Page 1

Damcos™ Local Power Unit

Service Manual

Service Manual

Version: SM 8000-1000-01 Ed 04

Release: February, 2017

Page 2

The content of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, expressed or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our

terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of our products at any time without notice. Damcos A/S accepts no responsibility for any errors that may appear in this publication.

As each system may be configured for each delivery, the content and illustrations in this manual may differ from your system.

Copyright © Damcos A/S, 2017

Service Manual for LPU in English

Page 3

Damcos LPU: Table of Contents Service Manual

February 2017 SM 8000-100-01 Ed 04

Table of Contents

Abbreviation and Denomination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Warning Levels Used in Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Service Instructions for LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

LPU and Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

LPU-S Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Overview LPU-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

LPU-S-Ex Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview LPU-S-Ex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LPU-S-Ex-ia Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview LPU-S-Ex-ia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

LPU-D Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overview LPU-D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

LPU-D-Ex Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Overview LPU-D-Ex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LPU-D-Ex-ia Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Overview LPU-D-Ex-ia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Troubleshooting Guide LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Fault Finding List LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

LPU-S frequently restarting in open position . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Motor not running and is hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Motor not running and is Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Motor not stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pump rendering too low (or no) pressure in one or both directions . . . . . . . 51

Solenoid valve not working. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Actuator only running in one direction

(the unit can either only open or only close) . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Noise from pump, but only at low pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3

Page 4

Service Manual Damcos LPU: Table of Contents

SM 8000-100-01 Ed 04 February 2017

Noise from pump, but only at high pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Noise from pump at both high and low pressure. . . . . . . . . . . . . . . . . . . . . . . . 55

Motor running hot, LPU is operating normally . . . . . . . . . . . . . . . . . . . . . . . . . . 56

LPU-D not maintaining pressure on actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Spring actuator only partly closing or not starting to close . . . . . . . . . . . . . . . 58

Emergency operation by key giving oil spillage through breather valve . . . . 59

Emergency operation by key not possible, hydraulically locked. . . . . . . . . . . 59

Emergency operation by hand pump giving oil spillage through breather valve

59

Emergency operation by hand pump not possible . . . . . . . . . . . . . . . . . . . . . . 60

Pump not rendering sufficient oil at high pressure (“valve running too slowly”)

61

Pump not rendering sufficient oil at low pressure (“valve running too slowly”)

61

Motor running for a short time and stops

High pressure on the port to which oil is led. . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Motor running for a short time and stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Motor ”diving” in RPM in end position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Motor ”diving” in RPM as spring actuator opens . . . . . . . . . . . . . . . . . . . . . . . . 63

Oil spillage, generally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Oil in electronic connection box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Oil spillage from breather valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Unit drawing too much current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Too little tank volume for operating actuator . . . . . . . . . . . . . . . . . . . . . . . . . . 66

LPU cannot raise pressure after hand pump operation

(but no problems after remote operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

LPU leaking from bleeder valve when hand pump is mounted . . . . . . . . . . . . 68

Spring actuator do not close by emergency hand pump operation. . . . . . . . 69

LPU-Ex motor do not run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

LPU-Ex has to be bulkhead mounted because of too little space or zone 0 at ac-

tuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Position indicator errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Operating LPU-S 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Operating LPU-D 2a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Emergency Operation of LPU V.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Speed adjustment for Actuator on LPU (v.2) . . . . . . . . . . . . . . . . . . . . . . 83

Pump pressure adjustment for LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4

Page 5

Damcos LPU: Table of Contents Service Manual

February 2017 SM 8000-100-01 Ed 04

Refill of Oil in LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Replace Pump in LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Replace DPCV in LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replace release valve in LPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Setup new P-net LPU circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Setup new P-net LPU circuit board in VIEW ver. 3.16 . . . . . . . . . . . . . . 103

Replace Printed Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Replace Solenoid Valve in LPU-D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Replace pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

LPU Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

LPU Power Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

LPU Power Control Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Operation LPU-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Operating LPU-D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

LPU with LED Position Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

LPU P-NET System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

LPU P-Net Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

PCB Diagram for Local Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

PCB Diagram for Stand Alone Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Hydraulic Hand Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Hydraulic Diagram for Direct Mounted LPU Handpump . . . . . . . . . . . . . . . . 138

Hydraulic Diagram for Bulkhead Mounted LPU Handpump . . . . . . . . . . . . . 139

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

5

Page 6

Service Manual Damcos LPU: Table of Contents

SM 8000-100-01 Ed 04 February 2017

6

Page 7

Damcos LPU: Abbreviation and Denomination Service Manual

February 2017 SM 8000-100-01 Ed 04

Abbreviation and Denomination

DPCV Double Pilot Operated Check Valve

HP Hand Pump

ISC Integrated Ship Control

LPU Local Power Unit

LPU-D LPU for double-acting actuator

LPU-S LPU for single-acting spring operated actuator

LPU-Ex LPU approved for mounting in hazardous area

PLC Programmable Logic Controller

BB-VPI Bulkhead mounted Valve Position Indicator

VPI Valve Position Indicator

7

Page 8

Service Manual Damcos LPU: Abbreviation and Denomination

SM 8000-100-01 Ed 04 February 2017

8

Page 9

Damcos LPU: Safety Service Manual

February 2017 SM 8000-100-01 Ed 04

Safety

A description of issues concerning

personal safety when handling

Damcos

TM

VRC

9

Page 10

Service Manual Damcos LPU: Safety

SM 8000-100-01 Ed 04 February 2017

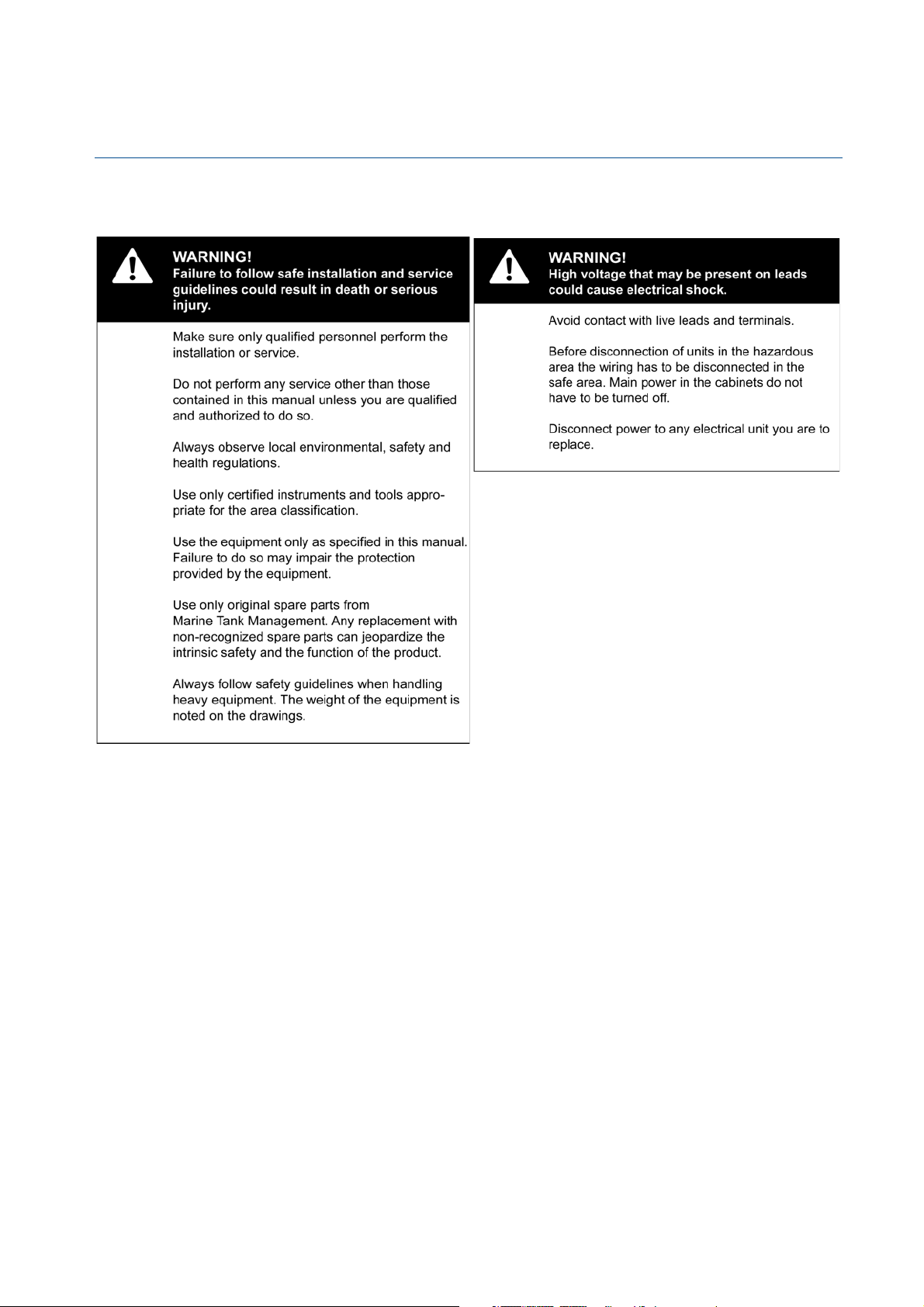

Warning Levels Used in Manuals

The following warning levels are used in the documentation of Damcos A/S for the safety of people

and equipment.

Warning! Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution! Indicates a potentially hazardous situation which, if not avoided, may result in prop-

erty damage.

Note! Indicates important information regarding the product.

Warnings

All personnel that handles Damcos LPU shall take part of and understand the following information

prior to handling the system. See warnings on next page.

10

Page 11

Damcos LPU: Safety Service Manual

February 2017 SM 8000-100-01 Ed 04

11

Page 12

Service Manual Damcos LPU: Safety

SM 8000-100-01 Ed 04 February 2017

12

Page 13

Damcos LPU: General Service Instructions for LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

General Service Instructions for LPU

This Chapter Describes the General Requirements

and Service Recommendations for the LPU

13

Page 14

Service Manual Damcos LPU: General Service Instructions for LPU

SM 8000-100-01 Ed 04 February 2017

General Considerations

Important notes on LPU equipment and systems:

• use original spare parts and tools

• use lifting facilities and transport equipment

• use handling instructions

• electrical cables are only to be connected by qualified personnel

Note! Read Safety chapter before handling any equipment!

Bleeder valve positions on LPU

It is extremely important that bleeder valve position is correctly chosen when mounting LPU with

actuator on pipe. Other positions are plugged when not used! This is normally done at installation.

Note! The choice of bleeder valve position is always selected at the highest point on LPU or actu-

ator tank!

For KC/KF/KFR bleed valve on top of actuator has no connection to LPU tank and must

always be present!

See next page for illustrated examples.

14

Page 15

Damcos LPU: General Service Instructions for LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D and LPU-S on KF/KFR - Bleed valve positions

LPU-S on BRCF - Bleed valve positions

15

Page 16

Service Manual Damcos LPU: General Service Instructions for LPU

SM 8000-100-01 Ed 04 February 2017

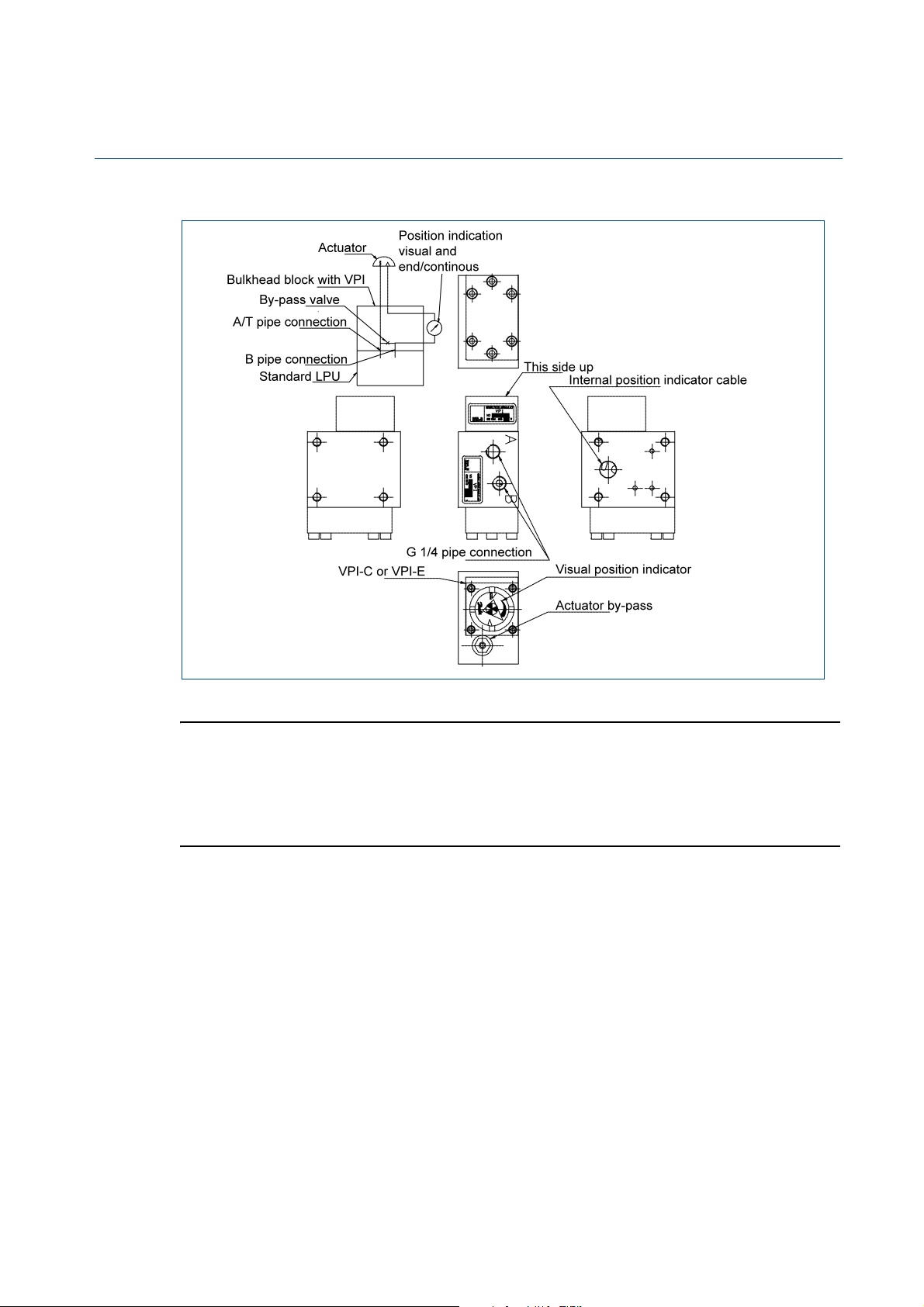

LPU and Optional Equipment

The LPU can be equipped with additional equipment, such as switches, indicators etc. Further more

the LPU can be bulkhead mounted, mounted with blocks or otherwise mounted in respect to customer requirements and system. Always check your specific system drawings and documents for

correct information. This manual is a guide on how to perform the service parts of your system. For

further information please contact Emerson service engineer or appointed agent.

Description

The LPU offers installation in both safe and hazardous area in two basic versions:

• LPU-S (fail safe) for single acting actuator

• LPU-D (fail set) for double acting actuator

Depending on safety zone requirements the LPU’s can be of Ex or Ex-ia, designed to meet the

requirements for mounting in hazardous areas. Be sure to use the designated equipment and spare

parts when performing service on your system.

The LPU system is designed to be controlled by two electrically different types of controls:

• Power controlled

• P-NET® bus controlled

The LPU can also be used as a stand-alone system.

LPU with an LED Position Indicator

LPU (except the Ex version) with an IP 68 LED indicator, showing clear RED or GREEN light when the

valve is CLOSED respectively OPEN is available in Power controlled and P-NET controlled LPU systems.

This may especially be useful if LPU is operated from a local hand pump, were the LPU is mounted in a

distance so the indication of the actuator is not visible. The LED must be supplied with 24 VDC.

LPU Mounting

The LPU can be mounted in the following ways:

• Direct mounting on BRC 250 - 16000, BRCF 250 - 16000, KC 65 - 400 and KF 65-250.

• Mounting on BRC 052, 072 and 092 is via inter-mediate block and with external position indica-

tion cable.

• Mounting on BRCF Fail Open and KF Fail Open is via special intermediate block.

• Mounting on BRC 125 and BRCF 125 has to be bulkhead mounted or supported otherwise.

• LPU may be bulk-head mounted via a standard B-block. - It is possible to use a B-block with inte-

grated VPI, (please see illustration). No external indication cable.

When decided on mounting method the pipe dimensions has to be considered as well.

16

Page 17

Damcos LPU: General Service Instructions for LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

B-VPI Block for bulk-head mounted LPU.

Note! If bulk-head mounted:

Oil level must be checked before starting up the LPU.

LPU must be placed with motor pointing down and breather valve on top, short suction

pipe recommend.

The LPU may be emergency operated as if mounted direct on actuator.

Properly de-airing via quick connections on the LPU.

17

Page 18

Service Manual Damcos LPU: General Service Instructions for LPU

SM 8000-100-01 Ed 04 February 2017

18

Page 19

Damcos LPU: LPU-S Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S Overview

This Chapter Describes the LPU-S with

Overview and Handling Instructions

19

Page 20

Service Manual Damcos LPU: LPU-S Overview

SM 8000-100-01 Ed 04 February 2017

Overview LPU-S

LPU-S Front View

Emergency Operation

How to Operate the LPU-S

Fault Finding

Technical Data

See “Emergency Operation of LPU V.2” on page 77.

See “Operating LPU-S 2” on page 73.

See “Troubleshooting Guide LPU” on page 43.

For technical data see “LPU Technical Data” on page 111.

20

Page 21

Damcos LPU: LPU-S Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S Top View with top cover made partly transparent.

LPU-S Bottom View

21

Page 22

Service Manual Damcos LPU: LPU-S Overview

SM 8000-100-01 Ed 04 February 2017

22

Page 23

Damcos LPU: LPU-S-Ex Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S-Ex Overview

This Chapter Describes the LPU-S-Ex with

Overview and Handling Instructions

23

Page 24

Service Manual Damcos LPU: LPU-S-Ex Overview

SM 8000-100-01 Ed 04 February 2017

Overview LPU-S-Ex

LPU-S Front View

Emergency Operation

How to Operate the LPU-S-Ex

Fault Finding

Technical Data

Cable Glands

Cable

See “Emergency Operation of LPU V.2” on page 77.

See “Operating LPU-S 2” on page 73.

See “Troubleshooting Guide LPU” on page 43.

For technical data see “LPU Technical Data” on page 111.

See “Cable Gland” on page 116.

See “Cables” on page 116.

24

Page 25

Damcos LPU: LPU-S-Ex Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S Top View with top cover made partly transparent.

LPU-S Bottom View

25

Page 26

Service Manual Damcos LPU: LPU-S-Ex Overview

SM 8000-100-01 Ed 04 February 2017

26

Page 27

Damcos LPU: LPU-S-Ex-ia Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S-Ex-ia Overview

This Chapter Describes the LPU-S-Ex-ia with

Overview and Handling Instructions

27

Page 28

Service Manual Damcos LPU: LPU-S-Ex-ia Overview

SM 8000-100-01 Ed 04 February 2017

Overview LPU-S-Ex-ia

LPU-S Front View

Emergency Operation

How to Operate the LPU-S

Fault Finding

Technical Data

Cable Glands

Zener barrier

See “Emergency Operation of LPU V.2” on page 77.

See “Operating LPU-S 2” on page 73.

See “Troubleshooting Guide LPU” on page 43.

For technical data see “LPU Technical Data” on page 111.

See “Cable gland LPU-Ex and LPU-Ex-ia” on page 116.

See “Zener barrier LPU-Ex-ia” on page 117.

28

Page 29

Damcos LPU: LPU-S-Ex-ia Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S-Ex-ia Top View with top cover made partly transparent.

LPU-S Bottom View

29

Page 30

Service Manual Damcos LPU: LPU-S-Ex-ia Overview

SM 8000-100-01 Ed 04 February 2017

30

Page 31

Damcos LPU: LPU-D Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D Overview

This Chapter Describes the LPU-D with

Overview and Handling Instructions

31

Page 32

Service Manual Damcos LPU: LPU-D Overview

SM 8000-100-01 Ed 04 February 2017

Overview LPU-D

LPU-D Front View

Emergency Operation

How to Operate the LPU-D

Fault Finding

Technical Data

See “Emergency Operation of LPU V.2” on page 77.

See “Operating LPU-D 2a” on page 75.

See “Troubleshooting Guide LPU” on page 43.

For technical data see “LPU Technical Data” on page 111.

32

Page 33

Damcos LPU: LPU-D Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D Top View with top cover made partly transparent.

*)Pressure switch is not present in all versions of LPU-D!

LPU-D Bottom View

33

Page 34

Service Manual Damcos LPU: LPU-D Overview

SM 8000-100-01 Ed 04 February 2017

34

Page 35

Damcos LPU: LPU-D-Ex Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D-Ex Overview

This Chapter Describes the LPU-D-EX with

Overview and Handling Instructions

35

Page 36

Service Manual Damcos LPU: LPU-D-Ex Overview

SM 8000-100-01 Ed 04 February 2017

Overview LPU-D-Ex

LPU-D Front View

Emergency Operation

How to Operate the LPU-D

Fault Finding

Technical Data

Cable Glands

Cable

See “Emergency Operation of LPU V.2” on page 77.

See “Operating LPU-D 2a” on page 75.

See “Troubleshooting Guide LPU” on page 43.

For technical data see “LPU Technical Data” on page 111.

See “Cable Gland” on page 116.

See “Cables” on page 116.

36

Page 37

Damcos LPU: LPU-D-Ex Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D Top View with top cover made partly transparent.

LPU-D Bottom View

37

Page 38

Service Manual Damcos LPU: LPU-D-Ex Overview

SM 8000-100-01 Ed 04 February 2017

38

Page 39

Damcos LPU: LPU-D-Ex-ia Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D-Ex-ia Overview

This Chapter Describes the LPU-D-Ex-ia with

Overview and Handling Instructions

39

Page 40

Service Manual Damcos LPU: LPU-D-Ex-ia Overview

SM 8000-100-01 Ed 04 February 2017

Overview LPU-D-Ex-ia

LPU-D Front View

Emergency Operation

How to Operate the LPU-D

Fault Finding

Technical Data

Cable Glands

Cable

Zener barrier

See “Emergency Operation of LPU V.2” on page 77.

See “Operating LPU-D 2a” on page 75.

See “Troubleshooting Guide LPU” on page 43.

For technical data see “LPU Technical Data” on page 111.

See “Cable Gland” on page 116.

See “Cables” on page 116.

See “Zener barrier LPU-Ex-ia” on page 117.

40

Page 41

Damcos LPU: LPU-D-Ex-ia Overview Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D Top View with top cover made partly transparent.

LPU-D Bottom View

41

Page 42

Service Manual Damcos LPU: LPU-D-Ex-ia Overview

SM 8000-100-01 Ed 04 February 2017

42

Page 43

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Troubleshooting Guide LPU

This Chapter Describes how to Identify

and Correct minor Problems for LPU

43

Page 44

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

44

Page 45

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Fault Finding List LPU

ACTUATOR CONNECTED PROBLEM

“Actuator only running in one direction (the unit can either only open or only close)” on page 53

“LPU-D not maintaining pressure on actuator” on page 57

“Spring actuator only partly closing or not starting to close” on page 58

“Too little tank volume for operating actuator” on page 66

“Spring actuator do not close by emergency hand pump operation” on page 69

ELECTRICAL PROBLEM

“Unit drawing too much current” on page 65

EMERGENCY OPERATION

“Emergency operation by key giving oil spillage through breather valve” on page 59

“Emergency operation by key not possible, hydraulically locked” on page 59

“Emergency operation by hand pump giving oil spillage through breather valve” on page 59

“Emergency operation by hand pump not possible” on page 60

“Spring actuator do not close by emergency hand pump operation” on page 69

LPU-D

“LPU-D not maintaining pressure on actuator” on page 57

LPU-Ex

“LPU-Ex motor do not run” on page 70

“LPU-Ex has to be bulkhead mounted because of too little space or zone 0 at actuator” on page 71

LPU-S

“LPU-S frequently restarting in open position” on page 47

MOTOR

“LPU-Ex motor do not run” on page 70

“Motor not running and is hot” on page 49

“Motor not running and is Cold” on page 49

“Motor not stopping” on page 50

“Motor running hot, LPU is operating normally” on page 56

“Motor running for a short time and stops High pressure on the port to which oil is led” on page 62

“Motor running for a short time and stops” on page 62

“Motor ”diving” in RPM in end position ” on page 63

“Motor ”diving” in RPM as spring actuator opens” on page 63

OIL LEAKAGE

“LPU leaking from bleeder valve when hand pump is mounted” on page 68

“Oil spillage, generally” on page 64

“Oil in electronic connection box” on page 64

“Oil spillage from breather valve” on page 64

45

Page 46

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

POSITION INDICATOR

“Position indicator errors” on page 72

PUMP

“Pump rendering too low (or no) pressure in one or both directions” on page 51

“Noise from pump, but only at low pressure” on page 54

“Noise from pump, but only at high pressure” on page 55

“Noise from pump at both high and low pressure” on page 55

“Pump not rendering sufficient oil at high pressure (“valve running too slowly”)” on page 61

“Pump not rendering sufficient oil at low pressure (“valve running too slowly”)” on page 61

PRESSURE

“Pump rendering too low (or no) pressure in one or both directions” on page 51

“LPU-D not maintaining pressure on actuator” on page 57

“LPU cannot raise pressure after hand pump operation (but no problems after remote operation)” on

page 67

SOLENOID VALVE

“Solenoid valve not working” on page 52

46

Page 47

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S frequently restarting in open position

Action: Place pressure gauge on quick connection B.

Read maximum pressure and observe if pressure drops when motor stops.

Then if: 1. Pressure is raised to approx. 150 bar, but drops to 95 - 105 bar before motor is restarted.

Goto “Leakage in the hydraulic system between check valve and actuator or in actuator” on

page 47.

2. Pressure is raised to approx. 150 bar and motor stops, but is restarted before pressure drops

below 115 bar.

Goto “Fault on pressure switch or wires, possibly on printed circuit board” on page 47.

3. Pressure is raised to below 120 bar and drops to 90 - 110 bar before motor is restarted.

Goto “Large leakage in the hydraulic system, or misadjusted safety valve” on page 48.

1. Leakage in the hydraulic system between check valve and actuator or in

actuator

Action: Mount hand pump, pressure gauge is already mounted (see above), and open actuator fully by hand

pump.

Then if: • Pressure remains constant

Leakage in solenoid valve or leakage at check valve in valve block:

– Check for leakage in solenoid valve.

– Check valve in valve block for external leakage, e.g. at pressure switch or closing speed adjust-

ment. Check for external leakage and if no leakage is found replace solenoid valve or check

valve.

• Pressure drops

Leakage in bypass valve at actuator, release valve, shuttle valve, emergency valve or actuator.

– Check o-rings on emergency slide and shuttle valve, possibly replace release valve or shuttle

valve if shuttle valve is version with internal slide.

– Check that bypass valve in actuator is closed.

– Possibly dismount LPU from actuator and check if actuator has leakage, internal or external.

2. Fault on pressure switch or wires, possibly on printed circuit board

Action: Wires to pressure switch are dismounted from pressure switch and connected to each others, simu-

lating high pressure.

Caution! For LPU power these wires are supplied by 230 V. When the LPU is energized, the motor

must run for 7 - 12 seconds, then stop, and not start until the wires are disconnected

from each other.

Pressure Switch is electrically measured fully pressurized for short breaks (loose connections). Pressure gauge is mounted on quick connection for B and pressure is read when pressure switch breaks.

Then if: • Pressure switch breaks above 105 bar

47

Page 48

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

– Pressure switch is adjusted, so that pressure switch breaks by falling pressure at

100 ±5 bar. Pressure switch must close below 125 bar by rising pressure.

• Short breaks of pressure switch

– Replace pressure switch! See “Replace pressure switch” on page 109.

• Pressure switch breaks below 105 bar, no short breaks

– Check electrical connections from pressure switch. If no other faults are detected, replace

printed circuit board. See “Replace Printed Circuit Board” on page 105.

3. Large leakage in the hydraulic system, or misadjusted safety valve

Action: Mount hand pump, actuator is fully opened by hand pump, pressure gauge is mounted.

Then if: • Pressure remains constant

Leakage in solenoid valve, quick connection B or external leakage, e.g. at pressure switch. Possibly too low adjusted pressure at pump relief valve (pump safety valve).

– Check for external leakage, if no leakage, adjust pump pressure (see “Pump pressure adjust-

ment for LPU” on page 85). If this cannot be adjusted any higher, check internal sealings and

flow reducing valve (opening speed adjustment).

– Replace solenoid valve (see “Replace Solenoid Valve in LPU-D” on page 107), flow reducing

valve or sealings. Then safety valve is readjusted to 150 bar (see “Pump pressure adjustment

for LPU” on page 85).

Note! If oil has too low viscosity or is very hot this might be the reason for a too low pressure.

• Pressure drops

Leakage in actuator, or possibly bypass valve, release valve, emergency valve or shuttle valve.

– Check o-rings on shuttle valve and emergency valve, possibly replace release valve, see

“Replace release valve in LPU” on page 99.

– Check for external leakage.

48

Page 49

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Motor not running and is hot

Action: Check that electrical connections to motor and capacitor are OK! Open bypass to release possible

pressure on pump and try to run the motor with opened bypass.

Then if: • Motor is running, but stops when bypass is closed.

Incorrectly connected motor or fault on motor or wires.

– Low supply voltage.

– Defective flow reducing valve, see “Motor ”diving” in RPM in end position ” on page 63.

• Motor is not running at all, even though bypass is opened.

– Disconnect current to LPU for measurement of resistance from N to CL and from N to OP on

printed circuit board (the easiest way is to disconnect the capacitor). Resistance must be

15

. The capacitor can on rare occasions be defective.

If connections and resistance are OK, the pump has stuck. New pump set is then mounted,

see “Replace Pump in LPU” on page 93. Reason for defective pump should be found, e.g.

insufficient quantity of oil, no stop of motor, impurities in oil etc.

Note! For LPU-Ex the temperature cut-off box might have interrupted power to motor due to too

high motor temperature. If this is the case the motor needs time to cool down, then 24 V

to LPU-Ex is interrupted for 10 seconds and LPU-Ex should be ready to run again.

Motor not running and is Cold

Action: • Check that there is 220 - 230 V AC over “N” and “open” or “close”, respectively when trying to

operate.

• Check that electrical connections to motor are OK. If the black wire is not connected, motor can-

not run.

• Dismount the motor wires. Check the resistance on the printed circuit board from “N” to the

centre motor wire, and from “open” and “close”, respectively to the two other motor connections. There must not be a measurable resistance.

• Check the resistance in the motor itself, there must be approximately 15

wire and each of the others. If the resistance differs widely, the motor is to be replaced.

Note! For LPU-Ex the temperature cut-off box will interrupt power to motor if 24 V is not present

or bounces when it is connected.

. between the black

49

Page 50

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Motor not stopping

Action: • The pressure on B-port is measured.

If the pressure is below 120 bar, while motor is running, see “Pump rendering too low (or no)

pressure in one or both directions” on page 51.

• Wires to the pressure switch are dismounted and connected to each others, simulating high

pressure.

Caution! LPU-Power wires are supplied by 230 V. When LPU terminal (“open”) is energized in the

relevant direction, motor must stop after 7 - 12 seconds.

LPU-S-power must not be restarted before wires are disconnected.

LPU-D-power must not be restarted before power is disconnected and reconnected

again.

• If pressure switch is correctly connected, and the pressure is correct, check that pressure switch

is closing as required. Pressure switches must close at maximum 125 bar and break between 95

to 105 bar.

Adjust and if necessary replace pressure switches, see “Replace pressure switch” on page 109.

LPU-D-P-Net

If motor does not stop at all, the printed circuit board must be replaced, see “Replace Printed Circuit

Board” on page 105.

If the motor runs longer than normal, but then stops, the fault should be found in the position indicator, the calibration of the analogue indicator or setup of extra time in circuit board. Check, that the

position signal is really “0” or “100”.

LPU-S-P-Net

If motor does not stop at all and pressure on B-port is above 125 bar, the printed circuit board must

be replaced, see “Replace Printed Circuit Board” on page 105.

If the motor runs longer than normal, but then stops, the fault should be found in the position indicator, the pressure switch, the calibration of the analogue indicator or setup of extra time in circuit

board. Check that the position signal really is “100”.

LPU Power Control

Check that the pressure switch is correctly connected. See “Pump rendering too low (or no) pressure

in one or both directions” on page 51.

50

Page 51

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Pump rendering too low (or no) pressure in one or both

directions

Action: • Check that solenoid valve is clicking at connection. If not see “Solenoid valve not working” on

page 52.

• If pump does not render any pressure at all check oil level.

Mount a plug giving a possibility of connecting compressed air instead of breather valve and

pressurize tank with maximum 2.5 bar, while the pump is running. If air pressure in tank does not

solve the problem, or if the pump renders pressure (but too low), hand pump with pressure

gauge is mounted and actuator is fully opened by hand pump.

LPU-D

If no opening pressure check that by-pass for tank filling (in front of LPU) is closed.

LPU-Power

Check that power supply is connected to terminal “open” and that terminal “close” is not connected.

If pressure remains constantly low

At too low pressure in one direction (LPU-S) or both directions (LPU-D) the safety valve is adjusted

according to instruction (see “Pump pressure adjustment for LPU” on page 85). If higher pressure

cannot be obtained, there is a possible leakage in the solenoid valve, or at DPCV-slide (LPU-D), or at

clearance between pump stator and rotor.

De-airing the flow reducing valve may be necessary, see “Pump not rendering sufficient oil at low

pressure (“valve running too slowly”)” on page 61.

If pressure drops quickly

Leakage in bypass valve (actuator), shuttle or emergency valve (LPU-S) or release valve. Check o-rings

on valves and if necessary replace release valve (see “Replace release valve in LPU” on page 99) or

shuttle valve.

51

Page 52

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Solenoid valve not working

Action: • Check that solenoid valve is energized (230 V on terminals “N” and “SV”).

• If coil is energized, but solenoid valve does not work, the resistance of the coil is measured (LPU-

D). The coil must have a resistance of approximate 520

tance cannot be measured for LPU-S coil. Another way to check the coil is to loosen it and try to

lift the coil when energized. If coil does not work, it is replaced.

• If coil works, the valve is to be replaced. See “Replace Solenoid Valve in LPU-D” on page 107.

for LPU-D. Due to a diode bridge resis-

52

Page 53

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Actuator only running in one direction

(the unit can either only open or only close)

LPU-D

If LPU-D can close, but not open check by-pass valve for oil filling. Check that solenoid valve is powered and working and that free travel of solenoid valve slide is OK.

LPU-S

If actuator can close, but not open see “Pump rendering too low (or no) pressure in one or both directions” on page 51. If actuator can open, but not close, see “Spring actuator only partly closing or not

starting to close” on page 58.

Note! BRCF and KF can always be closed by opening bypass valve at actuator. KFR can be closed

opening bypass valve and lifting valve for emergency operation by hand pump.

53

Page 54

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Noise from pump, but only at low pressure

Action: Adjust speed from maximum to minimum (see “Speed adjustment for Actuator on LPU (v.2)” on

page 83). If possible, place key on emergency operation shaft of the actuator and hold against rotating direction (i.e. operating pressure must be approximate 30 bar) (only possible for BRC 125, 250,

500).

Warning! Beware of huge force, actuator cannot be stopped by hand!

Then if: • Sound disappears

Too low compression of O-ring on motor shaft, so that rotor is vibrating on coupling.

Replace O-ring.

• Sound is unchanged

A pump piston is operating too tightly and does not follow the ball bearing curve during movement. At relatively high pressure it is pressed out hydraulically. The sound can disappear at starting-up. Otherwise pump is dismounted and pistons and rotor are checked for coverings or burrs.

Note! If pump rotor has to be replaced the stator version has to be checked (check placement

and number of expanding plugs). If stator versions are different both rotor and stator must

be exchanged (complete pump set, see “Replace Pump in LPU” on page 93).

54

Page 55

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Noise from pump, but only at high pressure

Reason: • Air in the pump if actuator has not been properly de-aired. Check oil level in tank.

• Too small tank volume for large actuators or long pipes in system.

• Piston in pump is sticking.

A pump piston is operating too tightly and does not follow the ball bearing curve during movement. At relatively high pressure it is pressed out hydraulically. The sound can disappear at starting-up. Otherwise pump is dismounted and pistons and rotor are checked for coverings or burrs.

Note! If pump rotor has to be replaced the stator version has to be checked (check placement

and number of expanding plugs). If stator versions are different both rotor and stator must

be exchanged (complete pump set, see “Replace Pump in LPU” on page 93).

Noise from pump at both high and low pressure

Reason: Motor and pump are not co-axial, pump stator is not mounted firmly in the block.

Action: • Check steering pins between blocks.

• Dismount pump and check that remounted stator is perpendicular to valve block.

See “Replace Pump in LPU” on page 93 for more information.

55

Page 56

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Motor running hot, LPU is operating normally

Caution! Motor is designed for 25% duty cycle only.

Action: • LPU-S

Observe that LPU does not restart.

If it is restarting frequently, the motor is running hot. See“LPU-S frequently restarting in open

position” on page 47.

• Measure the supply voltage (220 - 230 V AC) to LPU.

If it differs widely from the required voltage, the voltage must be modified.

• Measure the resistance over the motor windings, on the terminal (easiest with disconnected

capacitor). There must be approximately 15

tively.

If this resistance is not observed, the motor is to be replaced.

• The mechanical resistance of the motor can be too high.

If it cannot be turned easily with the fingers, it is to be replaced.

• The mechanical resistance of the pump can be too high, if ball bearing is blocked.

Dismount valve block and pump rotor as to change pump (see “Replace Pump in LPU” on

page 93) and check if ball bearing can rotate freely.

between “N” and “OPEN” and “CLOSE” respec-

56

Page 57

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D not maintaining pressure on actuator

Pressure drops only on 1 port

• Leakage in check valves for DPCV or release valve.

Change check valves for DPCV.

• A leakage in actuator might give pressure drop on only one port.

Replace the seal set in actuator with a new one.

Pressure drops on both ports

Leakage in bypass valve (actuator) or actuator.

• Check bypass valve, possibly replace release valve (see “Replace release valve in LPU” on

page 99).

• Check actuator.

57

Page 58

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Spring actuator only partly closing or not starting to close

Action: Check that throttle valve for adjustment of closing speed is not blocked.

Open bypass while motor is not operated.

Then if: • Spring actuator closes

Solenoid valve coil is still energized while valve is required to be closed!

This might be due to that valve has been opened by hand pump or filter below pressure switch is

blocked or too fast closing speed so that emergency valve has no pressure and is closing before

actuator is closed.

If this is the case then:

– repeat opening and closing command (by remote operation) for LPU.

If closing does not function check that the power for the solenoid valve is turned off.

If not check relay in control cabinet (power controlled with separately connected solenoid

valve), or on printed circuit board (P-Net).

Else remove coil from solenoid valve. Check filter below pressure switch (valve must be

closed). Adjust closing speed valve to fully closed, open it 1 revolution and check again. If the

actuator now closes closing speed can be increased step by step. If closing speed cannot be

sufficient then B-line between LPU and actuator is checked for blocks that can throttle oil flow.

• Spring actuator remains open

The fault is to be found outside the LPU.

For KFR push button for emergency operation might be blocked. Valve is sticking, or fault on

spring actuator.

58

Page 59

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Emergency operation by key giving oil spillage through

breather valve

Reason: When valve is emergency operated by key, oil is pumped from actuator to LPU tank and further on to

the actuator. If the oil flow from LPU tank to actuator gives more than 3 bar pressure drop, the oil can

be pressed through the breather valve instead of back to actuator.

Action: Carrying out emergency operation at the same opening and closing speed to which the valve is set at

remote operation can solve the problem.

Caution! Avoid replacement of breather valve with plug, as this might result in too high pressure

at motor shaft sealing.

Emergency operation by key not possible, hydraulically

locked

Reason: Bypass not active or bypass valve is blocked.

Action: Open bypass valve and keep it opened during emergency operation. If emergency operation is still

locked - bypass valve is to be dismounted and checked. If bore contains dirt, it has to be removed.

Emergency operation by hand pump giving oil spillage

through breather valve

Reason: Tank pressure in LPU is too high. The pressure drop over quick connections due to very fast operation

or defective or not properly connected quick connections. If LPU is bulkhead mounted the pressure

drop might be in piping as well if they are long or if the inside diameter is narrow.

If oil cannot return to the hand pump tank, an LPU-S may be opened without problems. When valve

closes again, the LPU tank overflows.

When LPU’s closed system is filled with oil, the exceeding oil is let out through the breather valve to

prevent overpressure in the LPU.

59

Page 60

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Emergency operation by hand pump not possible

Reason: • Hand pump is building up pressure, but actuator is not moving

– Slide for shuttle valve is sticking, so that change over to emergency operation cannot take

place (LPU-S).

– Outlet from actuator blocked so that return oil cannot pass.

– Fault on quick connections, so that check valve in hand pump quick connection is not open-

ing.

• Hand pump is pumping oil, but cannot build up pressure

– Leakage in DPCV (LPU-D), bypass valve, release valve, emergency valve (LPU-S) or actuator

• After a few strokes, hand pump is not pumping oil

– Insufficient oil in hand pump tank

60

Page 61

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Pump not rendering sufficient oil at high pressure (“valve

running too slowly”)

Reason: LPU is built up, so that oil quantity from pump, independent of adjusted speed, is reduced to approx-

imate 240 cm

“Pump rendering too low (or no) pressure in one or both directions” on page 51.

The pressure should only exceed 65 bar for a few seconds, when breaking valve away or clo sing

valve.

3

/min from pressure exceeding 75 bar. If flow is considerably below this quantity, see

Pump not rendering sufficient oil at low pressure (“valve

running too slowly”)

Action: • Check adjustment of opening and closing speed (see “Speed adjustment for Actuator on LPU

(v.2)” on page 83).

• While pump is running at high pressure in end position, valve housing for speed adjustment is

loosened by a 19 mm wrench (must be turned maximum 3 turns, as there is full pump pressure

below housing), until airless oil is running from it. Then valve housing is tightened, and pump

flow is checked again. If pump flow is still not OK, dismount adjusting screw for speed control,

check with a screw driver that the ball bearing behind this can be moved back and forth by pressing it. Check mobility of the piston in valve housing for speed adjustment.

• Dismount tank and check if filter in suction pipe is blocked.

• Dismount tank and valve block, check the mobility of the bearing, and observe if any pistons in

rotor are sticking. Stator is dismounted (pressed out from the tan side), and blown through, to

remove plugging, if any, in the longitudinal holes.

• Remounting of stator: stator must be pressed in until direction pin is below surface of block.

When seated correctly, the free stator length is approximate 19 mm. Do not use metal hammer

directly on the stator. (See “Replace Pump in LPU” on page 93).

61

Page 62

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Motor running for a short time and stops

High pressure on the port to which oil is led

Action: Mount pressure gauge on quick connection on return oil from actuator (LPU-D). At the same time

check that actuator is moving.

Then if: • High pressure on return oil. Actuator is not moving, or is hardly moving

DPCV does not open check valve for return oil. Check slide, sealings and check-valves for DPCV.

• Low pressure on return oil. Actuator is running, but not to end position

Operating pressure for actuator too high due to blocking in return, could be dirt in holes near the

port surface or in actuator.

• Low pressure on return oil. Actuator is not moving, or is hardly moving

Operating pressure for actuator too high due to blocking in return, could be dirt in holes near the

port surface or in actuator.

Fault in actuator, valve (requires a too high torque or more than 7 seconds before breaking away

from the seat), or choice of actuator for the valve in question.

Motor running for a short time and stops

Reason: Pressure switch does not break, or fault on control print.

Action: • Try dismounting a wire for the pressure switch in question. LPU shall then operate as long as ter-

minal is energized. If not so, there is a fault on the printed circuit board which is then replaced

(see “Replace Printed Circuit Board” on page 105).

• Control card receives a signal for stop of motor from pressure switch. For LPU-S and LPU-D-

Power, pressure switch connections and adjustment are to be checked. Pressure switch is possibly replaced (see “Replace pressure switch” on page 109).

62

Page 63

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Motor ”diving” in RPM in end position

Reason: Voltage too low, pump relief valve misadjusted, defective flow reducing valve (the displacement of

the pump is not reduced at high pressure), fault in motor, or faulty connection of motor. Possibly

fault in capacitor/connection.

Action: • Check voltage over the terminals during operation. If it is considerably below 220 V AC, the fault

is to be found here. Take corrective measures. (LPU can operate down to 185V at

60 Hz, but such a low voltage is an indication of something being wrong).

• Check connection of motor.

• Check connection of capacitor.

• Check the maximum pressure (connect a pressure gauge to the quick connection pressurised).

Possibly adjust relief valve to 150 bar.

• Dismount adjusting screw for speed control, check with a screwdriver that the ball bearing

behind this can be moved back and forth by pressing it.

Motor ”diving” in RPM as spring actuator opens

Reason: Voltage too low, mechanical resistance in ball bearing around pump, faulty connected motor or fault

in capacitor.

63

Page 64

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Oil spillage, generally

Avoid starting motor until the correct level in tank has been ensured. After elimination of faults,

replenish tank with the correct oil for the specific system.

Oil in electronic connection box

Action: • At a large oil volume in electric connection box: Avoid starting the motor until having ensured

that the oil level in tank is OK.

• Check pressure switch and solenoid valve for visible leakage, possibly by starting pump.

• For LPU-S, leakage at pressure switch or solenoid valve will result in a pressure drop, so that the

LPU motor / pump restarts if this function is engaged.

• Possible leakage from safety valve cannot be positively identified, until electronic connection

box has been dismounted.

• Leakage from actuator, led through the position indicator can occur at leakage from actuator to

indicator. In special cases, oil may even be led through the power/bus cables from one LPU to the

next.

• At leaking shaft seal on the electrical motor, the oil can run through motor and up in electronic

connection box.

• After repair of defects, the tank is replenished with the correct oil for the specific system.

Oil spillage from breather valve

• Oil spillage at emergency operation: see “Emergency operation by key giving oil spillage through

breather valve” on page 59 or “Emergency operation by hand pump giving oil spillage through

breather valve” on page 59.

• Oil spillage during operation when motor is changing direction: Compressed air in actuator.

Actuator is to be de-aired.

Especially linear actuators (KC, KF and KFR) may have to be loosened from valve to be able to

close completely before de-airing of actuator.

• Oil spillage when BRCF closes: Possibly air in actuator, actuator is to be de-aired. Breather valve

shall only be placed in BRCF or in LPU, not in both. Breather valve to be placed at highest possible

tank level. Too fast closing of actuator giving a high return pressure at closing letting oil out of

breather valve. Adjust closing speed to slower closing.

• Oil spillage when KF or KFR closes: Possibly air in actuator, actuator is to be de-aired. Breather

valve must always be placed on top of KFR, and in LPU, where breather valve has to be placed at

highest possible tank level. Too fast closing of actuator giving a high return pressure at closing

letting oil out of breather valve. Adjust closing speed to slower closing.

• Oil spillage at temperature rise in LPU-system: Oil tank overfilled or too great expansion at heat-

ing up, dependent on oil volume. At a large oil spillage due to heating up, an extended tank

should be used.

64

Page 65

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Unit drawing too much current

Reason: • Mechanical resistance in motor

• Mechanical resistance in pump

• Too small winding resistance in motor meaning a 110 V motor has been used instead of 230 V

motor

• Too high or too low supply voltage

• Too low frequency

• Faulty electrical connection of motor

• Defective capacitor

65

Page 66

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Too little tank volume for operating actuator

LPU

• Incorrect oil filling and de-airing of actuator. Check oil filling.

• Too high compressibility of oil in pipes between hand pump and LPU or between LPU and actua-

tor. Try more carefully de-airing of piping. It might be necessary to use an expansion tank at LPU.

Expansion tank at hand pump is not allowed as it gives risk of oil spillage at breather valve.

LPU-S

No connection from LPU-tank and hand pump tank to actuator tank/spring chamber. Hand pump

tank and LPU tank need tank connection to actuator to maintain constant oil volume in system for

mix of emergency and remote operation.

For large actuators

Oil compression by pressurizing actuator needs more oil than a standard tank can give. Use pressure

tank for LPU. This is the case for e.g. BRC/BRCF 16000, BRC 32000, BRCF 4000 HT, BRCF 8000 HT,

KC 325 and KC 400.

66

Page 67

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU cannot raise pressure after hand pump operation

(but no problems after remote operation)

Reason: • Leakage from LPU to hand pump.

– Portable hand pump must be disconnected.

– Make sure that by-pass at possible bulkhead hand pump is closed.

– Try to operate valve in the selected direction by hand pump first, then by LPU. If LPU can raise

pressure now, the DPCV valve slide has too high friction. If problem is not solved DPCV is leaking due to defect non return valve or slide is sticking.

67

Page 68

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

LPU leaking from bleeder valve when hand pump is

mounted

Reason: For LPU-S

• Bad T-connection from LPU to hand pump:

– Check piping and connections.

– Check that no by-pass valve is placed in T-side of hand pump, as free T-flow is essential for

function of hand pump.

For LPU-D

• At remote operating LPU is compressing oil in piping for hand pump or, when bulkhead mounted

LPU, for actuator. The oil volume needed for compressing this oil is depending on oil volume in

pipes and proper de-airing. This oil volume will be taken from hand pump tank and cannot be

returned because of DPCV in hand pump.

– If de-airing of piping is OK a pressure tank at LPU has to be mounted.

Caution! Pressure tank at hand pump is not allowed.

68

Page 69

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Spring actuator do not close by emergency hand pump

operation

Reason: • Spring actuators will not close by changing bulkhead hand pump to close, as there will be no

pressure rise to open the DPCV.

– Close actuator through by-pass valve at hand pump or actuator instead. Close by-pass valve

when the actuator is fully closed.

For KFR

If KFR is emergency opened at the actuator, an opening operation followed by closing the actuator is

necessary. Opening operation can be made by hand pump or remote control.

69

Page 70

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

LPU-Ex motor do not run

Reason: LPU-Ex-motors contain temperature sensors that have to be reset manually. After motor cut-off by

temperature sensors they have to be reset by turning off 24 V power for at least 10 sec.

If this don’t solve the problem, see “Motor not running and is hot” on page 49 and “Motor not run-

ning and is Cold” on page 49.

70

Page 71

Damcos LPU: Troubleshooting Guide LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-Ex has to be bulkhead mounted because of too little

space or zone 0 at actuator

Like other LPU’s LPU-Ex can be bulkhead mounted by means of BB-block or BB-VPI, but then needs an

intrinsically safe position indicator. All LPU-Ex can be delivered with integrated intrinsically safe outlet

for position indicator (ia) to solve the problem.

Note! For LPU-Ex with ia-outlet the hole for DPI in LPU must contain a special plug to ensure that

flameproof enclosure of LPU-Ex is maintained. This plug is delivered with ia-parts and

must always be used for ia-versions.

71

Page 72

Service Manual Damcos LPU: Troubleshooting Guide LPU

SM 8000-100-01 Ed 04 February 2017

Position indicator errors

Fault: • ON/OFF position indicator is not functioning correctly:

– Check the control cable connections.

– Check the function of the position indicator, measured on the position indicator wire connec-

tion. Possibly replace position indicator.

• Analogue position indicator cannot be calibrated

– Disconnect the wires from the position indicator, check the adjustment of the potentiometer,

and possibly re-adjust the indicator according to the relevant instruction

• Analogue position indicator not functioning correctly

For power controlled LPU:

– Check supply voltage at 4 - 20 mA transmitter which has to be 15 - 27 VDC.

– Disconnect the wires from the position indicator.

– Check the adjustment of the potentiometer, and possibly re-adjust the indicator according to

the relevant instruction

– Check the function of the potentiometer, measured on the indicator.

– Check the cable entry in cable glands. Shield has to be connected in both ends. If the indicator

and cable mounting is OK, replace the printed circuit board (see “Replace Printed Circuit

Board” on page 105). Otherwise replace the position indicator.

(*

.

(*

.

*) 300-350 Ohm between the "closed" and the "wiper" connection, while the valve is fully closed.

72

Page 73

Damcos LPU: Operating LPU-S 2 Service Manual

1. Tank for hydraulic oil

2. Suction filter

3. Electrical motor

4. Pressure controlled flow adjustment

5. Pump safety valve

6. Actuator relief valve

7. Quick connection for hand pump suction

8. Fail safe actuator, single-acting

9. Quick connection for hand pump,

opening w/filter

10.Shuttle valve for hand pump, opening

11.Throttle for closing speed adjustment

12.Pressure switch

13.Pressure filter

14.Solenoid valve

15.Non-return valve

16.Opening speed adjustment

17.Variable displacement pump

February 2017 SM 8000-100-01 Ed 04

Operating LPU-S 2

Hydraulic Diagram LPU-S

To open valve

To move the valve towards open, the motor (3) is activated.

The oil is led from tank through the pump and through the non-return valve (15), directly to the

actuator B port. To prevent the oil from flowing back to tank, the solenoid valve (14) must be energized. When the valve is fully open, the pressure rises to 150 bar which causes the pump safety valve

(5) to open and the oil flows back to tank. The motor is de-energized.

The actuator is now hydraulically locked in position by the solenoid valve.

Safety/Actuator relief valve

In case of a major increase of temperature, the pressure may rise. This will not cause any problems

because of the safety valve (6) which will open at approximately 225 bar.

To stop valve in intermediate position

The valve can be stopped (and hydraulically locked) in any intermediate position simply by de-energizing the motor.

If the pressure drops while valve is fully open - due to a minor leakage in the solenoid valve or due to

temperature variations -, the pressure switch (12) will detect this. The motor may then be activated

73

Page 74

Service Manual Damcos LPU: Operating LPU-S 2

SM 8000-100-01 Ed 04 February 2017

for some seconds in order to keep up the pressure, and prevent the valve from leaving the open position. - This may take place automatically.

Close valve

To move the valve towards closed, the solenoid valve is de-energized. The springs then move the

actuator, pressing the oil back from the actuator B port, through the throttle valve (11) and the solenoid valve (14) to the LPU tank.

Note! For power controlled LPU please see also “Operation LPU-S” on page 123.

74

Page 75

Damcos LPU: Operating LPU-D 2a Service Manual

1. Tank for hydraulic oil

2. Suction filter

3. Electrical motor

4. Pressure switch

5. Double pilot operated check valve,

closing side

6. Actuator relief valve, closing side

7. Quick connection for hand pump,

closing w/filter

8. By-pass valve

9. Double-acting actuator

10.Quick connection for hand pump,

opening w/filter

11.Actuator relief valve, opening side

12.Tank filling valve

13.Double pilot operated check valve,

opening side

14.Solenoid valve

15.Pump safety valve

16.Pressure controlled flow adjustment

17.Variable displacement pump

February 2017 SM 8000-100-01 Ed 04

Operating LPU-D 2a

Hydraulic Diagram LPU-D

To open valve

When the motor and solenoid valve are activated the oil is sucked from tank through the suction filter to the pump and pumped through the solenoid valve and the pilot operated check valve (13) to

the actuator port B. This causes the actuator to open the valve. The oil from actuator port A flows

back through the pilot operated check valve (5) (which is opened by the pressure in the B-line) and

returns through the solenoid valve to the tank.

When the valve is fully open, the pressure rises to 150 bar, which causes the pump safety valve to

open so that the oil flows back to tank. The motor and the solenoid valve are then de-energized.

The actuator is now hydraulically locked in position by the pilot operated check valves.

Safety/Actuator relief valve

In case of a major rise in temperature, the pressure may rise. This will not cause any problems

because of the actuator relief valve (6) and (11), which will open at approx. 225 bar.

75

Page 76

Service Manual Damcos LPU: Operating LPU-D 2a

SM 8000-100-01 Ed 04 February 2017

Close valve

Closing the valve follows exact the same procedure, except that the solenoid valve is not activated

which causes the ports A and B to be reversed.

When the motor is running the direction of oil- flow is solely determined by the activation of the solenoid valve.

Note! For power controlled LPU please see also “Operating LPU-D” on page 124.

76

Page 77

Damcos LPU: Emergency Operation of LPU V.2 Service Manual

February 2017 SM 8000-100-01 Ed 04

Emergency Operation of LPU V.2

For all operations: When the hand pump is disconnected and the by-pass valve is closed, the remote

control is allowed to operate the system again.

Note! For LPUv.2 emergency operation with hydraulic hand pump, a hand pump unit with reser-

voir can be used. To avoid overfilling of the LPU, both quick connections have to be

mounted.

Note! To close emergency opened actuator by remote, open the actuator first to release shuttle

valve and then close.

LPU with LED Position Indicator

LPU (except Ex version) with IP 68 LED indicator will show clear red or green light when the valve is

closed respectively open.

77

Page 78

Service Manual Damcos LPU: Emergency Operation of LPU V.2

SM 8000-100-01 Ed 04 February 2017

Firmly mounted hand pump

With a firmly mounted hand pump the following applies:

Emergency open a fail-open LPU

1. Open by-pass at the actuator or at the firmly mounted hand pump until the valve has reached

the desired position. Then close by-pass valve again.

2. If the actuator has been closed by remote control and power is still on “the keep closed” function

is activated and the LPU may start up trying to keep the actuator closed. You have to disconnect

power or remove close-command before manual operation is started.

The valve will now stay in position until operated with hand pump again or by remote control.

Emergency closing a fail-close actuator

1. Open by-pass at the actuator or at the firmly mounted hand pump until the valve has reached

the desired position. Then close by-pass valve again.

2. If the actuator has been opened by remote control and power is still on, “the keep open” func-

tion is activated and the LPU may start up trying to keep the actuator open. You have to disconnect power or remove open-command before manual operation is started.

The valve will now stay in position until operated with hand pump again or by remote control.

Emergency closing a fail-open LPU

or

Emergency opening of actuator

1. Turn the directional valve at the hand pump to position “OPEN”

2. Operate hand pump until the valve has reached the desired position.

The valve will now stay in position until operated with hand pump again or by remote control.

Emergency closing of a double acting actuator

1. Turn the directional valve at the hand pump to position “CLOSE”

2. Operate hand pump until the valve has reached the desired position.

The valve will now stay in position until operated with hand pump again or by remote control.

78

Page 79

Damcos LPU: Emergency Operation of LPU V.2 Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-D

Emergency operation of double acting actuator with key

Actuators that can be opened by emergency operation actuator:

BRC 125 - BRC 500

1. Open the crossover valve by turning counter clockwise.

2. Use the emergency operation key on the actuator.

3. Open by-pass valve at the actuator and turn

the key counter clockwise to open valve and

clockwise to close valve.

4. After emergency operation by key the

crossover valve is closed.

79

Page 80

Service Manual Damcos LPU: Emergency Operation of LPU V.2

SM 8000-100-01 Ed 04 February 2017

Emergency opening of double acting actuator with hand pump

1. Connect hand pump P-line with B-line quick connection at the LPU.

2. Connect hand pump T-line with A-line quick connection at the LPU.

3. Operate hand pump and actuator will open.

4. Disconnect hand pump

Emergency closing of double acting actuator with hand pump

1. Connect hand pump P-line with A-line quick connection at the LPU.

2. Connect hand pump T-line with B-line quick connection at the LPU.

3. Operate hand pump and actuator will close.

4. Disconnect hand pump

80

Page 81

Damcos LPU: Emergency Operation of LPU V.2 Service Manual

February 2017 SM 8000-100-01 Ed 04

LPU-S

Emergency opening of single acting actuator with hand pump

1. Connect hand pump P-line with B-line quick connection at the LPU.

2. Connect hand pump T-line with T-line quick connection at the LPU.

With suction to T and pressure to B the shuttle valve will change over and prevents the oil from

flowing to tank.

3. Operate hand pump and actuator will open.

4. Disconnect hand pump

Note! This procedure applies to fail-close actuators.

For Fail-open actuators please contact Emerson Process Management.

Emergency closing of single acting fail-close actuator

1. Open cross-over valve on actuator and let it stay open until the required position is reached.

2. When the valve is fully closed, the shuttle valve will be reset.

Emergency opening of single acting fail-open actuator

1. Open cross-over valve on actuator and let it stay open until the required position is reached.

2. When the valve is fully closed, the shuttle valve will be reset.

81

Page 82

Service Manual Damcos LPU: Emergency Operation of LPU V.2

SM 8000-100-01 Ed 04 February 2017

82

Page 83

Damcos LPU: Speed adjustment for Actuator on LPU (v.2) Service Manual

February 2017 SM 8000-100-01 Ed 04

Speed adjustment for Actuator on LPU (v.2)

Speed adjustment for double acting actuators

Speed will be adjusted by means of a 3 mm Allen key, see picture below where to adjust. By turning

the screw clockwise (fasten screw), the actuator will run slower, turning the screw counterclockwise

it runs faster. If the actuator has to run with maximum or minimum speed, the adjustment screw

shall only be tightened slightly (max 1.5 Nm).

Speed adjustment for single acting actuators

Opening and closing speed will be adjusted by means of a 3 mm Allen key, see picture below where

to adjust. By turning the screw clockwise (fasten screw), the actuator will run slower, turning the

screw counterclockwise it runs faster. If the actuator has to run with maximum or minimum speed,

the adjustment screw shall only be tightened slightly (max 1.5 Nm).

83

Page 84

Service Manual Damcos LPU: Speed adjustment for Actuator on LPU (v.2)

SM 8000-100-01 Ed 04 February 2017

84

Page 85

Damcos LPU: Pump pressure adjustment for LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Pump pressure adjustment for LPU

Warning! Parts inside housing of LPU are connected to 230 Volts, please do not touch these parts

without power supply securely OFF.

1. The pressure gauge is mounted on quick connection B (nearest to the motor) of the LPU. For

LPU-D the adjustment can also be carried out with the pressure gauge on quick connection A,

and thus the LPU shall only receive a ”Close”-command during adjustment.

2. Adjustment of the pump pressure is carried out with a 5 mm Allen key with ball head. The adjust-

ment screw is placed near the pressure switch (the one near the LPU-front in LPU-D).

3. The pressure has to be set to 150 bar. As there are some tolerances in the system, the pressure

might be varying, that’s why the pressure is set to 150 bar to assure a running pressure of 135

bar at the actuator. Tightening the screw will rise the pressure, loosening the screw will lower the

adjusted pressure.

4. For Power- controlled LPU: To obtain a longer operating time of the motor than standard 7 sec-

onds, the pressure switch cables to the specific pressure switch (for “B” it is the pressure switch

near the pressure adjustment) can possibly be dismounted from the print. These lines are from

print card connected to 220 Volt. The motor must be operated for max. 10 minutes.

5. For P-NET controlled LPU: To obtain a longer operating time of the motor than standard 7 sec-

onds, the indicator cables to the specific terminal can possibly be dismounted from the print.

The motor must be active for max. 10 minutes.

6. When the actuator is in end position, the pressure can be read on the pressure gauge, while the

motor is running.

7. The pressure is adjusted to approx. 150 bar. Then the motor is stopped, pressure released and

motor is started again for fine adjustment, if any.

8. After final adjustment the pressure gauge is dismounted, and the cables to the pressure switch/

indicator are mounted again.

85

Page 86

Service Manual Damcos LPU: Pump pressure adjustment for LPU

SM 8000-100-01 Ed 04 February 2017

86

Page 87

Damcos LPU: Refill of Oil in LPU Service Manual

February 2017 SM 8000-100-01 Ed 04

Refill of Oil in LPU

Refilling of oil is normally done when needed. Refill of oil should also be done when parts are

changed in LPU or if LPU starts to make special noises at operation.

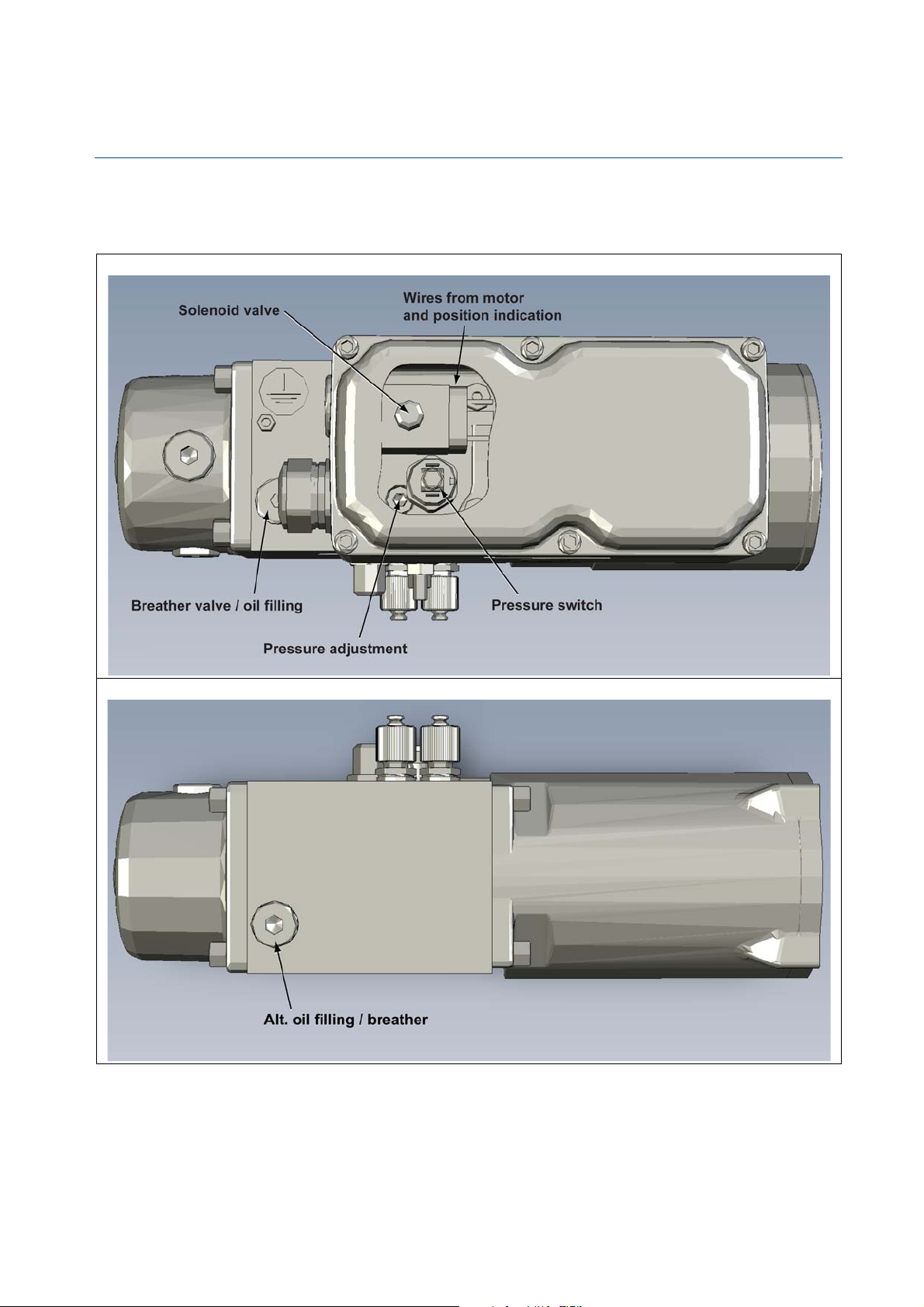

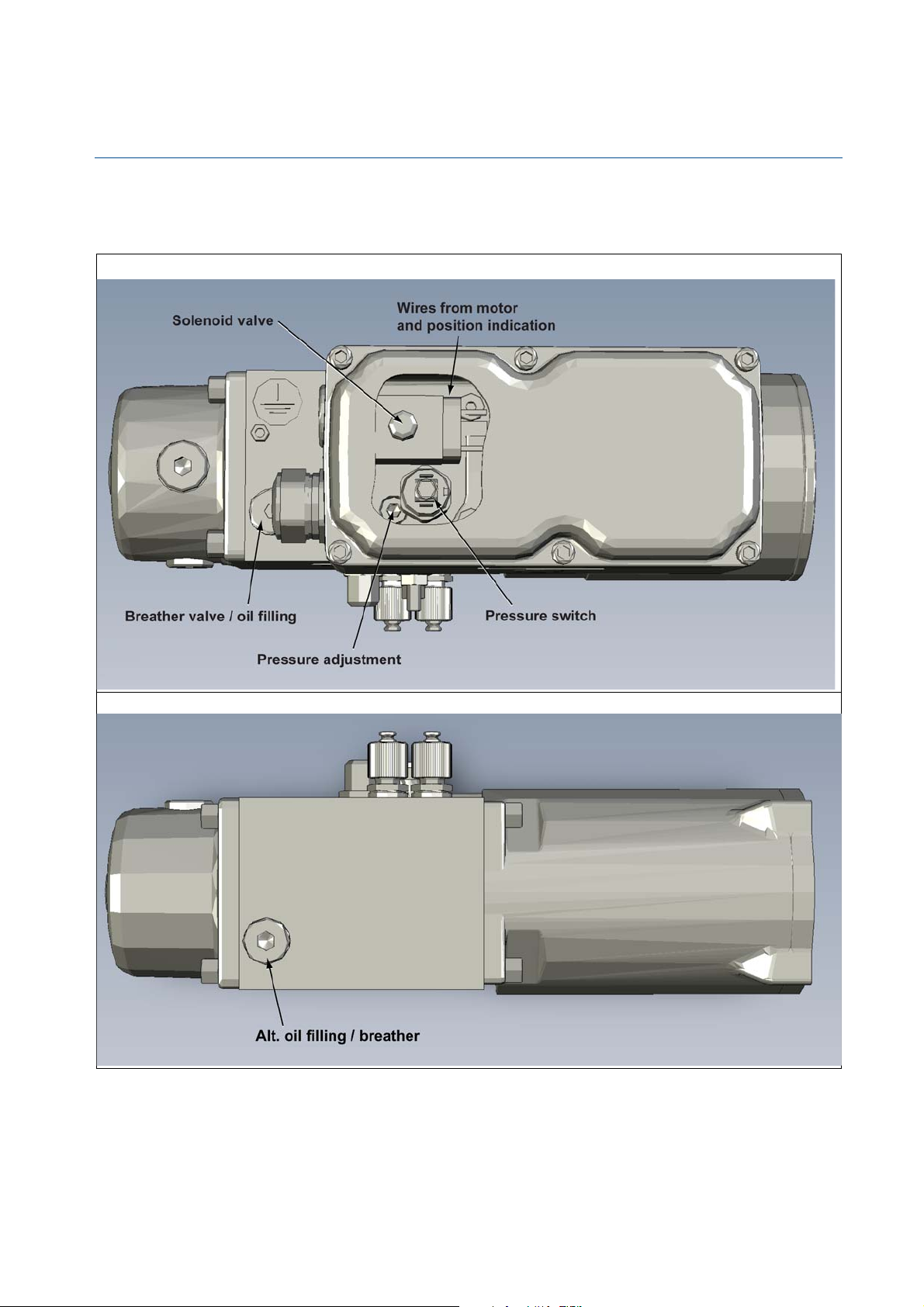

The LPU seen from above and below.

Recommended refill oil

Use an hydraulic oil, as specified for the system. The LPU is normally pre-filled with Shell Tellus T S2 V

32, for deck mounting Shell Tellus S4 VX.

87

Page 88

Service Manual Damcos LPU: Refill of Oil in LPU

SM 8000-100-01 Ed 04 February 2017

Procedures

LPU without pressurised reservoir using direct level control

1. Remove the breather valve, placed on top or bottom of the LPU or end of oil tank, depending on

the LPU mounting direction, see picture on page 87. For LPU-S on BRCF the breather valve might

be placed on top of BRCF.

2. Oil level must be max 15 mm below breather valve or plug in LPU.

For LPU-S on BRCF oil level in LPU tank must be above suction pipe at fully opened actuator.

3. If oil level is low, fill the reservoir with hydraulic oil as specified for the system. Oil filling may be

done directly through the hole for breather valve or with a hand pump.

4. LPU-S hand pump filling: Apply pressure from hand pump directly to T-quick connection of the

LPU. See “LPU-S mounted on BRCF oil filling with hand pump” on page 90

alt.

LPU-D hand pump filling: Open stop valve at front of LPU and apply pressure from hand pump

directly to B-quick connection. Close stop valve after filling. See “LPU-D Oil Filling Instruction

with hand pump” on page 91.

5. Remount the breather valve.

LPU with pressurised reservoir