Emerson Crosby J Series Installation, Operation And Maintenance Manual

CROSBY J SERIES PRESSURE RELIEF VALVE WITH FISHER™ 4320 WIRELESS POSITION MONITOR

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Before installation, these instructions must be carefully read and understood.

1 INTRODUCTION

TABLE OF CONTENTS

1. Introduction ...................................................1

1.1 General .....................................................1

1.2 Scope ........................................................1

1.3 Safety Precautions ..................................2

2. Calibration Procedure ...................................2

2.1 Magnetic sensor size selection ..............2

2.2 Calibration ...............................................3

3. Mounting Fisher 4320 to the

J- Series Valve ...............................................6

3.1 Installation ...............................................6

3.2 Bracket Kits .............................................7

4. Selection Tables ..............................................8

1.1 General

NOTICE

Refer to Fisher 4320 wireless position monitor

instruction manual for any difficulties with device

or calibration.

The Fisher 4320 Wireless Position Monitor is

used to monitor the lift of a Crosby J Series

Bellows Pressure Relief Valve. This data can be

wirelessly transmitted to a control station.

The Fisher 4320 wireless position monitor is

a true linkage-less non-contacting wireless

position transmitter and limit switch. It is a

rugged measurement device that provides a

precise wireless feedback signal to indicate

equipment position with a percent (%) of span

plus on/off indication. It is designed to be

simple to use, compact, and easily mounted.

The wireless position monitor periodically

reads the position of a measured device and

transmits that data over a wireless network.

1.2 Scope

Calibration of 4320 could be performed before

mounting to the Pressure Relief Valve by

using a calibration device that simulates the

mounting of the 4320 and the magnet sensor,

one can easily calibrate the 4320 by moving

the magnetic sensor. For the large T orifice

JLT-JBS-E, requires a calibration device

simulator due to the length of stroke.

Calibration could be also performed during

mounting to the pressure relief valve by using

calibration plate Emerson provides. This

procedure provides the calibration methods

during mounting 4320 to Crosby J Series

Bellows Pressure relief valve only.

1.3 Safety Precautions

The protection and safety of equipment,

property and personnel depends on the

proper operation of the pressure relief

valves described in this manual. All Emerson

pressure relief valves should be kept in proper

working condition in accordance with the

manufacturer’s written instructions. Periodic

testing and maintenance by the user of this

equipment is essential for reliable and safe

valve operation.

All installation, maintenance, adjustment,

repair and testing performed on pressure

relief valves should be done by qualified

technicians having the necessary skills and

training adequate to perform such work. All

applicable Codes and Standards, governing

regulations and authorities should be adhered

to when performing pressure relief valve

repair. No repair, assembly, adjustment or

testing performed by other than Emerson or

its authorized assemblers and representatives

shall be covered by the warranty extended by

Emerson to its customers. The user should use

only original, factory supplied OEM parts in any

maintenance or repair activity involving this

product.

SAFETY FIRST

To reduce the risk during installation:

• Comply with all information on the product, in

this manual, and in any local and national codes

that apply to this product.

• Do not allow untrained personnel to work with

his product.

• Use Emerson parts and work procedures

specified in this manual.

WARNING

The Crosby J Series valve must have a bellows

when using this position monitor.

Avoid personal injury from sudden release of

process pressure.

Failure to do so may result in injury to personnel

or cause damage to the equipment.

Emerson.com/FinalControl © 2019 Emerson. All rights reserved. VCIOM-11681-EN 19/03

CROSBY J SERIES PRESSURE RELIEF VALVE WITH FISHER™ 4320 WIRELESS POSITION MONITOR

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

WARNING

Sudden release of pressure may result if the valve

assembly is installed where service conditions

could exceed the limits on the appropriate

nameplates. Never use this equipment for any

purpose other than its intended use.

This manual is provided as a general guide for the

assembly or retrofit on the pressure relief valves

described herein. It is not possible to describe all

configurations or variations with such equipment.

The user is advised to contact Emerson or its

authorized assemblers and representatives for

assistance in situations that are not adequately

covered or described in this manual.

Failure to do so may result in injury to personnel

or cause damage to the equipment.

WARNING

Avoid personal injury from sudden release

of process pressure. Before performing any

maintenance operations:

• Do not remove any component from the valve

while the valve is still pressurized.

• Always wear protective gloves, clothing, and

eyewear when performing any maintenance

operations to avoid personal injury.

• Adhere to all safety standards and best

practices for operating the equipment.

• Use bypass valves or completely shut off the

process to isolate the valve from process

pressure. Relieve process pressure on both

sides of the valve. Drain the process media from

both sides of the valve.

• Use lock-out procedures to be sure that the

above measures stay in effect while you work on

the equipment.

• The valve may contain process media that are

pressurized, even when the valve has been

removed from the process.

• Check with your process or safety engineer for

any additional measures that must be taken to

protect against process media.

Failure to do so may result in injury to personnel

or cause damage to the equipment.

The escape of process media indicates that the

valve has NOT been properly vent, or process

pressure is trapped in the valve body. Check

with your process or safety engineer for any

additional measures that must be taken to

protect against process media. Never attempt

to remove the pressure relief valve from a

system that is pressurized. Never adjust

or perform maintenance on the pressure

relief valve while in service unless the valve

is isolated from the system pressure. If not

properly isolated from the system pressure,

the pressure relief valve may inadvertently

open resulting in serious injury. Remove the

pressure relief valve prior to performing any

pressure testing of the system.

CAUTION

When the pressure relief valve is under pressure

never place any part of your body near to the

outlet/exhaust of the valve. Failure to do so may

result in injury to personnel or cause damage to

the equipment.

CAUTION

This product is intended for a specific temperature

range and other application specifications.

Failure to adhere to these specifications could

result in the malfunction of the product, property

damage, or personal injury.

WARNING

If the process media starts to escape from the

valve or pilot, stop immediately!

Failure to do so may result in injury to personnel

or cause damage to the equipment.

The safety of lives and property often depends

on the proper operation of the pressure relief

valve. The valve must be maintained according

to appropriate instructions and must be

periodically tested and reconditioned to ensure

correct function.

WARNING

Use only genuine Emerson replacement parts.

Components that are not supplied by Emerson

should not, under any circumstances, be used.

Use of components not supplied by Emerson

may void your warranty, might adversely affect

the performance of the instrument and could

cause personal injury or property damage.

Failure to do so may result in injury to

personnel or cause damage to the equipment.

NOTICE

Contact your Emerson sales office for

replacement parts.

Before installation, the Installation and

Operational Safety Instructions should be fully

read and understood. These Instructions may

be requested from the factory or are available

at Emerson.com.

2 CALIBRATION PROCEDURE

CAUTION

When the pressure relief valve is under pressure

never place any part of your body near to the

outlet/exhaust of the valve. Never use this

equipment for any purpose other than its intended

use.

Failure to do so may result in injury to personnel

or cause damage to the equipment.

2.1 Magnetic Sensor Size Selection

To achieve an accurate valve position, the

correct magnet size must be selected. Refer to

Table 1 for selection.

CAUTION

The magnet material has been specifically chosen

to provide a long-term stable magnetic field.

However, as with any magnet, care must be taken

when handling the magnet assembly. Another

high-powered magnet placed in close proximity

(less than 25 mm) can cause permanent damage.

Potential sources of damaging equipment include,

but are not limited to: transformers, dc motors,

stacking magnet assemblies.

Failure to do so may result in equipment mal

function.

Tip: As a general rule, do not use less than 50% of

the magnet assembly for full travel measurement.

Performance will decrease as the assembly

is increasingly subranged. The linear magnet

assemblies have a valid travel range indicated by

arrows molded into the piece. This means that the

hall sensor (on the back of the 4320 housing) has to

remain within this range throughout the entire valve

travel. The linear magnet assemblies are symmetrical.

Either end may be up.

2

CROSBY J SERIES PRESSURE RELIEF VALVE WITH FISHER™ 4320 WIRELESS POSITION MONITOR

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

2.2 Calibration

Mounting the Fisher 4320 Wireless

Position Monitor

1. Install a battery into the Fisher 4320

Wireless Position Monitor.

WARNING

Due to the combustible nature of the lithium

content, the power module has special

installation, operation, storage, and/or shipping

requirements. Observe all warnings included with

the power module before installing, operating,

storing, or shipping the 4320 Position monitor.

Failure to do so may result in personal injury or

property damage from fire or explosion.

CAUTION

When installing components, proper means of

electrostatic discharge protection is required.

Failure to use a grounding strap, or other means

of electrostatic discharge protection can result in

damage to the electronics.

CAUTION

To avoid static discharge do not rub or clean the

antenna with solvents.

Failure to do so may result in personal injury or

property damage from fire or explosion.

8. Loosen the Screws on 4320 Bracket and line

up the mark on the back of 4320 with the top

mark on the magnet. Lock 4320 in place on

Bracket with quantity of 4, M6 x 10mm HEX

CAP Screws and Lock Washers with Torque

force listed in Table 2, Location 2. Center

the magnet assembly inside the 4320 slot by

slightly adjusting the magnet bracket, if it is

needed. This represents the “0% position”,

valve closed.

CAUTION

Do not install a magnet assembly that is shorter

than the physical travel of the valve. Loss of

control will result from the magnet assembly

moving outside the range of the index mark in the

feedback slot of the 4320 housing.

Failure to do so may result in personal injury or

property damage.

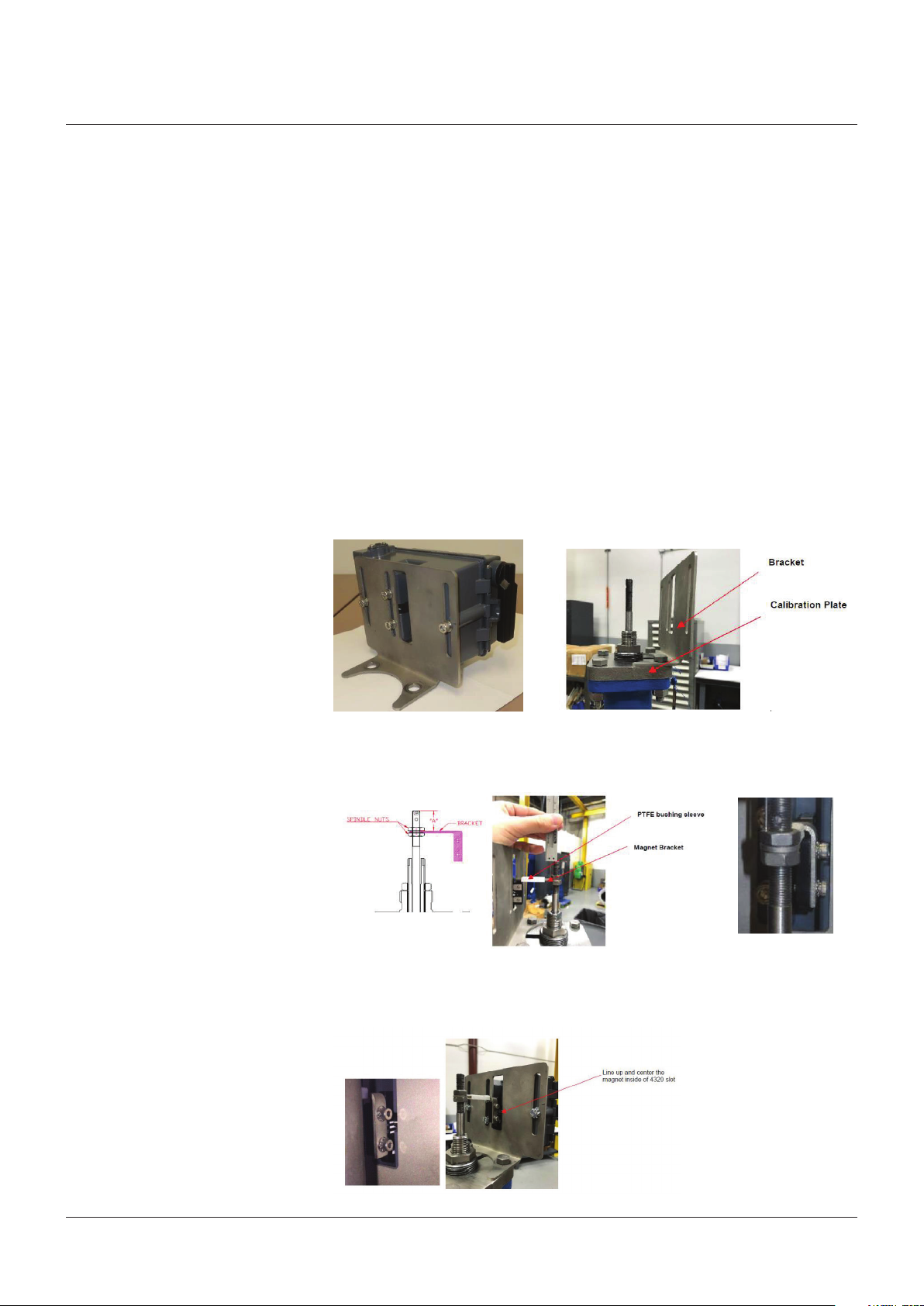

FIGURE 2-1

4320 and Bracket Assembly

FIGURE 2-2

Magnet Alignment

2. Mount the 4320 to the bracket and lightly

tighten screws enough to hold in place. The

screws will be tightened once calibration

step is complete.

3. Mount the calibration plate and bracket on

the pressure relief valve bonnet as shown

on Figure 2-2.

WARNING

Due to the combustible nature of the lithium

content, the power module has special

installation, operation, storage, and/or shipping

requirements. Observe all warnings included with

the power module before installing, operating,

storing, or shipping the 4320 Position monitor.

Failure to do so may result in personal injury or

property damage from fire or explosion.

4. Slide the Polytetrafluoroethylene (PTFE)

bushing sleeve on the magnet bracket.

The PTFE open slot should face in down

direction.

5. Secure the Magnet in place under the bend

in the Magnet Bracket with 2 screws and

lock washers provided with Magnet. Torque

force listed in Table 2, Location 1.

6. Position the magnet bracket assembly to

the valve stem at the dimension “A” shown

in Table 1. Lock in place.

7. Verify dimension “A” by caliper or depth

micrometer to ensure it is in the tolerance

as shown in the Table 1.

FIGURE 2-3

Measurement for Dim A

FIGURE 2-4

Measurement for Dim A

3

Loading...

Loading...