Emerson CROSBY STYLE HC ISOFLEX, CROSBY STYLE HCA ISOFLEX Installation, Maintenance And Adjustment Instructions

Page 1

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Before installation these instructions must be read fully and understood

TABLE OF CONTENTS

1. Style HC/HCA ISOFLEX - parts ..................... 2

2. Introduction ................................................... 3

3. Description of safety valve ............................ 4

4. Storage ........................................................... 4

5. Installation ..................................................... 5

6. Hydrostatic testing ........................................ 6

7. Operation ....................................................... 9

8. Testing.......................................................... 10

9. Valve maintenance ...................................... 12

General information .................................... 12

Disassembly ................................................ 12

Repair procedure ........................................ 14

10. Valve assembly ............................................ 16

11. Spare parts .................................................. 18

12. Field service requirements ......................... 19

13. Maintenance equipment ............................. 19

Safety precautions

Proper handling, storage, installation,

maintenance and operation is essential to the

safe and reliable functioning of any pressure

relief product.

Precautionary statements in the form of

warnings, cautions and notes are used

throughout this instruction to emphasize

important and critical factors where applicable.

Examples:

WARNING

An operating procedure or practice which, if not

observed strictly, may result in injury to personnel

or loss of life.

CAUTION

An operating procedure or practice which, if not

observed strictly, may result in damage to or

destruction of equipment.

NOTE

An operating procedure or condition which is

highlighted, underlined or printed in bold type for

emphasis.

These precautionary statements are by no means

exhaustive. Emerson cannot be expected to know,

evaluate and advise customers of all conceivable ways

in which tasks might be performed, or of the possible

hazardous consequences of each way.

Consequently, Emerson has not included

such comprehensive evaluation and disclaims

liability for work performed by other than

Emerson personnel. All personnel working with

Crosby products should be trained adequately

and be thoroughly familiar with the contents of

this manual.

Emerson cannot evaluate all conditions that

might injure personnel or damage equipment.

However, Emerson does offer the following

general safety precautions:

• Hearing and eye protection should be used

when working on a valve which is under

pressure.

• Never strike a valve which is under pressure.

Premature actuation can result.

• Never stand in front of the discharge outlet

of a pressure relief valve which is under

pressure.

Always approach and use any pressure relief

valvewith great care.

Often, the safety of lives and property

depends on the proper operation of the

safety valves. Consequently, the valves

should be kept clean and should be tested

periodically and reconditioned to make sure

theyfunctionproperly.

WARNING

Suitability of the material and product for

the use contemplated by the buyer is the

sole responsibility of the buyer. Also storage,

installation and proper use and application are

the sole responsibility of the purchaser. Emerson

disclaims any and all liability arising out of same.

Any installation, maintenance, adjustment,

repair and testing performed on safety relief

valves should be done in accordance with

the requirements of all applicable codes and

standards under which those performing such

work should maintain proper authorization

through appropriate governing authorities. No

repair, assembly and test work done by other

than Emerson shall be covered by the warranty

extended by Emerson to its customers.You

assume full responsibility for your work. In

maintaining and repairing Crosby products, you

should use only parts manufactured by Emerson.

Call your nearest Emerson sales office or our

factory for a service engineer should you wish

assistance with your field needs.

Engineering Doc. #IS-V3147A

Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved. VCIOM-06201-EN17/05

Page 2

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

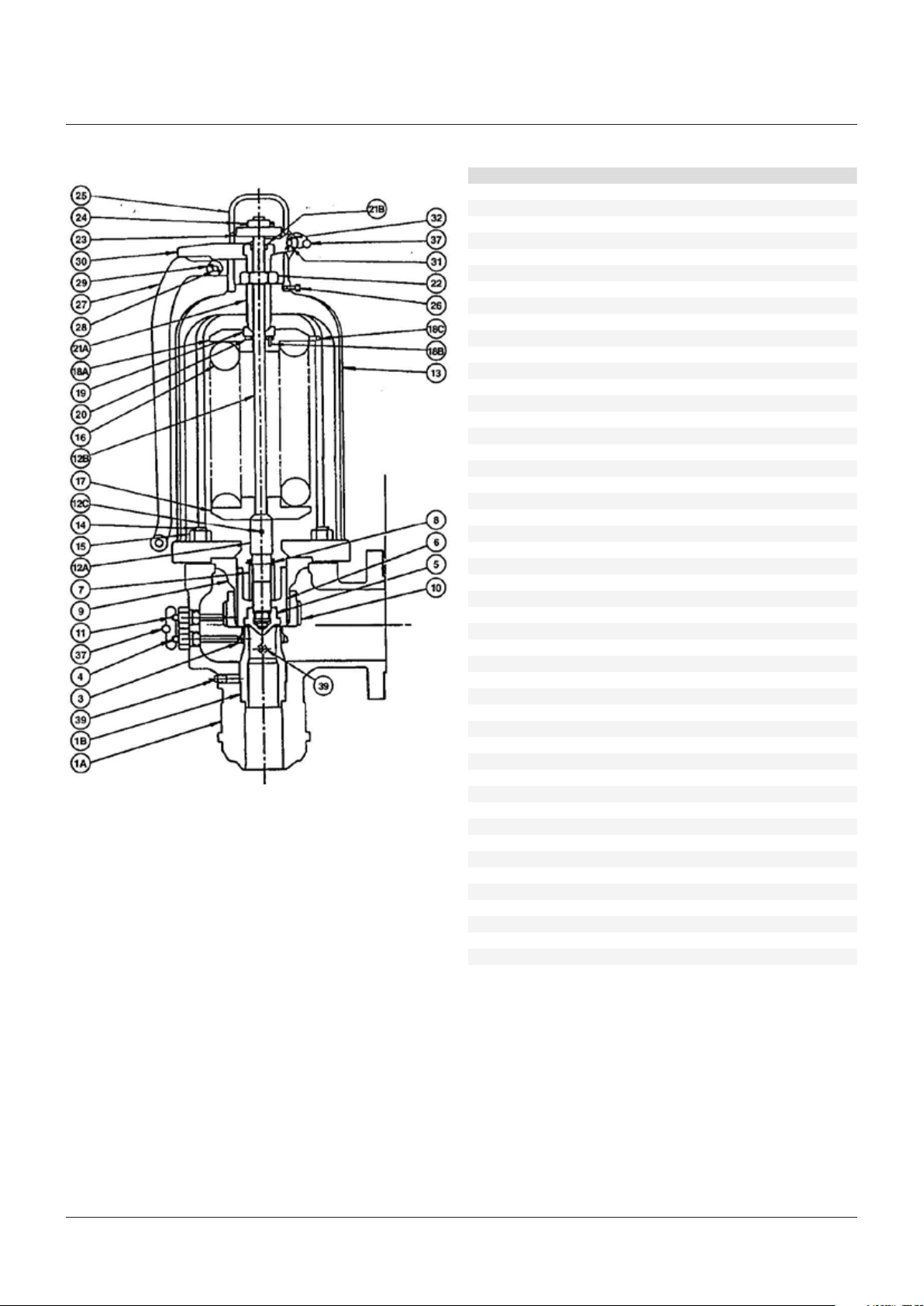

FIGURE 1 - STYLE HC ISOFLEX SAFETY VALVE

PARTS LIST

Part Part name Spare parts*

1A Body

1B Nozzle

3 Nozzle ring 3

4 Nozzle ring set screw

5 Disc insert 1

6 Disc holder 2

7 Disc holder retaining nut

8 Disc holder retaining cotter 1

9 Guide 3

10 Guide ring 3

11 Guide ring set screw

12A Spindle point 3

12B Spindle rod 3

12C Spindle rod pin 3

13 Bonnet

14 Bonnet stud

15 Bonnet stud nut

16 Spring 3

17 Bottom spring washer 3

18A Top spring washer 3

18B Bearing pin 3

18C Locking pin 3

19 Bearing adapter

20 Bearing

21A Adjusting bolt

21B Adjusting bolt bearing

22 Adjusting bolt nut

23 Spindle nut

24 Spindle nut cotter 1

25 Cap

26 Cap set screw

27 Lever

28 Lever pin

29 Lever pin cotter 1

30 Forked lever

31 Forked lever pin

32 Forked lever pin cotter 1

34 Test clamp

36 Test rod

37 Seal and wire

38 Protective hood

39 Drain plug

40 Hydro test plug assembly

41 Nameplate

42 Drive screw

43** Cooling spool

44** Cooling spool stud

45** Cooling spool stud nut

NOTES

* Spare parts designation (see notes 1, 2, 3 in Section 2)

** For Crosby Style HCA ISOFLEX only

2

Page 3

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

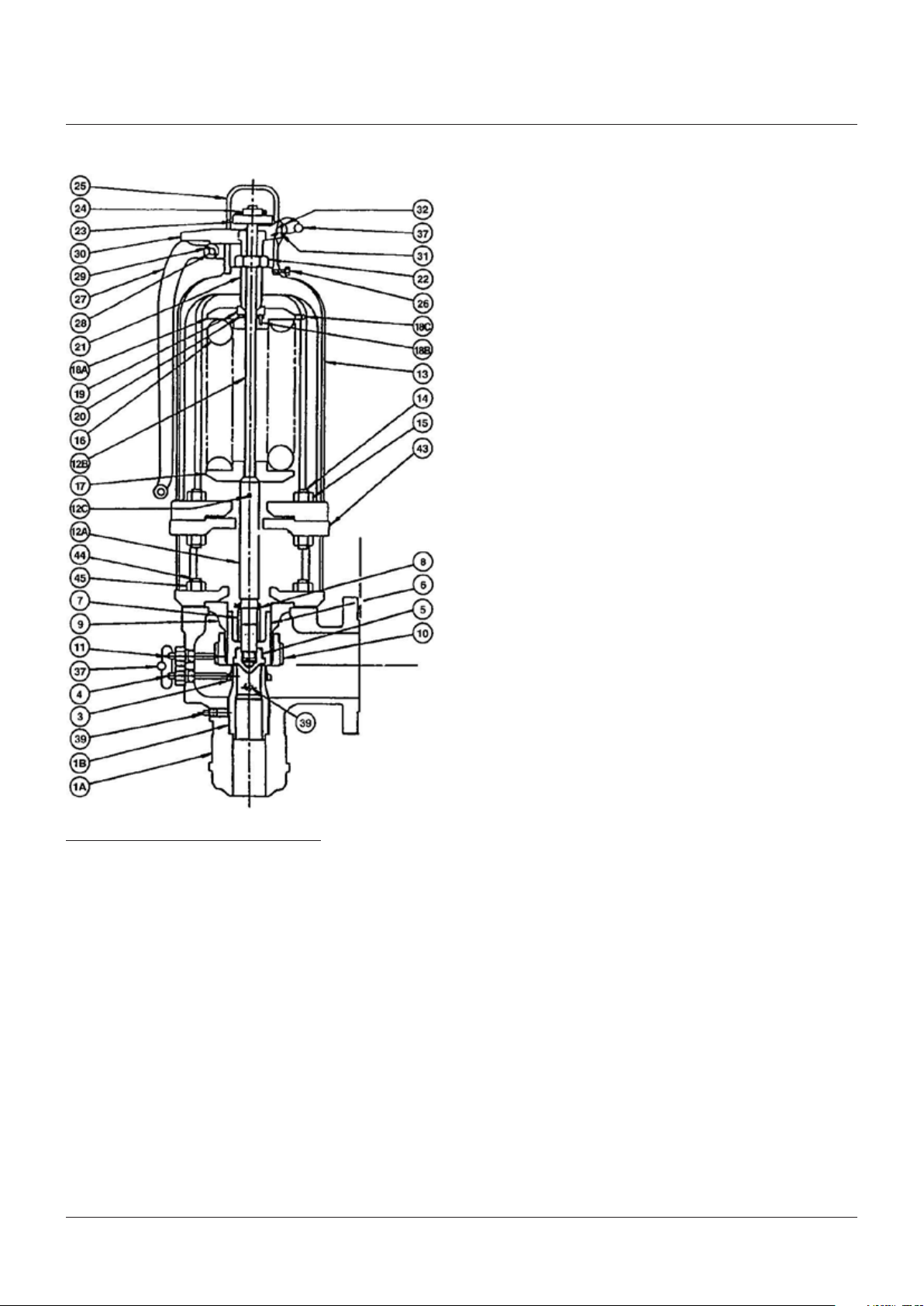

FIGURE 2 - STYLE HCA ISOFLEX SAFETY VALVE

2 INTRODUCTION

Crosby Style HC and HCA ISOFLEX safety

valves have been selected because of their

performance features, reliability and ease

ofmaintenance.

This manual contains information on

installation, hydrostatic testing, field testing

and adjustments and maintenance of these

valves. It is specific to the Isoflex design K

through M

orifice sizes. Adherence to the

2

installation and maintenance procedures

specified in this manual will provide the utmost

in safety, a minimum of maintenance and a

long service life.

Style HC is a high capacity reaction type safety

valve designed for saturated and superheated

steam applications to temperatures of 750°F.

Crosby Style HCA is a high temperature

version of the Style HC, with an alloy steel

construction suitable to temperatures

upto1020°F. TypicallyStyle HCA valves are

used for superheaters and reheater outlets.

DetailsofStyle HC and HCA safety valves,

materials of construction, sizes, pressuretemperature ratings, dimensions, weights and

certified capacities are available on request.

No special tools are necessary for the

maintenance of Style HC and HCA safetyvalves.

However, tools and equipment are available

to ease disassembly and on site testing of

the valves. Such tools and equipment include

the hydraulic set pressure device, the air

set pressure device (see Figure 15) and the

hydraulic jacking device (see Figure 14).

Detailed instructions on their use can be found

in instructions I-11288, T-1652 and I-1167

respectively.

Whenever Style HC/HCA safety valve parts

names are used in this manual, parts numbers

in parenthesis follow. The parts numbers are

an aid to identifying the parts in Figures 1 and 2

and the correlating parts list.

NOTES

1. Consumable spare parts: valve parts which should

be replaced as part of any disassembly, and discs

and disc inserts which must be replaced if seats

are damaged.

2. Repair spare parts: valve parts exposed to wear

and/or corrosion during normal operation.

They are in fluid flow paths and may require

replacement as part of any repair.

3. Insurance spare parts: valve parts exposed to

process or environmental wear and/or corrosion

and may require replacement as part of a

majorrepair.

Emerson recommends that sufficient inventory

of spare parts be maintained to support process

requirements. Always be sure to use genuine

Emerson parts to ensure continued product

performance and warranty.

3

Page 4

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

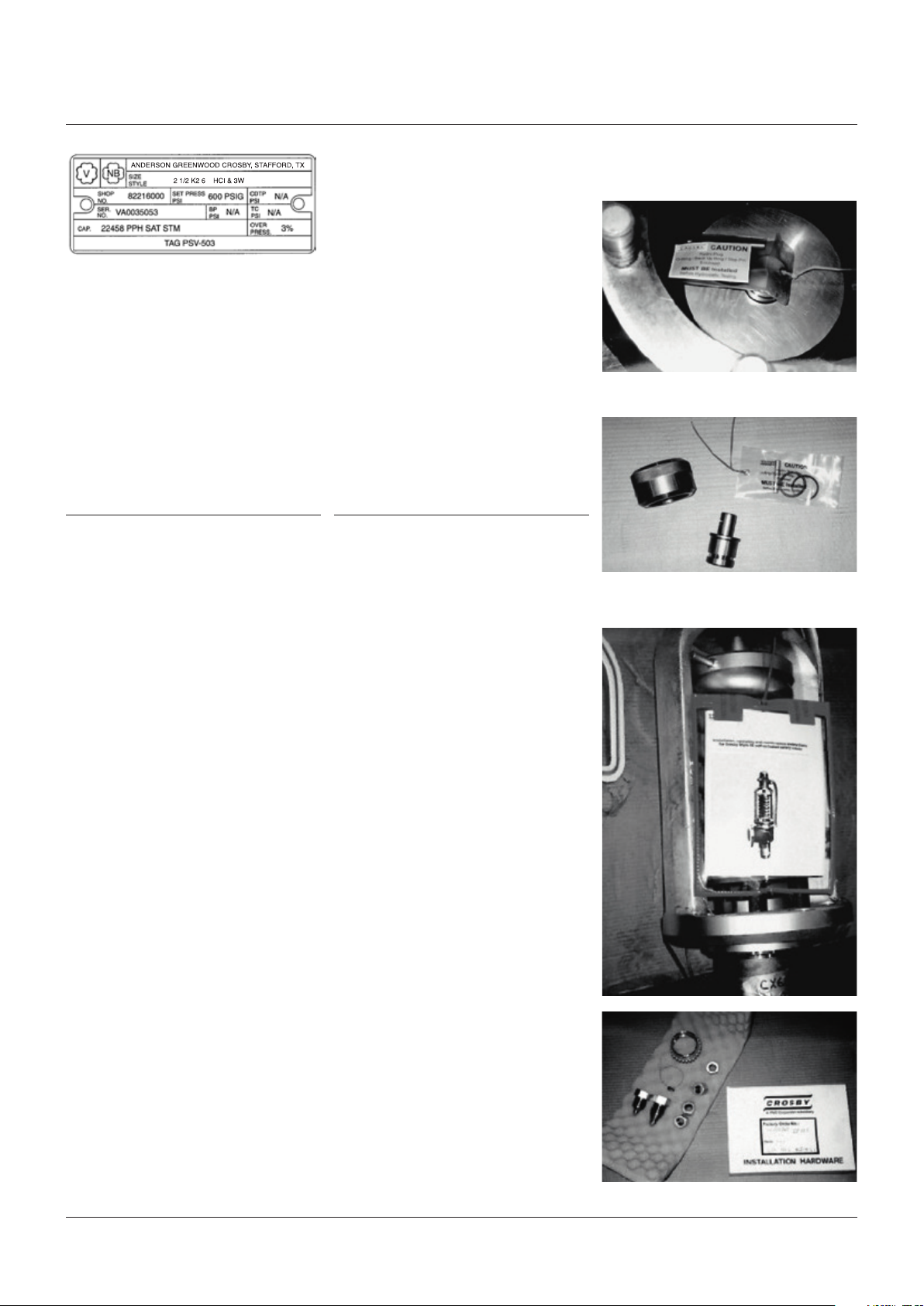

Crosby Style HC/HCA ISOFLEX nameplate

(With sample information for illustrative

purposes only)

Ordering spare parts

When ordering spare parts, the valve size,

style and shop number and/or serial number

should be given together with set pressure,

part name and reference number. The valve

assembly number is shown on the valve

nameplate as 'Shop number'. Spare parts may

be ordered from any Emerson sales office

orrepresentative.

3 DESCRIPTION OF SAFETY VALVES

Crosby Style HC/HCA safety valves are shown

in Figures 1 and 2. These drawings illustrate

the safety valves assembled in cross-section,

and cover the essential elements of the valves.

Approved drawings supplied with the valves

should be used when installation and/or

specific information is required.

Inside the body (1A) is housed the upper portion

of the nozzle (1B), nozzle ring (3), and the

guide ring (10). The disc insert (5) is held in

place in the disc holder (6) by the spindle and

disc holder retainer nut (7). The nozzle ring

and adjusting rings are held in place by the

nozzle ring set screw (4) and the guide ring set

screw(11), which are threaded into the body.

The guide (9) is retained between the body (1A)

and the bonnet (13) by the bonnet studs (14)

and the bonnet studs nuts (15). In the case of

Style HCA valves, a cooling spool (43) is placed

between the body and bonnet to protect the

spring from exposure to extreme temperatures.

The bonnet (13) contains the spring (16),

spring washers (17 and 18) and the spindle

assembly(12). The spindle point is held in

compression between the back face of the disc

insert (5) and the bottom spring washer. The

spring is compressed between the stationary

point of contact with the spindle and the

adjusting bolt (21A) atop the valve bonnet.

The adjusting bolt (21A) is locked in place by the

adjusting bolt nut (22) on top of the bonnet and

within the cap assembly. A means of manual

lifting is provided by the lever (27), lever pin (28),

forked lever (30), forked lever pin (31) and the

spindle nut (23).

4 STORAGE

Often, safety valves are on the job site

months before they are installed. Unless

they are stored properly and protected, their

performance may be affected seriously.

Rough handling may damage flanges or cause

misalignment of the parts. It is best to leave the

safety valves in their shipment cases and store

them in a dry place under cover until they are

tobe installed.

FIGURE 3 - VALVE BODY AS SHIPPED

TOP VIEW - BODY

HYDRO COMPONENTS (see note 1, page 5)

FIGURE 4 - VALVE SUPERSTRUCTURE AS

SHIPPED

4

Page 5

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Factory preparation of welded inlet valves

forshipment

All Crosby Style HC and HCA welded inlet safety

valves are equipped with hydrostatic test plugs

and shipped in two parts: valve body and valve

superstructure. This makes handling easier for

installation welding (seeFigures3and 4).

The welded inlet Style HC and HCA safety

valves are specially prepared for shipment

fromthe factory.

After the safety valve is tested as a complete

assembly for set pressure and tightness, the

spring set compression is held by spacer

blocks under the bottom spring washer as

illustrated in Figure 4.

The safety valve superstructure is then

removed from the valve body. The two portions

are boxed and shipped separately. Each portion,

ready for shipment, is illustrated in Figures 3

and 4.

Figure 3 shows the safety valve body as shipped

to the installation site. It is tagged as follows:

• Install and/or weld in place as required

• Prepare for hydrostatic test. See instruction

Hydrostatic plug in place

• Install O-ring and backup ring prior to

hydrostatic test.

Figure 4 shows the safety valve superstructure

as shipped to the installation site. It is boxed

separately from the valve body and is tagged

asfollows:

• Hold for assembly after hydrostatic test.

5 INSTALLATION

Inlet piping

Many safety valves are damaged when first

placed in service because of failure to clean

the connections properly before installation.

The safety valve inlet, the vessel and the line

on which the safety valve is mounted must be

cleaned thoroughly of all foreign matter.

Safety valves should be mounted in a vertical

position, directly on the pressure vessel.

The ASME boiler and pressure vessel code limits

the distance between the safety valve inlet and

the boiler to the length of a standard tee fitting.

The nozzle should have a well-rounded

approach that provides smooth, unobstructed

flow between the vessel and the safety valve.

A safety valve should never be installed on a

fitting having an inside diameter smaller than

the inlet connection of the valve.

Such restriction of flow can cause faulty

valveoperation.

Inlet piping (nozzles) must be designed to

withstand the total resultant forces due to

the safety valve discharging at the maximum

accumulated pressure and the expected

piping loads. The precise nature of the loading

and the resulting stresses will depend on

the configuration of the safety valve and the

discharge piping. Determination of outlet

reaction forces is the responsibility of the

designer of the vessel and/or piping.

Welding of welded inlet valve body to boiler

Welded inlet safety valve bodies should be

welded to the boiler in accordance with

applicable Code requirements. The protective

cover (Figure 3) should be left in place until

ready for the hydrostatic test of the unit.

If visual inspection is necessary, the protective

cover may be removed, but should be replaced.

NOTES

Note 1 to Figure 3

Delivered with the body and packaged in small

bag are the following:

• One O-ring (for hydrostatic test)

• One backup ring (for hydrostatic test)

• One hydrostatic test plug pin

Note 2 to Figure 4

Delivered with the superstructure and

packaged in a small box are the following:

• Valve nozzle ring*

• Valve nozzle ring set screw*

• Valve guide ring set screw*

• Seal wires

* Marked with valve identification number.

NOTE

When the above parts are removed from their boxes,

be sure that the identification of parts to valve number

is maintained and that the parts are stored to facilitate

later recovery for assembly.

Outlet piping

Discharge piping should be simple and

direct. Back pressures built up by discharge

flow affect the operation of safety valves.

Where possible, a short vertical pipe connected

through a long radius elbow discharging

directly into the atmosphere is the most

desirable type of outlet piping.

Discharge piping should not impose any loading

on the safety valve. Excessive discharge piping

loads may cause seat leakage or faulty valve

operation. The inside diameter of the discharge

pipe must never be less than that of the safety

valve outlet.

Valve effluent must discharge to a safe

disposalarea.

Safety valve bodies have pipe thread openings

for drains. These should be connected to

prevent any accumulation of fluid in the valve

body. In addition, discharge piping also should

be drained to prevent any accumulation of fluid.

Care must be taken to ensure that the drains

are directed or piped to a safe disposal area.

5

Page 6

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

6 HYDROSTATIC TESTING

General information

Depending on the type of inlet, hydrostatic

testing of safety valves may be carried out by

one of three means: blank flanges, test plugs or

test gags. In all cases, hydrostatic test pressure

must be limited to 1½ times the nameplate set

pressure of the valve.

CAUTION

Additionally, hydrostatic test pressure must be

limited to 10% above nameplate set pressure

when a test gag is used.

Welded inlet safety valves

All Style HC/HCA welded inlet safety valves are

prepared for shipment from the factory with

hydrostatic test plugs, as detailed in Section 4 paragraph 'Factory preparation of welded inlet

valves for shipment' and Figure 3.

Hydrostatic tests of these valves shall be

conducted using hydrostatic test plugs as

detailed in paragraph below 'Hydrostatic

testing using hydrostatic test plugs'.

Flanged inlet safety valves

Flanged inlet safety valves should not be

installed for hydrostatic testing. Blank flanges

should be used instead of gagging the safety

valves. This prevents possible damage to the

safety valves due to excessive tightening of

the gag screws or leakage during hydrostatic

test which may result in costly repairs.

Blank flanges must be removed and the

safety valve reinstalled before the vessel

isplacedinservice.

If blank flanges are not used and the safety

valves are to be installed for hydrostatic

tests, Emerson recommends that hydrostatic

test plugs be used for hydrostatic test.

The detailed procedure is outlined in the

paragraph following. Hydrostatic test plugs for

flanged valves are optional equipment and are

providedonly when ordered.

Remove the protective cover from the valve

body. Unscrew the cap from the nozzle.

Remove the test plug from the nozzle bore.

• Preparation for hydrostatic testing Flanged inlet safety valves

Flanged inlet safety valves are shipped

from the factory fully assembled. To use

the hydrostatic test plug, the valve must

be disassembled according to Section 9 paragraph 'Disassembly retaining spring

compression'.

• Installation of hydrostatic test plug

(seeFigure 3)

Inspect the hydrostatic test plug O-ring

groove.

Note: make sure the groove in the plug

isclean.

Install the O-ring and backup ring in the

testplug groove.

CAUTION

Be sure the test plug is seated on the 45°

angleonthe nozzle inside diameter.

Replace the test plug in the nozzle bore.

Place the test plug cap over the plug and

screwit down hand-tight.

CAUTION

Make sure the cap has hand-tight contact with

the plug. Make sure there is enough thread

engagement of the cap onto the nozzle.

Install the test plug pin.

The valve is now ready for hydrostatic test.

• Hydrostatic test

After the above preparation, the safety valve

is ready for hydrostatic test. Observations

should be made at the start of the test to

confirm that the O-rings have been installed

properly and there is no leakage when

pressure is applied.

To aid removal, place the hydrostatic test

plug pin in the hole in the plug extension.

Unscrew the cap, which will engage the plug

pin and exert an upward force as the cap is

turned, thus lifting the plug. Remove from

thevalvenozzle.

Clean the nozzle bore and seat and inspect

the seating surface. If seating surfaces are

damaged, repair according to the directions

in Section 9 - paragraph 'Repair procedure'.

Assemble the valves according to the

instructions in Section 6 - paragraph

'Initialsafety valve assembly'.

Contact Emerson field service for service

equipment (see Section 12 - paragraph

'Service equipment available').

Hydrostatic testing using hydrostatic

testplugs

Before imposing the hydrostatic test pressure

on the vessel or system, perform the following

operations:

CAUTION

Before hydrostatic testing, the O-ring and backup

ring must be installed.

• Preparation for hydrostatic testing Weldedinlet safety valves

The O-ring, backup ring and the test plug

pin are shipped in a box attached to the

superstructure (see Figure 3). The contents

ofthe box are marked for identification.

To install the O-ring and backup ring refer

toFigure 3.

CAUTION

Tightening of the cap will not reduce leakage.

If leakage is evident, remove all pressure from

the vessel or system. Replace the O-ring and

thebackup ring.

WARNING

Do not try to assemble the valve or remove

the steel blocks from under the bottom spring

washerwithout use of proper servicing and

assembly equipment.

• Assembly of valve

After completion of the hydrostatic test,

remove the hydrostatic test plug from

thenozzle.

6

Page 7

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

NORMAL GAGGING LOAD in ft·lb OF TORQUE (Nm) VS. ΔP

ΔP

(Overpressure less valve set pressure)

psi(bar)

50 (3.45) 1 (1.4) 1 (1.4) 2 (2.7) 2 (2.7)

100 (6.89) 2 (2.7) 3 (4.1) 4 (5.4) 4 (5.4)

150 (10.34) 2 (2.7) 4 (5.4) 5 (6.8) 6 (8.1)

200 (13.79) 3 (4.1) 5 (6.8) 7 (9.5) 8 (10.8)

250 (17.24) 4 (5.4) 6 (8.1) 9 (12.2) 10 (13.6)

300 (20.68) 5 (6.8) 7 (9.5) 11 (14.9) 12 (16.3)

Hydrostatic test using gag

The safety valve test gag shown in Figure 5 can

be used with both welded and flanged inlets,

but at pressures no greater than 10% above the

nameplate set pressure.

Gagging should be done very carefully in

K K

• After applying the necessary torque to the

gags, increase the hydrostatic test pressure

to the required amount. Observations should

be made during the rising pressure cycle to

determine if any of the safety valves show

seat leakage.

2

Orifice

psi (bar)

M M

ordernot to overload the valve spindle or

causedamage to the valve seats.

The following outlines the recommended

procedure for gagging valves for

CAUTION

Should any safety valve show seat leakage, the

pressure must be lowered until the leakage stops.

hydrostatictest:

• The torque should then be increased on the

CAUTION

gag about 10% above the initial torque value.

Gags should not be used when inlet pressures are

more than 10% greater than the safety valve set

pressure. Damage to the valve may result.

CAUTION

Never increase the gagging load while a safety

valve shows seat leakage. This can result

• Remove the lever (27), forked lever (30),

cap(25) and spindle nut (23).

in damage to the valve seats and bending

ofthespindle.

• Refer to Figure 5. Lubricate the threads and

pointed end of the gag screw. Install the

gag in place, being careful that the legs fit

uniformly. Contacts on both legs of the gag

should seat evenly on the underside of the

bonnet top.

• After the hydrostatic test, the pressure on the

system should be dropped to approximately

100psi below the nameplate set pressure of

the safety valve. The gags should be loosened

at this point and removed from the valves.

• Tighten the gag finger-tight only at this point.

• Raise the system pressure to approximately

100psig below the nameplate set pressure

ofthe safety valve.

• Apply the necessary torque to the gag in

accordance with the value shown in the

CAUTION

Valve gags should not be left on the valves in

a gagged or loaded position for an extended

period or under conditions where large thermal

variations are expected.

tableabove for the specific orifice size. This

torque value is determined as follows:

- Determine Δ by subtracting the valve set

pressure from the hydrostatic test pressure.

• After the hydrostatic test, the gag should be

removed and the cap reinstalled according

toSection 10 - paragraph 'Assembly of cap'.

- Read the value of Δ on the vertical scale.

Proceed horizontally to the appropriate

orifice size and then down to read the

torqueon the horizontal scale.

- The torque values (foot-pounds) obtained

should be increased by a factor of

approximately 25% to account for normal

variations in friction, safety valves and

testconditions.

FIGURE 5 - VALVE GAG

POSITION GAG EVENLY ON BONNET

2

7

Page 8

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Initial safety valve assembly

After hydrostatic testing using hydrostatic test

plugs, the safety valves should be assembled.

NOTE

It is recommended that, on completion of all

hydrostatic tests using hydrostatic test plugs on new

installations, a Emerson service technician be present

for assembly of the safetyvalves (see Section 12 'Field service requirements').

Check the valve identification numbers and

match the proper valve superstructure to each

valve body.

The nozzle ring (3) and the set screws (4 and11)

are packaged together and shipped with the

superstructure as shown in Figure 4.

CAUTION

Each valve superstructure, nozzle ring and set

screw is identified and matched to a specific valve

body by a tag number and should be assembled

accordingly. Although all parts have been cleaned

thoroughly, inspected, lubricated and protected

for shipment, the parts should be inspected

before installation for evidence of foreign matter

or damage. Special attention should be given

to the seating surfaces of the disc and nozzle.

These seats should be free from surface damage.

If cleaning or repair is necessary refer to

Section 9 - paragraph 'Repairprocedure'.

Initial assembly

Remove the body protective cover (see

Figure3).

Take the nozzle ring (3), nozzle ring set

screw(4) and guide ring set screw (11) from

their package (see Figure 4). Match the set

screws to the body (1A) and bonnet (13) valve

identification markings.

Screw the nozzle ring (3) onto the nozzle (1B).

NOTE

The top of the nozzle ring (3) should be about one ring

revolution above the nozzle (1B) seating surface.

Remove the guide (9) and guide ring (10)

from the superstructure. The guide ring

should be screwed onto the guide. Install

the guide and guide ring assembly into the

top of the body(1A). Make sure the guide is

seated correctly in the body. Make sure that

the nozzle(1B) and disc insert (5) seats are

clean and undamaged. If cleaning or repair

is necessary refer to Section 9 - paragraph

'Repair procedure'.

Remove the lever (27), forked lever (30) and

cap (25) from the valve superstructure. Do not

remove the spindle nut (23).

Using a suitable lifting device, lift the valve

superstructure with the spindle assembly(12)

vertical. Inspect and clean the guide-to-bonnet

fit and the body-to-guide fit. Position the

superstructure so the valve identification

number stamped on the bonnet (13) is

oppositethe valve outlet.

Lowering the valve superstructure slowly,

carefully lower the disc holder (6) into the

guide(9).

CAUTION

Do not permit any rocking motion of the

spindle(12) or any other part while lowering the

superstructure into the body (1A). Any rocking

motion could damage the valve seats.

After the superstructure in in place, inspect

tobe sure the bonnet (13) is fully seated on

theguide (9).

The nozzle ring (3) should now be lowered.

Lift the disc insert (5) slightly off the

seat by lifting the spindle assembly (12).

Place a screwdriver in the lower set screw hole.

Turn the nozzle ring to the left (clockwise) with

the screwdriver until the top edge of the nozzle

ring is below the nozzle (1B) seating surface.

The location can be checked by looking in

through the upper set screw hole while shining

a light through the lower set screw hole.

Lower the spindle assembly slowly until

it bottoms. Check that the nozzle ring

movesfreely.

Rotate the spindle clockwise several

revolutions to make sure that it is seated fully

on the disc insert and that the threads of the

spindle are not engaged.

The seating surfaces are now in full contact.

Install the bonnet stud nuts (15) on the bonnet

studs (14) and tighten uniformly in accordance

with Figure 6.

It is now necessary to remove the spacer blocks

under the bottom spring washer (17), thereby

transferring the spring load to the valve seats.

This should be done using the hydraulic jacking

device (see Figure 14). Refer to instruction

I-1167 for detailed instructions in the use of this

device.

After the spacer blocks have been removed, set

the nozzle ring (3) and guide ring (10) according

to Section 10 - paragraph 'Setting of rings'.

Lock the nozzle ring set screw (4) and the

guide ring set screw (11) in place, making sure

that the proper set screws are installed and

engaged fully in a notch. Lock wire them in

place and seal.

8

Page 9

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Torque (ft·lb) (Nm) to produce stress in stud bolts

30.000psi (2.068bar) 45.000psi (3.203bar) 60.000psi (4.137bar)

Stress Stress Stress

Stud thread

⅝-11

¾-10

⅞-9

1-8

1⅛-8

Complete the valve assembly with the cap assembly as described in Section 10 - paragraph 'Assembly of cap'

and seal wire the cap set screws.

NOTES

1. Valve studs and nuts shall be clean and inspected

visually to ensure freedom from any objectionable

foreign matter, rust, burnsor physical damage.

2. With the bonnet in place, lubricate the bonnet

studs threads, the nut threads and nut face with

'Never-Seez' compound (which conforms to

Government specification MIL-A-907B, Federal

stock number 803-286-5453) or equivalent.

3. Install nuts on the studs finger-tight.

4. Tighten the nuts in the sequence shown in Figure

6 to approximately one-half the torque value

shown in the table. Repeat the same sequence

of tightening to the torque value shown. Then,

starting with the number 1 nut, tighten each nut in

order in a clockwise or counterclockwise direction

to the value shown in the table above.

5. Wipe off excess lubricant.

ft·lb (Nm) ft·lb (Nm) ft·lb (Nm)

60 (81) 90 (122) 120 (163)

100 (136) 150 (203) 200 (271)

160 (217) 240 (325) 320 (434)

240 (325) 370 (502) 500 (6-78)

350 (475) 525 (712) 700 (949)

The sharp opening is produced in two stages.

The initial lift is produced when the steam

pressure under the disc insert (5) exceeds

the spring pressure. To aid in starting the

popping action, steam escapes between the

safety valve seats and is deflected by an angle

on the nozzle ring (3) as shown in Figure 7.

This escaping steam acts on the face of the disc

holder (6) causing an unbalance and the safety

valve pops open. As the disc holder moves

vertically, steam begins to react against the

guide ring(10) and to push the disc holder up

to a high lift as shown in Figure 8. The reaction

of the deflected steam pushes against the

underside of the disc holder and lifts it still

higher on an accumulation of pressure.

As the boiler pressure drops, the safety valve

disc insert (5) settles to a moderate lift and

closes sharply.

7 OPERATION

The nozzle ring (3) is primarily for ensuring

sharp opening action. Raising the nozzle

Crosby Style HC/HCA safety valves open with a

sharp pop at the set pressure and remain open,

relieving rated capacity at 3% overpressure.

As inlet pressure decays below the opening

pressure, the safety valve remains open until

a pressure about 4% below the set pressure

is reached. At that point, the safety valve

closessharply.

ring, bringing it closer to the face of the disc

holder(6), eliminates 'simmer' or 'warn'.

The guide ring (10) is primarily for controlling

blowdown. Raising the guide ring reduces the

reactive pressures against the disc holder and

reduces blowdown. Lowering the guide ring

increases the reactive pressures against the

disc holder and increases the blowdown.

FIGURE 6 - TIGHTENING OF BONNET AND/OR

COOLING SPOOL STUD NUTS

4 studs 6 studs

FIGURE 7 - EFFECT OF NOZZLE RING

Nozzle ring

FIGURE 8 - EFFECT OF GUIDE RING

Guide ring

9

Page 10

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

8 TESTING

Set pressure testing and valve adjustments

The set pressure of a safety valve may be

checked without removing the valve from

the system by two methods described in the

following paragraphs:

• Set pressure lift assist device

The first method of set pressure testing is

with the use of a set pressure lift device.

This allows set pressure testing of the safety

valves on the system at pressures below

normal system operating pressures.

Two devices are available for use on

Crosby Style HC/HCA safety valves: the air

set pressure device and the hydraulic set

pressure device. Refer to test procedure

T-1652 for detailed instructions in the use of

the air set pressure device and instruction

I-11288 for detailed instructions in the use of

the hydraulic set pressure device.

• System pressure

The second method of set pressure testing is

by raising the system pressure and popping

the safety valve. Set pressure testing using

this method will determine the safety valve

set and closing pressure (blowdown).

WARNING

Never strike a valve which is under pressure.

Premature actuation can result.

Setting the safety valve with the set pressure

lift device is recommended before raising

the system pressure for popping pressure

testing. This allows the set point to be

established without raising and lowering

system pressure several times to determine

the safety valve set pressure.

Before set pressure testing and raising the

system pressure, the following items should

be checked:

- A pressure gauge with known accuracy

should be located on the system

beingtested.

- Outlet piping should be anchored sufficiently

to prevent any vibrations while the safety

valve is discharging. The outlet piping

should be direct and there should be no

obstructions to restrict the safety valve

discharging.

- Set screws should be tight and lock

wired. The tapped holes in the body for

drains should be connected to the drain

orplugged.

- Lifting gear should be fastened securely to

the safety valve to assist personnel testing

the valve. A rope may be attached through

the hole provided in the lever should

mechanical lifting be necessary.

• Communications should be set up between

the control room and personnel in the

testarea.

WARNING

Hearing and eye protection should be used when

working on a valve which is under pressure. Never

stand in front of the discharge of a safety valve

which is under pressure.

CAUTION

All safety valves on the system except the

valve that is to be popped should be gagged.

System pressure should be 70% of valve set

pressure before gagging to prevent added loads

from being applied to the valve spindle due to

thermalexpansion.

Gagging must be done with care not to overload

the spindle since considerable damage may occur

to the spindle and other valve internals. However,

a minimum torque should be applied to the gag

byhand to ensure that the valve will not open.

Install the gags as follows (refer to Figure 5):

• Remove the lever (27), forked lever (30),

cap(25) and spindle nut (23).

• Lubricate the threads and pointed end

ofthegag screw.

• Install the gag in place, being careful that the

legs fit uniformly. Contacts on both legs of the

gag should seat evenly on the underside of

the bonnet (13) top.

• Tighten the gag finger-tight.

Raise the system pressure until the safety

valvepops.

Record the popping and reseating

pressures(pressure at which the safety

valvecloses sharply).

10

Page 11

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

• Set pressure adjustment

If the safety valve pops before the nameplate

set pressure is reached, or if it does not pop

at the nameplate set pressure, the following

steps for set pressure adjustment should

betaken:

WARNING

Set pressure adjustment should not be made until

the system pressure is 10% to 20% below the

actual popping pressure of the safety valve. The

adjusting bolt should never be turned when the

vessel pressure is near the set pressure of the

safety valve.

- Remove the lever (27), forked lever (30)

andcap (25).

- Loosen the adjusting bolt nut (22).

- If the safety valve has popped below the set

pressure stamped on the valve nameplate,

an increase in set pressure is necessary.

This is obtained by turning the adjusting

bolt(21) clockwise (compressing the

spring). If the safety valve popped above

the nameplate set pressure, decrease

the set pressure by turning the adjusting

bolt counterclockwise (relieving spring

compression).

- After each adjustment, the adjusting bolt

nut(22) should be tightened securely to

prevent loosening of the bolt. The lifting

gear should be reinstalled.

- After the safety valve has been adjusted to

open at the desired pressures, remove the

lifting gear and make sure the adjusting bolt

nut (22) is installed properly and tightened.

Install the cap assembly (25) according to

Section 10 - paragraph 'Assembly of cap',

1

making sure there is approximately

/

16”

clearance between the spindle nut (23)

and the forked lever (30). Seal wire the cap

screws(26) and set screws (4 and 11).

The nozzle ring and guide ring settings are

determined at the factory. Their locations are

stamped on the valve bonnet (13) where the

cap is seated. Adjusting (guide) ring positions

are recorded as plus (+) or minus (-) numbers

from the level position. An illustration of the

guide ring sign convention is presented in

Figure 9. However, if the desired blowdown was

not obtained, it will be necessary to adjust the

rings. The following steps shouldbe taken:

WARNING

Never make ring adjustments with the vessel

under pressure without gagging the safety valve

properly. Be careful to use only enough torque to

hold the valve closed. Over-gagging may damage

the valve internals.

• Nozzle ring and guide ring adjustment

The guide ring (10) is the principal blowdown

control ring in the safety valve. To change the

guide ring position, remove the guide ring

set screw (11) from the body (1A). Insert a

screwdriver or similar tool and engage one

ofthe notches (these can be seen through

theset screw hole).

The guide ring can then be turned to the

right or left as desired. Moving the guide

ring to the right (counterclockwise) raises

it and decreases the blowdown. The guide

ring should never be moved more than

ten notches either way without retesting

thevalve.

After each adjustment, always replace,

tighten and lock wire the set screw, being

careful that its point engages a notch.

The nozzle ring (3) is necessary for obtaining

the pop action of the safety valve. This

ring setting is determined at the factory

and rarely needs further adjustment.

However, in case the guide ring (10) does not

give the desired operating characteristics

under all conditions of operation, the nozzle

ring may be adjusted to control the valve

operation for very fine adjustment. The nozzle

ring is adjusted by removing the nozzle ring

set screw (4) from the valve body (1A).

Turning the ring to the right

(counterclockwise) raises it and results in a

strong pop action. Blowdown will increase.

Turning the ring to the left (clockwise) lowers

the ring, decreases the blowdown and may

result in warn or simmer if lowered too far.

The range of adjustment of the nozzle ring is

limited and it should not be moved more than

one notch at a time.

The valve performance should be checked

after each adjustment. After each adjustment,

always replace, tighten and lock wire the set

screw, being careful that its point engages

anotch.

Whenever ring adjustments are changed,

a record should be kept of the number of

notches and the direction in which the ring

was moved. This will make it possible to

return to the original setting in case of error.

After the safety valve has been adjusted to

close at the desired pressure, remove the

lifting gear and make sure the adjusting bolt

nut (22) and the set screws (4 and 11) are

installed properly and tightened.

If different ring locations are obtained

after testing, restamp the top of the valve

bonnet(13) with the new (tested) ring settings.

Install the cap assembly (25) according to

Section 10 - paragraph 'Assembly of cap',

1

making sure there is

/

16” clearance between

the spindle nut (23) and forked lever(30).

Sealwire the cap screws (26) and set

screws(4 and 11).

FIGURE 9 - RING SETTINGS AND ADJUSTMENTS

Guide ring

Disc holder

Steel rod to check

guidering position

Level position*

* Factory setting of guide ring

position (+/-) notches from

levelstamped on bonnet

11

Page 12

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

9 VALVE MAINTENANCE

General information

When possible, remove the safety valve from

the system before dismantling (flanged inlet).

Nozzle and guide ring set screws are custom

fitted to each safety valve and should never

beinterchanged.

The spring washers are fitted to each end of

thespring. The spring and washers must be

kept intact as a unit.

Before disassembly, spare parts and service

equipment such as lapping compound, lapping

blocks and jacking gear should be available.

WARNING

There should be no system pressure when

asafety valve is either dismantled in place

orremoved for shop repair.

Disassembly

• Disassembly retaining spring compression

If the safety valve is to be reconditioned

without retesting, the original set pressure

can be retained by use of a hydraulic jacking

device (see Figure 14). This device is a service

tool that can be obtained from Emerson

(see Section 13 - 'Maintenance equipment').

Refer to detailed instructions in the use of

this device in instruction I-1167.

Remove the lever (27), forked lever (30),

cap(25) and spindle nut (23).

Remove the nozzle ring set screw (4). Check

the setting of the nozzle ring (3) by turning it

to the right (counterclockwise), counting the

number of notches turned until it contacts

the disc holder (6) (see Figure 9). Record the

number of notches. This location is given as

minus (-) notches from this contact position.

Remove the guide ring set screw (11).

The guide ring (10) should be turned to the

right (counterclockwise) or left (clockwise)

whichever is necessary to return it to its level

position. The guide ring is in level position

when the bottom face of the guide ring is level

with the bottom face of the disc insert (5) or

disc holder (6). This position is illustrated in

Figure 9. The guide ring position is recorded

as minus (-) (down) or plus (+) (up) notches

from this level position.

Measure the distance between the bottom

face of the bottom spring washer (17) and the

bonnet flange (13) and record the dimension.

Cut three pieces of bar stock ⅛” longer than

the recorded dimension for spacer blocks.

Install the hydraulic jacking device in

accordance with the following (referring

toFigure 14):

- Install the bonnet spacer (5) on the bonnet.

Position the jacking device assembly by

lifting over the spindle and lowering down

on the bonnet spacer.

CAUTION

The piston (2) should be seated within the

housing(1) before continuing. This seated position

is reached when the first notch on the piston (2)

is level with or below the top of the housing (1)

asillustrated in Figure 14.

- Lubricate the spindle threads with a light

coat of 'Never-Seez

equivalent. Thread the appropriate spindle

adapter (6) on the spindle until it comes in

contact with the jacking device piston.

- Attach the hand-operated hydraulic

pump(7) and hose (8).

- To raise the valve spindle, pressure is

applied to the jacking device assembly

with the hand-operated hydraulic pump.

This activates the piston (2) which will rise,

compressing the spring in the process.

CAUTION

This device has a limited piston stroke that should

not be exceeded. If the piston stroke is exceeded,

the second notch on the piston (2) will be above

the top of the housing (1) and hydraulic fluid will

flow from the bleed hole located in the housing.

If hydraulic fluid is flowing from the bleed hole

but the piston stroke has not been exceeded,

the O-ring (3) and the backup ring (4) should

beinspected for wear or damage and replaced

ifnecessary.

After the spring load has been taken up and

the valve has been jacked about ⅛”, place

the spacer blocks under the bottom spring

washer(17). See Figure 4.

Release the hydraulic pressure to allow the

spring load to rest on the spacer blocks.

If so desired, the jacking device can now be

removed by releasing pressure in the pump.

Thread the spindle nut (23) on the spindle(12)

to hold the spindle in position during

disassembly or leave the jacking device in

place. Loosen and remove the bonnet stud

nuts(15).

Using suitable lifting means, lift the

superstructure carefully straight up and out

of the body.

®

', 'Molykote®-G' or

CAUTION

Do not permit any rocking motion of the spindle

or any other parts while lifting the superstructure

out of the body. Any rocking motion could damage

the valve seats.

Lay the superstructure down with the spindle

horizontal. Care must be exercised to prevent

the parts from being damaged.

Remove the spindle nut (23) or jacking device

from the spindle (12). Carefully slide the spindle

and disc holder (6) as an assembly from the

jacked and blocked spring (16) and bonnet (13).

Proceed with disassembly of the internals

according to Sectio 9 - paragraph 'Disassembly

of internal structure'.

12

Page 13

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

• Disassembly without retaining spring

compression

To disassemble the safety valve completely

and not retain the spring compression, the

following procedure should be used:

- Remove the lever (27), forked lever (30),

cap(25) and spindle nut (23).

- Remove the nozzle ring set screw (4). Check

the setting of the nozzle ring (3) by turning it

to the right (counterclockwise), counting the

number of notches turned until it contacts

the disc holder (6) (see Figure 9). Record the

number of notches. This location is given

as minus (-) (down) or plus (+) (up) notches

from this level position.

- Remove the guide ring set screw (11).

The guide ring (10) should be turned to the

right (counterclockwise) or left (clockwise)

whichever is necessary to return it to its

level position. The guide ring is in level

position when the bottom face of the guide

ring is level with the bottom face of the disc

holder. The guide ring position is recorded

as minus (-) (down) or plus (+) (up) notches

from this level position.

- Measure and record spindle (12) to adjusting

bolt (21A) dimension A; and adjusting bolt

to bonnet (13), dimension B. See illustration

below.

- Release spring tension by loosening

the adjusting bolt nut (22) and then the

adjustingbolt (21A).

WARNING

Never loosen the bonnet stud nuts (15) before

releasing the spring tension with the adjusting

bolt (21A).

- After making sure all spring tension has

been released, loosen and remove the

bonnet stud nuts.

- Strap the spring (16) into the bonnet (13)

to prevent the spring from falling out from

between the bonnet struts. Using suitable

lifting means, lift the spring and bonnet

assembly carefully straight up and over the

spindle (12). Set the assembly aside.

- Lift the spindle and internals carefully

straight up and out of the body (1A).

CAUTION

Do not permit any rocking motion of the spindle

or any other parts while lifting the spindle and

internals out of the body. Any rocking motion

could damage the valve seats.

- Lay the spindle down horizontally.

- Proceed with disassembly of the internals

according to paragraph below 'Disassembly

of internal structure'.

- Should lack of overhead space prevent the

bonnet (13) being lifted over the spindle (12),

the spindle nut (23) may be installed to hold

the spindle in position. Using suitable lifting

means, lift the superstructure carefully

straight up and out of the body.

CAUTION

Do not permit any rocking motion of the spindle

or any other parts while lifting the spindle and

internals out of the body. Any rocking motion

could damage the valve seats.

- Lay the superstructure down so the spindle

is horizontal. Care must be exercised to

prevent the parts from being damaged.

- Remove the spindle nut (23) from the

spindle (12). Remove the spindle, spring (16)

and washers (17 and 18A) carefully from the

bonnet (13).

- Proceed with disassembly of the internals

according to the following paragraphs.

• Disassembly of internal structure

Remove the guide (9) and guide ring (10) from

the body (1A) as an assembly and unscrew

the guide ring from the guide.

Remove the spindle (12) from the disc

insert(5) by lifting the spindle slightly to

engage the threads and unscrewing the

spindle from the disc insert.

Unscrew the nozzle ring (3) from the

nozzle(1B).

All the parts should be cleaned thoroughly,

paying special attention to guiding surfaces.

The seats should be lapped according to

section following 'Lapping or refurbishing

of valve seats'. If replacement parts are

required, refer to Section 2 - 'Ordering

spareparts'.

Spindle (12)

Adjusting bolt (21A)

Adjusting bolt nut (22)

(A)

(B)

Bonnet (13)

13

Page 14

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Top lapping

surface

Motion shown by

dotted lines

Bottom rough surface

Do not use

Lapping block to

besquared up

• Repair procedure

Lapping or refurbishing of valve seats

Good seating surfaces on the nozzle (1B)

and disc insert (5) are of the greatest

importance when reconditioning safety

valves. The seats should be flat and free

fromsurfacescratches.

Lapping block

This is made of a special grade of annealed

cast iron, perfectly flat on both sides. It must

remain flat to produce a flat seating surface.

In checking the lapping block and for

restoring flatness after use, a lapping block

resurfacing plate should be used.

Lapping block resurfacing plate

This is also made of a special grade of

annealed cast iron, machined and lapped

on the side that has small squares.

This is the surface on which lapping blocks

arereconditioned.

Lapping block

Lapping compound

Experience has proven that three grades

of compound - medium, fine and polish will condition almost any damaged valve

seat properly except where the damage

requires remachining. A medium coarse

compound may be used for fast cutting as

a first operation after machining, if desired.

The following lapping compounds, or their

commercial equivalents, are suggested:

Grit compound number Description

320 Medium coarse

400 Medium

600 Fine

900 Polish

CAUTION

Never lap the disc insert against the nozzle.

Lapping procedure

Different individuals have different methods

of lapping valve seats, but certain essential

steps must be taken to get satisfactory

results. The following procedure is suggested

for lapping of valve seats:

- Lap each part separately against a cast

iron lapping block of the proper size.

These blocks hold the lapping compound in

their surface pores but must be recharged

and reconditioned frequently.

- Check the lapping block frequently on a

good lapping block resurfacing plate to

make certain that it is perfectly flat on

bothsides.

- If considerable lapping is required, spread

a thin coat of medium lapping compound on

the block. After lapping with this compound,

lap again with fine compound using a new

lapping block surface. The first step can be

omitted unless much lapping is called for.

Next, lap again using a polish compound.

Orifice K K

'B' minimum

dimensionafterlapping

0.005in 0.006in 0.007in 0.007in

(0.127mm) (0.152mm) (0.178mm) (0.178mm)

FIGURE 10 - DISC INSERT MINIMUM SEAT HEIGHTS

2

M M

'B' minimum

afterlapping

2

14

Page 15

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Lap the block against the seat. Never rotate

the block continuously, but use an oscillating

movement.

When all the nicks and marks have

disappeared, remove all the compound from

the block and seat. apply polish compound to

another block and lap the seat with this. As the

lapping nears completion, only the compound

left in the pores of the block should be

present. This should give a very smooth finish.

If scratches appear, the cause is probably

dirty lapping compound. These scratches

should be removed by using compound free

offoreignmaterial.

Be extremely careful to keep the seats flat.

Refurbishment of disc and disc insert seats

When the damage to the disc insert (5) seat is

too severe to be removed by lapping, the disc

insert should be replaced. Disc inserts should

never be remachined. Remachining the insert

will change critical dimensions, affecting the

operation of the safety valve. The disc insert

seating surface may be lapped if the minimum

seat height shown in Figure 10 ismaintained.

Refurbishment of nozzle seats

If machining of the nozzle (1B) seat or other

major repairs are necessary, it is recommended

that a reseating machine be used (see Section

13 - 'Maintenance equipment'). All parts

must be accurately machined per Emerson

specifications. No safety valve will be tight nor

will it operate properly unless all parts are

machined correctly.

Machining dimensions for Crosby Style HC/HCA

safety valves are shown in Figure11. Remove

only enough metal to restore the surface to its

original condition. Turning to the smoothest

possible finish will facilitate lapping.

The nozzle (1B) must be replaced when

the maximum 'A' dimension is exceeded.

This critical dimension is shown in Figure 12.

NOTES

1. Maximum tolerance zone for surface parallel

todatum axis:

for orifice K2 through M2 .009”

2. Maximum tolerance zone for surface

perpendicular to datum axis:

for orifice K2 through M2 .0015”

MAXIMUM ‘A’ DIMENSION - ORIFICE AND VALVE CLASS

K K

3( ) - 9( ) 3( ) - 6( ) 7( ) - 9( ) 3( ) - 7( ) 8( ) - 9( ) 11( ) 11( )

in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) in (mm)

4.203 4.203 5.141 4.953 5.641 5.453 6.328

(106.756) (106.756) (130.581) (125.806) (143.281) (138.506) (160.731)

2

K

2

M and M

2

M and M

2

K and K

2

FIGURE 11 - NOZZLE SEAT CRITICAL DIMENSIONS FIGURE 12 - BODY TO NOZZLE SEAT DIMENSIONS

.014

Mach.

.010

Min. after lapping

.008

3.0°

1.5°

45°

.014

Mach.

.010

Min. after lapping

.008

'A' max

Datum

axis

Note 1

Note 2

Tolerance zone

parallel to datum

axis

Datum

axis

M and M

Tolerance zone

perependicular

todatum axis

Datum

axis

2

Interpretation

15

Page 16

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

10 VALVE ASSEMBLY

General information

Apply a light coat of 'Never-Seez

®

[1]

'

lubricant

on the new nozzle ring (3) threads. Screw the

nozzle ring on the nozzle leaving the top of the

ring slightly above the seating plane. This will

help protect the seating surface of the nozzle

during the assembly process.

Spot lap the disc insert (5) to the spindle (12)

and clean thoroughly. Apply a thin coat of

'Molykote

®

[2]

321R'

, or equivalent, dry film

lubricant to the bearing surface of the disc

insert and spindle tip.

Apply a light coat of 'Never-Seez

®

' to the

threads of the spindle (12), disc insert (5) and

disc holder retainer (7). Thread the disc holder

retainer on the spindle and slide the disc

holder(6) over the lower end of the spindle.

Thread the disc insert onto the spindle and set

the retainer clearance (see Figure 13).

Spot lap the guide (9) with the mating surface

on the body (1A) and clean the surface

thoroughly. Then place the guide into position

on the body.

With the disc holder (6), disc insert (5), disc

holder retainer (7) and spindle (12) assembled,

place the assembly into position in the body

andguide.

Place the spring and washer assembly into

position on the bonnet/cooling spool assembly.

Note that the anti-rotation pins of the top spring

washer should be straddling the bonnet.

The valve can be assembled further using

either of the following two methods.

Onemethod may be preferred over the

other depending on the valve size and/or set

pressure.

Assembly of the valve superstructure

and the compression of the spring may

be accomplished by two different method

asfollows:

• Valve assembly without using the hydraulic

jacking device

Utilizing a suitable lifting device, place the

bonnet/spring assembly over the spindle (12)

and into position on the body (1A). Note that

the adjusting bolt (21A) will be in the retracted

position thereby allowing the bonnet (13) to be

seated on the body.

With the assembly in place, turn the nozzle

ring (3) clockwise (with a screwdriver through

the set screw hole) until the top surface is

below the seating plane. The bonnet stud

nuts(15) may now be torqued in place.

Note that a criss-cross torquing pattern

should be utilized to ensure even

compression as illustrated in Figure 6.

Once the bonnet stud nuts (15) are in place,

the adjusting bolt (21A) may be turned,

thereby compressing the valve spring (16).

Tighten the adjusting bolt until the distance

is the same as that recorded when the valve

was disassembled (see page 11). At this point,

the adjusting bolt nut (22) shall be tightened

in place.

NOTE

The setting of the spring compression by this method

is only a very rough estimate of the valve set pressure.

The valve will require set pressure testing prior to

returning to service (refer to Section 8 - paragraph

'Set pressure testing and valve adjustment').

CAUTION

The cotter pin head should be turned so that it fits

between and into the retainer notch and makes

contact with the spindle. The split ends of the

cotter pin should both be bent downward.

Stand assembly on a clean surface making

certain that the end of the spindle rotates freely

on the disc insert bearing surface (not loading

on the insert threads). Thread the disc holder

retainer down until itmakes contact with the

disc holder.

Locate the hole in the spindle relative to a notch

on the retainer. Back off the retainer by turning

it counterclockwise to establish the proper

clearance.

The clearances, and the corresponding number

of notches, are listed in the table. With the

proper clearance established, install the

retainer cotter pinthrough the appropriate

notch and spindle.

NOTES

1. Never-Seez is manufactured by Bostik

Corporation.

2. Molykote is manufactured by Dow Corning

Corporation.

Retainer clearance

Valve orifice size

K .008 - .012 4 - 6

K2 .010 - .012 5 - 6

M/M2 .010 - .012 5 - 6

(inches)

Corresponding number

ofretainer notches

FIGURE 13 - RETAINER NUT CLEARANCE

Spindle

Cotter pin

Disc insert

Disc holder retainer

Disc holder

Retainer clearance

Clean surface

16

Page 17

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

• Valve assembly using the hydraulic

jackingdevice

Utilizing a suitable lifting device, place the

bonnet/spring assembly over the spindle(12)

and into position on the body. Note that

because the adjusting bolt is in a down

position, the bonnet (13) (or cooling spool (43))

will be raised slightly above the surface of the

body (1A).

Replace the bonnet stud nuts (15) and tighten.

Referring to Figure 14:

- Install the bonnet spacer (5) on the bonnet.

Position the jacking device assembly

by lifting over the spindle and lowering

- Lubricate the spindle threads with a light

coat of 'Never-Seez

®

', 'Molykote®-G' or

equivalent. Thread the appropriate spindle

adapter (6) on the spindle until it comes in

contact with the jacking device piston.

- Attach the hand-operated hydraulic

pump(7) and hose (8).

- To raise the valve spindle, pressure is

applied to the jacking device assembly

with the hand-operated hydraulic pump.

This activates the piston (2) which will rise,

compressing the spring in the process.

- Lift the valve spindle approximately ⅛”

andremove the spacer blocks.

downon the bonnet spacer.

CAUTION

The piston (2) should be seated within the

housing(1) before continuing. This seated position

is reached when the first notch on the piston (2)

is level with or below the top of the housing (1)

asillustrated in Figure 14.

Orifice and valve class

Piece

description

Bonnet spacer 086418 None None None

Spindle adapter 082893 083508 083508 083508

Tabulation of Crosby part numbers for manual jacking device for Crosby Style HC and HCA valves

assemblySA-52980 is always required. The spacer and adapter are required as shown in table above.

K K

7( ) - 9( ) 7( ) - 9( ) 7( ) - 9( ) 7( ) - 9( )

2

M M

FIGURE 14 - HYDRAULIC JACKING DEVICE

PARTS LIST

2

Part no. Description

1 Housing

2 Piston

3* O-ring

3A* O-ring

4* Back-up ring

4A* Back-up ring

5 Bonnet spacer

6 Spindle adapter

7 Hydraulic pump

8* ¼” hose

14 Valve spindle

20 Bonnet

23 Adjusting bolt

24 Adjusting bolt nut

* Recommended spare part

Bleed hole

.250-18 NPT

Piston stroke

indicator

NOTES

• Assembly SA55848 consists of Pc. Nos. 1, 2, 3, 3A,

4, 4A, 7, 8.

• Spacer (Pc. No. 5) and adapter (Pc. No. 6) must be

selected from table.

• Assembly SA52980 consists of Pc. Nos. 1, 2, 3, 3A,

4, 4A.

CAUTION

This device has a limited piston stroke that should

not be exceeded. If the piston stroke is exceeded,

the second notch on the piston (2) will be above

the top of the housing (1) and hydraulic fluid will

flow from the bleed hole located in the housing.

If hydraulic fluid is flowing from the bleed hole

but the piston stroke has not been exceeded,

the O-ring (3) and the backup ring (4) should be

inspected for wear or damage and replaced if

necessary.

17

Page 18

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Setting of rings

The nozzle ring (3) setting is stamped on the

machined surface of the bonnet (13) where the

cap (25) sits. For example, NR-15 means set

the nozzle ring fifteen notches below contact

with the disc holder (6). To set the nozzle ring,

turn it to the right (counterclockwise) until it

touches the disc holder. From this position,

lower it by the number of notches indicated to

the stamped position.

The guide ring (10) setting is obtained in

the same manner as the nozzle ring above.

For example, GR +30 means thirty notches

above level position. Level is when the bottom

of the guide ring is even (level) with the bottom

of the disc holder. This position is illustrated in

Figure9. With the safety valve already on the

system, level can be obtained by inserting a

metal rod with a hook on the end through the

lower set screw hole and feeling the position of

the ring in relation to thedischolder.

To set the guide ring, move it to the level

position. If the stamped guide ring position is

a positive number, turn the ring to the right

(counterclockwise) to raise the guide ring by

thenumber of notches indicated. If the stamped

guide ring position is a negative number, turn

the ring to the left (clockwise) to lower the ring

that number of notches.

Lubricate the set screws (4 and 11) threads.

Screw the set screws into the body (1A)

engaging both the nozzle ring (3) and guide

ring (10). Both rings should be able to move

back and forth slightly after the set screws

aretightened.

Assembly of cap (see Figure 1)

The assembly of the cap is referred to several

times in this instruction. The cap assembly

consists of the spindle nut (23); cap (25); forked

lever assembly: forked lever (30), forked lever

pin (31) and forked lever pin cotter (32); and the

lever assembly: lever (27), lever pin (28) and

lever pin cotter (29).

The lever assembly can be removed from

the safety valve independently of the cap.

The cap cannot be removed from the safety

valve without first removing the forked lever

assembly.

The cap set screws (26) are seal wired to

prevent tampering with the adjusting bolt (21).

To assemble the cap assembly, proceed as

follows:

If the spindle nut (23) was removed, lubricate

the spindle rod (12B) threads and install the

spindle nut (23) and the spindle nut cotter (24).

Install the lever (27), lever pin (28) and lever pin

cotter (29). Place the cap in position but do not

tighten the cap set screws yet.

Install the forked lever (30), forked lever pin (31)

and forked lever pin cotter (32). Be sure that

1

the forked lever is free to move from

/

16” to⅛”

before coming into contact with the spindle

nut(23).

If travel is excessive, remove the forked lever

and cap and turn the spindle nut clockwise or

counterclockwise to increase or decrease the

forked lever travel.

Be sure the spindle nut cotter (24) is installed

after the final adjustment.

11 SPARE PARTS

Emerson recommends spare parts as shown

on the parts list with corresponding notes.

When ordering spare parts, the valve assembly

number should be given together with part

number and valve size and style. The valve

assembly number is shown on the valve

nameplate as shop number (see Section 2paragraph 'Crosby Style HC/HCA ISOFLEX

nameplate'). AnyEmerson sales office or

representative canexpedite your spare parts

requirements.

18

Page 19

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

12 FIELD SERVICE REQUIREMENTS

Field service

Crosby operates an extensive field service

organization capable of adjusting, setting

and maintaining Crosby valves worldwide.

Emerson service technicians, factory trained

and long experienced in servicing safety valves,

are located throughout the world for fast

response to our customers’ needs. It is strongly

recommended that on new installations a

Emerson service technician be present for

assembly and testing of safety valves.

Service equipment available

All service equipment mentioned in this

instruction is available for purchase or rental.

Any Emerson sales office, representative or

service manager can expedite your service

equipment requirements.

13 MAINTENANCE EQUIPMENT

Reseating machines

Reseating machines will remachine the nozzle

seats in place without removing the safety valve

from the installation. Form cutters are used to

cut a new seat to exact dimensions. Reseating

machines, cutters and auxiliary equipment may

be rented or purchased. Contact the factory.

Jacking devices

When a safety valve is to be disassembled and it

is desired to retain spring compression, i.e., the

set pressure, a mechanical or hydraulic jacking

device may be used. Jacking devices are used

to lift the bottom spring washer sufficiently to

allow the disc or disc insert to lift clear of the

nozzle (permitting the entire bonnet assembly

to be removed). Jacking devices may be rented

or purchased. Contact the factory.

Air (ASPD) and hydraulic (HSPD) set

pressuredevices

The set pressure of safety valves may be

determined without raising system pressure

to the popping pressure of the valves by using

a set pressure device which may be rented or

purchased.

The apparatus consists of a lifting device

mounted on the bonnet and connected to the

spindle of the safety valve.The differential

force required to open the safety valve when

the system (steam) pressure is less than the

valve set pressure is applied by the operator.

The differential force at which the valve

opens is determined and the safety valve set

pressure is calculated from this measurement.

Contact the factory.

FIGURE 15

Air set

pressure device

Reseating machine

Hydraulic set

pressure device

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Crosby is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Emerson.com/FinalControl

19

Loading...

Loading...