Page 1

Quick Start Guide

MHM-97465

NC: 6540-90104

Rev.: 1.002

CSI 6500 Machinery Health™Monitor

A6151, Dual Channel Low Frequency Shaft Vibration Monitor

Page 2

Emerson Process Management

Machinery Health Management

835 Innovation Drive

Knoxville, TN 37932 USA

T 1(865) 675-2400

F 1(865) 218-1401

www.EmersonProcess.com

©2010, Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available on request.We reserve the right to modify or

improve the designs or specifications of our products at any time without notice.

All rights reserved. Machinery Health is a mark of one of the Emerson Process Management group of

companies. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are

the property of their respective owners.

Page 3

GB

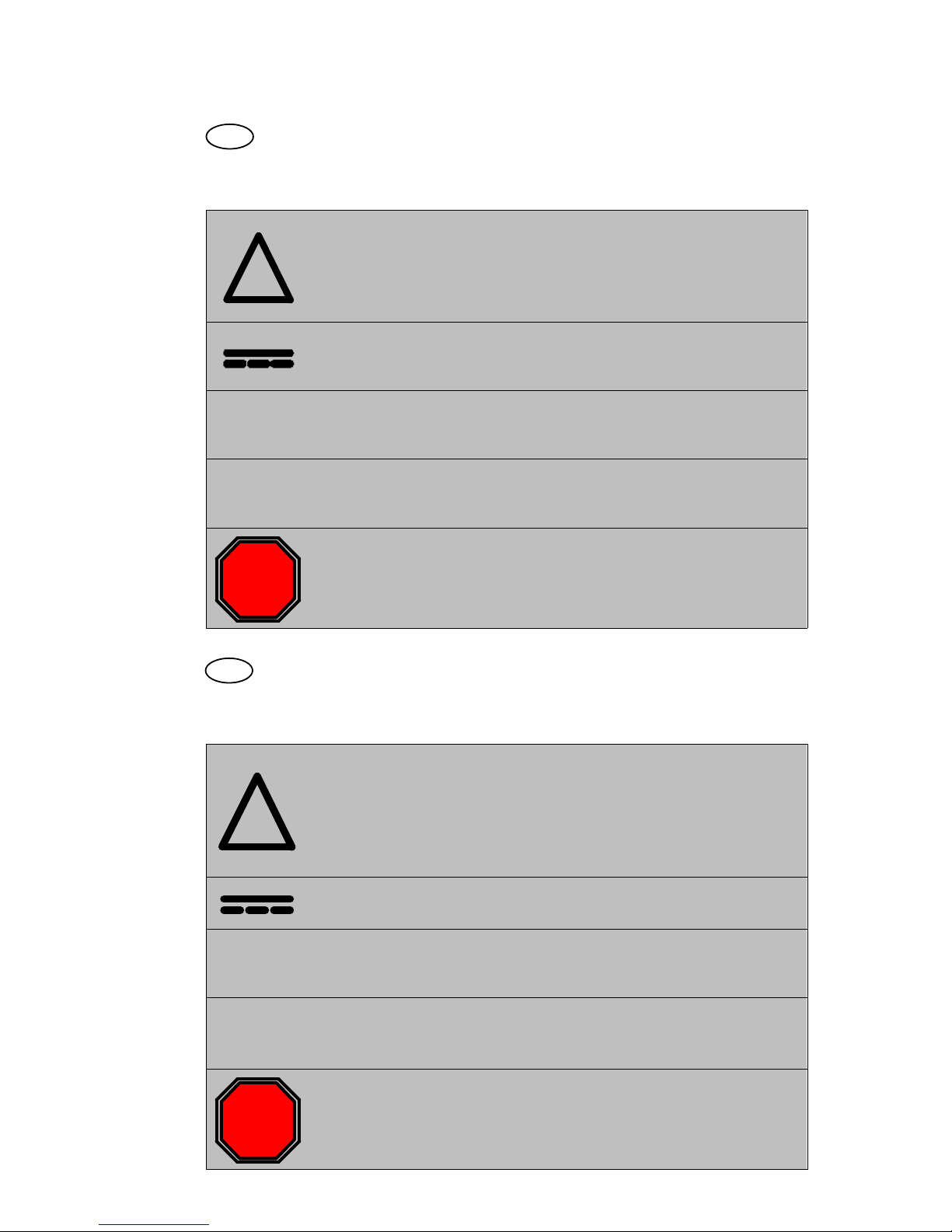

Explanation of symbols

!

If this symbol is printed on a device, according to IEC 61010 it means that the

documentation of the device must be completely read and understood before

installation and commissioning of the device. All safety−related instructions

of this document must be observed. These safety−related instructions are

marked by the “STOP” symbol in this document.

If this symbol is printed on a device, according to IEC 61010 it means that this

device must be operated with DC voltage.

i

This symbol identifies text that contains important information.

!

Not following instructions identified with this symbol can result in functional

issues and incorrect measurements without damaging the machine.

STOP

Safety and warning instructions are identified with this symbol.

Failure to observe these instructions can result in material damage or

personal injury.

D

Symbolerklärung

!

Ist dieses Symbol auf einem Gerät angebracht, so sagt dies nach IEC 61010

aus, das es zur Installation und Inbetriebnahme des Gerätes zwingend

erforderlich ist, die Dokumentation des Gerätes vollständig gelesen und

verstanden zu haben. Sicherheitsrelevante Hinweise in dieser

Dokumentation sind unweigerlich zu beachten und im weiteren Verlauf dieser

Dokumentation durch das “STOP” Symbol (siehe unten) gekennzeichnet.

Ist dieses Symbol auf einem Gerät angebracht, so sagt dies nach IEC 61010

aus, dass es mit Gleichspannung betrieben wird.

i

Dieses Symbol kennzeichnet Textstellen, die wichtige Informationen

enthalten.

!

Hinweise, die bei Nichtbeachtung zu Funktionsstörungen und

Fehlmessungen führen, ohne das Gerät zu beschädigen, sind mit diesem

Symbol gekennzeichnet.

STOP

Sicherheits- und Warnhinweise sind mit diesem Symbol gekennzeichnet.

Die Nichtbeachtung solcher Hinweise kann zu Sachbeschädigungen oder

Personenschäden führen.

Page 4

Product Service Centers

America

Emerson Process Management

835 Innovation Drive

Knoxville, TN 37932

Tel: 865−675−2110

Fax: 865−218−1401

Brazil

Emerson Process Management Ltd.

Av Hollingsworth 325

Sorocaba, SP

BRAZIL 18087−000

Phone: 55 15 2383788

Fax: 55 15 22823300

Europe, Middle East, Africa

Emerson Process Management

div. ESAD

MHM Repair Center

Piestanska 1202/44

915 28 Nove Mesto nad Vahom

Slowakia

Tel: +421/32/7700 538

Fax: +421/32/7700 884

Asia

Emerson Process Management / Asia

Pacific Private Ltd.

3904 Room Central Plaza

18 Harbour Road Wan−Chai

Hong Kong

Tel: 852−2802−9223

Fax: 852−2802−8227

Incoming goods inspection

Check the content of the shipment to ensure that it is

complete; visibly inspect the goods to determine if the

device may possibly have been damaged during

transport. The following parts are included in the scope

of delivery and must be contained in the shipment.

1. A6151

2. Product information

If the contents are incomplete, or if any defects are

observed, a complaint must be filed with the carrier

immediately. Moreover, the responsible Emerson sales

organization must be informed to enable repair or

replacement of the device. Repairs or calibration that

may be required, are only possible at the Emerson

factory.

In this case, a non−detachable tag with customer name,

defect observed and version of the A6910 configuration

software must be attached to the device.

Repair and maintenance

During operation, monitors do not require any maintenance.

Repair or calibration of monitors is only possible at

Emerson.

i

The additional PCB (controller board)

is calibrated with the main board and

must not be replaced.

If work with the opened device on−site is

unavoidable, this should only be performed by a

specialist who is familiar with the associated

hazards.

STOP

Capacitors in the device can still be

energized, even if the device has

been disconnected from all power

sources.

Page 5

If repair or recalibration of a monitor is required, it

must be sent to Emerson. Attach a non−detachable

tag to the monitor with customer name, defect

observed and version of the A6910 configuration

software.

Guidelines for Returning Equipment to the

Product Service Center

If repair or calibration of a monitor is required, it must

be sent to Emerson.

Occasionally, concerns with CSI technology

hardware could arise. Should this happen, customers

under warranty or a current support agreement are

entitled to no−charge repairs.

Follow the checklist below to minimize return time

and ensure proper processing of your equipment.

Before returning any equipment to a Product Support

Center, please review this information:

1. Obtain a Return Materials Authorization (RMA)

number and the address of the appropriate

Product Service Center by calling 865.675.4274*.

Listen to the options for receiving an RMA. You

will be routed to support personnel who will

document your concern and give you an RMA

number if you are under support or warranty. If

your hardware is not under support or warranty,

you must have a Purchase Order for the amount

of the repair service before you can receive an

RMA number. Pricing for your repair can be

obtained from support personnel or by calling

your local sales representative. Once you have

your purchase order, call 865.675.4274* for an

RMA.

2. Once you have received your RMA, send your

hardware to the appropriate product service

center. Your hardware package should include:

G RMA Number (plus Purchase Order if

applicable)

G Description of the hardware

problem

G Return shipping address including a

phone number (No P.O. boxes).

G Any special request regarding the

return shipment.

G A list of the model numbers of each

item(s) being returned, along with

the serial number.

G Your name, address, telephone

number and email address.

G Company Name.

A form for completing this information has

been provided.

Make a copy of the form, complete all lines,

and return a copy in each return shipment.

Out of warranty? Need to get under

support? Get a customized quote for

bringing all your CSI technologies under a

support agreement:

Phone: 865.675.2400*, ext. 2130

Fax: 865.218.1478*

Email:

mhm.supportagreement@emersonproces

s.com

*Customers outside the Americas and

Canada: please refer to the list of service

centers and contact the service center near

you.

All rights are strictly reserved

Reproduction or divulgation in any form

whatsoever is not permitted without written

authority from the copyright owner.

Page 6

RMA Required Information

RMA number issued by Product

Service Center:

For all items beingreturned, please

list Model / Serial Number:

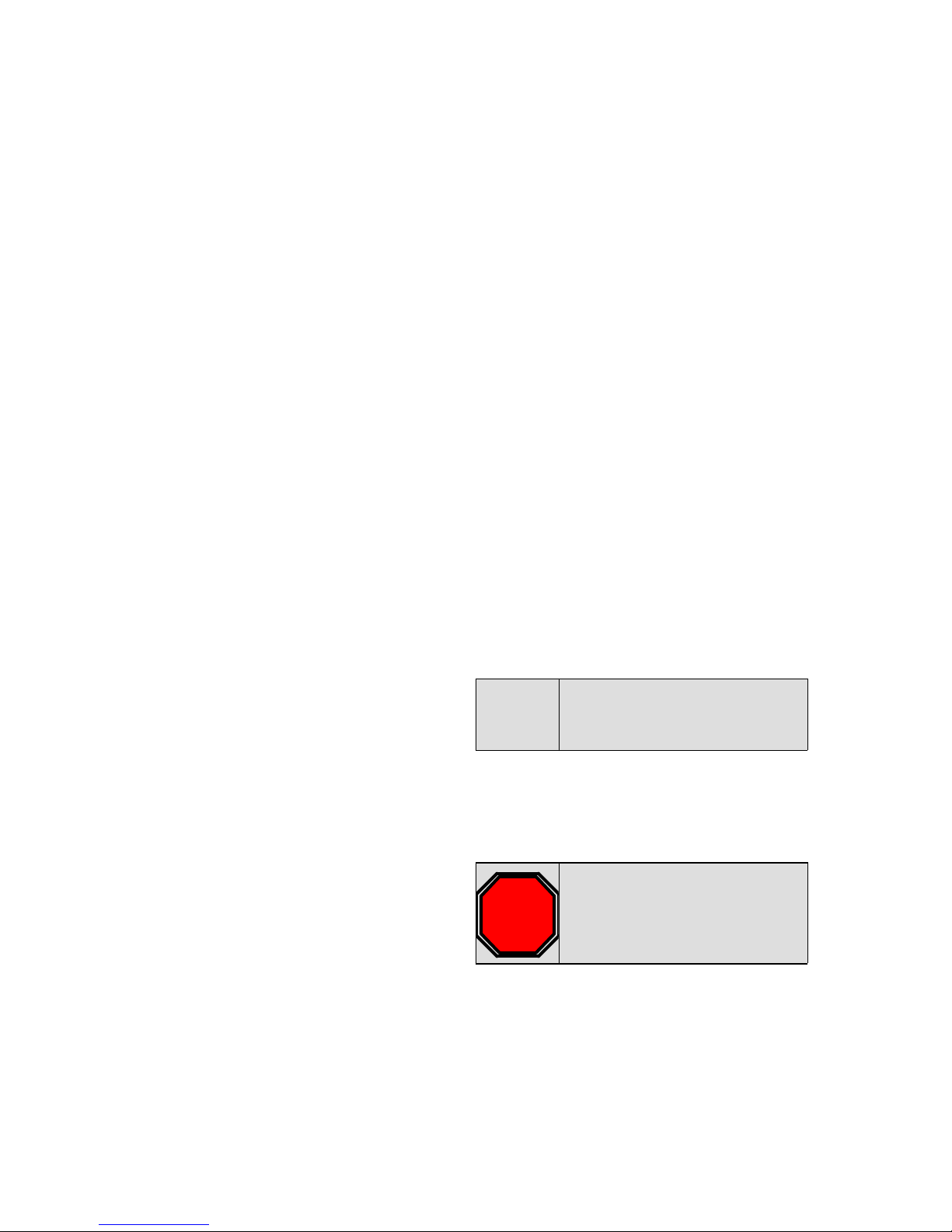

Are you under warranty or a current

support agreement (circle one)?

Yes No

If you answered no, what is your

purchase order number?

Company Name:

Contact Name:

Contact Address:

Contact Phone:

Contact Fax:

Contact Email:

Please describe the problem you are experiencing:

If we are to send the return shipment to someone other than the

Contact Name/Address above, please provide that address here,

including Contact Name and Phone Number:

Are there any special instructions regarding the return?

Please provide invoice address (if a purchase order was required):

Support customers − your instrument is shipped back to you the same

way that it is sent to our service center. For example, if you ship via

ground transportation, it is shipped back via ground.

Page 7

Page/Seite 7

Product Information / Produktinformation

A6151

1

GB

Shaft Vibration Monitor 9........................

1.1 Scope of Delivery 9...........................................

1.2 CSA Certification 10...........................................

1.3 CSA − Conditions of acceptability 10............................

1.4 Advice for Installation 10.......................................

1.5 Installation and Mounting 11...................................

1.5.1 Jumper RS 485 11..........................................................

1.5.2 Sensor raw signal 12........................................................

1.5.3 Installation 14..............................................................

1.6 Technical Data 14..............................................

1.6.1 Signal conditioning 14.......................................................

1.6.2 Channel monitoring 18......................................................

1.6.3 Limit value formation and alarms 19...........................................

1.6.4 Communication interfaces 20.................................................

1.6.5 Power supply 21............................................................

1.6.6 Environmental conditions 22.................................................

1.6.7 Mechanical structure 22.....................................................

2

D

Wellenschwingungsmonitor 23....................

2.1 Lieferumfang 23...............................................

2.2 CSA Zertifizierung 24..........................................

2.3 CSA − Akzeptanzkriterien 24....................................

2.4 Hinweis zur Installation 25......................................

2.5 Installation und Montage 25....................................

2.6 Technische Daten 28...........................................

2.6.1 Signalkonditionierung 28.....................................................

2.6.2 Kanalüberwachung 31.......................................................

2.6.3 Grenzwertbildung und Alarme 33.............................................

2.6.4 Kommunikationsschnittstellen 34.............................................

2.6.5 Spannungsversorgung 35....................................................

2.6.6 Umgebungsbedingungen 36..................................................

2.6.7 Mechanischer Aufbau 36....................................................

3 Connection Diagrams and Figures /

Anschlusspläne und Abbildungen 37....................

4 PI Revision List 41.....................................

Page 8

Page 8

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

1

GB

SHAFT VIBRATION MONITOR

The two−channel Low Frequency Shaft Vibration Monitor A6151 is a module of the A6000

machine monitoring system. The micro−processor controlled monitor is used in conjunction with

two eddy current measuring chains to measure and monitor the relative shaft vibration of hydro

turbines.

The two channels of the monitor can be used as separate channels or they can be linked together

via the configuration. The following operating modes are possible:

• Dual channel operation.

• The calculation and output of the maximum value S

max

.

• The calculation and output of the greater vibration width S

PPmax

The characteristic values can be output via a 0/4 ... 20mA current output per channel

i

In this product information the mounting and electrical connection of the

monitor is described. The configuration of the A6151 is similar to the

configuration of the A6110. Hence additional information concerning

configuration and installation can be found in the operation manual of the

A6110 (order number: 6110−90001) This operating manual is part of the

configuration software CD. All differences in installation and configuration are

described in this product information.

To ensure the safe operation of the monitor and to permit setting of all

functions, it is indispensable to use only the latest versions of configuration

software (version 2.07 Beta 78) and operating manual.

The use of old operating manuals or configuration programs out of date may

lead to malfunctions or limitations of the measuring functions.

1.1 Scope of Delivery

The following parts are included in the scope of delivery and must be contained in the shipment:

• Low Frequency Shaft Vibration Monitor A6151

• This product information

Accessories (not included in delivery):

• MMS ParaKit (order no.: 9510−00027)

If the contents are incomplete or if is there any damage, so directly complain at the bearer. The

competent epro sales agency must be informed also, to enable repair or replacement for the

monitor. Repair or calibration of this instrument may only be made at epro.

Page 9

Page 9

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

1.2 CSA Certification

STOP

For valid CSA certification, all devices (IMR 6000/xx and A6000 modules)

must be marked with the respective CSA lable.

If no CSA lable is available on the respective device, this device is not CSA

certified!

The respective CSA lable looks as shown in the following picture.

1.3 CSA − Conditions of acceptability

This device must be supplied with safety low voltage SELV LPS (C22.2 60950−1) 24V. The

voltage required for operation must be drawn from a separate power supply.

The system should be placed in a suitable fire enclosure.

The system is evaluated for an ambient Temperature of 0°C to 45°C.

Adequate ventilation space has to be provided so that heat does not build up. The ventilation

space must be at least 1 RU (1

3/4

inch) in all directions. If the ambient temperature of the rack

rises above 45 °C, cool this instrument with a forced air fan, cooler, or similar.

When mounting several IMR units above each other in one cabinet, install cooling fan racks in

between instead of the ventilation space. The necessary specifications for cooling fan racks

result from the environmental and sitting criterions of the cabinet and thus cannot be defined

generally.

1.4 Advice for Installation

STOP

According to the IEC 61010 directive, permanently installed systems must be

equipped with a power disconnect device (e.g. a switch or circuit−breaker

according to IEC60947−1 and IEC60947−3). When using an IMR rack, in

compliance with this directive, such a switch or breaker must be implemented

into the cabinet installation and easily accessible for the user. Furthermore,

each disconnect devices must be labeled in accordance to the associated

system.

Page 10

Page 10

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

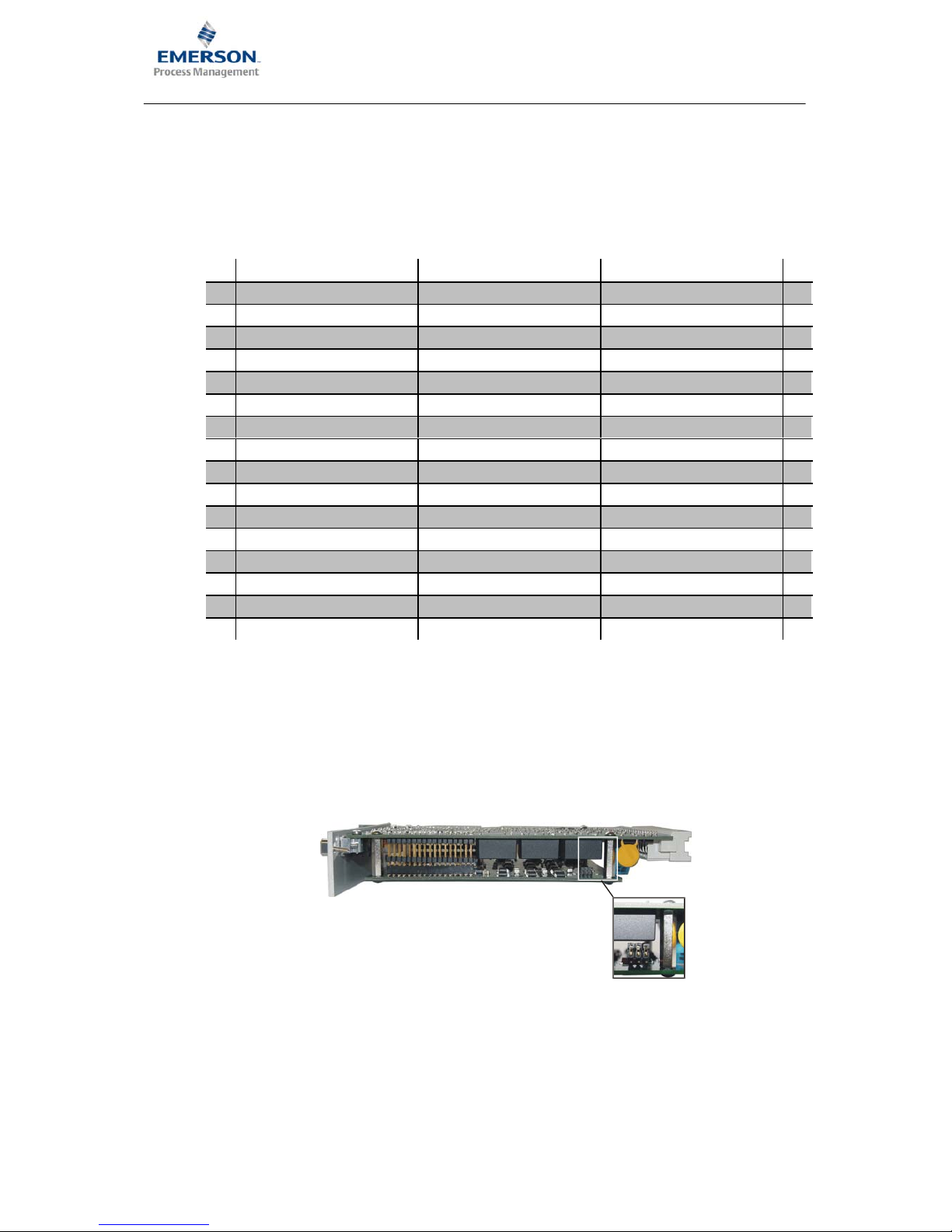

1.5 Installation and Mounting

A prepared 3U slot in a 19” rack, or other Intermas−compatible enclosure, is required for

mounting the A6151 monitor. The slot must be fitted with a 48−pin plug connector (DIN 41612,

design F 48 M). The pin assignment is listed in the following table.

d

b z

2

UN+ (+ 24V) U− (0V/Common) UB+ (+24V, redundant)

2

4

A (RS 485) GND (BP, Common, RS 485) B (RS 485)

4

6

Supply2+ (sensor) Supply1− (sensor) Supply1+ (sensor)

6

8

AIN2− (Input) Supply2− (sensor) AIN1− (Input)

8

10

AIN2+ (Input) GND AIN1+ (Input)

10

12

NGL2 (scaled dc−output) GND NGL1 (scaled dc−output)

12

14

EO1 (voltage output1) EI1 (voltage input1) AC1 (sensor raw signal1)

14

16

EO2 (voltage output2) EI2 (voltage input2) AC2 (sensor raw signal2)

16

18

GWM (limit value) I1− (current output common) I1+ (current output CH1)

18

20

NC I2− (current output common) I2+ (current output CH2)

20

22

KEY−N (key signal input) GND ES (external lock)

22

24

SC−A (oper. principle alert) GND SC−D (oper. principle danger)

24

26

D1−C (danger1 collector) A1−C (alert1 collector) CC1−C (ch. clear1 collector)

26

28

D1−E (danger1 emitter) A1−E (alert1 emitter) CC1−E (ch. clear1 emitter)

28

30

D2−C (danger2 collector) A2−C (alert2 collector) CC2−C (ch. clear2 collector)

30

32

D2−E (danger2 emitter) A2−E (alert2 emitter) CC2−E (ch. clear2 emitter)

32

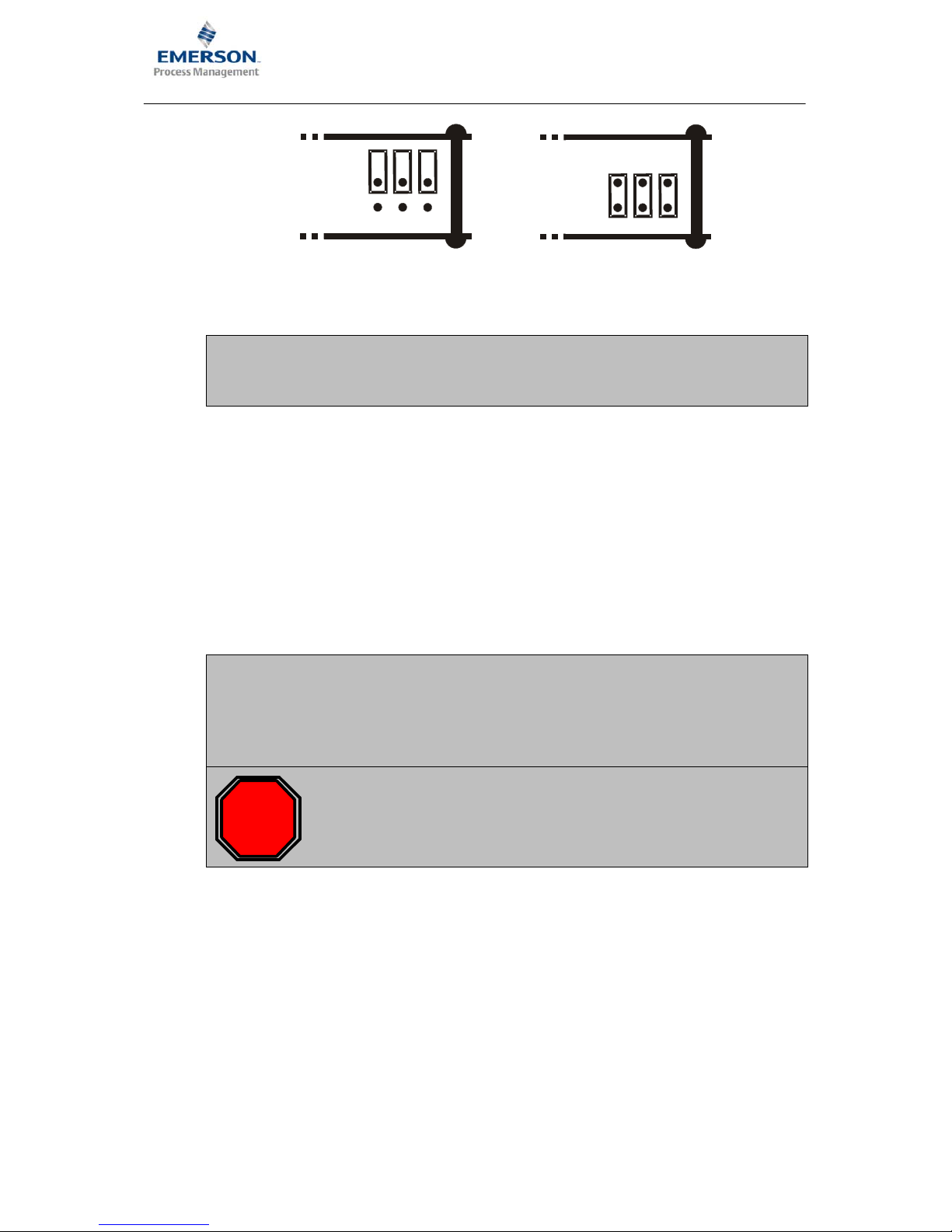

1.5.1 Jumper RS 485

RS 485 bus operation requires an electrical terminator on the first and last bus device.

This is done with plug−in jumpers, that are on the controller board. The figure shows the position

of the jumpers.

To activate the bus terminator and to place lines “A” and “B” on the references, plug the jumpers

as shown in Fig. b). Fig. a) shows the jumper position for deactivated bus termination and open

references (delivery status).

• Plug−in jumper 1−2 closed: Bus line “B” via pull−down resistor on ground

• Plug−in jumper 3−4 closed: 120 Ω resistor between “A” and “B”

• Plug−in jumper 5−6 closed: Bus line “A” via pull−up resistor on +5 V

Page 11

Page 11

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

1

35

2

46

1

35

2

46

a)

b)

i

For trouble−free operation of the RS 485 bus, the lines “A” and “B” must be

connected on their references (+5 V, ground) in one monitor. This is only

possible if the bus termination jumper at this monitor has been closed as well.

1.5.2 Sensor raw signal

The raw sensor signal (unfiltered, in−phase output signal of the converter with AC and DC

portion) is applied to the front panel SMB sockets and can be fed to the terminals z14: channel

1 and z16: channel 2 of the connection strip with the jumpers J2. As delivered, the J2 jumpers

are set, that on terminals z14 and z16 the dynamic portion of the sensor signal (scaled to output

range 0 ... 20 Vss) is applied. The controller board must be removed in order to switch the signal

on the connection strip. The following points describe the procedure:

i

The reference point for the raw sensor signal from channel 1 is the connection

strip terminal z6: Supply1(+), and for the raw sensor signal from channel 2 the

terminal d6: Supply2(+). If these terminals are connected with terminal b10,

then the reference point is connected to system ground (GND). In this case

the terninals b22: GND and b24: GND can be used as reference point.

STOP

When working at the monitor, ensure that there is adequate protection against

electrostatic discharge. For example, wear an ESD bracelet to prevent

electrostatic discharge via the monitor electronics.

Page 12

Page 12

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

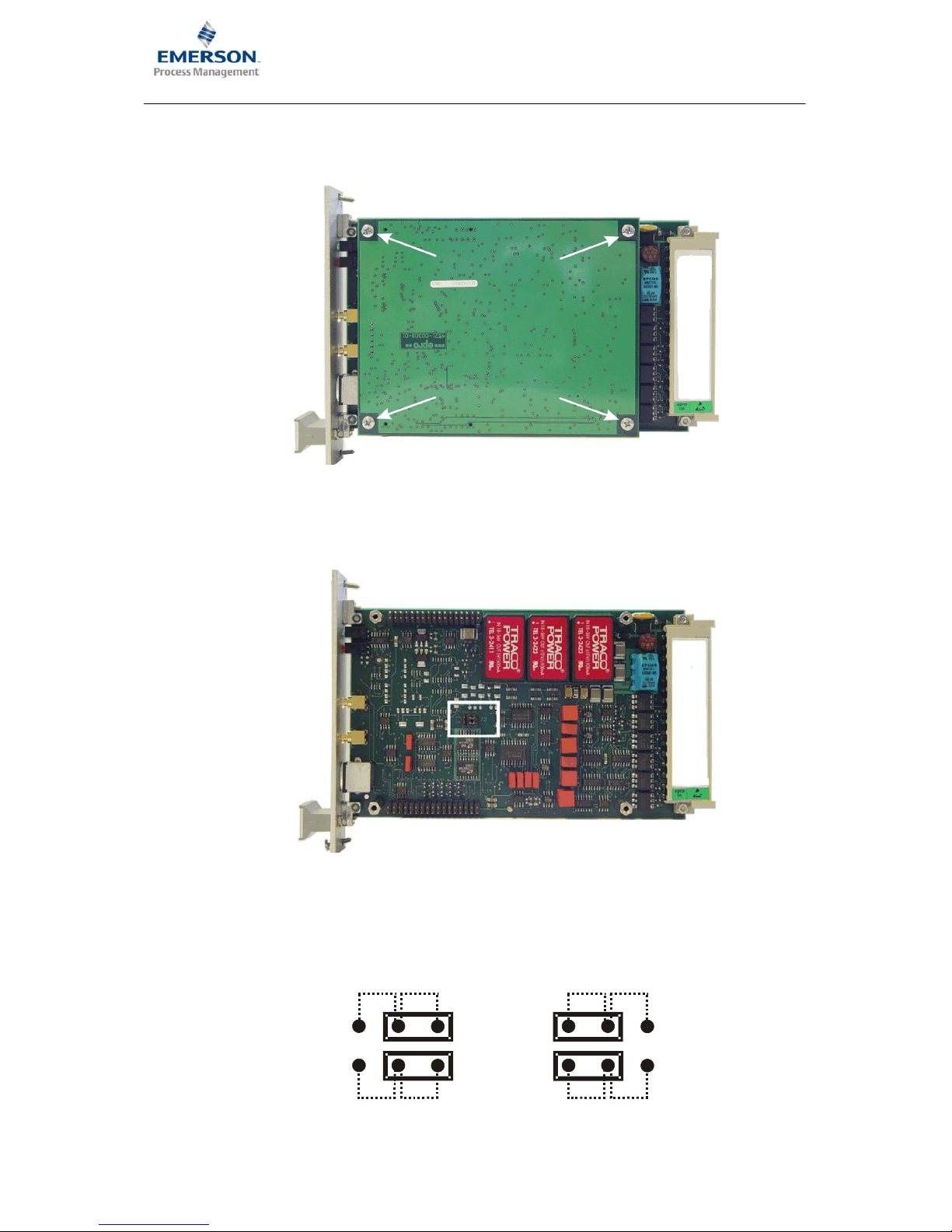

3. Use a cross head screwdriver to remove the four cross−headed screws, identified with the

arrows, in the following figure.

4. Carefully pull the controller board off the main board without tilting it. The position of the J2

jumpers on the main bard is identified with a white frame in the following figure.

5. To switch the raw sensor signal to terminals z14 and z16 place the jumpers as shown in b).

If the jumpers are set as shown in a) then the dynamic portion of the sensor signal is applied

on terminals z14 and z16.

J2

z14:

z16:

AC1

AC2

SENS1

SENS2

J2

z14:

z16:

AC1

AC2

SENS1

SENS2

a)

b)

Page 13

Page 13

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

6. Place the controller board back on the main board and secure it with the four screws. Now,

the raw sensor signal is on the connection strip.

1.5.3 Installation

1. Check the slot wiring prior to installing the monitor.

2. Push the A6151 monitor into the prepared slot and press it with light pressure into the plug

connector.

3. Hand tighten the two anchoring screws on the front panel to secure the monitor.

Any other information, e. g. shielding and grounding, configuration of the monitor, etc., can be

found in the direction for use of the A6110, order number: 6110−90001.

1.6 Technical Data

Only information with tolerances and limit values are considered as binding data. Data without

tolerances or error limits are provided as information only. We reserve the right to make technical

changes − particularly to the software.

All of the following information applies uniformly for channel 1 and channel 2, if not otherwise

specified.

1.6.1 Signal conditioning

Two separate signal inputs for channel 1 and channel 2 with uncoupled signal conditioning.

Measured value inputs

Differential voltage amplification inputs, non−reactive, open−circuit and short−circuit proof.

Channel 1 z8: AIN1 (−); z10: AIN1 (+)

Channel 2 d8: AIN2 (−); d10: AIN2 (+)

Input nominal range −1,0 ... −22.16 V

Limit range 0 ... −30 V DC

Input resistance > 100 kΩ

Page 14

Page 14

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

Signal conditioning

Sensor signal outputs Front sockets SMB and/or z14 / z16*, uncoupled,

open circuit and short circuit proof, non reactive.

Channel 1 − SENS 1 SMB K1

Channel 2 − SENS 2 SMB K2

Signal output −1 ... −24 V; signal 1:1 to sensor input signal

Precision ±1

% of f.s.d.

Frequency range 0.2 ... 200 Hz (−3 dB) ±20 %

Per. load resistance > 100 kΩ

Internal resistance 1 kΩ

*Depends on the jumper setting J2.

Dynamic outputs

The AC portion of the sensor signal is output as scaled value.

Channel 1 − AC1 / Channel 2 − AC2 z14 / z16* open−circuit and short−circuit proof, non−

reactive

Nominal range 0...20 Vpp

Measuring range Corresponds to the measuring range configured for

the characteristic value, min. 400 mVpp,

max. 8000 mVpp

Precision

±1

% of f.s.d.

Frequency range 0.2 Hz ... 200 Hz (−3 dB) ±20 %

Per. load resistance > 10 kΩ

Source impedance 10 kΩ

Internal resistance Approximately 20 Ω

*Depends on the jumper setting J2.

Scaled d.c. Outputs

The DC portion of the sensor signal (proportional to the static distance sensor / measurement

object) is output as standardized DC voltage NGL.

Channel 1 − NGL1 / channel 2 − NGL2 z12 / d12 open circuit and short circuit proof, non

reactive

Nominal range 0 ... +10 V DC

Measuring range According to the configured operating range of the

sensor

0 V corresponds to the lower value of the work range

+10 V corresponds to the upper value of the work

range

Precision / resolution

±1

% of f.s.d. / 12 Bit

Per. load resistance > 10 kΩ

Internal resistance Approximately 50 Ω

Page 15

Page 15

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

Signal conditioning for characteristic values

The input signals are conditioned by adjusting amplifier, range−dependent amplifier, high

pass, and low pass prior to digitalization.

Range setting Is determined in the configuration

Minimum measuring range 400 mVpp

Maximum measuring range

8000 mVpp

Frequency range

High pass filter Butterworth filter 2nd order

− Parameters can be set 0.2 Hz (−3 dB)

0.7 Hz (−3 dB)

− Tolerance ±20 %

Low pass filter

Butterworth filter 5nd order

Parameter range 10 Hz ... 200 Hz in 0.01 Hz

increments

Characteristic value formation Depends on the configuration

2−channel operation S1 and S2 separated characteristic values, optionally

in 0−P or P−P evaluation.

Maximum deflection S

max

S

max

= max sk (t);

sk(t) + s

1

(t)2) s2(t)

2

Ǹ

Maximum vibration amplitude S

ppm

S

ppm

= Max (s

p−p

1 or s

p−p

2 )

Current outputs−characteristic values

Characteristic value formation and evaluation depends on the functions specified in the

configuration.

Current output 1 − I1+ / I1− z18 / b18 (0 V / common)

Current output 2 − I2+ / I2− z20 / b20 (0 V / common)

Nominal range 0 ... 20 mA or 4 ... 20 mA, depending on the

configuration

−Life zero operation in 4 ... 20 mA operation you can specify via the

configuration that the output is set to 0 mA if a fault is

detected.

Precision / resolution ±1 % of f.s.d. / 16 Bit

Per. load resistance 500 Ω

Page 16

Page 16

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

Signal outputs EO 1 / EO 2

d14 / d16

voltage output 0 ... 10V. For modes with separate channels according to the characteristic

value. For modes S

max

and S

PPmax

outputs of the single−channel measured values.

Measuring range and evaluation according to the characteristic value.

Depending on the application and configuration the outputs EO can be used for linkage or for

display.

Open circuit and short circuit proof, non reactive.

Nominal range 0 ... +10 V DC

Resolution 8−bit

Per. load resistance > 10 kΩ

Internal resistance Approximately 50 Ω

Signal inputs EI1 / EI2

Inputs for single−channel measurement values 0 ... +10 V for connection with EO outputs.

Voltage input EI1 / EI2 b14 / b16

Nominal voltage range 0 ... +10 V DC

Resolution 10−bit

Input resistance > 100 kΩ

Signal input KEY

The key pulse is required for internal RPM determination for checking the measurements in

the measured value analysis.

Signal input KEY (N) d22

Signal level 24 V logic,: LOW = 0 ... 3 V; HIGH = 13 ... 48 V

Input resistance > 10 kΩ

Page 17

Page 17

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

1.6.2 Channel monitoring

Monitoring function Constant monitoring

Sensor signals GOOD range (configuration dependent)

GOOD thresholds

− Lower threshold value Sensor work range lower value −0.5 V

− Upper threshold value Sensor work range upper value +0.5 V

System voltages Voltage − OK

μP function (watchdog) WD − OK

Configuration & setting para−

meters

C&P − OK

External disable signal ES

Status channel monitoring

Channel status = no error (OK) if (voltage_OK = yes)

AND (WD_OK = yes)

AND (C&P_OK = yes)

AND (Sensor signal

in the GOOD range)

AND (Ext. disable = no)

Channel status = error If the previous condition is not satisfied

Channel status = release delayed When switching from error case to OK status or when

switching on the module a release delay of 15 s (±2 s)

is active

Visualization

Green LED on the front panel

Channel status = no error (OK) Continuous light

Channel status = error Dark

Channel status = release delayed Flashing light

Channel Clear outputs

Opto−decoupled collector/emitter segments

Channel Clear channel 1, C1C / C1E z26 (collector) / z28 (emitter)

Channel Clear channel 2, C2C / C2E z30 (collector) / z32 (emitter)

Ext. disabled or status = error or

release delayed

C−E disabled, max. perm. voltage: 48 V

Not ext. disabled and status = OK and

not release delayed

C−E conducting, max. perm. current: 100 mA

Page 18

Page 18

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

Input external disable ES

z22 − for disabling the limit value alarms; e.g. for service work etc.

Disable function Input LOW = disable the channel monitoring and limit

value formation

Release Input HIGH or not switched = enable of channel

monitoring and limit value formation

Signal level LOW: 0 ... +3 V, HIGH: +13 ... +48 V

1.6.3 Limit value formation and alarms

Two alarm channels, each with an alarm output ALERT and DANGER, and separate limit value

adjustment. Alarming if the characteristic value exceeds the limit value parameters. (current

value > limit value)

Setting the limit value

By setting parameters, depending on the configuration for measurement operation, characteristic value formation, range etc.

Setting condition Limit value ALERT < limit value DANGER

Setting range 0 ... 100

% of the measuring range parameters

Resolution and reproducibility 1 % based on the measuring range end value

Hysteresis Configurable, 0 ... 20 % based on the measuring range

end value

The hysteresis is only effective with decreasing

current value

Alarm delay

Can be configured to 0 (off), 1,2,3,4,5 sec.; effective on the alarm outputs.

Alarm blocking

Blocking If (C&P active = yes) OR

(Voltage or watchdog not OK) OR

(Ext. disable = disable) OR

(Channel status = error and limit value

suppression on*) OR

(Channel status = release delayed) AND

Channel monitoring effect = yes

No blocking

If the above condition is not satisfied

* In the configuration it is specified whether the alarm outputs will be blocked by channel

monitoring.

Page 19

Page 19

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

Alarm visualization

By red LEDs, each for channel 1 and channel 2

No limit value exceeded or alarm

blocked

LED off

ALERT, no DANGER LED flashes at 2 Hz (pulse/pause 1:1)

DANGER LED on continuously

Alarm outputs

Opto−decoupled collector/emitter segments

Alert channel 1 A1−C / A1−E b26 (collector) / b28 (emitter)

Danger channel 1 D1−C / D1−E d26 (collector) / d28 (emitter)

Alert channel 2 A2−C / A2−E b30 (collector) / b32 (emitter)

Danger channel 2 D2−C / D2−E d30 (collector) / d32 (emitter)

Maximum value for alarm outputs C−E disabled: max. perm. U

CE

: 48 V

C−E conductive: max. perm. U

CE

: 100 mA

Alarm status of the alarm outputs Conducting in open circuit mode, disabled in

closed−circuit mode

Open circuit mode / closed−circuit mode

The digital inputs SC−A and SC−D can be selected with external signals.

Switchover ALERT

d24 − SC−A = HIGH / blank

= open circuit mode

d24 − SC−A = LOW = closed−circuit mode

Switchover DANGER z24 − SC−D = HIGH / blank

= open circuit mode

z24 − SC−D = LOW = closed−circuit mode

Switch level LOW = 0 ... +3 V

HIGH = 13 ... 48 V

Input resistance > 10 kΩ

1.6.4 Communication interfaces

Interface RS 232

Front socket for connecting a laptop / computer for configuration and visualization purposes

Round plug connector on the front

side

Mini DIN socket type TM 0508A/6 for parameterization

cable (included in the operating kit)

Page 20

Page 20

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

Interface RS 485

d4, z4 bus interface for communication with an MMS 68xx epro Interface card and the

configuration software.

1.6.5 Power supply

The monitor system voltages, and thus the 0 V / common connections for the measurement

and monitoring inputs and outputs, are galvanically separated.

Supply voltage inputs Two redundant diode decoupled inputs for nominal

+24 V with common 0 V reference

Voltage input UB+ / UN+ d2 / z2

Common reference 0 V U− b2

Perm. voltage range 19 ... 31.2Vdc (IEC 654−2 class DC 4)

CSA: 24Vdc; SELV LPS

Power consumption max. 6 W, at 24 V max. 250 mA

Monitor system voltage

The system voltages required for the internal supply are constantly monitored. If undervoltage

is detected an error message is generated.

Sensor supply

For both channels of the monitor

Separation Decoupled and galvanically separated from the

supply voltage, can be operated in parallel with other

monitors, open circuit and short circuit proof, non

reactive.

Sensor supply channel 1 Supply1(−) / Supply1(+) b6/z6

Sensor supply channel 2 Supply2(−) / Supply2(+) b8/d6

supply voltage 26.75 V DC; Tolerance ±2

%

Residual ripple < 20 mVpp (at nominal current 20 mA)

Max. current 35 mA

Max. short−circuit current 0 mA ≤ I short−circuit ≤ 5 mA;

Open circuit and short−circuit proof

Page 21

Page 21

Product Information / Produktinformation

A6151

Shaft Vibration Monitor

1.6.6 Environmental conditions

Application class KTF in accordance with DIN 40040

Ambient temperature

Reference temperature +25 °C

Nominal use range 0...+45°C (CSA

requirement and recommended range)

max. range −10°C ... +65°C (not CSA conform)

Storage, transport temperature −30 ... +85 °C

Operating altitude up to 2000m above sea level

Relative humidity

≤ 95

% non condensing

Vibration In accordance with IEC−68 − 2 Part 6

Path 0.15 mm at 10 ... 55 Hz

Acceleration 19.6 mm/s

2

at 55 ... 150 Hz

Shock

In accordance with IEC-68 - 2 Part 29

Peak acceleration value 98 m/s

2

Nominal duration of shock 15 ms

Enclosure protection class IP 00, open design in accordance with DIN 40050

EMC immunity In accordance with EN 50 081−1 / EN 50 082−2

satisfied

Allowed degree of pollution Category 2 (According to IEC 61010−1)

Enviromental Area Indoor use only

1.6.7 Mechanical structure

PCB Euro format (100 mm x 160 mm) in accordance with

DIN 41494

Width 6 TE (approximately 30 mm)

Plug connector DIN 41612, form F 48 M

Front element

2 LEDs green Channel Clear channel 1 / 2

2 LEDs red Alarms channels 1 / 2

2 SMB socket connectors For sensor channel 1 / 2

1 mini DIN round socket connector RS 232 for connecting a laptop / computer

(for configuration and visualization purposes)

Weight Approximately 320 g without packaging,

approximately 450 g with standard packaging

Page 22

Seite 22

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

2

D

WELLENSCHWINGUNGSMONITOR

Der zweikanalige niederfrequenz Wellenschwingungsmonitor A6151 ist eine Baugruppe des

A6000 Maschinenüberwachungssystems. Der mikrocontrollergesteuerte Monitor dient in Ver-

bindung mit zwei Wirbelstrom−Messketten der Messung und Überwachung der relativen

Wellenschwingung an Wasserturbinen.

Die zwei Kanäle des Monitors können mittels der Konfiguration als getrennte Kanäle benutzt

oder miteinander verknüpft werden. Folgende Betriebsarten sind möglich:

• Der separate Zweikanalbetrieb.

• Die Berechnung und Ausgabe des Maximalwerts S

max

.

• Die Berechnung und Ausgabe der größeren Schwingbreite S

ssmax.

Die Kenngrößen können je Kanal über einen Stromausgang 0/4 ... 20 mA ausgegeben werden.

i

In dieser Produktinformation wird die Montage und der elektrische Anschluss

des Monitors beschrieben. Die Konfiguration des A6151 ist ähnlich der Konfiguration des A6110. Daher können zusätzliche Informationen bezüglich

Konfiguration und Installation der Gebrauchsanleitung des A6110 (Bestellnummer: 6100−90001) entnommen werden. Diese Gebrauchsanleitung ist

bestandteil der Konfigurationssoftware CD. Unterschiede in Installation und

Konfiguration werden in dieser Produktinformation beschrieben.

Um den sicheren Betrieb des Monitors zu gewährleisten und um alle

Funktionen des Gerätes einstellen zu können ist es erforderlich, die jeweils

aktuellsten Versionen von Konfigurationssoftware (ab Version 2.07 Beta 78)

und Gebrauchsanleitung zu verwenden.

Die Verwendung älterer Konfigurationsprogramme oder Gebrauchs−

anleitungen kann Funktionseinschränkungen oder Fehlfunktionen zur Folge

haben.

2.1 Lieferumfang

Folgende Teile gehören zum Lieferumfang und müssen in der Sendung enthalten sein:

• Wellenschwingungsmonitor A6151

• diese Produktinformation

Zubehör (nicht im Lieferumfang enthalten):

• MMS ParaKit (Best.−Nr. 9510−00027)

Sollte der Inhalt unvollständig sein oder irgend welche Defekte vorliegen, so muss dies beim

Überbringer sofort reklamiert werden. Außerdem muss die zuständige epro Verkaufsstelle

verständigt werden, um Reparatur oder Ersatz des Gerätes zu ermöglichen. Eventuell

erforderliche Reparaturen oder Kalibrierung von A6000 Monitoren sind nur im epro−Werk

möglich.

Page 23

Seite 23

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

2.2 CSA Zertifizierung

STOP

Zur gültigen CSA Zertifizierung müssen alle Geräte (IMR 6000/xx und A6000)

mit einem entsprechenden CSA Label versehen worden sein.

Für den Fall das kein CSA Label auf dem Gerät angebracht wurde ist dieses

Gerät nicht CSA zugelassen!

Das entspechende CSA Label sieht wie nachfolgend dargestellt aus.

2.3 CSA − Akzeptanzkriterien

Dieses Gerät muss mit Schutzkleinspannung SELV LPS (C22.2 60950−1) 24V betrieben

werden. Diese Betriebsspannung muss von einem seperaten Speisegerät bezogen werden.

Das System sollte in einem zweckmäßigen Feuerschutzgehäuse installiert werden.

Das System ist bewertet für einen Umgebungstemperaturbereich von 0°C bis 45°C.

Es muss angemessener Zirkulationsfreiraum vorgesehen werden damit sich keine Hitze

aufstauen kann. Der Zirkulationsfreiraum muss mindestens 1 HE (1

3/4

inch) in allen Richtungen

betragen. Für den Fall das die Umgebungstemperatur des Racks über 45°C steigt müssen die

gerätschaften mit einem festen Lüfter, einer Kühlvorrichtung etc. auf den entsprechend

zugelassenen Temperaturbereich heruntergekühlt werden.

Werden mehrere 19” Rahmen übereinander in einem Schaltschrank installiert so sollten

anstelle des Zirkulationsfreiraum entsprechende 1HE Lüftereinschübe installiert werden. Da die

notwendigen Spezifikationen derartiger Lüfter aus den Umgebungs− und Standortbedingungen

des Schaltschrankes resultieren können keine generellen Lüfterspezifikationen festgelegt

werden.

Page 24

Seite 24

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

2.4 Hinweis zur Installation

STOP

Gemäß der IEC 61010 Richtlinie müssen fest installierte Systeme mit einer

Trenneinrichtung (ggf. einem Schalter und/ oder einem Leitungsschutz−

schalter nach IEC60947−1 und IEC60947−3) zum unterbrechen der

Spannungsversorgung ausgestattet sein. Bei Verwendung eines IMR

Systems kann dies, unter Beachtung dieser Richtlinie, durch einen Schalter

oder Leistungsschalter erfolgen.

Dazu muss sich dieser in der Gebäude− bzw. Schaltschrankinstallation

befinden, in unmittelbarer Nähe zum System implementiert sein und für den

Anwender leicht zugänglich sein.

Des weiteren muss jede derartige Trenneinrichtung entsprechend dem

zugehörigen System gekennzeichnet bzw. beschriftet sein.

2.5 Installation und Montage

Für die Montage des A6151 Monitors wird ein vorbereiteter Steckplatz in einem 19“

Baugruppenträger mit 3 HE oder einem anderen Intermas−kompatiblem Gehäuse benötigt. Der

Steckplatz muss mit einem 48−poligen Steckverbinder (DIN 41612, Bauform F 48 M)

ausgestattet sein. Die Pin−Belegung ist in der nachfolgenden Tabelle aufgeführt.

d

b z

2

UN+ (+ 24V) U− (0V/Common) UB+ (+24V, redundant)

2

4

A (RS 485) GND (BP, Common, RS 485) B (RS 485)

4

6

Supply2+ (sensor) Supply1− (sensor) Supply1+ (sensor)

6

8

AIN2− (Input) Supply2− (sensor) AIN1− (Input)

8

10

AIN2+ (Input) GND AIN1+ (Input)

10

12

NGL2 (scaled dc−output) GND NGL1 (scaled dc−output)

12

14

EO1 (voltage output1) EI1 (voltage input1) AC1 (sensor raw signal1)

14

16

EO2 (voltage output2) EI2 (voltage input2) AC2 (sensor raw signal2)

16

18

GWM (limit value) I1− (current output common) I1+ (current output CH1)

18

20

NC I2− (current output common) I2+ (current output CH2)

20

22

KEY−N (key signal input) GND ES (external lock)

22

24

SC−A (oper. principle alert) GND SC−D (oper. principle danger)

24

26

D1−C (danger1 collector) A1−C (alert1 collector) CC1−C (ch. clear1 collector)

26

28

D1−E (danger1 emitter) A1−E (alert1 emitter) CC1−E (ch. clear1 emitter)

28

30

D2−C (danger2 collector) A2−C (alert2 collector) CC2−C (ch. clear2 collector)

30

32

D2−E (danger2 emitter) A2−E (alert2 emitter) CC2−E (ch. clear2 emitter)

32

Jumper für RS 485

Der Betrieb des RS 485 Busses erfordert einen elektrischen Abschluss jeweils am ersten und

letzten Gerät des Busses.

Page 25

Seite 25

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

Dies geschieht mit Steckbrücken, die sich auf dem Kontrollerboard befinden. Das Bild zeigt die

Position der Jumper.

Um den Bus−Abschluss zu aktivieren und die Leitungen “A” und “B” auf die Bezüge zu legen,

stecken Sie die Jumper wie in Bild b) gezeigt. Das Bild a) zeigt die Jumperposition für einen deaktivierten Bus−Abschluss und offene Bezüge (Auslieferungszustand).

• Steckbrücke 1−2 geschlossen: Busleitung “B” über Pull−down Widerstand an Masse

• Steckbrücke 3−4 geschlossen: 120 Ω Widerstand zwischen “A” und “B”

• Steckbrücke 5−6 geschlossen: Busleitung “A” über Pull−up Widerstand an +5 V

1

35

2

46

1

35

2

46

a)

b)

i

Für einen störungsfreien Betrieb des RS 485 Busses müssen die Leitungen

“A” und “B” in einem Monitor auf ihre Bezüge (+5 V; Masse) gelegt werden,

dies ist nur möglich wenn in diesem Monitor auch der Busabschluss−Jumper

gesetzt ist.

Sensorrohsignal

Das, an den SMB−Buchsen der Frontplatte anliegende Sensorrohsignal (ungefilterte phasenrichtige Ausgangssignal des Konverters mit AC und DC Anteil) kann mit den Jumpern J2 auf die

Klemmen z14: Kanal 1 und z16: Kanal 2 der Steckleiste umgeschaltet werden. Hierfür muss das

Kontrollerboard entfernt werden. Die folgenden Punkte beschreiben die Vorgehensweise:

i

Der Bezugspunkt für das Sensorrohsignal von Kanal 1 ist die Steckleistenklemme z6: Supply1(+) und für das Sensorrohsignal von Kanal 2 die Klemme

d6: Supply2(+). Sind diese Klemmen mit der Klemme b10 verbunden, liegt

der Bezugspunkt auf Systemmasse (GND). In diesem Fall können auch die

Klemmen b22: GND und b24: GND als Bezugspunkt verwendet werden.

STOP

Achten Sie bei Arbeiten am Monitor auf ausreichenden Schutz vor elektrostatischen Entladungen. Tragen Sie z.B. ein ESD−Armband, um elektrostatische

Entladungen über die Monitorelektronik zu verhindern.

Page 26

Seite 26

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

1. Lösen Sie mit einem Kreuzschraubendreher die vier, im folgenden Bild mit den Pfeilen

gekennzeichneten Kreuzschrauben.

2. Ziehen Sie das Kontrollerboard vorsichtig, ohne zu verkanten von dem Mainboard ab. Die

Position der Jumper J2 auf dem Mainboard sind im folgenden Bild mit einem weißen

Rahmen gekennzeichnet.

3. Um das Sensorrohsignal auf die Klemmen z14 und z16 zu schalten, stecken Sie die Jumper

wie in b) dargestellt. Sind die Jumper wie in a) gesetzt, liegt an den Klemmen z14 und z16

der dynamische Anteil des Sensorsignals.

Page 27

Seite 27

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

J2

z14:

z16:

AC1

AC2

SENS1

SENS2

J2

z14:

z16:

AC1

AC2

SENS1

SENS2

a)

b)

4. Stecken Sie das Kontrollerboard wieder auf das Mainboard und sichern Sie es mit den vier

Schrauben. Das Sensorrohsignal liegt nun auf der Steckleiste.

Monitor−Einbau

1. Überprüfen Sie vor Einbau des Monitors die Steckplatzverdrahtung.

2. Schieben Sie den A6151 Monitor in den vorbereiteten Steckplatz und drücken Sie ihn mit

leichtem Druck in den Steckverbinder.

3. Zur Sicherung des Monitors schrauben Sie die beiden Befestigungsschrauben auf der

Frontplatte leicht handfest an.

Alle weiteren Informationen, wie z. B. Schirmung und Erdung, Konfiguration des Monitors, usw.,

finden Sie in der Gebrauchsanleitung “Wellenschwingungsmonitor A6151”, Bestellnr.

6100−90001.

2.6 Technische Daten

Nur Angaben mit Toleranzen oder Grenzwerten sind verbindliche Daten. Daten ohne

Toleranzen bzw. ohne Fehlergrenzen sind informative Daten. Technische Änderungen − vor

allem der Software − bleiben vorbehalten.

Alle folgenden Angaben gelten, sofern nicht anders angeben, für Kanal 1 und Kanal 2

gleichermaßen.

2.6.1 Signalkonditionierung

Zwei separate Signaleingänge für Kanal 1 und Kanal 2 mit voneinander entkoppelter Signalkonditionierung.

Messwerteingänge

Differenzspannungsverstärkereingänge, rückwirkungsfrei, leerlauf− und kurzschlussfest.

Kanal 1 z8: AIN1 (−); z10: AIN1 (+)

Kanal 2 d8: AIN2 (−); d10: AIN2 (+)

Eingangsnennbereich −1,0 ... −22,16 V

Grenzbereich 0 ... −30 V DC

Eingangswiderstand > 100 kΩ

Page 28

Seite 28

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

Signalkonditionierung

Sensorsignalausgänge Frontbuchsen SMB und/oder z14 / z16* entkoppelt,

leerlauf− und kurzschlussfest, rückwirkungsfrei

Kanal 1 − SENS 1 SMB K1

Kanal 2 − SENS 2 SMB K2

Signalausgang −1 ... −24 V; Signal 1:1 zum Sensoreingangssignal

Genauigkeit ±1 % vom Endwert

Frequenzbereich 0.2 ... 200 Hz (−3 dB) ±20 %

Zul. Belastungswiderstand >100 kΩ

Innenwiderstand 1 kΩ

*Abhängig von der Jumperstellung J2.

Dynamische Ausgänge

Der AC−Anteil des Sensorsignal wird als normierter Wert ausgegeben.

Kanal 1 − AC1 / Kanal 2 − AC2 z14 / z16* leerlauf− und kurzschlussfest,

rückwirkungsfrei

Nennbereich 0 ... 20 V ss

Messbereich entsprechend dem für die Kenngröße konfigurierten

Messbereich, min. 400 mVss, max. 8000 mVss

Genauigkeit ±1 % vom Messbereichsendwert

Frequenzbereich 0,2 Hz ... 200 Hz (−3 dB), ±20 %

Zul. Belastungswiderstand >10 kΩ

Innenwiderstand ca. 20 Ω

*Abhängig von der Jumperstellung J2.

Normierte Gleichwertausgänge

Der DC−Anteil des Sensorsignal (proportional dem statischen Abstand

Aufnehmer / Messobjekt) wird als normierte Gleichspannung NGL ausgegeben.

Kanal 1 − NGL1 / Kanal 2 − NGL2 z12 / d12 leerlauf− und kurzschlussfest,

rückwirkungsfrei

Nennbereich 0 ... +10 V DC

Messbereich entsprechend dem konfigurierten Arbeitsbereich des

Sensors, 0 V entspricht dem unteren Wert des

Arbeitsbereichs +10 V entspricht dem oberen Wert

des Arbeitsbereichs

Genauigkeit / Auflösung ±1 % vom Messbereichsendwert / 12 Bit

Zul. Belastungswiderstand >10 kΩ

Innenwiderstand ca. 50 Ω

Page 29

Seite 29

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

Signalkonditionierung für Kenngröße

Die Eingangssignale werden vor der Digitalisierung konditioniert durch Anpassverstärker,

bereichsabhängigem Verstärker, Hochpass und Tiefpass.

Bereichseinstellung wird bei der Konfiguration bestimmt

minimaler Messbereich 400 mV ss

maximaler Messbereich 8000 mV ss

Frequenzbereich

Hochpass 2 pol. Butterworth−Charakteristik

− parametrierbar 0,2 Hz (−3 dB)

0,7 Hz (−3 dB)

− Toleranz ±20 %

Tiefpass 5 pol. Butterworth−Charakteristik

Parametrierbereich 10 Hz ... 200 Hz

in 0,01 Hz−schritten

Kenngrößenbildung abhängig von der Konfiguration

2 Kanal−Betrieb S1 und S2 getrennte Kenngrößen, wahlweise in 0−S

oder S−S−Bewertung

Maximalausschlag S

max

nach

DIN 45670 Kenngröße A

S

max

= max sk (t);

sk(t) + s

1

(t)2) s2(t)

2

Ǹ

Größere Schwingbreite S

ppm

nach

DIN 45670 Kenngr. B bzw.

Max (X,Y) nach API 670

S

ppm

= (Sss1, Sss2) Max

S

ppm

= Max (s

s−s

1 oder s

s−s

2 )

Stromausgänge−Kenngröße

Die Kenngrößenbildung und Bewertung ist abhängig von den bei der Konfiguration

bestimmten Funktionen.

Stromausgang 1 − I1+ / I1− z18 / b18 (0 V / common)

Stromausgang 2 − I2+ / I2− z20 / b20 (0 V / common)

Nennbereich 0 ... 20 mA oder 4 ... 20 mA, abhängig von der

Konfiguration

− Life zero−Betrieb im 4 ... 20 mA Betrieb kann mittels der Konfiguration

bestimmt werden, dass der Ausgang bei Erkennung

einer Störung auf 0 mA gesetzt wird.

Genauigkeit / Auflösung ±1 % vom Messbereichsendwert / 16 Bit

Zul. Belastungswiderstand 500 Ω

Page 30

Seite 30

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

Signalausgänge EO 1 / EO 2

d14 / d16

Spannungsausgang 0 ... 10V. Bei Betriebsart mit separaten Kanälen entsprechend der

Kenngröße. Bei den Betriebsarten S

max

und S

ssmax

Ausgänge der Einzelkanalmesswerte.

Messbereich und Bewertung entsprechend der Kenngröße.

Abhängig von der Applikation und Konfiguration können die Ausgänge EO zur Verknüpfung

oder zur Anzeige verwendet werden.

leerlauf− und kurzschlussfest, rückwirkungsfrei.

Nennbereich 0 ... +10 V DC

Auflösung 8 Bit

Zul. Belastungswiderstand > 10 kΩ

Innenwiderstand ca. 50 Ω

Signaleingänge EI1 / EI2

Eingänge für Einzelkanalmesswerte 0 ... +10 V zur Verknüpfung mit EO−Ausgängen.

Spannungseingang EI1 / EI2 b14 / b16

Nennspannungsbereich 0 ... +10 V DC

Auflösung 10 Bit

Eingangswiderstand >100 kΩ

Signaleingang KEY

Der Key−Impuls wird zur internen Drehzahlbestimmung zur Steuerung der Messungen bei der

Messwertanalyse benötigt.

Signaleingang KEY (N) d22

Signalpegel 24 V Logik,: LOW = 0 ... 3 V; HIGH = 13 ... 48 V

Eingangswiderstand >10 kΩ

2.6.2 Kanalüberwachung

Überwachungsfunktion ständige Überwachung

Sensorsignale GUT−Bereich (konfigurationsabhängig)

GUT−Schwellen

− unterer Schwellwert Sensor−Arbeitsbereich unterer Wert −0,5 V

− oberer Schwellwert Sensor−Arbeitsbereich oberer Wert +0,5 V

Systemspannungen Spannung − OK

Page 31

Seite 31

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

μP Funktion (watchdog) WD − OK

Konfiguration & Parametrierung K&P − OK

externes Sperrsignal ES

Status Kanalüberwachung

Kanalstatus = kein Fehler (OK) wenn ( Spannung_OK = Ja )

UND (WD_OK = Ja)

UND (K&P_OK = Ja)

UND (Sensorsignal

im GUT−Bereich)

UND (Ext. Sperren = Nein)

Kanalstatus = Fehler falls die vorherige Bedingung nicht erfüllt ist

Kanalstatus = Freigabe verzögert bei Umschaltung vom Fehlerfall in den OK−Status

oder beim Einschalten des Moduls wird eine

Freigabeverzögerung von 15 s (±2 s) aktiv

Visualisierung

Grüne LED auf der Frontplatte

Kanalstatus = kein Fehler (OK) Dauerlicht

Kanalstatus = Fehler Dunkel

Kanalstatus = Freigabe verzögert Blinklicht

Ausgänge Channel Clear

Opto−entkoppelte Kollektor/Emitter−Strecken

Channel Clear Kanal 1, C1C / C1E

z26 (Kollektor) / z28 (Emitter)

Channel Clear Kanal 2, C2C / C2E z30 (Kollektor) / z32 (Emitter)

Ext. gesperrt oder Status = Fehler

oder Freigabe verzögert

C−E gesperrt, max. zul. Spannung: 48 V

nicht ext. gesperrt und Status = OK

und nicht Freigabe verzögert

C−E leitend, max. zul. Strom: 100 mA

Eingang extern Sperren ES

z22 − zum Sperren der Grenzwertalarme; z. B. bei Wartungsarbeiten etc.

Funktion Sperren Eingang LOW = Sperren der Kanalüberwachung und

Grenzwertbildung

Freigabe Eingang HIGH oder unbeschaltet = kein Sperren der

Kanalüberwachung und Grenzwertbildung

Signalpegel LOW: 0 ... +3 V, HIGH: +13 ... +48 V

Page 32

Seite 32

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

2.6.3 Grenzwertbildung und Alarme

Zwei Alarmkanäle mit je einem Alarmausgang ALERT und DANGER und separater

Grenzwerteinstellung. Alarmierung, wenn die Kenngröße den parametrierten Grenzwert

überschreitet. (Istwert > Grenzwert)

Grenzwerteinstellung

Durch Parametrierung, abhängig von der Konfiguration für Messbetrieb, Kenngrößenbildung,

Bereich etc.

Einstellbedingung Grenzwert ALERT < Grenzwert DANGER

Einstellbereich 0 ... 100 % des parametrierten Messbereiches

Auflösung und Reproduzierbarkeit 1 % bezogen auf den Messbereichsendwert

Hysterese Konfigurierbar, 0 ... 20 % bezogen auf den Messbe-

reichsendwert

Die Hysterese ist nur bei sinkendem Istwert wirksam.

Ansprechverzögerung

konfigurierbar auf 0 (aus),1,2,3,4,5 sek.; wirksam auf die Alarmausgänge.

Alarmblockierung

Blockierung wenn (K&P aktiv = ja)

ODER

(Spannung oder watchdog nicht ok) ODER

(Ext. Sperren = sperren) ODER

(Kanalstatus = Fehler und Grenzwert−

unterdrückung = an*)

ODER

(Kanalstatus = Freigabe verzögert) UND

Kanalüberwachungseinwirkung = Ja

Keine Blockierung Wenn obige Bedingung nicht erfüllt ist

* In der Konfiguration wird festgelegt, ob die Blockierung der Alarmausgänge durch die Kanalüberwachung erfolgen soll.

Alarmvisualisierung

Durch je ein rotes LED für Kanal 1 und 2

Keine Grenzwertüberschreitung oder

Alarme blockiert

LED Aus

Voralarm (ALERT), kein Hauptalarm LED blinkt mit 2 Hz (Puls/Pause 1:1)

Hauptalarm LED hat Dauerlicht

Page 33

Seite 33

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

Alarmausgänge

Opto−entkoppelte Kollektor / Emitter−Strecken

Voralarm Kanal 1 A1−C / A1−E b26 (Kollektor) / b28 (Emitter)

Hauptalarm Kanal 1 D1−C / D1−E d26 (Kollektor) / d28 (Emitter)

Voralarm Kanal 2 A2−C / A2−E b30 (Kollektor) / b32 (Emitter)

Hauptalarm Kanal 2 D2−C / D2−E d30 (Kollektor) / d32 (Emitter)

Maximalwerte für Alarmausgänge C−E gesperrt: max. zuläss. U

CE

: 48 V

C−E leitend: max. zuläss. I

CE

: 100 mA

Alarmzustand der Alarmausgänge leitend im Arbeitsstrombetrieb, gesperrt im Ruhe-

strombetrieb

Arbeitsstrom− / Ruhestrombetrieb

Durch externe Verdrehung der Digitaleingänge SC−A und SC−D wählbar.

Umschaltung ALERT d24 − SC−A = HIGH / unbeschaltet

= Arbeitsstrom

d24 − SC−A = LOW = Ruhestrombetrieb

Umschaltung DANGER z24 − SC−D = HIGH / unbeschaltet

= Arbeitsstrom

z24 − SC−D = LOW = Ruhestrombetrieb

Schaltpegel LOW = 0 ... +3 V

HIGH = 13 ... 48 V

Eingangswiderstand > 10 kΩ

2.6.4 Kommunikationsschnittstellen

Schnittstelle RS 232

Frontbuchse zum Anschluss eines Laptops / Rechners zwecks Konfiguration und

Visualisierung

Rundsteckverbinder auf Frontseite Mini−DIN−Buchse Typ TM 0508A/6 für Parametrier-

kabel (im Operating Kit enthalten)

Schnittstelle RS 485

d4, z4 Busschnittstelle für Kommunikation mit z. B. einer Interfacekarte MMS 68xx und der

Konfigurationssoftware.

Page 34

Seite 34

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

2.6.5 Spannungsversorgung

Die Monitorsystemspannungen und somit auch die 0 V / common−Anschlüsse für die Mess−

und Überwachungsein− und −ausgänge sind voneinander galvanisch getrennt.

Versorgungsspannungseingänge zwei redundante, diodenentkoppelte Eingänge für

nominal +24 V mit gemeinsamen 0 V Bezug

Spannungseingang UB+ / UN+ d2 / z2

Gemeinsamer Bezug, 0 V U− b2

Zul. Spannungsbereich 19 ... 31,2 Vdc (IEC 654−2 Klasse DC 4)

CSA: 24Vdc; SELV LPS

Leistungsaufnahme max. 6 W, bei 24 V max. 250 mA

Monitorsystemspannung

Die für die interne Versorgung benötigten Monitor−Systemspannungen werden ständig auf

Unterspannung überwacht. Bei Erkennung einer Unterspannung wird eine Fehlermeldung

generiert.

Sensorspeisung

Für beide Kanäle des Monitors

Trennung entkoppelt und zu den übrigen Systemspannungen

und zur Versorgungsspannung galvanisch getrennt,

mit anderen Monitoren parallel rückwirkungsfrei

betreibbar,

leerlauf− und kurzschlussfest.

Sensorspeisung Kanal 1 Supply1(−) / Supply1(+) b6/z6

Sensorspeisung Kanal 2 Supply2(−) / Supply2(+) b8/d6

Speisespannung 26,75 V DC; Toleranz ±2 %

Restwelligkeit < 20 mVss (bei Nennstrom 20 mA)

max. Strom 35 mA

max. Kurzschlussstrom 0 mA ≤ I kurzschl. ≤ 5 mA;

leerlauf− und kurzschlussfest

Page 35

Seite 35

Product Information / Produktinformation

A6151

Wellenschwingungsmonitor

2.6.6 Umgebungsbedingungen

Anwendungsklasse KTF nach DIN 40040

Umgebungstemperatur

Bezugstemperatur +25°C

Nenngebrauchsbereich 0...+45°C (CSA

Anforderung und empfohlener Bereich)

max. Bereich −10°C ... +65°C (nicht CSA konform)

Lagerungs−, Transporttemperatur −30 ... +85°C

Betriebshöhe bis zu 2000m über NN

Relative Feuchte

≤ 95 % ohne Betauung

Schwingung nach IEC−68 − 2 Teil 6

Weg 0,15 mm bei 10 ... 55 Hz

Beschleunigung 19,6 mm/s

2

bei 55 ... 150 Hz

Schock nach IEC−68 − 2 Teil 29

Beschleunigungsspitzenwert 98 m/s

2

Nominelle Schockdauer 16 ms

Gehäuseschutzart IP 00, offene Bauweise nach DIN 40050

EMV−Festigkeit nach EN 50 081−1 / EN 50 082−2 erfüllt

Zulässiger Verschmutzungsgrad Kategorie 2 (nach IEC 61010−1)

Betriebsumgebung Gebrauch ausschließlich in geschlossenen Räumen

2.6.7 Mechanischer Aufbau

Leiterplatte Euro−Format (100 mm x 160 mm) nach DIN 41494

Breite 6 TE (ca. 30 mm)

Steckverbinder DIN 41612, Bauform F 48 M

Frontelemente

2 LEDs Grün Channel Clear Kanal 1 / 2

2 LEDs Rot Alarme Kanal 1 / 2

2 SMB Steckbuchse für Sensorsignal Kanal 1 / 2

1 Mini−DIN Rundsteckbuchse für RS 232 zum Anschluss eines Laptops / Rechners

(zwecks Konfiguration und Parametrierung)

Gewicht ca. 320 g (ohne Verpackung)

ca. 450 g mit Standardverpackung

Page 36

Page/Seite 36

Product Information / Produktinformation

A6151

Connection Diagrams and Figures / Anschlusspläne und Abbildungen

3 CONNECTION DIAGRAMS AND FIGURES /

ANSCHLUSSPLÄNE UND ABBILDUNGEN

Supply1+

Supply1−

Supply2+

Supply2−

AIN1+

AIN1−

AIN2−

AIN2+

GND

UN+

U−

UB+

ES

GWM

don‘t use

SC−A

AC1

signal 1

sensor raw

SC−D

GND

GND

KEY

signal 2

sensor raw

EI2

EI1

EO2

EO1

AC2

RS485−B

A2−C

RS485−A

CC1−C

CC1−E

CC2−C

CC2−E

D1−C

D1−E

A1−E

A1−C

D2−C

D2−E

A2−E

RS232

I1+

GND

GND

GND

front socket

I1−

I2+

I2−

NGL1

NGL2

b24

Block diagram / Blockschaltbild A6151

Page 37

Page/Seite 37

Product Information / Produktinformation

A6151

Connection Diagrams and Figures / Anschlusspläne und Abbildungen

AIN1−

AIN1+

Supply1−

Supply1+

AIN2−

AIN2+

Supply2−

Supply2+

GND

GND

Alert1

Danger1

Alert2

Danger2

Channel

Clear1

Channel

Clear2

EI1

EI2

FX

ES

KEY (N)

UN+

U−

UB+

A

B

BP

NGL1

GND

NGL2

EO1

EO2

AC1

GND

AC2

I1+

SC−D

SC−A

I2−

I2+

I1−

AC−C

A1−E

D1−C

D1−E

A2−C

A2−E

D2−C

D2−E

C1−C

C1−E

C2−D

C2−E

Shaft vibration

Monitor

A6151

OUT

−24V

CON0xx

PR642x

OUT

−24V

CON0xx

PR642x

measuring

ground

protective

ground

0 ... +10V

protective ground

to

Cabinet

Field

Factor x

Alarm stop

ext. lock

KEY

0 ... +10V

b14

b18

z22

d18

d22

z8

z10

z6

b6

d10

d6

b8

b22

b10

d8

d4

z4

b4

z12

b12

d12

d14

d16

z14

b24

z16

z18

b18

z20

b20

d24

z24

b26

b28

d26

d28

b30

b32

d30

d32

z26

z28

z30

z32

RS485 BUS

nominal dc output channel 1

voltage output CH1

voltage output CH2

sensor raw signal CH1 (Jumper J2)

sensor raw signal CH2 (Jumper J2)

current output CH1

current output CH2

alert:

danger:

0 ... +10V

0 ... +10V

0 ... +10V

0 ... +10V

0/4 ... +20mA

0/4 ... +20mA

0V 0V

−24V /1

0V (24V)

−24V /2

b2

z2

d2

nominal dc output channel 2

closed−/ open circuit current

closed−/ open circuit current

Connection diagram / Anschlussdiagramm

Page 38

Page/Seite 38

Product Information / Produktinformation

A6151

Connection Diagrams and Figures / Anschlusspläne und Abbildungen

2

6

4

8

10

12

14

16

18

20

22

24

26

28

30

32

2

6

4

8

10

12

14

16

18

20

22

24

26

28

30

32

db z

d

b

UB+ (+24V)

U− (0V/Common)

UN+ (+24V, redundant)

Supply2+ (sensor)

Supply1− (sensor)

Supply1+ (sensor)

AIN2− (input)

Supply2− (sensor)

AIN1− (input)

AIN2+ (input)

C Screen / Common

AIN1+ (input)

A (RS485) Common

B (RS485)

NGL2 (scaled dc output) GND Common

NGL1 (scaled dc output)

EO1 (voltage output1)

EI1 (voltage input1)

AC1 (sensor raw signal)*

EO2 (voltage output2) EL2 (voltage input2)

AC2 (sensor raw signal)*

GWM (limit value) I1−(current output common)

I1+ (current output CH1)

NC I2−(current output common)

I2+ (current output CH2)

KEY (N) (key signal input)

GND ES (external lock)

SC−A (oper. principle alert)

GND

SC−D (oper.principle danger)

D1−C (danger1 collector)

D2−C (danger2 collector)

A1−C (alert collector)

A2−C (alert2 collector)

C1−C (chan. clear1 collector)

C2−C (chan.clear2 collector)

D1−E (danger1 emitter)

D2−E (danger2 emitter)

A1−E (alert1 emitter)

A2−E (alert2 emitter)

C1−E (chan.clear1 emitter)

C2−E (chan.clear2 emitter)

z

*Only if Jumper J2 is closed. / Nur wenn Jumper J2 gesetzt ist.

Pin allocation / Steckerbelegung

Page 39

Page/Seite 39

Product Information / Produktinformation

A6151

Connection Diagrams and Figures / Anschlusspläne und Abbildungen

All dimensions in mm

Alle Abmessungen in mm

30.1

6 TE/HP

128.4

3 HE/RU

2.5

17

173.5

1

0

0

160

27

2.5

Dimensions A6151

Abmessungen A6151

Page 40

Page/Seite 40

Product Information / Produktinformation

A6151

PI Revision List

4 PI REVISION LIST

Version Date Changes Chapter

1.000 15.08.2011 Initial Version

1.001 21.09.2011 Translation corrections all

1.002 26.02.2013 Change of service address Europe

Page 41

EG-Konformitätserklärung

EC-Declaration of Conformity

Wir (We): epro GmbH, Jöbkesweg 3, 48599 Gronau

erklären in alleiniger Verantwortung, dass das Produkt:

declare under the exclusive liability that the product:

Produktbezeichnung (Product designation): System A6000

Produktbeschreibung (Product description): Modul zur Auswertung von dynamischen und

statischen Messwerten.

Module for evaluation of dynamic and static

measuring values

Artikelnummer (Product codes): 9199−00XXX

CEKennzeichnung entsprechend der EU− Richtlinie/ CE identification corresponds to EU directive:

98/336 / EWG (EMV) geändert/ modified 97/236 ; EWG 92/31 / EWG; 93/68 / EWG.

auf das sich diese Erklärung bezieht, mit der/den folgenden Norm(en) oder normativen Dokumenten übereinstimmt:

which is subject of this declaration, is in conformity with the following standards or normative

documents:

Bestimmungen der Richtlinie

Terms of the directive

Titel und/oder Nr.

Title and/or no.

Fachgrundnor m Störaussendung, Industriebereich

Engineering standard interference emission, industrial

applications

Fachgrundnorm Störfestigkeit, Industriebereich

Engineering standard interference immunity, industrial

applications

DIN EN 55011 + A1 + A2

DIN EN 61326 + A1 + A2 + A3

einschliesslich / including:

DIN EN 61000−4−2 + A1 + A2

DIN EN 61000−4−3 + A1

DIN EN 61000−4−4

DIN EN 61000−4−5 + A1

DIN EN 61000−4−6 + A1

Wir weisen darauf hin, dass

die Konformität und damit die Betriebserlaubnis erlischt, wenn dieses Erzeugnis ohne unsere

ausdrückliche Genehmigung geändert wird.

Nicht−Fachleute die Gegebenheiten des Einsatzgebietes und die daraus resultierenden

Anforderungen vor der Inbetriebnahme prüfen lassen sollen.

We point out that

the conformity and thus the approval for the operation lapses, if the product is modified without our

explicit permission (without consultation with us).

Non specialists should let check the conditions of the operational area and the requirements

resulting thereof before installation.

Gronau, 04.05.2011

Ort und Datum Geschäftsbereichsleiter Leiter Qualitätsmanagement

Place and date Divisional director Head of quality management

Certif_MMS_06_Rev_02

Loading...

Loading...