Emerson CROSBY STYLE HC ISOFLEX, CROSBY STYLE HCA ISOFLEX Installation, Maintenance And Adjustment Instructions

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Before installation these instructions must be read fully and understood

TABLE OF CONTENTS

1. Style HC/HCA ISOFLEX - parts ..................... 2

2. Introduction ................................................... 3

3. Description of safety valve ............................ 4

4. Storage ........................................................... 4

5. Installation ..................................................... 5

6. Hydrostatic testing ........................................ 6

7. Operation ....................................................... 9

8. Testing.......................................................... 10

9. Valve maintenance ...................................... 12

General information .................................... 12

Disassembly ................................................ 12

Repair procedure ........................................ 14

10. Valve assembly ............................................ 16

11. Spare parts .................................................. 18

12. Field service requirements ......................... 19

13. Maintenance equipment ............................. 19

Safety precautions

Proper handling, storage, installation,

maintenance and operation is essential to the

safe and reliable functioning of any pressure

relief product.

Precautionary statements in the form of

warnings, cautions and notes are used

throughout this instruction to emphasize

important and critical factors where applicable.

Examples:

WARNING

An operating procedure or practice which, if not

observed strictly, may result in injury to personnel

or loss of life.

CAUTION

An operating procedure or practice which, if not

observed strictly, may result in damage to or

destruction of equipment.

NOTE

An operating procedure or condition which is

highlighted, underlined or printed in bold type for

emphasis.

These precautionary statements are by no means

exhaustive. Emerson cannot be expected to know,

evaluate and advise customers of all conceivable ways

in which tasks might be performed, or of the possible

hazardous consequences of each way.

Consequently, Emerson has not included

such comprehensive evaluation and disclaims

liability for work performed by other than

Emerson personnel. All personnel working with

Crosby products should be trained adequately

and be thoroughly familiar with the contents of

this manual.

Emerson cannot evaluate all conditions that

might injure personnel or damage equipment.

However, Emerson does offer the following

general safety precautions:

• Hearing and eye protection should be used

when working on a valve which is under

pressure.

• Never strike a valve which is under pressure.

Premature actuation can result.

• Never stand in front of the discharge outlet

of a pressure relief valve which is under

pressure.

Always approach and use any pressure relief

valvewith great care.

Often, the safety of lives and property

depends on the proper operation of the

safety valves. Consequently, the valves

should be kept clean and should be tested

periodically and reconditioned to make sure

theyfunctionproperly.

WARNING

Suitability of the material and product for

the use contemplated by the buyer is the

sole responsibility of the buyer. Also storage,

installation and proper use and application are

the sole responsibility of the purchaser. Emerson

disclaims any and all liability arising out of same.

Any installation, maintenance, adjustment,

repair and testing performed on safety relief

valves should be done in accordance with

the requirements of all applicable codes and

standards under which those performing such

work should maintain proper authorization

through appropriate governing authorities. No

repair, assembly and test work done by other

than Emerson shall be covered by the warranty

extended by Emerson to its customers.You

assume full responsibility for your work. In

maintaining and repairing Crosby products, you

should use only parts manufactured by Emerson.

Call your nearest Emerson sales office or our

factory for a service engineer should you wish

assistance with your field needs.

Engineering Doc. #IS-V3147A

Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved. VCIOM-06201-EN17/05

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

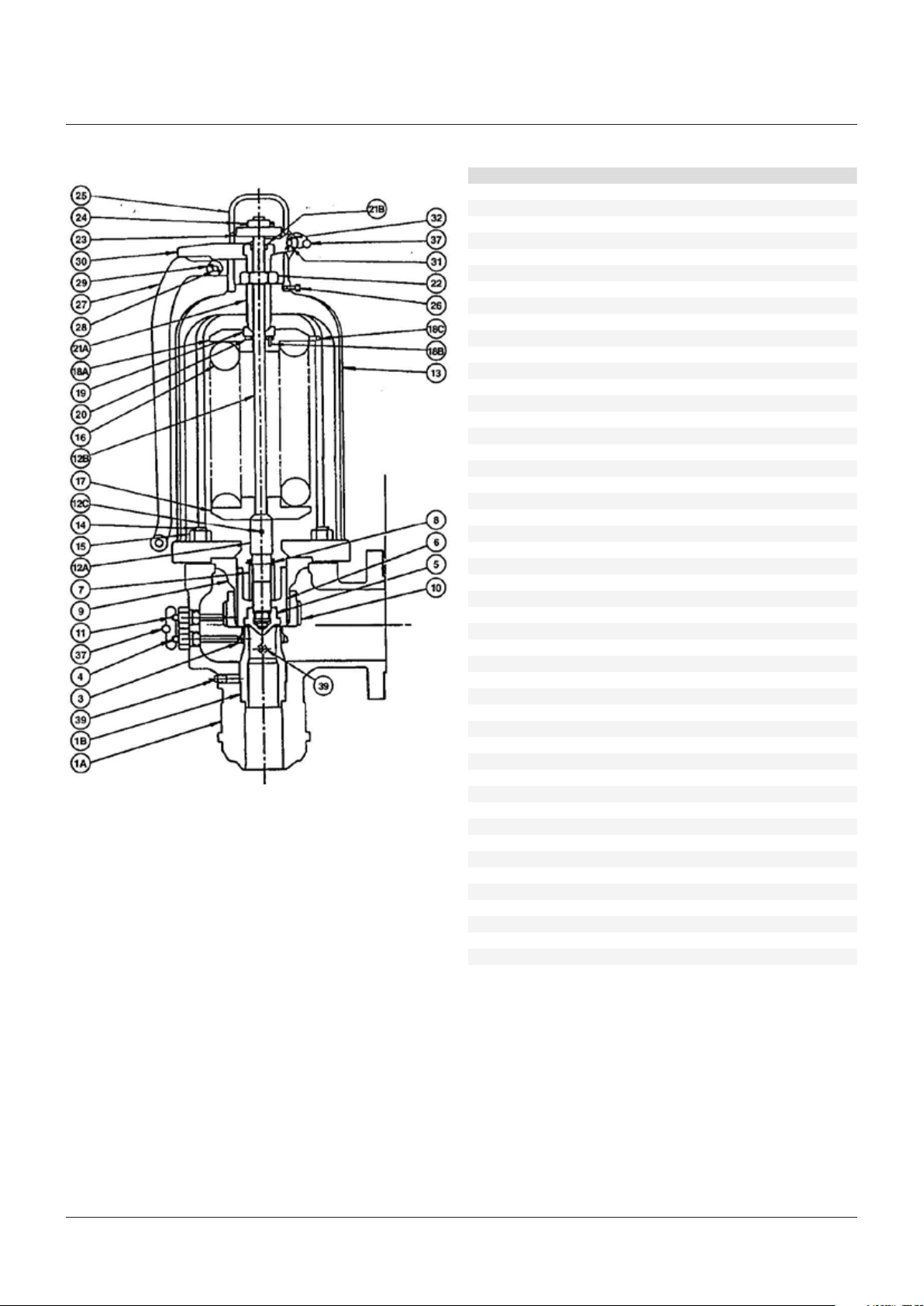

FIGURE 1 - STYLE HC ISOFLEX SAFETY VALVE

PARTS LIST

Part Part name Spare parts*

1A Body

1B Nozzle

3 Nozzle ring 3

4 Nozzle ring set screw

5 Disc insert 1

6 Disc holder 2

7 Disc holder retaining nut

8 Disc holder retaining cotter 1

9 Guide 3

10 Guide ring 3

11 Guide ring set screw

12A Spindle point 3

12B Spindle rod 3

12C Spindle rod pin 3

13 Bonnet

14 Bonnet stud

15 Bonnet stud nut

16 Spring 3

17 Bottom spring washer 3

18A Top spring washer 3

18B Bearing pin 3

18C Locking pin 3

19 Bearing adapter

20 Bearing

21A Adjusting bolt

21B Adjusting bolt bearing

22 Adjusting bolt nut

23 Spindle nut

24 Spindle nut cotter 1

25 Cap

26 Cap set screw

27 Lever

28 Lever pin

29 Lever pin cotter 1

30 Forked lever

31 Forked lever pin

32 Forked lever pin cotter 1

34 Test clamp

36 Test rod

37 Seal and wire

38 Protective hood

39 Drain plug

40 Hydro test plug assembly

41 Nameplate

42 Drive screw

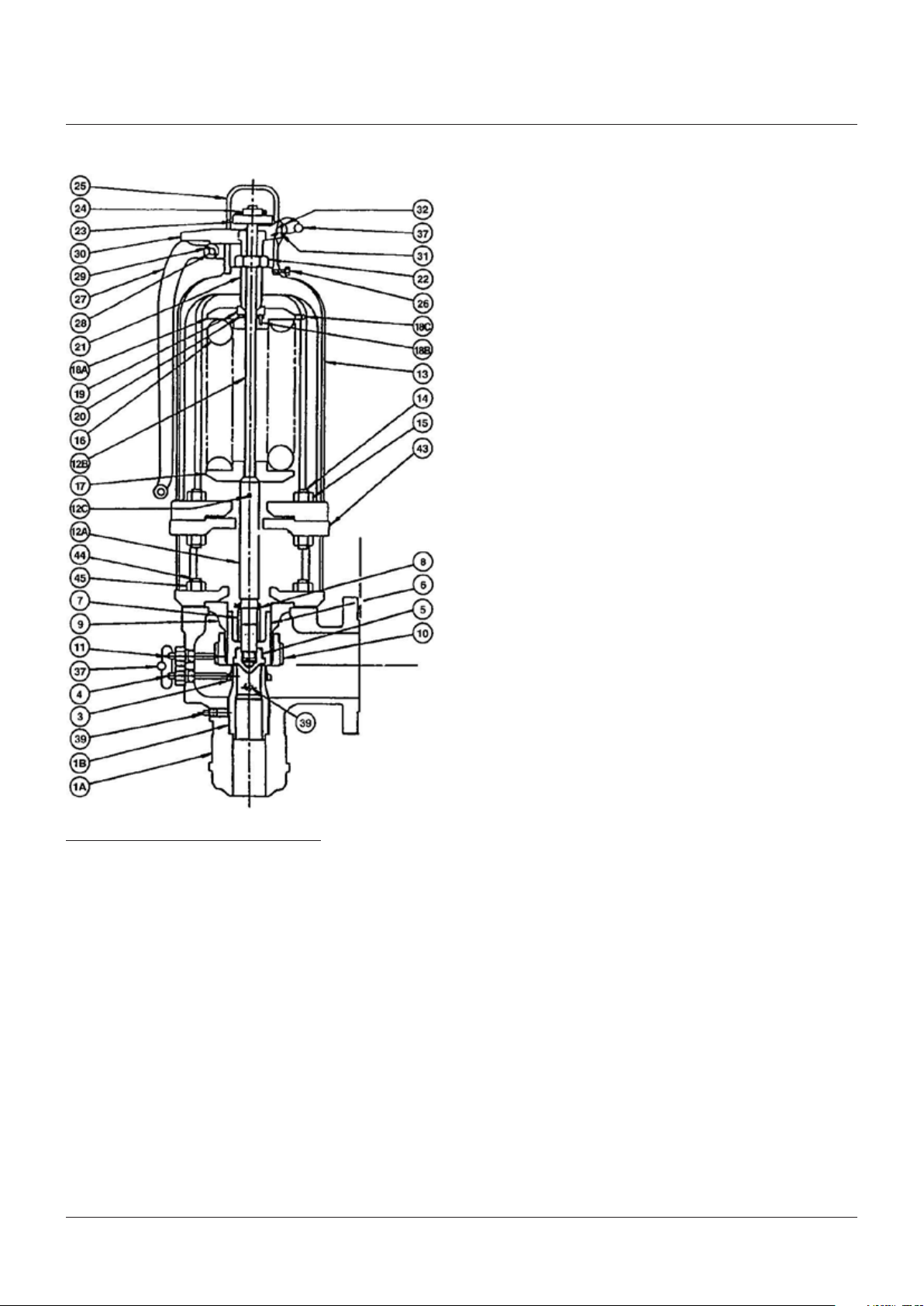

43** Cooling spool

44** Cooling spool stud

45** Cooling spool stud nut

NOTES

* Spare parts designation (see notes 1, 2, 3 in Section 2)

** For Crosby Style HCA ISOFLEX only

2

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

FIGURE 2 - STYLE HCA ISOFLEX SAFETY VALVE

2 INTRODUCTION

Crosby Style HC and HCA ISOFLEX safety

valves have been selected because of their

performance features, reliability and ease

ofmaintenance.

This manual contains information on

installation, hydrostatic testing, field testing

and adjustments and maintenance of these

valves. It is specific to the Isoflex design K

through M

orifice sizes. Adherence to the

2

installation and maintenance procedures

specified in this manual will provide the utmost

in safety, a minimum of maintenance and a

long service life.

Style HC is a high capacity reaction type safety

valve designed for saturated and superheated

steam applications to temperatures of 750°F.

Crosby Style HCA is a high temperature

version of the Style HC, with an alloy steel

construction suitable to temperatures

upto1020°F. TypicallyStyle HCA valves are

used for superheaters and reheater outlets.

DetailsofStyle HC and HCA safety valves,

materials of construction, sizes, pressuretemperature ratings, dimensions, weights and

certified capacities are available on request.

No special tools are necessary for the

maintenance of Style HC and HCA safetyvalves.

However, tools and equipment are available

to ease disassembly and on site testing of

the valves. Such tools and equipment include

the hydraulic set pressure device, the air

set pressure device (see Figure 15) and the

hydraulic jacking device (see Figure 14).

Detailed instructions on their use can be found

in instructions I-11288, T-1652 and I-1167

respectively.

Whenever Style HC/HCA safety valve parts

names are used in this manual, parts numbers

in parenthesis follow. The parts numbers are

an aid to identifying the parts in Figures 1 and 2

and the correlating parts list.

NOTES

1. Consumable spare parts: valve parts which should

be replaced as part of any disassembly, and discs

and disc inserts which must be replaced if seats

are damaged.

2. Repair spare parts: valve parts exposed to wear

and/or corrosion during normal operation.

They are in fluid flow paths and may require

replacement as part of any repair.

3. Insurance spare parts: valve parts exposed to

process or environmental wear and/or corrosion

and may require replacement as part of a

majorrepair.

Emerson recommends that sufficient inventory

of spare parts be maintained to support process

requirements. Always be sure to use genuine

Emerson parts to ensure continued product

performance and warranty.

3

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

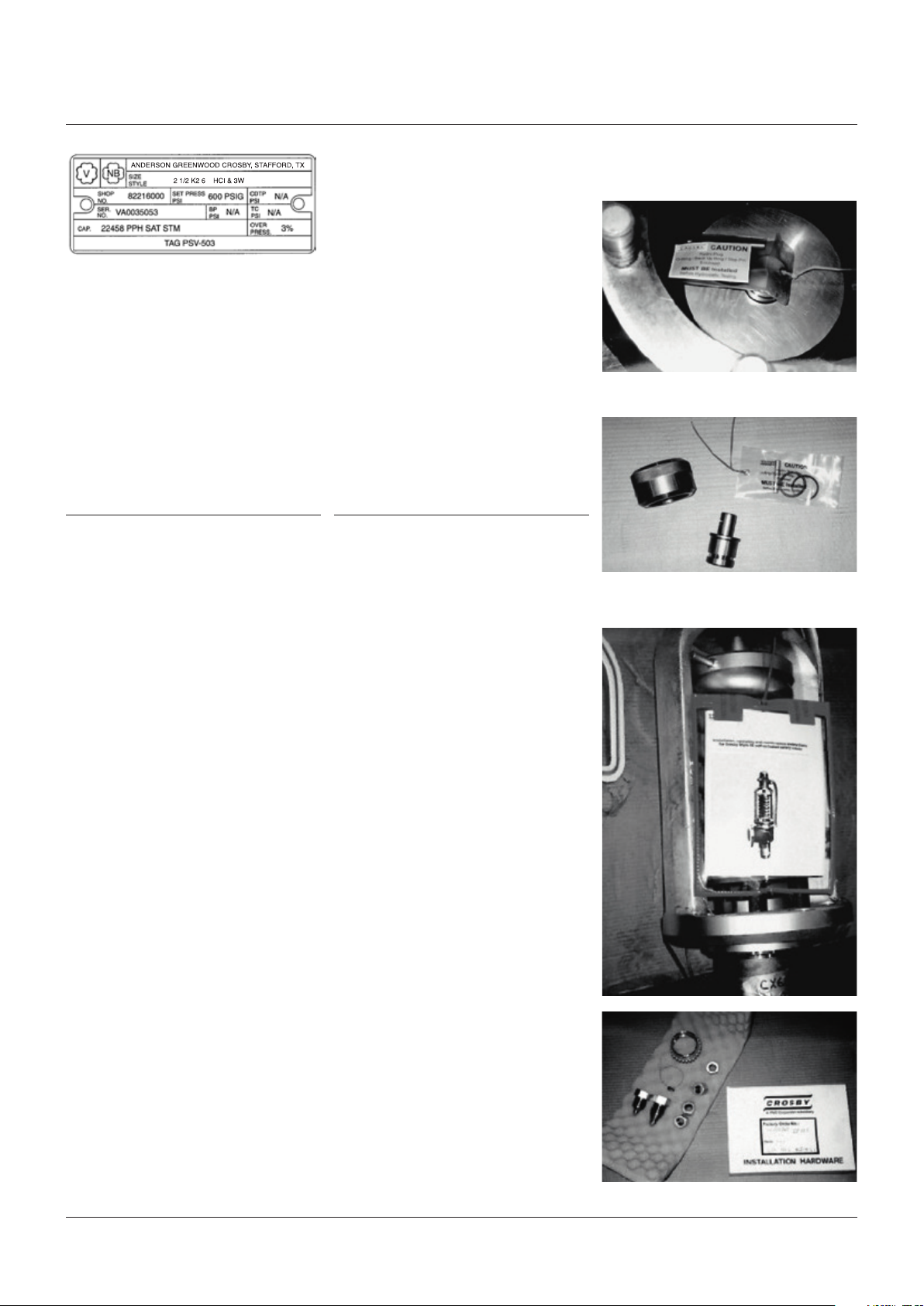

Crosby Style HC/HCA ISOFLEX nameplate

(With sample information for illustrative

purposes only)

Ordering spare parts

When ordering spare parts, the valve size,

style and shop number and/or serial number

should be given together with set pressure,

part name and reference number. The valve

assembly number is shown on the valve

nameplate as 'Shop number'. Spare parts may

be ordered from any Emerson sales office

orrepresentative.

3 DESCRIPTION OF SAFETY VALVES

Crosby Style HC/HCA safety valves are shown

in Figures 1 and 2. These drawings illustrate

the safety valves assembled in cross-section,

and cover the essential elements of the valves.

Approved drawings supplied with the valves

should be used when installation and/or

specific information is required.

Inside the body (1A) is housed the upper portion

of the nozzle (1B), nozzle ring (3), and the

guide ring (10). The disc insert (5) is held in

place in the disc holder (6) by the spindle and

disc holder retainer nut (7). The nozzle ring

and adjusting rings are held in place by the

nozzle ring set screw (4) and the guide ring set

screw(11), which are threaded into the body.

The guide (9) is retained between the body (1A)

and the bonnet (13) by the bonnet studs (14)

and the bonnet studs nuts (15). In the case of

Style HCA valves, a cooling spool (43) is placed

between the body and bonnet to protect the

spring from exposure to extreme temperatures.

The bonnet (13) contains the spring (16),

spring washers (17 and 18) and the spindle

assembly(12). The spindle point is held in

compression between the back face of the disc

insert (5) and the bottom spring washer. The

spring is compressed between the stationary

point of contact with the spindle and the

adjusting bolt (21A) atop the valve bonnet.

The adjusting bolt (21A) is locked in place by the

adjusting bolt nut (22) on top of the bonnet and

within the cap assembly. A means of manual

lifting is provided by the lever (27), lever pin (28),

forked lever (30), forked lever pin (31) and the

spindle nut (23).

4 STORAGE

Often, safety valves are on the job site

months before they are installed. Unless

they are stored properly and protected, their

performance may be affected seriously.

Rough handling may damage flanges or cause

misalignment of the parts. It is best to leave the

safety valves in their shipment cases and store

them in a dry place under cover until they are

tobe installed.

FIGURE 3 - VALVE BODY AS SHIPPED

TOP VIEW - BODY

HYDRO COMPONENTS (see note 1, page 5)

FIGURE 4 - VALVE SUPERSTRUCTURE AS

SHIPPED

4

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Factory preparation of welded inlet valves

forshipment

All Crosby Style HC and HCA welded inlet safety

valves are equipped with hydrostatic test plugs

and shipped in two parts: valve body and valve

superstructure. This makes handling easier for

installation welding (seeFigures3and 4).

The welded inlet Style HC and HCA safety

valves are specially prepared for shipment

fromthe factory.

After the safety valve is tested as a complete

assembly for set pressure and tightness, the

spring set compression is held by spacer

blocks under the bottom spring washer as

illustrated in Figure 4.

The safety valve superstructure is then

removed from the valve body. The two portions

are boxed and shipped separately. Each portion,

ready for shipment, is illustrated in Figures 3

and 4.

Figure 3 shows the safety valve body as shipped

to the installation site. It is tagged as follows:

• Install and/or weld in place as required

• Prepare for hydrostatic test. See instruction

Hydrostatic plug in place

• Install O-ring and backup ring prior to

hydrostatic test.

Figure 4 shows the safety valve superstructure

as shipped to the installation site. It is boxed

separately from the valve body and is tagged

asfollows:

• Hold for assembly after hydrostatic test.

5 INSTALLATION

Inlet piping

Many safety valves are damaged when first

placed in service because of failure to clean

the connections properly before installation.

The safety valve inlet, the vessel and the line

on which the safety valve is mounted must be

cleaned thoroughly of all foreign matter.

Safety valves should be mounted in a vertical

position, directly on the pressure vessel.

The ASME boiler and pressure vessel code limits

the distance between the safety valve inlet and

the boiler to the length of a standard tee fitting.

The nozzle should have a well-rounded

approach that provides smooth, unobstructed

flow between the vessel and the safety valve.

A safety valve should never be installed on a

fitting having an inside diameter smaller than

the inlet connection of the valve.

Such restriction of flow can cause faulty

valveoperation.

Inlet piping (nozzles) must be designed to

withstand the total resultant forces due to

the safety valve discharging at the maximum

accumulated pressure and the expected

piping loads. The precise nature of the loading

and the resulting stresses will depend on

the configuration of the safety valve and the

discharge piping. Determination of outlet

reaction forces is the responsibility of the

designer of the vessel and/or piping.

Welding of welded inlet valve body to boiler

Welded inlet safety valve bodies should be

welded to the boiler in accordance with

applicable Code requirements. The protective

cover (Figure 3) should be left in place until

ready for the hydrostatic test of the unit.

If visual inspection is necessary, the protective

cover may be removed, but should be replaced.

NOTES

Note 1 to Figure 3

Delivered with the body and packaged in small

bag are the following:

• One O-ring (for hydrostatic test)

• One backup ring (for hydrostatic test)

• One hydrostatic test plug pin

Note 2 to Figure 4

Delivered with the superstructure and

packaged in a small box are the following:

• Valve nozzle ring*

• Valve nozzle ring set screw*

• Valve guide ring set screw*

• Seal wires

* Marked with valve identification number.

NOTE

When the above parts are removed from their boxes,

be sure that the identification of parts to valve number

is maintained and that the parts are stored to facilitate

later recovery for assembly.

Outlet piping

Discharge piping should be simple and

direct. Back pressures built up by discharge

flow affect the operation of safety valves.

Where possible, a short vertical pipe connected

through a long radius elbow discharging

directly into the atmosphere is the most

desirable type of outlet piping.

Discharge piping should not impose any loading

on the safety valve. Excessive discharge piping

loads may cause seat leakage or faulty valve

operation. The inside diameter of the discharge

pipe must never be less than that of the safety

valve outlet.

Valve effluent must discharge to a safe

disposalarea.

Safety valve bodies have pipe thread openings

for drains. These should be connected to

prevent any accumulation of fluid in the valve

body. In addition, discharge piping also should

be drained to prevent any accumulation of fluid.

Care must be taken to ensure that the drains

are directed or piped to a safe disposal area.

5

CROSBY® STYLES HC AND HCA ISOFLEX™ SAFETY VALVES

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

6 HYDROSTATIC TESTING

General information

Depending on the type of inlet, hydrostatic

testing of safety valves may be carried out by

one of three means: blank flanges, test plugs or

test gags. In all cases, hydrostatic test pressure

must be limited to 1½ times the nameplate set

pressure of the valve.

CAUTION

Additionally, hydrostatic test pressure must be

limited to 10% above nameplate set pressure

when a test gag is used.

Welded inlet safety valves

All Style HC/HCA welded inlet safety valves are

prepared for shipment from the factory with

hydrostatic test plugs, as detailed in Section 4 paragraph 'Factory preparation of welded inlet

valves for shipment' and Figure 3.

Hydrostatic tests of these valves shall be

conducted using hydrostatic test plugs as

detailed in paragraph below 'Hydrostatic

testing using hydrostatic test plugs'.

Flanged inlet safety valves

Flanged inlet safety valves should not be

installed for hydrostatic testing. Blank flanges

should be used instead of gagging the safety

valves. This prevents possible damage to the

safety valves due to excessive tightening of

the gag screws or leakage during hydrostatic

test which may result in costly repairs.

Blank flanges must be removed and the

safety valve reinstalled before the vessel

isplacedinservice.

If blank flanges are not used and the safety

valves are to be installed for hydrostatic

tests, Emerson recommends that hydrostatic

test plugs be used for hydrostatic test.

The detailed procedure is outlined in the

paragraph following. Hydrostatic test plugs for

flanged valves are optional equipment and are

providedonly when ordered.

Remove the protective cover from the valve

body. Unscrew the cap from the nozzle.

Remove the test plug from the nozzle bore.

• Preparation for hydrostatic testing Flanged inlet safety valves

Flanged inlet safety valves are shipped

from the factory fully assembled. To use

the hydrostatic test plug, the valve must

be disassembled according to Section 9 paragraph 'Disassembly retaining spring

compression'.

• Installation of hydrostatic test plug

(seeFigure 3)

Inspect the hydrostatic test plug O-ring

groove.

Note: make sure the groove in the plug

isclean.

Install the O-ring and backup ring in the

testplug groove.

CAUTION

Be sure the test plug is seated on the 45°

angleonthe nozzle inside diameter.

Replace the test plug in the nozzle bore.

Place the test plug cap over the plug and

screwit down hand-tight.

CAUTION

Make sure the cap has hand-tight contact with

the plug. Make sure there is enough thread

engagement of the cap onto the nozzle.

Install the test plug pin.

The valve is now ready for hydrostatic test.

• Hydrostatic test

After the above preparation, the safety valve

is ready for hydrostatic test. Observations

should be made at the start of the test to

confirm that the O-rings have been installed

properly and there is no leakage when

pressure is applied.

To aid removal, place the hydrostatic test

plug pin in the hole in the plug extension.

Unscrew the cap, which will engage the plug

pin and exert an upward force as the cap is

turned, thus lifting the plug. Remove from

thevalvenozzle.

Clean the nozzle bore and seat and inspect

the seating surface. If seating surfaces are

damaged, repair according to the directions

in Section 9 - paragraph 'Repair procedure'.

Assemble the valves according to the

instructions in Section 6 - paragraph

'Initialsafety valve assembly'.

Contact Emerson field service for service

equipment (see Section 12 - paragraph

'Service equipment available').

Hydrostatic testing using hydrostatic

testplugs

Before imposing the hydrostatic test pressure

on the vessel or system, perform the following

operations:

CAUTION

Before hydrostatic testing, the O-ring and backup

ring must be installed.

• Preparation for hydrostatic testing Weldedinlet safety valves

The O-ring, backup ring and the test plug

pin are shipped in a box attached to the

superstructure (see Figure 3). The contents

ofthe box are marked for identification.

To install the O-ring and backup ring refer

toFigure 3.

CAUTION

Tightening of the cap will not reduce leakage.

If leakage is evident, remove all pressure from

the vessel or system. Replace the O-ring and

thebackup ring.

WARNING

Do not try to assemble the valve or remove

the steel blocks from under the bottom spring

washerwithout use of proper servicing and

assembly equipment.

• Assembly of valve

After completion of the hydrostatic test,

remove the hydrostatic test plug from

thenozzle.

6

Loading...

Loading...