Page 1

Precision Cooling

For Business-Critical Continuity

Liebert Envirosource

User Manual - 1.5 to 10 Tons, 60Hz

™

Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.0 SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

3.0 S

4.0 I

YSTEM COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

NSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FIGURES

Figure 1 General piping arrangement—Envirosource standby pump and cooling module with

Process Fluid Chiller 1-1/2 to 5 ton air cooled models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2 General piping arrangement—Envirosource standby pump and cooling module with

Process Fluid Chiller 8-10 ton air cooled models with electronic hot gas bypass . . . . . . . . . . . 6

Figure 3 Physical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4 Service clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5 Equipment layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 6 Cabinet dimensions for Envirosource ENV05G and ENV10G. . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7 Cabinet dimensions for Envirosource ENV20G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8 Electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TABLES

Table 1 Model numbers for minimum application flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2 Time delay settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 3 Connection sizes (NPT male) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4 Electrical data, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5 Technical data—Envirosource module, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

i

Page 4

ii

Page 5

1.0 INTRODUCTION

The Envirosource Module is an accessory to the Process Chiller, for use on systems that circulate

water and/or glycol solutions that require an isolated loop from the emergency water source. With the

heat exchanger providing fluid separation, the Envirosource automatically switches to the emergency

water source on a high fluid temperature alarm. Additionally, the module automatically switches to

standby pump operation (with interlock to shut down the Process Chiller pump) on a loss of flow

alarm.

The Envirosource Module is available in 208/230/460V, single-phase and three-phase, 60 Hz configurations. This module is a pre-piped and wired assembly that is encased in an almond colored, powder

coated and baked cabinet. It consists of a copper brazed stainless steel heat exchanger, stainless steel

pump, copper piping, RCM4 alarm monitor, adjustable time delay relays, high temperature thermostat, cooling solenoid valve, check valve and flow switch. It also includes a manual ball valve and double-check back-flow preventer on the city water line.

The integral RCM4 alarm monitor has a local display of normal operation, standby pump and standby

cooling, “on” LED. Terminal strips are included for two optional alarms (customer supplied dry contacts) and for common alarm output (dry contacts, NC/NO/COM).

Table 1 Model numbers for minimum application flow

Model # Range (gpm)

ENV05G-_00 0.3 - 1.1

ENV10G-_00 3.7 - 13.3

ENV20G-_00 3.7 - 13.3

Introduction

The Process Chiller is modified with a bypass line to permit water to flow around the chiller’s pump

when the standby pump in the Envirosource Module is operating. This bypass line runs from the

pump suction line to the pump discharge line and includes a ball valve and check valve (see

Figures 1 and 2).

1

Page 6

2.0 SEQUENCE OF OPERATION

During normal operation, cold fluid flow from the chiller passes across the flow switch, through the

heat exchanger, through the pump bypass check valve, past the supply temperature sensor and out to

the load (see Figures 1 and 2). The standby cooling solenoid valve is closed (de-energized) and the

standby pump is off.

If the flow switch senses loss of flow, a time delay is initiated to prevent nuisance switchovers. After

the delay (see Table 2 below), the alarm panel indicates “standby pump on” and the common alarm

contacts close, while the standby pump is brought on to resume flow and the chiller pump is locked

out. This mode is locked in until the reset button is pressed.

Similarly, if the thermostat senses high fluid temperature, a time delay is initiated to prevent

nuisance switchovers. After the delay (see Table 2 below), the alarm panel indicates “standby cooling

on” and the common alarm contacts close, while the solenoid valve is energized to resume cooling.

This mode is locked in until the reset button is pressed.

Table 2 Time delay settings

Condition Default

Loss of Flow 10 0 90

High Water Temp. 180 0 480

Minimum Maximum

Sequence of Operation

Delay (seconds)

Note that during normal operation, the auto/manual switches (see Figure 8) are set to “auto”. The

switch can be set to “manual” to force switchovers to standby pump and/or standby cooling for troubleshooting or maintenance.

Note that the “remote shutdown” function (see 4.0 - Installation) prevents emergency switchover

operation regardless of the status of other controls.

2

Page 7

3.0 SYSTEM COMPONENTS

RCM4 Monitor is configured to activate an LED and an audible alarm. The common alarm output

contacts will close in response to a loss of flow or high supply fluid temperature. The silence/reset button silences the alarm. The button also resets the LEDs and alarm contacts if the unit has returned to

normal mode.

Thermostat monitors supply fluid temperature. The thermostat (switchover) setpoint is adjustable

from 40°F to 90°F (4°C to 32°C). The setpoint has a differential of 3.0° to 12.0°. The recommended setting is 3.0°.

NOTE

Some applications may require different setpoints and differentials. Consult your local Liebert

representative or the factory for assistance.

Flow Switch monitors supply flow. The flow switch setpoint is adjustable. See Table 1 for minimum

flow switch setpoint range.

Solenoid Valve is 24VAC, 2-way, pilot or direct operated, with brass body.

Manual Ball Valve is 1/4 turn, brass body for shutoff or trimming of emergency water source flow.

Back-Flow Preventer is of double-check design and is located at the emergency water source piping

connection point.

System Components

3

Page 8

4.0 INSTALLATION

Prepare the location(s) for the unit (see Figure 4). Allow adequate clearance for convenient maintenance. Anchor the unit to the floor or bolt it securely to the wall using appropriate anchors (supplied

by others).

WARNING

!

Failure to fasten unit securely to wall studs or structural members with appropriate

anchors (supplied by others) may result in product failure and personal injury.

Connect the unit piping to the chiller, load, emergency water supply and drain (or recirculator). Piping connections are labeled on the unit. Be sure to bleed all air out of the fluid system. Note that the

pressure limit of the Envirosource Module is 100 psig.

CAUTION

!

To prevent leaks within the Envirosource Module, the fluid pressure should not exceed

100 psig. For installations using an Envirosource above this rating, a pressure-reducing

valve (supplied by others) is required.

Connect unit to the required AC power source through a remote on/off switch (field supplied) as indicated on the unit nameplate. Electrical service shall conform to national and local electrical codes.

Refer to unit nameplate for full load amps (FLA), wire size amps (WSA) and overcurrent protection

device (OPD) requirements. Refer to Figure 8 when making connections.

Installation

Connect pump interlock to Process Chiller. Connect optional control wiring for remote shutdown,

remote indication of loss of flow, remote indication of high temperature and common alarm, as

required.

4

Page 9

5.0 MAINTENANCE

Periodic preventive maintenance should include a monthly manual switchover to ensure that the system operates properly.

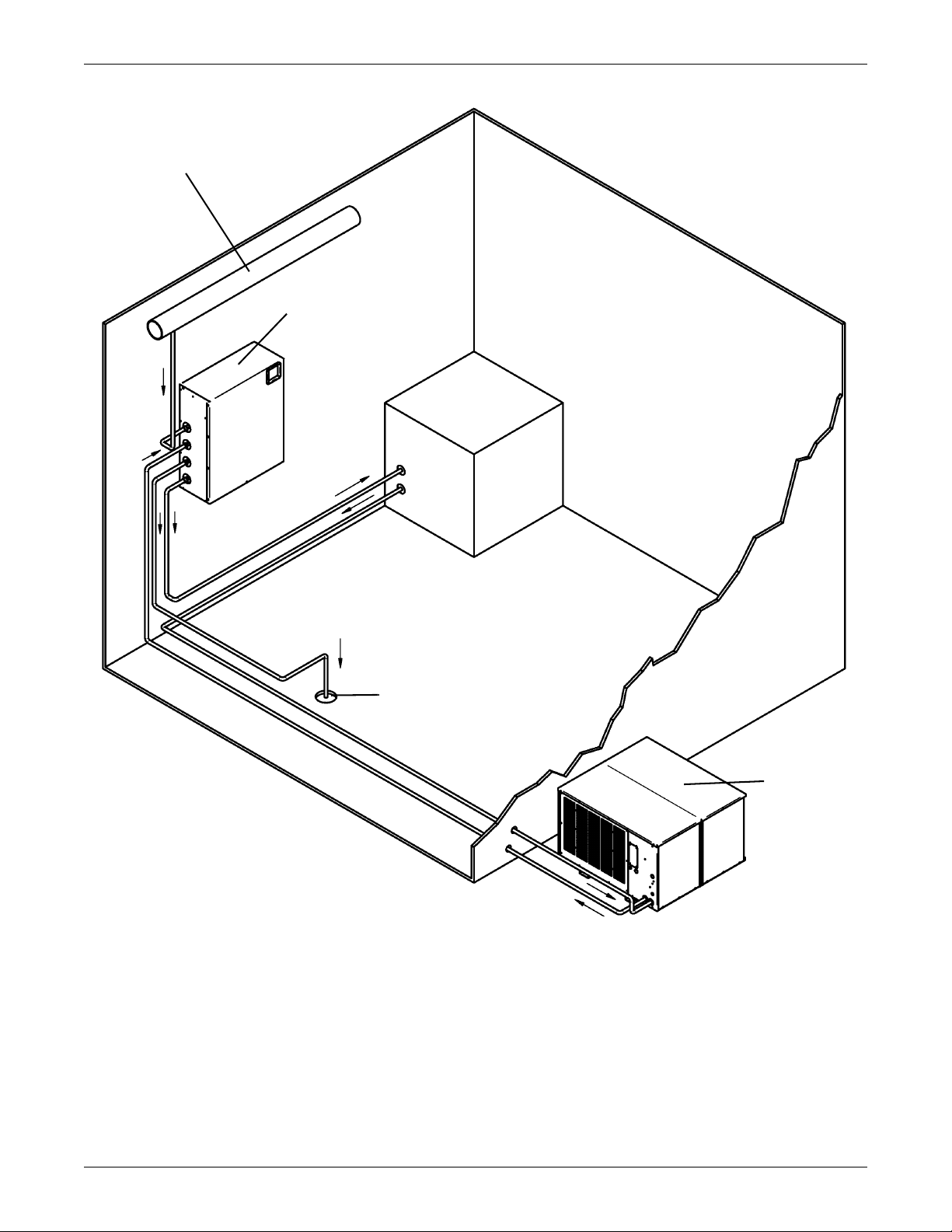

Figure 1 General piping arrangement—Envirosource standby pump and cooling module with

Process Fluid Chiller 1-1/2 to 5 ton air cooled models

Maintenance

5

Page 10

Figure 2 General piping arrangement—Envirosource standby pump and cooling module with

Process Fluid Chiller 8-10 ton air cooled models with electronic hot gas bypass

Maintenance

6

Page 11

Figure 3 Physical data

City Water Supply

Supply from Chiller

To D r a in

Maintenance

Supply to Load

Supply from

Chiller

Heat Exchanger

Pump

ENV05G-_00 / ENV10G-_00

Supply to

Load

To Drain

City Water

Supply

Heat

Exchanger

Pump

ENV20G-_00

7

Page 12

Maintenance

Table 3 Technical data—Envirosource module, 60 Hz

Process Fluid Chiller PS018A PS024A PS036A PS048A PS060A PS096A PS120A

Model Number ENV05G ENV05G ENV10G ENV10G ENV10G ENV20G ENV20G

Circulating Fluid—Water

Flow Rate, gpm (l/s)

Pressure Drop, feet (kPa)

Emergency Fluid—Water

Flow Rate, gpm (l/s)

Pressure Drop, feet (kPa)

To prevent leaks within the Envirosource Module, the water pressure should not exceed 100 psig.

2.4

(.151)

13.6

(40.65)

3.6

(.227)

21

(62.77)

3.3

(.208)

24.9

(74.43)

4.9

(.312)

27.7

(82.80)

5.3

(.334)

11.7

(34.97)

8.0

(.502)

31.4

(93.85)

7.9

(.498)

18.6

(55.60)

11.9

(.751)

51.1

(152.74)

10.2

(.644)

30.7

(91.76)

15.3

(.965)

74.4

(222.38)

16.0

(1.009)

14.2

(42.44)

24.0

(1.51)

65.1

(194.58)

20.0

(1.262)

23.7

(70.84)

30.0

(1.89)

73.7

(220.29)

Table 4 Connection sizes (NPT male)

Model ENV05G ENV10G ENV20G

Supply from Chiller 3/4" 1" 1-1/4"

From Emergency Water Supply 1/2" 3/4" 1"

To Drain or Recirculator 1/2" 3/4" 1"

Supply to Load 3/4" 1" 1-1/4"

Table 5 Electrical data, 60 Hz

ENV05G ENV10G ENV20G

Electrical

Requirements

FLA 7.6 3.5 1.6 8.8 4.6 2.1 -- 10.6 4.8

WSA 9.9 4.4 2.0 11.0 5.8 2.6 -- 13.6 6.0

OPD 15.0 15.0 15.0 15.0 15.0 15.0 -- 15.0 15.0

*Electrical data based on standard pump selection for 40% E.G.

208/230 460 208/230 460 208/230 460

1 Ph 3 Ph 3 Ph 1 Ph 3 Ph 3 Ph 1 Ph 3 Ph 3 Ph

8

Page 13

Figure 4 Service clearances

Maintenance

Shaded areas indicate

recommended clearance

for component access

and removal.

ENV05G / ENV10G / ENV20G

9

Page 14

Figure 5 Equipment layout

City Water

Maintenance

Envirosource

(ENV05G or ENV10G)

Load

Outdoor (Glycol) Application

Drain

Process

Chiller

10

Page 15

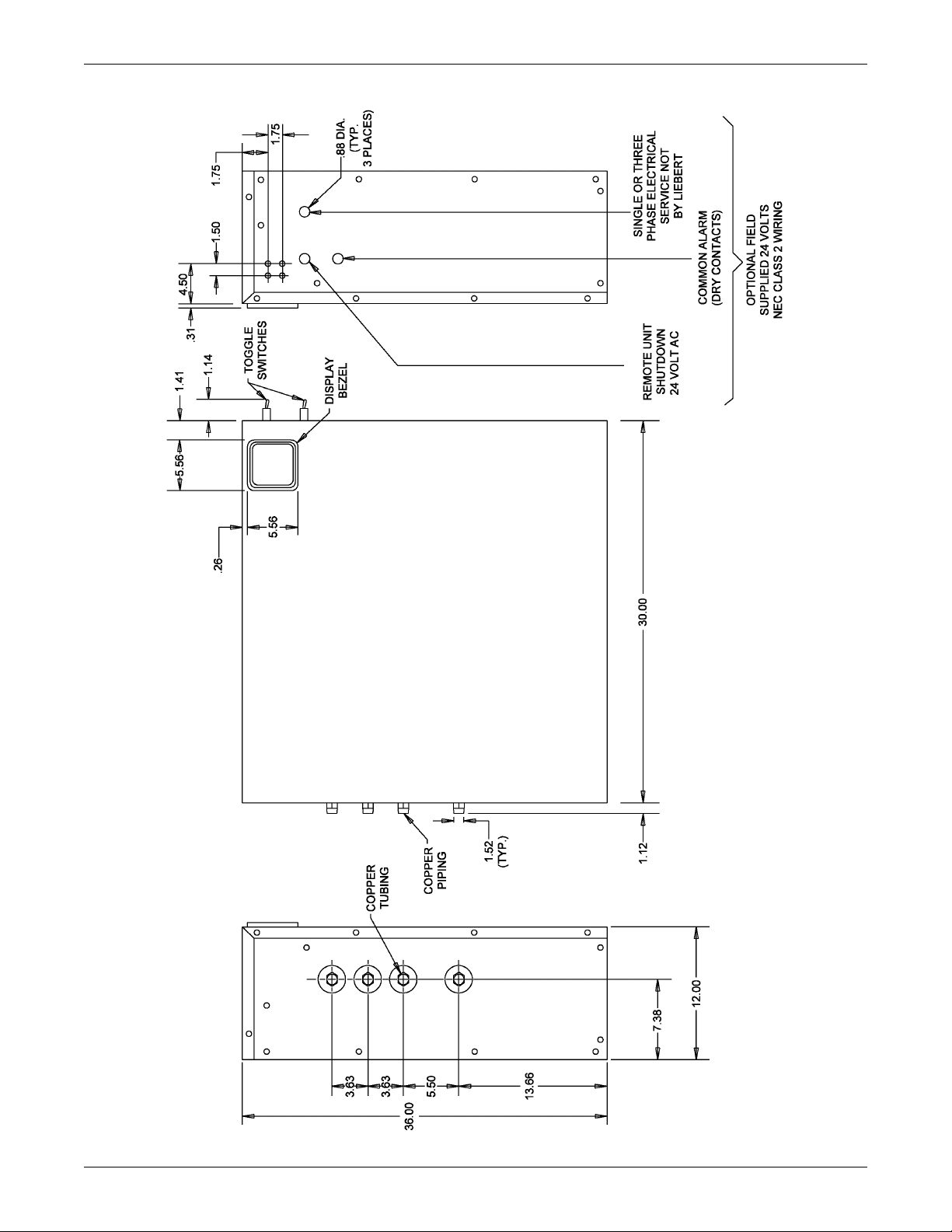

Figure 6 Cabinet dimensions for Envirosource ENV05G and ENV10G

Maintenance

11

Page 16

Figure 7 Cabinet dimensions for Envirosource ENV20G

Maintenance

12

Page 17

Figure 8 Electrical schematic

Maintenance

13

Page 18

Maintenance

14

Page 19

Page 20

Ensuring The High Availability

0f Mission-Critical Data And Applications.

Emerson Network Power, the global leader in enabling business-critical

continuity, ensures network resiliency and adaptability through

a family of technologies—including Liebert power and cooling

technologies—that protect and support business-critical systems.

Liebert solutions employ an adaptive architecture that responds

to changes in criticality, density and capacity. Enterprises benefit

from greater IT system availability, operational flexibility and

reduced capital equipment and operating costs.

While every precaution has been taken to ensure the accuracy

and completeness of this literature, Liebert Corporation assumes no

responsibility and disclaims all liability for damages resulting from use of

this information or for any errors or omissions.

© 2006 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change

without notice.

® Liebert and the Liebert logo are registered trademarks of Liebert

Corporation. All names referred to are trademarks

or registered trademarks of their respective owners.

Technical Support / Service

Web Site

www.liebert.com

Monitoring

800-222-5877

monitoring@emersonnetworkpower.com

Outside the US: 614-841-6755

Single-Phase UPS

800-222-5877

upstech@emersonnetworkpower.com

Outside the US: 614-841-6755

Three-Phase UPS

800-543-2378

powertech@emersonnetworkpower.com

Environmental Systems

800-543-2778

Outside the United States

614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

7/F, Dah Sing Financial Centre

108 Gloucester Road, Wanchai

Hong Kong

852 2572220

Fax: 852 28029250

SL-15700_REV1_08-06

Emerson Network Power.

™

The global leader in enabling Business-Critical Continuity

AC Power Systems

Connectivity

DC Power Systems

Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co.

©2006 Emerson Electric Co.

Embedded Computing

Embedded Power Power Switching & Control

Integrated Cabinet Solutions

.

Precision Cooling

EmersonNetworkPower.com

ServicesOutside Plant

Site Monitoring

Surge Protection

Loading...

Loading...