Page 1

Owner and operator manual

Daniel ™ Senior™ Orifice Fitting 2"-16"

2"- 16" 150-1500 / 2"-12" 2500

P/N 3-9008-001, Rev AT

October 2019

Page 2

2

Page 3

Flow Lifecycle Services for Daniel products

Location Telephone number Fax number

North America/Latin America +1.713.467.6000 +1.713.827.4805

Flow Lifecycle Services for Daniel products +1.713.827.6314 +1.713.827.6312

USA (toll free) +1.888.356.9001 +1.713.827.3380

Asia Pacific (Republic of Singapore) +65.6777.8211 +65.6777.0947.0743

Europe (Stirling Scotland, UK) +44 (0)1786.433400 +44 (0)1786.433401

Middle East Africa (Dubai, UAE) +971 4 8118100 +971 4 8865465

Daniel Measurement and Control, Inc. (Headquarters)

11100 Brittmoore Park Drive

Houston, TX 77041 USA

http://www.emerson.com

Email

• Customer Service: DanielCST.Support@Emerson.com

• Customer Support: Daniel.TechnicalSupport@Emerson.com

• Field Lifecycle Services: Tech.Service@Emerson.com

• Asia-Pacific: danielap.support@emerson.com

• Europe: danielEMA.cst@emerson.com

Return Material Authorization (RMA)

A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason. Access and

fill in the RMA form for Daniel products clicking on the link below.

http://go.emersonprocess.com/RMAOnlineForm

3

Page 4

Signal words and symbols

Pay special attention to the following signal words, safety alert symbols and statements:

Safety alert symbol

This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

Danger indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Warning indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Caution indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Notice is used to address safety messages or practices not related to personal injury.

Important

Important is a statement the user needs to know and consider.

Tip

Tip provides information or suggestions for improved efficiency or best results.

Note

Note is “general by-the-way” content not essential to the main flow of information.

4

Page 5

Important safety instructions

Daniel Measurement and Control, Inc. (Daniel) designs, manufactures and tests products to function within specific conditions.

Because these products are sophisticated technical instruments, it is important that the owner and operation personnel must

strictly adhere both to the information printed on the product and to all instructions provided in this manual prior to installation,

operation, and maintenance.

Daniel also urges you to integrate this manual into your training and safety program.

BE SURE ALL PERSONNEL READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ALL NOTICES AND PRODUCT WARNINGS.

WARNING

Failure to follow the installation, operation or maintenance instructions for a Daniel product could lead to serious injury or

death from explosion or exposure to dangerous substances.

To reduce the risk:

• Comply with all information on the product, in this manual, and in any local and national codes that apply to this product.

• Do not allow untrained personnel to work with this product.

• Use Daniel parts and work procedures specified in this manual.

Product owners (Purchasers):

• Use the correct product for the environment and pressures present. See technical data or product specifications for

limitations. If you are unsure, discuss your needs with your Daniel representative.

• Inform and train all personnel in the proper installation, operation, and maintenance of this product.

• To ensure safe and proper performance, only informed and trained personnel should install, operate, repair and maintain this

product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact

Daniel at 1-713-827-6314. You may also download the correct manual from: https://www.emerson.com/en-us/automation/

daniel.

• Save this instruction manual for future reference.

• If you resell or transfer this product, it is your responsibility to forward this instruction manual along with the product to the

new owner or transferee.

• ALWAYS READ AND FOLLOW THE INSTALLATION, OPERATIONS, MAINTENANCE AND TROUBLESHOOTING MANUAL(S) AND

ALL PRODUCT WARNINGS AND INSTRUCTIONS.

• Do not use this equipment for any purpose other than its intended service. This may result in property damage and/or serious

personal injury or death.

5

Page 6

Product operation (Personnel):

• To prevent personal injury, personnel must follow all instructions of this manual prior to and during operation of the product.

• Follow all warnings, cautions, and notices marked on, and supplied with, this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not the correct documentation, contact

Daniel at 1-713-827-6314. You may also download the correct manual from: https://www.emerson.com/en-us/automation/

daniel.

• Read and understand all instructions and operating procedures for this product.

• If you do not understand an instruction, or do not feel comfortable following the instructions, contact your Daniel

representative for clarification or assistance.

• Install this product as specified in the INSTALLATION section of this manual per applicable local and national codes.

• Follow all instructions during the installation, operation, and maintenance of this product.

• Ensure that all connections to pressure and electrical sources are secure prior to and during equipment operation.

• Use only replacement parts specified by Daniel. Unauthorized parts and procedures can affect this product's performance,

safety, and invalidate the warranty. “Look-a-like” substitutions may result in deadly fire, explosion, release of toxic substances

or improper operation.

• Save this instruction manual for future reference.

6

Page 7

Notice

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY, AND WHILE EVERY EFFORT HAS

BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR

IMPLIED, REGARDING THE PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE

GOVERNED BY DANIEL'S TERMS AND CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST. WE RESERVE THE RIGHT TO MODIFY

OR IMPROVE THE DESIGNS OR SPECIFICATIONS OF SUCH PRODUCTS AT ANY TIME.

DANIEL DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF ANY PRODUCT. RESPONSIBILITY FOR

PROPER SELECTION, USE AND MAINTENANCE OF ANY DANIEL PRODUCT REMAINS SOLELY WITH THE PURCHASER AND END-USER.

TO THE BEST OF DANIEL'S KNOWLEDGE THE INFORMATION HEREIN IS COMPLETE AND ACCURATE. DANIEL MAKES NO

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN NO EVENT, SHALL DANIEL BE LIABLE FOR ANY INCIDENTAL,

PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS,

LOSS OF REVENUE OR USE AND COSTS INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND

CLAIMS OF THIRD PARTIES.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY AND MAY BE TRADEMARKS/

REGISTERED TRADEMARKS OF THESE COMPANIES.

7

Page 8

Warranty and Limitations

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement & Control, Inc. (“Daniel”)

warrants that the licensed firmware embodied in the Goods will execute the programming instructions provided by Daniel, and

that the Goods manufactured by Daniel will be free from defects in materials or workmanship under normal use and care and

Services will be performed by trained personnel using proper equipment and instrumentation for the particular Service provided.

The foregoing warranties will apply until the expiration of the applicable warranty period. Goods are warranted for twelve (12)

months from the date of initial installation or eighteen (18) months from the date of shipment by Daniel, whichever period expires

first. Consumables and Services are warranted for a period of 90 days from the date of shipment or completion of the Services.

Products purchased by Daniel from a third party for resale to Buyer (“Resale Products”) shall carry only the warranty extended by

the original manufacturer. Buyer agrees that Daniel has no liability for Resale Products beyond making a reasonable commercial

effort to arrange for procurement and shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Daniel

thereof in writing during the applicable warranty period, Daniel shall, at its option, correct any errors that are found by Daniel in

the firmware or Services or repair or replace F.O.B. point of manufacture that portion of the Goods or firmware found by Daniel to

be defective, or refund the purchase price of the defective portion of the Goods/Services. All replacements or repairs necessitated

by inadequate maintenance, normal wear and usage, unsuitable power sources or environmental conditions, accident, misuse,

improper installation, modification, repair, use of unauthorized replacement parts, storage or handling, or any other cause not the

fault of Daniel are not covered by this limited warranty, and shall be at Buyer's expense. Daniel shall not be obligated to pay any

costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance by Daniel. All costs of

dismantling, reinstallation and freight and the time and expenses of Daniel's personnel and representatives for site travel and

diagnosis under this warranty clause shall be borne by Buyer unless accepted in writing by Daniel. Goods repaired and parts

replaced by Daniel during the warranty period shall be in warranty for the remainder of the original warranty period or ninety (90)

days, whichever is longer. This limited warranty is the only warranty made by Daniel and can be amended only in a writing signed

by Daniel. THE WARRANTIES AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR ANY OTHER

MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. Buyer acknowledges and agrees that corrosion or erosion of

materials is not covered by this warranty.

2. LIMITATION OF REMEDY AND LIABILITY: Daniel shall not be liable for damages caused by delay in performance. The remedies of

Buyer set forth in this agreement are exclusive. In no event, regardless of the form of the claim or cause of action (whether based

in contract, infringement, negligence, strict liability, other tort or otherwise), shall Daniel's liability to Buyer and/or its customers

exceed the price to Buyer of the specific goods manufactured or services provided by Daniel giving rise to the claim or cause of

action. Buyer agrees that in no event shall Daniel's liability to Buyer and/or its customers extend to include incidental,

consequential or punitive damages. The term “consequential damages” shall include, but not be limited to, loss of anticipated

profits, revenue or use and costs incurred including without limitation for capital, fuel and power, and claims of Buyer's customers.

8

Page 9

Owner and operator manual Contents

P/N 3-9008-001 October 2019

Contents

Part I Plan

Chapter 1 Introduction.................................................................................................................13

1.1 Definition of Acronyms...................................................................................................................13

1.2 Purpose of this manual................................................................................................................... 14

1.3 Product description........................................................................................................................ 14

1.4 Conditions and specifications......................................................................................................... 16

1.5 Parts and materials lists.................................................................................................................. 20

Part II Install

Chapter 2 General Information.....................................................................................................53

2.1 Installation..................................................................................................................................... 53

Part III Operate

Chapter 3 Commissioning............................................................................................................ 63

3.1 Commission the Daniel Senior Orifice Fitting..................................................................................63

3.2 Commission the line pressure test.................................................................................................. 65

3.3 Orifice Plate Installation..................................................................................................................67

Part IV Maintain

Chapter 4 Normal operation conditions....................................................................................... 73

4.1 Maintenance.................................................................................................................................. 73

4.2 Orifice plate installation and removal instructions.......................................................................... 78

Chapter 5 Supplemental information......................................................................................... 165

5.1 Recommended spare parts for a one-year operation.................................................................... 165

5.2 Lubricant information...................................................................................................................166

5.3 Torque information...................................................................................................................... 170

5.4 Plate and Valve Carrier clearances................................................................................................ 173

Owner and operator manual ix

Page 10

Contents Owner and operator manual

October 2019 P/N 3-9008-001

x Senior Orifice Fitting

Page 11

Owner and operator manual Plan

P/N 3-9008-001 October 2019

Part I

Plan

Owner and operator manual 11

Page 12

Plan Owner and operator manual

October 2019 P/N 3-9008-001

12 Senior Orifice Fitting

Page 13

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

1 Introduction

1.1 Definition of Acronyms

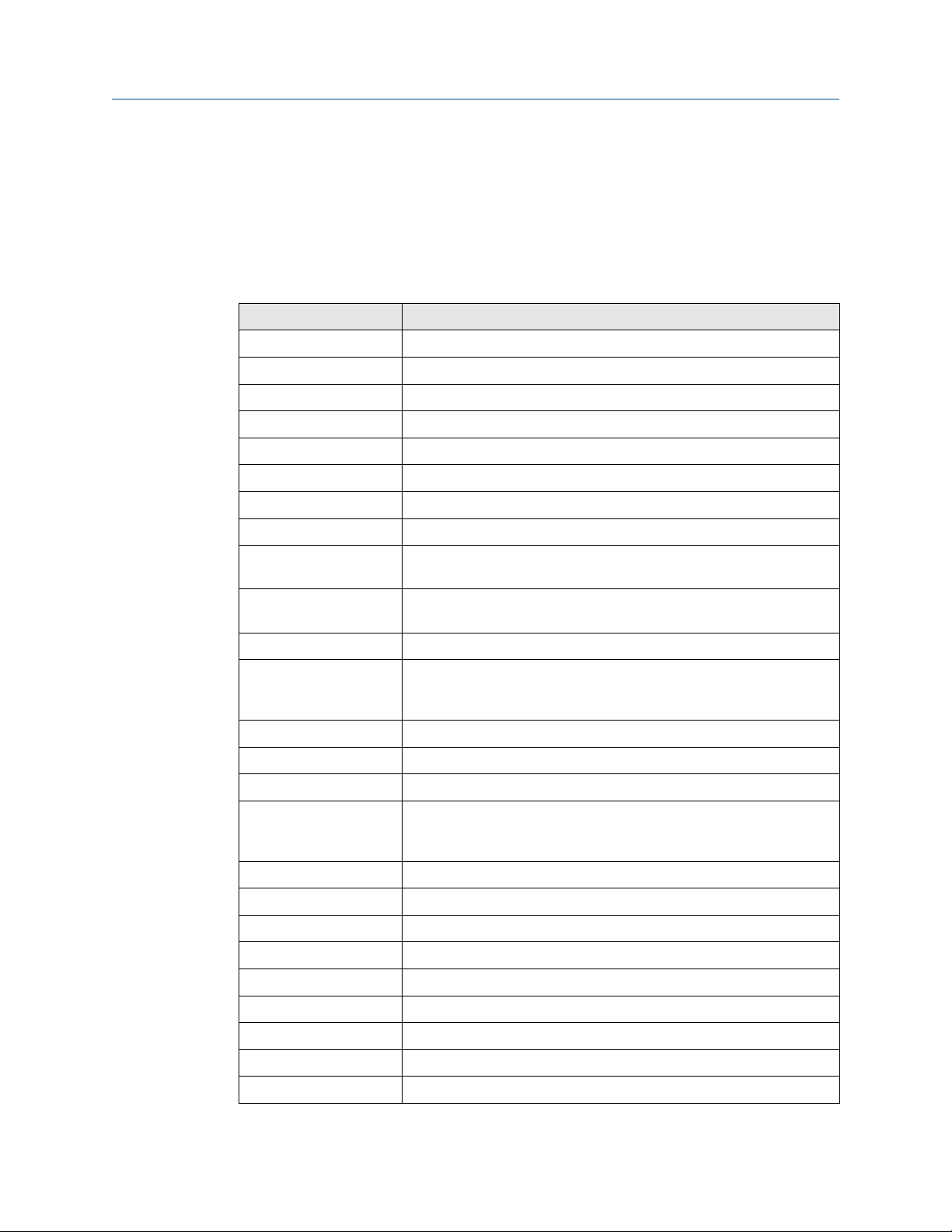

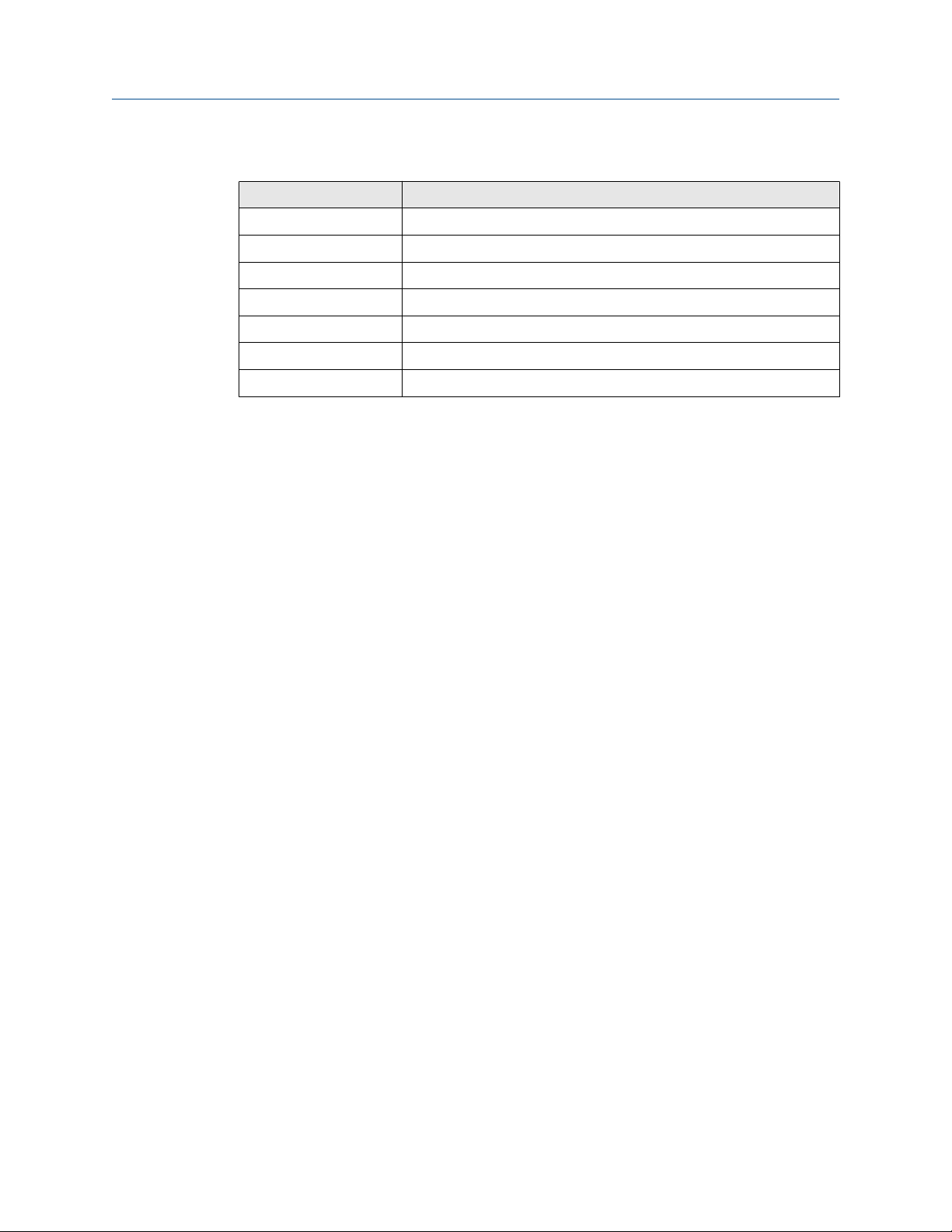

Table 1-1: Acronyms and their definition

Acronym Description

AGA

AISI

API

ANSI

ASME

ASTM

GPA

ISO

MSS

NACE

MPMS

API-14.3

ISO 5167

U/S

D/S

DP

CRS

CS

SS

YP

ZP

MAOP

NPSM

NPT

HBR

American Gas Association

American Iron and Steel Institute

American Petroleum Institute

American National Standards Institute

American Society of Mechanical Engineers

American Society of Testing and Materials

Gas Processors Association

International Organization of Standardization

Manufacturers Standardization Society of the Valve and Fittings

Industry, Inc

NACE International (formerly National Association of Corrosion

Engineers)

API Manual of Petroleum Measurement Standards

API-AGA joint flow measurement code (API MPMS Chapter 14, Section

3, Part 2:2000(R2011) - also AGA Report No. 3, Part 2 and GPA

8185-00, Part 2)

ISO flow measurement code (ISO 5167-2:2003(E))

upstream

downstream

differential pressure (ΔP) - differences of static pressures found on the

U/S and D/S faces of an orifice plate during the flow measurement

process

cold rolled steel

carbon steel

stainless steel

gold (yellow chromate) zinc plated

silver (clear chromate) zinc plated

maximum allowable operating pressure

national pipe straight mechanical thread

national pipe tapered thread

butadiene rubber

Owner and operator manual 13

Page 14

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-1: Acronyms and their definition (continued)

Acronym Description

HNBR

NBR

FFKM

FKM

PTFE

SBR

TFE

hydrogenated nitrile-butadiene rubber

nitrile-butadiene rubber

perfluoroelastomer rubber

fluoroelastomer rubber

polytetrafluoroethylene

styrene-butadiene rubber

tetrafluoroehtylene

1.2 Purpose of this manual

This manual provides guidance to owners and personnel in the installation, operation and

maintenance of the Daniel™ Senior™ Orifice Fitting.

To ensure safe and proper installation, operation and maintenance, it is imperative that

product owners and operation personnel read and follow the information contained in this

manual.

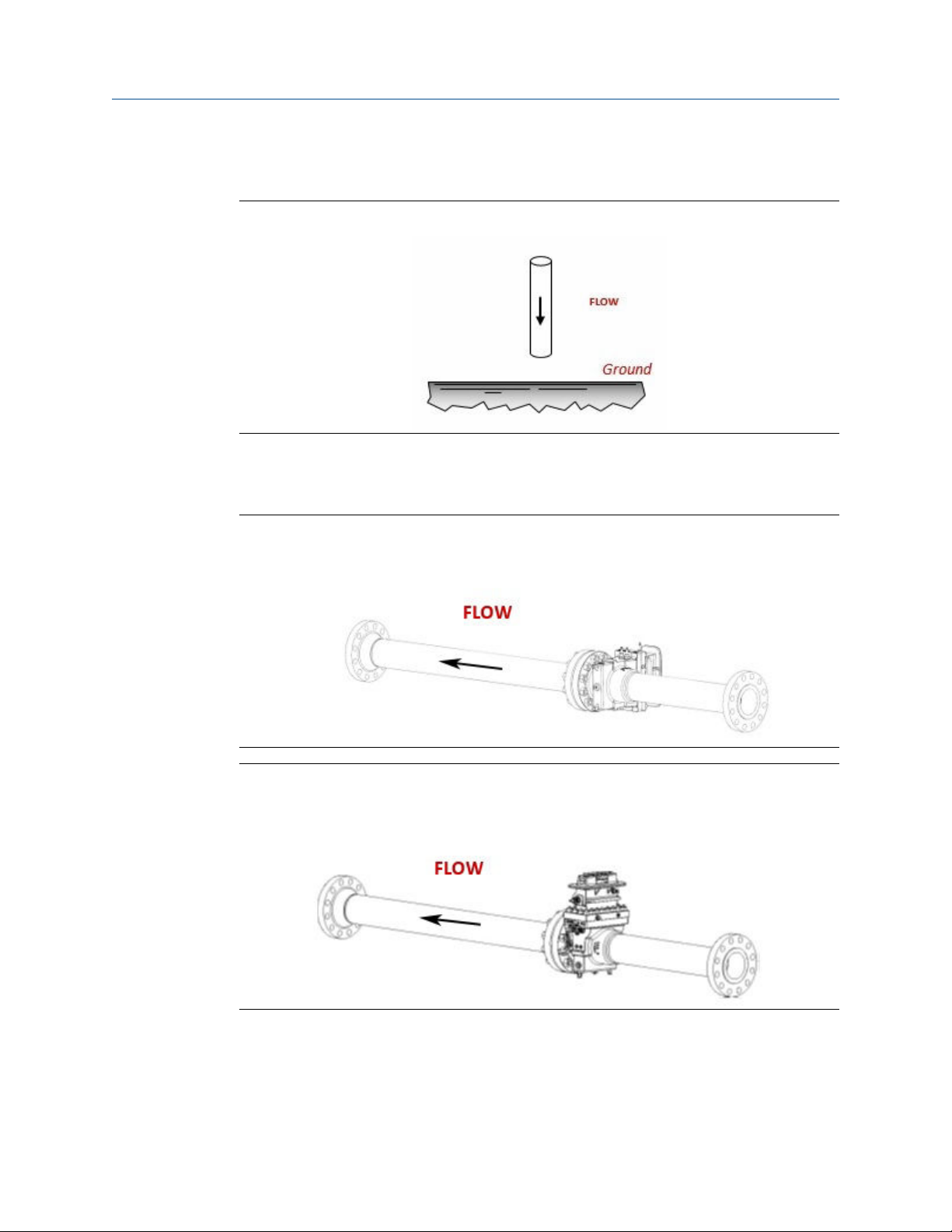

1.3 Product description

The Daniel Senior Orifice Fitting is an orifice plate holding device that houses, and

accurately positions, an orifice plate within a pipe or tube to measure fluid flow. It is one

component of a flow measurement system. The Senior Orifice Fitting (Senior) is designed

to:

• Position an orifice plate, concentric to flow moving through a pipeline, within API

-14.3, Part 2 or ISO 5167 installation requirements.

• Allow personnel to remove and replace an orifice plate without disturbing the flow

measurement system piping, with little, or no, interruption in service and without

removing the Senior from the system.

The orifice plate within a Senior restricts the fluid moving through a pipe. This restriction

creates a change in static pipe pressure of the fluid. Instrumentation measure the

difference in change of the fluid entering orifice plate bore, and once again after it exits

the plate bore. This instrumentation then combines that information, along with other

data gathered from the flowing fluid, and calculates the amount of fluid that passes

through the system.

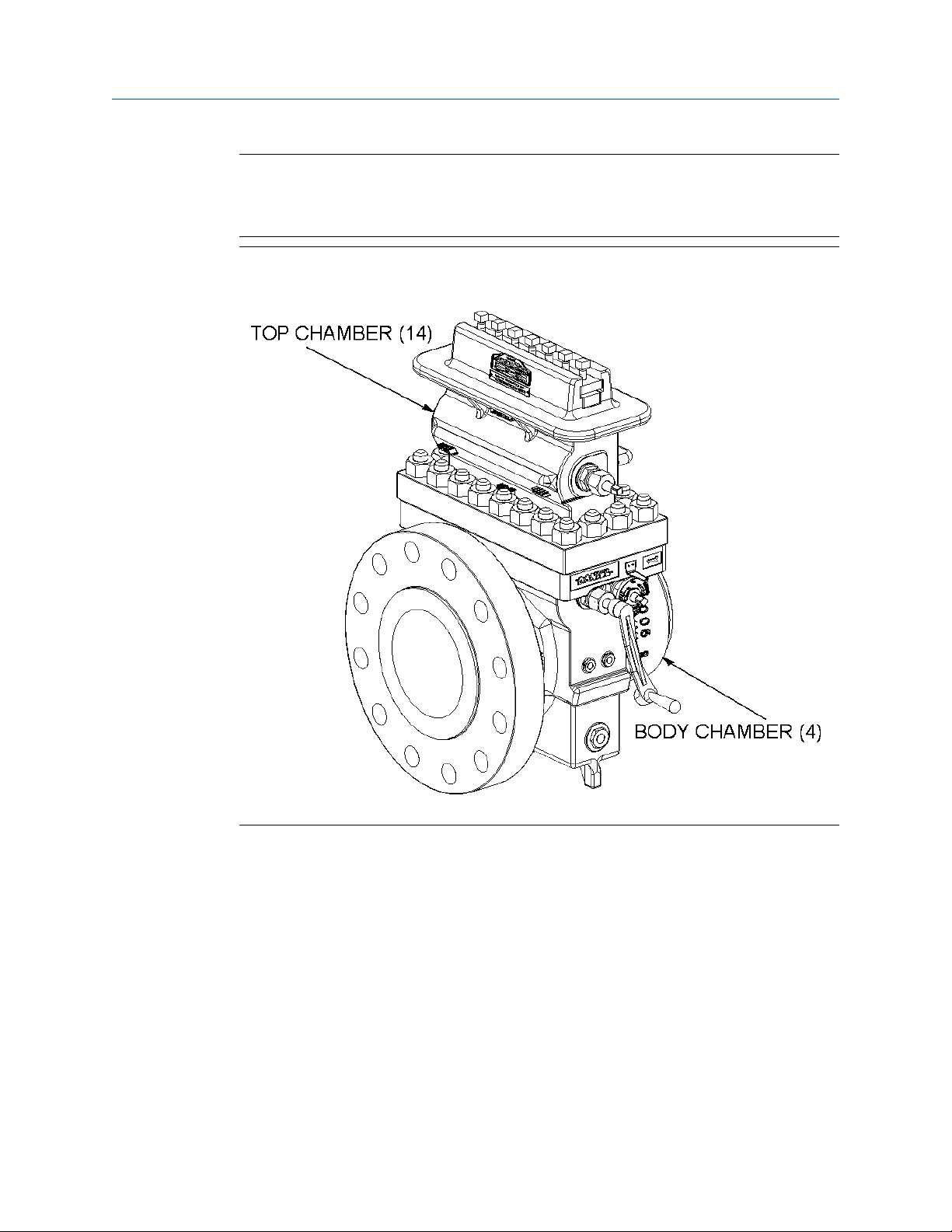

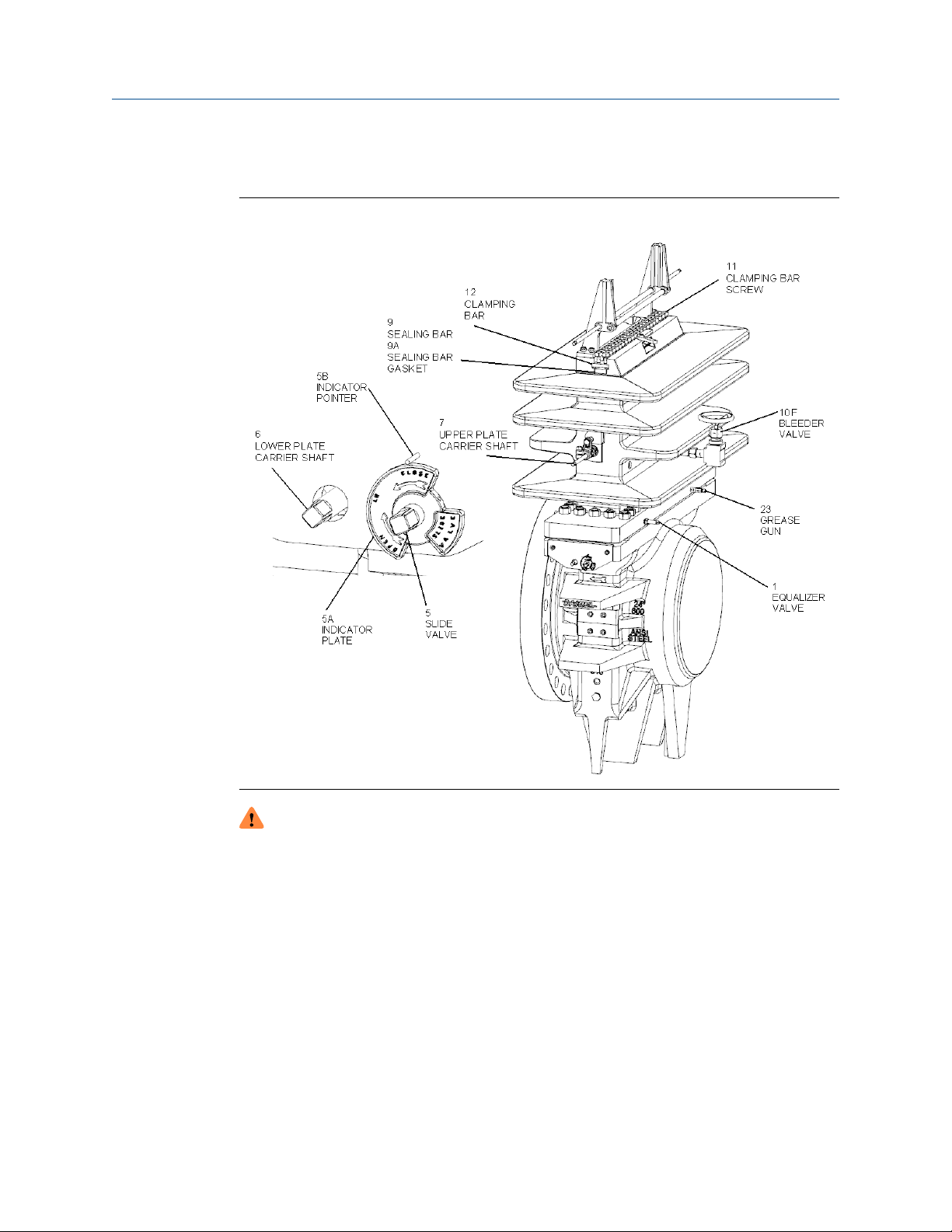

The first chamber, or Body (4), properly positions the orifice plate in the flow stream. The

second chamber, or Top (14), is a temporary holding place for the orifice plate during

removing or installing operations (Refer to Orifice plate installation and removal

instructions).

14 Senior Orifice Fitting

Page 15

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Important

The unit components have part numbers assigned on appropriate drawings and tables.

Refer to Figure 1-2 thru Figure 1-5 and Table 1-4 thru Table 1-8 for part numbers. Example:

Body (4).

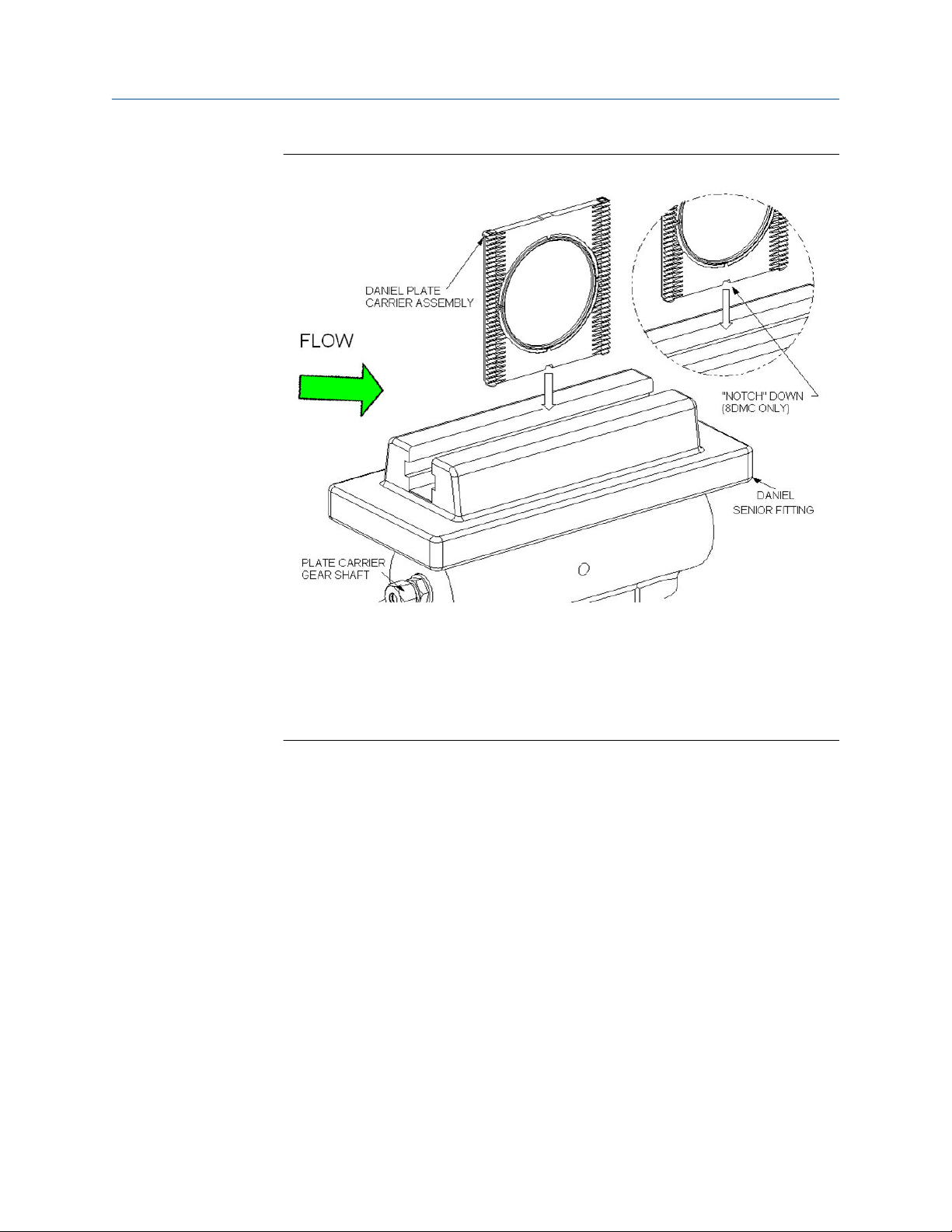

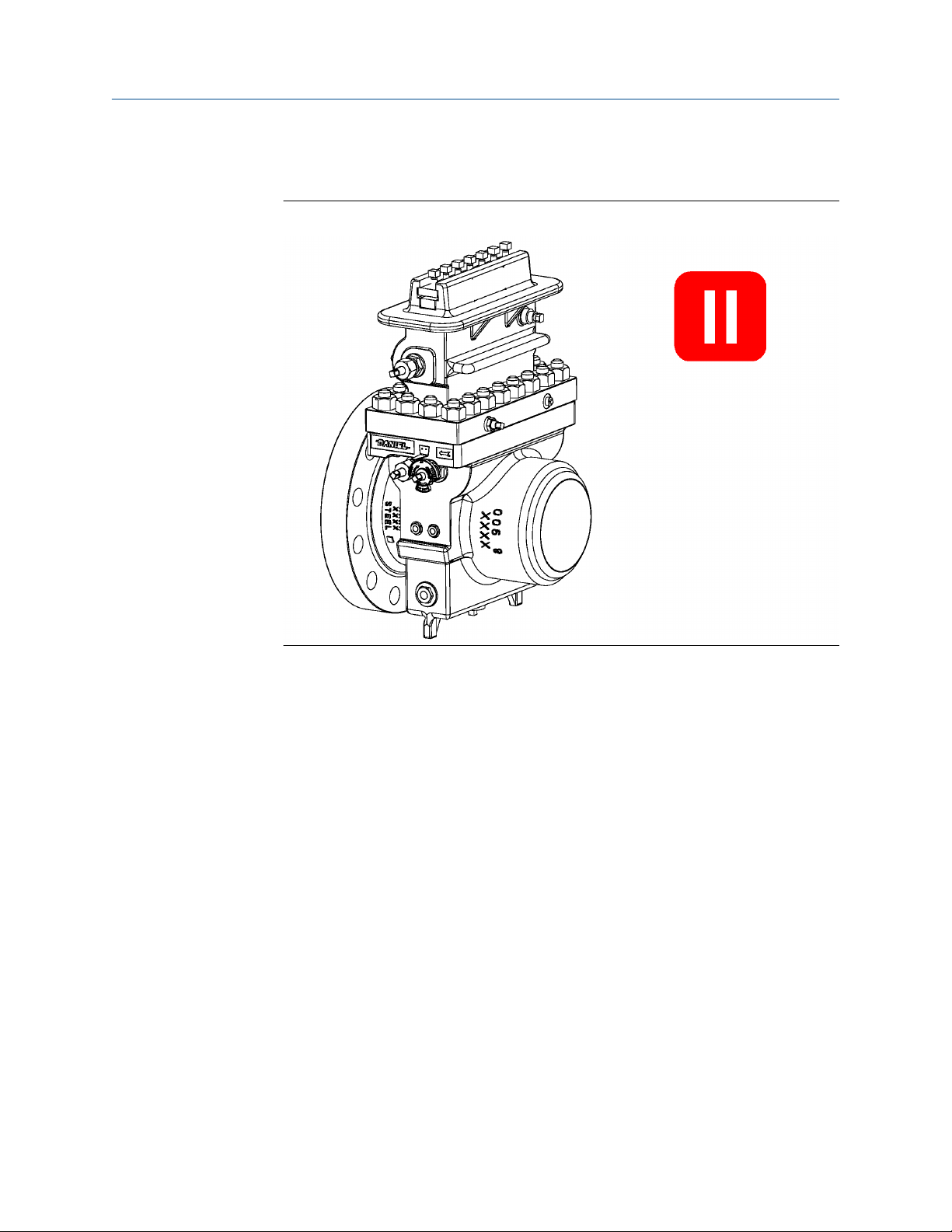

Figure 1-1: Daniel Senior Orifice Fitting - Flangnek option

Therefore, using a Senior may eliminate the need for bypass piping, valves, and other

fittings necessary with conventional orifice fitting installations. Maintenance technicians

can replace and repair all parts of the Senior, including the slide valve assembly, without

removing the Body (4) from the line (refer to Maintain).

Emerson designs and manufactures all Senior units to applicable API-14.3

recommendations and in accordance with selected ANSI, ASME and ASTM specifications.

As an option, Emerson Process Management also designs and manufactures fittings in

compliance with ISO 5167.

Products bearing the "CE" mark are designed and manufactured in compliance with the

European Union Pressure Equipment Directive (PED) 97/23/EC (available on the internet).

Refer to the "Daniel Orifice Fittings Installation and Operating Instructions specific to the

Pressure Equipment Directive", Part Number 3-9008-002 (available on the Emerson

Process Management website).

Owner and operator manual 15

Page 16

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

White papers (available on the Emerson Process Management website, Daniel products

section):

• Upp, E.L. "Application of the Orifice Meter for Accurate Gas Flow Measurement": Daniel

Measurement and Control Inc., Houston, Texas USA (1995)

• Upp, E.L. "Development of Orifice Meter Standards": Daniel Measurement and Control

Inc., Houston, Texas USA (1995)

• Daniel Measurement and Control Inc. "Fundamentals of Orifice Meter Measurement":

Daniel Measurement and Control Inc., Houston, Texas USA (1997)

• Kendrick, Ray. Effects of the Latest Revision of ANSI/API 2530/AGA 3 On Orifice Meter

Primary Elements" Daniel Measurement and Control Inc., Houston, Texas USA (1997)

• Daniel Measurement and Control Inc. "Getting the Best Value From Daniel Senior

Orifice Fittings": Daniel Measurement and Control Inc., Houston, Texas USA (1997)

• Cotton, Galen M. "Pulsation Effects on Gas Measurement": Daniel Measurement and

Control Inc., Houston, Texas USA (1980)

• Husain, Zaki D. "Theoretical Uncertainty of Orifice Flow Measurement": Daniel

Measurement and Control Inc., Houston, Texas USA (1990)

• Daniel Measurement and Control Inc. "Senior Orifice Fitting Technical Guide: DAN-DIF-

TG11-1003 "Daniel Measurement and Control Inc., Houston, Texas USA (2014).

1.4 Conditions and specifications

NOTICE

Follow all the safety and equipment limits recommended in Conditions and specifications

of this manual.

It is the owner's and/or purchaser's responsibility to comply with these parameters.

WARNING

PERSONAL PROTECTION HAZARD

Follow all parameters for the Senior Orifice indicated below.

Failure to comply may result in death and serious injury or equipment damage.

Table 1-2: Conditions and specifications

Product parameters and limitations:

Fluid static

pressures

Refer to ASME/ANSI B16 standards, and your fitting's material of construction,

to determine the maximum operating temperature and pressure of your

Senior. Emerson provides both the fitting's materials of construction and

ASME/ANSI ratings information on the product nameplate.

Fluid phases: Gas, liquid, vapor

Fluids measured: Most fluids

Fluid temperature

parameters:

16 Senior Orifice Fitting

-20° / +160° F (-29° C / +71° C) is the fluid temperature range for this product

based upon the materials of construction (Refer to ASME codes

Consult factory before operating this product outside of the specified

temperature range.

(1)

).

Page 17

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

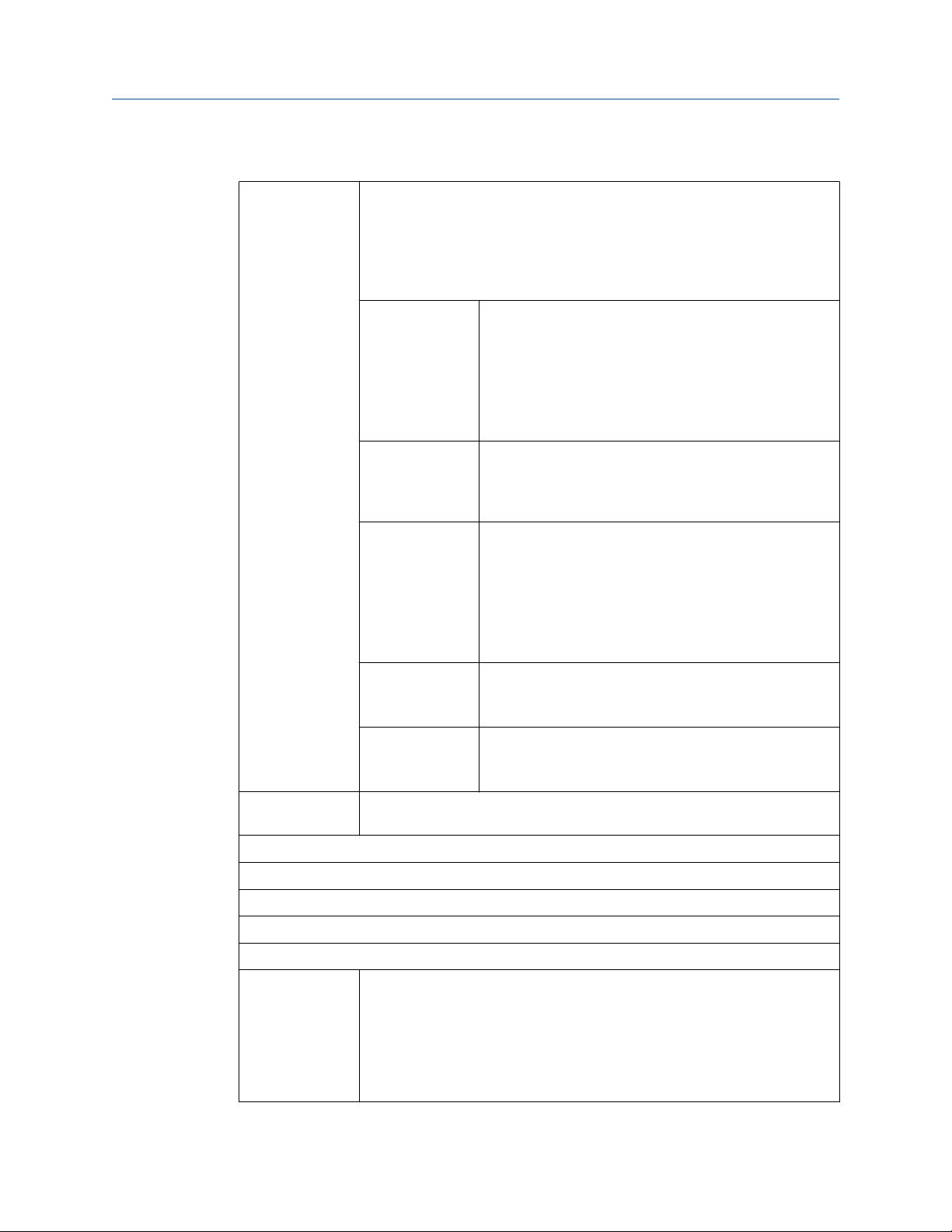

Table 1-2: Conditions and specifications (continued)

Temperature and

operating

pressure

limitations of

Orifice Plate Seal

materials:

-20° / +160° F (-29° C / +71° C) is the fluid temperature range for this product

based upon the materials of construction (Refer to ASME codes

(1)

) .

The following list describes the most common Orifice Plate Seal material and

their available forms offered for use in Daniel Senior fittings.

Consult factory before operating this product outside of the specified

temperature range.

HNBR: Loose or Bonded:

Material available for "loose" seal rings (2"-10") or "bonded"

seal to orifice plates (12" and larger). Operating pressure is

limited to lesser of ANSI Class MAOP or 1500 psig.

O-ring:

Used with Snap Seal Ring assemblies (2" and larger).

Operating pressure is limited to ANSI Class MAOP.

NBR: Loose or Bonded:

Material available for "loose" seal rings (2"-10") or "bonded"

seal to orifice plates (12" and larger). Operating pressure is

limited to lesser of ANSI Class MAOP or 1500 psig.

FKM: Loose or Bonded:

Material available for "loose" seal rings (2"-10") or "bonded"

seal to orifice plates (12" and larger). Operating pressure is

limited to lesser of ANSI Class MAOP or 1500 psig.

"O" Ring:

Used with Snap Seal Ring assemblies (2" and larger).

Operating pressure is limited to ANSI Class MAOP.

PTFE: Loose:

FFKM: "O" Ring:

Differential

Refer to API -14.3 or ISO 5167, as appropriate to your system.

pressure:

General arrangement dimensions:

See List item.

Time parameters:

See Orifice Plate changing instructions

Components:

Maintenance

intervals:

The owners and users of these products should perform regular scheduled

intervals of maintenance activities. The recommended intervals are every

month or as directed by the owner's maintenance procedures. Examine

components during each scheduled maintenance period, site visits and during

each orifice plate change.

Replace any component that shows signs of wear or when damaged with parts

specified for Daniel products.

Material used for orifice plate seal rings (2" and above).

Operating pressure is limited to ANSI Class MAOP.

Used with Snap Seal Ring assemblies (2" and larger).

Operating pressure is limited to ANSI Class MAOP.

Owner and operator manual 17

Page 18

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-2: Conditions and specifications (continued)

Seal replacement: Examine seals during each scheduled maintenance period, site visits and

during each orifice plate change.

Replace any worn or damaged or non-functioning seals with parts specified for

Daniel product.

Fastener torque

verification:

Corrosion

allowance:

Environmental parameters:

Application: Surface and offshore (not for use in subsea applications)

Confined/open: Designed for outdoor use. May be used in well ventilated spaces (buildings/

Site temperature: Recommended atmospheric temperature ranges

Check all fasteners for tightness during each scheduled maintenance period,

site visits and during each orifice plate change.

Use information provided in Section 5.3 as a starting point in establishing the

proper fastener torque values for your particular service environment.

Emerson machines the meter bore of each fitting to close tolerances. This is to

conform to industry measurement standards.

The fitting's meter bore dimensions DO NOT include an allowance for

corrosion.

It is the end user's responsibility to specify a fitting's material of construction

based upon their knowledge of the process fluid and environmental conditions

of an intended service.

Therefore, it is important that the end user to monitor any change in the gas or

liquid composition during monthly exercises, site visits and plate changes that

may create a corrosion concern (Reference: U.S. DOT, CFR Title 49: Part

192.477).

enclosed meter houses). Installation at product owner's discretion.

Maximum: +120 °F (+49 °C),

Minimum: -20 °F (-29 °C).

Site humidity: No limit

Site elevation: No limit

Proximity to

population:

Proximity to

traffic:

Proximity to

equipment:

Interface parameters:

Replacement

parts:

Aftermarket

attachments:

18 Senior Orifice Fitting

Reference: Class 1 location: U.S. DOT, CFR Title 49: Part 192.5.

The owner must protect the fitting from accidental damage by vehicular traffic

or other causes, by either placing the unit at a safe distance from the traffic, or

installing barricades around the unit.

Install the Senior in a well ventilated place, not less than 3 feet (914

millimeters) from any source of ignition or any source of heat which might

damage the unit.

Use only replacement parts specified for Daniel products. Unauthorized parts

and procedures can affect this product's performance and place the safe

operation of your process at risk.

Use of pressure sensing equipment, drain valves, and other accessories (e.g.,

needle valves, multi-port valves, transmitters, 3-pin recorders… etc.) are

permissible. The use of aftermarket equipment must be installed and operated

as directed by the after-market equipment manufacturer, and their warranties

and replacements are not contained within the scope of this document.

Page 19

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-2: Conditions and specifications (continued)

Pipe supports: The owner must employ sound engineering principles to design the support

systems for the flow measurement system (or meter tube).

It is important that the design engineer develop a method to support the

entire weight (equipment, piping and fluid) of the system.

The method developed must prevent bending to reduce the potential of

creating unwanted stress at welded joints and flanges. Unwanted stresses may

lead to leaks and may ultimately lead to failure or rupture of the flow

measurement system.

Vandalism/

Tampering:

(1) It is ultimately the responsibility of the Owner or End User to determine suitable materials of

construction suitable for a service conditions.

It is the responsibility of each product owner to protect the Senior from

vandalism, tampering or other unauthorized activity.

Owner and operator manual 19

Page 20

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

1.5 Parts and materials lists

1.5.1 Trim options

Table 1-3: Senior Fitting Trim options

(1)

"A"

"NACE"

AASG

316SS PIC

22CR duplex

Mildly corrosive

Moderately corrosive

Severely corrosive

mpy = mils (0.001") penetration per year of corrosion based on carbon steel

NOTICE

It is the ultimate responsibility of the owner and/or purchaser to specify a fitting's material of

construction, including trim option, based upon their knowledge of the process fluid and

environmental conditions of an intended service.

(1) Unless otherwise noted, materials as listed in the Parts Lists indicate standard "A" Trim product.

For applications outside all parameters listed, please consult the factory.

Materials offered for liquid or dry gaseous, non-corrosive ("sweet")

fluids

Materials offered for dry, non-corrosive ("sour") H2S-containing

gases

Materials offered for liquid or wet gaseous, mildly corrosive ("sour")

H2S-containing fluids

Materials offered for liquid or wet gaseous, moderately corrosive

("sour") H2S-containing fluids

Materials offered for liquid or wet gaseous, severely corrosive

("sour") H2S-containing fluids

≦3.0 mpy

> 3.0 - 8.0 mpy

>8.0 mpy

20 Senior Orifice Fitting

Page 21

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

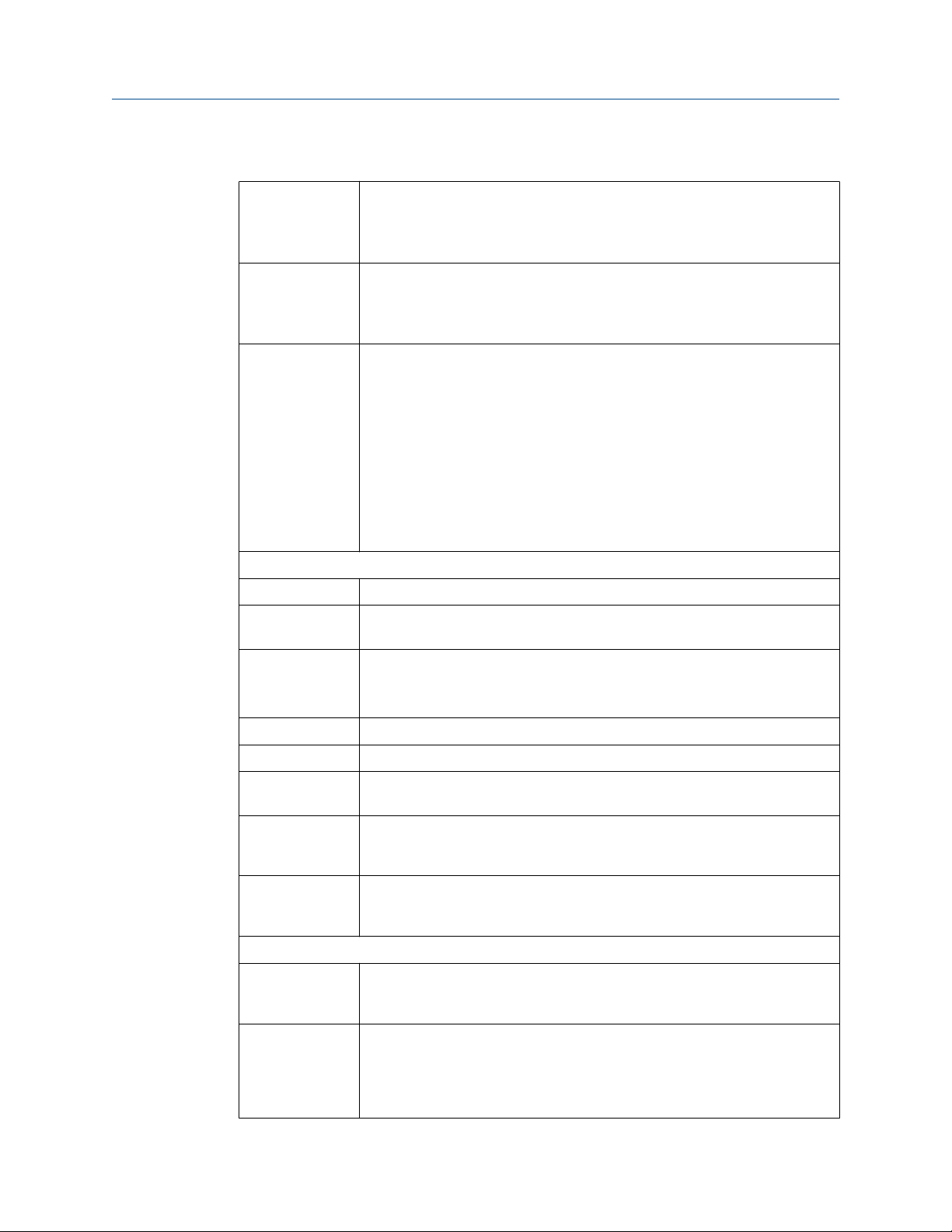

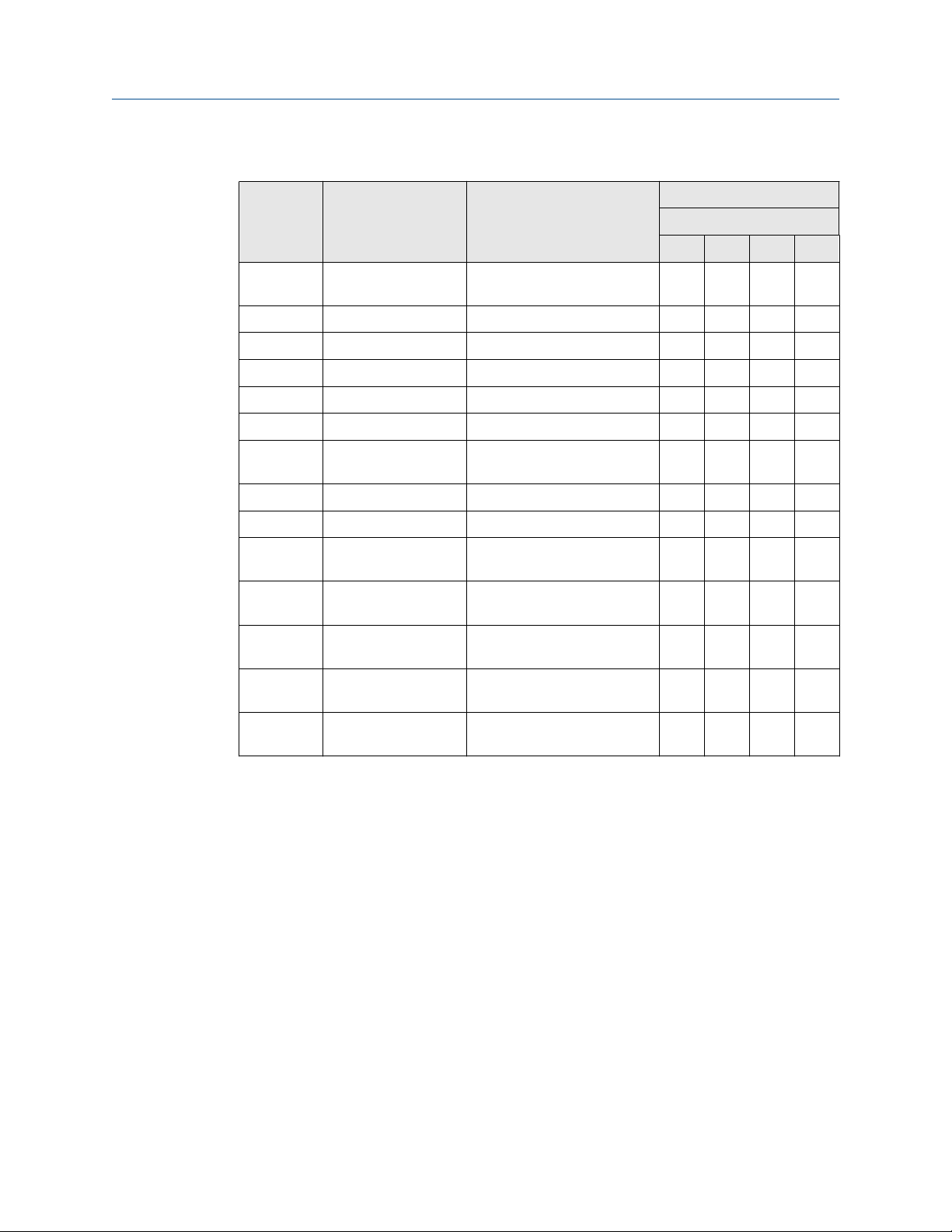

1.5.2 Daniel Senior Orifice Fitting sizes 2"- 8" 150-900

Figure 1-2: Daniel Orifice Fitting drawing 2"-8" 150-900

Owner and operator manual 21

Page 22

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

All Parts on Daniel Senior Orifice Fittings may be replaced or repaired without removing

the Daniel Senior Orifice Fitting body from the line.

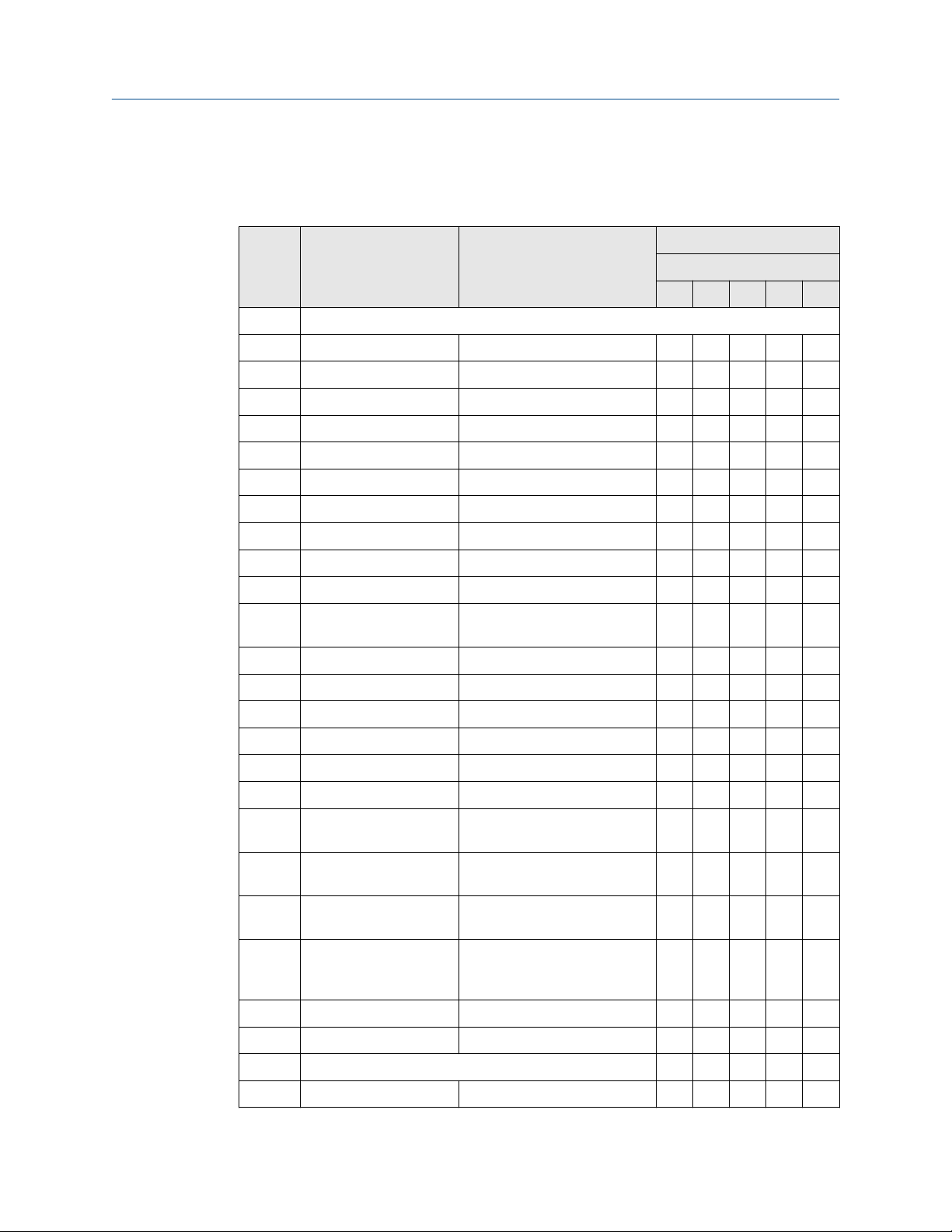

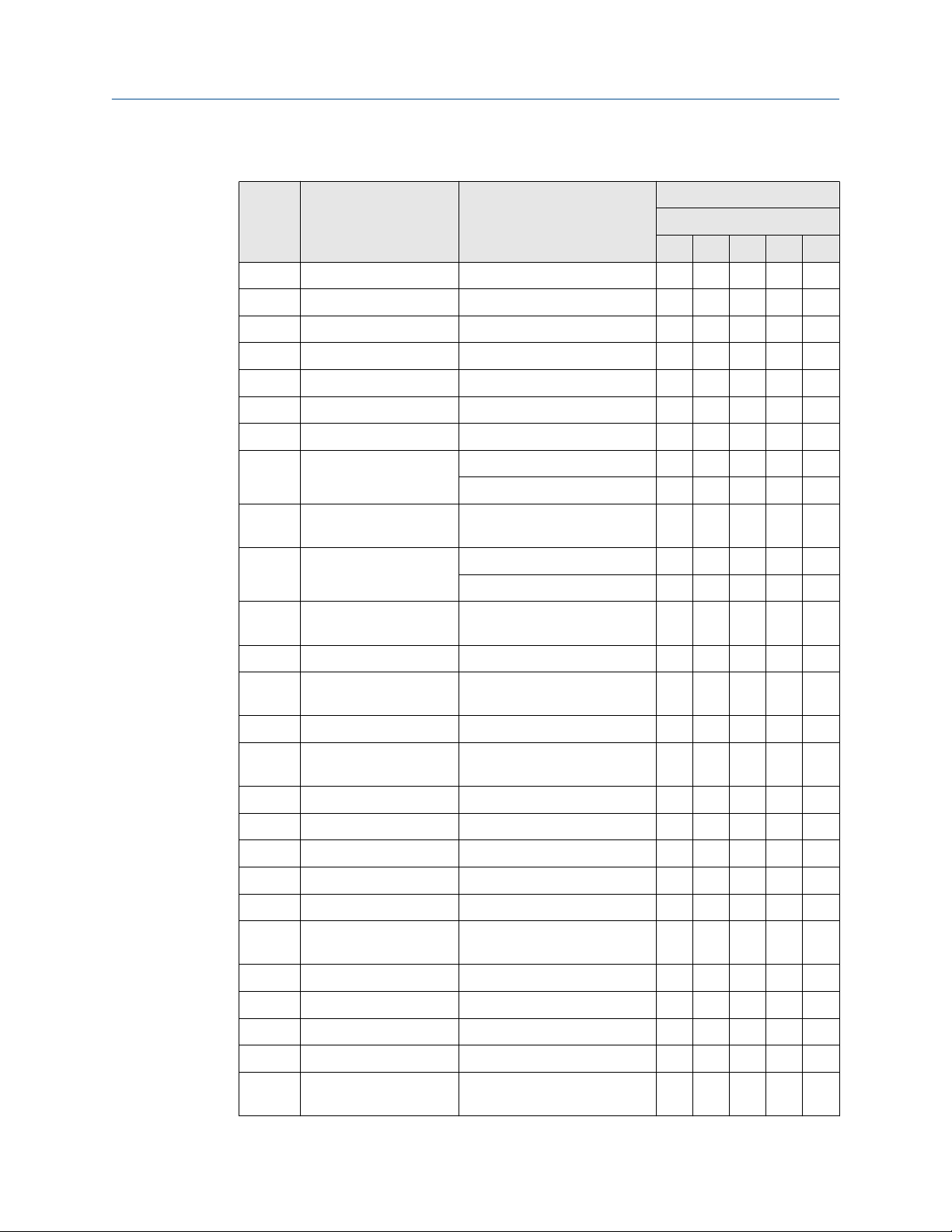

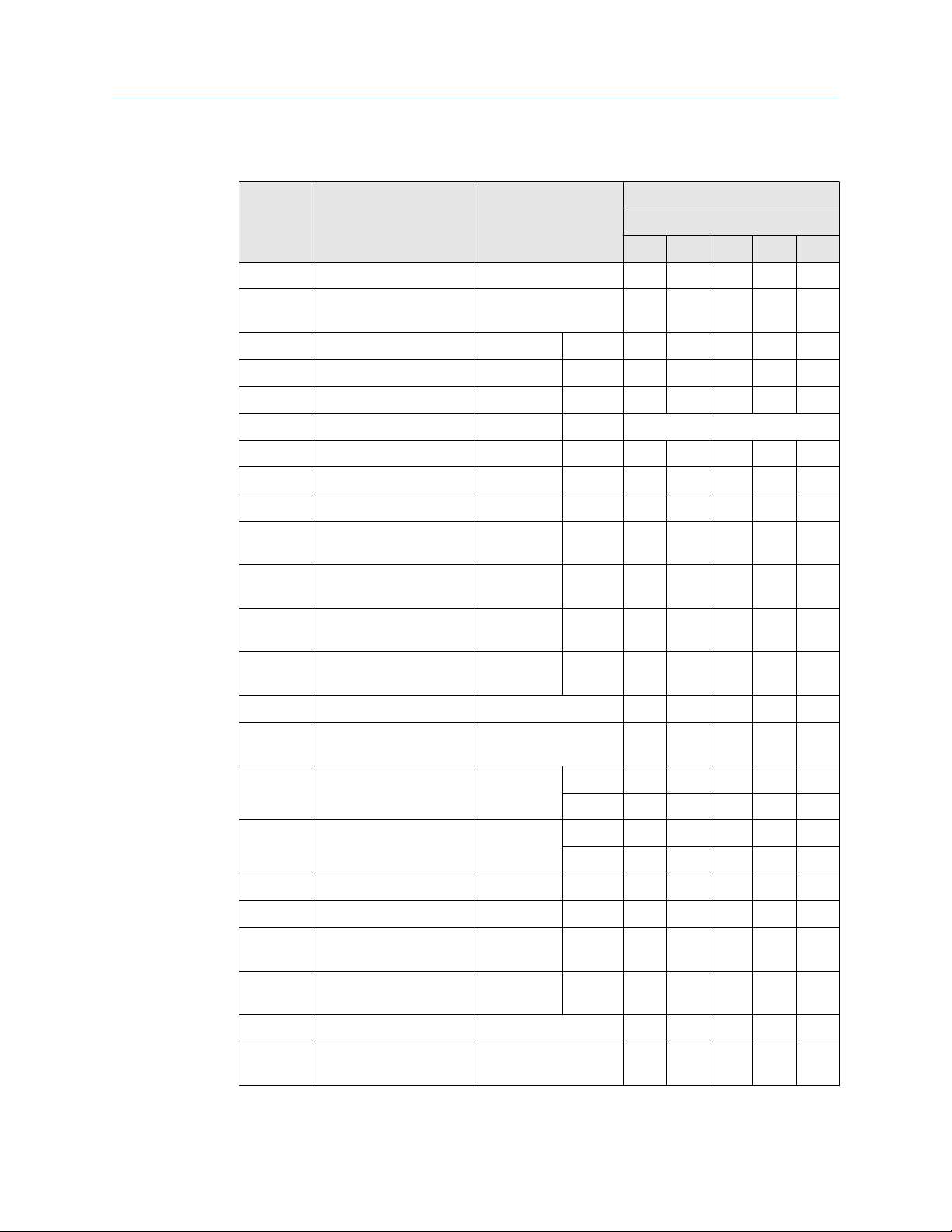

Table 1-4: Daniel Senior Orifice Fitting sizes 2"- 8" 150-600

Item

number

1 * Equalizer valve (complete):

1G*

1H* Packing nut CS (ZP) 1 1 1 1 1

1D*

1K*

1J*

2* Operating wrench Ductile iron 1 1 1 1 1

3

4

5

5A-LH* Indicator plate left-hand Cast aluminum 1 1 1 1 1

5A-RH* Indicator plate right-

5B* Indicator pointer Aluminum 2 2 2 2 2

5C Drive screws 18-8 SS 4 4 4 4 4

6

7

8A*

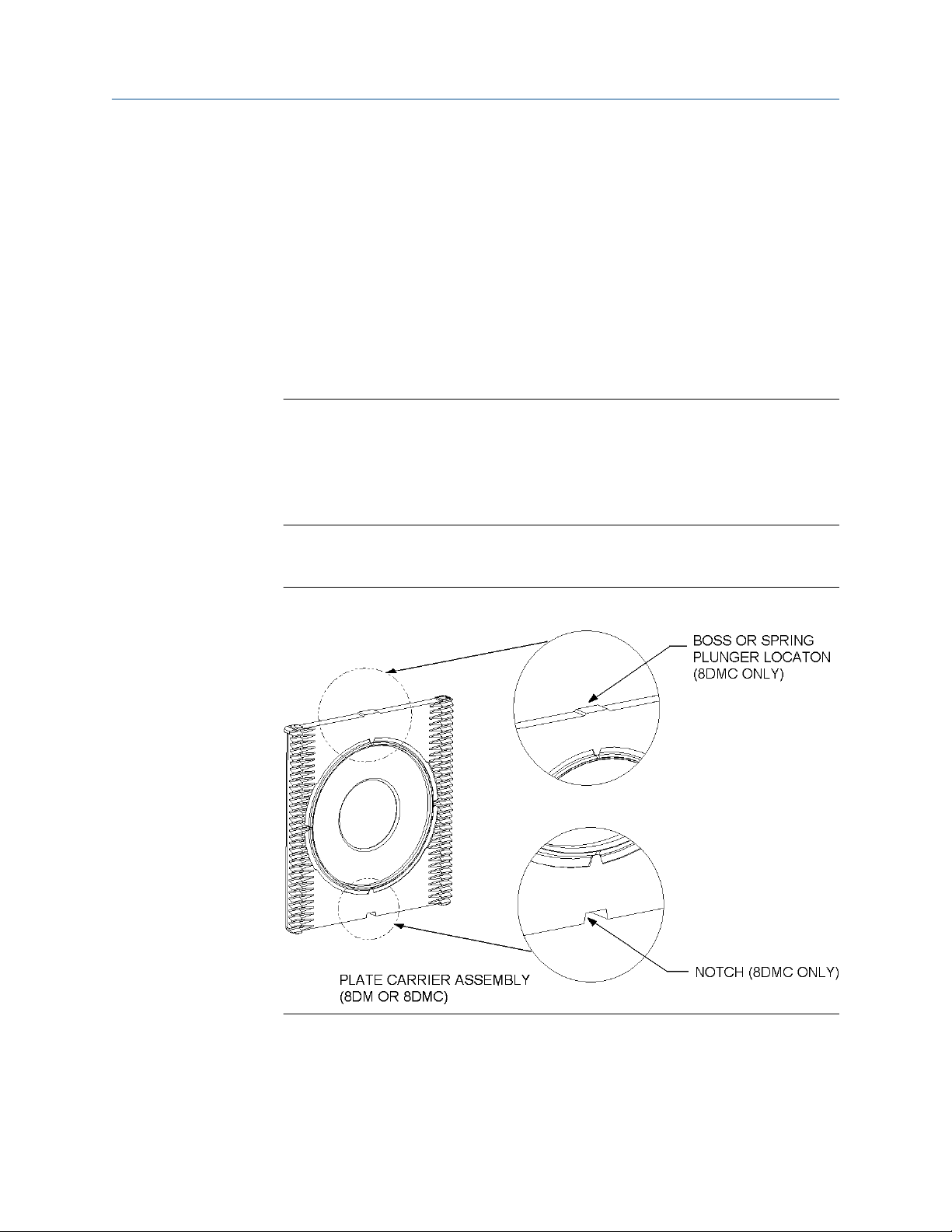

8DMC

8E-DSC

8TSC

8 MSC

8 SNC

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Stem 316 SS 1 1 1 1 1

Ball Tungsten-Carbide 1 1 1 1 1

Packing washer 17-4PH SS 1 1 1 1 1

Packing ring TFE/PTFE 2 2 2 2 2

Slide valve trip Type 410 1 1 1 1 1

Body Cast carbon steel 1 1 1 1 1

Slide valve shaft 316 SS 1 1 1 1 1

Cast aluminum 1 1 1 1 1

hand

Lower plate carrier shaft 316 SS 1 1 1 1 1

Upper plate carrier shaft 316 SS 1 1 1 1 1

Plate carrier spring pin 18-8 SS 1 1 1 1 1

Plate carrier 316 SS 1 1 1 1 1

Orifice plate sealing unit

150-600

Optional Orifice plate

sealing unit 150-600

Optional Snap Seal Ring

units for special services

Optional Snap Seal Ring

units for special services

NBR (Removable - orifice plate

not included)

TFE/PTFE (Removable - orifice

plate not included)

CS (ZP) (Removable - orifice

plate not included)

CS (ZP) or SS w/O-rings

(Removable - orifice plate not

included)

1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

9 Sealing bar CS (ZP) 1 1 1 1 1

9A

10B Bleeder Valve (complete)

10C*

22 Senior Orifice Fitting

Sealing bar gasket Composite 1 1 1 1 1

Body CS (ZP) 1 1 1 1 1

Page 23

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-4: Daniel Senior Orifice Fitting sizes 2"- 8" 150-600 (continued)

Item

number

10D*

10E*

10G* Set screw Alloy steel 1 1 1 1 1

11* Clamping bar screw Alloy steel (ZP) 4(1) 4(1) 5(1) 6(1) 7(1)

12

13

14

15*

16*

17

17A*

18

18A*

18B*

22A*

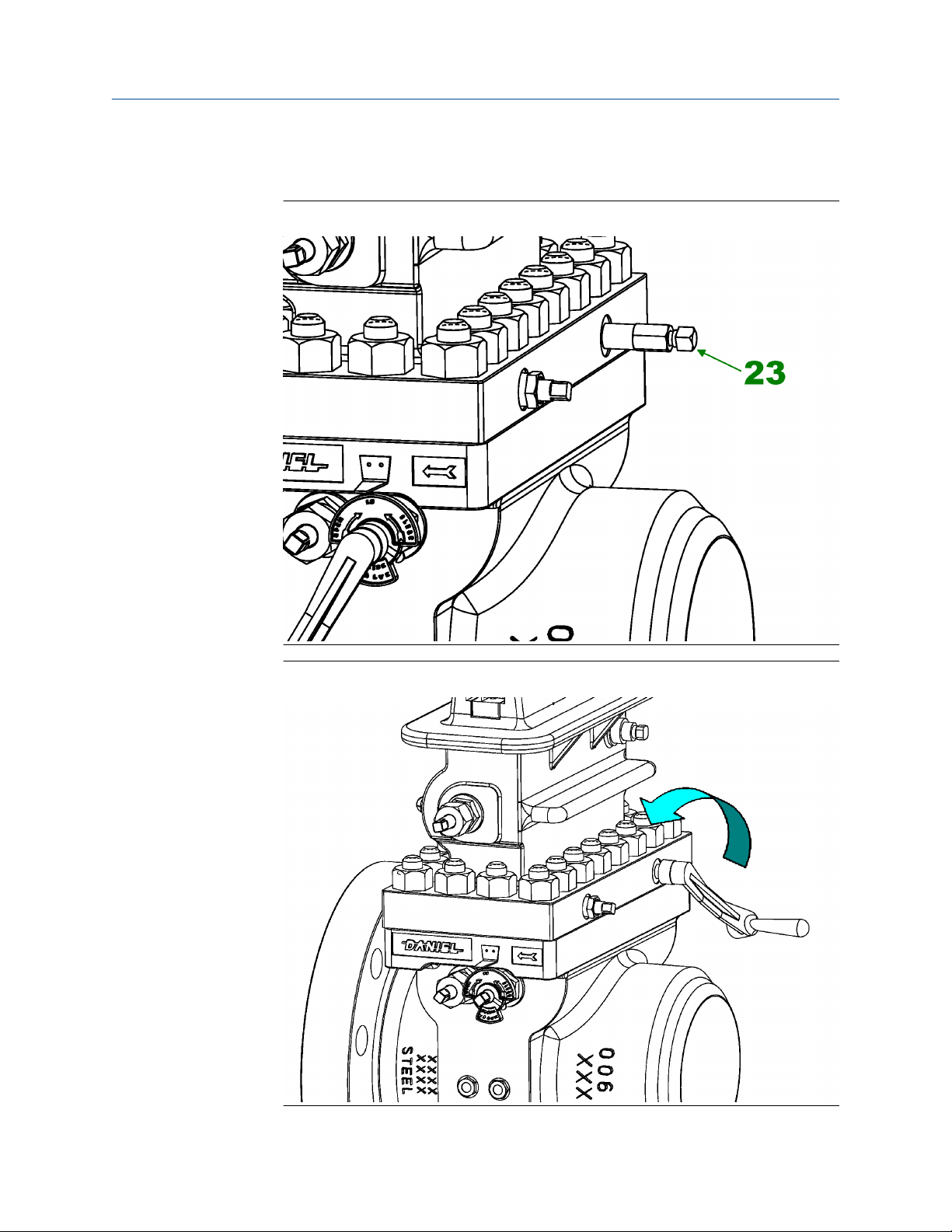

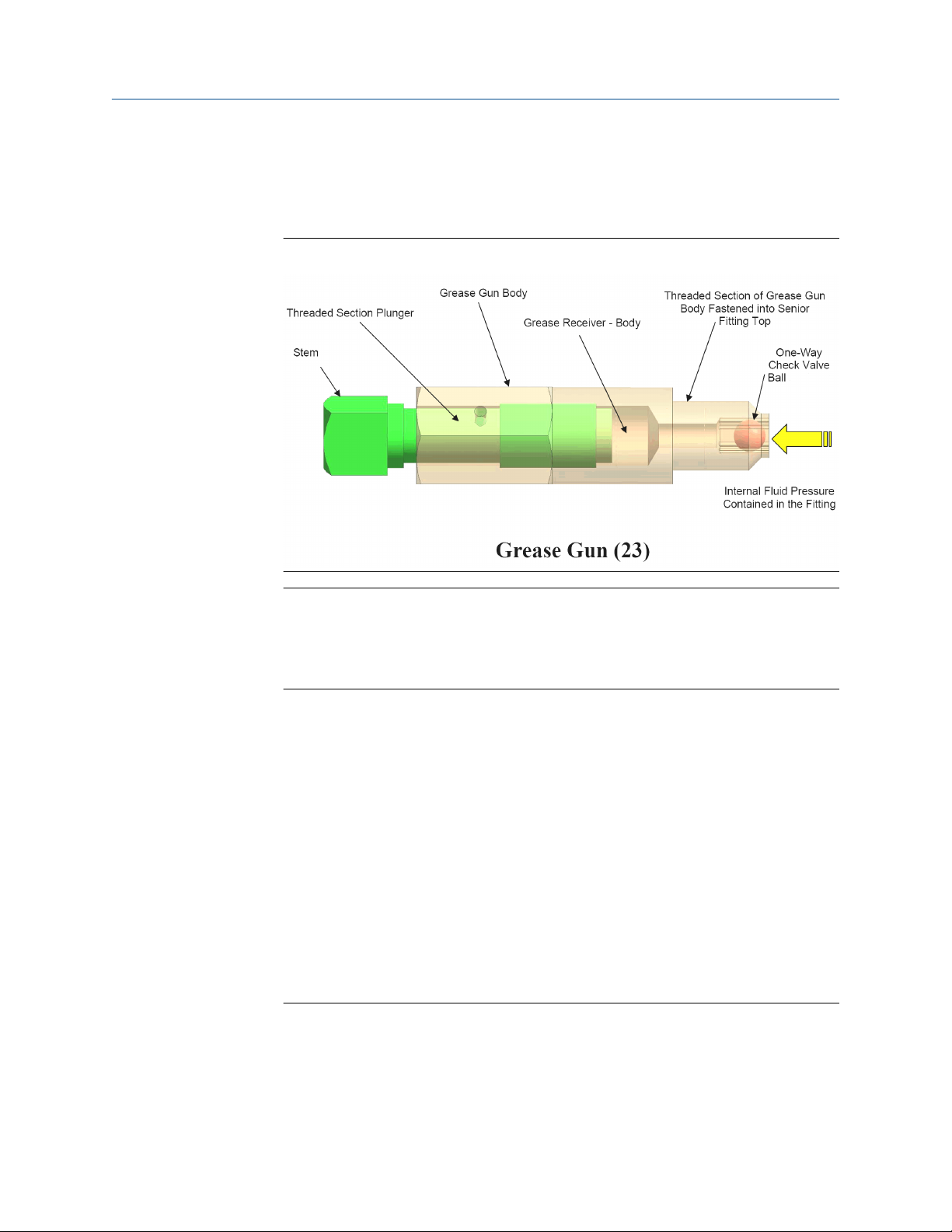

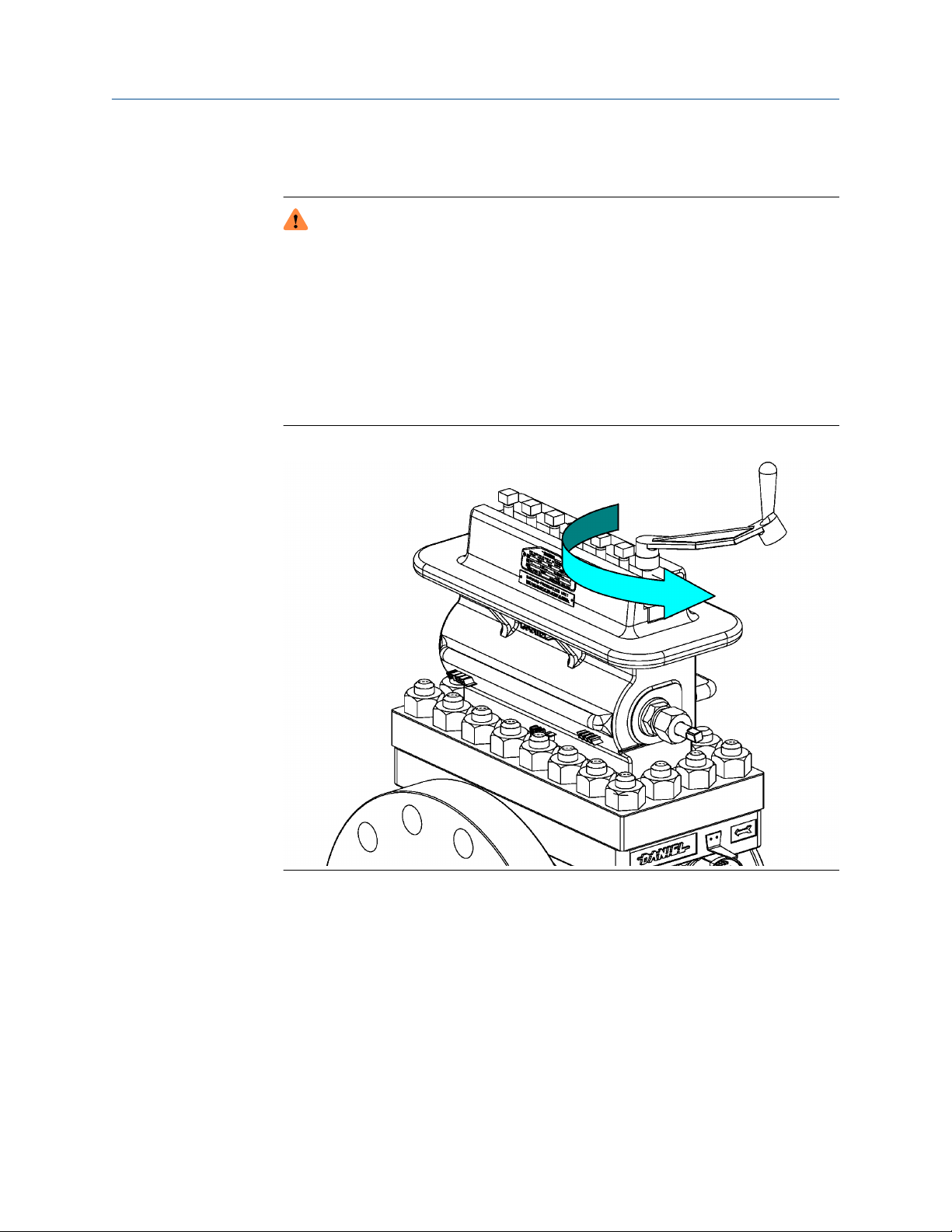

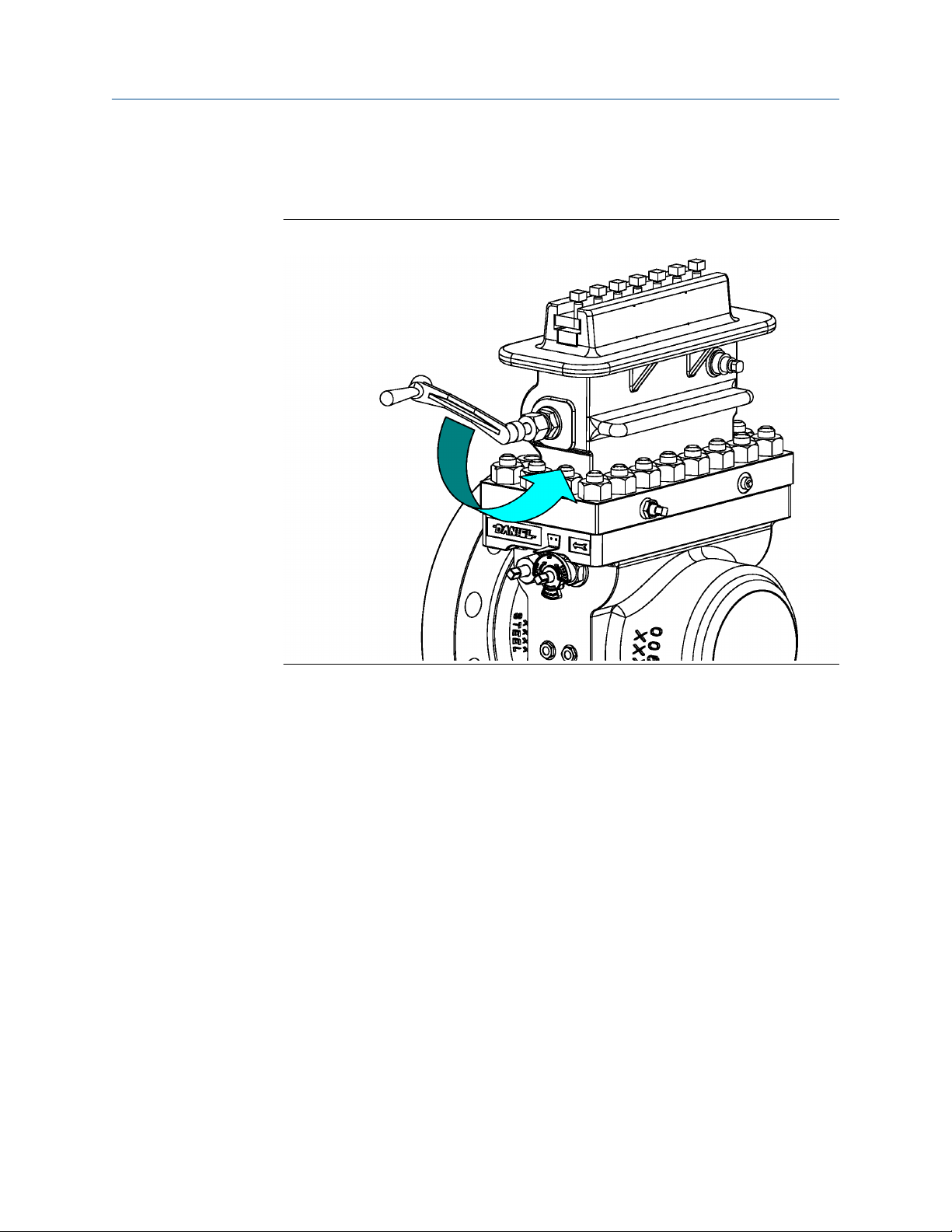

23*

24*

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Needle 316 SS 1 1 1 1 1

O-ring Synthetic rubber 1 1 1 1 1

Clamping bar CS (ZP) 1 1 1 1 1

Orifice plate Type 304 SS or 316 SS 1 1 1 1 1

Top Cast carbon steel 1 1 1 1 1

Slide valve springs Inconel X-750 4 4 4 6 6

Slide valve carrier guide 316 SS 2 2 2 2 2

Slide valve carrier Cast carbon steel 1 1 1 1 -

Cast Alloy Iron - - - - 1

Slide valve carrier stop

pin

Slide valve seat 13% chrome SS 1 1 1 1 1

Slide valve seat/top

gasket

Slide valve seat screw Alloy steel phosphate treat 8 10 11 14 16

Bearing plug and

stuffing box gasket

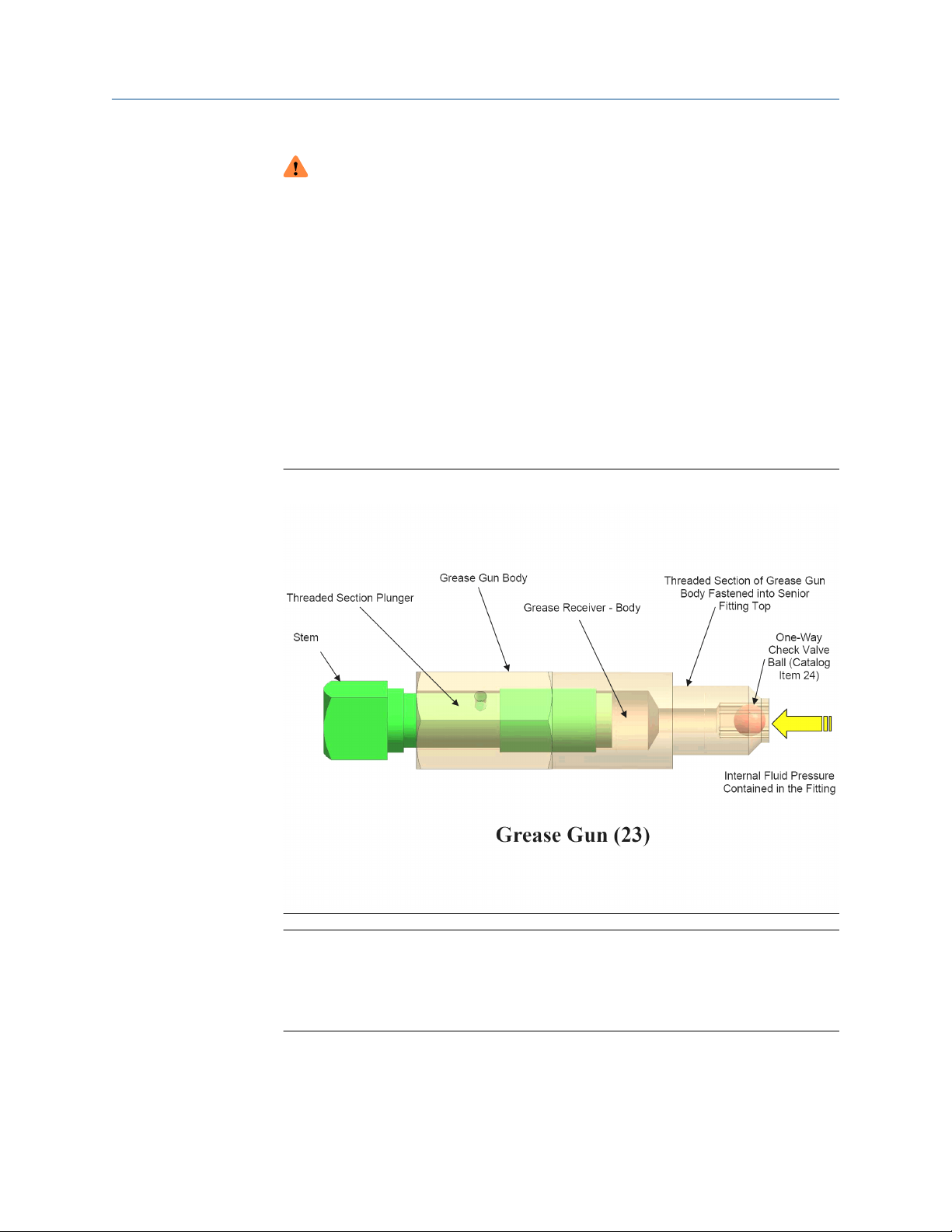

Grease gun (complete) CS (ZP) 1 1 1 1 1

Grease seal double ball

check valve

Carbon steel (ZP) 2 2 2 2 2

Composite 1 1 1 1 1

316 SS 6 6 6 6 6

316 SS with Tungsten-Carbide 1 1 1 1 1

25* Packing nut CS (ZP) 6 6 6 6 6

25A* Packing rings TFE/PTFE 12 12 12 12 12

25B* Centering ring TFE/PTFE 12 12 12 12 12

26* Stuffing box gland 316 SS 6 6 6 6 6

30(1)*

31(1)*

32 Hex nut CS 14 15 15 18 19

33 Stud Alloy steel 14 15 15 18 19

36*

37*

Owner and operator manual 23

Drain valve plug CS (ZP) 1 1 1 1 1

½ N.P.T. plug for

pressure meter tap

Stuffing box (upper) CS (ZP) 2 2 2 2 2

Stuffing box (lower) CS (ZP) 4 4 4 4 4

CS (chemically treated) 2 2 2 2 2

Page 24

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-4: Daniel Senior Orifice Fitting sizes 2"- 8" 150-600 (continued)

Item

number

40

41

42*

43*

44*

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Stuffing box sleeve

(upper)

Stuffing box sleeve

(lower)

Plate carrier stop pin CS (ZP) 1 1 1 1 1

Plate carrier stop pin

lock screw

Plate carrier stop pin

access plug

Slide valve lubricant

(boxes)

CS (ZP) 2 2 2 2 2

CS (ZP) 4 4 4 4 4

CS (ZP) 1 1 1 1 1

CS (ZP) 1 1 1 1 1

Castor oil based solid sticks 24 sticks per box

3 3 3 3 3

Notes for Table 1-4:

(1) All Daniel Senior Orifice Fittings are supplied with pipe plugs on the drains only. If pipe

plugs for the measurement tap holes are required, please contact the factory directly.

• Locations of Equalizer Valve (1), Bleeder Valve (10B), and Grease Gun (23) may differ

from diagrams shown in this manual.

• The clamping bar screw quantity and size listed here reflect ones used on our most

common fitting for that size and pressure rating. The actual number and size of

clamping bar screws may vary for that size and pressure rating due to a fitting's

material of construction and configuration. When ordering replacements, or

developing a maintenance program, always confirm the count and size of clamping bar

screws of your fitting.

• Slide Valve Lubricant: 0.38 in (9.53 mm) diameter by 1.5 in (38.1 mm) long is

equivalent to some lubricant manufacturers' "B" size stick. The quantity of lubricant a

fitting described in this manual will require is dependent upon the state and condition

of the fitting. Emerson recommends having one box of lubricant sticks (24 sticks per

box) on-hand when performing maintenance and plate inspection/change procedures.

(*) Indicates interchangeable parts for all line sizes of specified pressure rating(s).

(1) Indicates 1/2" - 13. See Table 1 for clamping bar screw recommended torque values.

General notes for Table 1-4:

• The materials listed in Table 1-4 indicate standard "NACE" trim.

• Materials of some items listed in Table 1-4 are changed for the "AASG" trimmed fittings.

• Several available trim options are shown in Table 1-3.

• Other trim options available upon request. Consult factory.

• Bolded item numbers are for parts which are fluid media PIC (parts in contact).

24 Senior Orifice Fitting

Page 25

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

When ordering parts, please specify

• Catalog number

• Size

• Serial number

• Item number

• Material

• Quantity of each item required

(1)

(1) Catalog number, size and serial number can be found on the fitting nameplate. Part item numbers and part materials for

"NACE" trim only are found in Daniel Senior Orifice Fitting sizes 2"- 8" 150-900.

Owner and operator manual 25

Page 26

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

All Parts on Daniel Senior Orifice Fittings may be replaced or repaired without removing

the Daniel Senior Orifice Fitting body from the line.

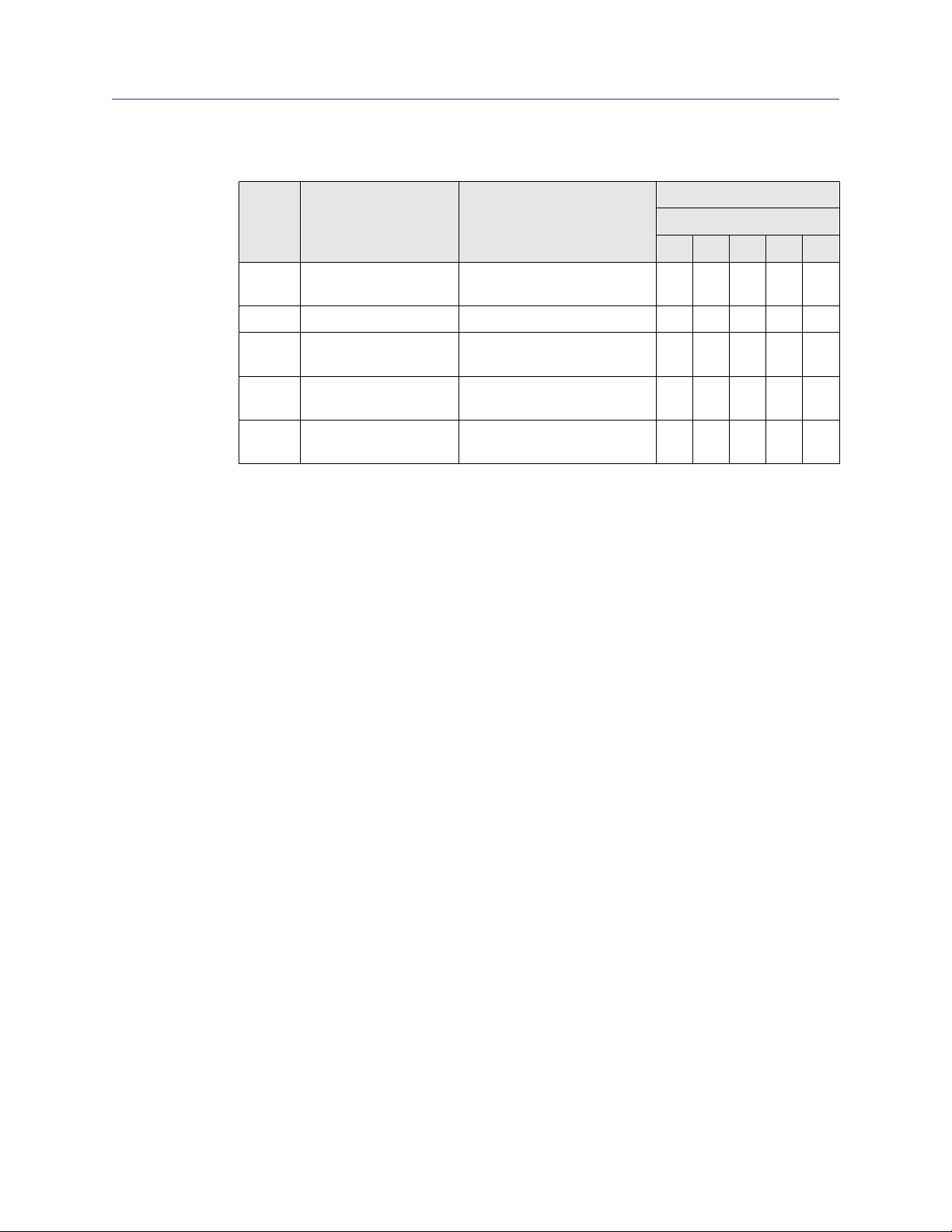

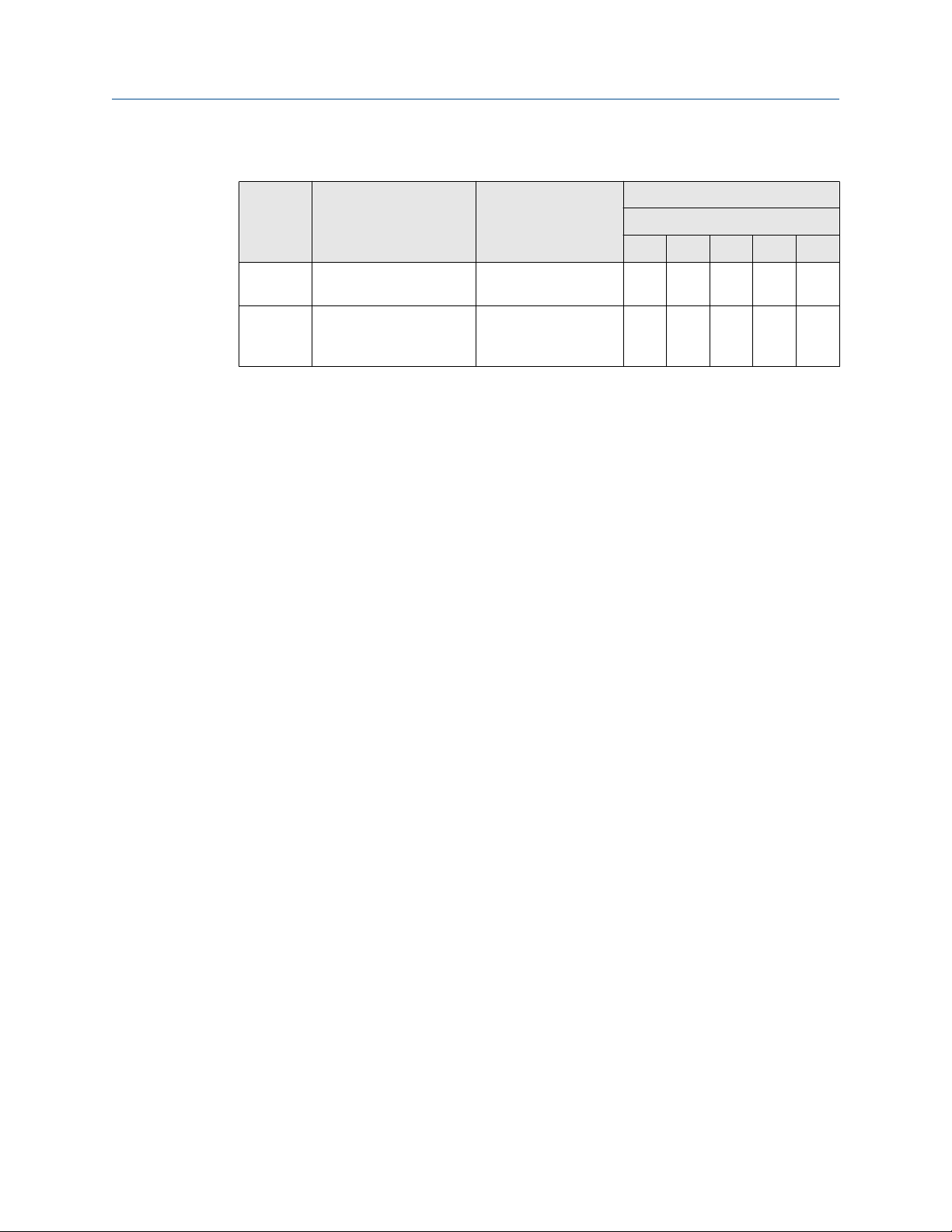

Table 1-5: Daniel Senior Orifice Fitting sizes 2"-8" 900

Item

number

1 * Equalizer valve (complete):

1G*

1H* Packing nut CS (ZP) 1 1 1 1 1

1D*

1K*

1J*

2* Operating wrench Ductile iron 1 1 1 1 1

3

4

5

5A-LH* Indicator plate left-hand Cast aluminum 1 1 1 1 1

5A-RH* Indicator plate right-

5B* Indicator pointer Aluminum 2 2 2 2 2

5C Drive screws 18-8 SS 4 4 4 4 4

6

7

8A*

8DMC

8TSC

8 MSC

8 SNC

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Stem 316 SS 1 1 1 1 1

Ball 18-8 SS 1 1 1 1 1

Packing washer 17-4PH SS 1 1 1 1 1

Packing ring TFE/PTFE 2 2 2 2 2

Slide valve trip Type 410 SS 1 1 1 1 1

Body Cast carbon steel 1 1 1 1 1

Slide valve shaft 316 SS 1 1 1 1 1

Cast aluminum 1 1 1 1 1

hand

Lower plate carrier shaft 316 SS 1 1 1 1 1

Upper plate carrier shaft 316 SS 1 1 1 1 1

Plate carrier spring pin 18-8 SS 1 1 1 1 1

Plate carrier 316 SS 1 1 1 1 1

Orifice plate sealing unit

alternate seals available

see catalog - #500

Optional Snap Seal Ring

units for special services

Optional Snap Seal Ring

units for special services

PTFE (Removable - orifice plate

not included)

CS (ZP) or 316 SS (plate not

included)

CS (ZP) or 316 SS w/O-rings

(plate not included)

1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

9 Sealing bar CS (ZP) 1 1 1 1 1

9A

10B Bleeder Valve (Complete)

10C*

10D*

10E*

26 Senior Orifice Fitting

Sealing bar gasket Composite 1 1 1 1 1

Body CS (ZP) 1 1 1 1 1

Needle 316 SS 1 1 1 1 1

O-ring Synthetic rubber 1 1 1 1 1

Page 27

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-5: Daniel Senior Orifice Fitting sizes 2"-8" 900 (continued)

Item

number

10G* Set screw Alloy steel 1 1 1 1 1

11* Clamping bar screw Alloy steel (ZP) 4(1) 4(1) 5(1) 6(1) 7(2)

12 Clamping bar CS (ZP) 1 1 1 1 1

13

14

15*

16*

17

17A*

18

18A*

18B*

22A*

23*

24*

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Orifice plate Type 304 SS or 316 SS 1 1 1 1 1

Top Cast carbon steel 1 1 1 1 1

Slide valve springs 316 SS 4 4 4 6 6

Slide valve carrier guide 316 SS 2 2 2 2 2

Slide valve carrier Cast carbon steel 1 1 1 1 -

Cast Alloy Iron - - - - 1

Slide valve carrier stop

pin

Slide valve seat Cast alloy iron 1 1 1 1 -

Slide valve seat/top

gasket

Slide valve seat screw Alloy steel phosphate treat 8 10 11 14 16

Bearing plug and

stuffing box gasket

Grease gun (complete) CS (ZP) 1 1 1 1 1

Grease seal double ball

check valve

Carbon steel (ZP) 2 2 2 2 2

Cast iron - - - - 1

Composite 1 1 1 1 1

316 SS 6 6 6 6 6

316 SS with chrome-steel balls 1 1 1 1 1

25* Packing nut CS (ZP) 6 6 6 6 6

25A*

25B*

26* Stuffing box gland 316 SS 6 6 6 6 6

30(1)*

31(1)*

32 Hex nut CS 14 15 15 18 20

33 Stud Alloy steel 14 15 15 18 20

36*

37*

40

Owner and operator manual 27

Packing rings TFE/PTFE 12 12 12 12 12

Centering ring TFE/PTFE 12 12 12 12 12

Drain valve plug CS (ZP) 1 1 1 1 1

½ N.P.T. plug for

pressure meter tap

Stuffing box (upper) CS (ZP) 2 2 2 2 2

Stuffing box (lower) CS (ZP) 4 4 4 4 4

Stuffing box sleeve

(upper)

CS (chemically treated) 2 2 2 2 2

CS (ZP) 2 2 2 2 2

Page 28

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-5: Daniel Senior Orifice Fitting sizes 2"-8" 900 (continued)

Item

number

41

42*

43*

44*

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Stuffing box sleeve

(lower)

Plate carrier stop pin CS (ZP) 1 1 1 1 1

Plate carrier stop pin

lock screw

Plate carrier stop pin

access plug

Slide valve lubricant

(boxes)

CS (ZP) 4 4 4 4 4

CS (ZP) 1 1 1 1 1

CS (ZP) 1 1 1 1 1

Castor oil based solid sticks 24 sticks per box

3 3 3 3 3

Notes for Table 1-5:

(1) All Daniel Senior Orifice Fittings are supplied with pipe plugs on the drains only. If pipe

plugs for the measurement tap holes are required, please contact the factory directly.

• Locations of Equalizer Valve (1), Bleeder Valve (10B), and Grease Gun (23) may differ

from diagrams shown in this manual.

• The clamping bar screw quantity and size listed here reflect ones used on our most

common fitting for that size and pressure rating. The actual number and size of

clamping bar screws may vary for that size and pressure rating due to a fitting's

material of construction and configuration. When ordering replacements, or

developing a maintenance program, always confirm the count and size of clamping bar

screws of your fitting.

• Slide Valve Lubricant: 0.38 in (9.53 mm) diameter by 1.5 in (38.1 mm) long is

equivalent to some lubricant manufacturers' "B" size stick. The quantity of lubricant a

fitting described in this manual will require is dependent upon the state and condition

of the fitting. Emerson recommends having one box of lubricant sticks (24 sticks per

box) on-hand when performing maintenance and plate inspection/change procedures.

(*) Indicates interchangeable parts for all line sizes of specified pressure rating(s).

(1) Indicates 1/2" - 13. See Clamping bar screw (LINK) for clamping bar screw

recommended torque values.

(2) Indicates 5/8" - 11. See Clamping bar screw (LINK) for clamping bar screw

recommended torque values.

General notes for Table 1-5:

• The materials listed in Table 1-5 indicate standard "A" trim.

• Materials of some items listed in Table 1-5 are changed for "NACE" and "AASG" trimmed

fittings.

• Several available trim options are shown in Table 1-3.

• Other trim options available upon request. Consult factory.

28 Senior Orifice Fitting

Page 29

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

• Bolded item numbers are for parts which are fluid media PIC (parts in contact).

When ordering parts, please specify

• Catalog number

• Size

• Serial number

• Item number

• Material

• Quantity of each item required

(2)

(2) Catalog number, size and serial number can be found on the fitting nameplate. Part item numbers and part materials for

"A" trim only are found in Table 1-5.

Owner and operator manual 29

Page 30

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

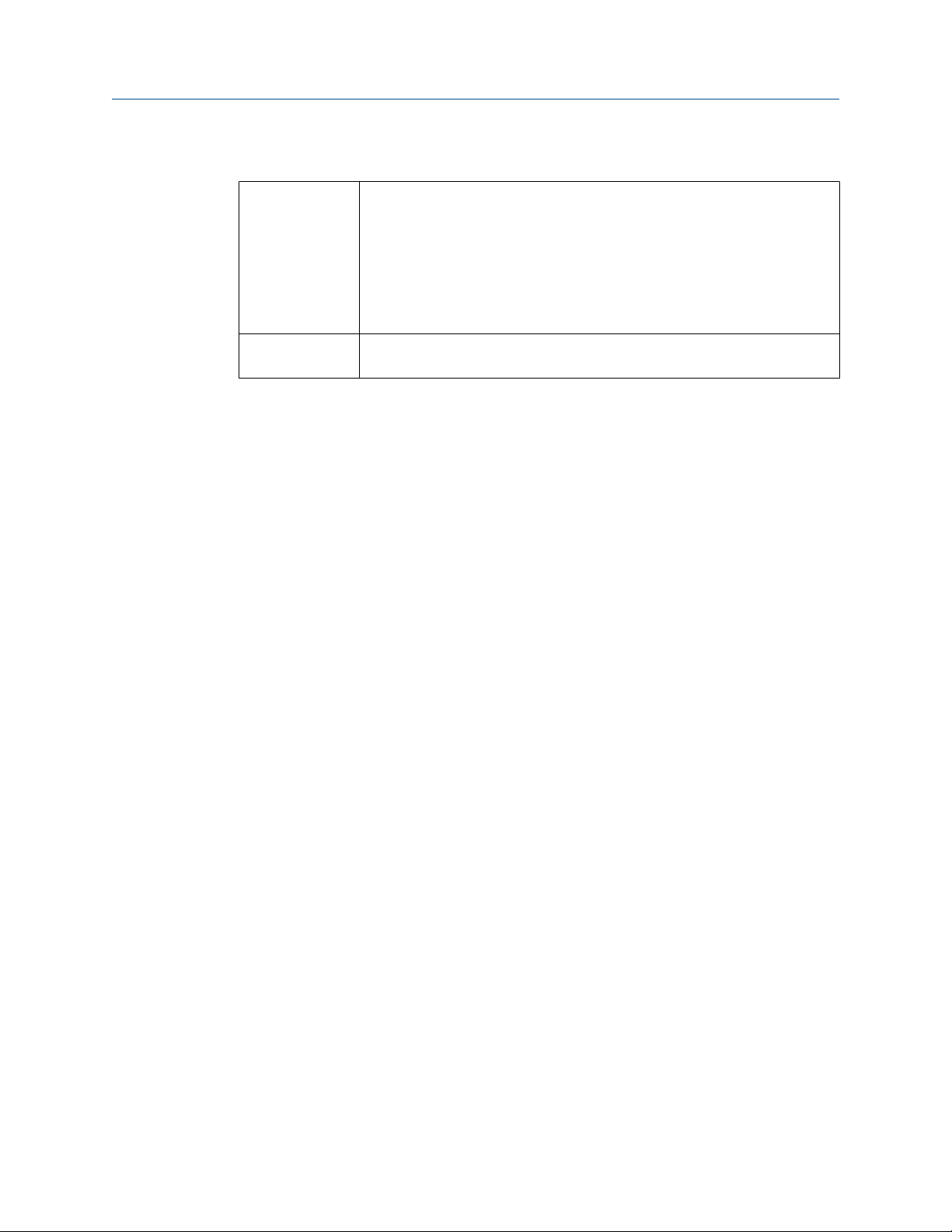

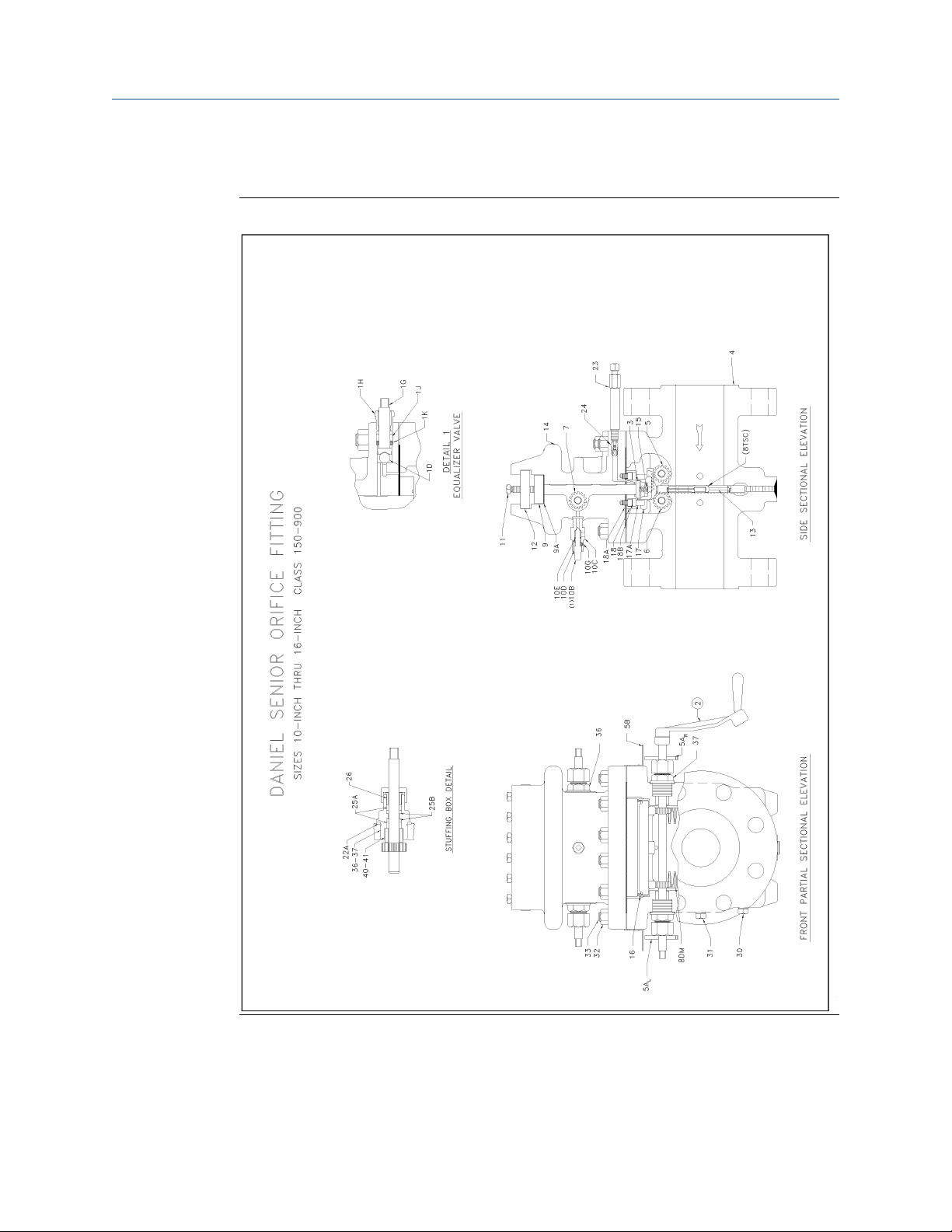

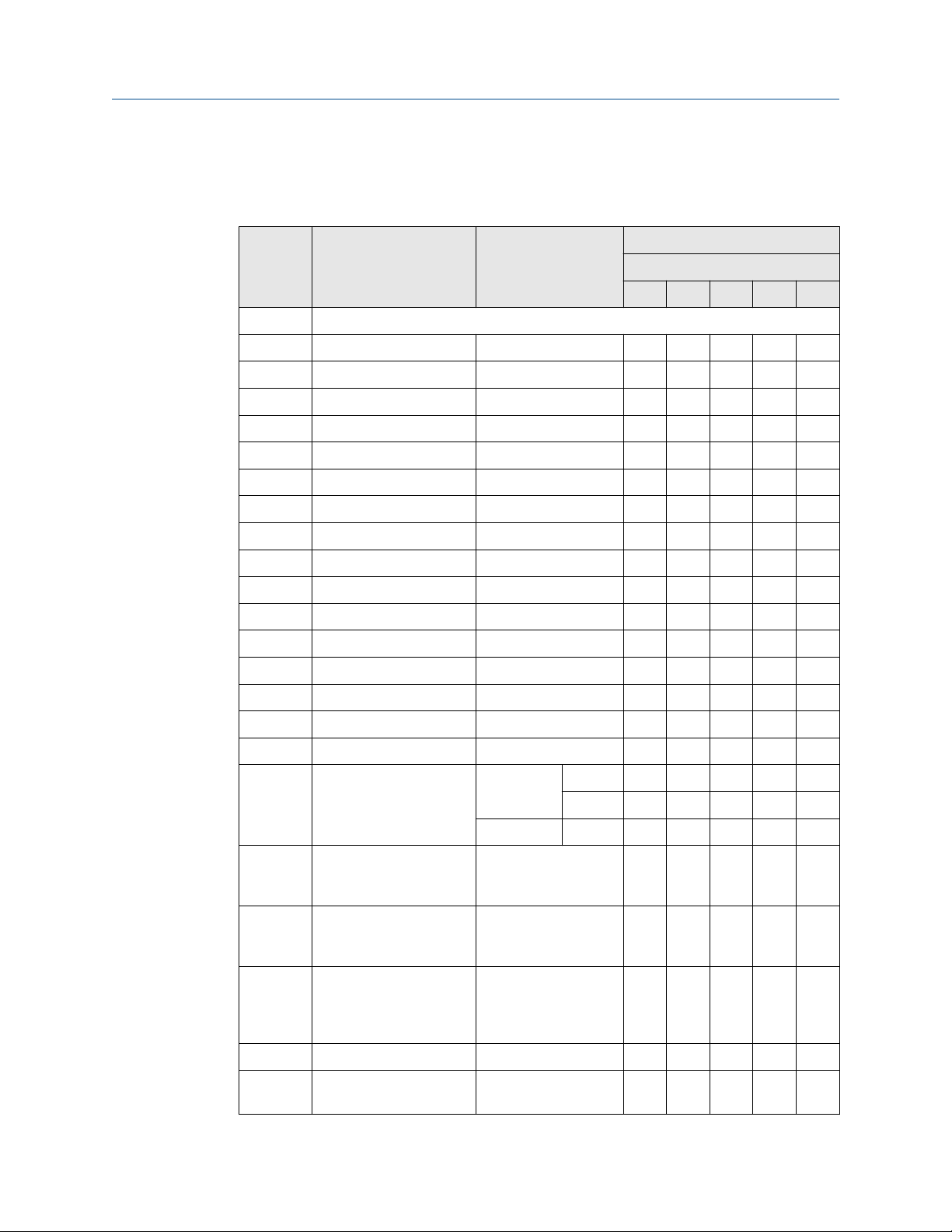

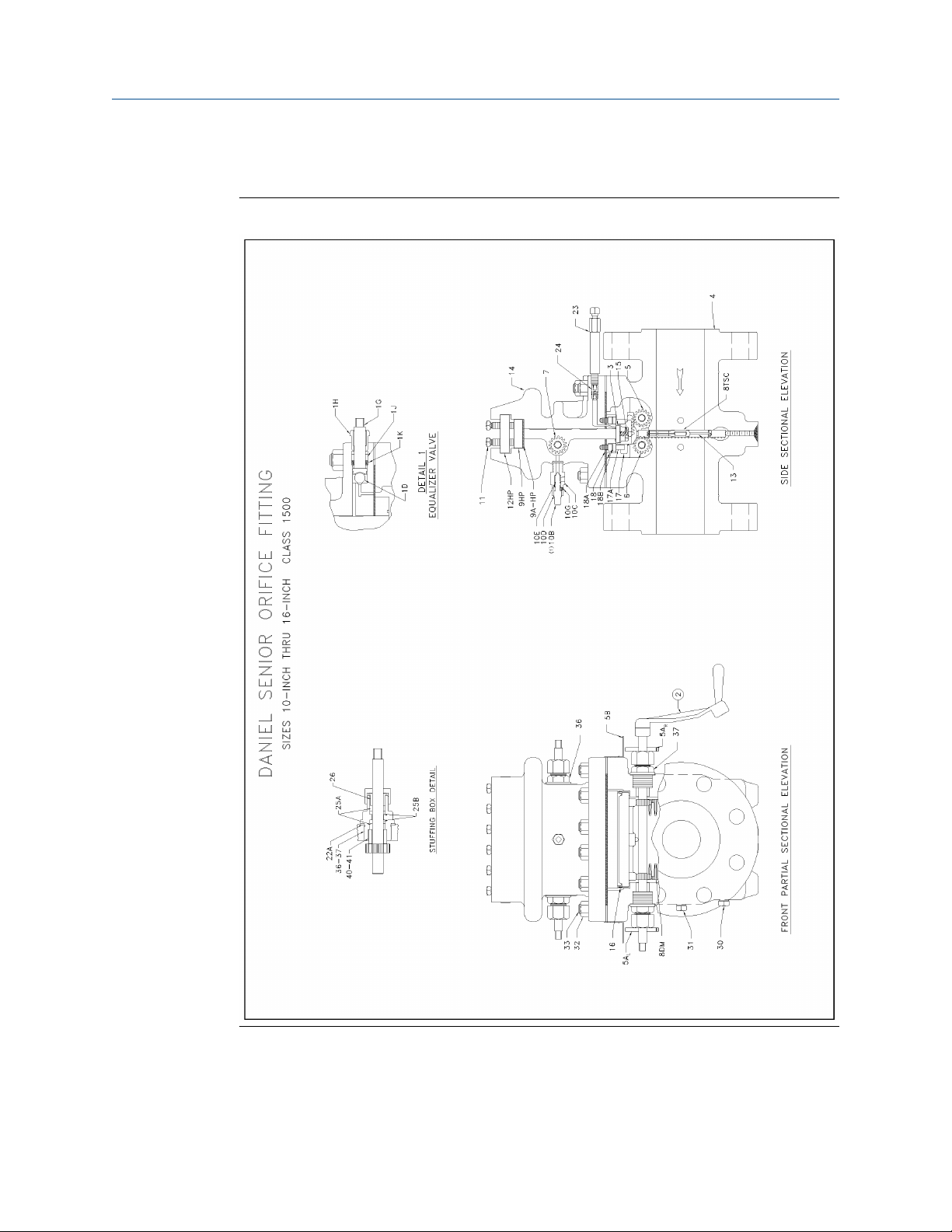

1.5.3 Daniel Senior Orifice Fitting sizes 10"-16" 150-900

Figure 1-3: Daniel Senior Orifice Fitting drawing sizes 10"-16" 150-900

30 Senior Orifice Fitting

Page 31

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

All Parts on Daniel Senior Orifice Fittings may be replaced or repaired without removing

the Daniel Senior Orifice Fitting body from the line.

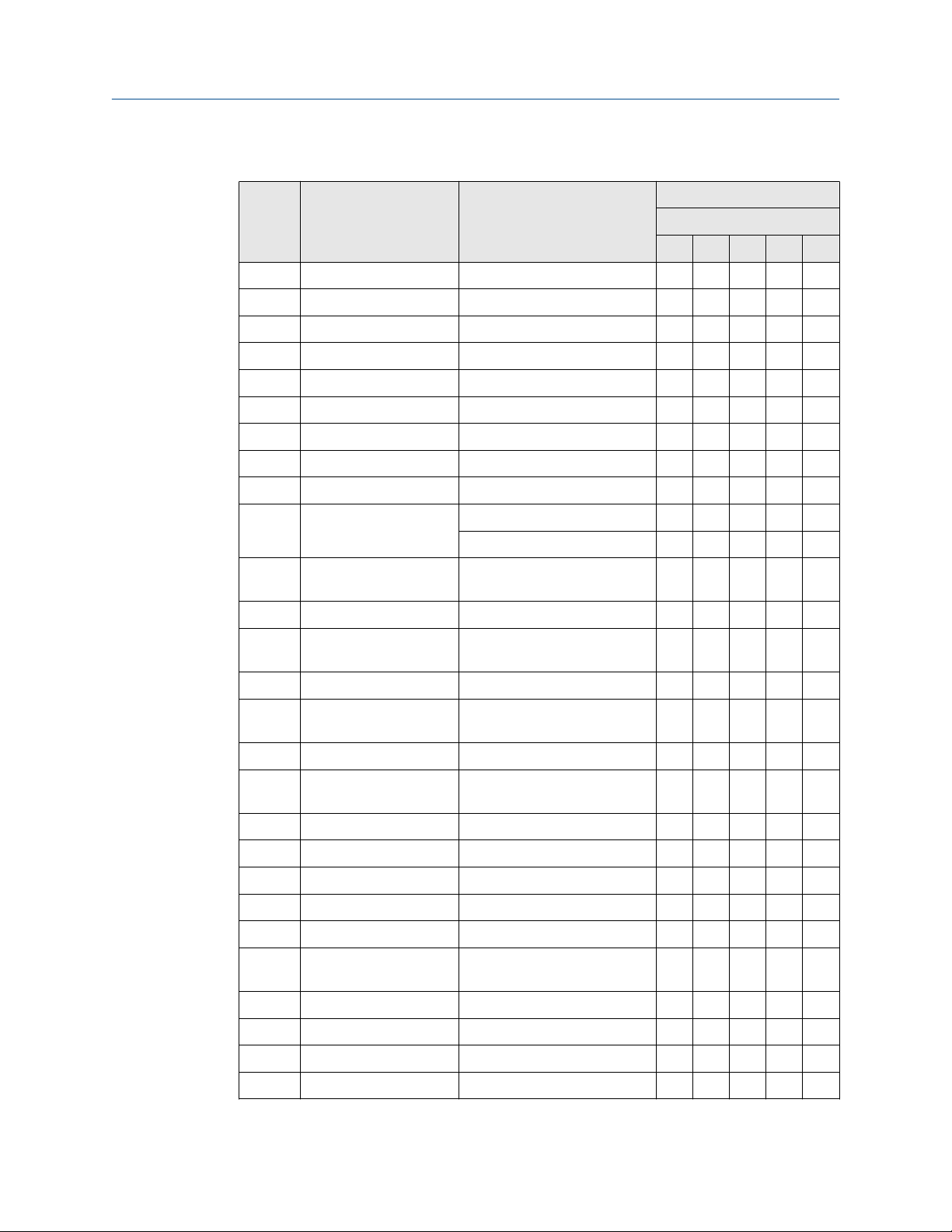

Table 1-6: Daniel Senior Orifice Fitting sizes 10"-16" 150-900

Item

Number

1* Equalizer valve (complete):

1G*

1H* Packing nut CS (ZP) 1 1 1 1

1D*

1K*

1J*

2* Operating wrench Ductile iron 1 1 1 2

3

4

5

5A-LH* Indicator plate left-

5A-RH Indicator plate right-

5B* Indicator pointer Aluminum 2 2 2 2

Description Material Quantity required

Size

10" 12" 14" 16"

Stem 316 SS 1 1 1 1

Ball 18-8 SS 1 1 1 1

Packing washer 17-4PH SS 1 1 1 1

Packing ring TFE/PTFE 2 2 2 2

Slide valve trip Type 410 SS 1 1 1 1

Body Cast carbon steel 1 1 1 1

Slide valve shaft 316 SS 1 1 1 1

Cast aluminum 1 1 1 1

hand

Cast aluminum 1 1 1 1

hand

5C Drive screws 18-8 SS 4 4 4 4

6

7

8DM

8E-DS

8E-DVS

8TS

8MS

8SN

Lower plate carrier

shaft

Upper plate carrier

shaft

Plate carrier 316 SS 1 1 1 1

Orifice plate sealing

unit 150-600

Orifice plate sealing

unit 150-600

Orifice plate sealing

unit 150-600, 900

optional alternate for

150-600

Optional sealing units

for special services

Optional snap seal

ring units for special

services

316 SS 1 1 1 1

316 SS 1 1 1 1

NBR (Removable - orifice plate

not included)

FKM (Bonded to both faces of

the orifice plate)

TFE/PTFE (removable) 1 1 1 1

CS (ZP) or 316 SS (Removable

- orifice plate not included)

CS (ZP) or 316 SS w/O-rings

(Removable - orifice plate not

included)

1 - - -

- 1 1 1

1 1 1 1

1 1 1 1

Owner and operator manual 31

Page 32

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-6: Daniel Senior Orifice Fitting sizes 10"-16" 150-900 (continued)

Item

Number

9 Sealing bar CS (ZP) 1 1 1 1

9A

10B* Bleeder valve

10C*

10D*

10E*

10G*

10F

10H

11* Clamping bar screw Alloy steel

12 Clamping bar CS (ZP) 1 1 1 1

13

14

15*

16*

17

17A*

18

Description Material Quantity required

Size

10" 12" 14" 16"

Sealing bar gasket Composite 1 1 1 1

1 1 1 (Complete 10" - 14"

only):

Body CS (ZP) 1 1 1 -

Needle 316 SS 1 1 1 -

O-ring Synthetic rubber 1 1 1 -

Set screw Alloy steel 1 1 1 -

Bleeder valve

(Complete)

Bleeder valve nipple - - - 1

Orifice Plate Type 304 SS or 316 SS 1 1 1 1

Top Cast Carbon steel 1 1 1 1

Slide valve springs 316 SS 6 7 8 10

Slide valve carrier

guide

Slide valve carrier Cast Carbon Steel 1 1 1 1

Slide valve carrier stop

pin

Slide valve seat Cast Alloy

CS (ZP) w/410 SS - - - 1

150-600 8(1) 10(1) 11(1) 12(1)

(ZP)

316 SS 2 2 2 2

CS (ZP) 2 2 2 2

Iron

900 8(2) 10(2) 22(2) 28(2)

150-600 1 1 1 1

TY 410 SS 900 1 - - -

17-4PH SS 900 - 1 1 1

18A

18B*

22A*

23*

32 Senior Orifice Fitting

Slide valve seat/top

gasket

Slide valve seat screw Alloy Steel Phosphate treat 18 20 24 26

Bearing Plug and

stuffing box gasket

Grease gun

(Complete)

Composite 1 1 1 1

316 SS 6 6 6 6

CS (ZP) 1 1 1 2

Page 33

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-6: Daniel Senior Orifice Fitting sizes 10"-16" 150-900 (continued)

Item

Number

24*

25* Packing Nut CS (ZP) 6 6 6 6

25A*

25B*

26* Stuffing box gland 316 SS 6 6 6 6

30(1)*

31(1)*

32 Hex nut CS 22 22 24 28

33 Stud Alloy steel 22 22 24 28

36*

37*

40

41

Description Material Quantity required

Size

10" 12" 14" 16"

Grease seal double

ball check valve

Packing Rings TFE/PTFE 12 12 12 12

Centering ring TFE/PTFE 12 12 12 12

Drain Valve plug CS (ZP) 1 1 1 1

½ NPT Plug for

pressure meter tap

Stuffing box body

(upper)

Stuffing box body

(lower)

Stuffing box sleeve

(upper)

Stuffing box sleeve

(lower)

316 SS with chrome-steel balls 1 1 1 2

CS (chemically treated) 2 2 2 2

CS (ZP) 2 2 2 2

CS (ZP) 4 4 4 4

CS (ZP) 2 2 2 2

CS (ZP) 4 4 4 4

Slide valve lubricant

(boxes)

Castor oil based solid sticks 24 sticks per box

3 3 3 3

Notes for Daniel Senior Orifice Fitting sizes 10"-16" 150-900

(1) All Daniel Senior Orifice Fittings are supplied with pipe plugs on the drains only. If pipe

plugs for the measurement tap holes are required, please contact the factory directly.

• Locations of Equalizer Valve (1), Bleeder Valve (10B), and Grease Gun (23) may differ

from diagrams shown in this manual.

• The clamping bar screw quantity and size listed here reflect ones used on our most

common fitting for that size and pressure rating. The actual number and size of

clamping bar screws may vary for that size and pressure rating due to a fitting's

material of construction and configuration. When ordering replacements, or

developing a maintenance program, always confirm the count and size of clamping bar

screws of your fitting.

• Slide Valve Lubricant: 0.38 in (9.53 mm) diameter by 1.5 in (38.1 mm) long is

equivalent to some lubricant manufacturers' "B" size stick. The quantity of lubricant a

fitting described in this manual will require is dependent upon the state and condition

of the fitting. Emerson recommends having one box of lubricant sticks (24 sticks per

box) on-hand when performing maintenance and plate inspection/change procedures.

Owner and operator manual 33

Page 34

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

(*) Indicates interchangeable parts for all line sizes of specified pressure rating(s).

(1) Indicates 1/2" - 13. See Clamping bar screw (LINK) for clamping bar screw

recommended torque values.

(2) Indicates 5/8" - 11. See Clamping bar screw (LINK) for clamping bar screw

recommended torque values.

General notes Daniel Senior Orifice Fitting sizes 10"-16" 150-900:

• The materials listed in Daniel Senior Orifice Fitting sizes 10"-16" 150-900 indicate

standard "A" trim.

• Materials of some items listed in Daniel Senior Orifice Fitting sizes 10"-16" 150-900 are

changed for "NACE" and "AASG" trimmed fittings.

• Several available trim options are shown in Table 1-3.

• Other trim options available upon request. Consult factory.

• Bolded part numbers are for items which are fluid media PIC (parts in contact).

When ordering parts, please specify

• Catalog number

• Size

• Serial number

• Item number

• Material

• Quantity of each item required

(3)

(3) Catalog number, size and serial number can be found on the fitting nameplate. Part item numbers and part materials for

"A" trim only are found in Daniel Senior Orifice Fitting sizes 10"-16" 150-900.

34 Senior Orifice Fitting

Page 35

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

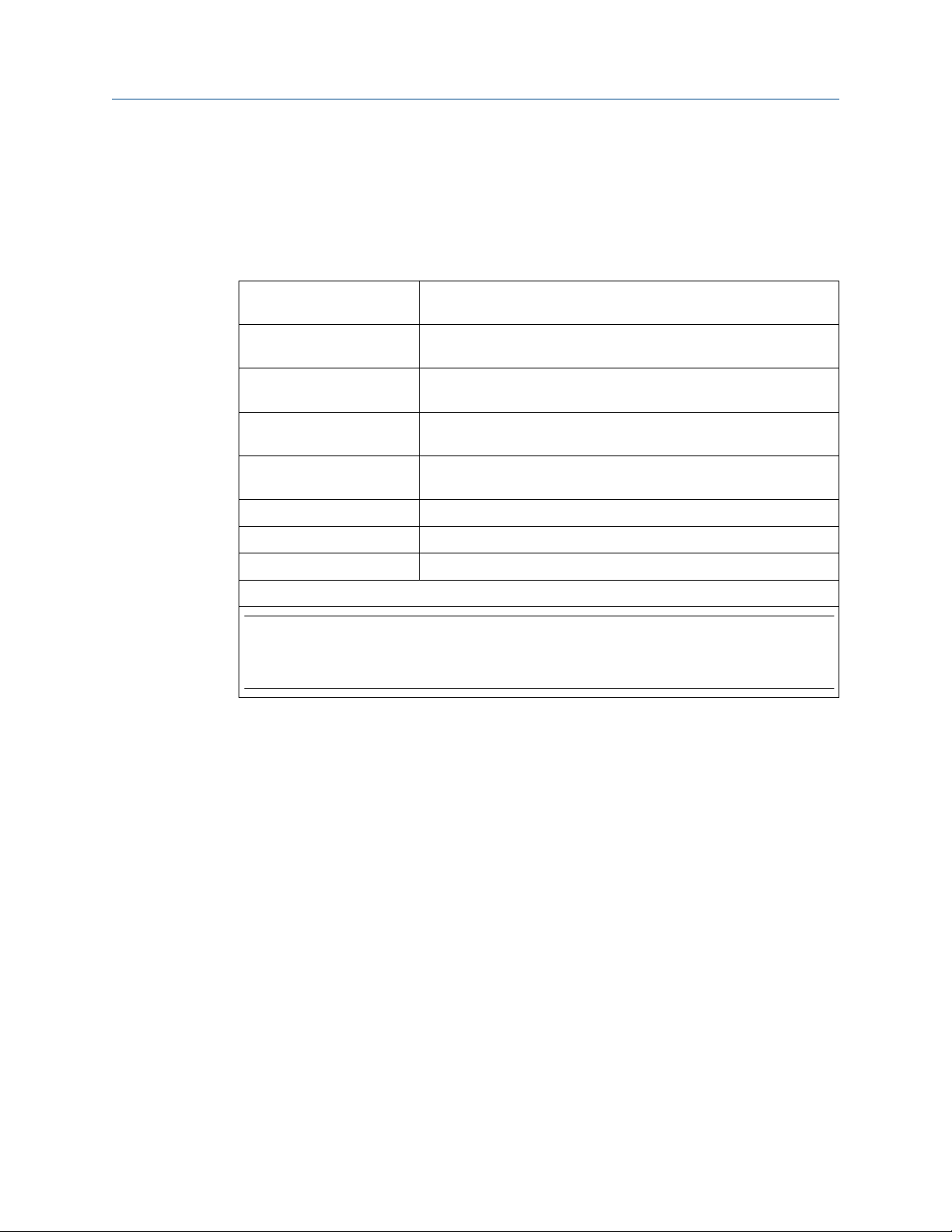

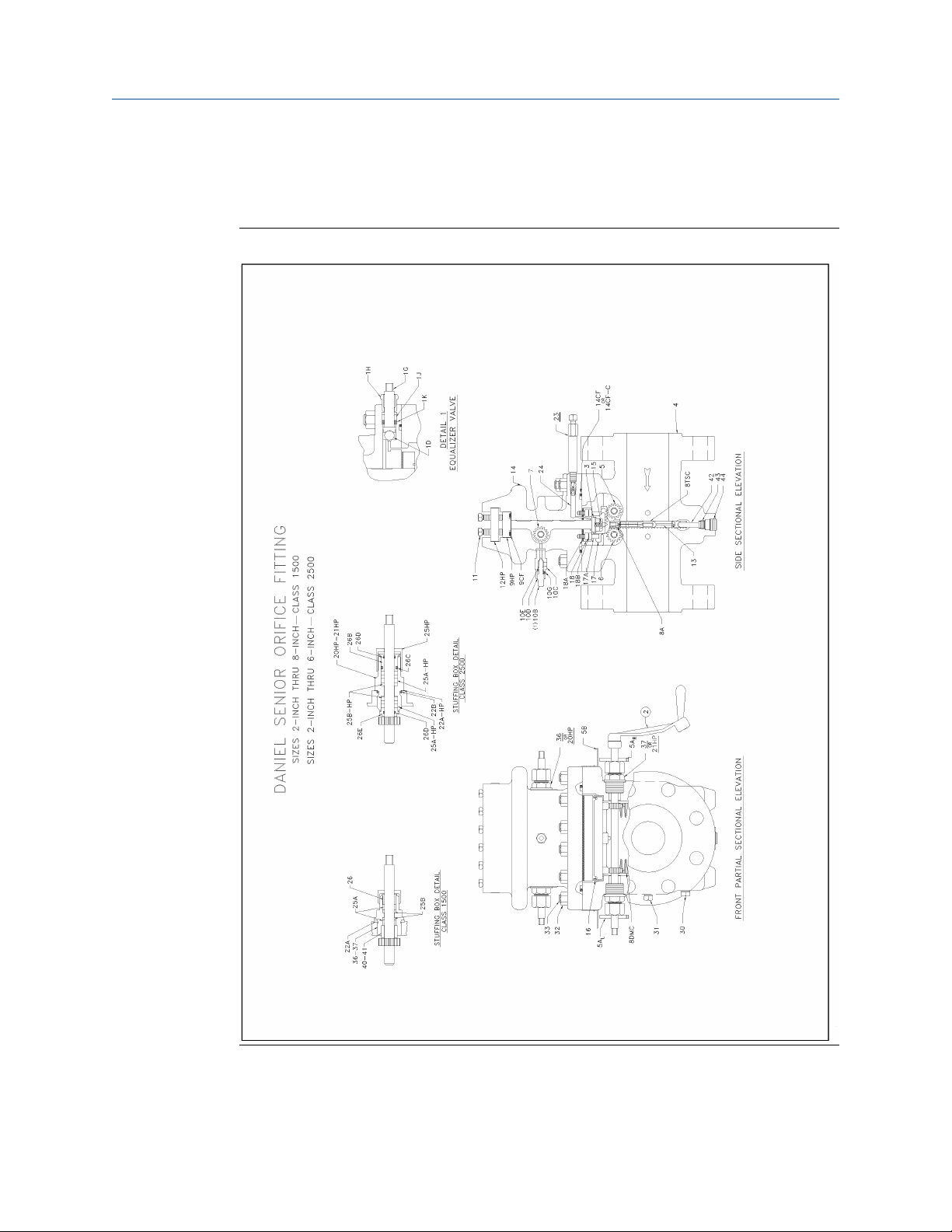

1.5.4 Daniel Senior Orifice Fitting sizes 2"-8" 1500 and 2"-6" 2500

Figure 1-4: Daniel Senior Orifice Fitting drawing sizes 2"-8" 1500 and 2"-6" 2500

Owner and operator manual 35

Page 36

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

All Parts on Daniel Senior Orifice Fittings may be replaced or repaired without removing

the Daniel Senior Orifice Fitting body from the line.

Table 1-7: Daniel Senior Orifice Fitting sizes 2"- 8" 1500 and 2"-6" 2500

Item

number

1 Equalizer valve (complete):

1G*

1H* Packing nut CS (ZP) 1 1 1 1 1

1D*

1K*

1J*

2* Operating wrench Ductile iron 1 1 1 1 1

3

4

5

5A-LH* Indicator plate left-hand Cast aluminum 1 1 1 1 1

5A-RH Indicator plate right-hand Cast aluminum 1 1 1 1 1

5B* Indicator pointer Aluminum 2 2 2 2 2

5C Drive screws 18-8 SS 4 4 4 4 4

6

7

8A*

8DMC

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Stem 316 SS 1 1 1 1 1

Ball 18-8 SS 1 1 1 1 1

Packing washer 17-4PH SS 1 1 1 1 1

Packing ring TTFE/PTFE 2 2 2 2 2

Slide valve strip Type 410 SS 1 1 1 1 1

Body Cast carbon steel 1 1 1 1 1

Slide valve shaft 316 SS 1 1 1 1 1

Lower plate carrier shaft 316 SS 1 1 1 1 1

Upper plate carrier shaft 316 SS 1 1 1 1 1

Plate carrier spring pin 18-8 SS 1 1 1 1 1

Plate carrier 316 SS 1500 1 1 1 1 1

2500 - - - 1 -

CS (ZP) 2500 1 1 1 - -

8TSC

8 MSC

8 SNC

9-HP

9A-CF

36 Senior Orifice Fitting

Orifice plate sealing unit TTFE/PTFE (Removable

- orifice plate not

included)

Optional Snap Seal Ring

units for special services

Optional Snap Seal Ring

units for special services

Sealing Bar CS (ZP) 1 1 1 1 1

Sealing Bar Gasket (Oring)

CS (ZP) or 316 SS

(Removable - orifice

plate not included)

CS (ZP) or 316 SS w/Orings (Removable orifice plate not

included)

Synthetic rubber 1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

Page 37

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-7: Daniel Senior Orifice Fitting sizes 2"- 8" 1500 and 2"-6" 2500 (continued)

Item

number

10B* Bleeder valve (complete):

10C*

10D*

10E*

10G* Set screw Alloy steel 1 1 1 1 1

11* Clamping bar screw (See

12HP Clamping bar CS (ZP) 1 1 1 1 1

13

14

14CF

14CF-C

15*

16*

17

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Body CS (ZP) 1 1 1 1 1

Needle 316 SS 1 1 1 1 1

O-ring Synthetic rubber 1 1 1 1 1

Alloy steel

Note 3 in NOTES for this

table)

Orifice plate Type 304 SS or 316 SS 1 1 1 1 1

Top Cast carbon steel 1 1 1 1 1

Body-top gasket ("o-ring) Special

Body-top gasket (MaleFemale Joint) Not

illustrated

Slide valve springs 316 SS 4 4 4 6 6

Slide valve carrier guide 316 SS 2 2 2 2 2

Slide valve carrier Cast carbon steel 1 1 1 1 -

(ZP)

compound

Synthetic

Rubber

1500 8(2) 10(2) 12(2) 14(2) 16(2)

2500 10(2) 10(2) 12(2) 14(2) -

1500 1 1 1 1 1

2500 1 1 1 1 -

Cast Alloy Iron - - - - 1

17A*

18

18A

18B*

20 HP

21 HP

22A*

22A -HP*

22B*

Owner and operator manual 37

Slide valve carrier stop

pin

Slide valve seat 13% chrome SS 1 1 1 1 1

Slide valve seat/top

gasket

Slide valve seat screw Alloy steel

Stuffing Box (Upper) CS (ZP) 2500 2 2 2 2 0

Stuffing Box (Lower) CS (ZP) 2500 4 4 4 4 0

Bearing plug and stuffing

box gasket

Bearing plug and stuffing

box gasket

Bearing plug and stuffing

box O-ring

Carbon steel (ZP) 2 2 2 2 2

Composite 1500 1 1 1 1 1

2500 Assembled metal-to-metal

1500 8 10 11 14 16

phosphate

treat

316 SS 1500 6 6 6 6 6

316 SS 2500 6 6 6 6 -

Synthetic

rubber

2500 10 10 11 14 12

2500 6 6 6 6 -

Page 38

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-7: Daniel Senior Orifice Fitting sizes 2"- 8" 1500 and 2"-6" 2500 (continued)

Item

number

23*

24*

25* Packing nut CS (ZP) 1500 6 6 6 6 6

25HP* Packing nut CS (ZP) 2500 6 6 6 6 6

25A*

25A-HP*

25B*

25B-HP*

26*

26B* External Stuffing box

26E*

26C*

26D*

30(1)*

31(1)*

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Grease gun (complete) CS (ZP) 1 1 1 1 1

Grease seal double ball

check valve

Packing rings TTFE/PTFE 1500 12 12 12 12 12

Packing rings TTFE/PTFE 2500 Varies with fitting size

Centering ring TTFE/PTFE 1500 12 12 12 12 12

Centering ring TTFE/PTFE 2500 12 12 12 12 -

Stuffing box gland 316 SS 1500 6 6 6 6 6

gland

Internal Stuffing box

gland

Stuffing box gland O-ring Synthetic

Stuffing box gland O-ring Synthetic

Drain valve plug CS (ZP) 1 1 1 1 1

½ N.P.T. plug for

pressure meter tap

316 SS with chromesteel balls

316 SS 2500 6 6 6 6 -

316 SS 2500 6 6 6 6 -

2500 6 6 6 6 rubber

2500 12 12 12 12 rubber

CS (chemically

treated)

1 1 1 1 1

2 2 2 2 2

32 Hex nut CS 1500 14 14 16 18 18

2500 16 16 16 18 -

33 Stud Alloy steel 1500 14 14 16 18 18

2500 16 16 16 18 -

36*

37*

40

41

42*

43*

38 Senior Orifice Fitting

Stuffing box (upper) CS (ZP) 1500 2 2 2 2 2

Stuffing box (lower) CS (ZP) 1500 4 4 4 4 4

Stuffing box sleeve

(upper)

Stuffing box sleeve

(lower)

Plate carrier stop pin CS (ZP) 1 1 1 1 1

Plate carrier stop pin lock

screw

CS (ZP) 1500 2 2 2 2 2

CS (ZP) 1500 4 4 4 4 4

CS (ZP) 1 1 1 1 1

Page 39

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-7: Daniel Senior Orifice Fitting sizes 2"- 8" 1500 and 2"-6" 2500 (continued)

Item

number

44*

Description Material Quantity required

Size

2" 3" 4" 6" 8"

Plate carrier stop pin

access plug

Slide valve lubricant

(boxes)

CS (ZP) 1 1 1 1 1

Castor oil based solid

sticks - 24 sticks per

box

3 3 3 3 3

Notes for Daniel Senior Orifice Fitting sizes 2"-8" 1500 and 2"-6" 2500

(1) All Daniel Senior Orifice Fittings are supplied with pipe plugs on the drains only. If pipe

plugs for the measurement tap holes are required, please contact the factory directly.

• Locations of Equalizer Valve (1), Bleeder Valve (10B), and Grease Gun (23) may differ

from diagrams shown in this manual.

• The clamping bar screw quantity and size listed here reflect ones used on our most

common fitting for that size and pressure rating. The actual number and size of

clamping bar screws may vary for that size and pressure rating due to a fitting's

material of construction and configuration. When ordering replacements, or

developing a maintenance program, always confirm the count and size of clamping bar

screws of your fitting.

• Slide Valve Lubricant: 0.38 in (9.53 mm) diameter by 1.5 in (38.1 mm) long is

equivalent to some lubricant manufacturers' "B" size stick. The quantity of lubricant a

fitting described in this manual will require is dependent upon the state and condition

of the fitting. Emerson recommends having one box of lubricant sticks (24 sticks per

box) on-hand when performing maintenance and plate inspection/change procedures.

(*) Indicates interchangeable parts for all line sizes of specified pressure rating(s).

(2) Indicates 5/8" - 11. See Clamping bar screw (LINK) for clamping bar screw

recommended torque values.

General notes for Daniel Senior Orifice Fitting sizes 2"-8" 1500 and 2"-6" 2500

• Most parts available in other materials upon customer request.

• CS (Carbon Steel), CRS (Cold Rolled Steel), NPT (National Pipe Thread), ZP (Zinc

Plated).

• The materials listed in Daniel Senior Orifice Fitting sizes 2"-8" 1500 and 2"-6" 2500

indicate standard "A" trim.

• Materials of some items listed in Daniel Senior Orifice Fitting sizes 2"-8" 1500 and 2"-6"

2500 are changed for "NACE" and "AASG" trimmed fittings.

• Several available trim options are shown in Table 1-3.

• Other trim options available upon request. Consult factory.

• Bolded part numbers are for items which are fluid media PIC (parts in contact).

Owner and operator manual 39

Page 40

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

When ordering parts, please specify

• Catalog number

• Size

• Serial number

• Item number

• Material

• Quantity of each item required

(4)

(4) Catalog number, size and serial number can be found on the fitting nameplate. Part item numbers and part materials for

"A" trim only are found in Daniel Senior Orifice Fitting sizes 2"-8" 1500 and 2"-6" 2500.

40 Senior Orifice Fitting

Page 41

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

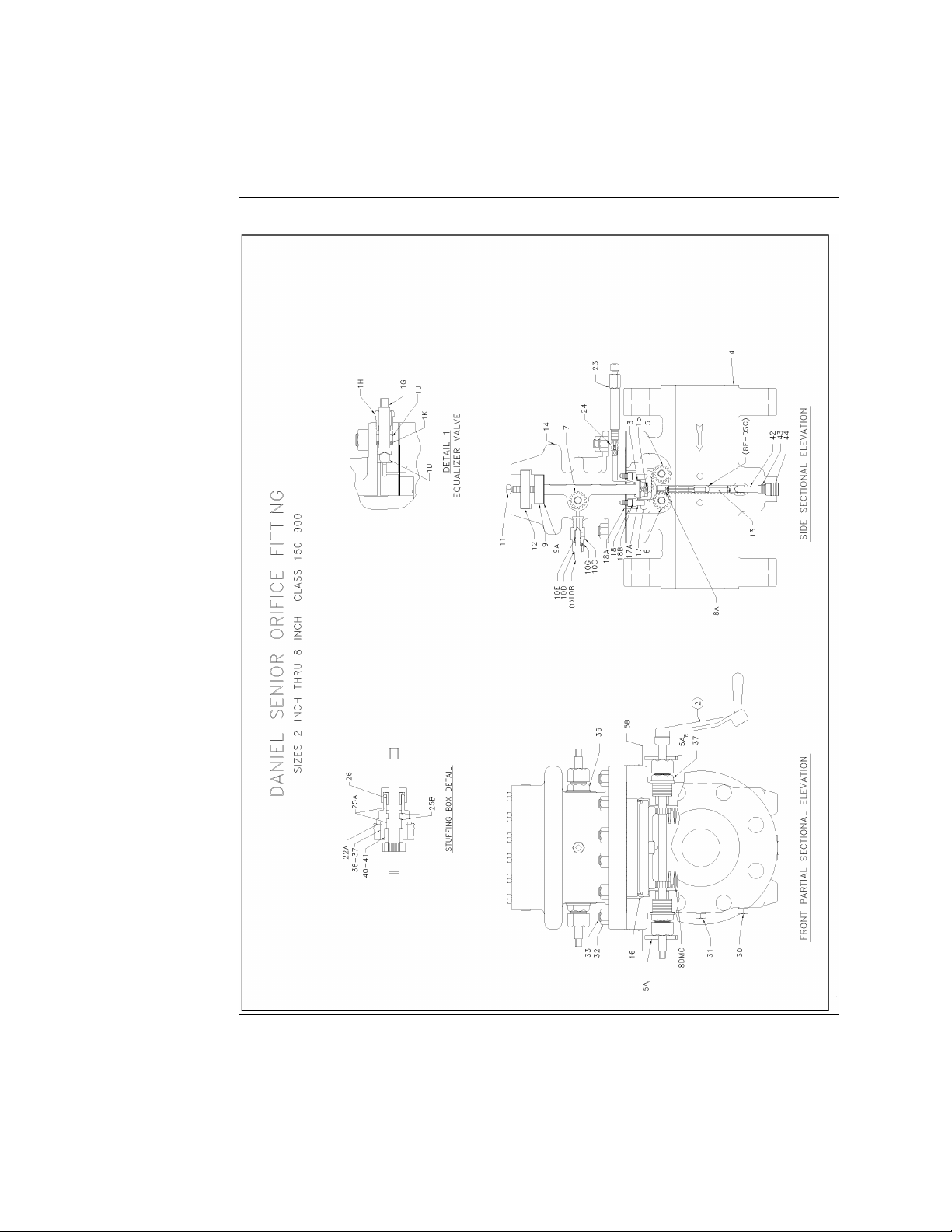

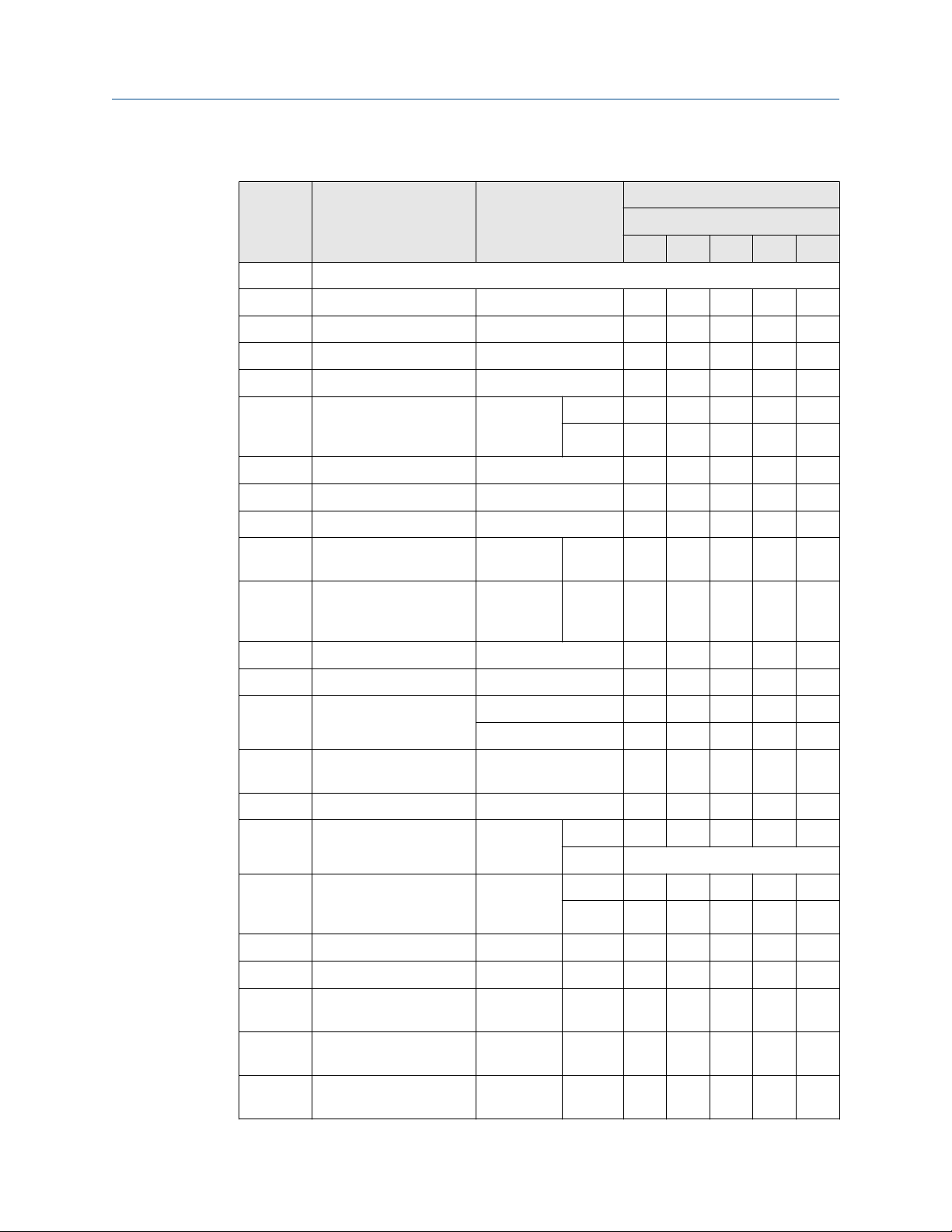

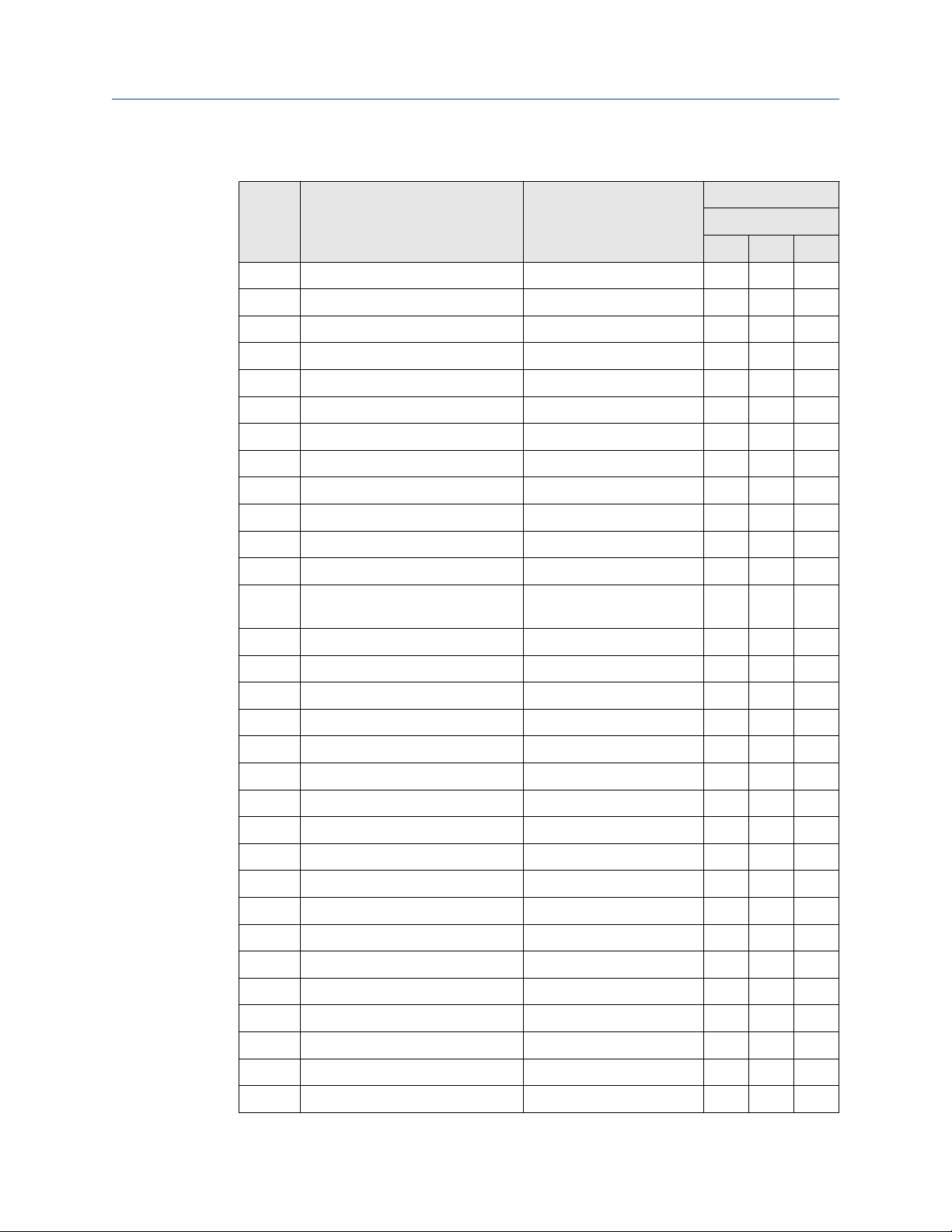

1.5.5 Daniel Senior Orifice Fitting sizes 10"- 16" 1500

Figure 1-5: Daniel Senior Orifice Fitting drawing sizes 10"- 16" 1500

Owner and operator manual 41

Page 42

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

All Parts on Daniel Senior Orifice Fittings may be replaced or repaired without removing

the Daniel Senior Orifice Fitting body from the line.

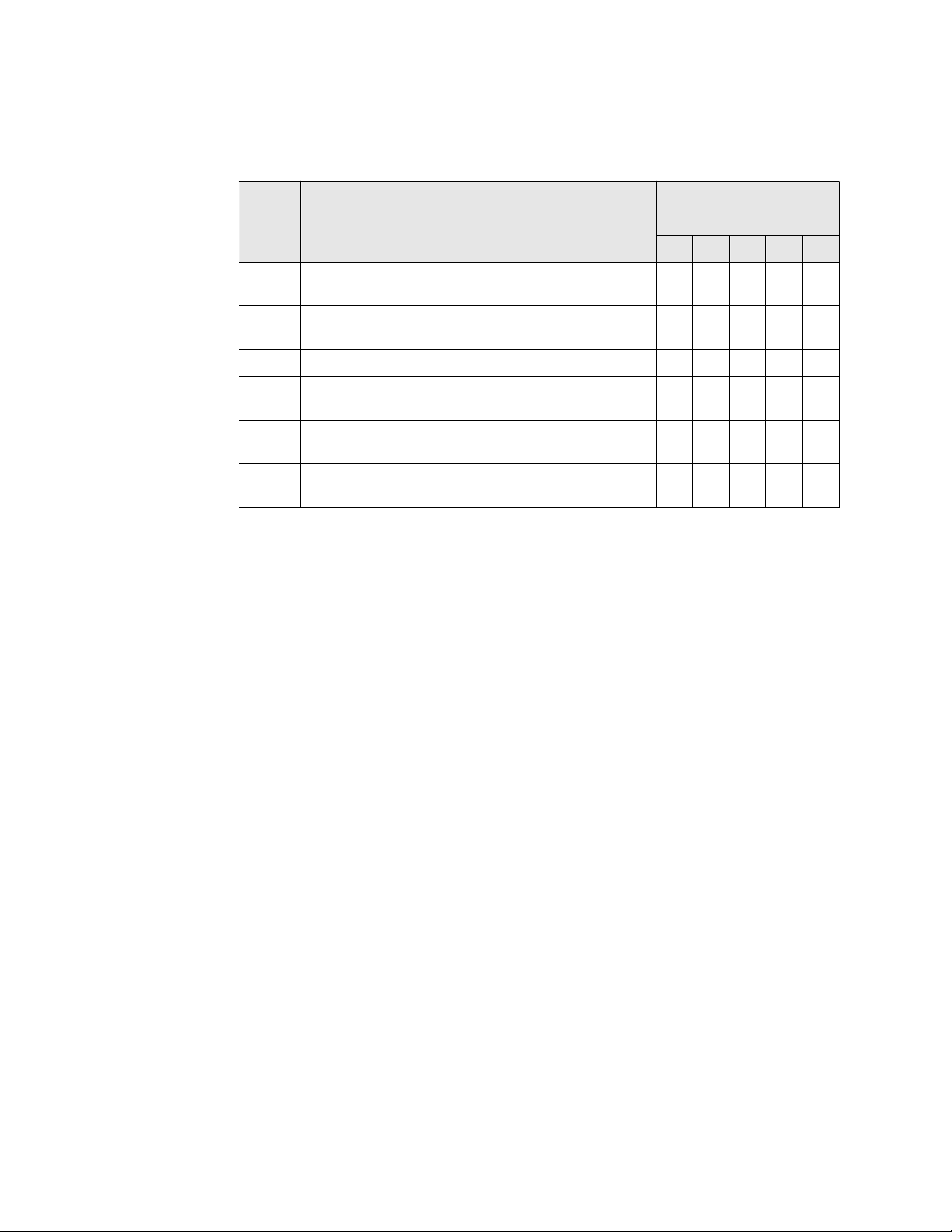

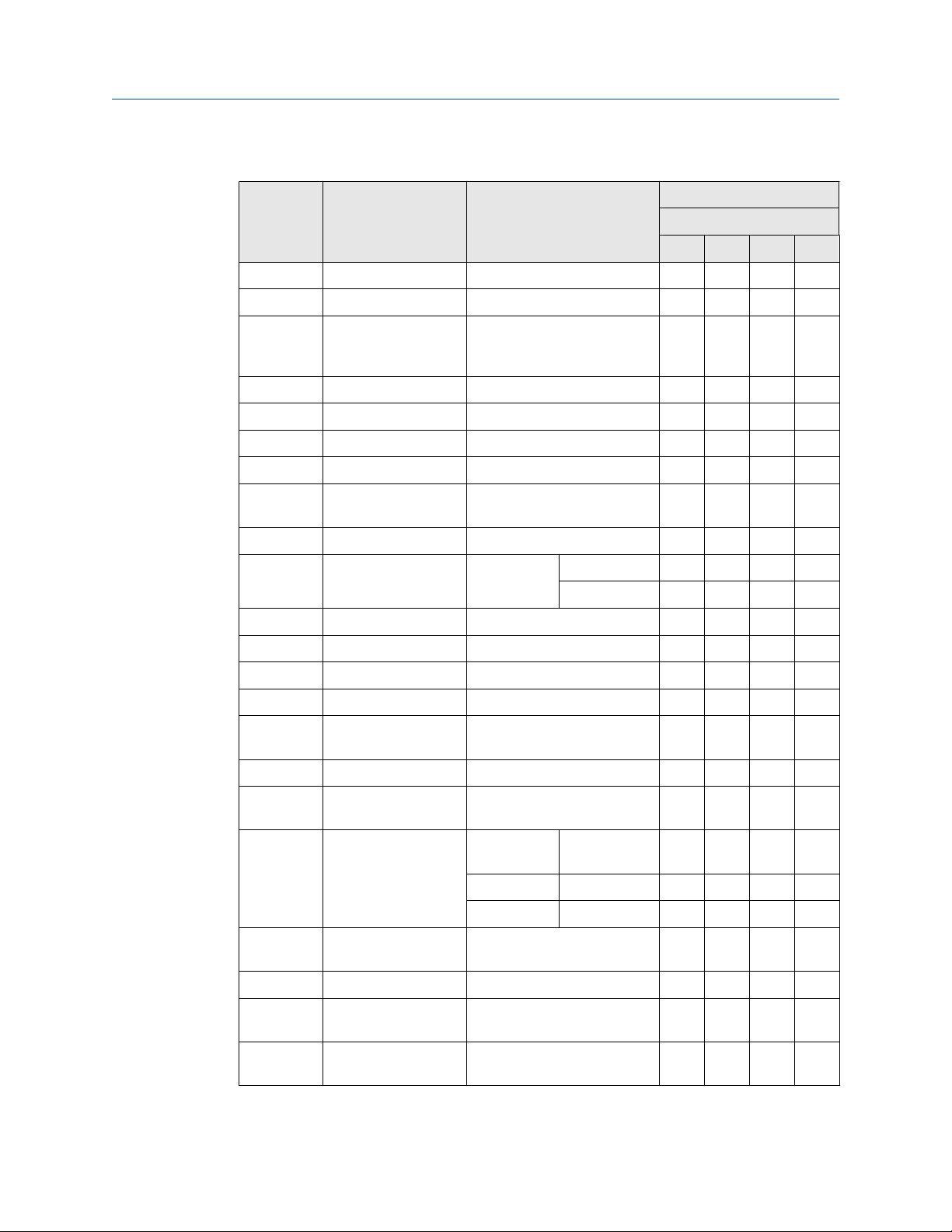

Table 1-8: Daniel Senior Orifice Fitting sizes 10"- 16" 1500

Item

Number

1* Equalizer valve (complete):

1G*

1H* Packing nut CS (ZP) 1 1 1 1

1D*

1K*

1J*

2* Operating wrench Ductile iron 1 1 1 2

3

4

5

5A-LH* Indicator plate left-hand Cast aluminum 1 1 1 1

5A-RH Indicator plate right-

5B* Indicator pointer Aluminum 2 2 2 2

5C Drive screws 18-8 SS 4 4 4 4

6

7

8DM

8TS

8MS

8SN

9HP

9A-HP

Description Material Quantity required

Size

10" 12" 14" 16"

Stem 316 SS 1 1 1 1

Ball 18-8 SS 1 1 1 1

Packing washer 17-4PH SS 1 1 1 1

Packing ring TFE/PTFE 2 2 2 2

Slide valve trip Type 410 SS 1 1 1 1

Body Cast carbon steel 1 1 1 1

Slide valve shaft 316 SS 1 1 1 1

Cast aluminum 1 1 1 1

hand

Lower plate carrier shaft 316 SS 1 1 1 1

Upper plate carrier shaft 316 SS 1 1 1 1

Plate carrier 316 SS 1 1 1 1

Orifice plate sealing unit TFE/PTFE (Removable -

orifice plate not included)

Optional sealing units

for special services

Optional snap seal ring

units for special services

Sealing bar CS (ZP) 1 1 1 1

Sealing bar gasket Composite 1 1 1 1

CS (ZP) or 316 SS

(Removable - orifice plate

w/O-rings not included)

CS (ZP) or 316 SS

(Removable - orifice plate

w/O-rings not included)

1 1 1 1

1 1 1 1

1 1 1 1

10B* Bleeder valve

(Complete)

10C*

10D*

42 Senior Orifice Fitting

Body CS (ZP) 1 1 1 -

Needle 316 SS 1 1 1 -

1 1 1 -

Page 43

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-8: Daniel Senior Orifice Fitting sizes 10"- 16" 1500 (continued)

Item

Number

10E*

10G* Set screw Alloy steel 1 1 1 -

10F

10H

11* Clamping bar screw Alloy steel (ZP) 20(2) 22(2) 22(2) 28(2)

12HP Clamping bar CS (ZP) 1 1 1 1

13

14

15*

16*

17

17A*

18

Description Material Quantity required

Size

10" 12" 14" 16"

O-ring Synthetic rubber 1 1 1 -

Bleeder valve

(Complete)

Bleeder valve nipple CS (ZP) - - - 1

Orifice Plate Type 304 SS or 316 SS 1 1 1 1

Top Cast Carbon steel 1 1 1 1

Slide valve springs 316 SS 6 7 8 10

Slide valve carrier guide 316 SS 2 2 2 2

Slide valve carrier Cast Carbon Steel 1 1 1 1

Slide valve carrier stop

pin

Slide valve seat Type 410 SS 1 - - -

CS (ZP) w/410 SS - - - 1

Carbon steel 2 2 2 2

17-4PH SS - 1 1 -

Duplex SS (UNS S31803) - - - 1

18A

18VSG

18BTG

18B*

22A*

23*

24*

25* Packing Nut CS (ZP) 6 6 6 6

25A*

25B*

26*

30(1)*

31(1)*

Slide valve seat/top

gasket

Slide valve seat gasket Composite (not shown) - - 1 1

Body/top gasket Composite (not shown) - - 1 1

Slide valve seat screw Alloy Steel Phosphate treat 18 20 24 26

Bearing Plug and

stuffing box gasket

Grease gun (Complete) CS (ZP) 1 1 1 2

Grease seal double ball

check valve

Packing Rings TFE/PTFE 12 12 12 12

Centering ring TFE/PTFE 12 12 12 12

Stuffing box gland 316 SS 6 6 6 6

Drain Valve plug CS (ZP) 1 1 1 1

½ NPT Plug for pressure

meter tap

Composite 1 1 1 1

316 SS 6 6 6 6

316 SS with chrome-steel

balls

CS (chemically treated) 2 2 2 2

1 1 1 2

Owner and operator manual 43

Page 44

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-8: Daniel Senior Orifice Fitting sizes 10"- 16" 1500 (continued)

Item

Number

32 Hex nut CS 22 22 28 32

33 Stud Alloy steel 22 22 28 32

36*

37*

40

41

Description Material Quantity required

Size

10" 12" 14" 16"

Stuffing box body

(upper)

Stuffing box body

(lower)

Stuffing box sleeve

(upper)

Stuffing box sleeve

(lower)

Slide valve lubricant

(boxes)

CS (ZP) 2 2 2 2

CS (ZP) 4 4 4 4

CS (ZP) 2 2 2 2

CS (ZP) 4 4 4 4

Castor Oil based solid sticks

- 24 sticks per box

3 3 3 3

Notes for Daniel Senior Orifice Fitting sizes 10"- 16" 1500

(1) All Daniel Senior Orifice Fittings are supplied with pipe plugs on the drains only. If pipe

plugs for the measurement tap holes are required, please contact the factory directly.

• Locations of Equalizer Valve (1), Bleeder Valve (10B), and Grease Gun (23) may differ

from diagrams shown in this manual.

• The clamping bar screw quantity and size listed here reflect ones used on our most

common fitting for that size and pressure rating. The actual number and size of

clamping bar screws may vary for that size and pressure rating due to a fitting's

material of construction and configuration. When ordering replacements, or

developing a maintenance program, always confirm the count and size of clamping bar

screws of your fitting.

• Slide Valve Lubricant: 0.38 in (9.53 mm) diameter by 1.5 in (38.1 mm) long is

equivalent to some lubricant manufacturers' "B" size stick. The quantity of lubricant a

fitting described in this manual will require is dependent upon the state and condition

of the fitting. Emerson recommends having one box of lubricant sticks (24 sticks per

box) on-hand when performing maintenance and plate inspection/change procedures.

(*) Indicates interchangeable parts for all line sizes of specified pressure rating(s).

(2) Indicates 5/8" - 11. See Clamping bar screw (LINK) for clamping bar screw

recommended torque values.

General notes for Daniel Senior Orifice Fitting sizes 10"- 16" 1500:

• The materials listed in Daniel Senior Orifice Fitting sizes 10"- 16" 1500 indicate standard

"A" trim.

• Materials of some items listed in Daniel Senior Orifice Fitting sizes 10"- 16" 1500 are

changed for "NACE" and "AASG" trimmed fittings.

• Several available trim options are shown in Table 1-3.

44 Senior Orifice Fitting

Page 45

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

• Other trim options available upon request. Consult factory.

• Bolded part numbers are for items which are fluid media PIC (parts in contact).

When ordering parts, please specify

• Catalog number

• Size

• Serial number

• Item number

• Material

• Quantity of each item required

(5)

(5) Catalog number, size and serial number can be found on the fitting nameplate. Part item numbers and part materials for

"A" trim only are found in Daniel Senior Orifice Fitting sizes 10"- 16" 1500.

Owner and operator manual 45

Page 46

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

1.5.6 Daniel Senior Orifice Fitting sizes 8"-12" 2500

Figure 1-6: Daniel Senior orifice Fitting drawing sizes 8" - 12" 2500

46 Senior Orifice Fitting

Page 47

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

All Parts on Daniel Senior Orifice Fittings may be replaced or repaired without removing

the Daniel Senior Orifice Fitting body from the line.

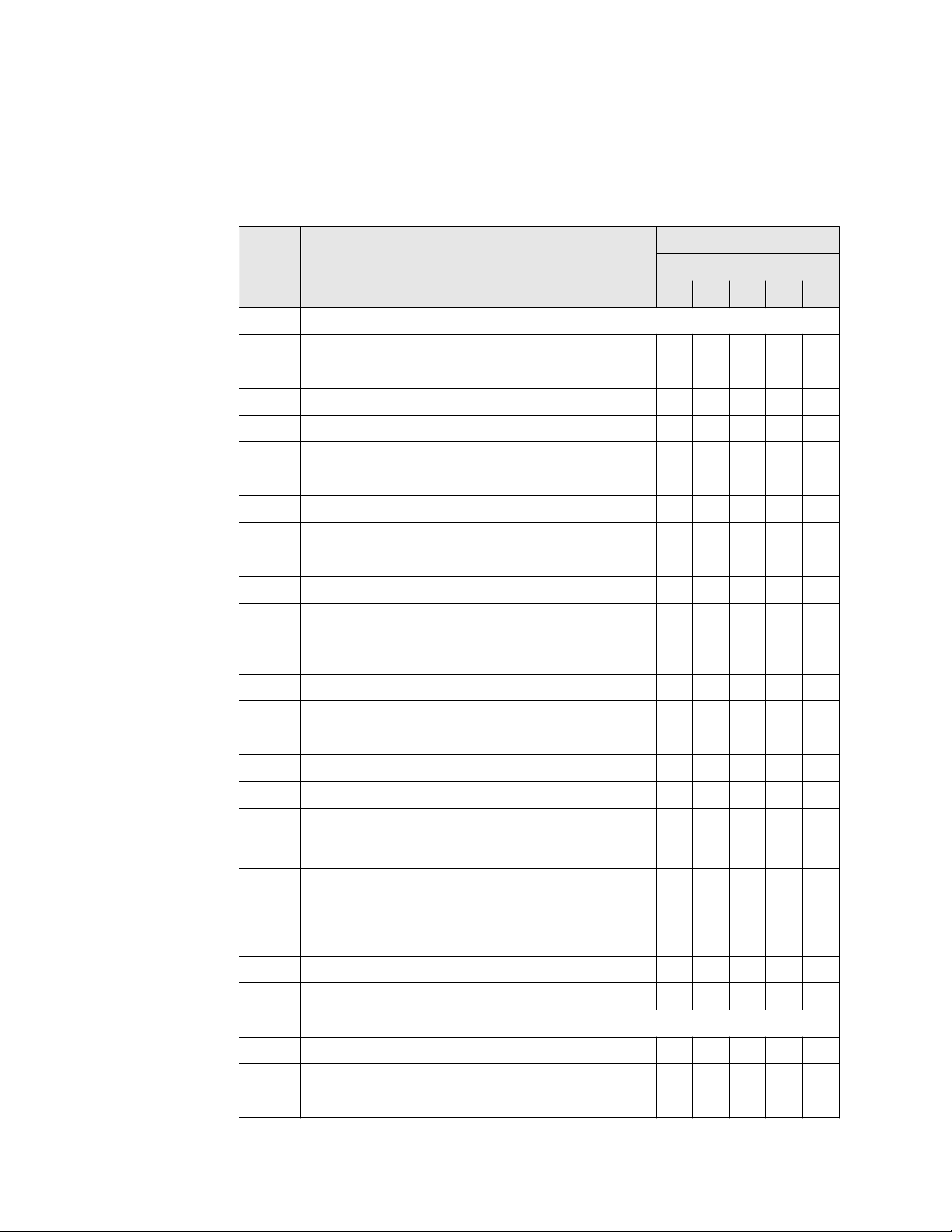

Table 1-9: Daniel Senior Orifice Fitting sizes 8"-12" 2500

Item

number

1D-HP

1G-HP

1K-HP

1L-HP

*2 Operating wrench - gear shafts Ductile iron 1 1 1

2A Operating wrench - clamping bar

4

*5A-LH Indicator plate left-hand Aluminum 1 1 1

*5A-RH Indicator plate right-hand Aluminum 1 1 1

5B Indicator pointer Aluminum 2 2 2

5D Indicator pointer attachment screw 316 SS 2 2 2

5, 6, 7

8DM

8TSC/8T

S

8MSC/8

MS

10C

10D

10E

Description Material Quantity required

Size

8" 10" 12"

Equalizer valve ball 18-8 SS 1 1 1

Equalizer valve stem 316 SS 1 1 1

Equalizer valve washer 316 SS 7 7 7

Equalizer valve stuffing box CS 1 1 1

Alloy steel 1 1 1

screws

RTJ-FI body Cast steel 1 1 1

Gear shaft 316 SS 3 3 3

Plate carrier CS 1 1 1

Orifice Plate Sealing Unit

1500-2500

Optional sealing units for special

services

Bleeder valve body CS (ZP) 1 1 1

Bleeder valve stem 316 SS 1 1 1

Bleeder Valve Stem O-ring gasket NBR 1 1 1

TFE/PTFE (Removable orifice plate not included)

(8TSC /8"; 8TS /10"-12")

CS (ZP) or 316 SS w/O-rings

(orifice plate not included)

(8SNC /8"; 8SN /10"-12")

1 1 1

1 1 1

10F SKTD HD set screw Alloy steel 1 1 1

11 Clamping bar screw Alloy steel (zinc plated) 26(2) 28(2) 28(2)

12-HP Clamping bar Carbon steel 1 1 1

13

14

14-HP

16

*16A

16B

Owner and operator manual 47

Orifice plate Type 304 SS or 316 SS 1 1 1

Top Cast steel 1 1 1

Body-top ring gasket Soft iron 1 1 1

Slide valve guide 316 SS 2 2 2

Slide valve guide attachment screw Alloy steel 2 2 2

Slide valve adjustment screw 316 SS 2 2 2

Page 48

Introduction Owner and operator manual

October 2019 P/N 3-9008-001

Table 1-9: Daniel Senior Orifice Fitting sizes 8"-12" 2500 (continued)

Item

number

16C

17-HP

17C-HP

17E-HP

17F-HP

17G-HP

18

18A

*18B

18C

20-HP

20E-HP

22A-HP

22B-HP

23-HP

Description Material Quantity required

Size

8" 10" 12"

Slide valve lock screw 316 SS 2 2 2

Slide valve 11-14% CHSS 1 1 1

Shaft spacer 316 SS 6 6 6

Stuffing box spring retainer 316 SS 6 6 6

Stuffing box spring 316 SS 6 6 6

Spring retainer set screw 316 SS 6 6 6

Valve seat 410 SS 1 1 1

O-ring, valve seat gasket NBR 1 1 1

Valve seat screw Alloy steel 12 12 12

O-ring, grease port (seat) gasket NBR 1 1 1

Stuffing box body CS 6 6 6

Stuffing box extension CS 6 6 6

Bearing plug and stuffing box

gasket

O-ring, stuffing box NBR 7 7 7

Grease fitting with #1 adapt. Comm. item 1 1 1

316 SS 7 7 7

25-HP packing nut CS 7 7 7

25A-HP

25B-HP

25C-HP

26B

26C

26D

30

31

32 Hex nut Alloy steel 20 20 20

33 Body-top stud (long) Alloy steel 16 16 16

33B Body-top stud (short) Alloy steel 4 4 4

*45 Senior ID plate (not shown) 304 SS 1 1 1

46-HP Instruction plate (not shown) 304 SS 1 1 1

*47 Warning plate (not shown) 316 SS 1 1 1

BNP Bleeder valve plate(not shown) 304 SS 1 1 1

Shaft packing ½" LG TFE/PTFE 27 27 27

Shaft packing ¼" LG TFE/PTFE 6 6 6

Stuffing box bushing TFE/PTFE 6 6 6

External stuffing box gland 316 SS 7 7 7

O-ring, stuffing box gland NBR 7 7 7

O-ring, stuffing box gland NBR 7 7 7

Drain plug CS 1 1 1

Meter tap plug CS 2 2 2

48 Senior Orifice Fitting

Page 49

Owner and operator manual Introduction

P/N 3-9008-001 October 2019

Table 1-9: Daniel Senior Orifice Fitting sizes 8"-12" 2500 (continued)

Item

number

ENP Equalizer valve plate(not shown) 304 SS 1 1 1

GNP Grease gun plate (not shown) 304 SS 1 1 1

Description Material Quantity required

Size

8" 10" 12"

Slide valve lubricant - Bulk or stick

as required

Castor oil based solid

Notes for Daniel Senior Orifice Fitting sizes 8"-12" 2500

(1) All Daniel Senior Orifice Fittings are supplied with pipe plugs on the drains only. If pipe

plugs for the measurement tap holes are required, please contact the factory directly.

• Locations of Equalizer Valve (1), Bleeder Valve (10B), and Grease Gun (23) may differ

from diagrams shown in this manual.

• The clamping bar screw quantity and size listed here reflect ones used on our most

common fitting for that size and pressure rating. The actual number and size of

clamping bar screws may vary for that size and pressure rating due to a fitting's

material of construction and configuration. When ordering replacements, or

developing a maintenance program, always confirm the count and size of clamping bar

screws of your fitting.

• Slide Valve Lubricant: 0.38 in (9.53 mm) diameter by 1.5 in (38.1 mm) long is

equivalent to some lubricant manufacturers' "B" size stick. The quantity of lubricant a

fitting described in this manual will require is dependent upon the state and condition

of the fitting. Emerson recommends having one box of lubricant sticks (24 sticks per

box) on-hand when performing maintenance and plate inspection/change procedures.

(*) Indicates interchangeable parts for all line sizes of specified pressure rating(s).

(2) Indicates 5/8" - 11. See Clamping bar screw (LINK) for clamping bar screw

recommended torque values.

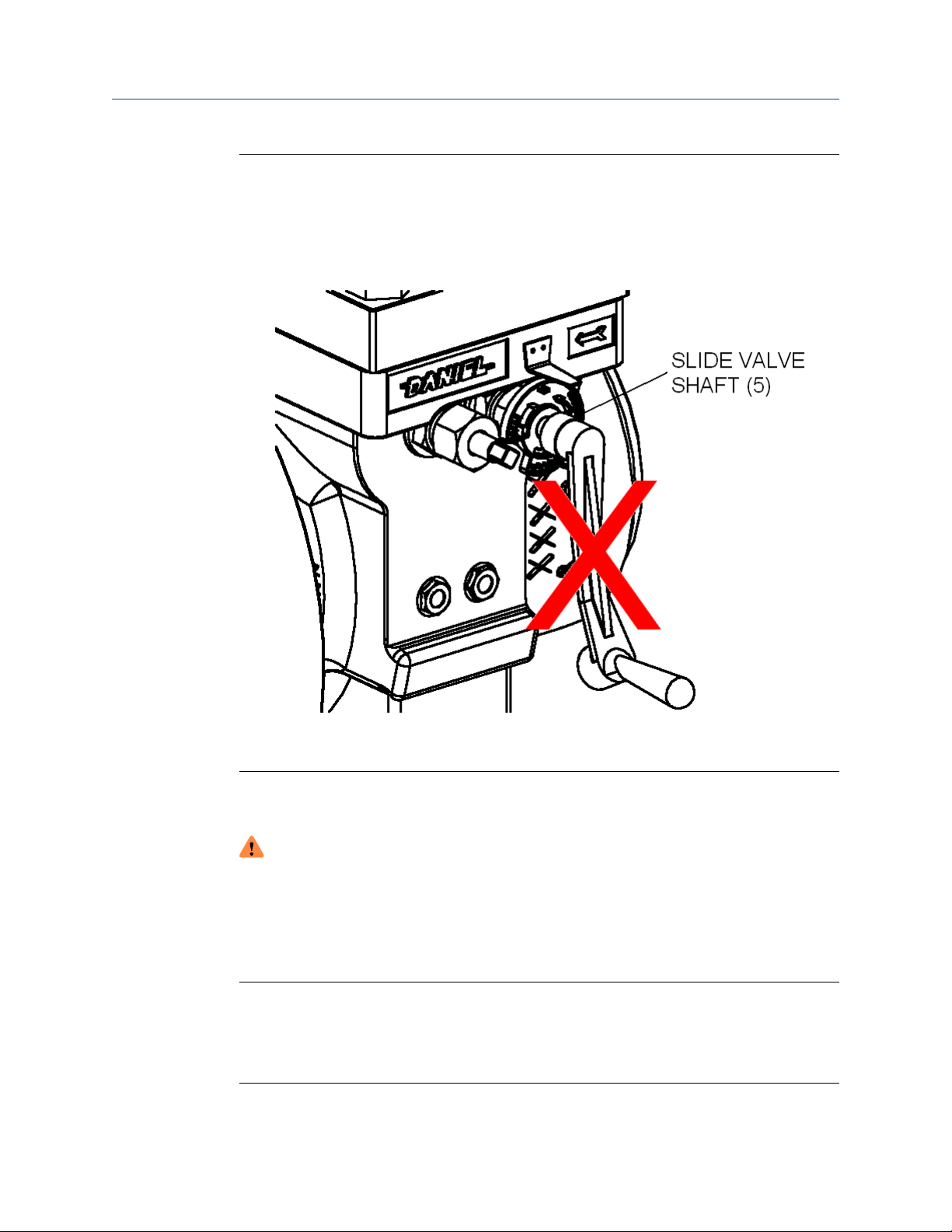

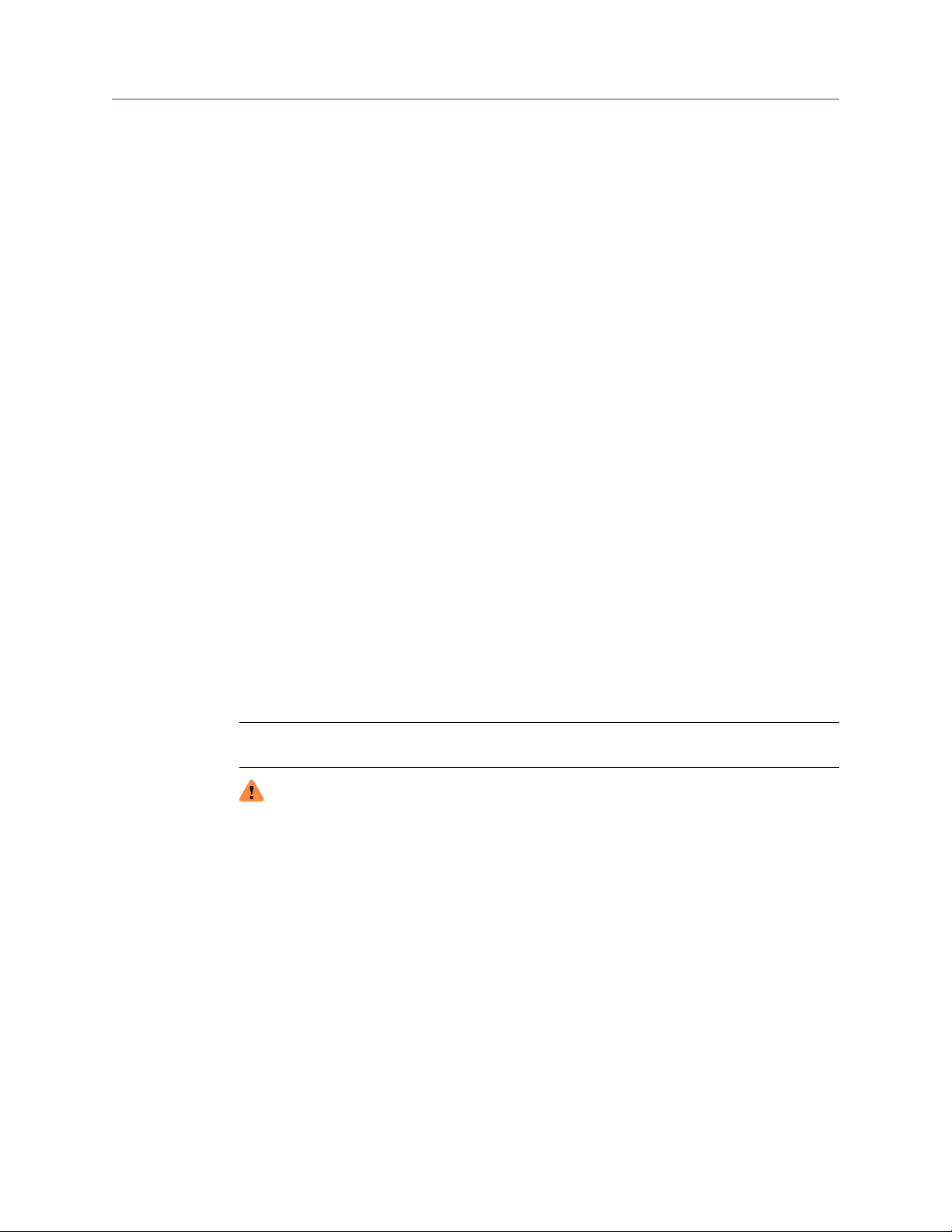

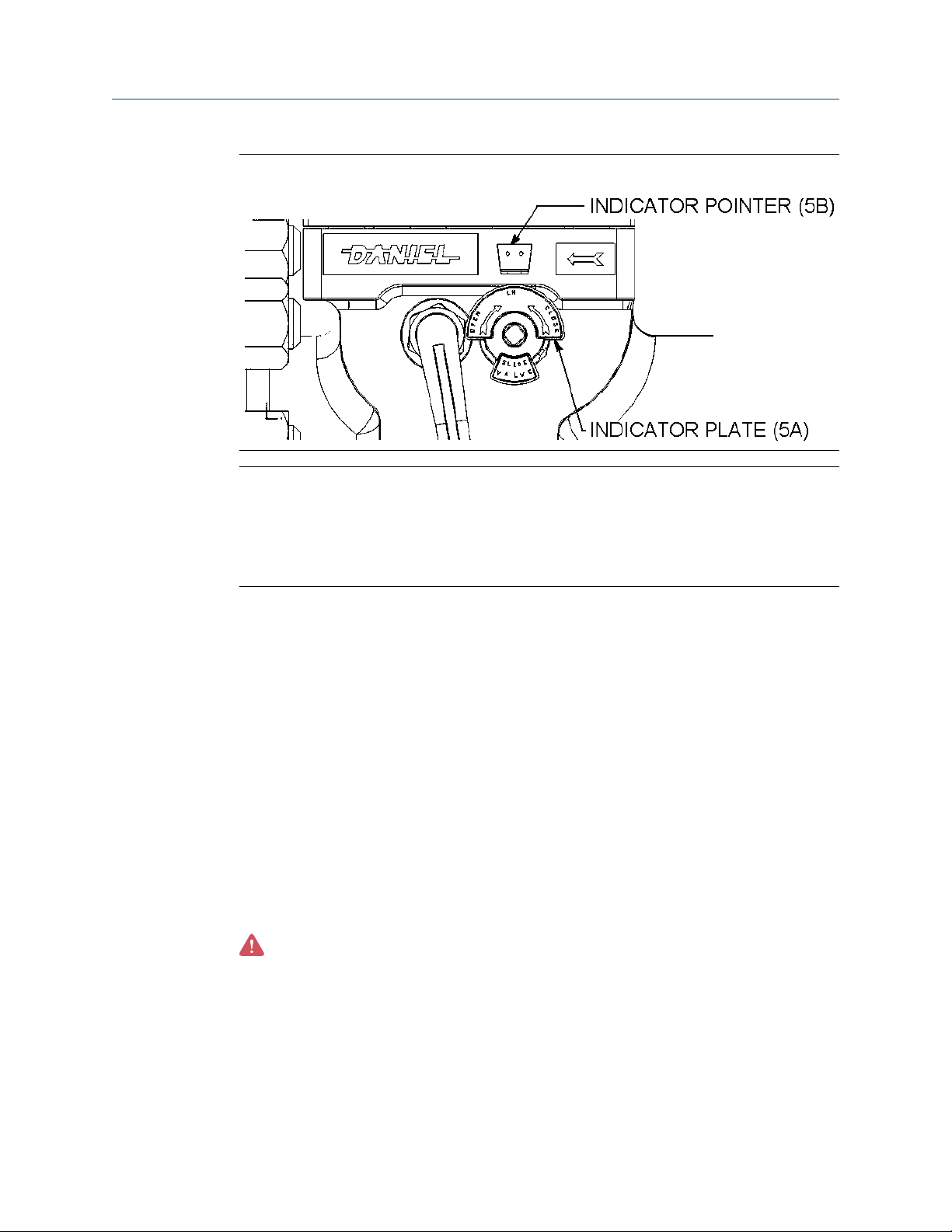

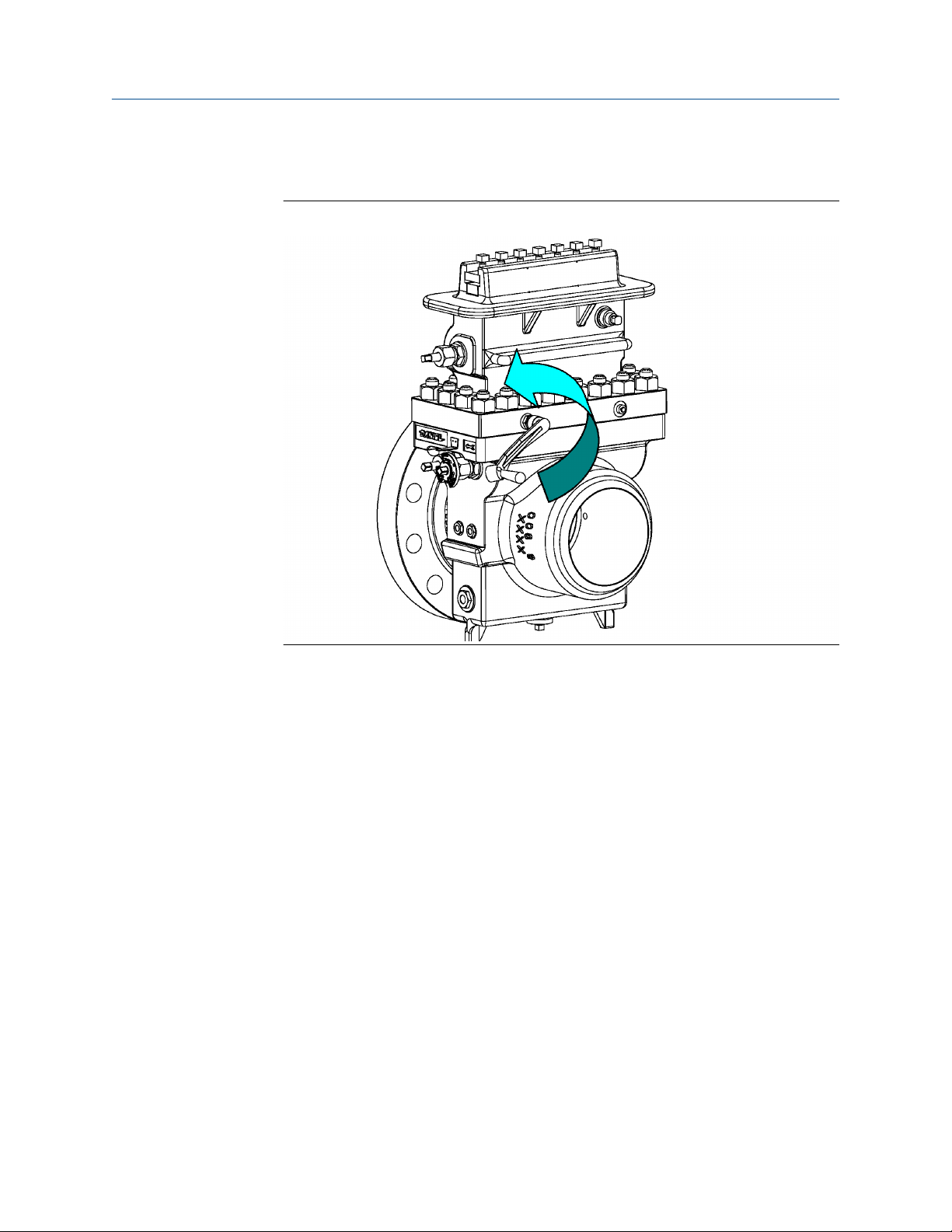

General notes for Daniel Senior Orifice Fitting sizes 8"-12" 2500: