Page 1

Operating instruction

EC3-D7x Digital Superheat Controller

EC3-D72 with TCP/IP communication capability

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

General information:

EC3-D72 is the superheat controller with TCP/IP connection for stepper motor

driven Electrical Control Valves EX4-6 from EMERSON and is optimiz ed to oper ate

with the Copeland Digital Scroll series utilizing a 0-10V input from a third-party

controller. The controller synchronizes the PWM digital compressor solenoid valve

with the superheat controlled by the electrical control valve; EX series.

The EC3-D73 has the same functionality but can only be set-up via the ECD-002

display. It has no external communication functi onality.

Safety instruc tions:

• Read operatin g ins tructi ons th orou ghly. Failur e to com ply c an res ult in device

failure, system damage or personal injury.

• According to EN 13313 it is intended for use by persons having the

appropriate knowledge and skill.

• Do not exceed the specified maximum ratings for pressure, temperature,

voltage and current.

• Before in stallation or service disconnect all voltages from system and device.

• Do not operate system before all cable connections are completed.

• Entire electr i c a l c on n e c t ions have to comply with local regulations.

Note: The EC3 -D7x series contains a VRLA battery = valve regulated rechargeable

lead-acid battery. The batte ry m ust NOT be dis posed of w ith othe r comme rcia l was te.

Instead, it is the use r ’s r es ponsi bility t o pass it to a desig na te d col le ctio n po int f or the

safe recycling of batteries (harmonized directive 2012/19/EU). For further

information contact your local environmental recycling center.

Mounting position:

The EC3-D7x is designed to be mounted onto a standard DIN rail. Mounting

position: on vertic al walls, with stepper motor conn ector on top side only.

Mounting of ECD-002:

• ECD-002 can be installed at any time also during operation.

• ECD-002 can be mounted in panels with

71x29 mm cutout.

• Push controller into panel cut-out.(1)

• Make sure that mounting lugs are flush with

outside of controller h ousing

• Insert Allen key into front panel holes and turn

clockwise. Mounting lugs will turn and gradually

move towards panel (2)

•

Turn Allen key until mounting lug barely touches

panel. Then move other mounting lug to the same

position (3)

• Tighten both sides very carefully until keypad is

secured. Do not over tighten as mounting lugs

will break easily.

Electrical Installation:

• Refer to the electrical wiring diagram for electrical connections.

• Do not apply voltage to the controller before completion of wiring.

• Ground the metal housing with a 6.3 mm spade connector.

• Keep controller and sensor wiring well separated from mains wiring. Minimum

recommended distance 30 mm.

• Use a class II category transformer for 24 VAC power supply. Do not ground the

24 VAC lines. We recommend using individual transformers for EC3 controller(s)

and for 3

rd

party controllers t o avoid poss ible in terference or gr oun ding p roblems

in the pow er suppl y. Connecting any EC3 inputs to mains voltage will permanently

damage the EC3.

• The use of the relay is essential to protect the system in case of power failure if the

communications interface or the ECD-002 are not utilized.

• If the output relay is not utilized, the user must ensure appropriate safety pre-

cautions are in place to protect the system against damage caused by a power

failure.

• In order to provide system protection in the event of power loss, it is recommended

to change the battery annually.

Digital input status is dependent to operation of compressor/ 0-10V input

System

Operating

condition

Digital Inputs

0-10V input from third party

controller

C1 &

C2 in stop mode

“Cooling demand” open (0 V)

“Comp 2 Running” open (0 V)

EXV remains cl o sed irrespec tive

of voltage input value

C1 in run &

C2 in stop mode

“Cooling demand” closed (24

V)

“Comp 2 Running” open (0

V)

EXV active

Input = 0V: dig. valve capacity =

10% default ca pa city.

If dig. comp. is in by-pass,

EXV will:

- close if capacity is <70%

- be inhibited if capacity is

>70%

C1 &

C2 in run mode

“Cooling demand” closed (24 V)

“Comp 2 Running” closed (24

V)

EXV active

EXV always modulates

even when

the dig. compr. is in by-pass mode.

C1 in stop &

C2 starts run

mode

“Cooling demand” open (0 V)

“Comp

2 Running” closed (24 V)

EXV remains clo sed irrespec t ive

of voltage input value

Note 1: C1 = Compressor 1, C2 = Compressor 2

Note 2: Digital comp. s ho uld always be regarded as base load compressor 1.

Wiring:

A: White wire

B: Black wire

C: Blue wire

D: Brown wire

E: M12 Plug cable assembly EXV-Mxx for connection to EX4-6

F: 24 V Triac output to PWM Digital Scroll valve

G: Remote control panel, system controll er.

H: Alarm relay, dry contact. Relay coil is not energized at alarm or power off.

I: Digital input “Cooling demand” (0 V/open = Stop; 24 V/closed = Start)

J: Transformer Class II, 24 VAC secondary / 25 VA

K: Third party controller (can use the analog output signal from EC3)

L: Pump down relay, dry contact. Relay is energized during normal operation

M: Digital input 2: “Comp 2 running”

(0 V/ open = Comp 2 stop; 24 V /closed = Comp. 2 running)

N: Discharge Temp. Sensor C opeland® NTC

O: 0-10 V Digital Scroll capacity demand signal from system controller

P: ECN-N60 Temperature sens o r

!

Page 2

Operating instruction

EC3-D7x Digital Superheat Controller

EC3-D72 with TCP/IP communication capability

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Preparation for Start-up:

• Vacuum the entire refrigeration system.

• Note: EMERSON Electrical Contr ol Valves EX4-6 a re delivered at half open

position. Do not char ge syst em before closure of valve.

• Apply supply voltage 24 V to EC3 while the digital input is 0 V (open). The valve

will be driven to close position.

• After closure of valve, start to charge the system with refrigerant.

• Start the system and check the superheat and operating conditions.

ECD-002 display /keypad unit: (LEDs and button functions)

Procedure for parameter modification using ECD-002:

• Note: Some of the functions/parameters (manual control and TCP/IP

configuration) cannot be modified when using ECD-002 comparing to a set-up by

PC via TCP/IP.

• Warning:

All alarms are disabled during manual control. We do not recommend

unattended operation of system during manual control.

• The parameters can be accessed via the 4-button keypad. The configuration

parameters are protected by a numerical password. The default password is “12”.

To select the parameter configuration:

• Press the PRG button for more than 5 seconds, a flashing “0” is displayed

• Press or until “12” is displayed (password)

• Press SEL to confirm password

• Press or to show th e code of the parameter that must be changed;

• Press SEL to displa y the selected par ameter value;

• Press or to increa se or decrease the value;

• Press SEL to temporarily confirm the new value and display its code;

• Repeat the procedure from the beginning "press or to show..."

• To exit and save the new settings: Press PRG to confirm the new values and exit

the parameters modification procedure.

• To exit without modifying any parameters: Do not press any button for at least

60 seconds (TIME OUT).

Special Functions :

The Special F un c t ions can be activated by:

• Press and together for more th an 5 seconds, a flashing “0” is displayed.

• Press or until the passw ord is displayed (default = “12”).

If password was changed, select the new password.

• Press SEL to confirm password

A “0” is displayed and the Special Function mode is activated.

• Press or to select the function. The number of special functions is dynamic

and controller dependent. See list below.

0: Reset controller to factory settings (this action is possible only when

digital input is 0 V i.e. open).

1: Displays the current TCP/IP address.

2: Assign temporary 192.168.1.101 as TCP/IP address if EC3-D72x has

different address.

• Press SEL to activate the func tion without leaving the speci al function mode.

• Press PRG to activate the function and leave the special function mo de.

Main parameters:

(must be checked and modified if necessary)

Code Parameter description and choices Min Max

Factory

setting

Field

setting

H5

Password

1

199

12 u0

System refrigerant

0

15 1

0 = R22 1 = R134a 2 = R507 3 = R404A 4 = R407C

5 = R410A 6 = R124 7 = R744 (subcritical applicatio n)

8 = R407A 9 = R407F 10 = R32* 11 = R448 A

12 = R449A 13 = R450A 14 = R513A 15 = R1234ze

uP

Installed pressure sensor type

0

2 0

0 = PT5-07x (for R22 / R134a / R507 / R404A / R407A / R407C /

R407F / R124 / R448 A /R449A / R450A / R513A /

R1234ze)

1 = PT5-18x (for R410A/ R32)

2 = PT5-30x (for R410A / R744 / R32)

ut

Installed valve type

1 3 2

1 = EX4 2 = EX5 3 = EX6

uu

Start valve opening (%)

10

100

50

u9

Start opening duration (second)

1

30 5

uL

Low superheat alarm function

0 2 1

0 = disable (for flooded evaporator)

1 = enable aut o reset 2 = enable manual reset

Cut-out at 0.5K (if it maintains 1 min.); Cut-in immediately at 3K

u5

Superheat set-point (K)

If uL enabled (auto or manual)

If uL disabled

3

0.5

30

30

6

6

u2

MOP function

0 1 1

0 = disable 1 = enable

u3

MOP set-point (°C) saturation temper atur e

* * **

**) Factory setting is according to selected refrigerant (u0):

+13°C - R22 +15°C - R134a +7°C - R507

+7°C - R404A +15°C - R407C +15°C - R410A

+50°C - R124 -5°C - R744 +10°C - R407A

+10°C - R407F +10°C - R32 +12°C - R448A

+12°C - R449A +19°C - R450A +13°C - R513A

+24°C - R1234ze

*) Min. and Max . setting values are dependent to selected type o f

refrigerant

┌┘

5

Units conversion

0 1 0

0 = °C, K, bar 1 = °F, R, psig

(Psig values are divided by 10. Example: Display 12.5 is 125 psig)

┌┘

1

Value to show

0 5 0

0 = Measured superheat (K) 1 = Measured evaporating pressure, (bar);

2 = Valve opening (%) 3 = Measured coil-out temperatur e (°C)

4 = Calculated evaporating temperature (°C) from the pressure

5 = Compressor capacity in %

u4

Superheat control mode

0 1 0

0 = Standard, 1 = Slow,

uH

High superheat alarm function

0 = disable, 1 = enable auto reset

1

uA

High superheat alarm setpoint

16

40

30

ud

High superheat alarm delay, min.

1

15 3

P2

Freeze prot ection cut-out, °C

-40

40 0

P3

Freeze prot ection cut-in, °C

-37

43 3

P4

Freeze protection alarm function

0 = disable, 1 = enable auto-reset,

2 = enable manual reset)

0 2 0

P5

Freeze protection alarm delay, sec.

5

199

30

P6

Pump-down function

(0 = disable, 1 = enable auto-reset)

0 1 0

P7

Pump-down cut-out, barg

-0,5

18

0.5 P8

Pump-down time delay, sec.

0

199

30

P9

Low pressure alarm function

(0 = disable, 1 = en able auto-reset,

2 = enable manu al reset)

0 2 0

PA

Low pressure alarm cut-out, barg

-0,8

17,7 0

Pb

Low pressure a larm delay, sec .

5

199 5

Pd

Low pressure alarm cut-in, barg

-0,5

18

0.3 L2

Output logic

0 3 1

0: Alarm = normal, pump down. = normal

1: Alarm = inverse, pump down. = normal

2: Alarm = normal, pump down. = inverse

3: Alarm = inverse, pump down. = in verse

Blinking: valve is closing

ON: valve is fully close

Blinking: valve is opening

ON: valve is fully open

ON: demand

OFF: no demand

Blinking: pump

down

ON: alarm

OFF: no alarm

Parameters setting/saving

Selecting/confirming

Next param eter/

value (higher)

Next param eter/

value (lower)

Prg&Sel (5 sec)

Manual reset f o r

blinking alarm codes

Page 3

Operating instruction

EC3-D7x Digital Superheat Controller

EC3-D72 with TCP/IP communication capability

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Code Parameter description and choices Min Max

Factory

setting

Field

setting

b1

Battery error management, when battery is

defective, see below

0 3 2

value

Alarm

display

Alarm relay

Valve

Reset possibility after

recovery/replacement

0 - - Regulating

-

1 Ab - Regulating

-

2 Ab

Signaling

Fully close

Auto

3 Ab

(blinking)

Signaling

Fully close

Manual

When setting b1 to option 0 or 1, the user must ensure appropriate safety

precautions are in pla ce to protect the s yst em against damage caused by

a power failure.

/6

Show decimal point; 0=yes, 1 = no

0 1 0 A6

Maximum dis charge temperat ure; °C

100

140

130 A7

Discharge temp. alarm de l ay; sec.

0

199

30

F2

Minimum capacity; %

10

100

10 F3

Maximum capacity; %

10

100

100

F6

Scroll Valve, PWM cycle time; sec.

10

20

20

t3

Monitor discharge temperature sensor

0 = no, 1 = Yes

0 1 0

ru

0-10V input filtering; 0 = off, 1 = on

0 1

*) Notes for R32: R32 is classified as low flammab le refrigeran t in Europe. EC3D7x is designed under consideration of European safety standards and directives for

none flammable refrigeran ts. The u se of EC3-D7x with R32 is for systems/regions

which it does not require consideration of additional safety standards as for

flammable refrigerant.

After selecting the parameters the EC3-D7x is fully functio nal w itho ut c on ne cte d PC

or keypad/display unit ECD-002.

Control (valve) start-up behavior: (Par ameter uu and u9)

EX4/5/6 ≤ 1.5 seconds

Pump down f unction: (if P6=1 and L2=1)

Digital input status

Alarm

condition

Pump down relay

24 V (ON)

NO

Activate

0 V (OFF)

NO

Deactivat e when pressure drops below

P7 and after elapsed time P8

0 V or 24V

YES

Deactivate

Possibilities of connecting EC3-D72 to a network or PC:

• A TCP/IP Controller Readme file is available on the www.emersonclimate.eu

website to provide detailed information about TCP/IP Ethernet connectivity.

Please refer to this file if you need information beyond the contents of this

instruction sheet.

• Connect t he E C3-D72 using the optional ECC-Nxx cable assembly or a standard

CAT5 netw or k cabl e with RJ45 pl ugs asse m bly t o a ne tw or k or route r that e na bl e s

the controller to receive a dynamic TCP/IP address or

• Connect the EC3-D72 to a computer using a crossover cable plugged directly into

the Ethernet port. In this case, the TCP/IP address of the computer must be

manually modified to be compatible with the default address of the controller.

Refer to the TCP/IP Controller-Readme file for more details.

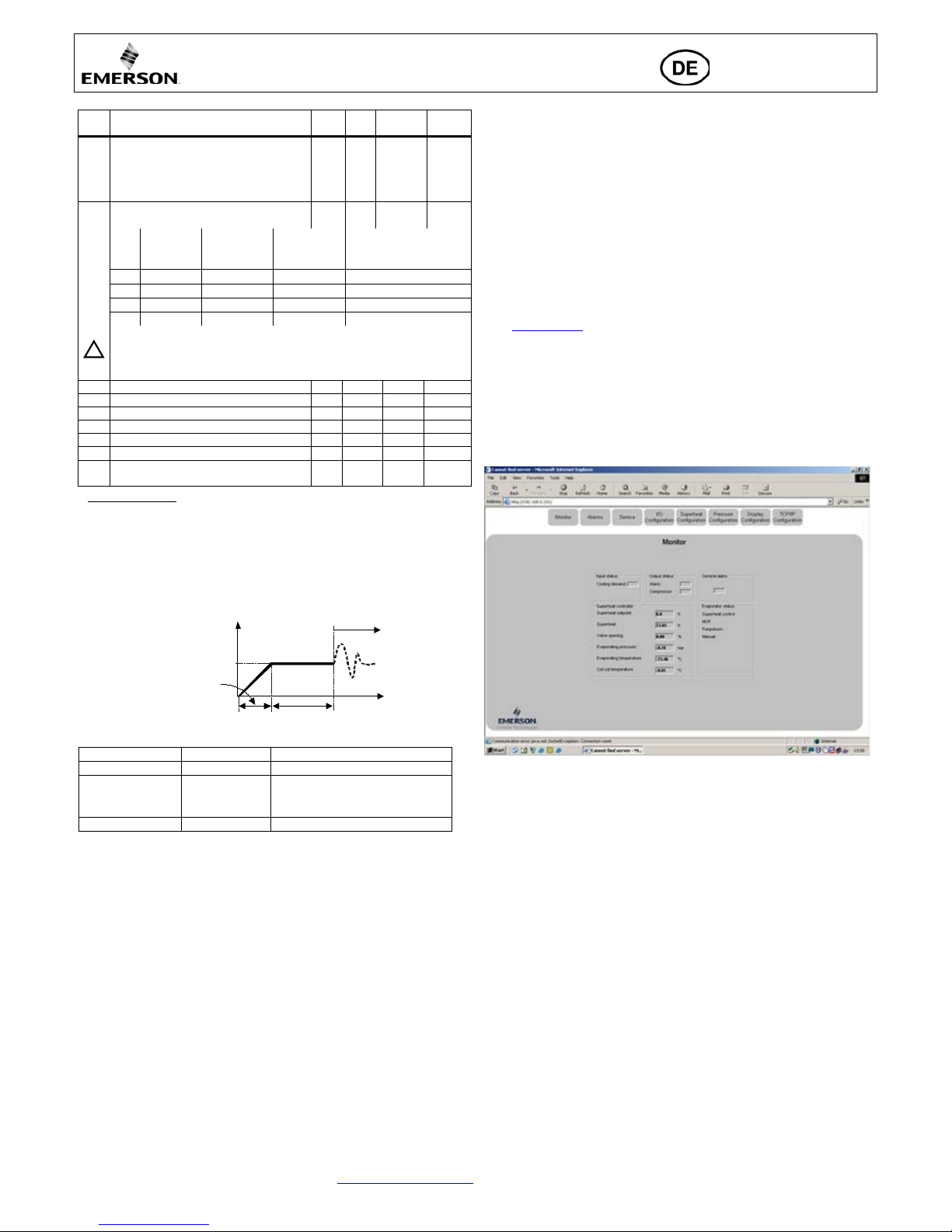

Setting and visualizing Data: WebPages

(recommended method)

• Make sure that digital input is 0V (open), turn the power supply ON.

• Four parameters i.e. refrigerant type (u0), pressure sensor type (uP), valve type (ut)

and control mode can be set only when digital input is open (0V) while the power

supply is O N (24 V). This feature is for added safety to prevent accidental damage

of compressors and other system components. All other parameters can be

modified at any time.

• The EC3-D72 has a TCP/IP Ethernet communication interface enabling the

controller t o be di rect ly conn ect ed to a net work or a P C via th e stand ard Eth ern et

port. The EC3-D72 controller has embedded WebPages to enable the user to

visualize the parameter lists using real t ex t labels.

• To view WebPages on the PC, a standard Web Br owser li ke Internet E xplorer ® or

Mozilla Firefox and JRE Java Runtime Environment is needed. JRE can be

downloaded at no charge from the www.java.com website.

• Open the Internet bro wser prog r a m o n the compute r and, if EC3-D72 is connected

directly to PC with a crossover cable enter the default TCP/IP address of the

controller (192.168.1.101) into the address line, or the dynamic address from the

DHCP server from network/Router. Refer to the TCP/IP Controller-Readme file

if a specific port is required.

• It is possible to identify the dynamic TCP/IP address assigned by DHCP of the

Router or network, refer to the TCP/IP Controller-Readme file.

• After a few moments, the default monitoring page should be displayed. If the

browser do es not open the defaul t pag e or display activ e data , the use r sho uld che ck

the Internet browser “Option” configuration. Refer to the TCP/IP Controller-

Readme file.

• The Monitoring and Alarm WebPages are read only and therefore it is not

necessary to enter a username or password. A username and password will be

requested u pon the initi al re quest to a ny of the o ther We bPage s. The factory defaul t

settings a re: Username: “EmersonID”, Password: “12”

• The default settings may be modified on the Display configuration page.

• Press the tabs at the top o f the Mon itor ing pa ge w ith a lef t clic k of the mo use butto n

to enter the respective Webp age.

• The param eters will b e visualized in real text together with the program code as

defined in the parameter list below.

• After the parameters have been modified, the complete list of settings can be saved

to the memory of the computer and used later to upload into another controller.

This can save a considerable amount of time when using multiple controllers and

over a period of time, a library can be created containing the parameter lists for

equipment for different applications.

• It is also possible to display live graphical data from the controller. Superhea t,

evaporating pressure, coil-out temperature and evaporating temperature are

available on a 15 minutes rolli ng chart. Ref er to the TCP/IP C ontroller-Readme

file for a comp lete descrip tion of the feat ures availa ble for the TCP/ IP series of

controllers.

!

Sec.

uu

u9

%

EC3-X3 BA.c dr

Page 4

Operating instruction

EC3-D7x Digital Superheat Controller

EC3-D72 with TCP/IP communication capability

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Error/Alarm handling:

Alarm

code

Description

Related

parameter

Alarm

relay

Valve What to do?

Requires manual

reset after resolvin g

alarm

E0

Pressure

transmitter error

- Signaling Fully close Check wiring connection and measure the signal 4…20 mA. No

E1

Temperature

sensor error

- Signaling Fully close Check wiring connect ion and measure the resistance of sensor. No

E3

Discharge temp.

sensor error

-

Signalling

Regulating

Check wiring connections an d measure the resistance of the

sensor. Also check the status of the I/O configuration (t3)

No

AΠ

EXV electrical

connection error

- Signaling -

Check wiring connection and measure the resistance of

winding.

No

Ab

Battery error

b1: 1

-

Regulating

Battery potentia lly does not have enough charge to close valve

in case of main power supply interruption. May occur

temporarily with new controllers or after long storage but

should disappear when battery is charged sufficiently. If Ab

remains active even when battery is charged, battery may be

defective and should be replaced. (Replacement kit: 807790).

No

Ab

b1: 2

Signaling

Fully close

No

Ab blinkin g

b1: 3 Signaling Fully close Yes

AE blinking

Pump down action

cannot

accomplished

P6: 1 Signaling -

Allocate the source, which does not let suction pressure drops

below desired set-point.

Yes

AF

Freeze prot ection

P4: 1

Signaling

Fully close

Check the system for cause of low pressure such as insufficient

load on evaporator.

No

AF blinking

P4: 2

Signaling

Fully close

Yes

AL

Low superheat

(<0,5K)

uL: 1

Signaling

Fully close

Check wiring connect ion and operation of valve.

No

AL

blinking

uL: 2 Signaling Fully close Yes

AH

High superheat

uH: 1

Signaling

Fully close

Check the system.

No

AP

Low pressure

P9: 1

Signaling

Fully close

Check the system for cause of lo w pressure such as refrigerant

loss.

No

AP blinking

P9: 2

Signaling

Fully close

Yes

dA

High discharge

temp.

A6: alarm

setpoint

Signalling

Fully close

Pumpdown

deactivated

Check the system

No

Fixed differential =

10°C

Er

Data error display

- out of range

- - -

Data send to the display is out of range. Check temperature and

pressure sensor.

No

---

No data to display - - -

Check Cable and plug connecti on between EC3-D7… and

ECD-002.

No

Note: When multiple alarms occur, the highest priority alarm is displayed until being cleared, then the next highest alarm is displayed until all alarms are cleared. Only then

will parameters be shown again.

Checking system operating conditions using local display/keypad ECD-002:

The data to be permanently shown on the display can be selected by the user (parameter ┌┘1). It is possible to temporarily display these values. However this function is

not available in an alar m co ndition. The display will show for one second the numerical identifier of the data (see ┌┘1 parameter) and then the selected data. After 5 minutes,

the display will return to the value selected by parameter ┌┘1.

Service / Troubleshooting:

Symptom Cause Action

Operating superheat is several degrees higher or lower

than set-point

Incorrect signal from pressure or

temperature sensors

1- Check the sensors.

2- Make sure EC N -N6 0 temperature sensor is used.

3- For optimum accuracy, please use:

PT5-07x (for R22 / R134 a / R507 / R404A / R407A / R407C /

R407F / R124 / R 4 48A /R449A / R450A / R513A /

R1234ze)

PT5-18x (for R410A/ R32 )

PT5-30x (for R410A / R744 / R32)

4- Make sure the s ensor cables are not installed along with other

high voltage cables

Operating superhea t is too low i.e. compressor wet running

1- Incorrect wiring of ECVs

2- Defective sensors

1- Check the wiring

2- Check the sensor

Valve is not full y clo sed

1- The digital input is ON (24 V)

2- Wrong setting of paramet er ut.

1- Valve is shut off only when the digital input is turned off (0 V).

2- Check the set t ing of paramet er ut.

Instable superheat (hunting)

Evaporator is designed to operate at

higher superheat

Increase th e superheat set-point.

Valve opens when EC3 commands to close and vice versa

Wrong wiring between EC3-D7...

and valve

Correct the wiring.

Superheat set-point is shifting after severa l m onths of

uninterrupted op eration or permanent jumper of 24 V

digital input

Stepper motor driven valves require

synchronization

Do not apply permanent 24 V digita l inp ut. Interrupt digital input

once every week for 5 seconds if compressor never stops.

Page 5

Operating instruction

EC3-D7x Digital Superheat Controller

EC3-D72 with TCP/IP communication capability

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Technical data

Power supply

24 VAC ±10%; 50/60 Hz; 1 A

Power consumption

25 VA max. including EX4-6

Plug-in connector

Removable screw terminals

wire size 0.14…1.5 mm2

Grounding

6.3 mm spade earth connector

Protection class

IP20

COM, TCP/IP connection

RJ45 Ethernet

Connection to optional ECD-002

ECC-Nxx or CAT5 cable with RJ45 connectors

Digital Input; Cooling demand

0/24 VAC/DC for stop/start function

EX valve closes during stop command. Typically thermostat or third party controller.

Digital Input; Comp2 running

0/24 VAC/DC typically connected to auxiliary connection

EXV control loop remains active when input is 24 V and the digital scroll is idle.

NTC input; Coil-out temperature sensor

EMERSON temperature sensor ECN-Nxx/ECN-Pxx

NTC input; Discharge temperature sensor

Copeland® NTC 86 kOhm at +25 °C

4-20 mA Anal o g input

EMERSON PT5 Pressure Transmitter

4-20 mA Analog output

Deviation from input signal

For connection to any 3rd party controller with 12/24 VDC power supply and appropriate burden

±8% max

Output alarm relay

(If L2 = 1) Activated:

Deactivated:

SPDT contacts 24 VAC/DC, 2 A inductive load

During normal operation (no alarm condition)

During alarm condition or power supply is OFF

Output pump down relay

(If L2 = 1) Activated:

Deactivated

SPDT contact 24 VAC/DC, 2 Amp inductive load

During normal operation

All other conditions

Output Digital Scroll Triac

24 V or 230 V AC output to activate PWM valve on Digital Scroll

Ambient temperature range

0…+60°C

+1…+25°C (for best batt ery life time)

> 35°C battery life time < 2 years

Marking

,

Dimensions [mm]:

EC3-D7x ECD-002

Page 6

Betriebsanleitung

EC3-D7x Digital Scroll Überhitzungsregler

EC3-D72 mit TCP/IP Schnittstelle

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Beschreibung:

EC3-D7x ist ein Überhitzungsregler zur Steuerung der schrittmotorgesteuerten

elektrischen Regelventile EX4-6 in Anlagen mit Copeland Digital Scroll. Der

Leistungsbedarf der Anlage wird über den 0...10 V Eingang von einem externen

Regler eingespeist. Der EC3-D7x synchr onisiert das Magnetventil des Digital Scr oll

mit dem elektrischen Expansionsventil. EC3-D73 besitzt die gleiche Steuerfunktion

wie EC3-D72 allerdings ohne TCP/IP Schnittstelle; zur Komm iss ionierung muss eine

ECD-002 Anzeige verwendet werden.

Sicherheitshinweise:

• Lesen Sie die Betriebsanleitung gründlich. Nichtbeachtung kann zum

Versagen oder zur Zerstörung des Gerätes und zu Verletzungen führen.

• Der Einbau darf gemäß EN 13313 nur von Fachkräften vorgenommen

werden.

• Die angegebenen Grenzwerte für Druck, Temperatur, Strom und Spannung

nicht überschreiten.

• Vor Installation oder Wartung sind die Anlage und das Bauteil spannungsfrei

zu schalten.

• Das Ventil nicht betreiben, wenn der Kompressor nicht läuft.

• Für den gesamten elektrischen Anschluss sind die länderspezifischen

Vorschriften einzuh a lt en.

Hinweis: EC3-D7x Regler entha lten einen wieder auf ladbaren B lei-Gel-Akku, der

nicht im normalen Haus- od er Gewerbem üll entsorgt werden darf. Er muss gemäß

Batteriev erordnung de m hierfür vorgesehe nen Entsorg u ngssyste m zugeführt werden

(Umsetzung d er 2012/19/EU in n ationales Recht) . Weitere Informa tionen er halten

Sie beim für Ihre Stadt zuständigen Recyclinghof.

Einbauort:

EC3-D7x sind für die Montage auf Standard DIN-Schienen geeignet.

Montageposition: Auf senkrechten Flächen, mit dem Motoranschluss nach oben.

Dauerhafte Montage der Anzeigeeinheit ECD-002:

• ECD-002 kann jed erzeit montiert werden, auch wäh r end dem Betrieb .

• Die Anzeigeeinheit ECD-002 wird in Frontplatten

mit einem Ausschnitt von 71x29 mm montiert.

• Anzeigeeinheit vors

ichtig mit eingefahrenen

Halterungen in den Frontplattenausschnitt einschieben (1).

•

Beiliegenden Imbusschlüssel in die Löcher auf der

Frontseite ein

stecken und im Uhrzeigersinn drehen.

Die Halterungen treten aus dem Gehäuse hervor und

bewegen sich in Richtung Frontplatte (2).

• Imbusschraube

drehen bis die erste Halterung die

Frontplat te leicht berühr t. Dann zweite Halter ung

in diese Position bringen (3).

• Beide Seiten gleichmäßig und nicht zu fest

anziehen.

Hinweis: durch zu festes Anzieh en können die

Halterungen abbrechen.

Elektrischer Anschluss:

• Den elektrischen Anschluss gem. Verdrahtungsschema durchführen!

• Versorgungssp annung erst nach kompletter Installation anlegen!

• Gehäuse m it einem 6.3 mm Flac hstecker erden!

• Signalleitungen und Leitungen mit Netzspannung in getrennt en Kabelschächten

verlegen, Mindestabstand 30 mm!

• Für die 24 V Stromversorgung sind aussch ließlich Trans formatoren der Klass e II

zu verwenden . Die 24 V Leitun gen dürfen n icht geerdet werden. Wir emp fehlen

die Verwend ung jeweils separ ater EMERSON Tran sformatoren für EC3 Regler

und die Regler a nderer Herstelle r, weil unter Um ständen über die Er dleitungen

Kurzschl üs s e e nts tehen können.

• Vor der Inbetriebnahme des EC3 müssen die H aupt-Parameter eingestellt und der

24V-Digital eingang darf nicht am EC3 angeschlossen werden.

• Das Alarmrelais dient zum Schutz des Systems bei Stromausfall, wenn

Kommunikations-Schnittstelle oder ECD-002 nicht verwendet werden!

• Wird das Alarmrelais nicht verwendet, muss das System auf andere Weise vor

Schäden durch Stromausf all geschützt werden.

• Um das System vor Schäden durch Stromausfall zu schützen empfehlen wir einen

jährlichen Austausch des Akkus.

Verdichterbetrieb al s Funktion der Digitaleingänge und de s 0 . .. 10 V Eingangs

System

Betriebs-

zustand

Digitaleingänge

0…10 V Signal

vom externen Regler

V1 & V2

ausgeschaltet

“Cooling demand” offen (0 V)

“Comp 2 Running” offen (0 V)

EXV bleibt geschlossen, unabhängig

vom Eingangssignal.

V1 ein & V2

ausgeschaltet

“ Cooling demand” geschl

. (24 V)

“Comp

2 Running” offen (0 V)

EXV aktiv

Eingang =0

V: Dig. Ventilleistung =

10% der Nennl eistung.

Wenn der Dig.

Scroll nicht pumpt

- Leistung < 70%: EXV wird

geschlossen;

- Leistung > 7 0% : Öffnungsgrad

des EXV bleibt konstant.

V1 & V2

eingeschaltet

“Cooling demand” geschl

. (24 V)

“Comp

2 Running” geschl. (24 V)

EXV aktiv

EXV wird immer geregelt, auch

wenn dig. Scroll gerade nicht pumpt.

V1 aus &

V2 startet

“Cooling demand” offen (0 V)

“Comp 2 Running” geschl. (24 V)

EXV bleibt geschlossen, unabhängig

vom Eingangssignal.

Hinweis 1: V1 = Verdichter 1, V2 = Verdic hter2;

Hinweis 2: Der Digital Scroll muss immer als Gr undlastver d ichter 1 arbeiten.

Verdrahtung:

Kabelfarben: A: Weiß B: Schwarz C: Blau D: Braun

E: M12 Kabel-Steckereinheit EXV-Mxx zur Verbindung mit

EX4-6.

F:

24 V/230 V Triac-Ausgang zum PWM Magnetventil des Digital Scroll

G: Schaltschrank, Anlagenregler

H. Alarmrelais, Wechsler. I naktiv be i Alarm oder fehlender Stromversorgung

I:

Digitaleingang 1: “Cooling demand” (=Kühlanforderung: Digital Scroll Ein)

(0 V/offen = Stop; 24 V/zu = Start der Regelung)

J: Trafo Klasse II, 24 VAC Sekundär/ 25 VA

K: Anlagenregler (kann analoges Ausgangssignal von EC3 nutzen)

L: Relais für Abpump-Betrieb, potential freier Kontakt. Relais ist im Normal-

betrieb unte r Sp a n nung

M: Digitaleingang 2: “Comp 2 running” (=Verdichter 2 Ein)

(0 V/offen = Verdichter 2 Aus; 24 V/zu = Verdichter 2 Ein)

N: Sensor Austrittstemperatur Copeland® NTC

O: 0-10 V Digital Scroll Kapazitätsanforderungssignal vom Anlagenregler

P: ECN-N60 Temperatursensor

!

Page 7

Betriebsanleitung

EC3-D7x Digital Scroll Überhitzungsregler

EC3-D72 mit TCP/IP Schnittstelle

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Blinkt: Ventil schließt

AN: Ventil ist geschlossen

Blinkt: Ventil öffnet

AN: Ventil ist offen

Parameter Eingabe/Speicherung

Nächster Parameter/Wert (höher)

AN: Anforderung

AUS

: keine Anford.

Blinkt: arbeitet

AN: Alarm

AUS: kein Alarm

auswählen/bestätigen

Nächster

Parameter/Wert (tiefer)

Manuelle Rückstellung für

alle blinkenden Alarme

(PRG & SEL) 5s drücken

Vorbereitungen f ür Inbetriebnahme:

• Den gesamt en Kältekreisla uf vakuumieren.

• Hinweis: Elek trische Regelv entile von E MERSON EX4-6 werden halbgeöffnet

ausgeliefert. Den Kältekreislauf nur bei geschlossenem Ventil mit Kältemittel

füllen.

• Versorgungsspannung 24 V zu EC3 einschalten, der Digitaleingang bleibt bei 0 V.

Das Ventil wird zugefahren.

• Bei gesch l o ssenem Ventil S ystem mit Kältemittel füllen.

• System starten, Überhitz u ng und Betriebsbeding ung en überprüf e n .

ECD-002 Anzeige einheit: (Funktion der LEDs und Tasten)

Parametereinstellung mit der Anzeigeeinheit ECD-002:

• Hinweis: Einige der Funktionen/Parameter (Handbetrieb und TCP/IP

Konfiguration) sind nicht mit der Anzeigeeinheit einstellbar.

• Warnung:

während des Handbetriebs sind alle Alarme blockiert. Wir empfehlen daher

das System während des Handbetriebs nicht unkontrolliert zu lassen.

• Parameteränderungen sind mit der Gerätetastatur möglich. Die Konfigurations-

parameter s in d pa ss wort ges ch ü t zt. Das werk s s eit i g ei n ges t ellt e Pa ss wor t i s t “1 2 ” .

Zur Auswahl der Parametereinstellungen:

• PRG Taste länger als 5 Sek. gedrückt halten, ei ne blinkende "0" erscheint

• oder Taste drücken bis Passwort (Standardwert 12) angezeigt wird

• SEL drücken - Passwort wird bestätigt

• oder Taste d rücken bis der gewünschte Paramet er erscheint;

• SEL drücken - der aktuell eingestell te Wert wird an g ezeigt

• oder Taste drücken - der Wert wird vergrößert oder verkleinert

• SEL drücken - der eingestellte Wert wird vorläufig b ehalten, muss aber noc h

gespeicher t werden. Die Parameterkennung wird wieder an gezeigt.

• Zur Änderung weiterer Parameter wird dieser Ablauf wiederholt:

• oder Taste drücken - nächste Par am eterkenn un g auswähle n.

• Parameter speichern und Konfigurationsmodus beenden: PRG Taste drücken

• Parameter nicht speichern und Konfigurationsmodus ohne Parameter-

änderung beenden: Mindestens 60 Sekunden lang keine Taste drücken

(Zeitsperre)

Spezialfunktionen:

• und Taste länger als 5 Sek. gedrückt halten bis blinkende "0" erscheint

• oder Taste drücken bis das Passwort (Standardwert 12) angezeigt wird

• SEL drücken - Passwort wird bestätigt

“0” wird angezeigt und der Modus für Spezialfunktionen ist aktiviert

• oder Taste drücken und den Code der Funktion auswählen. Die Anzahl der

Sonderfun kt ionen ist dy nam is ch und reg lerabhängig:

0: Regler auf Werkseinstellung zurücksetzen (Reset).

(nur bei offenem Digitaleingang (O V) möglich)

1: Aktuelle TCP/IP Adresse anzeigen.

2: Dem Regler vorübergehend die Standard TCP/IP-Adresse 192.168.1.101

zuweisen, f alls di eser ein e andere Ad resse b esitzt . Nach dem Absch alten

wird die zuv o r eingestellte Ad r esse wieder aktiviert.

• SEL drücken - alle Parameter werden auf Werkseinstellung zurückgesetzt.

• PRG drücken - die gewählte Funktion wird aktiviert und die Betriebsart Spezial-

funktionen verlassen.

Parametertabelle:

(im Regler hinterlegte Reihenfolge)

Code Beschreibung und Wahlmöglichkeiten Min Max Werk Kunde

H5

Passwort

1

199

12 u0

Kältemittel

0

15 1

0 = R22 1 = R134a 2 = R507 3 = R404A

4 = R407C 5 = R410A 6 = R124

7 = R744 (unterkritische Anwendung) 8 = R407A;

9 = R407F 10 = R32* 11 = R448A 12 = R449A

13 = R450A 14 = R513A 15 = R1234ze

uP

Installierter Drucktransmitter

0 2 0

0 = PT5-07x

(für R22 / R134a / R5 0 7 / R 4 04A / R407A / R407C / R407F /

R124 / R448A /R449A / R450A / R513A / R1234ze)

1 = PT5-18x (für R410A/ R32)

2 = PT5-30x (für R410A / R744 / R32)

ut

Installier te s EMERS O N Re gelventil

1 3 2

1 = EX4 2 = EX5 3 = EX6

uu

Startöffnung des Regelventils (%)

10

100

50 u9

Startzeit für Ventilöffnung (Sekunden)

1

30

5 uL

Alarm bei zu niedriger Überhitzung

0 2 1

0 = deaktiviert (für überfluteten Verdampfer)

1 = automat. Rückstellung 2 = manueller Rückstellung

Alarm Ein bei 0.5K (wenn länger als 1 Minute unterschritten);

Alarm Aus bei 3K (ohne Zeitverzug)

u5

Überhitzungseinstellung (K)

wenn uL aktiviert (autom. oder manuell)

wenn uL deaktiviert

3

0.5

30

30

6

6

u2

MOP Funktion

0 1 1

0 = deaktiviert 1 = aktiviert

u3

MOP (°C) Sättigungstemperatur

* * **

**) Werkseinstellung abhängig vom gewählten Kältemittel (u0):

+13°C - R22 +15°C - R134a +7°C - R507

+7°C - R404A +15°C - R407C +15°C - R410A

+50°C - R124 -5°C - R744 +10°C - R407A

+10°C - R407F +10°C - R32 +12°C - R448A

+12°C - R449A +19°C - R450A +13°C - R513A

+24°C - R1234ze

*) Min. und Ma x. Einstellungen sind vom gewählten Kältemittel

abhängig

┌┘5

Einheiten

0 1 0

0 = °C, K, bar 1 = °F, R, psig

(Psig Werte geteilt durch 10. Bsp : Display 12.5 bedeutet 125 psig)

┌┘1

Angezeigter Wert

0

5 0

0 = gemess. Überhitzung (K) 1 = gemessener Verdampfungsdruck (bar)

2 = Ventilöffnungsgrad (%) 3 = gemessene Sauggas-Temperatur (°C)

4 = aus gemessenem Druck errechnete Verdampfungstemperatur (°C)

5 = Verdichterleistung in %

u4

Regelverhalten der Überhitzung

0 = Standard 1 = langsam

0 1 0

uH

Alarm hohe Überhitzun g

0 = abgeschaltet 1 = ein mit Auto Res et

1

uA

Alarm Überhitzung Einstellwert

16

40

30 ud

Alarmverzögerung Überhitzung, min.

1

15 3

P2

Frostschutz Ausschaltpunkt, °C

-40

40 0

P3

Frostschutz Einschaltpunkt, °C

-37

43 3

P4

Frostschutz Alarmfunktion

0 = abgeschaltet 1 = ein mit Auto Reset

2 = ein mit Hand Reset

0 2 0

P5

Alarmverzögerung Frost schutz, sec.

5

199

30

P6

Abpumpen Einstellung

0 = aus 1 = ein mit Auto Reset

0 1 0

P7

Abpumpen A uss chaltpunkt, barg

-0,5

18

0.5

P8

Abpumpen Zeitverzögerung, sek.

0

199

30

P9

Niederdruck-Alarm

0 = aus 1 = ein mit Auto Reset

2 = ein mit Hand Reset

0 2 0

PA

Niederdruck-Alarm Ausschaltp u nk t, barg

-0,8

17,7 0

Pb

Niederdruck-Alarm Zeitverzögerung, sek.

5

199 5

Pd

Niederdruck-Alarm Einschaltpunkt, barg

-0,5

18

0.3

Page 8

Betriebsanleitung

EC3-D7x Digital Scroll Überhitzungsregler

EC3-D72 mit TCP/IP Schnittstelle

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Code Beschreibung und Wahlmöglichkeiten Min Max Werk Kunde

L2

Ausgabe Logik

0 3 1

0: Alarm = normal, Abpumpen = normal

1: Alarm = invers, Abpumpen = normal

2: Alarm = normal, Abpumpen = invers

3: Alarm = invers, Abpumpen = invers

b1

Batterie-Fehlermanagement bei defekter

Batterie:

0 3 2

Wert Display-

Anzeige

Alarmrelais Ventilzustand

Möglichkeit zur

Rückstellung nach

Erholung/Austausch

0 - - regelt

-

1 Ab - regelt

-

2 Ab

signalisierend

geschlossen

automatisch

3 Ab (blinkt)

signalisierend

geschlossen

manuell

Wird das Alarmrelais nicht verwendet (b1 = 0 oder = 1), muss das

System auf andere Weise vor Schäden durch Stromausfall geschützt

werden.

/6

Dezimalpunkt anzeigen; 0=ja, 1 = nein

0 1 0 A6

Maximale Austrittstemp eratur; °C

100

140

130 A7

Austrittstemperatu r. Alarmverzug; Sek.

0

199

30 F2

Minimal-Leistung; %

10

100

10 F3

Maximal-Leistung; %

10

100

100 F6

Scroll Ventil, Zykluszeit; sec.

10

20

20

t3

Austrittstemperatu rfühler vorhanden

0 = nein, 1 = ja

0 1 0

*) Hinwe is für R 32: R32 ist in Europa als entflammbares Kältemittel eingestuft.

EC3-D7x ist nach den Richtlinien für nicht brennbare Kältemittel entwickelt.

Die Verwendung des EC3-D7x für R32 ist nur in Regionen zulässig in denen keine

zusätzlichen Sicherheitsvorschriften für R32 bestehen bzw. Anzuwenden sind.

EC3-D7x sind auch ohne Anzeigeeinheit ECD-002 betriebsbereit, diese kann auch

während des Betriebs ein- oder ausgesteck t werden.

Startverhalten der Regelventile: (Parameter uu und u9)

EX4/5/6 ≤ 1,5 Sekunden

Abpump-Fun ktion (wenn P6=1 und L2=1)

Digitaleingang

Alarm

Relais für Abpumpen

24 V (AN)

NEIN

aktiviert

0 V (AUS)

NEIN

deaktiviert, wenn der Druck unter

P7 abfällt und die für P8 eingestellte

Zeit vergangen ist

0 V oder 24 V

JA

deaktiviert

Vernetzung von EC3- D72 und PC-Anbindung:

• Ausführlichere Informationen als hier beschrieben zur Einrichtung eines Ethernet

Netzwerkes stehen in der "TCP/IP Controller-Readme" Datei, die im Internet unter

www.emersonclimate.eu abgerufen werden kann.

• EC3-D72 mit dem optio nal en K abel ECC-N xx o der ha nde lsübl iche m C AT 5 K abel

mit RJ45 Stec kern am Netzwerk od er Router anschl ießen, da mit der R egler eine

dynamische TCP/IP-Adresse erhält, oder

• EC3-D72 mit einem Crossover-Kabel direkt am Ethernet Anschluss des

Computers ein st ecken . In di esem Fal l mus s di e TCP/ IP Adress e des P Cs manu ell

auf die Standardadresse des Reglers umgestellt werden. Einzelheiten hierzu

entnehmen S ie bitte der "TCP/IP Controller-R eadme" Datei.

Parametereinstellung und Datenanzeige auf Webseiten:

(empfohlene Methode)

• Während am Digitaleingang 0V anliegen Versorgungsspannung anschalten.

• Die vier Par ameter Kältemittel (u0), Drucksensor-Typ (uP), Ventil-Typ (ut) und

Kontroll mo de k önne n n ur ei ng es te ll t we r den, w enn d er D ig ital e ing ang o ffe n ( 0 V)

und die Versorgungsspannung AN (24 V) ist. Dies e Sic herhe itsfun ktion ver hinder t

die Beschädigung des Verdichters oder anderer Systemkomponenten. Alle anderen

Parameter können jederzeit verändert werden.

• Der EC3-D72 kann mit seiner TCP/IP Ethernet-Schnittstelle direkt an den

Ethernetanschluss eines PCs oder an ein lokales Netzwerk angeschlossen werden.

Übersicht liche Web seiten , auf den en die Para meterli sten angezeig t oder g eändert

werden können sind bereits eingebaut.

• Zur Darstellung der Internetseiten auf dem PC genügt ein Standard

InternetBr owser wie Int ernet Exp lore r® oder Mozi lla Fi refox und zusä tzli ch ein e

installierte Version der JRE Java Runtime Environment. JRE kann kostenlos von

der www.java.com

. Internetseite heruntergeladen werden.

• Am PC wird d er WebBrowser gestar tet und entweder die S tandardadresse d es

Reglers eingegeben (192.168.1.101), ode r die dy nami sc he A dre s se , die de r D HCP

Server vergeb en ha t. Weitere Hi nwei se sind in der "TCP /IP Cont roller-Readme"

Datei zu find en, falls ein spezieller Por t vergeben wer den muss od er die DHCP

Adresse ausgelesen werden soll

• Nach wenigen Sekunden erscheint die Monitorseite des Reglers (Homepage). Falls

diese Seite n icht erscheint, o der falls keine dynamischen Werte angezeigt werden,

müssen die "Opt ionen" des WebBrowsers ü berprüft werden. Weit ere Hinweise

dazu stehen i n der "TCP/IP Controller-Readme" Datei.

• Die Monitor- und Alarmseite lässt sich nicht änder n und ist daher nicht geschützt.

Beim erstmaligen Zugriff auf eine der anderen Seiten werden die Benutzerkennung

und ein Passwor t abgefragt. Ab Werk sind folgende Werte eingestellt:

Username: EmersonID Password : 12

• Auf der Seit e "Display Kon figura tion" lass en sich di ese Werte änd ern. Zu dies er

Seite gelangt man, indem man mit dem Mauszeiger über die entsprechende Schaltfläche oben an de r Monitorsei te fährt und dan n die linke Maustaste drückt.

• Die Parameter werden sowohl in Textform, als auch mit dem Code aus der

Parametert abelle oben an g ezeigt.

• Alle Einstellungen können auf dem PC gesichert und gegebenenfalls in einen

weiteren Controller geladen werden. Dies spart viel Zeit, wenn mehrere Regler mit

den gleich en Einstellungen eingesetzt werden . Im Laufe der Zeit lässt sich eine

kleine Bibliothek aufbauen, in der die Reglereinstellungen für unterschiedliche

Anwendungen gespeichert sind.

• Der zeitliche V er l auf v on Überhitzu ng , V e rdam pf ung sdr uc k und T e mpe ra tur ka nn

grafisch in ei nem rolli erenden 15 Minuten Zeitrast er dargest ellt werd en. Weit ere

Einzelheiten siehe "TCP/IP Controller-Readme" Datei.

!

Sec.

uu

u9

%

EC3-X3 BA.c dr

Page 9

Betriebsanleitung

EC3-D7x Digital Scroll Überhitzungsregler

EC3-D72 mit TCP/IP Schnittstelle

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Alarmanzeigen und Fe hlerbehebung:

Alarm

Code

Fehler

Beschreibung

Abhängiger

Parameter

Alarm

Relais

Ventil-

zustand

Fehlerlösung

Manuelle Rückstellung

nach Fehlerbehebung

notwendig

E0

Drucktransmitter

Fehler

- signalisierend geschlossen Verdrah t ung prüfen und 4 bis 20 mA Signal messen. Nein

E1

Temperatursensor

Fehler

- signalisierend geschlossen Verdrah t ung prüfen und Widerstand des Sensors messen. Nein

E3

Störung

Austrittstemperatur-

fühler

-

signalisierend

regelt

Verdrahtung prüfen und Widerstand des Sensors messen.

Falls kein Fühler eingesetzt, muss Parameter t3 au f 0 stehen.

Nein

AΠ

EXV Fehler

elektrischer

Anschluss

- signalisierend unbekannt

Verdrahtung prüfen und Widerstand der Wicklung messen.

Nein

Ab

Batteriefehler

b1: 1 - regelt

Batterieladung zu schwach für Schließen des Ventils bei

Stromausfall. Kann bei neuen Reglern oder langer Lagerzeit

auftreten und sollte nach ausreichender

Aufladung der Batterie

verschwinden. Ansonsten defekte Batteri e er setzen

(Austauschkit Best.-Nr. 807 790).

Nein

Ab

b1: 2 signalisierend geschlossen Nein

Ab blinkt

b1: 3 signalisierend geschlossen Ja

AE blinkt

Abpumpen ka nn

nicht vollendet

werden

P6: 1 signalisierend -

Herausfin de n weshalb der Saugdruck nich t un ter den

eingestellten Wert absin k t.

Ja

AF

Frostschutz

P4: 1

signalisierend

geschlossen

Ursache für zu niedrigen Druck wie z.B. unzur eichende

Verdampferfüllung ermitteln.

Nein

AF blinkt

P4: 2

signalisierend

geschlossen

Ja

AL

Überhitzung zu

niedrig

(<0,5K)

uL: 1

signalisierend

geschlossen

Verdrahtung prüfen und Funktionsprüfung des Ventils

durchführen.

Nein

AL blinkt

uL: 2 signalisierend geschlossen Ja

AH

Hohe Überhitzung

uH: 1

signalisierend

geschlossen

System auf Fehler überprüfen.

Nein

AP

Niedriger Druck

P9: 1

signalisierend

geschlossen

Ursache für zu niedrigen Druck wie z.B. Kältemittelverlust

ermitteln.

Nein

AP blinkt

P9: 2

signalisierend

geschlossen

Ja

dA

Hohe Austritts-

temperatur

A6: alarm

setpoint

signalisierend

Geschlossen;

Abpumpen

inaktiv

System auf Fehler überprüfen

Nein

Feste Differ enz = 10°C

Er

Daten außer halb des

Anzeigebereichs

- - -

Display kann Daten nicht darstellen, Einstellwert der

Parameter verändern.

Nein

---

Keine Daten - - -

Kable- und Steckerverbindungen zwischen EC3-D7.. u nd

ECD-002 prüfen.

Nein

Hinweis: Bei mehreren Alarmen gleichzeiti g wird der Alarm mit der höchsten Pri orität angezeigt, nach dessen Beseitigung wird der nächsthöhere angezeigt usw., bis alle

Alarme beseitigt sind. Danach werden wieder die Parameter angezeigt.

Überprüfung der Be triebsbedingungen mit E CD-002:

Die am Display permanent angezeigten Daten werden vom Anwender durch Parameter ┌┘1 bestimmt. Gleichzeitig können andere Daten vorübergehend am Display

angezeigt werd en, s ofern k ein Alarm vorli egt. Da s Disp lay zeigt n ach D rücken von SEL zuerst für 1 Sekunde den Code für den jeweiligen Wert (s. Parameter ┌┘1) und

dann die Daten. Nach 5 Minuten werden wieder di e permanenten Da ten angezeigt.

Service/Fehlersuche:

Fehlerbeschreibung Ursache Aktion

Überhitzung ist einige Grad höher oder niedriger als der

eingestellte Sollwert

Fehlerhaftes Signa l von Druck- oder

Temperatursensoren

1- Sensor überprüfen

2- ECN-N60 Temperatursensor einsetzen

3- EMERSON Drucktransmitter verwenden:

PT5-07x (für R22 / R134a / R507 / R404A / R407A / R407C /

R407F / R124 / R 4 48A /R449A / R450A / R513A /

R1234ze)

PT5-18x (für R410A/ R32)

PT5-30x (für R410A / R744 / R32)

4- Sensorkabel nicht zusammen mit stromführenden Leitungen

verlegen

Überhitzung ist zu niedrig, Verdichter läuft nass

1- Ventile falsch angeschlos sen

2- Defekter Sensor

1- Verdraht ung ü b e r prüfen.

2- Sensor überprüfen.

Ventil ist nicht vollständig geschlossen

1- Digitaleingang ist EIN (24 V)

2- Falsche Einstellung für Parameter ut

1- Ventil schließt nur, wenn der Digitaleing ang A US ist (0 V).

2- Einstellung für Parameter ut überprüfen.

Schwankende Überhitzung

eingesetzter Verdampfer ist für

höhere Überhitzung ausgelegt

Einstellwert für Überhitzung vergrößern.

Ventil öffnet, wenn EC3 Befehl zum schließen gibt

und umgekehr t

Fehlerhafte Verdrahtung zwischen

EC3-D7.. und Ventil

Verdrahtung gem. Verdrahtungsschema durchführen.

Überhitzungseinstellung verändert sich nach einigen

Monaten ununterbrochenen Betriebs- od er bei

Permanenterüberbrüc ku n g des 24 V Digitale ing a ng s

Ventile mit Schrittmotor erfordern

Synchronisation

Am 24 V Digitaleingang nicht dauerhaft Spannung anlegen; wenn

Verdichter u nunterbroch en läuft, Digitaleingang ein mal je Woche

für 5 Sekunden unterbrechen.

Page 10

Betriebsanleitung

EC3-D7x Digital Scroll Überhitzungsregler

EC3-D72 mit TCP/IP Schnittstelle

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 18.07.2017 EC3-D7x_OI_ML_R06_865019.docx

Technische Daten:

Versorgungsspannung

24 VAC ±10%; 50/60 Hz; 1 A

Leistungsaufnahme 25 VA max, inklusive EX4-6

Anschlüsse

Steckbare Schraubklemmen für Adern mit max.

0,14…1,5 mm2 Querschnitt

Erdungsanschluss für 6.3 mm Flachstecker

Schutzklasse

IP20

COM, TCP/IP Anschluss

RJ45 Ethernet

Verbindung z u EC D -002 (optional)

ECC-Nxx oder CAT5 Kabel mit RJ45 Anschlüssen

Digitaleingänge

Kühlanforderung (Cooling Demand)

0/24 VAC/DC zum Ein- bzw. Ausschalten durch einen Thermostat oder einen externen Regler.

Das EX Ventil wird bei Stopp geschlossen.

Digitalei ngang, Verdich ter2 läuft

(Comp 2 runni ng )

0/24VAC/DC zum Anschluss eines Hilfskontaktes.

Bei 24 V bleibt das EX Ventil akt iv, auch wenn der Digital Scroll i m Leerlauf arb eitet.

NTC Analogeingang

EMERSON Temperatur sensor ECN-N60 /ECN-P60

NTC Analogeingang für

Sensor Austrittstemperatur

Copeland® NTC 86 kOhm bei 2 5 ° C

4-20 mA Analogeingang EMERSON PT5 Drucktransmitter

4-20 mA Analogausgang

Abweichung vom Eingangs signal

für externen Regler mit 12/24 VDC Speisesp annung und geeignetem internen Widerstand

± 8% max.

Ausgang Alarmrelais

(wenn L2 = 1) Aktiviert

Inaktiviert:

Wechsler (für 24 VAC/DC), Induktive Last: 2 A

bei Normalbetrieb (kein Alarmzustand)

im Alarmzustand oder bei ab g eschalteter Sp annung

Ausgangsrelais abpumpen

(wenn L2 = 1) aktiviert:

deaktiviert

Wechsler (für 24 VAC/DC), Induktive Last: 2A

bei Normalbetrieb

bei allen an deren Betriebs zuständen

Triacausgang Digital Scroll

24V oder 230V AC zum Betätigen des PWM Ventils am Digital Scroll

Temperaturbereich

0…+60°C

+1…+25°C (für optimale Batterielebensdauer)

> 35°C Batter ielebensdauer < 2 Jahre

Kennzeichnung

,

Abmessu ngen [mm]:

EC3-D7x ECD-002

Loading...

Loading...