Page 1

Instruction Manual

D104632X012

February 2021

Enardo ES-850 and Enardo ES-950 Series

Enhanced Sealing Enardo ES-850 and

Enardo ES-950 Series Pressure/Vacuum

Relief Valve

P1854

MODEL ENARDO ES-850

P1854

MODEL ENARDO ES-950 MODEL ENARDO ES-950

Figure 1. Enardo ES-850 and Enardo ES-950 Series

Pressure/Vacuum Relief Valve

Table of Contents

Introduction ........................................................................... 2

Specifications .......................................................................2

Product Identification and Marking ....................................... 5

Principle of Operation ........................................................... 5

Installation ............................................................................8

Maintenance ....................................................................... 11

Adjustments ........................................................................ 14

Valve Repair ....................................................................... 16

MODEL ENARDO ES-850

Figure 2. Enardo ES-850 and Enardo ES-950 Series

with Smart Wireless option

WARNING

▲

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion, re and/or

chemical contamination causing property

damage and personal injury or death.

Fisher™ pressure/vacuum relief valve

must be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations,

and Emerson Process Management

Regulator Technologies Tulsa, LLC

(Emerson) instructions. These units are not

designed or intended for use in mobile, high

vibration or high acceleration applications.

Outside North America Only

Page 2

Enardo ES-850 and Enardo ES-950 Series

Specications

The Specications section on this page provides specications for the Enardo ES-850 and Enardo ES-950 Series pressure/

vacuum relief valve. Specication is stamped on the nameplate attached to the relief valve. Refer to Product Identication and

Marking section for the nameplate details.

Available Construction

See Figures 3 and 4

Inlet Connection Sizes

2 through 12 in. / 50 through 300 mm

Pressure Ranges

(1)(2)

For sizes up to 6 in. / 150 mm

0.5 to 32 oz./sq. in.

1.0 to 55 in. w.c.

2.15 to 138 mbar

22 to 1406 mm w.c.

For sizes 8 in. / 200 mm and larger

0.5 to 24 oz./sq.in.

1.0 to 41.5 in. w.c.

2.15 to 103 mbar

22 to 1055 mm w.c.

Vacuum Pressure Ranges

(1)(2)

Vacuum Pressure Ranges

For sizes 8 in. / 200 mm and larger

0.4 to 24 oz./sq. in.

1.0 to 41.5 in. w.c.

1.72 to 103 mbar

17.6 to 1055 mm w.c.

Construction Materials

Housing: Aluminum, Stainless steel or Carbon steel

Seat / Pallet: 316 Stainless steel

Pallet Seal: Nitrile (NBR), Fluorinated Ethylene

(3)

Propylene (FEP), Fluorocarbon (FKM) or

Fluorosilicone (FVMQ)

Hardware: Zinc-plated Carbon steel or Stainless steel

Weights: Zinc-plated Carbon steel, Stainless steel

or Lead

Gaskets: Nitrile (NBR), FEP, Fluorocarbon (FKM) or

Fluorosilicone (FVMQ)

(1)(2)

(continued)

(3)

For sizes up to 6 in. / 150 mm

0.4 to 32 oz./sq. in.

1.0 to 55 in. w.c.

1.72 to 138 mbar

17.6 to 1406 mm w.c.

1. The pressure limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Pressure or vacuum setting has an increment of 0.5 oz./sq.in., 0.5 in. w.c. or 2.2 mbar.

3. 8, 10 and 12 in. / 200, 250 and 300 mm sizes limited to a maximum pressure relief setting of 16 oz./sq.in. / 69 mbar when a vacuum relief setting of 0.4 oz./sq. in. / 1.72 mbar is used.

Failure to correct trouble could result in a

hazardous condition. Call a qualied service

person to service the unit. Installation,

operation and maintenance procedures

performed by unqualied person may result

in improper adjustment and unsafe operation.

Either condition may result in equipment

damage or personal injury. Only a qualied

person shall install or service the pressure/

vacuum relief valve.

Introduction

Scope of the Manual

This Instruction Manual provides instructions for installation,

maintenance and parts ordering information for the

Enardo ES-850 and Enardo ES-950 Series pressure/vacuum

relief valve (PVRV).

Product Description

Enardo ES-850 and Enardo ES-950 Series

The Enardo ES-850 and Enardo ES-950 Series pressure/

vacuum relief valves provide protection against positive or

vacuum overpressure and prevent air intake and evaporative

losses of product while helping to contain odorous and

potentially explosive vapors.

The Enardo ES-850 Series provides pressure and vacuum relief

in applications that require hazardous vapors to be piped away

rather than released into the atmosphere.

The Enardo ES-950 Series valve provides pressure and

vacuum relief for normal venting requirements while maintaining

a safe internal working pressure to prevent the routine expulsion

of waste gas to the atmosphere.

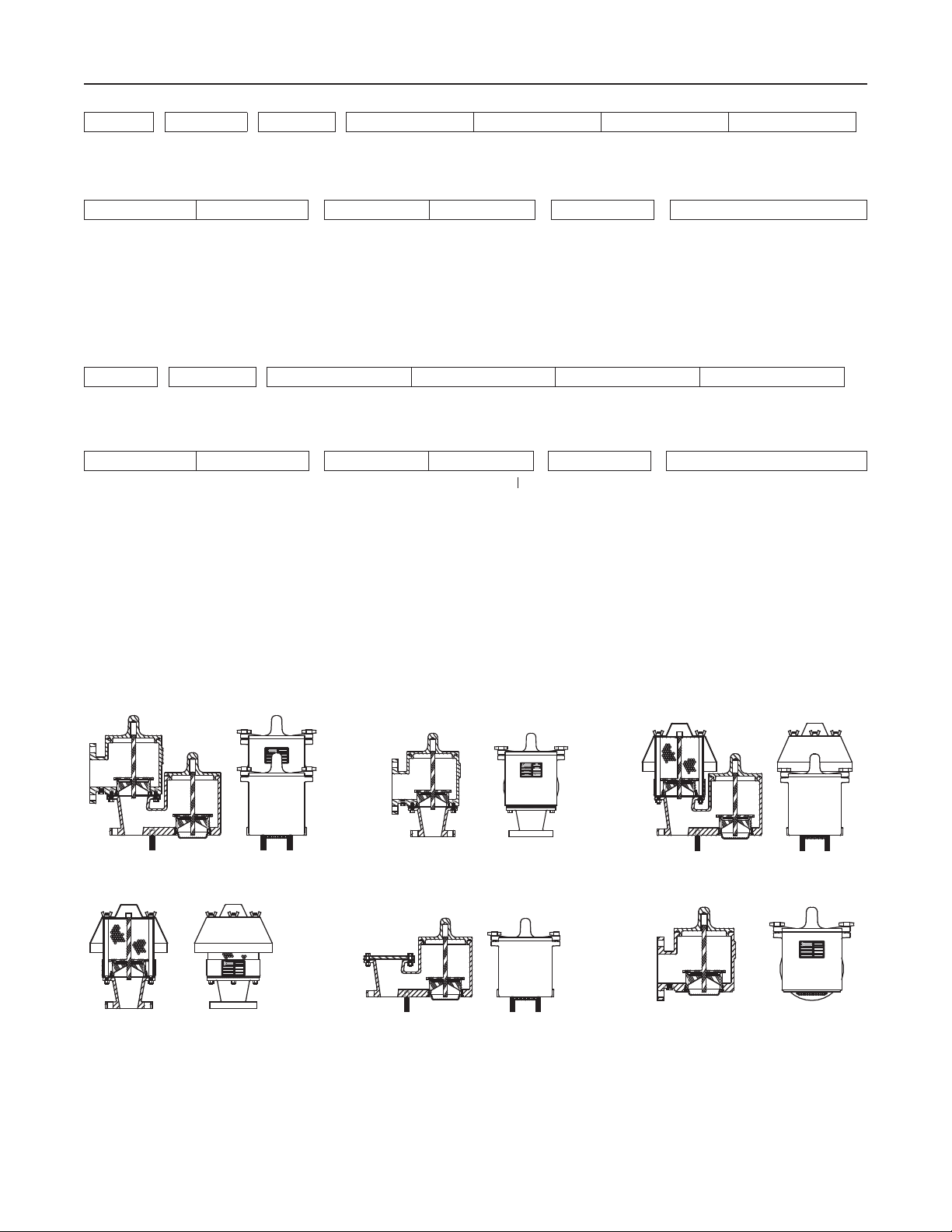

• Model Enardo ES-850: Pressure/Vacuum Relief Valve —

Pipe-Away

• Model Enardo ES-851: Top Mount Pressure or Side

Mount Vacuum Relief Valve — Pipe-Away

• Model Enardo ES-950: Pressure/Vacuum Relief Valve —

Vent-to-Atmosphere

• Model Enardo ES-951: Pressure Relief Valve —

Vent-to-Atmosphere

• Model Enardo ES-952: Top Mount Vacuum Relief

Valve — End-of-Line

• Model Enardo ES-953: Side Mount Vacuum Relief Valve

Outside North America Only

2

Page 3

Enardo ES-850 and Enardo ES-950 Series

Model - Inlet Size x Outlet Size - Housing Material Pallet and Seat Material Pallet Seal Material Body/Seat/Lid Seal Material -

Enardo ES-850 2 to 12 in. 3 to 14 in. 1 = Aluminum

Pressure Units Pressure Setting / Vacuum Units Vacuum Setting - Weight Material - Options

z = oz./sq.in.

n = in. w.c.

mm = mm w.c.

mb = mbar

0.5 to 32.0 oz./sq.in.

0.86 to 55.0 in. w.c.

22 to 1406 mm w.c.

2.2 to 138 mbar

MODEL ENARDO ES-850 PRESSURE/VACUUM RELIEF VALVE MODEL NUMBER

4 = 316SST

5 = Carbon Steel

z = oz./sq.in.

n = in. w.c.

mm = mm w.c.

mb = mbar

2 = 316SST 1 = FEP

0.5 to 32.0 oz./sq.in.

0.86 to 55.0 in. w.c.

22 to 1406 mm w.c.

2.2 to 138 mbar

C = CS ZP

S = SST

L = Lead

2 = Nitrile (NBR)

3 = Fluorocarbon (FKM)

4 = Fluorosilicone (FVMQ)

0 = No Options

F = Flat Face Flange (standard for Alumunim)

R = Raised Face Flange (standard for CS, SS)

X = Epoxy Coating

W1 = Wireless Pressure and Vacuum Monitoring

W2 = Wireless Pressure Monitoring Only

W3 = Wireless Vacuum Monitoring Only

W4 = Wired Pressure and Vacuum Monitoring

W5 = Wired Pressure Monitoring Only

W6 = Wired Vacuum Monitoring Only

1 = PTFE Body and FEP

Seat/Lid

2 = Nitrile (NBR)

3 = Fluorocarbon (FKM)

4 = Fluorosilicone (FVMQ)

Model - Inlet Size - Housing Material Pallet and Seat Material Pallet Seal Material Body/Seat/Lid Seal Material

Enardo ES-950 2 to 12 in. 1 = Aluminum

Pressure Units Pressure Setting / Vacuum Units Vacuum Setting - Weight Material - Options

z = oz./sq.in.

n = in. w.c.

mm = mm w.c.

mb = mbar

0.5 to 32.0 oz./sq.in.

0.86 to 55.0 in. w.c.

22 to 1406 mm w.c.

2.2 to 138 mbar

4 = 316SST

5 = Carbon Steel

z = oz./sq.in.

n = in. w.c.

mm = mm w.c.

mb = mbar

MODEL ENARDO ES-950 PRESSURE/VACUUM RELIEF VALVE MODEL NUMBER

Figure 3. Pressure/Vacuum Relief Valve Model Number

2 = 316SST 1 = FEP

0.5 to 32.0 oz./sq.in.

0.86 to 55.0 in. w.c.

22 to 1406 mm w.c.

2.2 to 138 mbar

2 = Nitrile (NBR)

3 = Fluorocarbon (FKM)

4 = Fluorosilicone (FVMQ)

C = CS ZP

S = SST

L = Lead

1 = PTFE Body and FEP Seat/Lid

2 = Nitrile (NBR)

3 = Fluorocarbon (FKM)

4 = Fluorosilicone (FVMQ)

0 = No Options

F = Flat Face Flange (standard for Alumunim)

R = Raised Face Flange (standard for CS, SS)

X = Epoxy Coating

W1 = Wireless Pressure and Vacuum Monitoring

W2 = Wireless Pressure Monitoring Only

W3 = Wireless Vacuum Monitoring Only

W4 = Wired Pressure and Vacuum Monitoring

W5 = Wired Pressure Monitoring Only

W6 = Wired Vacuum Monitoring Only

-

Outside North America Only

MODEL ENARDO ES-850 MODEL ENARDO ES-851 MODEL ENARDO ES-950

MODEL ENARDO ES-951 MODEL ENARDO ES-952 MODEL ENARDO ES-953

Figure 4. Enardo ES-850 and Enardo ES-950 Series Pressure/Vacuum Relief Valve Available Models

3

Page 4

Enardo ES-850 and Enardo ES-950 Series

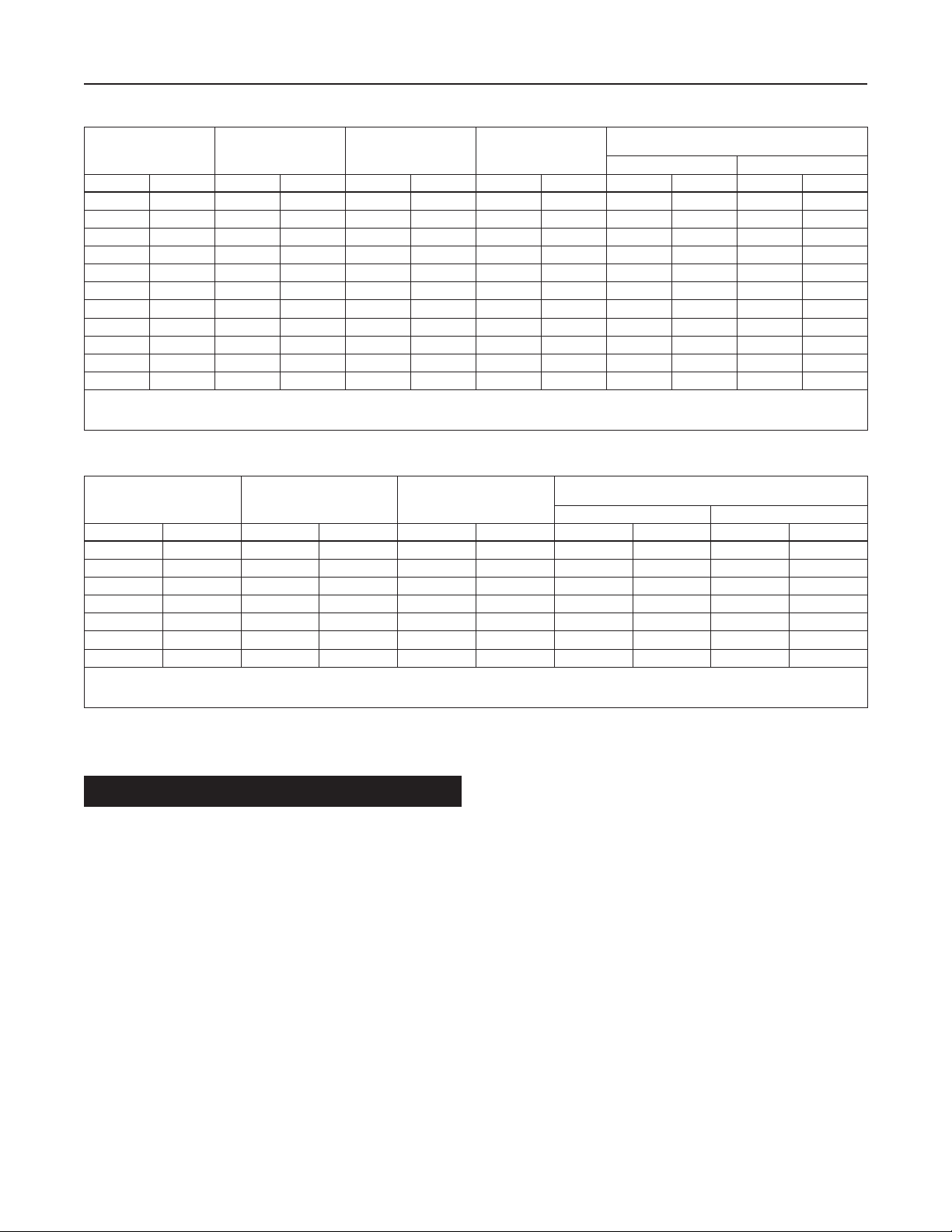

Table 1. Model Enardo ES-850 Weights

INLET CONNECTION OUTLET CONNECTION

In. mm In. mm Lb kg Lb kg Lb kg Lb kg

2 50 3 80 29 13 80 36 0.9 0.3 0.5 0.2

3 80 3 80 31 14 85 39 0.9 0.3 0.5 0.2

3 80 4 100 33 15 90 41 0.9 0.3 0.5 0.2

4 100 6 150 57 26 144 65 2.3 1.0 1.3 0.6

6 150 6 150 62 28 155 70 2.3 1.0 1.3 0.6

6 150 8 200 70 32 178 81 2.3 1.0 1.3 0.6

8 200 10 250 161 73 485 220 7.8 3.5 4.5 2.0

10 250 10 250 166 75 503 228 7.8 3.5 4.5 2.0

10 250 12 300 172 78 525 238 7.8 3.5 4.5 2.0

12 300 12 300 175 79 532 241 7.8 3.5 4.5 2.0

12 300 14 350 208 94 622 282 7.8 3.5 4.5 2.0

1. Unit weights indicate Net Weight of valve in pounds and kilograms at standard set pressure (0.5 oz/sq. in. pressure – 0.5 oz/sq. in. vacuum). It does not include shipping crate or box.

2. Multiply the relief setting by the value shown to determine the weight of the calibration weights used to achieve the desired relief setting.

3. Values shown for calibration weights are for reference purposes only. They are not intended to be used for determination of valve relief setting.

WEIGHT

(ALUMINUM)

WEIGHT

(STAINLESS STEEL OR

CARBON STEEL)

Table 2. Model Enardo ES-950 Weights

INLET CONNECTION

In. mm Lb kg Lb kg Lb kg Lb kg

2 50 21 10 54 24 0.9 0.3 0.5 0.2

3 80 23 10 58 26 0.9 0.3 0.5 0.2

4 100 41 19 110 50 2.3 1.0 1.3 0.6

6 150 45 20 123 56 2.3 1.0 1.3 0.6

8 200 123 56 362 164 7.8 3.5 4.5 2.0

10 250 129 59 383 174 7.8 3.5 4.5 2.0

12 300 144 65 405 184 7.8 3.5 4.5 2.0

1. Unit weights indicate Net Weight of valve in pounds and kilograms at standard set pressure (0.5 oz/sq. in. pressure – 0.5 oz/sq. in. vacuum). It does not include shipping crate or box.

2. Multiply the relief setting by the value shown to determine the weight of the calibration weights used to achieve the desired relief setting.

3. Values shown for calibration weights are for reference purposes only. They are not intended to be used for determination of valve relief setting.

WEIGHT

(ALUMINUM)

WEIGHT

(STAINLESS STEEL OR

CARBON STEEL)

(1)

WEIGHT OF CALIBRATION WEIGHTS REQUIRED TO

ACHIEVE DESIRED RELIEF SETTING

Weight per oz/sq. in. Weight per in. w. c.

(1)

WEIGHT OF CALIBRATION WEIGHTS REQUIRED TO ACHIEVE

Weight per oz/sq. in. Weight per in. w. c.

DESIRED RELIEF SETTING

(2)(3)

(2)(3)

Smart Wireless Monitoring Option

WARNING

▲

The surface resistivity of the antenna

assembly when the optional transmitter

is installed is greater than 1 GΩ. To avoid

electrostatic charge build up, it must not be

rubbed or cleaned with solvents or dry cloth.

The Smart Wireless Monitoring Option is available

with PVRV Models Enardo ES-850 (Pipe-away) and

Enardo ES-950 (Vent-to-atmosphere). This option allows the

remote sensing and “OPEN/CLOSED” value transmission

of the open or closed status of the pressure vent, the

vacuum vent or both. Use Option Code WP for pressure vent

monitoring, Option Code WV for vacuum vent monitoring

or WPV for the monitoring of both at the end of the model

string. Knowing whether a PVRV is open or closed can

enable immediate response to prevent problems related to

safety, emissions and quality of the tank contents.

4

The following are a few specic examples of how this added

visibility can help prevent problems:

Example #1 – Redundant PVRV’s

Redundant PVRV’s are commonly used for added safety. If

the primary PVRV fails closed or partially-closed, then the

backup PVRV automatically takes over. This is achieved by

establishing a pressure set point that is slightly higher for

the backup device. In this way, if the primary PVRV fails, the

tank remains protected. But redundancy is lost and should

be addressed as soon as possible. But how will you know

if this has occurred? Monitoring the open/closed position

of the backup PVRV can provide quick identication of this

issue, for either the pressure or vacuum side. Under normal

conditions, the backup PVRV remains closed. If the backup

PVRV is open, this points to either the primary PVRV not

functioning as expected or a separate pressure control

problem in the tank system that is causing both PVRV’s to

be open. Ideally, the wireless monitoring of both primary and

backup devices is preferred in order to gain the most insight.

Outside North America Only

Page 5

Enardo ES-850 and Enardo ES-950 Series

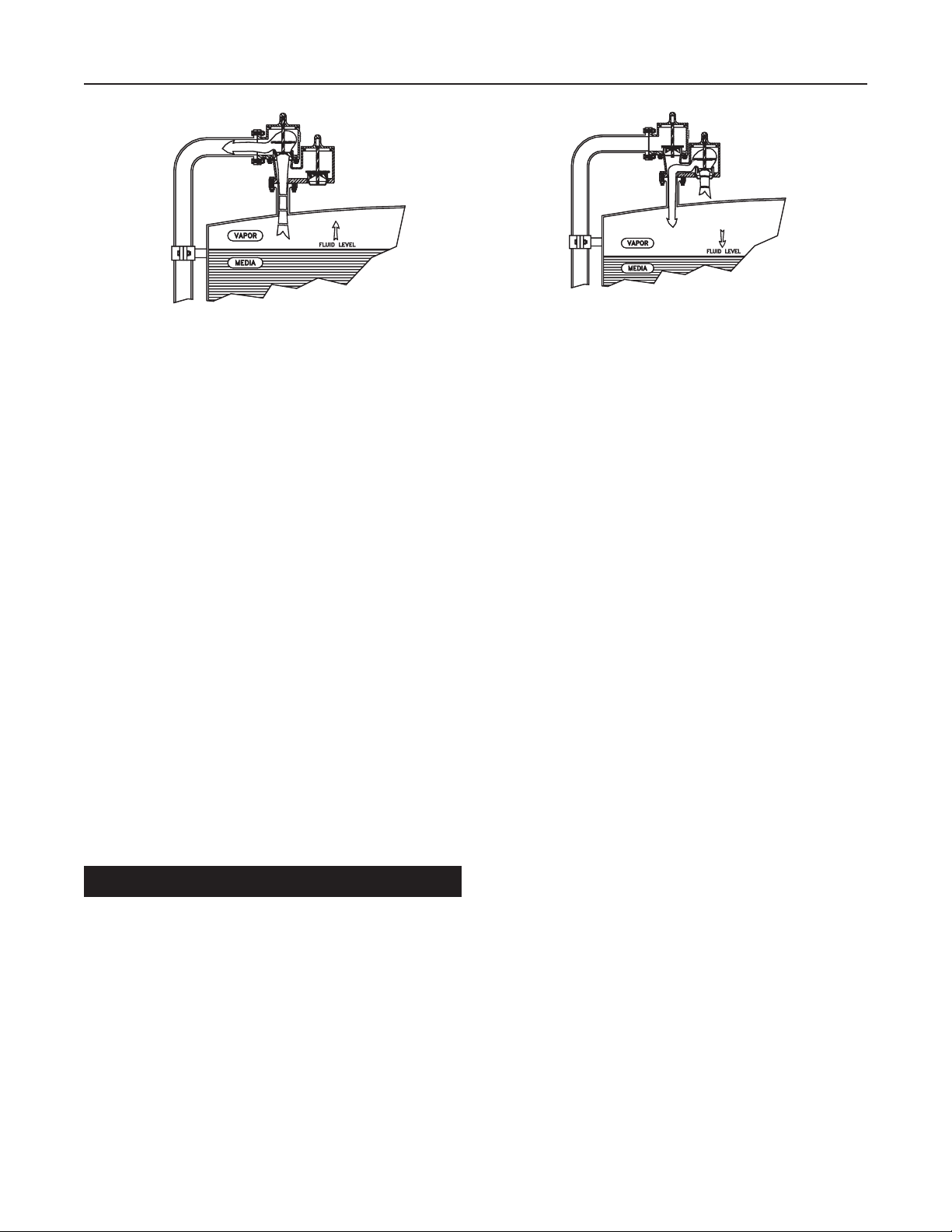

PRESSURE FLOW

Figure 5. Pressure and Vacuum Flow

Further troubleshooting can then be performed and the

problem can be detected and addressed.

Example #2 – Tank Blanketing

Tank blanketing is sometimes used in order to inert the vapor

space in a tank for added safety. A tank blanketing regulator

controls the inow of nitrogen or another blanketing gas

by responding to a low pressure set point. In this scenario,

a PVRV (vacuum side) generally acts as a backup to the

blanketing regulator. If the blanketing system fails for some

reason, the PVRV automatically takes over, as its set point is

slightly higher than that of the regulator. But once again, how

is one to know that this has occurred? A wireless-monitored

PVRV would indicate that the vacuum side is open. Under

normal operation, it should be closed.

Example #3 – Emergency Vent

A storage tank’s emergency vent should remain closed,

except in abnormal conditions. If an emergency vent is also

remotely monitored, and found to be open, then there may

be a pressure control issue somewhere in the system. In this

scenario, the PVRV should also be open. If it is not, it could

be part of the issue. Again, a wireless-monitored PVRV can

readily provide this information.

Product Identication and Marking

CAUTION

△

VACUUM FLOW

Hazardous Locations

Fisher™ pressure/vacuum relief valves are available with

outer housings of carbon steel, stainless steel or aluminum,

as indicated in Figure 5.

Nameplate

A nameplate is attached to the valve and contains the

following information:

• Model Number – Ex. VALVE, Enardo ES-950-4-1211

• Conn. Flange Size and Rating – Ex. 4 in.

• Serial Number

• Tag Number (Optional)

• Year – Ex. 08

Principle of Operation

Enardo ES-850 and Enardo ES-950 Series

The Enardo ES-850 and Enardo ES-950 Series pressure/

vacuum relief valves maintain a tight seal until system

pressure or vacuum exceeds the set pressure of the valve.

Set pressure is determined by stacking a series of weights

onto the valve pallet unless the pressure and vacuum set

points have been specied for the minimum settings. When

overpressure occurs, the weighted pallet lifts, breaking the

seal between the seat and pallet. This allows vapors to pass

through the valve orice and relieve pressure buildup. The

valve reseals upon relief and remains sealed.

Outside North America Only

As part of the legacy Model Enardo 850/

Enardo 950 ATEX certication, an

ignition risk analysis was performed.

Grounding of the unit is not deemed to be

necessary because all conducting parts

of the equipment are arranged such that

a dangerous potential dierence cannot

exist between them. However, grounding or

bonding allowances can be made at user

request if internal, local or national codes or

standards require.

It is important to know that relieving vapors near the set

pressure in a continuous manner may cause the pallet to

utter or oscillate inside the valve chamber. This is common

to products of this type. Operating the valve with utter or

oscillation may cause premature valve damage or wear over

time. Fisher pressure/vacuum relief valve ow charts and

sizing program results designate the “utter zone” to assist

with correct valve sizing. Contact your local Sales Oce with

any questions or additional assistance.

5

Page 6

Enardo ES-850 and Enardo ES-950 Series

LID AND UPPER

GUIDE

OUTLET FLANGE

VALVE PALLET

LID O-RING

PRESSURE CHAMBER

LID AND UPPER

GUIDE

VALVE SEAT

DRAIN PLUG

BODY ATTACHMENT

GASKET

GUIDE BUSHING

VENT ROD

VALVE PALLET

WEATHER

HOOD

VACUUM CHAMBER

VALVE PALLET STEM

VALVE PALLET SEAL

SEAT O-RING

INLET FLANGE

INSTALLATION STUD

MODEL ENARDO ES-850 PIPE-AWAY PRESSURE/VACUUM RELIEF VALVE

UPPER GUIDE

PRESSURE CHAMBER

(ATMOSPHERE)

LID AND UPPER

GUIDE

Outside North America Only

VACUUM CHAMBER

VALVE SEAT

VALVE PALLET STEM

VALVE PALLET SEAL

INLET FLANGE

VACUUM SCREEN

VACUUM SEAT RETAINER

MODEL ENARDO ES-950 VENT-TO-ATMOSPHERE PRESSURE/VACUUM RELIEF VALVE

Figure 6. Models Enardo ES-850 and Enardo ES-950 Pressure/Vacuum Relief Valve Assembly

6

Page 7

Enardo ES-850 and Enardo ES-950 Series

WIRELESS LID

WIRELESS STEM

SENSOR

TRANSMITTER

WIRELESS LID

SENSOR

WIRELESS

STEM

Figure 7. Model Enardo ES-850 with Smart Wireless Option

CONDUIT

CONDUIT

WIRELESS HOOD

WIRELESS STEM

VENT ROD

SENSOR

BRACKET

SET SCREW

SLEEVE

TRANSMITTER

WIRELESS LID

SENSOR

WIRELESS

STEM

Figure 8. Model Enardo ES-950 with Smart Wireless Option

CONDUIT

CONDUIT

Outside North America Only

7

Page 8

Enardo ES-850 and Enardo ES-950 Series

Installation

Enardo ES-850 and Enardo ES-950 Series

WARNING

▲

Take all necessary precautions and safety

measures when lifting valves into place

to prevent unbalanced load situations.

Do not install calibration weights or pallet

assemblies prior to mounting and installation

of valve. Special care must be taken during

installation to prevent damage to the seat

sealing surface.

Wear protective gloves and clothing

to prevent skin contact when handling

lead weights. Wear eye protection. Avoid

breathing dust/fumes/mist/vapors/spray.

Do not eat, drink or smoke while using the

product. Avoid release to the environment.

Wash hands with soap and water after

handling. Keep away from excessive heat

and open flames.

If lead weights need to be disposed of, follow

all local, regional and national regulatory

requirements for the safe and proper

disposal of lead.

2. Remove valve pallets from the unit. Separate the

protective cardboard coverings from the pallet stems

and seals. Gently clean the seal with a suitable solvent

and lint free, nonabrasive cloth to remove any dirt/

particles and achieve good seal tightness. Be careful not

to damage the pallet seal surface.

REMOVE CARDBOARD FROM PALLET STEMS

All product congurations use similar

packing methods.

CARDBOARD

Note

Make sure line is free of hazardous vapors

before installing or servicing the valve.

Product material of construction can include

aluminum, carbon steel and stainless steel.

Care should be taken to avoid mechanical

impacts that could result in a spark.

1. Loosen fasteners on top of the valve and remove the lid,

hood or guide.

CARDBOARDS

REMOVE CARDBOARD FROM PALLET STEMS

Outside North America Only

3. Reinsert uncovered valve pallets back into the unit.

Make sure that the lower stem is being guided by the

saber guides before lowering the pallet onto the seat

to avoid hitting the seat sealing edge with an o-set

pallet . If the pallet appears to be o-center to the

valve chamber, or if there is diculty positioning the

lid or guide, carefully inspect the pallet to ensure it is

inserted properly.

8

Page 9

Enardo ES-850 and Enardo ES-950 Series

4. Remove any protective ange covers.

Note

For more details on using weights

to adjust the pallet setting, read the

Adjustments section.

CAUTION

△

Use care when installing weights and

securing lids to avoid getting pinched.

5. Reinstall pressure and/or vacuum pallet assemblies into

their respective openings. Install the setting weights

(if required) by engaging the hole in the weight on the

appropriate pallet assembly stem.

5.1. The weights are marked with their pressure

equivalents and are shipped outside of the valve

chamber. Verify that the appropriate weights are

being installed to provide the specied pressure

and/or vacuum setting. Refer to the nameplate data

to verify the specied factory settings.

Note

Make sure that the pallet assembly stem

positively engages the stem guide hole in the

hood or cover. Each pallet assembly must be

free to move upwards, with the pallet stem

travelling into the stem guide.

CAUTION

△

Use care when installing weights and

securing lids to avoid getting pinched.

6. Install the covers and/or hood.

7. Re-use existing wing nuts or nuts and tighten to secure

covers/hoods in position.

8. Attach the valve to the appropriate mating ange using

appropriate ange gasket which is compatible with

process conditions (customer provided). To ensure

proper function, install the valve to a level surface,

not greater than 1° o horizontal so the pallet will

move vertically. Valves that are tilted during usage

may suer premature damage or wear, and may have

more leakage.

For proper bolt torquing of the valve connecting ange to the

piping, please refer to Tables 3 to 5.

5.2. To adjust valve settings higher than minimum,

use the weights to increase the pressure setting.

Weights are packed separately within the unit

shipping package and are labelled “PRESSURE”

and/or “VACUUM”. If weights are shipped with the

unit, they should be installed onto the pallets in the

valve chamber in which they are labelled. Gently

slide the weights onto the pallet stem and down on

top of the valve pallet.

For 10 in. / 250 mm FEP pallets make sure to

put the PTFE (Teon

before adding the weights.

®

) spacer on top of the pallet

Smart Wireless Monitoring

WARNING

▲

Do not thread wireless sensor too far into

lid. Sensor may contact pallet stem and

prevent valve from opening properly. This

condition may result in equipment damage or

personal injury.

Units with Smart Wireless are shipped as self-contained

and already connected. The only connection required is

installation of the transmitter battery (shipped separately)

which is intrinsically safe and does not require a

hot-work permit.

1. Install valves with the Smart Wireless monitoring option

in a similar manner to the standard PVRVs with a few

differences. Remove any cardboard or other packaging

from the inner chambers. Remove the lid(s) and/

or hood to allow insertion of the appropriate weights

during installation.

2. Remove any lid with the sensing equipment threaded

into it as a single unit. The sensor should remain

engaged with the lid during this process. Position all

Outside North America Only

Teon® is a mark owned by E.I. du Pont de Nemours and Co.

9

Page 10

Enardo ES-850 and Enardo ES-950 Series

Table 3. Torque Specifications - Raised Face Flange, Steel Only

NOMINAL PIPE DIAMETER NUMBER OF BOLTS BOLT DIAMETER, IN. TORQUE, FT-LBS

2 4 0.63 35

3 4 0.63 60

4 8 0.63 43

6 8 0.75 80

8 8 0.75 109

10 12 0.88 101

12 12 0.88 135

14 12 1.00 168

Assumptions: Use of SAE grade 5 bolts or studs or stronger. No lubricant. Compressed mineral ber material or similar.

Notes: If lubricant is used on bolts, apply torque reduction factor listed in Table 5. For best results, hardened steel washers should be used on all cast ange bolted connections.

Table 4. Torque Specifications - Flat Face Flange, Steel or Aluminum

NOMINAL PIPE DIAMETER NUMBER OF BOLTS BOLT DIAMETER, IN. TORQUE, FT-LBS

2 4 0.63 32

3 4 0.63 47

4 8 0.63 32

6 8 0.75 49

8 8 0.75 68

10 12 0.88 69

12 12 0.88 98

14 12 1.00 138

Assumptions: Use of SAE grade 5 bolts or studs or stronger. No lubricant. Elastomer <70 Durometer Shore A.

Notes: Flat faced anges should never be mated to a raised face ange for installation. If lubricant is used on bolts, apply torque reduction factor listed in Table 5. For best results,

hardened steel washers should be used on all cast ange bolted connections.

Table 5. Torque Reduction Factors per Lubricant

DESCRIPTION COEFFICIENT OF FRICTION MULTIPLY TORQUE VALUE IN TABLE BY

Machine Oil f = 0.15 0.75

API SA2 Grease f = 0.12 0.60

Nickel-based Lubricant f = 0.11 0.55

Copper-based Lubricant f = 0.10 0.50

Heavy-Duty Lubricating Paste f = 0.06 0.30

Outside North America Only

10

Page 11

Enardo ES-850 and Enardo ES-950 Series

sensors within 0.100 in. of the pallet stem. Maintain

this critical distance. If the sensor location within a lid is

altered, re-test the unit to ensure proper functioning of

the sensor and transmitter. If this is the case, re-apply

thread sealant to mitigate any leakage of the sensor/

lid interface.

Figure 9. Model Enardo ES-850, Installation of Weights

3. For the Model Enardo ES-950 PVRVs containing hoods,

the sensor is located at a proper distance away from

the stem by using a sleeve, bracket and set screw. The

sensor is held within the sleeve using two jam nuts.

Fasten the sleeve to the hood using a bracket. Using

a set screw, mate the bracket and sleeve to ensure

that the sensor is in the proper location and cannot

be adjusted. When installing weights, lift the hood and

sensor/bracket/sleeve off the vent rods as one. Remove

the sensor/bracket/sleeve from the hood and install the

weights. Reverse the process to reassemble the hood

and sensor.

Figure 10. Model Enardo ES-950,

Installation of Weights (continued)

Maintenance

Enardo ES-850 and Enardo ES-950 Series

WARNING

▲

Wear protective gloves and clothing to prevent

skin contact when handling lead weights. Wear

eye protection. Avoid breathing dust/fumes/

mist/vapors/spray. Do not eat, drink or smoke

while using the product. Avoid release to the

environment. Wash hands with soap and water

after handling. Keep away from excessive heat

and open flames. Ensure that all proper safety

procedures and safeguards are followed when

working on units, especially if they are in the

elevated position.

Make sure line is free of hazardous vapors

before installing or servicing the valve.

Observe all applicable safety requirements.

Only qualied and trained personnel

shall perform maintenance functions in

hazardous locations.

Valves should be removed from the location

having a potentially explosive atmosphere

and taken to a safe location for repair

and maintenance.

Outside North America Only

Figure 10. Model Enardo ES-950, Installation of Weights

CAUTION

△

When removing and installing seats, ensure

to handle it with care to prevent damage

(scratches, nicks, etc.) to the sealing surface.

11

Page 12

Enardo ES-850 and Enardo ES-950 Series

For preventive maintenance of the Fisher™ pressure/

vacuum relief valve, refer to the following instructions.

1. Loosen the fasteners on top of the valve and remove

the lid, hood or guide.

3. Inspect the pallets for any damage or buildup that

may aect its sealing characteristics or its ability to

move properly inside the valve. Gently clean the seal

with a suitable solvent and lint free, nonabrasive

cloth to remove any dirt/particles and achieve good

seal tightness.

4. Clear away any buildup on the weights or on

the housing.

2. Remove any valve pallets and weights from the unit.

Keep in mind that these will be reinstalled, so keep track

of the chamber from which they were removed.

12

Outside North America Only

5. Inspect the valve seats installed in the unit. The sealing

surfaces should be smooth and free of nicks or buildup.

A good, clean seat sealing surface free from defects is

essential to achieving a tight seal. Check the guides for

anything that may keep the valve pallet from moving

properly inside the valve. If necessary, gently clean the

seats with a suitable solvent and nonabrasive cloth.

Page 13

Enardo ES-850 and Enardo ES-950 Series

6. If the valve has a lid, clean any buildup that may exist

in or around the guide hole located in the center of

the part.

9. Reinstall weights onto their appropriate valve pallets.

7. If the valve is tted with a screen of some type, clear

away any blockage that may impede proper ow.

8. Reinstall valve pallets and weights into their proper

chambers. Make sure the lower stem on the pallet

is centered into the valve seat. If the pallet appears

to be o-center to the valve chamber, or if there is

diculty positioning the lid or guide, the pallet may be

inserted improperly.

Spirolox® is a mark owned by Smalley Steel Ring Company.

Outside North America Only

10. Replace any lid, hood or guide that was previously

removed and fasten securely. When tightening down

lids, make sure the O-ring in each lid has full contact

with the sealing surface.

11. For seat removal, see Figure 6 for the valve

conguration drawings. The valve seats are installed in

machined bores in both the upper body (pressure) and

in the lower body (vacuum) and are tted with O-ring

seals. Remove the upper body seat by removing the

upper body casting (Model Enardo ES-850) or the Vent

Hood assembly (Model Enardo ES-950). Then remove

the seat from the bore. The lower seat (vacuum) is

retained by a Spirolox® retaining ring. Remove this ring

with a at-bladed screwdriver as shown above.

13

Page 14

Enardo ES-850 and Enardo ES-950 Series

PLACE RETROFIT STICKER NEXT TO VALVE NAMEPLATE.

Figure 11. Model Enardo 950 PVRV Retrofit Sticker Placement

Smart Wireless Monitoring Maintenace

Remove ring using a at-bladed screwdriver

12. For seat replacement, the seats are installed in the

reverse order of the removal. Make sure the bores are

clean and that the O-ring seals are not damaged. Use a

light lubricant when replacing the O-ring and seat.

Retrot Kits

The stainless steel seats, pallet assemblies and gaskets

used in the Enardo ES Series valves are completely

backwards compatible with Models Enardo 850/Enardo 950

valves already installed; even those with PPS pallets and

seats. Existing valves can be upgraded via readily available

retrot kits. Each kit contains one (1) Enardo ES Series

valve seat, one (1) seat O-ring, one (1) lid O-ring, one (1)

body gasket and one (1) pallet seal. For 8, 10 and 12 in.

valves that require FEP pallet seals, the retrot kit contains

a complete pallet assembly. For valves that have both

pressure and vacuum relief capabilities, two (2) retrot kits

are required to upgrade the entire valve. Note that the kits

are not specic to the venting function and can be used on

either the pressure or vacuum side of the valve.

Follow the instructions outlined in the Maintenance section of

this manual to replace the existing seats, gaskets and when

required, pallet assemblies. Once the upgrade is complete,

place the green retrot sticker that is included with each kit

next to the nameplate of the valve as shown in Figure 11.

The sticker provides conrmation that the valve has been

upgraded to the Enardo ES Series conguration.

1. Maintain Wireless Models Enardo ES-850 and Enardo ES-950

PVRVs in the same way as all standard Models

Enardo ES-850 and Enardo ES-950 PVRVs. Clean the

pallet and seat sealing surfaces, remove any buildup

of residues on the weights and ensure any screens are

not blocked.

2. Take certain precautions when cleaning the transmitter.

The surface resistivity of the antenna assembly when

the optional transmitter is installed is greater than 1 GΩ.

To avoid electrostatic charge build-up, it must not be

rubbed or cleaned with solvents or dry cloth.

Adjustments

The Fisher™ pressure/vacuum relief valves have wide range

of pressure and vacuum settings in units of ounces per

square inch (oz./sq.in.) or inches of water column (in. w.c.)

as indicated in the specication section of this instruction

manual. Standard Fisher valve pallets assemblies are

marked with a minimum equivalent pressure value in the

specied units. Installed alone has minimum settings of

1/2 oz./sq. in. or 1 in. w.c. The pallets are calibrated by the

seal support located on the bottom side of the pallet. The

pallet’s setting of 1/2 oz./sq.in. or 1 in. w.c. is etched into

the support. When a valve requires a setting higher than the

1/2 oz./sq.in. or 1 in. w.c. standard pallet setting, use weights

to increase the pallet’s setting up to the required setting.

The same seal support used with FEP seals on 8 in. /

200 mm and larger valves. In this case, the base calibration

of the pallet assembly can be determined by examining the

upper and lower guide stems. Pallet assemblies calibrated

to 1.0 in. w.c. or 25 mm w.c. will have stems fabricated using

solid bar stock. Pallet assemblies calibrated to 0.5 oz./sq.in.

or 2.2 mbar will have stems that have been fabricated using

tubing with plugged ends.

Outside North America Only

14

Page 15

Enardo ES-850 and Enardo ES-950 Series

Figure 12. Weights on Pallet

Table 6. Valve Maintenance

PART REPLACEMENT

Simple replacement. Provided with gasket repair kit

Pallet Seals

Pallet Assemblies

Body Gaskets Requires disassembly. Provided with gasket repair kit

Seats

along with other gaskets. The pallet seals are fragile and should

be handled carefully to avoid damage. They must never be folded

or creased. Never use abrasive cleaners on a pallet seal.

Drop-in replacement. Requires removal of lid.

Replace pallet seal as needed. For best results replace entire pallet assembly.

Again, care must be taken not to damage the seals.

Requires O-ring gasket to be replaced as well.

Use care when removing and installing seats to prevent damage

(scratches, nicks, etc.) to the sealing surface.

Use a light lubricant when replacing the O-ring and installing the seat.

Additional calibration weights are marked with their

equivalent pressure value and should be added as

necessary to achieve the specied setting.

Fisher™ weights also come in units of ounces per square

inch (oz./sq. in.) or inches of water column (in. w.c.). The

individual setting of each weight is either etched or imprinted

into the weight. Emerson oers several dierent sizes of

pressure/vacuum relief valves. To ensure that the right

weight is placed on the right pallet, take note that the weights

and pallets that go together will have the same outside

diameter. Standard Fisher weights allow the user to stack in

increments of 1/2 oz./sq. in. or 1/2 in. w.c.

Pressure/vacuum relief valve is shipped with prepackaged

weight kits to set the valve pressure properly. The package

labelled “pressure” is for the pallet in the pressure chamber,

while the package labelled “vacuum” is for the pallet in the

vacuum chamber. All weights in these packages should be

installed. If one or neither of these packages is included with

your order, then they are not needed. For 8 in. / 200 mm

and larger valves that use FEP seals, a PTFE spacer is

included and must be installed on top of the pallet before any

calibration weights are added. The spacer is not used if no

additional calibration weights are needed.

If the pressure and vacuum weights are mixed together, sort

and reorganize the weights.

When installing weights for the Fisher pressure/vacuum

relief valve, check the required settings on the tag attached

to the valve. Add weights to the pallet to achieve the required

setting. If the relief valve’s setting is 6 oz./sq. in., add weights

with the total setting of 5-1/2 oz./sq. in. to the valve since

the pallet’s setting alone is 1/2 oz./sq. in. Hence, the valve

pressure setting is the sum of the settings of the pallet and

the weights. The relief pressure or vacuum setting is equal

to the sum of the pallet assembly and individual calibration

weight equivalent pressure value.

Outside North America Only

15

Page 16

Enardo ES-850 and Enardo ES-950 Series

Valve Repair

WARNING

▲

Make sure line is free of hazardous vapors

before installing or servicing the valve.

Observe all applicable safety requirements.

Only qualied and trained personnel

shall perform maintenance functions in

hazardous locations.

All replacement parts must be provided

by Emerson.

Remove the valve from the tank before attempting any

repairs beyond pallet assembly and weight maintenance as

described on Maintenance section.

Most repairs will consist of replacing pallet seals, lid gaskets

and in some cases, the body gaskets. The seats are also

replaceable if the need arises. These repairs are relatively

simple and can normally be handled by plant maintenance

personnel using common hand tools.

Most valve maintenance can be performed by the customer

or by a valve repair facility. See Table 6 for the proper

maintenance of the relief valve parts.

In most cases, it is not necessary to return the valves to

the factory. If the valve needs to be tested and certied at

a specied pressure and/or vacuum, return it to the factory

or send it to a qualied valve repair facility that is capable

of performing the necessary tests in accordance with

API Bulletin 2521 recommendations.

Contact your local Sales Oce with any questions or

additional assistance needed for repairing your valve.

Webadmin.Regulators@emerson.com

Fisher.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Tulsa, OK 74146 USA

T +1 918 662 6161

Europe

Bologna 40013, Italy

T +39 051 419 0611

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Asia Pacic

Singapore 128461, Singapore

T +65 6770 8337

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D104632X012 © 2021 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 02/21.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a business

of Emerson Automation Solutions.

The contents of this publication are presented for informational purposes

only, and while every eort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which

are available upon request. We reserve the right to modify or improve the

designs or specications of such products at any time without notice.

Emerson Process Management Regulator Technologies, Inc does not

assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Outside North America Only

Loading...

Loading...