Page 1

OCTOBER 2019

Dixell™ Universal-XR Controller

The Only Replacement Controller You’ll Ever Need

Simplify repair of refrigeration and heating controllers

By Joe Summers

Product Manager,

Power Electronics &

Integrated Solutions

Emerson

rom reach-in coolers to deli prep

tables to bread proofers, the

F

foodservice industry uses literally

thousands of different refrigeration and

heating units. It simply isn’t practical for

contractors and wholesalers to keep every

possible controller model on hand. But when

a controller fails, waiting on a specific

replacement can cause costly delays for

both the repair service and the customer.

Emerson responded to this common

problem by creating the Dixell™ UniversalXR controller. This dual-supply voltage

controller is capable of replacing thousands of SKUs, including more than 150

of the most common 32x74 mm format

controllers. The most typical applications

can be back up and running quickly —

often in just a few minutes — regardless of

the original make or manufacturer.

The Universal-XR controller is a boon

to repair contractors. The unit is stocked

at thousands of authorized Emerson

wholesalers nationwide, usually at a very

competitive cost compared to the controllers it can replace. With Universal-XR

units on their trucks, contractors won’t

have to waste as much time selecting a

specific controller. This saves time for

themselves and eliminates downtime for

their customers, enabling contractors to

get to their next jobs quicker.

Wholesalers also stand to benefit from

our controller. The unit can significantly

reduce the number of SKUs they need to

keep in stock. They can keep inventories

lower — yet still have the right controller

for the job available.

Key benefits of the Universal-XR

controller

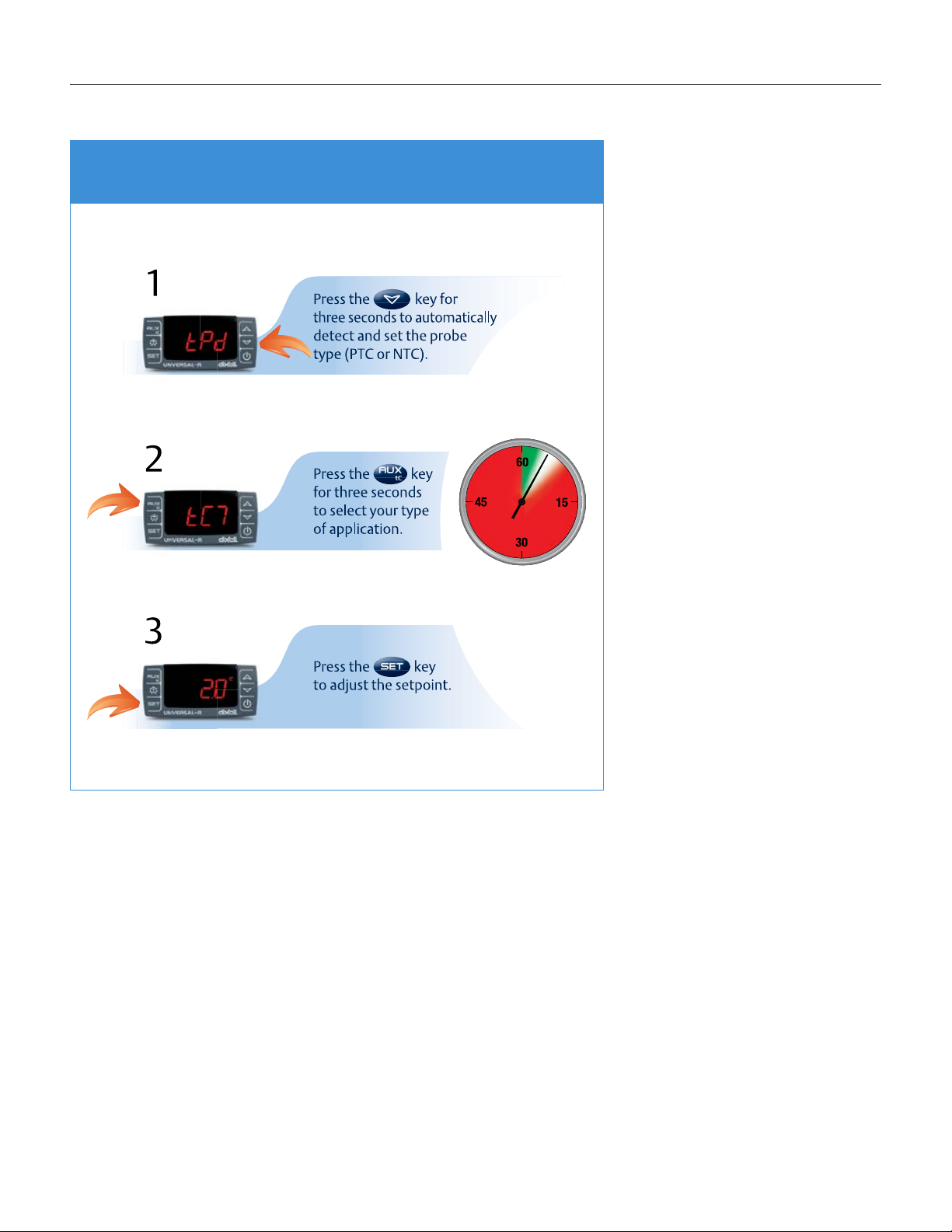

Quick installation and programming —

The Universal-XR controller gives repair

contractors a “drop-in” solution that can

be configured rapidly in just three simple

steps (see “Rapid setup in three simple

steps” sidebar).

• Dimensional footprint matches more

than 80 percent of the most common

controllers on the market.

• Simple wiring setup supports four to

eight connections.

• Hot key enables fast and simple

programming.

Page 2

Rapid setup in three simple steps

Dual-voltage power supply — The unit is

versatile enough to replace commonly

used low- and high-voltage controllers.

• Two different terminal blocks give

direct connections to 12VAC/DC or

230VAC power supplies. One unit

covers both standard voltages.

• Power supply isn’t needed to change

voltage in 230VAC configurations.

• 12VAC/DC configurations typically

don’t need an electrician to sign off

on the installation.

“Plug and play” functionality — Dixell’s

common five-pin connector, which is

similar to a USB device, enables a wide

variety of useful applications, including:

• Easy connectivity for downloading

parameters, fault history logs and

other data.

Seven pre-configured applications —

Support quick and easy startup. (See

the “Save time with pre-configured

applications” sidebar.)

• Seven different maps are selectable

from the intuitive interface, allowing

the most common applications to be

set up in just a few minutes.

• Automatically configure up to three

probes, four relays and two digital

inputs.

Self-learning automatic probe detection —

Other controllers are typically limited to

just one type of sensor: NTC or PTC. The

Universal-XR controller automatically

detects which type of sensor is in use and

configures itself appropriately.

• Single controller can manage both

common types of probes.

• One-touch smart sensing: just press

a single button for three seconds and

wait for the controller to detect the

probes.

• Contractors don’t have to worry that

the controller won’t work because of a

sensor mismatch or faulty reading.

• Enables custom parameters to be

uploaded into the controller.

• Factory reset to default configuration.

• Offers CTL serial connections.

• Allows connections to the cloud

or BMS, including the Emerson

XWEB300D and XWEB500D EVO

web servers for control and alarm

management.

Complete system management — The

controller manages every aspect of the

cooling or heating system.

• Activates and deactivates the compressor,

defroster, fan and motors.

• Senses the difference between readings

caused by the controlled devices versus

issues with wiring.

Page 3

Simple two-zone/twin evaporator defrost

support — Two evaporator probes and

specific parameters allow the unit to easily

control two different defrost terminations.

• The display alternates between the

temperatures of each zone.

• Users can monitor two zones (e.g.,

produce and ice cream) at a glance.

User-friendly front display — Easily

allows users to see what’s going on in

the system.

• Intuitive design enables customers

to see and understand compressor,

defroster, fan and motor activities in

a single glance.

Save time with pre-configured applications

Many typical jobs can be set up in minutes simply by selecting one of seven

pre-configured applications from the easy-to-use interface. Choosing the

controller that best fits the required application will automatically adjust all

relevant settings.

Pre-programmed applications include:

1. On/Off Thermostat (cooling)

2. Thermostat With Off-cycle Defrost (timed)

3. Thermostat With Electric/Hot Gas Defrost, Time Initiated/Time

Terminated

4. Thermostat With Electric/Hot Gas Defrost, Time Initiated/Temperature

Terminated

• Popular with many users.

By providing easy service replacement for

most major controllers, the Universal-XR

controller offers an instant replacement

solution for nearly every application.

Why keep trying to manage more than

150 separate products when a single

controller can take their place?

5. Thermostat With Electric/Hot Gas Defrost, Time Initiated/Temperature

Terminated Plus Evaporator Fan Delay

6. Thermostat for Twin Evaporator Defrost Applications

7. On/Off Thermostat (heating)

10/2019

Loading...

Loading...