Page 1

Instruction Manual

D103585X012

February 2021

EN-DFA Series

EN-DFA Series Detonation Flame Arrestor

(EN ISO 16852 Certied)

Table of Contents

Introduction .................................................................. 1

Product Description .................................................... 2

Specifications .............................................................. 2

Principle of Operation .................................................. 3

Factors Affecting Flame Arrestor Performance ............ 5

Installation ................................................................... 8

Maintenance .............................................................. 10

Recommended Spare Parts ...................................... 12

Parts Ordering ........................................................... 12

Figure 1. Typical EN-DFA Series Detonation Flame Arrestor

WARNING

▲

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Enardo™ detonation ame arrestor must

be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations

and Emerson Process Management

Regulator Technologies Tulsa,

(Emerson) LLC instructions.

Failure to correct trouble could result in

a hazardous condition. Call a qualied

service person to service the unit.

Installation, operation and maintenance

procedures performed by unqualied

person may result in improper adjustment

and unsafe operation. Either condition may

result in equipment damage or personal

injury. Only a qualied person must install

or service the detonation ame arrestor.

Introduction

Scope of the Manual

This Instruction Manual provides instructions for

installation, startup, maintenance and parts ordering

information for the EN-DFA Series detonation

ame arrestor.

Flame Arrestor Classication

The ame arrestors within the scope of this

document have been tested and certied as unstable

detonation ame arrestors and are therefore suitable

for deagrations, stable detonations and unstable

detonations, as dened by EN ISO 16852:2016,

propagating along pipe into connecting pipework.

This is the highest performance rating available for a

detonation arrestor and it exceeds the performance

rating of an arrestor certied for stable detonations and

deagrations only.

Detonation ame arrestors may be used for open and

closed pipe work on the unprotected (“hot”) side.

North America Only

Page 2

EN-DFA Series

Specications

The Specications table lists the specications for the detonation ame arrestors. The following information

is stamped on the nameplate attached to the arrestor: model number, ange size and rating, maximum initial

operating pressure, ISO reference number (International Standard), ISO type examination certicate, notied

body number, gas group, date of manufacture and serial number; other identication and customer tag number

are optional.

Available Constructions

See Table 1 and Figure 3

Operational Temperature (To)

-4 to 140°F / -20 to 60°C

(1)

Gas Group

IIA and IIB3

Flange Sizes and Rating

2 to 12 in. / 50 to 300 mm

Temperature Rating of Metal Reinforced Graphite

850°F / 450°C

Burning Time Rating

Less than 1 minute

CL150 RF and CL150 FF (standard)

Other connection ange sizes and ratings available

upon request

Housing Size

4 to 26 in. / 100 to 660 mm

Maximum Experimental Safe Gap (MESG)

Housing Material

Carbon steel, 304 Stainless steel,

316 Stainless steel and Hastelloy

Element Material

304 Stainless steel, 316 Stainless steel

and Hastelloy

®

See Table 4

EN Number (European Standard)

Maximum Initial Operating Pressure

EN ISO 16852:2016

See Table 5

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

Table 1. EN-DFA Series Detonation Flame Arrestor Available Construction (ATEX Approved)

MODEL

EN-DFA-0402 2 50 4 101

EN-DFA-0603 3 75 6.6 168

EN-DFA-0804 4 100 10 254

EN-DFA-1206 6 150 14 356

EN-DFA-1608 8 200 18 457

EN-DFA-2010 10 250 22 559

EN-DFA-2412 12 300 26 660

In. mm In. mm

FLANGE SIZE HOUSING SIZE

(1)

®

North America Only

Product Description

The EN-DFA Series detonation ame arrestor represents

the best value in ame arrestor protection. The

detonation ame arrestor provides protection against

ame propagation in piping systems that are manifolded

or have long run-up distances. These are typically

used for extended pipe length or multiple pipe bend

congurations to stop high pressures and ame velocities

with detonations and overdriven detonations. It also

stops conned and unconned, low and high pressure

Hastelloy® is a mark owned by Haynes International, Inc.

2

deagrations. The design is unique in the ability to

provide large ame channels which requires less frequent

maintenance and greater ease in cleaning when service

is required, translating to less down time. EN-DFA Series

detonation ame arrestors are bi-directional and proven

to stop an ignited ammable vapor mixture approaching

from either direction that can be travelling at subsonic

or supersonic velocities. The patented element oers

maximum ow to pressure drop characteristics enhancing

the value of the ame arrestor in any system.

Page 3

EN-DFA Series

Figure 2. Cut-away view of EN-DFA Series Detonation Flame Arrestor

EN DFA / - -

Detonation

Flame

Arrestor

(Concentric)

Housing

Size

04 = 4 in.

through

26 = 26 in.

Connection

Size

02 = 2 in.

through

12 = 12 in.

IEC

Gas

Group

IIA (D)

IIB3 (C)

Housing

Material

C = Carbon Steel

4 = 304 SST

6 = 316 SST

H = Hastelloy

®

Element

Material

4 = 304 SST

6 = 316 SST

H = Hastelloy

Connection

F = Flat face

®

R = Raised

Type

ange

face

ange

Options

1 = Drain Plug

2 = Pressure Tap

3 = Temperature Probe

Tap (standard)

4 = Miscellaneous

5 = Protective coating

6 = Special feature

Figure 3. EN-DFA Series Detonation Flame Arrestor Available Constructions and Model Numbering System

The EN-DFA Series is designed with anged connections,

and the arrestor provides the option of the removal of the

ame cell element for easy cleaning and replacement

without disconnecting of the pipe connection.

Principle of Operation

Detonation ame arrestor prevents ame propagation

as it enters the exposed side of the unit to the

protected side by absorbing and dissipating heat

using spiral wound crimped ribbon ame cells.

This detonation ame arrestor utilizes a patented

element assembly that dampens the high velocities

and pressures associated with deagrations and

detonations while quenching the ame front. These

cells allow maximum ow with maximum protection.

Detonation ame arrestor has the heat capacity

and structural design to withstand all the dynamic

conditions of ame propagation and still stop the

ame. Detonation ame arrestor is used when the

ame can be in any of the detonation states.

Limits for Use

The operational temperature, T0, shall be limited

as follows:

-4°F ≤ T0 ≤ 140°F / -20°C ≤ T0 ≤ 60°C

The operation pressure, p0, shall be limited as follows:

See Table 5

Hastelloy® C is a mark owned by Haynes International, Inc.

Flame arrestor use shall be limited to gas-air mixtures

with an Maximum Experimental Safe Gap (MESG)

equal to or greater than that tested.

Additional Protection Measures: Flame arrestors

may be used with additional protection measures.

The overall safety of the combined installation shall

be accessed, taking account of any hazardous area

classication (zones) and the likelihood of additional

ignition sources.

Factors Aecting Flame

Arrestor Performance

Gas Group

The type of gas in the system determines its gas

grouping and therefore predetermines the type of

arrestor element required. The element must be

designed to accommodate the specic gas group that

could possibly ignite and propagate in the system.

The more explosive gases require the ame cell to

absorb the heat more quickly and eciently. The

International Electrotechnical Commission (IEC)

groups gases and vapors into Groups IIA through IIC

categories depending on a number of factors including

the MESG of the gas.

North America Only

3

Page 4

EN-DFA Series

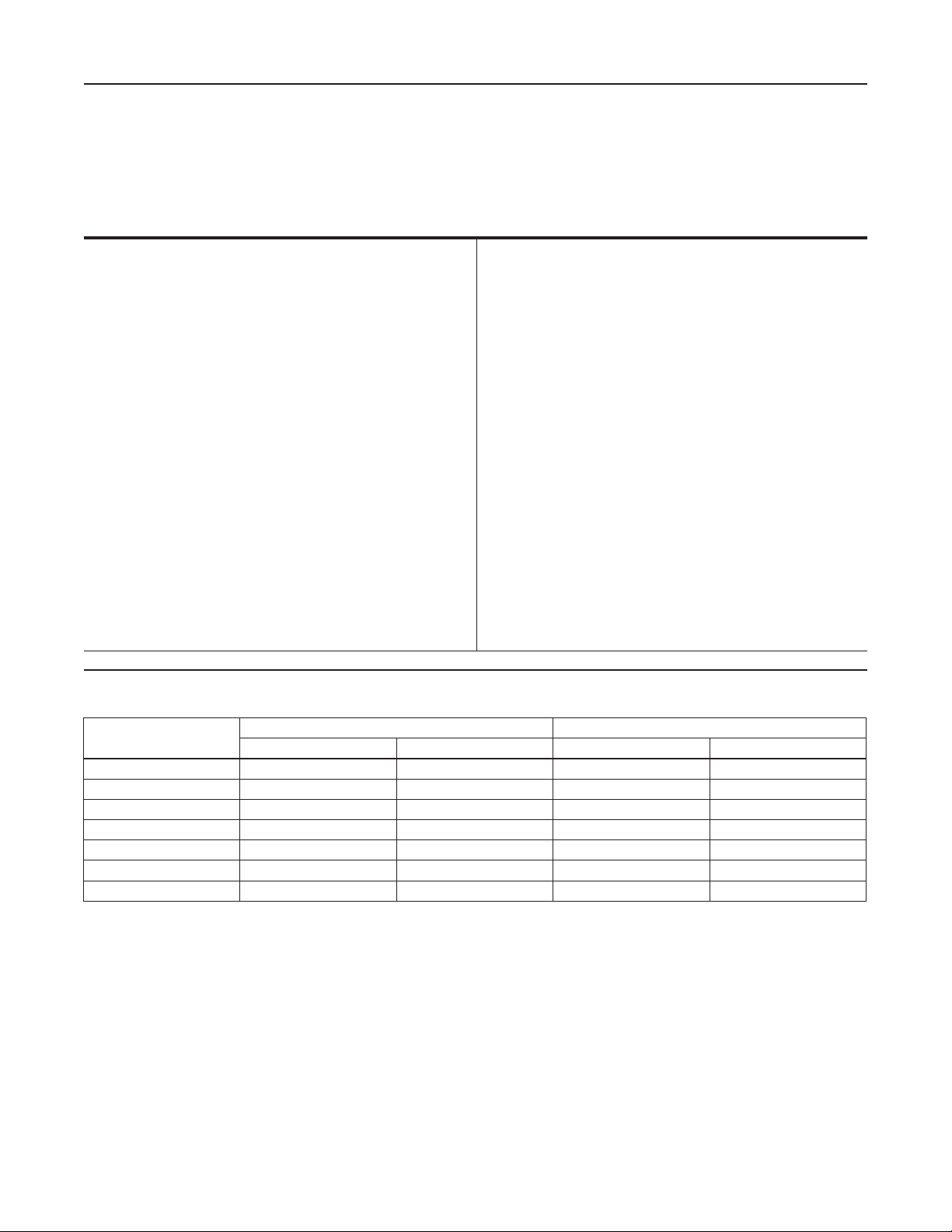

Flame Arrestors have installation and application limits

Type designation in accordance with EN ISO 16852:2016

DET 2 L

WARNING LABEL OF EN-DFA-0402/IIA THROUGH EN-DFA-1206/IIA (SEE TABLE 2)

Flame Arrestors have installation and application limits

Type designation in accordance with EN ISO 16852:2016

DET 2 L

WARNING LABEL OF EN-DFA-1608/IIA THROUGH EN-DFA-2412/IIA (SEE TABLE 2)

Flame Arrestors have installation and application limits

Type designation in accordance with EN ISO 16852:2016

DET 2 L

WARNING LABEL OF EN-DFA-0402/IIB3 THROUGH EN-DFA-2412/IIB3 (SEE TABLE 2)

/D = n/a

u

Ex. G IIA T

/D = n/a

u

Ex. G IIA T

/D = n/a

u

Ex. G IIB3 T

WARNING

BC: b; t

o

= 1 min

BT

= 60°C Po = 122.3 kPa (absolute)

WARNING

BC: b; t

o

= 1 min

BT

= 60°C Po = 116.3 kPa (absolute)

WARNING

BC: b; t

o

= 1 min

BT

= 60°C Po = 118.3 kPa (absolute)

HAZARDOUS LOCATIONS

Figure 4. Product Identification and Marking

North America Only

Figure 5. Marking Plate

4

Page 5

EN-DFA Series

Table 2. Warning Label Information

INFORMATION DESCRIPTION

DET Indicates product is a Detonation Flame Arrestor

2 Tested for unstable detonation without restriction

/D = n/a The ratio of pipe length (between the potential ignition source and the ame arrestor) and pipe diameter. It indicates unlimited

L

u

BC: b Indicates the ame arrestor is for short-time burning not to exceed 1 minute

Ex. G IIA Indicates the arrestor is rated for use in Explosion Group IIA vapors

Ex. G IIB3 Indicates the arrestor is rated for use in Explosion Group IIB3 vapors

T

o

P

o

MARKING PLATE FIELD MARKING

MODEL No. Per order, ex. EN-DFA-1206/IIA-C4R-2

Flange Size and Rating Per order, ex. 3 in CL150

Max Pressure (P

Lowest MESG Appropriate value from Table 4

Gas Group IIA or IIB3, per order

Direction of Flow Bi-directional. If product ordered with (1) temperature sensor, ow arrow will be added to unit

Serial Number

EU-Type Examination Certicate

Date of Manufacture

Customer Tag Number

) Appropriate value from Table 5

o

Indicates maximum operational temperature of ame arrestor

Indicates maximum operational pressure of ame arrestor

Table 3. Marking Plate Information

Per order

Based on unit ordered

Date of manufacture

Based on customer request

Table 4. Maximum Experimental Safe Gap (MESG)

NATIONAL ELECTRIC CODE

(NEC)

Group D Group IIA > 0.035 > 0.90 Propane

Group C Group IIB3 ≥ 0.026 ≥ 0.65 Ethylene

Group B Group IIC < 0.020 < 0.50 Hydrogen

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION (IEC)

Table 5. Maximum Initial Operating Pressure P

EXPLOSION GROUP

IIA 2 to 6 50 to 150 17.7 122.3

IIA 8 to 12 200 to 300 16.9 116.3

IIB3 2 to 12 50 to 300 17.2 118.3

CONNECTION SIZE P

In. mm psia kPa a

Maximum Experimental Safe Gap (MESG)

The MESG is the measurement of the maximum gap

between two equatorial anges on a metal sphere that

will prevent a ame from being transmitted from the

sphere to the surrounding ammable mixture. MESG

is dependent on gas composition. The stoichiometric

mixture (the ideal air/fuel ratio for the most ecient

combustion) is used to determine the minimum MESG

for a given gas.

MESG

In. mm

o

Maximum Initial Operating Pressure, p

TEST GAS LIST

O

0

Detonation ame arrestors tested at pTB (pressure

before ignition) are suitable for operational pressures

p0 ≤ pTB in the same or smaller pipe size when the

application is limited to mixtures with an MESG equal

to or greater than that tested. See Table 5 for maximum

initial operating pressure limits, p0. If p0 is exceeded

at the time of ignition, there is a risk of the ame

arrestor being unable to stop the ame front and ame

transmission through the ame arrestor is possible.

North America Only

5

Page 6

EN-DFA Series

Table 6. Temperature Sensor Safety Specifications

TECHNICAL DATA THERMOCOUPLE

Design Type Standard with thermowell Standard without thermowell

Model 185 03J1 Code 0185 thermocouple (IEC 584 Class 1) without thermowell

Manufacturer Emerson Rosemount Emerson Rosemount

EC-Type Approval Certificate

Temperature Sensor Design Type-K thermocouple Type-K thermocouple

Type of Ignition Protection

Protection Type (Connection Head)

Measuring Probe (Measuring Insert) 1/2 MPT or optional M24 x1.5. Intended for installation into thermowell. 1/2 MPT. Intended for installation without thermowell.

Connection Thread 1/2 MPT. Intended for installation into thermowell 1/2 MPT. Intended for installation without thermowell.

Transmitter Optional by customer request Optional by customer request

Intended Application In-line flame arrestors and detonation arrestors End-of-line flame arrestors. Free-vent style.

TECHNICAL DATA THERMOCOUPLE

Design Type Standard with thermowell Standard without thermowell

Model TC 10-2 (for additional Thermowell) TC10-H (threaded for direct insertion without thermowell)

Manufacturer WIKA WIKA

EC-Type Approval Certificate ATEX and IECEx certifications ATEX and IECEx certifications

Temperature Sensor Design Type-K thermocouple Type-K thermocouple

Type of Ignition Protection

Protection Type (Connection Head)

Measuring Probe (Measuring Insert)

Connection Thread 1/2 MPT or optional M24 x1.5. Intended for installation into thermowell. 1/2 MPT. Intended for installation without thermowell.

Transmitter Optional by customer request Optional by customer request

Intended Application In-line flame arrestors and detonation arrestors End-of-line flame arrestors. Free-vent style.

FM12ATEX0065X

ATEX: EN 60079-0:2012+A11:2013; EN 60079-1: 2014

II 2 G Ex d IIC T6...T1 Gb, T6(–50°C ≤ Ta ≤ + 40°C), T5...

T1 (–50°C ≤ Ta ≤ + 60°C)

Rosemount Aluminum

Explosion proof, 2-wire, 3-wire, 4-wire type A, 4-Wire type as specified

by customer

Intrinsically safe option is available

II 2 G Ex d IIC T6...T1 Gb, T6(–50°C ≤ Ta ≤ + 40°C), T5...

T1 (–50°C ≤ Ta ≤ + 60°C)

Explosion proof, 2-wire, 3-wire, 4-wire type A, 4-Wire type as specified

by customer.

Intrinsically safe option is available .

Spring loaded plate

Probe allows use of transmitter.

Length varies by flame arrestor size.

FM12ATEX0065X

ATEX: EN 60079-0:2012+A11:2013; EN 60079-1: 2014

II 2 G Ex d IIC T6...T1 Gb, T6(–50°C ≤ Ta ≤ + 40°C), T5...

T1 (–50°C ≤ Ta ≤ + 60°C)

Rosemount Aluminum

Explosion proof, 2-wire, 3-wire, 4-wire type A, 4-Wire type as specified

by customer

Intrinsically safe option is available

II 2 G Ex d IIC T6...T1 Gb, T6(–50°C ≤ Ta ≤ + 40°C), T5...

T1 (–50°C ≤ Ta ≤ + 60 °C)

Explosion proof, 2-wire, 3-wire, 4-wire type A, 4-Wire type as specified

by customer.

Intrinsically safe option is available.

Probe length varies by flame arrestor size.

Adjustable insertion length.

North America Only

Table 7. Torque Values for Raised Face Connection Flange (Steel Only)

NOMINAL PIPE DIAMETER NUMBER OF BOLTS

1 4 0.50 12.70 9 12.20

1-1/4 4 0.50 12.70 13 17.63

1-1/2 4 0.50 12.70 18 24.40

2 4 0.63 16.00 35 47.45

2-1/2 4 0.63 16.00 41 55.59

3 4 0.63 16.00 60 81.35

3-1/2 8 0.63 16.00 34 46.10

4 8 0.63 16.00 43 58.30

6 8 0.75 19.05 80 108.5

8 8 0.75 19.05 109 147.8

10 12 0.88 22.4 101 136.9

12 12 0.88 22.4 135 183.0

Assumptions: Use of SAE grade 5 bolts or studs or stronger

Notes: If lubricant is used on bolts, apply torque reduction factor listed in Lubricant Table. For best results hardened steel washers should be used on all cast flange bolted connections.

No lubricant

Compressed mineral fiber material or similar

6

BOLT DIAMETER TORQUE

In. mm Ft-lb N•m

Page 7

EN-DFA Series

Table 8. Torque Values for Flat Face Connection Flange (Steel Only)

NOMINAL PIPE DIAMETER NUMBER OF BOLTS

1 4 0.50 12.70 14 18.98

1-1/4 4 0.50 12.70 16 21.69

1-1/2 4 0.50 12.70 18 24.41

2 4 0.63 16.00 32 43.39

2-1/2 4 0.63 16.00 43 58.30

3 4 0.63 16.00 47 63.72

3-1/2 8 0.63 16.00 26 35.25

4 8 0.63 16.00 32 43.39

6 8 0.75 19.05 49 66.44

8 8 0.75 19.05 68 92.20

10 12 0.88 22.4 69 93.55

12 12 0.88 22.4 98 132.9

Assumptions: Use of SAE grade 5 bolts or studs or stronger

Notes: If lubricant is used on bolts, apply torque reduction factor listed in Lubricant Table. For best results hardened steel washers should be used on all cast flange bolted connections.

No lubricant

Elastomer < 70 Durometer Shore A

Table 9. Torque Correction Factors for Common Lubricants Applied on Connection Fasteners

DESCRIPTION COEFFICIENT OF FRICTION MULTIPLY TORQUE VALUE IN TABLE 8 BY

Machine Oil f = 0.15 0.75

API SA2 Grease f = 0.12 0.60

Nickel-based Lubricant f = 0.11 0.55

Copper-based Lubricant f = 0.10 0.50

Molydisulfide Based Lubricating Paste f = 0.06 0.30

BOLT DIAMETER TORQUE

In. mm Ft-lb N•m

Burn Time Rating

WARNING

▲

Temperature sensors must be used with

this product if there is a potential for

stabilized burning inside the arrestor.

Additional external safety equipment

is required to ensure appropriate

corrective measures are taken within

30 seconds to protect the system if an

abnormal temperature is detected. Never

disconnect or remove these devices in

active process systems.

All Model EN-DFA detonation ame arrestors are rated

for short time burning, tBT not to exceed one minute in

accordance with EN ISO 16852:2016. This burn time

was determined at atmospheric pressure. If there are

operating conditions which can lead to a stabilized

burning event, additional safety measures are

required. Depending on the operating conditions, the

devices shall be equipped with temperature sensors

on one or both sides of the ame arrestor element.

These temperature sensors are installed into the

system in such a way that they trigger the initiation of

measures for the elimination of the stabilized burning

(for example, emergency functions like switchingo the system, inerting or similar). These measures

must occur within half of the time for which the ame

arrestor is short-time burn proof (0.5 x t

). See Figure

BT

4 for warning labels showing burn rating, tBT. This

requires that measures must be able to be taken within

30 seconds.

Threaded instrumentation ports, with standard 3/4 NPT

threads, are integrated into each end section. Other

instrumentation port thread sizes can be requested.

If the user requests the addition of temperature

sensors by Emerson, they will either be installed and

shipped threaded into the appropriate instrumentation

ports in the ame arrestor end sections or shipped

separately with the ame arrestor. To install the

temperature sensors that have been shipped

separately, simply remove any protective packaging

from the temperature sensors and thread the

temperature sensors into the appropriate threaded

instrumentation ports on the ame arrestor end

sections making sure to follow temperature sensor

manufacturer’s instructions, particularly for wiring.

In the case where only one temperature sensor was

requested from Emerson, the ame arrestor will be

marked with a ow arrow to indicate ow direction

and the temperature sensor will be installed on the

downstream or unprotected (“hot”) side of the ame

arrestor. This is the side of the ame arrestor closest

to the source of ignition. If the temperature sensor is

shipped separately, the user shall be responsible for

North America Only

7

Page 8

EN-DFA Series

4

8

1

1

4

5

8

4

1

12

5

9

2

3

1 2

16

12

8

4

14

10

6

2

Figure 6. Flange Pattern Tightening Sequence

6

2

1

5

9

13

3

7

11

15

installing the temperature sensor in the appropriate

instrumentation port on the downstream or unprotected

(“hot”) side of the ame arrestor. Model EN-DFA

detonation ame arrestors are bi-directional, so if a

temperature sensor is not requested with the ame

arrestor, then no ow arrow will be installed on the unit,

and the end user shall be responsible for installation of

the temperature sensor on the unprotected (“hot”) side

of ame arrestor. This is the side of the ame arrestor

closest to the source of ignition.

A temperature rise of 20 K (36°F / 20°C) above the

ame arrestor maximum operating temperature or 20 K

(36°F / 20°C) above the process operating temperature,

whichever is lower but not to exceed 20 K (36°F / 20°C)

above the ame arrestor operating temperature, is the

recommended activation temperature for initiation of

measures against stabilized burning.

Note that a rise in temperature measured by

the temperature sensor can indicate to the user

deagration and/or detonation events have occurred

as well. This should be used as a trigger to investigate

what conditions have lead to ignition of ammable

vapors, to inspect the ame arrestor for damage, and

to initiate appropriate corrective actions relative to

process system and safety.

Temperature sensors installed by Emerson or installed

by the user shall follow the specications or Table 6.

Dierent temperature sensors may be installed by

the end user, however these must comply with the

safety specications in Table 6. The use of alternate

8

3

7

16

12

8

4

18

14

10

6

10

6

2

3

1

20

5

9

13

17

3

7

11

15

19

2

54

3

7

11

temperature sensors must include evidence of

equivalent response rates to the specied sensors in

Table 6, particularly as the EN-DFA Series is rated for

short time burning.

If tBT is exceeded during a short-time burning situation,

the ame arrestor safety cannot be assured.

If an elevated temperature has been detected by

the temperature sensor, whether due to ash back

or stabilized burn, the temperature sensor shall be

inspected for damage and replaced as necessary.

If the recorded temperature exceeds the design

temperature of the temperature sensor then the

measuring probe shall be replaced.

Pipe Length

Extended lengths of pipe allow the ame to advance

into more severe states of ame propagation such as

high pressure deagrations and detonations. Although

the detonation ame arrestor is not limited by pipe

length, using a minimum length is a preferred design

and installation practice.

Bends and/or Flow Obstructions

CAUTION

△

For maximum safety, avoid bends

and ow obstructions within 10 pipe

diameters but not less than 10 ft / 3 m

on the protected side of the detonation

ame arrestor.

North America Only

Page 9

EN-DFA Series

-LB / N•m)

(1)(2)

Table 10. Tightening Steps and Torque Values for Body Fasteners for Element Assembly

MODEL PATTERN

EN-DFA-402 1 5/8-11 Snug 10 / 14 35 / 47

EN-DFA-603 2 3/4-10 Snug 30 / 41 80 / 108

EN-DFA-804 2 3/4-10 Snug 50 / 68 100 / 135 160 / 217

EN-DFA-1206 3 7/8-9 Snug 50 / 68 100 / 135 175 / 237

EN-DFA-1608 4 1-8 Snug 50 / 68 120 / 163 200 / 271 285 / 386

EN-DFA-2010 5 1-1/8-8 Snug 50 / 68 120 / 163 200 / 271 310 / 420

EN-DFA-2412 5 1-1/4-8 Snug 75 / 102 150 / 203 280 / 380 400 / 542 535 / 725

1. Using machine oil as lubricant. See Bolt Lubrication section on page 12 and torque correction factors for other lubricants in Table 11.

2. Alloy steel element assembly fasteners are provided with a low friction polymer coating. No additional lubrication should be required. When stainless steel fasteners are provided,

lubrication is recommended to reduce tightening torque and to prevent potential galling.

3. See Figure 6.

DESCRIPTION COEFFICIENT OF FRICTION MULTIPLY TORQUE VALUE IN TABLE 7 BY

API SA2 Grease f = 0.12 0.80

Nickel-based Lubricant f = 0.11 0.73

Copper-based Lubricant f = 0.10 0.67

Molydisulde Based Lubricating Paste f = 0.06 0.40

(3)

BOLT SIZE

Table 11. Torque Correction Factors for Common Lubricant

Machine Oil f = 0.15 1.00

1 2 3 4 5 6

Bends in piping, pipe expansions and/or contractions,

valves, orice plates or ow obstructing devices of any

kind cause turbulent ow. Turbulent ow enhances

mixing of the combustible gases, greatly increasing

the combustion intensity. This can result in increased

ame speeds, higher ame temperatures and higher

ame front pressures than would occur in normal

ow conditions. Obstructions in protected side piping

can cause reective pressures that might inhibit the

eective performance of the EN-DFA Series under

certain conditions.

TIGHTENING STEPS AND TORQUE (FT

Standard compressed ber gaskets that will withstand

temperatures of 450°F / 232°C or higher are normally

used, but other materials of equal or higher temperature

capability may be used at the customer’s discretion.

Flow Direction

This EN-DFA Series is bi-directional and can be installed

either vertically or horizontally. Consideration should

be given to non-symmetrical assemblies that include

features such as clean-out ports, temperature sensors

or other devices that might have a preferred installation

direction to suit the needs of the customer. Compliance

Installation

with warning associated with temperature sensors is

essential. See Burning Time Rating section.

North America Only

WARNING

▲

Always make sure that the system is

at atmospheric pressure and there is

no ignitable gas that could ash when

either installing or maintaining the unit.

Connection

EN-DFA Series are normally provided with CL150 or

PN 16 raised or at faced anges. Other anges are

sometimes provided on special request. Make sure the

companion anges installed in adjacent piping match the

anges on the detonation ame arrestor.

For proper bolt torquing of the detonation arrestor to

the piping, please refer to Tables 7, 8 and 9.

Positioning

WARNING

▲

If the detonation ame arrestor is

equipped with a single factory installed

temperature sensor, the arrestor shall

be installed with the sensor on the

unprotected side of the arrestor, the side

nearest the potential source of ignition.

CAUTION

△

The detonation ame arrestor is

tted with lugs for lifting the element

assembly during servicing operations.

9

Page 10

EN-DFA Series

These lugs are not intended for lifting

the entire unit during installation.

Damage to the detonation ame arrestor

may result from improper lifting. The

unit should be lifted using appropriately

rated Nylon (PA) straps rigged on the

outside of the tension studs.

The arrestor should be positioned such that the entire

arrestor is accessible for removal. Models that have

drain plugs are designed for horizontal installation

and should be installed with the drain plugs aligned

at the bottom of the unit. Models that have pressure

taps are designed to allow pressure gauges to be

installed on both sides of the ame cell assembly

to determine blockage. The pressure taps should

be aligned at the top to allow easy viewing of the

gauges. Units that are equipped with optional internal

cleaning systems should be connected to a source of

cleaning media such as water, steam or other suitable

solvent. Observe recommended installation practice as

previously described.

Piping Expansions and Reductions

Adjacent to Detonation Flame Arrestor

WARNING

▲

a length of pipe at least 120 pipe diameters must be

installed between the detonation ame arrestor and

the expansion. A pipe diameter is considered as the

inside diameter of pipe having a nominal size equal to

the detonation ame arrestor’s connecting anges.

Maintenance

WARNING

▲

Isolate gas supply and bring system

to atmospheric pressure to prevent

ignitable gas from ashing while

performing maintenance.

CAUTION

△

The ame cells in the arrestor’s element

assembly are not retained once the

element assembly has been removed

from the arrestor. They can slide

out of the housing during handling.

It is recommended that the element

assembly only be removed after the

entire arrestor has been removed from

the piping system.

No instrument, tubing or other device

whatsoever shall circumvent the

detonation ame arrestor in such a

manner to allow a ame path to exist

around the ame element of the arrestor.

When instrumentation is installed in

such a manner that it creates a path

circumventing the ame element of an

arrestor, measures must be taken to

prevent passage of ame through the

instrumentation device and/or system.

Instrumentation must be capable of

withstanding the maximum and minimum

pressures and temperatures to which the

device may be exposed and at a minimum

be capable of withstanding a hydrostatic

pressure test of 350 psig / 24 bar.

For an in-line ame arrestor, the pipe diameter on

the protected (“cold”) side shall be no less than the

pipe diameter on the unprotected (“hot”) side. For

an in-line ame arrestor, the pipe diameter on the

unprotected (“hot) side shall be no greater than the

ame arrestor connection. When it is necessary to

increase the diameter of the piping on the downstream

side (unprotected) of the detonation ame arrestor,

Element Disassembly

1. Loosen all nuts on tension studs between conical

sections of the detonation ame arrestor.

CAUTION

△

Element assemblies are heavy and will

require the use of adequate equipment

and manpower to prevent injury.

2. Carefully force the two conical sections apart

while the nuts are still on the tension studs.

When the two ange faces have separated,

remove enough of the tension studs such that

the element assembly can be removed. Not all

studs are required to be removed to be able to

rotate the element assembly out of the housings.

It is possible for the elements to come out of the

housing once the end sections have been removed.

Inspecting and Cleaning the Flame Cells

1. Inspect ame cells for damage immediately

following a deagration, detonation and/or

stabilized burn.

North America Only

10

Page 11

EN-DFA Series

2. Carefully remove the element assembly from the

arrestor. Place the element assembly on a soft

surface such as plywood and push the ame cells

from the housing. It might be necessary to tilt the

housing to facilitate removal of the ame cells.

3. Note the order in which the ame cells were

removed. For Group IIA units, there are four 2 in. /

51 mm thick ame cells. For Group IIB3 units, the

outer two ame cells are 2 in. / 51 mm thick and

the two inner ame cells are 1 in. / 25 mm thick. A

screen of expanded metal is located between each

adjacent set of ame cells.

4. Inspect the ame cells and the screens visually

for any signs of corrosion or other damage and

inspect the ame cells with a calibrated pin gauge

to ensure maximum crimp size openings do not

exceed the following values for their respective

gas group:

• Explosion Group IIA – 0.051 in. / 1.295 mm

• Explosion Group IIB3 – 0.0216 in. / 0.549 mm

5. If any damage is noted or crimp openings exceed

maximum size allowable, the ame cells and/or

the screens must be replaced.

8. The cleaning interval should be governed by the

amount and type of particulate in the system to

which it is installed and must be determined by

the user. To determine the maintenance interval

the user should check the element in the rst few

months of operation to nd how quickly particulate

accumulates in the cells.

9. Thoroughly clean the gasket sealing faces being

careful not to damage the sealing surface. For

reassembly a new gasket must be used and

placed in the machined recess of each interior

ange on the two conical sections.

10. Replace the ame element assembly with a new

assembly or properly cleaned and inspected

existing unit.

11. Locate the ame cell assembly such that it seats

onto the gaskets.

12. Replace all tensioning studs and tighten the outer

nuts hand tight only.

13. Torque the bolts in sequence as shown in the

following instructions.

Torquing Instructions

Note

Under no circumstance shall any other

screens not provided by Emerson be used

in this assembly. Failure to use the correct

screens may lead to arrestor failure.

6. It is important to keep the element openings clean

to prevent loss of eciency in absorbing heat. The

element assembly should be removed and the

elements cleaned to prevent the openings from

becoming clogged with particulate matter or other

contaminants. Clean the element with a suitable

cleaning media (solvent, soap, water or steam)

then blow dry using compressed air. Special care

should be taken not to damage or dent the cell

openings as this would hamper the eectiveness

of the unit. Arrestor elements shall not be cleaned

by rodding with wire or other hard objects to

remove blockages, as this practice could damage

the elements and seriously impair the arrestor’s

performance. If the arrestor element cannot be

cleaned satisfactorily, it must be replaced.

7. For best cleaning results, a high pressure sprayer

with spray wand should be used (1500 to 3000 psig /

103 to 207 bar) to clean the entire element surface.

The spray nozzle should be held perpendicular to

the surface being cleaned to maximize spray media

penetration into the element. Alternately spray each

side of the element surface until clean.

CAUTION

△

Excessive or uneven torque can cause

permanent damage to gaskets

and housing.

Tools/Supplies Required

• Hand operated conventional torque wrench or

power assisted torque wrench appropriate for the

specied torque.

• Socket wrenches of the proper size to t the hex

nuts being tightened.

• Lubricant for fasteners, as appropriate.

• Brush suitable for applying lubricant to the studs.

• Wiping rags necessary for the clean up of

excessive lubricant.

Procedure

1. Use studs and nuts that are free of visible

contamination and corrosion.

2. Apply lubricant to the threads of the stud protruding

outboard of the interior anges and to the face of the

hex nuts which will contact the ange for stainless

steel fasteners. Alloy steel fasteners have a polymer

coating and do not require additional lubrication.

North America Only

11

Page 12

EN-DFA Series

3. Assemble the nuts to the studs such that the

amount of thread extending outboard beyond the

nut is approximately equal on both ends.

4. Tighten the nuts to the torque values shown in

Table 10 following the designated sequence,

repeating he sequence as shown. Flange pattern

tightening sequences are shown in Figure 6.

Bolt Lubrication

Lubrication will aect required torque of clean

fasteners in good condition more than any other factor.

In fact, 90% of applied torque goes to overcome

friction while only 10% actually stretches the bolt.

Table 10 assumes that only factory polymer coating is

used for alloy steel fasteners and machine oil is used

for stainless steel fasteners as a lubricant. Table 9

shows a list of several common lubricants and their

eect on torque required to stretch bolts to 50% of

their yield strength. Most are available from local

bearing distributors.

Recommended Spare Parts

The crimp openings in Enardo™ detonation ame

arrestors are relatively large and are therefore quite

easy to clean. Plugging will normally be limited to the

ame cell and screen that are installed at the inlet side

of the arrestor’s element assembly. If plugging should

occur, the plugged ame cell(s) and screen(s) can be

cleaned as detailed above, reinstalled and used again,

provided there is no damage and not plugged to an

extent that cleaning is not eective. For installations

with dirty process conditions where frequent

maintenance is necessary, it is recommended that the

user purchase a spare element assembly and several

spare element gaskets. The spare element assembly

can be installed immediately and the dirty assembly

can then be cleaned and be stored as a spare for the

next maintenance interval.

Note

Element gaskets must be replaced each

time the cell assembly is loosened and

removed. Gasket must be made from

high temperature graphite material. It is

recommended that replacement gaskets

be ordered from Emerson.

Parts Ordering

When corresponding with your local Sales Oce

about this equipment, always reference the equipment

serial number and model number stamped on

the nameplate.

Webadmin.Regulators@emerson.com

Enardo.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Tulsa, OK 74146 USA

T +1 918 662 6161

Europe

Bologna 40013, Italy

T +39 051 419 0611

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D103585X012 © 2014, 2021 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 02/21.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. All other marks are the property of their prospective owners.

Enardo™ is a mark owned by Regulator Technologies Tulsa, LLC, a

business of Emerson Automation Solutions.

The contents of this publication are presented for informational purposes

only, and while every eort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use

or applicability. We reserve the right to modify or improve the designs or

specications of such products at any time without notice.

Emerson Process Management Regulator Technologies

Tulsa, LLC does not assume responsibility for the selection, use or

maintenance of any product. Responsibility for proper selection, use

and maintenance of any Emerson Process Management Regulator

Technologies Tulsa, LLC product remains solely with the purchaser.

North America Only

Loading...

Loading...