Emerson Liebert Deluxe System-3 VE, DE, Liebert Deluxe System-3 DH, Liebert Deluxe System-3 VH User Manual

Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert Deluxe System/3

Operation and Maintenance Manual

50 and 60 Hz, 6-30 Ton DX Systems (DH/DE/VH/VE); 12-60 Ton CW Systems (FH/UH)

™

Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Compressorized Two-Step Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Compressorized Four-Step Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.3 Chilled Water Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.4 GLYCOOL

1.1.5 Dual Source Cooling Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 INITIAL START-UP PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0.1 Additional Considerations for Upflow Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.0 ADVANCED MICROPROCESSOR CONTROLS SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Display the Main Menu—AM Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Main Menu (AM)—Status/Alarm Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.1 Active Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.2 Operating Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.3 Alarm History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.4 Run Hours Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.5 Analog Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Main Menu (AM)—Setpoints/Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.1 View Setpoints Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.2 Setup System Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4.3 Run Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.4 Change Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Main Menu (AM)—Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

™

(Chilled Glycol Cooling) Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.6 Main Menu (AM)—Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7 Load Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7.1 Short Cycle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7.2 Sequential Load Activation Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7.3 Compressor Sequencing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.8 Control Circuit Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.8.1 LCD Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.8.2 Nonvolatile Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.8.3 DIP Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.8.4 Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.9 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.9.1 Monitor functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.9.2 View/Change Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.0 ADVANCED MICROPROCESSOR WITH GRAPHICS CONTROL SETUP . . . . . . . . . . . . . . . . . . .18

4.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Display the Main Menu—AG Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Main Menu (AG)—Status Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

i

Page 4

4.4 Main Menu (AG)—View/Set Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.1 Active Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.2 Alarm History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.3 Setup Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.4 Set Up Custom Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.5 View Water Detect Floor Plan (for optional LTM1000/LT750) . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.6 Setup Water Detect Floor Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Main Menu (AG)—Operating Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Main Menu (AG)—View/Set Control Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7 Main Menu (AG)—Setup System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7.1 Setup Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7.2 Select Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7.3 Calibrate Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7.4 Calibrate Valve Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7.5 Select Control Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7.6 Select Humidity Sensing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.7.7 Set Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.7.8 Change Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.8 Main Menu (AG)—Run Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.8.1 Show Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.8.2 Test Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.8.3 Test Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.8.4 DIP Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.9 Main Menu (AG)—Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.10 Main Menu (AG)—Plot Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.10.1 Modify Plot Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.11 Main Menu (AG)—Analog/Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.11.1 Read Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.11.2 Setup Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.11.3 Read Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.11.4 Set Up Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.12 Main Menu (AG)—View Run Hours Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.12.1 View 24 Hour Run Time History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.12.2 View Total Run Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.13 Load Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.13.1 Short Cycle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.13.2 Sequential Load Activation Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.13.3 Compressor Sequencing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.14 Control Circuit Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.14.1 LCD Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.14.2 Nonvolatile Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.14.3 DIP Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.14.4 Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.15 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.15.1 Monitor functions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.15.2 View/Change Functions:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ii

Page 5

5.0 RESPONSE BY CONTROL TYPE—ADVANCED MICROPROCESSOR CONTROLS . . . . . . . . . . . 33

5.1 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.1 Cooling/Heating Required, in Percent (%) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.2 Response to Control Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.3 Cooling Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1.4 Heating Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2 Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.1 Dehumidification/Humidification Required, in Percent (%) . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.2 Control Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.3 Dehumidification Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.4 Humidification Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.5 Control Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3 Load Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.1 Short Cycle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.2 Sequential Load Activation Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.3 Compressor Sequencing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4 Analog Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4.1 Connecting the Analog Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4.2 Water Detection Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.5 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.5.1 Monitor functions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.5.2 View/Change Functions:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.0 ALARM DESCRIPTIONS AND SOLUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.1 Standard Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1.1 Change Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1.2 Compressor Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1.3 Custom Alarms (Only With Advanced Controls) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.4 High Head Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.5 High Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.6 High Humidity and Low Humidity (Simultaneously) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.7 High Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.8 High Temperature and Low Temperature (Simultaneously) . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.9 Humidifier Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1.10 Loss of Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.11 Loss of Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.12 Low Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.13 Low Suction Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.14 Low Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.15 Main Fan Overload. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.16 Short Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2 Optional/Custom Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2.1 Loss of Water Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2.2 Smoke Detected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2.3 Standby GC Pump On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2.4 Standby Unit On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2.5 Water Under Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

iii

Page 6

7.0 COMPONENT OPERATION AND MAINTENANCE, CHECKS AND ADJUSTMENTS. . . . . . . . . . . . 48

7.1 System Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.1.1 Environmental Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.1.2 Electric Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3 Blower Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.1 Fan Impellers and Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.2 Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.3 Electronic Variable Speed Drive (Inverter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4 Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4.1 Compressor Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4.2 Suction Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.3 Discharge Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.4 Suction Superheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.5 Thermostatic Expansion Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.6 Hot Gas Bypass Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4.7 Air Cooled Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.4.8 Water/Glycol Cooled Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4.9 Compressor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.5 Humidifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.5.1 Infrared Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.5.2 Steam Generating Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.6 Electric Reheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

9.0 MAINTENANCE INSPECTION CHECKLIST—MONTHLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.0 MAINTENANCE INSPECTION CHECKLIST—SEMIANNUAL . . . . . . . . . . . . . . . . . . . . . . . . . . .71

iv

Page 7

FIGURES

Figure 1 Advanced microprocessor control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2 Advanced microprocessor (AM) control menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3 Advanced microprocessor with graphics control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 4 Advanced microprocessor with graphics (AG) control menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 5 Analog input jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 6 Connecting the LT750. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 7 Hot gas bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 8 Outdoor fan/condenser configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 9 Infrared humidifier lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 10 Steam generating humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 11 Run/drain switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 12 Steam generating humidifier control board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

TABLES

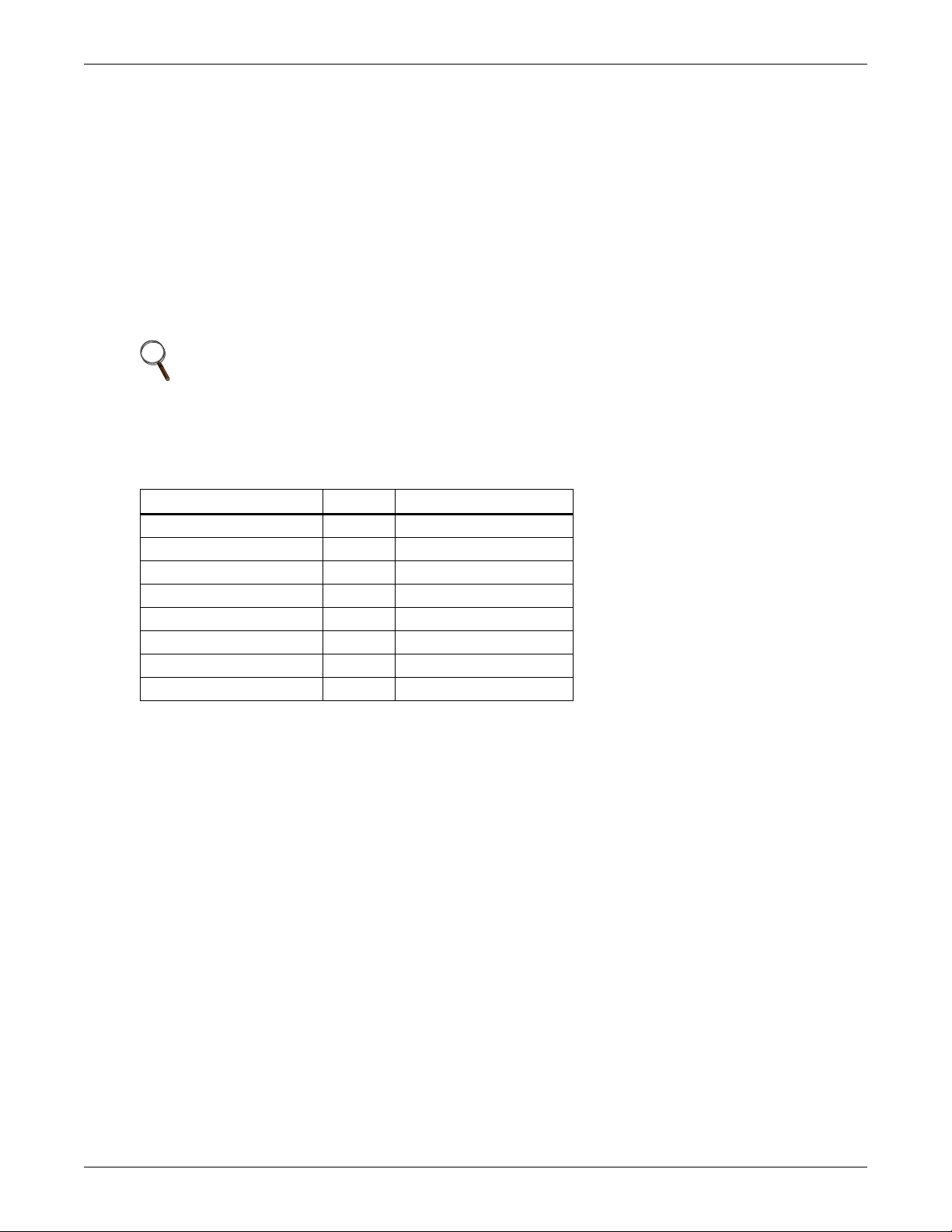

Table 1 Default control and alarm setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2 Setup functions and factory default values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3 Select options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 4 DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 5 Alarm default time delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 6 Control output LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

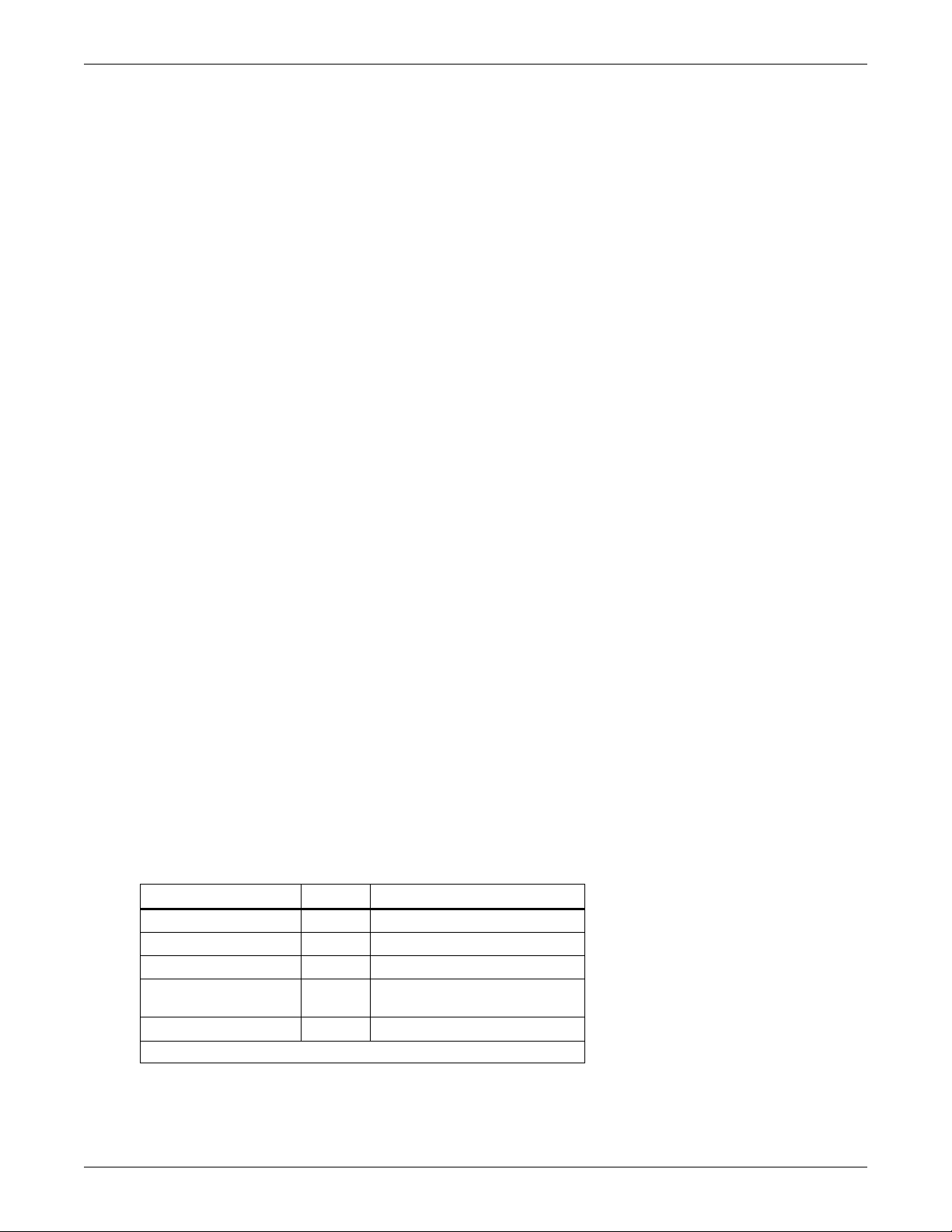

Table 7 Alarm default time delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 8 Default control and alarm setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 9 Setup functions and factory default values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 10 Select options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 11 DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 12 Control output LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 13 Changing factory-set sensor inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 14 Additional connections available after unit delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 15 Suction pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 16 Discharge pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 17 Humidifier canister part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 18 Faults—canister generator humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 19 Steam generating humidifier capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 20 DIP switch settings for steam generating humidifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 21 Blower troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 22 Chilled water troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 23 Compressor and refrigeration system troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 24 Dehumidification troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 25 Glycol pumps troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 26 Humidifier—steam generator troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 27 Humidifier—infrared troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 28 Reheat troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

v

Page 8

vi

Page 9

1.0 INTRODUCTION

1.1 System Description

Liebert Deluxe environmental control systems are available in several configurations. Each configuration can operate with either Advanced Microprocessor Controls (AM), or Advanced Microprocessor

Controls with Graphics (AG). A brief description of each, including operational differences, are listed

below. Check model numbers to see what is supplied with your unit.

1.1.1 Compressorized Two-Step Systems

These systems may be air, water, or glycol cooled - depending on the heat rejection method selected.

Cooling

Two stages of mechanical refrigeration

Heating

Three stages of electric reheat standard; steam/hot water, hot gas on water and glycol-cooled systems

optional

Humidification

Infrared standard, steam grid and steam generating optional

Introduction

Dehumidification

Utilizes the lag compressor

1.1.2 Compressorized Four-Step Systems

The 4-stage systems have all the features of a compressorized 2-stage system plus cylinder unloaders

on one head of each compressor. This permits the compressors to operate at a reduced level and

increases energy efficiency during low load conditions. The system responds to an increasing room

load with either a two step or a four step process of increasing the unit's cooling.

Cooling

Four stages of mechanical refrigeration:

1. Lead compressor at reduced capacity.

2. Lead and lag compressors at reduced capacity.

3. Lead compressor at full capacity; lag compressor at reduced capacity.

4. Lead and lag compressors at full capacity.

Heating

Three stages of electric reheat standard; hot water/steam optional

Humidification

Infrared standard, steam grid and steam generating optional

Dehumidification

Utilizes the lag compressor

1

Page 10

1.1.3 Chilled Water Systems

These systems utilize a central chiller and control cooling by modulating a control valve in the chilled

water line.

Cooling

Modulating output water valve

Heating

Three stages of electric reheat standard; steam/hot water optional

Humidification

Infrared standard, steam grid and steam generating optional

Dehumidification

Chilled water valve opens proportionally in response to room needs

1.1.4 GLYCOOL™ (Chilled Glycol Cooling) Systems

GLYCOOL™ systems have all of the features of a compressorized water or glycol system, plus a second cooling coil that is connected into the water circuit. When fluid temperature is sufficiently low

(below room temperature), cooling is provided by circulating the fluid through the second cooling coil

(with the flow controlled by a motorized valve). This is then the primary cooling source, greatly reducing the compressor operation.

Introduction

Cooling

Modulated cooling valve opens proportionally to match room needs (primary), two or four stages of

mechanical refrigeration (secondary)

Heating

Three stages of electric reheat standard

Humidification

Infrared standard; steam generating optional

Dehumidification

Utilizes the lag compressor

1.1.5 Dual Source Cooling Systems

This system has all the features of a compressorized system but adds a second cooling coil that is connected to a source of chilled water. This second coil is controlled by a modulating control valve. It is

the primary source of cooling and dehumidification so compressor operation is reduced.

Cooling

Second coil opens proportionally in response to the room needs (primary), two or four stages of

mechanical refrigeration (secondary)

Heating

Three stages of electric reheat standard

Humidification

Infrared standard; steam generating optional

Dehumidification

Standard Controls use the lag compressor. Advanced Controls use the chilled water valve and then

the lag compressor if required by the load.

2

Page 11

2.0 INITIAL START-UP PROCEDURE

Before beginning start-up, make certain that unit was installed according to the instructions in the

Installation Manual. All exterior panels must be in place.

Locate the Start-Up form supplied with your unit documents. Complete the form during your start-up

and mail it to Liebert when start-up is completed. Contact your Liebert supplier if you have any questions or problems during your unit installation, start-up, or operation.

WARNING

!

Potentially lethal voltages exist within this equipment during operation. Observe all cautions

and warnings on the unit and in this manual. Failure to do so could result in serious injury or

death. Only qualified service and maintenance personnel should work with this equipment.

1. Disconnect all power to the environmental control unit.

2. Tighten all electrical wiring connections on electric panel and at all major components such as

compressors, reheats, humidifiers and motors which may have loosened during shipping.

3. Remove all line voltage fuses except the main fan fuses at the far right of the electric panel and

the Control Voltage fuses at the far left of the electric panel. For units supplied with circuit

breakers, open them instead of removing fuses.

4. Turn on power and check line voltage on main unit disconnect switch. Line voltage must be

within 10% of nameplate voltage.

5. Turn ON main unit disconnect switch and check secondary voltage at transformer T1. Voltage at

T1 must be 24 VAC ±2.5 VAC (check at TB1-1 and TB1-8). T1 voltage must not exceed 28 VAC.

Change primary tap if necessary.

6. Push ON button. Blower will start and ON lamp will light (lighted switch on Standard Controls

only).

7. If you do not want your unit to operate at factory default settings, set temperature and humidity

setpoints and sensitivity, alarms, and other control functions. Refer to 3.0 - Advanced

Microprocessor Controls Setup or to Advanced Microprocessor with Graphics Control

Setup on page 18.

8. Turn OFF main unit disconnect and main breaker. Unit ON button should be OFF.

9. Replace all fuses you removed during step three (or reset circuit breakers).

10. Restore power to unit; turn ON the main unit disconnect switch.

11. Check the current draw on all line voltage components and match with serial tag.

12. Push ON button, putting the unit into operation.

13. Check for unusual noises and vibration.

14. Check all refrigerant and water lines for leaks.

15. Test all functions of your unit for proper operation.

Initial Start-Up Procedure

Return completed startup form to:

Liebert Corporation

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

2.0.1 Additional Considerations for Upflow Units

These units are manufactured with factory supplied adjustable motor sheaves. Due to variations in

applications, a fixed motor pulley may be desired and can be substituted for the adjustable sheave

after obtaining and confirming the desired air flow. This will reduce vibration and wear on the belts

and pulleys. Consult Liebert Applications Engineering for more information.

3

Page 12

3.0 ADVANCED MICROPROCESSOR CONTROLS SETUP

The Advanced Microprocessor (AM) Control for your Liebert Deluxe unit features an easy to use

menu driven LCD display. The menus, control features, and circuit board details are described in this

section. For more control details refer to 5.0 - Response by Control Type—Advanced Micropro-

cessor Controls, and for more alarm information refer to 6.0 - Alarm Descriptions and Solutions.

3.1 Basics

Control keys include ON/OFF, MENU/ESCAPE, ENTER, Increase (UP) arrow, and Decrease

(DOWN) arrow. Refer to Figure 1. These keys are used to move through the menus as prompted on

the LCD display (refer to Figure 2).

To turn the unit on, press the ON/OFF key after power is applied. To turn the unit off, press the ON/

OFF key before power is disconnected.

Active alarms are displayed on the LCD screen. An audible beeper also annunciates alarms. To

silence an alarm, press the ENTER key as prompted on the display. The unit stores the 10 most

recent alarms for review.

Setpoints, DIP switch settings, and other selections were made on your unit before testing at the factory. Setpoints were chosen based on typical operating experience. Other selections were made based

on options included with your unit. Make adjustments to the factory default selections ONLY if they

do not meet your specifications. When entering setpoints, time delays, etc., the allowable ranges are

displayed and may require a password, if enabled.

Advanced Microprocessor Controls Setup

Figure 1 Advanced microprocessor control panel

3.2 Display the Main Menu—AM Control

Press the MENU/ESC key to display the Main Menu. The menu selections include:

STATUS/ALARM DATA

SETPOINTS/SETUP

DATE AND TIME

STATUS DISPLAY

4

Page 13

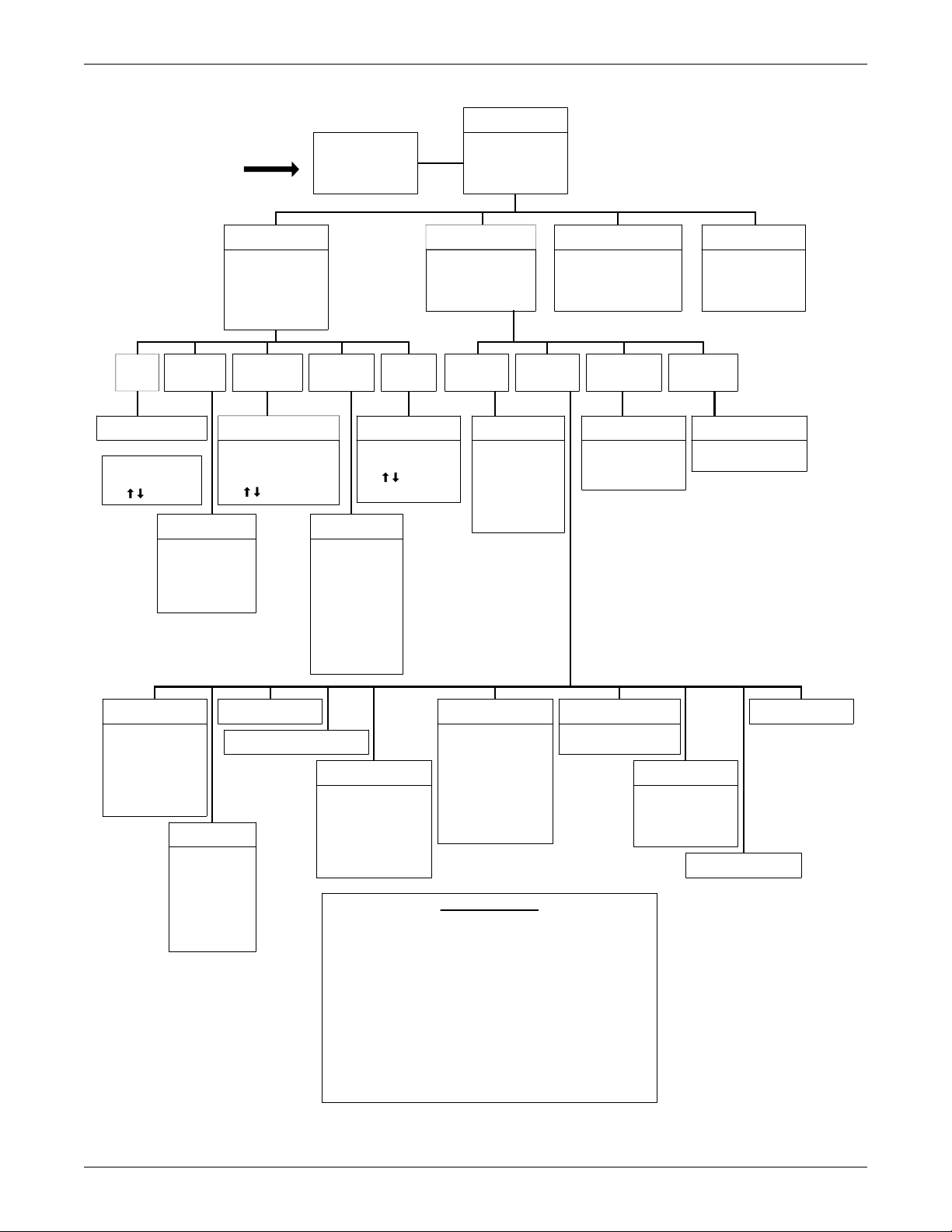

Figure 2 Advanced microprocessor (AM) control menu

Main Menu

Normal

Display

72° 50% Reheat

Cooling

Dehumidifying

No Alarms Present

Status/Alarm Data

Setpoints/Setup

Date and Time

Status Display

Advanced Microprocessor Controls Setup

Active

Alarms

Operating

Status

No Alarms Present

OR

Alarm 01 of 01

High Head PR

Use / to Scroll

Operating Status

DX Cool %

Heat %

Econo Cool %**

CW Valve %**

Dx Deh/Hum

Status Alarm Data

Active Alarms

Operating Status

Alarm History Log

Run Hours Log

Analog Sensors

Alarm

History Log

Alarm History Log

Alarm 01 of 03

15-APR-09:20:45

High Humidity

Use / to Scroll

Run

Hours Log

Analog Sensors

Analog 1(2,3,4)xx

AD#1(2,3,4)

Use / to Scroll

ESCape to Exit

Run Hours Log

C1

C2

™

Glycool

Fan

Hum

RH1

RH2

RH3 - selectable

**

CW Coil

View Setpoints

Setup System

Run Diagnostics

Change Passwords

Analog

Sensors

Setpoints/Setup

View

Setpoints

View Setpoints

Temp Setpoints

Sensitivity

Hi Temp Alarm

Lo Temp Alarm

Hi Hum Alarm

Lo Hum Alarm

Date and Time

15-APR-2001 09:30:00

ENTER to change

ESCape to exit

Setup

System

Diagnostics

Run Diagnostics

Show Inputs

Test Outputs

Test Control Board

Run

Status Display

75°F 59% RH

Cooling

Dehumidifying

No Alarms Present

Change

Passwords

Change Passwords

Setpoint Password

Setup Password

Setup Operation

Cold Start TO

Restart TO

IR Fill Rate

F/C Degrees

Min CW Temp

CW/HW Flush

Select Options

Heating

Humidifier

Dehumidifier

Hum Pan

Hot Gas Reh

Heat Stages

Dehum Stages

Calibrate Sensors

Show DIP Switches (1-7)

Select Control Type

Intelligent

Proportional

Tunable PID

Proportional

Derivative Gain

Integral Gain

Standard Alarms

Humidifier Problems

High Head Pressure

Change Filter

Loss of Air Flow

High Temperature

Low Temperature

High Humidity

Low Humidity

Short Cycle

Low Suction Pressure

Loss of Power

* Some alarms require optional equipment

** Optional

Setup Alarms

Set Time Delays

Enable Alarms

Hum Control Method

Relative

Absolute

Enable Common

Alarm

Set Custom Alarms

Select Alarm

Change Custom

TXT 1,2

Alarms Available*

Custom Alarms

Programmed Alarm Messages

Water Under Floor

Smoke Detected

Standby GC Pump On

Loss of Water Flow

Standby Unit On

User Customized Alarm Messages

Available for Custom Alarms

Calibrate Actuator

Analog Setup

A/O Input 1 (2,3,4)

Slope

Text

Intercept

Set Status Display

5

Page 14

3.3 Main Menu (AM)—Status/Alarm Data

Selecting STATUS/ALARM DATA from the Main Menu will display the following selections:

ACTIVE ALARMS

OPERATING STATUS

ALARM HISTORY LOG

RUN HOURS LOG

ANALOG SENSORS

3.3.1 Active Alarms

This screen, a submenu of Status/Alarm Data, displays any active alarm. The alarms are numbered,

#1 being the most recent. If there are no active alarms, then “NO ALARMS PRESENT” will be displayed.

3.3.2 Operating Status

The Operating Status submenu of Status/Alarm Data informs the user what the control is calling for

the system to do.

NOTE

There may be some time lapse before a specific component matches the displayed number.

For example: The display indicates the chilled water valve is 68% open. On a new call for cooling, it

takes several seconds for the valve to travel from fully closed to 68% open. So when the display reads

68%, it may take a few seconds for the valve to actually open 68%. Also, if the display indicates a compressor is operating but the compressor has not turned on yet, it may be off because of the short cycle

control (see 5.3.1 - Short Cycle Control).

Advanced Microprocessor Controls Setup

3.3.3 Alarm History Log

The Alarm History Log, submenu of Status/Alarm Data, employs nonvolatile memory to retain the

unit’s 10 most recent alarms along with the date and time each occurred. The first alarm in the History Log is the most recent, and the tenth is the oldest. If the alarm history is full—showing 10

alarms—and a new alarm occurs, the oldest is lost and the newest is saved, becoming the first in the

list in alarm history location 1. The rest are moved down the list by one position—the second alarm

becomes the third and so on. The Alarm History Log on a new unit may show the results of factory

testing. Check the unit delivery date to see if this is the case.

3.3.4 Run Hours Log

The total operating hours of all major components in the unit can be monitored from this display, a

submenu of Status/Alarm Data. The information is retained in nonvolatile memory. Run times are

available for the following:

• C1: compressor 1

• C2: compressor 2

• GLYCOOL

•Fan

• HUM: humidifier

• RH1: reheat 1 (or Hot Water Reheat)

•RH2: reheat 2

•RH3: reheat 3

• CW: Chilled Water Coil

The component run hours for each individual component can be reset by selecting the run hours display screen for the desired component, then pressing ENTER within five (5) minutes of applying

power to the control. The user will then be prompted to press ENTER to clear the selected component's run hours.

™

Coil (or Dual Cool Coil)

NOTE

Run hours for a component should only be reset when the component has been replaced.

6

Page 15

3.3.5 Analog Sensors

The four (4) analog sensor inputs can be monitored from this submenu of Status/Alarm Data. The

inputs are filtered and displayed along with the text label assigned during setup. See Analog

Setup on page 12.

3.4 Main Menu (AM)—Setpoints/Setup

Selecting Setpoints/Setup from the Main Menu will display the following selections:

VIEW SETPOINTS

SETUP SYSTEM

RUN DIAGNOSTICS

CHANGE PASSWORDS

NOTE

Setpoints and system setup parameters are kept in nonvolatile memory.

3.4.1 View Setpoints Selection

Control and alarm setpoints can be reviewed or changed with this submenu of Setpoints/Setup. The

following table lists the default setpoints and their allowable ranges.

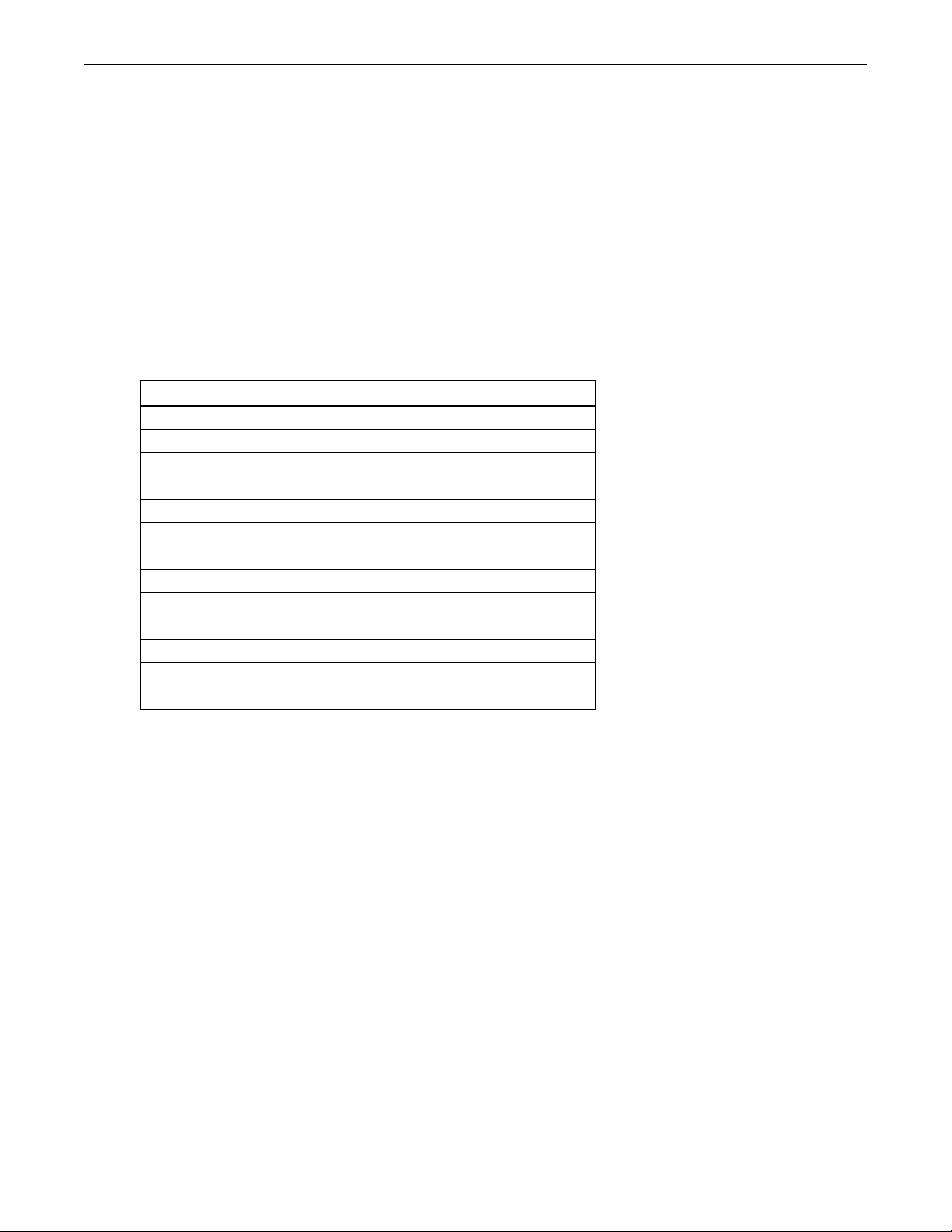

Table 1 Default control and alarm setpoints

Setpoint Default Range

Temperature Setpoint 72°F 40 to 90°F (5 to 32°C)

Temperature Sensitivity 2.0°F 1 to 9.9°F (0.6 to 5.6°C)

Humidity Setpoint 50% 20 to 80% RH

Humidity Sensitivity 5% 1 to 30% RH

High Temperature Alarm 80°F 35 to 95°F (2 to 35°C)

Low Temperature Alarm 65°F 35 to 95°F (2 to 35°C)

High Humidity Alarm 60% 15 to 85% RH

Low Humidity Alarm 40% 15 to 85% RH

Advanced Microprocessor Controls Setup

3.4.2 Setup System Selection

The Setup System, a submenu of Setpoints/Setup, includes the following selections:

SETUP OPERATION

SELECT OPTIONS

CALIBRATE SENSORS

SHOW DIP SWITCHES

SELECT CONTROL TYPE

SETUP ALARMS

HUM CONTROL METHOD

ANALOG SETUP

SET STATUS DISPLAY

CALIBRATE ACTUATOR

7

Page 16

Advanced Microprocessor Controls Setup

Setup Operation

The Setup Operation permits the review and/or adjustment of the unit configuration. The menu may

include:

Cold Start: This feature, also referred to as Positive Start or Winter Start Kit, allows for the lowpressure switch to be ignored for the programmed time during a cold start of the compressors,

enabling the unit to run at low suction pressures. Entering a “0” for this time will bypass this feature.

A “1”, will bypass the low-pressure switch for one minute, a “2” for two minutes, etc. The programmed

value can be from 0 to 3 minutes. This delay is factory set to 0 for water-cooled, glycol cooled, and

GLYCOOL

Restart: This feature allows for the unit to restart automatically after a loss of power. The programmed value is in 0.1 minute (6 seconds) intervals. A programmed value of zero (0) would require

the user to manually press the ON/OFF key to start the unit, i.e. no auto restart. The purpose of this

feature is to prevent several units from starting at the same time after a loss of power. The message

“Restart delay -- Please wait” will be displayed when the system is in the AUTO RESTART mode. (It

is suggested that multiple unit installations be programmed with different auto restart times.)

IR Fill Rate (infrared humidifiers only): An autoflush system automatically controls a water makeup

valve to maintain proper level in the infrared humidifier water pan during humidifier operation. If

humidification is needed and 15 hours have elapsed since the last time the humidifier was on, the

humidifier is held off until the valve completes an initial fill of the humidifier pan. This pre-fill is

about 35 seconds for a small pan and 60 seconds for a large pan. The valve continues to fill and flush

the pan for about 4 1/2 minutes for a small pan or 7 1/2 minutes for a large pan. Pan size is selected

based on unit specifications and is preset at the factory.

™

units. Typically, only air-cooled units need a “Winter Start” time.

During humidifier operation, with the flush rate set at the default of 150%, the valve is opened periodically to add water to the pan (about 45 seconds every 7 minutes of humidifier operation for a small

pan, or 80 seconds every 10 minutes of operation for a large pan). This adds enough water to the pan

to cause about a third of the total water used to be flushed out the overflow standpipe located in the

humidifier pan. This action helps to remove solids from the pan. The flush rate is adjustable from

110% to 500%. If the water quality is poor, it may be desirable to increase the water flushing action

above the normal 150% rate. Also, if the supply water pressure is low, the flush rate adjustment can

be increased so that sufficient water level is maintained during humidification.

Chilled Water/Hot Water/Econ-O-Coil Flush: This feature will flush the respective coil for three

(3) minutes after the programmed number of hours of non-use. For example, if the flush time is programmed with 24 hours on a hot water reheat type system and heating is not required for 24 hours,

the hot water valve will be open for three (3) minutes to allow the coil to be flushed. The programmed

value can be from 0 (zero) (no flush) to 99 (99 hours of non-use).

F/C Degrees: The control can be selected to show readings and setpoints in either degrees Fahrenheit (°F) or Celsius (°C).

The following table lists the Setup functions, their factory default values, and the allowable ranges

that can be programmed:

Table 2 Setup functions and factory default values

Function Default Range

Cold Start Time Delay* 3 0 to 3 min (0 = no delay)

Restart Time Delay 0.1 0 to 9.9 min (0 =manual restart)

Infrared Fill Rate 150 110 to 500%

Chilled/Hot Water

Coil Flush

F/C Degrees F C or F

*Factory set to 0 for water-cooled, glycol, and GLYCOOL™ units.

24 0 to 99 hrs (also Econ-o-coil)

8

Page 17

Advanced Microprocessor Controls Setup

Select Options

The following table lists choices on the Select Options menu. These should match the options installed

with your unit and should not need to change during normal operation.

Table 3 Select options

Option Selection

Heating Yes or No

Humidifier Yes or No

Dehumidifier Yes or No

Humidifier Pan Small or Large

Hot Gas Reheat Yes or No

Heat Stages* 2 or 3

Dehumidification Stages 1 or 2

*If heat stage is set to 2 on a chilled water unit, the

reheat 3 output is energized on a call for dehumidification.

Calibrate Sensors

The temperature and humidity sensors can be calibrated by selecting this menu item. “Sensor” shows

the actual sensor reading or raw reading. “Calibrated” shows the sensor reading after the calibration

offset has been added. The temperature sensor can be calibrated ±5 degrees Fahrenheit and the

humidity sensor can be calibrated ±10% RH. When calibrating the humidity sensor, the value shown

will always be % RH, even though absolute humidity control may be selected. If absolute humidity

control is selected, the Normal Status Display will display the adjusted reading and may not agree

with the relative humidity reading displayed while in calibration.

Show DIP Switches

The DIP switch settings can be reviewed from the display panel. Changing the DIP switches requires

opening the upper panel for access to the DIP switches on the microprocessor control board.

NOTE

Power must be cycled off, then on from the unit disconnect switch for the control system

to update the DIP switch settings (except for switch 8).

Table 4 DIP switch settings

DIP

Switch

Number OFF ON

1 DX Compressor Cool Chilled Water

2 Electric/Hot Gas Reheat Hot Water Reheat

3 2 Step DX 4 Step DX

4 No GLYCOOL GLYCOOL

5 No Dual Cooling Dual Cooling

6 Not Used Not Used

7 Delayed Reheat Dehumidification with Normal Reheat

These selections should match options installed on your unit and should not need to change during

normal operation. Switches 1 through 6 are self-explanatory. Switch 7 is described in more detail

below. DIP switch 8, not shown above, enables the password feature when set to ON and disables the

password feature if set to OFF.

9

Page 18

Advanced Microprocessor Controls Setup

Dehumidification with Normal or Delayed Reheat: Dehumidification with normal reheat allows

for operating BOTH compressors and reheats simultaneously. It is very important that electrical service to the unit be sized and wired for this option if selected.

CAUTION

!

If the electrical service to the unit is not properly sized for this option, it could trip the

building circuit breakers (or fuses) or, in extreme cases, damage the building wiring.

With delayed reheat selected, the reheats are prevented from turning on when dehumidifying with

both compressors until the point at which 100% heating is called for. At this time, the compressors

are turned off until the reheats bring the temperature back up to the point at which the reheats are

turned off.

Select Control Type

• INTELLIGENT

• PROPORTIONAL

• TUNABLE PID

The type of system control method used by the microprocessor can be selected from the front panel.

The default setting is INTELLIGENT, which approximates the actions that a human operator would

take to maintain precise, stable control. The control logic uses Artificial Intelligence techniques

including “fuzzy logic” and “expert systems” methods to maintain precise, stable control and increase

reliability by reducing component cycles. PROPORTIONAL is a standard control method that uses

one gain factor (temperature sensitivity adjustment). TUNABLE PID (Proportional, Integral, and

Derivative) uses three gain factors selected by the operator. PID allows precision tuning, but requires

an experienced operator and seasonal adjustments. Note that if PID is selected, it is used for temperature control while humidity will continue to use Proportional Control. For chilled water units with

the optional Variable Speed Drive, Intelligent Control is required for proper operation.

Refer to 5.0 - Response by Control Type—Advanced Microprocessor Controls for more detail

on types of control.

Setup Alarms

Selecting SETUP ALARMS will step to the following menu:

•SET TIME DELAYS

• ENABLE ALARMS

• ENABLE COMMON ALARM

• SET CUSTOM ALARMS

Each individual alarm can be programmed with a time delay from 0 to 255 seconds. Each individual

alarm can be ENABLED or DISABLED and each individual alarm can be programmed to energize or

not to energize the Common Alarm Relay.

Set Time Delays: By programming a time delay for an alarm, the system will delay the specified

amount of time before recognizing the alarm. The alarm condition must be present for the amount of

time programmed for that alarm before it will be annunciated. If the alarm condition goes away

before the time delay has timed out, the alarm will not be recognized and the time delay timer will be

reset. For software alarms such as Loss of Power, Short Cycle, and Low Suction Pressure, a time

delay will only delay the annunciation of that alarm. The condition of the alarm is not applicable

because the condition has already occurred. For these alarms the time delay should be left at the factory default of 0. The following table shows the default time delays for each alarm.

10

Page 19

Table 5 Alarm default time delay

Alarm Default Delay (seconds)

Humidifier Problem 2

High Head Pressure 1 2

High Head Pressure 2 2

Change Filter 2

Loss of Air Flow 3

Custom Alarm #1 0

Custom Alarm #2 0

Custom Alarm #3 0

Custom Alarm #4 6

High Temperature 30

Low Temperature 30

High Humidity 30

Low Humidity 30

Low Suction Pressure 1, 2 0

Short Cycle 1, 2 0

Compressor #1 Overload 2

Compressor #2 Overload 2

Main Fan Overload 5

Loss of Power 0

Advanced Microprocessor Controls Setup

Enable Alarms: Each individual alarm can be selected to be ENABLED (annunciated audibly, visually, and communicated to a Site Products System) or DISABLED (ignored).

Enable Common Alarm: Each individual alarm can be selected to energize or to not energize the

common alarm relay. If the energize common alarm function is set to YES, the relay is energized

immediately as the alarm is annunciated and de-energized when the alarm condition goes away (only

after the alarm has been recognized). If the function is set to NO, the alarm has no effect on the common alarm relay regardless of whether the alarm is ENABLED or DISABLED.

Set Custom Alarms: The custom alarm messages can be from a list of standard alarm messages or

you can create your own message.

NOTE

Only one (1) or two (2) of the alarm messages can be your own message.

They can be in any location(s) 1 through 4. The text for custom alarms can be changed at any time by

selecting “SET CUSTOM ALARMS”. To change the text for a custom alarm, select “SELECT

ALARM”. Then, select which alarm you would like to change, 1 through 4. Using the UP/DOWN

arrows will step through the list of five standard alarm messages (see Standard Alarm

Messages on page 12) and the two custom alarms.

NOTE

The two custom alarm message will be shown with what was previously programmed in them

and can be changed.

Press ENTER to make your selection. To modify the two custom alarm messages, go back one screen

and select “CHANGE CUSTOM TXT 1” (or 2). Text can be up to 20 characters in length and can be

any of the following characters (or a blank space):

ABCDEFGHIJKLMNOPQRSTUVWXYZ#%*-0123456789.

11

Page 20

Advanced Microprocessor Controls Setup

Standard Alarm Messages

• Water under floor

• Smoke detected

• Standby GC pump on

• Loss of water flow

• Standby unit on

For more information concerning alarms, see 6.0 - Alarm Descriptions and Solutions.

Humidity Control Method

The user may select between relative (direct) and absolute (predictive) humidity control. If relative is

selected, the RH control is taken directly from the RH sensor. If absolute is selected, the RH control is

automatically adjusted as the return air temperature deviates from the desired temperature setpoint.

This results in a predictive humidity control. The display will indicate % RH for both methods of control, but the adjusted humidity reading will be displayed if absolute is selected. With predictive

humidity control, the humidity control is automatically adjusted approximately 2% RH for each

degree difference between the return air temperature and the temperature setpoint.

With relative humidity control, unnecessary dehumidification can result when overcooling occurs during a dehumidification cycle. This is because a higher than normal RH reading is caused by overcooling the room (about 2% RH for each degree of overcooling). This extends the dehumidification cycle.

Later, when the dehumidification ends and the temperature rises to the setpoint, the RH reading

falls. The final RH reading will then be lower than actually desired. If the overcooling was significant

enough, the RH could be low enough to activate the humidifier.

If absolute humidity control is selected, over-dehumidification is avoided. When overcooling occurs,

causing an increase in the RH reading, the humidity control program “predicts” what the RH will be

when the dehumidification cycle ends and temperature returns to the setpoint. This allows the dehumidification cycle to end at the proper time. The predictive humidity control can reduce energy consumption by minimizing compressor and reheat operation, and eliminating unnecessary humidifier

operation.

Analog Setup

For installation of analog sensors, see 5.0 - Response by Control Type—Advanced Microprocessor Controls.

After selecting a compatible sensor and properly wiring it to the terminals, set up the control to monitor the sensor as follows:

Slope: The slope is a multiplier used to scale the input signal. The slope can be positive (rising) or

negative (falling) and can range from 0 (resulting in a horizontal line) to ±999. The slope for a 0-5 volt

input is per 1 volt input, for 0-10 volt input is per 2 volt input, and for 4-20 mA is per 4 mA input. For

example, assuming an intercept of 0, for a 0-10 volt sensor input with a slope of 50, an input of 1 volt

would be displayed as 25: (1x[50/2]); 2 volts would be 50: (2x[50/2]); 3 volts would be 75: (3x[50/2]); etc.

Intercept: The intercept is an offset from point 0 corresponding to 0 volts or 0 mA input. The intercept can be positive or negative and can be a point from 0 to ±999. Adding an intercept of 100 to the

slope example above, 1 volt would be 125: 100 + (1x[50/2]); 2 volts would be 150: 100 + (2x[50/2]); 3

volts would be 175: 100 + (3x[50/2]); etc.

NOTE

For a 4-20 mA input sensor, if the desired reading at 4 mA input is 0, then an intercept of -1 x

slope would be required. For example, assuming a slope of 50, the formula would be ([-1 x 50] +

4 x [50/4]) = 0. The intercept is -50.

Text: You may enter a custom label for each analog input. The text label can be 20 characters in

length including any of the following characters (or a blank space):

ABCDEFGHIJKLMNOPQRSTUVWXYZ#%*-0123456789

12

Page 21

Set Status Display

The Status Display can be set to show the return air temperature and humidity SENSOR READINGS or the temperature and humidity control SETPOINTS through this selection. When SETPOINTS is selected, the status display indicates so by displaying “SETPTS.” If SENSOR READINGS

is selected, the Status Display will show the return air sensor readings.

Calibrate Actuator

For systems that use a valve actuator for chilled water or glycol cooling, the actuator timing may be

calibrated or adjusted. This is the time it takes for the valve to travel from full closed to full open. It is

programmable from 0 to 255 seconds. The factory default time is 165 seconds and should not be

changed unless the actual valve travel time is not correct. The full valve travel time is used by the

control to determine the appropriate valve position. For example, if the valve travel time is 165 seconds and 50% cooling is being called for, the valve will open for 83 seconds to achieve 50% open. To

change the valve travel time, first enter the CALIBRATE ACTUATOR screen. The display will show

the present period used by the control for valve actuator full travel. Press ENTER and adjust the time

using the UP/DOWN arrows. When the correct time is displayed, press ENTER to store the new time

in memory.

3.4.3 Run Diagnostics

From the Run Diagnostics menu, maintenance personnel can check system inputs, outputs, and complete a test of the microcontroller circuit board, all from the front panel. Review of the system inputs

and the microcontroller test can be done without interrupting normal operation. To test the system

outputs, the normal system control is temporarily suspended. DO NOT leave the unit in the diagnostics mode any longer than is necessary for troubleshooting. The control system will return to normal

operation in 5 minutes, automatically, if no key is pressed.

Advanced Microprocessor Controls Setup

Show Inputs

With the unit on and the fan running, the input state for the following devices may be displayed:

• Air sail switch: normally off unless Loss of Air Alarm is active

• Custom alarm #1: normally off unless this alarm is active

• Custom alarm #2: normally off unless this alarm is active

• Custom alarm #3: normally off unless this alarm is active

• Custom alarm #4: normally off unless this alarm is active

• Humidifier problem: normally on unless this alarm is active

• Filter clog: normally off unless Change Filters Alarm is active

• Main fan overload: normally on unless Main Fan Overload Alarm is active

• High Head Comp 2: normally off unless High Head Pressure Alarm Compressor 2 is active

• Comp 2 Overload: normally on unless Compressor 2 Overload Alarm is active

• Shutdown device: normally on unless unit is off through the Fire Stat or Remote Shutdown

Device

• Low press switch 2: normally on if compressor circuit 2 is in operation

• Low press switch 1: normally on if compressor circuit is in operation

• Comp 1 Overload: normally on unless Compressor 1 Overload Alarm is active

• High Head Comp 1: normally off unless High Head Pressure Alarm Compressor 1 is active

13

Page 22

Advanced Microprocessor Controls Setup

Test Outputs

When this feature is selected, the unit is effectively turned off. When stepping from one load to the

next, the previous load, if on, is turned off automatically. The loads can also be toggled on/off by

selecting “ENTER”. Once turned on, the output will remain on for 5 minutes unless toggled off or the

Test Outputs function is exited by selecting “MENU/ESC”. (Compressor is limited to 15 seconds on to

prevent damage.) The outputs are as follows:

• Main fan: main fan contactor

• Comp 1: compressor 1 contactor

• LLSV1: liquid line solenoid valve 1

• HGBP/CUV1: hot gas bypass or compressor 1 unloader valve (on certain units)

• Comp 2: compressor 2 contactor

• LLSV2: liquid line solenoid valve 2

• HGBP/CUV2: hot gas bypass or compressor 2 unloader valve (on certain units)

• CWV/CGV: chilled water or GLYCOOL valve

• R5 relay: Relay 5 (heat rejection)

• Reheat 1: Reheat 1 contactor (also energizes fan for safety)

• Reheat 2: Reheat 2 contactor (also energizes fan for safety)

• RH 3/ Dehum Damper: Reheat 3/ dehum damper contactor (also energizes fan for safety)

• HWR/Steam: hot water or steam valve

• Humidifier: humidifier contactor (also energizes humidifier makeup valve and fan for safety)

• HMV: humidifier makeup valve

• Comm alarm: common alarm relay

CAUTION

!

Do not test a compressor output for more than a few seconds. Compressor damage could

result!

Test Control Board

By selecting this function, the microcontroller will perform a self test lasting approximately 10 seconds. At the end of the test, the ROM checksum, ROM part number and version number will be displayed.

3.4.4 Change Passwords

This function prompts you to enter a three-digit password when making changes. The system

includes two (2) passwords, one for setpoints and one for setup. The system allows the passwords to be

changed by first entering the present password, factory set as “123” for setpoints and “321” for setup.

The password function provides system security, so only personnel authorized to make changes

should know the passwords. If unauthorized changes are being made, the passwords may be compromised and new ones should be selected. The password function can be disabled by setting DIP switch

8 to OFF.

3.5 Main Menu (AM)—Date and Time

The current date and time is available through the display. This feature allows the date and time to

be read or changed and is accessed by selecting Date and Time from the Main Menu.

The Date and Time is used by the control only for recording the Alarm History.

NOTE

The clock uses the 24 hour system. For example, 17:00 is 5:00 PM. The date and time are

protected by a battery backup.

14

Page 23

3.6 Main Menu (AM)—Status Display

The Status Display shows the present room temperature, humidity, active status functions (cooling,

heating, dehumidifying, humidifying), and active alarms. This is the data normally shown on the control screen. If no key is pressed for five minutes, the system automatically switches to the Status Display. The Status Display may also be selected from the Main Menu. While the Main Menu is

displayed, pressing the MENU/ESC key returns to the Status Display.

3.7 Load Control Features

3.7.1 Short Cycle Control

The control system monitors both compressors and prevents each from turning on within 3 minutes of

being turned off. If this (on, off, on) occurs too often, ten (10) times in one hour, a Short Cycle alarm

could occur.

3.7.2 Sequential Load Activation Control

The control allows only one load output to be energized at a time on a restoration of power or microcontroller reset. Each additional load output will be activated at one second intervals until desired

operating conditions have been met.

3.7.3 Compressor Sequencing Control

The lead compressor is the first one to be turned on when compressor operation is required. The lag

compressor is turned on second if both compressors are required. The control monitors the operating

time of both compressors and will automatically switch lead/lag compressor operation to maintain

less than eight hours difference between the running times of two compressors.

Advanced Microprocessor Controls Setup

When the operating hours on the lead compressor become eight hours greater than on the lag compressor, the lead/lag operation is automatically switched. If the lead compressor is operating by itself

at that time, it will be turned off, the lead/lag operation will be changed, and the new lead compressor

will be turned on.

NOTE

If the hot gas reheat option has been selected, compressor 2 is always the lead compressor.

3.8 Control Circuit Board

The control circuit board is located inside the unit behind the LCD display and control key panel.

Open the front panel for access to the board.

The control board includes an adjustment for LCD display contrast, nonvolatile memory, DIP

switches (which should not require customer changes), control output LEDs and jumpers for board

configuration. The jumpers should be placed as follows:

P5—removed

P12—removed

P19—installed on Pins 1 and 2

P47—installed on Pins 1 and 2

P48—installed on Pins 1 and 2

P50—all jumpers installed for 4-20 mA analog inputs. See Table 14 for other configurations

P51—removed

3.8.1 LCD Display Contrast

The level of contrast due to viewing angle of the LCD display can be adjusted using a small thumb

wheel at the upper left of the control board just under the cable going to the display. The control is

labeled R6.

NOTE

The LED backlighting on the text (4 x 20) display is always lit.

15

Page 24

3.8.2 Nonvolatile Memory

All critical information is stored in nonvolatile memory. Setpoints, setup parameters, and component

run hours are kept inside the microcontroller in EEPROM. Information retained for the alarm history

is kept in non-volatile RAM.

3.8.3 DIP Switches

Equipment options are selected and enabled using DIP switches 1 to 7. These are located at the upper

left of the control board and are labeled SW1. Switch 1 is at the top. These switches are factory set

and should not require any user changes. The setting and function of the switches can be read from

the LCD display and are also described in more detail in 4.8.4 - DIP Switches.

3.8.4 Control Outputs

Active control outputs are indicated with LEDs on the lower section of the control board. Each LED is

lit if the control output is active (on). The LEDs assist in troubleshooting the system.

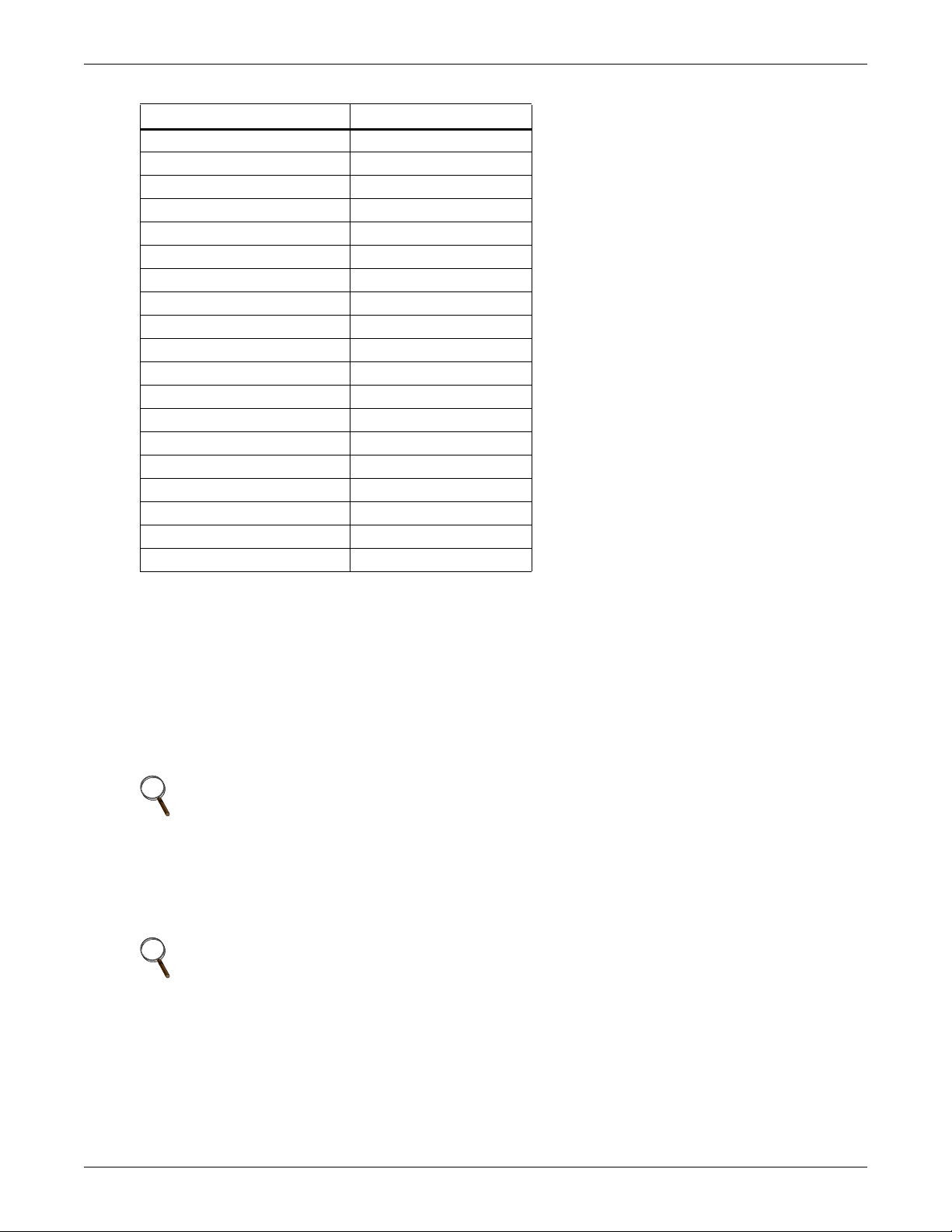

Table 6 Control output LEDs

LED Control Output

R5 Heat Rejection

LLSV1 Liquid Line Solenoid Valve 1

HGBP1 Hot Gas By-Pass or Compressor Unloader Valve

C1 Compressor 1

C2 Compressor 2

RH1 Reheat Stage 1 or Hot Gas Reheat Solenoid

RH2 Reheat Stage 2

RH3 Reheat Stage 3

HUM Humidifier

HGBP2 Hot Gas Bypass 2 or Compressor Unloader Valve 2

FAN Main Fan

HMV Humidifier Make-Up Valve

LLSV2 Liquid Line Solenoid Valve 2

Advanced Microprocessor Controls Setup

3.9 Communications

The control system uses a two-wire, RS-422 channel to communicate with remote monitoring systems

via Liebert Site Products. This communication, directly out of the control, uses a proprietary protocol.

Your unit can have a variety of different Site Product devices wired to this port depending on the

monitoring system you are using.

Liebert Site Product Device

• SiteScan Centralized Monitoring System—Stand-alone facility monitoring system

• SiteLink BMS Interface Module—For Modbus or BACnet communication to a third party monitoring system

• OpenComms Network Interface Card—For Ethernet connection using SNMP protocol

• OpenComms D.O. Interface Card—For discrete outputs of status and alarm conditions

• Mini-Remote—Stand-alone individual unit remote monitor

• ECA2 Communication Adapter—For remote service monitoring directly or via a modem

Consult the user manual of the appropriate device for specific installation and operation information.

16

Page 25

3.9.1 Monitor functions

1. Temperature/Humidity: Present readings

2. Status: Cooling/Heating and Humidifying/Dehumidifying operating status in percent

3. Present Alarms: Alarms presently active

4. Alarm History: 10 most recent alarms (60 most recent alarms for AG)

5. Run Time Log: Operating hours on major components

6. Daily Log: High and Low Temperature & Humidity

3.9.2 View/Change Functions

1. Setpoints

Temperature Setpoint

Temperature Sensitivity

Humidity Setpoint

Humidity Sensitivity

High Temperature Alarm

Low Temperature Alarm

High Humidity Alarm

Low Humidity Alarm

Cold Start Delay

Humidifier Flush Rate

Chilled Water Flush Rate

2. Control Type: proportional, PID, intelligent

3. PID Parameters: Proportional, Derivative and Integral Gains

4. On/Off Status

5. Time: View Only

6. Silence Alarm

Advanced Microprocessor Controls Setup

17

Page 26

Advanced Microprocessor with Graphics Control Setup

4.0 ADVANCED MICROPROCESSOR WITH GRAPHICS CONTROL SETUP

The Advanced Microprocessor with Graphics (AG) Control for your Deluxe unit features an easy-touse, menu-driven LCD Graphics Display. The menus, control features, and circuit board details are

described in this section. For more details on the control refer to 5.0 - Response by Control Type—

Advanced Microprocessor Controls; for details on the alarms refer to 6.0 - Alarm Descriptions

and Solutions.

4.1 Basics

Control keys include ON/OFF, Menu/ESCape, ENTER, Increase (up) arrow, and Decrease (down)

arrow. Refer to Figure 3. These keys are used to move through the menus as prompted on the LCD

display Figure 4.

To turn the unit on, press the ON/OFF key after power is applied. To turn the unit off, press the ON/

OFF key before power is disconnected.

Active alarms are indicated on the LCD screen by a ringing bell graphic. Alarms are also annunciated

by an audible beeper. To silence an alarm, press the ENTER key as prompted on the display. The unit

stores the 60 most recent alarms for review.

Setpoints, DIP switch settings, and other selections were made on your unit after testing at the factory and are kept in nonvolatile memory. Setpoints were chosen based on typical operating experience. Other selections were made based on options included with your unit. Make adjustments to the

factory default selections ONLY if they do not meet your specifications. When entering setpoints, time

delays, etc., the allowable ranges are displayed and may require a password, if enabled.

Figure 3 Advanced microprocessor with graphics control panel

18

Page 27

Advanced Microprocessor with Graphics Control Setup

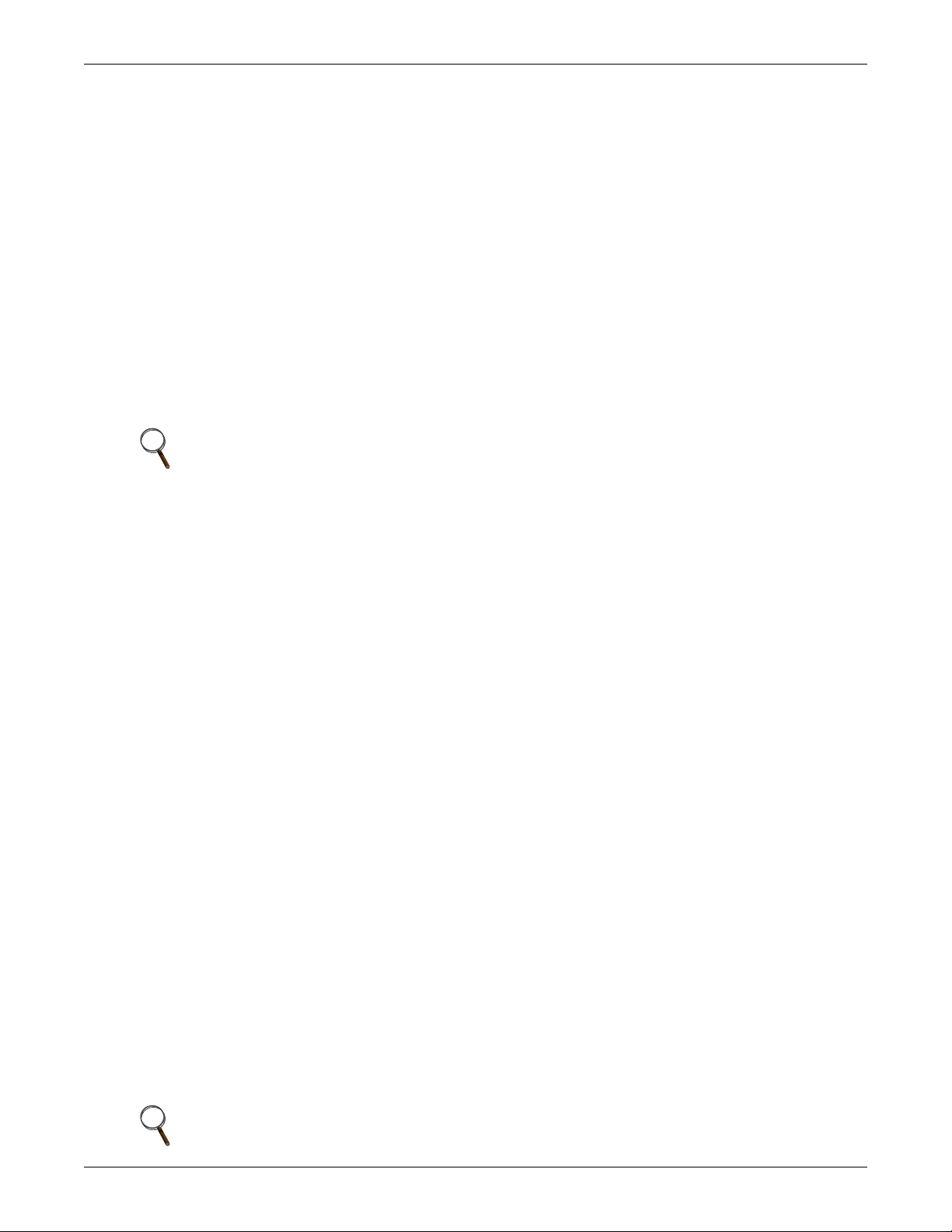

Figure 4 Advanced microprocessor with graphics (AG) control menu

View/Set

Alarms

Compressor Cooling %

Heating %

Glycool %**

Chilled Water Valve %**

Humidification %

Active Alarms

Alarm History Log

Setup Alarms

High Temperature

Low Temperature

High Humidity

Low Humidity

Low Suction Comp 1

Low Suction Comp 2

Short Cycle Comp 1

Short Cycle Comp 2

Compressor 1 Overload

Compressor 2 Overload

Main Fan Overload

Loss of Power

Humidifier Problem

High Head Pressure 1

High Head Pressure 2

Change Filters

Loss of Air Flow

Custom Alarm 1

Custom Alarm 2

Custom Alarm 3

Custom Alarm 4

Setup Custom Alarms

Setup Custom Alarm Text

Change Custom Text 1

Change Custom Text 2

Change Custom Text 3

Change Custom Text 4

View Water

Setup Water

Use / to Locate File

Use ENTER to define file

** Optional

Operating

Status

Operating Status

Detect Floor Plan

Detect Floor Plan

Normal

Display

View/Set Control

Setpoints

Setup Operation

Cold Start Delay

Auto Restart Delay

IR Flush Overfill

CW/HW Coil Flush

Display in Degrees (F/C )

Min Chilled Water Temp**

Select Options

Reheat

Humidify

Dehumidify

Humidifier Pan Size

Hot Gas Reheat

Stages of Reheat

Dehumidification Stages

Calibrate Sensors

Temperature Sensor

Humidity Sensor

Calibrated Reading

Calibrate Valve Actuator

Select Control Algorithm

Proportional

Intelligent

Tunable PID

Proportional Gain

Derivative Gain

Integral Gain

Select Humidity