Page 1

Table of Contents

Introduction ..................................... 1

Specications ...................................2

Principle of Operation .............................9

Installation and Overpressure Protection ..............9

Startup ........................................ 13

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance and Inspection .......................14

Parts Ordering .................................. 15

Parts List ......................................16

Introduction

Scope of the Manual

This Instruction Manual provides installation and

maintenance instructions and parts list information for

CSB700 Series regulators. Instructions and parts lists for

other equipment mentioned in this instruction manual are

found in separate manuals.

Figure 1. CSB700 Series Pressure Reducing Regulators

P2142

P2138 P2155

P2222

TYPE CSB700 REGULATOR

TYPE CSB750 HIGH PRESSURE

REGULATOR

TYPE CSB704 WITH

TYPE VSX8 SLAM-SHUT REGULATOR

TYPE CSB754 HIGH PRESSURE WITH

TYPE VSX8 SLAM-SHUT

CSB700 Series

Instruction Manual

D103483X012

October 2018

CSB700 Series Commercial / Industrial

Pressure Reducing Regulators

Page 2

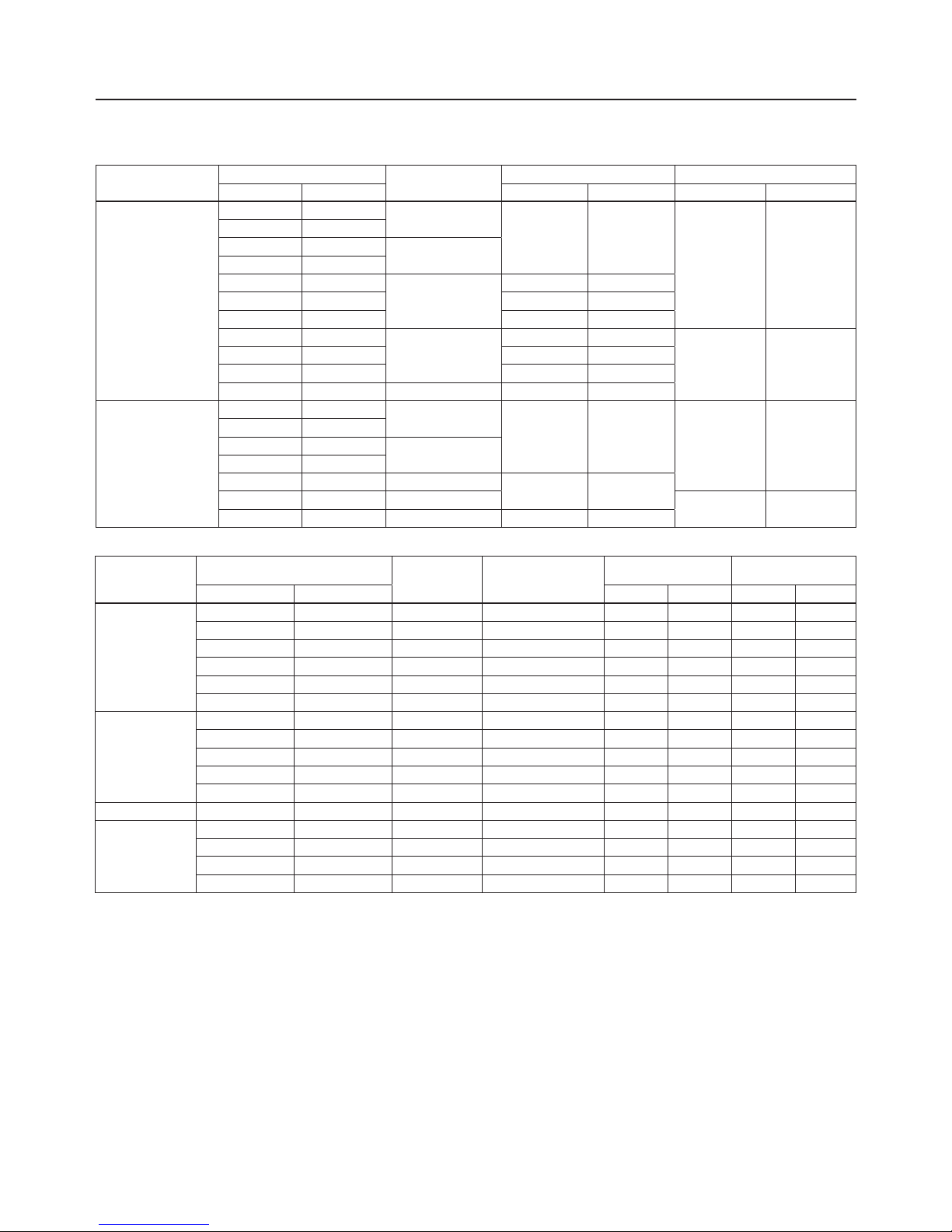

Specifications

The Specifications section lists the specifications for the CSB700 Series regulators. The following information is stamped on

the nameplate of CSB700 Series: Type and Class, Maximum Outlet Pressure and Spring Range.

Available Configurations

See Table 1

Regulator Type

Differential Strength (DS)

Accuracy Class

Up to AC5 (depending on Outlet Pressure)

Lockup Class

Up to SG10 (depending on Outlet Pressure)

Failure Mode per EN334

Fail Open (FO)

Integral Strength (IS) Pressure Ratings

(1)

See Table 4

Differential Strength (DS) Pressure Ratings

(1)

See Table 5

Body Sizes, Materials, End Connections and

Pressure Ratings

(1)

See Table 6

Operating Pressure Range

(1)

Regulator: See Table 7

Slam-Shut Module:

See Tables 8a, 8b, 8c and 8d

Maximum Outlet Pressure

(1)

Emergency Casing:

Type CSB700/CSB700F/CSB720/CSB720F:

4.0 bar / 58.0 psig

Type CSB750: 5.0 bar / 72.5 psig

To Avoid Internal Metallic Parts Damage:

Type CSB700/CSB700F/CSB720/CSB720F:

0.34 bar / 5.0 psig over set pressure

Type CSB750: 1.5 bar / 21.8 psig — not to exceed

maximum emergency outlet

Operating Casing:

Type CSB700/CSB720: 1.1 bar / 16 psig

Type CSB750: 5.0 bar / 72.5 psig

Outlet Pressure Ranges

(1)

9.0 mbar to 4.0 bar / 0.13 to 58.0 psig

See Table 7

Orifice Size:

35 mm / 1-3/8 in.

Flow and IEC Sizing Coefficients:

See Table 5

Pressure Registration

External

Temperature Capabilities

(1)(2)(3)

According to PED Standards:

-20 to 66°C / -4 to 151°F

Non-PED:

-30 to 66°C / -22 to 151°F

Spring Case Vent Connection

1 NPT: Types CSB700 and CSB720

1/2 NPT: Type CSB750

Type VSX8 Slam-Shut Device Maximum Inlet

Pressure (P

umax

)

(1)

:

Differential Strength (DS): 16 bar / 232 psig

Integal Strength (IS): 6.0 bar / 87 psig

Approximate Weights

with Threaded body

Type CSB700/CSB720: 13 kg / 29 lbs

Type CSB750: 14 kg / 31 lbs

Type CSB704/CSB724: 14 kg / 31 lbs

Type CSB754: 15 kg / 33 lbs

with Flanged body

Add 5.2 kg / 11 lbs to weights listed

Designed, Tested and Evaluated Consistent With:

ANSI B16, ASME BPVC Sec. VIII Div. I, ASTM B117

(Corrosion Resistance), EN334 and EN14382

PED Conformity Statement and Information

The CSB700 Product Series is in conformity with the

Pressure Equipment Directive PED 2014/68/EU. Pressure

regulator does not require any supplementary upstream

safety accessory for protection against overpressure

compared with its design pressure PS, when upstream

reducing station is sized for a max downstream incidental

MIPd <= 1.1 PS.

PED Related Information

See Table 2

1. The pressure/temperature limits in this Instruction Manual or any applicable standard limitation should not be exceeded.

2. Standard token relief set values listed in Tables 8a, 8b, 8c and 8d are based on -20 to 60°C / -4 to 140°F.

3. Product has passed Emerson Process Management Regulator Technologies, Inc. (Emerson) testing for lockup, relief start-to-discharge and reseal down to -40°.

CSB700 Series

2

Page 3

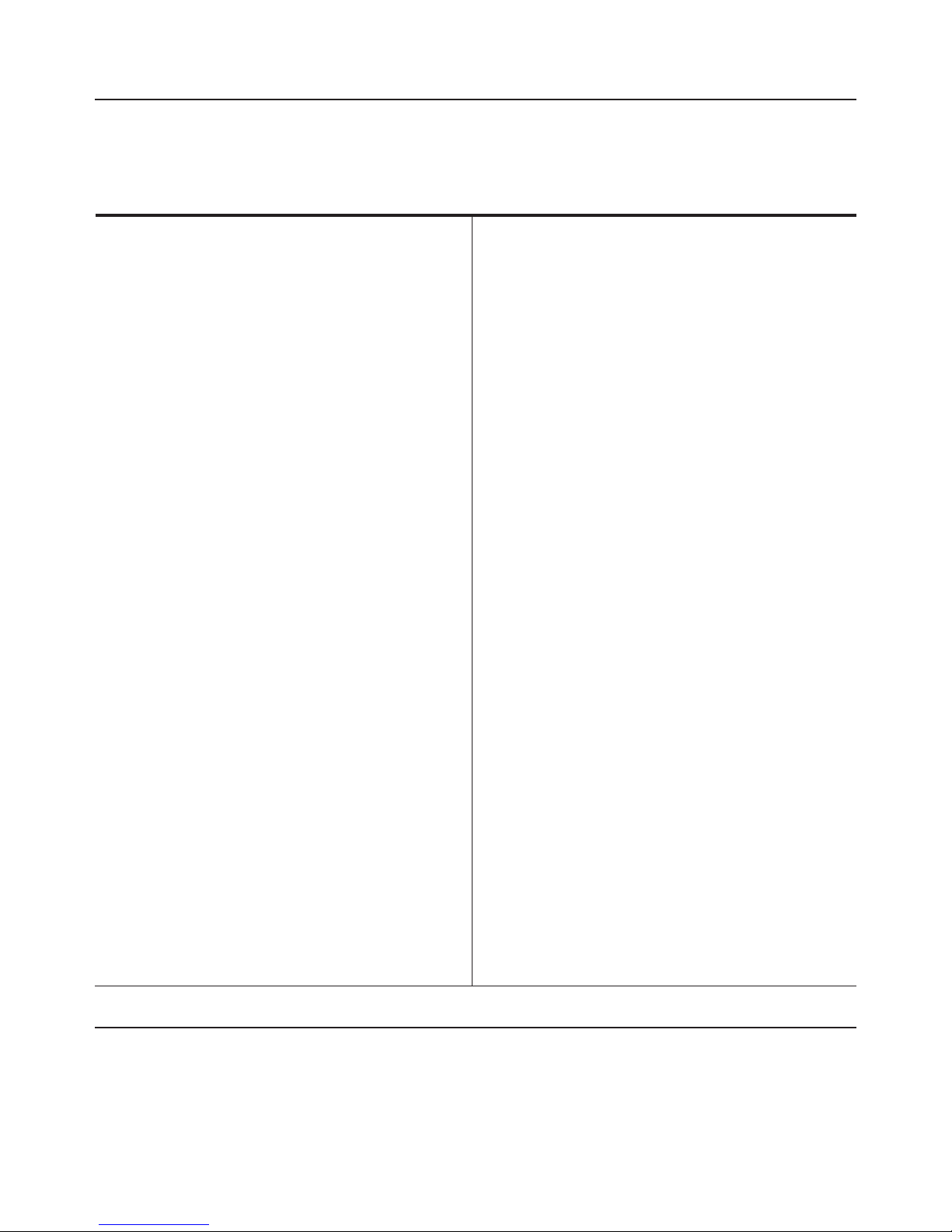

Table 2. PED Information

TYPE DESCRIPTION PED CATEGORY FLUID GROUP

CSB700, CSB700F, CSB720,

CSB720F and CSB750

Base regulator I

Groups 1 and 2 according to PED 2014/68/EU,

1st and 2nd family gas according to EN437 or

other gases (compressed air, nitrogen). The gas

must be non-corrosive, clean (ltration on inlet

side necessary) and dry.

CSB704, CSB704F, CSB724,

CSB724F and CSB754

Regulator with Slam-shut Module IV

European EN Reference Standards EN334, EN14382

Table 1. Available Congurations

TYPE NUMBER

OPTION

C S B 7

PRESSURE CONSTRUCTION

0 Low Pressure Applications (Outlet Pressure: 9.0 to 110 mbar / 3.6 in. w.c. to 1.6 psig)

(2)

2 Medium Pressure Applications (Outlet Pressure: 61 to 780 mbar / 0.9 to 11.3 psig)

(2)

5 High Pressure Applications (Outlet Pressure: 0.70 to 4.0 bar / 10.2 to 58.0 psig)

(2)

OVERPRESSURE PROTECTION

0 Without Overpressure Protection Module

0F Without Overpressure Protection Module (Outlet Pressure: 9.0 to 110 mbar / 3.6 in. w.c. to 1.6 psig and 270 to 325 mbar / 3.9 to 4.7 psig only)

(2)

4 With Type VSX8 Slam-shut Module

(1)

4F With Type VSX8 Slam-shut Module

(1)

(Outlet Pressure: 9.0 to 110 mbar / 3.6 in. w.c. to 1.6 psig and 270 to 325 mbar / 3.9 to 4.7 psig only)

(2

PRESSURE REGISTRATION

E External

RELIEF

N None

T Token Internal Relief

(3)

Example: Type number CSB724ET: Type CSB700 regulator constructed for medium pressure applications, with Type VSX8 Slam-shut Module, with

External pressure registration and with Token relief.

1. Reference Instruction Manual D103127X012 for information regarding the Type VSX8 Slam-shut Module.

2. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

3. Token relief not available for outlet pressure above 500 mbar / 8 psig.

.

!

WARNING

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or fire

causing property damage and personal

injury or death.

Fisher™ regulators must be installed, operated

and maintained in accordance with federal,

state and local codes, rules and regulations

and Emerson instructions.

If the regulator vents gas or a leak develops

in the system, service to the unit may be

required. Failure to correct trouble could

result in a hazardous condition.

Call a gas service person to service the

unit. Only a qualified person must install or

service the regulator.

Table 3. Directive ATEX Information

TYPE CLASSIFICATION ATEX ASSEMBLIES ATEX LABELLING

CSB704, CSB704F,CSB724,

CSB724F, CSB754 version

with VSX8

Non-electrical equipment Not falling under the ATEX Directive 2014/34/EU No

CSB704, CSB704F, CSB724,

CSB724F and CSB754

with limit switch

Non-electric equipment equipped with an

electrical device falling under the scope of the

ATEX Directive 2014/34/EU

Constitutes an assembly according to the

ATEX Directive 2014/34/EU

2 G T

CSB700 Series

3

Page 4

Table 4. Integral Strength (IS) Pressure Ratings

(1)

TYPE

MAXIMUM ALLOWABLE PRESSURE /

MAXIMUM EMERGENCY INLET PRESSURE

MAXIMUM OPERATING INLET PRESSURE

(2)

P

S

P

UMAX

bar psig bar psig

CSB700 and CSB704

4.0 58.0 4.0 58.0

CSB700F and CSB704F

CSB720 and CSB724

CSB720F and CSB724F

CSB750 and CSB754 5.0 72.5 5.0 72.5

1. Applicable only to applications where the inlet rating cannot exceed the outlet rating.

2. For the Integral Strength (IS version), the maximum value of P

s

and P

umax

should be similar to the PSD used for the Dierential Strength (DS) version.

Table 5. Dierential Strength (DS) Pressure Ratings and Flow and Sizing Coecients

TYPE

SPECIFIC MAXIMUM

ALLOWABLE PRESSURE /

MAXIMUM EMERGENCY

OUTLET PRESSURE

(1)

MAXIMUM ALLOWABLE PRESSURE /

MAXIMUM EMERGENCY INLET

PRESSURE

(1)

MAXIMUM

OPERATING INLET

PRESSURE

(1)

ORIFICE SIZE

WIDE-OPEN FLOW

COEFFICIENT

IEC SIZING

COEFFICIENT

P

SD

P

S

P

UMAX

bar psig bar psig bar psig mm In. C

g

C

v

C1XTFDF

L

CSB700 and

CSB704

4.0 58.0

12.0 174

10 145

35 1-3/8 1080 27.7 39 0.96 0.89 0.66

CSB700F and

CSB704F

6 87

CSB720F and

CSB724F

CSB720 and

CSB724

20.0 290 16 232

CSB750 and

CSB754

5.0 72.5 20.0 290 16 232

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

PATENT

PENDING

TS

REGULATOR SLAMSHUT SERIAL NO.

TEMP CLASS DOM

PS FLUID GROUP C AT LOC

Std: EN334

TYPE PSD

Pumax Pmax

Matl

Wds

Case

Failure Mode

REGULATOR

DN SEAT BODY

PN MATL

0062

PED mfg: Chartres,

France

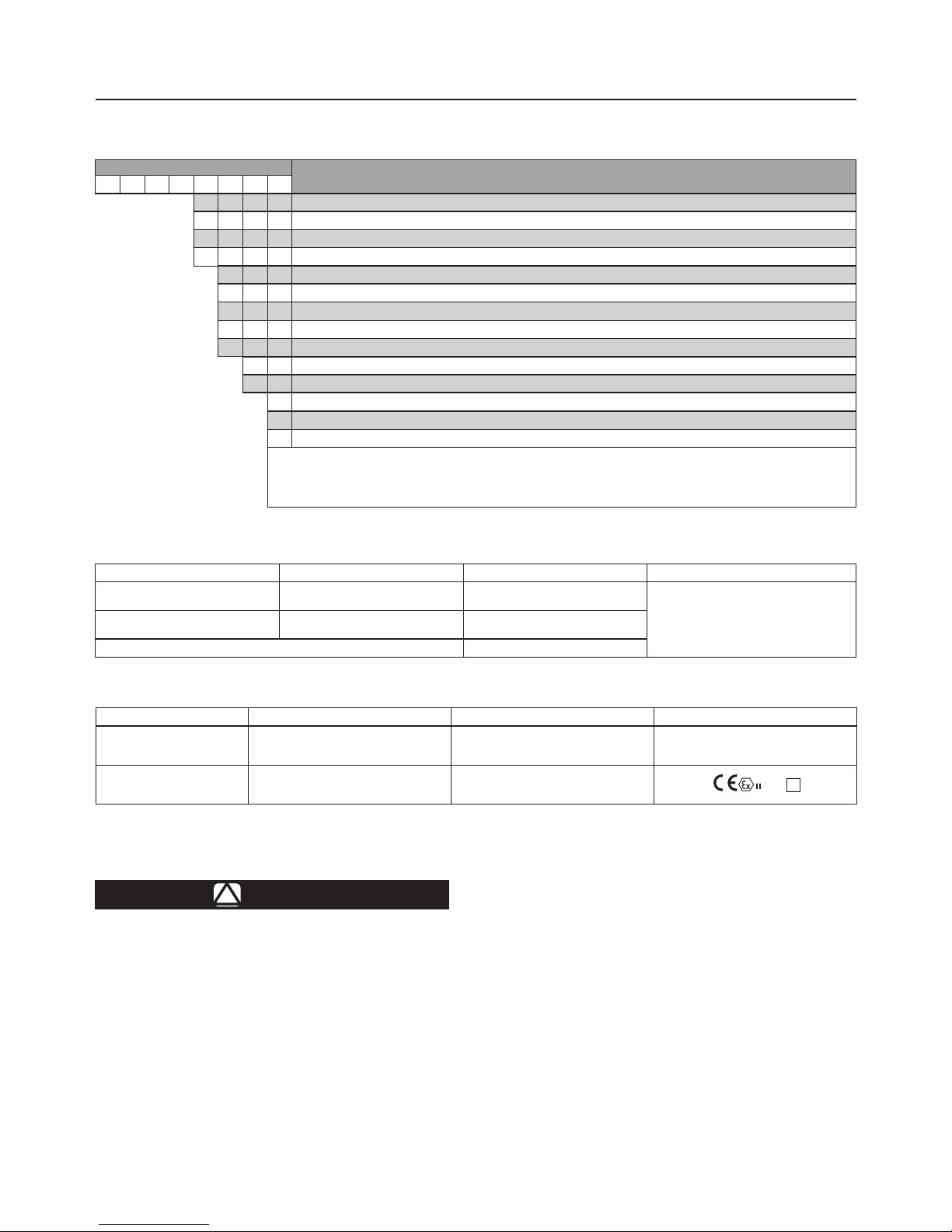

Figure 2. CSB700 Series Regulator and Slam-shut Nameplates and Labels

REGULATOR NAMEPLATES

SLAM-SHUT NAMEPLATE NAMEPLATE FOR EXPLOSIVE ATMOSPHERE IF ATEX ASSEMBLED

Std: EN14382

SLAM-SHUT

PED mfg: Gallardon,

France

Pumax

Max IN

CLASS

TYPE

VSX8L VSX8H

VSX4L VSX4H

RELAIS

RELAY

Pdmax

Max OUT

MATL

CASE

Wdso

OP range

Alum

Pressure range following

service condition

IS 6 bar

DS 16 bar

LP 1.5 bar

HP 5.5 bar

PSD

Wdsu

UP range

A Min, Min and

Max installation

B Max installation

only

VSX8L VSX8H

IS 6.0 bar

DS 16.0 bar

LP 1.5 bar

HP 5.5 bar

IS PS 6.0 bar P

umax

6.0 bar PSD 6.0 bar

DS PS 20.0 bar P

umax

16.0 bar PSD 6.0 bar

Pressure range following

service condition

A Min, Min and

Max installation

B Max installation

only

No de Série

SERIAL No.

TYPE

FRANCEL SAS

Chartres FRANCE

An

YEAR

Utilisation

INTENDED USE

2 G T

CSB700 Series

4

Page 5

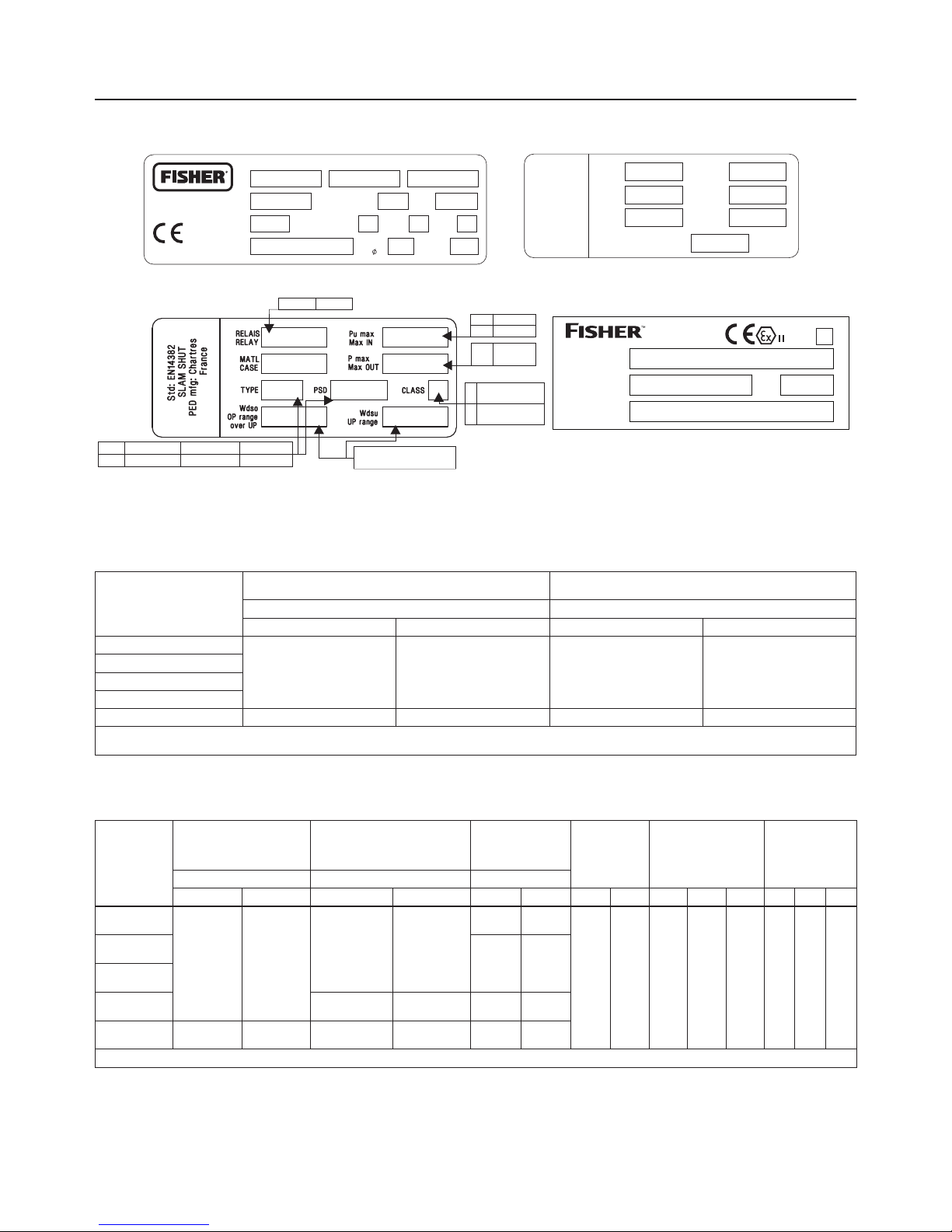

Table 6. Body Sizes, Material, End Connections and Cold Working Pressure Ratings

BODY MATERIAL

BODY SIZE

END CONNECTION

FACE-TO-FACE DIMENSION BODY PRESSURE RATING

DN NPS mm In. bar psig

Ductile Iron

40 1-1/2

NPT

155 6.10

17.2 250

50 2

40 1-1/2

Rp

50 2

50 2

CL125 FF/CL150 FF

191 7.52

50 2 254 10.0

50 2 267 10.5

50 2

PN 10/16

191 7.52

16.0 232

50 2 200 7.87

50 2 254 10.0

40 1-1/2 PN 16 Slip-On 222 8.74

WCC Steel

40 1-1/2

NPT

155 6.10

20.0 290

50 2

40 1-1/2

Rp

50 2

50 2 CL150 RF

254 20.0

50 2 PN 10/16

16.0 232

50 2 PN 10/16 191 7.52

Table 7. CSB700 Series Primary Regulator Outlet Pressure Ranges

TYPE

OPERATING PRESSURE RANGES, W

d

PART NUMBER

SPRING

COLOR

SPRING WIRE

DIAMETER

SPRING FREE LENGTH

mbar psig mm In. mm In.

CSB700, CSB704,

CSB700F and CSB704F

9 to 14 3.6 to 5.6 in.w.c. GE30336X012 Silver 3.00 0.118 224 8.82

13 to 24 5.2 to 9.6 in.w.c. ERSA01138A0 Red 3.50 0.138 264 10.4

22 to 39 8.8 to 15.7 in.w.c. GE30338X012 Black Stripe 4.32 0.170 172 6.78

32 to 50 12.8 to 20.1 in.w.c. GE30339X012 Purple 4.34 0.171 187 7.35

42 to 70 16.9 to 28.1 in.w.c. GE30340X012 White Stripe 4.62 0.182 188 7.40

61 to 110 0.9 to 1.6 ERSA03656A0 Dark Green 4.88 0.192 224 8.82

CSB720 and CSB724

61 to 110 0.9 to 1.6 ERSA03656A0 Dark Green 4.88 0.192 224 8.82

105 to 220 1.5 to 3.2 ERSA03657A0 Blue 5.94 0.234 217 8.53

210 to 380 3.1 to 5.5 GG06247X012 Black 8.00 0.315 206 8.13

320 to 570 4.6 to 8.3 ERSA01582A0 Red with White Stripe 8.71 0.343 177 6.97

510 to 780 7.4 to 11.3 ERSA05055A0 Blue with White Stripe 10 0.394 181 7.13

CSB720F and CSB724F 270 to 325 3.9 to 4.7 ERAA11747A0 Black with White Stripe 6.5 0.256 235 9.25

CSB750 and CSB754

0.7 to 1.19 bar 10.2 to 17.3 GE30345X012 Purple Stripe 9.00 0.354 225 8.87

1.05 to 2.7 bar 15.2 to 39.2 GE30346X012 Brown 11.0 0.433 226 8.88

2.3 to 3.25 bar 33.4 to 47.1 ERSA01125A0 Grey with Red Stripe 12.6 0.496 225 8.87

3.1 to 4 bar 45 to 58 ERSA01126A0 Grey with Orange Stripe 13.7 0.539 226 8.89

Description

CSB700 Series regulators are typically installed on industrial

and commercial applications. See Table 1 for Available

Configurations. Types under CSB700 Series are utilized

for high capacities. Low, Medium and High outlet pressure

constructions are available via Types CSB700, CSB720 and

CSB750 respectively, that provide outlet setpoints ranging

from 9.0 mbar to 4.0 bar / 0.13 to 58.0 psig.

The Types CSB704, CSB724 and CSB754 are examples of

CSB700 Series configurations that offer a slam-shut module

that shuts off the flow of gas to the downstream system in

the event of outlet pressure rising above or falling below the

predefined levels due to a failure.

Optional token relief is available, which acts as a low

capacity internal relief valve to relieve minor overpressure

situations due to nicks or other minor damage to the

orifice or disk or due to thermal expansion of the

downstream system.

External outlet pressure registration requires an external

control line/sense line.

CSB700 Series

5

Page 6

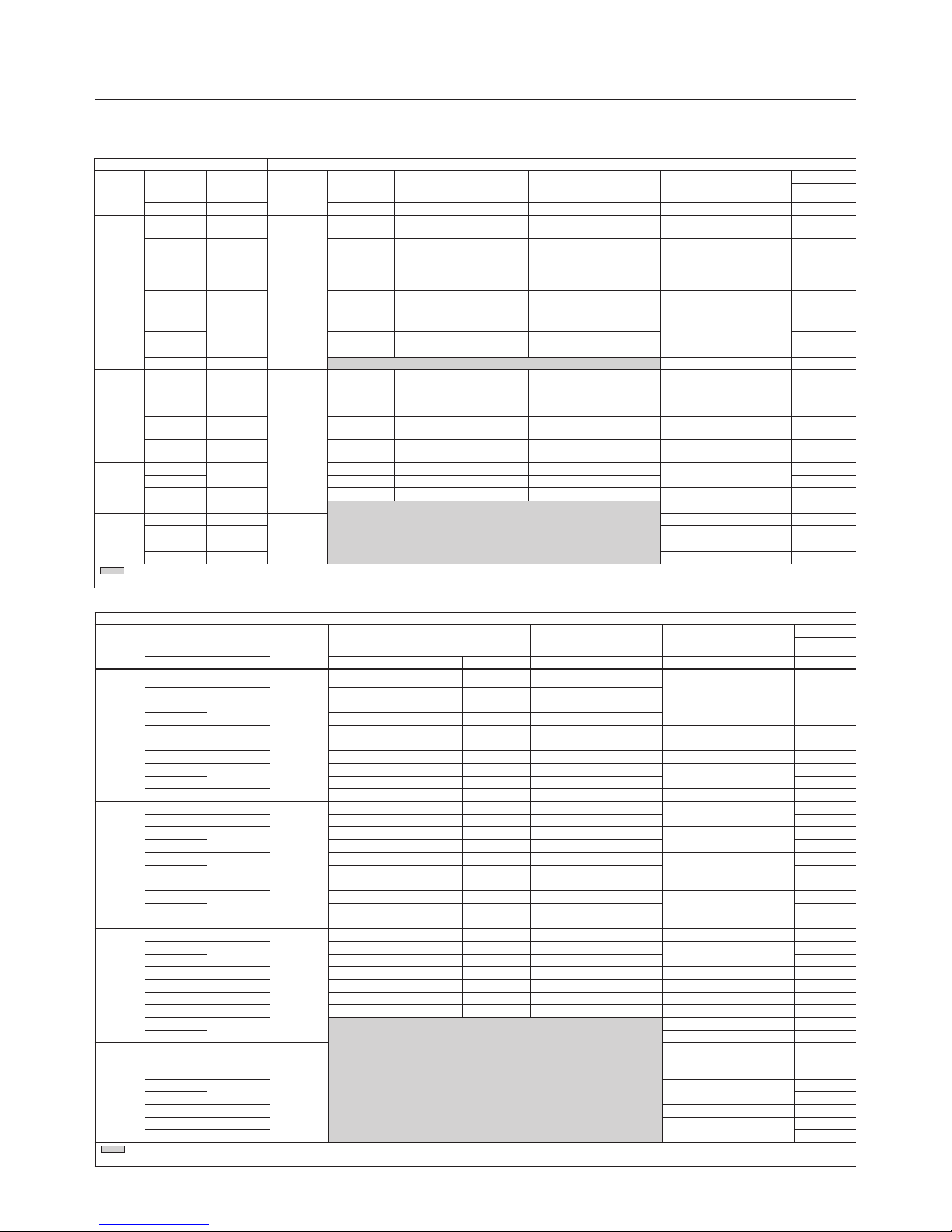

Table 8b. European Overpressure Shut-o OPSO Only Ranges

REGULATOR SLAM SHUT DEVICE

Type

Typical

Setpoint

Spring

Range

Type

(Maximum

Operating

Inlet)

Token

Relief Set

Relief Range Shown as a %

of Regulator Setpoint

Required Difference Between

Token Relief and OPSO

Over Pressure Shut-off

(OPSO) Set Range

Factory Set

OPSO

mbar mbar mbar min max mbar mbar mbar

CSB704F

10 9 to 14

VSX8L

(8.6 bar)

17 170 215 8

30 to 60 32

15 13 to 24 26 170 215 6

20

13 to 24

34 170 215 6

30 to 60 40

21 36 170 215 4

27

22 to 39

41 150 160 5

30 to 60

46

30 45 150 160 10 60

35 22 to 39 53 150 160 10 40 to 110 70

50

42 to 70

70 140 158 16

60 to 193

90

60 84 140 158 16 105

75 61 to 110 98 130 140 20 60 to 193 130

CSB704

10 9 to 14

VSX8L

(16 bar)

17 170 215 8

30 to 60

40

15 13 to 24 26 170 215 10 50

20

13 to 24

34 170 215 10

30 to 60

55

21 36 170 215 10 55

27

22 to 39

41 150 160 10

30 to 60

55

30 45 150 160 10 60

35 22 to 39 53 150 160 10 40 to 110 70

50

42 to 70

70 140 158 16

60 to 193

90

60 84 140 158 16 105

75 61 to 110 98 130 140 20 60 to 193 130

CSB724

100 61 to 110

VSX8L

(16 bar)

130 130 140 20 60 to 193 170

120

105 to 220

156 130 140 40

95 to 280

205

150 195 130 140 40 250

160 105 to 220 208 130 140 40 95 to 280 265

200 105 to 220 250 125 140 50 138 to 500 330

300 210 to 380 375 125 140 50 138 to 500 450

500 320 to 570 625 125 140 60 221 to 760 700

600

510 to 780

400 to 915

(1)

840

750 400 to 1100

(1)

1050

CSB724F 300 270 to 325

VSX8L

(8.6 bar)

138 to 500 450

CSB754

1000 700 to 1190

VSX8H

(16 bar)

400 to 1450 1320

1200

1050 to 2700 900 to 3000

1600

1500 1900

2000 1050 to 2700 1600 to 4000

(1)

2400

3000 2300 to 3250

1600 to 5000

(1)

3400

4000 3100 to 4000 4400

- Gray areas indicate that token relief is not available above 500 mbar setpoint.

1. Max OPSO setpoint truncated to reect maximum outlet pressure for spring range.

Table 8a. North American Overpressure Shut-o OPSO Only Ranges

REGULATOR SLAM SHUT DEVICE

Type

Typical

Setpoint

Spring

Range

Type

(Maximum

Operating

Inlet)

Token

Relief Set

Relief Range Shown as a %

of Regulator Setpoint

Required Difference Between

Token Relief and OPSO

Over Pressure Shut-off

(OPSO) Set Range

Factory Set

OPSO

psig psig psig min max psig psig psig

CSB704F

7 in. w.c.

5.2 to

9.6 in. w.c.

VSX8L

(125 psi)

12 in. w.c. 170 215 3.2 in. w.c. 12 to 24 in. w.c. 22 in. w.c.

11 in. w.c.

8.8 to

15.7 in. w.c.

17 in. w.c. 150 160 4 in. w.c. 16 in. w.c. to 1.6 psig 25 in. w.c.

14 in. w.c.

12.8 to

20.0 in. w.c.

21 in. w.c. 150 160 4 in. w.c. 24 in. w.c. to 2.8 psig 1.1

1

24 in. w.c. to

1.6 psig

1.4 140 150 6.4 in. w.c. 1.4 to 4.1 2

CSB724F

2

1.5 to 3.2

2.6 130 140 0.6

2.0 to 7.3

3.5

3 3.8 125 140 0.6 5

5 3.1 to 5.5 6.2 125 140 0.7 3.2 to 11.0 7

10 7.4 to 11.3 5.8 to 13.3

(1)

12

CSB704

7 in. w.c.

5.2 to

9.6 in. w.c.

VSX8L

(232 psi)

12 in. w.c. 170 215 3.2 in. w.c. 12 to 24 in. w.c. 22 in. w.c.

11 in. w.c.

8.8 to

15.7 in. w.c.

17 in. w.c. 150 160 4 in. w.c. 16 in. w.c. to 1.6 psig 25 in. w.c.

14 in. w.c.

12.8 to

20.0 in. w.c.

21 in. w.c. 150 160 4 in. w.c. 24 in. w.c. to 2.8 psig 1.1

1

24 in. w.c. to

1.6 psig

1.4 140 150 6.4 in. w.c. 1.4 to 4.1 2

CSB724

2

1.5 to 3.2

2.6 130 140 0.6

2.0 to 7.3

3.5

3 3.8 125 140 0.6 5

5 3.1 to 5.5 6.2 125 140 0.7 3.2 to 11.0 7

10 7.4 to 11.3 5.8 to 13.3

(1)

12

CSB754

15 10.2 to 17.3

VSX8H

(232 psi)

13.1 to 39.1

(1)

19

20

15.2 to 39.2 13.1 to 43.5

25

30 35

40 33.4 to 47.1 23.2 to 72.5

(1)

45

- Gray areas indicate that token relief is not available above 8 psig setpoint.

1. Max OPSO setpoint truncated to reect maximum outlet pressure for spring range.

CSB700 Series

6

Page 7

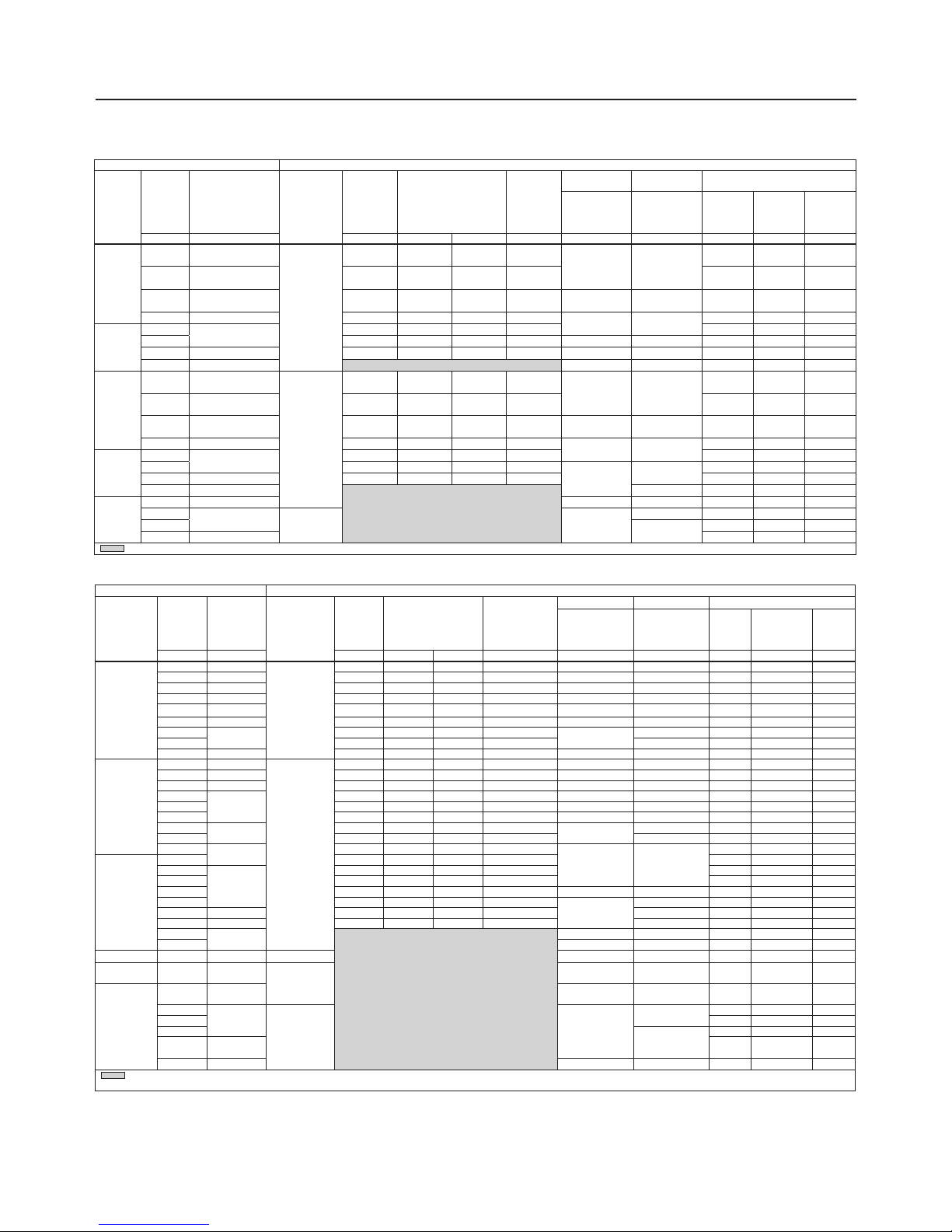

Table 8c. North American Overpressure and Underpressure Shut-o UPSO/OPSO Ranges

Table 8d. European Overpressure and Underpressure Shut-o UPSO/OPSO Ranges

Example: If a non-standard setpoint is needed, see the following example for the proper use of Tables 8a, 8b, 8c and 8d. In this

example, the non-standard regulator setpoint is 140 mbar / 2.0 psig. The minimum factory token relief set pressure is 130% of the

non-standard setpoint. The resulting token relief set pressure is 183 mbar / 2.6 psig. The minimum factory OPSO and UPSO set

pressures are 165% and 50% of the non-standard setpoint, respectively. The resulting minimum settings are: OPSO = 231 mbar /

3.4 psig and UPSO = 70 mbar / 1.0 psig.

REGULATOR SLAM SHUT DEVICE

Type

Typical

Setpoint

Spring

Range

Type

(Maximum

Operating

Inlet)

Token

Relief Set

Relief Range Shown

as a % of Regulator

Setpoint

Required

Difference

Between Token

Relief and

OPSO

UPSO OPSO Factory Set

Set Range

Shut-off (OPSO)

Set Range Over

UPSO Setpoint

UPSO

Adjusted

OPSO Range

OPSO

mbar mbar mbar min max mbar mbar mbar mbar mbar mbar

CSB704F

15 13 to 24

VSX8L (8.6 bar)

26 170 215 6 7 to 11 30 to 44 8 38 to 52 40

20 13 to 24 34 170 215 6 7 to 11 30 to 44 10 40 to 54 40

21 13 to 24 36 170 215 4 7 to 11 30 to 44 10 40 to 54 40

27 22 to 39 41 150 160 5 7 to 15 32 to 44 14 46 to 58 46

30 22 to 39 45 150 160 10 7 to 30 40 to 72 15 55 to 87 60

35 22 to 39 53 150 160 10 7 to 30 40 to 72 18 58 to 90 70

50

42 to 70

70 140 158 16

10 to 75

48 to 74 25 73 to 99 90

60 84 140 158 16 48 to 74 30 78 to 104 100

75 61 to 110 98 130 140 20 25 to 160 83 to 221 38 121 to 259 130

CSB704

15 13 to 24

VSX8L (16 bar)

26 170 215 6 7 to 30 40 to 55 8 48 to 63 50

20 13 to 24 34 170 215 6 7 to 30 40 to 55 10 50 to 65 55

21 13 to 24 36 170 215 4 7 to 30 40 to 55 10 50 to 65 55

27

22 to 39

41 150 160 5 7 to 30 40 to 55 14 54 to 69 55

30 45 150 160 10 7 to 30 45 to 76 15 60 to 91 60

35 53 150 160 10 7 to 30 45 to 76 18 63 to 94 70

50

42 to 70

70 140 158 16

10 to 75

50 to 80 25 75 to 105 90

60 84 140 158 16 50 to 80 30 80 to 110 100

75

61 to 110

98 130 140 20

25 to 160 83 to 221

38 121 to 259 130

CSB724

100 130 130 140 20 50 133 to 271 170

120

105 to 220

156 130 140 40 60 143 to 281 205

150 195 130 140 40 75 158 to 296 250

160 208 130 140 40 25 to 160 83 to 221 80 163 to 301 265

200 250 125 140 50

100 to 500

114 to 261 100 214 to 361 330

300 210 to 380 375 125 140 50 179 to 386 150 329 to 536 450

500 320 to 570 625 125 140 60 241 to 565 250 491 to 815 700

600

510 to 780

100 to 500 241 to 565 300 541 to 865 840

750 100 to 750 460 to 932 375 835 to 1120

(1)

1050

CSB724F 300 270 to 325 VSX8L (8.6 bar) 100 to 500 179 to 386 200 379 to 586 400

CSB754 GrDF 1 bar

0.7 to

1.19 bar

VSX8L (16 bar)

100 to 500 460 to 932 750 1210 to 1682 1210

CSB754

1 bar

0.7 to

1.19 bar

100 to 500 460 to 932 500 960 to 1432 1320

1.2 bar

1.05 to

2.7 bar

VSX8H (16 bar)

500 to 2000

1050 to 1570

600 1650 to 2170 1650

1.5 bar 750 1800 to 2320 1900

2 bar

1250 to 2300

1000 2250 to 3300 2400

3 bar

2.3 to

3.25 bar

1500 2750 to 3800 3400

4 bar 3.1 to 4 bar 500 to 2800 2100 to 3750 2000 4100 to 5000

(1)

4400

- Gray areas indicate that token relief is not available above 500 mbar setpoint.

1. Max OPSO setpoint truncated to reect maximum outlet pressure for spring range.

REGULATOR SLAM SHUT DEVICE

Type

Typical

Setpoint

Spring Range

Type

(Maximum

Operating

Inlet)

Token

Relief Set

Relief Range Shown

as a % of Regulator

Setpoint

Required

Difference

Between

Token

Relief and

OPSO

UPSO OPSO Factory Set

Set Range

Shut-off (OPSO)

Set Range Over

UPSO Setpoint

UPSO

Adjusted

OPSO

Range

OPSO

psig psig psig min max psig psig psig psig psig psig

CSB704F

7 in. w.c. 5.2 to 9.6 in. w.c.

VSX8L

(125 psi)

12 in. w.c. 170 215 3.2 in. w.c.

3 to 12 in. w.c. 16 to 29 in. w.c.

3 in. w.c.

19 in. w.c.

to 1.2 psig

22 in. w.c.

11 in. w.c. 8.8 to 15.7 in. w.c. 17 in. w.c. 150 160 4 in. w.c. 6 in. w.c.

22 in. w.c.

to 1.3 psig

25 in. w.c.

14 in. w.c. 12.8 to 20.0 in. w.c. 21 in. wc 150 160 4 in. w.c.

4 in. w.c. to

1.1 psig

20 in. w.c. to

1.8 psig

9 in. w.c.

1 to

2.1 psig

1.1

1 24.0 in. w.c. to 1.6 psig 1.4 140 150 6.4 in. w.c.

10 in. w.c. to

2.3 psig

1.2 to 3.2

14 in. w.c. 1.7 to 3.7 2

CSB724F

2

1.5 to 3.2

2.6 130 140 0.6 1 2.2 to 4.2 3.5

3 3.8 125 140 0.6 1.5 to 7.3 2.6 to 5.6 2 4.6 to 7.6 5

5 3.1 to 5.5 6.2 125 140 0.7 1.5 to 7.3 3.5 to 8.2 3 5.6 to 8.6 7

10 7.4 to 11.3 1.5 to 7.3 3.5 to 8.2 5 8.5 to 13.2 12

CSB704

7 in. w.c. 5.2 to 9.6 in. w.c.

VSX8L

(232 psi)

12 in. w.c. 170 215 3.2 in. w.c.

3 to 12 in. w.c. 18 to 30 in. w.c.

3 in. w.c.

21 in. w.c.

to 1.2 psig

22 in. w.c.

11 in. w.c. 8.8 to 15.7 in. w.c. 17 in. w.c. 150 160 4 in. w.c. 6 in. w.c.

24 in. w.c.

to 1.3 psig

25 in. w.c.

14 in. w.c. 12.8 to 20.0 in. w.c. 21 in. w.c. 150 160 4 in. w.c.

4 in. w.c. to

1.1 psig

25 in. w.c. to

1.9 psig

9 in. w.c. 1.2 to 2.2 1.1

1 24.0 in. w.c. to 1.6 psig 1.4 140 150 6.4 in. w.c.

10 in. w.c. to

2.3 psig

1.2 to 3.2

14 in. w.c. 1.7 to 3.7 2

CSB724

2

1.5 to 3.2

2.6 130 140 0.6 1 2.2 to 4.2 3.5

3 3.8 125 140 0.6

1.5 to 7.3

2.6 to 5.6

2 4.6 to 7.6 5

5 3.1 to 5.5 6.2 125 140 0.7 3 5.6 to 8.6 7

10 7.4 to 11.3 3.5 to 8.2 5 8.5 to 13.2 12

CSB754

15 10.2 to 17.3 1.5 to 10.9 6.7 to 13.5 7 13.7 to 20.5 19

20

15.2 to 39.2

VSX8H

(232 psi)

7.3 to 29.0

15.2 to 22.8 10 25.2 to 32.8 25

30

18.1 to 33.4

15 33.1 to 48.4 35

40 33.4 to 55.1 20 38.1 to 53.4 45

- Gray areas indicate that token relief is not available above 8 psig setpoint.

CSB700 Series

7

Page 8

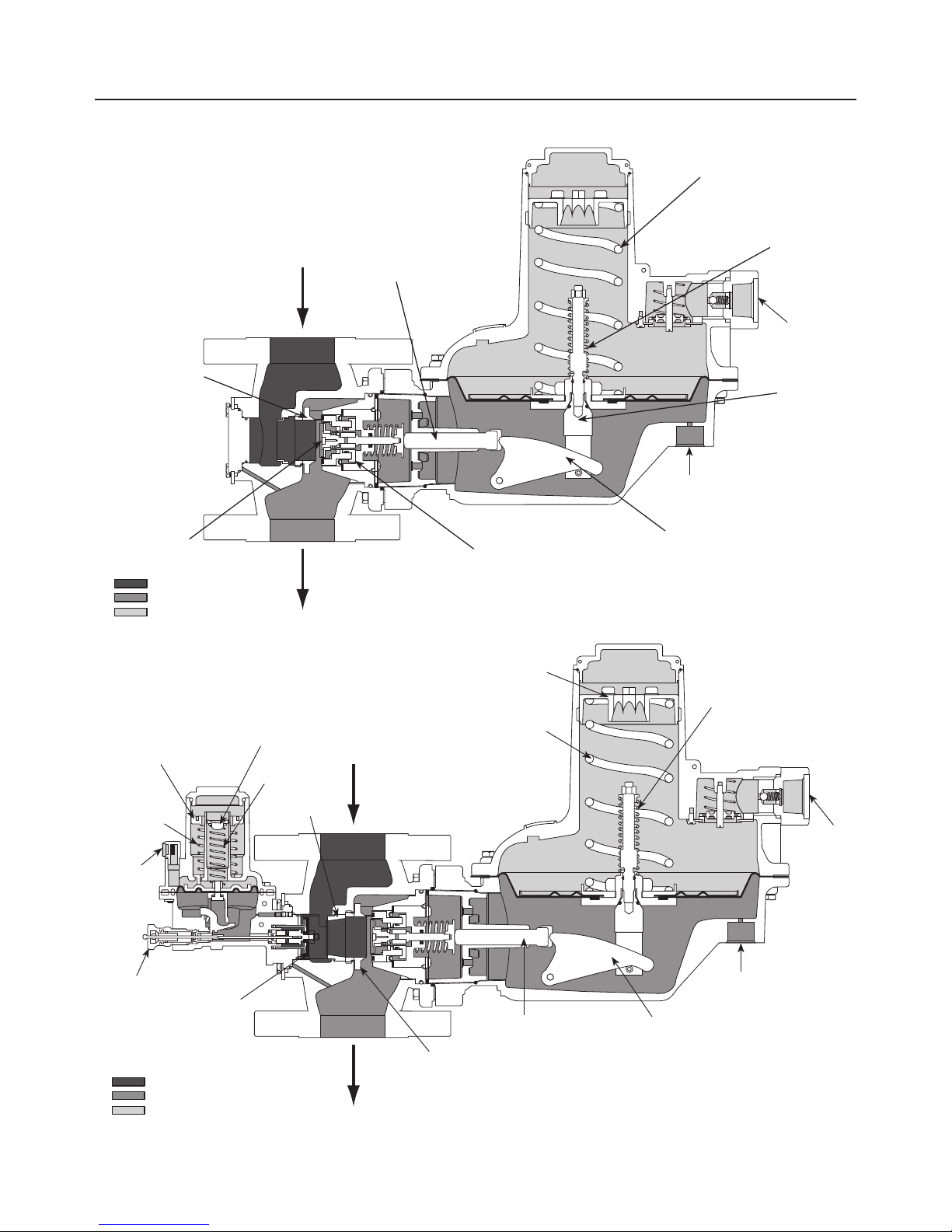

ERSA01618_02

ERSA01618_06

Figure 4. Type CSB704ET, Externally Registered Regulator and Slam-Shut Operational Schematic

Figure 3. CSB700 Series with External Registration Operational Schematics

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

CONTROL SPRING

TOKEN RELIEF

SPRING

PUSHER POST

LEVER

BALANCED PORT ASSEMBLY

REGULATOR ORIFICE

REGULATOR DISK

VALVE STEM

EXTERNAL CONTROL

LINE (SENSE LINE)

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

PRIMARY REGULATOR

TYPE VSX8 SLAM-SHUT MODULE

VENT

OPSO SET

SPRING

UPSO SPRING

UPSO

ADJUSTING

SCREW

OPSO

ADJUSTING

SCREW

SLAM-SHUT

ORIFICE

REGULATOR ORIFICE

VALVE STEM

LEVER

EXTERNAL CONTROL

LINE (SENSE LINE)

REGULATOR CONTROL SPRING

REGULATOR ADJUSTING SCREW

TOKEN RELIEF

SPRING

VENT

VENT

RESET KNOB

SLAM-SHUT DISK

CSB700 Series

8

Page 9

Principle of Operation

Type CSB700 Base Regulator Operation

Refer to Figure 3. When downstream demand decreases,

the pressure under the regulator diaphragm increases.

This pressure overcomes the regulator setting which

is set by the regulator control spring. The action of the

pusher post assembly, lever, and valve stem moves the

balanced port assembly closer to the orifice and reduces

gas flow. If downstream demand increases, pressure

under the regulator diaphragm decreases. Spring force

pushes the pusher post assembly downward, the balanced

port assembly moves away from the orifice and the gas

flow increases downstream as the regulator opens in

response to the decreased pressure underneath the

regulator diaphragm.

Type numbers with a “T”, for example Type CSB700ET,

provide a token or low capacity relief. The token relief

provides relief from minor overpressure caused by nicks or

dents on the orifice or by thermal expansion of gas in the

downstream line. Token relief also provides a token or signal,

in the form of odor, that indicates an overpressure situation

is occurring.

Type CSB704/CSB704F/CSB724/CSB724F/

CSB754 Slam-Shut Operation

The Type VSX8 slam-shut module on the Type CSB704

regulator is a fast-acting shutoff device that provides

overpressure (OPSO) or over and underpressure

(OPSO/UPSO) protection by completely shutting off the

flow of gas to the downstream system. See Table 8 for

guidance regarding the typical setpoints of the regulator

and associated slam-shut module OPSO and combined

OPSO and UPSO setpoints. The Type VSX8’s actions

are independent of the Type CSB704 regulator and of

variations to the inlet pressure. The Type VSX8 comes

standard with external downstream pressure registration.

External registration requires a downstream sensing line.

See Figure 6 for guidance regarding installation of the

downstream control line.

The Type VSX8 shutoff disk is normally in the open (reset)

position, see Figure 4. If the downstream pressure below

the slam-shut diaphragm increases (or decreases) until

it reaches the slam-shut setpoint, this diaphragm moves

upward (or downward) to release the trip mechanism which

allows the spring force on the stem to push the disk against

the seat, shutting off all gas flow. To reset the slam-shut

after gas flow has been shut off, refer to the Type VSX8

Instruction Manual for additional details D103127X012.

!

WARNING

In order for the Underpressure Shutoff

(UPSO) of any slam-shut to be triggered,

the downstream pipe pressure must drop

below the UPSO setpoint. In the case of a

downstream line break, numerous factors

can prevent the downstream pipe pressure

from decreasing below the slam-shut UPSO

setpoint. These factors include the distance

of pipe to the break, the diameter of the

pipe, size of the break and the number of

restrictions, such as valves, elbows and

bends, downstream of the regulator and/

or slam-shut device. Due to these factors

additional protections should be installed to

stop flow in the event of a line break.

Installation and

Overpressure Protection

Install in accordance with provisions of EN12186 / EN12279.

!

WARNING

Personal injury or system damage may

result if this regulator is installed, without

appropriate overpressure protection, where

service conditions could exceed the limits

given in the Specifications section and/or

regulator nameplate. Regulator and equipment

installation should be adequately protected

from physical damage.

All vents should be kept open to permit

free flow of gas to the atmosphere. Protect

openings against entrance of rain, snow,

insects or any other foreign material that

may plug the vent or vent line. On outdoor

installations, point the spring case vent

downward, see Figures 5 through 6. This

minimizes the possibility of freezing and of

water or other foreign materials entering the

vent and interfering with proper operation.

For Type CSB704/CSB704F/CSB724/ CSB724F/

CSB754 with Slam-shut, point the vents of

both the primary regulator and slam-shut

downward to resist collection of precipitation

and moisture. From the factory, the slam-shut

vent will always point in the same direction as

that of the primary regulator.

CSB700 Series

9

Page 10

Figure 5. CSB700 Series Regulator Installed with the Vent Pointed Downward and with a

Type 289H Relief Valve for High Capacity Relief

Figure 6. Type CSB704 Downstream Control Line Installation

CSB700 SERIES

REGULATOR

PROTECT VENT PIPE

WITH RAIN CAP

DN 50 / NP S 2 TYPE 289H

RELIEF VALVE

PRIMARY REGULATOR

SLAM SHUT

UPSTREAM

BLOCK VALVE

DOWNSTREAM

BLOCK VALVE

MINIMUM OF 6 X OUTLET

PIPING DIAMETER

INLET PRESSURE

OUTLET PRESSURE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

M1063

ATMOSPHERIC PRESSURE

CSB700 Series

10

Page 11

Under enclosed conditions or indoors,

escaping gas may accumulate and be

an explosion hazard. In these cases,

the vent should be piped away from the

regulator to the outdoors. See Vent Line

Installation section for the recommended

venting practice.

CAUTION

CSB700 Series regulators have an outlet

pressure rating lower than their inlet

pressure rating. If actual inlet pressure can

exceed the outlet pressure rating, outlet

overpressure protection is necessary.

However, overpressuring any portion of

the regulators beyond the limits in the

Specifications section may cause leakage,

damage to regulator parts or personal injury

due to bursting of pressure-containing parts.

Some type of external overpressure

protection should be provided to the

CSB700 Series if inlet pressure will be

high enough to damage downstream

equipment. Common methods of external

overpressure protection include relief valves,

monitoring regulators, shutoff devices and

series regulation.

If the regulator is exposed to an

overpressure condition, it should be

inspected for any damage that may have

occurred. Regulator operation below the

limits specified in the Specifications section

and regulator nameplate does not preclude

the possibility of damage from external

sources or from debris in the pipeline.

!

WARNING

The usage of an assembly incorporating

an electrical accessory in an explosive

atmosphere the Type CSB704 regulators

equipped with an electrical accessory (proxy,

microswitch) are:

– are classified “assembly” in conformity

with the ATEX Directive 2014/34/EU (ref

CEN/SFG-I Guidance sheet-February 2015)

– can be installed in any type of classified

zones according to the Directive

1999/92/EC dated 16 December 1999,

according to the following conditions:

a.) the equipment is connected to a

suitable and certified intrinsically

safe apparatus/electric circuit

(zener barrier)

b.) the equipment is used according to

the appropiate instruction manual

issued by the manufactuer and/or

available on our website

c.) when the equipment is used in a

natural gas pressure reducing and/or

metering station in compliance with

the following European standards:

EN 12186, EN 12279 and EN 1776.

General Installation Instructions

Before installing the regulator:

• Check for damage, which might have occurred

during shipment.

• Check for and remove any dirt or foreign material, which

may have accumulated in the regulator body.

• Blow out any debris, dirt or copper sulfate in the copper

tubing and the pipeline.

• Apply pipe compound to the external threads of the pipe

before installing the regulator.

• Make sure gas flow through the regulator is in the same

direction as the arrow on the body.

• Verify that:

- Equipment limits of utilization (PS, TS) correspond to

the desired operating conditions.

- The inlet is protected by an appropriate device(s) to

avoid exceeding the allowable limits (PS, TS).

• When designing a pressure reducing station, make an

analysis if it is necessary to take into account the effect

of wind, snow and temperature to avoid unnecessary

load and movement to the flanges of the equipment.

• If needed, a support may be used under the piping and

regulator/slam-shut body to avoid excessive pressure

force on the regulator/slam-shut.

Installation Location

• The installed regulator should be adequately

protected from vehicular traffic and damage from other

external sources.

• Install the regulator with the vent pointed vertically down,

see Figures 5 through 6. If the vent cannot be installed

in a vertically down position, the regulator must be

installed under a separate protective cover. Installing

the regulator with the vent down allows condensation to

drain, minimizes the entry of water or other debris from

entering the vent and minimizes vent blockage from

freezing precipitation.

CSB700 Series

11

Page 12

• Do not install the regulator in a location where there

can be excessive water accumulation or ice formation,

such as directly beneath a downspout, gutter or roof

line of building. Even a protective hood may not provide

adequate protection in these instances.

• Install the regulator so that any gas discharge through

the vent or vent assembly is over 0.91 m / 3 ft away from

any building opening.

Regulators Subjected to Heavy

Snow Conditions

Some installations, such as in areas with heavy snowfall,

may require a hood or enclosure to protect the regulator

from snow load and vent freeze over.

Downstream Control Line Installation

!

WARNING

Failure to install a downstream control line

could result in a hazardous condition. Install

downstream control line(s) to the slam-shut

device when construction uses external

pressure registration. The regulator and

slam-shut device will not control pressure

or shut off if a downstream control line is

not installed on those constructions where

external pressure registration is required.

CSB700 Series regulators with an “ET” or “EN” in the type

number use external pressure registration. To communicate

the downstream pressure to the regulator, connect a

downstream control line tubing to the 3/4 NPT control line

tapping in the lower diaphragm casing and connect the other

end of the tubing downstream of the regulator outlet with a

minimum distance of 6 times the outlet pipe diameter.

For all types with external control lines, use tubing with an

inner diameter of 16 mm / 0.63 in. or larger.

Downstream Control Line Installation with

Slam-Shut Device

Refer to Figure 6. When installing the Types CSB704ET,

CSB704FET, CSB704FEN CSB704EN, CSB724ET,

CSB724EN, CSB724FET, CSB724FEN and CSB754EN

regulators, connect downstream control line tubing to the

lower casing of the regulator and run the tubing downstream

of the regulator outlet with a minimum distance of 6 times

the outlet pipe diameter. Connect a second, separate

downstream control line tubing to the lower casing of

the slam-shut and run the tubing downstream of the

regulator outlet a minimum distance of 6 times the outlet

pipe diameter.

For all types with external control lines, use tubing with an

inner diameter of 16 mm / 0.63 in. or larger for the primary

regulator and 6.4 mm / 0.25 in. or larger for the slam-shut.

Installation with External Overpressure Protection

If the regulator is used in conjunction with a Type 289H

relief valve, it should be installed as shown in Figure 5.

The outside end of the vent line should be protected with a

rainproof assembly. The Type 289H is typically set 25 mbar /

10 in. w.c. higher than the outlet pressure setting of the

regulator, up to 75 mbar / 30 in. w.c. outlet pressure. For

pressure greater than this, set the Type 289H 0.05 bar /

0.73 psi higher than the outlet pressure setting of the

regulator. Refer to the 289 Series Instruction Manual

(D100280X012) for more information.

Vent Line Installation

CSB700 Series regulators have a 1 NPT screened vent

opening in the spring case. If necessary to vent escaping

gas away from the regulator, install a remote vent line in

the spring case tapping. Vent piping should be as short

and direct as possible with a minimum number of bends

and elbows. The remote vent line should have the largest

practical diameter. Vent piping on regulators with token relief

must be large enough to vent all relief valve discharge to

atmosphere without excessive backpressure and resulting

excessive pressure in the regulator.

For types with optional token relief, this low capacity relief

is located in the spring case of the primary regulator. If

necessary to vent escaping gas away, install a remote vent

line in the spring case tapping of the primary regulator as

described above. Periodically check all vent openings to be

sure that they are not plugged or obstructed.

For Types CSB700/CSB700F/CSB720/CSB720F, outlet

pressure higher than 0.34 bar / 5.0 psig above the setpoint

may damage internal metallic parts. For Type CSB750,

outlet pressure higher than 1.5 bar / 21.8 psig above the

setpoint may damage internal metallic parts. The maximum

emergency (casing) outlet pressure for all types is

4.0 bar / 58 psig except for Type CSB750 which is

5.0 bar / 72.5 psig.

CSB700 Series

12

Page 13

Startup

CAUTION

Pressure gauges must always be

used to monitor downstream pressure

during startup.

With the downstream system depressurized, use the

following procedure to start up the regulator.

1. Check to see that all appliances are turned off.

2. Slowly open the upstream shutoff valve.

3. Check inlet and outlet pressure for correct values.

4. Check all connections for leaks.

5. Turn on utilization equipment and recheck

the pressures.

Adjustment

Note

For types that include the slam-shut module,

refer to the instruction manual for Type VSX8

slam-shut (D103127X012) for adjustment and

maintenance of the slam-shut.

The range of allowable pressure settings for

the primary regulator is printed or stamped

on the nameplate. If the required setting is

not within this range, substitute the correct

spring (as shown in Table 7). If the spring is

changed, change the nameplate to indicate

the new pressure range.

A pressure gauge must always be used

to monitor downstream pressure while

adjustments are being made.

For Types CSB700, CSB700F, CSB720F

and CSB720

!

WARNING

During setpoint adjustment, do not mistake

the Token Relief Spring Nut (key 46) for

the main spring adjusting screw. Turning

the Token Relief Spring Nut will change

the token relief setting and if rotated

counterclockwise could result in gas

discharge and possible personal injury.

1. Remove the closing cap (key 60, Figure 12).

2. To increase the outlet setting, turn the adjusting screw

(key 65) clockwise. To decrease the outlet setting, turn

the adjusting screw counterclockwise.

3. Replace the closing cap (key 60).

For Type CSB750

1. Loosen the hex nut (key 67, Figure 12).

2. To increase the outlet setting, turn the adjusting bolt

(key 64) clockwise. To decrease the outlet setting, turn

the adjusting bolt counterclockwise.

3. Tighten the hex nut (key 67).

CSB700 Series with Slam-Shut

When adjusting the primary regulator and slam-shut for

operation, reference Table 8 for the OPSO setpoints and

combined OPSO and UPSO setpoints of the slam-shut

module for the given regulator spring ranges.

Resetting Type VSX8 Slam-Shut after

Overpressure/Underpressure

CAUTION

Internal regulator parts and installed

downstream equipment can be damaged

if the following procedure in resetting the

Type VSX8 controller is not followed.

If the regulator is exposed to an

overpressure condition, it should be tested

for lockup or shut-off after reseting the

slamshut to verify the regulator is not

damaged. Regulator operation below the

limits specified in the Specifications section

and regulator nameplate does not preclude

the possibility of damage from external

sources or from debris in the pipeline.

1. Slowly pull the reset button (refer to Type VSX8

Instruction Manual D103127X012) away from the

controller. This slow movement allows for a slow bleed

of the pressure across the controller’s disk and seat

area. The operator should be able to hear the pressure

bleeding through the system.

2. When the pressure has equalized and the air

bleeding sound has dissipated, the reset button (refer

to Type VSX8 Instruction Manual D103127X012)

should be pulled completely away from the controller

by hand until the internal shut-off mechanism has

been re-latched.

3. Once the operator feels the click of the re-latch

occurring, the reset button (refer to Type VSX8

Instruction Manual D103127X012) should be pushed

completely back into its original position.

4. It is recommended to test the regulator for lockup or

shut-off after resetting the slam-shut.

CSB700 Series

13

Page 14

Shutdown

Installation arrangements may vary, but in any installation

it is important that the valves be opened or closed slowly

and that the outlet pressure be vented before venting

inlet pressure to prevent damage caused by reverse

pressurization of the regulator. The steps below apply to the

typical installation as indicated.

1. Slowly close the upstream shutoff valve

2. Open vent valves downstream of the regulator.

3. Inlet pressure should automatically be released

downstream as the regulator opens in response to the

lowered pressure under the diaphragm.

4. Close outlet shutoff valve.

Maintenance and Inspection

!

WARNING

To avoid personal injury or equipment

damage, do not attempt any maintenance

or disassembly without first isolating

the regulator from system pressure and

relieving all internal pressure as described in

“Shutdown” section.

Regulators that have been disassembled for

repair must be tested for proper operation

before being returned to service. Only parts

manufactured by Emerson should be used

for repairing Fisher™ regulators. Restart

gas utilization equipment according to

normal startup procedures.

Due to normal wear or damage that may

occur from external sources, this regulator

should be inspected and maintained

periodically. The frequency of inspection

and replacement depends on the severity

of service conditions or the requirement of

local, state and federal rules and regulations.

In accordance with the applicable National or

Industry codes, standards and regulations/

recommendations, all hazards covered by

specific tests after final assembly and before

applying the CE marking, shall be covered

also after every subsequent reassembly

at installation site, in order to ensure that

the equipment will be safe throughout its

intended life.

Periodic inspection must be performed on

the CSB700 Series that include the slam-shut

overpressure protection module to ensure

protection of the downstream system in the

event the primary regulator losses pressure

control. This inspection must test that slamshut functions as intended.

Main Diaphragm Maintenance

CAUTION

For version with token relief measure the

distance before disassembly and note for

reassembly (see Figure 10).

Failure to follow the instructions regarding

measurement could impact the token

relief’s set-point

Perform the following steps to disassemble, inspect and

replace the main diaphragm:

1. Remove the closing cap (key 60, Figure 12) or loosen

hex nut (key 67). Turn the adjusting screw (key 65)

or adjusting bolt (key 64) counterclockwise to ease

spring compression.

Note

When disassembling a CSB700 Series

regulator, support the adjusting screw

(key 65) to prevent damage or contamination

due to falling.

2. Remove the adjusting screw (key 65) or the adjusting

bolt (key 64), then the bonnet (key 61), upper spring

seat (key 63) and sealing washer (key 113). Check the

sealing washer and replace if damaged. Remove the

spring (key 38).

3. Remove hex nuts (key 16, Figure 7 or 8) and bolt

(key 15). Separate the upper spring case (key 1) from

the lower casing assembly (key 9).

Note

When disassembling a CSB700 Series

regulator, lift the upper spring case (key 1,

Figure 7 or 8) straight up in order to avoid

hitting the stem (key 44).

4. Slide the diaphragm assembly (key 55, Figure 10) away

from the body (key 70) to unhook the pusher post from

the lever (key 10). Lift out the diaphragm assembly

(key 55) and its attached parts like pusher post (key 50)

and relief valve seat (key 51).

5a. For non-relieving units such as Type CSB700EN, see

Figure 10 — Non-relief assembly. Remove the screw

(key 45) and nut (key 40) to separate relief valve spring

seat (key 43), diaphragm assembly (key 55) and pusher

post (key 50). Check the diaphragm (key 55A) for damage

and replace if necessary.

CSB700 Series

14

Page 15

5b. For units with token relief such as Type CSB700ET,

see Figure 10 — Token Relief Assembly. Remove

token relief nut (key 46), spring retainer (key 42), relief

spring (key 41), nut (key 40) and relief valve spring

seat (key 43). Unscrew the stem (key 44) to separate

diaphragm assembly (key 55) and pusher post (key 50).

Check the diaphragm (key 55A) for damage and replace

if necessary.

Note

The diaphragm assembly (key 55) and the

upper spring case and lower casing must be

reassembled in a level, horizontal orientation

to ensure the relief stem is centered in the

upper spring case during use.

6. Reassemble the diaphragm assembly (key 55) unit in

the reverse order of the above steps. Assembly torques

for the diaphragm assembly are provided in Figure 10.

Before tightening the screw (key 45, for non-relief)

or stem (key 44, for token relief) into the pusher post

(key 50), place the loosely-assembled diaphragm

assembly (key 55) into position in the lower casing

(key 9, Figure 7 or 8), being sure that the pusher post is

hooked on the lever (key 10, Figure 7 or 8). Rotate the

diaphragm so that the diaphragm and lower casing holes

are aligned. Tighten the stem or screw using the proper

torque values (see Figure 10).

7. Reassemble the remaining parts by following steps 1 to 3

in reverse order. Tighten the hex nuts (key 16) and bolts

(key 15) in a crisscross pattern and tighten to the proper

torque value (see Figure 7 or 8).

Valve Disk, Balanced Port

Assembly Diaphragm and Regulator

Orifice Maintenance

Perform the following steps to disassemble, inspect and

replace the Valve Disk, Balanced Port Assembly Diaphragm

and Regulator Orifice:

1. Remove the cap screw (key 71, Figure 7 or 8) which

hold the lower spring casing (key 9) to the body

(key 70). Separate the lower spring casing from

the body.

2. Check the body O-ring (key 19 or key 21) for wear

replace if damaged.

3. Remove the balanced port assembly (key 36, Figure 7

or 8) from the body (key 70).

4. Examine the valve disk (key 36J, Figure 9) for nicks or

other damage. If damage is present, replace both the

disk and the balanced port diaphragm (key 36E) and

associated diaphragm O-ring (key 36N), that comes

into direct contact with the inner flange of the balanced

port diaphragm. Start the process of replacing the disk

by disassembling the balanced port assembly (key 36).

Remove the four cap screws (key 36R) and then the

retainer plate (key 36S).

5. Grasp the spring retainer (key 36B) and slide the housing

(key 36F) away to expose the diaphragm (key 36E)

and disk (key 36J). Still grasping the spring retainer,

insert a 5 mm / 0.20 in. Allen wrench into the disk screw

(key 36D) and unscrew.

6. Remove the disk (key 36J), discard and replace if

damaged. Slide the diaphragm O-ring (key 36N)

off the stem (key 36A) along with the diaphragm

(key 36E). Slide the new diaphragm over the stem in

the same manner that it was removed, make sure that

it completely contacts the surface of the diaphragm

retainer (key 36H).

7. Reassemble the balanced port assembly in reverse

order of the above. Ensure Dow Corning

®

33 or

comparable extreme low temperature lubricant

completely coats the O-rings (keys 36N and 36P),

stem (key 36A) and the center bore of the brass cap

(key 36G). Assemble with proper torques provided in

Figure 9.

8. Examine the seating edge of the orifice (key 25,

Figure 7 or 8). If it is nicked or rough, replace the orifice

and O-ring (key 82). The orifice installation torque range

is provided in Figure 7 or 8. If a slam-shut is installed

on the backside of the body, reference the Type VSX8’s

Instruction Manual for inspection and removal of the

overpressure protection orifice (key 26, see Figure 13)

and O-ring (key 27).

9. Reassemble the regulator in reverse order of the

above steps. Tighten the bolts (key 71) using the proper

torque values (see Figure 7 or 8).

Regulator Reassembly

As indicated by the square callouts in Figures 7 to 13, it

is recommended that a good quality low temperature pipe

thread sealant be applied to pressure connections and

fittings and a good quality low temperature lubricant be

applied to O-rings. Also apply an anti-seize compound to the

adjusting screw threads and other noted areas as needed.

Tighten bolts, screws and stem using proper torque (see

Figures 7 to 12).

Parts Ordering

The type number, orifice size, spring range and date of

manufacture are stamped on the nameplate. Always provide

this information in any correspondence with your local Sales

Office regarding replacement parts or technical assistance.

When ordering replacement parts, reference the key

number of each needed part as found in the following parts

list. Separate kit containing all recommended spare parts

is available.

Dow Corning® is a registered trademark owned by Dow Corning Corporation.

CSB700 Series

15

Page 16

Parts List

Key Description Part Number

1 Spring Case, Aluminum

For Type CSB700/CSB720 GE26100X012

For Type CSB750 ERSA01009A0

4 Stabilizer Guide, Stainless steel

For Type CSB700/CSB720 GE27061X012

5 Stabilizer, Lustran

®

648

For Type CSB700/CSB720 GE27063X012

6 Spring, Stainless steel

For Type CSB700/CSB720 GE35010X012

7 Retainer Ring, Zinc-plated Carbon Steel

For Type CSB700/CSB720 GE27024X012

8 Stabilizer Screw, Zinc-plated Steel (3 required)

For Type CSB700/CSB720 GE29724X012

9 Lower Casing, Aluminum

For Type CSB700/CSB720 GE26103X012

For Type CSB750 ERSA01010A0

10 Lever, BP Steel

For Type CSB700/CSB700F/CSB704/

CSB704F/CSB720/CSB724/

CSB720F/CSB724F (Lever Ratio 2:1) GE27409X012

For Type CSB750/CSB754 (Lever Ratio 1:1) ERSA01012A0

11 Stem, BP, Aluminum

For Type CSB700/CSB700F/CSB704/

CSB704F/CSB720/CSB724/

CSB720F/CSB724F GE27485X012

For Type CSB750/CSB754 ERSA01025A0

13 Lever Pin, Carbon Steel GE29701X012

14 Lever Screw, Plated-Carbon Steel (2 required) GE30039X012

15 Bolt, Steel (8 required) GE29974X012

16 Nut, Steel (6 required for low and

medium pressure, 8 required for high pressure) ERAA21202A0

17 Union Ring, Aluminum GE26416X012

18 Snap Ring, Zinc-plated steel GE27018X012

19* O-ring, Nitrile (NBR) GE29755X012

20 Stem Guide, Aluminum

For low and medium pressure only GE26107X012

21* O-ring, Nitrile (NBR)

For low and medium pressure only GE29754X012

25* Orifice, Aluminum

35 mm / 1-3/8 in. GE32085X012

26* Orifice, Aluminum (with slam-shut module)

35 mm / 1-3/8 in. GE32066X012

27* O-ring, Nitrile (NBR) (with slam-shut module) GE32723X012

36* Balanced Port Assembly

Type CSB700/CSB704

With External Registration GG04073X012

Type CSB700F/CSB704F

With External Registration ERSA00986A0

Type CSB720/CSB720F/CSB724F/

CSB750/CSB754

With External Registration ERSA01429A0

36A Stem, Stainless steel

Type CSB700/CSB704/CSB720/CSB724/

CSB720F/CSB724F/CSB750/CSB754 GE27012X012

Type CSB700F/CSB704F ERSA00988A0

36B Spring Retainer, Zinc-plated steel

Type CSB700/CSB704/CSB720/CSB724/

CSB720F/CSB724F/CSB750/CSB754 GG01431X012

Type CSB700F/CSB704F ERSA01311A0

36C Spring, Stainless steel

Type CSB700/CSB704/CSB700F/CSB704F GE27014X012

Type CSB720/CSB724/CSB720F/CSB724F/

CSB750/CSB754 ERSA00987A0

36D Screw, steel

External registration

Type CSB700/CSB704/CSB700F/CSB704F ERSA03894A0

Type CSB720/CSB724/CSB720F/

CSB724F/CSB750/CSB754 GE27015X012

36E Diaphragm, Nitrile (NBR) and Polyester Fabric GE30431X012

36F Housing

With External Registration GG05166X012

36G Cap, Brass GE27007X012

36H Diaphragm Retainer, Zinc-plated steel

Type CSB700/CSB704/CSB720/CSB724/

CSB720F/CSB724F/CSB750/CSB754 GE27009X012

Type CSB700F/CSB704F ERSA00989A0

36J Disk, Nitrile (NBR)

Type CSB700F/CSB704F GE27010X012

Type CSB700/CSB704/CSB720/CSB724/

CSB720F/CSB724F/CSB750/CSB754 ERSA02796A0

36K Disk Retainer

Type CSB700/CSB704/CSB700F/CSB704F ERSA03893A0

Type CSB720/CSB724/CSB720F/

CSB724F/CSB750/CSB754 GE27011X012

36L* O-ring, Nitrile (NBR) GE32673X012

36M* O-ring, Nitrile (NBR) GE32966X012

36N* O-ring, Nitrile (NBR) GE32702X012

36P* O-ring, Nitrile (NBR) GE32676X012

36R Screw, Zinc-plated Steel (4 required) GE34243X012

36S Retainer Plate GE27253X012

36V Stabilizer,

Type CSB700/CSB704/CSB700F/CSB704F

(External Registration) ERSA03550A0

36W Retaining Ring

Type CSB700F/CSB704F only ERSA00993A0

36X Connector

Type CSB700F/CSB704F only ERSA00991A0

36Z Stabilizer Spring

Type CSB700/CSB704/CSB700F/CSB704F

(External Registration) ERSA03549A0

38 Spring, Music wire

9 to 14 mbar / 3.6 to 5.6 in.w.c., Silver GE30336X012

13 to 24 mbar / 5.2 to 9.6 in.w.c., Red ERSA01138A0

22 to 39 mbar/ 8.8 to 15.7 in.w.c., Black Stripe GE30338X012

32 to 50 mbar / 12.8 to 20.1 in.w.c., Purple GE30339X012

42 to 70 mbar / 16.9 to 28.1 in.w.c., White Stripe GE30340X012

61 to 110 mbar / 0.9 to 1.6 psig, Dark Green ERSA03656A0

105 to 220 mbar / 1.5 to 3.2 psig, Blue ERSA03657A0

210 to 380 mbar / 3.1 to 5.5 psig, Black GG06247X012

270 to 325 mbar / 3.92 to 4.71 psig,

Black with White Stripe ERAA11747A0

320 to 570 mbar / 4.6 to 8.3 psig,

Red with White Stripe ERSA01582A0

510 to 780 mbar / 7.4 to 11.3 psig,

Blue with White Stripe ERSA05055A0

0.7 to 1.19 bar / 10.2 to 17.3 psig, Purple Stripe GE30345X012

1.05 to 2.7 bar / 15.2 to 39.2 psig, Brown GE30346X012

2.3 to 3.25 bar / 33.4 to 47.1 psig,

Grey with Red Stripe ERSA01125A0

3.1 to 4.0 bar / 45 to 58 psig,

Grey with Orange Stripe ERSA01126A0

40 Relief Valve Seat Nut, Zinc-plated steel GE46959X012

41 Token Relief Spring, Stainless steel

Type CSB700/CSB700F/CSB704/CSB704F GG06009X012

Type CSB720/CSB724/CSB720F/CSB724F ERAA17935A0

Type CSB750/CSB754 ERSA01128A0

Key Description Part Number

*Recommended spare part.

Lustran® is a mark owned by INEOS ABS (USA) Limited.

CSB700 Series

16

Page 17

Key Description Part Number Key Description Part Number

42 Spring Retainer, Zinc-plated steel

(with token relief)

Type CSB700/CSB704/CSB700F/CSB704F/

CSB720/CSB724/CSB720F/CSB724F GE46956X012

Type CSB750/CSB754 GG06010X012

43 Spring Seat, Zinc-plated steel GG06011X012

44 Stem, Zinc-plated steel (with token relief) ERAA00767A0

45 Screw, Zinc-plated steel (without token relief) ERSA01141A0

46 Token Relief Nut, Steel ERAA21202A0

50 Pusher Post, Aluminum

For Types CSB700 and CSB720 GE27405X012

For Type CSB750 ERSA01139A0

51 Relief Valve Seat

For all types except Type CSB720/724

(510 to 780 mbar / 7.4 to 11.3 psig), Aluminum GE46957X012

For Type CSB720/724

(510 to 780 mbar / 7.4 to 11.3 psig) ERAA33372A0

52* Pusher Post O-ring, Nitrile (NBR) GE47389X012

53 Pin, Stainless steel GE29761X012

54 Roller Pin, Brass GE27060X012

55* Diaphragm Assembly

For Types CSB700 and CSB720

(9 to 570 mbar / 3.6 in. w.c. to 8.3 psig) GE30529X012

For Type CSB720

(510 to 780 mbar / 7.4 to 11.3 psig) ERAA33533A0

For Type CSB750 ERSA01024A0

60 Closing Cap, Aluminum

All types except Types CSB750 and CSB754 GE26109X012

61 Bonnet, Zinc-plated steel

For Types CSB750 and CSB754 only GE26812X012

62* O-ring, Nitrile (NBR) GE29750X012

63 Upper Spring Seat, Zinc-plated Carbon Steel

For Types CSB750 and CSB754 only GE26809X012

64 Adjusting Bolt, Steel

For Types CSB750 and CSB754

0.7 to 2.7 bar / 10.2 to 39.2 psig ERSA01362A0

2.3 to 4 bar / 33.4 to 58.0 psig GE27026X012

65* Adjusting Screw, Aluminum

All types except Types CSB750 and CSB754 GE26108X012

66 Ball, Stainless Steel

For Types CSB750 and CSB754 only GE33131X012

67 Hex Nut, Stainless steel

For Types CSB750 and CSB754 only GE49038X012

68 Retainer Ring, Steel GE33772X012

70 Body

Ductile iron

1-1/2 NPT ERAA02453A1

2 NPT ERAA02437A1

Rp 1-1/2 ERAA03878A1

Rp 2 ERAA02715A1

DN 50 / NPS 2

CL125 FF/CL150 FF

191 mm / 7.5 in. face-to-face dimension GE48292X012

254 mm / 10 in. face-to-face dimension ERAA02711A1

267 mm / 10.5 in. face-to-face dimension ERAA02718A1

PN 10/16

191 mm / 7.5 in. face-to-face dimension GE48296X012

200 mm / 7.87 in. face-to-face dimension GE48296X012

254 mm / 10 in. face-to-face dimension ERAA02719A1

DN 40 / NPS 1-1/2

PN 16 Slip-On

222 mm / 8.74 in. face-to-face dimension ERAA03878A2

70 Body (continued)

WCC Steel

1-1/2 NPT ERAA02453A2

2 NPT ERAA02437A2

Rp 1-1/2 ERAA03878A2

Rp 2 ERAA02715A2

DN 50 / NPS 2

CL150 RF ERAA02720A2

PN 10/16

191 mm / 7.5 in. face-to-face dimension GE48296X022

254 mm / 10 in. face-to-face dimension ERAA02719A2

71 Cap Screw, Steel (4 required) GE29974X012

72 Pipe Plug, 1/4 NPT

Steel 1C333528992

Stainless Steel 1C3335X0012

74* Blanking Plug, Aluminum

(without slam-shut module) GE31255X012

75* O-ring, Nitrile (NBR) GF03442X012

76 Snap Ring Flange (2 required) GF01942X012

77* O-ring, Nitrile (NBR) GF03443X012

80 Screw, Steel (4 required) GE38176X012

82* O-ring, Nitrile (NBR) GE30397X012

90 Nameplate - - - - - - - - - - 91 Warning Label - - - - - - - - - - 93 Label - - - - - - - - - - 94 Overlay Label - - - - - - - - - - 95 Grommet, Nitrile (NBR)

(for low and medium pressure) GE35358X012

96 Rubber Washer, Nitrile (NBR) ERSA01501A0

100 Lockwire - - - - - - - - - - -

101

(1)

Hub, Zinc-Plated Steel (2 required) GG05925X012

102

(1)

Sip-On Flange (2 required) M0244690X12

103

(1)

O-ring, Nitrile (NBR) (2 required) GE41121X012

104

(2)

Spacer ERSA00992A0

105 Restriction Plate, Stainless steel

For high pressure only GG06008X012

106 Diaphragm Stem O-ring, Nitrile (NBR)

For types with token relief only GE49041X012

111 Damper Assembly (no damper on

Type CSB700F/CSB704F)

For Type CSB700/CSB704/CSB720/

CSB724/CSB720F/CSB724F GG06048X012

For Type CSB750/CSB754 GG06058X012

111A Connector (not on Type CSB700F/CSB704F)

For Type CSB700/CSB704/CSB720/

CSB720F/CSB724/CSB724F ERAA21077A0

For Type CSB750/CSB754 ERAA21078A0

111B Retainer Ring (not on

Type CSB700F/CSB704F external registration) GG06054X012

111C Spring, Stainless steel (not on

Type CSB700F/CSB704F external registration) GG06055X012

111D Spring Retainer, Zinc-plated steel (not on

Type CSB700F/CSB704F external registration) GG06056X012

111E Plastics Ball, (not on

Type CSB700F/CSB704F external registration) GG06057X012

111F Vent Screen T1121338982

111G Retaining Ring T1120925072

112 Stem Cap ERAA18503A0

113* Sealing Washer,

For Type CSB750/CSB754 only 11A9681X012

114 Elbow (on Type CSB750/CSB754 only) ERAA21079A0

115 Thrust Washer

Type CSB720/CSB724/

CSB720F/CSB724F only GE47292X012

116 Drive Screw ERAA01884A0

117 Diaphragm Plate (For Type CSB720/724,

510 to 780 mbar / 7.4 to 11.3 psig only) ERAA33373A0

*Recommended spare part.

1. 222 mm / 8.74 in. face-to-face dimension.

2. 200 mm / 7.74 in. face-to-face dimension.

CSB700 Series

17

Page 18

Figure 7. CSB700 and CSB720 Series Regulator Assembly

APPLY LUBRICANT

(1)

L1 = ANTI-SEIZE LUBRICANT

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

1. Lubricants must be selected such that they meet the temperature requirements.

L1

40

106

42

41

L1

38

46

L1

TORQUE:

14 TO 18 N•m /

10 TO 13 FT-LBS

TORQUE:

12 N•m / 9 FT-LBS MAX

TORQUE:

34 TO 47 N•m /

25 TO 35 FT-LBS

TORQUE:

6 TO 8 N•m /

4 TO 6 FT-LBS

111C

111D

111B

111F

L1

25

L2

82

L2

36

71

80

20

21

L2

L2

L1

65

62

L1

L2

100

8

TORQUE:

1.7 TO 3.4 N•m /

15 TO 30 IN-LBS

95

6

111E

111A

TORQUE:

10 TO 13 N•m /

7 TO 10 FT-LBS

111G

43

55

9

1

4

7

5

TORQUE:

1.7 TO 3.4 N•m /

15 TO 30 IN-LBS

51

44

52

TORQUE:

6 TO 7 N•m /

50 TO 60 IN-LBS

L2

50

54

53

68

112

13

14

10

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

18

17

11

L2

76

77

75

19

96

74

L2

L2

L2

DETAIL N

DAMPER FOR TYPE CSB700F

111F

111G

111A

70

17

16

15

60

INITIAL TORQUE:

7 TO 9 N•m /

5 TO 7 FT-LBS

MINIMUM RELAXATION TORQUE:

5 N•m / 4 FT-LBS

GE2791_DM

CSB700 Series

18

Page 19

Figure 8. CSB750 Series Regulator Assembly

APPLY LUBRICANT

(1)

L1 = ANTI-SEIZE LUBRICANT

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

1. Lubricants must be selected such that they meet the temperature requirements.

L1

61

64

L1

L2

67

113

62

L252

50

100

114

111F

111A

111C

111G

111D

111B

111E

55

1

9

43

105

TORQUE:

10 TO 13 N•m /

7 TO 10 FT-LBS

L2

53

19

L2

75

L2

54

L2

77

7674 96

10

14

13

112

1118

68

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

L2

L2

82

L1

25

TORQUE:

34 TO 47 N•m /

25 TO 35 FT-LBS

80

TORQUE:

6 TO 8 N•m /

4 TO 6 FT-LBS

TORQUE:

6 TO 7 N•m /

50 TO 60 IN-LBS

TORQUE:

12 N•m /

9 FT-LBS MAX

51

45

40

L1

38

63

66

36

71

TORQUE:

14 TO 18 N•m /

10 TO 13 FT-LBS

70

17

16

15

INITIAL TORQUE:

7 TO 9 N•m /

5 TO 7 FT-LBS

MINIMUM RELAXATION TORQUE:

5 N•m / 4 FT-LBS

GE2791_DM

CSB700 Series

19

Page 20

36B

36A

36C

36S

36L

36F

36G

36E

36J

36D

L2

TORQUE:

6.5 TO 7.5 N•m /

58 TO 66 IN-LBS

L2

36V

36Z

36K

36N

36H

36X

36M

36P

36W

36R

TORQUE:

3 TO 4 N•m /

27 TO 35 IN-LBS

L2

L2

L2

TORQUE:

2 TO 3 N•m /

17.7 TO 26.6 IN-LBS

L2

L2

L2

36K

36E

36N

36H

36M

36P

36B

36R

TORQUE:

3 TO 4 N•m /

27 TO 35 IN-LBS

TORQUE:

1.3 TO 1.8 N•m /

11.5 TO 16 IN-LBS

L2

S2

36A

36C

36S

36L

36F

36G

36J

36D

TORQUE:

5 TO 6 N•m /

44 TO 52 IN-LBS

TORQUE:

6.5 TO 7.5 N•m /

58 TO 66 IN-LBS

36C

36S

36L

36F

36G

36J

36V

36D

TORQUE:

6.5 TO 7.5 N•m /

58 TO 66 IN-LBS

L2

36B

36P

36R

36M

L2

TORQUE:

1.3 TO 1.8 N•m /

11.5 TO 16 IN-LBS

TORQUE:

3 TO 4 N•m /

27 TO 35 IN-LBS

L2

S2

36A

TORQUE:

6.5 TO 7.5 N•m /

58 TO 66 IN-LBS

36H

36E

L2

36N

36K

36Z

BALANCED PORT ASSEMBLY FOR TYPES CSB700EN, CSB700ET, CSB704EN AND CSB704ET

GG04073_GB

Figure 9. CSB700 Series Balanced Port Assembly

BALANCED PORT ASSEMBLY FOR TYPES CSB720EN, CSB720ET, CSB724EN, CSB724ET, CSB750EN, CSB754EN, CSB750ET AND CSB754ET

BALANCED PORT ASSEMBLY FOR TYPES CSB700FEN, CSB700FET, CSB704FEN AND CSB704FET

ERSA00986_FC

ERSA01429_FC

APPLY LUBRICANT OR SEALANT

(1)

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

S2 = MEDIUM TO HIGH STRENGTH THREADLOCKER

1. Lubricants and sealants must be selected such that they meet the temperature requirements.

CSB700 Series

20

Page 21

Figure 10. CSB700 Series Diaphragm and Relief Assemblies

APPLY LUBRICANT OR SEALANT

(1)

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

S2 = MEDIUM TO HIGH STRENGTH THREADLOCKER

1. Lubricants and sealants must be selected such that they meet the temperature requirements.

GE2791_DM

DETAIL Y

NOTE DIRECTION OF

RETAINING RING INSTALLATION

TYPES CSB700 AND CSB720 (61 TO 570 mbar / 0.9 TO 8.3 psig) NON-RELIEF

54

L2

L2

TORQUE:

15 TO 20 N•m /

11 TO 15 FT-LBS

TORQUE:

6 TO 7 N•m /

50 TO 60 IN-LBS

43

52

50

53

55A

40

45

51

68

68

55C

55B

S2

NOTE DIRECTION OF

RETAINING RING INSTALLATION

TYPE CSB750 NON-RELIEF

54

L2

TORQUE:

15 TO 20 N•m /

11 TO 15 FT-LBS

TORQUE:

6 TO 7 N•m /

50 TO 60 IN-LBS

43

40

52

50

53

51

45

105

55B

55C

68

55A

S2

L2

Y

NOTE DIRECTION OF

RETAINING RING INSTALLATION

TYPES CSB700 AND CSB720 (61 TO 570 mbar / 0.9 TO 8.3 psig) TOKEN RELIEF

46

42

41

40

43

L2

55A

52

50

53

54

68

51

55B

106

44

55C

TORQUE:

15 TO 20 N•m /

11 TO 15 FT-LBS

TORQUE:

6 TO 7 N•m /

50 TO 60 IN-LBS

S2

L2

L2

MEASURE THE DISTANCE

BEFORE DISASSEMBLY AND

NOTE FOR REASSEMBLY

40

43

55A

TORQUE:

15 TO 20 N•m /

11 TO 15 FT-LBS

45

51

68

TORQUE:

6 TO 7 N•m /

50 TO 60 IN-LBS

S

52

50

53

L2

TYPE CSB720

(510 TO 780 mbar / 7.4 TO 11.3 psig) NON RELIEF

54

L2

55C 55B

117

CSB700 Series

21

Page 22

Figure 11. Lever Positions and Stem Congurations

APPLY LUBRICANT

(1)

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

1. Lubricants must be selected such that they meet the temperature requirements.

TYPE CSB750

LEVER 1:1

TYPE CSB750

LEVER 1:1

TYPES CSB700/CSB700F/CSB720/CSB720F

LEVER 2:1 ‘B’ POSITION

TYPES CSB700/CSB700F/CSB720/CSB720F

LEVER 2:1 ‘B’ POSITION

11

13

112

14

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

11 13

112

14

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

11

13

112

14

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

11

13

112

14

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

11 13 10

112

L2

11

13

112

14

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

112

14

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

11 13 10

112

L2

11

13

14

10

TORQUE:

3.5 TO 4 N•m /

31 TO 35 IN-LBS

112

L2

GE2791_DM

CSB700 Series

22

Page 23

65

S3

L1

65

67

67

64

38

64

38

L1

115

36R

TYPE CSB700/CSB700F TYPE CSB720/CSB720F

TORQUE:

3 TO 4 N•m /

27 TO 35 IN-LBS

TYPES CSB750 AND CSB754

0.7 TO 2.7 bar / 10.2 TO 39.2 psig

TYPES CSB720 AND CSB724

210 TO 780 mbar / 3.05 TO 11.3 psig

TYPES CSB750 AND CSB754

2.3 TO 4.0 bar / 33.4 TO 58.0 psig

Figure 12. CSB700 Series Control Spring Adjustment Assemblies

1. Lubricant and sealant must be selected such that they meet the temperature requirements.

APPLY LUBRICANT OR SEALANT

(1)

L1 = ANTI-SEIZE LUBRICANT

S3 = PERMANENT HIGH-STRENGTH THREADLOCKER

ORIFICE AND SLAM-SHUT ASSEMBLY

25 26

L2

27

L2

L2

82

SLAM-SHUT ASSEMBLY

80

Figure 13. CSB700 Series Slam-Shut Module

APPLY LUBRICANT

(1)

L2 = EXTREME LOW-TEMPERATURE BEARING GREASE

1. Lubricants must be selected such that they meet the temperature requirements.

GE2791_DM

GE2791_DM

CSB700 Series

23

Page 24

91

91

93

94

90

90

170 mm /

6.7 in.

93

94

WHEN APPLYING

LABEL SHOW TEXT

THIS DIRECTION

WHEN APPLYING

LABEL SHOW TEXT

THIS DIRECTION

TYPES CSB700 AND CSB720 LOW AND MEDIUM PRESSURE ASSEMBLY

Figure 14. CSB700 Series Nameplate and Label

GE32791_DM

TYPE CSB750 HIGH PRESSURE ASSEMBLY

CSB700 Series

Facebook.com/EmersonAutomationSolutions

LinkedIn.com/company/emerson-automation-solutions

Twitter.com/emr_automation

Webadmin.Regulators@emerson.com

Emerson Automation Solutions

The distinctive swirl pattern cast into every actuator casing

uniquely identies the regulator as part of the Fisher™ brand

Commercial Service Regulator family and assures you of the

highest-quality engineering, performance, and support traditionally

associated with Fisher™ and Tartarini™ regulators. Visit

www.fishercommercialservice.com to access interactive applications.

Fisher.com

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853

+1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Asia Pacic

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa