Page 1

Operating instruction

!

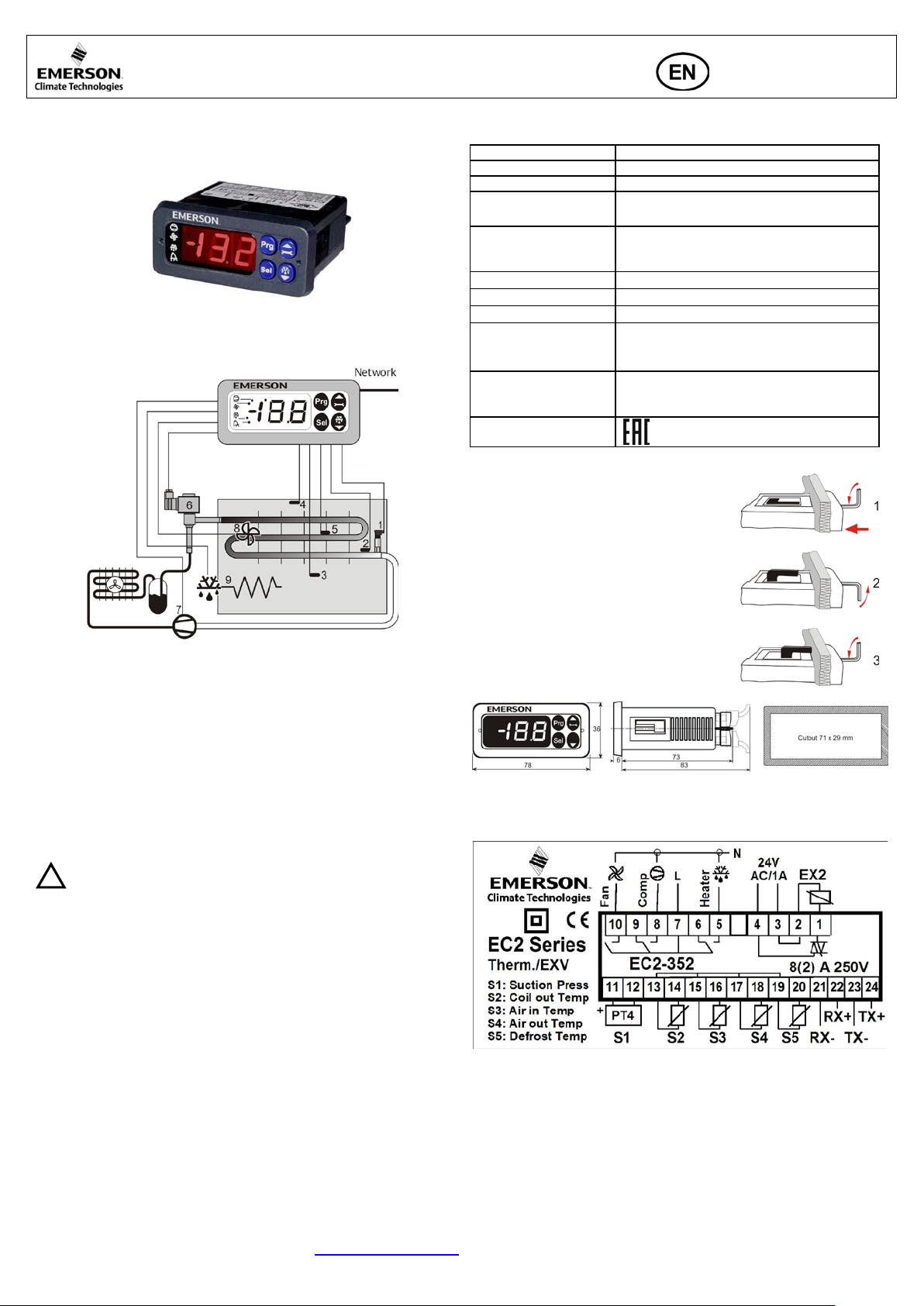

Power supply

24VAC ±10% ; 50/60Hz; Class I I

Power consumption

20VA max including EX2

Communication

TCP/IP Ethernet 10MBit/s

Plug-in connector size

Removable screw terminals

Temperature

operating

0 … +60°C

Humidity

0…80% r.h. non co ndensing

Protection class

IP65 (front protection with gasket)

Pressure transmitter input

24VDC, 4...20mA

Output relays (3)

SPDT conta cts, AgCdO

Inductive (AC15) 250V/2A

Resistive (AC1) 250V/8A; 12A total return current

Triac output for EX2

Coil (ASC 24V only)

24V AC, 0.1 … 1A

The EC2-352 can be mounted in panels with a 71 x

29 mm cutout. See dimensional drawing below for

Make sure that mounting lugs are flush with outside

allen key into front panel holes and turn

clockwise. Mounting lugs will turn and gradually

Turn allen key until mounting lug barely touches

panel. Then move other mounting lug to the same

y until controller is

secured. Do not over ti ghten as mounting lugs will

break easi ly.

EC2-352 Display Case and Coldroom Controller

Note: This document contains short form instructions for experienced users.

Use last column in List of Parameters to document your individual settings.

More detailed information can be found in the User Manual.

Technical Data:

EC2 Series Controller

wire size 0.14 … 1.5 mm2

The EC2-352 is a dedicated refrigeration controller with superheat and a driver for

an Alco Controls El ect ric C ontrol Va lve E X2 . In ad di tion th e EC2-352 controls air

temperature and manages defrost and fan (s ).

A PT5 pressure transmitter (1) and an ECN-Pxx pipe temperature sensor (2)

measure saturated suction gas pressure and suction gas temperature at the

evaporator outlet and feed the signals into the superheat control loop. The

superheat controller output modulates the opening of the EX2 pulse width

modulated Elec trical Control Valve ( 6) thus optimizing the refrigerant mass flow

through the evaporator. The ECN-Sxx air temperature sensors (3) and (4) measure

air-in and out temperature of the evaporator and feed signals into the air

temperature thermostat. The ECN-Fxx fin sensor (5) is used for defrost

termination. The controller has 3 relay outputs to control the compressor (7),

defrost heater (9) and evaporator fan (8). Please consult the technical data (right)

for input and output ratings.

In case of power loss, due to the positive shut-off characteristics of the EX2

Electrical Control Valves, a liquid line solenoid valve is not needed to prevent

flooding of the compr essor.

storage

-20 … +65°C

Electrical Control Valve

Marking

Mounting:

space requirements including rear connectors.

Push controller in to panel cutout.(1)

of controller housing

Insert

move towards panel (2)

position (3)

Tighten both sides very carefull

Electrical Installation:

Refer to the electrical wiring diagram (below) for electrical connections. A copy of

this diagram is labeled on the controller. Use connection wires/ cables su itable for

90°C operation (EN 60730-1)

Safety instruc tions:

• Read installation instructions thoroughly. Failure to comply can result in

device failure, system damage or personal injury.

• The product is intended for use by persons having the appropriate

knowledge and skills.

• Ensure electrical ratings per technical data are not exceeded.

• D iscon nect all voltages from system bef o re ins ta llation.

• Keep temperatures wit h in n ominal limits.

• Comply with local electrical regulations when wiring

EC2 analog inputs are for dedicated sensors only and should not be connected to

any other devices. C onnecting any EC2 inpu ts to mains voltage will per manently

damage the EC2.

Important: Keep controller an d sensor wiring well separated from mains wiring.

Minimum re commended distance 30mm.

Warning: Use a class II category transformer for 24VAC power supply (EN

60742). Do not ground the 24VAC lines. We recommend to use one transformer

per EC2 controller an d to use separate transformers for 3

rd

party controllers, to

avoid possible interference or grounding problems in the power supply. Connecting

any EC2 inputs to main s voltage will permanently dam age the EC2.

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 15.06.2016 EC2-352_OI_EN_R07_864925.doc

Page 2

Operating instruction

Ethernet activity LED

(only active when service pin is pressed)

IR LED

EC2-352 Display Case and Coldroom Controller

Recommended Senso r Positi ons in Deta il:

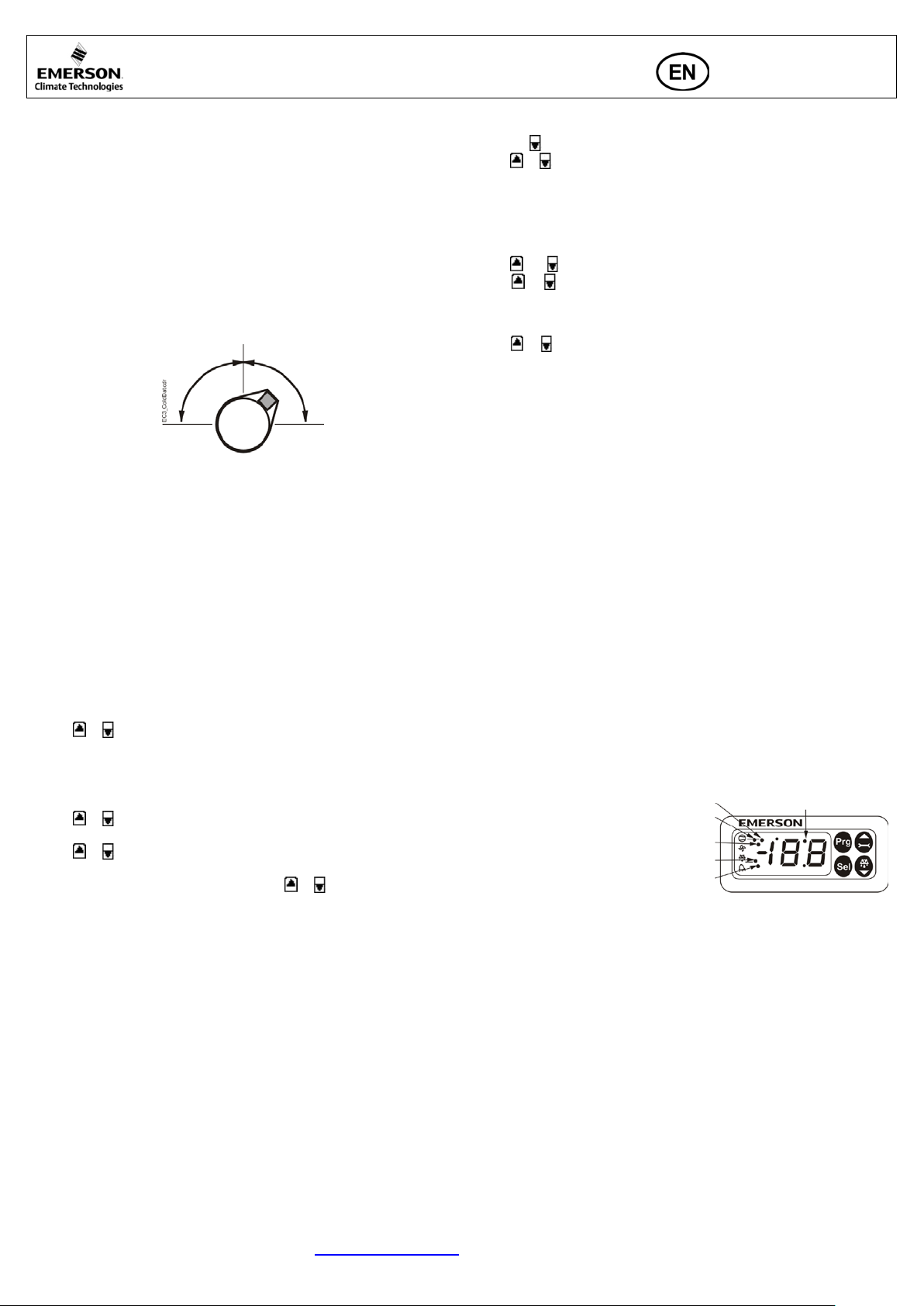

(2) ECN-Pxx coil-out temp eratur e sensor: Posi tion di rectly aft er the evap orator on

the common suction line.

(3) ECN-Sxx air-in temperature sensor: Position in the middle of the cabinet as

high as possible.

(4) ECN-Sxx air-out temperature sensor: Position asymmetric closer to the

expansion valve as hi gh as possible.

(5) ECN-Fxx fin temperature sensor: Position on the evaporator, asymmetric closer

to the expansion va lve.

Recommendations for mounting the pipe sensor: Insure proper thermal contact by

using a metallic pipe clamp or temperature resistant plastic straps. Do not use

standard plastic tie wraps (as used for electrical wiring) as they may become loose

over time, which could result in faulty temperature measurements and poor

superheat control performance. It is recommended to insulate the pipe temperature

sensor with ARMAFLEX™ or equivalent. The recommended position of the pipe

sensors is between 9 and 3 o’clock as shown in the picture.

(1) PT5-07M suction pressure transmitter: Position on the common suction line

close to coil-out temperature sensor (2)

Both air tem perature s ensors shou ld be mount ed on spacers i n the air duct so that

there is airflow around.

Caution: The sensor cables can be extended if necessary. The connection must be

protected against water and dust.

The evaporator outlet temperature sensor should be mounted on the common

suction header of the eva porator.

A calibration correction can be made using the parameter u1 (see procedure

below).

Setup and Paramete r Modifi cation Usi ng the Keypad

For convenience, an infrared receiver for the optional IR remote control unit is

build-in, enab ling quick and eas y modification of th e system parameters wh en a

computer interface is not available.

Alternatively, the parameters can be accessed via the 4-button keypad. The

configuration parameters are protected by a numerical password. The default

password is “12”. To select the parameter configuration:

• Press the PRG button for more than 5 seconds, a flashing “0” is displayed

• Press

or until “12” is displayed (password)

• Press SEL to confirm password

The first mo d ifiable pa r ameter code is displayed (/1).

To modify parameters see Parameters mo dification below.

Parameter Modification: Procedure:

• Press

or to show the code of the parameter that has to be changed;

• Press SEL to display the selected parameter value;

• Press

or to increase or decr ease the value;

• Press SEL to temporarily confirm the new value and display its code;

• Repeat the procedure from the beginning "press

or to show..."

To exit and save the new settings :

• Press PRG to confirm the new values and exit the parameters modification

procedure.

To exit without modifying any parameter:

• Do not press any button for at least 60 seconds (TIME OUT).

• Press “ESC” on IR remote control.

Defrost Activation:

A defrost cyc le can be activated locally from the keypad:

• Press the

• Press

button for more than 5 sec onds, a flashing “0” is displaye d

or until “12” is displayed (password)

• Press SEL to confirm password

The defrost cycle is activated.

Special Function s:

The Special F unctions can be ac tivated by:

• Press

• Press

and together f or m or e than 5 seconds, a flashing “0” is displayed.

or until the password is displayed (default = 12). If password was

changed, s elect the new pa ssword.

• Press SEL to confirm password, a “0” is displayed and the Special Function

mode is activated.

• Press

or to select the function. The number of special functions is dynamic

and controller dependent. See list below.

• Press SEL to activate the function without leaving the special functi on mode.

• Press PRG to activate the fu nction and leave the speci al function m o de.

Most of the Special Functions work in a toggle mode, the first call activates the

function , and the second call deactivates the function.

The indication of the function can only be displayed after exiting the special

function mode.

• 0: Display test function

• 1: Clear alarm messages

• 2: Cleaning mode. The cleaning mode is effectively a manual defrost with the

option of the fans on/off. The cleaning mode should not be used in order to

isolate the applicatio n for maintenance purposes.

• 3: Fans only

• 4: Set the electronic control valve to 100% open

• 5: Displays the current TCP/IP address

• 6: Set the controller's TCP/IP address to 192.168.1.101 (default value). This

change is only temporary. A power down will reset the previous address.

• 7: Resets all parameters to the factory default setting. The controller will

indicate “oF” during the reset and the va lv e will close.

Display of Data:

The data to be permanently shown on the display can be selected by the user

(parameter /1). In case of an alarm, the alarm code is displayed alternately with the

selected data. The user can inhibit the alarm code.

It is possible to temporarily display these values. This is a useful feature when

initially setting-up the system without the aid of the WebPages. Press the SEL

button to scroll through all possible displayable data.. The display will show for

one second the numerical identifier of the data (see /1 parameter) and then the

selected data. After two minutes the display will return to the by parameter /1

selected data. This action is only valid when parameter H2 = 3.

Logical status of compressor relay

Logical status of fan relay

Logical status of defrost heater relay

Alarm condition

Am Borsigturm 31 I 13507 Berlin I Germany Date: 15.06.2016 EC2-352_OI_EN_R07_864925.doc

Emerson Climate Technologies GmbH www.emersonclimate.eu

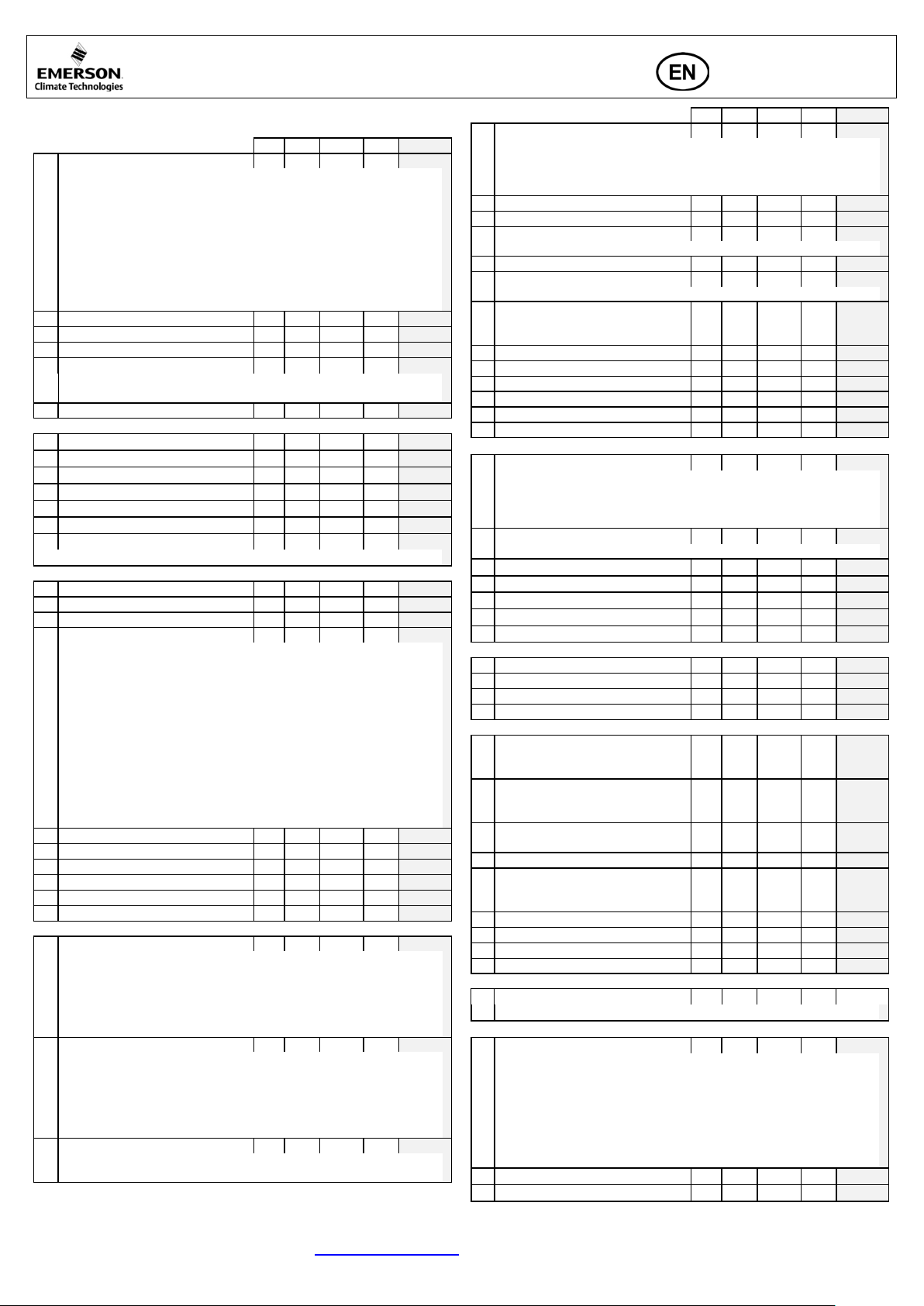

Page 3

/

DISPLAY PARAMETERS

Min

Max

Unit

Def.

Custom

/1

Value to show

0 9 - 0

0 = Thermostat control temperature with Temp. alignment /C

9 = Displays defrost status

/2

Alarm suppression 0 = off, 1 = on

0 1 - 0

/5

Temperature Unit 0 = °C, 1 = °F

0 1 - 0

/6

Decimal point 0 = yes, 1 = no

0 1 - 0

/7

Display dur in g defrost

0 2 -

0

0 = dF (= defrost mode); 1 = dF + defrost termination temp.

2 = dF + control temperature

/C

Temperature alignment for /1=0

-20

20

K / °F

0.0 A

ALARM PARAMETERS

A0

Mean factor alarm temperature

0

100 % 100

A1

Low temp alarm delay

0

180

min

5

A2

High temp alarm delay

0

180

min

5 A3

Alarm delay after defrost

0

180

min

10

AH

High temp alar m limit

AL

70

°C / K

40

AL

Low temp alarm limit

-55

AH

°C / K

-50

At

Alarm limit ty pe

0 1 - 0

0=absolu te temperatur es °C; 1= relative temperatures K to setpoint

r

THERMOSTAT PARAMETERS

r1

Min setpoint

-50

r2

°C

-50 r2

Setpoint max

r1

60

°C

40 r3

Day/night control 0 = off, 1 = on

0 1 - 1

r4

Thermostat mode

0 4 - 1

0 = off, no thermostat function, continues cooli ng air in sensor

sensor monitoring off. Temp. alarm s wil l be generated

r6

Setpoint night

r1

r2

°C

4.0 r7

Differential night

0.1

20.0 K 2.0 r8

Mean factor, day operat ion

0

100 % 100 r9

Mean factor, night operation

0

100 % 50 rd

Differential day

0.1

20.0 K 2.0 St

Setpoint day

r1

r2

°C

2.0 d

DEFROST PARAMETERS

d0

Defrost mode

0 2 - 1

0 = natural defrost, defrost heater not activated

defrost termin a t io n us i ng nv iS t a r tU p v ia SN MP

d1

Termination by:

0 3 - 0

0 = termination by tem perature,

3 = last, by time and temperature, no alarm

d2

Defrost terminati on sensor

0 1 - 1

0 = Dedicated defrost sensor must be installed

1 = Air-out sensor used for defrost termination

Min

Max

Unit

Def.

Custom

d3

Pulsed defrost

0 1 - 0

0 = off, no pulsed defrost, heaters switched off at defrost termination

dH and switched on again at dH – dd

d4

Defrost at startup 0 = no, 1 = yes

0 1 - 0

d5

Delay power up defrost

0

180

min

0

d6

Pump down de l a y

0

180

sec 0

Compressor will run during pump down delay while valve is closed

d7

Drain delay

0

15

min

2 d8

Injection del ay

0

180

sec 0 Valve is open during injection delay while compressor is not running

d9

Demand defr ost mode

timed defrost

0 2 - 0

dd

Pulsed defrost differential

1

20 K 2 dH

Pulsed defrost setpoint

-40

dt

°C 5

dt

Defrost termination temperature

-40

90

°C 8

dP

Max defrost duration

0

180

min

30 dI

Defrost interval

0

192 h 8 du

Start up delay after synch

0

180

min

30

F

FAN PARAMETERS

F1

Fan startup by: 0 = on

0 4 - 0

1 = delayed by time Fd, error on temperature

4 = last, time and tempera t ure must come, no alarm

F2

During no cooling

0 2 - 0

0 = on; 1 = off; 2 = delayed by F4; 3 = off, when door open

F3

During defrost 0 = on, 1 = off

0 1 - 0

F4

Stop delay time

0

30

min

0 F5

During cle aning 0 = off, 1 = on

0 1 - 0

Fd

Fan delay after defrost

0

30

min

0

Ft

On temp after defrost

-40

40

°C 0

C

COMPRESSOR PARAMETERS

C0

Delay first start after power up

0

15

min

0 C1

Cycle time

0

15

min

0 C2

Min. stop time

0

15

min

0 C3

Min. run time

0

15

min

0 u

SUPERHEAT PARAMETERS

u0 Refrigerant 0 = R22 1 = R134a

5 = R410A 6 = R124 7 = R744

0 7 - 3

u1

Correction glide / dp

Pressure dr op = negativ e v alues

-20.0

20.0 K 0.0

u2

MOP control

0 = MOP of f, 1 = MOP on

0 1 - 0

u3

MOP temperature

-40

40

°C 0

u4

Superheat mode 0 = off

2 = adaptive s u perheat

0 2 - 1

u5

Superheat init setpoint

u6

u7 K 6 u6

Superheat setpoint min.

3

u7 K 3 u7

Superheat setpoint max.

u6

20 K 15 uu

Start opening

25

75 % 30

P

ANALOG SENSOR PARAMETERS

P1

Pressure sensor type sel ection

0 2 - 0 0 = PT5-07M; 1 = PT5-18M; 2 = PT5-30M

H OTHER PARAMETERS

H2

Display access

0 4 - 3

0 = all disabled (Caution, access to controller only via the TCP/IP Ethernet

Control setpoint with SEL key and manual defrost enabled.

H3

IR access code

0

199 - 0 H5

Password

0

199 - 12

List Of Parameters

EC2-352 Display Case and Coldroom Controller

1 = Air-in temperature °C

2 = Air-out temperature °C

3 = Alarm temp er ature °C

4 = Defrost termination temperature °C

5 = Coil-in temperature °C calculated from the pressure

6 = Coil-out temperature °C

7 = Calculated superheat °K

8 = Valve opening in %

Operating instruction

temperature dt or max. time dP whatever is selected

1 = on, pulsed defrost, dd and dH in use, heaters are switched off at

0 = off, 1 = on, 2 = on together with

2 = by temperature Ft, error on time

3 = first, whatever comes first time or temperature, no alarm

monitoring off, no t emp. alarms generated

1 = cooling, deadband control

cut in = set-point + difference

cut out = set-point

2 = cooling, modulating thermostat

cut in = set-p oint

cut out = set-point – difference /2

3 = heating, deadband control

2 = R507 3 = R404A 4 = R407C

cut in = set-point – difference

cut out = set-point

4 = on, external control using nvi Valve via SNMP. Air in and air out

Glide = positive values

1 = fixed superheat

pulsed defrost not possible

1 = forced defrost, defro st heater activated, pulsed

defrost possible

2 = forced defrost, defro st heater activated, pulsed defrost possible,

termination by time will generate an alarm

1 = termination by time ,

terminat ion by temperature will generate an ala r m

2 = first, what ever comes first time or temperature, no alarm

network possible)

1 = Keyboard enabled

2 = IR remote control enabled

3 = Keyboard and IR remote control; Temporary data display and manual

defrost enabled.

4 = Keyboard and IR remote control; Temporary data display disabled.

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 15.06.2016 EC2-352_OI_EN_R07_864925.doc

Page 4

Operating instruction

EC2-352 Display Case and Coldroom Controller

Formula for Mean Factors A0, r8, r9

Temperature calculation by the following formula:

Temperature = Air

* (1 - Mean Factor / 100) + Air

in

* Mean Factor / 100

out

Examples:

Mean factor = 0 Temperature = Air in

Mean factor = 100 Temperature = Air ou t

Mean factor = 50 Temperature = Average between Air-in and Air-out

Alarm Codes

E0 Pressure sensor alarm

E1 Coil out sensor alarm

E2 Air-in sensor alarm This Alarm Code is inhibited if no air-in sensor used

(A0, r8 and r9 = 100)

E3 Air-o ut s enso r alar m This Alarm Code is inhibited if no air-out sensor used

(A0, r8 and r9 = 0) and fin sensor installed (d2 = 1)

E4 Fin sensor alarm This Alarm Code is inhibi ted if no fin sensor used (d2 = 0)

Explanations for E0 … E4 Alarms: No sensor connected, or the sensor and/or the

sensor cable is broken or short-circuited.

Er Data erro r disp la y - ou t of range

Data send to the display is out of range.

AH High temperature alarm

AL Low temperature al a rm

AE Thermostat emergency operation

Air sensor failure, system is in continuous cooli ng mode

AF Valve Status

Valve closed due to compr essor safety loop active

Ao Superheat, emergen c y operation

Sensor(s) failure

Ar No refrigerant flow detected

No refrigera nt flow was detected

Au Valve open 100% for more than 10 minutes

dt Forced defrost termination (time or temperature)

Ft Forced fan startup (time or temperature)

Messages

--- No data to display

The display will show an “---” at node start up and when no data is send to

the display.

In Reset to default values activated

The display will show an “In” when the factory default configuration data set

is initialized.

Id Wink request received

The display will show a flashing “Id” when the wink request was received.

The flashing “Id” will be shown on the display until the service button will

be pressed, or a 30 min delay timer will expire or a second wink request is

received. This function is action only when using SNMP protocol

OF Node is offline

The node is offline and no application is running. This is the result of a

network management command and will happen for example during node

installation.

dS Defrost standby

dP Pump down

dF Defrost cycle

dd Defrost drain delay

dI D efr ost inj ection delay

du Defrost start-up delay

Cn Cleaning

CL A larms are cl eared

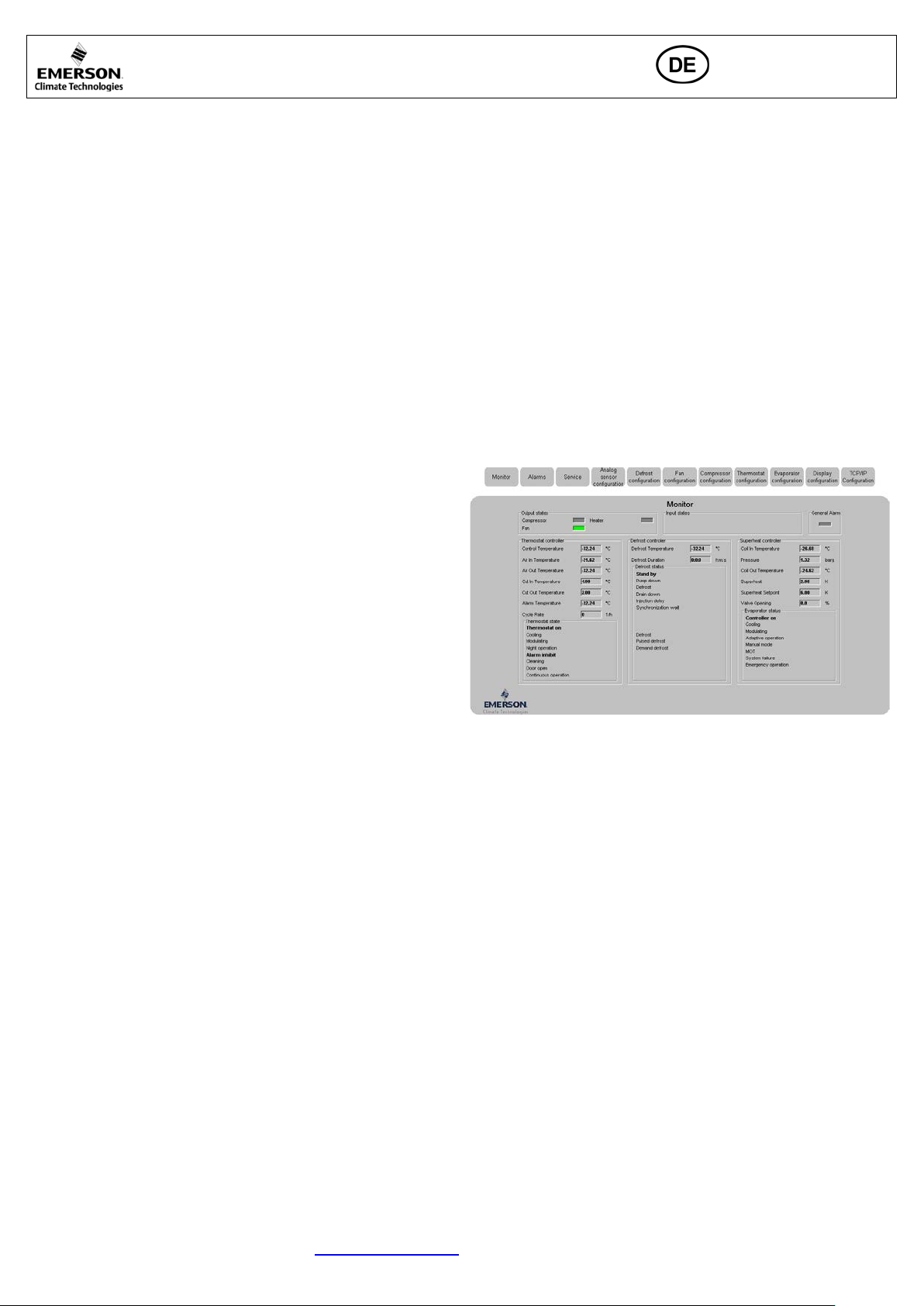

Visualising Data : WebPages

A TCP/IP Controller-Readme file is available on the www.emersonclimate.eu

website

to provide detailed information about TCP/IP Ethernet connectivity. Please refer to this

file if you need info rm ation bey ond the conte nts of this instr uction s hee t.

The EC2-352 has a TCP/IP Ethernet communication interface enabling the

controller to be direct ly connected to a PC or network via the standard Eth ernet

port. The EC2-352 controller h as emb edd ed WebPages to ena ble th e user t o easi ly

visualise the parameter lists using real text labels.

No special software or hardware is required .

Connect t he EC2-352 using the optional ECX-N60 cable assembly to a network or

hub that enables the controller to receive a dynamic TCP/IP address. If a DHCP

server is not available, the controller can be connected to a computer using a

crossover cable plugged directly into the Ethernet port. In this case, the TCP/IP

address of the computer must be manually modified to be compatible with the

default ad dress of th e cont roller. Refer to th e TCP/IP Co ntroller -Readme file for

more detai l s.

Open the Internet browser program on the compu ter and enter th e default TCP /IP

address of the controller into the address line of the Internet browser: 192.168.1.101

or the dyna mic address from the DHCP server. Refer to th e TCP/IP Controller-

Readme file if a specific port is required.

After a few moments, the default monitoring page should be displayed. If the

browser does not open the default page or display active data, the user should check

the Internet browser “Option” configuration. Refer to the TCP/IP Controller-

Readme file.

The Monitoring and Alarm WebPages are read only and therefore it is not

necessary to enter a username or password. A username and password will be

requested upon the initial request to any of the other WebPages. The factory default

settings are:

Username: EmersonID Password: 12

The default settings may be modified in the Display configuration page.

Press the tabs at the top of the Monitoring page with a left click of the mouse button

to enter the respective Webpage.

The paramet ers will be visuali sed in real text together with the program code as

defined in the parameter list below.

After the p ara meter s hav e been mod ified , th e com plet e lis t of s ett ings can be saved

to the memory of the com puter and used later to upload into an other controller.

This can save a considerable amount of time when using multiple controllers and

over a period of time, a library can be created containing the parameter lists for

equipment for different applications.

It is also possible to display live graphical data from the controller. In addition, a

permanent 30 days log file containing the control temperature at 15 minutes

intervals is stored in the non-volatile memory to be la ter transferred using FTP t o

the computer. The log file can be imported into a standard spreadsheet program

such as Excel. Refer to the TCP/IP Controller-Readme file for a complete

description of the features available for the TCP/IP series of controllers.

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 15.06.2016 EC2-352_OI_EN_R07_864925.doc

Page 5

Betriebsanleitung

!

Versorgungsspannung

24VAC ±10%; 50/60Hz; Klasse II

Leistungsaufnahme

20VA max inkl. EX2

Kommunikation

TCP/IP Ethernet 10MBit/s

Anschlüsse

Steckbare Schraubklemmen für Adern mit max.

Temperaturen

Betrieb

0 … +60°C

Feuchtigkeit

0…80% r.h. nicht kondensierend

Schutzart

IP65 (Einbau in Schalttafel mi t D ichtung)

Drucktransmitter Eingang

24VDC, 4... 2 0mA

Ausgangsrelais (3)

Wechsler, AgCdO

Induktive Last (AC15) 250V/2A

Ohm’sche Last (AC1) 250V/8A;

12A max im Nullleiter

Triacausgang für EX2 Spule

24VAC, 0.1 … 1A

Der EC2-352 wird auf Frontplatten mit einem

Ausschnitt von 71 x 29mm montiert, siehe

Beiliegenden Imbusschlüssel in die Löcher auf der

Die Halterungen treten aus dem Gehäuse hervor und

ng

die Frontplatte leicht berührt. Dann auch die zweite

nicht zu fest

anziehen , d ie Halterungen können sons t abbrechen .

EC2-352 Kühlstellenregler

Hinweis: Das vorliegende Dokument ist eine Kurzanleitung für erfahrene

Anwender. Die letzte Spalte der Parameterliste dient zur Dokumentation der

gewählten Einstellungen. Detailierte Informationen stehen im Handbuch.

Technische Daten:

EC2 Kühlstellenre gl er

0.14 … 1.5mm2 Querschnitt

Der EC2-352 ist ein Kühlstellenregler mit Überhitzungsregelung in Verbindung

mit einem elek trischen Regel ventil der Bau reihe EX2 von ALCO Con trols. Zum

Funktionsumfang gehören auch die Temperaturregelung, sowie Abtau- und

Lüftersteuerung

Der PT5 Drucktransmitter (1) und der ECN-Pxx Rohrsensor (2) messen den Druck

und die Temperatur des gesättigten Sauggases am Verdampferaustritt und speisen

die Signale in den Überhitzungsregelkreis ein. Dieser bestimmt den Öffnungsgrad

des pulsbreitenmodulierten elektrischen Regelventils (6) der Baureihe EX2 und

optimiert dadurch den Massenstrom durch den Verdampfer. Der Thermostat für die

Lufttemperatur arbeitet mit den Signalen der Lufttemperaturfühler ECN-Sxx (3)

und (4). Der "Finsensor" ECN-Fxx (5) dient zur Bestimmung der Abtauendtemperatur. 3 Relaisausgänge steuern den Verdichter (7), die Abtauheizung (9) und

den Verdam pferlüfter (8). Bit te beachten Sie di e elektrischen Dat en (rechts) der

Ein- und Ausgänge.

Bei einem Stromausfall schließt sich das elektrische Regelventil EX2 (6) und

verhindert dadurch eine Überflutung des Verdichters. Auf Grund der Schließfunktion ist ein zusätzliches Magnetventil nicht erforderlich.

Lagerung

-20 … +65°C

Kennzeichnung

Montage:

Abmessungen unten für Platzbedarf incl Stecker.

Anzeigeeinheit vorsichtig mit eingefahrenen Halterungen in den F r o nt pl a t tenausschnitt einschieben (1).

Frontseit e einsteck en und im Uhrzeigers inn d rehen.

bewegen sich in Richtung Frontplatte (2).

Imbusschraube solange weiterdrehen bis Halteru

Halterung in diese Position bringen (3).

Beide Seit en gleichmäßig und vor sichtig anziehen,

bis der Regler stabil sitzt. Achtung -

Elektrischer Anschluss:

Die Anschlußklemmen sind auf dem Regler bezeichnet, siehe unten. Die

Anschlußdrähte/-kabel müssen für Betrieb bis 90°C zugelassen sein(EN 60730-1).

Sicherheitshinweise:

• Lesen Sie bitte die Einbauanleitung gründlich. Nichtbeachtung kann zum

Versagen oder zur Zerstörung des Gerätes und zu Verletzungen führen.

• Der Einbau darf nur von Fachkräften vorgenommen werden.

• Achten Sie darauf, daß die für Spannungen und Strö me spezifizierte n Werte

nicht überschreiten werden.

• Schalten Sie vor der Verdrahtung alle Spannungen stromlos.

• Halten Sie die Temperaturen innerhalb der vorgeschriebenen Grenzen.

• Beachten Sie die einschlägigen Vorschriften für die Installation elektrischer

Anlagen.

Suction Press = Saugdruck Fan = Lüfter

Coil out Temp = Verdampfer-Austrittstemp Comp = Verdichter

Air in Temp = Temperatur am Lufteintritt Heater = Heizung

Air out Temp = Temperatur am Luftaustritt

Defrost Temp = Abtau-Endtemperatur

Die Analogeingänge des EC2 sind nur zum Anschluß der bezeichneten Sensoren

zugelassen. Der Anschluß eines Einganges an die Netzspannung zerstört den EC2!

Wichtig: Signalleitungen und Leitu ngen mit Netzspannung sollten in getrenn ten

Kabelschächten verlegt werden. Mindestabstand: 30mm.

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 13.06.2016 EC2-352_OI_DE_R07_864925.doc

Achtung: Für die 24V Stromversorgung sind ausschließlich Transformatoren der

Klasse II zugela ssen (EN 60742). Die 24V Leitungen dürfen nicht geerdet werden!

Bei Nichtb eachten kann di e eingebaute St romversorgung b eschädigt werd en. Wir

empfehlen die Verwendung separater Transformatoren für EC2 Regler und

separater Transformatoren fü r die Regler and erer Hersteller, weil unt er Umständen

über die Erdleitungen Kurzschlüsse entstehen können.

Page 6

Betriebsanleitung

Schaltzustand des Relais für die Abtauheizung

IR LED

EC2-352 Kühlstellenregler

Einbauposition der Sensoren: (siehe Grafik auf S eite 1)

(2) Der Verdampferaustrittstemperat urfühler ECN-Pxx wird a uf der Oberseit e der

Sammelleitung kurz hinter dem Verdampfer, mit einer Rohrschelle aus Metall

montiert (ideale Position zwischen 9 und 15 Uhr, siehe Bild). Auf guten

Temperaturübergang achten. Rohrschellen aus Kunststoff müssen temperaturbeständig sein. Normale Kabelbinder aus Kunststoff dürfen nicht verwendet

werden, weil sie sich mit der Zeit lockern und dann zu falschen Temperaturmessungen und schlechter Überhitzungsregelung führen. Der Verdampferaustrittstemperaturfühler sollte mit ARMAFLEX™ oder vergleichbaren Materialien

isoliert wer den

(3) ECN-Sxx Lufttemperaturfühler mit Hilfe eines Abstandshalters in der Mitte des

Lufteintritts möglichst hoch montieren, so daß er gut umströmt wird.

(4) ECN-Sxx Lufttemperaturfühler mit Hilfe eines Abstandshalters in der Mitte des

Luftaustritts, unsymmetrisch näher am EX2, möglichst hoch montieren.

(5) ECN-Fxx Der Abtaufühler wird in der Mitte des Verdampfers, etwas näher

beim Expansionsventil montiert.

(1) Der Drucktransmitter PT5-07M wird auf der gemeinsamen Saugleitung in der

Nähe des Verdampferaustrittst emperaturfühlers (2) montiert

Hinweis: Die Fühlerleitungen können bei Bedarf verlängert werden. Verbindung

gegen Wasser und Schmutz schützen

Mit Hilfe des Parameters u1 kann die Temperaturmessung korrigiert werden (siehe

Parametertabelle)

Parametereinstellung mit der Tastatur:

Falls kein PC angeschlossen ist, lassen sich die Parameter des Reglers mit der

Infrarotfernbedienung EC2-IRD bequem verändern.

Parameteränderungen sind auch mit der Gerätetastatur möglich. Die

Konfigurationspar am eter sind passwor tg e s chü tzt.

Änderung der Konfi guratio nspara meter:

• PRG Tast e länger als 5 Sek. gedrückt halten bis eine blinkende "0" erscheint

•

oder Tasten so oft drücken bis das Paßwort (Standardwert 12) angezeigt

wird

• Mit SEL Taste bestätigen

Der erste Kon figurationsparameter ( /1) wird ang ezeigt.

Parameter einstellen:

•

oder Tasten so oft drücken bis die gewünschte Parameterkennung erscheint

• Mit SEL wird der aktuell eingestellte Wert angezeig t

oder wird dieser Wert vergrößert o der verkleinert

• Mit

• Mit SEL wird der eingestellte Wert vorläufig behalten, aber noch nicht

gespeichert. Die Parameterkennun g wird wieder angezeigt.

• Zur Änderung weit erer P ar am et er wir d di ese P rozed u r wi ed erh olt ; m it

oder

nächste Pa rameterkenn u ng auswählen.

Parameter speichern und Konfigurationsmodus beenden:

• PRG Taste drücken

Konfigurationsmodus ohne Parameteränderung beenden:

• Mindestens 1 Min. lang keine Taste drücken (Zeitsperre)

• An der Fernbedienung “ESC” drücken.

Abtauung manuell s tarten :

• Taste

•

länger als 5 Sek. gedrückt halten bis eine blinkende „0“ erscheint

oder Tasten so oft drücken bis das Paßwort (Standardwert 12) angezeigt

wird mit SEL Taste Paßwort bestätigen;

der Abtauvorgang beginnt.

Spezialfunktionen:

Diese Betriebsart wird folgendermaßen aufgerufen:

•

und Tasten zusammen mehr als 5 Sek. gedrückt halten bis eine blinkende

"0" erscheint

•

oder Tasten so oft drücken bis das Paßwort (Standardwert 12) angezeigt

wird

• mit SEL Taste Paßwort bestätigen, es erscheint eine blinkende „0“ für di e 1.

Spezialfunktion

• Mit

oder eine andere Funktionskennung auswählen. Die Funktions-

kennungen sind je nach Regler unterschiedlich. Siehe Tabelle unten.

• Mit SEL wird die eingestellte Funktion aktiviert, die Betriebsart

Spezialf un ktionen bleibt aktiv.

• Mit PRG wird die gewählte Funktion aktiviert und die Betriebsart Spezial-

funktionen verlassen.

Die meisten Spezialfunktionen arbeiten im Wechselmodus, d.h. der 1. Aufruf

aktiviert, der 2. A uf r uf de ak tiviert die Funktion.

Eine Anzeige der Spezialfunktion erfolgt erst nach dem Verlassen dieser

Betriebsart.

Tabelle Spezialfunktionen

• 0: Funktionstest der Anzeige

• 1: Alarmmeldungen löschen

• 2: Reinigungsbetri eb. Beim Rei nigungsb etrieb han delt es sic h um ein e manuelle

Abtauung, bei der die Lüfter ein- oder ausgeschaltet werden können. Der

Reinigungsbetrieb sollte nicht zum Abzuschalten der Anlage bei Wartungsarbeiten genutzt werden.

• 3: Lüfter aktivieren

• 4: Elektrisch es Regelventil 100% öffnen

• 5: Aktuelle TCP/IP Adresse anzeigen

• 6: TCP/IP Adresse auf 192.168.1.101 (Werkseinstellung) setzen. Diese Änderung

ist nur temp orär. Nach dem Abschalten wird die zu vor eingestellte Adresse

wieder aktiviert.

• 7: Alle Parameter auf Werkseinstellung zurücksetzen. Anzeige während der

Rückstellung: "oF", Regelventil schließt.

Schnelle Datenanzeige:

Im Normalbet rieb ist auf der Anzei ge einer von 10 Meßwert en sichtbar. Dieser

Wert wird mi t dem Parameter / 1 ausgewählt (si ehe Parameterta belle). Bei ein em

Alarm wird d er Alar mc od e a b wech sel n d mi t d em M eßwert a n gez ei gt . Di e Anz ei ge

des Alarmcodes kann unterdrückt werden.

Mit "SEL" können die Meßwerte aller Fühler nacheinander angezeigt werden.

Dies ist hilfreich, wenn das System ohne WebSeiten eingestellt werden soll.

Hierbei is t zuerst ein e Sekunde lang d ie Parameter kennung, dana ch der Meßwert

sichtbar. Dies funktioniert nur, wenn der Parameter H2 = 3 ist.

Schaltzustand des Verdichterrelais

Ethernet aktiviert

(wenn der Service Pin gedrüc kt wurde).

Schaltzustand des Lüfterrelais

Alarm

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 13.06.2016 EC2-352_OI_DE_R07_864925.doc

Page 7

/

ANZEIGEPARAMETER

Min

Max

Einheit

Werk

Kunde

/1

Datenanzeige Normalbetrieb

0 9 - 0

0 = Thermostat Kontrolltemperatur mit Korrekturfaktor

9 = Abtaustatus

/2

Alarm Unterdrückun g 0= aus, 1 = ein

0 1 - 0

/5

Temperatur Einheit 0 = °C, 1 = °F

0 1 - 0

/6

Dezimalstelle 0 = ja, 1 = nein

0 1 - 0

/7

Anzeige während Abtauung

0 2 -

0

0 = dF (= Abtaubetrieb); 1 = dF abwechselnd mit AbtauEndtemperatur; 2 = dF abwechselnd mit Kontroll-Temperatur

/C

Korrekturfaktor für Temperaturanzeige Parameter /1=0

-20

20

K / °F

0.0

A

ALARM-PARAMETER

A0

Mittelwert Alarmtemperatur

0

100 % 100 A1

Alarmverzug Regeltemp Min.

0

180

min

5

A2

Alarmverzug Regeltemp Max.

0

180

min

5

A3

Alarmverzug bei Abtauende

0

180

min

10

AH

Alarmgrenze Regeltemp Max.

AL

70

°C / K

40

AL

Alarmgrenze Regeltemp Min.

-55

AH

°C / K

-50 At

Gleitende Al armgrenzen

0 1 - 0 0=absolu te Temp.werte °C; 1= Temp.werte K rel. zum Sollwert

r

THERMOSTAT-PARAMETER

r1

Sollwert Gr enze Min.

-50

r2

°C

-50 r2

Sollwert Gr enze Max.

r1

60

°C

40 r3

Tag-/Nachtumschaltung 0= aus, 1= ein

0 1 - 1

r4

Thermostatfunktion

0 4 - 1

0 = aus; keine Therm ostatfunktio n ; keine Überw a chung der

Temperaturalarm wird ausgelöst.

r6

Sollwert Nacht

r1

r2

°C

4.0 r7

Differenz Nacht

0.1

20.0 K 2.0 r8

Mittelwert Tag

0

100 % 100 r9

Mittelwert Nacht

0

100 % 50 rd

Differenz Tag

0.1

20.0 K 2.0 St

Sollwert Tag

r1

r2

°C

2.0

d

ABTAU-PARAMETER

d0

Abtaumethode

0 2 - 1

0 = natürlich, Abtauheizung wird nich t aktiviert;

Synchronis ation durch nviStartUp über SNMP

d1

Abtauung be endet bei:

0 3 - 0

0 = Erreichen der Abtauendtemper atur;

3 = Erreichen von Abtauendtemperatur und -Zeit; kein Alarm

d2

Fühler für Abtautemperatur

0 1 - 1

0 = Abtaufühler (Fin sensor) muß installiert werden

1 = Abtautemperatur wird mit dem Fühler am Luftaustritt gemessen

Min

Max

Einheit

Werk

Kunde

d3

Pulsierende Abtauung

0 1 - 0

0 = aus; je nach Auswahl wird die Abtauheizung bei Erreichen der

bei dH – dd wieder eingeschaltet

d4

Abtauung be i E i ns chalten

0 = nein,1 = ja

0 1 - 0

d5

Abtauung be i E i ns chalten Verzug

0

180

min

0 d6

Pump-down Verzögerung

0

180

sec 0

Verdichter arbeitet s o lange bei geschlossenem Ven til

d7

Abtropfverzögerung

0

15

min

2 d8

Einspritzverzögerung

0

180

sec 0 Ventil ist während dieser Zeit geöffnet, Verdichter läuft nicht

d9

Bedarfsabtauung

0 2 - 0

0 = aus, 1 = ein , 2 = ein zusammen mit zeitlich g esteuerter Abtauung

dd

Pulsierende Abtauung Differenz

1

20 K 2 dH

Pulsierende Abtauung Sollwert

-40

dt

°C 5

dt

Abtauendtemperatur

-40

90

°C 8

dP

Abtaudauer Max

0

180

min

30

dI

Abtauintervall

0

192 h 8 du

Kühlverzug nach synch. Abtauung

0

180

min

30

F

VENTILATOR-PARAMETER

F1

Lüfter nach Abtauung: 0 = ein

0 4 - 0

1 = Verzögert durch Zeit Fd , Temperaturalarm

4 = Wenn Zeit und Temperatur erreicht sind, kein Alarm

F2

Lüfter während Nichtkühlen

0 2 - 0

0 = ein; 1 = aus; 2 = verzögert durch F4; 3 = aus, wenn Tür geöffnet

F3

Lüfter währ e nd Abtauung 0=ein, 1=aus

0 1 - 0

F4

Ausschaltverzögerung

0

30

min

0

F5

Lüfter währe nd Wartung 0 = aus,1 = ein

0 1 - 0

Fd

Einschaltverzug nach Abtauung

0

30

min

0 Ft

Einschaltte mp nach Abtauu ng

-40

40

°C 0

C

VERDICHTER -PARAMETER

C0

Erster Verdichter Verzug nach Neustart

0

15

min

0 C1

Zykluszeit

0

15

min

0 C2

Mindeststillstandszeit

0

15

min

0 C3

Mindestlaufzeit

0

15

min

0

u

ÜBERHITZUNGS-PARAMETER

u0 Kältemittel 0 = R22 1 = R134a

5 = R410A 6 = R124 7 = R744

0 7 - 3

u1

Korrektur Gleit / Druckverlust

Druckverlust = negative Werte

-20.0

20.0 K 0.0

u2

MOP Begrenzung

0= MOP aus, 1= MOP ein

0 1 - 0

u3

MOP Temperatur

-40

40

°C 0

u4

Überhitzungsfunktion

0 2 - 1

0=Überhitzungsregelung aus, 1=feste Überhitzung, 2= Adaptiv

u5

Überhitzu ng Startsollw er t

u6

u7 K 6

u6

Überhitzung Sollwert Min.

3

u7 K 3 u7

Überhitzung Sollwert Max.

u6

20 K 15 uu

Startöffnung

25

75 % 30 P

DRUCKTRANSMITTER

P1

Auswahl Drucktransmitter

0 2 - 0

0 = PT5-07M; 1 = PT5-18M; 2 = PT5-30M

H

WEITERE PARAMETER

H2

Bediengeräte Zugriff

0 4 - 3

0 = alles gesperrt (Zugriff auf EC3 nur über TCP /IP möglich);

manuelle Abtauung möglich.

H3

Infrarot Adresse

0

199 - 0

H5

Paßwort

0

199 - 12

Parametertabelle

Parameter /C

1 = Temperatur am Lufteintritt °C

2 = Temperatur am Luftaustritt °C

3 = Alarmtemperat ur °C

4 = Abtau-Endtemperatur °C

5 = Verdampfer-Eintrittstemp. °C (berechnet aus dem Druck)

6 = Verdampfer-Austrittstemp. °C

7 = Überhitzung °K (berechnet)

8 = Öffnungsgrad des Ventils in %

Betriebsanleitung

EC2-352 Kühlstellenregler

Abtauuendtemperatur dt oder der max. Abtauzeit dP ausgeschaltet

1 = ein; Abtauheizung wird bei Temperatur dH aus und

2 = Verzögert durch Temperatur Ft, Zeitalarm

3 = Wenn Zeit oder Temperatur erreicht ist; kein Alarm

Lufttemperatur; es wird kein Temperaturalar m ausgelöst

1 = Kühl temperaturregelung mi t Hysterese:

Kühlung ein bei Sollwert + Differenz;

Kühlung aus bei Sollwert

2 = Kühltemperaturregelung mit moduliertem Thermostat:

Kühlung ein bei Sollwert;

Kühlung aus bei Sollwert - Differenz / 2

3 = Heiztemperaturregelung mi t Hysterese:

Heizung ein bei Sollwert – Differenz;

Heizung aus bei Sollwert

4 = ein; externe Regelung durch nvi Ventil über SNMP;

keine Überwachung der Lufttemperatur;

pulsierte Abtauung nicht möglich

1 = elektrisch aktivierte Abtauung, pulsierte Abtauung möglich

2 = elektrisch aktivierte Abtauung, pulsierte Abtauung möglich;

Überschreitung des Zeitlimits löst einen Alarm aus

1 = Erreichen der Abtauzeit;

Überschreitung der Temperatur löst einen Alarm aus

2 = Erreichen der Abtauendtemperatur oder -Zeit; kein Alarm

2 = R507 3 = R404A 4 = R407C

Glide = positive Werte

1 = Eingabe übe r T as ten möglich;

2 = Eingabe über Fernbedienung möglich;

3 = keine Sperrung;

temporäre Datenanzeige und manuelle Abtauung m ö g lich.

4 = Eingabe über Tasten und Fernbedienung möglich; temp.

Datenanzeige unterdrückt; Sollwert mit SEL verstellbar,

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 13.06.2016 EC2-352_OI_DE_R07_864925.doc

Page 8

Betriebsanleitung

EC2-352 Kühlstellenregler

Formel für Mittelwerte A0, r8, r9

Die Temperat urberechnung erfolgt n ach folgender Formel:

Temperatur = Luft

* (1 - Mittelwert / 100) + Luft

eintritt

* Mittelwert / 100

austritt

Beispiele:

Mittelwert = 0 Temperatur = Lufteintritt

Mittelwert = 100 Temperatur = Luftaustritt

Mittelwert = 50 Temperatur = Durchschnitt zwischen Lufteintritt und -austritt

Alarmanzeigen

E0 Alarm Drucktransmitter

E1 Fühleralarm Verdampfer Austritt

E2 Fühleralar m Lufteintritt Diese Alar manzei ge wird un terdrü ckt, wenn kein

Lufteintrittsfühler angeschlossen ist (A0, r8 und r9 = 100)

E3 Fühleralar m Luftaustritt Diese Alarmanzeige wird unterdrückt, wenn kein

Luftaustrittsfühler angeschlossen ist (A0, r8 und r9 = 0) und der Abtausensor

installiert is t (d 2 = 1) .

E4 Fühleralarm Lamellensensor Diese Alarm anzeige wird unterd rückt, wenn

kein Abtausensor angeschlossen wurde (d2 = 0)

Fehlerursachen für die Alarmanzeigen E0 ... E4: Kein Fühler angeschlossen;

Fühlerkabel unterbrochen oder kurzgeschlossen.

Er Datenfehler am Display

Bereichsüberschreitung bei den Anzeigedaten.

AE Kühlung im Notbetrieb

Fehler an Lufteintritts- und Luftaustrittssensor, System arbeitet im Dauer-

betrieb

AF Ventilstatus

Ventil geschlossen, weil Sicherheitskette des Verdichters Alarm meldet

AH Regeltemperatur zu h och

AL Regeltemperatur zu niedrig

Ao Überhitzung im Notb et rieb

Fühlerausfall

Ar Ke in Kältemittel

Von der Anlage wurde kein Kältemittelstrom erkannt

Au Ventil ist länger als 10 Minuten 100% geöffnet

dt Abtaufehler durch Zeit- oder Temperaturüberschreitung

Ft Lüfterstartfehler durch Zeit- oder Temperaturüberschreitung

Sonstige Anzeigen

--- Keine Daten

Bei Start und wenn die Anzeige kein e Daten erhält, wird "---" angezeigt.

In Rücksetzen auf Werkseinstellung läuft

Anzeige solange die Konfigurationsdaten zurückgesetzt werden.

Id "Wink" - Anforderung erhalten

Wenn der Controller eine "Wink" Anforderung erhalten hat blinkt Id auf.

Diese Anzeig e bleibt so lan ge stehen, bis di e Service Taste ged rückt wird,

oder bis 30 Minuten vergangen sind, oder bis eine zweite "Wink"

Anforderung eintrifft. Diese Funktion wird nur beim SNMP Protokol aktiv.

OF Netzwerkknoten ist off-line

Der Knoten ist offline - keine Anwendung aktiv. Dieser Zustand wird durch

einen Netzwerkverwaltungsbefehl a usgelöst, z. B. bei der Knoteninstallation.

dS Abtauung bereit

dP Pump-down Betrieb

dF Abtauung aktiv

dd Abtropfverzug aktiv

dI Einspritzverzug aktiv

du Kühlverzug nach Abtauung aktiv

Cn Wartungsmodus aktiv

CL Alarme gelöscht

Datenvisualisierung: WebSeiten

Detailinformationen zur Errichtung eines kleinen Ethernet Netzwerkes stehen in der

"TCP/IP Controller-Readme" Datei, die von folgender WebSeite heruntergeladen

werden kann: www.emersonclimate.eu.

Der EC2-352 kann mit seiner TCP/IP Ethernet-Schnittstelle direkt an den

Ethernetanschluss eines PCs oder ein lokales Netzwerk angeschlossen werden.

Übersicht liche Webseiten, auf denen die Parameterlis ten angezeigt oder geän dert

werden können sind bereits eingebaut. Spezielle Hard- und Software ist nicht

erforderlich.

Der EC2-352 wird über das konfektionierte Kabel ECX-N60 (Zubehör) am Netz-

werk oder ei nem Hub an geschlossen . Dieser vergi bt dem Regler eine dyn amische

Adresse. Falls kein DHCP Server vorhanden ist, kann man den Regler mit einem

Crossover-Kabel direkt am Ethernet Anschluß des Computers einstecken. In diesem

Fall muß die TC P/IP Ad ress e des PCs man u ell au f die St anda rdadr esse d es Reg lers

umgestellt werden. Einzelheiten hierzu entnehmen Sie bitte der "TCP/IP

Controller-Readme" Datei.

Am PC wird der WebBrowser gestartet und entweder die Standardadresse des

Reglers ein gegeben (192.168.1.101), oder die dynami sche Adresse, die der DHC P

Server vergeb en hat. Weitere Hi nweise sind in d er "TCP/IP Controller-Readme"

Datei zu finden, fa l ls ein speziell er Port vergeben werden mu ß .

Nach wenigen Sekun den ers chei nt die Mo nit orseit e des R eglers (H omepag e). Fal ls

diese Seite nicht sichtbar ist, oder falls keine dynamischen Werte angezeigt werd en,

müssen die "Optionen" des WebBrowsers überprüft werden. Weitere Hinweise

stehen in der "TCP/IP Controller-Readme" Datei.

Die Monitor- und Alarmseite läßt keine Änderungen zu und ist daher nicht

geschützt . Beim erstmali gen Zugriff auf and ere Seiten wird d ie Benutzerkennung

und ein Paßwort abgefragt. Ab Werk sind folgende Werte eingestellt:

Username: EmersonID Password : 12

Auf der Seite "Display Configuration" lassen sich diese Werte ändern. Zu dieser

Seite gelan gt man, indem m an mit dem Maus zeiger ü ber die en tspr echend e Schal tfläche oben a n der Monitorsei te fährt und dann die linke Maustas te drückt.

Die Parameter werden sowohl in Textform, als auch mit dem Code aus der

Parametertabelle oben angezeigt.

Alle Einstellungen können auf dem PC gesichert und gegebenenfalls in einen

weiteren Con troller gelad en werd en. Dies spa rt viel Zeit , wenn mehrere R egler mi t

den gleichen Einstellungen eingesetzt werden. Im Laufe der Zeit läßt sich eine

kleine Bibliothek aufbauen, in der die Reglereinstellungen für unterschiedliche

Anwendungen gespeichert sind.

Der zeitliche Verlauf von Temperatur, Druck oder Überhitzung ist auch grafis ch

darstellbar. Im nichtflüchtigen Speicher des Reglers wird alle 15 Minuten die

Kontrolltemperatur abgelegt. Der hierfür res ervierte Speicherbereich bietet Platz für

einen Zeitraum von maximal 30 Tagen. Mit FTP Befehlen kann diese Logdatei zum

PC übertragen und mit Tabellenkalkulationsprogrammen, wie Excel ausgewert

werden. Einzelheiten siehe "TCP/IP Controller-Readme" Datei.

Emerson Climate Technologies GmbH www.emersonclimate.eu

Am Borsigturm 31 I 13507 Berlin I Germany Date: 13.06.2016 EC2-352_OI_DE_R07_864925.doc

Loading...

Loading...