Page 1

Instruction Manual

D100345X012

March 2021

1805 Series Relief Valves

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or re causing property damage and

personal injury or death.

Fisher™ relief valves must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations, and Emerson Process

Management Regulator Technologies,

Inc. instructions.

1805 Series

If a leak develops or if the outlet

continually vents gas, service to the unit

may be required.

Failure to correct trouble could result in

a hazardous condition. Only a qualied

person must install or service the unit.

Call a gas service person to service the

unit. Only a qualied person must install

or service the 1805 Series Relief Valves.

Introduction

Scope of the Manual

This Instruction Manual provides installation,

adjustment, maintenance and parts ordering

information for 1805 Series relief valves.

P1026

Figure 1. 1805 Series Relief Valve

Description

The 1805 Series relief valves are primarily designed

for use in farm tap applications where a safety relief

valve is needed between the first and second stage

regulators. The 1805 Series is suitable for service on

natural gas, air, propane or any operating medium that

is not corrosive to the internal parts. Relief pressure

ranges from 5 to 125 psi / 0.34 to 8.6 bar. Maximum

pressure, including buildup, is 150 psi / 10.3 bar.

Page 2

1805 Series

Specications

The Specications section lists the specications for the 1805 Series relief valve. The following information

is stamped on the relief valve at the factory: type number, date of manufacture, spring range, maximum inlet

pressure and maximum allowable inlet pressure.

Available Constructions

Type 1805-2: Cast iron spring case, closing cap

with 1/4 NPT vent placed over the adjusting screw.

Available in 3/4 and 1 NPT body sizes.

Type 1805-3: Cast iron spring case, closing cap

with 1/4 NPT vent placed over the adjusting screw.

Available in 1-1/2 and 2 NPT body sizes.

Body Sizes and End Connection Style

3/4, 1, 1-1/2 or 2 NPT

Maximum Inlet Pressure

150 psig / 10.3 bar including buildup

Relief Valve Set Pressure Ranges

See Table 1

Type 1805-4: Cast iron spring case. Available in

3/4 and 1 NPT body sizes.

Type 1805-5: Cast iron spring case.

Available in 1-1/2 and 2 NPT body sizes.

Type 1805-7: Cast iron spring case, closing

cap with 1/4 NPT vent placed over the adjusting

screw, screen in outlet. Available in 3/4 and 1 NPT

body sizes.

Body Style

Flow and IEC Sizing Coefficients

See Table 2

Temperature Capabilities

-20 to 150°F / -29 to 66°C

Approximate Shipping Weights

3/4 to 1 NPT bodies: 5 lbs / 2 kg

1-1/2 to 2 NPT bodies: 13 lbs / 6 kg

Globe body

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

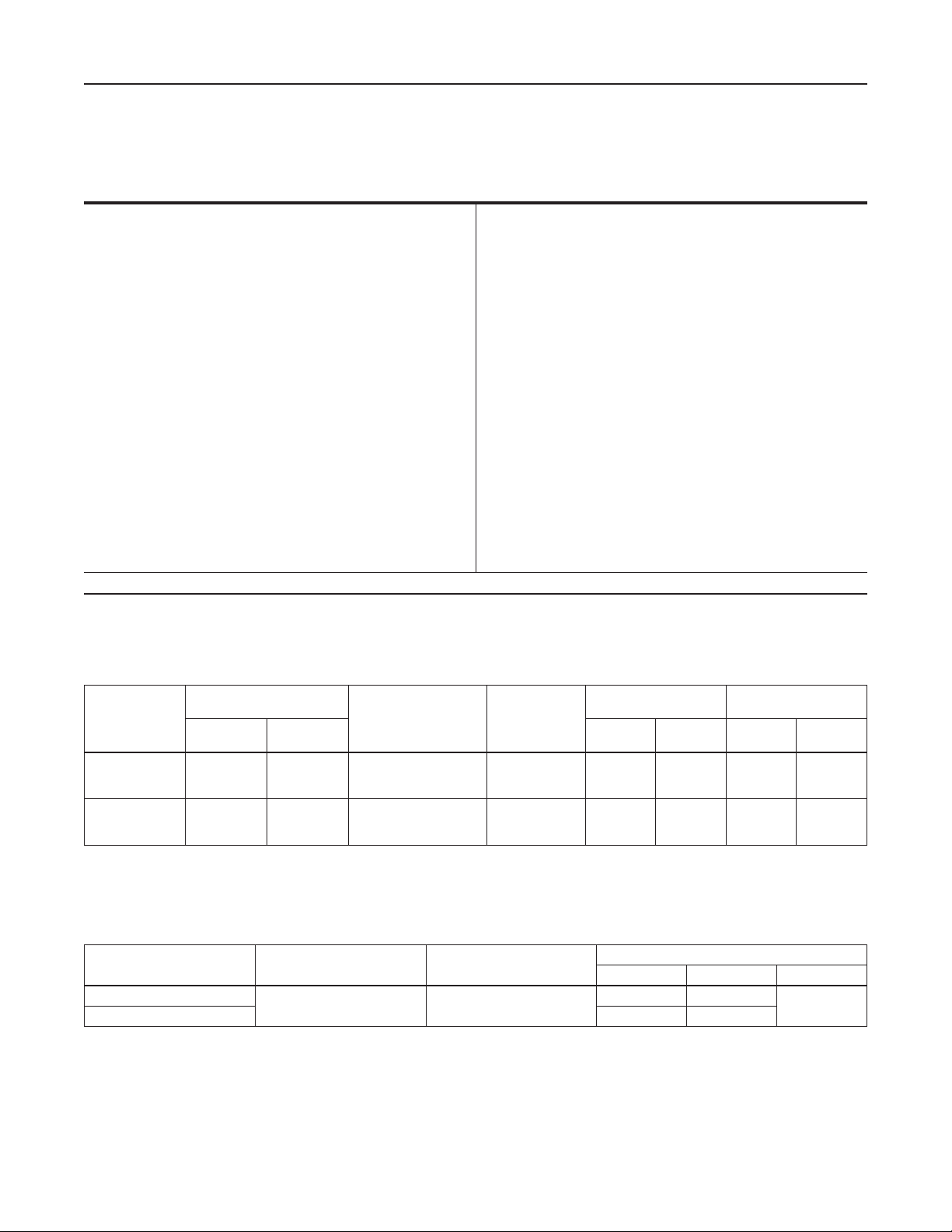

Table 1. Relief Set Pressure Ranges

(1)

(1)

BODY SIZE

3/4 or 1 NPT

1-1/2 or 2 NPT

RELIEF PRESSURE RANGE

psig bar In. mm In. mm

5 to 35

10 to 60

20 to 125

5 to 20

10 to 50

35 to 125

0.34 to 2.4

0.69 to 4.1

1.4 to 8.6

0.34 to 1.4

0.69 to 3.5

2.4 to 8.6

SPRING

PART NUMBER

1B986027212

1B788327022

1B788427022

1D892327022

1D665927022

1E543627142

SPRING COLOR

CODE

Green

Silver

Blue

Red

Blue

Yellow

SPRING FREE LENGTH

2.25

2.13

1.94

2.94

2.50

2.31

Table 2. Flow and IEC Sizing Coecients

BODY SIZE C

3/4 to 1 NPT

1-1/2 to 2 NPT 0.94 0.44

1

35 0.79

K

m

IEC SIZING COEFFICIENTS

X

T

0.73 0.39

57.2

54.1

49.3

74.7

63.5

58.7

SPRING WIRE

0.12

0.14

0.18

0.17

0.22

0.28

F

D

DIAMETER

0.89

F

3.05

3.56

4.57

4.32

5.59

7.11

L

2

Page 3

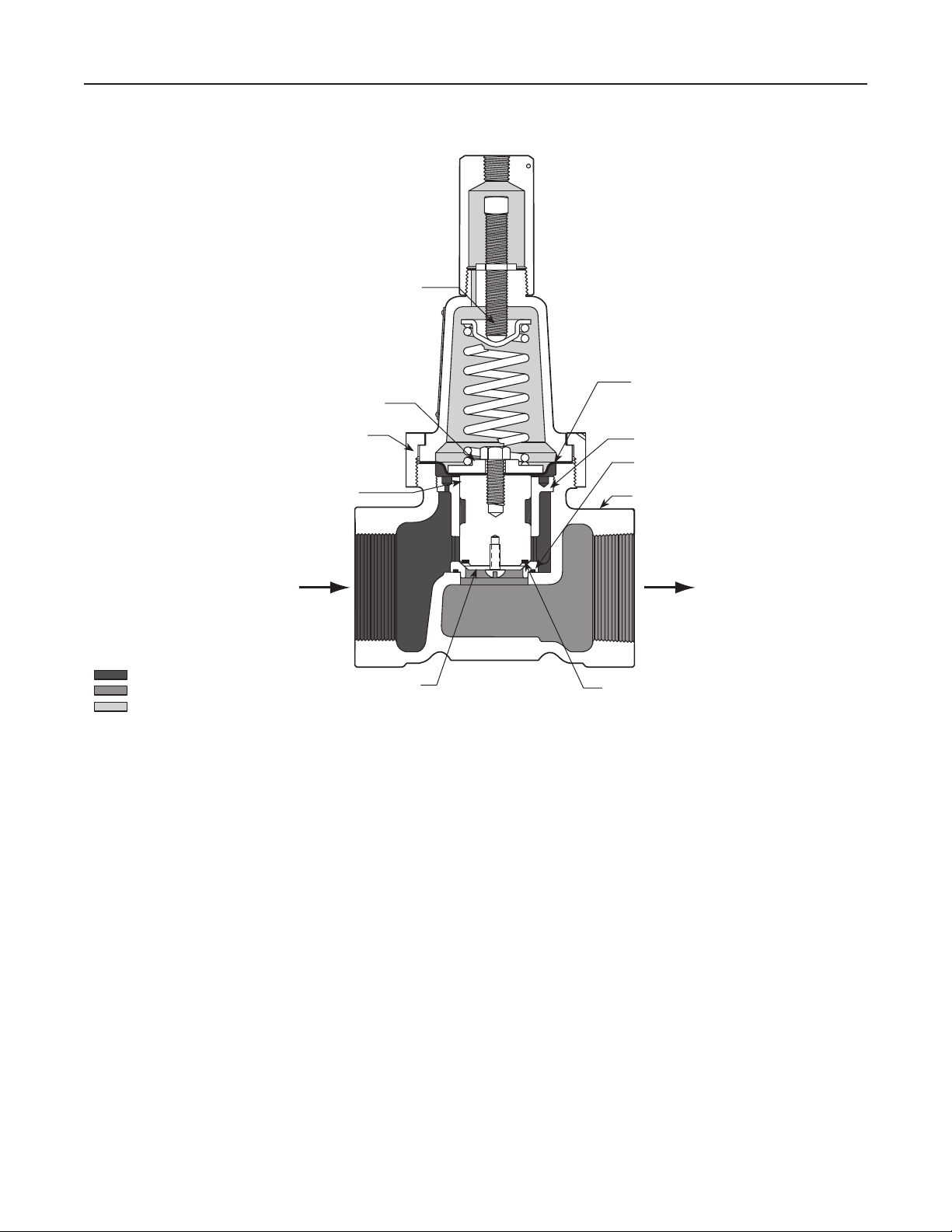

UPPER

SPRING

SEAT

1805 Series

A6671

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

DIAPHRAGM

HEAD

UNION NUT

O-RING

HOLDER

O-RING WASHER

Figure 2. 1805 Series Operational Schematic

DIAPHRAGM

BODY

O-RING

VALVE GUIDE

ORIFICE

O-RING

Principle of Operation

See Figure 2. Relief valves respond to changes in

upstream pressure. If upstream pressure increases

and exceeds the relief valve setting, the valve will

open and allow gas to vent to the atmosphere. When

upstream pressure returns to normal level (below the

setting of the relief valve), the relief valve automatically

closes and normal system operation resumes.

In the 1805 Series relief valves, the upstream pressure

registers underneath the diaphragm. Gas reaches

the diaphragm through the space between the O-ring

holder and the valve guide orifice in 3/4 and 1 NPT

bodies or through registration holes in the valve guide

orifice in 1-1/2 and 2 NPT bodies. When the upstream

pressure increases beyond the spring setting, the force

on the diaphragm overcomes spring compression.

The O-ring holder moves upward, carrying the O-ring

away from the valve seat. This opens the flow line,

allows gas to flow to the atmosphere and relieves the

overpressure condition. When upstream pressure

registered on the diaphragm decreases to a level

below that of the spring setting of the relief valve, the

spring force pushes the diaphragm plate and O-ring

holder toward the valve seat. Contact between O-ring

and valve seat prevents further flow to atmosphere.

3

Page 4

1805 Series

TYPE CS200IN

SET AT 8 IN. W.C. / 20 mbar

TYPE 1805 SET AT 40 psi /

2.8 bar ROTATE PIPING SO

DISCHARGE FROM RELIEF

VALVE MISSES REGULATOR

TYPE 627

SET AT 25 psi / 1.7 bar

INLET PRESSURE UP TO

750 psi / 51.7 bar

AF9932

TEST GAUGE CONNECTION

PLUGGED-OPTIONAL

HAND VALVE

OR PLUG COCK

OPTIONAL

Figure 3. Typical Farm Tap Installation

Installation

After unpacking, check the relief valve for shipping

damage. Remove pipe scale and other foreign

material from the connecting pipeline. Coat the male

pipe threads with a suitable pipe compound. The unit

can be installed in any position as long as the ow is in

the direction indicated by the arrow cast on the body.

Protect the outlet and vents from entrance of rain,

snow or other foreign material that may plug them.

Outdoor installations should include a rain cap

over the vents and outlet if they point upward.

Periodically check the openings to ensure that they are

not plugged.

Protect the relief valve against damage from vehicles

or other external sources.

Vents

WARNING

!

Venting gas may accumulate and be

an explosion hazard under enclosed

conditions such as in pit or underground

installations. Install remote vent lines to

carry gas to a safe area.

If remote vent lines are necessary, use the

Type 1805-2, -3 or -7 which have 1/4 NPT vent

connections in the closing cap. Remove the screen

if one is present in the outlet, and install remote vent

lines in the outlet and closing cap openings. Remote

vent lines must have the largest practical diameter as

possible. The vent lines should be as short as possible

with a minimum number of bends or elbows.

4

Page 5

1805 Series

Overpressure

Relief pressure ratings are from 5 to 125 psi / 0.34

to 8.6 bar. The maximum inlet pressure, including

buildup, is 150 psi / 10.3 bar. System operation

within these limitations does not eliminate the

possibility of damage from external sources or

from debris in the gas line. The relief valve should

be inspected for damage regularly and after any

overpressure condition.

Startup

Key numbers are shown in Figure 4. With proper

installation completed and system equipment properly

adjusted, close any vent valves and slowly open the

upstream shut-o valve while using pressure gauges

to monitor pressure.

If set pressure adjustment is necessary, monitor

the inlet pressure with a gauge during the

adjustment procedure.

Adjustment

The range of allowable pressure settings is stamped

on the spring case (Types 1805-2, -4 and -7) or on the

nameplate (Types 1805-3 and -5). If a pressure setting

beyond the indicated range is required, substitute

the appropriate spring. Be sure to label the relief

valve to indicate the new pressure range. Always

use a pressure gauge to monitor pressure when

making adjustments.

1. On Types 1805-2, -3 and -7 remove the closing

cap (key 17).

2. Loosen hex nut (key 15).

3. To increase the relief setting, turn the adjusting

screw (key 14) clockwise. To decrease the relief

setting, turn the adjusting screw counterclockwise.

4. Tighten the hex nut.

Due to normal wear that may occur in relief valves,

the O-rings and diaphragm must be inspected

periodically and replaced as necessary. The frequency

of inspection and replacement depends upon the

severity of service conditions or the requirements of

state and federal laws. Instructions are given below for

disassembly of the relief valve and replacement of the

O-rings and diaphragm. The 1805 Series relief valves

do not have to be removed from the pipeline to inspect

internal parts. Refer to Figure 4 while servicing the

relief valves.

Disassembly/Assembly

1. To ease spring compression, remove the closing

cap (key 17, Types 1805-2, -3 and -7), loosen

the hex nut (key 15) and turn the adjusting screw

(key 14) counterclockwise.

2. Unscrew the union nut (key 16) and remove it

with the spring case (key 13), spring (key 11) and

upper spring seat (key 12).

3. Pull the O-ring holder (key 4) out of the valve

guide orifice (key 2).

4. Remove the diaphragm cap screw (key 10) from

the O-ring holder. Take off the diaphragm plate

(key 9) and inspect the diaphragm (key 8).

5. Take the machine screw (key 7) out of the

opposite end of O-ring holder, remove the O-ring

washer (key 6) and inspect the O-ring (key 5).

6. Remove the valve guide orifice (key 2) from the

body and check the Tetraseal® O-ring (key 3).

7. Reassemble the relief valve in reverse order of

the above steps. To ensure proper slack in the

diaphragm, tighten the union nut finger-tight only.

Turn the adjusting screw clockwise to apply some

spring force to the diaphragm. Complete the

tightening of the union nut.

Shutdown

Close the upstream shut-o valve and release all

pressure from the relief valve.

Maintenance

WARNING

!

To avoid personal injury and equipment

damage, isolate the relief valve from

all pressure. Cautiously release

pressure from the relief valve before

attempting disassembly.

Tetraseal® is a mark owned by of Goshen Rubber Company.

Parts Ordering

When corresponding with your local Sales Oce or the

factory concerning these relief valves, include the type

number and all other pertinent information stamped

on the spring case, closing cap or on the nameplate.

Specify the eleven-character part number when

ordering new parts from the following parts list.

When ordering replacement parts, reference the key

number of each needed part as found in the following

parts list. Separate kit containing all recommended

spare parts is available.

5

Page 6

1805 Series

17

14

15

25

13

12

18

19

11

10

9

16

8

2

4

5

3

BE9481

6

1

7

Figure 4. Type 1805-3 Relief Valve Assembly (Also typical of Type 1805 Relief Valves)

6

Page 7

Parts List

Key Description Part Number

Parts kit

(included are keys 3, 5 and 8)

3/4 and 1 NPT body sizes R1805X00012

1-1/2 and 2 NPT body sizes R1805X00022

1 Valve Body

Types 1805-2 and -4

3/4 NPT

Cast iron 1E621119012

Ductile iron (NACE) 1F192019062

1 NPT

Cast iron 1E621219012

Ductile iron (NACE) 1F192119062

Types 1805-3 and -5

1-1/2 NPT Cast iron 1E824019012

2 NPT Cast iron 1E824319012

Type 1805-7

3/4 NPT Cast iron 1H242519012

1 NPT Cast iron 1H242619012

2 Valve Guide Orifice, Aluminum

3/4 and 1 NPT body sizes 1K314709012

1-1/2 and 2 NPT body sizes 1N939909012

3* Tetraseal®/O-ring, Nitrile (NBR)

3/4 and 1 NPT body sizes 1K314806992

1-1/2 and 2 NPT body sizes 1N940306562

4 O-ring Holder, Aluminum

3/4 and 1 NPT body sizes 1E621609092

1-1/2 and 2 NPT body sizes 1E824609092

5* O-ring, Nitrile (NBR)

3/4 and 1 NPT body sizes 1D288806992

1-1/2 and 2 NPT body sizes 1C5622X0022

6 O-ring Washer Stainless steel

3/4 and 1 NPT body sizes 1D335935072

1-1/2 and 2 NPT body sizes 1E824235072

7 Machine Screw, Steel

3/4 and 1 NPT body sizes 16A0429X012

1-1/2 and 2 NPT body sizes 1B420428982

8* Diaphragm, Nitrile (NBR)

3/4 and 1 NPT body sizes 1E621702052

1-1/2 and 2 NPT body sizes 1E824102052

9 Diaphragm Plate, Brass

3/4 and 1 NPT body sizes 1E621814012

1-1/2 and 2 NPT body sizes 1E824714012

1805 Series

Key Description Part Number

10 Cap Screw, Zinc-plated steel

3/4 and 1 NPT body sizes 1B290524052

1-1/2 and 2 NPT body sizes 1E760324052

11 Spring, Zinc-plated steel

3/4 and 1 NPT body sizes

5 to 35 psig / 0.34 to 2.4 bar 1B986027212

10 to 60 psig / 0.69 to 4.1 bar 1B788327022

20 to 125 psig / 1.4 to 8.6 bar 1B788427022

1-1/2 and 2 NPT body sizes

5 to 20 psig / 0.34 to 1.4 bar 1D892327022

10 to 50 psig / 0.69 to 3.5 bar 1D665927022

35 to 125 psig / 2.4 to 8.6 bar 1E543627142

12 Upper Spring Seat, Steel

3/4 and 1 NPT body sizes 1B798525062

1-1/2 and 2 NPT body sizes 1D667125072

13 Spring Case, Cast Iron

3/4 and 1 NPT body sizes 2E770819012

1-1/2 and 2 NPT body sizes 2E824919042

14 Adjusting Screw, Brass

3/4 and 1 NPT body sizes 1E770914012

1-1/2 and 2 NPT body sizes 1E543214012

15 Hex Nut, Zinc-plated steel

3/4 and 1 NPT body sizes 1A946324122

1-1/2 and 2 NPT body sizes 1D667728982

16 Union Nut, Ductile iron

3/4 and 1 NPT body sizes 1E471119062

1-1/2 and 2 NPT body sizes 1E766619062

17 Closing Cap, Brass

Types 1805-2 and -7 1E770614012

Type 1805-3 1E823914012

19 Drive Screw, Steel (4 required)

1-1/2 and 2 NPT body sizes 1E501728982

20 Screen, Stainless steel (not shown)

Type 1805-7 1E564843122

21 Snap Ring, 302 Stainles steel (not shown)

Type 1805-7 1E564937022

22 NACE Tag, 18-8 Stainless steel (not shown) 19A6034X012

23 Tag Wire, 304 Stainless steel (not shown) 1U7581X0022

24 Pipe Plug, Alloy-plated steel 1C333528992

25 O-ring

3/4 and 1 NPT body sizes 1F463606992

1-1/2 and 2 NPT body sizes T14380T0012

*Recommended spare part.

Tetraseal® is a mark owned by of Goshen Rubber Company.

7

Page 8

1805 Series

Webadmin.Regulators@emerson.com

Fisher.com

Emerson Automation Solutions

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

D100345X012 © 1975, 2021 Emerson Process Management Regulator

Technologies, Inc. All rights reserved. 03/21.

The Emerson logo is a trademark and service mark of Emerson Electric

Co. All other marks are the property of their prospective owners.

Fisher™ is a mark owned by Fisher Controls International LLC, a business

of Emerson Automation Solutions.

The contents of this publication are presented for informational purposes

only, and while every eort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which

are available upon request. We reserve the right to modify or improve the

designs or specications of such products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does

not assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any

Emerson Process Management Regulator Technologies, Inc. product

remains solely with the purchaser.

Loading...

Loading...