Page 1

Operating instruction

EC3-P33 Superheat Controller and

ECD-002 Keypad / Display Unit

Installation in non explosive environment

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 04.05.2017 EC3-P33_OI_ML_R01_865919.docx

General information:

EC3-P33 is the superheat controller for systems with flammable refrigerants

(A2L/A3) and able to drive EMERSON Valves EX4-7-…FLR via M12 Conn ector

ECV05A.

Note: This document contains short form instructions for experienced users.

Warning:

• EC3-P33 has a potential ignition source and does not comply with ATEX

requirements. Installation only in non-explosive environment.

• EX4-7…FL R are currently released for R29 0 in term of compat ibility. The

other listed refrigerants are subject to qualification at later stage. No

warranty or product liability if EX4-7…FLR to be used with other

refrigerants stored in software of EC3-P33.

Safety instruc tions:

• Read operatin g instru ctions th oroughl y. Failu re to comp ly can result i n device

failure, system damage or personal injury.

• According to EN 13313 it is intended for use by persons having the

appropriate knowledge and skill.

• Ensure that the system is correctly labeled with applied refrigerant type and

a warning for ex p losion risk.

• Do not exceed the specified maximum ratings for temperature (max.+60°C),

voltage and current.

• Before installation or service disconnect all voltages from system and device.

• Do not operate system before all cable connections are completed.

• Entire electrical connections have to comp ly wit h l o cal regulati on s .

Note: The E C3-P33 series contains a VRLA battery = valve regulated rechargeable

lead-acid battery. The batte ry m ust NOT be dis posed of w ith othe r comme rcia l was te.

Instead, it is the use r’s re sponsi bility to pass it to a des igna te d co ll e ctio n po i nt fo r t he

safe recycling of batteries (harmonized directive 2012/19/EU). For further

information contact your local environmental recycling center.

Mounting position:

The EC3-P33 is designed to be mounted onto a standard DIN rail. Mounting position:

on vertical walls, with stepper motor connector on top side only.

Mounting of ECD-002:

• ECD-002 can be installed at any time also during operation.

• ECD-002 can be mounted in panels with

71x29 mm cutout.

• Push controller into panel cut-out.(1)

• Make sure that mounting lugs are flush with

outside of controller h ousing

• Insert Allen key into front panel holes and turn

clockwise. Mounting lugs will turn and gradually

move towards panel (2)

•

Turn Allen key until mounting lug barely touches

panel. Then move ot her mounting lug to the same

position (3)

• Tighten both sides very carefully until keypad is

secured. Do not over tighten as mounting lugs

will break easily.

Electrical Installation:

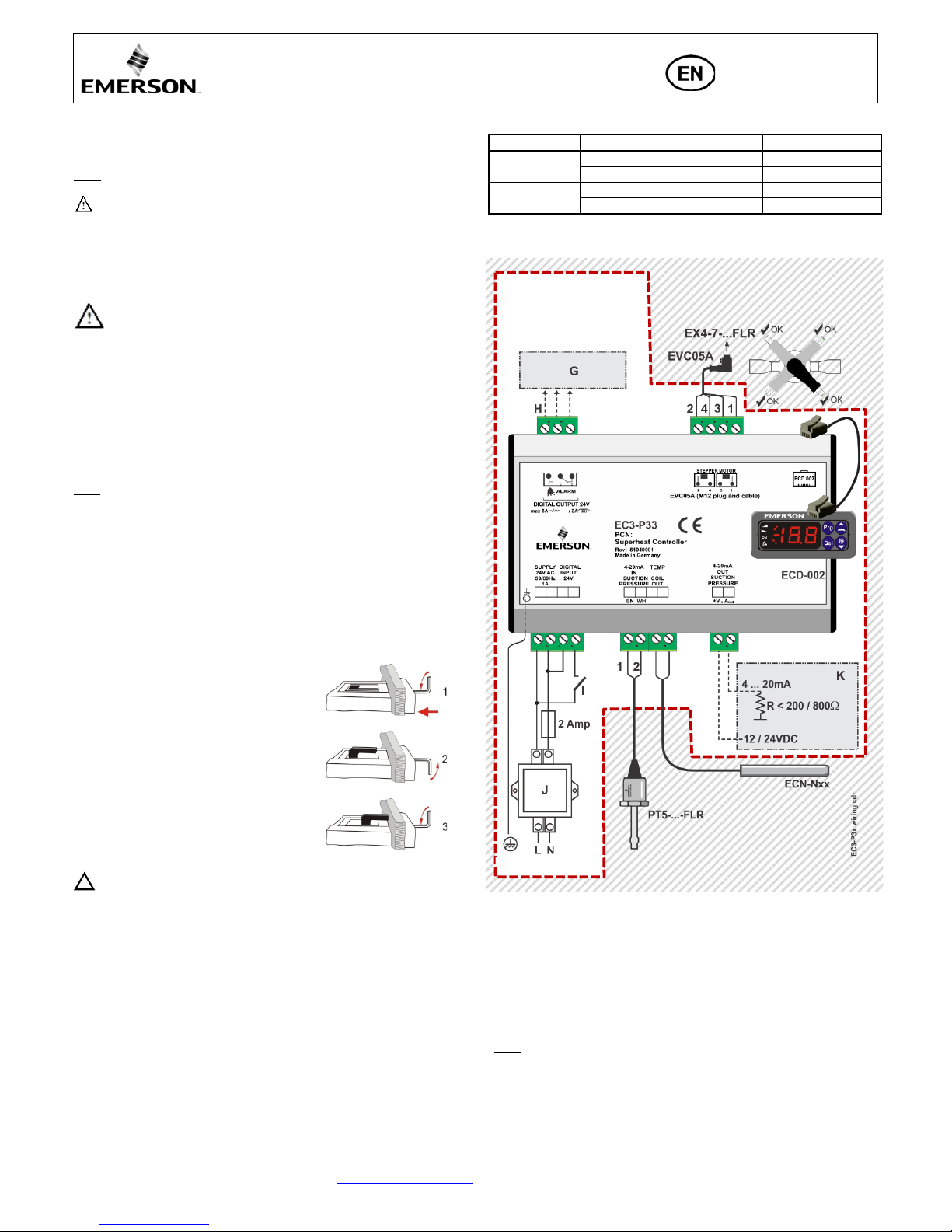

• Refer to the electrical wiring diagram for electrical connections.

• Do not apply voltage to the controller before completion of wiring.

• Ground the metal housing with a 6.3 mm spade connector.

• Keep controller and sensor wiring well separated from mains wiring.

Minimum recommended distance 30 mm!

• Ensure that cables are not mounted near sharp edges.

• Use a class II category transformer for 24 VAC power supply. Do not ground the

24 VAC lines. We recommend using individual transformers for EC3 controller(s)

and for 3

rd

party controllers t o avoid poss ible in terference or grounding problems

in the power supply.

• Connecting any EC3 inputs to mains voltage will permanen tly damage the EC3.

• The use of the relay is essential to protect the system in case of power failure if the

communications interface or the ECD-002 are not utilized.

• If the output relay is not utilized, the user must ensure appropriate safety pre-

cautions are in place to protect the system against damage caused by a power

failure.

• In order to provide system protection in the event of power loss, it is recommended

to change the battery annually.

Digital input status is dependent to operation of compressor/th ermostat

Commander

Operating condition

Digital input (I)

Compressor

Compressor starts

Closed / 24 V (Start)

Compressor stops

Open / 0 V (Stop)

Thermostat

Demand (compressor must be ON)

Closed / 24 V (Start)

No demand

Open / 0 V (Stop)

Wiring:

v

2: White wire 4: Black wire 3: Blue wire 1: Brown wire

G: Remote control panel, system controller

H: Alarm relay, dry contact. Relay coil is not energized at alarm or power off.

I: Digital input (0V/open = Stop; 24 V/closed = Start)

J: Transformer Class II, 24 VAC secondary / 25 VA

K: Third party controller (can use the analog output signal from EC3)

Preparation for Start-up:

• Vacuum the en tire refrigeration system

• Note: EX4-7-…FLR are d elivered at half op en position. Do not ch arge system

before closur e of valve.

• Apply suppl y voltage 24 V to EC3 while the dig ital input is 0 V (open). The valve

will be driven to close position.

• After closure of valve, start to charge the system with refrigerant.

• Start the system and check the superheat and operating conditions.

!

Non-explosiv

environment

Page 2

Operating instruction

EC3-P33 Superheat Controller and

ECD-002 Keypad / Display Unit

Installation in non explosive environment

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 04.05.2017 EC3-P33_OI_ML_R01_865919.docx

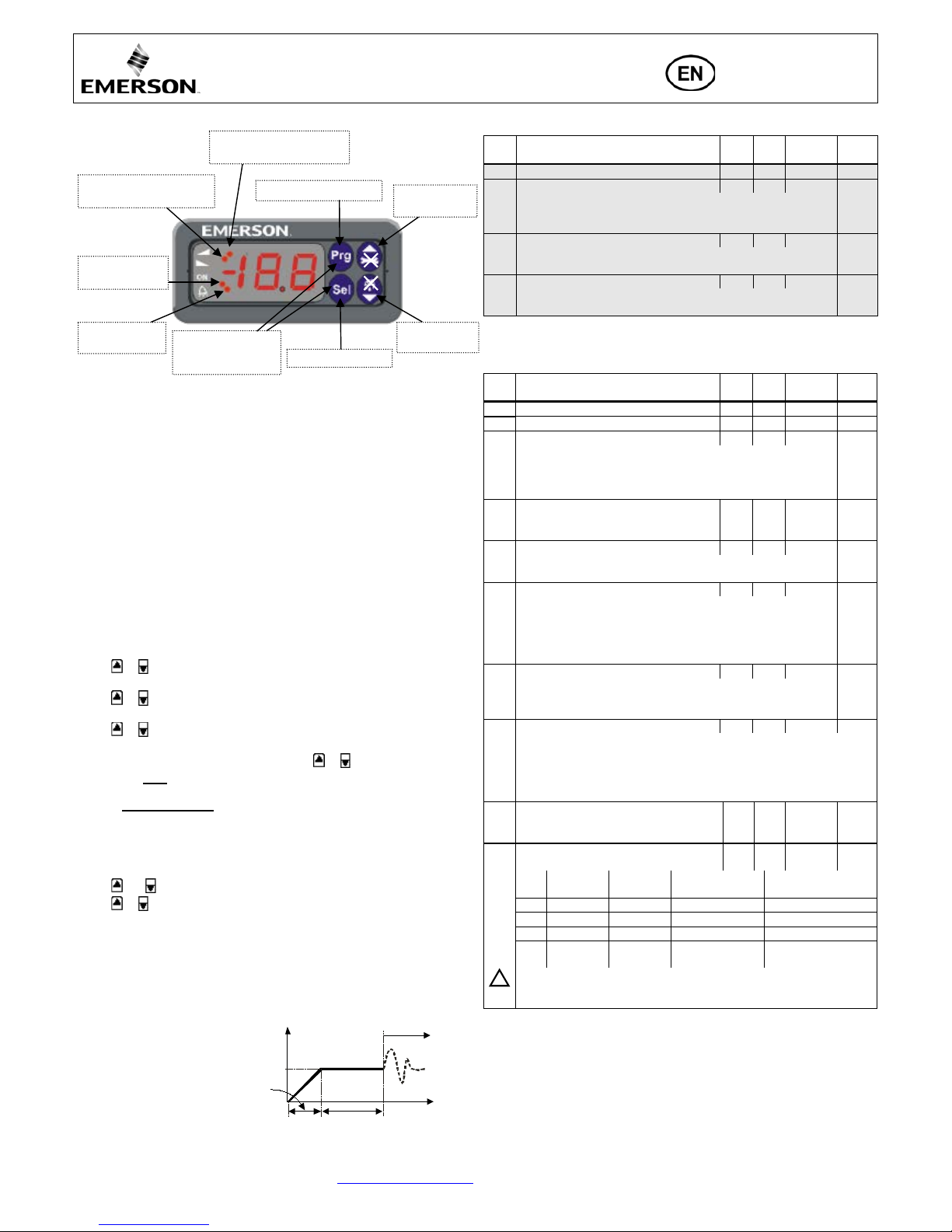

ECD-002 display/keypad unit: (LE Ds and button functio ns)

Setup of main para meters u sing ECD-002:

(need to be checked/modified before start-up)

• Make sure that digi tal input is 0 V (open). Turn the power supply ON.

• Important: Three ma in pa r am et ers i.e. r efri g era n t t yp e (u0 ) , p ress u re s en sor t ype

(uP) and valve type (ut) can be set only when digital input is open (0 V) while the

power supply is ON (24 V). This feature i s for added safet y to p revent acc iden tal

damage of compressors and other system components.

• For easy sett ing of main parameters, fo llow the pictorial pr ocedure of “Quick

start-up” on the attached individual p a pe r.

• Once the main parameters have been selected/saved the EC3 is ready for

startup. All other parameters can be modified at any time during operation

or standby if it is necessary.

Procedure for parameters modification using ECD-002:

• The parameters can be accessed via the 4-button keypad. The configuration

parameters are protected by a numerical password. The default password is “12”.

To select the parameter configuration:

• Press the PRG button for more than 5 seconds. A flashing “0” i s displaye d

• Press or until “12” is displayed; (password)

• Press SEL to confirm password

• Press or to show the code of the param eter that has to b e changed;

• Press SEL to display the selected param eter value;

• Press or to increas e o r decrease the value;

• Press SEL to temporarily confirm the new value and display its code;

• Repeat the procedure from the beginning "press or to show..."

• To exit and save the new settings: P

ress PRG to confirm the new values and exit

the parameters modification procedure.

• To exit without modifying any parameters: Do not press any button for at least

60 seconds (TIME OUT).

Reset all parameters to factory setting:

• Make sure that digi tal input is 0 V (open).

• Press and together for more than 5 seconds. A fl a sh ing “ 0 ” i s di splayed.

• Press or until the passw o rd is displayed (Factory setting = 12).

If password was changed, select the new password.

• Press SEL to confirm password

“0” is displayed.

• Press SEL to reset all parameters to factory setting

• Press PRG to activat e the function and leave the special function mod e.

Control (valve) start-up behavior: (Parameter uu and u9)

EX4/5/6-…FLR ≤ 1.5 seconds

EX7-…FLR ≤ 3.2 seconds

Main parameters:

(must be checked and modified if necessary)

Code Parameter description and choices Min Max

Factory

setting

Field

setting

H5

Password

1

199

12 u0

System refrigerant

0 6 0

0 = R290; 1 = R32; 2 = R1234ze;

3 = R1234yf; 4 = R1270;

5 = R227; 6 = R600a

uP

Installed pressure sensor type

PT5-30L-FLR

ut

Installed valve type

0 3 1

0=EX4-…FLR; 1=EX5-…FLR;

2=EX6-…FLR; 3=EX7-…FLR

Optional paramete rs:

(recomm e n d ed factory setting fo r majority of app l i c at ions)

After selecting the parameters the EC3-P33 is fully functional without

keypad/display unit. ECD-002 may be removed or connected at any time.

Code Parameter description and choices Min Max

Factory

setting

Field

setting

uu

Start valve opening (%)

5

100

10 u9

Start opening duration (second)

1

120 5

uL

Low superheat alarm function

0 2 1

0 = disable (for flooded evaporator)

1 = enable aut o reset

2 = enable manual reset

Cut-out at 0.5K (if it maintains 1 min.); Cut-in immediately at 3K

u5

Superheat set-point (K)

If uL enabled (auto or manual)

If uL disabled

3

0.5

30

30

6

6

u2

MOP function

0 1 1

0 = disable

1 = enable

u3

MOP set-point (°C) saturation temper atur e

* * X

Factory setting is ac cording to selected refrigerant (u0):

+13°C for R290 +15 °C for R32

+15°C for R1234ze +15°C for R1234 yf

+13°C for R1270 +15°C for R227

+15°C for R600a

┌┘5

Units conversion (only for u3, u5, ┌┘1)

0 1 0

0 = °C, K, bar

1 = °F, R, psig

(Psig values are divided by 10. Example: Display 12.5 is 125 psig)

┌┘

1

Value to show

0 4 0

0 = Measuredsuperheat (K)

1 = Measured evaporating pressure, (bar);

2 = Valve opening (%)

3 = Measured coil-out temperature (°C)

4 = Calculated evaporating temperature (°C) from the pressure

u4

Superheat control mod e

0 1 0

0 = Standard,

1 = Slow

b1

Battery error management, when battery is

defective, see below

0 3 2

value

Alarm

display

Alarm relay Valve

Reset possibility after

recovery/replacement

0 - - Regulating

-

1

Ab - Regulating

-

2

Ab

Signalling

Fully close

Auto

3 Ab

(blinking)

Signalling

Fully close

Manual

When setting b1 to option 0 or 1, the user must ensure appropriate safety

precautions are in place to protect the system against damage c

aused by

a power failure.

!

Blinking: valve is closing

ON: valve is fully close

Blinking: valve is opening

ON: valve is fully open

ON: demand

OFF: no demand

ON: alarm

OFF: no alarm

Parameters setting/saving

Selecting/confirming

Next param eter/

value (higher)

Next param eter/

value (lower)

Prg&Sel (5 sec)

Manual reset f o r

blinking alarm codes

Sec.

uu

u9

%

EC3-X3 BA.cdr

Page 3

Operating instruction

EC3-P33 Superheat Controller and

ECD-002 Keypad / Display Unit

Installation in non explosive environment

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 04.05.2017 EC3-P33_OI_ML_R01_865919.docx

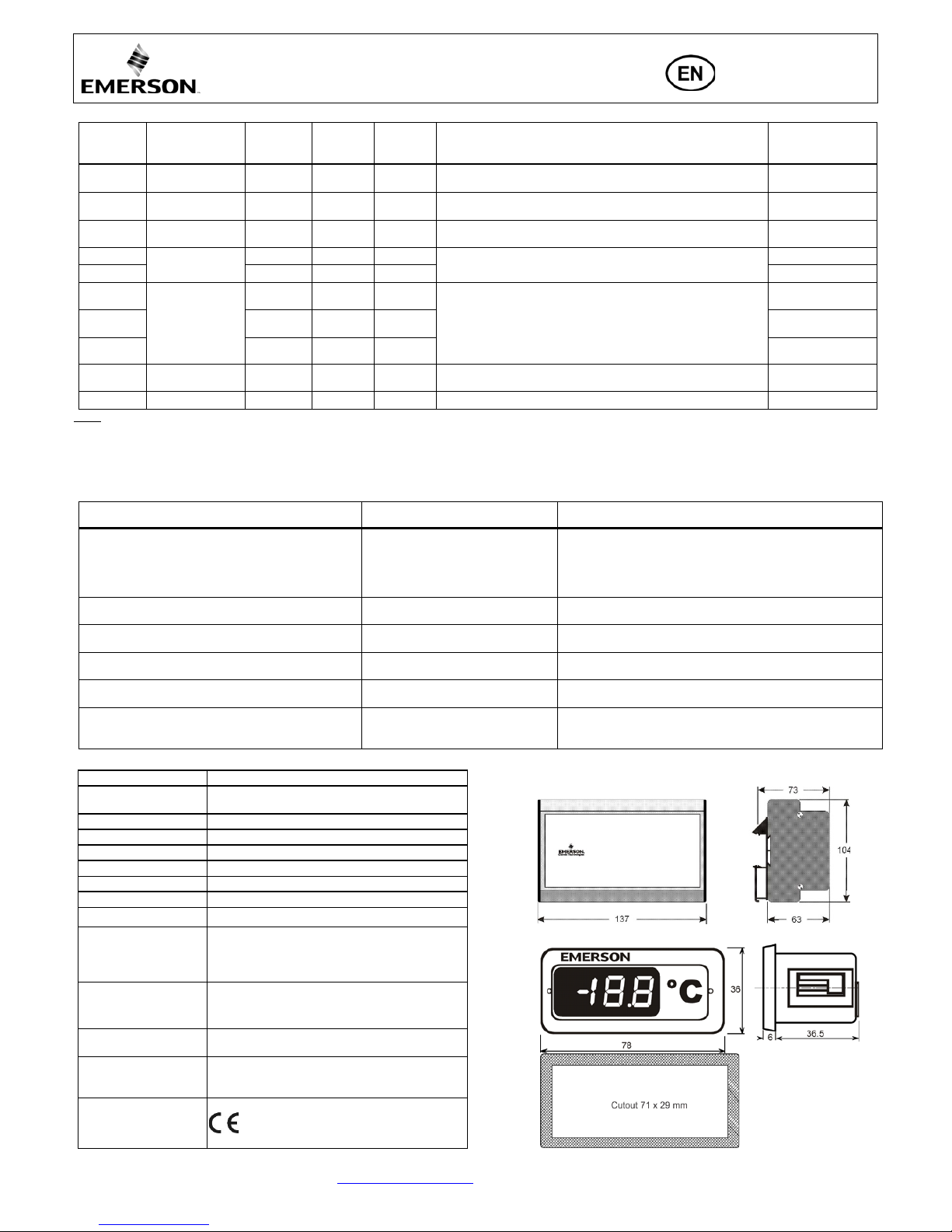

Error/Alarm handling:

Alarm code Description

Related

parameter

Alarm

relay

Valve What to do?

Requires manual

reset after resolvin g

alarm

E0

Pressure

transmitter error

- Signalling Fully close Check wiring connection and measure the signal 4…20 mA No

E1

Temperature

sensor error

- Signalling Fully close Check wiring connection and measur e the resistance of sensor No

AΠ

EXV electrical

connection error

- Signalling - Check wiring connection and measure the resistance of winding No

AL

Low superheat

(<0,5K)

uL: 1

Signalling

Fully close

Check wiring connect ion and operation of valve

No

AL blinking

uL: 2

Signalling

Fully close

Yes

Ab

Battery error

b1: 1 - Regulating

Battery potentia lly does not have enough charge to close valve in

case of main power supply interruption. May occur temporarily with

new controllers or after lon g s torage but should disap pear when

battery is charged sufficiently. If Ab remains active even when

battery is c harged, battery may be defective and should be replaced.

(Replacement kit: 807790).

-

Ab

b1: 2 Signalling Fully close -

Ab blinking

b1: 3 Signalling Fully close Yes

Er

Data error display

- out of range

- - -

Data send to the display is out of range. Check temperature and

pressure sensor.

No

---

No data to display

- - -

Check Cable and plug connection between EC3-X33 and ECD-002.

No

Note: When multiple alarms occ ur , the highest prio r ity alarm is displ a yed until being cleared, then the next highest a l ar m is displayed until all alarms are cleared. Only then

will parameters be shown again.

Checking system ope rating conditions:

The data to be permanently shown on the display can be selected by the user

(parameter ┌┘1). It is possible to temporarily display other values. However this

function is not avail a bl e in an ala r m condition. The dis play wil l s how for one s econd

the numerical identifier of the data (see ┌┘1 parameter) and then the selected data.

After 5 minutes, the display will return to the value selected by parameter┌┘1.

Service / Troubleshooting:

Symptom Cause Action

Operating superheat is several degrees higher or lower

than set-point

Incorrect signal from pressure or

temperature sensors

1- Check the sensors

2- Make sure EC N -N6 0 temperature sensor is used

3- For optimum accuracy, please use: PT5-30L-FLR

4- Make sure the s ensor cables are not installed along with other

high voltage cables

Operating superhea t is too low i.e. compressor wet

running

1- Incorrect wiring of ECV05A

2- Defective sensors

1- Check the wiring

2- Check the sensor

Valve is not full y clo sed

1- The digital input is ON (24 V)

2- Wrong setting of paramet er ut.

1- Valve is shut off only when the digital input is turned off (0 V)

2- Check the set t ing of paramet er ut

Instable superheat (hunting)

Evaporator is designed to operate at

higher superheat

Increase th e superheat set-point

Valve opens when EC3 commands to close and vice versa

Wrong wiring between EC3-P33 and

valve

Correct the wiring

Superheat set-point is shifting after severa l m onths of

uninterrupted op eration or permanent jumper of 24 V

digital input

Stepper motor driven valves require

synchronization

Do not apply permanent 24V digital input. Interrupt digital input

once every week for 5 seconds if compressor never stops.

Technical data Dimensions [mm]:

Power supply

24 VAC ±10%; 50/60 Hz; 1 A

EC3-P3

3

Power consumption

25 VA max.

including EX4-7-…FLR.

Plug-in connector

Removable screw terminals wire size 0.14…1.5 mm2

Grounding

6.3 mm spade earth connector

Protection class

IP20 Connection to ECD-002

ECC-Nxx or CAT5 cable with RJ45 connectors

Digital Inputs

0/24VAC/DC for stop/start function

NTC input

EMERSON temperature sensor ECN-N60

4…20 mA Analog input EMERSON PT5-30L-FLR Pressure Tran smitter

4-20 mA Analog output

Deviation from input

signal

For connection to any 3rd party controller with

12/24 VDC power suppl y and appropria te burden

±8% max

ECD-002

Output alarm relay

SPDT contacts 24 VAC/DC, 2 Amp inductive load

Activated:

During normal operation (no alarm condition)

Deactivated:

During alarm condition or power supply is OFF

Stepper motor output for

EX4-7

Maximum cur r ent 0.8 A with nominal 24 VDC

operating voltage

Ambient temperature

range

0…+60°C

+1…+25°C (for best battery life t ime)

> 35°C battery life time < 2 years

Marking

Page 4

Betriebsanleitung

EC3-P33 Überhitzungsregler mit

ECD-002 Anzeige- / Einstelleinheit

Installation in nicht explosionsgefährdeter Umgebung

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 04.03.2017 EC3-P33_OI_ML_R01_865919.docx

Beschreibung:

Der Überhitzungsregler EC3-X33 steuert in Anlagen mit flammbaren Kältemitteln

(A2L/A3) EMERSON EX4-7-…FLR Ventile mittels M12 Steckerverbindung

EVC05A.

Hinweis: Dieses Dok umen t enthält für erfahren e An wender eine Kurza nleitun g.

Warnung:

• EC3-P33 hat eine potentielle Zündquelle und entspricht nicht den ATEX

Bestimmungen. Installation nur in nicht explosionsgefährde ter Umgebung.

• EX4-7…FLR sind derzeit für das Kältemittel R290 zugelassen. Andere

aufgeführte Kältemittel unterliegen einer späteren Freigabe. Die Garantie

oder Produkthaftung werden ausgeschlossen, wenn EX4-7-…FLR Ventile

unter anderen Kä ltem itten in der Softw are von EXD-P33 gespeichert werden.

Sicherheitshinweise:

• Lesen Sie die Betriebsanleitung gründlich. Nichtbeachtung kann zum

Versagen oder zur Zerstörung des Gerätes und zu Verletzungen führen.

• Der Einbau darf gemäß EN 13313 nur von Fachkräften vorgenommen

werden.

• Die Anlage ist von außen gut sichtbar mit dem verwendeten Kältemittel und

einer Warnung vor erhöhtem Explosionsrisiko zu kennzeichnen.

• Die angegebenen Grenzwerte für Temperatur (max. +60°C), Strom und

Spannung nicht überschreiten.

• Vor Installation oder Wartung sind die Anlage und das Bauteil spannungsfrei

zu schalten.

• Das Ventil nicht betreiben, wenn der Kompressor nicht läuft.

• Für den gesamten elektrischen Anschluss sind die länderspezifischen

Vorschriften einzuh a lt en.

Hinweis: EC3-P33 R egler enth alten einen wieder au fladbaren Blei -Gel-Akku, der

nicht im normalen Haus- oder Gewerbemü ll entsorgt werden darf. Er muss gemäß

Batteriev erordnung dem hierfür vorgesehenen Entsor g u n g s s ystem zug e führt werden

(Umsetzung d er 2012/19/EU in n ationales Recht) . Weitere Informa tionen er halten

Sie beim für Ihre Stadt zuständigen Recyclinghof.

Einbauort:

EC3-P33 sind für die Montage auf Standard DIN-Schienen geeignet.

Montageposition: Auf senkrechten Flächen, mit dem Motoranschluss nach oben.

Dauerhafte Montage der Anzeigeeinheit ECD-002:

• ECD-002 kann jederzeit montiert werden, auch währ end dem Betrieb .

• Die Anzeigeeinheit ECD-002 wird in Frontplatt e n m it

einem Ausschnitt von 71x29 mm montiert.

• Anzeigeeinheit vors

ichtig mit eingefahrenen

Halterungen in den Frontplattenausschnitt ein

schieben

(1).

•

Beiliegenden Imbusschlüssel in die Löcher auf der

Frontseite einstecken und im Uhrzeigersinn drehen. Die

Halterungen treten aus dem Gehäuse herv

or und

bewegen sich in Richtung Frontplatte (2).

•

Imbusschraube drehen bis die erste Halterung die

Frontplatte leicht berührt. Dann zweite Halterung in

diese Position bringen (3).

• Beide Seit en g leichmäßig und nicht zu fest anziehen.

Hinweis: durch zu festes Anziehen können d ie

Halterungen abbrechen.

Elektrischer Anschluss:

• Den elektrischen Anschluss gem. Verdrahtungsschema durchführen!

• Versorgungsspann u ng ers t n ach kompletter Installat i on anl eg en!

• Gehäuse mit einem 6.3 mm Flachstecker erden!

• Signalleitungen und Leitungen mit Netzspannung in getrennten

Kabelschächten verlegen, Mindestabstand 30 mm!

• Kabel so verlegen, dass sie nicht an scharfen Kanten beschädigt werden.

• Für die 24 V Stromversorgung sind ausschli eßlich Transfor matoren der Klasse I I

zu verwenden. Die 24V L eitu ngen dür fen ni cht g ee rdet w e rden. Wir empf ehle n die

Verwendun g jeweils sepa rater EMERSON Transforma toren fü r EC3 Regler und

die Regler anderer Hersteller, weil unter Umständen über die Erdleitungen

Kurzschl üs s e e nts tehen können.

• Vor der Inbetriebnahme des EC3 müssen die Haupt-Parameter ein ges t ellt un d der

24 V-Digital eingang darf n icht am EC3 ang e s c hl ossen wer de n.

• Das Alarmrelais dient zum Schutz des Systems bei Stromausfall, wenn

Kommunikations-Schnittstelle oder ECD-002 nicht verwendet werden!

• Wird das Alarmrelais nicht verwendet, muss das System auf andere Weise vor

Schäden durch Stromausfall geschützt werden.

• Um das System vor Schäden durch Stromausfall zu schützen empfehlen wir einen

jährlichen Austausch des Akkus.

Funktion des Digitaleingangs bei Verdichter- oder Therm ost at-Betrieb:

Befehlsgeber

Betriebszustand

Digitaleingang

Verdichter

Verdichter startet

zu / 24 V (Start )

Verdichter stoppt

offen / 0 V (Stopp)

Thermostat

Anforderung (Verdichter Ein)

zu / 24 V (Start )

Keine Anforderung

offen / 0 V (Stopp)

Verdrahtung:

Kabelfarben: 2: Weiß 4: Schwarz 3: Blau 1: Braun

G: Schaltschrank, Anlagenregler

H: Alarmrelais, Wechsler. Inaktiv bei Alarm oder fehlender Stromversorgung

I: Digitaleingang (0V = Aus; 24 V = Ein)

J: Trafo Klasse II, 24 VAC Sekundär/ 25 VA

K: Anlagenregler (kann analoges Ausgangssignal von EC3 benutzen)

Vorbereitungen f ür Inbetriebnahme:

• Den gesamten Kältekreislauf vakuumieren.

• Hinweis: EX4-7-…FLR werden halbgeöffnet ausgeliefert. Den Kältekreislauf nur

bei geschlossenem Ventil mit Kältemittel füllen.

• Versorgungsspannung 24 V zu EC3 einschalten, der Digitaleingang bleibt bei 0 V.

Das Ventil wird zugefahren.

• Bei geschlossenem Ventil System mit Kältemittel füllen.

• System starten, Überhitzung und Betriebsbedingungen überprüfen.

!

Nicht explosions-

gefährdete Umgebung

Page 5

Betriebsanleitung

EC3-P33 Überhitzungsregler mit

ECD-002 Anzeige- / Einstelleinheit

Installation in nicht explosionsgefährdeter Umgebung

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 04.03.2017 EC3-P33_OI_ML_R01_865919.docx

ECD-002 Anzeige einheit: (Funktion der LEDs und Tasten)

Einstellung der Ha upt-Parameter mit ECD-002

(vor der ersten Inbetriebnahme prüfen bzw. anpassen)

• Während am Digitaleingang 0 V anliegen Versorgungsspannung einschalten.

• Wichtig: Die drei Parameter Kältemi ttel ( u0), Dru cksen sor-Typ (uP) und Ventil-

Typ (ut) können nur eingestellt werden, wenn der Digitaleingang AUS (0 V) und

die Verso r g ungsspannung AN (24 V) ist. Diese Sicherheitsf u nktion verhind ert die

Beschädigung des Verdichters oder anderer S ystemkomponenten.

• Zu m einfachen Einstellen der Parameter gibt es ein e Schnellstart-Anleitung mit

Bildern (s. separate Seite).

• Nach Einst el l ung de r H a upt-Parameter und aktivieren des Digitaleingangs sind die

EC3-P33-Regler betri ebsbereit. Alle and eren Parameter können jederzeit, auch

während des Betriebs oder im Standby angepasst werden.

Parametereinstellung mit der Anzeigeeinheit ECD-002:

• Parameteränderungen sind mit der Gerätetastatur möglich. Die Konfigurations-

parameter s in d pa ss wort ges ch ü t zt. Das werk s s eit i g ei n ges t ellt e Pa ss wor t i s t “1 2 ” .

Zur Auswahl der Parametereinstellungen:

• PRG Taste län ger als 5 Sek. gedrü ckt halten, ein e blinkende "0" er scheint

• oder Taste drücken bis Passwort (Standardwert 12) angezeigt wird

• SEL drücken - Passwort wird bestätigt

• oder Taste drücken bis der gewünschte Parameter erscheint;

• SEL drücken - der aktuell eingestellte Wert wird angezeigt

• oder Taste drücken - der Wert wird vergrößert oder verkleinert

• SEL drücken - der eingestellt e Wert wird vorläufi g behalten, muss aber n och

gespeicher t werden. Die Parameterkennung wird wieder an gezeigt.

• Zur Änderung weiterer Parameter wird dieser Ablauf wiederholt:

• oder Taste drücken - nächste Param eterkenn ung a u s wählen.

• Parameter speichern und Konfigurationsmodus beenden: PRG Taste drücken

• Parameter nicht speichern und Konfigurationsmodus ohne Parameter-

änderung beenden: Mindestens 60s lang keine Taste drücken (Zeitsperre)

Parameter auf Werkseinstellung zurücksetzen:

• und Taste länger als 5 Sek. gedrückt halten bis blinkende "0" erscheint

• oder Taste drücken bis das Passwort (Standardwert 12) angezeigt wird

• SEL drücken - Passwort wird bestätigt, “0” wird angezei g t

• SEL drücken - alle Parameter werden auf Werkseinstellung zurückges etzt

• PRG drücken - die gewählte Funktion wird aktiviert und die Betriebsart Spezial-

funktionen verlassen

Startverhalten der Regelventile: (Parameter uu und u9)

EX4/5/6-…FLR ≤ 1,5 Sekunden

EX7-…FLR ≤ 3,2 Sekunden

Haupt-Parameter:

(müssen ggf. angepasst werden)

Code Beschreibung und Wahlmöglichkeiten Min Max Werk Kunde

H5

Passwort

1

199

12

u0

Kältemittel

0 6 0

0 = R290; 1 = R32; 2 = R1234ze;

3 = R1234yf; 4 = R1270;

5 = R227; 6 = R600a

uP

Installierter Drucktransmitter

PT5-30L-FLR

ut

Installier te s EMERS O N Re gelventil

0 3 1

0 = EX4-…FLR 1 = EX5-…FLR

2 = EX6-…FLR 3 = EX7-…FLR

Sonstige Parameter:

(Anpassung nur für spezielle Anwendungen)

EC3-P33 sind auch ohne Anzeigeeinheit ECD-002 betri ebsbereit, dies e kann auch

während des Betriebs ein- o der ausgesteckt werden.

Code Beschreibung und Wahlmöglichkeiten Min Max Werk Kunde

uu

Startöffnung des Regelventils (%)

5

100

10 u9

Startzeit für Ventilöffnung (Sekunden)

1

120 5

uL

Alarm bei zu niedriger Überhitzung

0 2 1

0 = deaktiviert (für überfluteten Verdampfer)

1 = automat. Rückstellung

2 = manueller Rückstellung

Alarm Ein bei 0.5K (wenn länger als 1 Minute unterschritten);

Alarm Aus bei 3K (ohne Zeitverzug)

u5

Überhitzungseinstellung (K)

wenn uL aktiviert (autom. oder manuell)

wenn uL deaktiviert

3

0.5

30

30

6

6

u2

MOP Funktion

0 1 1

0 = deaktiviert

1 = aktiviert

u3

MOP (°C) Sättigungstemperatur

* * X

Werkseinstellung abhängig vom gewählten Kältemittel (u0):

+13°C for R290 +15 °C for R32

+15°C for R1234ze +15°C for R1234 yf

+13°C for R1270 +15°C for R227

+15°C for R600a

┌┘5

Einheiten (nur für u3, u5, ┌┘1)

0 1 0

0 = °C, K, bar

1 = °F, R, psig

(Psig Werte geteilt durch 10. Bsp: Display 12.5 bedeutet 125 psig)

┌┘

1

Angezeigter Wert

0 4 0

0 = gemess. Überhitzung (K)

1 = gemessener Verdampfungsdruck (bar)

2 = Ventilöffnungsgrad (%)

3 = gemessene Sa uggas-Temperatur (°C)

4 = aus gemessenem Druck errechnete Verdampfu ngstemperatur (°C)

u4

Überhitzungsregelung (nach 01. 03 . 0 8)

0 = Standard,

1 = langsam

0 1 0

b1

Batterie-Fehlermanagement bei defekter

Batterie

0 3 2

Wert

Display-

Anzeige Alarmrelais Ventilzustand

Möglichkeit zur

Rückstellung nach

Erholung/Austausch

0 - - regelt

-

1

Ab - regelt

-

2

Ab

signalisierend

geschlossen

automatisch

3 Ab

(blinkt)

signalisierend

geschlossen

manuell

Wird das Alarmrelais nicht verwendet (b1 = 0 oder = 1), muss das

System auf andere Weise vor Schäden durch Stromausfall geschützt

werden

!

Sec.

uu

u9

%

EC3-X3 BA.cdr

Blinkt: Ventil schliesst

AN: Ventil ist geschlossen

Blinkt: Ventil öffnet

AN: Ventil ist offen

Parameter Ei ngabe/Speicherung

Nächster Parameter/Wert (höher)

AN: Anforderung

AUS

: keine

Anford.

AN: Alarm

AUS: kein

auswählen/bestätigen

Nächster Parameter/Wert (tiefer)

Manuelle Rückstellung für

alle blinkenden Alarme

(PRG & SEL) 5s drücken

Page 6

Betriebsanleitung

EC3-P33 Überhitzungsregler mit

ECD-002 Anzeige- / Einstelleinheit

Installation in nicht explosionsgefährdeter Umgebung

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 04.03.2017 EC3-P33_OI_ML_R01_865919.docx

Alarmanzeigen und Fe hlerbehebung:

Alarm

Code

Fehler

Beschreibung

Abhängiger

Parameter

Alarm

Relais

Ventil-

zustand

Fehlerlösung

Man. Rückstellung

nach Fehlerbehebung

notwendig

E0

Drucktransmitter

Fehler

- signalisierend geschlossen Verdrahtung prüfen und 4…20 mA Signal mess en Nein

E1

Temperatursensor

Fehler

- signalisierend geschlossen Verdrahtung prüfen und Widerstand des Sensors messen Nein

AΠ

EXV Fehler elektr.

Anschluss

- signalisierend unbekannt Verdrahtung prüfen und Widerstand der Wicklung messen Nein

AL

Überhitzung zu

niedrig (<0,5K)

uL: 1

signalisierend

geschlossen

Verdrahtung prüfen und Funktionsprüfung des Ventils

durchführen

Nein

AL blinkt

uL: 2

signalisierend

geschlossen

Ja

Ab

Batteriefehler

b1: 1 - regelt

Batterieladung zu schwach für Schließen des Ventils bei

Stromausfall. Kann bei neuen Reglern oder langer Lagerzeit

auftreten und sollte nach ausreichender Aufladung der Batterie

verschwinden. Ansonsten defekte Batteri e er setzen

(Austauschkit Bestell-Nr. 807790).

-

Ab

b1: 2 signalisierend geschlossen -

Ab blinkt

b1: 3 signalisierend geschlossen Ja

Er

Daten außerhalb

Anzeigebereich

- - -

Display kann Daten nicht darstellen, Einstellwert der Parameter

verändern.

Nein

---

Keine Daten auf

dem Display

- - -

Kabel- und Steckerve r bin dungen zwis chen EC3-P33 und ECD002 prüfen

Nein

Hinweis: Bei mehreren Alarmen gl eichzeitig wi rd der Alarm mit der höchsten Priorität angezeigt, nach dessen Beseitigung wird d er n ächsthöhere angezeigt usw., bis alle

Alarme beseitigt sind. Danach werden wieder die Parameter angezeigt

Überprüfung der Be triebsbedingungen:

Die am Display permanent angezeigten Daten werden vom Anwender durch Parameter

┌┘1 bestimmt. Gleichz eitig können andere Daten vorübe rgehend am Dis play angezeigt werden,

sofern kein Alarm vorl ieg t. Das Displ ay zeig t nach Dr ücken vo n SEL z uers t für 1 Se kunde den Code für den jewe ilige n Wer t (s . Parame ter

┌┘1) und dann die Date n. Nac h 5 Minute n

werden wieder die permanenten Daten angezeigt.

Service / Fehlersuche:

Fehlerbeschreibung Ursache Aktion

Überhitzung ist einige Grad höher oder niedriger als der

Einstellwert

Fehlerhaftes Signa l von Druck- oder

Temperatursensoren

1- Sensoren überprüfen.

2- ECN-N60 als Temperatursen sor einsetzen.

3- EMERSON Drucktransmitter verw enden: PT5-30L-FLR

4- Sensorkabel nicht zusammen mit stromführenden Leitungen

verlegen.

Überhitzung ist zu niedrig, Verdichter läuft nass

1- Ventile falsch angeschlos sen

2- Defekter Sensor

1- Verdraht ung ü b e r prüfen.

2- Sensor überprüfen.

Ventil ist nicht vollständig geschlossen

1- Digitaleingang ist EIN (24 V)

2- Falsche Einstellung für Parameter ut

1- Ventil schließt nur, wenn der Digitaleing ang A US ist (0 V).

2- Einstellung für Parameter ut überprüfen.

Schwankende Überhitzung

Eingesetzter Verdampfer ist für

höhere Überhitzung ausgelegt

Einstellwert für Überhitzung Vergrößern.

Ventil öffnet, wenn EC3 Befehl zum Schließen gibt

und umgekehr t

Fehlerhafte Verdrahtung zwischen

EC3-P33 und Ventil

Verdrahtung gem. Verdrahtungsschema durchführen.

Überhitzungseinstellung verändert sich nach einigen

Monaten ununterbrochenen Betriebs oder bei Permanenter-

überbrücku ng des 24 V Digitaleingangs

Ventile mit Schrittmotor erfordern

Synchronisation

Am 24 V Digitaleingang nicht dauerhaft Spannung anlegen; wenn

Verdichter ununterbrochen läuft Digitaleingang einmal je Woche

für 5 Sekunden unterbrechen.

Technische Daten: Abmessungen [mm]:

Versorgungsspannung

24 VAC ±10%; 50/60 Hz; 1 A

EC3-P33

Leistungsaufnahme

25 VA max, inklusive EX4-7…FLR

Anschlüsse

Steckbare Schraubklemmen für Adern mit max.

0,14…1,5 mm2 Querschnitt

Erdungsanschluss

für 6.3 mm Flachstecker

Schutzklasse

IP20 Verbindung z u EC D -002

ECC-Nxx oder CAT5 Kabel mit RJ45 Anschlüssen

Digitaleingänge

0/24 VAC/DC zum Ein- bzw. Ausschalten

NTC Analogeingang

EMERSON Temperatur sensor ECN-N60

4-20 mA Analogeingang

EMERSON P T5-30L-FLR Drucktransmitter

4…20 mA Analogausgang

Abweichung vom

Eingangssignal

für externen Regler mit 12/24 VDC

Speisespannung & geeignetem internen Widerstand

± 8% max.

ECD-002

Ausgang Alarmrelais

Wechsler (geeignet für 24 VAC/DC),

Induktive Last: 2 A

Aktiviert:

Bei Normalb etrieb (kein Alarm zustand)

Inaktiviert:

im Alarmzustand oder bei ab g eschalteter Sp annung

Schrittmotorausgang für

EX4-7

Maximalstrom 0,8 A mit nominal 24 VDC

Betriebsspannung

Temperaturbereich

0…+60°C

+1…+25°C (für optimale Batterielebens d auer)

> 35°C Batter ielebensdauer < 2 Jahre

Kennzeichnung

Page 7

EC3-P33 Superheat Controller and ECD-002

Keypad / Display Unit

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 04.03.2017 EC3-P33_OI_ML_R01_865919.docx

2

2a

2b

0 = R290 4 = R1270

1 = R32 5 = R227

2 = R123ze 6 = 600a

3 = R123yf

2

3 3a

3b

PT5-30L-FLR (R290)

3c

4

4a

4b

0 = EX4-…FLR

1 = EX5-…FLR

2 = EX6-…FLR

3 = EX7-…FLR

4c 4d

4e

Display of Data:

0

1

1a

1b

1c

1d

1e

EX7-…FLR

5 sec.

1-199

88

12x

EX4, EX5

EX6, EX7

EX8

Po => To

Ts

Vo (%)

Ts (°C)

To (°C)

SH = Ts - To (K)

100%

0%

Po (barg)

EC

3

X_

65

1

30

.c

d

r

R22

Loading...

Loading...