Page 1

P/N 3-9008-562, Rev E

Daniel™ Models 762, 763, 765, 766 and 767

Control Valves

NPS 2 through 16 / Class 150-600

User manual

January 2016

Page 2

Flow Lifecycle Services for Daniel products

Location Telephone number Fax number

North America/Latin America +1.713.467.6000 +1.713.827.4805

Flow Lifecycle Services for Daniel products +1.713.827.6314 +1.713.827.6312

USA (toll free) +1.888.356.9001 +1.713.827.3380

Asia Pacific (Republic of Singapore) +65.6777.8211 +65.6777.0947.0743

Europe (Stirling Scotland, UK) +44 (0)1786.433400 +44 (0)1786.433401

Middle East Africa (Dubai, UAE) +971 4 8118100 +971 4 8865465

Daniel Measurement and Control, Inc. (Headquarters)

11100 Brittmoore Park Drive

Houston, TX 77041 USA

http://www.EmersonProcess.com

Email

• Customer Service: tech.service@emersonprocess.com

• Customer Support: daniel.cst.support@emerson.com

• Asia-Pacific: danielap.support@emerson.com

• Europe: DanielEMA.CST@EmersonProcess.com

Return Material Authorization (RMA)

A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason. Download the

RMA form from the Support Services web page by selecting the link below.

http://www2.emersonprocess.com/EN-US/BRANDS/DANIEL/SUPPORT-SERVICES/Pages/Support-Services.aspx

Page 3

Signal words and symbols

Pay special attention to the following signal words, safety alert symbols and statements:

Safety alert symbol

This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey all safety messages that follow this symbol

to avoid possible injury or death.

DANGER!

Danger indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING!

Warning indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION!

Caution indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Notice is used to address safety messages or practices not related to personal injury.

Important

Important is a statement the user needs to know and consider.

Tip

Tip provides information or suggestions for improved efficiency or best results.

Note

Note is “general by-the-way” content not essential to the main flow of information.

Page 4

Important safety instructions

Daniel Measurement and Control, Inc. (Daniel) designs, manufactures and tests products to function within specific conditions.

Because these products are sophisticated technical instruments, it is important that the owner and operation personnel must

strictly adhere both to the information printed on the product and to all instructions provided in this manual prior to installation,

operation, and maintenance.

Daniel also urges you to integrate this manual into your training and safety program.

BE SURE ALL PERSONNEL READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ALL NOTICES AND PRODUCT WARNINGS.

WARNING!

Failure to follow the installation, operation or maintenance instructions for a Daniel product could lead to serious injury or death

from explosion or exposure to dangerous substances.

To reduce the risk:

• Comply with all information on the product, in this manual, and in any local and national codes that apply to this product.

• Do not allow untrained personnel to work with this product.

• Use Daniel parts and work procedures specified in this manual.

Product owners (Purchasers):

• Use the correct product for the environment and pressures present. See technical data or product specifications for

limitations. If you are unsure, discuss your needs with your Daniel representative.

• Inform and train all personnel in the proper installation, operation, and maintenance of this product.

• To ensure safe and proper performance, only informed and trained personnel should install, operate, repair and maintain

this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact

Daniel at 1-713-827-6314. You may also download the correct manual from: http://www.daniel.com.

• Save this instruction manual for future reference.

• If you resell or transfer this product, it is your responsibility to forward this instruction manual along with the product to the

new owner or transferee.

• ALWAYS READ AND FOLLOW THE INSTALLATION, OPERATIONS, MAINTENANCE AND TROUBLESHOOTING MANUAL(S) AND

ALL PRODUCT WARNINGS AND INSTRUCTIONS.

• Do not use this equipment for any purpose other than its intended service. This may result in property damage and/or

serious personal injury or death.

Page 5

Product operation (Personnel):

• To prevent personal injury, personnel must follow all instructions of this manual prior to and during operation of the

product.

• Follow all warnings, cautions, and notices marked on, and supplied with, this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact

Daniel at 1-713-827-6314. You may also download the correct manual from: http://www.daniel.com.

• Read and understand all instructions and operating procedures for this product.

• If you do not understand an instruction, or do not feel comfortable following the instructions, contact your Daniel

representative for clarification or assistance.

• Install this product as specified in the INSTALLATION section of this manual per applicable local and national codes.

• Follow all instructions during the installation, operation, and maintenance of this product.

• Connect the product to the appropriate pressure and electrical sources when and where applicable.

• Ensure that all connections to pressure and electrical sources are secure prior to and during equipment operation.

• Use only replacement parts specified by Daniel. Unauthorized parts and procedures can affect this product's performance,

safety, and invalidate the warranty. “Look-a-like” substitutions may result in deadly fire, explosion, release of toxic

substances or improper operation.

• Save this instruction manual for future reference.

Page 6

Notice

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY, AND WHILE EVERY EFFORT HAS

BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR

IMPLIED, REGARDING THE PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE GOVERNED

BY DANIEL'S TERMS AND CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST. WE RESERVE THE RIGHT TO MODIFY OR IMPROVE

THE DESIGNS OR SPECIFICATIONS OF SUCH PRODUCTS AT ANY TIME.

DANIEL DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF ANY PRODUCT. RESPONSIBILITY FOR

PROPER SELECTION, USE AND MAINTENANCE OF ANY DANIEL PRODUCT REMAINS SOLELY WITH THE PURCHASER AND END-USER.

TO THE BEST OF DANIEL'S KNOWLEDGE THE INFORMATION HEREIN IS COMPLETE AND ACCURATE. DANIEL MAKES NO

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN NO EVENT, SHALL DANIEL BE LIABLE FOR ANY INCIDENTAL,

PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS,

LOSS OF REVENUE OR USE AND COSTS INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS

OF THIRD PARTIES.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY AND MAY BE TRADEMARKS/

REGISTERED TRADEMARKS OF THESE COMPANIES.

Page 7

Warranty and Limitations

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement & Control, Inc. (“Daniel”)

warrants that the licensed firmware embodied in the Goods will execute the programming instructions provided by Daniel, and that

the Goods manufactured by Daniel will be free from defects in materials or workmanship under normal use and care and Services

will be performed by trained personnel using proper equipment and instrumentation for the particular Service provided. The

foregoing warranties will apply until the expiration of the applicable warranty period. Goods are warranted for twelve (12) months

from the date of initial installation or eighteen (18) months from the date of shipment by Daniel, whichever period expires first.

Consumables and Services are warranted for a period of 90 days from the date of shipment or completion of the Services. Products

purchased by Daniel from a third party for resale to Buyer (“Resale Products”) shall carry only the warranty extended by the original

manufacturer. Buyer agrees that Daniel has no liability for Resale Products beyond making a reasonable commercial effort to

arrange for procurement and shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Daniel thereof in

writing during the applicable warranty period, Daniel shall, at its option, correct any errors that are found by Daniel in the firmware

or Services or repair or replace F.O.B. point of manufacture that portion of the Goods or firmware found by Daniel to be defective, or

refund the purchase price of the defective portion of the Goods/Services. All replacements or repairs necessitated by inadequate

maintenance, normal wear and usage, unsuitable power sources or environmental conditions, accident, misuse, improper

installation, modification, repair, use of unauthorized replacement parts, storage or handling, or any other cause not the fault of

Daniel are not covered by this limited warranty, and shall be at Buyer's expense. Daniel shall not be obligated to pay any costs or

charges incurred by Buyer or any other party except as may be agreed upon in writing in advance by Daniel. All costs of dismantling,

reinstallation and freight and the time and expenses of Daniel's personnel and representatives for site travel and diagnosis under

this warranty clause shall be borne by Buyer unless accepted in writing by Daniel. Goods repaired and parts replaced by Daniel

during the warranty period shall be in warranty for the remainder of the original warranty period or ninety (90) days, whichever is

longer. This limited warranty is the only warranty made by Daniel and can be amended only in a writing signed by Daniel. THE

WARRANTIES AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR WARRANTIES OF ANY

KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR ANY OTHER MATTER WITH RESPECT

TO ANY OF THE GOODS OR SERVICES. Buyer acknowledges and agrees that corrosion or erosion of materials is not covered by this

warranty.

2. LIMITATION OF REMEDY AND LIABILITY: Daniel shall not be liable for damages caused by delay in performance. The remedies of

Buyer set forth in this agreement are exclusive. In no event, regardless of the form of the claim or cause of action (whether based in

contract, infringement, negligence, strict liability, other tort or otherwise), shall Daniel's liability to Buyer and/or its customers

exceed the price to Buyer of the specific goods manufactured or services provided by Daniel giving rise to the claim or cause of

action. Buyer agrees that in no event shall Daniel's liability to Buyer and/or its customers extend to include incidental, consequential

or punitive damages. The term “consequential damages” shall include, but not be limited to, loss of anticipated profits, revenue or

use and costs incurred including without limitation for capital, fuel and power, and claims of Buyer's customers.

Page 8

Page 9

Contents

Contents

Part I Plan

Chapter 1 Introduction ..................................................................................................................3

1.1 Purpose of this manual ................................................................................................................3

1.2 Description of the Models 762, 763, 765, 766 and 767 Control Valves ........................................3

1.2.1 General features of the control valve ............................................................................3

1.2.2 Control valve application ..............................................................................................4

1.2.3 Operation overview of the control valve .......................................................................5

1.2.4 Parts list for the Models 762, 763, 765, 766 and 767 Control Valves .............................9

1.3 Agency certifications for the Models 762, 763, 765, 766 and 767 Control Valves ......................41

Chapter 2 Operating conditions and specifications ...................................................................... 43

2.1 Operating conditions for the control valve ................................................................................43

2.1.1 Design considerations ................................................................................................44

2.1.2 Environmental conditions .......................................................................................... 45

2.2 Specifications for the control valve ........................................................................................... 46

2.2.1 Interface requirements ...............................................................................................46

2.2.2 Requirements and limitations for installation ............................................................. 47

2.2.3 Minimum clearances for installation, operation and maintenance ..............................48

Chapter 3 Control valve handling ................................................................................................ 55

3.1 Receive the control valve .......................................................................................................... 55

3.1.1 Unpack and inspect the control valve ......................................................................... 55

3.2 Store the control valve ..............................................................................................................55

3.2.1 Rust inhibitor ............................................................................................................. 55

3.2.2 Pack the control valve ................................................................................................ 55

3.2.3 Storage conditions .....................................................................................................55

Chapter 4 Prepare the control valve for use ................................................................................. 57

4.1 Lifting conditions ......................................................................................................................57

4.2 Lifting requirements for personnel ............................................................................................58

4.2.1 Safety precautions using appropriately rated lifting slings ..........................................58

4.3 Configure the control valve .......................................................................................................59

4.3.1 Orientation and position of the control valve ..............................................................59

4.3.2 Piping recommendations ...........................................................................................60

Part II Install

Chapter 5 Installation prerequisites .............................................................................................65

5.1 Pre-start checks ........................................................................................................................ 65

5.2 Torque information .................................................................................................................. 65

5.3 Torque values (flanges) .............................................................................................................66

5.4 Torque pattern sequences ........................................................................................................ 66

5.5 Tools required for control valve installation ...............................................................................67

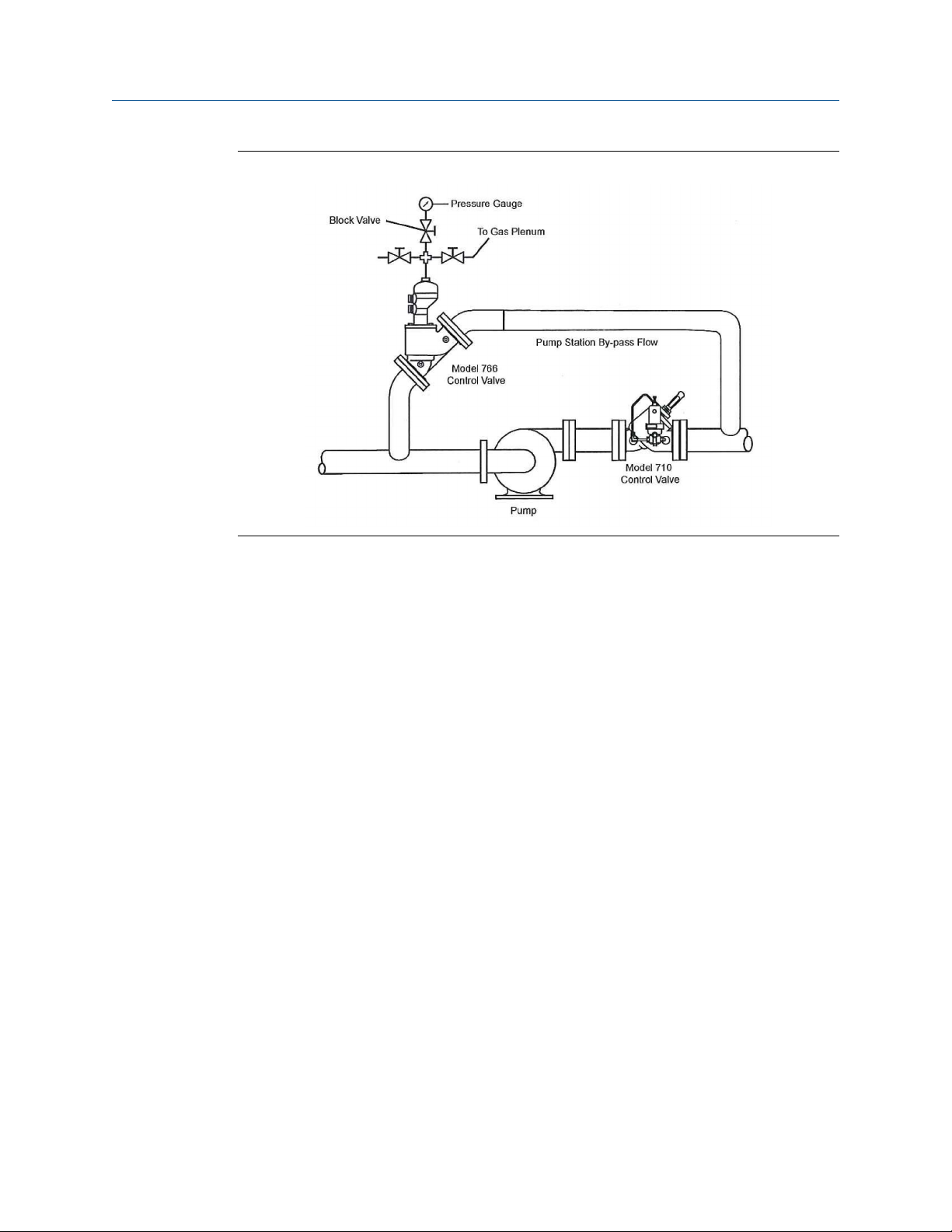

5.6 Typical installation .................................................................................................................... 68

5.7 Nitrogen system ....................................................................................................................... 68

User manual i

Page 10

Contents

5.8 Gas plenum tank installation and sizing .................................................................................... 69

5.9 Nitrogen system panel ..............................................................................................................70

Chapter 6 Installation procedure ................................................................................................. 73

6.1 External components assembly ................................................................................................ 73

6.1.1 Fasteners ....................................................................................................................73

6.2 Oil filling procedure for valve with drain port .............................................................................74

Chapter 7 Testing the product ..................................................................................................... 77

7.1 Commission the control valve ...................................................................................................77

Part III Operate

Chapter 8 Operation parameters .................................................................................................81

8.1 Control valve normal operation ................................................................................................ 81

8.2 Features and benefits ................................................................................................................81

8.3 Oil reservoir .............................................................................................................................. 81

8.4 Applications ............................................................................................................................. 83

Part IV Maintain

Chapter 9 Planned maintenance ..................................................................................................87

9.1 Maintenance considerations ..................................................................................................... 87

9.2 Tools required for mechanical components .............................................................................. 87

9.3 Mechanical disassembly ............................................................................................................88

9.3.1 Cylinder disassembly (NPS 2-12) ................................................................................ 88

9.3.2 Cylinder disassembly NPS 16 valve only ......................................................................89

9.4 Mechanical assembly ................................................................................................................ 91

9.4.1 Valve torque specifications ........................................................................................ 91

9.4.2 Cylinder reassembly (2" - 12" valves with socket head screws in circular pattern on

cylinder head) B style ................................................................................................. 92

9.4.3 Cylinder reassembly (NPS 16 valve only) .....................................................................93

9.5 Planned maintenance tasks ...................................................................................................... 94

Chapter 10 Corrective maintenance .............................................................................................. 95

10.1 Control valve troubleshooting .................................................................................................. 95

10.2 Verify the return to operational condition .................................................................................95

Chapter 11 Spare parts ..................................................................................................................97

11.1 Recommended spare parts ....................................................................................................... 97

Chapter 12 Decommission .......................................................................................................... 101

12.1 Shut down the control valve ................................................................................................... 101

12.2 Shipment of the control valve ................................................................................................. 101

ii Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 11

Part I

Plan

Plan

Chapters covered in this part:

• Introduction

• Operating conditions and specifications

• Control valve handling

• Prepare the control valve for use

User manual 1

Page 12

Plan

2 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 13

1 Introduction

Topics covered in this chapter:

• Purpose of this manual

• Description of the Models 762, 763, 765, 766 and 767 Control Valves

• Agency certifications for the Models 762, 763, 765, 766 and 767 Control Valves

1.1 Purpose of this manual

This manual provides guidance to owners and personnel in the installation, operation and

maintenance of the DanielTM Models 762, 763, 765, 766 and 767 Control Valves manual,

3-9008-562. It is imperative that product owners and operation personnel read and follow

the information contained in this manual to ensure that the control valve is installed

correctly and is operating according to the design certifications and safety considerations.

Introduction

1.2 Description of the Models 762, 763, 765, 766

and 767 Control Valves

1.2.1 General features of the control valve

In many applications, such as pipelines, storage terminals and marine loading and

unloading, it is necessary to include surge relief systems for the purpose of equipment and

personnel protection. Surge pressures result from a sudden change in fluid velocity and,

without surge relief, these surge pressures can damage pipes, other piping components,

equipment and personnel.

These pressure surges can be generated by anything that causes the liquid velocity in a line

to change quickly (e.g., valve closure, pump trip, Emergency Shut Down (ESD) closure) and

subsequently packing pressure. Total surge pressure may be significantly above the

maximum allowable pressure of the system, leading to serious damage to your valuable

assets.

The fundamental requirements of surge relief systems include the need for fast acting,

high capacity valves which can open very quickly to remove surge pressures from the line

and then return to the normal (closed) state quickly but without causing additional

pressure surge during closure. These valves are often required to open fully in very short

periods of time, so that they may pass the entire flowing stream if conditions dictate.

Long pipelines can produce dangerous pressures when static product is shut-in between

valves and thermal expansion occurs. In this situation, pressure relief will be required.

Although the time of operation and valve capacities are not as crucial in such applications,

they remain as key elements of safety in the system and proper regard to selection and

operation is imperative.

User manual 3

Page 14

Introduction

In general, all systems where pressure is contained must have some form of pressure relief,

which is often mandated and regulated by local authorities. The design of such systems is

dependent on a complex range of factors including, but not limited to, the potential for

pressures increases, the volumes which must be passed by the pressure relief equipment

in operation and the capacity of the system to contain pressures.

Typical tank and pressure vessel systems are required to release pressure without passing

large volumes of liquid. Usually these systems operate to relieve vapor from the space

above the liquid using self acting pressure relief valves.

Although these valves are commonly used as pressure relief devices, the nozzle size is

quite small and hence, the capacity for passing liquids is extremely limited. Therefore, such

designs are limited to tank and vessel protection, where overpressure is readily relieved

without the need to pass significant quantities of liquid.

1.2.2 Control valve application

The Daniel Models 762, 763, 765, 766 and 767 Gas Loaded Relief/Back Pressure Control

Valves are specifically designed to regulate and control maximum pipeline pressures or to

maintain a minimum back pressure in a system. They have proven to be reliable, rugged

and very responsive in controlling pipeline surges and pressures. The Daniel Models 762,

763, 765, 766 and 767 Gas Loaded Relief/Back Pressure Control Valves are not pilot

operated. They incorporate an integral oil reservoir mounted on the external surface of the

valve cylinder head, which upon installation, is partially filled with a light oil. Gas under

pressure is then applied to the reservoir. The oil is a moveable barrier between the gas and

the valve piston. This insures that nitrogen gas does not permeate the piston seals which

would result in nitrogen consumption and the need to constantly replenish the system. A

major benefit of the valve design is that all internal parts, including cylinder, piston and

seat ring are removed as a cartridge assembly which keeps your line connections intact.

Applications

• Back pressure control

• Pipeline pump station by-pass

• Pipeline pressure and surge relief

• By-pass pressure control

Features and benefits

• Modular construction

• No diaphragms or stuffing boxes

• Linear control characteristics

• Exceptionally fast response speed

• Positive shut-off

• High flow capacity

• Balanced piston design

• No pilot controls

• Can pass dirty or viscous products

4 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 15

• Screwed seat rings on all sizes

• No consumption of nitrogen gas

NOTICE

The Daniel Models do not comply with any internationally over-pressurization protection

recognized codes. What the Daniel Models do is to allow the movement of an undetermined

amount of substance within a pressurized system, not from a pressurized system.

1.2.3 Operation overview of the control valve

The Daniel Models 762, 763, 765, 766 and 767 control valves are normally closed and

open on increasing inlet pressure. The basic valve is of the balanced piston operated

design. Pressure applied to the inlet side of the piston is equally transmitted to the spring

side of the piston. When the line pressure on the inlet side exceeds the gas pressure plus

the pressure exerted by the spring, the moveable barrier of oil compresses the gas and the

valve opens. As line pressure falls below set point, the gas pressure, added to the spring

pressure, closes the valve and it remains closed as long as gas pressure is greater than the

line pressure. Opening and closing speeds are controlled by a check valve mounted to the

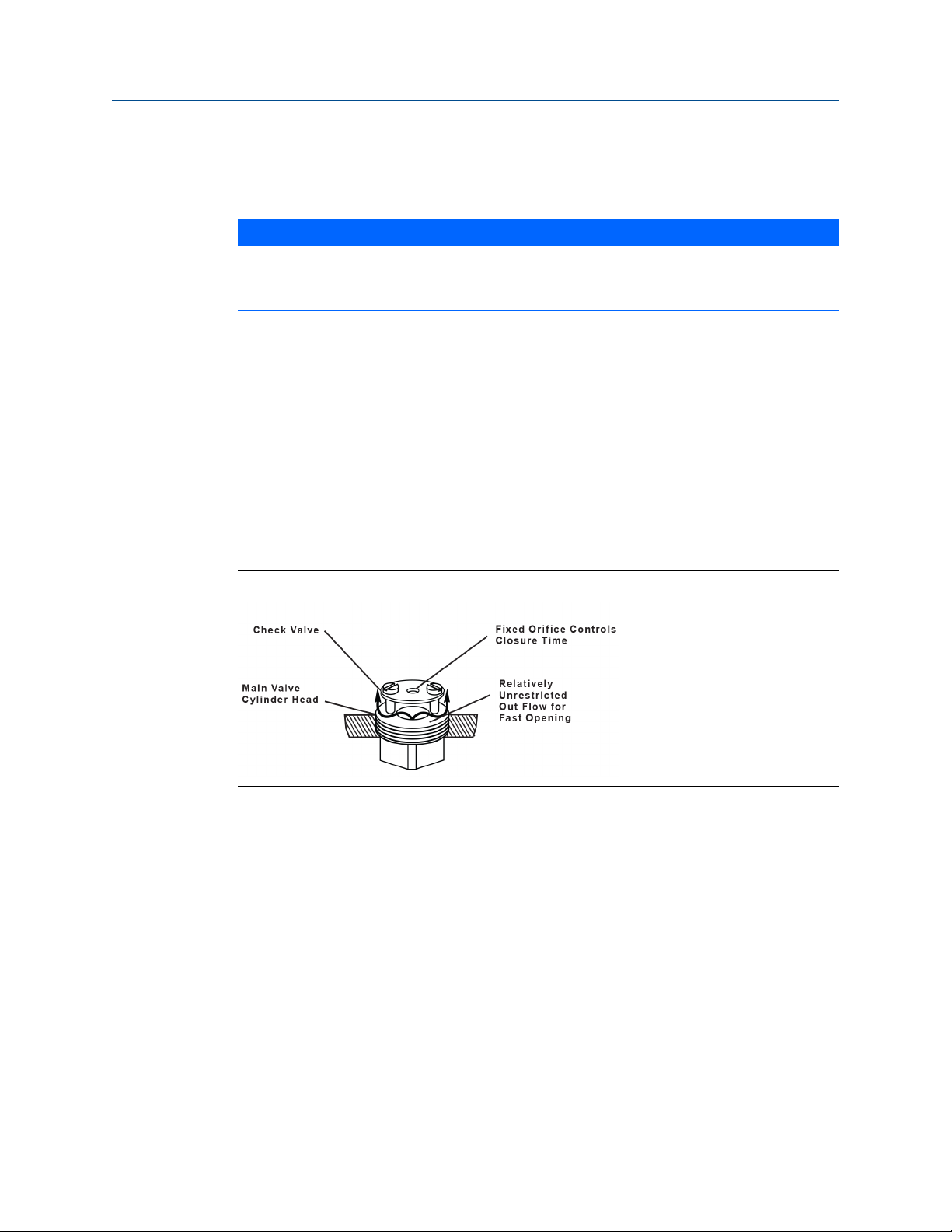

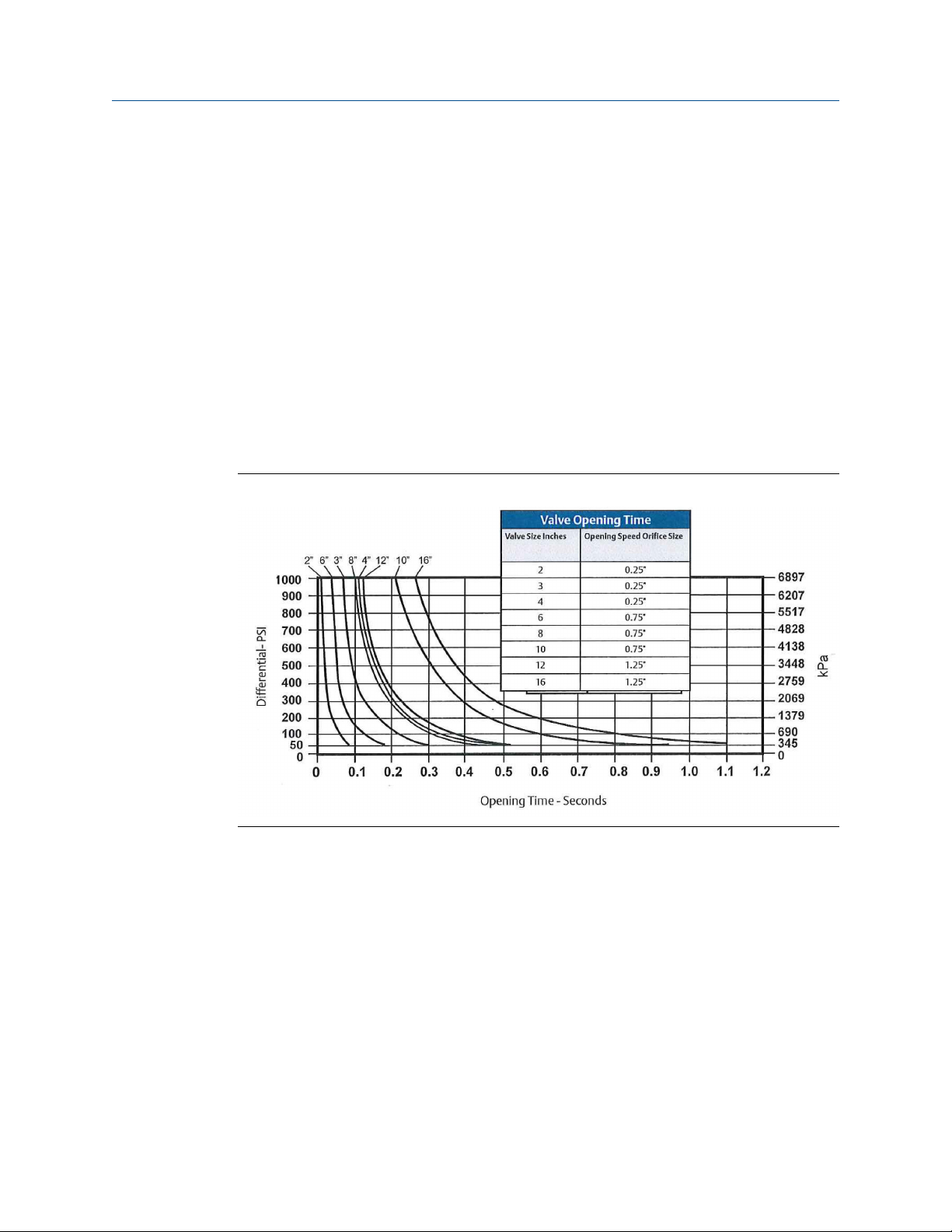

internal surface of the cylinder head as shown in Figure 1-1.

Introduction

Check valveFigure 1-1:

Opening speed is relatively unrestricted which results in very fast opening speed. Closing

speed is controlled by the fixed orifice in the check valve.

These valves are normally closed and open on increasing inlet pressure. The basic valve is

the balanced piston design. Nitrogen gas is used to pressurize the valve piston to keep it in

the closed position. The valve incorporates an integral oil reservoir mounted on the

external surface of the cylinder head, which upon installation, is partially filled with a light

oil. Gas under pressure is applied to the reservoir. The pressure of the nitrogen gas, minus

the 4 psi (force of the valve spring) is the effective set point of the valve. When the pipeline

pressure is less than this total force, the valve will be tightly closed. As pipeline pressure

increases the spring and gas pressure is overcome and the valve opens. The oil is a

moveable barrier between the gas and the valve piston. This should eliminate any

possibility of gas permeating the piston seal which would result in gas bypassing the piston

and gas consumption.

The valve may be mounted in a 45° angle position, horizontally or vertically. Whichever

orientation is specified, the oil reservoir must be vertical.

User manual 5

Page 16

Introduction

Valve orientationFigure 1-2:

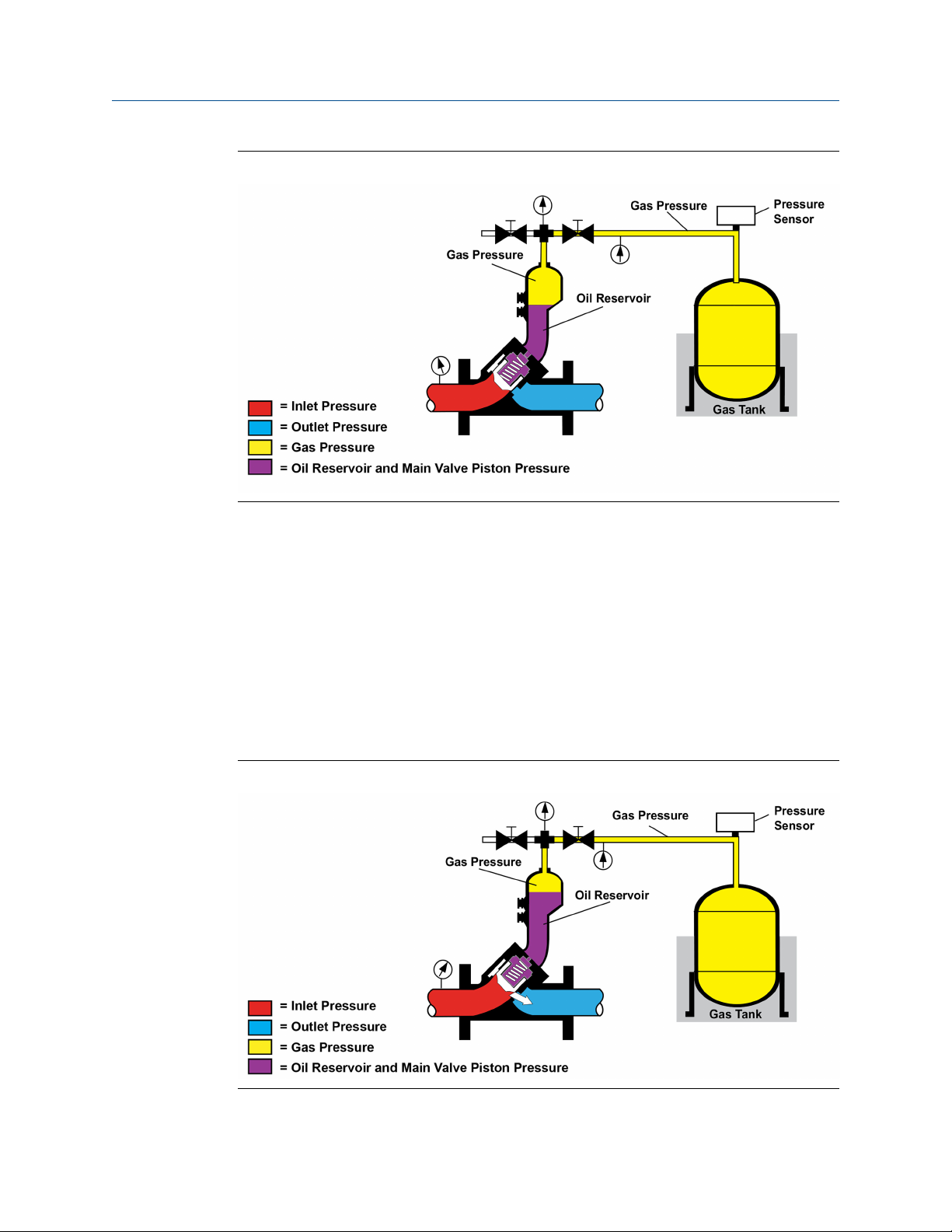

Closed position

Line pressure on the nose of the piston is equally transmitted to the spring side of the

piston. When the nitrogen pressure is applied to the top of the oil, (which is in effect a

moveable barrier between the piston and nitrogen) plus the spring pressure is greater than

line pressure, the valve will be in the closed position. (See below.)

6 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 17

Introduction

Closed positionFigure 1-3:

• The oil reservoir is supplied with two sight gauges. When the valve is closed the oil

level in the reservoir will show oil covering the lower sight glass only.

• Oil visible in both the lower and upper sight gauges indicates that the valve is in the

open position.

• Absence of oil in the lower sight gauge indicates that proper oil capacity has not

been reached or that reservoir oil is leaking into the product system. (See below.)

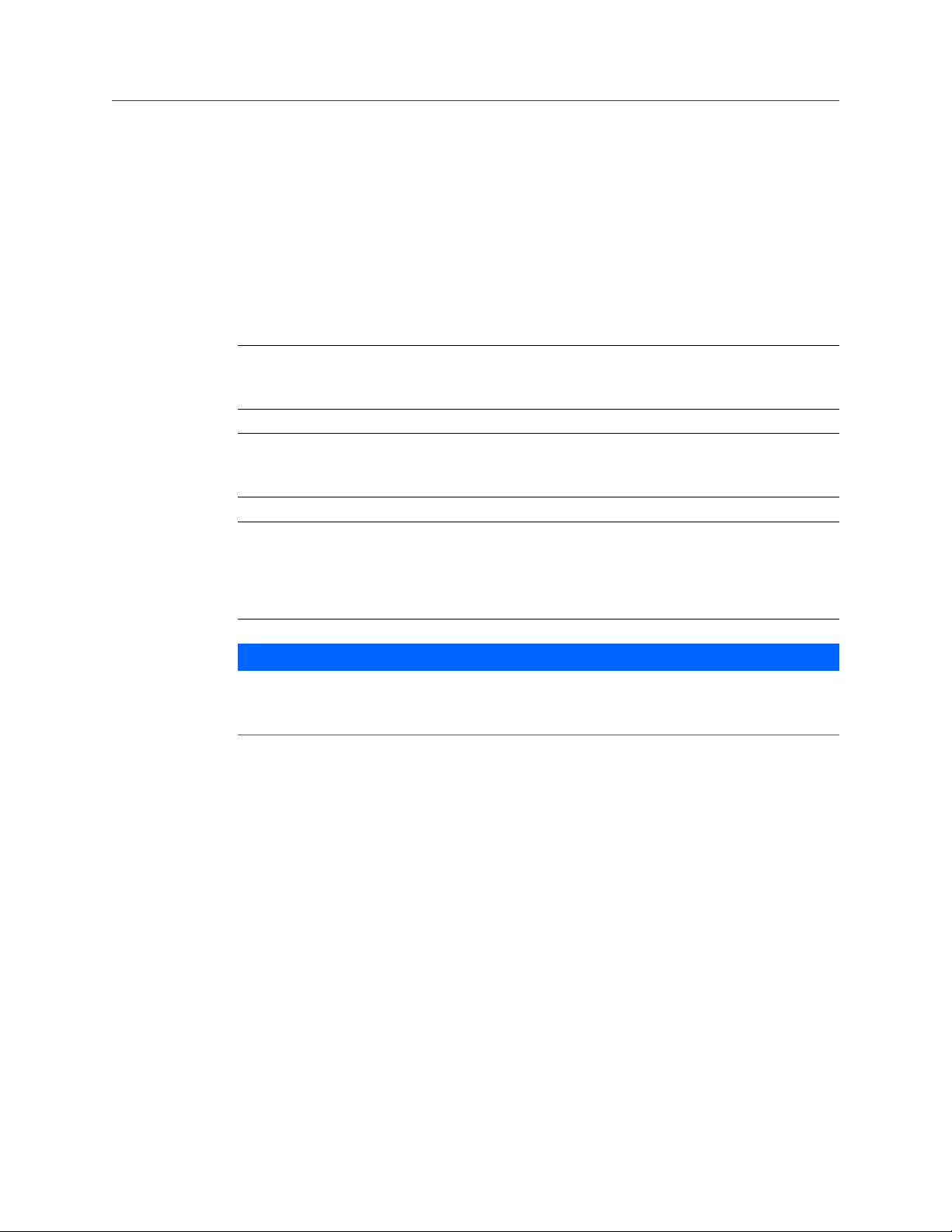

Open position

As pipeline pressure increases, the combined force of the spring and nitrogen gas pressure

is overcome and the valve opens.

Open positionFigure 1-4:

User manual 7

Page 18

Introduction

• Opening and closing speed is controlled by a unique check valve mounted to the

internal surface of the cylinder head. The opening of the valve is relatively

unrestricted, and response time is typically under 100 msec.

• This results in an extremely fast opening response. The opening and closing speeds

are controlled by an orifice in the check valve.

A simple routine visual check can be done to determine if the oil in the sight glass is within

the recommended limits. This makes it easy for a pipeline operations team to be confident

of the surge relief valves readiness.

Note

The spring in the Daniel Nitrogen Loaded Surge Relief Valve is for shipping purposes to ensure piston

movement does not cause damage during shipment. This is the only purpose of this spring.

Note

Equal area on both sides of the piston allow the nitrogen pressure to be set at the actual set point

minus spring force rather than a calculated percentage.

Note

Oil in the reservoir of the Daniel Nitrogen Loaded Surge Relief Valve has many advantages. It allows

the piston seals to be exposed to a clean, lubricant fluid which helps to extend the service life of the

seals tremendously. In addition, it should eliminate the possibility of nitrogen gas permeating the

seals which will ultimately result in a leak and nitrogen consumption.

NOTICE

The Daniel Models do not comply with any internationally over-pressurization protection

recognized codes. What the Daniel Models do is to allow the movement of an undetermined

amount of substance within a pressurized system, not from a pressurized system.

8 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 19

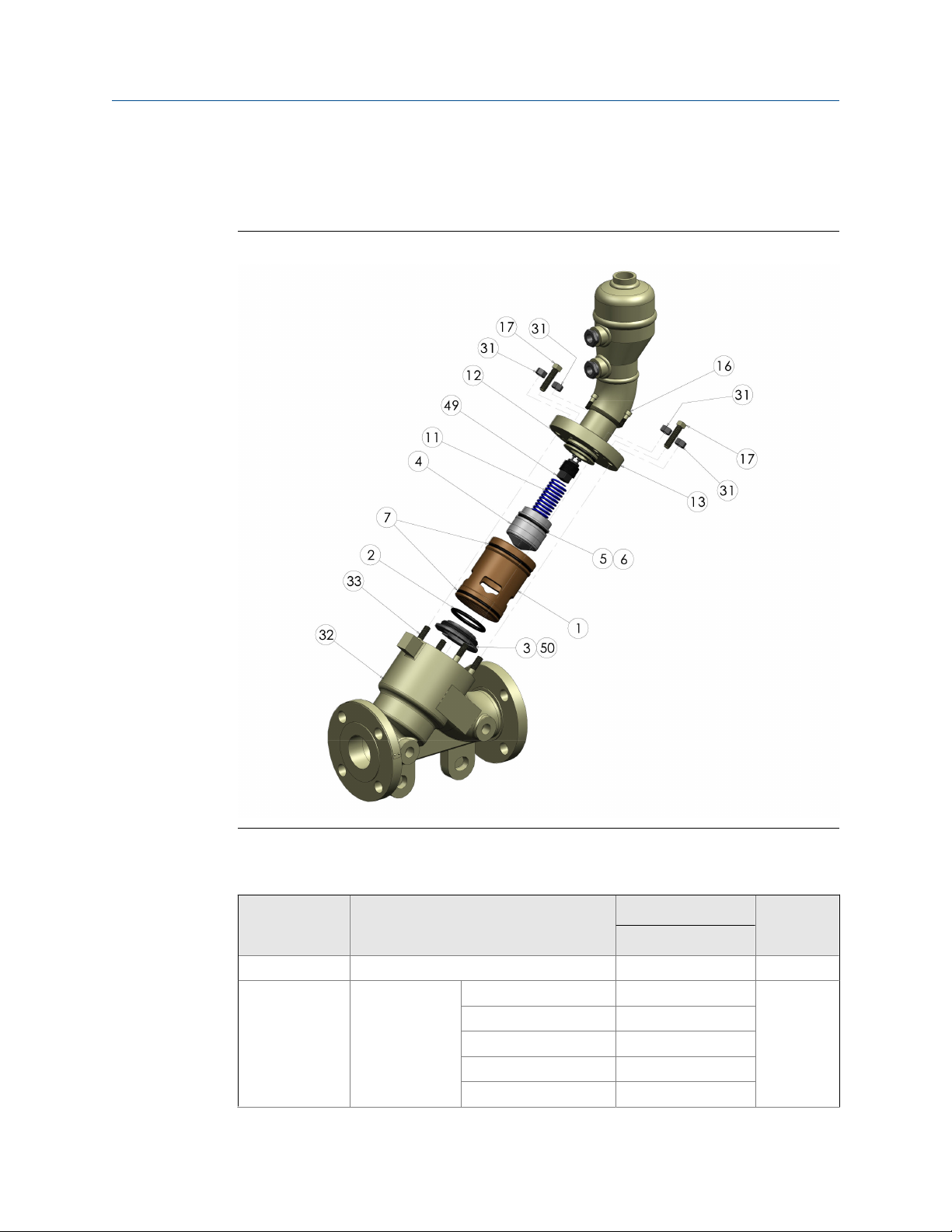

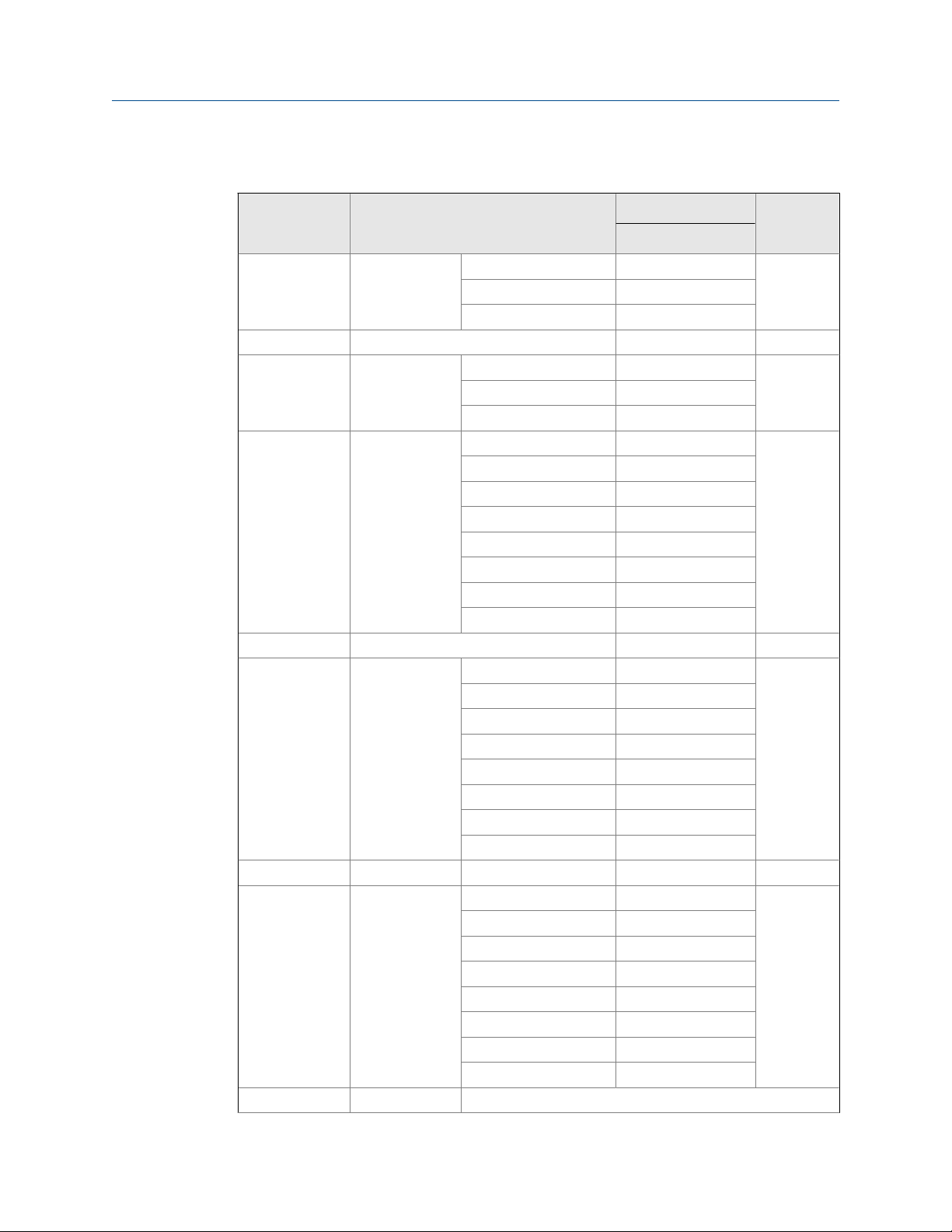

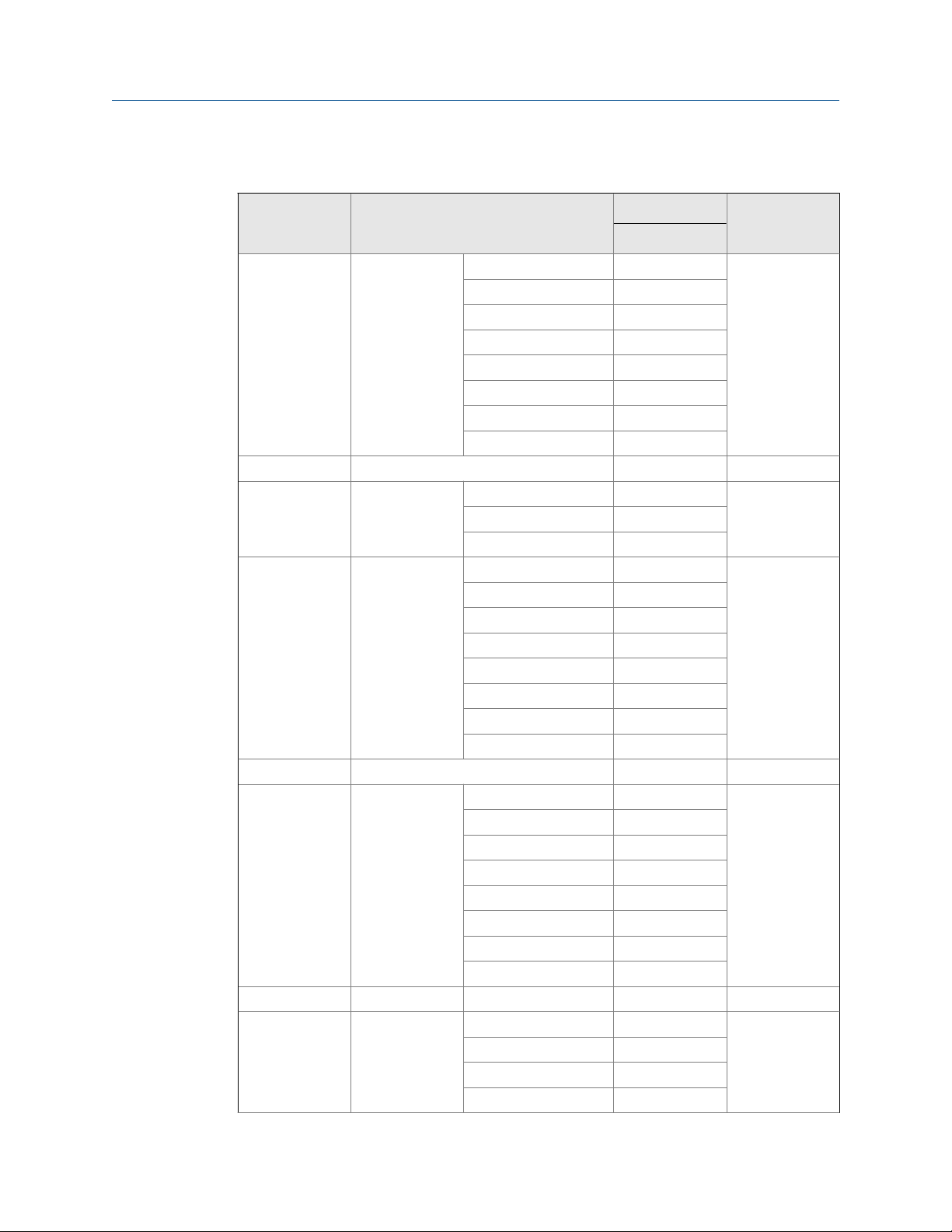

1.2.4 Parts list for the Models 762, 763, 765, 766 and 767 Control Valves

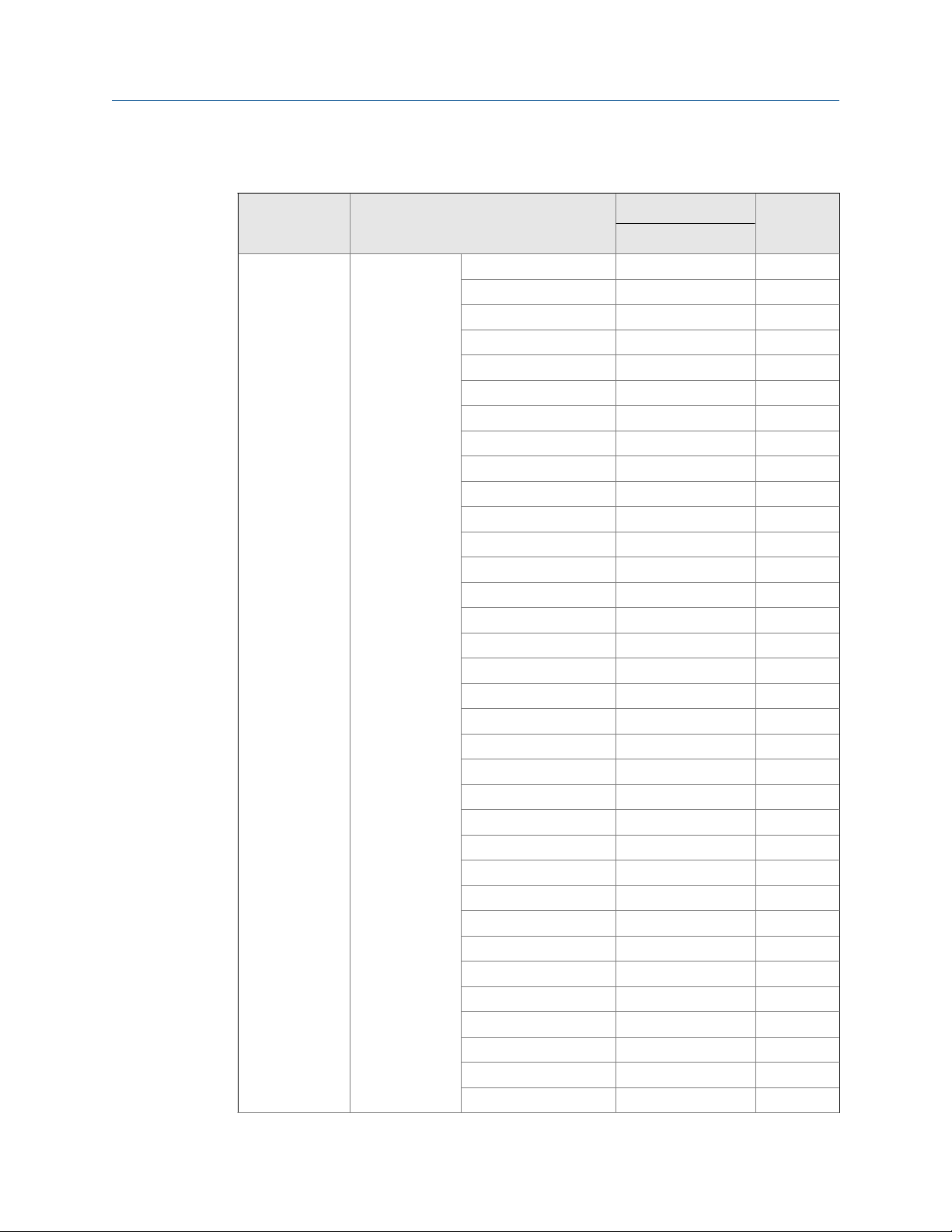

Models 762, 763, 765, 766 and 767 Control Valves NPS 2"-12"Figure 1-5:

Introduction

Table 1-1:

Item number Description

1 Cylinder 526471-690 1

2 O-ring Buna-N 1500399 1

User manual 9

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

2

Part number

2 inch

EPR 1500399-005

FFKM 1500399-075

NBR (Low-swell) 1500399-120

CR 1500399-116

Quantity

Page 20

Introduction

Table 1-1:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

2 (continued)

Part number

Item number Description

FKM 1500399-022

FKM GFLT 1500399-027

FKM V1289 1500399-029

3 Seat ring 526024-610 1

4 Piston Standard 520024-691 1

AP option 520024-693

High-pressure 526024-691

5 O-ring Buna-N 152073 1

EPR 152073-005

FFKM 152073-075

NBR (Low-swell) 152073-120

CR 152073-116

FKM 152073-022

FKM GFLT 152073-027

FKM V1289 152073-029

6 Backup ring 157194 2

7 O-ring Buna-N 157000 2

EPR 157000-005

FFKM 157000-075

NBR (Low-swell) 157000-120

CR 157000-116

FKM 157000-022

FKM GFLT 157000-027

FKM V1289 157000-029

11 Spring Light (blue) 530031 1

12 O-ring Buna-N 157029 1

EPR 157029-005

FFKM 157029-075

NBR (Low-swell) 157029-120

CR 157029-116

FKM 157029-022

FKM GFLT 157029-027

FKM V1289 157029-029

13 Cylinder head Horizontal

2 inch

Quantity

10 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 21

Introduction

Table 1-1:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

2 (continued)

Part number

Item number Description

Class 150 and 300 520754-590M 1

Class 600 526754-590M

45°

Class 150 and 300 520854-590M 1

Class 600 526854-590M

Vertical

Class 150 and 300 520954-590M 1

Class 600 526954-590M

16 Screw Class 150 and 300 151066M 4

Class 600 151032M 4

17 Jack-out screws 150691 2

27 Bal-seal 159775 2

28 Piston seal retainer 520027-690 2

29 External retaining ring 156576 2

31 Nuts Class 150 and 300 151546M 4

Class 600 151553M 4

32 Valve body Class 150 521001M 1

Class 300 523001M

Class 600 526001M

DIN PN 16 521001-016M

DIN PN 40 523001-040M

DIN PN 64 526001-064M

DIN PN 100 526001-100M

33 Studs Class 150 and 300 151309M 4

Class 600 151451M 4

34 Pipe plug 154721 2

49 Check valve assembly 520045-701 1

50 Set screw 150975 1

A Cylinder

assembly class

150 and 300

Horizontal

Buna-N 520770-690 1

EPR 520770-697 1

FFKM 520770-695 1

NBR (Low-swell) 520770-696 1

CR 520770-693 1

2 inch

Quantity

User manual 11

Page 22

Introduction

Table 1-1:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

2 (continued)

Item number Description

Cylinder

assembly class

600

Part number

2 inch

FKM 520770-692 1

FKM GFLT 520770-69G 1

FKM V1289 520770-69M 1

45°

Buna-N 520870-690 1

EPR 520870-697 1

FFKM 520870-695 1

NBR (Low-swell) 520870-696 1

CR 520870-693 1

FKM 520870-692 1

FKM GFLT 520870-69G 1

FKM V1289 520870-69M 1

Vertical

Buna-N 520970-690 1

EPR 520970-697 1

FFKM 520970-695 1

NBR (Low-swell) 520970-696 1

CR 520970-693 1

FKM 520970-692 1

FKM GFLT 520970-69G 1

FKM V1289 520970-69M 1

Horizontal

Buna-N 526770-690 1

EPR 526770-697 1

FFKM 526770-695 1

NBR (Low-swell) 526770-696 1

CR 526770-693 1

FKM 526770-692 1

FKM GFLT 526770-69G 1

FKM V1289 52770-69M 1

45°

Buna-N 526870-690 1

EPR 526870-697 1

FFKM 526870-695 1

Quantity

12 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 23

Introduction

Table 1-1:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

2 (continued)

Item number Description

Part number

Quantity2 inch

NBR (Low-swell) 526870-696 1

CR 526870-693 1

FKM 526870-692 1

FKM GFLT 526870-69G 1

FKM V1289 526870-69M 1

Vertical

Buna-N 526970-690 1

EPR 526970-697 1

FFKM 526970-695 1

NBR (Low-swell) 526970-696 1

CR 526970-693 1

FKM 526970-692 1

FKM GFLT 526970-69G 1

Table 1-2:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

3

Part number

Item number Description

1 Cylinder 536471-690 1

2 O-ring Buna-N 1500480 1

EPR 1500480-005

FFKM 1500480-075

NBR (Low-swell) 1500480-120

CR 1500480-116

FKM 1500480-022

FKM GFLT 1500480-027

FKM V1289 1500480-029

3 Seat ring 536026-610 1

4 Piston Standard 530024-691 1

AP option 530024-693

High-pressure 536024-691

5 O-ring Buna-N 152075 1

EPR 152075-005

3 inch

Quantity

User manual 13

Page 24

Introduction

Table 1-2:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

3 (continued)

Part number

Item number Description

FFKM 152075-075

NBR (Low-swell) 152075-120

CR 152075-116

FKM 152075-022

FKM GFLT 152075-027

FKM V1289 152075-029

6 Backup ring 157195 2

7 O-ring Buna-N 152095 2

EPR 152095-005

FFKM 152095-075

NBR (Low-swell) 152095-120

CR 152095-116

FKM 152095-022

FKM GFLT 152095-027

FKM V1289 152095-029

11 Spring Light (blue) 540031 1

12 O-ring Buna-N 159575 1

EPR 159575-005

FFKM 159575-075

NBR (Low-swell) 159575-120

CR 159575-116

FKM 159575-022

FKM GFLT 159575-027

FKM V1289 159575-029

13 Cylinder head Horizontal

Standard 530754-590M 1

High-pressure 536754-590M

45°

Standard 530854-590M 1

High-pressure 536854-590M

Vertical

Standard 530954-590M 1

High-pressure 536954-590M

16 Screw Class 150 and 300 151012M 6

3 inch

Quantity

14 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 25

Introduction

Table 1-2:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

3 (continued)

Part number

Item number Description

Class 600 151033M 6

17 Jack-out screws 150695 2

27 Bal-seal 159714 2

31 Nuts Class 150 and 300 151547M 4

Class 600 151553M 8

32 Valve body Class 150 531001M 1

Class 300 533001M

Class 600 536001M

DIN PN 16 531001-016M

DIN PN 40 533001-040M

DIN PN 64 536001-064M

DIN PN 100 536001-100M

33 Studs Class 150 and 300 151305M 4

Class 600 151451M 8

34 Pipe plug 154721 2

49 Check valve assembly 530045-701 1

50 Set screw 150975 1

A Cylinder

assembly class

150 and 300

Horizontal

Buna-N 530770-690 1

EPR 530770-697 1

FFKM 530770-695 1

NBR (Low-swell) 530770-696 1

CR 530770-693 1

FKM 530770-692 1

FKM GFLT 530770-69G 1

FKM V1289 530770-69M 1

45°

Buna-N 530870-690 1

EPR 530870-697 1

FFKM 530870-695 1

NBR (Low-swell) 530870-696 1

CR 530870-693 1

FKM 530870-692 1

FKM GFLT 530870-69G 1

3 inch

Quantity

User manual 15

Page 26

Introduction

Table 1-2:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

3 (continued)

Item number Description

Cylinder

assembly class

600

Part number

3 inch

FKM V1289 530870-69M 1

Vertical

Buna-N 530970-690 1

EPR 530970-697 1

FFKM 530970-695 1

NBR (Low-swell) 530970-696 1

CR 530970-693 1

FKM 530970-692 1

FKM GFLT 530970-69G 1

FKM V1289 530970-69M 1

Horizontal

Buna-N 536770-690 1

EPR 536770-697 1

FFKM 536770-695 1

NBR (Low-swell) 536770-696 1

CR 536770-693 1

FKM 536770-692 1

FKM GFLT 53670-69G 1

FKM V1289 536770-69M 1

45°

Buna-N 536870-690 1

EPR 536870-697 1

FFKM 536870-695 1

NBR (Low-swell) 536870-696 1

CR 536870-693 1

FKM 536870-692 1

FKM GFLT 536870-69G 1

FKM V1289 536870-69M 1

Vertical

Buna-N 536970-690 1

EPR 536970-697 1

FFKM 536970-695 1

NBR (Low-swell) 536970-696 1

CR 536970-693 1

Quantity

16 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 27

Introduction

Table 1-2:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

3 (continued)

Part number

Item number Description

FKM 536970-692 1

FKM GFLT 536970-69G 1

Table 1-3:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

4

Part number

Item number Description

1 Cylinder 546471-690 1

2 O-ring Buna-N 152080 1

EPR 152080-005

FFKM 152080-075

NBR (Low-swell) 152080-120

CR 152080-116

FKM 152080-022

FKM GFLT 152080-027

FKM V1289 152080-029

3 Seat ring 546026-610 1

4 Piston Standard 540024-691 1

AP option 540024-693

High-pressure 546024-691

5 O-ring Buna-N 152078 1

EPR 152078-005

FFKM 152078-075

NBR (Low-swell) 152078-120

CR 152078-116

FKM 152078-022

FKM GFLT 152078-027

FKM V1289 152078-029

6 Backup ring 157196 2

7 O-ring Buna-N 152094 2

EPR 152094-005

FFKM 152094-075

NBR (Low-swell) 152094-120

4 inch

Quantity3 inch

Quantity

User manual 17

Page 28

Introduction

Table 1-3:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

4 (continued)

Part number

Item number Description

CR 152094-116

FKM 152094-022

FKM GFLT 152094-027

FKM V1289 152094-029

11 Spring Light (blue) 540031 1

12 O-ring Buna-N 157032 1

EPR 157032-005

FFKM 157032-075

NBR (Low-swell) 157032-120

CR 157032-116

FKM 157032-022

FKM GFLT 152078-027

FKM V1289 152078-029

13 Cylinder head Horizontal

Standard 540754-590M 1

High-pressure 546754-590M

45°

Standard 540854-590M 1

High-pressure 546854-590M

Vertical

Standard 540954-590M 1

High-pressure 546954-590M

16 Screw Class 150 and 300 151012M 6

Class 600 151033M

17 Jack-out screws 150695 2

27 Bal-seal 159715 2

31 Nuts Class 150 and 300 151547M 6

Class 600 151551M 8

32 Valve body Class 150 541001M 1

Class 300 543001M

Class 600 546001M

DIN PN 16 541001-016M

DIN PN 40 543001-040M

DIN PN 64 546001-064M

4 inch

Quantity

18 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 29

Introduction

Table 1-3:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

4 (continued)

Part number

Item number Description

DIN PN 100 546001-100M

33 Studs Class 150 and 300 151305M 6

Class 600 151454M 8

34 Pipe plug Class 150 and 300 154721M 2

Class 600 154704M

49 Check valve assembly 540045-701 1

50 Set screw 150975 1

A Cylinder

assembly class

150 and 300

Horizontal

Buna-N 540770-690 1

EPR 540770-697 1

FFKM 540770-695 1

NBR (Low-swell) 540770-696 1

CR 540770-693 1

FKM 540770-692 1

FKM GFLT 540770-69G 1

FKM V1289 540770-69M 1

45°

Buna-N 540870-690 1

EPR 540870-697 1

FFKM 540870-695 1

NBR (Low-swell) 540870-696 1

CR 540870-693 1

FKM 540870-692 1

FKM GFLT 540870-69G 1

FKM V1289 540870-69M 1

Vertical

Buna-N 540970-690 1

EPR 540970-697 1

FFKM 540970-695 1

NBR (Low-swell) 540970-696 1

CR 540970-693 1

FKM 540970-692 1

FKM GFLT 540970-69G 1

FKM V1289 540970-69M 1

4 inch

Quantity

User manual 19

Page 30

Introduction

Table 1-3:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

4 (continued)

Item number Description

Cylinder

assembly class

600

Part number

Quantity4 inch

Horizontal

Buna-N 546770-690 1

EPR 546770-697 1

FFKM 546770-695 1

NBR (Low-swell) 546770-696 1

CR 546770-693 1

FKM 546770-692 1

FKM GFLT 546770-69G 1

FKM V1289 546770-69M 1

45°

Buna-N 546870-690 1

EPR 546870-697 1

FFKM 546870-695 1

NBR (Low-swell) 546870-696 1

CR 546870-693 1

FKM 546870-692 1

FKM GFLT 54670-69G 1

FKM V1289 546870-69M 1

Vertical

Buna-N 546970-690 1

EPR 546970-697 1

FFKM 546970-695 1

NBR (Low-swell) 546970-696 1

CR 546970-693 1

FKM 546970-692 1

FKM GFLT 546970-69G 1

FKM V1289 546970-69M 1

Table 1-4:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

6

Part number

Item number Description

1 Cylinder 566471-590 1

6 inch

Quantity

20 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 31

Introduction

Table 1-4:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

6 (continued)

Part number

Item number Description

2 O-ring Buna-N 1500407 1

EPR 1500407-005

FFKM 1500407-075

NBR (Low-swell) 1500407-120

CR 1500407-116

FKM 1500407-022

FKM GFLT 1500407-027

FKM V1289 1500407-029

3 Seat ring 566026-610 1

4 Piston Standard 560024-691 1

AP option 560024-693

High-pressure 566024-691

5 O-ring Buna-N 157002 1

EPR 157002-005

FFKM 157002-075

NBR (Low-swell) 157002-120

CR 157002-116

FKM 157002-022

FKM GFLT 157002-027

FKM V1289 157002-029

6 Backup ring 157197 2

7 O-ring Buna-N 152079 2

EPR 152079-005

FFKM 152079-075

NBR (Low-swell) 152079-120

CR 152079-116

FKM 152079-022

FKM GFLT 152079-027

FKM V1289 152079-029

11 Spring Light (blue) 560031 1

12 O-ring Buna-N 159576 1

EPR 159576-005

FFKM 159576-075

NBR (Low-swell) 159576-120

6 inch

Quantity

User manual 21

Page 32

Introduction

Table 1-4:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

6 (continued)

Part number

Item number Description

CR 159576-116

FKM 159576-022

FKM GFLT 159576-027

FKM V1289 159576-029

13 Cylinder head Horizontal

Standard 560754-590M 1

High-pressure 566754-590M

45°

Standard 560854-590M 1

High-pressure 566854-590M

Vertical

Standard 560954-590M 1

High-pressure 566954-590M

16 Screw Class 150 and 300 151012M 8

Class 600 151068M 8

17 Jack-out screws 150695 2

27 Bal-seal 159716 2

31 Nuts Class 150 and 300 151553M 8

Class 600 151558M 8

32 Valve body Class 150 561001M 1

Class 300 563001M

Class 600 566001M

DIN PN 16 561001-016M

DIN PN 40 563001-040M

DIN PN 64 566001-064M

DIN PN 100 566001-100M

33 Studs Class 150 and 300 151347M 8

Class 600 151450M 8

34 Pipe plug Class 150 and 300 154721M 2

Class 600 154704M 2

49 Check valve assembly 560045-701 1

50 Set screw 150975 1

A Cylinder Horizontal

Buna-N 560770-690 1

6 inch

Quantity

22 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 33

Introduction

Table 1-4:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

6 (continued)

Item number Description

assembly class

150 and 300

Cylinder

assembly class

600

Part number

6 inch

EPR 560770-697 1

FFKM 560770-695 1

NBR (Low-swell) 560770-696 1

CR 560770-693 1

FKM 560770-692 1

FKM GFLT 560770-69G 1

FKM V1289 560770-69M 1

45°

Buna-N 560870-690 1

EPR 560870-697 1

FFKM 560870-695 1

NBR (Low-swell) 560870-696 1

CR 560870-693 1

FKM 560870-692 1

FKM GFLT 560870-69G 1

FKM V1289 560870-69M 1

Vertical

Buna-N 560970-690 1

EPR 560970-697 1

FFKM 560970-695 1

NBR (Low-swell) 560970-696 1

CR 560970-693 1

FKM 560970-692 1

FKM GFLT 560970-69G 1

FKM V1289 560970-69M 1

Horizontal

Buna-N 566770-690 1

EPR 566770-697 1

FFKM 566770-695 1

NBR (Low-swell) 566770-696 1

CR 566770-693 1

FKM 566770-692 1

FKM GFLT 566770-69G 1

FKM V1289 566770-69M 1

Quantity

User manual 23

Page 34

Introduction

Table 1-4:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

6 (continued)

Item number Description

Part number

Quantity6 inch

45°

Buna-N 566870-690 1

EPR 566870-697 1

FFKM 566870-695 1

NBR (Low-swell) 566870-696 1

CR 566870-693 1

FKM 566870-692 1

FKM GFLT 566870-69G 1

FKM V1289 566870-69M 1

Vertical

Buna-N 566970-690 1

EPR 566970-697 1

FFKM 566970-695 1

NBR (Low-swell) 566970-696 1

CR 566970-693 1

FKM 566970-692 1

FKM GFLT 566970-69G 1

FKM V1289 566970-69M 1

Table 1-5:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

8

Part number

Item number Description

1 Cylinder 586471-500 1

2 O-ring Buna-N 157006 1

EPR 157006-005

FFKM 157006-075

NBR (Low-swell) 157006-120

CR 157006-116

FKM 157006-022

FKM GFLT 157006-027

FKM V1289 157006-029

3 Seat ring 586026-600 1

8 inch

Quantity

24 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 35

Introduction

Table 1-5:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

8 (continued)

Part number

Item number Description

4 Piston Standard 580057-601 1

AP option 580057-630

High-pressure 586057-601

5 O-ring Buna-N 157005 1

EPR 157005-005

FFKM 157005-075

NBR (Low-swell) 157005-120

CR 157005-116

FKM 157005-022

FKM GFLT 157005-027

FKM V1289 157005-029

6 Backup ring 157198 2

7 O-ring Buna-N 157004 2

EPR 157004-005

FFKM 157004-075

Low-swell NBR 157004-120

CR 157004-116

FKM 157004-022

FKM GFLT 157004-027

FKM V1289 157004-029

11 Spring Light (blue) 580031 1

12 O-ring Buna-N 157074 1

EPR 157074-005

FFKM 157074-075

NBR (Low-swell) 157074-120

CR 157074-116

FKM 157074-022

FKM GFLT 157074-027

FKM V1289 157074-029

13 Cylinder head Horizontal

Standard 580754-590M 1

High-pressure 586754-590M

45°

Standard 580854-590M 1

8 inch

Quantity

User manual 25

Page 36

Introduction

Table 1-5:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

8 (continued)

Part number

Item number Description

High-pressure 586854-590M

Vertical

Standard 580954-590M 1

High-pressure 586954-590M

16 Screw Standard 151072 4

High-pressure 151038 4

17 Jack-out screws 150696 2

27 Bal-seal 159651 2

31 Nuts Class 150 and 300 151558M 4

Class 600 151559M 4

32 Valve body Class 150 581008M 1

Class 300 583001M

Class 600 586001M

DIN PN 16 581001-016M

DIN PN 40 583001-040M

DIN PN 64 586001-064M

DIN PN 100 586001-100M

33 Studs Class 150 and 300 151335M 4

Class 600 151455M 4

34 Pipe plug 154704M 2

49 Check valve assembly 580045-701 1

50 Set screw 150975-019 1

A Cylinder

assembly class

150 and 300

Horizontal

Buna-N 580770-690 1

EPR 580770-697 1

FFKM 580770-695 1

NBR (Low-swell) 580770-696 1

CR 580770-693 1

FKM 580770-692 1

FKM GFLT 580770-69G 1

FKM V1289 580770-69M 1

45°

Buna-N 580870-690 1

EPR 580870-697 1

8 inch

Quantity

26 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 37

Introduction

Table 1-5:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

8 (continued)

Item number Description

Cylinder

assembly class

600

Part number

8 inch

FFKM 580870-695 1

NBR (Low-swell) 580870-696 1

CR 580870-693 1

FKM 580870-692 1

FKM GFLT 580870-69G 1

FKM V1289 580870-69M 1

Vertical

Buna-N 580970-690 1

EPR 580970-697 1

FFKM 580970-695 1

NBR (Low-swell) 580970-696 1

CR 580970-693 1

FKM 580970-692 1

FKM GFLT 50970-69G 1

FKM V1289 580970-69M 1

Horizontal

Buna-N 586770-690 1

EPR 586770-697 1

FFKM 586770-695

NBR (Low-swell) 586770-696

CR 586770-693

FKM 586770-692

FKM GFLT 586770-69G 1

FKM V1289 586770-69M 1

45°

Buna-N 586870-690 1

EPR 586870-697 1

FFKM 586870-695 1

NBR (Low-swell) 586870-696 1

CR 586870-693 1

FKM 586870-692 1

FKM GFLT 586870-69G 1

FKM V1289 586870-69M 1

Vertical

Quantity

User manual 27

Page 38

Introduction

Table 1-5:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

8 (continued)

Part number

Item number Description

Buna-N 586970-690 1

EPR 586970-697 1

FFKM 58970-695 1

NBR (Low-swell) 586970-696 1

CR 586970-693 1

FKM 586970-692 1

FKM GFLT 586970-69G 1

FKM V1289 586970-69M 1

Table 1-6:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

10

Part number

Item number Description

1 Cylinder 606471-510 1

2 O-ring Buna-N 157014 1

EPR 157014-005

FFKM 157014-075

NBR (Low-swell) 157014-120

CR 157014-116

FKM 157014-022

FKM GFLT 157014-027

FKM V1289 157014-029

3 Seat ring 606026-600 1

4 Piston Standard

Buna-N 600057-600 1

FFKM 600057-608

NBR (Low-swell) 600057-60L

CR 600057-603

FKM 600057-602

AP option 600057-631 1

High-pressure

Buna-N 606057-600 1

FKM 606057-602

10 inch

Quantity8 inch

Quantity

28 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 39

Introduction

Table 1-6:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

10 (continued)

Part number

Item number Description

5 O-ring Buna-N 157015 1

EPR 157015-005

FFKM 157015-075

NBR (Low-swell) 157015-120

CR 157015-116

FKM 157015-022

FKM GFLT 157015-027

FKM V1289 157015-029

6 Backup ring 157190 2

7 O-ring Buna-N 157013 2

EPR 157013-005

FFKM 157013-075

NBR (Low-swell) 157013-120

CR 157013-116

FKM 157013-022

FKM GFLT 157013-027

FKM V1289 157013-029

11 Spring Light (blue) 600031 1

12 O-ring Buna-N 157340 1

EPR 157340-005

FFKM 157340-075

NBR (Low-swell) 157340-120

CR 157340-116

FKM 157340-022

FKM GFLT 157340-027

FKM V1289 157340-029

13 Cylinder head Horizontal

Standard 600754-510M 1

High-pressure 606754-590M

45°

Standard 600854-590M 1

High-pressure 606854-590M

Vertical

Standard 600954-590M 1

10 inch

Quantity

User manual 29

Page 40

Introduction

Table 1-6:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

10 (continued)

Part number

Item number Description

High-pressure 606954-590M

16 Screw Standard 151017M 4

High-pressure 151026M 4

17 Jack-out screws 150698 2

27 Bal-seal 159805 2

31 Nuts Class 150 and 300 151559M 4

Class 600 151560M 4

32 Valve body Class 150 601001M 1

Class 300 603001M

Class 600 606001M

DIN PN 16 601001-016M

DIN PN 40 603001-040M

DIN PN 64 606001-064M

DIN PN 100 606001-100M

33 Studs Class 150 and 300 151345M 4

Class 600 151456M 4

34 Pipe plug 154704M 2

49 Check valve assembly 600045-701 1

50 Set screw 150977-019 1

A Cylinder

assembly class

150 and 300

Horizontal

Buna-N 600770-690 1

EPR 600770-697 1

FFKM 600770-695 1

NBR (Low-swell) 600770-696 1

CR 600770-693 1

FKM 600770-692 1

FKM GFLT 600770-69G 1

FKM V1289 600770-69M 1

45°

Buna-N 600870-690 1

EPR 600870-697 1

FFKM 600870-695 1

NBR (Low-swell) 600870-696 1

CR 600870-693 1

10 inch

Quantity

30 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 41

Introduction

Table 1-6:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

10 (continued)

Item number Description

Cylinder

assembly class

600

Part number

10 inch

FKM 600870-692 1

FKM GFLT 600870-69G 1

FKM V1289 600870-69M 1

Vertical

Buna-N 600970-690 1

EPR 600970-697 1

FFKM 600970-695 1

NBR (Low-swell) 600970-696 1

CR 600970-693 1

FKM 600970-692 1

FKM GFLT 60970-69G 1

FKM V1289 600970-69M 1

Horizontal

Buna-N 606770-690 1

EPR 606770-697 1

FFKM 606770-695 1

NBR (Low-swell) 606770-696 1

CR 606770-693 1

FKM 606770-692 1

FKM GFLT 606770-69G 1

FKM V1289 606770-69M 1

45°

Buna-N 606870-690 1

EPR 606870-697 1

FFKM 606870-695 1

NBR (Low-swell) 606870-696 1

CR 606870-693 1

FKM 606870-692 1

FKM GFLT 606870-69G 1

FKM V1289 606870-69M 1

Vertical

Buna-N 606970-690 1

EPR 606970-697 1

FFKM 60970-695 1

Quantity

User manual 31

Page 42

Introduction

Table 1-6:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

10 (continued)

Part number

Item number Description

NBR (Low-swell) 606970-696 1

CR 606970-693 1

FKM 606970-692 1

FKM GFLT 606970-69G 1

FKM V1289 606970-69M 1

Table 1-7:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

12

Part number

Item number Description

1 Cylinder 626471-500 1

2 O-ring Buna-N 157017 1

EPR 157017-005

FFKM 157017-075

NBR (Low-swell) 157017-120

CR 157017-116

FKM 157017-022

FKM GFLT 157017-027

FKM V1289 157017-029

3 Seat ring 626026-600 1

4 Piston Standard

Buna-N 620057-600 1

FKM 620057-602

FKM V1289 620057-6M

AP 620057-630 1

High-pressure

FKM 626057-602 1

FKM V1289 626057-60M

5 O-ring Buna-N 157018 1

EPR 157018-005

FFKM 157018-075

NBR (Low-swell) 157018-120

CR 157018-116

12 inch

Quantity10 inch

Quantity

32 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 43

Introduction

Table 1-7:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

12 (continued)

Part number

Item number Description

FKM 157018-022

FKM GFLT 157018-027

FKM V1289 157018-029

6 Backup ring 157172 2

7 O-ring Buna-N 157019 2

EPR 157019-005

FFKM 157019-075

NBR (Low-swell) 157019-120

CR 157019-116

FKM 157019-022

FKM GFLT 157019-027

FKM V1289 157019-029

11 Spring Light (blue) 620031 1

Medium (bronze) 620029

Heavy (green) 620059-012 1

12 O-ring Buna-N 157030 1

EPR 157030-005

FFKM 157030-075

NBR (Low-swell) 157030-120

CR 157030-116

FKM 157030-022

FKM GFLT 157030-027

FKM V1289 157030-029

13 Cylinder head Horizontal

Standard 620754-590M 1

High-pressure 626754-590M

45°

Standard 620854-590M 1

High-pressure 626854-590M

Vertical

Standard 620954-590M 1

High-pressure 626954-590M

16 Screw Standard 151052M 4

12 inch

620059-018

Quantity

User manual 33

Page 44

Introduction

Table 1-7:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

12 (continued)

Part number

Item number Description

High-pressure 151074M 4

17 Jack-out screws 150697 2

31 Nuts Class 150 and 300 151060M 4

Class 600 151561M 4

32 Valve body Class 150 621001M 1

Class 300 623001M

Class 600 626001M

DIN PN 16 621001-016M

DIN PN 40 623001-040M

DIN PN 64 626001-064M

DIN PN 100 626001-100M

33 Studs Class 150 and 300 151395M 4

Class 600 151457M 4

34 Pipe plug 154704M 2

49 Check valve assembly 620045-701 1

50 Set screw 150977-019 1

A Cylinder

assembly class

150 and 300

Horizontal

Buna-N 620770-690 1

EPR 620770-697 1

FFKM 620770-695 1

NBR (Low-swell) 620770-696 1

CR 620770-693 1

FKM 620770-692 1

FKM GFLT 620770-69G 1

FKM V1289 620770-69M 1

45

Buna-N 620870-690 1

EPR 620870-697 1

FFKM 620870-695 1

NBR (Low-swell) 620870-696 1

CR 620870-693 1

FKM 620870-692 1

FKM GFLT 620870-69G 1

FKM V1289 620870-69M 1

12 inch

Quantity

34 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 45

Introduction

Table 1-7:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

12 (continued)

Item number Description

Cylinder

assembly class

600

Part number

12 inch

Vertical

Buna-N 620970-690 1

EPR 620970-697 1

FFKM 620970-695 1

NBR (Low-swell) 620970-696 1

CR 620970-693 1

FKM 620970-692 1

FKM GFLT 62970-69G 1

FKM V1289 620970-69M 1

Horizontal

Buna-N 626770-690 1

EPR 626770-697 1

FFKM 626770-695 1

NBR (Low-swell) 626770-696 1

CR 626770-693 1

FKM 626770-692 1

FKM GFLT 626770-69G 1

FKM V1289 626770-69M 1

45°

Buna-N 626870-690 1

EPR 626870-697 1

FFKM 626870-695 1

NBR (Low-swell) 626870-696 1

CR 626870-693 1

FKM 626870-692 1

FKM GFLT 626870-69G 1

FKM V1289 626870-69M 1

Vertical

Buna-N 626970-690 1

EPR 626970-697 1

FFKM 62970-695 1

NBR (Low-swell) 626970-696 1

CR 626970-693 1

FKM 626970-692 1

Quantity

User manual 35

Page 46

Introduction

Table 1-7:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

12 (continued)

Item number Description

Part number

Quantity12 inch

FKM GFLT 626970-69G 1

FKM V1289 62970-69M 1

36 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 47

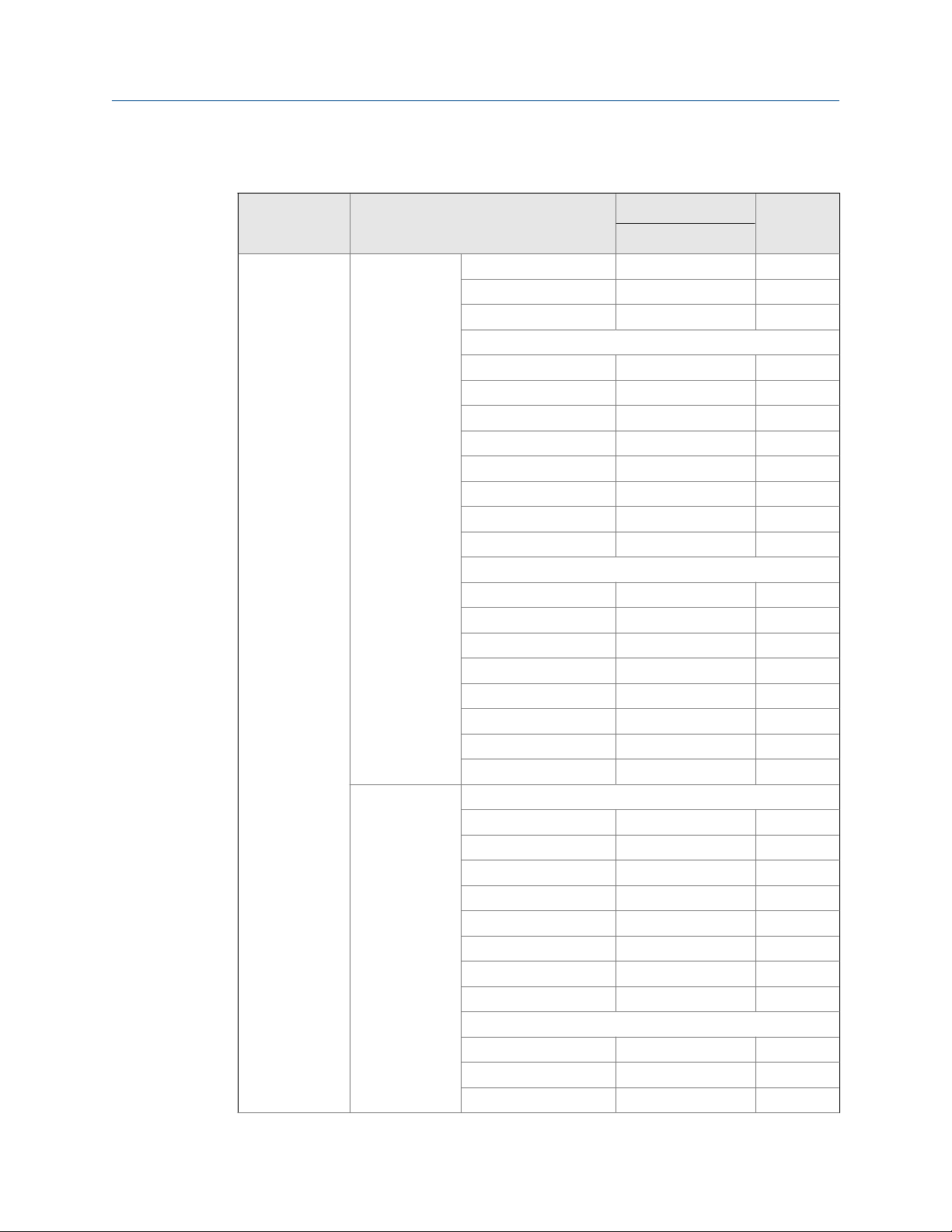

Introduction

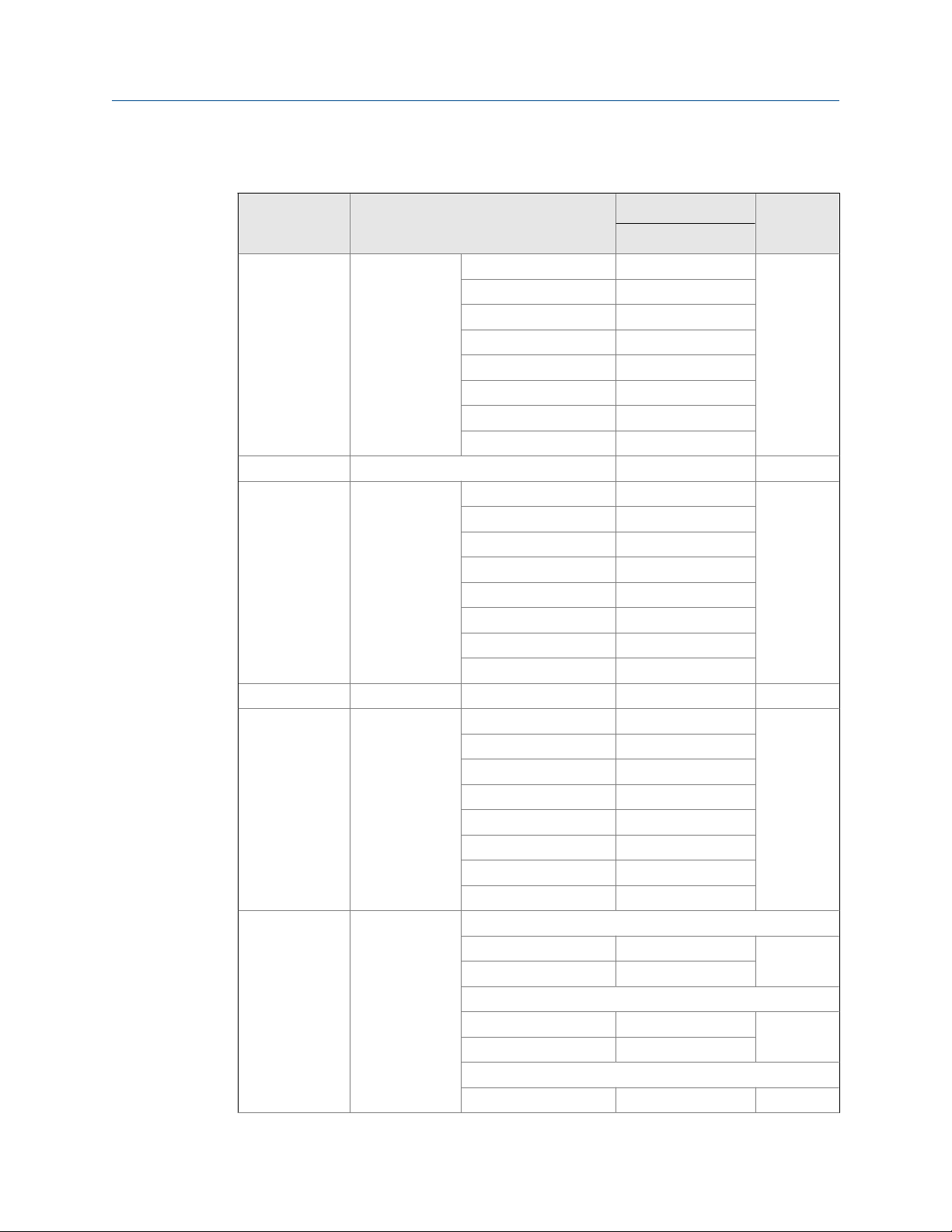

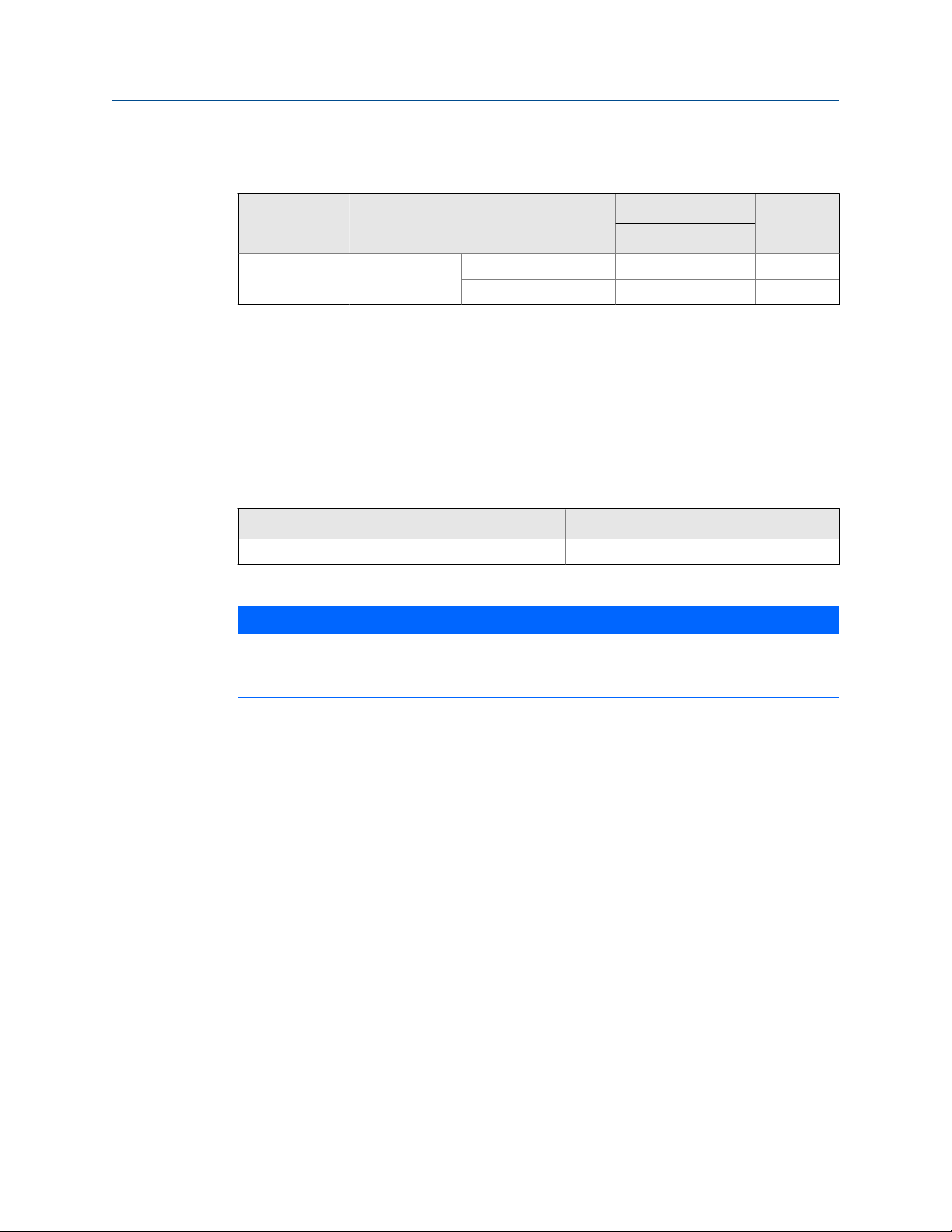

Models 762, 763, 765, 766 and 767 Control Valves NPS 16"Figure 1-6:

User manual 37

Page 48

Introduction

Table 1-8:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

16

Part number

Item number Description

1 Cylinder 666021-500 1

2 O-ring Buna-N 157095 2

EPR 157095-005

FFKM 157095-075

NBR (Low-swell) 157095-120

CR 157095-116

FKM 157095-022

FKM GFLT 157095-027

FKM V1289 157095-029

3 Seat ring 666026-500 1

4 Piston Standard 660124-600 1

AP Consult factory

High-pressure 666057-601

5 O-ring Buna-N 157086 1

EPR 157086-005

FFKM 157086-075

NBR (Low-swell) 157086-120

CR 157086-116

FKM 157086-022

FKM GFLT 157086-027

FKM V1289 157086-029

6 Backup ring 157201 2

7 O-ring Buna-N 157087 2

EPR 157087-005

FFKM 157087-075

NBR (Low-swell) 157087-120

CR 157087-116

FKM 157087-022

FKM GFLT 157087-027

FKM V1289 157087-029

11 Spring Light (blue) 660031 1

13 Cylinder head Standard 660754-500 1

High-pressure 666754-500

16 Screw 151019 24

16 inch

Quantity

38 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 49

Introduction

Table 1-8:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

16 (continued)

Part number

Item number Description

17 Jack-out screws Standard 151453-100M 2

High pressure 151399-100M

31 Nuts Class 150 and 300 151560M 4

Class 600 151563M 4

32 Valve body Class 150 661001M 1

Class 300 663001M

Class 600 666001M

DIN PN 16 661001-016M

DIN PN 40 663001-040M

DIN PN 64 666001-064M

DIN PN 100 666001-100M

33 Studs Class 150 and 300 151453M 4

Class 600 151399M 4

34 Pipe plug Standard 154704M 2

High pressure 154718-074M

38 Cap plug 154774 1

39 Check valve 620043-701 1

A Cylinder

assembly class

150 and 300

Cylinder

assembly class

600

Horizontal

Buna-N 660770-690 1

EPR 660770-697 1

FFKM 660770-695 1

NBR (Low-swell) 660770-696 1

CR 660770-693 1

FKM 660770-692 1

FKM GFLT 660770-69G 1

FKM V1289 660770-69M

Buna-N 660870-690 1

EPR 660870-697 1

FFKM 660870-695 1

NBR (Low-swell) 660870-696 1

CR 660870-693 1

FKM 660870-692 1

FKM GFLT 660870-69G 1

FKM V1289 660870-69M 1

16 inch

Quantity

User manual 39

Page 50

Introduction

Table 1-8:

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

16 (continued)

Item number Description

Part number

16 inch

Vertical

Buna-N 660970-690 1

EPR 660970-697 1

FFKM 660970-695 1

NBR (Low-swell) 660970-696 1

CR 660970-693 1

FKM 660970-692 1

FKM GFLT 66970-69G 1

FKM V1289 660970-69M 1

Horizontal

Buna-N 666770-690 1

EPR 666770-697 1

FFKM 666770-695 1

NBR (Low-swell) 666770-696 1

CR 666770-693 1

FKM 666770-692 1

FKM GFLT 666770-69G 1

FKM V1289 666770-69M 1

45°

Buna-N 666870-690 1

EPR 666870-697 1

FFKM 666870-695 1

NBR (Low-swell) 666870-696 1

CR 666870-693 1

FKM 666870-692 1

FKM GFLT 666870-69G 1

FKM V1289 666870-69M 1

Vertical

Buna-N 666970-690 1

EPR 666970-697 1

FFKM 66970-695 1

NBR (Low-swell) 666970-696 1

CR 666970-693 1

FKM 666970-692 1

Quantity

40 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 51

Introduction

Table 1-8:

Item number Description

Part description for a model 762, 763, 765, 766 and 767 Control Valve NPS

16 (continued)

Part number

Quantity16 inch

FKM GFLT 66970-69G 1

FKM V1289 66970-69M 1

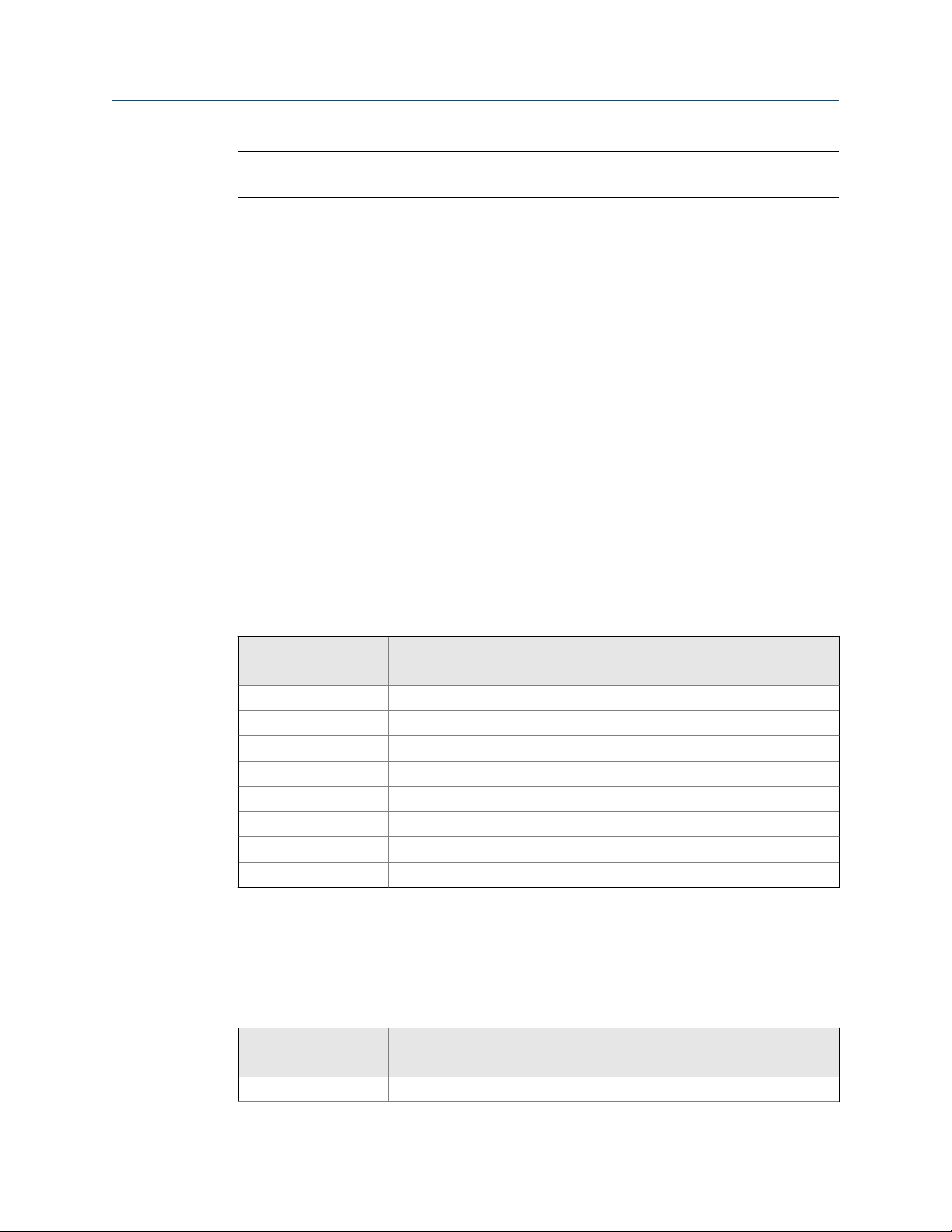

1.3 Agency certifications for the Models 762, 763, 765, 766 and 767 Control Valves

The following product agency certifications are applicable to the Daniel Control Valves.

Agency certifications for control valvesTable 1-9:

Certification type Description

Pressure equipment PED

NOTICE

The Daniel Models do not comply with any internationally over-pressurization protection

recognized codes. What the Daniel Models do is to allow the movement of an undetermined

amount of substance within a pressurized system, not from a pressurized system.

User manual 41

Page 52

Introduction

42 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 53

Operating conditions and specifications

2 Operating conditions and

specifications

Topics covered in this chapter:

• Operating conditions for the control valve

• Specifications for the control valve

2.1 Operating conditions for the control valve

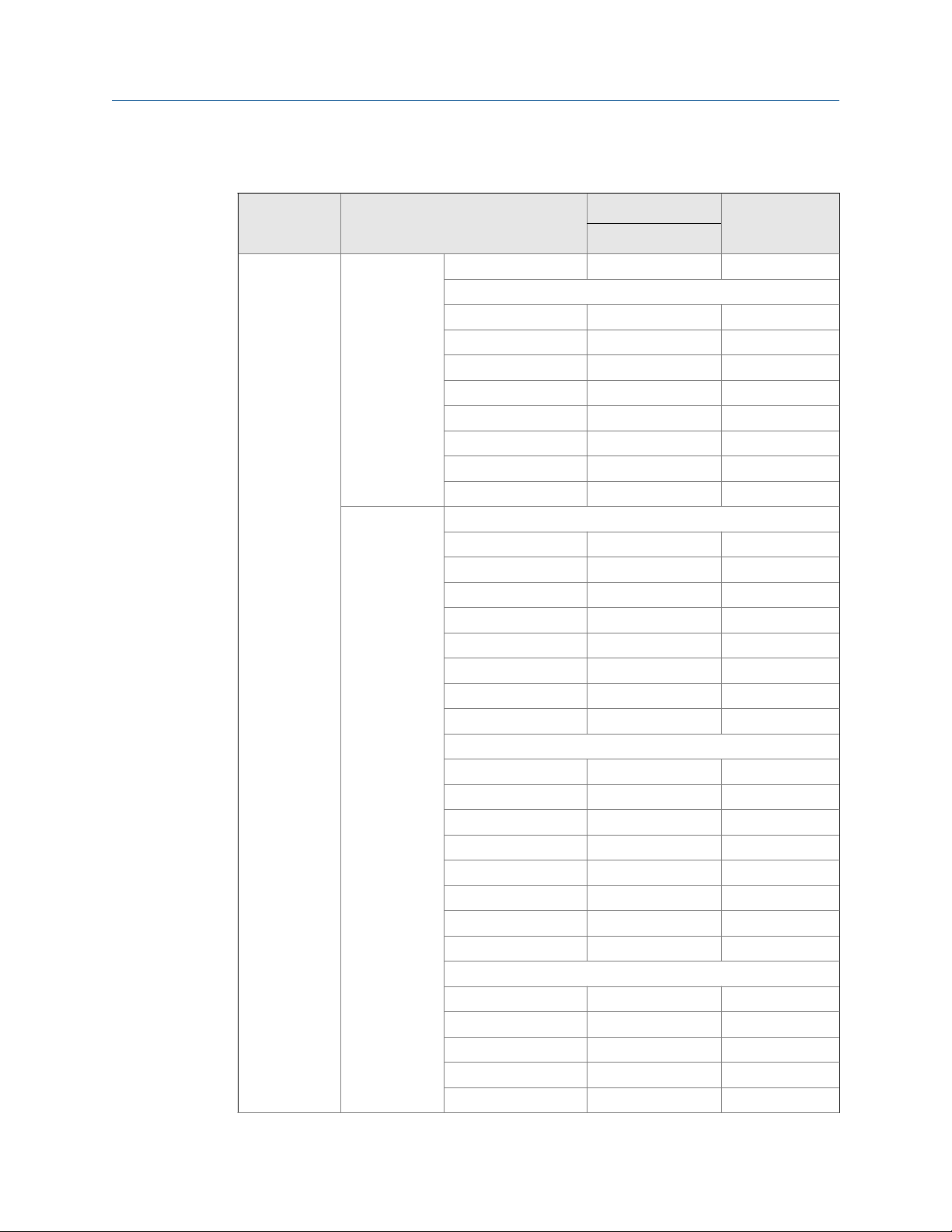

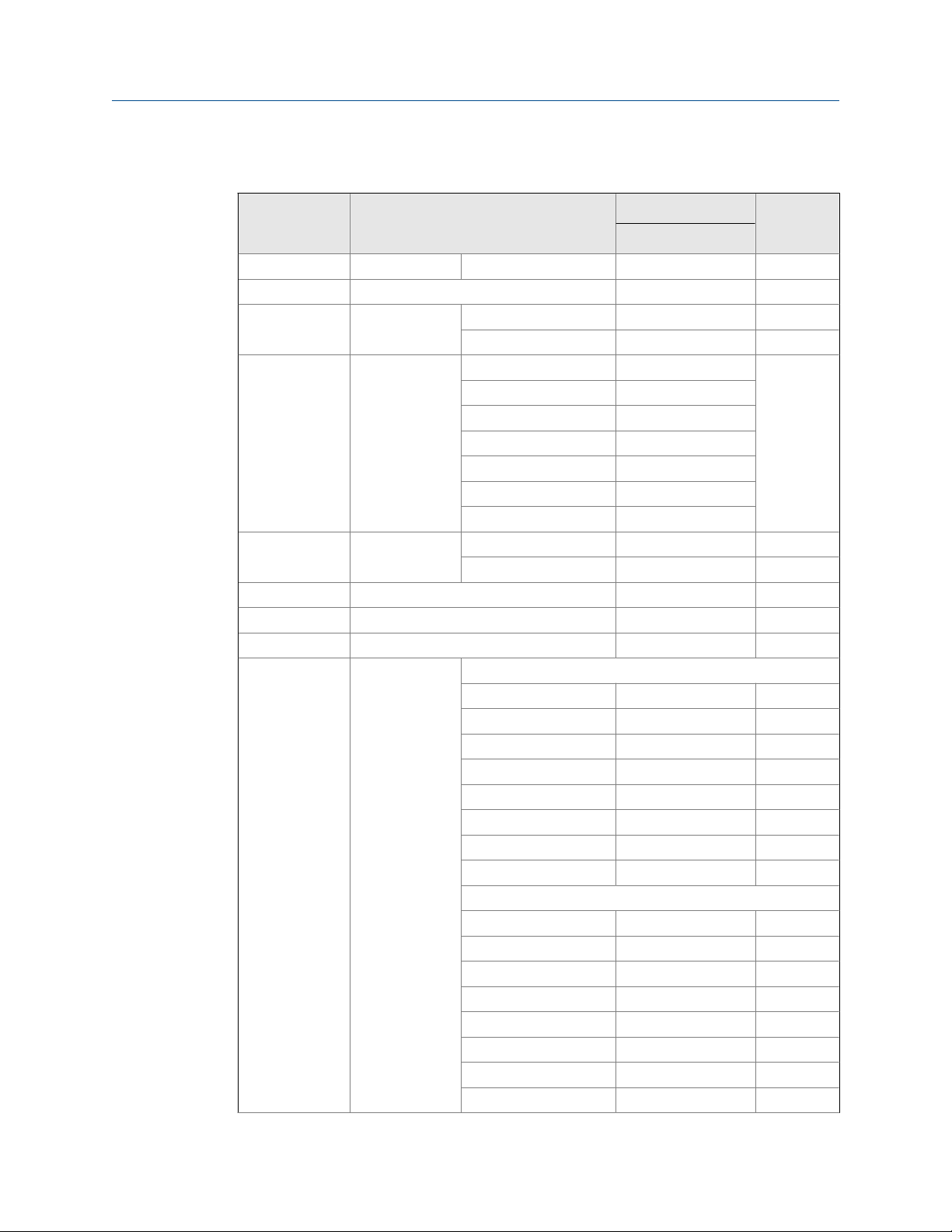

Operating conditions for the control valveTable 2-1:

Condition type Description

Fluid phase Liquid

Process temperature -26°C to 205°C (-15°F to 400°F)

Optional process temperature

Fluid velocity Operational recommended flow velocity up to 58 ft/sec, beyond this

Fluid(s) controlled • Low/Medium viscosity crude oils and condensates

Viscosity limits on valves • Maximum valve viscosity is 8800 Cst

Differential pressure The maximum allowable differential pressure across a control valve is

Atmospheric pressure Absolute

Sizes (NPS) 2, 3, 4, 6, 8,10,12,16

Pressure class (ANSI) 150, 300, 600

Maximum safe working

temperature range

-46°C to 205°C (-51°F to 400°F)

point will result in a high pressure drop and increased wear.

• Refined products and intermediates (ie: gasoline, diesel, kerosene,

light fuel oils, jet fuel, LPG, butanes, naphtha, alkylate, reformate,

straight run gasoline, cat-cracked gasoline)

• Petrochemicals (ie: benzene, toluene, xylenes, cumene, olefins, py-

rolysis gasoline)

• Natural gas liquids

• Maximum viscosity for valves with pilots is 440 Cst due to re-

sponse time of high viscosity pilot

6894 kPa (1,000 psi). Consult factory for location of first shut down

valve.

• -26°C to 205°C (-15°F to 400°F)

• Using FKM O-rings

• Temperature range is dependent of O-ring T

• Consult the factory for other safe working temperatures

min

and T

max

User manual 43

Page 54

Operating conditions and specifications

Condition type Description

Maximum safe working

pressure

Materials of construction Main valve body: Steel, ASTM-A352 Gr. LCC

Valve capacity Cv is a capacity coefficient that defines as the number of US gpm of

Operating conditions for the control valve (continued)Table 2-1:

Flange connections/Ratings (DIN) for valve sizes DN50 and DN400:

• DIN PN16 MWP at 120°C: 16 bar

• DIN PN25 MWP at 120°C: 25 bar

• DIN PN40 MWP at 120°C: 40 bar

• DIN PN64 (class 300) MWP at 120°C: 51 bar

• DIN PN64 (class 600) MWP at 120°C: 64 bar

• DIN PN100 MWP at 120 °C: 100 bar

Flange connections/Ratings (ANSI) for valve sizes 2"-16":

• Class 150 MWP at 100°F: 285 psi

• Class 300 MWP at 100°F: 740 psi

• Class 600 MWP at 100°F: 1480 psi

* MWP: Maximum Working Pressure

Main valve cylinder:

• NPS 2-4: Stainless steel

• NPS 6 and larger: Nickel coated steel

Main valve piston: Stainless steel (standard)

Seat ring:

• Class 150 and 300:

- NPS 2-6: Stainless steel

- NPS 8-16: Nickel coated steel

• Class 600: Stainless steel

O-Rings:

• Standard: FKM

• Optional: CR, EPR, FKM V1289, NBR, FFKM, FKM GLT

• For other material contact the factory

Other internal parts: Stainless steel

water that flows through a valve with a pressure drop of 1 psi across

the valve. Daniel valves have the following Cv:

• NPS 2: 86 gpm

• NPS 3: 186 gpm

• NPS 4: 309 gpm

• NPS 6: 688 gpm

• NPS 8: 1296 gpm

• NPS 10: 2040 gpm

• NPS 12: 2920 gpm

• NPS 16: 5360 gpm

*Cv based on wide open valve with water temperature at 16°C (60°F)

2.1.1 Design considerations

Some conditions to consider:

44 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 55

Operating conditions and specifications

• Service operating pressure

• Service testing pressures

• Service process temperature and ambient site temperatures

• Chemical composition and toxicity of fluid in operating conditions

• Traffic, wind and earthquake at loading site

• Adverse force or stress caused by inadequate supports, attachments, piping, etc.

• Corrosion, erosion, fatigue, etc.

• Decomposition of unstable fluids in operating and test conditions

• Possible damage from external fire

• Mass fluid in process and test conditions

WARNING!

FUNCTIONAL AND ENVIRONMENTAL HAZARD

Evaluate the functional and environmental conditions prior to installing a control valve. Install

the control valve in a well-designed piping system.

Failure to comply may result in death or serious injury from pipe failure.

NOTICE

The Daniel Models do not comply with any internationally over-pressurization protection

recognized codes. What the Daniel Models do is to allow the movement of an undetermined

amount of substance within a pressurized system, not from a pressurized system.

2.1.2 Environmental conditions

WARNING!

EQUIPMENT HAZARD

Never use this equipment for any purpose other than its intended use.

Failure to comply may result in death, serious personal injury and/or property damage.

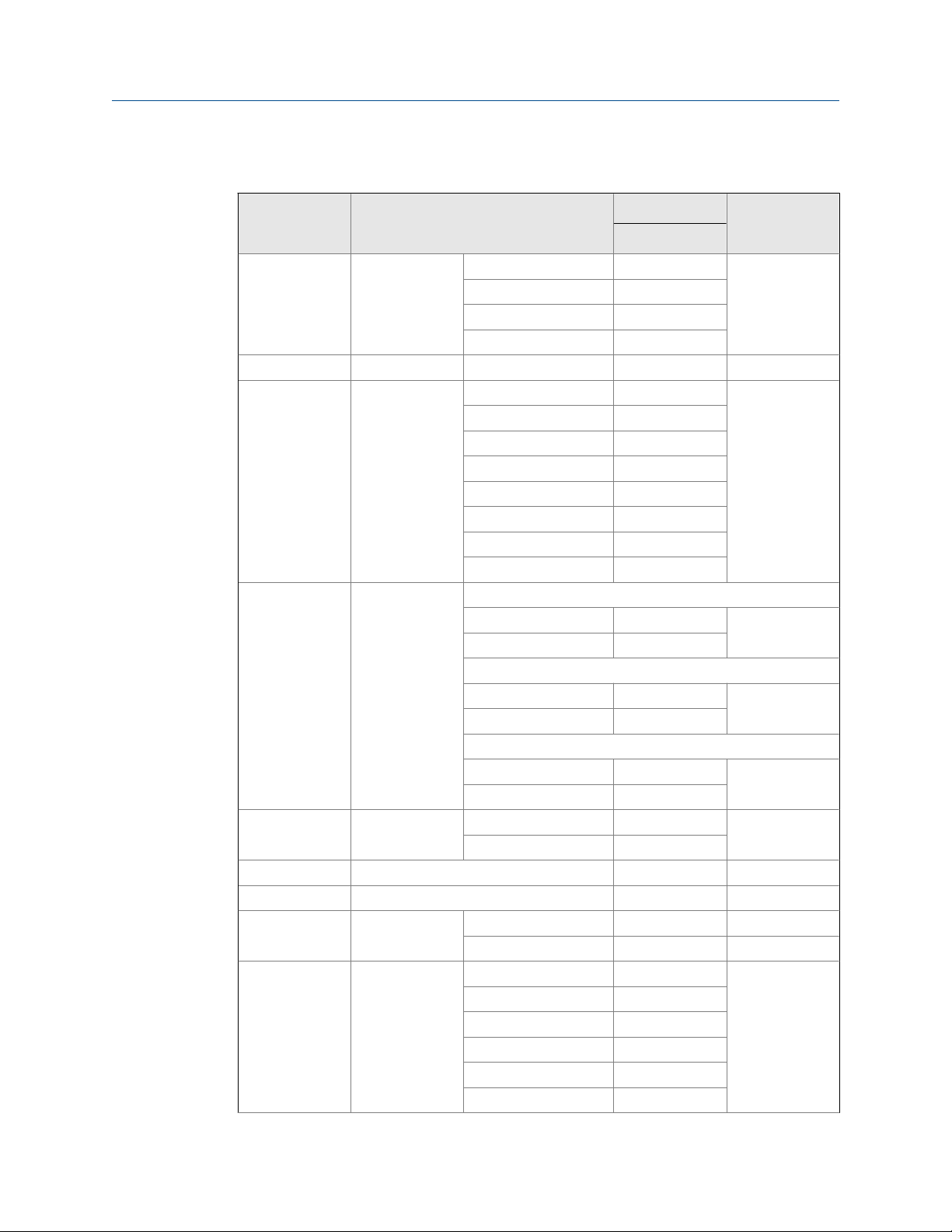

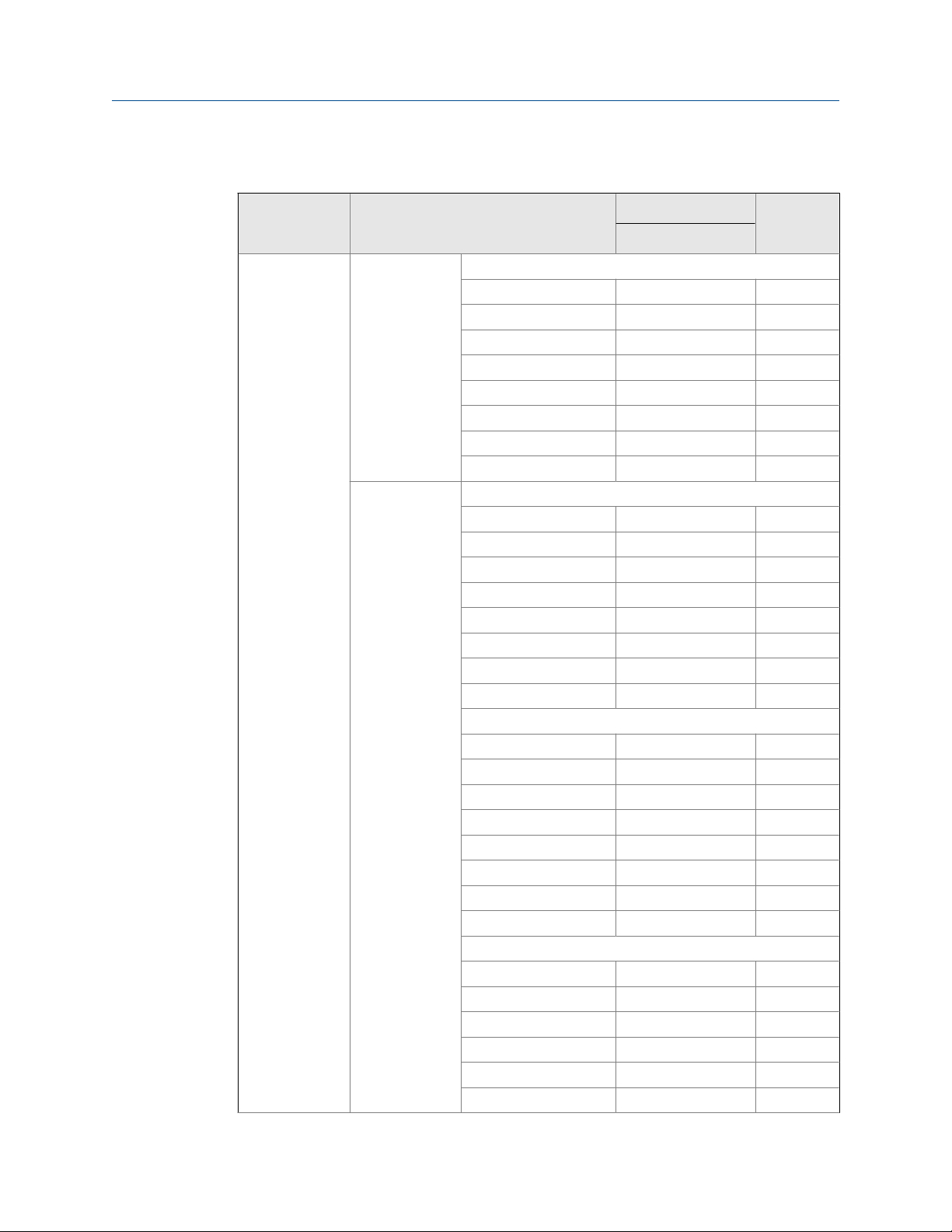

Environmental conditionsTable 2-2:

Parameter type Description

Severe service conditions Ensure that piping or other attachments connected to the valve

are not under stress. The design of the control valve has not

been assessed for the effects of wind, earthquake loading and

severe weather conditions.

User manual 45

Page 56

Operating conditions and specifications

Parameter type Description

Additional severe service conditions

Corrosive service Select the material compatible with the specific processes and

Populated areas For new installations, locate the control valve to an area that has

Closed, poorly ventilated areas Install the control valve in a well ventilated area, not less than

Elevation No limit

Humidity No limit

Proximity to open flame Provide fire prevention measures and equipment per local regu-

Proximity to vehicular traffic The design of the control valve has not been assessed for the ef-

Environmental conditions (continued)Table 2-2:

The valves are designed to be used on liquid applications for

crude oil and refined products.

The use of aggressive additives or oxygenates requires the use

of the Aggressive Products (AP) option. The AP option valve cylinder incorporates cup-seals (PTFE Bal Seals) and an O-ring

made from appropriate materials for severe conditions.

atmospheric environments. Implement a periodic inspection

and maintenance program to ensure that pressure retaining

components are free from corrosion and erosion.

The valve is not designed with corrosion allowance. Inspect the

valve's metal parts periodically for corrosion and erosion, and inspect the seals and O-rings for wear and chemical deterioration.

fewer than 10 buildings intended for human occupancy within

an area that extends 200 meters (220 yards) radially from the

control valve. (Reference: Class 1 Location: U.S. DOT, CFR Title

49: Part 192.5)

one meter (approximately three feet) from source of ignition or

source of heat which might damage the unit.

lations.

fects of traffic.

2.2 Specifications for the control valve

2.2.1 Interface requirements

WARNING!

EXCEEDING REQUIREMENTS HAZARD

Control valve requirements are defined to ensure safe equipment operation. Do not exceed

published specifications.

Failure to comply may result in death, serious injury and/or damage to the equipment.

46 Daniel Models 762, 763, 765, 766 and 767 Control Valves

Page 57

Operating conditions and specifications

Interface requirementsTable 2-3:

Requirements Description

Flange type The mechanical connections for Models 762,

763, 765, 766 and 767 control valve NPS 2 to 16

are standard class 150, 300 and 600 ANSI R.F.

flanges, which are available only in carbon steel.

Other types of flange connections are available