Page 1

Operations manual

DAN-20057316, Rev AA

Daniel™ 3410 Series Gas Ultrasonic Flow

meters

Model 3418

January 2019

Page 2

2

Page 3

Flow Lifecycle Services for Daniel products

Location Telephone number Fax number

North America/Latin America +1.713.467.6000 +1.713.827.4805

Flow Lifecycle Services for Daniel products +1.713.827.6314 +1.713.827.6312

USA (toll free) +1.888.356.9001 +1.713.827.3380

Asia Pacific (Republic of Singapore) +65.6777.8211 +65.6777.0947.0743

Europe (Stirling Scotland, UK) +44 (0)1786.433400 +44 (0)1786.433401

Middle East Africa (Dubai, UAE) +971 4 8118100 +971 4 8865465

Daniel Measurement and Control, Inc. (Headquarters)

11100 Brittmoore Park Drive

Houston, TX 77041 USA

http://www.emerson.com

Email

• Customer Service: DanielCST.Support@Emerson.com

• Customer Support: Daniel.TechnicalSupport@Emerson.com

• Field Lifecycle Services: Tech.Service@Emerson.com

• Asia-Pacific: danielap.support@emerson.com

• Europe: danielEMA.cst@emerson.com

Return Material Authorization (RMA)

A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason. Access and

fill in the RMA form for Daniel products clicking on the link below.

http://go.emersonprocess.com/RMAOnlineForm

3

Page 4

Signal words and symbols

Pay special attention to the following signal words, safety alert symbols and statements:

Safety alert symbol

This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

Danger indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Warning indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Caution indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Notice is used to address safety messages or practices not related to personal injury.

Important

Important is a statement the user needs to know and consider.

Tip

Tip provides information or suggestions for improved efficiency or best results.

Note

Note is “general by-the-way” content not essential to the main flow of information.

4

Page 5

Important safety instructions

Daniel Measurement and Control, Inc. (Daniel) designs, manufactures and tests products to function within specific conditions.

Because these products are sophisticated technical instruments, it is important that the owner and operation personnel must

strictly adhere both to the information printed on the product and to all instructions provided in this manual prior to installation,

operation, and maintenance.

Daniel also urges you to integrate this manual into your training and safety program.

BE SURE ALL PERSONNEL READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ALL NOTICES AND PRODUCT WARNINGS.

WARNING

Failure to follow the installation, operation or maintenance instructions for a Daniel product could lead to serious injury or

death from explosion or exposure to dangerous substances.

To reduce the risk:

• Comply with all information on the product, in this manual, and in any local and national codes that apply to this product.

• Do not allow untrained personnel to work with this product.

• Use Daniel parts and work procedures specified in this manual.

Product owners (Purchasers):

• Use the correct product for the environment and pressures present. See technical data or product specifications for

limitations. If you are unsure, discuss your needs with your Daniel representative.

• Inform and train all personnel in the proper installation, operation, and maintenance of this product.

• To ensure safe and proper performance, only informed and trained personnel should install, operate, repair and maintain this

product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact

Daniel at 1-713-827-6314. You may also download the correct manual from: https://www.emerson.com/en-us/automation/

daniel.

• Save this instruction manual for future reference.

• If you resell or transfer this product, it is your responsibility to forward this instruction manual along with the product to the

new owner or transferee.

• ALWAYS READ AND FOLLOW THE INSTALLATION, OPERATIONS, MAINTENANCE AND TROUBLESHOOTING MANUAL(S) AND

ALL PRODUCT WARNINGS AND INSTRUCTIONS.

• Do not use this equipment for any purpose other than its intended service. This may result in property damage and/or serious

personal injury or death.

5

Page 6

Product operation (Personnel):

• To prevent personal injury, personnel must follow all instructions of this manual prior to and during operation of the product.

• Follow all warnings, cautions, and notices marked on, and supplied with, this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact

Daniel at 1-713-827-6314. You may also download the correct manual from: https://www.emerson.com/en-us/automation/

daniel.

• Read and understand all instructions and operating procedures for this product.

• If you do not understand an instruction, or do not feel comfortable following the instructions, contact your Daniel

representative for clarification or assistance.

• Install this product as specified in the INSTALLATION section of this manual per applicable local and national codes.

• Follow all instructions during the installation, operation, and maintenance of this product.

• Ensure that all connections to pressure and electrical sources are secure prior to and during equipment operation.

• Use only replacement parts specified by Daniel. Unauthorized parts and procedures can affect this product's performance,

safety, and invalidate the warranty. “Look-a-like” substitutions may result in deadly fire, explosion, release of toxic substances

or improper operation.

• Save this instruction manual for future reference.

6

Page 7

Notice

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY, AND WHILE EVERY EFFORT HAS

BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR

IMPLIED, REGARDING THE PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE

GOVERNED BY DANIEL'S TERMS AND CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST. WE RESERVE THE RIGHT TO MODIFY

OR IMPROVE THE DESIGNS OR SPECIFICATIONS OF SUCH PRODUCTS AT ANY TIME.

DANIEL DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF ANY PRODUCT. RESPONSIBILITY FOR

PROPER SELECTION, USE AND MAINTENANCE OF ANY DANIEL PRODUCT REMAINS SOLELY WITH THE PURCHASER AND END-USER.

TO THE BEST OF DANIEL'S KNOWLEDGE THE INFORMATION HEREIN IS COMPLETE AND ACCURATE. DANIEL MAKES NO

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN NO EVENT, SHALL DANIEL BE LIABLE FOR ANY INCIDENTAL,

PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS,

LOSS OF REVENUE OR USE AND COSTS INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND

CLAIMS OF THIRD PARTIES.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY AND MAY BE TRADEMARKS/

REGISTERED TRADEMARKS OF THESE COMPANIES.

7

Page 8

Warranty and Limitations

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement & Control, Inc. (“Daniel”)

warrants that the licensed firmware embodied in the Goods will execute the programming instructions provided by Daniel, and

that the Goods manufactured by Daniel will be free from defects in materials or workmanship under normal use and care and

Services will be performed by trained personnel using proper equipment and instrumentation for the particular Service provided.

The foregoing warranties will apply until the expiration of the applicable warranty period. Goods are warranted for twelve (12)

months from the date of initial installation or eighteen (18) months from the date of shipment by Daniel, whichever period expires

first. Consumables and Services are warranted for a period of 90 days from the date of shipment or completion of the Services.

Products purchased by Daniel from a third party for resale to Buyer (“Resale Products”) shall carry only the warranty extended by

the original manufacturer. Buyer agrees that Daniel has no liability for Resale Products beyond making a reasonable commercial

effort to arrange for procurement and shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Daniel

thereof in writing during the applicable warranty period, Daniel shall, at its option, correct any errors that are found by Daniel in

the firmware or Services or repair or replace F.O.B. point of manufacture that portion of the Goods or firmware found by Daniel to

be defective, or refund the purchase price of the defective portion of the Goods/Services. All replacements or repairs necessitated

by inadequate maintenance, normal wear and usage, unsuitable power sources or environmental conditions, accident, misuse,

improper installation, modification, repair, use of unauthorized replacement parts, storage or handling, or any other cause not the

fault of Daniel are not covered by this limited warranty, and shall be at Buyer's expense. Daniel shall not be obligated to pay any

costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance by Daniel. All costs of

dismantling, reinstallation and freight and the time and expenses of Daniel's personnel and representatives for site travel and

diagnosis under this warranty clause shall be borne by Buyer unless accepted in writing by Daniel. Goods repaired and parts

replaced by Daniel during the warranty period shall be in warranty for the remainder of the original warranty period or ninety (90)

days, whichever is longer. This limited warranty is the only warranty made by Daniel and can be amended only in a writing signed

by Daniel. THE WARRANTIES AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR ANY OTHER

MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. Buyer acknowledges and agrees that corrosion or erosion of

materials is not covered by this warranty.

2. LIMITATION OF REMEDY AND LIABILITY: Daniel shall not be liable for damages caused by delay in performance. The remedies of

Buyer set forth in this agreement are exclusive. In no event, regardless of the form of the claim or cause of action (whether based

in contract, infringement, negligence, strict liability, other tort or otherwise), shall Daniel's liability to Buyer and/or its customers

exceed the price to Buyer of the specific goods manufactured or services provided by Daniel giving rise to the claim or cause of

action. Buyer agrees that in no event shall Daniel's liability to Buyer and/or its customers extend to include incidental,

consequential or punitive damages. The term “consequential damages” shall include, but not be limited to, loss of anticipated

profits, revenue or use and costs incurred including without limitation for capital, fuel and power, and claims of Buyer's customers.

8

Page 9

Operations manual Contents

DAN-20057316 January 2019

Contents

Chapter 1 Startup........................................................................................................................ 11

1.1 Checklist.........................................................................................................................................11

Chapter 2 Communications..........................................................................................................13

2.1 Setup meter communications........................................................................................................ 13

Chapter 3 Optional feature keys...................................................................................................21

3.1 General overview of the Optional feature keys................................................................................21

3.2 Configure optional keys..................................................................................................................22

Chapter 4 Measurement.............................................................................................................. 23

4.1 Flow measurement.........................................................................................................................23

4.2 Signal processing............................................................................................................................25

4.3 Acquisition mode........................................................................................................................... 27

4.4 Chord gas and sound velocity measurements.................................................................................28

4.5 Volumetric flow rate values............................................................................................................ 32

4.6 3410 Series gas flow meter characterizations................................................................................. 37

Chapter 5 Configurations............................................................................................................. 39

5.1 Calibrate and configure the meter..................................................................................................39

5.2 Calibrate analog inputs and outputs............................................................................................... 51

5.3 Calibrate meter factors...................................................................................................................54

5.4 Configure frequency outputs..........................................................................................................59

5.5 Configure digital input/outputs......................................................................................................61

5.6 Outputs test mode......................................................................................................................... 62

5.7 Configure temperature and pressure..............................................................................................63

5.8 Configure Gas Chromatograph parameters....................................................................................66

Chapter 6 Directory..................................................................................................................... 83

6.1 Archive logs....................................................................................................................................83

Chapter 7 Commands.................................................................................................................119

7.1 Tools commands..........................................................................................................................119

Appendix A Conversion factors..................................................................................................... 137

A.1 Conversion factors per unit of measurement................................................................................137

Appendix B Miscellaneous equations............................................................................................ 139

B.1 K-Factor and Inverse K-Factor....................................................................................................... 139

B.2 Calculation of Chord "L" dimension............................................................................................... 140

Appendix C Troubleshooting comm., mech., and elec................................................................... 141

C.1 Communications troubleshooting................................................................................................141

C.2 Mechanical/Electrical troubleshooting......................................................................................... 142

Model 3418 GUSM 9

Page 10

Contents Operations manual

January 2019 DAN-20057316

Appendix D Flow Rate charts.........................................................................................................145

D.1 Summary charts for Flow rate...................................................................................................... 145

Appendix E Write-protected configuration...................................................................................149

E.1 Parameters for Write-protected configuration..............................................................................149

Appendix F Engineering drawings................................................................................................ 163

F.1 3410 Series engineering drawings................................................................................................ 163

10 Operations manual

Page 11

Operations manual Startup

DAN-20057316 January 2019

1 Startup

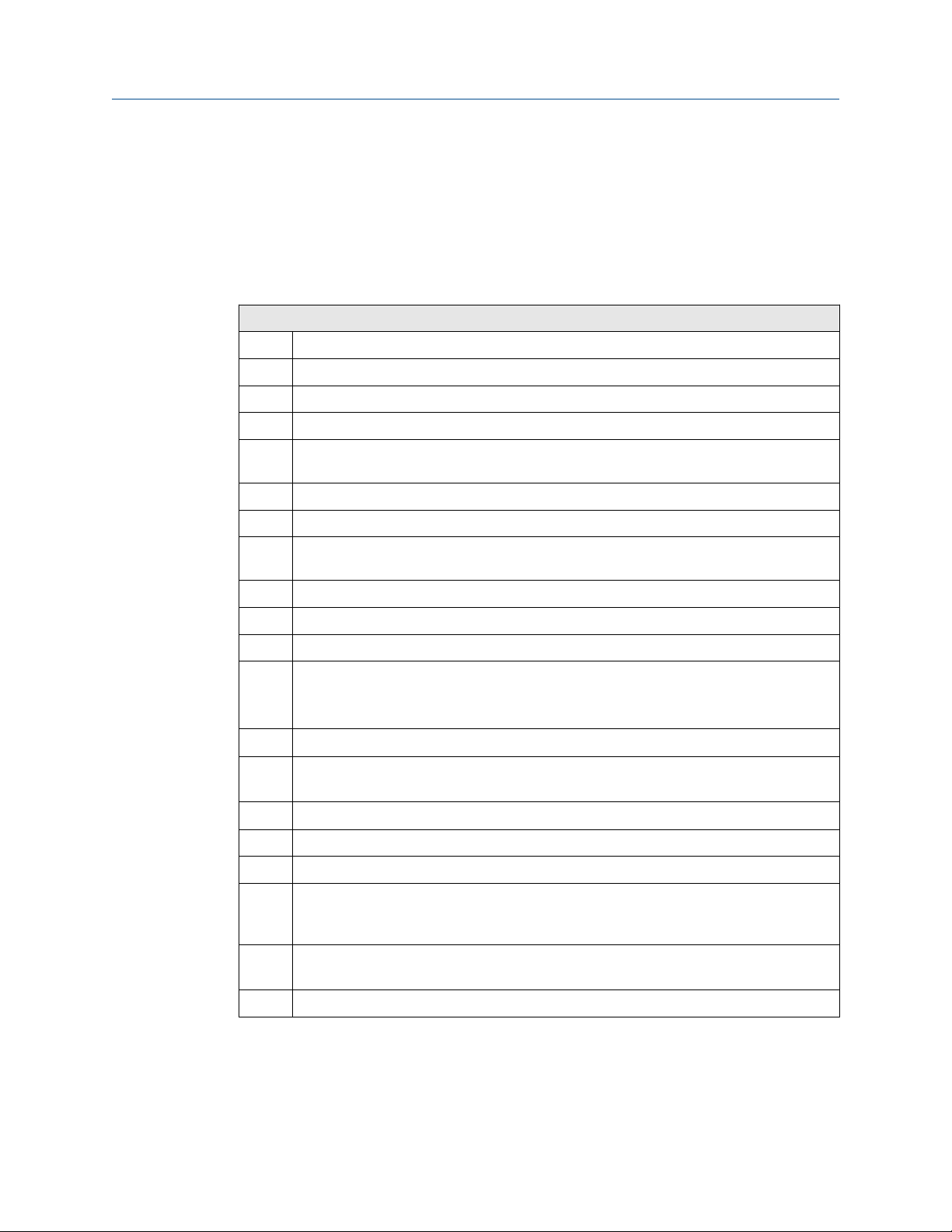

1.1 Checklist

During meter startup, have the following equipment and information on hand:

Mater startup checklist

Site pipe and ID drawings with elevations

Site wiring diagrams

Daniel Gas Ultrasonic Meter calibration data

Daniel Gas Ultrasonic Meter manuals

Information and manuals for all other flow instrumentation - flow computers, pressure

and temperature transmitter data sheets, and wiring

Shutoff and control valve information, specifications, operation and setup data.

Ethernet (Cat 5 cables) or serial cables to link the laptop to the meter

Field service representative's telephone numbers for major components; valves, meter,

flow computer, communication gear, transmitters, site designers or integrators.

Check all ultrasonic meter wiring.

Check the settings of any bit switches on transmitter I/O cards.

Establish flow in the meter (at lease 3 feet per second to ensure good thermal mixing)

Save the meter configuration file - your "As Found" record of the meter. In Daniel

MeterLink™ select Tools > Edit/Compare Configuration.

Click the Read button and select File Save.

Open File > Program Settings and customize Daniel MeterLink™ user preferences.

Open Meter > Monitor and check the measurement paths or chords and that they agree

with each other to approximately 0.2%.

Check for alarms, open Meter > Monitor and click Check Status.

Check for good signal strength (usually shown as "SNR") or, Signal to Noise Ratio.

Check for reasonably correct flow profile

From the Logs/Reports menu, click Maintenance Logs/Reports, collect and save a

Maintenance Log to record the initial performance of your meter (this is your "as Found"

record).

From the Meter > Field Setup Wizard menu. Make any configuration adjustments, such

as setting the frequency output variable and frequency full scale.

Save another Maintenance Log (this is your "As Left" record).

Model 3418 GUSM 11

Page 12

Startup Operations manual

January 2019 DAN-20057316

12 Operations manual

Page 13

Operations manual Communications

DAN-20057316 January 2019

2 Communications

2.1 Setup meter communications

After the installation of your Daniel Ultrasonic Meter, install Daniel MeterLink™ on your PC

or laptop as described in the Daniel MeterLink Software for Gas and Liquid Ultrasonic Flow

Meters Quick Start Manual (P/N 3-9000-763) for your operating system (Windows® 7 or

Windows® 8, Windows® 10), then configure the meter.

The Daniel MeterLink Software for Gas and Liquid Ultrasonic Flow Meters Quick Start Manual

(P/N 3-9000-763) is made available with the meter.

The Daniel MeterLink installation program is available for download from the Daniel

Measurement and Control, Inc. website: https://www.emerson.com/en-us/catalog/daniel-

meterlink.

2.1.1

Daniel MeterLink utilities

Daniel MeterLink™ provides the following utilities to configure the meter's flow

measurement units, meter output parameters, communications settings, output tests

and logs and reports file management.

Field Setup Wizard

• Startup

• General

• Frequency/Digital Output Sources

• Frequency Outputs

• Meter Digital Outputs

• Current Outputs

• Meter Corrections

• Temperature and Pressure

• Gas Chromatograph Setup

• AGA8

• Continuous Flow Analysis

• Local Display

Tools

• Edit/Compare Configuration

• Waveform Viewer

• SOS Calculator

• Outputs Test

• Transduce Swap-Out

Model 3418 GUSM 13

Page 14

Communications Operations manual

January 2019 DAN-20057316

• Program Download

• Communications Analyzer

Log/Reports

• Maintenance logs and reports

• Trend maintenance logs

• Meter archive logs

• Compare Excel® meter configurations

Calibration

• Analog inputs

• Meter Factors

• Flow calibration

Setup the meter directory

Setup the connection properties for your meter. By default, the meter directory contains

only one record named New Meter, that is defaulted to connect to a Daniel Gas Ultrasonic

meter configured as shipped from the factory.

Create a new meter record

Procedure

1. Select Insert, Insert Duplicate, or Add from the File pull-down menu to create a

new record.

2. Setup the record by entering a Meter Name, Short Desc, Meter Type, and select the

connection type(s) checkboxes Direct, Modem, Ethernet.

3. For each connection type selected, a button will be enabled at the bottom of the

dialog with the same name. Click these buttons to edit the connection properties

for that connection method. After choosing the connection properties, click OK

accept the changes or click Cancel to discard any changes and close the dialog.

a) Direct connection - to connect to the meter directly through one of the serial

ports on the meter using one of the serial ports on your computer. Click

Direct to set the following parameters.

• Protocol: TCP/IP is a read-only field and is the only protocol Daniel

MeterLink uses.

Note

Daniel Ultrasonic meters still support Modbus ASCII and Modbus RTU

when talking to other applications or devices.

• Comms Address: Enter the communication address that is configured in

the meter hardware. The default address for meters from the factory is

32. For Daniel Ultrasonic meters the valid range is from 1 to 247.

• Port: Select the available driver from the list of those installed on your

machine.

14 Operations manual

Page 15

Operations manual Communications

DAN-20057316 January 2019

Note

For Windows® 7, you cannot use the Communications cable between two

computers at this time and must use the Daniel Direct Connection driver.

• Baud Rate: Select the serial port baud rate from the drop-down list for

which the meter hardware is configured. The default Baud Rates is 19200.

• Check Box labeled Route IP packets to connection to configure MeterLink

to automatically connect to both Transmitter heads of DualConfiguration meters when data sharing is enabled. This requires

Ethernet connection between the two heads.

b) Modem connection- set the following properties to connect to the meter via

a modem.

• Protocol and Comms Address: Use the Protocol and Comms Address

parameters in Step 3a.

• Modem: Select the modem to use from the drop-down list. Only modems

installed in Windows® show in the drop-down list. If the drop-down list is

blank, then no modems have been installed for Windows®.

Note

Do not select Daniel Direct Connection or Communications cable

between two computers for the modem. This is a NULL modem driver for

direct connection to Daniel Ultrasonic meters only. It will not work for the

Modem connection.

Daniel MeterLink uses the Microsoft® Dial-up Networking for making

modem and direct serial connections to a meter. Click Modem Properties

to bring up the Dial-up networking entry Daniel MeterLink™ has created

for this meter. Most of the information required is setup correctly by

Daniel MeterLink™.

• Baud Rate: Select the desired Baud Rate from the drop-down list.

• Telephone #: Enter the telephone number for the modem to which the

meter is connected. Include digits to obtain to an outside line, if

necessary. Inserting commas between the digits pauses the dialing rate.

Each comma is approximately equal to two seconds.

• Modem Properties: configures the properties associated with the

modem.

Daniel MeterLink uses the Microsoft® Dial-up Networking for making

modem and direct serial connections to a meter. Click Modem Properties

to bring up the Dial-up networking entry Daniel MeterLink has created for

this meter. Most of the information required is setup correctly by Daniel

MeterLink. Click OK to accept the changes or click Cancel to discard any

changes and return to the Meter Directory dialog box.

c) Ethernet connection - Set the following properties to configure the Daniel

ultrasonic meter hardware for Ethernet connectivity.

Model 3418 GUSM 15

Page 16

Communications Operations manual

January 2019 DAN-20057316

NOTICE

It is strongly recommended that the meter be configured using an

independent (off- network) single host computer. After configuration of the

meter, the DHCP option should be disabled.

• IP Address: Enter the IP Address for the meter's Ethernet port.

The factory set IP Address is 172.16.17.200 for Daniel Gas Ultrasonic

meters or you can use 192.168.135.100 if DHCP is enabled in the meter

(see DHCP below for more details).

Dynamic Host Configuration Protocol (DHCP): Business PCs are usually

configured to work in a network environment where a DHCP server

assigns an IP address to each computer when they connect to the

network.

If a PC is configured to obtain an IP address from a DHCP server and it is

going to connect through the Ethernet Cable (1-360-01-596) to a Daniel

meter that is not connected to a network, then the DHCP server in the

meter must be enabled so it can assign an IP address to the PC when it

connects.

The DHCP server can be enabled on the meter by setting the DHCP switch

on the CPU module to the ON position.

When connecting to a meter with DHCP enabled, use the IP address of

192.168.135.100 to connect to the meter. In this mode you can create

just one Meter Directory record with this IP address to connect to all your

meters with DHCP enabled. When the connection is made, select to use

the Meter Name in the meter instead of the Meter Directory Name in

order to keep all log files and configurations separate from each meter.

Click OK to accept the changes or click Cancel to discard any changes and

return to the Meter Directory dialog box.

Ethernet initial connection steps

Procedure

1. Power up the meter.

2. Shutdown the PC.

3. Plug the Ethernet adapter cable Phoenix end into the meter Field Connection Board

connector J8 and connect the RJ-45 end into the PC Ethernet connector.

4. Enable the Ethernet LAN connector DHCP server on the CPU Module by moving the

DHCP (switch-1) to the ON position (see direction arrow on the CPU Module label).

5. Power up (boot) the PC and log in to the initial Windows logon prompt.

6. Verify the Ethernet connection status by the CPU Module “LINK” LED which should

be on solid green.

7. Launch Daniel MeterLink and create a new meter record.

Import a meter record

Procedure

1. Select File > Import from the Meter Directory drop-down menu or click Import.

16 Operations manual

Page 17

Operations manual Communications

DAN-20057316 January 2019

2. The Import Meter Directory File dialog which allows you to select a meter

directory .DAT file to import the file into the currently used meter directory file.

If an identical meter record already exists and a duplicate is trying to be imported,

Daniel MeterLink inserts the duplicate meter record. The Import button performs

the same operation.

Export a meter record

Use the Export command to save the current meter directory to file. Select File > Meter

Directory from the Meter Directory drop-down menu or click Export.

Procedure

1. Enable the meter directory record checkbox you want to export or click Select All.

2. Click OK to begin exporting the meter record(s). Use the Export Meter Directory File

dialog to save the exported record to the default folder (C:\Ultrasonic Data) or enter

another location.

3. Click Save. If you have an existing METER_DIRECTORY_EXPORT.DAT file, you are

prompted to change the file name or replace the file. If changing the file name,

keep the .DAT extension to maintain functionality when importing the file to the

new machine.

4. Copy the exported file to the new machine.

5. Use the Import command to select this file and import it into the Meter directory.

Important

Due to limitations in the Microsoft® Dial-Up Networking, not all of the directory

information for Direct and Modem connection can be exported to the

METER_DIRECTORY.DAT file for Daniel Ultrasonic meters. It will be able to export

the meter names, Comms Address, Interface, and Telephone numbers. It will still be

necessary to recheck the connection properties and verify the communication

parameters such as COM port, data bits, and parity are configured correctly.

Connect to the meter

Procedure

1. From the menu bar, select Meter > Connect or click

toolbar.

2. The Connect to Meter dialog box displays a list of meters setup in Daniel MeterLink.

Click Direct, Modem or Ethernet next to the Meter Name to establish a connection

with your Daniel Ultrasonic meter.

, the Connect icon, on the

Collect “As Found” logs and reports

Use the Daniel MeterLink Logs/Reports menu and collect and save the logs and reports for

a historical record of the meter at several velocities within the operating range of the

meter. This will establish a baseline to be used for the trending of the meter diagnostics.

Save the following logs and reports for the "As Found" settings (factory default).

• Maintenance log

Model 3418 GUSM 17

Page 18

Communications Operations manual

January 2019 DAN-20057316

• System log

• Save your meter's configuration file

• Use the Tools > Edit/Compare Configuration menu to display the dialog. Enable the

View All or Metrology radio button and click Read.

The All View displays the meter's extended configuration parameters. Grayed out

values are read-only, but help describe the configuration. The Metrology View displays

the path dimensions, pipe diameter, transducer delay parameters, zero flow calibration

coefficients, and flow calibration coefficients.

Click the question mark icon, , for the data point to display additional information.

• Click Save to save the configuration file. By default, the file is saved to the Data Folder

setup in File > Program Settings.

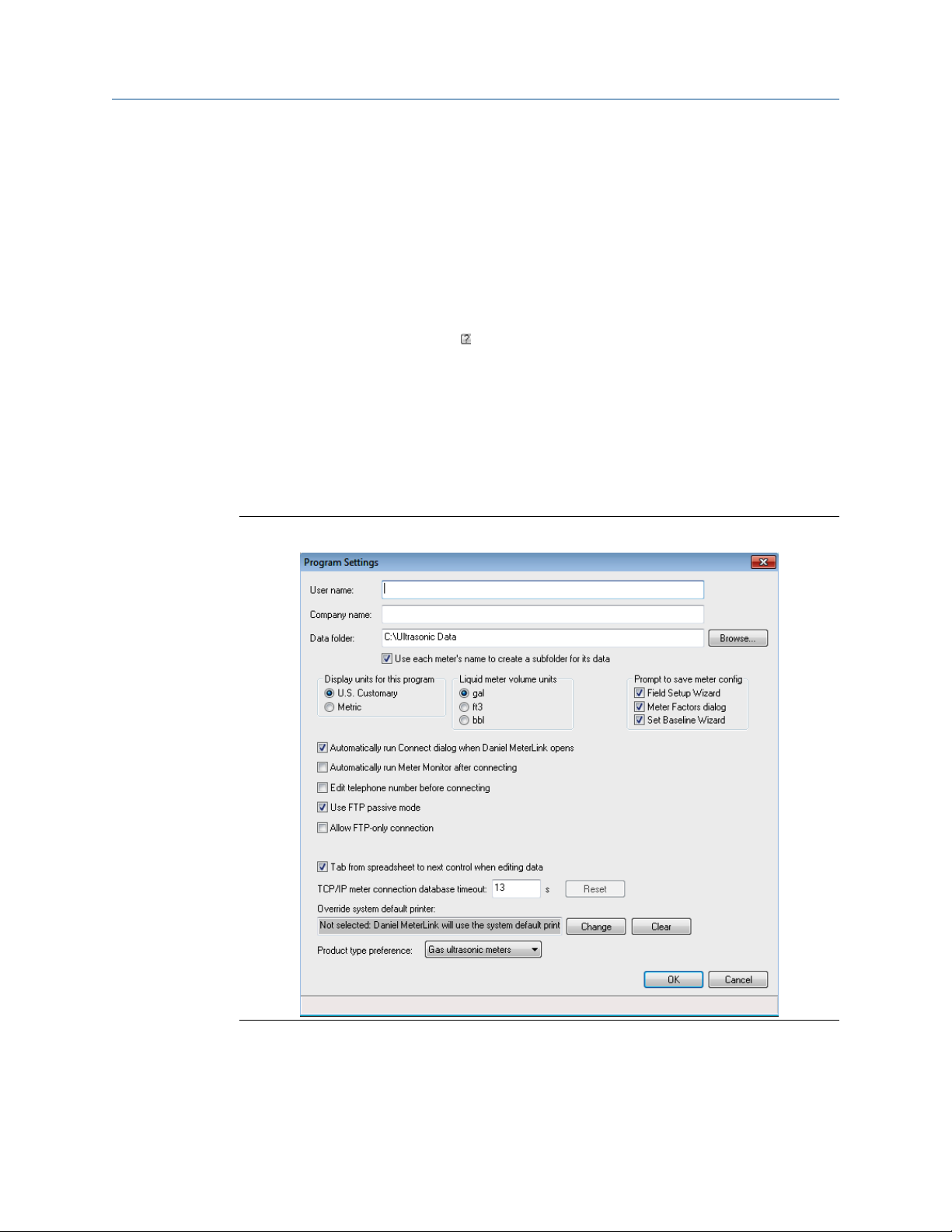

Customize Daniel MeterLink settings

Open Daniel MeterLink and access File > Program Settings, then input the desired settings

for your meter. Your user name and company name is included on reports and logs

generated with Daniel MeterLink.

Figure 2-1: Program Settings

• User name

• Company name

• Data folder (where meter's data is stored)

18 Operations manual

Page 19

Operations manual Communications

DAN-20057316 January 2019

• Select the checkbox to create a subfolder with the meter's name under Data folder for

saving and opening files for your meter

• Display units (of measurement); U.S. Customary or Metric for necessary unit

conversions read by the meter

• Meter volume units; gal, cubic feet, or bbl

• Prompt to save meter config (configuration) prompts you to save a copy of the meter

configuration after writing changes to the meter

• Run Connect dialog automatically after connecting

• Run Meter Monitor automatically after connecting

• Run Meter Monitor summary or detailed view after connecting

• Edit telephone number before connecting with a modem

• Use FTP passive mode (client - server pot communications)

• FTP-only connection - used to download firmware to Daniel Ultrasonic meters

• Tab from spreadsheet to next control instead of next cell

2.1.2

• TCP/IP meter connection database timeout - amount of time Daniel MeterLink waits to

respond to a request for data from the meter database (default 13 seconds)

• Override system default printer - used to change printer

• Product type preference - meter type you will most often connect, gas or liquid.

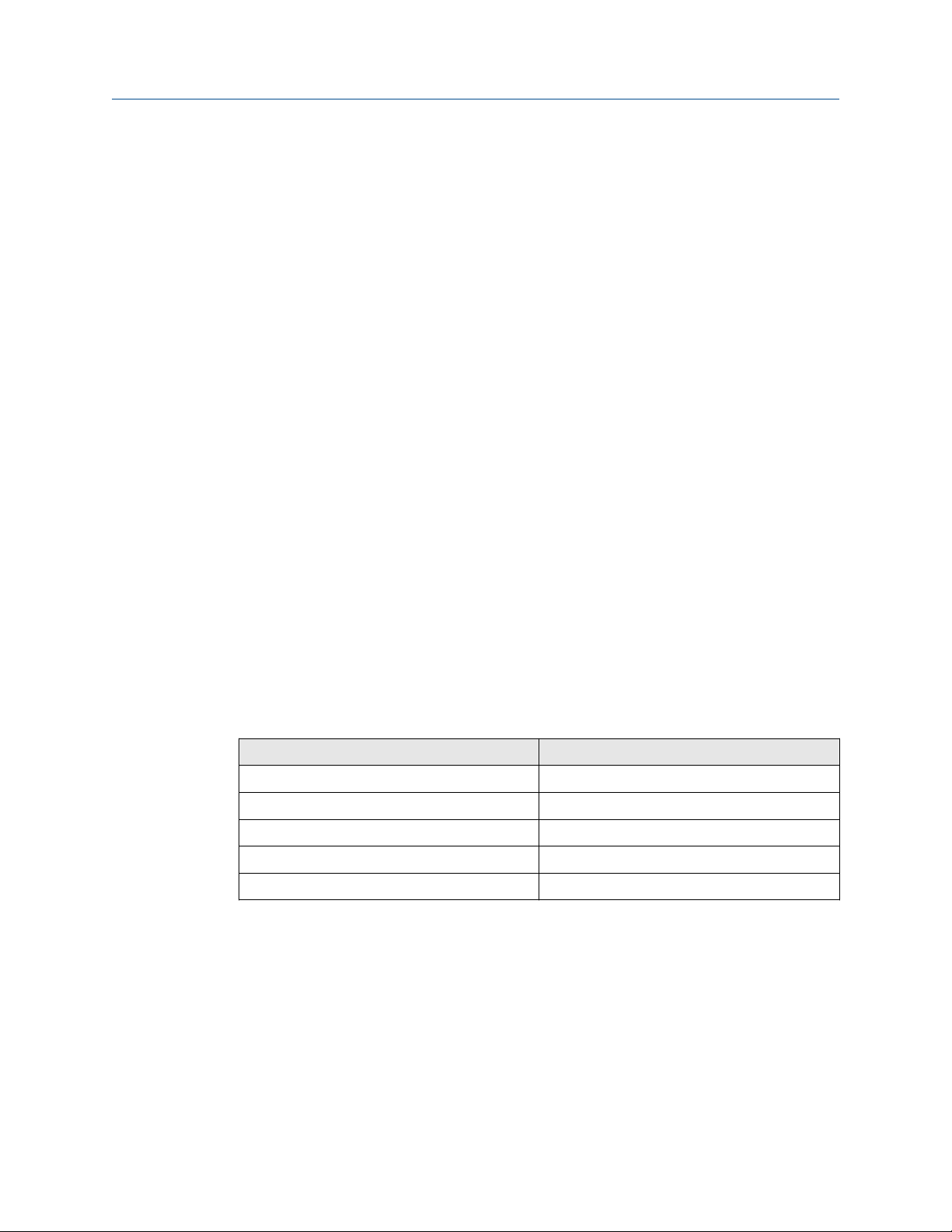

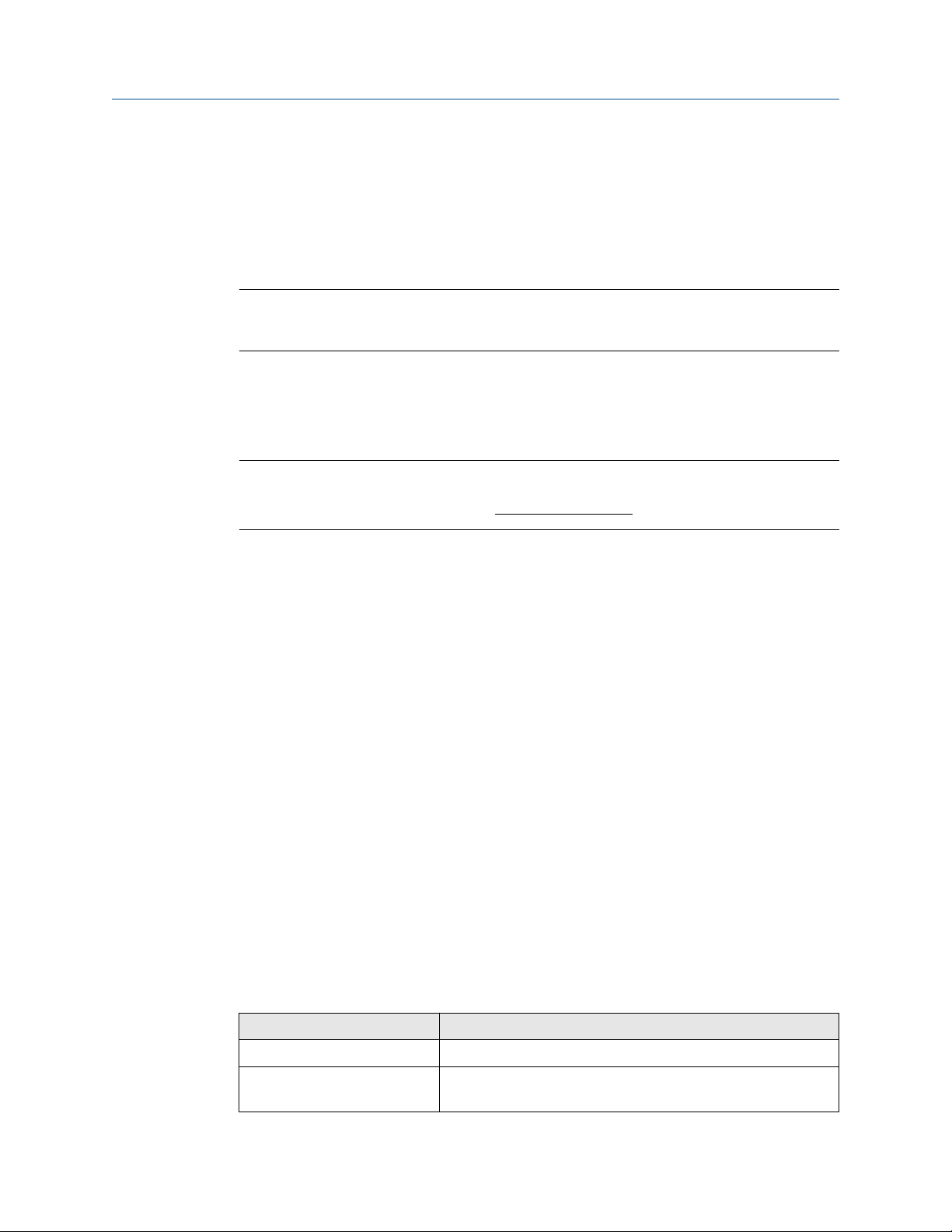

Setup Modbus communications

Daniel 3410 Gas Ultrasonic Flow Meters support RS-232 or RS-485 4-wire or 2-wire half

duplex serial interface to an external system (e.g., flow computer) using Modbus ACSII

protocol with the following parameters:

Setting

Baud rate 19200

Data bits 7

Stop bits 1

Parity even

Protocol Modbus ACSII

Refer to your flow computer user manual to set I/O settings required to allow serial

communication with the Daniel 3410 Gas Ultrasonic Flow Meters.

The Daniel 3410 Gas Ultrasonic Flow Meters supports ASCII and RTU Modbus

communication. For ASCII Modbus, both 7E1 and 7O1 are supported. For RTU Modbus,

8N1 is supported. The communication ports provide automatic protocol detection - only

the baud rate and Modbus ID need to be specified. Also, refer to the Daniel website and

select the Product page for the model of your meter:

Value

https://www.emerson.com/en-us/automation/daniel

Model 3418 GUSM 19

Page 20

Communications Operations manual

January 2019 DAN-20057316

20 Operations manual

Page 21

Operations manual Optional feature keys

DAN-20057316 January 2019

3 Optional feature keys

3.1 General overview of the Optional feature keys

Daniel 3410 Series Gas Ultrasonic Flow Meters offer many industry-leading features

including Chapter 21-compliant data log access, gas chromatograph (GC) interface,

AGA10 sound velocity calculation (with comparison to measured sound velocity) and

Continuous Flow Analysis diagnostics.

Daniel recognizes that these features are valuable to many, but not all customers. The

optional keys may be purchased with the meter or at a later time and this key enables all

optional features available. All keys are unique to the CPU board's serial number, so a key

entered for one meter will not work in another meter.

The Continuous Flow Analysis optional feature is enabled via a software "key" value that is

specific to the meter's CPU Board. This software feature key consists of 16 characters

divided into four hyphen-separated, 4-character groups (such as 1234-5678-90AB-CDEF).

This dialog is only available while connected to a meter with firmware that contains option

keys to enable.

3.1.1

3.1.2

In Daniel MeterLink, access the Key Manager to view key statuses, add keys or change the

key values.

Obtaining optional keys

If you do not have a valid key to enter to enable a feature, you must have the CPU board

serial number available, which displays in the Meter > Key Manager dialog and the Meter

Menu > Meter Information dialog, when you contact Daniel to obtain the key. The keys

can be given verbally over the phone or they can be e-mailed in a Key file for easy entry.

• E-mail: tech.service@emersonprocess.com

• Web: http://www.emerson.com/en-us/support

• Also see, Daniel MeterLinkHelp > Technical_Support

GC interface key

The optional GC interface feature allows the meter to read gas property data (composition

and heating value) from a Daniel gas chromatograph.

The meter can use the gas composition data to:

1. Calculate AGA8 compressibilities for converting volumetric flow rate and volumes

to standard (base) condition

2. Calculate AGA8 density for calculating mass rate and mass totals

3. To optionally calculate the AGA10 sound velocity (see AGA10 key (sound velocity

calculation)). The meter uses the GC-reported gas heating value to calculate the

energy rate and totalized energy rate values. This feature is enabled/disabled via the

GCKey data point.

Model 3418 GUSM 21

Page 22

Optional feature keys Operations manual

January 2019 DAN-20057316

3.1.3 AGA10 key (sound velocity calculation)

The optional AGA10 sound velocity calculation feature allows the meter to calculate the

predicted sound velocity based upon the gas composition and compare this value to the

measured average sound velocity. The gas composition can be either specified via data

points or optionally read live from a GC (see above). This feature is enabled or disabled via

the AGA10Key data point.

3.1.4 Continuous Flow Analysis (CFA) key

The Continuous Flow Analysis key enables all optional features and provides extensive

diagnostics for the meter's operational health.

3.1.5

Key status

The Status column will indicate if the key entered is a Valid key or if the key is disabled.

Leaving the Key field empty or entering 0000-0000-0000-0000 will disable the feature

once Write to Meter is clicked.

3.2 Configure optional keys

Procedure

1. Open Daniel MeterLink and connect to your meter.

2. Use the Meter Menu drop-down list and click Key Manager. Daniel MeterLink

displays the Key Manager dialog.

3. Enter the key you obtained in the appropriate field in the Key Manager dialog.

The field turns yellow indicating a change was made and the status will be updated.

When at least one change is made and none of the keys are Invalid, the Write to

Meter button is enabled so the changes can be written to the meter.

The Status column indicates if the key you entered is a Valid key.

4. Click Write to Meter to write the keys to the meter. After the keys are written

successfully, the Key Manager dialog closes.

If for any reason, one or more keys were not written successfully, before the Key

Manager closes, a message displays stating which keys could not be written to the

meter. This could occur if communications to the meter is lost between entering

the Key Manager dialog and clicking Write to Meter.

5. If desired, on the Field Setup Wizard-Startup page, enable the View Gas

Chromatograph setup and View Continuous Flow Analysis setup checkboxes to

display these pages later in the Field Setup Wizard. The Gas Chromatograph Setup

page provides the serial port configuration option to collect live gas compositions.

The Continuous Flow Analysis Setup page allows you to configure the SOS

comparison, liquid detection, abnormal profile detection, blockage detection, and

internal bore buildup detection features.

22 Operations manual

Page 23

Operations manual Measurement

DAN-20057316 January 2019

4 Measurement

4.1 Flow measurement

Daniel 3410 Gas Ultrasonic Flow Meters measure the transit times of ultrasonic pulses

passing through the medium on two parallel planes. The measurement paths (also

referred to as "chords") are angled to the pipe axis, and each chord has two transducers

acting alternately as transmitter and receiver as shown in Direct path transit-time

measurement principle. This permits the transit times to be measured both with and

against the flow (upstream and downstream).

The transducers are mounted on the meter body at accurately known locations for each

pipe size so the distance L between opposing transducers and the angle are precisely

defined for the measurement path.

The 3418 combines the power of two interlocked 4-path British Gas design meters in one

flowmeter body. The second set of chords is the mirror image of the first, which allows the

meter to cancel out the effects of swirl and cross flow.

4.1.1

Figure 4-1: Direct path transit-time measurement principle

Transducer timing control

The following terms are used in explaining the effects of transducer timing control, the

performance of batch data collection and calculation updates in Daniel 3410 Gas

Ultrasonic Flow Meters.

Model 3418 GUSM 23

Page 24

Measurement Operations manual

January 2019 DAN-20057316

Figure 4-2: Signal Analyzer - update rate, stack size, filter and emission rate

Terminology

• Sequence - a complete cycle of firing all enabled transducers in a single round of

transducer operation.

• Stacking - the process of modifying a sequence so that each individual transducer is

fired "x" times (where x equals the stack size) before the next transducer in the

sequence is fired.

• Stack size - the multiple of times each transducer is fired before the next transducer

within the sequence is fired. (When stacking is absent or disabled, the stack size is

actually 1, because each enabled transducer is fired once during the sequence. When

stacking is applied or enabled, it is applied increments of 2, 4, 8, and 16 and are the

only stack size choices, so that each enabled transducer is fired 2, 4, 8, or 16 times

before the next transducer in the sequence is fired.)

• Emission rate - the time elapsed before the next transducer in a sequence is fired,

regardless of stack size (minimum emission rate is 2 milliseconds with the Filter ON or

OFF). We recommend the default Filter setting, which is the OFF position.

• Stack emission rate - the time elapsed before a single transducer is re-fired when

stacking is enabled (minimum stack emission rate is 2 milliseconds with the Filter OFF).

• Chords inactive or active - the exclusion or inclusion of a chord-forming pair of

transducers in the sequence of transducer operation.

• Update time - the time elapsed, in seconds, between each processing, or recalculation

of data that is collected from sequences of transducer firings.

• Batch period, or batch cycle - synonymous with Update time, as defined above.

24 Operations manual

Page 25

Operations manual Measurement

DAN-20057316 January 2019

• Sample - refers to one point on the waveform as in samples per cycle. The data that is

collected from one Sequence of transducer operation. (This term is displayed in the

Daniel MeterLink™ Signal Analyzer screen, and is nearly synonymous with Sequence, as

defined above. That is, Samples/update, as displayed in the Daniel MeterLink™ Signal

Analyzer Wizard, could be interpreted as Sequences/update.) This shows the average

number of new samples collected during an update period.

4.2 Signal processing

The signal at the receiving transducer is amplified, digitized and processed digitally to

provide accurate transit time measurement.

A measure of the signal "quality" is the signal-to-noise ratio (SNR). The higher the SNR, the

better the signal. In general there are two types of noise: "white" noise and "colored" noise.

White noise is noise that occurs across the frequency spectrum and is asynchronous to the

transmitted signal. Colored noise is concentrated around a particular frequency and can

be synchronous with the transmitted signal. The meter provides two methods for

improving the received signal waveform SNR by reducing the noise energy: Stacking and

Filtering.

4.2.1

4.2.2

Stacking

Stacking is a method of firing a transducer multiple times and averaging the received

signals on a point-by-point basis.

Stacking is effective on asynchronous noise such as is typically seen with valve noise. This

method is not useful for removing synchronous noise and should not be used when there

is a great deal of signal "jitter." Meters are configured by default with a stack size of 1 (no

stacking).

Care should be taken when turning on stacking and it is recommended to consult with

Daniel Customer Service if you are unsure of how stacking a signal can affect the meter's

operation. Refer to Technical Support under the Help menu of Daniel MeterLink for

contact information.

The number of consecutive times to fire each transducer is specified via the StackSize data

point. Available stack sizes are 1 (None), 2, 4, 8, and 16. A stack size of 1 selects no

stacking (i.e., stacking disabled). Stacking is only available when the standard update rate

is selected (see Batch update period).

Filtering

Filtering applies a bandpass filter that removes noise that is above and below the

transducer frequency.

Filtering is effective on noise outside of the frequency passband of the filter (e.g., filtering

works on any noise outside of the passband of the filter).

Filtering is enabled/disabled via the Filter data point (TRUE=enable filtering, FALSE=disable

filtering). Meters are configured by default with filtering disabled. The minimum emission

rate for the gas meter is 2 milliseconds with the filter ON or OFF. We recommend the

default Filter setting, which is the OFF position.

Model 3418 GUSM 25

Page 26

Measurement Operations manual

January 2019 DAN-20057316

Care should be taken when enabling/disabling filtering and it is recommended to consult

with Flow Lifecycle Services for Daniel products if you are unsure of how this change can

affect the meter's operation. Refer to Technical Support under the Help menu of Daniel

MeterLink™ for contact information.

4.2.3 Batch cycle processing

Batch update period

Calculation updates performed by the meter, for deriving volume and velocity, are based

on batches of data samples collected from sequences of transducer firings. The batch

update period is dependent upon the user specified batch update period

(SpecBatchUpdtPeriod)and the stack size (StackSize) as shown in Table 4-1. The Standard

batch update period is the default. The actual batch update period is readable via the

BatchUpdatePeriod data point.

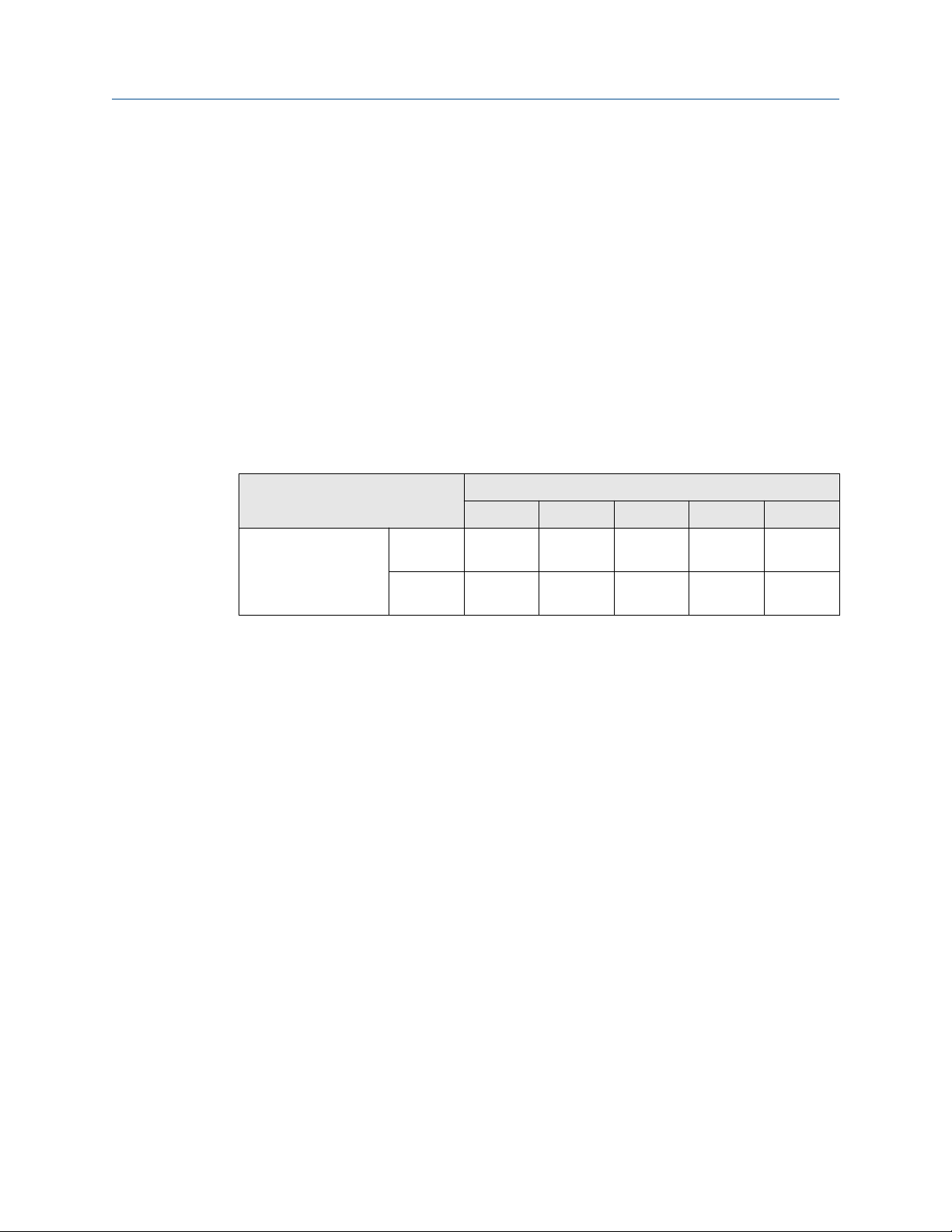

Table 4-1: Actual meter update period

Stack size

1 (None) 2 4 8 16

SpecBatchUpdtPeriod Rapid

(250 ms)

Standard

(1000 ms)

Emission rates

The emission rate is the period between firing two different transducers. The stacked

emission rate is the period between consecutive firings of a single transducer when

stacking is used (i.e., the stack size is not set to None).

The actual emission rates used (readable via the EmRateActual and StackEmRateActual

data points) are functions of the desired emission rates, meter type, firing sequence, stack

size, and pipe diameter.

The user specifies the desired emission rates via the EmRateDesired and

StackEmRateDesired data points. If a desired emission rate is set to zero, the meter uses

the fastest possible emission rate which can be as short as is 2 milliseconds. Otherwise, the

meter uses the fastest possible emission rate that is not less than the desired value. We

recommend setting the Filter to the OFF position.

The Signal Analyzer (Meter > Signal Analyzer) is used to configure the EmRateDesired and

StackEm-RateDesired. These values are set to zero to achieve the most transducer firings

per batch update.

0.25 sec N/A N/A N/A N/A

1 sec 1 sec 1.5 sec 3 sec 5 sec

4.2.4

26 Operations manual

Smoothing

The Daniel 3410 Series Gas Ultrasonic Flow Meter applies a method for smoothing the

output (particularly the frequency output) by averaging times collected from past batch

periods with new times for the current batch period.

Page 27

Operations manual Measurement

DAN-20057316 January 2019

Smoothing can be applied in the following increments: 0 (i.e., smoothing is disabled), 20,

40, 60, or 80%.

For example, setting Smoothing to 20% means that of the samples used for the current

update, 20% will be from previously collected samples and 80% will be from the newly

collected samples. Thus, if eight new samples are collected, then those eight samples

along with the last two previous samples would be used together for the current update

period calculations.

Meters are configured by default for Smoothing of 0% (only new samples are used for the

Current Update period).

4.3 Acquisition mode

Daniel 3410 Gas Ultrasonic Flow Meters have two modes of normal operation: Acquisition

and Measurement. The Acquisition mode is used to acquire the ultrasonic signals. This

mode is entered when power is applied to the meter.

Once the ultrasonic signals are acquired, the Measurement mode is entered and the flow

velocity is measured. The meter remains in the Measurement mode as long as at least one

chord is operational.

4.3.1

If while in the Measurement mode all chords fail, then the meter re-enters the Acquisition

mode. If the VelHold data point is set to a value greater than zero, then, while in the

Acquisition mode, the meter holds the average weighted flow velocity to the last good

value for up to the VelHold number of batches before setting the velocity to zero. The

VelHold default value is 0.

The Acquisition mode uses the chords' "L" dimensions (LA…LH as appropriate to the meter

type) and the specified minimum and maximum sound velocities (SSMin and SSMax)

determines the signal search range. MinHoldTime and MaxHoldTime are also used to

determine the signal search range. The meter uses the more restrictive of SSMin/

MaxHoldTime and SSMax/MinHold time.

Re-acquisition

When fewer than MinChord (default 1) chords are good, then the meter re-enters the

Acquisition mode. If MinChord is set to the number of active chords, the meter will

reacquire on the first time a chord is failed for a batch.

Note that failed for a batch is different from hard failed. A chord fails for a batch when PctGood[A1..H2] is less than MinPctGood.

Hard fails occur after AlarmDef number of batches in a row.

If the VelHold data point is set to a value greater than zero, then, while in the Acquisition

mode, the meter holds the average weighted flow velocity to the last good value for up to

the VelHold number of batches before setting the velocity to zero. The VelHold default

value is 0.0.

Model 3418 GUSM 27

Page 28

Measurement Operations manual

January 2019 DAN-20057316

4.4 Chord gas and sound velocity measurements

At each batch update period, each firing path's transit time measurements are averaged.

The average (mean) value for each path is available via data points MeanTmA1...

MeanTmH2 (as appropriate for the meter type).

NOTICE

The data point names often use a "short-hand" way of identifying the receiving transducer.

The last two characters identify the chord (A...H) and the transducer (1=upstream,

2=downstream). For example, MeanTmA1 is the mean transit time for the chord A

upstream transducer.

The difference between a chord's average upstream transit time and average downstream

transit time is the average delta time. The chord's average times and the chord "X" and "L"

dimensions are used to calculate the gas velocity and sound velocity measured by the

chord as shown in Equation 4-1 and Equation 4-2.

Equation 4-1: Chord Gas Velocity

2

V

chord

L

=

2X

chord

chord

t1‐t

t1t

2

2

and

Equation 4-2: Chord Sound Velocity

C

chord,classic

C

=C

chord

L

=

chord,classic

t1+t

chord

2

t1t

2

2

×PortAngleFactor

where the PortAngleFactor is a dimensionless factor that is dependent upon the chord port

angle

with respect to the meter body:

For 60 degree port angles,

PortAngleFactor= 1+ 0.5•

2

V

chord

2

C

chord,classic

•

2

X

chord

2

L

chord

•tan260°

For 75 degree port angles,

PortAngleFactor= 1+ 0.5•

2

V

chord

2

C

chord,classic

•

2

X

chord

2

L

chord

•tan275°

For all other port angles,

PortAngleFactor=1

where

V

= chord average gas velocity (m/s) (FlowVelA ... FlowVelH)

chord

C

= chord average sound velocity (m/s) (SndVelA ... SndVelH)

chord

28 Operations manual

Page 29

Operations manual Measurement

DAN-20057316 January 2019

L

= chord "L" dimension (m) (LA ... LH)

chord

X

= chord "X" dimension (m) (XA ... XH))

chord

t1 = chord average transit time in the upstream direction (s) (MeanTmA1 ...

MeanTmH1)

t2 = chord average transit time in the downstream direction (s) (MeanTmA2 ...

MeanTmH2)

Important

Note that a positive chord gas velocity indicates flow in the forward direction whereas a

negative chord gas velocity indicates flow in the reverse direction.

4.4.1 Average sound velocity

The Average Sound Velocity is calculated as the average of the active chord sound velocity

measurements as shown in the equation below:

Equation 4-3: Average sound velocity

c

Avg

∑

ActiveCℎords

=

NumActiveCℎords

• C

cℎord

4.4.2

where

C

= average sound velocity (m/s) (AvgSndVel)

Avg

C

= chord average sound velocity (m/s) (SndVelA... SndVelH)

chord

NumActiveChords = number of active chords

Optional AGA10 sound velocity calculation and comparison

The Daniel 3410 Series Gas Ultrasonic Flow Meter offers an option to calculate the sound

velocity (using AGA10 equations and gas property data) and compare the result to the

meter- measured sound velocity on an hourly basis.

This feature is enabled via the AGA10 Key (see AGA10 key (sound velocity calculation)).

The gas property data required for using this feature can be specified via data points or

optionally read from a Daniel GC (Configure Gas Chromatograph parameters). The AGA8

Detailed Method must be selected (via the HCH_Method data point, Configure Gas

Chromatograph parameters) in order for the AGA10 calculations to be performed (as the

AGA10 calculations require AGA8 Detailed method calculation intermediate results).

Every five seconds the meter updates the AGA10-calculated sound velocity. This value is

readable via the AGA10SndVel data point and the calculation status value is readable via

the AGA10SndVelStatus data point. The status values are as listed in the table below:

Table 4-2: AGA10 calculation status

AGA10SndVelStatus value Description

0 Calculation OK (no errors)

1 Calculation not performed as the feature is not enabled (see

Configure optional keys). AGA10SnVel is set to zero.

Model 3418 GUSM 29

Page 30

Measurement Operations manual

January 2019 DAN-20057316

Table 4-2: AGA10 calculation status (continued)

AGA10SndVelStatus value Description

2 Calculation not performed as the selected AGA8 method is not

the Detailed method (HCH_Method not set to Detailed Method

(3)). AGA10SnVel is set to zero.

3 Calculation not performed due to invalid AGA8 calculation

results. AGA10SndVel is set to zero.

4 Calculation error due to division by zero. AGA10SndVel is set to

zero.

Over the course of an hour (starting from the top of the hour), the meter calculates the

average measured sound velocity (the average of the average weighted sound velocity)

and the average AGA10-calculated sound velocity. At the end of the hour, the two

averages are compared; the comparison error (%) is readable via the SndVelCompErr data

point.

Note that the comparison error is only calculated at the end of the hour if during the hour

all of the following are true:

4.4.3

• No AGA10 sound velocity calculation errors occurred (i.e., AGA10SndVelStatus always

equal to 0),

• the measured flow velocity was always above the minimum sound-speed-check flow

velocity (specified via the SndSpdChkMinVel data point which has a default value of 1

m/ s), and

• the measured sound velocity was always valid (as indicated by the QMeterValidity data

point).

Average weighted gas flow velocity

When all active chords are non-failed, the average weighted gas flow velocity is a weighted

sum of the chord velocity measurements as shown in Equation 4-4 where the chord

weights are determined by the meter geometry.

Equation 4-4: Average weighted gas flow velocity

where

V

Wtd

V

V

AvgWtd

= average weighted gas flow velocity (m/s) (AvgWtdFlowVel)

AvgWtd

= chord weight (dimensionless) (WtA ... WtH)

chord

= chord average gas velocity (m/s) (FlowVelA ... FlowVelH)

chord

= ∑

ActiveCℎordsWtcℎordVcℎord

4.4.4

30 Operations manual

Average weighted flow velocity using chord proportions

In the event of one or more chord failure(s), the meter operation is dependent upon the

number of non-failed chords. If there is at least one operating chord, then the meter uses a

velocity estimation method described in the following paragraphs.

Page 31

Operations manual Measurement

DAN-20057316 January 2019

If all chords fail, then the meter re-enters the Acquisition mode as described in the Re-

acquisition section.

The meter partitions the velocity range (for forward and reverse flow) into ten

consecutive, non- overlapping "bins" (where the velocity range is as specified via the

MeterMaxVel data point).

The meter maintains a set of bins for each active chord where each bin contain three data

values: (1) the chord's average velocity (within the bin's velocity range), (2) the chord's

average proportion value, and (3) an indicator that the value is still the default (Is[Fwd/

Rev]Prop[A..H]DfltBin[1..10]). A chord proportion value is the ratio of the chord velocity

to the average weighted flow velocity as shown in Equation 4-5 below. The default

indicator is used to determine if a bin's velocity and proportion data values have been

updated from their initialized values. The bins are initialized with the average velocity over

the bin's range and meter-geometry-dependent proportion values. All default indicators

are initialized to TRUE. The bin data is stored in non-volatile memory.

Equation 4-5: Chord proportion calculation

V

Prop

cℎord

−

cℎord

V

AvgWtd

where

Prop

V

chord

V

AvgWtd

= chord proportion (dimensionless)

chord

= chord velocity (m/s) (FlowVelA ... FlowVelH)

= average weighted gas flow velocity (m/s) (AvgWtdFlowVel)

When the meter has operated for a user-specified number of consecutive batches without

any chord failures, the meter updates each chord's data values for the bin containing the

chord velocity as shown in Equation 4-6 and sets the bin's default indicator to FALSE. The

PropUpdtBatches data point, configurable via the Daniel MeterLink Edit/Compare

Configuration screen, specifies the number of consecutive failure-free batches required

for updating the bin data (range: [1, 1000], default: 24). The NumVals data point (that

determines how quickly an average value changes) is also configurable via the Edit/

Compare Configuration screen (range: [1, 1000], default: 10).

Equation 4-6: Updating chord proportion bin data values

AvgVel

AvgProp

CℎordBin

CℎordBin

n + 1

n + 1

−

AvgVel

−

CℎordBin

AvgProp

CℎordBin

NumVals − 1 + V

⋅

n

NumVals

NumVals − 1 + Prop

⋅

n

NumVals

cℎord

cℎord

where

AvgVel

AvgVel

ChordBin

ChordBin

= chord bin (n+1)st average velocity (m/s)

n+1

= chord bin nth average velocity (m/s)

n

NumVals = update factor data point (dimensionless) (NumVals)

V

= chord velocity (m/s) (FlowVelA ... FlowVelH)

chord

AvgProp

AvgVel

Prop

chord

ChordBin

ChordBin

= chord proportion (dimensionless)

= chord bin (n+1)st average proportion value (dimensionless)

n+1

= chord bin nth average proportion value (dimensionless)

n

Model 3418 GUSM 31

Page 32

Measurement Operations manual

January 2019 DAN-20057316

In the event of a chord failure with at least one operating chord, the meter's average

weighted flow velocity is estimated as shown in Equation 4-7.

Equation 4-7: Estimating average flow velocity using proportion values

V

cℎord

∑

V

AvgWtd

Non − Failedcℎord(s)

−

InterProp

est

∑

Non − Failedcℎord(s)

cℎord

where

V

AvgWtd

V

Chord

InterProp

= estimated average weighted flow velocity (m/s) (AvgWtdFlowVel)

est

= (non-failed) chord velocity (m/s) (FlowVelA ... FlowVelH)

= (non-failed) chord interpolated proportion value (dimensionless)

chord

For each non-failed chord, the interpolated proportion value used in Equation 4-7 is

calculated as follows:

• If the chord's velocity is surrounded by non-default (average velocity, average

proportion) data pairs, then the interpolated proportion is the linear interpolation

between the two data pairs.

• If the chord's velocity has a non-default (average velocity, average proportion) data

pair on one side of it but not the other, then the interpolated proportion is the data pair

average proportion.

• If there are only default (average velocity, average proportion) data pairs, then the

interpolated proportion is the corresponding bin's default average proportion value.

4.5 Volumetric flow rate values

The Daniel 3410 Series Gas Ultrasonic Flow Meter meter provides three volumetric flow

rate values: raw, (expansion-corrected and/or profile-effect corrected) flow-condition, and

base- condition. Note that a positive volumetric flow rate indicates flow in the forward

direction whereas a negative volumetric flow rate indicates flow in the reverse direction.

4.5.1

Raw volumetric flow rate

The "raw" volumetric flow rate is calculated from the average gas flow velocity (wetcalibration gas flow velocity) as shown in Raw volumetric flow rate.

Equation 4-8: Raw volumetric flow rate

2

Q

Raw

= V

WetCal

πD

⋅

⋅ 3600 s/ℎ

4

where

Q

= “raw” volumetric flow rate (m3/h) (QMeter)

Raw

V

= wet-calibration gas flow velocity (m/s) (AvgFlow)

WetCal

π = geometric constant, pi (dimensionless) (3.14159...)

D = pipe inside diameter (m) (PipeDiam)

32 Operations manual

Page 33

Operations manual Measurement

DAN-20057316 January 2019

4.5.2 Flow-condition volumetric flow rate

The flow-condition volumetric flow rate is the result of applying expansion correction and

flow- profile correction to the raw volumetric flow rate as shown in Flow-condition

volumetric flow rate subject to the low- flow cut-off. If the resulting value is below the low-

flow cut-off value, it is set to zero. The low-flow cut-off volumetric flow rate (CutRate) is

the specified low-flow velocity threshold (ZeroCut) converted to a volumetric flow rate.

Q

= Q

Flow

where

Q

= flow-condition volumetric flow rate (m3/h) (QFlow)

Flow

Q

= “raw” volumetric flow rate (m3/h) (QMeter)

Raw

ExpCorrP = expansion correction factor due to pressure (dimensionless)

(ExpCorrPressure) calculated as shown in Equation 4-9.

ExpCorrT = expansion correction factor due to temperature (dimensionless)

(ExpCorrTemperature) calculated as shown in Equation 4-11.

ExpCorrPExCorr

Raw

T

4.5.3

Pressure-effect expansion correction

The meter is capable of correcting the raw volumetric flow rate for the effect of pipe

expansion due to pressure changes.

Note that for the pressure-effect expansion correction factor to be calculated, the

correction must be enabled (via the EnableExpCorrPress data point) and the flowcondition pressure must be available (i.e., the EnablePressureInput data point must be set

to 'Live'(1) or 'Fixed'(2), see Configure the pressure parameters for the meter. The

pressure-effect calculation is shown in Equation 4-9. If the pressure-effect expansion

correction factor is not calculated, it is set to 1.0.

Equation 4-9: Pressure-effect expansion correction

ExpCorrP= 1 + 3 × β × P

ExpCorrP = expansion correction factor due to pressure (dimensionless)

(ExpCorrPressure)

ß = pipe linear expansion coefficient due to temperature (MPaas-1)

(StrainPerUnitStress) calculated as shown in Equation 4-8.

P

= flow-condition absolute pressure (MPaa) (AbsFlowPressure) calculated as

abs,f

shown in Equation 4-12

P

= reference absolute pressure (MPaa) (0.101325MPaa) reference temperature for

ref

the pipe linear expansion coefficient (K)

abs, f

− P

ref

Equation 4-10: Pressure-effect strain per unit stress

β=

2

D

out

1+υ + D

E× D

2

out

‐D

2

in

2

in

1‐2υ

β = pipe strain per unit stress (MPaa-1) (StrainPerUnitStress)

Model 3418 GUSM 33

Page 34

Measurement Operations manual

January 2019 DAN-20057316

D

= outside diameter of the meter or pipe (m) (PipeOutsideDiameter)

out

Din = inside diameter of the meter or pipe (m) (PipeDiam)

ʋ = Poisson’s Ratio (dimensionless) (PoissonsRatio)

E = Young’s Modulus of elasticity (MPaa) (YoungsModulus)

4.5.4 Temperature-effect expansion correction

The meter is capable of correcting the raw volumetric flow rate for the effect of pipe

expansion due to temperature changes.

Note that for the temperature-effect expansion correction factor to be calculated, the

correction must be enabled (via the EnableExpCorrTemp data point) and the flowcondition temperature must be available (i.e., the EnableTemperatureInput data point

must be set to 'Live'(1) or 'Fixed'(2), see Temperature expansion correction). The

temperature-effect calculation is shown in Temperature-effect expansion correction. If the

temperature-effect expansion correction factor is not calculated, it is set to 1.0.

Equation 4-11: Temperature-effect expansion correction

4.5.5

ExpCorrT= 1 + 3 × α × Tf− T

ref

ExpCorrT = expansion correction factor due to temperature (dimensionless)

(ExpCorrTemperature)

α = pipe linear expansion coefficient due to temperature (K-1) (LinearExpansionCoef)

Tf = flow-condition temperature (K) (FlowTemperature)

T

= reference temperature for the pipe linear expansion coefficient (K)

ref

(RefTempLinearExpCoef)

Base-condition volumetric flow rate

The base-condition volumetric flow rate is the result converting the flow-condition

volumetric flow rate to the base pressure-temperature condition.

This conversion requires (1) AGA8 calculations to be either performed internally (i.e., by

the meter) or externally (with the resulting compressibilities specified to the meter via the

SpecZFlow and SpecZBase data points), and (2) the flow-condition temperature and

pressure to be live or fixed. If AGA8 calculations are not performed (i.e., neither internally

nor externally) or the flow-condition temperature and/or pressure are/is not enabled, then

the base-condition volumetric flow rate is set to zero. The base-condition volumetric flow

rate is calculated as shown in Equation 4-12.

Equation 4-12: Base-condition volumetric flow rate

Q

Base

= Q

Flow

P

abs, f

P

abs, b

T

Z

b

b

T

Z

f

f

where

Q

= “raw” volumetric flow rate (m3/h) (QMeter)

Base

Q

= flow-condition volumetric flow rate (m3/h) (QFlow)

Flow

34 Operations manual

Page 35

Operations manual Measurement

DAN-20057316 January 2019

P

= flow-condition absolute pressure (MPaa) (AbsFlowPressure) calculated as

abs,b

shown in Equation 4-9.

Tb = base-condition temperature (K) (TBase)

Tf = flow-condition temperature (K) (FlowTemperature)

Zb = base-condition compressibility factor (ZBase)

Zf = flow-condition compressibility factor (ZFlow)

4.5.6 Volume

The Daniel 3410 Series Gas Ultrasonic Flow Meter provides forward and reverse volume

accumulators for each of the three volumetric flow rate values: raw, flow-condition (raw

with expansion and/or profile correction), and base-condition.

Each volume accumulator is actually stored as a data pair: (64-bit unsigned integer

portion, 32-bit floating point fractional portion). For example, a volume of 12345.750 m

is stored as 12345 m3 for the integer portion and 0.750 m3 as the fractional portion. Note

that while a volumetric flow rate can be positive (indicating forward flow) or negative

(indicating reverse flow), the volume accumulators are always positive values.

The non-volatile volume accumulator data points are as listed in the table below:

Table 4-3: Volume accumulation data points

Volumetric

flow rate type

Raw

Flow-condition

Base-condition

Forward Direction Reverse direction

Integer Fraction Integer Fraction

PosVolUncorr PosVolUncorrFrac NegVolUncorr NegVolUncorrFrac

PosVolFlow PosVolFlowFrac NegVolFlow NegVolFlowUncorr

PosVolBase PosVolBaseFrac NegVolBase NegVolBaseUncorr

4.5.7 Energy rate and totals

These calculations require that the flow-condition pressure and temperature are available

(either fixed or optional analog inputs, Flow-condition pressure and temperature, the gas

property data (composition and heating value) are available (either fixed or optionally read

from a GC, Flow-condition pressure and temperature), and the AGA8 calculations are

performed (internally by the meter or externally with the results written to the meter,

Flow-condition pressure and temperature).

3

The energy rate is calculated as shown in Energy rate

Equation 4-13: Energy rate

QE= Q

Base

× HV ×

1MJ

1000kJ

×

1000dm

3

1m

3

where

QE = energy rate (MJ/h) (EnergyRate)

Q

= base-condition volumetric flow rate (m3/h) (QBase)

Base

HV = "in-use" heating value (kJ/dm3) (HeatingValueInUse)

Model 3418 GUSM 35

Page 36

Measurement Operations manual

January 2019 DAN-20057316

The sign of the energy rate indicates the flow direction: a positive value indicates flow in

the forward direction, a negative value indicates flow in the reverse direction.

The energy rate validity is indicated by the EnergyRateValidity data point TRUE(1)

indicates valid). The energy rate is valid if the base-condition volumetric flow rate is valid

(indicated by QBaseValidity where TRUE(1) indicates valid) and if the in-use gas properties

are valid (indicated by AreGasPropertiesInvalidInUse where FALSE(0) indicates valid).

The energy rate is accumulated into the corresponding direction energy total regardless of

the energy rate validity.

The forward and reverse direction energy totals are each stored in non-volatile memory as

a data pair: a 64-bit unsigned integer portion and a 32-bit floating point fractional portion.

For example, an energy total of 12345.750 MJ is stored as 12345 MJ for the integer portion

and 0.750 MJ as the fractional portion. Note that while the energy rate can be positive

(indicating forward flow) or negative (indicating reverse flow), the energy totals are always

positive values.

The non-volatile energy total data points are as listed in the table below:

Forward direction Reverse direction

Integer Fraction Integer Fraction

PosEnergy PosEnergyfrac NegEnergy NegEnergyFrac

4.5.8 Mass rate and totals

The Daniel 3410 Series Gas Ultrasonic Flow Meter meter calculates the mass rate and mass

totals (forward and reverse).

These calculations requires that the flow-condition pressure and temperature are available

(either fixed or optional analog inputs, Gas properties), the gas composition is available

(either fixed or optionally read from a GC, Gas property data), and the AGA8 calculations

are performed (internally by the meter or externally with the results written to the meter,

Configure Gas Chromatograph parameters).

The mass rate is calculated as shown in Mass rate

Equation 4-14: Mass rate

MassRate = mass rate (kg/h) (MassRate)

Q

= flow-condition volumetric flow rate (m3/h) (QFlow)

Flow

ρ

= "in-use" flow-condition gas mass density (kg/m3) (RhoMixFlow)

Flow

The sign of the mass rate indicates the flow direction: a positive value indicates flow in the

forward direction, a negative value indicates flow in the reverse direction.

MassRate = Q

Flow

× ρ

Flow

The mass rate validity is indicated by the MassRateValidity data point (TRUE(1) indicates

valid). The mass rate is valid if the flow-condition volumetric flow rate is valid (indicated by

QFlowValidity where TRUE(1) indicates valid) and if the AGA8 flow-condition calculation is

valid (indicated by AGA8FlowCalcValidity where TRUE(1) indicates valid).

36 Operations manual

Page 37

Operations manual Measurement

DAN-20057316 January 2019

The mass rate is accumulated into the corresponding direction mass total regardless of

the mass rate validity.

The forward and reverse direction mass totals are each stored in non-volatile memory as a

data pair: a 64-bit unsigned integer portion and a 32-bit floating point fractional portion.

For example, a mass total of 12345.750 kg is stored as 12345 kg for the integer portion

and 750 kg as the fractional portion. Note that while the mass rate can be positive

(indicating forward flow) or negative (indicating reverse flow), the mass totals are always

positive values.

The non-volatile mass total data points are as listed in the table below:

Table 4-4: Mass total data points

Forward direction Reverse direction

Integer Fraction Integer Fraction

PosMass PosMassFrac NegMass NegMassFrac

4.6 3410 Series gas flow meter characterizations

Symmetry

For Daniel 3410 Series Gas Ultrasonic Flow Meter SeniorSonic meters only, the following

flow characterizations are calculated/estimated: symmetry, cross-flow, chord turbulence,

profile factor, and swirl angle. Alarm limits are provided for the chord turbulence and swirl

angle values.

Symmetry is a dimensionless measure of the flow symmetry comparing the upper chords

to the lower chords and is readable via the Symmetry data point. Ideally the Symmetry

should be 1.0.

Cross-flow