Page 1

Reference Manual

00809-0100-4245, Rev AB

Rosemount™ CT4215 Leak Detection System

July 2018

Page 2

Preface

Published by EmersonTM.

All possible care has been taken in the preparation of this publication, but EmersonTM and its agents and distributors accept no

liability for any inaccuracies that may be found. This manual reflects the state of the product at the issure date below, but further

enhancements while in service may mean that the manual does not reflect your particular system.

Emerson reserves the right to make changes without notice both to this publication and the products which it describes.

Document number: 00809-0100-4245

Rev AB, July 2018

©

Emerson 2018. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic,

mechanical, photocopying, recording, or otherwise without the express prior written permission of the copyright holder.

If you require additional technical assistance, request help from (cascade.support@emerson.com) or Emerson distribution partners.

General inquiries should be sent to cascade.support@emerson.com.

All trademarks used within this document are the property of their respective owners.

Page 3

Important information

Important

Users must read, understand, and comply with the following information before proceeding.

All users, installers, operators, and maintainers must be familiar with operating the detector. To install, start up, operate, maintain,

and service the detector in a safe manner, it is MANDATORY to read all additional instruction manuals shipped with the detector.

The following instruction manual(s) are available and / or referenced within this manual:

RosemountTM CT4215 Quick Start Guide: 00825-0100-4245

User information

Important

All users must read this page before proceeding!

EmersonTM designs, manufactures, and tests its products to meet many national and international standards. The Rosemount

TM

CT4215 is a sophisticated technical product, and to ensure it continues to operate as designed and within normal specifications, it

MUST be installed, used, and maintained correctly.The following instructions MUST be adhered to and integrated into your safety

program when installing, using, and maintaining RosemountTM products.

• Failure to follow the proper instructions may cause:

- Loss of life

- Personal injury

- Damage to property

- Damage to this instrument

- Warranty invalidation

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your RosemountTM representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the installation instructions of the appropriate manual and in accordance with

applicable local and national codes.

• Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

• When replacement parts are requried, ensure that qualified people use replacement parts specified by EmersonTM.

• Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk,

and VOID YOUR WARRANTY. Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• To prevent electrical shock and personal injury, all equipment doors must be closed and protective covers in place, except

when maintenance is being performed by qualified personnel.

• The information contained in this document is subject to change without notice.

Page 4

General safety notice/residual risk

Installation, operation, and maintenance of the detector must be in accordance with these instructions.

When operated as intended and all applicable safety instructions are observed, an element of risk will remain, including, but not

limited to, the following:

• Explosion protection measures may become ineffective on the occurrence of one failure (for Category 3 instruments).

• The emission of gases hazardous to health may be possible when all gas connections have been correctly made.

To avoid exposure to the dangers of residual risks, take particular care when installing, operating, maintaining, and servicing the

detector.

Authorized personnel

In-depth specialist knowledge is an absolute requirement for working with and on the detector. Personnel installing, operating,

servicing, and maintaining the detector must be instructed, trained, qualified, and authorized for hazardous areas with the

operating company and the manufacturer. It is the operating company's responsibility to:

• Train staff.

• Observe safety regulations.

• Follow the safety instructions and procedures in the product manual.

Operators must:

• Be trained.

• Read and understand all relevant sections of the product manual before commencing work.

• Know the safety mechanisms and regulations.

WARNING!

To avoid explosions, loss of life, personal injury, and damage to this equipment and on-site property, do not install, operate,

maintain, or service this instrument before reading and understanding this instruction manual and receiving appropriate training.

Page 5

Regulations and standards

Regulations / Standards Description

2014/35/EU The Low Voltage Directive

2014/30/EU The Electromagnetic Compatibility Directive

2012/19/EU Waste Electrical and Electronic Equipment (WEEE) Directive

USA 21 CFR 1040.1 Laser products

BS EN 60825-1 Safety of laser products. Equipment classification and require-

ments (identical to IEC 608250-1 2007)

BS EN 61010-1 2010 IEC 61010-1 2010 Safety requirements for electrical equipment for measurements,

control, and laboratory use. General requirements

BS EN 61326-1: 2013 Electrical equipment for measurement, control, and laboratory

use. EMC requirements. General requirements

Associated publications

Quick Start Guide:

Compliance approvals

This product complies with USA 21 CFR 1040.10.

This product is designed and manufactured under an approved quality management system to ISO 9001: 2008.

Waste disposal

Emerson and the detector have satisfied the requirements for applying the CE

marking to the detector.

This equipment meets all requirements of the EMC and Low Voltage directives.

Do not dispose of measuring tools into household waste.

Only for EC countries:

In accordance with European Directive 2012/19/EU for Waste Electrical and Electronic Equipment and its implementation into national right, measuring tools that are no longer usable must be collected separately and disposed of in

an environmentally correct manner.

Page 6

Safety and information notices

This article is in accordance with IEC 60079-0: 2011 Clause 30. This article must not be changed amended or removed.

DANGER!

WILL CAUSE DEATH

Failure to follow this warning will result in death or serious injury to personnel.

WARNING!

DANGER TO PERSONNEL

Failure to follow this warning may result in serious injury to personnel.

CAUTION!

MAY CAUSE DAMAGE TO EQUIPMENT

Failure to follow this warning may result in damage to the equipment.

NOTICE

Important or tip messages will appear in this format.

Page 7

Safety Information

All authorized users, including installation, operation, and maintenance personnel, must observe the following safety precautions

and warnings.

DANGER!

ELECTRIC SHOCK

The detector operates using mains voltage that is dangerous to life. Make sure that the circuit breakers are set to OFF and tagged off

before removing the top cover or opening the front cover.

Failure to observe this precaution will cause death, personal injury, and/or damage to persons and/or property.

WARNING!

OPTICAL RADIATION EXPOSURE HAZARD

The detector contains lasers. Opening the detector and attempting to perfrom adustments and procedures other than those

specified in this manual may result in hazardous optical radiation exposure.

All lasers within the detector are Class 1. The emitted laser light is invisible (mid-infrared) and the combined laser powers are

sufficiently low at the first accessible aperture that the unprotected eye will not be damaged. This class is eye safe under all

operating conditions.

It is, however, possible to cause damage to the eye through not following correct procedures. Do not look at the laser with any kind

of magnifier or optical measuring device.

WARNING!

HAZARDOUS SUBSTANCES

The detector may contain hazardous substances. Always handle the detector assemblies and components with extreme caution.

Gas handling components within the detector will contain particulate matter from the sample gases. Over the life of the detector,

the concentration of particulate matter will become enriched within the gas handling components. When performing repairs and

maintenance on the detector:

• Handle used gas handling components with extreme caution.

• Avoid direct skin contact with used gas handling components.

• Do not smoke, drink, or eat in the work area.

• Wear goggles or eye shields.

• Wear a suitable face mask to protect against inhalation of particulate matter.

• Do not wet fingers, eyes, or any exposed skin.

• Pack used gas handling components for disposal in sealed packaging and label them Contaminated.

Dispose of contaminated items as hazardous material according to the applicable local, national, or international health and safety

regulations and pollution regulations.

WARNING!

EXPLOSION HAZARD

Always lock-out tag-out the gas handling system when shutting down the detector. Unauthorized operation of the gas handling

system when maintenance is being performed on the detector or its associated pipes/hoses may result in highly flammable gas

being released, causing fire or explosion.

Page 8

WARNING!

HIGH PRESSURE GAS AND AIR

The compressed air supply operates at a pressure that can cause injury, e.g., damage to eyes and skin punctures from debris blown

by the high pressure gas or compressed air.

Always lock off or tag off the calibration gas supply and compressed air supply when shutting down the detector.

WARNING!

EXPLOSION HAZARD

The sample gas in the system must be vented to prevent fire or explosion during maintenance and to prevent damage to the

detector during startup.

The sample gas in the pipes leading to the detector must be purged to prevent hazards to personnel during maintenance. Purge the

sample gas in accordance with the safe working procedures for the site.

Allow the detector and system for returning the sample gas to run for five minutes to allow any sample gas in the system to be

returned to the exhaust.

WARNING!

HEAVY INSTRUMENT

The detector weighs 119 kg (268 lb.) and is designed to be floor mounted. It must be moved in accordance with local safety

regulations. EmersonTM recommends that a minimum of two people using suitable tools for transportation and lifting are employed.

Use suitable fasteners for the weight of the unit.

Make sure the unit is mounted on a solid, stable, and suitable floor.

Failure to follow this warning could cause an explosion or potentially hazardous situation, which if not avoided, could result in death

or serious injury.

WARNING!

ELECTRICAL SHOCK HAZARD

Only trained, qualified personnel may install and connect power and signal cables. The installation/connection must be in

accordance with all legislative requirements and applicable standards.

Only qualified personnel, familiar with the resulting potential risks, should install these instruments.

Instruments providing screw terminals for electric connections may require working near live parts.

Failure to follow this warning could cause an explosion or potentially hazardous situation, which if not avoided, could result in

warranty invalidation, property damage, death, or serious injury.

WARNING!

HIGH PRESSURE HAZARD

The maximum compressed air pressure at the inlet valve must not exceed 10 bar (145 psi). Failure to follow this warning could cause

a potentially hazardous situation,which if not avoided, could result in death or serious injury.

WARNING!

LOOSE ITEMS

Do not place any loose items on top of the system or inside the compartments when doors or covers are open.

Make sure that all loose items, tools, and equipment are removed from the compartments before closing doors and covers.

Failure to follow this warning could cause a potentially hazardous situation, which if not avoided, could result in death or serious

injury.

Page 9

WARNING!

On completion of any maintenance and/or modifications, make sure:

• All tools and equipment are removed.

• No contamination (water/dust) is in the compartments.

• The detector is wiped clean.

• Vents are clear and not obstructed.

• The system is in a safe state for operation.

Failure to follow this warning could cause a potentially hazardous situation, which if not avoided, could result in death or serious

injury.

WARNING!

TRANSPORTATION HAZARD

Use safety approved lifting equipment. Ensure that the equipment is tested, meets the lifting ratings for the weight of the

equipment, and is in good operational condition. Failure to verify that equipment meets the lifting ratings and is in good operational

condition may injure personnel or damage the detector.

CAUTION!

EQUIPMENT DAMAGE

Always follow the startup procedure. Damage to the detector may result from a failure to follow this procedure.

Failure to perform pre-system startup checks may cause damage to equipment.

CAUTION!

EQUIPMENT DAMAGE

Always follow the shutdown procedure. Damage to the detector may result from a failure to follow this procedure.

CAUTION!

EQUIPMENT DAMAGE

Ensure that the local power voltage where the unit is to be installed corresponds to the unit’s nominal voltage as given on the name

plate label.

NOTICE

As a general principle, if any optical component other than the cell assembly, the laser modules, and the detectors is unserviceable,

EmersonTM must repair the detector. This is because the repair, replacement, and alignment of the optical components requires the use of

special optical testcalibration equipment and procedures. When an item is unserviceable, and no replacement procedure is given in this

manual, EmersonTM must repair the fault.

Page 10

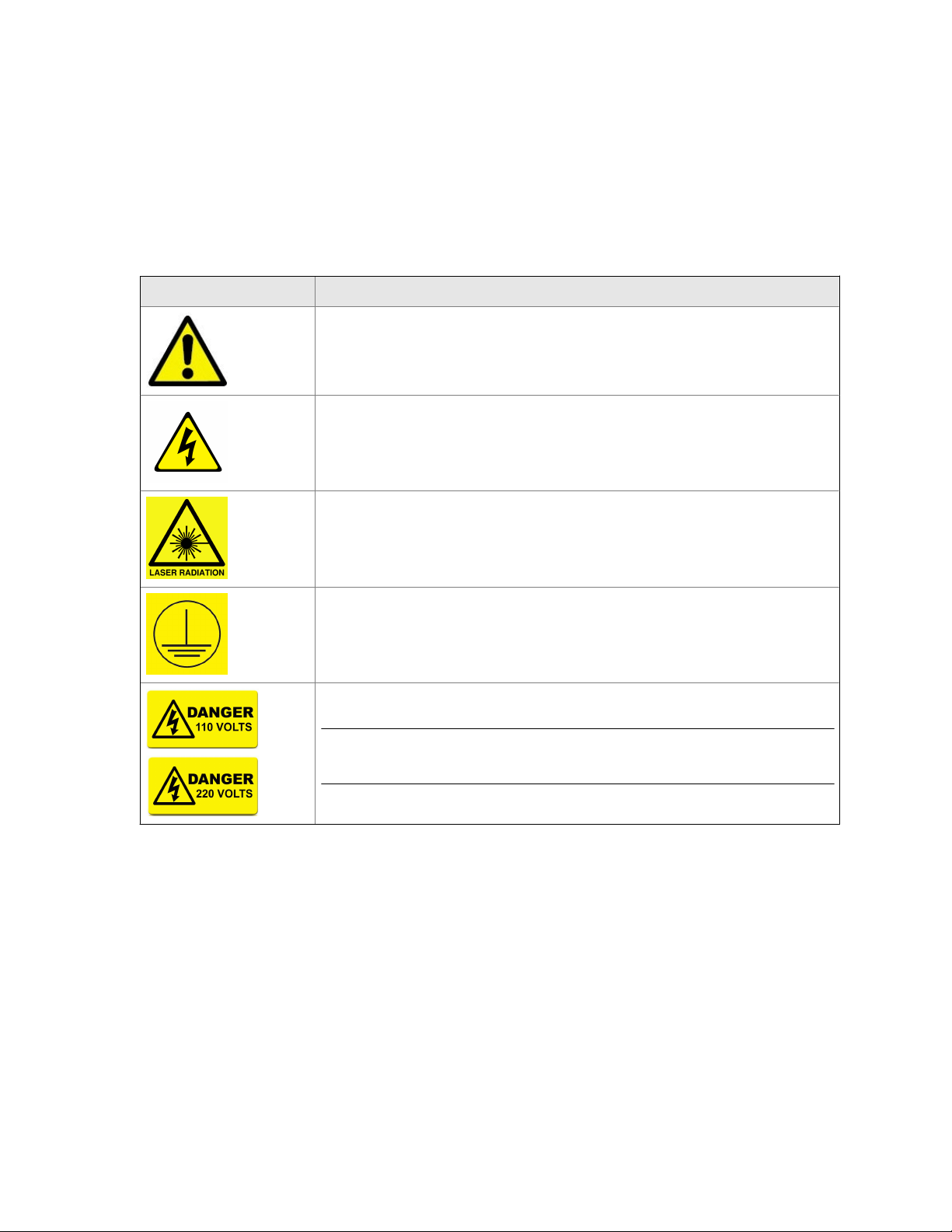

Symbols displayed on and inside the detector

To minimize risk, labels displaying warning signs are fixed to the transmitter. You must

understand their meaning, take suitable precautions, and read all instructions given in the

accompanying manuals before conducting any operations.

The following table gives examples and definitions of each symbol used.

Symbol Definition

General warning

Refer to instruction manual before proceeding.

Danger electricity

Make sure that the system is disconnected from all electrical power supplies prior to opening

doors or removing covers.

Laser radiation

Earth (ground) identification

AC power supply

Note

The label shown is for illustration only. It is possible that the image will show a voltage in the range of

100 to 240 Vac.

Page 11

Contents

Contents

Chapter 1 Leak detection overview ................................................................................................ 1

1.1 System overview ..........................................................................................................................2

Chapter 2 Equipment and accessories ............................................................................................ 3

2.1 Typical installation ....................................................................................................................... 3

2.2 System connections .....................................................................................................................4

2.3 Typical sample head .................................................................................................................... 6

2.4 Air preparation plate ....................................................................................................................7

2.5 Upper enclosure .......................................................................................................................... 8

Chapter 3 Installation .....................................................................................................................9

3.1 Installation requirements .............................................................................................................9

3.2 Installation instructions ............................................................................................................. 12

Chapter 4 Startup .........................................................................................................................17

Chapter 5 Shutdown .................................................................................................................... 19

Chapter 6 Operation .................................................................................................................... 21

6.1 Leak detector manager (LDM) software ..................................................................................... 22

6.2 Data logging and reporting ........................................................................................................25

6.3 Status lamps / errors .................................................................................................................. 27

6.4 Line stop .................................................................................................................................... 29

6.5 PLC configuration screen ........................................................................................................... 30

Chapter 7 Maintenance ................................................................................................................33

7.1 Scheduled maintenance ............................................................................................................ 33

7.2 Clean cell mirrors ....................................................................................................................... 33

7.3 Air filter ......................................................................................................................................35

7.4 Control system .......................................................................................................................... 37

7.5 Sample head ..............................................................................................................................37

7.6 Recommended spare parts ........................................................................................................ 37

Chapter 8 Troubleshooting and diagnostics ................................................................................. 39

Appendices and reference

Appendix A Specifications ...............................................................................................................43

Reference Manual i

Page 12

Contents

ii Rosemount CT4215

Page 13

1 Leak detection overview

Gas concentrations are measured using mid-infrared optica absorption spectroscopy. The

light sources are Quantum Cascade Lasers (QCLs), which are operated to produce

wavelength sweeps that cover the absorption lines of the target gases.

The laser is mounted in the baseplate between the upper and lower enclosures of the leak

detector, and light is directed through the measurement cell and onto a detector. When

molecules from a leaking container enter the measurement cell, they partially absorb the

laser light. The variation in the intensity of the light indicates a leaking container, and the

container is rejected from the line.

The leak detector identifies packaged products that have a break in seal integrity as they

are carried along a conveyor belt at speed. The leak detection system consists of a

sampling head which draws air from around the product. The air is passed through the

measurement cell for high speed analysis.

Leak detection overview

Reference Manual 1

Page 14

Leak detection overview

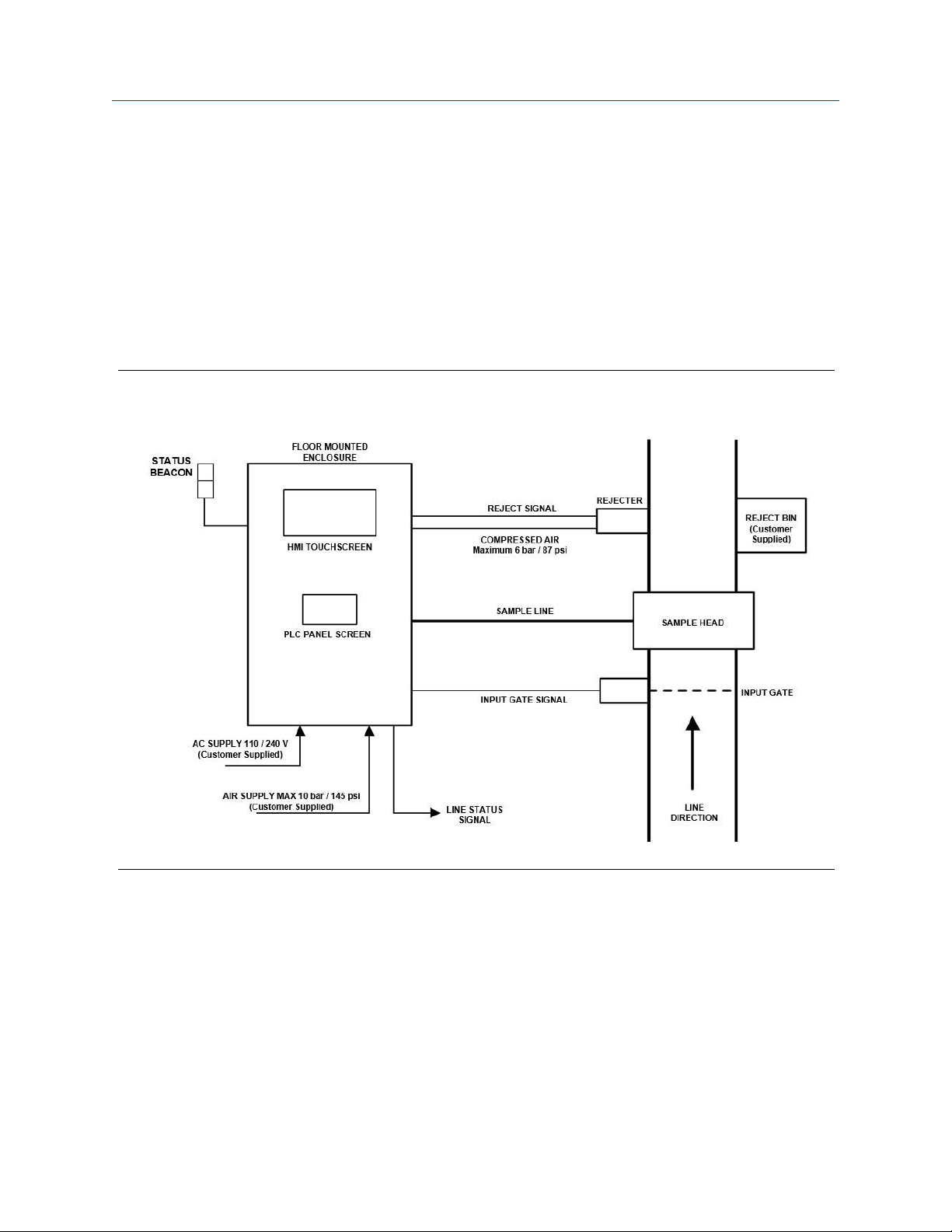

1.1 System overview

The Rosemount™ CT4215 Leak Detector is used on packaged lines and comprises an all

metal enclosure containing the Quantum Cascade Laser (QCL) analyzer, PLC control,

compressed air preparation, and vacuum. The external component may include light

gates, sample head, and a rejection mechanism to safely remove defective products from

the line.

Figure 1-1 shows the leak detection system.

Leak Detection System Block DiagramFigure 1-1:

2 Rosemount CT4215

Page 15

2 Equipment and accessories

2.1 Typical installation

Figure 2-1 shows a typical installation for a Rosemount™ CT4215 on a food handling line.

Rosemount™ CT4215 PartsFigure 2-1:

Equipment and accessories

A. Sample head1: draws air from around the packaged product into the measurement cell.

B. Analysis cell: the laser beam and sample gas pass through here for analysis.

C. Electronics: laser, detector, PLC, and DC power supply.

D. Air preparation: compressed air must be filtered and dried for optimum performance.

E. Vacuum pump: high flow rate pump for fast sample delivery to measurement cell.

F. Reject mechanism2: compressed air reject mechanism.

G. Touchscreen HMI: user interface for system.

H. PLC panel screen: screen set to certain PLC parameters. This will be locked to operators under

normal operation.

1. Sample head is modular and may differ depending on application.

2. May differ depending on application.

Reference Manual 3

Page 16

Equipment and accessories

2.2 System connections

Figure 2-1 shows a typical installation for a Rosemount™ CT4215 on a food handling line.

Figure 2-2 shows the external connections of the packaged leak detection system. These

are located at floor level on the rear of the unit.

External ConnectionsFigure 2-2:

A. Ethernet

B. Status, 24 Vdc (line stop)

C. Reject

D. Input gate

E. Air in

F. Air out

G. Mains supply

4 Rosemount CT4215

Page 17

Equipment and accessories

External ConnectionsTable 2-1:

Letter Designation Type Max rating Description

A Ethernet RJ45 Ethernet N/A Communication with

sensor

B Status, 24 Vdc (line stop) Bulgin 4P female 250 Vac/dc, 6 A Customer supplied 24 V

signal when line is running. Rosemount

CT4215 health status is

returned (see

Section 6.4).

C Reject Bulgin 3P female 250 Vac/dc, 10 A 24 V signal to the rejec-

tion solenoid when a defective pack is detected.

D Input gate Bulgin 4P female 250 Vac/dc, 6 A Gate signal to the sensor

to count incoming

packs.

E Air in 8 mm push fit 10 bar (145 psi) Customer supplied com-

pressed air

F Air out 8 mm push fit 6 bar (90 psi) Regulated compressed

air for accessories, i.e.,

rejection

G AC supply Mennekes right angle

2P+E

Yellow: 110 - 130 V

Blue: 200 - 250 V

Customer supplied

mains

16A

™

Reference Manual 5

Page 18

Equipment and accessories

2.3 Typical sample head

The sample head is used to draw air from around the product and deliver it to the

measurement cell.

To ensure a high air flow rate, the sample head is connected to the leak detector using a ¾in. hose, shown in Figure 2-3. There is a central roller with a sample head at either side.

Note

The sample head shown is for food packaging; this may change depending on the product/

production line.

Sample Head (Closed)Figure 2-3:

WARNING!

CRUSH AND CUT HAZARD

Moving parts can crush and cut.

Do not operate with the sample head open.

Failure to observe this warning may cause serious injury to personnel.

6 Rosemount CT4215

Page 19

2.4 Air preparation plate

The customer supplied compressed air is filtered to remove impurities and is pressureregulated.

The assembly shown in Figure 2-4 is mounted inside the leak detector control system

cabinet.

Compressed Air Preparation PlateFigure 2-4:

Equipment and accessories

A. Shut off valve

B. Pressure regulator with 40 µm filter

C. 0.1 µm filter

D. Pressure switch (MPa)

E. Membrane dryer

F. Solenoid switch

Reference Manual 7

Page 20

Equipment and accessories

2.5 Upper enclosure

The upper enclosure is accessible with an 8 mm Allen key and comprises the following

components shown in Figure 2-5. The upper enclosure is the main area for maintenance

access (see Chapter 7).

Upper enclosureFigure 2-5:

A. Measurement cell with insulating jacket

B. Manual purge button

C. Cell lid clamps

D. Cell input mirror, directs laser into cell

E. Cell output mirror, directs laser onto the detector

8 Rosemount CT4215

Page 21

3 Installation

3.1 Installation requirements

The customer provides the following:

Installation RequirementsTable 3-1:

Customer provided Specification

Mains supply (defined by customer) 110/120 Vac, 50 Hz

or

Mains supply (defined by customer) 220/240 Vac, 60 Hz

Circuit breaker 16A (maximum)

Mounting Affix to floor or building structure

Compressed air 8-10 bar / 115 - 145 psi

Installation

For the electrical power wiring, use 16 AWG stranded, three conductor copper plain or tin

plated wire, rated for a minimum of 250 Vac for the required cable length. Cables must be

terminated in accordance with national/local electrical standards and must be rated for

operation in ambient temperatures > 176 °F (80 °C).

Emerson™ does not supply a switching system with the instrument. The customer must

supply a suitably rated switch or circuit breaker to be included with this installation. Check

the installation of the switch for conformity in accordance with national/local regulations

and standards by inspection. The switch or circuit breaker must be suitably located, easily

reached, and identified as the disconnection device for the leak detection system.

The leak detection system provides a protective earth terminal. To prevent electrical shock

hazards, connect the instruments to a protective earth. Any interruption of the earth

connector inside or outside the instrument or disconnecting the earth terminal may cause

potential electrical shock hazard.

Reference Manual 9

Page 22

Installation

Line Installation LocationFigure 3-1:

Ground FixingFigure 3-2:

10 Rosemount CT4215

Page 23

Installation

Installation of Reject MechanismFigure 3-3:

Sample Head InstallationFigure 3-4:

Reference Manual 11

Page 24

Installation

3.2 Installation instructions

Only Rosemount™ Customer Care Representatives should install this instrument.

WARNING!

LIFTING HAZARD

The system weighs 268 lb. (119 kg). Beware of collision injury and topple injury when moving.

Emerson™ recommends using a forklift to move the system.

WARNING!

CRUSH HAZARD

Be careful not to crush hands and feet when moving the system.

WARNING!

DRILL INJURY

Be careful to avoid injuring hands and eyes when drilling. Wear correct personal protective

equipment (PPE) at all times.

Procedure

1. Place the delivery crate in an open and easily accessible area, close to where the unit

will be assembled and installed.

2. Remove the instrument from the crate.

a. Remove the fixing screws (marked in red) from the front panel of the crate and

the front panel section. Place the front panel section from the crate in a safe

place well away from the working area.

b. Release the two straps located on the unit upright section.

c. Carefully remove the unit from the crate.

d. Remove all additional parts from the crate and place them to the side of the unit.

3. Ensure that all additional parts shown are present after unloading the crate.

Required parts are shown below.

Rosemount

Item Description Quantity

A Reject assembly 1

B Light gate assembly 1

C Sample head 1

D Hardware kit 1

™

CT4215 Installation PartsTable 3-2:

4. Place the unit enclosure at the desired position on the product line.

12 Rosemount CT4215

Page 25

Installation

Line Installation LocationFigure 3-5:

5. Ground the instrument.

a. Lower the feet to the ground.

b. Raise the unit a few inches off the ground.

c. Remove the wheel brackets.

d. Lower the unit to the floor.

e. Use the feet to level of unit if required.

f. Bolt the unit to the floor as per site standards.

Reference Manual 13

Page 26

Installation

Ground FixingFigure 3-6:

Refer to the fastener manufacturer's guide for fixing instructions and torque.

g. Place the cap covers over the access holes.

6. Attach the light gate to the track.

a. Drill the location hole(s) into the track side faces in the approximate positions

required for input gate.

Use track location T slots if available (no drilling required).

b. Place the light gate in the required position on the track using the fasteners

supplied in the hardware kit. Hand tighten the fasteners only at this time.

WARNING!

DRILL INJURY

Be careful to avoid injuring hands and eyes when drilling. Wear correct PPE at all

times.

c. Adjust the angle and height of the light gate to suit the package being scanned.

d. Secure the light gate in place using the fasteners fitted previously.

e. Torque the fasteners to 7.6 Nm (5.6 ft.-lb.).

14 Rosemount CT4215

Page 27

7. Attach the reject mechanism.

WARNING!

DRILL INJURY

Be careful to avoid injuring hands and eyes when drilling. Wear correct PPE at all times.

a. Drill two location holes into the track side face in the approximate positions

required for the reject mechanism.

Use track location T slots if available (no drilling required).

b. Attach the reject mechanism on the track in the approximate position required

using two M6 socket head cap screws, two spring washers, and two washers.

c. Leave the reject mechanism loose by hand tightening the fasteners only.

d. Secure the reject mechanism in place using previously fitted bolts.

e. Torque fasteners to 5.6 ft-lb. (7.6 Nm).

f. Adjust the angle and depth of the the reject mechanism as required. Loosen the

side bolts to adjust the angle and then tighten them when aligned.

Installation

8. Attach the sample head.

WARNING!

DRILL INJURY

Be careful to avoid injuring hands and eyes when drilling. Wear correct PPE at all times.

a. Drill four location holes into the track side face in the approximate position

required for the sample head.

Use track location T slots if available (no drilling required).

b. Place the sample head on the track in the approximate position required using

four M6 socket head cap screws, two spring washers, and two washers.

c. Leave the sample head loose by hand tightening the fasteners only.

d. Secure the sample head in place using previously fitted fixings.

e. Torque fasteners to 5.6 ft-lb. (7.6 Nm).

f. Adjust the sample head height to the track as required to suit pack thickness.

Loosen side bolts to adjust the height on the slots and then tighten them when

aligned to the required pack height.

Reference Manual 15

Page 28

Installation

16 Rosemount CT4215

Page 29

4 Startup

The Leak Detection System must be installed and fully commissioned by qualified

Rosemount™ personnel prior to customer operation.

1. Turn the unit isolator switch (shown below) to the ON position.

Once power has been started, the system takes approximately two minutes to boot.

Startup

Isolation SwitchesFigure 4-1:

2. Ensure the compressed air supply is open.

3. When production begins, turn the blower isolator to the ON position.

NOTICE

Emerson™ recommends that the blower is switched off when the production line is not

running. This will extend the lifetime of the sample air filter.

4. Press the Reset button on the front of the console and ensure there is a green light

on the beacon.

Reference Manual 17

Page 30

Startup

18 Rosemount CT4215

Page 31

5 Shutdown

Complete the following steps to safely shut down the system when it is not in use.

CAUTION!

EQUIPMENT DAMAGE

Failure to follow the correct shutdown procedure may damage the instrument. Only use the

isolation switch on its own to shut down the system in an emergency as a last resort to remove

power from the system.

Procedure

1. Press the PowerDown button at the upper right corner of the human machine

interface (HMI).

Shutting Down the SystemFigure 5-1:

Shutdown

This shuts down the HMI.

2. Turn the unit isolator to the OFF position.

Reference Manual 19

Page 32

Shutdown

NOTICE

Turning the unit isolator switch to OFF switches the system off. At this point, mains

voltage is still applied inside the enclosure. Before opening the packaged Leak Detection

System, isolate the mains to the enclosure at the mains supply.

3. Close the compressed air supply if required.

20 Rosemount CT4215

Page 33

6 Operation

The packaged Leak Detection System is designed to run autonomously with minimal user

interaction required. After the startup procedure in Chapter 4, the system needs only a

green light to run.

There are up to three components mounted onto the packaged production line. The

layout of the line is shown schematically in Figure 6-1.

Schematic Layout of the System On LineFigure 6-1:

Operation

The packs flow on the schematic above from left to right. The packs pass through the input

gate which is located before the sample head. A space of at least 1 in. (2.5 cm) is required

between packs in order to ensure correct counting and rejection. A space of at least 6 in.

(15.2 cm) is advised for best operation.

The sample head then analyzes the pack/container.

The reject mechanism safely removes faulty containers from the production line without

the need to stop the line. The distances between the components is set at the time of

install and is determined by the speed of the production line.

Reference Manual 21

Page 34

Operation

6.1 Leak detector manager (LDM) software

The LDM software is designed to give clear information at-a-glance.

LDM Home screenFigure 6-2:

A. Start/Stop Monitoring: Automatically starts monitoring during startup. Pressing the button again

will pause the system and stop measuring.

B. Configure: Accesses the settings and parameters of the system and is password protected.

C. Reset Alarms: Clears alarms and resets status alarms to green.

D. Reset Counters: Returns the counters to 0.

E. Reports: Accesses the logging features of the system. Use a USB to log and export production

statistics and rejection data.

F. Power Down: Safely shuts down the HMI.

G. Outputs: Explained in Section 6.3.

H. Counters

I. Tab selection: Toggle between the three tabs to change which visual information is displayed.

A. Pulse: Displays the laser pulse amplitude in volts (see Figure 6-2).

B. Concentration: Displays the CO2 measurement plot and shows a spike for a leaking pack (see

Figure 6-3).

C. UNIT: Displays the measurement plot between the gates, refreshing for each pack (see

Figure 6-4).

22 Rosemount CT4215

Page 35

Operation

Concentration TabFigure 6-3:

Figure 6-3

shows the Concentration tab with one leaking package passing through. When

the blue line reaches the upper threshold (red line), the sensor sends a rejection signal to

the PLC and then the rejection solenoid to remove the faulty pack from the line. The lower

threshold is typically approximately 80 percent of the upper threshold and prevents the

system from missing a marginal leak.

Reference Manual 23

Page 36

Operation

UNIT TabFigure 6-4:

Figure 6-4

shows the UNIT tab when a leaking pack has passed through. The plot shows all

data points between the input and output gate and records the size of the rejection spike.

24 Rosemount CT4215

Page 37

6.2 Data logging and reporting

The system can store production statistics like packs processed and number of rejects. This

can be transferred from the HMI on a USB stick to be analyzed elsewhere.

To enable the Reporting screen, click the Reports tab. The Reporting screen is password

protected, and the password will be supplied or changed during installation.

Reports Popup WindowFigure 6-5:

Operation

A. Enable/Disable Reports: Turn reporting on or off.

B. Delete Report: Delete a file from a specified location.

C. Create report: Set the file name and save location.

D. Save Report: Save the current file to a specified location.

E. Copy Report File: Move a file from one location to another.

Note

The file must be saved as <filename>.txt

You can export the .txt report file to a USB stick and process it elsewhere. If you open the

file using Microsoft® Excel or a similar program, it will look like the example below.

Reference Manual 25

Page 38

Operation

Sample Report FileFigure 6-6:

• Client/Product/Batch: These are entered during the creation of the log file.

• Date/Time: The timestamp for each unit; this is set by the PC.

• Leak (abs): The maximum concentration value for each unit. If this value is greater than the upper

threshold, this package will be rejected.

• Leak (cal): For certain applications, a calibration factor may be applied in order to have units for

leakage (i.e., bubbles/second or mg/day).

• UT: The upper threshold value. If the concentration exceeds this value, the package is rejected.

• LT: The lower threshold: If two consecutive concentration points exceed this value, the package is

rejected.

• Noiselevel: the noise value at the time when the package is logged.

• Reject: Packages which do not breach thresholds are reject = 0, and those which breach

thresholds are reject =1.

Note

If you want to view only rejected packages, then filter column H to show only rows with 1 in them.

NOTICE

The CanInfo type is logged for all units processed; the Reject type only shows the reject value.

26 Rosemount CT4215

Page 39

6.3 Status lamps / errors

There are a number of errors that the Leak Detection System monitors, which may occur

during the normal operation of the system. The errors are displayed as an illuminated lamp

on the front of the enclosure. All errors latch and are cleared by the RESET button on the

front of the enclosure. The errors are detailed below and, when activated, will trigger the

red beacon bulb and line stop (if applicable).

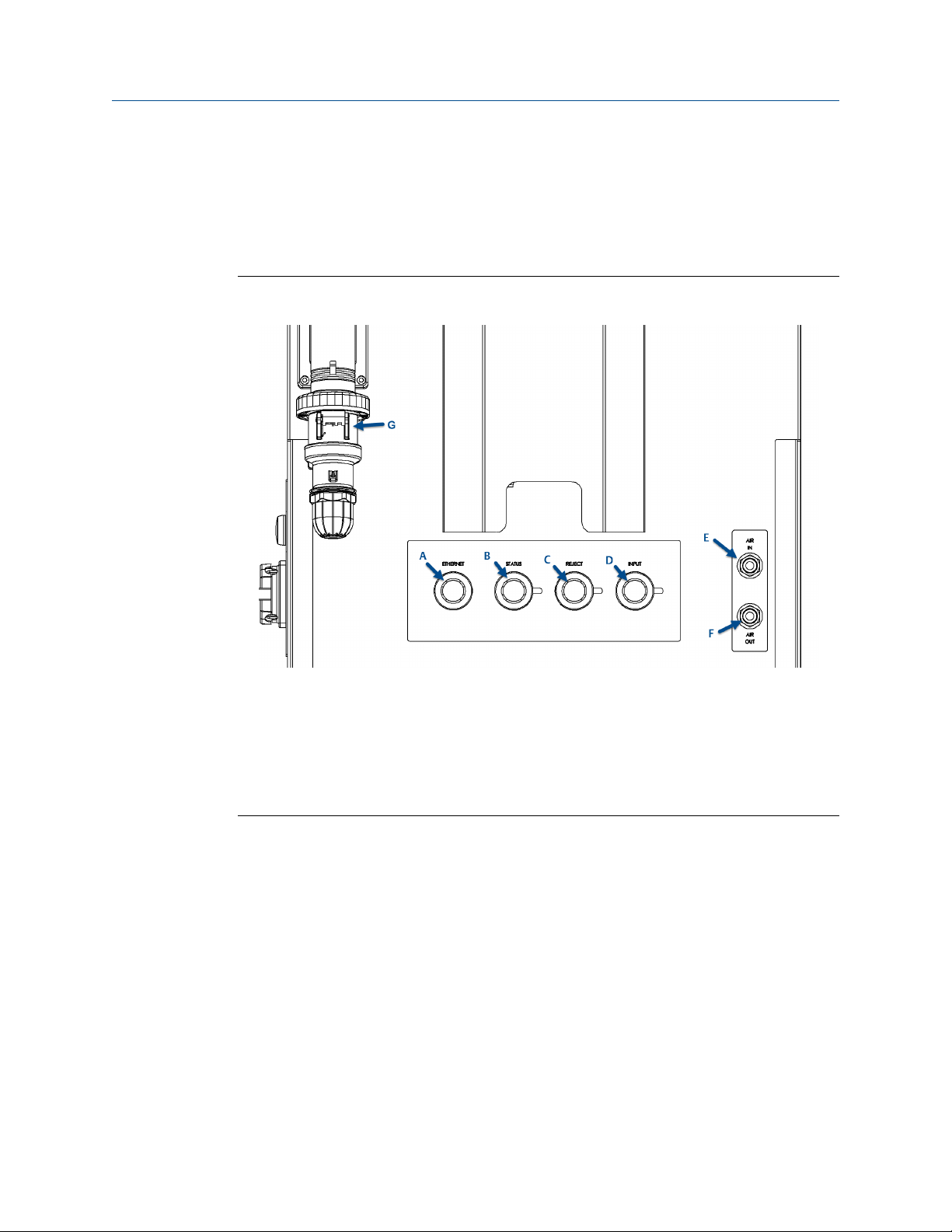

Cabinet Status IndicatorsFigure 6-7:

Operation

A. Alarm beacon: Green for healthy; red for unhealthy/line stop.

B. RESET button to clear latched alarms.

C. AIR status bulb. Illuminates when blower or compressed air is off.

D. Blower status: A status bulb turns on when power is supplied to the blower. If the power is

interrupted, the bulb doesn't turn on, and the AIR warning bulb turns on.

Reference Manual 27

Page 40

Operation

LDM Software ErrorsFigure 6-8:

1. System Ready: Shows when the system is ready for use. This is red during system

start up.

2. System Healthy: The system can become unhealthy if the gate in/out count is

different or if there have been n consecutive rejects (the default value is five

consecutive rejects). Press Reset counters on the HMI to clear the error.

3. Laser Healthy: The laser becomes unhealthy if it is below the threshold value (see the

red line in Figure 6-2). Check the beam path for obstruction or clean the cell mirrors

as described in Section 7.2. This error automatically clears when the pulse amplitude

is above the threshold.

4. Maintenance: The yellow warning triangle appears if the laser pulse amplitude is

below the warning threshold value. System performance is not affected, but you

should consider activating the mirror purge or cleaning the cell mirrors soon. This

error automatically clears when the pulse amplitude is above the warning threshold.

5. Too many Consecutive Rejects: If several packs are rejected in a row, this error is

triggered. Figure 6-9 shows the error message generated. To reset this error, press

the Reset Alarms button on the touch screen.

28 Rosemount CT4215

Page 41

Operation

Consecutive Rejects ErrorFigure 6-9:

6.4 Line stop

The control system provides a signal that can stop the production line if there are errors on

the system.

The signal is sent to the STATUS connector shown in Figure 2-2. The connection is a voltfree contact and can be configured in Normally Closed (NC) and Normally Open (NO) from a

customer supplied 24 V.

Line Stop Plug Pin NumberingTable 6-1:

Normally Closed (NC) 1 2

Normally Open (NO) 3 2

The overall system is high when healthy (green light) and low when unhealthy (red light).

24 V line 0 V line

Reference Manual 29

Page 42

Operation

6.5 PLC configuration screen

CAUTION!

EQUIPMENT DAMAGE

The PLC settings directly control the analysis and rejection of defective containers. Only trained

personnel should change the settings listed below. The PLC screen has password protection in

order to prevent unauthorized access. The credentials are provided to the relevant department

during installation. Following any change to line speed, pack size, or pack spacing, qualified

personnel should verify the system.

The system is designed to accommodate changes in pack size and line speed. There are

five configurable parameters highlighted in red below.

PLC Configurable ParametersFigure 6-10:

The PLC screens are shown in Figure 6-11 with an explanation of each button in Table 6-2.

PLC Configuration ScreensFigure 6-11:

30 Rosemount CT4215

Page 43

PLC Configuration ParametersTable 6-2:

Parameter name Description Range

Pack Length The length of time a pack takes to pass

the input gate. This timer is a debounce to prevent double counting of

uneven packs.

Measurement Start The delay between the pack passing

the input gate and the sensor counting it IN and beginning analysis.

Measurement End The delay between the pack being

counted in and the sensor finishing

analysis. This ensures complete inspection from leading edge to trailing

edge. This also generates the pack

OUT count on the software screen.

Reject Delay The time between the bag being

counted OUT and the rejection mechanism.

Reject Duration The length of time for which the rejec-

tion solenoid is open for rejection.

0 - 2000 ms

0 - 9000 ms

0 - 10000 ms

60000 ms (1 minute)

10000 ms

Operation

Reference Manual 31

Page 44

Operation

32 Rosemount CT4215

Page 45

7 Maintenance

The packaged Leak Detection System is inherently reliable at reducing the requirement for

routine maintenance. This section provides information on the schedule of maintenance

you should perform to ensure the reliable performance of the system.

WARNING!

ELECTRIC SHOCK

For all maintenance inside the lower section of the console, the system must be powered off

using the shutdown procedure detailed in Chapter 5. Inside the console there are potentially

dangerous voltages.

7.1 Scheduled maintenance

The maintenance activities and their related frequencies are shown below.

Maintenance

7.2 Clean cell mirrors

Follow the steps below to clean the cell mirrors in the Rosemount™ CT4215.

CAUTION!

EQUIPMENT DAMAGE

The cell mirrors are an optical device; only clean them when required. Avoid over cleaning the

mirrors. Use only the cleaning parts listed in this document.

If the laser pulse amplitude drops below the laser warning threshold (default 0.4 V), then

the yellow Maintenance warning message appears on the HMI (Figure 7-1).

Figure 7-1:

The system performance is not affected and runs as normal, but consider purging the cell

or prepare to clean the cell mirrors soon.

Error Message for Pulse Amplitude below Warning Threshold

Reference Manual 33

Page 46

Maintenance

If the laser pulse amplitude drops below the laser threshold (default 0.2 V), the Laser

Healthy alarm turns red, and the LASER bulb on the front of the control system is red. At

this point, the line stops, because of the red light; clean the mirrors.

Error Message for Pulse Amplitude below ThresholdFigure 7-2:

Procedure

1. Switch off the BLOWER ISOLATOR and compressed air supply.

2. Open the upper enclosure to see the red measurement cell jacket.

3. Release the two clamps on top of the cell lid.

4. Remove the top cover of the cell jacket.

5. Remove the black cell cover.

6. Use only Thor Labs lens cleaning tissue (P-5000-0613) to gently wipe the mirrors on

each side of the cell (see Figure 7-3).

CAUTION!

EQUIPMENT DAMAGE

Avoid skin contact with the mirrors as oils can be deposited.

Cleaning the Cell MirrorsFigure 7-3:

34 Rosemount CT4215

Page 47

7. Once the mirrors have been cleaned, check the pulse amplitude on the HMI and

ensure it is > 0.4 V, resetting any alarms.

8. Replace the black cell lid, red cell cover, and clamps.

9. Switch on the BLOWER ISOLATOR and press the Purge button for a few short bursts.

10. Clsoe the upper enclosure and reset any alarms.

7.3 Air filter

The air filter is located externally at the rear of the upper enclosure and prevents dust and

debris from reaching the cell. Emerson™ recommends inspecting the filter at monthly

intervals. The steps below show how to access the air filter for inspection or changing.

1. Isolate the blower so that there is no air flow through the filter and cell.

2. Using circlip pliers, remove the circlip from the end of the filter housing, Figure 7-4.

Maintenance

Removing the Circlip from the Filter HousingFigure 7-4:

3. Remove the end fitting from the filter housing, taking care not to damage the O-ring

or the filter housing in the process, Figure 7-5.

Reference Manual 35

Page 48

Maintenance

Removing the End Fitting from the Filter HousingFigure 7-5:

4. Remove the filter for inspection/cleaning or replacement, Figure 7-6.

Retain the O-ring.

Removing the Filter from the Filter HousingFigure 7-6:

36 Rosemount CT4215

Page 49

7.4 Control system

The leak detector system is inherently tolerant to high levels of contamination/dust

without a reduction in performance.

Depending on the factory cleaning regulations, wipe down the control cabinet with

suitable cleaning products as required. Emerson™ recommends doing this monthly.

7.5 Sample head

The sample head comes into contact with packages, so it should be cleaned and inspected

in line with the factory standards. Only clean the sample head when the system is switched

off, compressed air is off, and the conveyor is off.

7.6 Recommended spare parts

The following parts are available from Emerson™.

Maintenance

Spare PartsTable 7-1:

Part number Part description

P-6000-00358 Valve, solenoid

P-6000-00357 Filter/regulator, 40 m

P-6000-00355 Filter 0.01 m

P-6000-00495 Lens cleaning tissue (pack of 5)

B-6000-0007-C PCB, digitiser, Mk5

E-4004-6002-B PCB, motherboard

E-4004-6001-D PCB, pulse module

E-4001-9001-B PCB, opto

M-3000-0936 Assy Assy, cell mirror

M-3000-1367-B Assy, pneumatic plate

P-6001-00052 Module, detector

P-6000-00139 Relay, 110 Vac

P-6000-01303 Blower, side channel

B-6000-0007-C PCB, digitiser

Reference Manual 37

Page 50

Maintenance

38 Rosemount CT4215

Page 51

Troubleshooting and diagnostics

8 Troubleshooting and diagnostics

The Rosemount™ CT4215 leak detection system is designed to run unattended and to

recover from system issues where possible. This section is designed to assist in the

identification and solution of potential problems. If in doubt, contact Rosemount

customer services for clarification on solutions before continuing.

Possible Problems and SolutionsTable 8-1:

Fault symptom Order of troubleshooting Action or item to be replaced

System is not switching on. Check the mains power is connected

and on at the supply. (There may be a

customer-provided circuit breaker fitted in a nearby cabinet).

Check the system isolator is set to the

ON position.

Check the 12/24 V MCBs Q1/Q2 have

not tripped.

Check inside AC distribution box.

Laser pulse is not displayed. Check the network connection on the

motherboard for flashing LED.

Check the HMI ethernet for flashing

LED.

Check network switch hub for flashing

LED.

Check UDP addresses match in Config-

uration screen and Setup screen.

Check the laser ribbon cable. Reconnect the cable (do not hot plug

Check the detector ribbon cable and

SMA.

Concentration graph is not updating. Check the network connection on the

motherboard for flashing LED.

Check the HMI ethernet for flashing

LED.

Check network switch hub for flashing

LED.

Check UDP addresses match in Config-

uration screen and Setup screen.

Check the laser ribbon cable. Reconnect the cable (do not hot plug

Check the detector ribbon cable and

SMA (do not hot plug).

Reset customer MCB if tripped.

Switch the isolator ON.

Reset MCBs if tripped.

Default values for the UDP addresses

are 65501 and 65502.

if loose).

Reconnect the cable (do not hot plug

if loose).

Default values for the UDP addresses

are 65501 and 65502.

if loose).

Reconnect the cable (do not hot plug

if loose).

™

Reference Manual 39

Page 52

Troubleshooting and diagnostics

Possible Problems and Solutions (continued)Table 8-1:

Fault symptom Order of troubleshooting Action or item to be replaced

Maintenance alarm on LDM. If the pulse is below the LASER warn-

ing threshold, consider purging the

cell with compressed air.

Note

The system will still be healthy.

Purge the cell.

Consider cleaning the cell mirrors

soon when pulse is below threshold.

Laser unhealthy. If the pulse is below the laser thresh-

old, clean the cell mirrors.

Check the laser beam path for obstructions.

System unhealthy. If the pulse is below the laser thresh-

old, clean the cell mirrors.

Check the laser beam path for obstructions.

If the system has rejected n consecutive rejects, press the Reset alarms

button on LDM.

If the IN/OUT count does not match,

reset the counters.

AIR warning light illuminated. Check the blower isolator is in the ON

position and the blower status bulb is

illuminated.

Check the compressed air supply is

open.

Check the compressed air supply pressure is within the specified range of

the pressure switch (0.3 - 0.5 MPa).

Pressure switch should be green.

Traffic light is red and does not reset

to green when Reset pressed.

System is not counting packs. Check the INPUT gate cable is attach-

Check if the LDM dasboard is green. Repeat the rows Laser unheathy and

Check if the AIR warning light is illuminated.

ed at both ends: control system and

light gate.

Clean the mirrors.

Clean the mirrors.

Clear any obstructions from the laser

beam path.

Clean the mirrors.

Clear any obstructions from the laser

beam path.

Press the Reset button (see

Section 6.3).

Reset the counters.

Switch the isolator ON.

Turn on the air.

Confirm the supply pressure. (See

Section 2.4 for location of the pressure

regulator).

System unhealthy above.

Repeat the row AIR warning light illuminated above.

Attach the cable (do not hot plug if

loose).

40 Rosemount CT4215

Page 53

Troubleshooting and diagnostics

Possible Problems and Solutions (continued)Table 8-1:

Fault symptom Order of troubleshooting Action or item to be replaced

Check that the orange LED is flashing

on the light gate when a pack enters

the system.

Gate sensitivity can be adjusted using

the dial on the light gate. It should

flash orange when the beam is broken

at a distance of approximately 20 to

200 mm.

Reference Manual 41

Page 54

Troubleshooting and diagnostics

42 Rosemount CT4215

Page 55

Appendix A

Specifications

The following table shows the general characteristics of the Leak Detection System.

System SpecificationsTable A-1:

Item Measurement Notes

Control enclosure

Dimensions 33 x 23 x 69 (74) in.

840 x 588 x 1743 (1900) mm

Weight 268 lb.

119 kg

Sample head

Dimensions 19 x 20 x 13 in.

480 x 500 x 320 mm

Weight 30.9 lb.

14 kg

Depth x width x height (top of beacon)

Depth x width x height

Specifications

Detectable gases

Standard Ethanol - drinks

Specify on order CO2 - food

Environment

Air temperature 23 to 86 °F

-5 to 30 °C

Humidity range 10 to 95% Relative humidity (non-condensing) at

Production line area services required

System operating voltage 110/240 Vac, 50/60 Hz Specify on order

System power consumption 600 W Maximum power requirement

Factory air supply 116 psi to 145 psi

8 to 10 Bar

Line space requirement 3.9 ft.

1.2 m

Air filter particulate filter 5 µm Inline filter

Ambient

95 °F (35 °C)

Clean, dry, and oil free

Standard free line (approximate, dependent on line speed)

Reference Manual 43

Page 56

00809-0100-4245

Rev AB

2018

CASCADE TECHNOLOGIES

Castle Business Park

Stirling FK9 4TZ

Scotland

+44 1786 447 721

+44 1786 475 822

cascade.support@emerson.com

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a PO Box 1046

CH-6340 Baar

Switzerland

T +41 (0) 41 768 6111

F +41 (0) 41 768 6300

cascade.support@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

google.com/+RosemountMeasurement

AnalyticExpert.com

GLOBAL HEADQUARTERS

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

cascade.support@emerson.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

T +971 4 811 8100

F +971 4 886 5465

cascade.support@emerson.com

©

2018 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies. All other marks are the property of their

respective owners.

AMERICAS

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

+1 800 999 9307

+1 952 949 7001

cascade.support@emerson.com

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6 777 8211

F +65 6 777 0947

cascade.support@emerson.com

Loading...

Loading...