Page 1

Instruction Manual

ETC00303

02/2007

Instruction Manual

BINOS® E

Economic & Enhanced Gas Analyzer

rd

3

Edition 02/2007

www.EmersonProcess.com

Page 2

BINOS® E Instruction Manual

ETC00303

02/2007

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 11/2000 2nd Edition 05/2001

3rd Edition 02/2007

© 2000-2007 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Rosemount Analytical

CONTENTS

Table of Contents

SAFETY SUMMARY S - 1

General S - 2

Gases and Gas Conditioning (Sample Handling) S - 4

Supply Voltage S - 4

BINOS E specific notes for the user S - 5

Additional notes for service / maintenance S - 6

Electrostatic Discharge S - 7

PREFACE P - 1

DESCRIPTION

1. Technical Description 1 - 1

1.1 Front Panel 1 - 1

1.2 Rear Panel 1 - 4

1.3 Internal Construction (Component Layout) 1 - 5

1.3.1 Internal Gas Paths 1 - 7

1.3.2 Printed Circuit Boards 1 - 9

2. Measuring Principle 2 - 1

2.1 NDIR Measurement 2 - 1

2.1.1 Opto - Pneumatic Measuring Principle 2 - 3

2.1.2 Interference Filter Correlation (IFC Principle) 2 - 4

2.2 NDUV Measurement 2 - 6

2.3 Oxygen Measurement 2 - 7

2.3.1 Paramagnetic Measurement 2 - 7

2.3.2 Electrochemical Measurement 2 - 9

2.4 (Vacant) 2 - 11

3. (vacant)

4. (vacant)

ETC00303(1) BINOS E e (2.0) 11/00

I

Page 4

CONTENTS

OPERATION (STARTUP)

5. Installation and Preparation of Startup 5 - 1

5.1 Installation Site 5 - 2

5.2 (vacant) 5 - 3

5.2.1 Pressure Sensor (Option) 5 - 4

5.2.4 Gas Flow 5 - 4

5.3 Gas Connections 5 - 5

6. Startup Procedue (Switching On) 6 - 1

6.1 Supply Voltage 6 - 2

7. Measurement / Calibration / Switching (Shut) Off 7 - 1

7.1 Measurement 7 - 1

7.2 Calibration 7 - 2

7.2.1 Calibration (Test) Gases 7 - 2

7.3 Switching (Shut) Off 7 - 4

Rosemount Analytical

8. BINOS E Front Panel Program 8 - 1

8.1 Requirements 8 - 1

8.2 Installation and Startup 8 - 2

8.2.1 Installation 8 - 2

8.2.2 Startup 8 - 4

8.3 Function Keys 8 - 4

8.4 Status Display ("Status") 8 - 10

8.5 Display Page 8 - 11

8.6 Recorder Page 8 - 14

8.6.1 Averaging 8 - 15

8.6.2 Spooling 8 - 15

8.6.3 Recording 8 - 15

8.7 Messages Page 8 - 16

8.8 Analog Output Link and Adjustment Page 8 - 18

9. BINOS E Data Exchange 9 - 1

II

ETC00303(1) BINOS E e (2.0) 11/00

Page 5

Rosemount Analytical

10. TROUBLESHOOTING

10.1 (vacant)

11. Test Procedure / Test Points (vacant)

12. Removal / Replacement of Components (vacant)

13. MAINTENANCE 13 - 1

14. Leak Testing 14 - 1

CONTENTS

15. Opening the Housing 15 - 1

15.1 BINOS E (Metal-sheet housing) 15 - 1

15.1.1 Housing Cover 15 - 1

15.2 BINOS E (1/2 19" housing) 15 - 2

15.2.1 Housing Cover 15 - 2

16. (vacant)

17. Replacement and Cleaning of Photometric Components 17 - 1

17.1 Removal of the Photometer Assembly 17 - 1

17.2 Light Source Replacement (IR) 17 - 2

17.3 Cleaning of Analysis Cells and Windows 17 - 3

17.3.1 Removal of Analysis Cells 17 - 3

17.3.2 Cleaning 17 - 4

17.3.3 Reinstalling of Analysis Cells 17 - 5

17.4 Reinstalling of the Photometer Assembly 17 - 6

17.5 Physical Zeroing 17 - 7

18. Check / Replacement of electrochemical Oxygen Sensor 18 - 1

18.1 Check of the Sensor 18 - 2

18.2 Replacement of the Sensor 18 - 3

18.2.1 Removal of the Sensor 18 - 3

18.2.2 Replacing the Sensor 18 - 4

18.2.3 Reinstalling of the Sensor 18 - 4

18.2.4 Basic conditions for the Oxygen Sensor 18 - 5

19. Cleaning of Housing Outside 19 - 1

ETC00303(1) BINOS E e (2.0) 11/00

III

Page 6

CONTENTS

Rosemount Analytical

20. TECHNICAL DATA 20 - 1

20.1 Housing 20 - 1

20.2 Options 20 - 2

20.3 General Specifications 20 - 2

20.3.1 BINOS E Specifications 20 - 3

20.3.2 Cross Sensitivities 20 - 4

20.3.3 Dimensions 20 - 5

20.4 Voltage supply 20 - 6

20.4.1 Electrical Safety 20 - 6

20.4.2 Power Supply 20 - 6

SUPPLEMENT

21. Pin Assignments 21 - 1

21.1 24 V dc Input 21 - 1

21.2 Serial Interfaces (vacant) 21 - 2

21.3 Analog Signal Outputs (vacant) 21 - 2

22. Calculation of Water Content from Dew-Point 22 - 1

to Vol.-% or g/Nm

3

IV

ETC00303(1) BINOS E e (2.0) 11/00

Page 7

Rosemount Analytical

SAFETY SUMMARY

Safety Summary

Outside and/or inside BINOS E or at operation manual resp . diff erent symbols gives you a hint

to special sources of danger.

Source of danger !

See Operation Manual!

High V oltage !

GENERAL

Electrostatic Discharge (ESD) !

Explosives !

Hot components !

Toxic !

UV Radiation !

Risk to health !

BINOS E specific notes for the user !

In operation manual we will give partly additional informations to these symbols.

Strictly follow these instructions please !

ETC00303(1) BINOS E e (2.0) 11/00

S - 1

Page 8

SAFETY SUMMARY

GENERAL

Rosemount Analytical

1. General

◆ The following gener al safety precautions must be observed during all phases of operation,

service and repair of this instrument !

Failure to comply with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture and intended use of this instrument !

F ailure to comply with these precautions may lead to personal injury and damage to this

instrument !

◆ Fisher-Rosemount GmbH & Co. does not tak e responsibility (liability) for the customer´s

failure to comply with these requirements !

◆ Do not attempt internal service or adjustment unless other person, capable of rendering first

aid and resuscitation, is present !

◆ Because of the danger of introducing additional hazards, do not perfo rm any unauthorized

modification to the instrument !

Return the instrument to a Fisher-Rosemount Sales and Service office for service or repair

to ensure that safety features are maintained !

◆ Instruments which appear damaged or defective should be made inoper ative and secured

against unintended operation until they can be repaired b y qualified service personnel.

S - 2

ETC00303(1) BINOS E e (2.0) 11/00

Page 9

Rosemount Analytical

SAFETY SUMMARY

GENERAL

Operating personnel must not remove instrument covers !

Component replacement and internal adjustments must be made by qualified

service personnel only !

Read and understand all operation manuals and receiving appropriate training

before attempting to operate with the instrument !

Be sure to observe the additional notes, saf ety precautions and warnings given

in the individual operation manuals !

Do not operate the instrument in the presence of flammable gases or explosiv e

atmosphere without supplementary protective measures !

At photometer or heated components there could be exist hot components !

The optional UV lamp contains mercury. Lamp breakage could result in mercury

exposure ! Mercury is highly toxic !

If the lamp is broken, avoid any skin contact to mercury and inhalation of mercury

vapors !

ETC00303(1) BINOS E e (2.0) 11/00

S - 3

Page 10

SAFETY SUMMARY

GASES AND GAS CONDITIONING (SAMPLE HANDLING) / SUPPLY VOLTAGE

2. Gases and Gas Conditioning (Sample Handling)

Be sure to observe the safety regulations for the respective gases

(sample gas and test gases / span gases) and the gas bottles !

Flammable or e xplosive gas mixtures must not be purged into the instrument

without supplementary protective measures !

To avoid a danger to the operators by explosive, toxic or unhealthy gas

components, first purge the gas lines with ambient air or nitrogen (N2) before

cleaning or exchange parts of the gas paths.

Rosemount Analytical

Pressure of sample gas / test gases max. 1,500 hPa !

3. Supply Voltage

The socket outlet shall be installed near the equipment and shall be easily

accessible to disconnect the device from the socket outlet.

Verify whether the line voltage stated on the instrument ore power supply agrees

with that of your mains line!

Be sure to observe the safety precautions and warnings given by

manufacturer of power supply !

◆ BINOS E is a Safety Class 2 ( ) instrument.

S - 4

Verify correct polarity for 24 V dc operation !

Use only power supply UPS 01 T, SL5, SL10 (SL 5/10 for cabinet mounting

only) or equivalent pow er supplys to be in agreement with the CE conformity.

ETC00303(1) BINOS E e (2.0) 11/00

Page 11

Rosemount Analytical

4. BINOS E specific notes for the user

Before startup unscrew transfer safety lock (knurled-head screws)

of the BINOS E (Item 5. of operation manual) !

The installation site for the instrument has to be dry and remain above freezing

point at all times.

The instrument must be exposed neither to direct sunlight nor to strong sources

of heat. Be sure to observe the permissible ambient temperature !

For outdoor sites, we recommend to install the instrument in a protective cabinet.

At least, the instrument has to be protected against rain (e.g., shelter).

SAFETY SUMMARY

BINOS E SPECIFIC NOTES FOR THE USER

Free flow of air into and out of the BINOS E (ventilation slits) must not be

hindered by nearby objects or walls !

Do not interchange gas inlets and gas outlets !

All gases have to be supplied to the BINOS E as conditioned gases !

When the instrument is used with corrosive gases, it is to be verified that there

are no gas components which may damage the gas path components.

The exhaust gas lines have to be mounted in a declining, descending,

pressureless and frost-free and according to the valid emission legislation !

In case it is necessary to open the gas paths, close the analyzers

gas connections with PVC caps immediatly !

Pressure of sample gas / test gases max. 1,500 hPa !

By using of optional delivering terminal strip adapters with BINOS E the

analyzer is not be in agreement with the CE conformity. In this case CE

conformity has to be declared by customer as “manufacturer of system”.

Use only optional delivered cables from our factory or equivalent shielded

cables to be in agreement with CE conformity.

The customer has to prove that the shield is connected on both sides.

Shield and connectors housing has to be connected conductive.

Sub.-min.-D-plugs/sockets have to be screwed to the analyzer.

ETC00303(1) BINOS E e (2.0) 11/00

S - 5

Page 12

SAFETY SUMMARY

ADDITIONAL NOTES FOR SERVICE / MAINTENANCE

5. Additional notes for service / maintenance

Operating personnel must not remove instrument covers !

Component replacement and internal adjustments must be made by qualified

service personnel only !

Always disconnect power, discharge circuits and remove external voltage

sources before troubleshooting, repair or replacement of any component !

Any work inside the instrument without switching off the power must be

performed by a specialist, who is familiar with the related danger, only !

Rosemount Analytical

To avoid a danger to the operators by explosive, toxic or unhealthy gas

components, first purge the gas lines with ambient air or nitrogen (N2) before

cleaning or exchange parts of the gas paths.

At photometer or heated components there could be exist hot components !

In case of exchanging fuses the customer has to be certain that fuses of specified

type and rated current are used. It is prohibited to use repaired fuses or defective

fuse holders or to short-circuit fuse carriers (fire hazard).

UV source operates with high voltage !

[Voltage supply UVS (Fig. 1-3)]

Ultraviolet light from UV lamp can cause permanent eye damage !

Do not look directly at the ultraviolet source !

S - 6

At component replacement or installation the RF shielding contacts must not

be bended !

ETC00303(1) BINOS E e (2.0) 11/00

Page 13

Rosemount Analytical

ELECTROSTATIC DISCHARGE

SAFETY SUMMARY

6 Electrostatic Discharge

The electronic parts of the analyzer can be irreparably damaged if exposed to electrostatic

discharge (ESD).

The instrument is ESD protected when the covers hav e been secured and safety precautions

observed. When the housing is open, the internal components are not ESD protected anymore.

Although the electronic parts are reasonable safe to handle, you should be aware of the

following considerations:

Best ESD example is when you walked across a carpet and then touched an electrical

grounded metal doorknob. The tiny spark which has jumped is the result of electrostatic

discharge (ESD).

You prevent ESD by doing the following:

Remove the charge from y our body before opening the housing and maintain during work with

opened housing, that no electrostatic charge can be built up.

Ideally you are opening the housing and working at an ESD - protecting workstation.

Here you can wear a wrist trap.

Howe ver , if you do not ha ve such a workstation, be sure to do the follo wing procedure exactly:

Discharge the electric charge from your body. Do this by touching a device that is grounded

electrically (any device that has a three - prong plug is grounded electrically when it is plugged

into a power receptacle).

This should be done sev eral times during the operation with opened housing (especially after

leaving the service site because the movement on a low conducting floors or in the air might

cause additional ESDs).

ETC00303(1) BINOS E e (2.0) 11/00

S - 7

Page 14

SAFETY SUMMARY

Rosemount Analytical

S - 8

ETC00303(1) BINOS E e (2.0) 11/00

Page 15

Rosemount Analytical

Preface

The BINOS E analyzers offer multi-component, multi-method analysis. Different measurement

methods can be combined in one analyzer.

BINOS E is designed to measure up to max. 4 gas components and up to 8 secondary

parameters (pressure, temperature and flow). Primary measurements include photometer

and non-photometer-channels (possible combinations: see price matrix):

- Non-dispersive Infrared (up to two channels)

- Non-dispersive Ultraviolet (one channel)

- Paramagnetic Oxygen (up to two channels)

PREFACE

- Electrochemical Oxygen (up to two channels)

BINOS E can combine up to two photometer and up to two non-photometer channels.

BINOS E is designed for OEM customers, for bench and sensor integrators, f or universities and

institutes. That means for anybody who likes a modern new measuring philosophy with

communication via serial interface.

System builders create their own Control Units or Platforms. They need either high performance optical or sensor benches (fast response, lo w ranges and/or high dynamic measurements) or robust photometer/sensor technologies but with no need f or an instrument displa y.

There is also no need for digital inputs or outputs, often e ven no necessity f or analog outputs.

That is why BINOS E offers as a standard only communication via serial interface. Analog

outputs are available as option. Relay contacts, digital inputs and outputs are not provided.

Main applications for BINOS E are:

- Automotive (Internal Combustion Engine Emissions, ICEE)

- Fast response capnography (Lung function tests)

- Solids Analyzers (C, S, H, N analysis)

- TOC/ TN/ TS Analyzers (Total organic carbon, nitrogen or sulphur)

- Metallurgical Business (Oven atmosphere, hardening, ceramic)

BINOS E is specially designed to measure high dynamic ranges such as low carbon mono xide

concentrations for automotive applications combined with other measurements:

CO

: 0 - 50 ... 5,000 ppm

low

CO

: 0 - 0.5(1) ... 10 Vol.-%

high

CO2: 0 - 1 ... 16 (20) Vol.-%

O2: 0 - 1 (2) ... 10 (25) Vol.-%

ETC00303(1) BINOS E e (2.0) 11/00

P - 1

Page 16

PREFACE

Rosemount Analytical

An additional NO, SO2 or C6H14 channels are av ailable as option for automotiv e applications:

NO: 0 - 250 ... 2,500 ppm

SO2: 0 - 130 ... 3,000 ppm (NDUV)

C

: 0 - 300 ... 3,000 ppm

6H14

NO2: 0 - 250 ... 1,000 ppm (NDUV)

For medical application we offer CO and CH4 with IFC principles:

CO: 0 - 3,000 ppm

CH4: 0 - 3,000 ppm

Solids analyzers can be equipped with:

CO: 0 - 1 ... 10 Vol.-%

CO2: 0 - 1 ... 16 (20) Vol.-%

SO2: 0 - 1 ... 10 Vol.-%

H2O: 0 - 1 ... 3(4) Vol.-%

For T OC/ TN/ TS applications we can provide:

CO2: 0 - 1 ... 16 (20) Vol.-% or 0 - 100 (200) ... 2,000 (3,000) ppm

NO: 0 - 250 ... 2,500 ppm

SO2: 0 - 130 ... 3,000 ppm (NDUV)

For metallurgical applications we offer:

CO: 0 - 1 ... 20 Vol.-% or 0 - 20 ... 100 Vol.-%

CO2: 0 - 5 ... 100 Vol.-%

This is an overview about main applications with main configurations/components. Other

components and applications may be provided on request.

The following list of abbreviations gives an overview about terms used in this manual:

IR = measurement at infrared spectral range

UV = measurement at ultraviolet spectral range

VIS = measurement at visual spectral range

PO2= paramagnetic oxygen measurement

EO2= electrochemical oxygen measurement

P - 2

ETC00303(1) BINOS E e (2.0) 11/00

Page 17

Rosemount Analytical

TECHNICAL DESCRIPTION

FRONT PANEL

1. Technical Description

BINOS E is different from common gas analyzers as follows:

The BINOS E analyzer is assembled as a b lind instrument without need of anoperation front

panel.

Communication is done via serial interface RS 232 with the Fisher-Rosemount Front Panel

Program (option) or via DPS protocol to support a user designed program.

The Front P anel Program is described in chapter 8 while chapter 9 gives information about the

DSP protocol.

Compared with NGA 2000 ML T 1 the A CU (analyzer control unit) is missing and the cardcage

is modified by replacing the optional PCB's SIO, DIO and LEM (network board) with a new

I/O board LIO (low cost I/O). Thus, BINOS E is a stand-alone analzer without network

functionality. The operation procedure is performed by an external PC via serial interface.

All components of a BINOS E analyzer are incorporated into a metal-sheet housing or a 1/2

19" housing.

The 1/2 19" housings are available as rack-mounting or tab le-top versions.

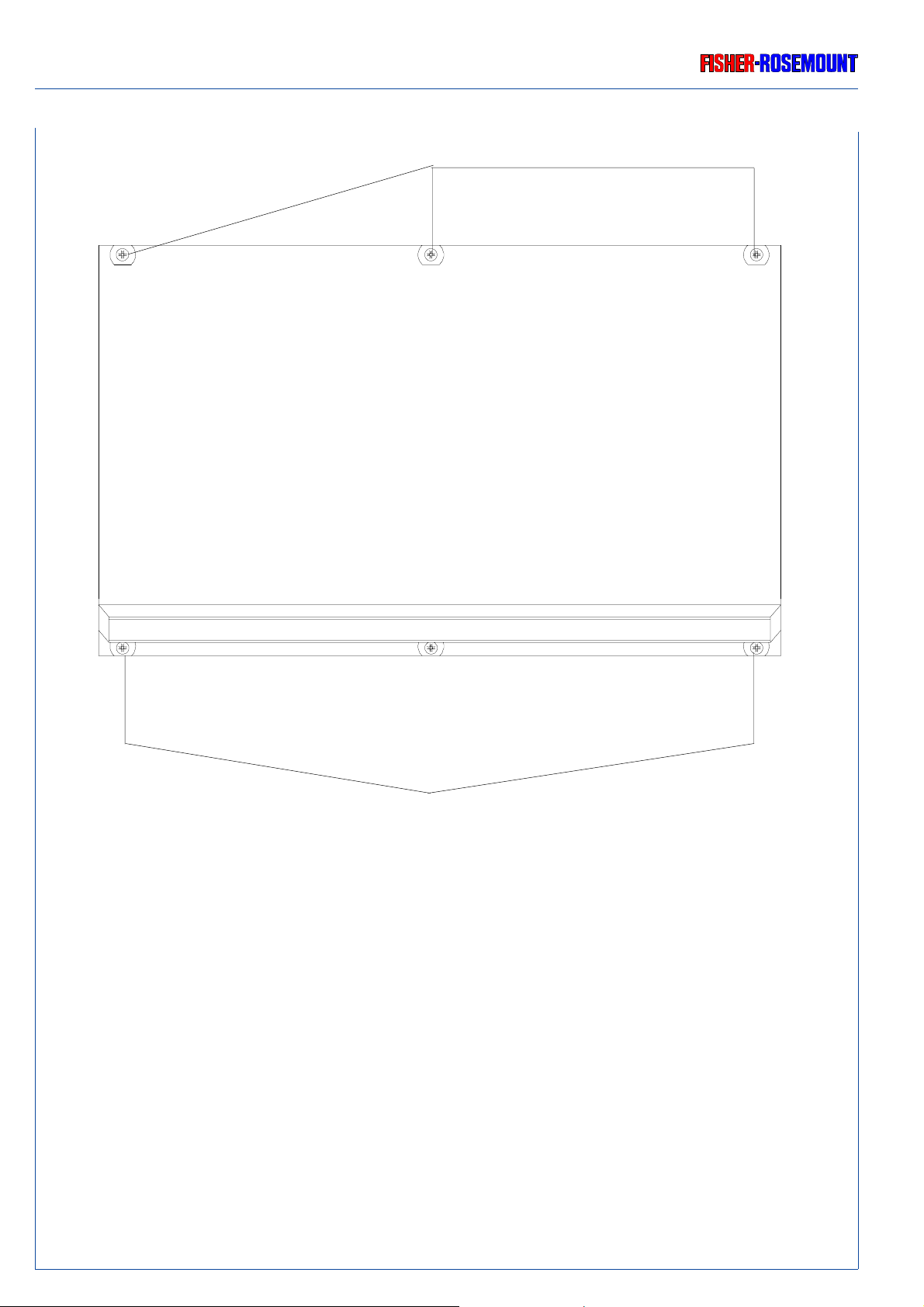

1.1 Front Panel

The front panel of the BINOS E analyzer shows a blind plate instead of an operation front panel.

The 1/2 19" housing front panel is shown in Fig. 1-1(rack-mountable version).

The metal-sheet versions have a blind plate too (see Fig. 1-2).

No electrical and gas connections are realized from the front panel.

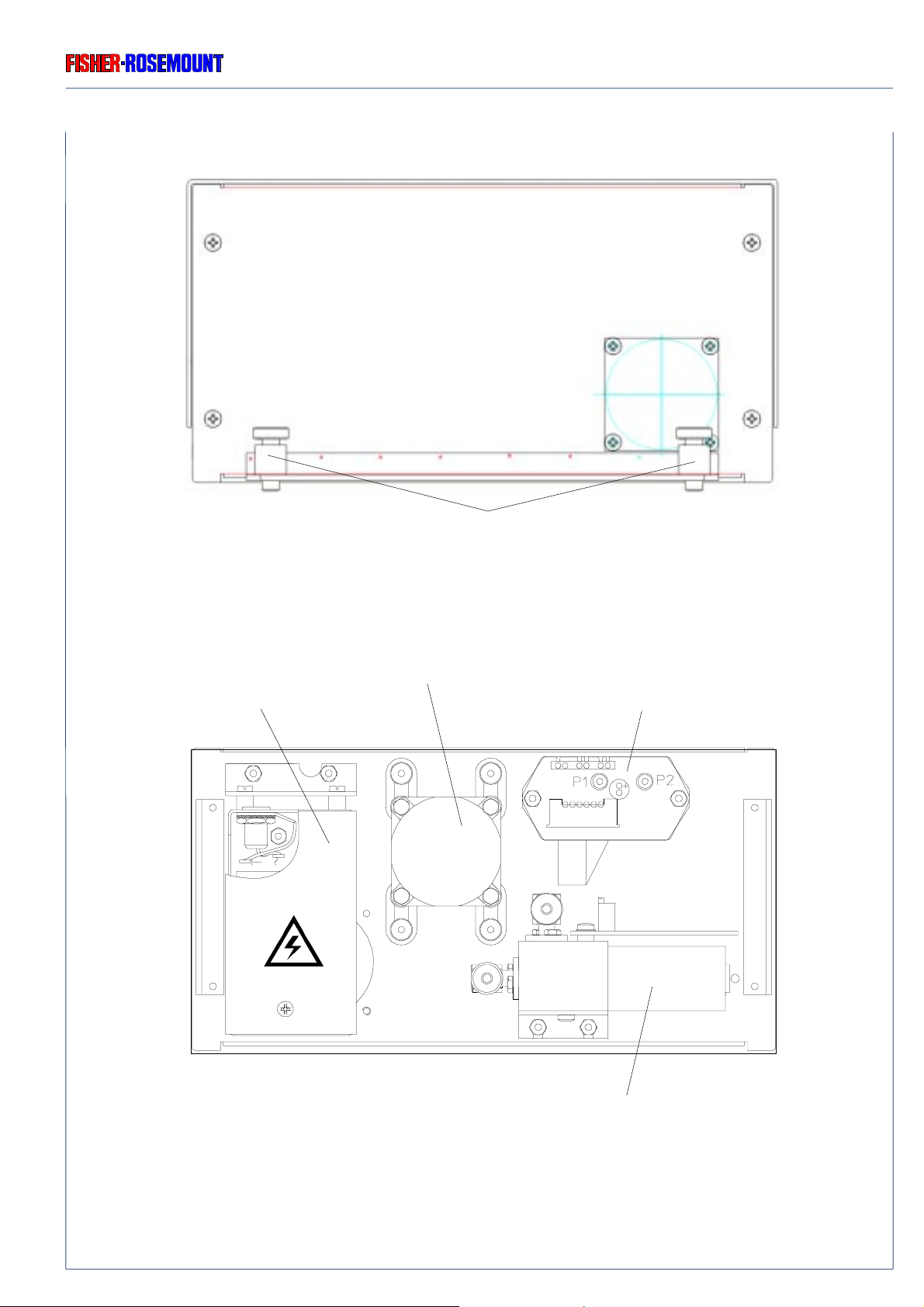

At BINOS E front panel rear side (see Fig. 1-3) there are mounted different components if the

corresponding options are chosen.

ETC00303(1) BINOS E e (2.0) 11/00

1 - 1

Page 18

TECHNICAL DESCRIPTION

FRONT PANEL

Fastening screws for rack mounting or carrying-strap bracket

Rosemount Analytical

1 - 2

Fastening screws for rack mounting or carrying-strap bracket

Fig. 1-1: BINOS E front panel, Front view

ETC00303(1) BINOS E e (2.0) 11/00

Page 19

Rosemount Analytical

TECHNICAL DESCRIPTION

FRONT PANEL

Fig. 1-2: BINOS E Sheet-metal Housing , Front panel, Front view

UVS (Voltage Supply for UV Source)

[Option]

Retention pins

Fan [depending on

configuration]

Pressure Sensor

[Option]

OUT

ETC00303(1) BINOS E e (2.0) 11/00

IN

O2 Sensor, electrochemical

[Option]

Fig. 1-3: BINOS E, Front panel, Rear view

1 - 3

Page 20

TECHNICAL DESCRIPTION

REAR PANEL

Rosemount Analytical

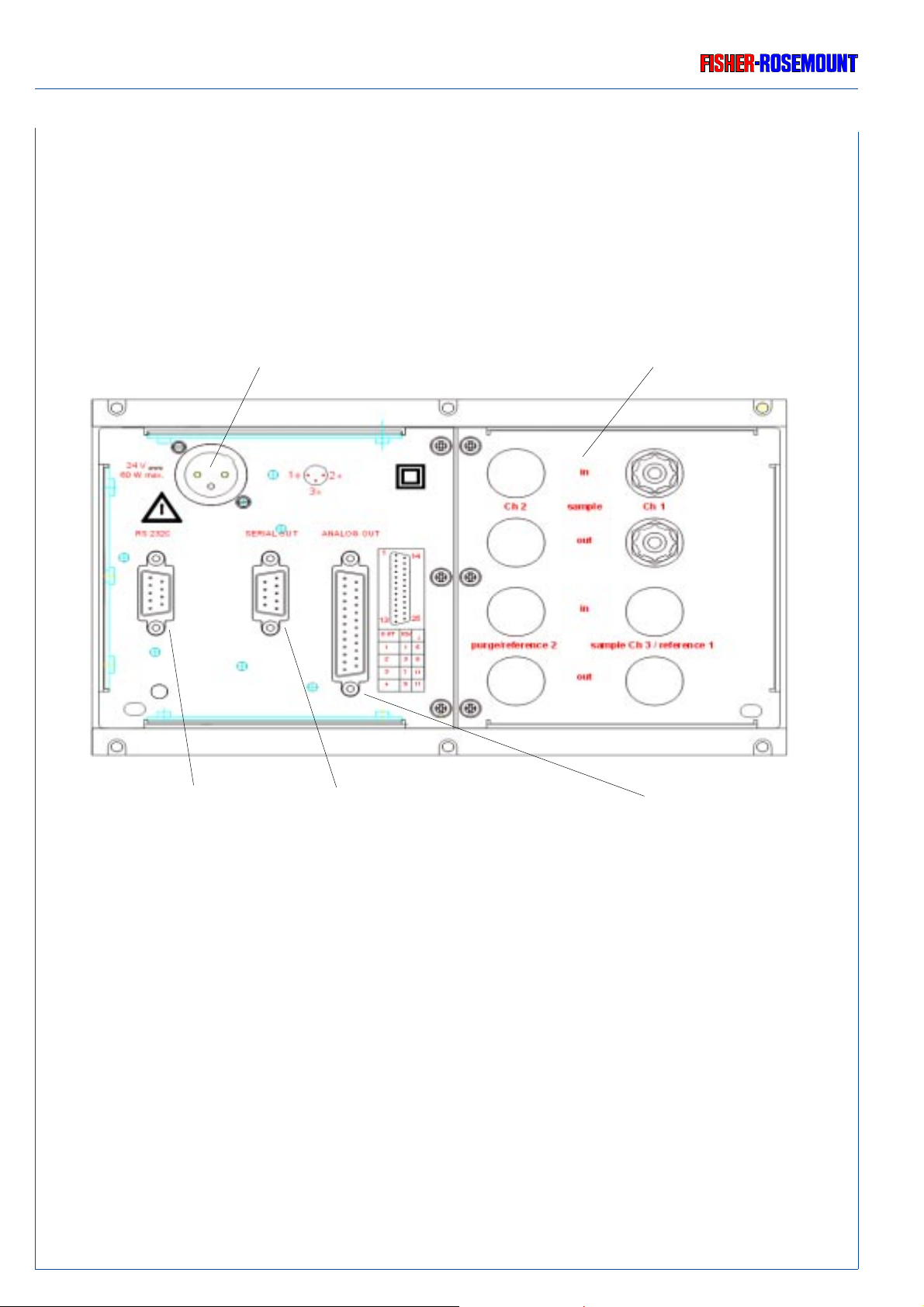

1.2 Rear Panel

On the BINOS E rear panel the connector for 24 Vdc supply, the gas connections and the

connectors for Input/output modules (standard and optional I/O's) are accommodated.

Input 24 V dc Gas connections

Serial Interface RS 232

(Standard)

Serial out: RS 232 or CAN open

(Option)

Fig. 1-4: BINOS E, Rear panel (including all options)

4 Analog Outputs

(Option)

1 - 4

ETC00303(1) BINOS E e (2.0) 11/00

Page 21

Rosemount Analytical

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

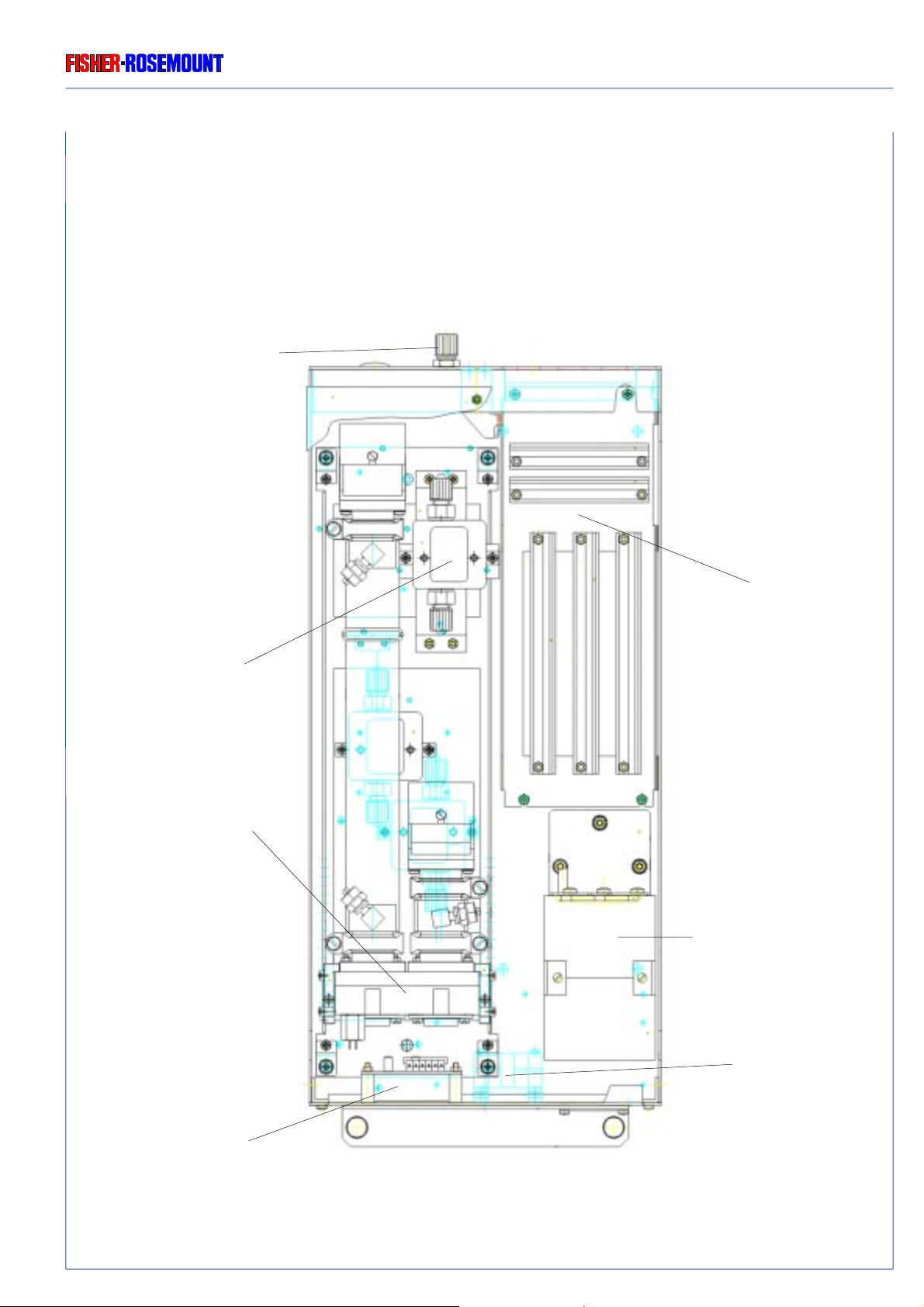

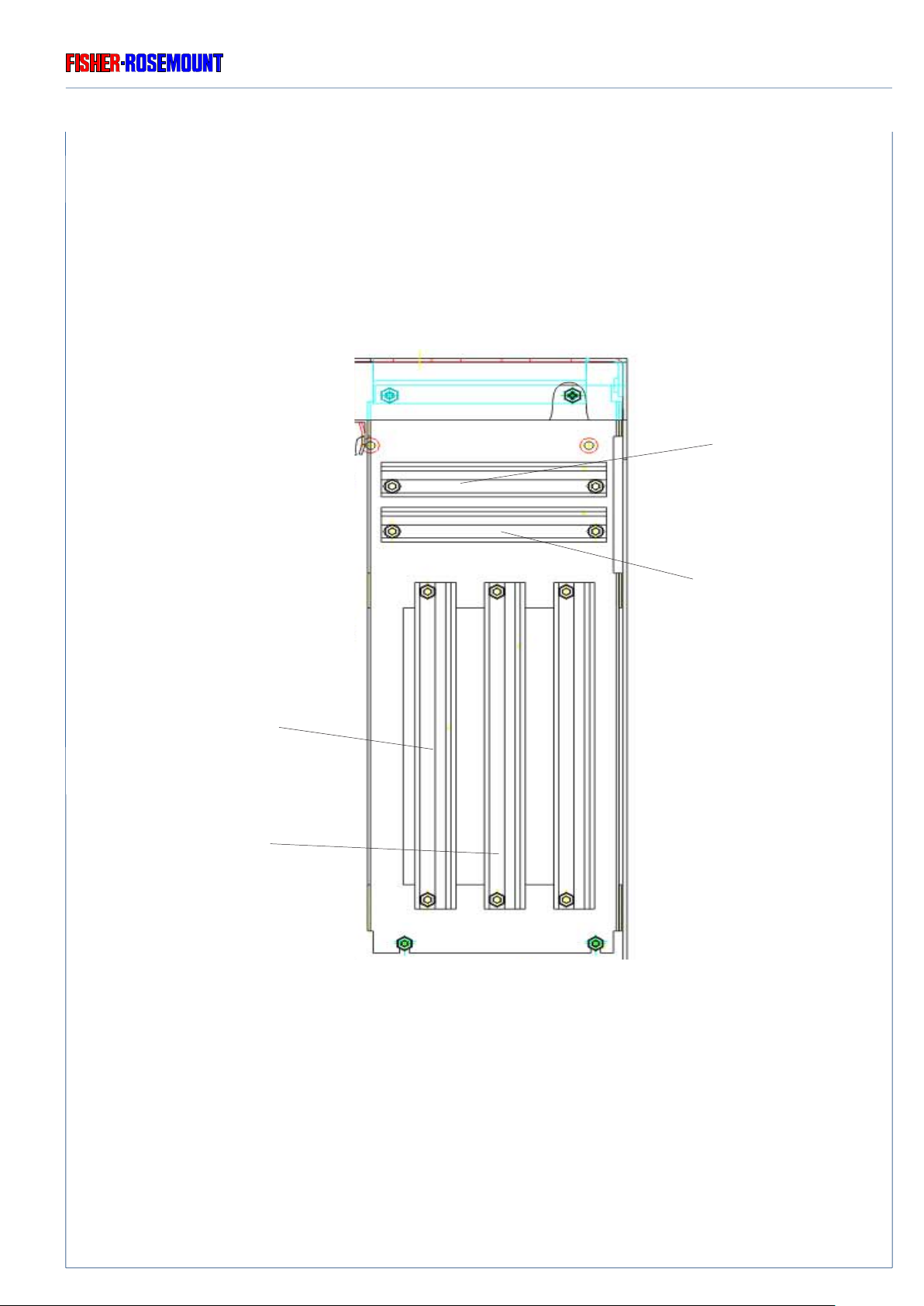

1.3 Internal Construction (Component Layout)

Regarding BINOS E from the front, the electronic unit with interconnection PCB and other

PCBs are located on the right. The photometer assembly and other parts are located on the

left.

Gas Connections

Flow Sensor

(Option)

Photometer Bench with

Gas Detectors

(single or dual channel

assembly)

Card Cage

(see Item 1.3.2)

O2 Sensor, paramagnetic

(Option)

Pressure Sensor

(Option)

ETC00303(1) BINOS E e (2.0) 11/00

Fan

Fig. 1-5: BINOS E, Sheet-metal Housing, Top view

(with 2 NDIR channels & paramagnetic O2 Sensor)

1 - 5

Page 22

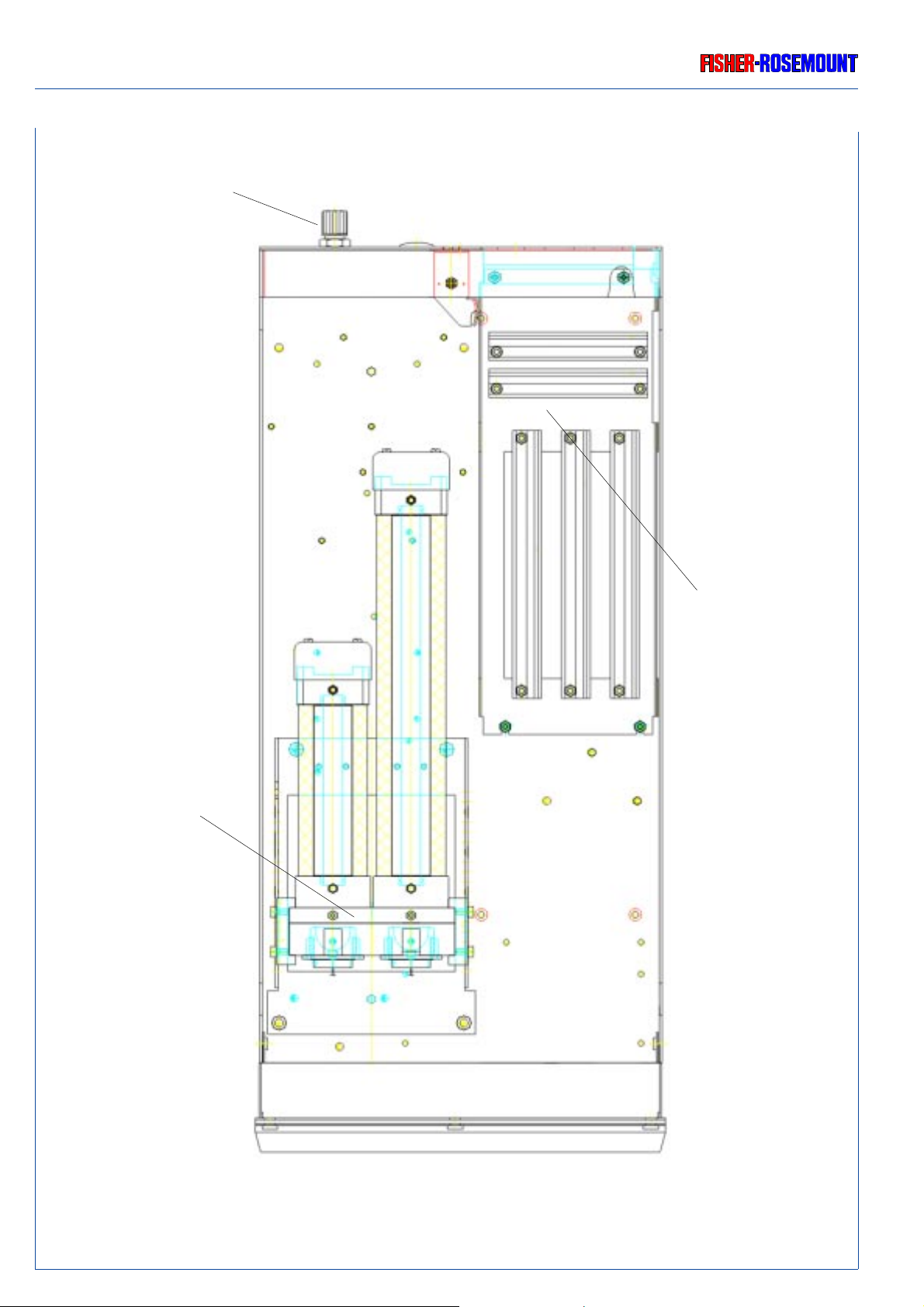

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Gas Connections

Rosemount Analytical

Photometer Bench with

Pyroelectrical Detectors

(single or dual channel

assembly)

Card Cage

(see Item 1.3.2)

1 - 6

Fig. 1-6: BINOS E, 1/2 19" Analyzer Housing, Top view

(with 2 NDIR channels)

ETC00303(1) BINOS E e (2.0) 11/00

Page 23

Rosemount Analytical

TECHNICAL DESCRIPTION

INTERNAL GAS PATHS

1.3.1 Internal Gas Paths

The materials used for the gas paths may be selcted to suit the intendend application. In

marking such selection the diffusion rates of the individual gas components, their corrosivity,

and the temperature and pressure of the sampled gas must be taken into account.

a) Gas Path Material

The physical and chemical properties of the sample gas and the operating conditions

(temperature and pressure) of the analyzer determine the materials which may be used for gas

paths and gas fittings.

Fittings

For standard applications the analyzers are provided with PVDF fitting, 6/4 mm. The analyzers

can be shipped with swagelok® fittings, stainless steel, 6/4 mm or 1/4" as option.

Additional fittings to be delivered on request, consult factory.

Tubing

For standard applications the analyzers are provided with Viton or PTFE tubing (6/4 mm).

Stainless steel tubing is available for one or two gas p aths. Other configurations with ss tubing

may be provided on request. Special tubings may be on request af ter consulting factory.

Safety Filter

For standard applications the analyzers are provided with a safety filter (PTFE). This filter is no

substitute for a fine dust filter in the sample handling system.

ETC303(1) BINOS E e (2.0) 02/2007

1 - 7

Page 24

TECHNICAL DESCRIPTION

Rosemount Analytical

INTERNAL GAS PATHS

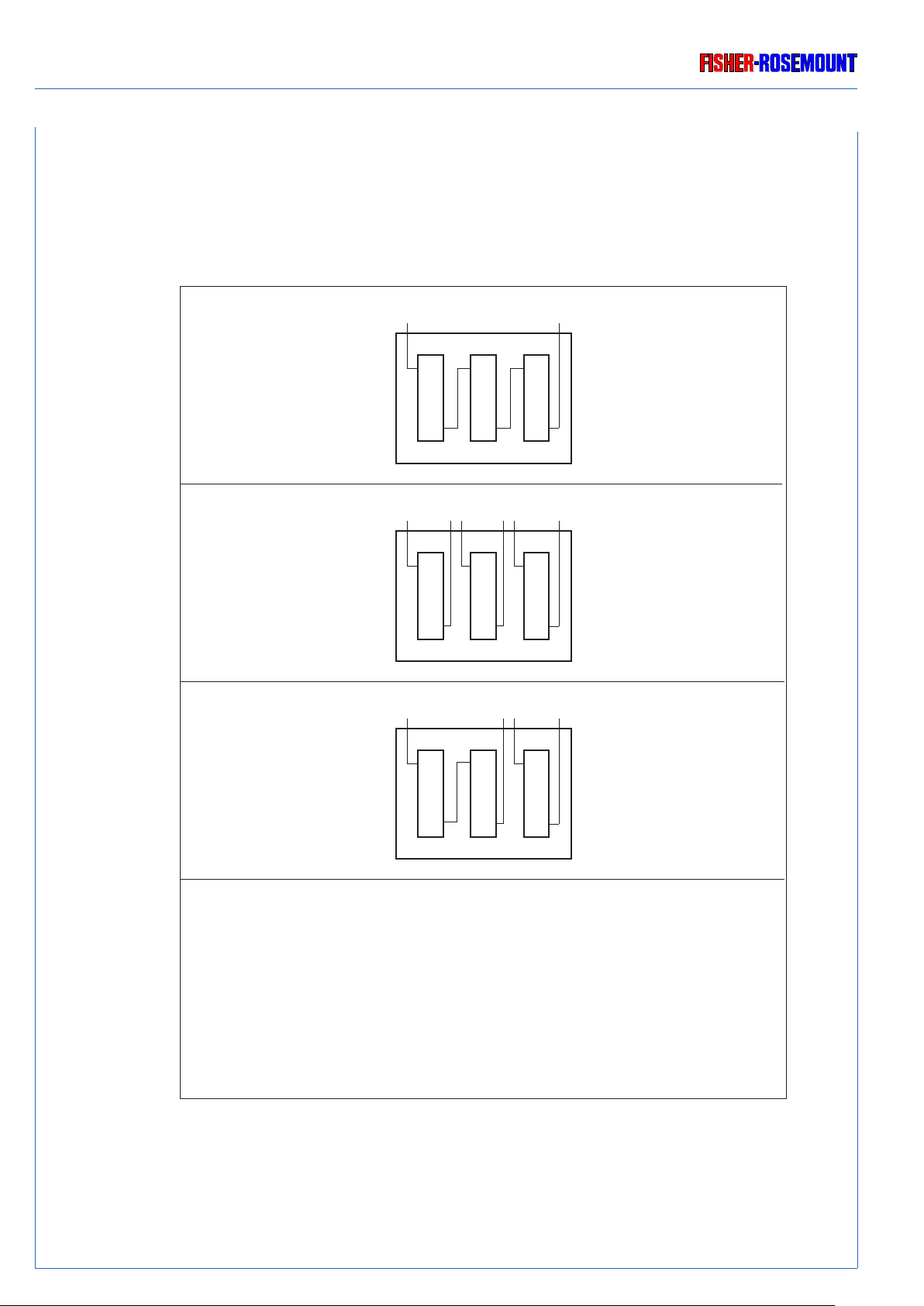

b) Gas Path Layout (internal tubing)

The principle various possible layouts of the internal gas lines are summarized in the table 1-

1.

OutIn

tubing in series

tubing in parallel

combined tubing:

series and parallel

(special tubing)

ULCO

special tubing:

external in series,

internal parallel

low

ultra

CO

OutOut In In

Out In

O

/H

CO

high

CO

OutIn

OutIn

OutIn

2

2

Note:

Tubing must not be

changed by customer

!

1 - 8

Table 1-1: Possible internal tubings (examples with 3 measuring channels)

ETC303(1) BINOS E e (2.0) 02/2007

Page 25

Rosemount Analytical

TECHNICAL DESCRIPTION

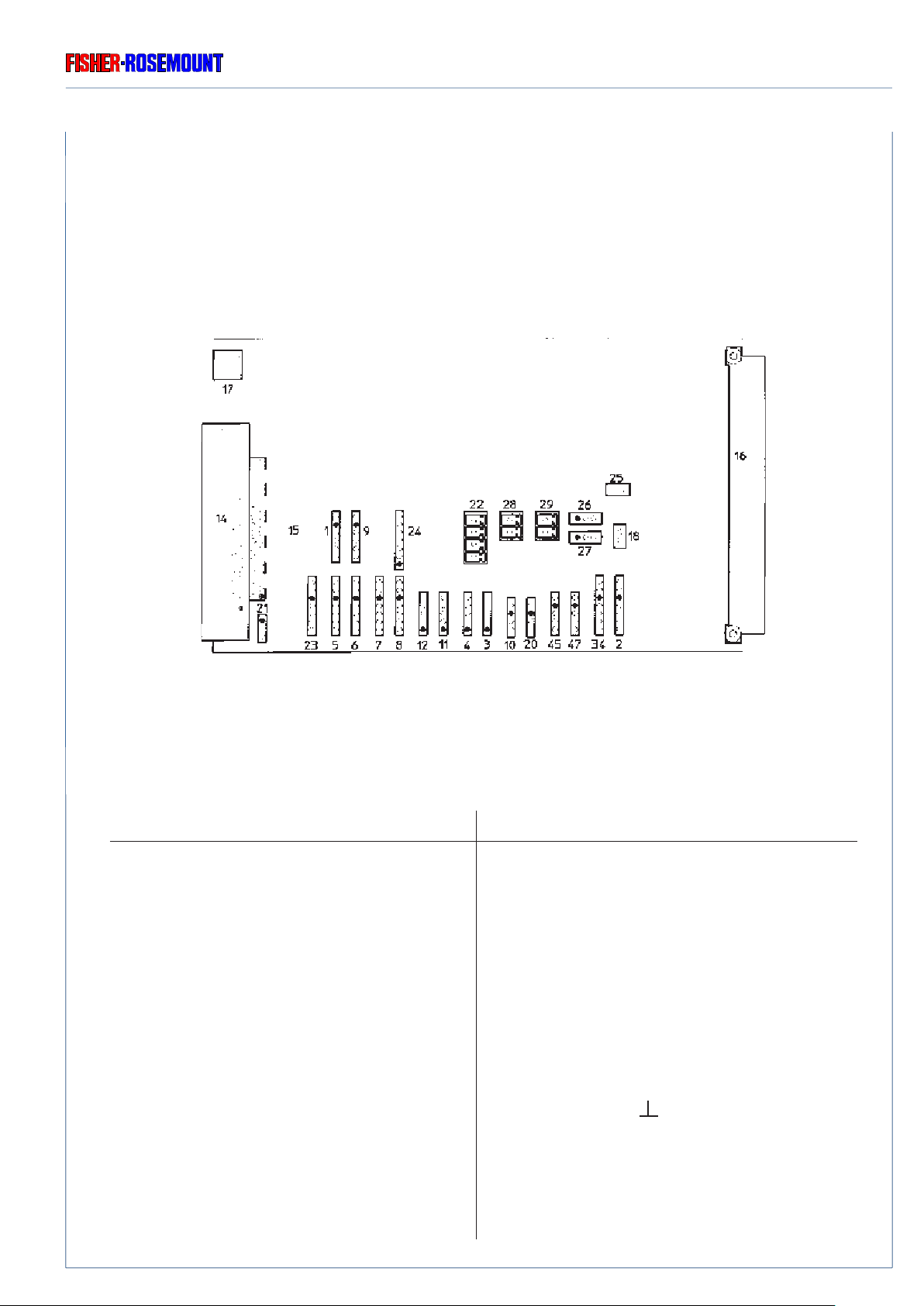

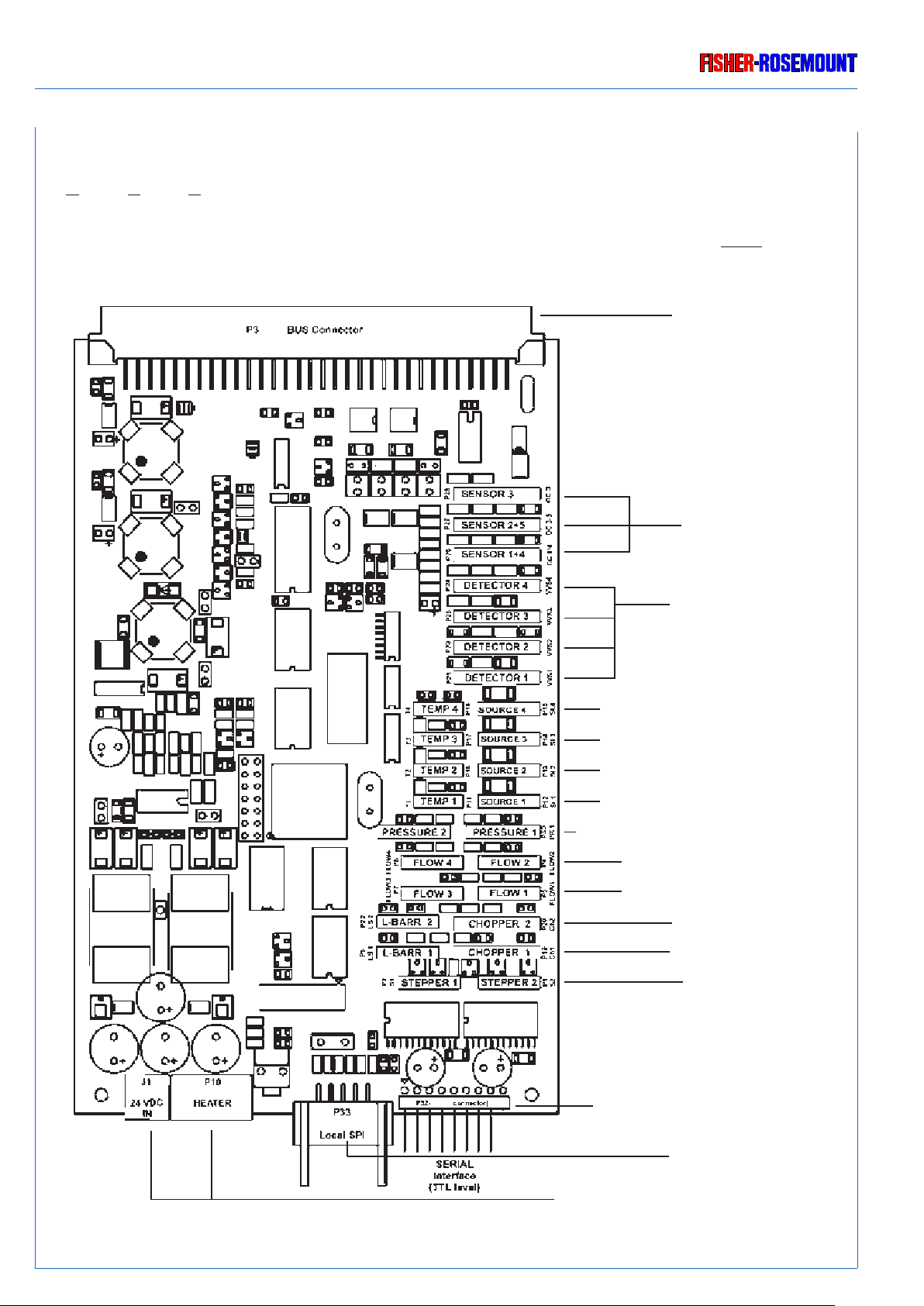

1.3.2 Printed Circuit Boards

All necessary PCBs are placed into a cardcage, which is identically for all BINOS E versions

(see Fig. 1-7).

BINOS E Rear Panel

Cardcage

LIO

(optional with 4 analog outputs

[optically isolated, common

ground] and RS 232 [optically

isolated] or CAN open bus

interface)

PCB

Physical Interface

(PIC*)

Signal Processing

(PSV*)

BINOS E Front Side

* For new models the combination PIC/PSV is replaced by a single DSP board.

Interconnection Board

(ICB)

ETC303(1) BINOS E e (2.0) 02/2007

Fig. 1-7: Card Cage BINOS E, Top View

1 - 9

Page 26

TECHNICAL DESCRIPTION

PCB

Rosemount Analytical

ICB

ICB is an interconnection board consisting of six 64-pin ICB bus slots to accommodate printed

circuit boards (PCB of Euro standard format).

LIO

The printed circuit board LIO offers the serial interface RS 232 and as an option 4 analog outluts

and an optically isolated serial interface or CAN open.

PSV/PIC Combination

*)

The PSV card (signal processing) carries out the A/D conversion and the real evaluation of

each measuring signal. This includes also all primary and all secondary variables: all

concentrations, temperatures, pressures and flow measurements. Any temperature and

pressure compensation is carried out from PSV . Linearization, zero and span calibration are

also executed in the PSV card.

The PIC card (Physics Interface Card) supplies the photometer components and the

individual sensors with the individual required operating voltages and transmits all measuring

signals to the signal processing unit PSV .

DSP (alternatively to PSV/PIC Combination)

*)

The DSP card (Digital Signal Processing) supplies the photometer components and the

individual sensors with the individual required operating voltages and carries out the A/D

conversion and the real evaluation of each measuring signal.

*) For new models the combination PIC/PSV is replaced by a single DSP board.

1 - 10

ETC303(1) BINOS E e (2.0) 02/2007

Page 27

Rosemount Analytical

TECHNICAL DESCRIPTION

PIC

The PIC card (Physics Interface Card) supplies the photometer components and the individual

sensors with the individual required operating voltages and transmits all measuring signals to

the signal processing unit PSV.

PCB

1

2

3

Fig. 1-8: Plug pin assignment PCB PIC

The plugs shown in Fig. 1-20 are used as follows:

Plug No. used

34 Chopper 1 (channel 1+2)

2 Chopper 2 (channel 3+4)

47 Flow sensor 1

45 Flow sensor 2

20 Temperature sensor 1 (chopper 1)

10 Temperature sensor 2

3 Source channel 4

4 Source channel 3

11 Source channel 2

12 Source channel 1

8 Detector channel 4

7 Detector channel 3

6 Detector channel 2

5 Detector channel 1

23 Detector channel 5 (O

)

2

Plug No. used

1 Pressure senor 1

9 Pressure senor 2

24 PCB OKI (P2) Flow sensor 3

PCB OKI (P1) Flow sensor 4 (P1)

or

PCB OKI (P4) Temperature sensor 3

PCB OKI (P3) Temperature sensor 4

21.2 Proof peak (test peak) channel 1

21.3 Ground ( )

ETC303(1) BINOS E e (2.0) 02/2007

1 - 11

Page 28

TECHNICAL DESCRIPTION

Rosemount Analytical

Digital Signal Processing Card (DSP)

Instead of using the 2 PCB's PIC and PSV alternatively those can be replaced by ONE board

containing both functions in the Digital Signal Processing Board DSP.

Bus connector

Input DC sensors

(e.g. O2/H2 sensors)

Input AC sensors

(e.g. IR/VIS/UV sensors)

Temp. sensor 4/IR(UV) source

Temp. sensor 3/IR(UV) source

Temp. sensor 2/IR(UV) source

Temp. sensor 1/IR(UV) source

Pressure sensor 2/Pressure sensor 1

Flow sensor 4/Flow sensor 2

Flow sensor 3/Flow sensor 1

not used/Chopper 2

not used/Chopper 1

4

3

2

1

1 - 12

not used/not used

Serial interface connector

Local SPI connector

24 VDC input/Heater connector

Fig. 1-9: Plug pin assignment PCB DSP

ETC303(1) BINOS E e (2.0) 02/2007

Page 29

Rosemount Analytical

MEASURING PRINCIPLE

IR MEASUREMENT

2. Measuring Principle

BINOS E can employ up to f our different measuring principles depending on the configuration

chosen. The methods are: NDIR, NDUV, paramagnetic and electrochemical Oxygen.

2.1 Non-dispersive Infrared (NDIR Measurement)

The non-dispersive infrared method is based on the principle of absorption of IR radiation by

the sample gas component being measured. The gas - specific wa velengths of the absorption

bands characterize the type of gas while the strength of the absorption gives a measure of the

concentration of the gas component being measured. An optical bench is in principle consisting

of an infrared light source, a chopper wheel to alternate the radiation intensity between the

reference and measurement (sample) side, an analysis cell, filter cells and a photometric

detector . Due to a rotation chopper wheel, the radiation intensities coming from measuring and

reference side of the analysis cell produce periodically changing signals within the detector.

The detector signal amplitude thus alternates between concentration dependent and concentration independent values. The difference between the two is a reliable measure of the

concentration of the absorbing gas component.

The principle photometer assembly is shown in Fig. 2-1.

Depending on the gas being measured, the application, the gas composition and the gas

concentration, one of two different measuring methods may be used as follows:

ETC00303(1) BINOS E e (2.0) 11/00

2 - 1

Page 30

MEASURING PRINCIPLE

IR MEASUREMENT

Rosemount Analytical

to electronic

14

12

11

10

14

13

11

10

99

8

7

8

7

5

3

1

Fig. 2-1: Measuring Principle for NDIR / UV Measurement

1 IR source with reflector

2 VIS / UV source with reflector

3 Chopper wheel

4 Eddy current drive

5 Filter cell with dividing wall (IR channel)

6 Filter cell with dividing wall (UV channel)

7 Analysis cell

6

4

2

8 Measuring side

9 Reference side

10 Filter cell without dividing wall

(for IFC measurement with optical filters)

11 Window

12 Pneumatic or pyroelectrical (solid-state) detector

13 VIS / UV semiconductor detector

14 Preamplifier

2 - 2

ETC00303(1) BINOS E e (2.0) 11/00

Page 31

Rosemount Analytical

MEASURING PRINCIPLE

IR MEASUREMENT

2.1.1 Opto - Pneumatic Measuring Principle

In the opto-pneumatic method, a thermal radiator ( heating coil in the light source) generates

the infrared radiation (1) which passes through the chopper wheel (3).

Due to the special shape of the chopper wheel, the IR radiation passes through a filter cell (5)

and alternately reaches the measuring side (8) and reference side (9) of the analysis cell [(7)

separated in the middle into two halv es by an internal separating wall] with equal intensity.

The filter cell (5) screens interfering radiation areas out of the radiation spectrum.

After the analysis cell the radiation passes a second filter cell (10) and reaches the gas detector

(12), which compares the IR radiation intenisities from measuring side and reference side and

converts it into an AC voltage signal proportional to their respective intensity.

The opto-pneumatic detector (Fig. 2-2) consists of 2 gas-filled chambers, an absorption

chamber and a compensation chamber which are connected by a flow channel in which a

Microflow filament sensor is mounted.

In principle the detector is filled with the infrared active gas to be measured and is only sensitive

to this distinct gas with its characteristic absorption spectr um. The absorption chamber is

sealed with a window which are transparent for infrared radiation [usually CaF

(Calcium

2

fluoride), sometimes BaF2 (Barium fluoride)].

Absorption chamber

Flow channel with

Microflow sensor

CaF2 / BaF2 window

Gas intake connection

Compensation chamber

Fig. 2-2: Principle Design of the Opto-Pneumatic Gas Detector

ETC00303(1) BINOS E e (2.0) 11/00

2 - 3

Page 32

MEASURING PRINCIPLE

IR MEASUREMENT

Rosemount Analytical

When the IR radiation passes through the reference side of the analysis cell into the detector ,

no pre-absorption occurs. Thus, the gas inside the absorption chamber is heated, expands and

some of it passes through the flow channel into the compensation chamber.

When the IR radiation passes through the measurement side of the analysis cell into the

detector , a part of it is absorbed depending on gas concentration. The gas in the absorption

chamber, theref ore, is heated less than in the case of radiation coming from the reference side.

Now absorption chamber gas become colder, gas pressure in the absorption chamber is

reduced and some gas of compensation chamber passes through the flow channel into the

absorption chamber.

The flow channel geometry is designed in such a way that it hardly impedes the gas flow by

restriction. Due to the radiation of chopper wheel, the different radiation intensities lead to

periodically repeated flow pulses within the detector.

The Microflow sensor ev aluates these flow pulses and con verts them into electrical voltages.

The electronics, which follow, evaluate the signals and convert them into the corresponding

display and output format.

The high chopping rate used, permits using a portion of the perimeter of the chopper wheel

for responsivity recalibration. A special pattern of the chopper wheel illuminates the detector

with about 1/4 and then with about 3/4 of the total light intensity creating a so-called "proof

peak". Thus , with any chopper rotation, an automatic gain control is used f or automatic span

(sensitivity) control. The result is a high long-term stability of sensitivity.

2.1.2 Interference Filter Correlation (IFC Principle)

With the IFC method the analysis cell is alternately illuminated with filtered IR light concentrated in one of two spectrally separated wave length ranges. One of these two wavelength

bands is chosen to coincide with an absorption band of the sample gas and the other is chosen

such that none of the gas constituents expected to be encountered in practice absorbs

anywhere within the band.

The spectral transmittance curves of the interference filters used in the BINOS and the spectr al

absorption of the gases CO and CO

are shown in Fig. 2-3. It can be seen that the absorption

2

bands of these gases each coincide with the passbands of one of the interference filters.

2 - 4

ETC00303(1) BINOS E e (2.0) 11/00

Page 33

Rosemount Analytical

MEASURING PRINCIPLE

IR MEASUREMENT

9075604530150

Transmittance [%]

Transmittance [%]

CO

CO

HC

2

Reference

4400 460042004000 48003000 3200 3400 3600 3800 5000 5200 5400 5600 5800 6000

Wave Length [nm]

CO

2

CO

Interference

Filter

Absorption band

18 36 54 72 900

Fig. 2-3: Absorption Bands of Sample Gase Components and Transmittance of

Interference Filters

The interference filter, used for generating a reference signal, has its passband in a spectral

region where none of these gases absorb. Most of the other gases of interest also do not absorb

within the passband of this reference filter.

The photometer assembly is similar to the assembly with “gas detector” (Fig. 2-1) with the

exception of the analysis cell and the detector . The analysis cell is not devided into measuring

and reference side (selectivity by interference filters). After the analysis cell the radiation

passes a second filter cell (10) to reach the pyroelectrical (solid-state) detector (12).

The detector records the incoming IR radiation. This radiation will be reduced by the absorption

of the gas at the corresponding wav elengths. By comparing the intensities from the measuring

and reference wa velengths, an alternating voltage signal is produced. This signal results from

cooling and heating the pyroelectrical material.

ETC00303(1) BINOS E e (2.0) 11/00

2 - 5

Page 34

MEASURING PRINCIPLE

UV MEASUREMENT

Rosemount Analytical

2.2 UV Measurement

The absorption measurement in the UV spectral range is based on the same principle as the

IR measurement (Fig. 2-1).

A glow-discharge lamp [2] is used as radiation source.

The UV radiation passes through the chopper [3] and a filter cell [6] into the dual-section

analysis cell [7].

A second filter cell [6] is installed after the analysis cell. The photodetector [13], which follows,

converts the pulsating radiation intensities from measuring [8] and reference side [9] of the

analysis cell into electrical voltages.

As the glow-discharge lamp needs a specific and as constant as possible temperature , the UV

lamp is thermostat controlled to about 55 °C for BINOS E.

2 - 6

ETC00303(1) BINOS E e (2.0) 11/00

Page 35

Rosemount Analytical

2.3 Oxygen Measurement

Depending on analyzer model different two measuring methods will be used.

2.3.1 Paramagnetic Measurement

MEASURING PRINCIPLE

OXYGEN MEASUREMENT

The determination of O

concentration is based on the paramagnetic principle (magneto-

2

mechanic principle).

Two nitrogen-filled (N2 is diamagnetic) quartz spheres are arranged in a "dumbbell" configuration and suspended free to rotate on a thin platinum ribbon in a cell.

A small mirror that reflects a light beam coming from a light source to a photodetector, is

mounted on this ribbon. A strong permanent magnet especially shaped to produce a strong

highly inhomo-geneous magnetic field inside the analysis cell, is mounted outside the wall.

When oxygen molecules enter the cell, their paramagnetism will cause them to be drawn

towards the region of greatest magnetic field strength. The O2 molecules thus exert different

forces which produce a torque acting on the sphere arrangement, and the suspended

“dumbbell”, along with the mirror mounted on its suspension ribbon, will be angulary rotated

away from the equilibrium position.

The mirror then will deflect an incident light beam onto the photodetector which itself produces

an electric voltage. The electric signal is amplified and fed back to a conducting coil at the

“dumbbell”, forcing the suspended spheres back to the equilibrium position.

The current required to generate the restoring torque to return the “dumbbell” to its equilibrium

position is a direct measure of the O2 concentration in the gas mixture.

The complete analysis cell consists of analysis chamber, permanent magnet, processing

electronics, and a temperature sensor. BINOS E provides a thermostat controlled sensor at

approx. 55 °C. The temperature sensor is used to control the heating system.

ETC00303(1) BINOS E e (2.0) 11/00

2 - 7

Page 36

MEASURING PRINCIPLE

OXYGEN MEASUREMENT

Rosemount Analytical

2 - 8

Fig. 2-4: Principle Construction of paramagnetic Analysis Cell

1 Permanent magnet

2 Platinum wire

3 Mirror

4 Quartz spheres

5 Wire loop

6 Photodetector

7 Light source

8 Amplifier

9 Display

ETC00303(1) BINOS E e (2.0) 11/00

Page 37

Rosemount Analytical

MEASURING PRINCIPLE

OXYGEN MEASUREMENT

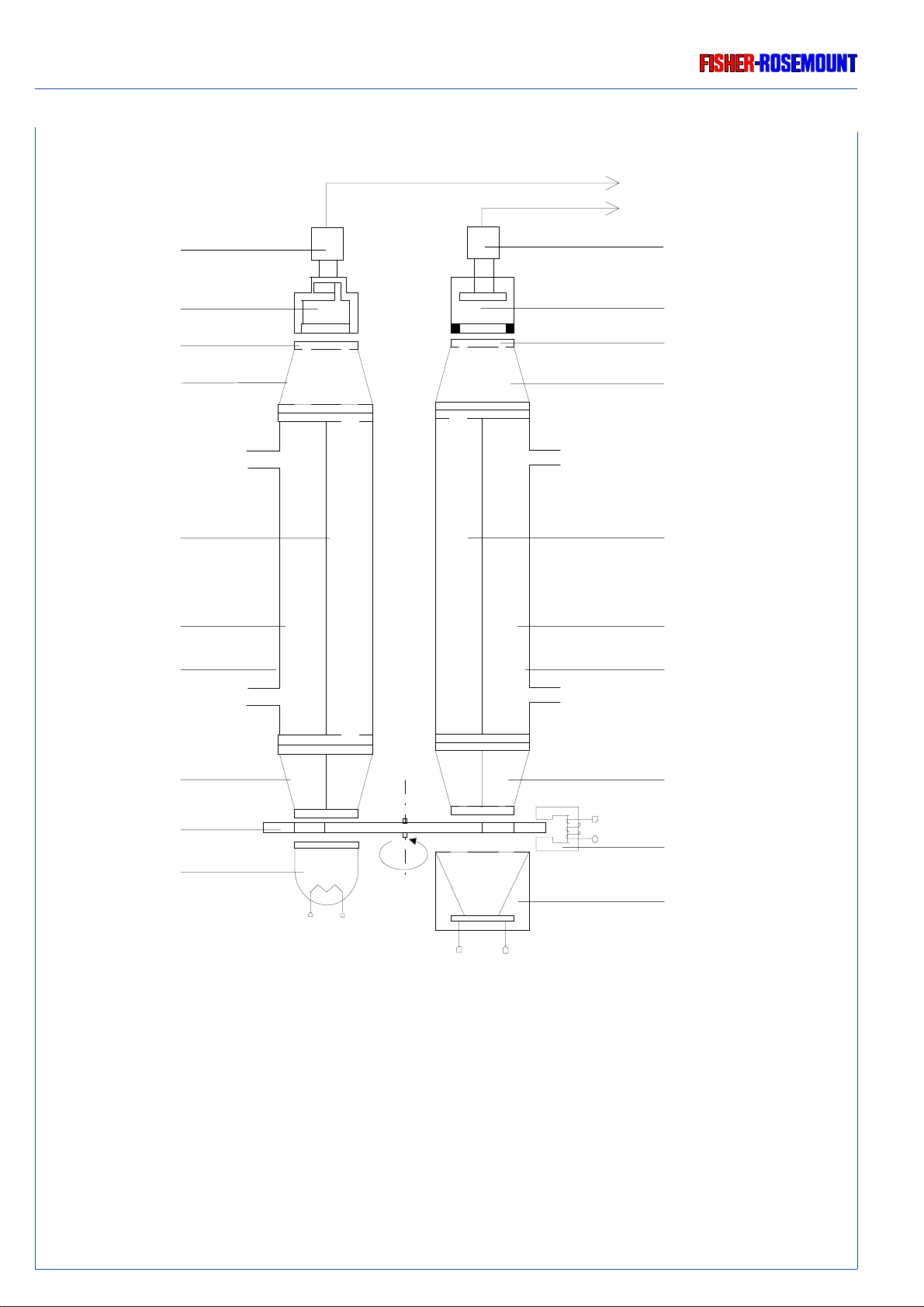

2.3.2 Electrochemical Measurement

The determination of O2 concentrations is based on the principle of a galvanic cell.

The principle structure of the oxygen sensor is shown in Fig. 2-5.

(Black)

Lead wire (Anode)

Lead wire (Cathode)

Anode

(Lead)

(1)

O ring (8)

Plastic disc (9)

Plastic top (10)

Cathode

Teflon membrane (4)

(Red)

Resistor (6)

Thermistor (5)

Acid electrolyte (3)

Sponge disc (7)

(Gold film)

(2)

Fig. 2-5: Structure of electrochemical Oxygen Sensor

The oxygen sensor incorporates a lead/gold oxygen cell with a lead anode (1) and a gold

cathode (2), using a specific acid electrolyte. To avoid moisture losses at the gold electrode a

sponge sheet is inserted on the purged side.

Oxygen molecules diffuse through a non-porous Teflon membrane (4) into the electrochemical

cell and are reduced at the gold-cathode. Water results from this reaction.

On the anode lead oxide is f ormed which is transfered into the electrolyte . The lead anode is

regenerated continuously and the electrode potential theref ore remains unchanged for a long

time.

The rate of diffusion and so the response time (t90) of the sensor is depending on the thickness

of the Teflon membrane.

ETC00303(1) BINOS E e (2.0) 11/00

2 - 9

Page 38

MEASURING PRINCIPLE

OXYGEN MEASUREMENT

Rosemount Analytical

(Red) (Black)

Thermistor (5)

(-)

Gold-

Cathode (2)

O2 + 4 H+ + 4 e- → 2 H2O

Summary reaktion O

(11)

Resistor (6)

2 Pb + 2 H2O → 2 PbO + 4 H+ + 4 e

Electrolyte (3)

(ph 6)

+ 2 Pb → 2 PbO

2

Fig. 2-6: Reaction of galvanic cell

(+)

Lead-

Anode (1)

-

The electric current between the electrodes is proportional to the O2 concentration in the gas

mixture to be measured. The signals are measured as terminal voltages of the resistor (6) and

the thermistor (5) for temperature compensation.

The change in output voltages (mV) of the sensor (11) represents the oxygen concentr ation.

Note !

Depending on measuring principle the electrochemical O

of oxygen (residual humidity av oids drying of the cell) . Supply cells continuously with dry sample gas

of low grade o xygen concentration or with o xygenfree sample gas could result a reversib le detuning

sensitivity. The output signal will become unstable.

of O

2

For correct measurement the cells hav e to be supplied with O

We recommend to use the cells in intervall measurement (purge cells with conditioned (dust removal

but no drying) ambient air during measurement breaks).

If it is necessary to interrupt oxygen supply f or several hours or da ys, the cell has to regenerate (supply

cell for about one day with ambient air). Temporary flushing with nitrogen (N2) for less than 1 h (e.g.

analyzer zeroing) will have no influence to measuring value.

cell needs a minimum internal consumption

2

concentrations of at least 0.1 Vol.-%.

2

2 - 10

ETC00303(1) BINOS E e (2.0) 11/00

Page 39

Rosemount Analytical

INSTALLATION AND PREPARATION OF STARTUP

5. Installation and Preparation of Startup

Please check the packing and its contents immediately upon arrival.

If any item is damaged or lost you are kindly requested to notify the f orwarder to undertake a

damage survey and report the loss or damage to us immediately.

If vibration decoupling is installed: Unscrew tr ansf er safety loc k of BINOS E !

Unscrew both knurled-head screws on bottom side of the housing

(Fig. 5-1a) ! For protection against loss screw the knurled-head screws into the

respective holders at housing rear side (Fig. 5-1b) !

Fig. 5-1a: Transfer safety lock

(housing side view, detail sketch)

Fig. 5-1b: BINOS E, Rear panel

Front panel

Transfer safety lock (two knurled-head screws)

(holder for safety lock)

ETC00303(1) BINOS E e (2.0) 11/00

5 - 1

Page 40

INSTALLATION AND PREPARATION OF STARTUP

INSTALLATION SITE

5.1 Installation Site

Be sure to observe the additional notes, safety precautions and w arnings given

in the individual manuals!

The BINOS E must not operate in e xplosive atmosphere without supplementary protective measures !

Free flow of air into and out of the BINOS E (ventilation slits) must not be

hindered by nearby objects or walls !

Rosemount Analytical

The installation site for the BINOS E has to be dry and remain above freezing

pointat all times. The BINOS E m ust be exposed neither to direct sunlight nor

to strong sources of heat.

Be sure to observe the permissible ambient temperatures (c.f. Item 20:

T echnical Data). F or outdoor installation, we recommend to install the BINOS

E in a protective cabinet. At least, the BINOS E has to be protected against rain

(e.g., shelter).

The BINOS E has to be installed as near as possible to the sample point, in order to avoid

low response time caused by long sample gas lines.

In order to decrease the response time, a sample gas pump with a matching high pumping rate

may be used. Eventually , the BINOS E has to be operated in the bypass mode or b y an overflow

valve to prevent too high flow and too high pressure (Fig. 5-2).

Exhaust

5 - 2

Overpressure valve

Gas sampling pump

BINOS E

Filter

Fig. 5-2: BINOS E, Bypass installation

Flow meter

Exhaust

ETC00303(1) BINOS E e (2.0) 11/00

Page 41

Rosemount Analytical

INSTALLATION AND PREPARATION OF STARTUP

GAS CONDITIONING (SAMPLE HANDLING)

5.2 Gas Conditioning (Sample Handling)

The conditioning of the sample gas is of greatest importance for the successful operation of

any analyzer according to extractive method.

All gases have to be supplied to the BINOS E as conditioned gases !

When the instrument is used with corrosive gases, it is to be verified that there

are no gas components which may damage the gas path components.

The gas has to fullfil the following conditions:

It must be

❏ free of condensable constituents

❏ free of dust

❏ free of aggressive constituents which are not compatible with the material of the gas

paths.

❏ have temperatures and pressures which are within the specifications shown in “T echnical

Data” of this manual.

Flammable or (potential) explosive gas mixtures may not be introduced into

the BINOS E without supplementary protective measures !

When analysing vapours, the de wpoint of the sample gas has to be at least 10 °C belo w the

ambient temperature in order to avoid the precipitation of condensate in the gas paths.

Suitable gas conditionning hardware ma y be supplied or recommended for specific analytical

problems and operating conditions.

ETC00303(1) BINOS E e (2.0) 11/00

5 - 3

Page 42

INSTALLATION AND PREPARATION OF STARTUP

GAS CONDITIONING (SAMPLE HANDLING)

Rosemount Analytical

5.2.1 Pressure Sensor (Option)

It is possible to integrate up to two pressure sensors with a range of 800 - 1100 hPa.

The concentration values computed by the analyzer will then be corrected to reflect the

barometric pressure to eliminate faulty measurements due to changes in barometric pressure

(see technical data). BI NOS E front panel progr am will indicate whether pressure correction

is actual.

5.2.2 Gas Flow Rate / Internal Flow Sensor (Option)

The gas flow rate should be within the range 0.2 l/min to maxi. 1.5 l/min !

A constant flow rate of about 1 l/min is recommended.

The gas flow rate for BINOS E with paramagnetic oxygen sensor

is allowed to max. 1.0 l/min !

Internal flow sensor: max. 2.0 l/min !

It is possible to integrate up to three flow sensors. In this case gas flow can be shown via

BINOS E front panel program.

5.3 Gas Connections

The installed gas connections are specific to the different BINOS E. All fittings are clearly

marked. The fittings are located on the rear panel of the BINOS E instrument.

5 - 4

The exhaust gas lines have to be mounted in a declining, pressureless

and frost-free way and according to the valid emission legislation !

Do not interchange gas inlets and gas outlets !

ETC00303(1) BINOS E e (2.0) 11/00

Page 43

Rosemount Analytical

INSTALLATION AND PREPARATION OF STARTUP

GAS CONNECTIONS

5.3.1 Standard

Depending on BINOS E version the following gas connections are installed:

in = Gas inlet out = Gas outlet

Channel 1 = measuring channel 1 Channel 2 = measuring channel 2

Channel 3 = measuring channel 3 reference = Reference gas (Differential measurement)

purge = purge gas (housing)

Zero gas and span gas are introduced directly via the sample gas inlet. The test gas containers

have to be set up according to the current legislation.

Be sure to observe the safety regulations for the respective gases

(sample gas and test gases / span gases) and the gas bottles !

ETC00303(1) BINOS E e (2.0) 11/00

Fig. 5-3: BINOS E, standard gas connections

5 - 5

Page 44

INSTALLATION AND PREPARATION OF STARTUP

Rosemount Analytical

5 - 6

ETC00303(1) BINOS E e (2.0) 11/00

Page 45

Rosemount Analytical

STARTUP PROCEDURE (SWITCHING

6. Startup Procedure (Switching On)

Be sure to observe the safety precautions and warnings !

Be sure to observe the additional notes, safety precautions and w arnings given

in the individual manuals !

Once the instrument has been correctly assembled and installed in accordance with the

general instructions given in section 5., the equipment is ready for operation.

ON)

The equipment is switched on b y providing the required voltage.

Upon switching on, the analyzer will perform a self-diagnostic test routine.

The BINOS E front panel program should be installed bef ore connecting the BINOS E to the

designated COM port.

The following devices are recommended to connect BINOS E with the PC:

- Zero modem cable (part number: ETC00257)

- Gender changer (part number: ETC00258)

For additional informations about recommended hardware and software requirements, see

chapter "Front Panel Program".

Analyzer needs 15 to 50 minutes to warm-up after switch on,

depending on the installed detectors (themostat controlled temperature) !

ETC00303(1) BINOS E e (2.0) 11/00

6 - 1

Page 46

STARTUP PROCEDURE (SWITCHING ON)

SUPPLY VOLTAGE

Rosemount Analytical

6.1 Supply Voltage

The BINOS E is specified for an operating voltage of 24 V DC (± 5 %).

24 Vdc is to be connected via a 3-pole XLR flange (male).

The dc supply voltage is to be provided b y option UPS 01 T, SL5, SL10 or equivalent power

supply.

❍ Connect power supply and BINOS E (Fig. 6-1, Plug 24 V DC).

Verify correct polarity before operation (Fig. 21-1) !

❍ Connect mains line and power supply.

Be sure to observe the safety precautions and warnings given by

manufacturer of power supply !

Pin assignments

Plug 24 V dc

6 - 2

Fig. 6-1: BINOS E, Rear panel, Voltage supply

ETC00303(1) BINOS E e (2.0) 11/00

Page 47

Rosemount Analytical

MEASUREMENT/CALIBRATION/SWITCHING (SHUT) OFF

MEASUREMENT

7. Measurement / Calibration / Switching (Shut) Off

7.1 Measurement

The primary step in the measurement of the concentration of a gas component is the admission

of sample gas to the analyzer.

Analyzer needs 15 to 50 minutes to warm-up after switch on,

depending on the installed detectors (thermostat controlled temperature) !

❍ Admit sample gas at the respective gas inlet fitting (see Item 5.).

❍ Set the gas flow rate to allowable rate.

Before starting an analysis, however, the following should be performed:

❏ BINOS E front panel program should be installed and BINOS E should be connected to

the designated COM port. Initialization from connected analyzer or from configuration file

should have been carried out.

❏ Zero and span gas calibration of the BINOS E (see chapter 8).

Note for analyzers with electrochemical O2 cell!

Depending on measuring principle the electrochemical O

of oxygen (residual humidity av oids drying of the cell). Supply cells continuously with dry sample gas

of low grade o xygen concentr ation or with oxygenfree sample gas could result a reversib le detuning

of O

sensitivity. The output signal will become unstable.

2

For correct measurement the cells have to be supplied with O

We recommend to use the cells in intervall measurement (purge cells with conditioned (dust remov al

but no drying) ambient air during measurement breaks).

If it is necessary to interrupt oxygen supply for sev eral hours or days, the cell has to regenerate (supply

cell for about one day with ambient air). Temporary flushing with nitrogen (N2) for less than 1 h (e.g.

analyzer zeroing) will have no influence to measuring value.

cell needs a minimum internal consumption

2

concentrations of at least 0.1 Vol.-%.

2

90002929(6) NGA-MLT e 30.10.99

7 - 1

Page 48

MEASUREMENT/CALIBRATION//SWITCHING (SHUT) OFF

CALIBRATION

Rosemount Analytical

7.2 Calibration

To insure correct measurement results, zeroing and spanning should be carried out once a

week.

The zero level must always first be set before any other calibrations are attempted.

For the calibration procedure the required test gases have to be fed to the analyzer through

the respective gas inlets (cf . section 5.3) with a no - back - pressure gas flow rate of about 1

l/min (the same as with sample gas) !

7.2.1 Calibration (Test) Gases

a) Zero Gas

For zeroing, the analyz er has to be purged with nitrogen (N

) or adequate zero gas [e. g. synth.

2

air or conditioned air (not as a standard for O2 measurement)].

.

b) Span Gas

The calibration of all another analyzers should be done with pure span gases in order to prev ent

interferences between the gases (e. g., CO2 and CO) measured by the analyzer. Test gas

mixtures are also possible depending on the mixed components (c.f. or test gas supplier).

The concentration range of the span gas has to be in a range of 80 - 110 % of the full scale

range of the respective measuring channel. For low er span gas concentrations the measuring

accuracy could be lower for sample gas concentrations, which are higher than the span gas

concentration! For test gas concentration see certification of the test gas bottles.

Spanning for o xygen measurement can be done using conditioned ambient air as span gas ,

if the oxygen concentration is known and constant.

To calibrate a H2O channel (0 - 3(4) Vol.-%), use water vapor saturated N2 according to

saturation characteristic (Item 22.) as span gas. Purge N2 through a gas-blubber bottle, filled

with distilled water and in a little bit higher ambient temperature as necessary. Connect a

second vessel into a kyrostat (to hold ambient temperature constant) in series to get defined

dew point.

7 - 2

90002929(6) NGA-MLT e 30.10.99

Page 49

Rosemount Analytical

MEASUREMENT/CALIBRATION/SWITCHING (SHUT) OFF

SWITCHING (SHUT) OFF

Be sure to observe the safety regulations for the respective gases

(sample gas and test gases / span gases) and the gas bottles !

Pressure of sample gas / test gases normally max. 1,500 hPa !

7.3 Switching (Shut) Off

Before switching off the analyzer, we recommend first purging all the gas lines for about 5

minutes with zeroing gas (N2) or adequate conditioned air . The full procedure for shutting off

is as follows:

All analyzers with electrochemical O2 cell have to be purged with conditioned

ambient air prior to disconnect the gas lines !

Then the gas line fittings have to be closed f or transport or depositing analyzer.

❍ Admit zeroing gas at the respective gas inlet fitting.

❍ Set the gas flow to permissible rate.

After 5 minutes have elapsed:

❍ Switch off by disconnecting the voltage supply.

❍ Shut Off the gas supply.

❍ Disconnect gas lines.

❍ Close all gas line fittings immediately.

90002929(6) NGA-MLT e 30.10.99

7 - 3

Page 50

MEASUREMENT/CALIBRATION//SWITCHING (SHUT) OFF

Rosemount Analytical

7 - 4

90002929(6) NGA-MLT e 30.10.99

Page 51

Rosemount Analytical

FRONT PANEL PROGRAM

8. BINOS E Front Panel Program

The description of the BINOS E Front Panel Program includes the following information:

1. Requirements

2. Installation and Startup

3. Function Keys

4. Status Display

5. Display Page

6. Recorder Page

7. Messages Page

8. Analog Output Link and Adjustment Page

REQUIREMENTS

8.1 Requirements

Listed below are the minimum recommended hardware and software requirements for installing the BINOS E front panel program in a Microsoft Windows 95, 98 or NT operating

system:

· Pentium processor with 233 MHz or better

· 32 MB RAM (higher RAM improves performance)

· Sufficient available hard disk space. The required available space depends on the

data acquisition rate (see chapter 5) (Calculate approx. 63 MB per day if the fastest

data acquisition is running without data compression).

· 8 MB graphic board

· Serial interface (RS 232 COM port)

The following devices are recommended to connect the BINOS E with your PC:

· Zero modem cable (part number: ETC00257)

· Gender changer (part number: ETC00258)

These accessories can be provided by Fisher-Rosemount with the BINOS E analyzer as

options.

ETC00303(1) BINOS E e (2.0) 11/00

8 - 1

Page 52

FRONT PANEL PROGRAM

INSTALLATION

Rosemount Analytical

8.2 Installation and Startup

8.2.1 Installation

Start Setup.exe for the BINOS E front panel program installation and follow the program

instructions.

The following operations must be activated:

a) Desired language

b) Designated COM port

8 - 2

ETC00303(1) BINOS E e (2.0) 11/00

Page 53

Rosemount Analytical

The program will then create the following directory:

C:\ Programs\ Fisher-Rosemount\ BINOS E.

FRONT PANEL PROGRAM

INSTALLATION

The following files are available in the installation listing:

Ascii.dad (after first measurement), Binos.exe, Binos.eni, BinosOEM.INI, BinosCustom.OEM

(after first start, see chapter 8.2), ConfigOEM.INI, daten.ddd, daten.ddt, Default.OEM,

README.txt, Install.log, Unwise.exe, Unwise.ini as well as a listing ”Data”.

After successful installation, a corresponding program group will be generated

and the BINOS E program is ready to start.

ETC00303(1) BINOS E e (2.0) 11/00

8 - 3

Page 54

FRONT PANEL PROGRAM

STARTUP

Rosemount Analytical

8.2.2 Startup

The first time the BINOS E program is started, a dialog box will inform you that the configuration data is loaded. This procedure may take several seconds.

Based on this data, a standard file ”BinosCustom.OEM” will be created. This file will be loaded

automatically on any future start to initialize the BINOS E front panel.

Any front panel page (Display, recorder , messages or analog out) offers a headline showing the following information about the specific instrument:

· BINOS E software version (Release Number)

· Adjusted COM port

· BINOS E serial number (important for service and maintenance)

8.3 Function Keys

The function keys F1 through F12 are located on the upper right side of any front panel page:

F1 Display:

The ”Display” function key enables you to reach the display page

of this program (see chapter 8.5) .

F2 Recorder:

The ”Recorder” function key enables you to reach the recorder

page of this program (see chapter 8.6).

F3 Messages:

The ”Messages” function key enables you to reach the messages

page of this program (see chapter 8.7).

F4 Analog out.:

The ”Analog out.” function key (Analog Output Link and Adjustment Page) allows you to link and adjust measuring channels or

secondary parameters to the analog outputs and change the settings (see chapter 8.8).

8 - 4

ETC00303(1) BINOS E e (2.0) 11/00

Page 55

Rosemount Analytical

F5 Zero Gas Calib.:

The ”Zero gas calib.” function k ey starts the dialog for zero gas calibration.

A TTENTION: Before starting zero gas adjustment make certain that zero gas is

available!

FRONT PANEL PROGRAM

FUNCTION KEYS

The dialog allows you to select single channels for calibration or to calibrate all channels

simultaneously.

ETC00303(1) BINOS E e (2.0) 11/00

8 - 5

Page 56

FRONT PANEL PROGRAM

FUNCTION KEYS

Rosemount Analytical

During zero gas adjustment the deviation of the actual value is compared with the max.

deviation (threshold value) from the file ”BinosOEM.INI”.

The menu provides the ability to change the

threshold value from 1 % of full scale up to the

maximum threshold value.

If the threshold value is exceeded, an alarm message will appear offering the option to stop the

zero gas calibration procedure.

F6 Span gas calib.:

The ”Span gas calib.” function k ey starts the dialog for span gas calibration.

ATTENTION: Bef ore starting span gas adjustment, ensure that span gas with

the desired concentration is available!

To protect this function against unauthorized access, a password (access code)

option is available.

If no password has been set you will be

asked to define one (this is not required).

Within this dialog box you can also

change the existing access code.

If a password is defined, it can be

changed but not eliminated entirely.

8 - 6

ETC00303(1) BINOS E e (2.0) 11/00

Page 57

Rosemount Analytical

FRONT PANEL PROGRAM

FUNCTION KEYS

As with zero gas adjustment, you can run span

gas calibration with individual selectable channels or with all channels

simultaneously.

Unavailable channels will

be refused.

You can set the nominal

value (set point) in the field

behind the corresponding

channel.

During span gas adjustment, the deviation of the actual value is compared with the max.

deviation (threshold v alue) from the file ”BinosOEM.INI”. The menu provides the opportunity to

change the threshold value from 1 % of full scale up to the maximum threshold value.

ETC00303(1) BINOS E e (2.0) 11/00

If the value falls below the threshold

value, the span gas calibration procedure is stopped.

To enable a span gas calibration, the

maximum threshold value may be set

(if this does not work contact our Service Support Center).

8 - 7

Page 58

FRONT PANEL PROGRAM

FUNCTION KEYS

Rosemount Analytical

If any dialog or communication does not work correctly you will get a message indicating

the wrong input.

If for example no channel is selected for zero calibration the following message will show

up:

F7 Start measure.:

The "Start measure." function key initiates the measuring procedure. After any successful

startup the measurement itself needs to be started. Otherwise you see a display being not

illuminated.

F8 Stop measure.:

The ”Stop measure.” function key terminates the measuring procedure. Please wait appro ximately 30 seconds before any ne w start.

F9 Raw/Measure:

The ”Raw/Measure” function key enables the user to switch from raw data mode [not corrected

(unlinearized, not temperature compensated) data] to measurement mode [concentrations].

This procedure may take several seconds.

8 - 8

ETC00303(1) BINOS E e (2.0) 11/00

Page 59

Rosemount Analytical

F10 Initialization:

FRONT PANEL PROGRAM

FUNCTION KEYS

The ”Initialization” function

key enables two different

methods for initialization leading to the dialog box ”device

data”:

If you select in the dialog box ”read device data” the option ”from connected analyzer” the data

will be loaded directly from the connected BINOS E instrument.

If you select the option ”from configuration file” within this dialog box, the corresponding

configuration file will be selected and loaded.

ATTENTION:

The file ”BinosCustom.OEM” initially created will not be changed in that

case! At the next program start with the option ”from connected analyzer”

the original status will be restored.

F12 Quit:

ETC00303(1) BINOS E e (2.0) 11/00

The ”Quit” function key

ends the program with ”Exit

BINOS E program”.

8 - 9

Page 60

FRONT PANEL PROGRAM

STATUS DISPLAY

Rosemount Analytical

8.4 Status Display (”Status”)

The status display on the lower right side of any front panel page shows the actual state of the

program:

LED ”Data”: This LED flashes when the BINOS E data is available.

LED ”Raw data”: This LED is illuminated if the analyzer is working in raw

data mode.

LED ”Non-lin. Mode”: This LED is illuminated during the instrument

mode ”not linearized”.

LED ”Meas. active”: This LED is illuminated during measurement.

LED ”Load”: This LED is illuminated when configuration data from a

connected BINOS E or a file is loaded.

LED ”Reset”:This LED is illuminated if the software is reset at the

instrument. This happens after each initialization.

8 - 10

ETC00303(1) BINOS E e (2.0) 11/00

Page 61

Rosemount Analytical

FRONT PANEL PROGRAM

DISPLAY PAGE

8.5 Display Page

The ”Display page” [F1 Display] shows all the connected channels and the accompanying data

for the respective gas.

The LED’s under the category ”Information”

indicate the selected configurations and options for each channel. If the LED ”Message” is

illuminated, a failure message for the respective channel is available on the messages

page.The measuring gas and the corresponding smallest and highest ranges are indicated.

A maximum of five channels can be displayed. Active channels are illuminated.

The ”smoothing” that allows the t90 time to be adjusted to

strong, weak or medium. Selection is activated by clicking

the RIGHT MOUSE BUTT ON.

ETC00303(1) BINOS E e (2.0) 11/00

8 - 11

Page 62

FRONT PANEL PROGRAM

DISPLAY PAGE

Rosemount Analytical

Secondary Parameters:

The option to show five more secondary parameters

(signal sources) such as temperature, flow or pressure

on an extra panel is available.

To select the source, the user must click the RIGHT

MOUSE BUTTON on the title strip of the panel and

then select the respective source from the menu.

If a sensor is not available the following signals are

displayed:

Temperature: - 273 °C

Flow: 0 ml/min [cc/min]

Pressure: 2000 hP a [mbar]

The free selectable sensor can be Temperature, Flow

or Pressure indicated by the unit (flow = ml/min).

Decimal Places:

The decimal places for

the measuring gas

concentrations can be

adjusted respectively

to the ranges.

To adjust the decimal places, click the RIGHT MOUSE BUTT ON on the corresponding digital

display . If the concentration is indicated in V olume percent (V ol.-%), a maximum of five decimal

places can be selected; in the case of ppm, a maximum of three decimal places can be

selected.

8 - 12

ETC00303(1) BINOS E e (2.0) 11/00

Page 63

Rosemount Analytical

FRONT PANEL PROGRAM

DISPLAY PAGE

Additional Data Source:

An additional data source may be adjusted at the bottom of this display page (”Signal

selection”).

Signal selection can be done with the mouse in the same manner as noted above (RIGHT

MOUSE BUTT ON).

ETC00303(1) BINOS E e (2.0) 11/00

8 - 13

Page 64

FRONT PANEL PROGRAM

RECORDER PAGE

Rosemount Analytical

8.6 Recorder Page

For all active channels, a recorder channel is available [F2 Recorder]. Up to five channels can

be shown.

For each channel, the recorder adjustments can be set individually. In this case , a dialog box

appears after touching the respective button (Recorder 1, 2, 3 ...). Options to adjust the scale

individually (manually), to reproduce the factory settings (default values) or to view the actual

scale of the recorder (Auto range) are also available.

The decimal places of the scale may be configured here as well.

8 - 14

ETC00303(1) BINOS E e (2.0) 11/00

Page 65

Rosemount Analytical

8.6.1 Averaging:

FRONT PANEL PROGRAM

RECORDER PAGE

Using a rotary regulator and a selectable multiplier (1x, 10x, 100x) an average can be calculated for data compression. To calculate the

average, the respective multiplier and the desired value at the rotary regulator must be adjusted. The data will then be averaged.

During the measurement no change of averaging is possible!

8.6.2 Spooling:

8.6.3 Recording:

Four spool buttons are available so the user can spool

forward, backwards, to the beginning and to the end of

the recorded text.

The recorded data may be stored in

two formats:

a) As ASCII file

b) As recorder file

ETC00303(1) BINOS E e (2.0) 11/00

The recorder file can later be loaded

into the recorder again.

Using the ”Load” and ”Close” options,

any available file can be loaded or

closed again.

8 - 15

Page 66

FRONT PANEL PROGRAM

MESSAGES PAGE

Rosemount Analytical

8.7. Messages Page

On the Messages page [F3 Messages] the status of the program and the connected BINOS E

instrument is shown.

Events:

On the upper left side an error report (failures, messages) is recorded which also indicates the

time and date.

Zero or span gas calibration

reports are shown reporting

the adjusted channels. The

failure (sum error) of a channel (signal) will be indicated

as ”unlock” while ”locked”

appears when the failure

disappears.

8 - 16

ETC00303(1) BINOS E e (2.0) 11/00

Page 67

Rosemount Analytical

FRONT PANEL PROGRAM

MESSAGES PAGE

Below this area a failure of the serial interface is shown via LED (illuminated in case or error).

After that you can start the error report again with ”read status/messages again”. You can store the error

reports into the directory ”Data” with

”save messages” before activating a

new error report.

Detailed information to the failure messages are indicated

under the category ”Messages” in the lower area of this

page. For each connected channel failure messages – split

up in six areas - are indicated. In case of any failure the

corresponding LED is illuminated.

In the expert level (Service has access) differentiated messages are available. Special

messages for the Service are shown in the lowest part of this area (consult our Service Support

Center).

ETC00303(1) BINOS E e (2.0) 11/00

On the upper right side of this page, under ”Status”, is

the hardware configuration of the BINOS E instrument

showing the presence of the 6 defined or the 2 pairs of

selectable optional sensors (signal sources). The a vailability of 1-2 temperature and 1-2 pressure sensors is

indicated via LED (not possible for the 2 flow sensors).

The display will also indicate whether the additional

selectable pairs of sensors are temperature or flow

sensors.

Beside this is information about the AD changers or

transmission rates.

8 - 17

Page 68

FRONT PANEL PROGRAM

ANALOG OUTPUT LINK AND ADJUSTMENT PAGE

Rosemount Analytical

8.7. Analog Output Link and Adjustment Page

On the ”Analog Output Link and Adjustment Page” [F4 Analog out.] the four optional analog

outputs of a BINOS E analyzer can be linked to the respective channels or secondary

parameters (sensors).

To view the actual settings, press the button

”read analog link” (LED ”reading active” is

illuminated).

ATTENTION: Stop Measurement with F8 before adjustments can be perf ormed!

Now new channel adjustments (concentration measurements) can be performed. Beside

concentrations also secondary signal sources (temperature, pressure or flow) can be selected.

Any ”begin of range” or ”end of range” can be set individually. The corresponding units are

assigned automatically.

8 - 18

ETC00303(1) BINOS E e (2.0) 11/00

Page 69

Rosemount Analytical

FRONT PANEL PROGRAM

ANALOG OUTPUT LINK AND ADJUSTMENT PAGE

A TTENTION: Please remember that beside any customer settings, the specifications are valid only if the end of range is fixed between the ordered minimum and

maximum end of range. Suppressed ranges (increased begin of range) must be

indicated in the purchase order as well.

The default settings from

factory may not go conform

with the secondary sensor

properties. Please adjust

according to your needs.