Page 1

Liebert® CW™ Thermal Management System

System Design Manual—26 kW — 400 kW, Upflow and Downflow, 50 Hz – 60 Hz

Page 2

Page 3

Table of Content

1.0 Nomenclature and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Liebert CW Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Blower Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.0 Liebert CW System Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.0 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.0 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Cabinet and Floor-planning

Dimensions—Downflow Models with EC Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Cabinet and Floor-planning

Dimensions—Upflow Models with EC Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Cabinet and Floor-planning Dimensions

—Downflow Models with Forward-curved Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5 Cabinet and Floor-planning Dimensions

—Upflow Models with Forward-curved Blowers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.6 Floor-stand Dimensions—Units with EC Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.7 Floor-stand Dimensions—Units with Forward-curved Blowers. . . . . . . . . . . . . . . . . . . . . 46

4.8 Plenum Dimensions—Units with EC Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.9 Plenum Dimensions—Units with Forward-curved Blowers. . . . . . . . . . . . . . . . . . . . . . . . 50

5.0 Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.1 Piping General Arrangement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.2 Piping Connections—Downflow Models with EC Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.3 Piping Connections—Downflow Models with Forward-curved Blowers . . . . . . . . . . . . . . 62

5.4 Piping Connections—Upflow Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

iLiebert

®

CW™ System Design Manual

Page 4

6.0 Electrical Field Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1 Electrical Field Connections—Downflow Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1.1 Standard Electrical Connections for Downflow Models CW146 and CW181 . . . . . . . . . . 71

6.1.2 Optional Electrical Connections for Downflow Models CW146 and CW181. . . . . . . . . . . 72

6.1.3 Optional Low-Voltage Terminal Package Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.1.4 Optional Low-Voltage Terminal Package Connections

for Downflow Models CW146 and CW181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2 Electrical Field Connections—Upflow Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendix A: Optional Configuration

for Liebert CW Seismic Application . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1 Seismic Certification Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1 Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.2 Requirements for Seismic Anchorage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

A.3 Anchor and Load Requirements of Seismic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Appendix B: Optional Liebert Air Economizer™ for Liebert CW . . . . . . . . 95

B.1 Customer-supplied Equipment and Ductwork. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Appendix C: Guide Specifications—Chilled Water

Environmental Control System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Liebert® CW™ System Design Manual ii

Page 5

List of Figures

Figure 1-1: Downflow model component locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 1-2: Upflow model component locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 1-3: Blower configurations—Downflow, front and rear supply, EC fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 1-4: Blower configurations—Downflow, bottom and under-floor supply, EC fans. . . . . . . . . . . . . . . . . . . . . 5

Figure 1-5: Blower configurations—Downflow, under-floor supply, forward-curved blowers . . . . . . . . . . . . . . . . . . 6

Figure 1-6: Blower configurations—Upflow, EC fans in plenum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 1-7: Blower configurations—Upflow, front return, forward-curved blowers. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 1-8: Blower configurations—Upflow, rear return, forward-curved blowers . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4-1: Cabinet and floor-planning dimensions, downflow, CW026 – CW084 with EC fans . . . . . . . . . . . . . . 24

Figure 4-2: Cabinet and floor-planning dimensions, downflow,

CW026, CW038 and CW041, with EC fans, front discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 4-3: Cabinet and floor-planning dimensions, downflow,

CW051, CW060, CW076 and CW084, with EC fans, front discharge. . . . . . . . . . . . . . . . . . . . . 26

Figure 4-4: Cabinet and floor-planning dimensions, downflow,

CW089, CW106 and CW114 with EC fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 4-5: Cabinet and floor-planning dimensions, downflow,

CW089, CW106 and CW114 with EC fans, front discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 4-6: Cabinet and floor-planning dimensions, downflow, CW146 and CW181 with EC fans . . . . . . . . . . . . 29

Figure 4-7: Cabinet and floor-planning dimensions, downflow

CW146 and CW181, with EC fans, front discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 4-8: Cabinet and floor-planning dimensions, downflow,

CW300, CW400 with EC fans and filter plenums. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 4-9: Cabinet and floor-planning dimensions, upflow, CW026 – CW084 with EC fans, front air return. . . . 32

Figure 4-10: Cabinet and floor-planning dimensions, upflow,

CW026 - CW084 with EC fans, rear and bottom air return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 4-11: Cabinet and floor-planning dimensions, upflow, CW106, CW114 with EC fans, front return. . . . . . . 34

Figure 4-12: Cabinet and floor-planning dimensions, upflow, CW106, CW114 with EC fans, rear return . . . . . . . 35

Figure 4-13: Cabinet and floor-planning dimensions, downflow,

CW026 - CW084, with forward-curved blowers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 4-14: Cabinet and floor-planning dimensions, downflow,

CW106 and CW114 with forward-curved blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 4-15: Cabinet and Floor-planning dimensions, upflow, CW026 – CW084 with forward-curved blowers . . 38

Figure 4-16: Cabinet and Floor-planning dimensions, upflow,

CW106 and CW114 with forward-curved blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 4-17: Floor-stand and floor-planning dimensions, downflow, CW026 – CW041 with EC fans . . . . . . . . . . 40

Figure 4-18: Floor-stand and floor-planning dimensions, downflow, CW051 and CW060 with EC fans . . . . . . . . 41

Figure 4-19: Floor-stand and floor-planning dimensions, downflow, CW076 and CW084 with EC fans . . . . . . . . 42

Figure 4-20: Floor-stand and floor-planning dimensions, downflow, CW089, CW106 and CW114 with EC fans . 43

Figure 4-21: Floor-stand and floor-planning dimensions, downflow, CW089, CW106 and CW114 with EC fans . 44

Figure 4-22: Floor-stand and floor-planning dimensions, downflow, CW300 and CW400 with EC fans . . . . . . . . 45

Figure 4-23: Floor-stand planning dimensions, CW026 – CW084 with forward-cu rved blowers. . . . . . . . . . . . . . 46

Figure 4-24: Floor-stand planning dimensions, CW106 and CW114 with forward-curved blowers. . . . . . . . . . . . 47

Figure 4-25: Plenum dimensions, upflow, CW026 — CW084 with EC fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 4-26: Plenum dimensions, upflow, CW106, CW114 with EC fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

iii Liebert® CW™ System Design Manual

Page 6

Figure 4-27: Plenum dimensions, upflow, CW026 – CW084 with forward-curved blowers . . . . . . . . . . . . . . . . . . 50

Figure 4-28: Plenum dimensions, upflow. CW106 and CW11 4 with forward-curved blowers . . . . . . . . . . . . . . . . 51

Figure 5-1: Piping general arrangement, downflow, CW026 – CW114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 5-2: Piping general arrangement, downflow, CW146 – CW181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 5-3: Piping general arrangement, upflow, CW026 – CW114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 5-4: Primary connection locations, downflow, CW026 – CW041 with EC fans. . . . . . . . . . . . . . . . . . . . . . 56

Figure 5-5: Primary connection locations, downflow, CW051 and CW060 with EC fans. . . . . . . . . . . . . . . . . . . . 57

Figure 5-6: Primary connection locations, downflow, CW076 – CW084 with EC fans. . . . . . . . . . . . . . . . . . . . . . 58

Figure 5-7: Primary connection locations, downflow, CW089, CW106 and CW114 with EC fans. . . . . . . . . . . . . 59

Figure 5-8: Primary connection locations, downflow, CW146 and CW181 with EC fans. . . . . . . . . . . . . . . . . . . . 60

Figure 5-9: Primary connection locations, downflow, CW300 and CW400 with EC fans. . . . . . . . . . . . . . . . . . . . 61

Figure 5-10: Piping connections, downflow, CW026 – CW084 with forward-curved blowers . . . . . . . . . . . . . . . . 62

Figure 5-11: Piping connections, downflow, CW106 and CW114 with forward-curved blowers . . . . . . . . . . . . . . 63

Figure 5-12: Piping connections, upflow, CW026 – CW084 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 5-13: Piping connections, upflow, CW106 and CW114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 6-1: Electrical field connections, downflow, CW026 – CW084 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 6-2: Electrical field connections (Ethernet), downflow, CW026 – CW084. . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 6-3: Electrical field connections, downflow, CW089, CW106 and CW114 . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 6-4: Electrical field connections (Ethernet), downflow, CW089, CW106 and CW114. . . . . . . . . . . . . . . . . 70

Figure 6-5: Electrical field connections, downflow, CW146 and CW181 with EC fans . . . . . . . . . . . . . . . . . . . . . 71

Figure 6-6: Electrical field connections (high voltage), upflow, CW026 – CW084 . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 6-7: Electrical field connections (low voltage), upflow, CW026 – CW084. . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 6-8: Electrical field connections (Ethernet), upflow, CW026 – CW084. . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 6-9: Electrical field connections (high-voltage), upflow, CW089 – CW114. . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 6-10: Electrical field connections (low-voltage), upflow, CW089 – CW114. . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 6-11: Electrical field connections (low voltage Ethernet), upflow, CW089 – CW114. . . . . . . . . . . . . . . . . . 79

Figure A-1: Field-welding of anchor bracket—Seismic anchorage rigid floor stand, upflow, CW026 – CW114. . . 85

Figure A-2: Anchor detail—Seismic anchorage rigid floor stand, downflow, CW026 – CW181. . . . . . . . . . . . . . . 86

Figure A-3: Seismic certification as tested connection detail, upflow, CW114 and CW181. . . . . . . . . . . . . . . . . . 87

Figure A-4: IBC-certified seismic floor stand data, downflow, CW026 – CW114 with EC fans . . . . . . . . . . . . . . . 88

Figure A-5: IBC-certified seismic floor stand data, downflow, CW146 – CW181 with EC fans . . . . . . . . . . . . . . . 89

Figure A-6: Upflow plenum seismic mounting data, CW026 – CW114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure A-7: Downflow plenum seismic mounting data, CW026 – CW114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure A-8: Seismic duct connection considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure A-9: Seismic electrical wiring considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure A-10: Seismic piping considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure B-1: Liebert Air Economizer ducting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure B-2: Dimensions—Liebert Air Economizer and Liebert CW models CW106D/114D . . . . . . . . . . . . . . . . . 97

Figure B-3: Dimensions—Liebert Air Economizer and Liebert CW models CW026D – CW084D. . . . . . . . . . . . . 98

Liebert® CW™ System Design Manual iv

Page 7

Figure B-4: Liebert Air Economizer temperature and humidity sensor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure B-5: Liebert Air Economizer supply limit thermistor wiring and restricted airflow switch adjustment . . . . 100

Figure B-6: Liebert Air Economizer damper wiring, CW026 – CW084 models . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure B-7: Liebert Air Economizer damper wiring, CW106/CW114 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure B-8: Liebert Air Economizer deactivation switch terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

vLiebert

®

CW™ System Design Manual

Page 8

Liebert® CW™ System Design Manual vi

Page 9

List of Tables

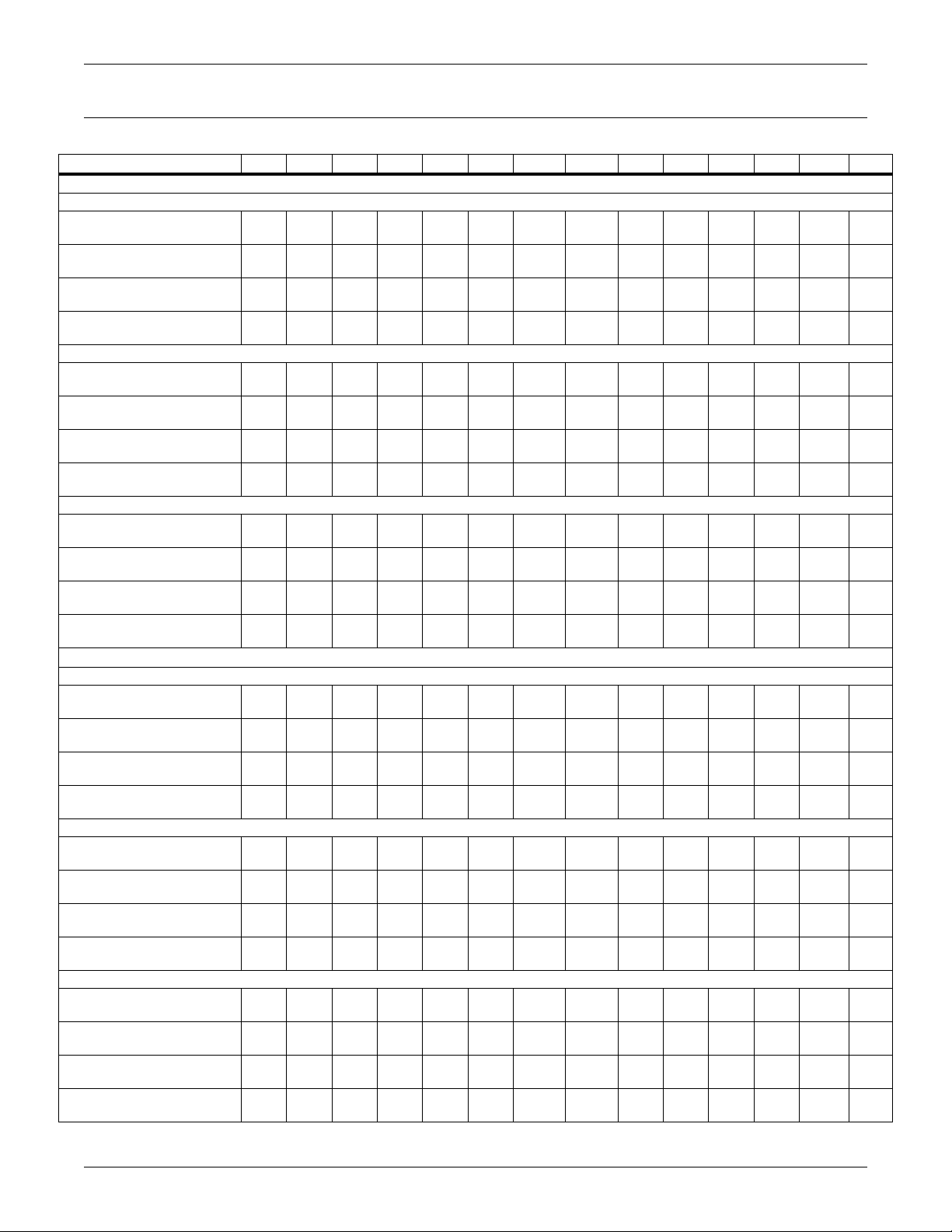

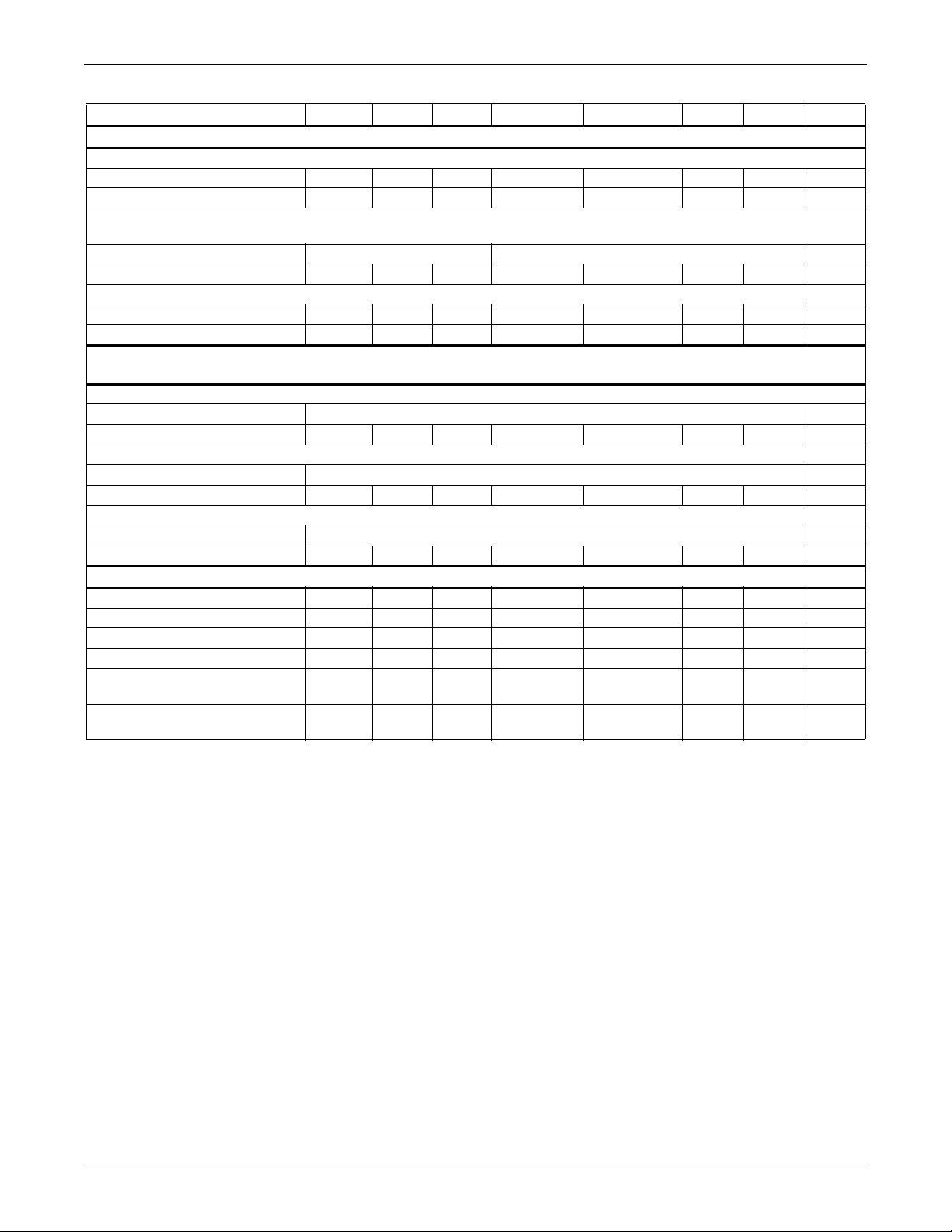

Table 2-1: Performance data, CW026-CW400, 50/60Hz, upflow and downflow models with EC fans . . . . . . . . . . 9

Table 2-2: Performance data, CW026-CW114, 50/60Hz,

upflow and downflow models with forward-curved blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2-3: Performance data for select Liebert CW Units with EC fans, High Delta T conditions . . . . . . . . . . . . . 11

Table 2-4: Motor size required to deliver rated airflow, models with forward-curved blowers . . . . . . . . . . . . . . . . 12

Table 2-5: Maximum airflow

with maximum motor size at listed static pressure, models with forward-curved blowers . . . . . . . . . 12

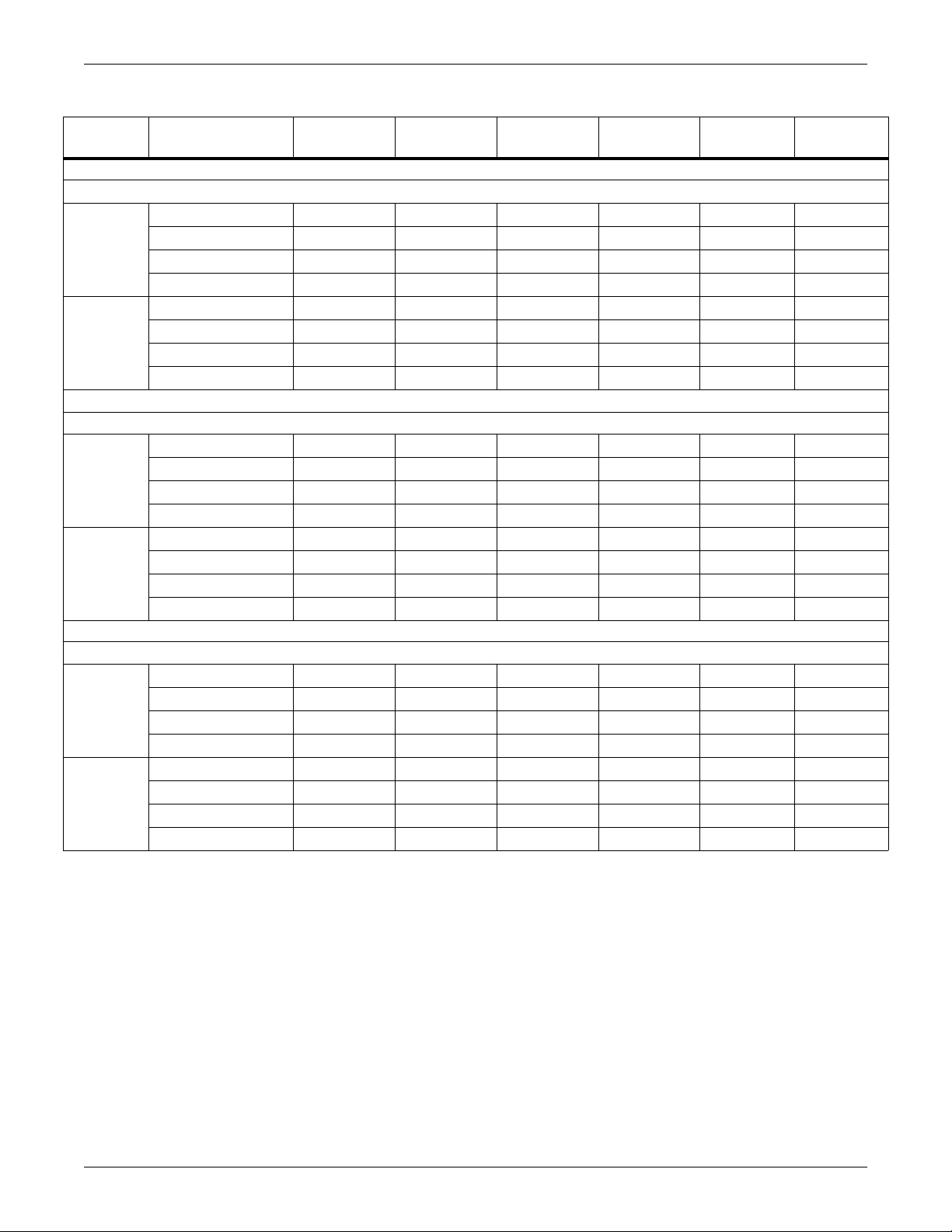

Table 2-6: Physical data, Liebert CW026 - CW089, 50/60Hz models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2-7: Physical data—Liebert CW106 - CW400, 50/60Hz models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

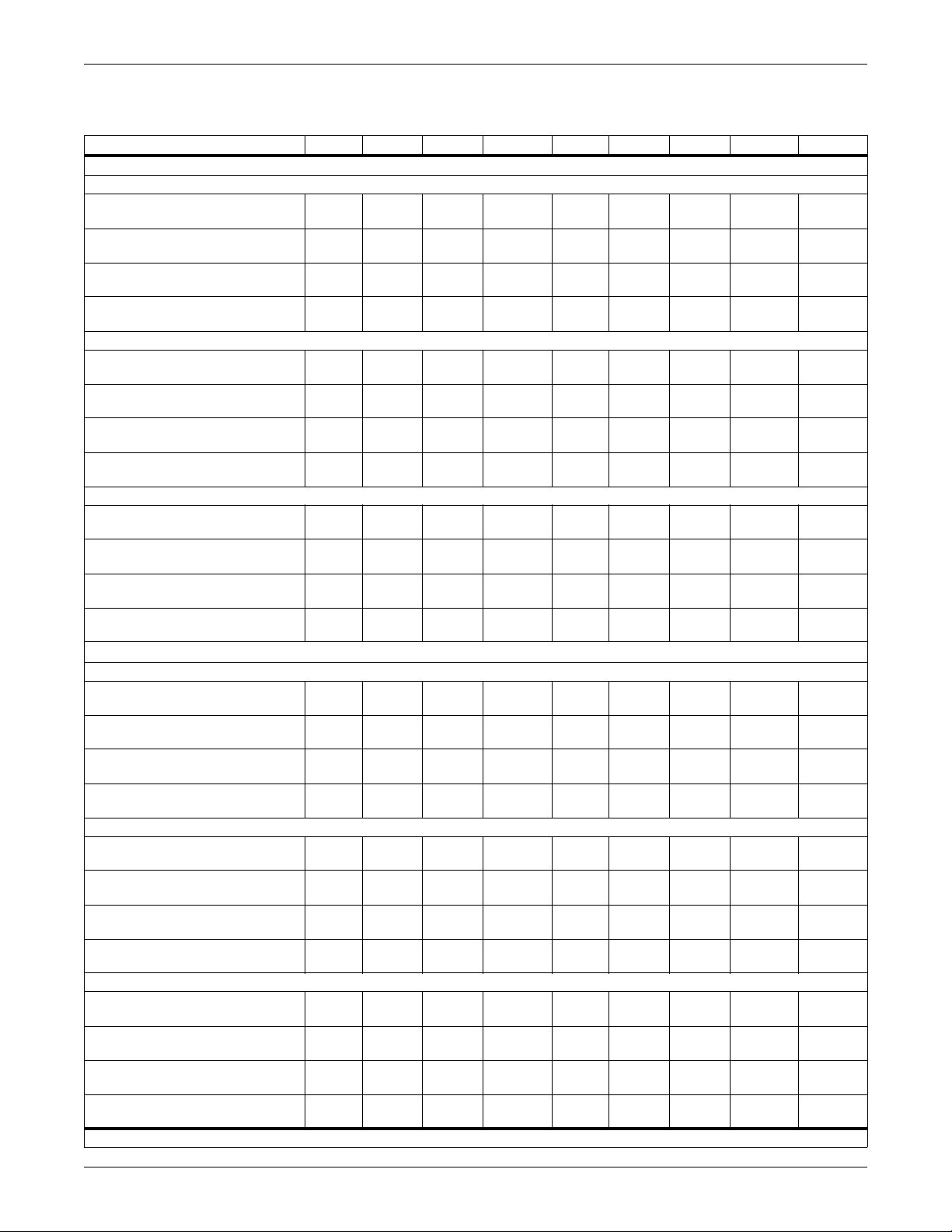

Table 3-1: Electrical data, Liebert CW with EC fans, 60Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 3-2: Electrical data—Forward-curved Blowers, 60Hz systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 3-3: Indoor evaporator fan motor electrical requirements—60Hz systems . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 3-4: Electrical data—EC fan models, 50Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 3-5: Electrical data—Forward-curved blowers, 50Hz systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 3-6: Indoor evaporator fan motor electrical requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

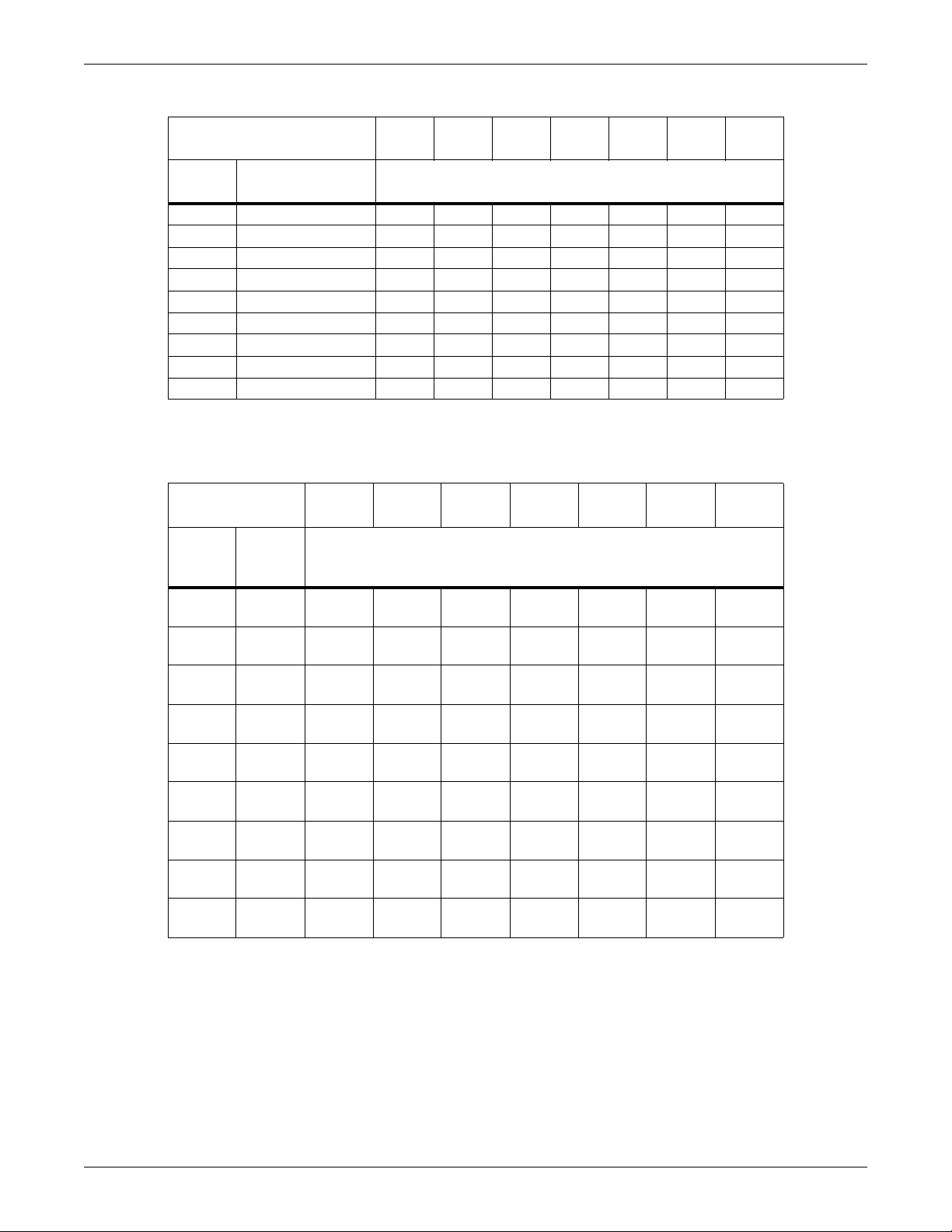

Table A-1: Comparison of certification criteria, 2000-2006. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table A-2: Downflow Liebert CW models on floor stand with 36" plenum, CW026-CW081 . . . . . . . . . . . . . . . . . 82

Table A-3: Upflow Liebert CW models on floor stand with 36" plenum, CW026-CW114. . . . . . . . . . . . . . . . . . . . 83

Table A-4: Downflow Liebert CW models on floor stand without plenum, CW026-CW081 . . . . . . . . . . . . . . . . . . 83

Table A-5: Upflow Liebert CW models on floor stand without plenum, CW026-CW114. . . . . . . . . . . . . . . . . . . . . 83

Table A-6: Upflow Liebert CW models direct mount to concrete without plenum, CW026-CW114 . . . . . . . . . . . . 84

Table A-7: Upflow Liebert CW models direct mount to concrete with 36" plenum, CW026-CW114. . . . . . . . . . . . 84

Table B-1: Dimensions—Liebert Air Economizer and Liebert CW models CW026D-CW084D . . . . . . . . . . . . . . . 98

vLiebert

®

CW™ System Design Manual

Page 10

Page intentionally left blank.

Liebert® CW™ System Design Manual vi

Page 11

1.0 Nomenclature and Components

CW

CW = Liebert CW

Floor Mount Chilled

Water

Unit

026 D C S A 2 1234 A

Nominal Capacity, kW

026

038

041

051

060

076

084

089

106

114

146

181

300

400

D = Downflow

U = Upflow

C = Chilled Water

S = Forward-Curved Blower with

Standard Motor

V = Forward-Curved Blower with

Variable Speed Drive

1 = EC Fan

H = EC Fan with THD

2 = 2-Way Valve, Standard Pressure

3 = 3-Way Valve, Standard Pressure

1 = 2-Way Valve, High Pressure

T = 3-Way Valve, High Pressure

A-Z = Standard

configuration

S = SFA

A = 460/3/60

B = 575/3/60

C = 208/3/60

D = 230/3/60

2 = 380/3/60

F = 380/3/50

G = 415/3/50

M = 380-415/3/50

XXXX

1.1 Liebert CW Nomenclature

Liebert CW Nomenclature

Not all combinations of options are available on all units.

Models CW089, CW146, CW181, CW300, and CW400 only available in downflow configuration.

Balance Valve

• Not available on models CW146, CW181, CW300, CW400

Cut Down Frame Height Reduction of Downflow Units

• Not available on units with EC fans

Disconnect Switch, Locking/Non-Locking

• Not available on 208V units with 20hp motor

Flow Switch that Activates the Warning System

• Not available with two-way valve

Humidification and Reheat

• Not available on CW300 or CW400

Steam Generating Canister Humidifier

• Not available on units with EC fans

Steam Humidifier

• Steam Humidifier with upflow units requires a plenum to contain the steam distribution components.

The minimum height for this plenum is 22-3/4 in. (58 cm).

Steam/Hot Water Reheat Package

• Not available on units with EC fans

Turning Vanes

• Not available on upflow units

• Not available on units with EC fans

1Liebert

®

CW™ System Design Manual

Page 12

Nomenclature and Components

Upflow Models

• Front, rear or bottom return must be specified. (Bottom return is not available on CW106 and CW114

models)

THD Transformer

• Available only on the Liebert CW106, CW114, CW146, or CW181 units; required for units requiring a

575V power input

Variable Speed Drive

• Not available on 106 and 114 units with steam generating canister humidifier

• Not available on units with EC fans

• Not available on CW089, CW146, CW181, CW300 or CW400 units

Liebert® CW™ System Design Manual 2

Page 13

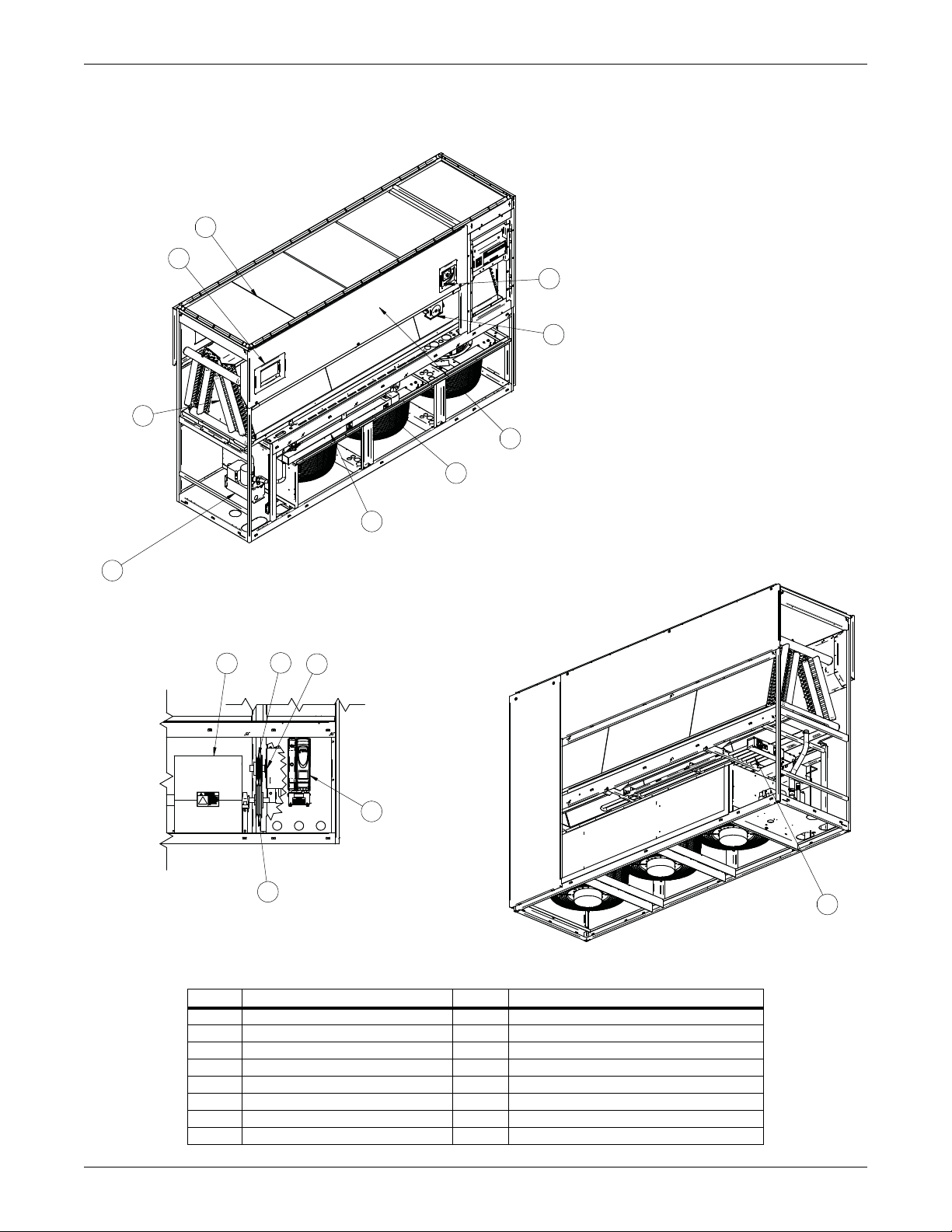

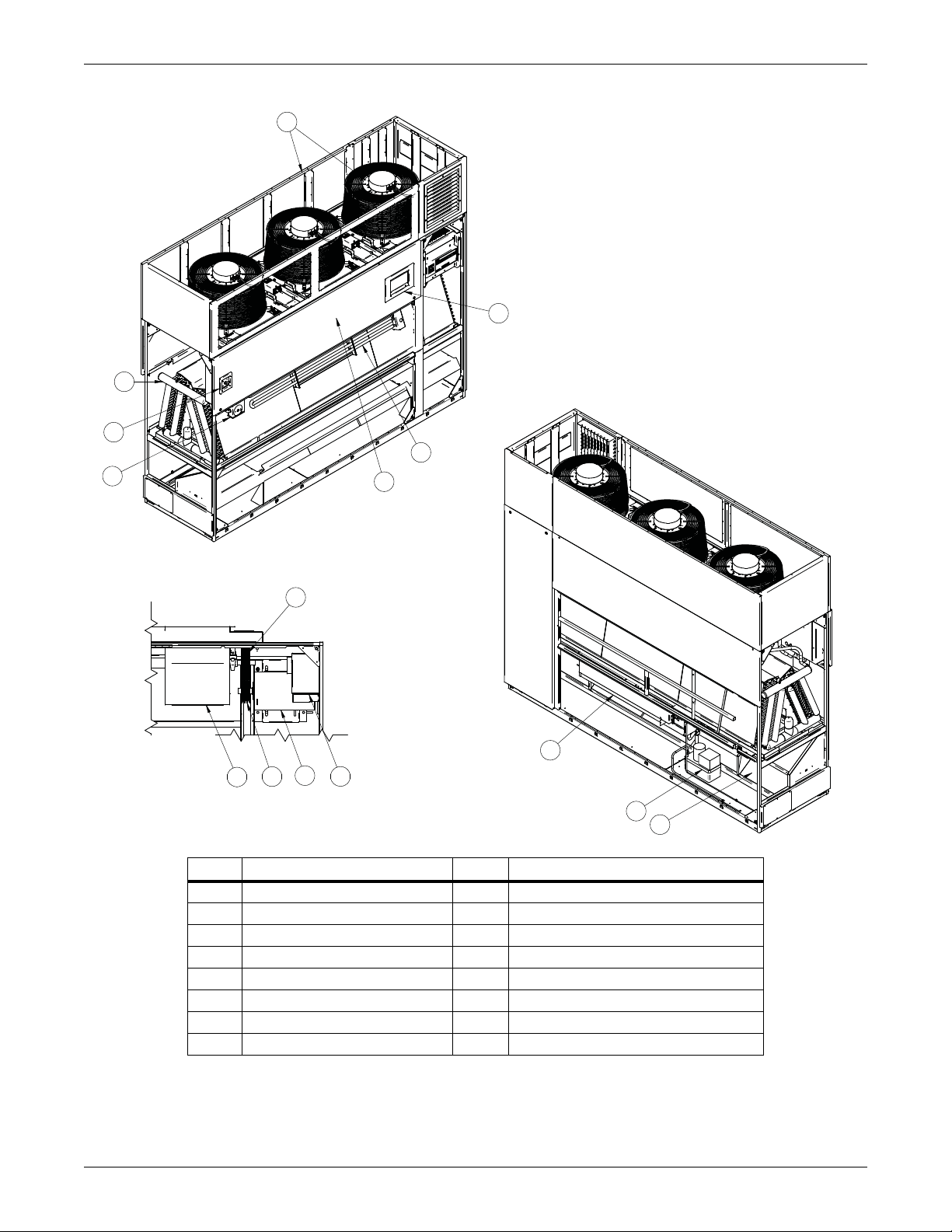

1.2 Components

Optional EC Fan Configuration

Front View

3

10

Rear View

Ships loose for field installation

on CW026-CW060 units.

1

11

15

14

9

12

4

2

5

6

7

8

13

Optional Forward-Curved Blower View

DPN002869

Rev. 3

Optional EC Fan Configuration

Figure 1-1 Downflow model component locations

Components

Item Description Item Description

1 iCOM control display 9 Infrared humidifier (optional)

2 Electric box 10 Reheat (optional)

3 Filters 11 Disconnect (optional)

4 Coil 12 Condensate pump (optional)

5 Motor 13 Variable-frequency drive (optional)

6Blower 14EC fans

7 Fan pulley 15 Smoke detector (optional)

8 Motor sheave and belts

3Liebert

®

CW™ System Design Manual

Page 14

Nomenclature and Components

Optional Forward-curved Blower Configuration

Front View

1

2

3

4

5

6

7

8

9

11

12

13

14

10

15

Optional EC Fan Configuration

Front View

Optional EC Fan Configuration

Rear View

Ships loose for field installation

on bottom return units.

Ships loose for

field installation

DPN002868

Rev. 1

Figure 1-2 Upflow model component locations

Item Description Item Description

1 iCOM control display 9 Infrared humidifier (optional)

2 Electric box 10 Reheat (optional)

3 Filters 11 Disconnect (optional)

4 Coil 12 Condensate pump (optional)

5 Motor 13 Variable-frequency drive (optional)

6 Blower 14 Plenum with EC fans (optional)

7 Fan Pulley 15 Smoke Detector (optional)

8 Motor sheave and belts

Liebert® CW™ System Design Manual 4

Page 15

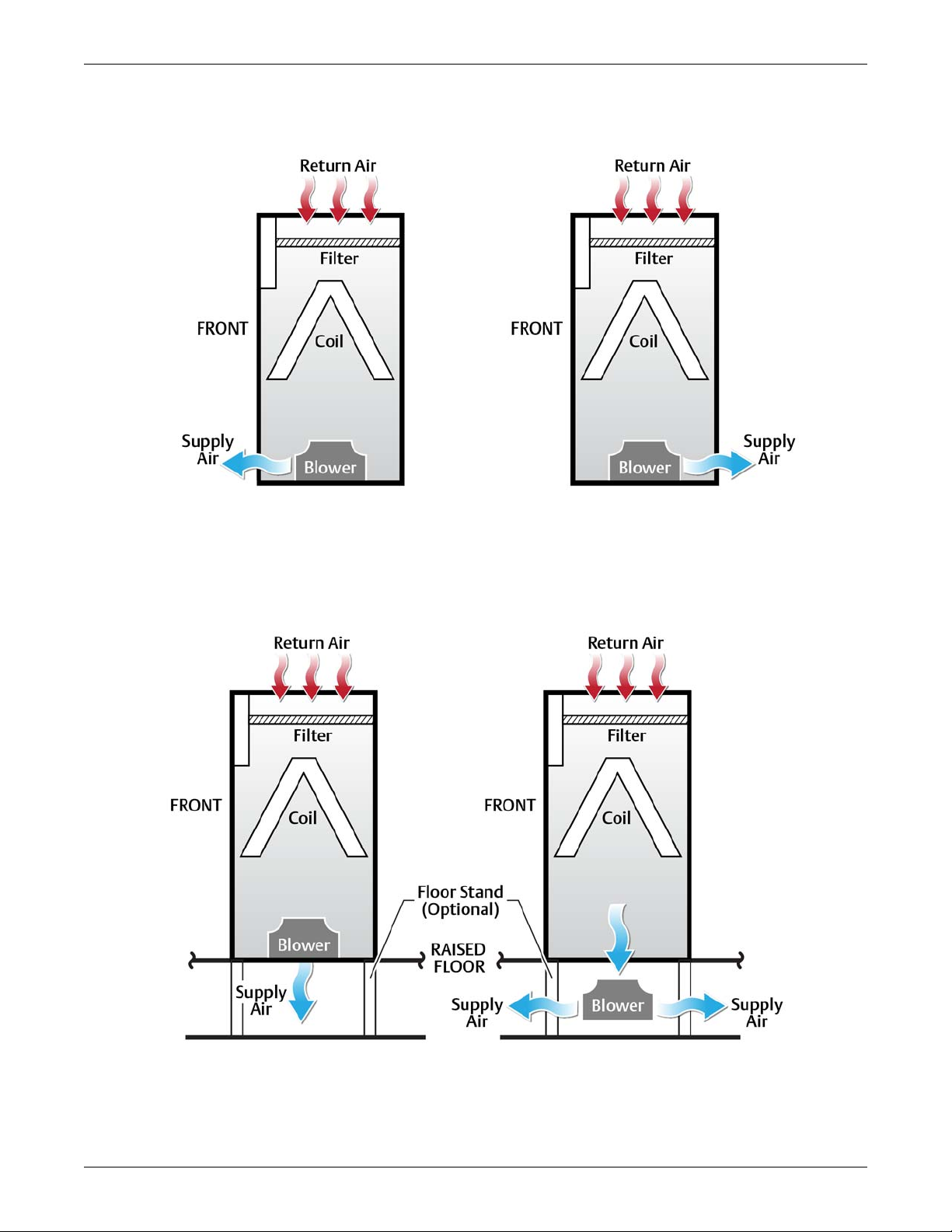

1.3 Blower Configurations

Rear Supply

Applicable to installations

without raised floors

Front Supply

Applicable to installations

without raised floors

Under-Floor Supply

(requires 24" minimum height)

Bottom Supply

Figure 1-3 Blower configurations—Downflow, front and rear supply, EC fans

Blower Configurations

Figure 1-4 Blower configurations—Downflow, bottom and under-floor supply, EC fans

5Liebert

®

CW™ System Design Manual

Page 16

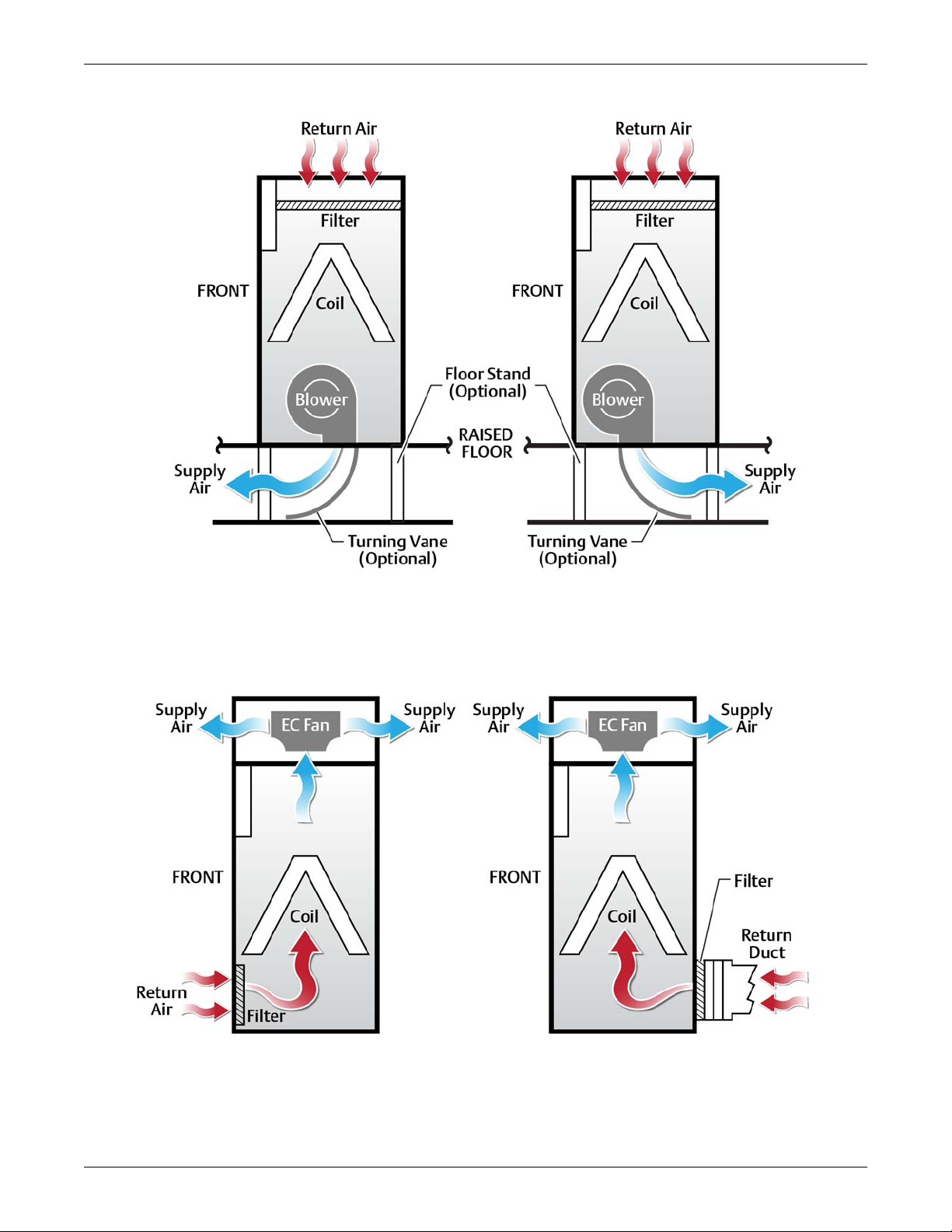

Nomenclature and Components

Front Throw

Rear Throw,

Front Return

Rear Return, Ducted

Figure 1-5 Blower configurations—Downflow, under-floor supply, forward-curved blowers

Figure 1-6 Blower configurations—Upflow, EC fans in plenum

Liebert® CW™ System Design Manual 6

Page 17

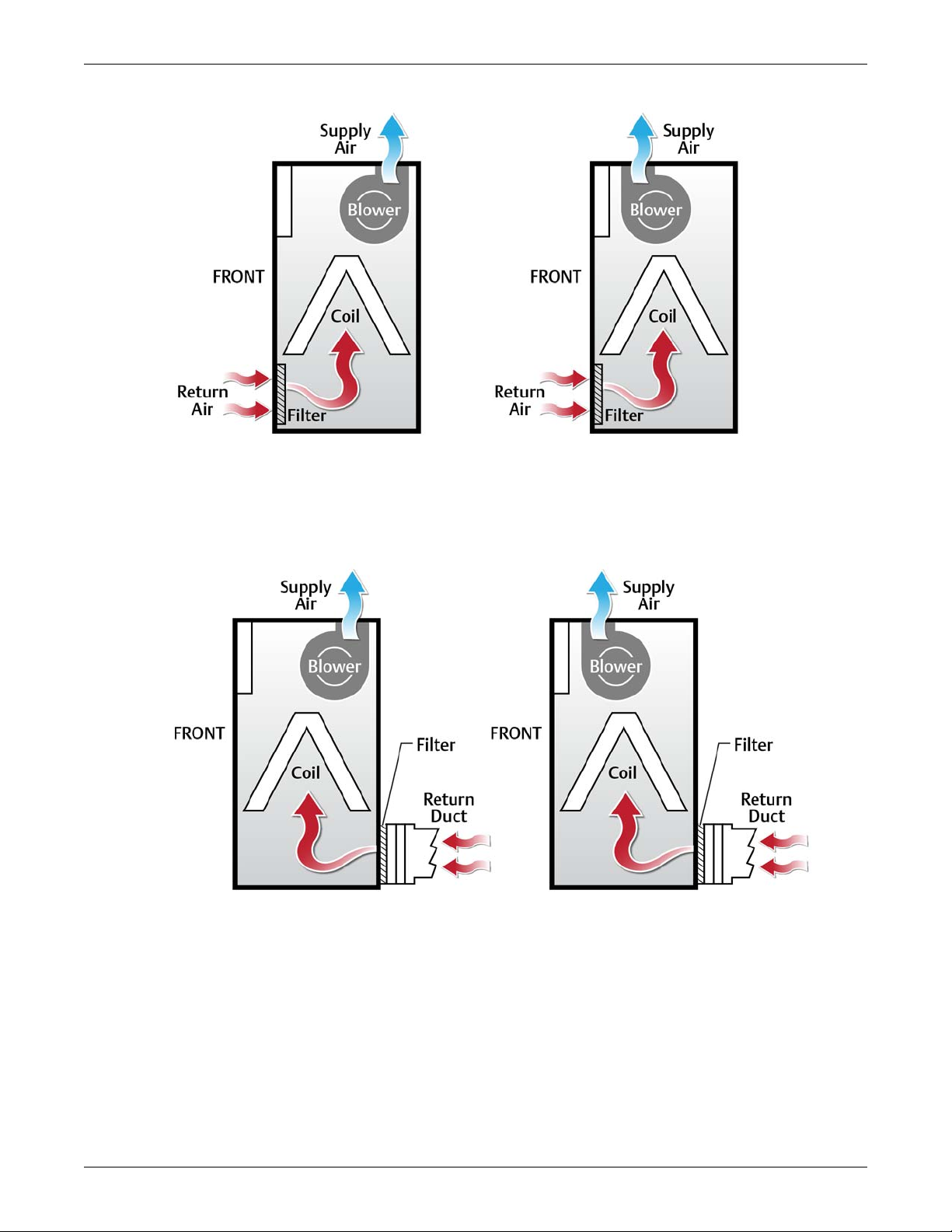

Figure 1-7 Blower configurations—Upflow, front return, forward-curved blowers

Front Throw

Rear Throw

Rear Throw,

Front Throw

Blower Configurations

Figure 1-8 Blower configurations—Upflow, rear return, forward-curved blowers

7Liebert

®

CW™ System Design Manual

Page 18

Nomenclature and Components

Page intentionally left blank.

Liebert® CW™ System Design Manual 8

Page 19

2.0 Liebert CW System Data

Table 2-1 Performance data, CW026-CW400, 50/60Hz, upflow and downflow models with EC fans

Model No. 026 038 041 051 060 076 084 089 * 106 114 146 * 181 * 300 * 400 *

CAPACITY DATA BTU/H (KW) BASED ON 45°F (7.2°C) ENTERING WATER, 10°F (5.5°C) WATER RISE

75°F DB, 61°F WB (23.9°C DB, 16.1°C WB) 45% RH

83.2

115.3

152.7

175.3

231.5

205.5

(60.2)

49.4

(3.1)

10.2

(30.5)

279.5

(81.9)

251.1

(73.6)

14.1

(42.2)

325.7

(95.4)

295.4

(86.6)

68.2

(4.3)

18.4

(55.0)

152.9

(44.8)

152.9

(44.8)

28.2

(1.8)

3.6

(10.7)

202.3

(59.3)

202.3

(59.3)

36.4

(2.3)

5.7

(17.1)

248.7

(72.9)

248.7

(72.9)

44.1

(2.80)

8.1

(24.3)

240.6

(70.50)

230.3

(67.50)

51.6

(3.3)

10.3

(30.7)

297.2

(87.1)

285.5

(83.7)

62.9

(4.0)

14.8

(44.2)

352.1

(103.2)

339.4

(99.4)

73.9

(4.7)

19.9

(59.4)

156.5

(45.9)

156.5

(45.9)

29.1

(1.8)

3.5

(10.5)

215.5

(63.1)

215.5

(63.1)

38.9

(2.5)

6.0

(17.9)

271.5

(79.5)

271.5

(79.5)

48.2

(3.0)

8.8

(26.5)

Total Capacity, kBTUH (kW)

(24.4)

(33.8)

(44.7)

(51.4)

(67.80)

Sensible Capacity, kBTUH (kW) 83.2

Flow Rate, GPM (l/s) 17.6

Pressure Drop, ft (kPA) 11.8

80°F DB, 62.8°F WB (26.7°C DB, 17.1°C WB) 38% RH

Total Capacity, kBTUH (kW) 105.5

Sensible Capacity, kBTUH (kW) 105.5

Flow Rate, GPM (l/s) 22.1

Pressure Drop, ft (kPA) 18.0

85°F DB, 64.5°F WB (29.4°C DB, 18.1°C WB) 32.3% RH

Total Capacity, kBTUH (kW) 127.2

Sensible Capacity, kBTUH (kW) 127.2

Flow Rate, GPM (l/s) 26.4

Pressure Drop, ft (kPA) 25.1

CAPACITY DATA BTU/H (KW) B ASE D ON 50° F (10 °C ) EN T ERI NG WAT ER , 12°F ( 6.66 °C ) WA TE R R IS E

75°F DB, 61°F WB (23.9°C DB, 16.1°C WB) 45% RH

Total Capacity, kBTUH (kW) 46.5

Sensible Capacity, kBTUH (kW) 46.5

Flow Rate, GPM (l/s) 8.6

Pressure Drop, ft (kPA) 3.0

80°F DB, 62.8°F WB (26.7°C DB, 17.1°C WB) 38% RH

Total Capacity, kBTUH (kW) 74.5

Sensible Capacity, kBTUH (kW) 74.5

Flow Rate, GPM (l/s) 13.3

Pressure Drop, ft (kPA) 6.7

85°F DB, 64.5°F WB (29.4°C DB, 18.1°C WB) 32.3% RH

Total Capacity, kBTUH (kW) 97.5

(28.60)

Sensible Capacity, kBTUH (kW) 97.5

(28.60)

Flow Rate, GPM (l/s) 17.1

Pressure Drop, ft (kPA) 10.8

* Models CW089, CW146, CW181, CW300 and CW400 available only in downflow.

(24.4)

(1.1)

(35.2)

(30.9)

(30.9)

(1.4)

(53.7)

(37.3)

(37.3)

(1.7)

(75.2)

(13.6)

(13.6)

(0.5)

(9.0)

(21.8)

(21.8)

(0.8)

(20.2)

(1.1)

(32.5)

113.1

(33.1)

24.6

(1.6)

18.1

(54.2)

143.0

(41.9)

140.4

(41.1)

30.1

(1.9)

26.7

(79.7)

169.9

(49.8)

167.2

(49.0)

35.5

(2.2)

36.5

(109.1)

75.3

(22.1)

75.3

(22.1)

13.9

(0.9)

6.0

(17.9)

104.7

(30.7)

104.7

(30.7)

18.7

(1.2)

10.6

(31.7)

132.5

(38.8)

132.5

(38.8)

23.4

(1.50)

16.1

(48.2)

136.6

(40.0)

32.3

(2.0)

16.4

(49.0)

183.8

(53.9)

166.6

(48.8)

38.5

(2.4)

22.6

(67.5)

213.9

(62.7)

195.7

(57.3)

44.5

(2.8)

29.4

(87.8)

102.3

(30.0)

102.3

(30)

18.5

(1.2)

5.9

(17.6)

134

(39.3)

134

(39.3)

23.8

(1.5)

9.2

(27.7)

164.2

(48.1)

164.2

(48.1)

28.8

(1.80)

13.1

(39.2)

173.6

(50.9)

37.8

(2.4)

9.3

(28.0)

219.6

(64.3)

217.3

(63.7)

46.6

(2.9)59(3.7)

13.8

(41.4)

262.4

(76.9)

259.8

(76.1)

55.2

(3.5)

19.0

(56.8)

108.3

(31.7)

108.3

(31.7)

20.4

(1.3)

2.9

(8.6)

158.6

(46.5)

158.6

(46.5)

28.8

(1.8)

5.5

(16.4)

203.6

(59.7)

203.6

(59.7)

36.2

(2.3)

8.4

(25.3)

297.2

(87.1)

264.7

77.60)

63.1

(4.0)

17.9

(53.5)

357.6

(104.8)

322.7

(94.6)

75.1

(4.70)

24.6

(73.6)

415.9

(121.9)

379.2

(111.1)

86.7

(5.5)

32.1

(95.8)

198.7

(58.2)

198.7

(58.2)

36.3

(2.3)

6.4

(19.1)

260.2

(76.2)

260.2

(76.2)

46.5

(2.9)

10.0

(30.0)

318.8

(93.4)

318.8

(93.4)

56.2

(3.6)

14.2

(42.5)

347.1

(101.7)

295.5

(86.6)

72.5

(4.6)

21.6

(64.5)

411.9

(120.70)

356.9

(104.6)

85.4

(5.4)

29.2

(87.1)

474.1

(138.9)

416.6

(122.1)

97.8

(6.2)

37.4

(111.8)

230.1

(67.4)

230.1

(67.4)

41.0

(2.6)

7.5

(22.4)

294.9

(86.4)

294.9

(86.4)

51.8

(3.3)

11.4

(34.2)

356.5

(104.5)

356.5

(104.5)

62.0

(3.9)

15.9

(47.5)

358.4

(105.0)

336.8

(98.7)

76.6

(4.8)

20.1

(60.1)

438.0

(128.3)

414.6

(121.5)

92.4

(5.8)

28.5

(85.1)

515.4

(151)

490.9

(143.8)

107.9

(6.8)

38.0

(113.4)

238.5

(69.9)

238.5

(69.9)

43.9

(2.8)

7.1

(21.2)

320.4

(93.9)

320.4

(93.9)

57.6

(3.6)

11.6

(34.8)

398.9

(116.9)

398.9

(116.9)

70.6

(4.5)

17.0

(50.7)

448.8

(131.5)

393.5

(115.3)

95.5

(6.0)

35.8

(106.9)

537.3

(157.4)

478.6

(140.2)

113.1

(7.1)

48.9

(146)

622.5

(182.4)

561.4

(164.5)

130.1

(8.2)

63.3

(189.2)

300.4

(88.0)

300.4

(88)

55.0

(3.5)

12.7

(38.0)

389.4

(114.1)

389.4

(114.1)

69.8

(4.4)

19.7

(58.9)

474.6

(139.1)

474.6

(139.1)

83.9

(5.3)

27.6

(82.6)

522.9

(153.2)

472.5

(138.4)

109.2

(6.9)

10.9

(32.5)

630.3

(184.7)

575.6

(168.7)

130.6

(8.2)

15.1

(45.2)

733.9

(215.0)

676.1

(198.1)

151.2

(9.5)

19.8

(59.2)

351.3

(102.9)

351.3

(102.9)

62.6

(4.0)

3.8

(11.5)

461.0

(135.1)

461.0

(135.1)

80.8

(5.1)

6.1

(18.3)

565.4

(165.7)

565.4

(165.7)

98.2

(6.2)

8.7

(26.2)

720.1

(211)

604.6

(177.1)

151.1

(9.5)

25.2

(75.3)

850.1

(249.1)

728.4

(213.4)

177

(11.2)

33.7

(100.6)

974.9

(285.6)

848.8

(248.7)

201.9

(12.7)

42.9

(128.1)

478.1

(140.1)

478.1

(140.1)

85.8

(5.4)

8.8

(26.4)

607.6

(178)

607.6

(178)

107.3

(6.8)

13.2

(39.6)

731.1

(214.2)

731.1

(214.2)

127.9

(8.1)

18.2

(54.4)

1003.0

(293.90)

911.4

(267.0)

209.9

(13.2)

10.1

(30.2)

1211.0

(354.8)

1112.0

(325.8)

251.3

(15.9)

14.1

(42.0)

1412.0

(413.7)

1307.0

(383.0)

291.4

(18.4)

18.5

(55.2)

672.7

(197.1)

672.7

(197.1)

120.1

(7.6)

3.5

(10.6)

885.4

(259.4)

885.4

(259.4)

155.5

(9.8)

5.7

(17.1)

1088.0

(318.8)

1088.0

(318.8)

189.2

(11.9)

8.2

(24.4)

1390.0

(407.3)

1163.0

(340.8)

292.6

(18.5)

23.8

(71.0)

1641.0

(480.8)

1402.0

(410.8)

342.6

(21.6)

31.7

(94.8)

1881.0

(551.1)

1634.0

(478.8)

390.6

(24.6)

40.3

(120.5)

920.3

(269.6)

920.3

(269.6)

166.1

(10.5)

8.3

(24.8)

1170

(342.8)

1170

(342.8)

207.6

(13.1)

12.4

(37.2)

1412.0

(413.7)

1407.0

(412.3)

247.9

(15.6)

17.2

(51.4)

9Liebert

®

CW™ System Design Manual

Page 20

Liebert CW System Data

Table 2-2 Performance data, CW026-CW114, 50/60Hz, upflow and downflow models

with forward-curved blowers

Model No. 026 038 041 051 060 076 084 106 114

Capacity Data BTU/H (kW) Based on 45°F (7.2°C) Entering Water, 10°F (5.5°C) Water Rise

75°F DB, 61°F WB (23.9°C DB, 16.1°C WB) 45% RH

Total Capacity, kBTUH (kW) 77.5

(22.7)

Sensible Capacity, kBTUH (kW) 77.5

(22.7)

Flow Rate, GPM (l/s) 17.1

(1.1)

Pressure Drop, ft (kPA) 11.2

(33.4)

80°F DB, 62.8°F WB (26.7°C DB, 17.1°C WB) 38% RH

Total Capacity, kBTUH (kW) 99.2

(29.1)

Sensible Capacity, kBTUH (kW) 99.2

(29.1)

Flow Rate, GPM (l/s) 21.5

(1.4)

Pressure Drop, ft (kPA) 17.0

(51.0)

85°F DB, 64.5°F WB (29.4°C DB, 18.1°C WB) 32.3% RH

Total Capacity, kBTUH (kW) 120.4

(35.3)

Sensible Capacity, kBTUH (kW) 120.4

(35.3)

Flow Rate, GPM (l/s) 25.7

(1.6)

Pressure Drop, ft (kPA) 23.9

(71.4)

Capacity Data BTU/H (kW) Based on 50°F (10°C) Entering Water, 12°F (6.66°C) Water Rise

75°F DB, 61°F WB (23.9°C DB, 16.1°C WB) 45% RH

Total Capacity, kBTUH (kW) 41.0

(12.0)

Sensible Capacity, kBTUH (kW) 42.0

(12.0)

Flow Rate, GPM (l/s) 8.2

(0.5)

Pressure Drop, ft (kPA) 2.7

(8.3)

80°F DB, 62.8°F WB (26.7°C DB, 17.1°C WB) 38% RH

Total Capacity, kBTUH (kW) 69.1

(20.2)

Sensible Capacity, kBTUH (kW) 69.1

(20.2)

Flow Rate, GPM (l/s) 12.9

(0.8)

Pressure Drop, ft (kPA) 6.4

(19.2)

85°F DB, 64.5°F WB (29.4°C DB, 18.1°C WB) 32.3% RH

Total Capacity, kBTUH (kW) 91.5

(26.8)

Sensible Capacity, kBTUH (kW) 91.5

(26.8)

Flow Rate, GPM (l/s) 16.6

(1.1)

Pressure Drop, ft (kPA) 10.3

(30.8)

Model CW089 not available with forward-curved blowers.

107.1

(31.4)

105.1

(30.8)

24.0

(1.5)

17.3

(51.7)

133.4

(39.1)

131.9

(38.6)

29.2

(1.8)

25.2

(75.3)

159.5

(46.7)

157.9

(46.3)

34.4

(2.2)

34.5

(103.0)

68.1

(20.0)

68.1

(20.0)

13.5

(0.9)

(17.1)

96.8

(28.4)

96.8

(28.4)

18.3

(1.2)

10.1

(30.3)

124.0

(36.3)

124

(36.3)

22.8

(1.4)

15.4

(46.0)

5.7

142.8

(41.8)

128

(37.50)

31.3

(2.0)

15.5

(46.3)

172.6

(50.6)

157.0

(46.0)

37.2

(2.4)

21.3

(63.5)

201.8

(59.1)

185.4

(54.3)

43.0

(2.7)

27.7

(82.7)

94.4

(27.7)

94.4

(27.7)

18.0

(1.1)

5.6

(16.8)

125.2

(36.7)

125.2

(36.7)

23.2

(1.5)

8.8

(26.4)

154.6

(45.3)

154.6

(45.3)

28

(1.8)

12.5

(37.3)

236.7

(69.4)

152.6

(44.7)

51.2

(3.2)

16.5

(49.3)

376.1

(110.2)

192.9

(56.5)

79.0

(5.0)

37.4

(111.7)

524.1

(153.6)

228.8

(67.0)

108.5

(6.8)

68.2

(203.7)

101.8

(29.8)

101.8

(29.8)

20.3

(1.3)

2.8

(8.5)

152.1

(44.6)

152.1

(44.6)

28.6

(1.8)

5.4

(16.3)

196.9

(57.7)

196.9

(57.7)

36.1

(2.3)

8.4

(25.1)

229.5

(67.2)

203.4

(59.6)

49.9

(3.2)

10.4

(31)

278.1

(81.5)

249.5

(73.1)

59.6

(3.8)

14.3

(42.9)

324.7

(95.1)

294.3

(86.2)

68.8

(4.3)

18.7

(56.0)

150.3

(44.0)

150.3

(44.0)

28.5

(1.8)

3.6

(10.9)

200.1

(58.6)

200.1

(58.6)

36.7

(2.3)

5.8

(17.4)

247.1

(72.4)

247.1

(72.4)

44.6

(2.8)

8.2

(24.7)

231.6

(67.9)

221.4

(64.9)

51.9

(3.3)

10.4

(31.1)

288.6

(84.6)

276.9

(81.1)

63.3

(4.0)

14.9

(44.6)

343.8

(100.7)

331.2

(97.0)

74.3

(4.7)

20.1

(60.1)

147.0

(43.1)

147

(43.1)

29.3

(1.8)

3.5

(10.6)

206.4

(60.5)

206.4

(60.5)

39.1

(2.5)

6.0

(18.1)

262.7

(77)

262.7

(77.0)

48.5

(3.1)

9.0

(26.8)

290.6

(85.1)

258

(75.6)

63.7

(4.0)

18.2

(54.5)

351.7

(103.0)

316.7

(92.8)

75.9

(4.8)

25.1

(75.0)

410.6

(120.3)

373.8

(109.5)

87.6

(5.5)

32.7

(97.6)

191.2

(56)

191.2

(56.0)

36.6

(2.3)

6.5

(19.5)

253.4

(74.2)

253.4

(74.2)

47.0

(3.0)

10.2

(30.6)

312.6

(91.6)

312.6

(91.6)

56.8

(3.6)

14.5

(43.3)

345.0

(101.1)

323.4

(94.8)

76.1

(4.8)

19.9

(59.4)

424.1

(124.3)

400.7

(117.4)

91.8

(5.8)

28.1

(84.1)

501.0

(146.8)

476.4

(139.6)

107.2

(6.8)

37.5

(112)

225.8

(66.2)

225.8

(66.2)

43.7

(2.8)

7.0

(20.9)

307.2

(90.0)

307.2

(90.0)

57.2

(3.6)

11.5

(34.3)

385.2

(112.9)

385.2

(112.9)

70.2

(4.4)

16.7

(50.1)

427.8

(125.3)

371.4

(108.8)

92.7

(5.9)

33.9

(101.2)

513.0

(150.3)

453.1

(132.8)

109.7

(6.9)

46.2

(138)

595

(174.3)

532.7

(156.1)

126.0

(8.0)

59.7

(178.3)

281.8

(82.6)

281.8

(82.6)

53.1

(3.4)

11.9

(35.7)

367.4

(107.6)

367.4

(107.6)

67.3

(4.2)

18.4

(55.1)

449.3

(131.6)

449.3

(131.6)

80.9

(5.1)

25.8

(77.2)

Liebert® CW™ System Design Manual 10

Page 21

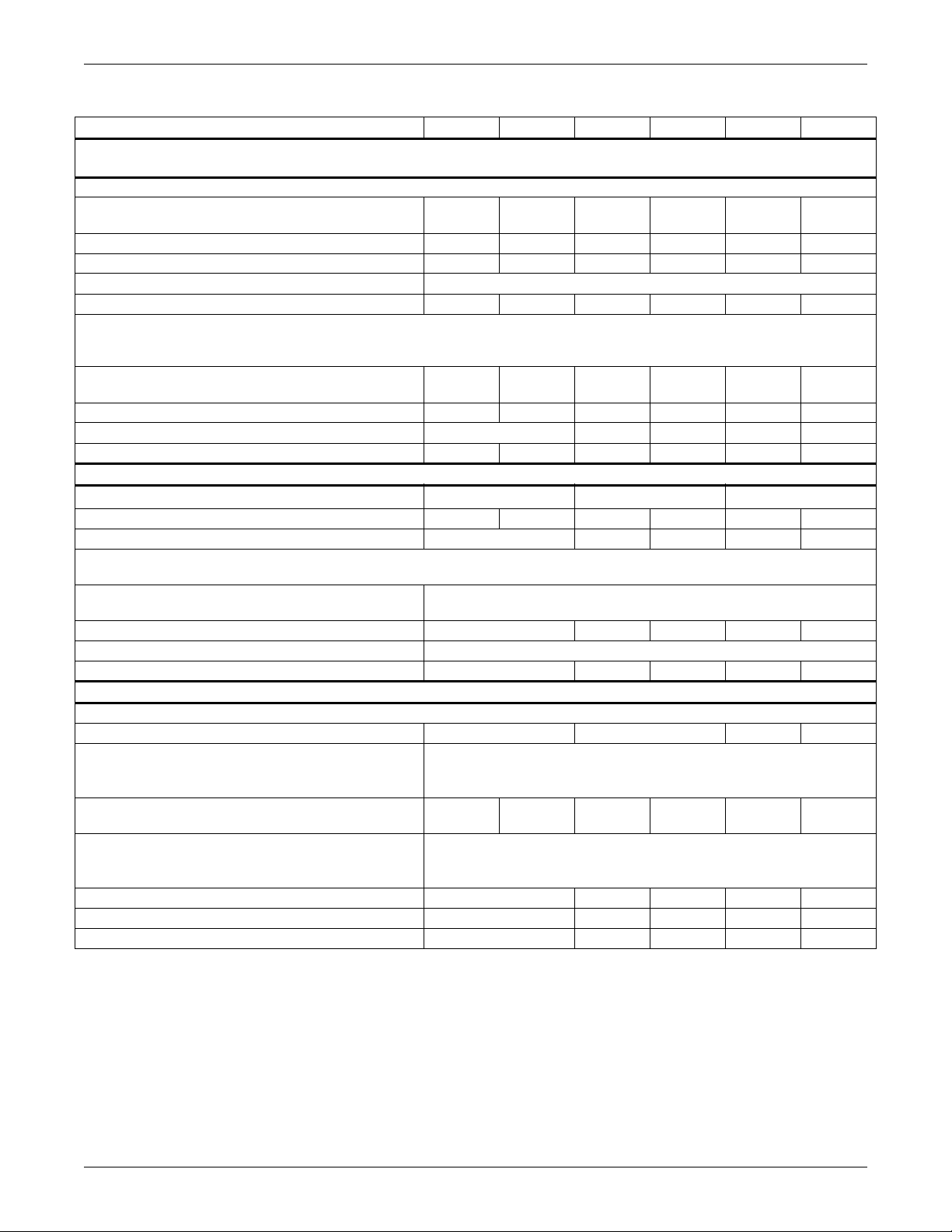

Table 2-3 Performance data for select Liebert CW Units with EC fans, High Delta T conditions

Entering

Water

Return Air Conditions of 80°F DB, 62.8°F WB, 52.3°F Dew Point (26.6°C DB, 17.1°C WB) 38.1% RH

14°F (7.8°C)

Water Rise

16°F (8.9°C)

Water Rise

Return Air Conditions of 85°F DB, 64.5°F WB, 52.3°F Dew Point (29.4°C DB, 18.1°C WB) 32.4% RH

14°F (7.8°C)

Water Rise

16°F (8.9°C)

Water Rise

Return Air Conditions of 90°F DB, 66.1°F WB, 52.3°F Dew Point (32.2°C DB, 18.9°C WB) 27.6% RH

14°F (7.8°C)

Water Rise

16°F (8.9°C)

Water Rise

Liebert CW Model

Numbers CW106 CW114 CW146 CW181 CW300 CW400

CAPACITY DATA BTU/HR (KW) BASED ON 50°F (10°C) ENTERING WATER, 0.2" ESP WITH ASHRAE 127-2012 STANDARD

Total, kBTUH (kW)

Sensible, kBTUH (kW)

Flow Rate, GPM (l/s)

Press. Drop, ft (kPa)

Total, kBTUH (kW)

Sensible, kBTUH (kW)

Flow Rate, GPM (l/s)

Press. Drop, ft (kPa)

CAPACITY DATA BTU/HR (KW) BASED ON 50°F (10°C) ENTERING WATER, 0.2" ESP WITH ASHRAE 127-2012 STANDARD

Total, kBTUH (kW)

Sensible, kBTUH (kW)

Flow Rate, GPM (l/s)

Press. Drop, ft (kPa)

Total, kBTUH (kW)

Sensible, kBTUH (kW)

Flow Rate, GPM (l/s)

Press. Drop, ft (kPa)

CAPACITY DATA BTU/HR (KW) BASED ON 50°F (10°C) ENTERING WATER, 0.2" ESP WITH ASHRAE 127-2012 STANDARD

Total, kBTUH (kW)

Sensible, kBTUH (kW)

Flow Rate, GPM (l/s)

Press. Drop,- ft (kPa)

Total, kBTUH (kW)

Sensible, kBTUH (kW)

Flow Rate, GPM (l/s)

Press. Drop, ft (kPa)

301.6 (88.3) 376.7 (110.3) 439.2 (128.6) 588.8 (172.4) 797.1 (233.4) 1054.6 (308.8)

301.6 (88.3) 376.7 (110.3) 439.2 (128.6) 588.8 (172.4) 797.1 (233.4) 1054.6 (308.8)

46.6 (2.9) 58.0 (3.7) 66.1 (4.2) 89.3 (5.6) 120.8 (7.6) 161.6 (10.2)

7.8 (23.3) 14.0 (41.8) 4.2 (12.6) 9.4 (28.1) 3.6 (10.8) 7.9 (23.6)

273.9 (80.2) 353.5 (103.5) 405.0 (118.6) 560.1 (164.0) 733.2 (214.7) 1004.7 (294.2)

273.9 (80.2) 353.5 (103.5) 405.0 (118.6) 560.1 (164.0) 733.2 (214.7) 1004.7 (294.2)

37.4 (2.4) 47.8 (3.0) 53.6 (3.4) 74.6 (4.7) 97.8 (6.2) 135.1 (8.5)

5.2 (15.5) 9.8 (29.3) 2.9 (8.7) 6.8 (20.3) 2.4 (7.2) 5.7 (17.0)

383.9 (112.4) 466.2 (136.5) 548.8 (160.7) 717.2 (210.0) 998.9 (292.5) 1284.8 (376.2)

383.9 (112.4) 466.2 (136.5) 548.8 (160.7) 717.2 (210.0) 998.9 (292.5) 1284.8 (376.2)

58.3 (3.7) 70.7 (4.5) 81.8 (5.2) 107.6 (6.8) 149.5 (9.4) 194.4 (12.3)

11.9 (35.6) 20.1 (60.1) 6.2 (18.5) 13.2 (39.5) 5.3 (15.8) 11.0 (32.9)

359.3 (105.2) 446.0 (130.6) 519.4 (152.1) 692.9 (202.9) 944.3 (276.5) 1242.8 (363.9)

359.3 (105.2) 446.0 (130.6) 519.4 (152.1) 692.9 (202.9) 944.3 (276.5) 1242.8 (363.9)

48.0 (3.0) 59.3 (3.7) 67.9 (4.3) 91.1 (5.7) 124.1 (7.8) 164.9 (10.4)

8.3 (24.8) 14.5 (43.3) 4.4 (13.2) 9.8 (29.3) 3.7 (11.1) 8.1 (24.2)

463.1 (135.6) 552.2 (161.7) 654.0 (191.5) 840.5 (246.1) 1192.9 (349.3) 1506.1 (441.0)

463.1 (135.6) 552.2 (161.7) 654.0 (191.5) 840.5 (246.1) 1192.9 (349.3) 1506.1 (441.0)

69.6 (4.4) 83.0 (5.2) 96.7 (6.1) 125.1 (7.9) 177.1 (11.2) 225.8 (14.2)

16.5 (49.3) 27.0 (80.7) 8.5 (25.4) 17.4 (52.0) 7.2 (21.5) 14.5 (43.3)

440.6 (129.0) 533.8 (156.3) 627.4 (183.7) 819.3 (239.9) 1142.7 (334.6) 1469.9 (430.4)

440.6 (129.0) 533.8 (156.3) 627.4 (183.7) 819.3 (239.9) 1142.7 (334.6) 1469.9 (430.4)

58.1 (3.7) 70.3 (4.4) 81.3 (5.1) 106.9 (6.7) 148.8 (9.4) 193.1 (12.2)

11.7 (35.0) 19.8 (59.2) 6.1 (18.2) 13.0 (38.9) 5.2 (15.5) 10.8 (32.3)

11 Liebert® CW™ System Design Manual

Page 22

Liebert CW System Data

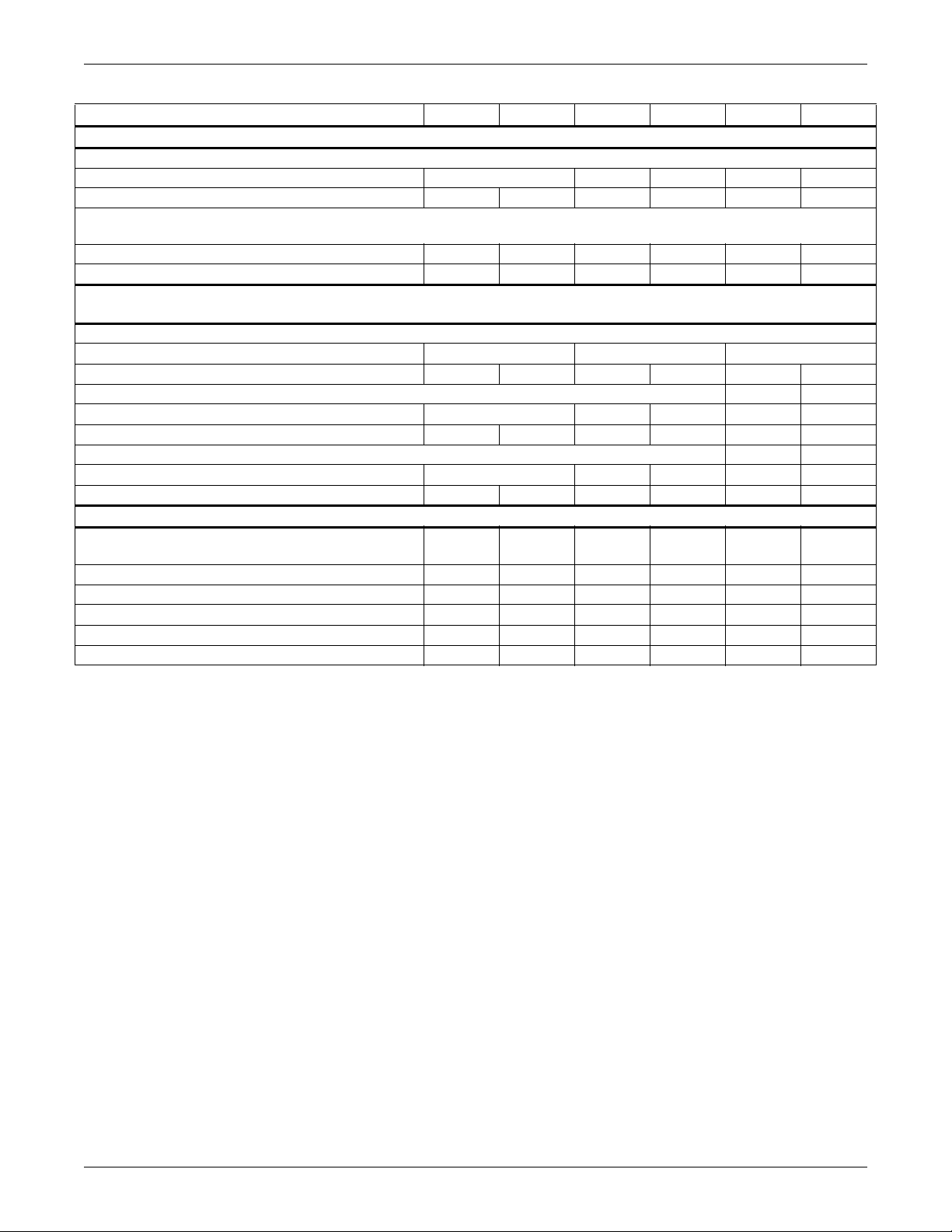

Table 2-4 Motor size required to deliver rated airflow, models with forward-curved blowers

External Static

Model

026 5050 (2383) 3555555

038 5850 (2761) 5 5 5 — — —

041 5750 (2714) 5 ——————

051 9150 (4318) 7.5 7.5 —————

060 8900 (4200) 7.5 7.5 —————

076 12100 (5711) 10 15 15 15 15 — —

084 11650 (5498) 10 15 15 15 15 — —

106 17100 (8070) 15 15 15 15 15 — —

114 16500 (7787) 15 15 15 15 — — —

* Delivered airflow is less than rated airflow

Table 2-5 Maximum airflow with maximum motor size at listed static pressure,

External Static

Pressure 0.2" 0.4" 0.6" 0.8" 1.0" 1.2" 1.4"

Model

026

038

041

051

060

076

084

106

114

Pressure 0.2" 0.4" 0.6" 0.8" 1.0" 1.2" 1.4"

Rated Airflow

CFM (l/s) Motor Size, hp

models with forward-curved blowers

Rated

Airflow

CFM (l/s) Airflow, CFM (l/s)

5050

(2383)

5850

(2761)

5750

(2714)

9150

(4318)

8900

(4200)

12100

(5711)

11650

(5498)

17100

(8070)

16500

(7787)

5050

(2383)

5850

(2761)

5750

(2714)

9150

(4318)

8900

(4200)

12100

(5711)

11650

(5498)

17100

(8070)

16500

(7787)

5050

(2383)

5850

(2761)

5750

(2714)

9150

(4318)

8900

(4200)

12100

(5711)

11650

(5498)

17100

(8070)

16500

(7787)

5050

(2383)

5850

(2761)

5600

(2643)

9100

(4295)

8750

(4130)

12100

(5711)

11650

(5498)

17100

(8070)

16500

(7787)

5050

(2383)

5750

(2714)

5450

(2572)

8900

(4200)

8550

(4035)

12100

(5711)

11650

(5498)

17100

(8070)

16500

(7787)

5050

(2383)

5600

(2643)

5350

(2525)

8700

(4106)

8400

(3964)

12100

(5711)

11650

(5498)

17100

(8070)

16100 — —

5050

(2383)

5450

(2572)

——

8550

(4035)

8200

(3870)

11600

(5475)

11400

(5380)

16400

(7740)

5050

(2383)

5350

(2525)

8350

(3941)

8050

(3799)

11000

(5191)

NA

16100

(7598)

Liebert® CW™ System Design Manual 12

Page 23

Table 2-6 Physical data, Liebert CW026 - CW089, 50/60Hz models

Model Sizes 026 038 041 051 060 076 084 089

FAN SECTION

Some options or combinations of options may result in reduced airflow. Consult your sales representative for recommendations.

Fan Data - EC Fans - Available in Upflow and Downflow Orientations (CW089 available in downflow only)

Nominal Air Volume, CFM (CMH) 5,250

(8,925)

Fan Motor, Maximum hp (kW),

Fan Motor, Max hp (kW),

Standard Ext Static Pressure, inches of

Fan Data - Forward-curved Blowers - Variable Pitch, Two-Belt Drive Package - Available in Upflow and Downflow* Configurations

Fan Motor, Maximum hp (kW), each 3.0 (2.2) 5.0 (3.7) 7.5 (5.6) 10.0 (7.5)

Standard Ext Static Pressure, inches of

Face Velocity, EC Fans, FPM (m/s) 450

Chilled Water Valves (Standard valves, Maximum design water pressure 150 PSI[1034.3 kPA]. Higher pressure available as an option.

Consult your sales representative for information).

Valve Actuator, Sensors, and Body Modulating Valve Actuator with Proportional Sensors and either

2-Way Valve (Opt) Close-off Pressure,

Electric Reheat - Three Stage, Fin/Tube

Steam Reheat: 218°F (103.3°C)

Steam, 75°F (23.9°C) EAT

Hot Water Reheat @ 180°F (82.2°C)

EWT & 75°F (23.8°C) EAT

Pressure Drop, PSI (kPA) 3.5 (24.1) 1.6 (11.0) 1.6 (11.0)

Downflow, each

4.0 (3.0) 4.0 (3.0) 4.0 (3.0)

Upflow, each

water (PA)

Number of Fans 1 1 1 2 2 2 2 2

Nominal Air Volume,

CFM (CMH)

water (PA)

Number of Fans 1 1 1 2 2 2 2 2

Face Area, ft

Number of Rows 3 4 6 4 6 4 6 6

Valve CV 11.6 11.6 28.9 28.9 46.2 46.2 46.2 46.2

Valve Size, in. 1 1-1/4 1-1/2 1-1/2 2 2 2 2

PSI (kPA)

Capacity, BTU/HR (kW) 34,130 (10) 51,195 (15) 68,260 (20) 83,325 (25) 102,390 (30)

Capacity, BTU/HR (kW) 85,800

Capacity, BTU/HR (kW) 47,000

Flow Rate, GPM (l/s) 5 (0.31) 5 (0.31) 5 (0.31) 8 (0.50) 8 (0.50) 8 (0.50) 8 (0.50) N/A

4.0 (3.0) 4.0 (3.0) 4.0 (3.0) 4.0 (3.0) 4.0 (3.0) 4.0 (3.0) 4.0 (3.0) 4.0 (3.0)

0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50)

5,050

(8,580)

0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50) 0.2 (50)

2

(m2)

(2.28)

(25.1)

(13.7)

6,050

(10,285)

5,850

(9,940)

11.7 (1.1) 18.5 (1.7) 25.0 (2.3) 36.3 (3.4)

519

(2.63)

86 (593) 70 (483) 45 (310) 45 (310)

85,800

(25.1)

49,500

(14.5)

5,950

(10,115)

5,750

(9,770)

CHILLED WATER COIL

(2.59)

REHEAT SECTION

Modulating 2-way, 150 PSI (1034.3 kPa) max operating pressure.

Unit CFM reduced by 300 with standard motor (142 l/s)

85,800

(25.1)

Modulating 2-way, 150 PSI (1034.3 kPa) max operating pressure.

Unit CFM reduced by 300 with standard motor (142 l/s)

49,500

(14.5)

9,200 (15,640) 9,200 (15,640)

3.6

for 208/230 V

3.4

for 380 to 460V,

60 Hz/50 Hz

9,150

15,550

510

503

(2.55)

2-Way or 3-Way Valve Body

Not applicable to units with EC fans.

93,400 (27.4) 144,500 (42.4)

Not applicable to units with EC fans.

89,900 (26.3) 89,900 (26.3)

for 208/230 V

for 380 to 460V,

60 Hz/50 Hz

3.6

3.4

8,900

(15,120)

503

(2.55)

12,400

(21,080)

4.0 (3.0) 4.0 (3.0) 4.0 (3.0)

12,100

(20,560)

496

(2.51)

163,200

(47.8)

125,200

(36.7)

11,900

(20,230)

11,650

(19,790)

476

(2.41)

163,200

(47.8)

125,200

(36.7)

12,100

(20,570)

(1.69)

N/A

333

N/A

N/A

13 Liebert® CW™ System Design Manual

Page 24

Liebert CW System Data

Table 2-6 Physical data, Liebert CW026 - CW089, 50/60Hz models (continued)

Model Sizes 026 038 041 051 060 076 084 089

HUMIDIFIER SECTION

Infrared Humidifier

Capacity, lb/hr (kg/h) 1 1 (5.0) 11 (5.0) 11 (5.0) 17.4 (7.9) 17.4 (7.9) 22.1 (10) 22.1 (10) 22.1 (10)

kW 4.8 4.8 4.8 6.4 6.4 9.6 9.6 9.6

Steam Generating Humidifier,

Not applicable to units with EC fans. (Water Conductivity between 200-500 micro-ohms is required for ideal operation)

Capacity, lb/hr (kg/h) 11 (5.0) 22 (10.0) N/A

kW 3.6 3.6 3.6 7.2 7.2 7.2 7.2 7.2

Steam Grid Humidifier - All Models (Standard Selection, 5 PSIG (34.5 kPa), Steam 14 lb/hr. [6.4 kg/h])

Supply Steam Pressure, PSIG (kPa) — 2 (13.8) 4 (27.6) 5 (34.5) 6 (41.4) 8 (55.2) 10 (68.9) N/A

Capacity, lb/hr (kg/h), w/ 5/32” orifice — 8 (3.6) 12 (5.4) 14 (6.4) 16 (7.3) 19 (8.6) 21 (9.5) N/A

FILTER SECTION

Disposable Type - Nominal Size and Quantities, MERV8 and MERV11 (option)

Downflow Models

Nominal Size, in 18 x 24 24 x 31

Quantity 4 4 4 6 6 8 8 5

Upflow Models (Front Return)

Nominal Size, in 24 x 24 N/A

Quantity 2 2 2 3 3 4 4 N/A

Upflow Models (Bottom and Rear Return)

Nominal Size, in 18 x 24 N/A

Quantity 4 4 4 6 6 8 8 N/A

CONNECTION SIZES

Chilled Water, OD Copper 1-1/8 1-3/8 1-5/8 1-5/8 2-1/8 2-1/8 2-1/8 2-5/8

Infrared Humidifier, OD Copper 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

Condensate Drain, FPT 3/4 3/4 3/4 3/4 3/4 3/4 3/4 1-1/4

Steam Reheat, MPT, FC Blower only 1/2 1/2 1/2 1/2 3/4 3/4 3/4 N/A

Hot Water Reheat, OD Copper, FC

Blower only

Steam Grid Humidifier, MPT, FC

Blower only

5/8 5/8 5/8 7/8 7/8 7/8 7/8 N/A

1/2 1/2 1/2 1/2 1/2 1/2 1/2 N/A

Liebert® CW™ System Design Manual 14

Page 25

Table 2-7 Physical data—Liebert CW106 - CW400, 50/60Hz models

Model Sizes 106 114 146 181 300 400

FAN SECTION

Some options or combinations of options may result in reduced airflow. Consult your Emerson representative for recommendations.

Fan Data - EC Fans - CW106 & CW114 are available in Upflow and Downflow Orientations. CW146 to CW400 are available in Downflow only.

Nominal Air Volume, CFM (CMH) 17,300

(29,410)

Fan Motor, Maximum hp (kW), Downflow, each 4.0 (3.0) 4.0 (3.0) 3.7 (2.8) 4.9 (3.7) 4.2 (3.4) 5.4 (4.4)

Fan Motor, Maximum hp (kW), Upflow, each 4.0 (3.0) 4.0 (3.0) — — — —

Standard Ext Static Pressure, inches of water (PA) 0.2 (50)

Number of Fans 3 3 3 3 6 6

Fan Data -Forward-curved Blowers - Variable Pitch, Two-Belt Drive Package CW106 & CW114 are available in Upflow and Downflow Orientations.

CW146 to CW400 are available with EC Fans in downflow orientation only.

Nominal Air Volume, CFM (CMH) 17,100

(29,050)

Fan Motor, Maximum hp (kW), each 3.0 (2.2) 5.0 (3.7) — — — —

Standard Ext Static Pressure, inches of water (PA) 0.2 (50) — — — —

Number of Fans 3 3 — — — —

CHILLED WATER COIL

2

Face Area, ft

Number of Rows464646

Face Velocity, EC Fans, FPM (m/s) 476 (1.34) 373 (1.89) 427 (2.16) 359 (1.82) 406 (2.06)

Chilled Water Valves (Standard valves, Maximum design water pressure 150 PSI [1034.3 kPA]. Higher pressure available as an option. Consult

your Emerson representative for information).

Valve Actuator, Sensors, & Body Modulating Valve Actuator with Proportional Sensors and

Valve Size, in. 2

2-Way Valve (Opt) Close-off Pressure, PSI (kPA) 45 (310) 200 (1,378) 200 (1,378) 200 ( 1,378) 200 (1,378)

Electric Reheat - Three-Stage, Fin Tube

Capacity, BTU/HR (kW) 102,390 (30) 102,390 (30) — —

Steam Reheat: 218°F (103.3°C) Steam, 75°F (23.9) EAT Modulating 2-way, 150 PSI (1034.3 kPa) maximum operating

Capacity, BTU/HR (kW) 84,100

Hot Water Reheat @ 180°F (82.2°C) EWT 75°F (23.8°C) EAT Modulating 2-way, 150 PSI (1034.3 kPa) maximum operating pressure.

Capacity, BTU/HR (kW) 133,700 (39.2) — — — —

Flow Rate, GPM (l/s) 8 (0.50) — — — —

Pressure Drop, PSI (kPA) 1.6 (11.0) — — — —

(m2)

Valve CV 46.2 46.2; qty 2 46.2; qty 2 46.2; qty 4 46.2; qty 4

REHEAT SECTION

(24.6)

17,300

(29,410)

16,500

(28,030)

36.3 (3.4) 56.3 (5.3) 112.6 (10.6)

pressure. Not applicable to units with EC fans.

Unit CFM reduced by 300 with standard motor (142 l/s)

85,800

(25.1)

Unit CFM reduced by 300 with standard motor (142 l/s)

21,000

(35,700)

————

either 2-Way or 3-Way Valve Body

————

Not applicable to units with EC fans.

24,000

(40,800)

40,500

(68,850)

45,700

(77690)

15 Liebert® CW™ System Design Manual

Page 26

Liebert CW System Data

Table 2-7 Physical data—Liebert CW106 - CW400, 50/60Hz models (continued)

Model Sizes 106 114 146 181 300 400

HUMIDIFIER SECTION

Infrared Humidifier Note (50Hz Models are 22.1 lb/h (10.0 kg/h); 9.6 kW)

Capacity, lb/hr (kg/h) 22.1 (10) 22.1 (10) 22.1 (10) — —

kW 9.6 9.6 9.6 9.6 — —

Steam Generating Humidifier (Water Conductivity between 200-500 micro-ohms is required for ideal operation) - Not applicable to units with EC

fans.

Capacity, lb/hr (kg/h) 22 (10.0) 22 (10.0) — — — —

kW9.69.6————

FILTER SECTION

Disposable Type - Nominal Size and Quantities, MERV8 and MERV11 (option)

Downflow Models

Nominal Size, in 24 x 31 21.5 x 24 29.5 x 28.5

Quantity 5 5 10 10 12 12

Upflow Models (Front Return)

Nominal Size, in 18 x 24 N/A N/A N/A N/A

Quantity 2 2 N/A N/A N/A N/A

Upflow Models (Bottom & Rear Return)

Nominal Size, in 18 x 24 N/A N/A N/A N/A

Quantity 10 10 N/A N/A N/A N/A

CONNECTION SIZES

Chilled Water, OD Copper

Infrared Humidifier, OD Copper 1/4” 1/4” 1/4” 1/4” N/A N/A

Condensate Drain, FPT 1-1/4” 1-1/4” 1-1/4” 1-1/4” 1-1/4” 1-1/4”

Steam Reheat, MPT 3/4” 3/4” N/A N/A N/A N/A

Hot Water Reheat, OD Copper 7/8” 7/8” N/A N/A N/A N/A

Steam Humidifier, MPT 1/2” 1/2” N/A N/A N/A N/A

2-1/8” 2-5/8” 3-1/8” 3-1/8”

3-1/8”

(qty 2)

3-1/8”

(qty 2)

Liebert® CW™ System Design Manual 16

Page 27

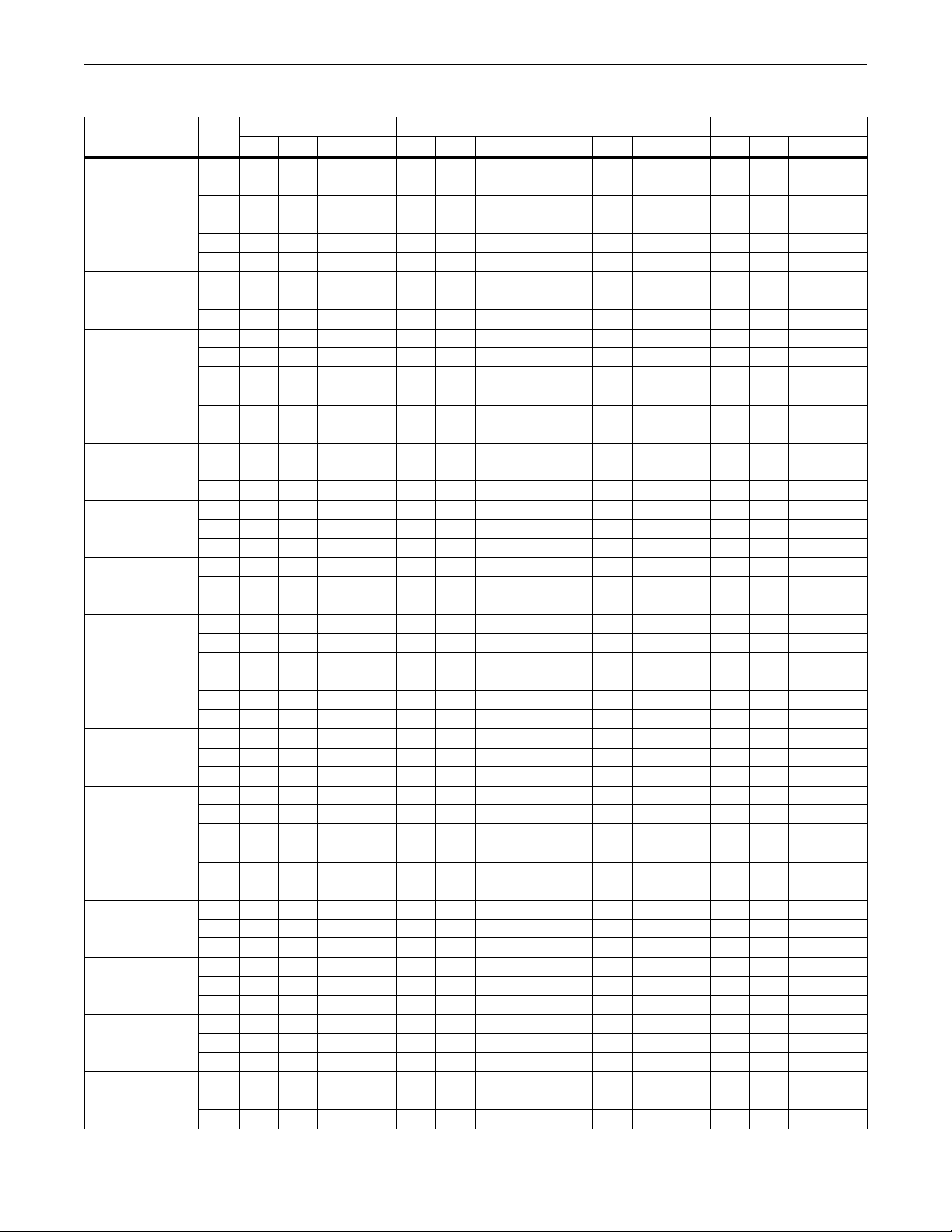

3.0 Electrical Data

Table 3-1 Electrical data, Liebert CW with EC fans, 60Hz

Reheat/Humidifier No Reheat/Humidifier Reheat/No Humid ifier No Reheat/No Humidifier

Models Volts

CW026

CW038

CW041

CW051

Downflow

CW051

Upflow

CW060

Downflow

CW060

Upflow

CW076

CW084

CW089

Downflow

CW106

CW114

CW146

Downflow

CW181

Downflow

CW300

Downflow

CW400

Downflow

208 230 380 460 575 208 230 380 460 575 208 230 380 460 575 208 230 380 460 575

FLA 50.3 46.5 24.7 23.0 20.6 22.5 20.3 11.0 9.8 10.6 37.0 35.4 18.6 17.2 13.2 9.2 9.2 4.9 4.0 3.2

WSA 62.9 58.1 30.9 28.8 25.8 28.1 25.4 13.8 12.3 13.3 46.3 44.3 23.3 21.5 16.5 11.5 11.5 6.1 5.0 4.0

OPD70 60 3530303030151515 45 45 2020152020151515

FLA 64.1 59.4 31.6 29.5 25.7 22.5 20.3 11.0 9.8 10.6 50.8 48.3 25.5 23.7 18.3 9.2 9.2 4.9 4.0 3.2

WSA 80.1 74.3 39.5 36.9 32.1 28.1 25.4 13.8 12.3 13.3 63.5 60.4 31.9 29.6 22.9 11.5 11.5 6.1 5.0 4.0

OPD90 80 4040353030151515 70 70 3530252020151515

FLA 64.1 59.4 31.6 29.5 25.7 22.5 20.3 11.0 9.8 10.6 50.8 48.3 25.5 23.7 18.3 9.2 9.2 4.9 4.0 3.2

WSA 80.1 74.3 39.5 36.9 32.1 28.1 25.4 13.8 12.3 13.3 63.5 60.4 31.9 29.6 22.9 11.5 11.5 6.1 5.0 4.0

OPD90 80 4040353030151515 70 70 3530252020151515

FLA 98.7 91.3 47.4 45.3 — 43.2 38.8 20.0 19.1 — 72.1 69.1 35.2 32.4 — 16.6 16.6 7.8 6.2 —

WSA 123.4 114.1 59.3 56.6 — 54.0 48.5 25.0 23.9 — 90.1 86.4 44.0 40.5 — 18.7 18.7 8.8 7.0 —

OPD 125 125 60 60 — 60 45 30 25 — 100 90 45 45 — 20 20 15 15 —

FLA 100.5 93.1 49.4 47.1 40.0 45.0 40.6 22.0 20.9 19.9 73.9 70.9 37.2 34.2 26.5 18.4 18.4 9.8 8.0 6.4

WSA 125.6 116.4 61.8 58.9 50.0 56.3 50.8 27.5 26.1 24.9 92.4 88.6 46.5 42.8 33.1 20.7 20.7 11.0 9.0 7.2

OPD 150 125 70 60 60 50 50 25 30 25 100 90 50 45 35 25 25 15 15 15

FLA 112.6 104.3 54.3 51.8 — 43.2 38.8 20.0 19.1 — 86.0 82.1 42.1 38.9 — 16.6 16.6 7.8 6.2 —

WSA 140.8 130.4 67.9 64.8 — 54.0 48.5 25.0 23.9 — 107.5 102.6 52.6 48.6 — 18.7 18.7 8.8 7.0 —

OPD 150 150 70 70 — 60 45 30 25 — 110 110 60 50 — 25 25 15 15 —

FLA 114.4 106.1 56.3 53.6 45.0 45.0 40.6 22.0 20.9 19.9 87.8 83.9 44.1 40.7 31.5 18.4 18.4 9.8 8.0 6.4

WSA 143.0 132.6 70.4 67.0 56.3 56.3 50.8 27.5 26.1 24.9 109.8 104.9 55.1 50.9 39.4 20.7 20.7 11.0 9.0 7.2

OPD 150 150 80 70 60 50 50 25 30 25 110 110 60 60 40 25 25 15 15 15

FLA 124.1 119.2 63.1 58.7 48.1 45.0 40.6 22.0 19.6 18.0 97.5 97.0 50.9 47.1 36.5 18.4 18.4 9.8 8.0 6.4

WSA 155.1 149.0 78.9 73.4 60.1 56.3 50.8 27.5 24.5 22.5 121.9 121.3 63.6 58.9 45.6 20.7 20.7 11.0 9.0 7.2

OPD 175 150 80 80 70 50 50 25 20 25 125 125 70 60 50 25 25 15 15 15

FLA 124.1 119.2 63.1 58.7 48.1 45.0 40.6 22.0 19.6 18.0 97.5 97.0 50.9 47.1 36.5 18.4 18.4 9.8 8.0 6.4

WSA 155.1 149.0 78.9 73.4 60.1 56.3 50.8 27.5 24.5 22.5 121.9 121.3 63.6 58.9 45.6 20.7 20.7 11.0 9.0 7.2

OPD 175 150 80 80 70 50 50 25 20 25 125 125 70 60 50 25 25 15 15 15

FLA — — — 58.7 48.1 — — — 19.6 18.0 — — — 47.1 36.5 — — — 8.0 6.4

WSA — — — 73.4 60.1 — — — 24.5 22.5 — — — 58.9 45.6 — — — 9.0 7.2

OPD — — — 80 70 — — — 20 25 — — — 60 50 — — — 15 15

FLA 133.3 128.4 68.0 62.7 51.3 54.2 49.8 26.9 23.6 21.2 106.7 106.2 55.8 51.1 39.7 27.6 27.6 14.7 12.0 9.6

WSA 166.6 160.5 85.0 78.4 64.1 67.8 62.3 33.6 29.5 26.5 133.4 132.8 69.8 63.9 49.6 29.9 29.9 15.9 13.0 10.4

OPD 175 175 90 80 70 70 70 35 30 30 150 150 70 70 50 35 35 20 15 15

FLA 133.3 128.4 68.0 62.7 51.3 54.2 49.8 26.9 23.6 21.2 106.7 106.2 55.8 51.1 39.7 27.6 27.6 14.7 12.0 9.6

WSA 166.6 160.5 85.0 78.4 64.1 67.8 62.3 33.6 29.5 26.5 133.4 132.8 69.8 63.9 49.6 29.9 29.9 15.9 13.0 10.4

OPD 175 175 90 80 70 70 70 35 30 30 150 150 70 70 50 35 35 20 15 15

FLA — — — 61.8 50.7 — — — 22.7 20.6 — — — 50.2 39.1 — — — 11.1 9.0

WSA — — — 77.3 63.4 — — — 28.4 25.8 — — — 62.8 48.9 — — — 12.0 9.8

OPD — — — 80 70 — — — 30 30 — — — 70 50 — — — 15 15

FLA — — — 66.3 54.3 — — — 27.2 24.2 — — — 54.7 42.7 — — — 15.6 12.6

WSA — — — 82.9 67.9 — — — 34.0 30.3 — — — 68.4 53.4 — — — 16.9 13.7

OPD — — — 90 70 — — — 35 35 — — — 70 60 — — — 20 15

FLA— — ———————— — — ——————22.2—

WSA— — ———————— — — ——————23.1—

OPD— — ———————— — — ——————25—

FLA— — ———————— — — ——————31.2—

WSA— — ———————— — — ——————32.5—

OPD— — ———————— — — ——————35—

17 Liebert® CW™ System Design Manual

Page 28

Electrical Data

Models / Motor

HP Volts

CW026

2.0 HP

CW026

3.0 HP

CW038

3.0 HP

CW038

5.0 HP

CW041

3.0 HP

CW041

5.0 HP

CW051

5.0 HP

CW051

7.5 HP

CW060

5.0 HP

CW060

7.5 HP

CW076

7.5 HP

CW076

10.0 HP

CW084

7.5 HP

CW084

10.0 HP

CW106

10.0 HP

CW106

15.0 HP

CW106

20.0 HP

(Upflow only)

Table 3-2 Electrical data—Forward-curved Blowers, 60Hz systems

Reheat/Humidifier No Reheat /Humi dif ier Reheat/ No Hu midif ier No Reheat/ No Hu midi fier

208 230 460 575 208 230 460 575 208 230 460 575 208 230 460 575

FLA 48.6 44.1 22.4 20.1 20.8 17.9 9.2 10.1 35.3 33.0 16.6 12.7 7.5 6.8 3.4 2.7

WSA60.855.128.025.126.022.411.512.644.141.320.815.9 9.4 8.5 4.3 3.4

MFCB 60 50 25 30 30 25 15 15 40 40 20 15 15 15 15 15

FLA 51.746.923.821.323.920.710.611.338.435.818.013.910.6 9.6 4.8 3.9

WSA 64.658.629.826.629.925.913.314.148.044.822.517.413.312.0 6.0 4.9

MFCB 60 50 25 30 35 30 15 15 50 45 20 15 20 20 15 15

FLA 65.559.830.326.423.920.710.611.352.248.724.519.010.6 9.6 4.8 3.9

WSA 81.974.837.933.029.925.913.314.165.360.930.623.813.312.0 6.0 4.9

MFCB 90 80 40 35 35 30 15 15 60 70 35 20 20 20 15 15

FLA 71.665.433.128.630.026.313.413.558.354.327.321.216.715.2 7.6 6.1

WSA 89.581.841.435.837.532.916.816.972.967.934.126.520.919.0 9.5 7.6

MFCB 90 80 40 35 50 45 20 20 70 70 35 25 35 30 15 15

FLA 65.559.830.326.423.920.710.611.352.248.724.519.010.6 9.6 4.8 3.9

WSA 81.974.837.933.029.925.913.314.165.360.930.623.813.312.0 6.0 4.9

MFCB 90 80 40 35 35 30 15 15 60 70 35 20 20 20 15 15

FLA 71.665.433.128.630.026.313.413.558.354.327.321.216.715.2 7.6 6.1

WSA 89.581.841.435.837.532.916.816.972.967.934.126.520.919.0 9.5 7.6

MFCB 90 80 40 35 50 45 20 20 70 70 35 25 35 30 15 15

FLA 98.889.946.739.743.337.420.519.672.267.733.826.216.715.2 7.6 6.1

WSA 123.5 112.4 58.4 49.6 54.1 46.8 25.6 24.5 90.3 84.6 42.3 32.8 20.9 19.0 9.5 7.6

MFCB 125 110 60 50 60 50 30 25 90 80 40 30 35 30 15 15

FLA 106.3 96.7 50.1 42.6 50.8 44.2 23.9 22.5 79.7 74.5 37.2 29.1 24.2 22.0 11.0 9.0

WSA 132.9 120.9 62.6 53.3 63.5 55.3 29.9 28.1 99.6 93.1 46.5 36.4 30.3 27.5 13.8 11.3

MFCB 125 110 60 50 80 70 35 30 100 100 50 40 50 45 20 20

FLA 112.7 102.9 53.2 44.7 43.3 37.4 20.5 19.6 86.1 80.7 40.3 31.2 16.7 15.2 7.6 6.1

WSA 140.9 128.6 66.5 55.9 54.1 46.8 25.6 24.5 107.6 100.9 50.4 39.0 20.9 19.0 9.5 7.6

MFCB 150 125 70 60 60 50 30 25 110 110 50 40 35 30 15 15

FLA 120.2 109.7 56.6 47.6 50.8 44.2 23.9 22.5 93.6 87.5 43.7 34.1 24.2 22.0 11.0 9.0

WSA 150.3 137.1 70.8 59.5 63.5 55.3 29.9 28.1 117.0 109.4 54.6 42.6 30.3 27.5 13.8 11.3

MFCB 150 125 80 60 80 70 35 30 110 110 50 45 50 45 20 20

FLA 129.9 122.8 61.7 50.7 50.8 44.2 22.6 20.6 103.3 100.6 50.1 39.1 24.2 22.0 11.0 9.0

WSA 162.4 153.5 77.1 63.4 63.5 55.3 28.3 25.8 129.1 125.8 62.6 48.9 30.3 27.5 13.8 11.3

MFCB 175 150 80 60 80 70 35 30 125 125 60 50 50 45 20 20

FLA 136.5 128.8 64.7 52.7 57.4 50.2 25.6 22.6 109.9 106.6 53.1 41.1 30.8 28.0 14.0 11.0

WSA 170.6 161.0 80.9 65.9 71.8 62.8 32.0 28.3 137.4 133.3 66.4 51.4 38.5 35.0 17.5 13.8

MFCB 175 150 80 60 90 80 40 35 125 125 70 50 60 60 30 20

FLA 129.9 122.8 61.7 50.7 50.8 44.2 22.6 20.6 103.3 100.6 50.1 39.1 24.2 22.0 11.0 9.0

WSA 162.4 153.5 77.1 63.4 63.5 55.3 28.3 25.8 129.1 125.8 62.6 48.9 30.3 27.5 13.8 11.3

MFCB 175 150 80 60 80 70 35 30 125 125 60 50 50 45 20 20

FLA 136.5 128.8 64.7 52.7 57.4 50.2 25.6 22.6 109.9 106.6 53.1 41.1 30.8 28.0 14.0 11.0

WSA 170.6 161.0 80.9 65.9 71.8 62.8 32.0 28.3 137.4 133.3 66.4 51.4 38.5 35.0 17.5 13.8

MFCB 175 150 80 60 90 80 40 35 125 125 70 50 60 60 30 20

FLA 136.5 128.8 64.7 52.7 57.4 50.2 25.6 22.6 109.9 106.6 53.1 41.1 30.8 28.0 14.0 11.0

WSA 170.6 161.0 80.9 65.9 71.8 62.8 32.0 28.3 137.4 133.3 66.4 51.4 38.5 35.0 17.5 13.8

MFCB 175 150 80 60 90 80 40 35 125 125 70 50 60 60 30 20

FLA 151.9 142.8 71.7 58.7 72.8 64.2 32.6 28.6 125.3 120.6 60.1 47.1 46.2 42.0 21.0 17.0

WSA 189.9 178.5 89.6 73.4 91.0 80.3 40.8 35.8 156.6 150.8 75.1 58.9 57.8 52.5 26.3 21.3

MFCB 200 175 90 70 125 110 50 45 175 150 80 60 100 90 45 35

FLA 165.1 154.8 77.7 63.7 86.0 76.2 38.6 33.6 138.5 132.6 66.1 52.1 59.4 54.0 27.0 22.0

WSA 206.4 193.5 97.1 79.6 107.5 95.3 48.3 42.0 173.1 165.8 82.6 65.1 74.3 67.5 33.8 27.5

MFCB 225 200 110 90 150 125 70 60 200 200 90 70 125 110 60 45

Liebert® CW™ System Design Manual 18

Page 29

Models / Motor

HP Volts

CW114

10.0 HP

CW114

15.0 HP

CW114

20.0 HP

(Upflow only)

Table 3-2 Electrical data— Fo rward-curved Blowers, 60Hz system s (c on t in u ed )

Reheat/Humidifier No Reheat /Humi dif ier Reheat/ No Hu midif ier No Reheat/ No Hu midi fier

208 230 460 575 208 230 460 575 208 230 460 575 208 230 460 575

FLA 136.5 128.8 64.7 52.7 57.4 50.2 25.6 22.6 109.9 106.6 53.1 41.1 30.8 28.0 14.0 11.0

WSA 170.6 161.0 80.9 65.9 71.8 62.8 32.0 28.3 137.4 133.3 66.4 51.4 38.5 35.0 17.5 13.8

MFCB 175 150 80 60 90 80 40 35 125 125 70 50 60 60 30 20

FLA 151.9 142.8 71.7 58.7 72.8 64.2 32.6 28.6 125.3 120.6 60.1 47.1 46.2 42.0 21.0 17.0

WSA 189.9 178.5 89.6 73.4 91.0 80.3 40.8 35.8 156.6 150.8 75.1 58.9 57.8 52.5 26.3 21.3

MFCB 200 175 90 70 125 110 50 45 175 150 80 60 100 90 45 35

FLA 165.1 154.8 77.7 63.7 86.0 76.2 38.6 33.6 138.5 132.6 66.1 52.1 59.4 54.0 27.0 22.0

WSA 206.4 193.5 97.1 79.6 107.5 95.3 48.3 42.0 173.1 165.8 82.6 65.1 74.3 67.5 33.8 27.5

MFCB 225 200 110 90 150 125 70 60 200 200 90 70 125 110 60 45

19 Liebert® CW™ System Design Manual

Page 30

Electrical Data

Table 3-3 Indoor evaporator fan motor electrical requirements—60Hz systems

208 230 460 575

Hp

2.0 7.5 46.9 6.8 40.8 3.4 20.4 2.7 16.2

3.0 10.6 66.0 9.6 58.0 4.8 26.8 3.9 23.4

5.0 16.7 105.0 15.2 91.0 7.6 45.6 6.1 36.6

7.5 24.2 152.0 22.0 132.0 11.0 66.0 9.0 54.0

10.0 30.8 193.0 28.0 168.0 14.0 84.0 11.0 66.0

15.0 46.2 290.0 42.0 252.0 21.0 126.0 17.0 102.0

20.0 59.4 321.0 54.0 290.0 27.0 145.0 22.0 116.0

1. Refer to General Data Section for standard fan motor size on units.

2. FLA = Full Load Amps (does not reflect typical operating amps)

WSA = Wire Sizing Amps (Minimum supply circuit ampacity)

MFCB = Maximum Fuse or Circuit Breaker Size

3. Amperage requirements are based on the rated max FLA current of each component in the unit. The rated

max FLA current of the unit is not the sum total of all components, but is the total of the components which

operate during maximum electrical load conditions.

4. The values in the chart are for power of the unit only.

5. Units are 3 phase, 60 cycle.

6. For units with other variations not listed above, consult your Emerson representative for electrical

requirements.

7. SCCR - Short Circuit Current Rating 65,000 rms (less than 480V), 25,000 rms (575V).

FLA LRA FLA LRA FLA LRA FLA LRA

Liebert® CW™ System Design Manual 20

Page 31

Table 3-4 Electrical data—EC fan mo de ls , 50 Hz

Models Volts

FLA 25.7 11.3 19.3 4.9

CW026

CW038

CW041

CW051

Downflow

CW051

Upflow

CW060

Downflow

CW060

Upflow

CW076

CW084

CW089

Downflow

CW106

CW114

CW146

Downflow

CW181

Downflow

WSA 32.1 14.1 24.1 6.1

OPD35152515

FLA 33.0 11.3 26.6 4.9

WSA 41.3 14.1 33.3 6.1

OPD45153515

FLA 33.0 11.3 26.6 4.9

WSA 41.3 14.1 33.3 6.1

OPD45153515

FLA 49.5 20.6 36.7 7.8

WSA 61.9 25.8 45.9 8.8

OPD70305015

FLA 51.5 22.6 38.7 9.8

WSA 64.4 28.3 48.4 11.0

OPD70255015

FLA 56.7 20.6 43.9 7.8

WSA 70.9 25.8 54.9 8.8

OPD80306015

FLA 58.7 22.6 45.9 9.8

WSA 73.4 28.3 57.4 11.0

OPD80256015

FLA 65.9 22.6 53.1 9.8

WSA 82.4 28.3 66.4 11.0

OPD90257015

FLA 65.9 22.6 53.1 9.8

WSA 82.4 28.3 66.4 11.0

OPD90257015

FLA 65.9 22.6 53.1 9.8

WSA 82.4 28.3 66.4 11.0

OPD90257015

FLA 70.8 27.5 58.0 14.7

WSA 88.5 34.4 72.5 15.9

OPD90358020

FLA 70.8 27.5 58.0 14.7

WSA 88.5 34.4 72.5 15.9

OPD90358020

FLA 68.7 25.4 55.9 12.6

WSA 85.9 31.8 69.9 13.7

OPD90357015

FLA 74.7 31.4 61.9 18.6

WSA 93.4 39.3 77.4 20.2

OPD 100 40 80 25

Reheat/

Humidifier

400 400 400 400

No Reheat/

Humidifier

Reheat/

No Humidifier

No Reheat/

No Humidifier

21 Liebert® CW™ System Design Manual

Page 32

Electrical Data

Table 3-5 Electrical data—Forward-curved blowers, 50Hz systems

Reheat/

Humidifier

Models Motor hp Volts

CW026

CW038

CW041

CW051

CW060

CW076

CW084

2.0 FLA 46.7 43.4 24.3 19.8 17.2 9.9 33.9 32.3 17.9 7.0 6.1 3.5

3.0 FLA 49.8 46.1 25.9 22.9 19.9 11.5 37.0 35.0 19.5 10.1 8.8 5.1

3.0 FLA 62.9 59.0 33.2 22.9 19.9 11.5 50.1 47.9 26.8 10.1 8.8 5.1

5.0 FLA 68.6 63.9 36.0 28.6 24.8 14.3 55.8 52.8 29.6 15.8 13.7 7.9

3.0 FLA 62.9 59.0 33.2 22.9 19.9 11.5 50.1 47.9 26.8 10.1 8.8 5.1

5.0 FLA 68.6 63.9 36.0 28.6 24.8 14.3 55.8 52.8 29.6 15.8 13.7 7.9

5.0 FLA 94.6 88.4 49.6 41.2 35.9 20.7 69.2 66.2 36.8 15.8 13.7 7.9

7.5 FLA 103.9 96.5 54.2 50.5 44.0 25.3 78.5 74.3 41.4 25.1 21.8 12.5

5.0 FLA 107.9 101.4 56.8 41.2 35.9 20.7 82.5 79.2 44.0 15.8 13.7 7.9

7.5 FLA 117.2 109.5 61.4 50.5 44.0 25.3 91.8 87.3 48.6 25.1 21.8 12.5

7.5 FLA 126.6 122.6 68.6 50.5 44.0 25.3 101.2 100.4 55.8 25.1 21.8 12.5

10.0 FLA 131.7 128.4 71.2 55.6 49.8 27.9 106.3 106.2 58.4 30.2 27.6 15.1

7.5 FLA 126.6 122.6 68.6 50.5 44.0 25.3 101.2 100.4 55.8 25.1 21.8 12.5

10.0 FLA 131.7 128.4 71.2 55.6 49.8 27.9 106.3 106.2 58.4 30.2 27.6 15.1

200 230 380-415 200 230 380-415 200 230 380-415 200 230 380-415

10.0 FLA 131.7 128.4 71.2 55.6 49.8 27.9 106.3 106.2 58.4 30.2 27.6 15.1

CW106

15.0 FLA 147.1 142.4 78.9 71.0 63.8 35.6 121.7 120.2 66.1 45.6 41.6 22.8

20.0 FLA 161.5 152.8 86.1 85.4 74.2 42.8 136.1 130.6 73.3 60.0 52.0 30.0

10.0 FLA 131.7 128.4 71.2 55.6 49.8 27.9 106.3 106.2 58.4 30.2 27.6 15.1

CW114

15.0 FLA 147.1 142.4 78.9 71.0 63.8 35.6 121.7 120.2 66.1 45.6 41.6 22.8

20.0 FLA 161.5 152.8 86.1 85.4 74.2 42.8 136.1 130.6 73.3 60.0 52.0 30.0

1. FLA = Full Load Amps (does not reflect typical operating amps)

2. Amperage requirements are based on the rated max FLA current of each component in the unit. The rated max FLA current of the unit is

not the sum total of all components, but is the total of the components which operate during maximum electrical load conditions.

3. The values in the table are for power demand of the unit only.

4. Units are 3-phase, 50-cycle.

5. Consult your sales representative for electrical requirements of units with variations not listed above.

6. SCCR—Short Circuit Current Rating 65,000 rms (less than 480V), 25,000 rms (575V)

No Reheat/

Humidifier

Reheat/

No Humidifier

No Reheat/

No Humidifier

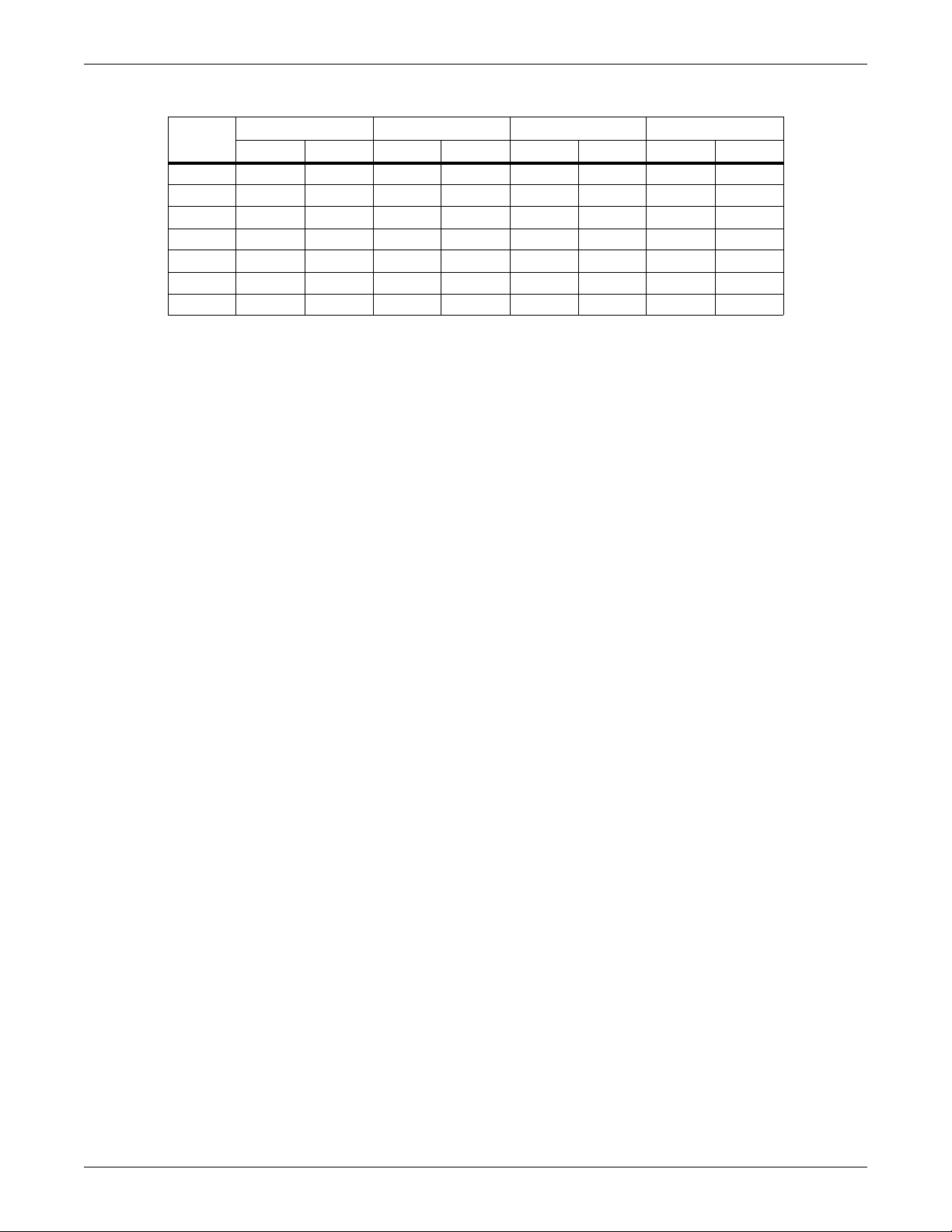

Table 3-6 Indoor evaporator fan motor electrical requirements

Hp Volts 200 230 380-415

2.0 FLA 7.0 6.1 3.5

3.0 FLA 10.1 8.8 5.1

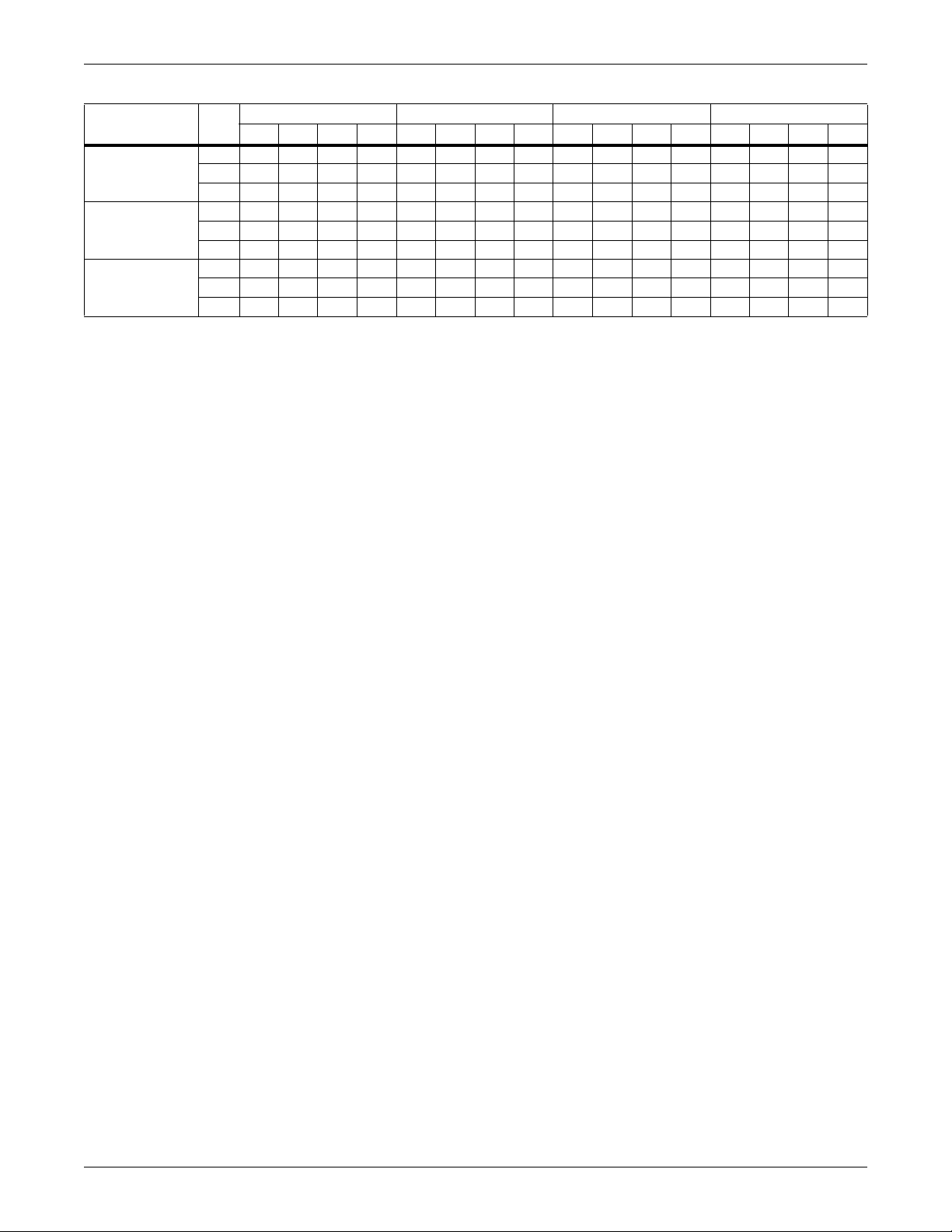

5.0 FLA 15.8 13.7 7.9

7.5 FLA 25.1 21.8 12.5

10.0 FLA 30.2 27.6 15.1

15.0 FLA 46.2 42.0 24.2

20.0 FLA NA NA 30.0

1. Refer to General Data Section for standard fan motor size on units.

2. FLA = Full Load Amps

Liebert® CW™ System Design Manual 22

Page 33

4.0 Dimensions

4.1 Location Considerations

For a downflow unit, the unit can sit on an accessible, elevated flooring system. It may be necessary to

furnish additional pedestal support below the unit to ensure maximum structural support. A separate floor

stand for the unit may be used as support, independent of the elevated floor and installed prior to the

flooring system.

For downflow and upflow units, provide approximately 34" (864mm) service clearance on the left, right a nd

in front of the unit whenever possible. The minimum space required for service is 18" (457mm) on the left

end, 18" (457mm) on the right end and 24" (610mm) in front of the unit. This space is necessary to permit

routine maintenance, such as replacing filters and adjusting the fan speed. On downflow and upflow

CW106 and CW114 models, left-end and right-end minimum clearances are 0" (0 mm), with the exception

of rear return.

Avoid installing units in an alcove or at the extreme end of a room that has a high aspect ratio (long narrow

room). Also avoid installing units too close together. This tends to reduce the effectiveness of the air

distribution as compared to units located 30-40 feet (9-12m) apart.

Location Considerations

23 Liebert® CW™ System Design Manual

Page 34

Dimensions

UNIT DIMENSIONAL DATA

C

CABINET

D

AIR

RETURN

A

OVERALL

B AIR

RETURN

MODELS

W/ PRE-FILTERS

F PLENUM

OVERALL

G

AIR RETURN

A

UNIT & PLENUM OVERALL

B

AIR RETURN

72"

1829mm

72"

1829mm

9"

229mm

F

OVERALL

FRONT OF UNIT

FRONT OF UNIT

FRONT OF UNIT

SHADED AREA INDICATES A RECOMMENDED

CLEARANCE OF 36" (914mm) BE PROVIDED

FOR COMPONENT ACCESS AND FILTER REMOVAL

ON ALL CW026-CW084 UNIT T YPES

SHADED AREA INDICATES

A RECOMMENDED CLEARANCE

OF 36" (914mm) BE PROVIDED

FOR COMPONENT ACCESS AND

FILTER REMOVAL ON ALL

CW026-CW084 UNIT TYPES

NOTES:

1. MINIMUM CLEARANCE OF 24" (610mm) REQUIRED BELOW

THE UNIT TO LOWER THE FANS. FANS MAY ALSO REMAIN

IN UNIT IF DESIRED.

2. VIEWS OF ELECTRICAL & AIR DI SCHARGE OPENINGS ARE

FROM INSTALLER'S POINT OF VIEW.

CW026 - 041

Electrical

Openings

Standard Piping

Opening

E

H

31"

787mm

33"

838mm

J

CW051 - 060

E

H

24 1/4"

615mm

24 1/2"

624mm

33"

838mm

31"

787mm

TYP.

Standard Piping

Opening

Electrical

Openings

CW076 - 084

E

H

28 1/16"

713mm

28 1/16"

713mm

J

33"

838mm

31"

787mm

TYP.

Electrical

Openings

Standard

Piping

Opening

J

STANDARD PIPING, ELECTRICAL & AIR DISCHARGE OPENINGS DPN003192

Rev. 2

4.2 Cabinet and Floor-planning Dimensions—Downflow Models with EC Fans

Figure 4-1 Cabinet and floor-planning dimensions, downflow, CW026 – CW084 with EC fans

Chilled

Water

Model

CW026

50 (120) 46 (1168)

74 (1880) 70 (1778) 72 (1829) 51-1/4 (1302)

99 (2515) 95 (2413) 97 (2464) 60-3/4 (1543) 8-7/8 (225)

CW038 840 (381)

CW041 900 (408)