Page 1

Maintenance and Troubleshooting Manual

Par t Number 3-9000-764 Rev ision F

DanielTM 3814 Liquid Ultrasonic Flow Meter

December 2017

Page 2

Page 3

Flow Lifecycle Services for Daniel products

Location Tel ephone number Fax number

North America/Latin America +1.713.467.6000 +1.713.827.4805

Daniel Customer Service +1.713.827.6314 +1.713.827.6312

USA (toll free) +1.888.356.9001 +1.713.827.3380

Asia Pacific (Republic of Singapore) +65.6777.8211 +65.6777.0947.0743

Europe (Stirling Scotland, UK) +44 (0)1786.433400 +44 (0)1786.433401

Middle East Africa (Dubai, UAE) +971 4 8118100 +971 4 8865465

Daniel Measurement and Control, Inc. (Headquarters)

11100 Brittmoore Park Drive

Houston, TX 77041 USA

http://www.Emerson.com

Email

• Customer Service: Daniel.SystemSales@Emerson.com

• Customer Support: Daniel.SystemSales@Emerson.com

• Asia-Pacific: danielap.support@emerson.com

• Europe: danielEMA.cst@emerson.com

Return Material Authorization (RMA)

A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason. Download the

RMA form from the Support Services web page by selecting the link below.

http://www.daniel/rma

Page 4

Signal words and symbols

This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey

all safety messages that follow this symbol to avoid possible injury or death.

Safety alert symbol

Danger indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

Warning indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Pay special attention to the following signal words, safety alert symbols and statements:

Tip: Tip provides information or suggestions for improved efficiency or best results.

Note: Note is “general by-the-way” content not essential to the main flow of information.

Page 5

Important safety instructions

Installing, operating or maintaining a Daniel product improperly could lead to serious injury or

death from explosion or exposure to dangerous substances. To reduce this risk:

• Comply with all information on the product, in this manual, and in any local and national

codes that apply to the product.

• Do not allow untrained personnel to work with this product.

• Use Daniel parts and work procedures specified in this manual.

Daniel Measurement and Control, Inc. (Daniel) designs, manufactures and tests products to

function within specific conditions. Because these products are sophisticated technical

instruments, it is important that the owner and operation personnel strictly adhere both to the

information printed on the product and to all instructions provided in this manual prior to

installation, operation, and maintenance.

Daniel also urges you to integrate this manual into your training and safety program.

BE SURE ALL PERSONNEL READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ALL

NOTICES AND PRODUCT WARNINGS.

Product owners (Purchasers):

• Use the correct product for the environment and pressures present. See technical data

or product specifications for limitations. If you are unsure, discuss your needs with your

Daniel representative.

• Inform and train all personnel in the proper installation, operation, and maintenance of

this product.

• To ensure safe and proper performance, only informed and trained personnel shou

install, operate, repair and maintain this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from

• Save this instruction manual for future reference.

• If you resell or transfer this product, it is your responsibility to forward this instruction

manual along with the product to the new owner or transferee.

• ALWAYS READ AND FOLLOW THE INSTALLATION, OPERATIONS, MAINTENANCE AN

TROUBLESHOOTING MANUALS AND ALL PRODUCT WARNINGS AND INSTRUCTIONS.

• Do not use this equipment for any purpose other than its intended service. This ma

result in property damage and/or serious personal injury or death.

:

http://www.daniel.com

ld

D

y

Page 6

Product Operation Personnel:

• To prevent personal injury, personnel must follow all instructions of this manual prior to

and during operation of the product.

• Follow all warnings, cautions, and notices marked on, and supplied with, this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from

• Read and understand all instructions and operating procedures for this product.

• If you do not understand an instruction, or do not feel comfortable followin

instructions, contact your Daniel representative for clarification or assistance.

• Install this product as specified in the INSTALLATION section of this manual per

applicable local and national codes.

• Follow all instructions during the installation, operation, and maintenance of this

product.

• Connect the product to the appropriate pressure and electrical sources when and

where applicable.

• Ensure that all connections to pressure and electrical sources are secure prior to and

during equipment operation.

• Use only replacement parts specified by Daniel. Unauthorized parts and procedures can

affect this product's performance, safety, and invalidate the warranty. "Look-a-like"

substitutions may result in deadly fire, explosion, release of toxic substances

improper operation.

• Save this instruction manual for future reference.

:

ht

tp://www.daniel.com

g the

or

Page 7

Notice

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY,

AND WHILE EVERY EFFORT HAS BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO

BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR IMPLIED, REGARDING THE

PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE

GOVERNED BY DANIEL'S TERMS AND CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST. WE

RESERVE THE RIGHT TO MODIFY OR IMPROVE THE DESIGNS OR SPECIFICATIONS OF SUCH

PRODUCTS AT ANY TIME.

DANIEL DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF

ANY PRODUCT. RESPONSIBILITY FOR PROPER SELECTION, USE AND MAINTENANCE OF ANY

DANIEL PRODUCT REMAINS SOLELY WITH THE PURCHASER AND END-USER.

TO THE BEST OF DANIEL'S KNOWLEDGE THE INFORMATION HEREIN IS COMPLETE AND

ACCURATE. DANIEL MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT

TO THIS MANUAL AND, IN NO EVENT, SHALL DANIEL BE LIABLE FOR ANY INCIDENTAL, PUNITIVE,

SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF

PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS INCURRED INCLUDING

WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF THIRD PARTIES.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY

AND MAY BE TRADEMARKS/REGISTERED TRADEMARKS OF THESE COMPANIES.

DANIEL AND THE DANIEL LOGO ARE REGISTERED TRADEMARKS OF DANIEL INDUSTRIES, INC.

THE EMERSON LOGO IS A TRADEMARK AND SERVICE MARK OF EMERSON ELECTRIC CO.

Page 8

Warranty and Limitations

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement &

Control, Inc. ("Daniel") warrants that the licensed firmware embodied in the Goods will execute the

programming instructions provided by Daniel, and that the Goods manufactured by Daniel will be free from

defects in materials or workmanship under normal use and care and Services will be performed by trained

personnel using proper equipment and instrumentation for the particular Service provided. The foregoing

warranties will apply until the expiration of the applicable warranty period. Goods are warranted for twelve

(12) months from the date of initial installation or eighteen (18) months from the date of shipment by Daniel,

whichever period expires first. Consumables and Services are warranted for a period of 90 days from the date

of shipment or completion of the Services. Products purchased by Daniel from a third party for resale to Buyer

("Resale Products") shall carry only the warranty extended by the original manufacturer. Buyer agrees that

Daniel has no liability for Resale Products beyond making a reasonable commercial effort to arrange for

procurement and shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Daniel

thereof in writing during the applicable warranty period, Daniel shall, at its option, correct any errors that are

found by Daniel in the firmware or Services or repair or replace F.O.B. point of manufacture that portion of the

Goods or firmware found by Daniel to be defective, or refund the purchase price of the defective portion of the

Goods/Services. All replacements or repairs necessitated by inadequate maintenance, normal wear and usage,

unsuitable power sources or environmental conditions, accident, misuse, improper installation, modification,

repair, use of unauthorized replacement parts, storage or handling, or any other cause not the fault of Daniel

are not covered by this limited warranty, and shall be at Buyer's expense. Daniel shall not be obligated to pay

any costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance

by Daniel. All costs of dismantling, reinstallation and freight and the time and expenses of Daniel's personnel

and representatives for site travel and diagnosis under this warranty clause shall be borne by Buyer unless

accepted in writing by Daniel. Goods repaired and parts replaced by Daniel during the warranty period shall be

in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This

limited warranty is the only warranty made by Daniel and can be amended only in a writing signed by Daniel.

THE WARRANTIES AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. Buyer acknowledges

and agrees that corrosion or erosion of materials is not covered by this warranty.

2. LIMITATION OF REMEDY AND LIABILITY

PERFORMANCE. THE REMEDIES OF BUYER SET FORTH IN THIS AGREEMENT ARE EXCLUSIVE. IN NO EVENT,

REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT,

INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL DANIEL'S LIABILITY TO

BUYER AND/OR ITS CUSTOMERS EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS MANUFACTURED OR

SERVICES PROVIDED BY DANIEL GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO

EVENT SHALL DANIEL'S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXTEND TO INCLUDE INCIDENTAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM "CONSEQUENTIAL DAMAGES" SHALL INCLUDE, BUT NOT

BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, REVENUE OR USE AND COSTS INCURRED INCLUDING

WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF BUYER'S CUSTOMERS.

: DANIEL SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN

Page 9

Maintenance and Troubleshooting Manual Table of Contents

3-9000-764 Rev F December 2017

Contents

Preface

Section 1: Routine maintenance

1.1 Meter maintenance ......................................................................................... 1

1.2 Field hydrostatic pressure testing procedures ................................................... 3

1.3 Routine Maintenance ...................................................................................... 4

1.3.1 Maintenance logs and reports .............................................................................. 4

1.3.2 Pipeline cleaning maintenance ............................................................................ 7

1.3.3 High Viscosity piping requirements...................................................................... 8

Section 2: Troubleshooting

2.1 Meter status alarms ........................................................................................ 9

2.1.1 Check status....................................................................................................... 10

2.1.2 System alarm ..................................................................................................... 10

2.1.3 Chord A, Chord B, Chord C and Chord D alarm.................................................... 11

2.1.4 Field I/O alarm.................................................................................................... 11

2.1.5 Validity alarm ..................................................................................................... 11

2.1.6 Comms alarm..................................................................................................... 11

2.1.7 Communications................................................................................................ 11

2.2 Troubleshooting the meter ............................................................................ 12

2.2.1 Meter maintenance............................................................................................ 19

2.2.2 Unable to connect direct serial or external serial modem ................................... 28

2.2.3 Unable to connect to meter ............................................................................... 28

2.2.4 Ethernet connections ......................................................................................... 28

2.2.5 Direct serial connections .................................................................................... 28

2.3 Troubleshoot Maintenance log files and trend files .......................................... 29

2.3.1 Files Do Not Appear in Workbook....................................................................... 29

2.3.2 Microsoft® Excel® Log/Export Options are not Available ................................... 29

2.3.3 Maintenance Logs or Trend files are not created................................................. 30

2.3.4 Windows® XP with Security Update................................................................... 33

Section 3: Meter maintenance

3.1 Meter maintenance ....................................................................................... 35

3.2 Transducer field removal and installation ........................................................ 38

3.2.1 Transducer removal and installation................................................................... 40

Table of Contents i

Page 10

Table of Contents Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

3.3 Transducer housing removal and installation ...................................................43

3.3.1 Manually modifying the Calibration Parameters .................................................48

3.4 Transducer cable removal and installation ....................................................... 52

3.5 Replace the meter electronics ........................................................................60

3.5.1 Replace CPU Module or optional I/O Module.......................................................61

3.5.2 Fuse Replacement ..............................................................................................63

3.5.3 Replace Backplane, I.S. Barrier or Power Supply board ........................................64

3.5.4 Acquisition Module replacement ........................................................................70

Appendix A: Conversion factors

A.1 Conversion factors per units of measurement..........................................................75

A.2 K Factor conversions ................................................................................................76

K-Factor and inverse K-Factor 76

Appendix B: Engineering Drawings

B.1 Daniel 3410 Series Ultrasonic Flow Meter Drawings.................................................77

Appendix C: Index

C.1 Manual Index ...........................................................................................................79

ii Table of Contents

Page 11

Maintenance and Troubleshooting Manual List of Tables

3-9000-764 Rev F December 2017

List of Tables

Table 2-1 Troubleshooting .............................................................................................................. 12

Table 2-2 Maintenance.................................................................................................................... 20

Table A-1 Conversion factors per units of measurement .................................................................. 75

List of Tables iii

Page 12

List of Tables Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

iv List of Tables

Page 13

Maintenance and Troubleshooting Manual List of Figures

3-9000-764 Rev F December 2017

List of Figures

Figure 1-2 Flange stabilizers .......................................................................................................... 2

Figure 1-3 Maintenance log collection parameters ........................................................................ 4

Figure 1-4 Trend log collection ...................................................................................................... 5

Figure 1-5 Archive log collection parameters................................................................................. 6

Figure 1-6 High Viscosity meter tube and Venturi piping requirements......................................... 8

Figure 2-1 Meter Monitor status alarms......................................................................................... 9

Figure 2-2 Status summary............................................................................................................ 9

Figure 2-3 Status Summary ......................................................................................................... 10

Figure 2-4 Meter Monitor (Summary) view ................................................................................. 19

Figure 2-5 Meter Monitor (Detailed) view ................................................................................... 19

Figure 2-6 Excel® 2000 Tools Menu ............................................................................................ 30

Figure 2-7 Excel® Trusted Access Setting.................................................................................... 31

Figure 2-8 Excel® 2007 Tools Menu ............................................................................................ 31

Figure 2-9 Excel® 2007 Developer tab - Macro Security .............................................................. 32

Figure 3-2 Flange stabilizers ........................................................................................................ 36

Figure 3-3 Transducer (LT-01/LT-04/LT-08) ................................................................................. 38

Figure 3-4 Transducer (LT-03/LT-05/LT-09) ................................................................................. 38

Figure 3-5 Transducer assembly ................................................................................................. 39

Figure 3-6 Tools required............................................................................................................. 40

Figure 3-7 Transducer security seal removal ............................................................................... 41

Figure 3-8 Transducer installation ............................................................................................... 42

Figure 3-9 Transducer housing ................................................................................................... 43

Figure 3-10 Transducer disassembly ............................................................................................. 44

Figure 3-11 Transducer installation ............................................................................................... 47

Figure 3-12 Transducer Swap Out Wizard ..................................................................................... 48

Figure 3-13 Transducer Swap Out Wizard - Select Components Page ........................................... 49

Figure 3-14 Transducer Swap Out Wizard - Select Components Page ........................................... 50

Figure 3-15 Flow meter transducer cables and ports ..................................................................... 52

Figure 3-16 Transducer security seal removal ............................................................................... 53

Figure 3-17 Flow meter transducer tie wraps ................................................................................ 54

Figure 3-18 Flow meter Acquisition Module wiring........................................................................ 56

Figure 3-19 Transmitter Electronics Enclosure security seals ......................................................... 58

Figure 3-20 Base Enclosure security seals....................................................................................... 59

List of Figures v

Page 14

List of Figures Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Figure 3-21 Transmitter electronics ..............................................................................................60

Figure 3-22 CPU or I/O Module replacement..................................................................................61

Figure 3-23 Transmitter electronics enclosure security seals .........................................................62

Figure 3-24 Fuse holder cap ...........................................................................................................63

Figure 3-25 Backplane board replacement ...................................................................................64

Figure 3-26 I.S. Barrier board replacement ...................................................................................66

Figure 3-27 Transmitter electronics enclosure security seals .........................................................67

Figure 3-28 Power Supply board replacement ..............................................................................68

Figure 3-29 Conduit removal .........................................................................................................70

Figure 3-30 Transmitter Electronics Enclosure and Base Enclosure security seal removal ...............71

Figure 3-31 Transmitter Electronics Enclosure removal .................................................................71

Figure 3-32 Acquisition Module cable and transducer wiring ........................................................72

vi List of Figures

Page 15

Maintenance and Troubleshooting Manual Section 1: Routine maintenance

SURFACE TEMPERATURE HAZARD

The meter body and piping may be extremely hot or cold

Wear appropriate personal protective equipment when coming in contact with the meter. Failure to do so may

result in injury.

TRANSPORTATION HAZARD

When moving the meter, do not insert the forks of a forklift into the bore.

inserting the forks may cause the meter to become unstable, resulting in injury or damage to the bore and

sealing face.

TRIPPING HAZARD

Clear all obstacles or obstructions from the work area when transporting, installing or removing the

meter.

Failure to clear the work area may cause injury to personnel.

Prior to lifting the unit, refer to the flow meter nameplate or outline dimensional (general arrangement)

drawing for the assembled weight.

3-9000-764 Rev F December 2017

11

Section 1: Routine maintenance

1.1 Meter maintenance

This section includes discussion of the maintenance of Daniel 3814 Liquid Ultrasonic Flow

Meters.

For reference, you may download the Daniel MeterLink Quick Start Manual from:

http://www2.emersonprocess.com/en-US/brands/daniel/Flow/ultrasonics/Pages/Ultrasonic.aspx

Meter maintenance 1

Page 16

Section 1: Routine maintenance Maintenance and Troubleshooting Manual

Figure 1-2 Flange stabilizers

CRUSHING HAZARD

Do not remove flange stabilizers

Attempting to do so may allow the meter to roll, resulting in serious injury or equipment damage.

A.

A. Flange stabilizers

ESCAPING FLUIDS HAZARD

The purchaser of the meter is responsible for the selection of Daniel components/seals and materials

compatible with the chemical properties of the measurement fluid.

Failure to select suitable meter components/seals may cause escaping fluids, resulting in injury or equipment

damage.

December 2017 3-9000-764 Rev F

2 Meter maintenance

Page 17

Maintenance and Troubleshooting Manual Section 1: Routine maintenance

LEAKAGE OR PRESSURE CONTAINING PARTS FAILURE

Use precautions to eliminate hazards to personnel in the event of leakage or failure of

the liquid ultrasonic meter pressure containing parts or failure of the test equipment

and to prevent over-pressurization during the test procedure.

Failure to do so may result in injury to personnel or cause damage to the equipment.

3-9000-764 Rev F December 2017

1.2 Field hydrostatic pressure testing procedures

The Daniel 3814 Liquid Ultrasonic Flow Meter can be hydro-tested without any special

preparations. The transducers are not exposed to the process pressure and can remain installed

in the meter.

The liquid ultrasonic meter pressure containing parts include but are not limited to the

transducer housings. These pressure containing parts are pressure tested while attached to the

meter body as a completed ultrasonic meter assembly. The hydrostatic test is verification of the

pressure containing capability of the liquid ultrasonic meter pressure containing parts and the

seals that seal them.

Field hydrostatic pressure testing procedures 3

Page 18

Section 1: Routine maintenance Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

1.3 Routine Maintenance

Routine maintenance operations requires adherence to all applicable regulations and laws and

safety training for personnel to perform the maintenance operations. Review your

organization’s best practices procedures before performing routine maintenance.

1.3.1 Maintenance logs and reports

To monitor the performance health of the meter, and ensure it is operating within acceptable

specifications, routine diagnostics should be performed. Collecting a maintenance log gives

you a snapshot of the current health of the meter and you can compare the inspection reports

from previously saved logs. Use the Logs/Reports menu and click Maintenance Logs and

Reports. Daniel MeterLink displays the Maintenance Logs and Reports dialog. Choose the time

duration, log format and collection rate for the output file and click the Start button. You can

open the file immediately after it is generated or view it at a later time. It is recommended that a

Maintenance log be collected after an upset in the system.

In establishing a baseline to be used for the trending of the meter diagnostics, it is very helpful if

a set of log files are collected immediately after the meter has been installed in the field.

Preferably, collect the log files at several velocities within the operating range of the meter. This

helps establish that the flow profile is relatively constant throughout the meters operating

range (except velocities below 3 ft/sec where the profile may vary).

Maintenance log collection

Figure 1-3 Maintenance log collection parameters

4 Routine Maintenance

Page 19

Maintenance and Troubleshooting Manual Section 1: Routine maintenance

3-9000-764 Rev F December 2017

Trend maintenance log collection

Merging the results of two or more Maintenance logs into a single file, allows you to build a

historical database of the meter’s performance. Trending the logs indicates changes from the

original installation of the meter over time. Looking at a single inspection report, that is either

collected monthly or quarterly, will only give you an indication of the meter's current health.

Figure 1-4 Trend log collection

This is important since many diagnostics change slowly over time. Trending the maintenance

logs helps identify these changes and makes problems much more obvious than merely viewing

a single inspection report. The Trending feature is integral to Daniel MeterLink which allows all

important parameters to be trended. Daniel MeterLink supports trending files in a Microsoft®

Excel® workbook from multiple 3814 meter maintenance logs. Some parameters like gain,

signal level, and noise level level may show a shift over time which can be useful in detecting

changes in the meter and the installation.

Maintenance logs to be trended must all have matching column headings. This means the logs

must be in the same units (i.e. U.S. Customary or Metric), must have the same pressure type (i.e.

gage or absolute), and must have the same time base (1/second, 1/minute, 1/hour, 1/day). If

not, an error message will be displayed stating the column headings do not match and the file

will not be added to the Workbook to trend list.

Maintenance logs and reports 5

Page 20

Section 1: Routine maintenance Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Archive log collection

Archive logs may be collected and the options include:

• Daily log - generated every 24 hours on the Contract Hour.

• Hourly log - generated every hour at the top of the hour.

• Event log - collects the alarm and event log records.

Figure 1-5 Archive log collection parameters

The logs may be collected in a single file or you can choose to collect one type of log. Each of the

Meter Archive logs include the Meter Configuration file.

6 Maintenance logs and reports

Page 21

Maintenance and Troubleshooting Manual Section 1: Routine maintenance

BURST HAZARD

Before pipeline cleaning and maintenance (“pigging operations”), remove straightening vanes or flow

conditioners. Failure to do so may cause excessive pressure in the meter system, resulting in serious injury/death

or equipment damage.

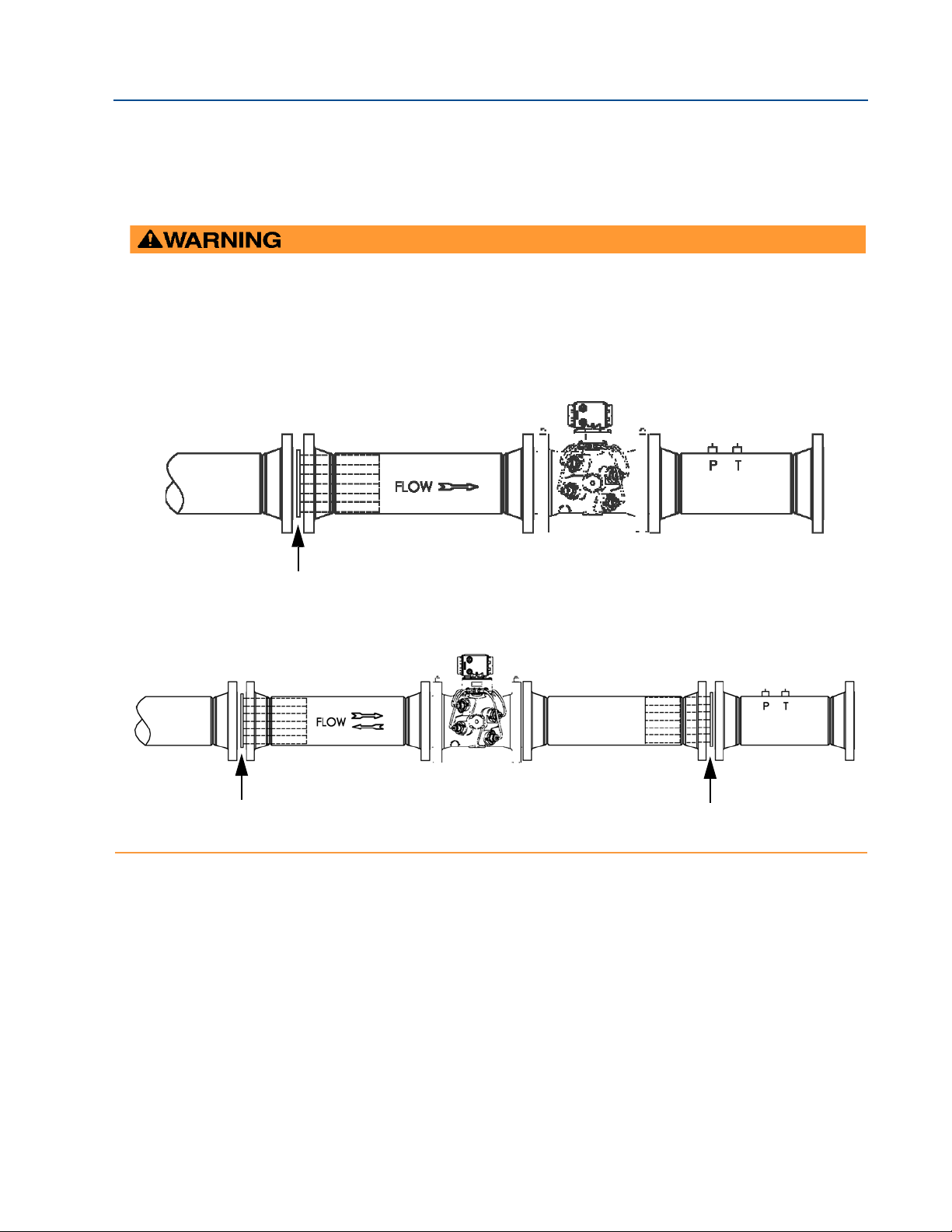

3814 Liquid Ultrasonic Flow Meter with flow conditioner for uni-directional flow

3814 Liquid Ultrasonic Flow Meter with flow conditioner for bi-directional flow

Flow conditioner

Straightening device

Flow conditioner

Straightening device

Flow conditioner

Straightening device

3-9000-764 Rev F December 2017

1.3.2 Pipeline cleaning maintenance

Straightening vanes or flow profilers must be removed during pipeline cleaning maintenance

operations (“pigging operation”). if the meter run is pigged with a flow conditioner in line,

pressure may build up and cause the pipes and flanges to burst and severely injure personnel.

The excessive pressure may damage the meter or the transducer ports may collect debris which

may impede data acquisition and flow measurement.

Pipeline cleaning maintenance 7

Page 22

Section 1: Routine maintenance Maintenance and Troubleshooting Manual

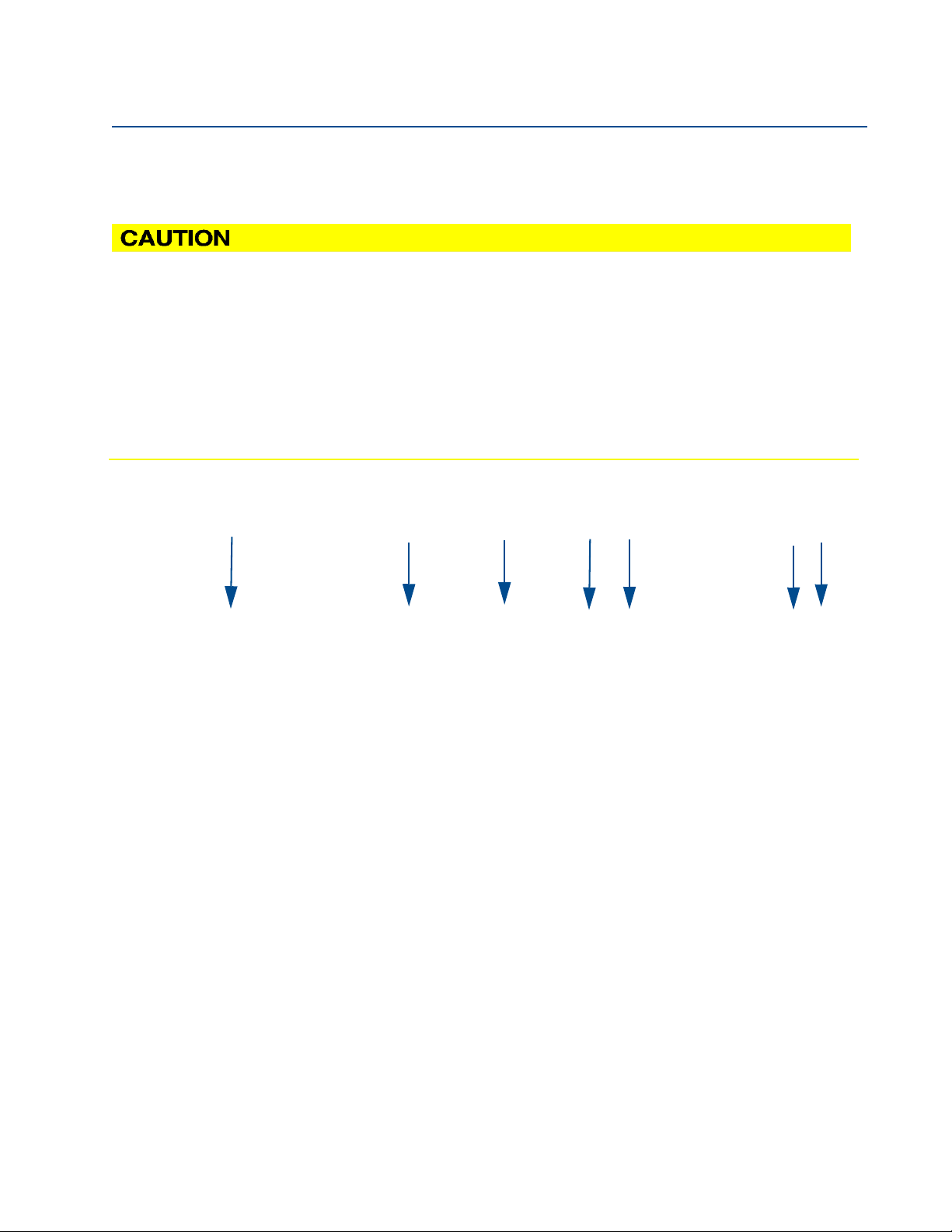

HIGH VISCOSITY FLOW MEASUREMENT METER RECALIBRATION

In high viscosity meter applications, if the connection between the upstream meter flange

(Figure 1-6, Item D) and the Venturi reducer (Figure 1-6, Item C) is disassembled or disturbed for

any reason, the meter will need to be recalibrated in accordance with Daniel recommendations. Alignment of this flange joint is critical in the performance of the meter. It is

recommended to consult Daniel Support for assistance when re-aligning this joint.

Failure to recalibrate the meter and correctly reinstall the flanged joint will result in faulty flow measurement.

A.

B.

C.

E.

F.

G.

B. Flow conditioner and flange gaskets

C. Venturi conical reducer

D. Upstream meter flange

E. 3814 Liquid Ultrasonic Flow Meter

F. Pressure tap

D.

A. Meter tube

G. Temperature tap

December 2017 3-9000-764 Rev F

1.3.3 High Viscosity piping requirements

The piping requirements for High Viscosity meter applications are shown in Figure 1-6.

Figure 1-6 High Viscosity meter tube and Venturi piping requirements

8 High Viscosity piping requirements

Page 23

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

APPENDIX A:DANIEL METERLINK

Section 2: Troubleshooting

2.1 Meter status alarms

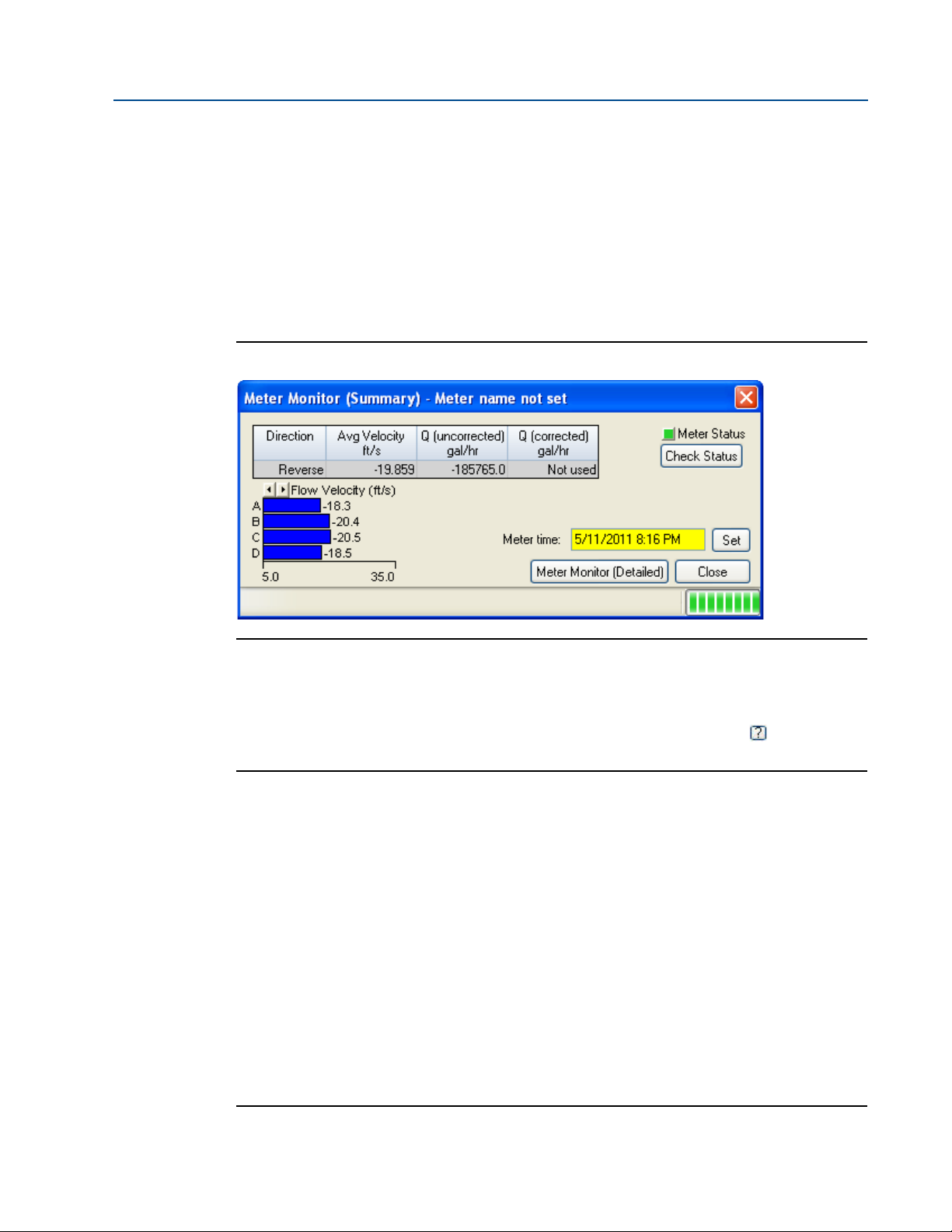

Run Daniel MeterLink and open the Meter Monitor (Summary) view to perform a diagnostics

health check.

Figure 2-1 Meter Monitor status alarms

If the meter is measuring flow and operating within the established parameters the Meter Status

LED is green. If the Meter Status LED is red, an active alarm exists that requires you to take

corrective action. Click the Check Status button to display the Status Summary screen. The

alarms are shown with the primary causes listed first. Click the question mark next to the

alarm to display a help topic related to the alarm and recommended actions to resolve the issue.

Figure 2-2 Status summary

Section 2: Troubleshooting 9

Page 24

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

A.

B.

A. Active alarm conditions from Meter Monitor page

B. Status summary page with alarm examples

December 2017 3-9000-764 Rev F

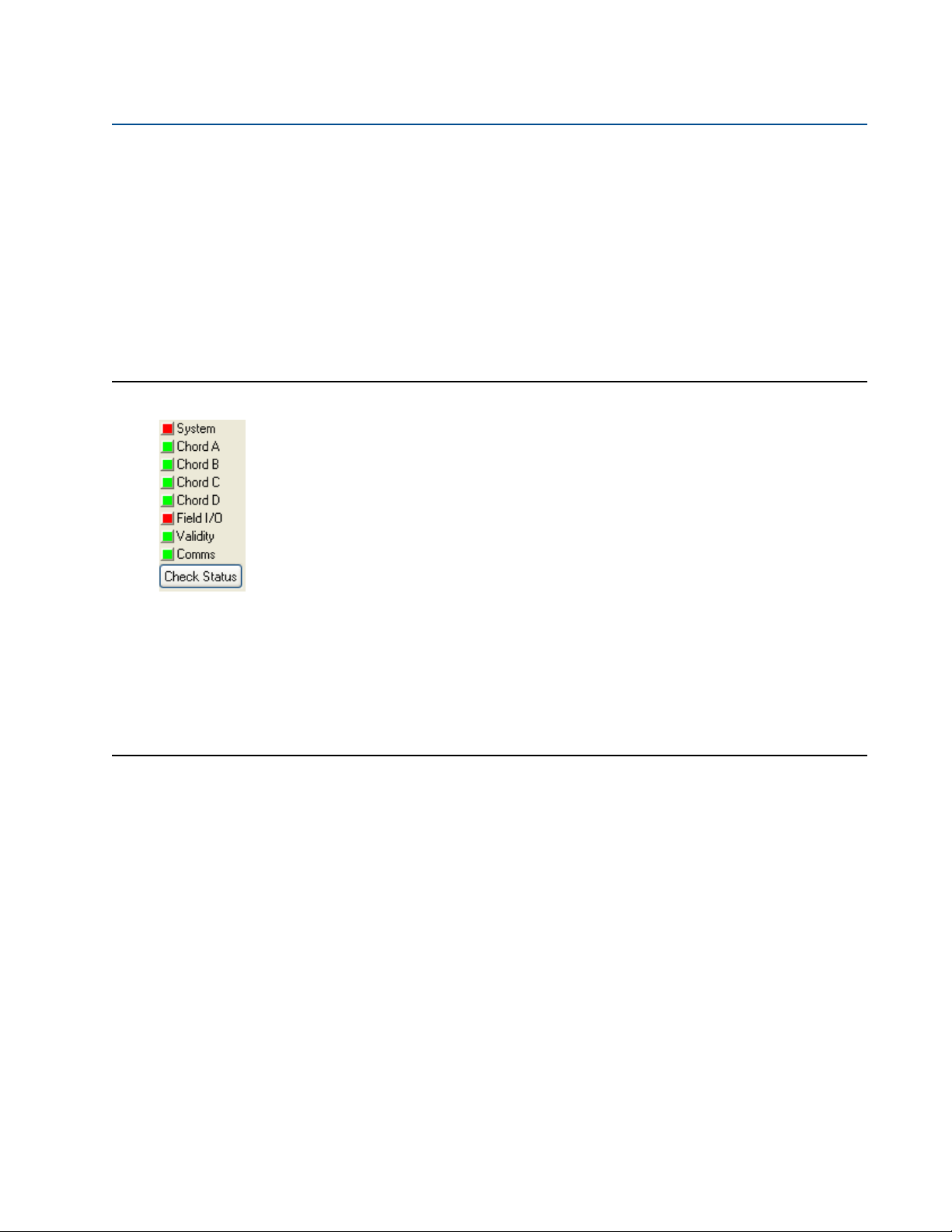

2.1.1 Check status

Click the Check Status button if any of the LEDs are yellow or red to see more specific

information causing the status alarm. Some alarms do not require an acknowledge and will clear

automatically when the alarm condition goes away. Alarms that require a user to acknowledge

them will have a button to the right titled

Wait and sends a request to the meter to clear the alarm. The alarm will disappear from the

to

Check Status dialog once the alarm actually clears.

ACK. Clicking the AC K button changes the button text

Click the

description of all alarms present.

Figure 2-3 Status Summary

Following is a list and a brief description of the types of alarms:

Check Status button and DUI opens the Status Summary dialog box that gives a short

• System

• Power Loss

• Field I/O

• Validity

• Comms

• Check Status

2.1.2 System alarm

The System alarm indicates a failure in the hardware that should be addressed by a service

technician. This includes memory checksum errors and communication errors within the

hardware. A Red LED indicates a System alarm condition. Collect a Maintenance log and an

audit/alarm log and then, contact your Daniel service representative.

10 Check status

Page 25

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

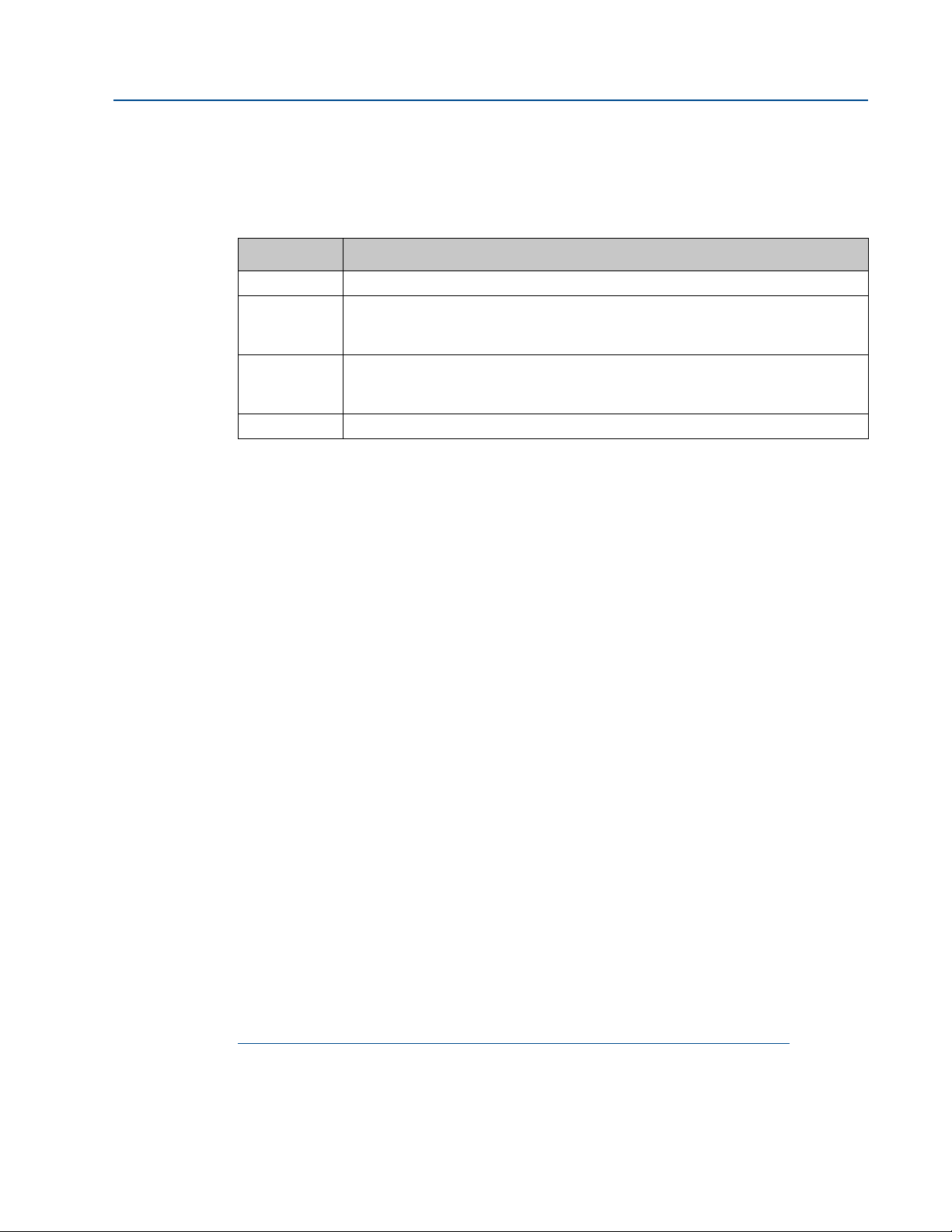

2.1.3 Chord A, Chord B, Chord C and Chord D alarm

Chord A, Chord B, Chord C, and Chord D - These alarms indicate how a chord is functioning.

LED Color Problem

Green No alarms are present. Chord is operating properly.

Yellow At least one sample in the batch caused an alarm but it did not cause the chord to fail.

The sample will not be used in the batch. Discarding occasional samples can occur

during normal operation such as during flow velocity changes.

Red The chord has failed or is in acquisition. This chord is not used for this batch. Chords

that have failed or are shown to be in acquisition for repeated batches indicates that the

meter should be inspected by a service technician.

Gray The chord has manually been set to inactive.

2.1.4 Field I/O alarm

Reports various field I/O devices that are in alarm. Click the Check Status button for more details

on specific alarms. The field is grayed out if the Daniel 3810 Series Ultrasonic Flow Meter does

not support this alarm.

2.1.5 Validity alarm

This alarm indicates that the meter may not be measuring accurately. Click Check Status to see a

description of which validity alarms are active. The validity alarms

issue with the meter collecting enough information from the chords to make an accurate

measurement. The validity alarms for pressure and temperature indicate that the value is above

or below the alarm limits for these values. Red and green are the only colors used for this alarm.

2.1.6 Comms alarm

The Comms alarm indicates that communications between DUI and the meter failed. This could

be due to a poor communication link. DUI continues to retry communications. Red and green

are the only colors used for this alarm.

2.1.7 Communications

The Communications Analyzer (via Daniel MeterLink Tools> Menu>Communications Analyzer

menu path) displays communications between Daniel MeterLink and the ultrasonic meter. This

utility is useful for troubleshooting communications to the meter. It displays many of the TCP/IP

commands between Daniel MeterLink and the connected meter.

For troubleshooting communications with the 475 Field Communicator for the HART®

Protocol, refer to Section 5 of the Emerson 475 Field Communicator User’s Manual, Rev D. This

manual may be downloaded from the following location:

QMeter and QFlow indicate an

http://www2.emersonprocess.com/en-US/brands/Field-Communicator/Pages/Support.aspx

For troubleshooting communications with AMS Device Manager, refer to the help

documentation and support at the following web site:

http://www2.emersonprocess.com/en-US/brands/amssuite/amsdevicemanager/Pages/AMSDeviceManager.aspx

Chord A, Chord B, Chord C and Chord D alarm 11

Page 26

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

2.2 Troubleshooting the meter

Table 2-1 and the following sections show errors that may occur with the meter hardware,

firmware or connections and recommended actions to resolve the problem(s).

Table 2-1 Troubleshooting

Error Recommended action(s)

Acquisition Module Error

Acquisition Module is not compatible with firmware

Chord failure

CPU Module LINK LED

• Check interconnect cable between Acquisition Module and the CPU Module.

• Attempt the Program Download procedure to install the firmware.

— Cycle power to the meter.

— Replace the Acquisition Module.

— If the Acquisition Module cannot be reprogrammed, collect a complete

Archive log and contact your local area Daniel service representative.

• Upgrade the firmware in the meter to the latest version using Daniel MeterLink

(Too ls| Pro gram Downloa d). Contact your Daniel service representative to obtain

the latest firmware or download the firmware from:

http://www2.emersonprocess.com/en-US/brands/daniel/Pages/Daniel.aspx

• Replace the Acquisition Module.

• Chord is hard failed (Chord A, Chord B, Chord C or Chord D) and meter is unable to

obtain measurement data from this pair of transducers.

— If Chord A is failed and no other transducers are failed or are reporting status

alerts, the issue is most likely isolated to this pair of transducers or its cabling.

Check the transducer wiring for this pair of transducers to make sure connections are secure and wired correctly.

— Verify that the meter run is not partially full where the top transducer pair are

not submerged in the process fluid.

— Verify the average gain of this transducer pair is not above 90dB. The gain

value can be read in Daniel MeterLink on the Monitor page.

— Remove the transducer cable from the transducer and measure the resistance

with an Ohm meter across the two pins on the back of the transducer

housing. If the value is over 2 ohms, replace the transducers.

— If transducer cabling allows, swap cabling of failed transducer pair with a pair

with equal path lengths. If the alarm remains active for this chord, then the

transducers are working properly. If this alarm clears but the chord that was

swapped now fails, the issue is with the transducer.

— Collect a Maintenance Log, Configuration file and Waveform stream file with

Daniel MeterLink and contact your Daniel service representative.

• When connecting directly:

— Check the cross-over cable connection (P/N 1-360-01-596)

• When Using a Hub:

— Use straight-through patch cable between the meter and the hub and a

straight-through patch cable between the hub and the PC

— Do not connect either the meter or PC to the hub UPLINK port.

— Check the CPU Module LED 1 is on (either solid red or flashing green). If the

LED is not on, check power to the meter.

— If the LED is on, check the Ethernet cable connections

12 Troubleshooting the meter

Page 27

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

Table 2-1 Troubleshooting

Error Recommended action(s)

CPU Module LINK LED is on but I

can't communicate with the meter

using Ethernet

Communication line connected to

the flow computer but no signal is

received

If you are connecting for the first time,

• Enable the DHCP switch on the CPU Module

• Verify that the PC has received an IP address from the meter as follows:

— bring up Command prompt window (Start->Run->(type)cmd)

— in the Command prompt window, type ipconfig

• If you get the following: IP 192.168.135.35 (note: the last .35 can be up to .44) with

a Subnet Mask of 255.255.255.0 and Default Gateway you should be able to

connect to the meter

• If you get the following:

— Ethernet adapter Local Area Connection 1:

— IP Address: 0.0.0.0

— the PC has not yet received an IP address from the DHCP server wait (up to 30

seconds) to receive an IP address before attempting to connect to the meter

— after 30 seconds the PC has not received an IP address from the DHCP server

or the IP address shown above (from ipconfig) is different from the range of

192.168.135.35 through 192.168.135.44, verify that the PC is configured to

receive its IP address automatically (via DHCP)

• Check for loose connections at the flow meter and the flow computer.

• Check the CPU Module settings.

Troubleshooting the meter 13

Page 28

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Table 2-1 Troubleshooting

Error Recommended action(s)

Communication issues due to

blocked network ports

Communicating with meter but all

chords display failures

Cannot communicate with Daniel

MeterLink program

• Blocked network ports on the computer running Daniel MeterLink or on a company

LAN can prevent connections to the meter or prevent certain features from

working. These issues may occur over Ethernet, Modem and Direct serial connections. Reference the list of network ports used by Daniel MeterLink in the Help file

and the symptoms of having blocked ports. Contact your IT department for

assistance in resolving these issues.

• Error condition of a blocked network:

— Cannot connect to a meter

— Cannot collect Archive log files

— Cannot view or stream waveforms in Waveform Viewer or Signal Analyzer.

— Cannot upgrade firmware.

— Communications lost over serial or modem connections while

Daniel MeterLink is idle on a screen.

• Symptoms of blocked network:

— If a PING is blocked on this network port, serial or modem connections could

be lost after approximately 15 seconds of inactivity. This issue can be

confirmed by checking the log_meter log file in the Temp data folder. The

path of the Temp data folder is shown in the Daniel MeterLink About dialog.

— A blocked FTP port will generally not prevent a connection to the meter, but

will prevent log collections and program downloads. A blocked FTP port could

prevent a connection in the event the meter is running a newer version of

firmware for which Daniel MeterLink does not currently have a database configuration file. If this is a case, a message stating “Error reading database

config file dbconfig<databaseversion>.xml from the meter.” will be displayed.

— A blocked DB API port will report “Error 10001 opening database connection

to <IP address>”.

— A blocked Streaming port will report an error message “Unable to open a

control socket”. This will occur when opening the Signal Analyzer window or

clicking Read or Stream to File in the Waveform Viewer.

• Verify that the resistance of transducers is within Specification (2 Ω).

• Check the Acquisition Board.

• Check the interconnect cables between the Base assembly and the Transmitter

Electronics Enclosure.

• Ensure that the meter is properly powered.

• Ensure that the computer cable is properly connected and check your interface pins

(RS-485 or RS-232).

• Verify that the communication parameters of the Daniel MeterLink

correctly set.

program are

• Check RS-485 or RS-232 communication.

14 Troubleshooting the meter

Page 29

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

Table 2-1 Troubleshooting

Error Recommended action(s)

Cannot communicate with 475 Field

Communicator

Cannot communicate with AMS

Device Manager

Connect to multiple meters via

Ethernet when they are on the same

LAN

Connect to multiple meters via

Ethernet when they are on the same

hub but not connected to an

intranet LAN

Configuration changed

Configuration lost

Electronics Temperature is Out Of

Nominal Range

• Refer to the Emerson 475 Field Communication User’s Manual, Rev F. This manual may

be downloaded from the following location:

http://www2.emersonprocess.com/en-US/brands/Field-Communicator/Pages/

Documentation.aspx

— Note: The 375 Field Communicator is no longer available for purchase since the

release of the 475 Field Communicator. Customer support for the 375 Field

Communicator remains available

• Refer to the AMS help documentation and support at the following web site:

http://www.emersonprocess.com/ams/suppinde.htm

• Configure each meter with a unique user-specified IP address following the initial

communication quick start instructions.

• Contact your IT department for valid IP addresses for your LAN and Gateway

addresses.

• Disable the DHCP server.

• Configure each meter with a unique user-specified IP address

following the initial communication quick start instructions.

• Assign each meter on the hub a unique IP address within the range

192.168.135.150 through 192.168.135.254 (Gateway address for each meter may

be left unconfigured as 0.0.0.0).

• A PC may receive its IP address from an external DHCP server; in this case, one and

only one meter must have its DHCP ser ver enabl ed (the DHCP ser ver will ser ve up to

10 IP addresses to PCs attempting to talk to all meters on the hub).

• Once a meter's IP address is configured, the meter may be connected to the hub

and accessed using that IP address.

• One or more parameters have been modified in the meter's configuration

— Collect an Audit log using Daniel MeterLink in order to see what configuration

parameters changed and when they changed.

— Save the configuration file.

• The meter configuration has reset to default values and the meter is not configured

correctly to measure flow and the meter has performed a Cold Start.

— Unless the Cold Start occurred after upgrading firmware, replace the CPU

board.

— If the cold start occurred after a firmware upgrade, fully re-configure the

meter from a previously saved configuration using the

Edit/Compare Configuration in Daniel MeterLink.

• Temperature of the electronics is out of nominal operating range (below -40 °C or

above 100 °C) which could lead to a system failure.

— Attempt to warm or cool the meter electronics housing.

— If the electronics is mounted to the meter and the process fluid in the meter is

over 65 °C, you must remote mount the electronics off of the meter body.

— Collect a Maintenance log using Daniel MeterLink while the meter is experi-

encing the issue and contact your Daniel service representative.

Troubleshooting the meter 15

Page 30

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Table 2-1 Troubleshooting

Error Recommended action(s)

Flow pressure is outside the alarm

limits

Flow temperature is outside the

alarm limits

• Startup Issues:

— Verify that there is voltage to the pressure sensor from either the meter's

power supply board or from an external power supply.

— If using an analog pressure device, verify that the pressure sensor is properly

wired to the connector.

— Verify the input is properly configured for your pressure input.

— If using a flow computer to write pressure to the meter, verify that it is

properly writing to fixed flow pressure in the proper units.

• Run Time Issues:

— Adjust pressure of process fluid to within alarm limits.

— If using an analog pressure device and input reading is 0, check if IsAI1Avail is

equal to 1 in the Meter Information dialog in Daniel MeterLink. If it is not 1,

either the I/O Board has been removed or is damaged. Reinstall or replace the

board if this value is 0.

— If using an analog pressure device, verify that the pressure sensor is working

properly.

— If using an analog pressure device, recheck wiring and switch settings.

— If a flow computer is writing values to the fixed flow pressure, verify that the

flow computer is still writing valid values without Modbus write errors.

— Reverify the pressure input settings are correct.

• Startup Issues:

— Verify that there is voltage to the temperature sensor from either the meter's

power supply board or from an external power supply.

— If using an analog temperature device, verify that the temperature sensor is

properly wired to the connector.

— Verify the input is properly configured for your temperature input.

— If using a flow computer to write temperature to the meter, verify that it is

properly writing to fixed flow temperature in the proper units.

• Run Time Issues:

— Adjust temperature of process fluid to within alarm limits.

— If using an analog temperature device and input reading is 0, check if

IsAI2Avail is equal to 1 in the Meter Information dialog in Daniel MeterLink. If

it is not 1, either the I/O Board has been removed or is damaged. Reinstall or

replace the board if this value is 0.

— If using an analog temperature device, verify that the temperature sensor is

working properly.

— If using an analog temperature device, recheck wiring and switch settings.

— If a flow computer is writing values to the fixed flow temperature, verify that

the flow computer is still writing valid values without Modbus write errors.

— Reverify the temperature input settings are correct.

16 Troubleshooting the meter

Page 31

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

Table 2-1 Troubleshooting

Error Recommended action(s)

Program download failed during

firmware upgrade

No power to the unit

• If the meter power fails during a firmware upgrade process, perform a backup

upgrade in an attempt to connect to the meter and download the program again.

— In Daniel MeterLink go to the File pull-down menu and select Program

Settings.

— Enable the Allow FTP-only connection

— For Serial Port Connections: for Daniel 3810 Series Liquid Ultrasonic meters

connect to Port A. You may need to adjust your Meter Directory settings for

the connection so that they match the port default settings. Port A will default

to 19200 baud with a Modbus address of 32.

— For Ethernet Connections: If you are connecting to the meter over an Ethernet

port, you should be able to connect with the same IP address as normal. If this

is unsuccessful, the meter may have defaulted to 192.168.135.100 with a

subnet of 255.255.255.0. Make sure your PC has a compatible address and

attempt a connection using this IP address.

— Make sure your cabling and your Meter Directory record are setup, then

attempt to connect to the meter.

— You will receive a message “Error 10001 opening database connection to...”.

Click OK and you will be prompted to “Attempt FTP-only connection ….”. Click

Yes and if successful, the Daniel MeterLink™ caption displays “…Connected to

<meter name>…”. Go to the To ol s pull down menu and select Program

Download to attempt the firmware upgrade again.

— If the firmware upgrade is successful, the meter should start working as

normally as the meter’s configuration is not normally lost.

— If the configuration is lost, use Daniel MeterLink

to write the saved configuration back to the meter. The saved configuration

files are typically stored in C:\Ultrasonic Data folder.

Edit/Compare Configuration

— Restart the meter to install the firmware. Daniel MeterLink prompts you with a

message that it must disconnect from the meter. Once the firmware upgrade

is complete you will be able to reconnect to the meter with Daniel MeterLink.

— When the meter restarts, it takes about two minutes before you will be able to

reconnect depending on the firmware upgrade being performed. If the

database does need to be reinitialized, it could take up to five minutes.

— After an upgrade, it is recommended to reconnect to the meter and repeat

the Program Download process.

— If all the program components are successfully updated, they will show to be

the same date and version as the Currently Installed Versions and the

Download button will be disabled.

— If one or more components are still not updated, click Download to continue

the upgrade process.

• Check for correct voltage (24 VDC) (refer to the System Wiring Diagram).

• Check the main power source for blown fuse or tripped circuit breaker. Reference

your “as built” installation drawings for your location.

Troubleshooting the meter 17

Page 32

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Table 2-1 Troubleshooting

Error Recommended action(s)

One or more of the chords is not

indicating a reading (reporting

zeros)

Power Failure

Sound velocity is outside defined

limits

Waveform contains an excessive

amount of noise

• Check for loose connections at the cable connectors.

• Check the resistance of the transducers (should be approximately 2 Ω).

• Problem also may be caused by a bad Acquisition Board or interconnect cable.

• Check system status in the Daniel MeterLink program for any flagged errors.

• Check the CPU Module.

• Check the resistance of the failed transducer.

• If Chord A is not indicating, change the transducer cables from Chord B to chord A.

If Chord B then fails, the transducers are bad on Chord A.

• Meter has had power removed for a period of time or the meter restarted itself such

as after a firmware upgrade. The Audit log in the meter indicates the power fail

time.

— If this was an unexpected restart of the meter, verify the integrity of the power

to the meter and make sure that the voltage level is in the range of 11-36 VDC

at the meter.

— If this was a known power fail or restart of the meter, just acknowledge this

alarm.

• The meter's measured average sound velocity is outside the defined limits.

— Verify that all chords are measuring the same Speed of Sound within about

0.15%. Look for alarms that indicate transducer problems and resolve any of

these issues. This could include failing transducers, debris buildup on transducers, or incorrectly entered path lengths in the configuration.

— If the chords agree, adjust the SSMin or SSMax using the Edit/Compare

Config utility in Daniel MeterLink

within these limits.

so the meter's average speed of sound falls

— Collect a Maintenance log using Daniel MeterLink and contact your Daniel

service representative.

• Use the Daniel MeterLink Meter>Signal Analyzer to increase the StackSize until

noise level decreases (settings can be 1 (none) 2, 4, 8, or 16). If increasing the

StackSize is not successful, try turning on the filter or consult with Daniel Customer

Service if you are unsure of how stacking a signal can affect the meter's operation.

18 Troubleshooting the meter

Page 33

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

2.2.1 Meter maintenance

The Monitor (Summary) includes the direction of flow measurement, velocity rate, units of

measurement, uncorrected or corrected flow (if applicable for your meter) and a bar graph for a

visual comparison between the velocities for each chord.

Figure 2-4 Meter Monitor (Summary) view

Run Daniel MeterLink and open the Meter Monitor (Detailed) view to perform a diagnostics

health check and or adjust parameters for your site requirements. If you wish to use the Monitor

(Detailed) dialog as the default view, click the checkbox in the lower portion of the dialog box

Figure 2-5 Meter Monitor (Detailed) view

Meter maintenance 19

Page 34

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

The following details the information displayed in this dialog box.

• Flow Properties Table - the table at the top of the Meter Monitor dialog box shows basic

information about the condition of the flow in the meter.

• Flow Velocity/Flow Ratios Bar Graph - provides a visual comparison between the

velocities for each chord.

• Chord Speeds of Sound Bar Graph - a visual comparison between the speeds of sound

for each chord.

• Gain/Performance Bar Graph - provides either a visual comparison of the average

upstream and downstream gains for each chord or a visual comparison of the average

upstream and downstream performance for each chord.

• Signal to Noise Bar Graph - provides a visual comparison between the signal to noise

ratio for each chord direction.

• Meter Status Alarms - provides a visual indication of the meter’s status.

• Run time - displays how long the monitor screen has been collecting data.

• Meter Time - the time displayed is the time from the Ultrasonic meter.

(NOTE: If the time displayed has a yellow background, that is an indication that the

meter’s time is more than 10 minutes apart from the PC’s time.)

• Meter Data List - displays read-only data selected from the drop-down list

• Chart - the chart utility displays the data collected for the value selected from the Chart

drop-down list.

Refer to

Table 2 -1 for error resolutions and Tab le 2- 2 for meter maintenance hardware diagnostics.

Table 2-2 Maintenance

Daniel MeterLink utility Diagnostics Action(s)

Meter Monitor (Summary) view

• Check Status for active alarms • Meter Status LED is green if there are

no active alarms. This indicates the

meter is measuring flow and

operating within the calibrated

parameters.

• Meter Status LED is red. This indicates

an active alarm. Resolve and acknowledge active alarms as displayed on

the Status Summary page. Click the

Help button beside the alarm

description to display information

about the alarm and recommended

actions to resolve the issue.

20 Meter maintenance

Page 35

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

Table 2-2 Maintenance

Daniel MeterLink utility Diagnostics Action(s)

Meter Monitor (Detailed) view

• Flow Profile • Flow profile ratios can be viewed by

clicking on the arrows in the upper

left of the chart.

• The flow profile ratios for chords A

and D and chords B and C should be

equal lengths.

• The flow velocity ratio between

chords A & D or chords B & C should

not differ by more than 10%, changes

will be reflected by the symmetr y and

flow profile values.

• If the difference persists, the flow

conditioner (if installed) should be

checked for blockages and if required

the upstream piping should be

cleaned.

• Per path Speed of Sound (SOS) differ-

ences should not be more than .35%,

these can be viewed by clicking on the

arrows in the upper left of the chart.

Negative values are shown in blue.

• The SOS difference can be caused by

buildup on the transducer, incorrect

geometrical and delay time values

and stratification at lower velocities.

• Gains and Signal to Noise Ratios (SNR)

are displayed in decibels and should

be compared to the initial values in

the maintenance logs taken during

the calibration or initial start-up.

• The average chord signal amplitudes

should be compared to the initial

values in the maintenance logs.

• The Check Status chord LED will turn

from green to red if a path is hard

failed. The issue or issues causing the

failure must be corrected before the

alarm can be cleared.

Meter maintenance 21

Page 36

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Table 2-2 Maintenance

Daniel MeterLink utility Diagnostics Action(s)

Meter Monitor (Summary) view

Meter Flow Properties Table

Meter Monitor (Detailed) view

Monitor Chart Selection list

• Flow velocity • Check the flow direction. If reverse

flow is detected, check for valve leaks.

• If the meter run typically has reverse

flow when flow is stopped, reconfigure the ReverseFlowVolLmt to allow a

higher volume from the Field Setup

Wizard> General Page.

• Speed of Sound • Compare Speed of Sound deviation

from measured SOS relative to the

average SOS.

• Check the chord’s SOS.

• Check and correct geometry configu-

ration (pipe diameter, distance

between the transducers (LA), and

delay time).

• If present, resolve transducer issues

(failed transducer, cabling or debris

buildup on the transducer face, or

path length configured incorrectly).

• If SOS is out of range and all checks

were positive, adjust SSMin or SSMax

(consult with a Daniel Service representative before making these adjustments).

22 Meter maintenance

Page 37

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

Table 2-2 Maintenance

Daniel MeterLink utility Diagnostics Action(s)

Meter Monitor (Detailed) view

Meter Data List

Meter Monitor (Detailed) view

Meter Data List

• Electronics Temperature out of

range

• Temperature of the electronics is out

of nominal operating range

below -40 °C or above 100 °C (-40 °F

or above 212 °F).

— Heat or cool the meter electron-

ics housing. If operating

temperature exceeds 65

remote mount the Transmitter

Electronics Enclosure.

o

C,

• Electronics voltage out of range • Systems voltages are valid if 1.0V,

1.2V, 2.5V, 3.3V or the Acquisition

Module valid voltages are 1.2V, 2.5V

or 3.3V.

• Replace the CPU Module if one or

more of the System Voltages is out of

range.

• Replace the Acquisition Module if one

or more of the voltages is out of

range.

MeterLink Tools Menu‘

• Frequency output • Run the Frequency Outputs test

• If the output reads zero, you may

require a pull up resistor 1.2kOHM,

0.5W.

Meter maintenance 23

Page 38

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Table 2-2 Maintenance

Daniel MeterLink utility Diagnostics Action(s)

MeterLink Tools Menu

MeterLink Tools Menu

• Analog outputs • Run Analog Outputs test and verify

outputs are within 4mA -20mA range

— 0% = 4mA

— 25% = 8mA

— 50% = 12mA

— 75% = 16mA

— 100% = 20 mA

• Digital outputs • Run the Digital Outputs test.

• Digital Output Content is in relation

to frequency validity and flow

direction configuration and polarity.

24 Meter maintenance

Page 39

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

Meter Hardware Diagnostics Action(s)

Meter Electronics

MeterLink Logs/

Reports Menu

• Acquisition Module communications error • Check firmware revision and upgrade if

necessary using Daniel MeterLink Tools>Program Download.

• If the CPU Module LED 5 is not flashing green,

check interconnect cable between acquisition

Module and the CPU Module.

• If the CPU Board LED 5 is not flashing green,

replace Acquisition Module.

• Meter performed a Warm Start or a Warm

start required

• Meter performed a Warm Start:

— Collect an Archive event log (Audit log)

using Daniel MeterLink to view configuration parameters changes and when

they changed.

• Warm start required:

— When you make changes to the trans-

ducer characteristics, sample rates, the

device number, or a Modbus map file.

Meter maintenance 25

Page 40

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

Meter Hardware Diagnostics Action(s)

MeterLink Tools>Edit/

Compare Configuration Menu

MeterLink Logs/

Reports Menu

• Meter performed a Cold Start • The meter configuration has reset to default

values and the meter is not configured

correctly to measure flow.

• Unless the cold start occurred after upgrading

firmware, you may need to replace the CPU

Module.

• If the Cold Start occurred after a firmware

upgrade, you must reconfigure the meter

from a previously saved configuration file

using the Edit>Compare Configuration screen.

Then clear the latched alarm on the Status

Summary page.

• Power failure • If this was a known power fail or restart of the

meter just acknowledge this alarm on the

Status Summary page.

• If this was an unexpected restart of the meter,

verify the integrity of the power to the meter

and make sure that the voltage level is in the

range of 11-36 VDC at the meter.

Meter Hardware Diagnostics Action(s)

Daniel MeterLink

Meter Monitor

(Summary) view

• Chord Failure Daniel MeterLink

Meter Monitor (Summary) view

• The meter is unable to obtain measurement

data from a pair of transducers.

• The cause may be isolated to one pair of trans-

ducers or its cabling. Check the transducer

wiring for this pair of transducers to make sure

connections are secure and wired correctly.

• Verify that the meter run is not partially full

where this top transducer pair is not

submerged in the process fluid.

• Verify the average gain of this transducer pair

is not above 90dB. Read the value from the

Daniel MeterLink Monitor Page or using AMS

under Service Tools|Path performance.

• Remove the transducer and clean the trans-

ducer face. Reapply coupling fluid to the

transducer face and reinstall.(see

Section 3.2.1 Transducer removal procedure).

26 Meter maintenance

Page 41

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

Meter Components Visual Inspection Action(s)

Security seals

External ground wiring

Conduit seals

• Endcap seals

• Endcaps latches

• Transmitter Electronics Enclosure

• Base Enclosure

• Shroud seals

• Transmitter Electronics Enclosure

ground lug

• Only authorized personnel may

remove security seals. Follow your

standard operating procedure to

report seals that have been tampered

with or removed and replace the seals

per instructions in Section 3.6.8 in the

Installation Manual (3-9000-765).

• Inspect ground lug wiring and make

sure the wiring is tightly secured.

• Transmitter Electronics Enclosure • Inspect the conduit sealant and follow

your standard operating procedure to

report tampering with the conduit

sealant.

• Your operating procedures may

require a certified electrician and

company witness to reseal the

conduit.

Flanges

CRUSHING HAZARD

Do not remove flange stabilizers.

Attempting to do so may allow the meter to roll, resulting in serious injury or equipment damage.

• Inspect for leaks

• Inspect flange stabilizers

• Perform leak tests on flanges

• Ensure flange stabilizers are installed.

Meter maintenance 27

Page 42

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

2.2.2 Unable to connect direct serial or external serial modem

If you are using Windows® XP, Windows® Vista or Windows® 7 make sure that you do not have

more than one modem driver installed to the same COM port. Typically this will only be

necessary if you use one COM port to talk direct (serial communications) and use the same COM

port to connect to an external modem. This is an apparent limitation in Microsoft’s® Dial-up

Networking. If more than one modem driver is installed for a particular COM port, Dial-up

Networking will always use the last driver installed regardless of what is selected. The only work

around is to only install one modem driver per COM port on the PC at a time. Refer to the Daniel

MeterLink Quick Start Manual (P/N 3-9000-763) for phone and modem details. The manual

may also be downloaded from the Daniel website.

http://www2.emersonprocess.com/en-US/brands/daniel/Flow/ultrasonics/Pages/Ultrasonic.aspx

2.2.3 Unable to connect to meter

If you receive the error message “Unable to connect to meter” when trying to connect to a

Daniel 3814 Liquid Ultrasonic Flow Meter, refer to the following:

• Ethernet Connections (

• Direct Serial Connections (

Section 2.2.4)

Section 2.2.5)

2.2.4 Ethernet connections

If you received this message while trying to connect over Ethernet, verify you have the correct IP

address in the Meter Directory record. If the meter is to assign the IP address, make sure the IP

address is set to 192.168.135.100 and that the DHCP switch is in the ON position on the CPU

Module. If the meter has a fixed IP address, verify the IP address, Subnet, and Gateway are

correct in the meter. If going through a hub, verify that the computer and meter are connected

to the hub with straight-through patch cables.

2.2.5 Direct serial connections

Verify the Comm settings on the CPU Module. Also, verify your wiring between the meter and

the computer running DUI using the Field Wiring drawing DMC- 004946. Verify the Comms

Address and Baud rate are correct in the Meter Directory record.

For additional information on wiring and configuring the meter for the various communication

options refer to the Daniel 3814 Liquid Ultrasonic Flow Meter Installation Manual (P/N 3-9000760, Section 3.5).

28 Unable to connect direct serial or external serial modem

Page 43

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017

2.3 Troubleshoot Maintenance log files and trend files

2.3.1 Files Do Not Appear in Workbook

Maintenance Log files and Trend files that exist on the PC do not appear in the Microsoft®

Excel® workbooks tree under Trend Maintenance Logs.

This is most likely caused by the fact that the desired file or files are already open in Microsoft®

Excel®. Open files can not be verified as Maintenance Log files or Trend Files by

Daniel MeterLink and are left out of the list. Simply close the files in Microsoft® Excel® and then

close and reopen the Trend Maintenance Logs dialog box to include them in the list.

2.3.2 Microsoft® Excel® Log/Export Options are not Available

In order for the Excel® log/export options to be available, Excel® 2000 or later must be installed

on the machine and at least one printer must be installed under the Windows® operating

system.

If Excel® 2000 or later is installed and you have printers installed but the Excel® option is still

unavailable, it may be because Excel® cannot access the printer driver information of the

Windows® default printer. If the Windows® default printer is a network printer and you are not

currently connected to the network, then Excel® will most likely not be able to access the

printer driver information and Daniel MeterLink cannot use Excel® to generate reports or logs.

One solution is to install a local printer on your machine tied to LPT1. The local printer driver you

installed can be for any printer and the printer does not actually have to exist or be connected to

the PC. If you install a local printer, you can configure Daniel MeterLink to temporarily change

your Windows® default printer over to this local printer while running Daniel MeterLink. Do this

by selecting this local printer for the Override system default printer selection in the Program

Settings dialog. Daniel MeterLink will automatically change the Windows® default printer to

the selected override printer when it starts and will set the Windows® default printer back to its

original printer when it closes.

Troubleshoot Maintenance log files and trend files 29

Page 44

Section 2: Troubleshooting Maintenance and Troubleshooting Manual

December 2017 3-9000-764 Rev F

2.3.3 Maintenance Logs or Trend files are not created

When using Excel® XP or later, some of the worksheets in the Maintenance Logs or Trend files

are not created.

If the Inspection sheet of the Maintenance Log file or the Charts sheet of a Trend file is not

generated, it is probably because Excel® is not configured to allow Daniel MeterLink to run the

Visual Basic® script that generates the page. Excel® can be configured to allow Daniel

MeterLink to run the Visual Basic® script by following the instructions below.

To enable Excel® 2000 to work with Daniel MeterLink,

1. Select

Figure 2-6 Excel® 2000 Tools Menu

2. The Security dialog appears. Select the

Tools>Macros>Security menu path.

Trusted Sources tab.

30 Maintenance Logs or Trend files are not created

Page 45

Maintenance and Troubleshooting Manual Section 2: Troubleshooting

3-9000-764 Rev F December 2017