Page 1

User Guide

Modbus

Digistart

0477-0009-01

www.controltechniques.com

Page 2

English

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect install ation or adj ustment

of the optional parameters of the equipment or from mismatching the starter with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or the

content of the guide without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including, photocopying, recording or by an information storage or retrieval system, without perm issi on in writing f rom the publisher.

Copyright: © October 2009 Control Techniques Ltd

Issue: 1

Product Version 4

Page 3

Contents

1. Introduction ....................................................................................................................................................... 4

2. Installation ......................................................................................................................................................... 4

3. Modbus Module Connection and Configuration ............................................................................................ 5

3.1 Adjustment ............................................................................................................................................................................. 5

3.2 Connection............................................................................................................................................................................. 5

3.3 Network Status LED ............................................................................................................................................................... 6

4. Master Configuration ........................................................................................................................................ 6

5. Modbus Functions ............................................................................................................................................ 6

5.1 Modbus register ..................................................................................................................................................................... 7

5.2 Trip codes .............................................................................................................................................................................. 8

5.3 Examples ............................................................................................................................................................................... 9

5.4 Modbus error codes ............................................................................................................................................................... 9

6. AP ASCII Protocol ........................................................................................................................................... 10

6.1 Commands .......................................................................................................................................................................... 10

6.2 Status retrieval ..................................................................................................................................................................... 11

6.3 Data retrieval ....................................................................................................................................................................... 11

6.4 Calculating the checksum (LRC) .......................................................................................................................................... 12

7. Modbus Control via Remote Keypad ............................................................................................................ 13

7.1 Grounding and shielding ...................................................................................................................................................... 13

7.2 Termination resistors............................................................................................................................................................ 13

7.3 RS485 data cable connection .............................................................................................................................................. 13

7.4 Remote Keypad RS485 network connection specifications .................................................................................................. 13

7.5 Using the Remote Keypad with Digistart CS ........................................................................................................................ 14

7.6 Programming ....................................................................................................................................................................... 14

7.7 Troubleshooting ................................................................................................................................................................... 15

8. Specifications .................................................................................................................................................. 16

Modbus Module User Guide 3

Issue 1 www.controltechniques.com

Page 4

WARNING

08627.A

03550.A

1. Introduction

Control Techniques soft starters can be controlled and monitored across an RS485 serial communication network using the Modbus

RTU and AP ASCII protocols.

For users requiring simple control of Digistart CS and Digistart IS soft starters using Modbus RTU or AP ASCII, the instructions below

describe the installation and operation of the Modbus Module.

Digistart CS soft starters can also connect to the network via a correctly configured Remote Keypad - see Modbus Control via Remote

Keypad on page 13 for details.

2. Installation

Remove mains and control voltage from the soft starter before attaching or removing accessories.

Install the Modbus Module using the following procedure:

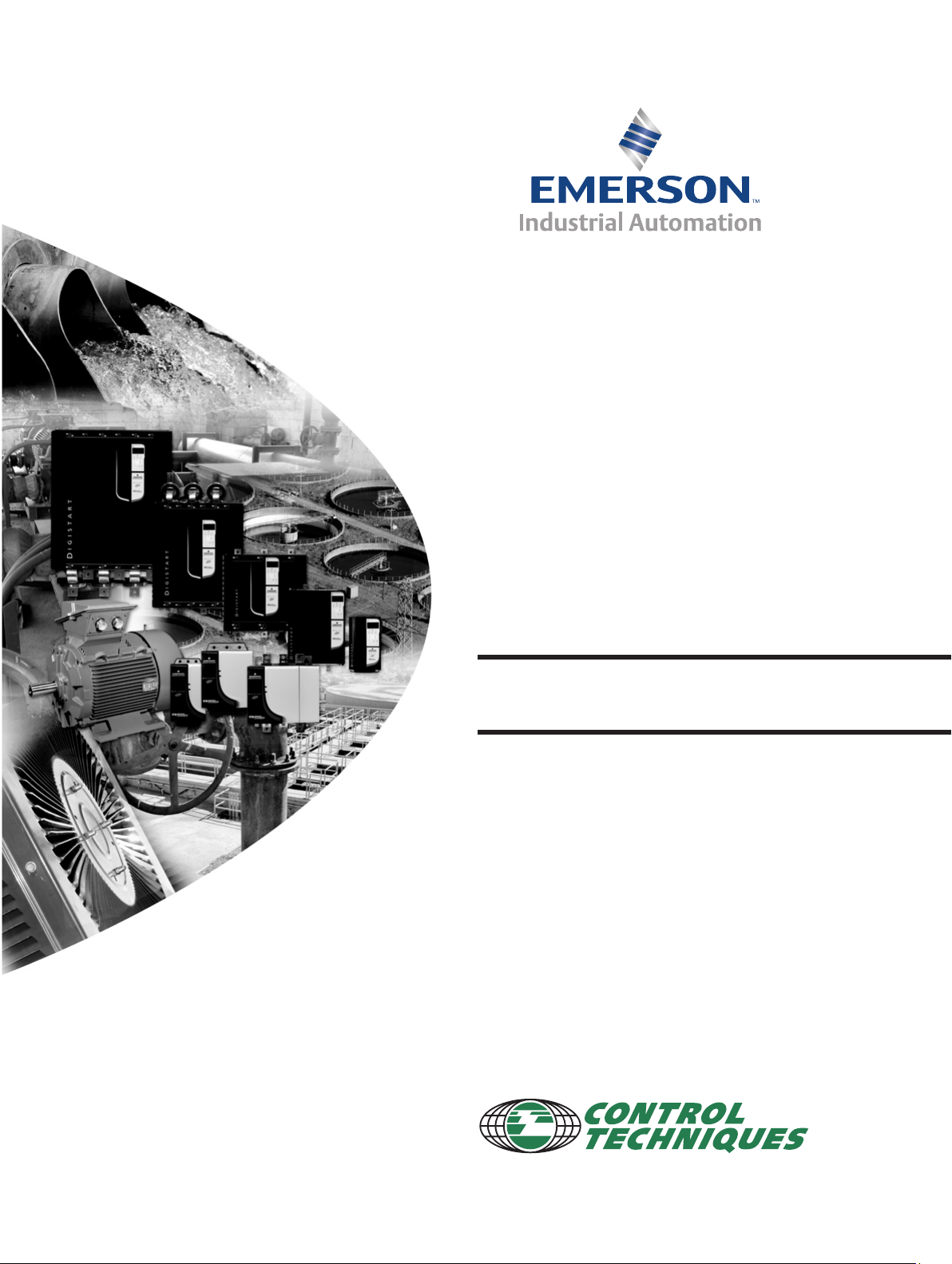

Figure 2-1 Attach the module to the starter

Digistart CS

Plug the module onto the side of the soft starter.

Digistart IS :

1. Line the module up with the comms port slot.

2. Press the top retaining clip of the module into the soft starter

chassis.

3. Press in the bottom retaining clip.

Figure 2-2 Remove the module from the starter

Remove the module using the following procedure:

1. Take the module off-line.

2. Remove control power and mains supply from the soft starter.

3. Disconnect all field wiring from the module.

4. Push a small flat-bladed screwdriver into the slots at the top and bottom of the module

and depress the retaining clips.

5. Pull the module away from the soft starter.

4 Modbus Module User Guide

www.controltechniques.com Issue 1

Page 5

Protocol

Address

Baud Rate

Parity

Timeout

(seconds)

4800

OFF

OFF

9600

OFF

ON

19200

ON

38400

ON

ONOFF

No Parity

OFF

OFF

ODD

OFF

ON

EVENON10 bit

ON

ON

OFF

No Time Out

OFF

OFF

10 s

OFF

ON

60 sON100 s

ON

ONOFF

AP

ASCII

OFF

RTU

ON

Example: Address = 24

+16

+8

+4

+2

+1

0

0

0

0

0

ON

+16

+8

+4

+2

+1

0

0

0

0

0

ON

08649.A

1

2

3

08650.A

1

2

3

Modbus Module – RS485 serial port

DI2, +24V: Stop

NOTE

3. Modbus Module Connection and Configuration

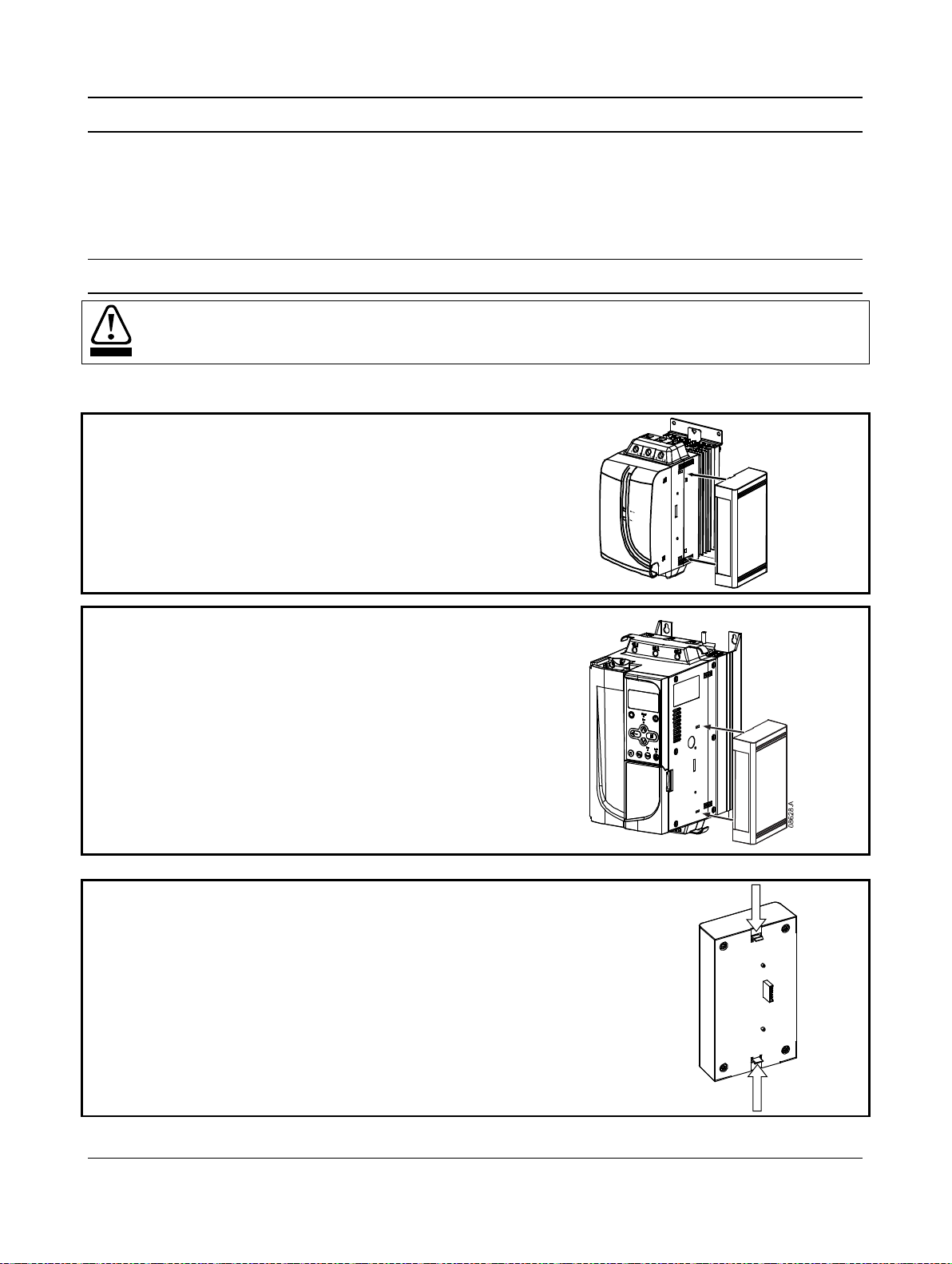

3.1 Adjustment

Network communication parameters must be set on the Modbus Module. DIP switch settings take effect on the power-up of the Modbus

Module via the soft starter.

Figure 3-1 Adjustment switches

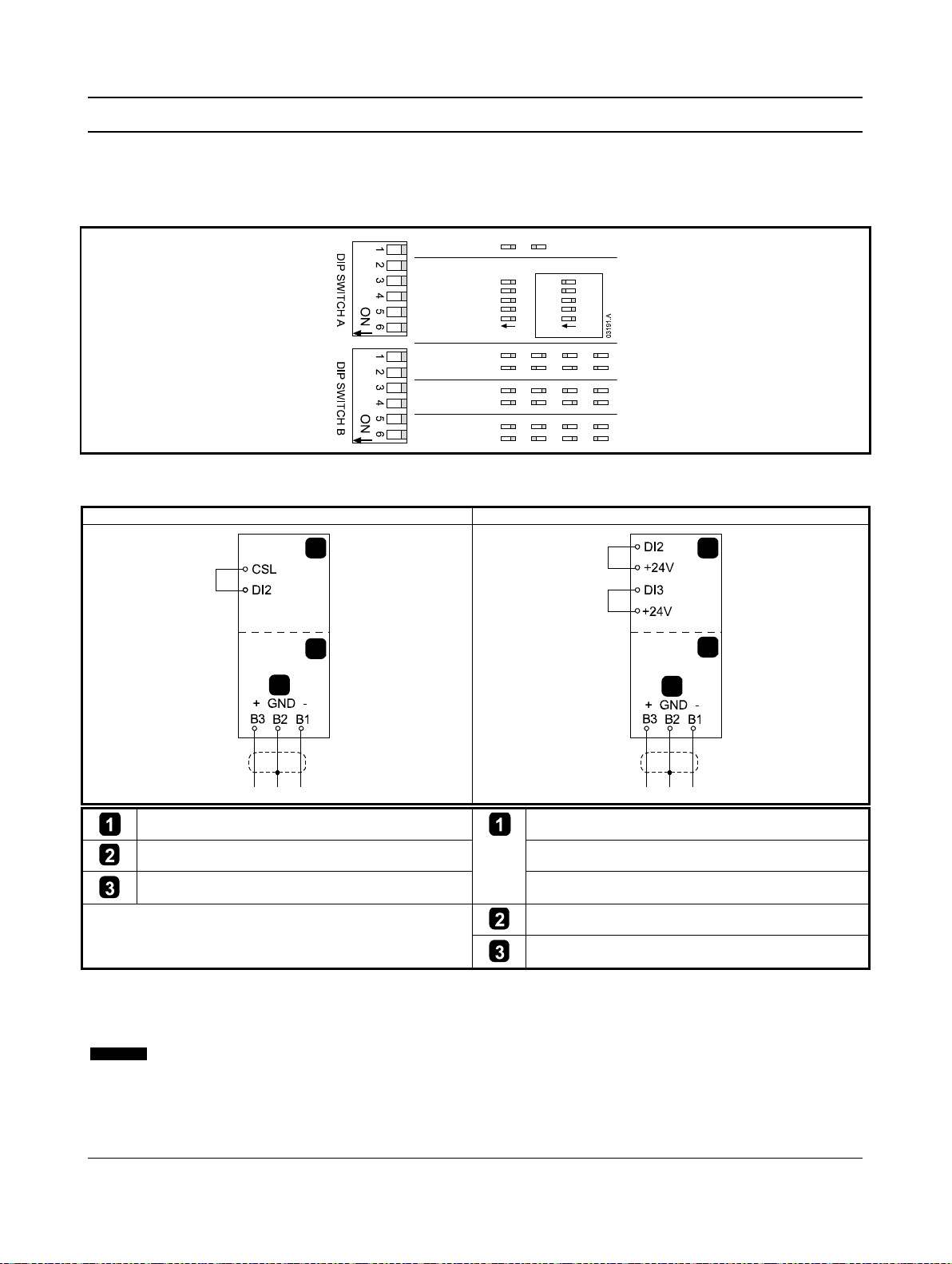

3.2 Connection

Figure 3-2 Modbus Module connec t io ns

Digistart CS Digistart IS

Digistart CS

RS485 connection onto Modbus network

For the Modbus Module to accept serial commands, a link must be fitted across terminals CSL-DI2 on Digistart CS starters.

Input links are required across terminals DI2, +24V and DI3, +24V if the Digistart IS soft starter is being operated in Remote mode. In

Local mode, links are not required.

Digistart IS Pr 3O Comms in Remote selects whether the soft starter will accept Start, Stop or Reset commands from the

Modbus Module User Guide 5

Issue 1 www.controltechniques.com

Serial Network Master while in Remote mode. See the Digistart IS User Manual for parameter details.

Digistart IS (Remote mode)

DI3, +24V: Reset

Modbus Module – RS485 serial port

RS485 connection onto Modbus network

Page 6

03193.C

1

NOTE

NOTE

3.3 Network Status LED

The Network Status LED (1) indicates the state of the communications link between the module and the network. LED operation is as

follows:

Figure 3-3 Feedback LEDs

Off No connection or soft starter not powered up

On Communication active

Flashing Communication inactive

If communication is inactive, the soft starter may trip if the Communications Timeout function has been set on the module.

When communication is restored, the soft starter will require a Reset.

4. Master Configuration

For standard Modbus 11-bit transmission, the Master must be configured for 2 stop bits with No Parity and 1 stop bit for odd or even

parity.

For 10-bit transmission, the Master must be configured for 1 stop bit.

In all cases, the Master baud rate and slave address must match those set on the Modbus Module DIP switches.

5. Modbus Functions

The Modbus Module supports the following Modbus functions:

• 03 Read multiple registers

• 06 Write single register

Modbus broadcast functions are not supported.

Digistart CS soft starters (including Remote Keypad):

• Read multiple registers 40003 to 40008

• Write single register 40002

Digistart IS so ft starters:

• Read multiple registers starting from 40003 up to a maximum of 119 register blocks.

• Write single register 40002 or 40009 to 40599.

A multiple read across register boundary 40008/40009 will result in a Modbus Error code 05 at the Master.

6 Modbus Module User Guide

www.controltechniques.com Issue 1

Page 7

5.1 Modbus register

Register

Type

Description

Digistart

Digistart IS

Remote

40002

Single

1 = Start

Command

write

2 = Stop

5 = Forced communication trip

6 = Start using Parameter Set 1

3

3

status

2 = Starting

3 = Running

check)

6 = Tripped

5

1 = Current exceeds full load current

1 = Initialised

7

0 = Communications are OK

1 = Communications device fault

40005 1

Multiple

Average 3 phase motor current (A)

temperature

Product type

read

0 to 2

Product parameter list version

and version

3 to 7

4 = Digistart CS

version

40009

2

Single

read

Pr 1A Motor Full Load Current to Digistart IS maximum

NOTE

Table 5-1 Modbus register

Address

3 = Reset

4 = Quick stop (coast to stop)

40003 Multiple Bit Description

Starter read

7 = Start using Parameter Set 2

0 to 3 1 = Ready

4 1 = Positive phase sequence (only valid if bit

6 0 = Uninitialised

4 = Stopping (including braking)

5 = Restart delay (including Temperature

7 = Program mode

8 = Jog forward

9 = Jog reverse

6 = 1)

CS

Keypad

40004

Trip Code

Motor current

40006

Motor

40007 Multiple Bit Description

40008

Serial protocol

Parameter

management

1

For Digistart IS models IS-0076B and smaller this value will be 10 times greater than the value displayed on the keypad.

2

See the relevant soft starter literature for a complete parameter list. The first product parameter is always allocated to register 40009.

The last product parameter is allocated to register 40XXX, where XXX = 008 plus total number of available parameters in the product.

3

Ensure that the programmable input is not set to Motor Set Select before using this function.

Multiple

read

read

Multiple

read

See Trip Code table

Motor 1 temperature (thermal model)

8 = Digistart IS

Multiple

read

write and

multiple

If Pr 3A Input A Function is set to motor set select, this will cause a conflict with motor set selection via serial

communications.

register address (starter software dependent)

Modbus Module User Guide 7

Issue 1 www.controltechniques.com

Page 8

Trip

Trip Name

Digistart CS

Digistart IS

2

Motor overload (thermal model)

4

Current imbalance

5

Frequency

6

Phase sequence

8

Power loss

11

Motor connection

13

FLC too high (FLC out of range)

16

Network communication (between module and network)

20

Ground fault

24

Input B trip

27

L2 phase loss

29

L1-T1 shorted

31

L3-T3 shorted

32

Motor 2 overload (thermal model)

37

RTD/PT100 A

39

RTD/PT100 C

41

RTD/PT100 E

43

RTD/PT100 G

47

Overpower

255

No trip

5.2 Trip codes

Table 5-2 Trip messages

Code

1 Excess start ti me

3 Motor thermistor

10 Heatsink overtemperature

12 Input A trip

14 Unsupported option (function not available in inside delta)

15 Starter communication (between module and soft starter)

17 Internal fault

18 Overvoltage

19 Undervoltage

23 Parameter out of range

26 L1 phase loss

28 L3 phase loss

30 L2-T2 shorted

331 Time-overcurrent (Bypass overload)

35 Battery/clock

36 Thermistor circuit

38 RTD/PT100 B

40 RTD/PT100 D

42 RTD/PT100 F

45 RTD/PT100 circuit

46 Analog input trip

48 Underpower

1

For Digistart IS, time-overcurrent protection is only available on internally bypassed models.

8 Modbus Module User Guide

www.controltechniques.com Issue 1

Page 9

5.3 Examples

Command: Start

Message

Starter Address

Function Code

Register Address

Data

CRC

In

20

06

40002

1

CRC1, CRC2

Out

20

06

40002

1

CRC1, CRC2

Starter status: Running

Message

Starter Address

Function Code

Register Address

Data

CRC

In

20

03

40003

1

CRC1, CRC2

Out

20

03 2 xxxx0011

CRC1, CRC2

Message

Starter Address

Function Code

Register Address

Data

CRC

Out

20

03 2 00000010

CRC1, CRC2

Download parameter from starter

Message

Starter Address

Function Code

Register Address

Data

CRC

In

20

03

40011

1

CRC1, CRC2

Out

20

03

2

10

CRC1, CRC2

Digistart IS Write parameter 12 (Pr 2H), Stop Mode, set = 4 'STV Soft Stop'

Message

Starter Address

Function Code

Register Address

Data

CRC

In

20

06

40020

4

CRC1, CRC2

Out

20

06

40019

4

CRC1, CRC2

Code

Description

Example

01

Illegal function code

Function other than 03 or 06

02

Illegal data address

Register number invalid

04

Not writable data

Register not allowed for data writing

06

Invalid command code

e.g. writing "6" into 40003

07

Illegal parameter read

Invalid parameter number

09

Unsupported command

Sending a serial command to Digistart IS with Pr 3O = Disable control in RMT.

NOTE

Trip code: Motor overload

In 20 03 40004 1 CRC1, CRC2

Digistart IS: Read parameter 3 (Pr 1C) Locked Rotor Time, 10 seconds

Upload parameter to starter

5.4 Modbus error codes

Table 5-3 Error codes

03 Not readable data Register not allowed for data reading

05 Data boundary fault Multiple data transfer across data boundary or data size more than 125

08 Illegal parameter write Invalid parameter number, read only, or hidden parameter

10 Local communication error Comm uni cation error between Modbus slave and starter

Some of the above codes are different from those defined in the Modbus Application Protocol Specification available

on

www.modbus.org .

Modbus Module User Guide 9

Issue 1 www.controltechniques.com

Page 10

NOTE

(Hexadecimal Character String)

Send address

EOT

(04h

[nn]

[nn]

[lrc]

[lrc]

ENQ or

05h)

Send request

(02h

[ccc]

[lrc]

03h)

Receive data

STX

(02h

[dddd]

[lrc]

[lrc]

ETX or

03h)

(06h)

NAK (negative acknowledge)

NAK

(15h)

or

ccc =

three byte ASCII command number where each character is represented by c.

dddd =

four byte ASCII number representing the current or temperature data where each decimal digit is represented by d.

ssss =

four byte ASCII number. The first two bytes are ASCII zero. The last two bytes represent the nibbles of a single byte of

address

command

Possible error responses:

NAK

(Invalid LRC)

(soft starter)

Command

ASCII

Comment

Start

B10

Initiates a start

Stop

B12

Initiates a stop

Reset

B14

Resets a trip state

ignored.

Forced communication trip

B18

Causes a communications trip

6. AP ASCII Protocol

The message fragments used to communicate with the Modbus Module as an AP ASCII slave device are shown below. The message

fragments may be assembled into complete messages as described in the sections that follow.

Data must be transmitted in 8-bit ASCII, no parity, one stop bit.

Table 6-1 AP ASCII message fragments

Send command STX [ccc] [lrc] ETX or

Receive status STX

ACK (acknowledge) ACK

Message Fragment Type

(02h

ASCII Character String or

[dddd]

[ssss]

[ssss]

or

[lrc]

[lrc]

ETX or

03h)

ERR (error) BEL

nn = two byte ASCII number representing the soft starter address where each decimal digit is represented by n.

(07h)

or

lrc = two byte longit udi nal redundancy check in hexadecimal.

status data in hexadecimal.

6.1 Commands

Commands can be sent to the soft starter using the following format:

Figure 6-1 Command format

Send

= Master

Quick stop B16 Initiates an immediate removal of voltage from the motor. Any soft stop settings are

ACK

Send

= Slave

ACK

10 Modbus Module User Guide

www.controltechniques.com Issue 1

Page 11

6.2 Status retrieval

=

Master

=

Slave

Request

ASCII

Receive Status (ssss)

Trip code

C18

See the trip code table.

2 = Starting

3 = Running

5 = Restart delay (including Temperature check)

7 = Program mode

5

1 = Current exceeds FLC

1 = Initialised

7

0 = Communications are OK

1 = Communications device fault

Send

ACK Send

Receive

=

Master

=

Slave

Request

ASCII

Receive Data (dddd)

Motor current

D10

Requests motor current. The data is four byte decimal ASCII. Minimum value 0000 A, maximum

temperature

data is four byte decimal ASCII. Minimum value is 0000%. Trip point is 0105%.

Soft starter status can be retrieved using the following format:

Figure 6-2 Status retrieval format

Send

address

Possible error responses:

ACK

Send

request

Receive

status

NAK (Invalid LRC)

Starter status C22 Bit Description

0 to 3 1 = Ready

4 = Stopping (including braking)

6 = Tripped

4 1 = Positive phase sequence (only valid if bit 6 = 1)

6 0 = Uninitialised

6.3 Data retrieval

Data can be retrieved from the soft starter using the following format:

Figure 6-3 Data retrieval format

address

Possible error responses:

request

(soft starter)

data

NAK (Invalid LRC)

(soft starter)

value 9999 A.

Motor

D12 Requests the calculated value of the motor thermal model as a % of motor thermal capacity. The

Modbus Module User Guide 11

Issue 1 www.controltechniques.com

Page 12

6.4 Calculating the checksum (LRC)

Each command string sent to and from the starter includes a checksum. The form used is the longitudinal redundancy check (LRC) in

ASCII hex. This is an 8-bit binary number represented and transmitted as two ASCII hexadecimal characters.

To calculate LRC:

1. Sum all ASCII bytes

2. Mod 256

3. 2's complement

4. ASCII convert

For example Command String (Start):

ASCII STX B 1 0

or 02h 42h 31h 30h

ASCII Hex Binary

STX 02h 0000 0010

B 42h 0100 0010

1 31h 0011 0001

0 30h 0011 0000

A5h 1010 0101 SUM (1)

A5h 1010 0101 MOD 256 (2)

5Ah 0101 1010 1's COMPLEMENT

01h 0000 0001 + 1 =

5Bh 0101 1011 2's COMPLEMENT (3)

ASCII 5 B ASCII CONVERT (4)

or 35h 42h LRC CHECKSUM

The complete command string becomes:

ASCII STX B 1 0 5 B ETX

or 02h 42h 31h 30h 35h 42h 03h

To verify a received message containing an LRC:

1. Convert last two bytes of message from ASCII to binary

2. Left shift 2nd to last byte four bits

3. Add to last byte to get binary LRC

4. Remove last two bytes from message

5. Add remaining bytes of message

6. Add binary LRC

7. Round to one byte

8. The result should be zero

Response or status bytes are sent from the starter as an ASCII string:

STX [d1]h [d2]h [d3]h [d4]h LRC1 LRC2 ETX

d1 = 30h

d2 = 30h

d3 = 30h plus upper nibble of status byte right shifted by four binary places

d4 = 30h plus lower nibble of status byte

For example status byte = 1Fh, response is:

STX 30h 30h 31h 46h LRC1 LRC2 ETX

12 Modbus Module User Guide

www.controltechniques.com Issue 1

Page 13

03250.B

1 2

3

Remote Keypad RS485

7. Modbus Control via Remote Keypad

To control a soft starter via an RS485 serial communications network using the Remote Keypad, connect the Remote Keypad to the

network as described in the following sections.

7.1 Grounding and shielding

Twisted pair data cable with ground shield is recommended. The cable shield should be connected to the GND device terminal at both

ends and one point of the site protective ground.

7.2 Termination resistors

In long cable runs prone to excessive noise interference, termination resistors should be installed between the data lines at bot h ends of

the RS485 cable. This resistance should match the cable impedance (typically 120

Figure 7-1 Installation with termination resistors

Network master RS485

Ω). Do not use wire wound resistors.

Soft starter RS485

7.3 RS485 data cable connection

Daisy chain connection is recommended. This is achieved by parallel connections of the data cable at the actual device terminals.

7.4 Remote Keypad RS485 network connection specifications

Input impedance: 12 kΩ

Common mode voltage range: - 7 V to + 12 V

Input sensitivity: ± 200 mV

Minimum differential output voltage: 1.5 V (with max loading of 54

Ω)

Modbus Module User Guide 13

Issue 1 www.controltechniques.com

Page 14

+ GND -

+ GND -

- GND +- GND ++ - ~/+ ~/-

1

2

4

3

B6, B7, B8 - RS485 network connection

NOTE

7.5 Using the Remote Keypad with Digistart CS

Figure 7-2 Modbus Module connec t io ns

Digistart CS

Modbus Module – RS485 serial port

Remote Keypad

B10, B11 - 4 to 20 mA analog output

B1, B2, B3 - RS485 starter connection

1, 2 - Supply voltage (18 to 30 Vac/Vdc)

RS485 Serial communication network connection

(Modbus RTU or AP ASCII)

7.6 Programming

The Remote Keypad must be configured to operate on the network. In order to access Programming Mode, the Remote Keypad must

be powered up when the soft starter is not running.

7.6.1 Programming Procedure

1. To enter Programming Mode, hold down the Data/Prog pushbutton for four seconds. The default value of the first parameter will

be displayed.

2. Use the Data/Prog pushbutton to advance to the next parameter.

3. Use the Stop and Reset pushbuttons to adjust parameter values.

Programming Mode closes when the Data/Prog pushbutton is pressed after Pr 9.

There is a 20 second timeout when the Remote Keypad is in Programming Mode. Programming Mode will automatically

close if no input is registered for 20 seconds. Any changes already made will be saved.

14 Modbus Module User Guide

www.controltechniques.com Issue 1

Page 15

7.6.2 Programmable Parameters

Parameter

Description

Default

Adjustable Range

satellite address

3

RS485 network

0 seconds

0 to 100 seconds

5

Modbus protocol

0

0 = no parity

6

Motor FLC (A)

10

1 to 2868

8

Start, Stop, Quick

0

0 = Remote Keypad and Network start, stop, quick stop function enabled.

Display

Indication

Problem

Possible Solution

SP flashing on

network.

The Remote Keypad offers the following programmable parameters:

Table 7-1 Programmable parameters

Number

1 RS485 network

baud rate

Setting

4

(9600 baud)

2 = 2400 baud

3 = 4800 baud

4 = 9600 baud

5 = 19200 baud

6 = 38400 baud

2 RS485 network

timeout

4 RS485 network

protocol

parity

20 1 t o 99

(= off)

1

(AP ASCII)

(no parity)

1 = AP ASCII protocol

2 = Modbus RTU protocol

1 = odd parity

2 = even parity

3 = 10-bit transmission

7 Analog output

100 80 to 120

4 mA offset (%)

stop function

disable

9

1

Remote Keypad Reset pushbutton is always enabled.

2

RS485 Network reset and forced communication trip functions are always enabled.

Current ÷ 10

0 0 = off (required for Digistart CS)

1 = Remote Keypad start, stop, quick stop function enabled. Network start, stop,

quick stop function disabled.

2 = Remote Keypad start, stop, quick stop function disabled. Network start, stop,

quick stop function enabled.

3 = Remote Keypad start, stop, quick stop function disabled. Network start, stop,

quick stop function disabled.

1

2

1, 2

1 = on (not suitable for Digistart CS)

7.7 Troubleshooting

The Remote Keypad display and status indication LEDs can indicate abnormal operating and system conditions.

Table 7-2 Error codes

nEt on display

A loss of communication has

been detected on the RS485

link to the network.

The Remote Keypad has an RS485 Network Timeout Protection setting (Pr 3). This

error is reported when no communication occurs for longer than the timeout setting.

The system will become active as soon as communication is restored.

To clear nEt from the display, press the Data/Prog pushbutton momentarily or send

a Reset command from the network Master.

Soft starter is off and being

display

Modbus Module User Guide 15

programmed from the serial

Finish soft starter network programming procedure and exit Programming Mode.

Issue 1 www.controltechniques.com

Page 16

8. Specifications

Enclosure

Dimensions ........................................................................................................................... 35 mm (W) x 157 mm (H) x 90 mm (D)

Weight ..................................................................................................................................................................................... 250 g

Protection .................................................................................................................................................................................. IP20

Mounting

Spring-action plastic mounting clips (x 2)

Connections

Soft starter ......................................................................................................................................................... 6-way pin assembly

Network ................................................................................................... 5-way male and unpluggable female connector (supplied)

Maximum cable size ........................................................................................................................................................... 2.5 mm2

Settings

Protocol ....................................................................................................................................................... Modbus RTU, AP ASCII

Address range ....................................................................................................................................................................... 0 to 31

Data rate (bps) ......................................................................................................................................... 4800, 9600, 19200, 38400

Parity .......................................................................................................................................................... None, Odd, Even, 10-bit

Timeout ................................................................................................................................................. None (off), 10 s, 60 s, 100 s

Certification

C ........................................................................................................................................................................... IEC 60947-4-2

CE ............................................................................................................................................................................ IEC 60947-4-2

16 Modbus Module User Guide

www.controltechniques.com Issue 1

Loading...

Loading...