is connected to the AC supply by a plug

and socket. The AC supply terminals of the inverter are

connected to the internal capacitors through rectifier diodes

that are not intended to give safety isolation. If the plug

terminals can be touched when the plug is disconnected

from the socket, a means of automatically isolating the plug

from the inverter must be used (e.g. a latching relay).

1.6.6 Earthing Requirement

Earth the inverter properly. Failure to observe this may

cause electric shock

1.6.7 Capacitor And Varistors

Because the inverter outputs PWM pulse wave, capacitor

and varistors should not be connected with the output

terminals of the inverter, or the inverter may trip or

components may be damaged, as shown in Figure 1-1.

M

U

V

W

EV3200

inverter

Figure 1-1 Capacitor connection with inverter output

prohibited

1.7 Disposing Of Unwanted Inverter

When disposing the inverter, note that the capacitors may

explode when they are burnt and poisonous gas may be

generated when plastic parts are burnt. Please dispose the

inverter as industrial waste.

Page 7

Chapter 2 Product Specifications 3

EV3200 Door Control Inverter User Manual

Chapter 2 Product Specifications

This chapter provides model description and specifications of the inverter.

2.1 Model Description

The following figure provides the model description of the inverter.

EV3200 - 2 S 0004 A

Drive series

Code

Voltage level

220V 2

Input Volt

Single-phase

Code

S

Code

Load type

Asynchronous motor for

elevator door control

Code

Motor power (kW)

0004

0002

0.4

0.2

A

S

Synchronous motor for

elevator door control

Figure 2-1 Inverter model description

2.2 Nameplate

The nameplate is on the bottom of the inverter enclosure, as shown in Figure 2-1.

-2S0002A

0.2kW

1PH AC 200~240V

3PH AC 0~240V

Hz 0.5kVA 1.3A

MODEL:

POWER:

INPUT:

00

OUTPUT:

S/N:

-2

0.2kW

1PH AC 200~240V

2.65A 50/60Hz

3PH AC 0~240V

Hz 0.5kVA 1.3A

00

-2

0.2kW

1PH AC 200~240V

3PH AC 0~240V

Hz 0.5kVA 1.3A

00

EV3200

-2

0.2kW

1PH AC 200~240V

2.65A 50/60Hz

3PH AC 0~240V

0~128

Hz 0.5kVA 1.3A

Drive model

Motor capacity

Rated input voltage,

current and frequency

00

Emerson Network Power Co., Ltd.

Rated output capacity, current,

frequency range and voltage

Bar code

Figure 2-2 Inverter nameplate

2.3 Models

Inverter model Rated input current (A) Rated capacity (kVA) Rated output current (A) Motor power (kW)

EV3200-2S0002A

EV3200-2S0002S

2.65 0.5 1.3 0.2

EV3200-2S0004A

EV3200-2S0004S

5.3 1.0 2.5 0.4

Page 8

4 Chapter 2 Product Specifications

EV3200 Door Control Inverter User Manual

2.4 Installation Size

Table 2-1 Inverter external size and installation size

Installation size External size

Inverter model

A (mm) B (mm) L (mm) W (mm) H (mm)

Installation hole

diameter (mm)

Weight (kg)

EV3200-2S0002A

EV3200-2S0002S

EV3200-2S0004A

EV3200-2S0004S

289 172.5 298 190 60 Φ4 0.9

2.5 Specifications

Items Subitems Specifications

Voltage range Single-phase AC power, 180V ~ 264V

Input

Frequency range 50Hz ± 5%, 60Hz ± 5%

Voltage range Three-phase: 0V ~ input voltage

Frequency range 0Hz ~ 128Hz

Output

Overload ability 150% rated current for 1 minute, 180% rated current for 10 seconds

Load motor type Three-phase AC asynchronous motor, three-phase AC synchronous motor

Modulation mode Optimized space voltage vector PWM modulation

Control algorithm Sensorless vector control, vector control with speed sensor

Operation mode

Two modes: 1. The inverter operates as an inverter specially used for controlling the elevator door

(elevator door control mode), 2. The inverter operates as a general purpose inverter

Frequency

resolution

Digital setting: 0.01Hz

Door width auto

learning

The inverter operates at the auto-learnt speed, and operates in the logic procedure of close door (CD)

→

open door (OD)→CD→stop. After the auto-learning operation, the door width information is saved

and the auto learning process is over

Auto tuning of

motor's

parameters

Purpose of auto tuning function of inverter is to obtain the motor's parameters automatically, and these

parameters will be saved automatically after the tuning process is over

Main control

functions

Speed-adjusting

range

Under rated load condition, 1:100 for vector control with speed sensor; 1:50 for sensorless vector

control

OD, CDcontrol

command input

Terminal control mode; keypad control mode; communication control mode (reserved)

Frequency setting Set the frequency via keypad; communication control mode (reserved)

Multi-function

terminal input

signal

External reset signal, light curtain signal, safety edge signal, OD position limiting signal, CD position

limiting signal, OD speed decrease signal, CD speed decrease signal, OD prohibition signal, torque

maintaining signal, slow OD and CD signals, lock signal, emergency firemen service (EFS) signal, rush

hour operation enable operation, operation enable signal, auto-learning command signal

Operation

functions

Output signal 3 relay-output: 250Vac/2A (cosΦ=1), 250Vac/1A (cosΦ=0.4), 30Vdc/1A

Display 4-digit LED display

Running frequency, reference frequency, output voltage, output current, output torque, DC bus voltage,

status of input terminals, status of output terminals, door-operating position (pulse number)

Page 9

Chapter 2 Product Specifications 5

EV3200 Door Control Inverter User Manual

Items Subitems Specifications

Protection functions

Over current protection, over voltage protection, low voltage protection, over heat protection, overload

protection, output phase failure protection, motor protection, motor tuning error alarm, parameter

setting error alarm, door width auto-learning error alarm, OD/CD error alarm, pulse generator (PG) error

alarm, current detection circuit fault alarm, EEPROM read/write error alarm, over-speed protection

Application

environment

Inside, free from direct sunlight, dust, corrosive gas, combustible gas, oil mist, steam, water drop, and

so on

Altitude

Lower than 1000m. Max altitude: 3000m (deration curve should be observed at 1000m ~ 3000m:

derated 10% for every rise of 100m)

Working

temperature

-10°C ~ + 40°C, temperature change less than 0.5°C /minute

Must be derated above 40°C: The output current must be derated 2% for every rise of 1°C.

Max temperature: 50°C

Humidity Less than 95%RH, no condensation

Vibration 3.5mm (2 ~ 9Hz), 10m/s2 (9 ~ 200Hz), 15m/s2 (200 ~ 500Hz)

Environment

Storage

temperature

-40°C ~ + 70°C

Protection IP21

Structure

Cooling

Forced air cooling (EV3200-2S0004A and EV3200-2S0004S)

Natural air cooling (EV3200-2S0002A and EV3200-2S0002S)

Page 10

6 Chapter 3 Electrical Installation

EV3200 Door Control Inverter User Manual

Chapter 3 Electrical Installation

This chapter introduces the positions, specifications, and connections of the input and output terminals of the inverter.

·

Disconnect the input power of the inverter and wait for at least 10 minutes before removing the inverter cover.

·

Only trained and authorized professionals shall make cable connection within the inverter.

·

Carefully examine the cable connection before and after connecting the emergency stop or safety circuit loop.

·

The inverter had gone through voltage withstand test in factory, users shall not conduct voltage withstand test to the inverter.

·

It is prohibited to connect the input power cables of the inverter to the U, V, W output terminals of the inverter.

·

Generally the earth cable should be copper cable with section area great than 2.5mm

2

, the earth resistance shall be less

than 10Ω.

·

To ensure safety, the inverter and motor must be earthed properly.

·

An air breaker or fuse should be fitted on the input circuit to the inverter to provide input overcurrent protection and facilitate

maintenance.

·

The control circuits are isolated from the power circuits in the drive by basic insulation (single insulation) only. The installer

must ensure that the external control circuits are insulated from human contact by at least one layer of insulation

(supplementary insulation) rated for use at the AC supply votlage.

·

If the control circuits are to be connected to other circuits classified as Safety Extra Low Voltage (SELV) (for example, to

personal computer), an additional isolating barrier must be included in order to maintain the SELV classification.

·

The control terminals of the inverter are on ELV circuit, do not touch them when they are energized.

·

If external equipment has interfaces that allow access with power on (that is, SELV circuit), protective isolation device shall

be installed. Otherwise, the safety voltage characteristics of the SELV circuit of the external equipment will be reduced to the

safety voltage characteristic of ELV circuit.

3.1 Wiring Of Power Terminals

3.1.1 Introduction To Power Terminals

A

EV3200

A amplified view

PE L N

Figure 3-1 Input power terminals

Table 3-1 Function description of input power terminals

Terminal Function description

L, N Single-phase 220Vac power input terminal

PE Protective earth point

Page 11

Chapter 3 Electrical Installation 7

EV3200 Door Control Inverter User Manual

A

EV3200

PB

P(+)U (-)

WV

A amplified view

Figure 3-2 Output power terminals

Table 3-2 Function description of input power terminals

Terminal Function description

P ( + ), PB, (-) P ( + ): positive DC bus output terminal; PB: reserved; (-): negative DC bus output terminal

U, V, W Motor connection terminal

Safety earth point

3.1.2 Connection Of Power Terminals

1. It is recommended to install an MCCB used for overcurrent protection in the input circuit of the inverter.

2. The cable diameter and MCCB capacity should be selected according to Table 3-3.

Table 3-3 Recommended MCCB capacity and copper-core insulating cable specifications

Power cables (mm2)

Inverter model MCCB (A)

Input cables Output cables Earth cables

EV3200-2S0002A

EV3200-2S0002S

6 1.0 1.0 2.5

EV3200-2S0004A

EV3200-2S0004S

10 1.0 1.0 2.5

Proper overload/short-circuit protection devices must be added to the AC input side. In the north America region,

it is recommended to use the UL listed slow-blow fuse.

The protection ground cable may carry DC current. If Residual Current Device (RCD) is to be used, use Type B

RCD.

Note

Max torque of the power terminals is 0.5Nm.

Page 12

8 Chapter 3 Electrical Installation

EV3200 Door Control Inverter User Manual

3.2 Control Terminals

A amplified view

X2P24 ACOM B X1 COMX4X3 X5 CDOD

A

EV3200

Figure 3-3 Control terminals

Table 3-4 Function description of control terminals

Terminal Terminal function Specifications

P24, COM

User terminal 24V power supply (COM being the

reference earth)

+24V ± 15%, max output current: 200mA, with output

shortcircuit protection function

A, B AB pulse input terminal of incremental PG

Meeting the input requirements of pulse signal with frequency

below 35kHz

X1 ~ X5

Multi-function input terminals (functions programmable,

COM being the reference earth), or Z pulse input

terminal of incremental PG

OD OD command input terminal

CD CD command input terminal

Terminal command valid when shorted with COM

Note

If the control cables are multi-core cables, it is recommended that the sectional area of a single strand of the control cables be 0.5mm2. If

the control cables are single-core cables, the cable sectional area should be greater than 1.0mm

2

.

3.3 User Relay Output Terminals

A

EV3200

A amplified view

PA2PA1 PC1 PC3PA3PC2 PB3

Figure 3-4 User relay output terminals

Table 3-5 Function description of user relay output terminals

Terminal Terminal function Specifications

PA1, PC1

When F9.22 is 0: normally closed contact output

When F9.22 is 1: normally open contact output

PA2, PC2

When F9.22 is 0: normally closed contact output

When F9.22 is 1: normally open contact output

PA3, PB3, PC3

PA3, PB3: Normally closed contact output

PA3, PC3: Normally open contact output

Contact rating

AC: 250V/1A (cosΦ=0.4), 250V/2A (cosΦ=1)

DC: 30V/1A

Page 13

Chapter 3 Electrical Installation 9

EV3200 Door Control Inverter User Manual

3.4 PG Terminals Of Synchronous Motor

The motor of inverters EV3200-2S0002S and EV3200-2S0004S is three-phase AC synchronous motor. It can use the UWV

incremental PG. For the UWV incremental PG, the PG signal is connected to terminal SK2. The pin assignment of terminal

SK2 is shown in Figure 3-5.

15

6

10

11

15

Figure 3-5 Pin assignment of terminal SK2

Table 3-6 Description of terminal SK2

Pin No. Signal description Pin No. Signal description Pin No. Signal description

1 U- 6 U+ 11 /

2 V- 7 V+ 12 +5V

3 A- 8 A+ 13 GND

4 B- 9 B+ 14 Z-

5 W- 10 W+ 15 Z+

3.5 Wiring Diagram Of Inverter

The basic wiring between the inverter's input, output terminals and external equipment is illustrated in Figure 3-6.

In the figure, the control terminals are used to control the inverter operation, and output the inverter status data to external

monitoring equipment. The wiring method depends on your application.

L

N

L

N

Single phase

power supply

50/60Hz

M

A

B

X1

CD

Increm ental

PG signal input 1

Multi-function input terminal 1

P24

U

V

W

PE

Auxiliary

supply

MCCB

Defined as fault relay by default:

Normal: PA3-PB3 closed

Fault: PA3-PC3 closed

COM

OD

OD comma nd input

PB3

PC3

PA3

PC1

PA1

PC2

PG power supply

PA2

15

6

10

11

15

SK2

(configured only for EV3200-2S0002S

and EV3200-2S0004S )

X2

X3

X4

X5

PG signal input 2

Multi-function input terminal 2

Multi-function input terminal 3

Multi-function input terminal 4

Multi-function input terminal 5

CD command input

Synchronous motor UV W PG s ignal input

Defined as co mplete OD relay by default:

Incomplete: PA1-PC1 closed

Complete: PA1-P C1 open

Defined as co mplete CD relay by default:

Incomplete: PA2-PC2 closed

Complete: PA2-P C2 open

Increm ental

Figure 3-6 Basic wiring diagram

The 24V incremental PG of EV3200 door control inverter can input the following two kinds of PG signals. The PG working

power supply should be 24V.

Page 14

10 Chapter 3 Electrical Installation

EV3200 Door Control Inverter User Manual

1. The wiring of open-collector output PG is shown in Figure 3-7.

EV3200

VCC

GND

A

●

●

●

B

●

GND

GND

P24

PE

COM

●

●

●

●

●

3.3V

VCC

VCC

A

B

Using shielding cable

Closer end of shielding

cable is connected to PE

same as

interface

circuit 1

Open collector output PG

(the part in dashed line is

voltage output PG)

Interface circuit 1

Interfac e

circuit 2

Figure 3-7 Wiring diagram of open-collector output PG

2. The wiring of the push-pull output PG is shown in Figure 3-8.

EV3200

P24

PE

COM

A

●

●

●

B

●

●

3.3V

GND

A

●

●

●

●

B

Closer end of shielding

cable is connected to PE

VCC

VCC

GND

VCC

GND

Push-pull PG

Using shielding cable

Interface circuit 1

same as

interface

circuit 1

Interface

circuit 2

Figure 3-8 Wiring diagram of push-pull output PG

3.6 EMC

1. It is recommended to install an EMI filter and AC input reactor at the input side of the inverter.

With EMI filter installed, EV3200 series inverters comply with the requirements in IEC 61800-3 in the fields of conducted

emission and radiated emission, with un-shielded AC power supply cables, and shielded output cable to the motor.

With AC input reactor installed, EV3200 series inverters comply with the requirements in IEC 61800-3 in the field of harmonic

emission.

For the technical parameters of the EMI filter and the AC input reactor, see Appendix 1 EMI Filter And AC Input Reactor.

Note

1. The input EMI filter should be as close to the inverter as possible.

2. The EMI filter can reduce the interference of the inverter on other equipment connected to the same mains.

3. The EMI filter's enclosure must be properly earthed.

4. The EMI filter inside the enclosure should be placed closed to the input AC power supply and its power input cables inside the enclosure

should be as short as possible.

5. The distance between the input cable and output cable of the EMI filter should be as far as possible, otherwise the high frequency noise

may be coupled between the cables and thus bypass the filter.

Page 15

Chapter 3 Electrical Installation 11

EV3200 Door Control Inverter User Manual

2. Selection of control cables

Generally, the control cables should be shield cables, and the shield must be connected to the metal enclosure of the inverter

by cable clamps at both ends.

3. Control cables, power cables and motor cables should be installed separately

Adequate clearance should be left between the cables, especially when the cables are laid in parallel and long. If the signal

cables have to cross over the power cables, keep them vertical to each other, as shown in Figure 3-9.

Power source

or motor cable

Motor cable

Signal/control cable

Power cable

>50cm

>30cm

>20cm

Signal/control cable

Figure 3-9 Wiring requirements

4. Installation requirements of relay, contactor and electro-magnetic braking kit, which may generate great interference, should

be installed outside of the inverter and installed with surge suppressors.

The suppressors are generally varistor, RC filter or diode as illustrated in Figure 3-10.

220Vac

Varistor

Relay

output

220Vac

RC-filter

Diode

+24Vdc

+

-

Method 1

Method 2

Method 3

Figure 3-10 Relay, contactor and brake device

Page 16

12 Chapter 4 Operation

EV3200 Door Control Inverter User Manual

Chapter 4 Operation

This chapter tells how to use the operation keypad of the inverter, and introduces the basic application of the inverter.

4.1 Operation

4.1.1 Operation Keypad

LED

Programming key

Shift key

OD key

CD key

Digit modification key

Function and data

switchover key

Save key

Stop key

Reset key

Figure 4-1 Operation keypad

Table 4-1 Operation keypad key runctions

Key Name Function

Programming

Switches between stopping

status/operating status and programming

state.

Function

/Data

Select data monitor mode and data input

confirmation

Up Increase

Down Decrease

Shift

In the status of RUN and STOP, press this

key to select the parameters that you want

to display on the screen; when setting

data, press this key to select the digit you

want to modify

OD key

In the keypad control mode, pressing this

key opens the door (or initiates forward

(FWD) spinning)

CD key

In the keypad control mode, pressing this

key closes the door (or initiates reverse

(REV) spinning)

Stop/Reset

In the keypad control mode, press this key

to stop operating, or to reset and exit fault

alarming status.

Note

1. In the keypad control mode of elevator-door control, pressing

the

key opens the door, pressing the

key closes the door.

2. Under general-purpose inverter keypad mode, pressing the

key initiates forward spinning, pressing the

key initiates

reverse spinning.

4.1.2 Description Of Inverter Operating Status

An inverter has 4 operating status.

Stopping status-The inverter is switched on, has no

fault, but without any operation.

Programming state-Use operation keypad to modify

and set function parameters.

Operating status-The inverter's output terminals U, V

and W have electricity outputs.

Fault alarming status-When fault occurs either from

external equipment, internal or wrong operation, the

inverter's LED will display the fault code and lock

output.

4.1.3 Description Of Inverter Operating Mode

The inverter has 4 operating modes: speed control, distance

control 1, distance control 2, distance control 3.

Page 17

Chapter 4 Operation 13

EV3200 Door Control Inverter User Manual

4.1.4 Parameter Classification

The inverter has 141 function parameters, divided into 11

groups according to their functions:

1. F0 (F0.00-F0.08): basic operation function parameters

2. F1 (F1.00-F1.15): OD curve parameters

3. F2 (F2.00-F2.16): CD curve parameters

4. F3 (F3.00-F3.18): enhanced function parameters

5. F4 (F4.00-F4.12): door width auto-learning parameters

6. F5 (F5.00-F5.07): multi-function terminal parameters

7. F6 (F6.00 ~ F6.13): motor parameters

8. F7 (F7.00 ~ F7.10): vector control parameters

9. F8 (F8.00 ~ F8.10): communication parameters, reserved

10. F9 (F9.00 ~ F9.22): display and monitoring parameters

11. FE: factory parameters, for factory use, not open to

users

4.1.5 Parameter Setting Method

The function parameters are set through the operation

keypad.

Look at the example below: modifying F1.04 (max CD

speed) from 20Hz to 30Hz.

1. Press the

key to enter programming state. The LED

on the keypad will display the F0 parameter group.

2. Press the

key to search the desired parameter group

(F1).

3. Press the

key to enter the corresponding function

parameter F1.00 in F1 parameter group.

4. Press the

key to enter the desired function parameter

F1.04.

5. Press the

key to display the function parameter value

(20.00, with

the

ones place “0” blinking).

6

. Press the

key to shift to the digit to be modified, and

press the

or key to change the setting to 30.00.

7. Press the

key to save and display the next parameter

(F1.05).

8. Press the

key to exit to parameter group F1.

9. Press the

key to exit programming state (30.00

blinking).

Figure 4-2 shows the application chart.

(LED display)

-F0- -F1-

F1.00

F1.04

30.00

Exit after modification

Abandon the modification

20.00

F1.05

▲

▲

-F1-

/

▲

1. Press PRG

to enter

programming

state and

display curent

parameter

group

2. Press ▲ to

search the

desired

parameter

group F1

3. Press FUNC/

DATA to enter the

corresponding

function parameter

F1.00 in F1

parameter group

4. Press ▲ to

enter the desired

function parameter

F1.04

5. Press FUNC/

DATA to display

the function

parameter value

6. Press▲, ,

to change the

setting to 30.00

7. Press FUNC/

DATA to save

and display the

next parameter

F1.05

Continue to modify parameters

Return to previous display

Figure 4-2 Function parameter setting method

Note

Some parameters cannot be modified because they are detected

values or status parameters, e.g. F9.16, F9.17, and so on.

4.1.6 Display Of Parameters

1. Define the displayed parameters during operation or in

stopping state through F9.00 and F9.01.

2. During operation, the parameters defined by F9.00 can

be displayed one by one by pressing the

key on the

keypad.

3. In stopping status, the parameter defined by F9.00 can

be displayed one by one by pressing

key on the keypad.

4.2 Basic Applications

4.2.1 Motor Tuning

EV3200 series inverter uses vector control technique. It is

necessary to tune the motor parameters before operation.

Tuning can be started through the operation keypad. Before

tuning, motor must be free of load; otherwise, the results will

be inaccurate.

1. Tuning method in the case the load is asynchronous

motor.

Example where the inverter settings are factory settings:

1) Set general-purpose inverter keypad control mode: Set

F0.02 to 0.

2) Set PG type: Set F4.00 to 0 (24V incremental PG).

Page 18

14 Chapter 4 Operation

EV3200 Door Control Inverter User Manual

3) Set motor type: Set F6.00 to 0 (asynchronous motor).

4) Input motor nameplate parameters: Input correct motor

nameplate parameters through parameters F6.01 ~

F6.03 and F6.05 ~ F6.06.

5) Set parameter tuning enable function: Set F6.07 to 1.

6) Press the

key to start motor tuning and the LED

displays "

". In the tuning state, the motor runs in a

fixed mode, so you need not interfere. After the tuning is

over, the inverter stops automatically, F6.07 will be

restored "0" and the settings of F6.08 ~ F6.13 will be

updated. If the tuning is obviously abnormal, press the

key to stop it. Check the connections and motor ratings,

then set F6.07 to 1 again. Press the key to start

tuning.

A successful tuning can ensure correct control of the motor.

2. Tuning method in the case the load is synchronous motor.

The PG must be connected before synchronous motor

tuning.

Taking the inverter with default settings as an example:

1) Set general-purpose inverter keypad control mode: Set

F0.02 to 0.

2) Set the control mode as distance control 1 (close loop

vector control at this time): Set F0.01 to 1.

3) Set motor type: Set F6.00 to 1 (synchronous motor).

4) Input motor nameplate parameters: Input correct motor

nameplate parameters into F6.01 ~ F6.03 and F6.05 ~

F6.06.

5) Set the PG pulse No. per revolution: Set F4.01.

6) Set PG type. Set F4.00 to 1 (for UVW incremental

PG).

7) Set parameter tuning enable function: Set F6.07 to 1.

8) Press the

key to start motor tuning and the LED

displays " ". In the tuning state, the motor runs in a

fixed mode, so you need not interfere. After the tuning is

over, the inverter stops automatically, F6.07 will be

restored "0" and the settings of F6.08 ~ F6.13 and F4.03

will be updated.

A successful tuning can ensure correct control of the motor.

Note

1. If in tuning the keypad displays fault, press the key to reset

the inverter, change the setting of F4.02, check the connections

and motor ratings, set F6.07 to 1 again, and press the key to

start tuning.

2. In synchronous motor tuning, if the PG direction is reversed by

cable connection, the inverter will report E025 fault (PG fault). In

this case, exchange the connections of any two-phase cables of the

motor and restart the tuning.

3. For synchronous motors, you should conduct the tuning at least

twice, and see if the difference between the magnetic pole initial

angles (F4.03) obtained from the tuning is less than 10°. If

bigger than 10°, the error is unacceptable, you should restart the

tuning. If the difference is an integral multiple of 360°/motor

polarity pair number, the tuning result is acceptable.

4.2.2 Basic Operating Modes

1. Operating frequency settings, tuning and operating

control can be done via operation keypad.

1) In stopping state, press

the

key to enter

programming state and display parameter group F0.

2) Press the

key to enter the parameters in F0

parameter group.

3) Set the main parameters (other parameters can use

the defaults).

F0.01=0, speed control 1 (sensorless vector control)

F0.02=0, keypad control mode

4) Press the

key to return.

5) Press the

key for FWD running, press the

key

for REV running.

6) Press the

key ,

the inverter stops (decelerates to

stop).

7) Power-off.

2. Frequencies can be set and modified via the keypad and

operating control through control terminals.

EV3200

OD

COM

.

.

CD

.

k1

k2

Figure 4-3 Wiring

Connect power cables according to Figure 4-3, and switch

on after confirming the connection.

1) Press the

key to enter programming state.

2) Set the main parameters (other parameters can use

the defaults).

F0.01=0, speed control 1 (sensorless vector control)

F0.02=5, in terminal control mode, the operating

command is given via the control terminal. OD

controls FWD running and CD controls REV running

3) Press the

key to return to stopping status.

4) Switch on K1, the inverter runs forward.

5) Switch off K1 and switch on K2, the inverter runs REV.

6) Switch off K1 and K2, the inverter stops (decelerates

to stop).

7) Power-off.

Page 19

Chapter 5 Parameter Table 15

EV3200 Door Control Inverter User Manual

Chapter 5 Parameter Table

This chapter lists the inverter parameters, briefly introduces the setting ranges, min. units, defaults of the parameters and

marks whether they can be modified.

In the "Mod." column of the tables,

"O" means that the parameter can be modified during operation

"×" means that the parameter cannot be modified during operation

"*" means the actual measured or fixed parameters can not be modified

"-" means that it is set by the manufacturer and can not be modified by the user

Abbreviation in the table:

OD: opening door

CD: closing door

MS: multi-speed

5.1 Basic Operation Parameters F0

Parameter Name Setting range Min. unit Default Mod.

F0.00

User password 0 ~ 9999 (0000 means no password)

1

0

○

F0.01

Control mode

0: speed control

1: distance control 1

2: distance control 2

3: distance control 3

1 0 ×

F0.02

Control command

selection

0: keypad control mode of general-purpose inverter

1: keypad control mode of the inverter used for controlling elevator door

2: terminal control mode of the inverter used for controlling elevator door

3: communication control mode of the inverter used for controlling

elevator door (reserved)

4: Auto-demo mode

5: terminal control mode of general-purpose inverter

6: reserved

7: communication control mode of general-purpose inverter (reserved)

1 0 ×

F0.03

Running direction

selection

0: same as direction preset by actual motor wiring

1: reverse to direction preset by actual motor wiring

1 0 ×

F0.04 Max.output frequency 50.00Hz ~ 128.0Hz 0.01Hz 50.00Hz ×

F0.05 ~ F0.08 Reserved

5.2 OD Operation Parameters F1

Parameter Name Setting range Min. unit Default Mod.

F1.00 OD start creep time for speed control 10 ~ 9999ms 1ms 500ms

○

F1.01 OD start creep distance for distance control 0 ~ 30.0% (door width) 0.1% 15.0%

○

F1.02 OD start creep speed 1.00 ~ 25.00Hz 0.01Hz 7.00Hz

○

F1.03 OD Acc time 0.1 ~ 3600s 0.1s 2s

○

F1.04 OD reference frequency 0.00 ~ F0.04 max frequency 0.01Hz 20.00Hz

○

F1.05 Rush hour operation OD speed 0.00 ~ F0.04 max frequency 0.01Hz 25.00Hz

○

F1.06 OD speed decrease point in distance control 60% ~ 95% (door width) 0.1% 70.0%

○

F1.07 OD Dec time 0.1 ~ 3600s 0.1s 2s

○

F1.08 OD ending creep speed 0 ~ 15.00Hz 0.01Hz 3.00Hz

○

F1.09 OD position limit in distance control 1 ~ 9999 (pulse number) 1 600

○

Page 20

16 Chapter 5 Parameter Table

EV3200 Door Control Inverter User Manual

Parameter Name Setting range Min. unit Default Mod.

F1.10

Switching point of OD complet maintaining

torque

0.0% ~ 100.0% (motor rated torque) 0.1% 50.0%

○

F1.11 OD complet maintaining torque 0.0% ~ 100.0% (motor rated torque) 0.1% 50.0%

○

F1.12

OD operation curve selection in distance

control

0: selecting manually preset curve

1: selecting optimum curve by auto-learning

1 0 ×

F1.13 OD optimum curve correction factor 3.0% ~ 15.0% (door width) 0.1% 10.0%

○

F1.14 ~ F1.15 Reserved

5.3 CD Operation Parameters F2

Parameter Name Setting range Min. unit Default Mod.

F2.00 CD start creep time for speed control 10 ~ 9999ms 1ms 500ms

○

F2.01 CD start creep distance 0 ~ 30.0% (door width) 0.1% 15.0%

○

F2.02 CD start creep speed 1.00 ~ 25.00Hz 0.01Hz 6.00Hz

○

F2.03 CD Acc time 0.1 ~ 3600s 0.1s 2s

○

F2.04 CD reference frequency 0.00 ~ F0.04 max frequency 0.01Hz 15.00Hz

○

F2.05 Rush hour operation CD speed 0.00 ~ F0.04 max frequency 0.01Hz 20.00Hz

○

F2.06 CD speed decrease point in distance control 60% ~ 95% (door width) 0.1% 70.0%

○

F2.07 CD Dec time 0.1 ~ 3600s 0.1s 2s

○

F2.08 CD ending creep speed 0 ~ 15.00Hz 0.01Hz 2.00Hz

○

F2.09 CD position limit in distance control 1 ~ 9999 (pulse number) 1 600

○

F2.10

Swithcing point of CD complete maintainging

torque

0.0% ~ 100.0% (motor rated torque) 0.1% 50.0%

○

F2.11 CD complete maintainging torque 0.0% ~ 100.0% (motor rated torque) 0.1% 50.0%

○

F2.12 CD speed for EFS 5.00 ~ 25.00Hz 0.01Hz 10.00Hz

○

F2.13 CD operation curve selection in distance control

0: selecting manually preset curve;

1: selecting optimum curve by auto-learning

1 0 ×

F2.14 CD optimum curve correction factor 3.0% ~ 15.0% (door width) 0.1% 10.0%

○

F2.15 Distance control CD door locking point

000 ~ 9999

1 800

○

F2.16 CD speed after door locking point

0.00 ~ 20.00Hz 0.01Hz 5.00Hz

○

5.4 Enhanced Function Parameters F3

Parameter Name Setting range Min. unit Default Mod.

F3.00 INI operation speed 0.00 ~ 20.00Hz 0.01Hz 5.00Hz

○

F3.01

OD time limit 0 ~ 3600s 1s 300s

○

F3.02

CD time limit 0 ~ 3600s 1s 300s

○

F3.03

Slow speed operation time limit 0 ~ 3600s 1s 400s

○

F3.04

Delay time for external OD command 0 ~ 9999S 1s 0s

○

F3.05

Delay time for external CD command 0 ~ 9999S 1s 0s

○

F3.06

Position of safety edge lift signal output 0% ~ 40.0% (door width) 0.1% 10.0% ×

F3.07

Function selection of OD upon CD obstruction 0: stop; 1: open the elevator door 1 1 ×

F3.08

CD obstruction sensitivity 0 ~ 150.0% (motor rated torque) 0.1% 100.0%

○

F3.09

Dec time upon CD obstruction 10 ~ 2500ms 1ms 300ms

○

F3.10

OD obstruction sensitivity 0 ~ 150.0% (motor rated torque) 0.1% 0%

○

F3.11

Maintaining time for complete OD in demo mode 1 ~ 3600s 1s 2s

○

F3.12

Maintaining time for complete CD in demo mode 1 ~ 3600s 1s 2s

○

F3.13

Preset CD/OD times in demo mode 0 ~ 9999 1 0

○

F3.14

CD/OD times record in demo mode 0 ~ 9999 1 0

○

F3.15

Auto reset times upon fault 0 ~ 100 1 0 ×

F3.16

Torque enhance coefficient 100% ~ 350% 1% 115% ×

Page 21

Chapter 5 Parameter Table 17

EV3200 Door Control Inverter User Manual

Parameter Name Setting range Min. unit Default Mod.

F3.17

Fan control

0: fan does not start during inverter

operation

1: fan starts when heatsink temperature is

higher than 65°C during inverter operation

2: fan starts during inverter operation

1 0 ×

F3.18 Percentage or pulse number selection

0: F1.01, F1.06, F1.13, F2.01, F2.06 and

F2.14 are percentages.

1: F1.01, F1.06, F1.13, F2.01, F2.06 and

F2.14 are numbers

0 0 ×

5.5 Door Width Self-learning Parameters F4

Parameter Name Setting range Min. unit Default Mod.

F4.00 PG type

0: 24V incremental PG

1: UVW incremental PG (5V)

1 0

×

F4.01 Pulse number per revolution 0 ~ 4000 1 100 ×

F4.02 PG direction

0: same as direction preset by PG wiring

1: reverse to direction preset by PG wiring

1 0 ×

F4.03 Magnetic pole initial angle 0.0 ~ 359.9° 0.1 0 ×

F4.04 Speed during door width auto-learning 2 ~ 20.00Hz 0.01Hz 5.00 ×

F4.05 Selection of door-width auto-learning

0: disabled

1: enabled

1 0 ×

F4.06 Low digits of pulse count for door wicth 0 ~ 9999 (pulse number) 1 0 ×

F4.07 High digits of pulse count for door width 0 ~ 9999 (×10000) 1 0 ×

F4.08 Actual door width 0 ~ 9999mm 1mm 0mm ×

F4.09

PG cable broken detection time for

asynchronous motor

0 ~ 10s 0.1s 0s ×

F4.10 Ratio of gear 1 ~ 100 1.0 1.0 ×

F4.11 Asynchronous single/dual motor selection

0: single motor control (asynchronous or

synchronous).

1: dual motors control (asynchronous)

0 0 ×

F4.12 Reserved

Page 22

18 Chapter 5 Parameter Table

EV3200 Door Control Inverter User Manual

5.6 Multi-function Input Terminal Parameters F5

Parameter Name Setting range Min. unit Default Mod.

F5.00

F5.01

F5.02

F5.03

F5.04

Function selection for

control terminals X1 ~ X5

0: No functions (can be set repetitively)

1: External reset (RESET) signal input

2: Normally open input contacts for light curtain signal

3: Normally closed input contacts for light curtain signal

4: Normally open input contacts for safety edge

5: Normally closed input contacts for safety edge

6: Normally open input for OD position limiting

7: Normally closed input for OD position limiting

8: Normally open input for CD position limiting

9: Normally closed input for CD position limiting

10: Normally open input contacts for OD speed decrease

11: Normally closed input contacts for OD speed decrease

12: Normally open input contacts for CD speed decrease

13: Normally closd input contacts for CD speed decrease

14: Terminal for inputting OD prohibition signal

15: Terminal for inputting torque maintaining prohibition signal

16: Low speed OD/CD enable signal input

17: Normally open input for lock signal

18: Normally closed input for lock signal

19: Emergency Firemen Service (EFS) function input

20: Rush hour operation enable signal input

21: Operation enable signal input (valid for X5 only)

22: Door width auto-learning command input (valid for X5 only)

1 0 ×

F5.05

Function of programmable

relay output PA1/PC1

2

F5.06

Function of programmable

relay output PA2/PC2

3

F5.07

Function of programmable

relay output PA3/PB3/PC3

0: Output signal 0 for complete OD

(immediately output upon position limiting)

1: Output signal 0 for complete CD

(immediately output upon position limiting)

2: Output signal 1 for complete OD

(output after position limiting and lock)

3: Output signal 1 for complete CD

(output after position limiting and lock)

4: Output signal 2 for complete OD

(output after position limiting, lock, and door lock invalid)

5: Output signal 2 for complete CD

(output after position limiting, lock, and door lock valid)

6: Fault relay output 1

(not including POFF status)

7: Fault relay output 2

(including POFF status)

8: Safety edge lift signal output

9: Lock signal synchronous output

10: Re-opening signal output

11: Obstruction signal output

1

6

×

5.7 Motor Parameters F6

Parameter Name Setting range Min. unit Default Mod.

F6.00 Motor type selection

0: asynchronous motor;

1: synchronous motor

1 0 ×

F6.01 Motor rated power 0 ~ 500W 1W 370 ×

F6.02 Motor rated voltage 0 ~ 250V 1V 220 ×

F6.03 Motor rated current 0.10 ~ 9.90A 0.01A 1.94 ×

F6.04

Motor max allowable operation

current

100.0% ~ 200.0% (motor rated current) 0.1% 150.0% ×

F6.05 Motor rated frequency 1.00Hz ~ 128.0Hz 0.01Hz 50.00Hz ×

F6.06 Motor rated spinning speed 1 ~ 9999rpm 1r/min 1400 ×

Page 23

Chapter 5 Parameter Table 19

EV3200 Door Control Inverter User Manual

Parameter Name Setting range Min. unit Default Mod.

F6.07 Motor tuning 0: disable 1: enable 1 0 ×

F6.08 Stator resistance 00.00 ~ 99.99ohm 0.01ohm Applicable motor value ×

F6.09 Stator inductance 0 ~ 9999mH 1mH Applicable motor value ×

F6.10 Rotor resistance 00.00 ~ 99.99ohm 0.01ohm Applicable motor value ×

F6.11 Rotor inductance 0 ~ 9999mH 1mH Applicable motor value ×

F6.12 Mutual inductance 0 ~ 9999mH 1mH Applicable motor value ×

F6.13 Exciting current with no load 0.00 ~ 99.99A 0.01A Applicable motor value ×

5.8 Vector Control Parameters F7

Parameter Name Setting range Min. unit Default Mod.

F7.00 ASR proportional gain 1 0.000 ~ 6.000 0.001 0.600 ×

F7.01 ASR integral time 1 0 (integral function disabled), 0.032-32.00s 0.001s 1.000 ×

F7.02 ASR proportional gain 2 0.000 ~ 6.000 0.001 0.600 ×

F7.03 ASR integral time 2 0 (integral function disabled), 0.032-32.00s 0.001s 1.000 ×

F7.04 ASR changing frequency 0.00 ~ 50.0Hz 0.01Hz 5.00 ×

F7.05 Slip compensation gain

0 (reserved), 50.0 ~ 250.0% (for

accounting the slip value)

0.1% 100.0% ×

F7.06 Motoring torque limit 0.0 ~ 200.0% (inverter rated current) 0.1% 100.0% ×

F7.07 Braking torque limit 0.0 ~ 200.0% (inverter rated current) 0.1% 100.0% ×

F7.08 Current loop’s proportional gain KP 0 ~ 9999

1

500

○

F7.09 Current loop’s integral time KI 0 ~ 9999

1

300

○

F7.10 Filtering coefficient 0 ~ 63

1

27

○

5.9 Communication Parameters F8 (Reserved)

Parameter Name Setting range Min. unit Default Mod.

F8.00 Modbus baud rate selection

0: 1200bps

1: 2400bps

2: 4800bps

3: 9600bps

4: 19200bps

5: 38400bps

6: 76800bps

7: 125000bps

1 4 ×

F8.01 Modbus data format

0: RTU, 1 start bit, 8 data bits, 2 stop bits, no parity

1: RTU, 1 start bit, 8 data bits, 1 stop bit, even parity

2: RTU, 1 start bit, 8 data bits, 1 stop bit, odd parity

3: ASCII, 1 start bit, 7 data bits, 2 stop bits, no parity

4: ASCII, 1 start bit, 7 data bits, 1 stop bit, even parity

5: ASCII, 1 start bit, 7 data bits, 1 stop bit, odd parity

1 0 ×

F8.02 Local number 0 (broadcast address), 1 ~ 127 1 5 ×

F8.03

Modbus communication

failure detection time

0: disable the function

0.1 ~ 100.0s

0.1s 0 ×

F8.04 Modbus communication delay 0.01 ~ 1.000s 0.001s 0.01s ×

F8.05

CAN communication station

enable

Bit0: station 1 enable

Bit1: station 2 enable

Bit2: station 3 enable

Bit3: station 4 enable

Corresponding station =1 means to enable the station

Corresponding station=0 means to disable the station

1

0

×

F8.06 CAN baud rate selection

0: 10000bps

1: 20000bps

2: 40000bps

3: 80000bps

4: 1250000bps

1 0 ×

Page 24

20 Chapter 5 Parameter Table

EV3200 Door Control Inverter User Manual

Parameter Name Setting range Min. unit Default Mod.

F8.07

CAN communication failure

detection time

0: disable the function

0.1 ~ 100.0s

0.1s 0s ×

F8.08 CAN communication delay 0.01 ~ 1.000s 0.001s 0.01s ×

F8.09 ~ F8.10 Reserved

5.10 Monitoring And Recording Parameters F9

Parameter Name Setting range Min. unit Default Mod.

F9.00 Parameters displayed by LED

The display of each parameter is controlled by a binary bit.

“1” for display:

Bit0: running frequency (Hz)

Bit1: reference frequency (Hz)

Bit2: output voltage (V)

Bit3: output current (A)

Bit4: output torque (%)

Bit5: DC bus voltage (V)

Bit6: Status of input terminal (No unit)

Bit7: Status of output terminal (No unit)

Bit8: low digits of pulse of door position (0 ~ 9999)

Bit9: high digits of pulse of door position (0 ~ 9999)

1

31

(0000011111B)

○

F9.01

Selection of parameters

displayed by LED in stopping

status (blink)

0: preset OD frequency (Hz)

1: preset CD frequency (Hz)

2: status of input terminal (no unit)

3: status of output terminal (no unit)

4: DC bus voltage (V)

5: low digits of pulse counted for door position (0 ~ 9999)

6: high digits of pulse counted for door position (0 ~ 9999)

1 0

○

F9.02

F9.03

F9.04

Type of latest fault

Type of second lastest fault

Type of third lastest fault

0: no fault record

1: Over-current in Acc process (E001)

2: Overcurrent in Dec process (E002)

3: Overcurrent in constant speed operation (E003)

4: Overvoltage in Acc process (E004)

5: Overvoltage in Dec process (E005)

6: Overvoltage in constant speed operation (E006)

7 ~ 8: Reserved

9: Output phase loss (E009)

10: Reserved

11: Heatsink overheating (E011)

12: Reserved

13: Inverter overload (E013)

14: Motor protection (E014)

15: Reserved

16: EEPROM read or write fault (E016)

17: Reserved

18: Reserved

19: Current detecting circuit fault (E019)

20 ~ 23: Reserved

24: Motor tuning error (E024)

25: PG error (E025)

26: Overspeed protection (E026)

27: Reserved

28: Parameter setting error (E028)

29: Door width auto-learning error (E029)

30: OD overtime error (E030)

31: CD overtime error (E031)

1 0 *

F9.05

DC Bus Voltage (V) at the

latest fault

0 ~ 999V 1V 0V *

F9.06

Output current (A) at the latest

fault

0.00 ~ 99.99A 0.01A 0.00A *

Page 25

Chapter 5 Parameter Table 21

EV3200 Door Control Inverter User Manual

Parameter Name Setting range Min. unit Default Mod.

F9.07

Frequency (Hz) at the latest

fault

0.00Hz ~ 128.00Hz 0.01Hz 0.00Hz *

F9.08

Status of input terminal at the

latest fault

0 ~ 127 (0: OFF;1: ON)

CD/OD/X5/X4/X3/X2/X1

1 0 *

F9.09

Status of output terminal at the

latest fault

0 ~ 7 (0: OFF;1: ON)

PC3/PC2/PC1

1 0 *

F9.10

High digits of pulse counted

for door position at fault time

0 ~ 9999 (×10000) 1 0 *

F9.11

Low digits of pulse counted for

door position at fault time

0 ~ 9999 1 0 *

F9.12 High digit of OD times 0 ~ 9999 (×10000) 1 0 *

F9.13 Low digit of OD times 0 ~ 9999 1 0 *

F9.14 High digit of CD times 0 ~ 9999 (×10000) 1 0 *

F9.15 Low digit of CD times 0 ~ 9999 1 0 *

F9.16 Total operation time 0 ~ 65535 hours (max.) 1 hour 0 *

F9.17 Total running time 0 ~ 65535 hours (max) 1 hour 0 *

F9.18 Parameter initialization

0: no operation

1: Clear the record

2: Load defaults

3 ~ 100: reserved

1

0

×

F9.19 Software version No. 1.00 ~ 99.99 0.01

Actual version

No.

-

F9.20 Product configuration No. 3200 ~ 3299 1

Actual

configuration

No.

-

F9.21 Heatsink temperature 0 ~ 100°C 1 0 *

F9.22 Relay output polarity selection

0: relays PA1/PC1 and PA2/PC2 serve as output NC relays

1: relays PA1/PC1 and PA2/PC2 serve as output NO relays

1 0 ×

Page 26

22 Chapter 6 Parameter Description

EV3200 Door Control Inverter User Manual

Chapter 6 Parameter Description

This chapter introduces in detail the inverter parameters, their setting ranges, defaults, and points needing attention.

Only qualified personnel is allowed to test this product,

otherwise, accidents might occur

Make sure that the mechanical system and electrical

connections of elevator door are correct, accidents

might occur

All the parameters must be set properly according to

relevant industrial standards, otherwise, accidents

might occur

Don't walk to the area where the door is under testing,

otherwise, personal injuries might occur

Reference frequency: Target frequency at which the inverter

operates stably.

Operating frequency: The inverter's actual output frequency

during operation.

The data in "【】" are defaults of corresponding parameters.

6.1 Basic Operation Parameters F0

F0.00 User passward

Setting range: 0 ~ 9999【0】

Set up any non- zero number as user's password to enable

the password protection function.

0000: no password

Note

Once user's password is set, you can only read the parameters but

not set or modify them if you don't input the correct password.

F0.01 Control mode

Setting range: 0 ~ 3【0】

0: speed control

The inverter operates in sensorless vector control mode.

When the inverter is used to control an elevator door, the

speed can be changed by connecting different speed

contacts, and the complete CD or OD can is controlled by a

limit switch.

1: distance control 1

The inverter operates in vector control mode with speed

sensor. The PG parameters must be set correctly, otherwise

the accuracy of control and door width cannot be ensured.

When the inverter controls an elevator door, the door width

should be obtained by auto-learning, and the result will be

saved. Besides, the distance control parameters should be

set correctly. During operation, the pulse count value will be

compared with the preset value to achieve speed decrease

and complete CD or OD.

In this mode, PG must be connected to the motor shaft.

2: distance control 2

The inverter operates in vector control mode without speed

sensor. When the inverter controls elevator door, the PG

parameters must be set correctly, otherwise the accuracy of

door width cannot be ensured. The door width should be

obtained via auto-learning, and the door width information

should be saved after auto-learning. Besides, the distance

control parameters should be set correctly. During operation,

the pulse count will be compared with the preset value to

achieve speed decrease and complete CD or OD.

In this mode, PG may not be connected to the motor shaft.

3: distance control 3

The inverter operates in vector control mode without speed

sensor. When the inverter controls elevator door, the PG

parameters must be set correctly, otherwise the accuracy of

door width cannot be ensured. The door width should be

obtained via auto-learning, and the door width information

should be saved after auto-learning. Besides, the distance

control parameters should be set correctly. During operation,

the pulse count will be compared with the preset value to

achieve speed decrease and complete CD or OD.

CD and OD completion judgement logic: when OD position

limiting pulse and OD limit switch mounted on the elevator

door are both active, OD is complete; when CD position

limiting pulse and CD limit switch mounted on the elevator

door are both active, CD is complete.

In this mode, PG may not be connected to the motor shaft.

F0.02 Control command selection

Setting range: 0 ~ 7【0

】

0: keypad control mode of general-purpose inverter

The starting and stopping of the inverter is controlled

through the keypad of the inverter. The inverter runs forward

if the

key is pressed, reversely if the

key is pressed,

and stops if the key is pressed. In this control mode, the

inverter operates as a general-purpose inverter and will not

follow the command for elevator door control. Besides, the

motor parameters tuning is only active in keypad control

mode.

1: key control mode for controlling elevator door

The starting and stopping of the inverter is controlled

through the keypad of the inverter. Pressing the

key

opens the elevator door, pressing the

key closes the

elevator door, and pressing the

key stops the inverter.

2: terminal control mode for controlling elevator door

Page 27

Chapter 6 Parameter Description 23

EV3200 Door Control Inverter User Manual

The elevator control system sends OD and CD commands

to realize door opening or closing. The operating logic is

shown in Figure 6-1.

0

K1K

2

0

10

0

1

11

Running

command

OD

CD

Stop

K

1

K

2

OD

COM

CD

EV3200

inverter

.

.

.

OD

Figure 6-1 Terminal control logic

3: communication control mode for controlling elevator door

(reserved)

OD, CD and auto-learning are performed according to the

definition of the control word in protocol.

4: auto-demo mode

Auto-demo mode is used for demonstrating the operation or

commissioning of the inverter in the factory, no need to be

controlled by the control system. The auto-demo mode can

be set after the inverter's operation curve is set in keypad

control mode for elevator door control. Press the key to

start the demonstration of OD and CD repetitively, the times

and interval between CD and OD can be set by F3.11,

F3.12 and F3.13. Pressing the

key stops the demo.

5: terminal control mode of general-purpose inverter

The starting and stopping of the motor can be controlled via

OD and CD terminals. The operation logic is shown in

Figure 6-2. In this control mode, the inverter will not perform

the functions of elevator door control.

0

K1K

2

0

10

0

1

11

Running

command

FWD

REV

Stop

K

1

K

2

OD

COM

CD

EV3200

inverter

.

.

.

FWD