Emerson Crosby HSJ Series Installation, Operation And Maintenance Instructions

CROSBY SERIES HSJ SAFETY VALVES

InstallatIon, operatIon and maIntenance InstructIons

Before installation these instructions must be fully read and understood

WARNING

The safety of lives and property often depends

on the proper operation of the safety valves.

Consequently, the valves should be kept clean and

should be tested periodically and reconditioned to

make sure they function properly.

EMERSON FIELD SERVICE AND REPAIR

PROGRAMS

Field service

Emerson field service provides on-site, in

line testing and repair capability for all types

of pressure relief devices. It is strongly

recommended that on new installations, a

Emerson service engineer be present for

assembly and testing of safety valves.

SPARE PARTS

Emerson recommends spare parts as shown

on the outline drawing Figure 1. When ordering

spare parts, the valve size, style and assembly

number and/or serial number should be

given together with set pressure, part name,

and reference number from Figure 1. The

valve assembly number is shown on the valve

nameplate as 'Shop No'. Spare parts may be

ordered from any Emerson regional sales office

or representative.

SERVICE RECORDS

Service records should be completed before

a valve is returned to service. These records

are important and will provide guidance on

establishing time intervals between repairs as

well as providing the historical record of repairs

and service conditions. Well kept records will

be useful in predicting when to retire a valve

and which spare parts should be maintained in

inventory to ensure uninterrupted plant operation.

Parts

Emerson will help you establish the right mix

of on-site spares with our own distribution and

manufacturing support.

Training

Emerson offers intensive factory or on-site

training seminars to improve maintenance

and application skills.

Testing

Emerson has the capability to evaluate safety

valve operability either in the field or at various

Emerson facilities. Special qualification

programs may also be conducted in our

laboratories.

Contract management

Emerson will combine a group of services to

satisfy your special maintenance needs.

Emerson’ full-spectrum service

• Valve repair

• Field service

• Replacements parts

• Contract management

• Training

• Testing

• Contract

Emerson.com/FinalControl

Engineering Doc. #IS-V3146

© 2017 Emerson. All Rights Reserved. VCIOM-01062-EN 17/12

CROSBY SERIES HSJ SAFETY VALVES

InstallatIon, operatIon and maIntenance InstructIons

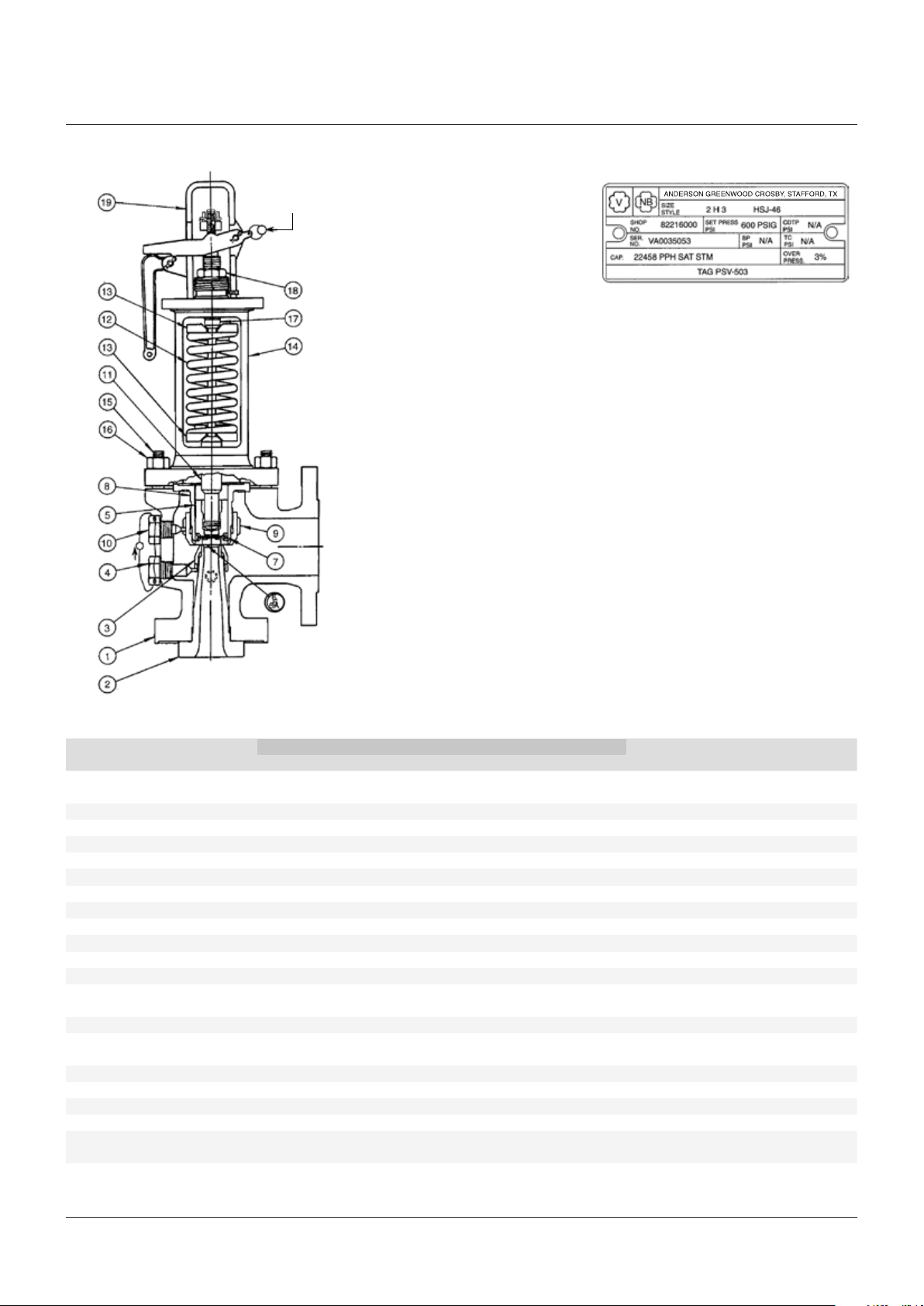

FIGURE 1

Seal and wire

Seal and

wire

NOTES

1. Consumable spare parts: soft goods (gaskets,

etc.) which should be replaced as part of any

disassembly, and disc inserts which must be

replaced if seats are damaged.

2. Repair spare parts: goods exposed to wear and/

or corrosion during normal operation. They are in

fluid flow paths and may require replacement as

part of any repair.

3. Insurance spare parts: hard goods exposed to

process or environmental wear and/or corrosion

and may require replacement as part of a major

repair.

Emerson recommends that sufficient inventory

of spare parts be maintained to support process

requirements.

Always be sure to use genuine Emerson parts to

ensure continued product performance and warranty.

VALVE NAMEPLATE

NOTES

On Series HSJ with closed bonnet option

(except Series HSJ-DOW) the bonnet vent

MUST REMAIN OPEN. Keeping the bonnet vent

open is essential for proper valve operation.

On Series HSJ-DOW (for organic fluid vaporizer

generator applications) use a closed bonnet having

the bonnet vent plugged and Type A screwed cap.

PARTS LIST

Material and maximum temperature

Part No. Part name

1 Body Carbon steel Alloy steel

2 Nozzle Stainless steel Stainless steel 3

3 Nozzle ring Stainless steel Stainless steel 3

4 Nozzle ring set screw Stainless steel Stainless steel 3

5* Disc holder Nickel alloy Nickel alloy 2

6* Disc insert Stainless steel Stainless steel 1

6A* Disc Stainless steel Stainless steel 1

7* Disc insert cotter Stainless steel Stainless steel 1

8 Guide Nickel alloy Nickel alloy 3

9 Guide ring Stainless steel Stainless steel 3

10 Guide ring set screw Stainless steel Stainless steel 3

11 Spindle assembly Stainless steel Stainless steel 3

12 Spring Alloy steel Alloy steel 3

13 Spring washers Steel Steel 3

14 Bonnet Carbon steel Alloy steel

15 Bonnet stud ASME SA-193 Gr. B7 ASME SA-193 Gr. B7

16 Bonnet stud nut ASME SA-194 Gr. 2H ASME SA-194 Gr. 2H

17 Adjusting bolt Stainless steel Stainless steel 3

18 Adjusting bolt nut Steel Steel 3

19 Cap lever assembly Steel/iron Steel/iron

Gaskets Organic fiber non asbestos Organic fiber non asbestos 1

750°F (399°C) 1000°F (538°C)

ASME SA-216 Gr. WCB ASME SA-217 GR. WC6

Corrosion resistant coating Corrosion resistant coating

ASME SA-216 Gr. WCB ASME SA-217 GR. WC6

Spare parts designation

(See notes 1, 2, 3)

* One piece disc (6A) replaces part reference numbers 5, 6 and 7 in orifice sizes F, G, H, and J for CL 150, CL 300 and CL 600.

2

CROSBY SERIES HSJ SAFETY VALVES

InstallatIon, operatIon and maIntenance InstructIons

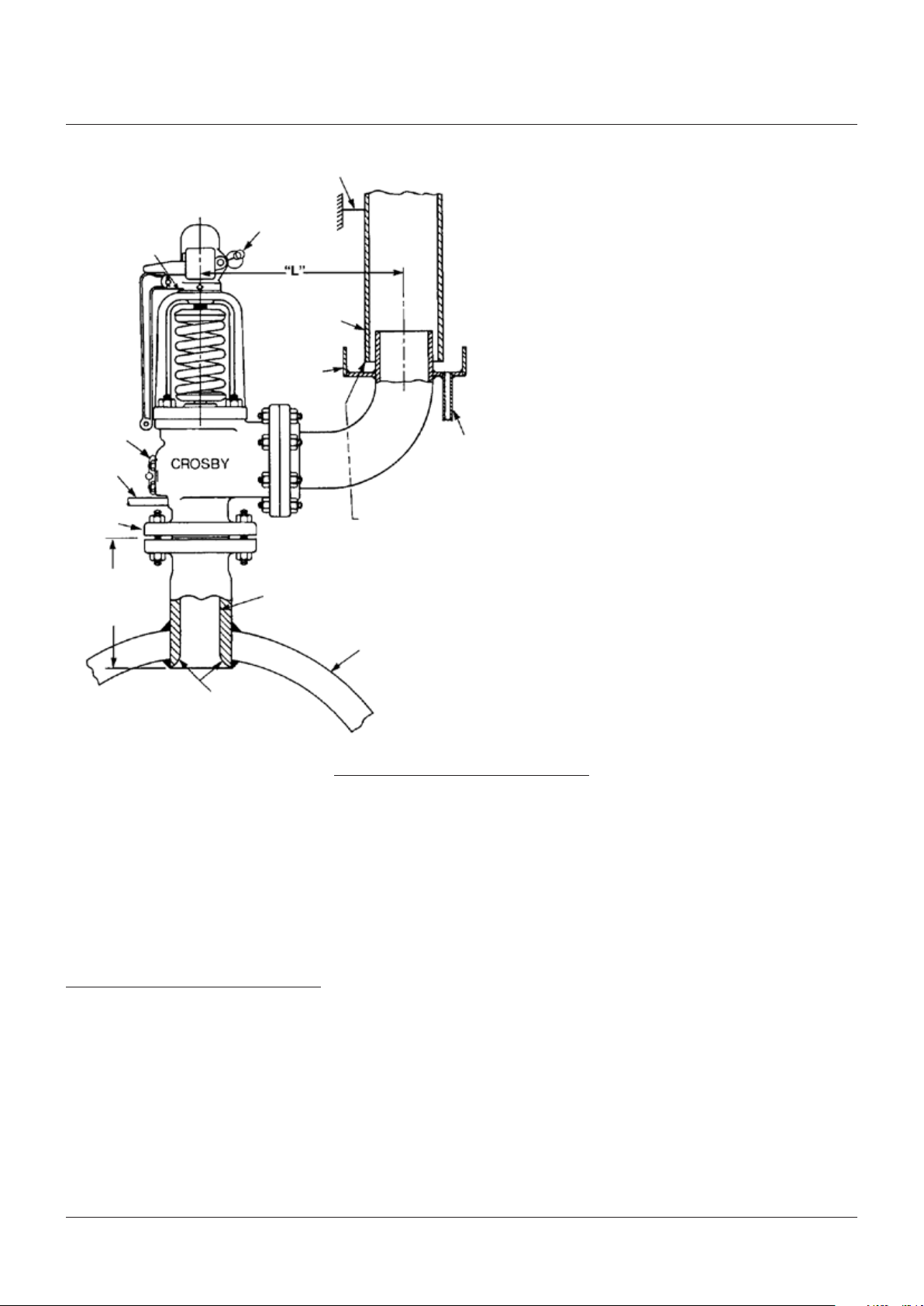

FIGURE 2

Ring positions

stamped here

Wire and

seal

Drain

Shortest

possible

length*

Fixed support anchored to building structure

Seal wire

Discharge pipe

Drip pan

See note **

Recommended minimum diameter ½” larger than valve inlet

Drain

NOTES

Refer to ASME boiler code section 1, pg-71.2

*

** Allow sufficient space to prevent bottoming or side binding of the drip

pan to the discharge pipe under maximum conditions of expansion

Rounded smooth length

CAUTION

The valve should never be lifted or handled using

the lifting lever.

WARNING

To have trouble-free performance be sure to

clean the inlets and outlets of valves thoroughly

before installing. All dirt, sediment and scale in

the protected vessel and piping must be removed

completely before installation (foreignmaterial

entering the valve may cause seat leakage,

plugging and valve malfunction).

1 INTRODUCTION

Crosby Series HSJ safety valves have been

selected because of their performance features,

reliability and ease of maintenance. Adherence

to the installation and maintenance procedures

specified herein will provide the utmost in safety, a

minimum of maintenance and a long service life.

Crosby Series HSJ safety valves are manufactured

in accordance with the requirements of Section 1,

Power Boilers, and Section VIII, Unfired Pressure

Vessels, of the ASME Boiler and Pressure Vessel

Code.

Boiler drum

2 STORAGE AND HANDLING

Often, valves are on hand at the job site months

before they are installed. Unless stored and

protected properly, valve performance may be

affected adversely.

Rough handling and dirt may damage or

cause misalignment of the valve parts. It is

recommended that the valves be left in their

original shipping containers and that they be

stored in a warehouse or at a minimum on a

dry surface with a protective covering until they

are used.

3

CROSBY SERIES HSJ SAFETY VALVES

InstallatIon, operatIon and maIntenance InstructIons

3 INSTALLATION

Rigging

S

afety valves must be handled carefully and

never subjected to sharp impact loads. While

in the shipment case or when uncrated they

should not be bumped or dropped. Rough

handling may alter the pressure setting, deform

valve parts and affect seat tightness adversely.

When it is necessary to use a hoist, a sling

should be placed around the valve body and

bonnet in a manner that will ensure that

the valve is in a vertical position to facilitate

installation.

Flange protectors should remain in place until

the valve is ready to be installed on the system.

Inspection

Safety valves should be inspected visually

before they are installed to ensure that no

damage has occurred during shipment or while

in storage. All protective material, sealing plugs

and any extraneous material inside the valve

body or nozzle must be removed.

The valve nameplate and other identifying tags

should be checked to ensure that the particular

valve is being installed at the location for

which it was intended. The seals protecting the

spring setting and ring adjustments should be

intact. If seals are not intact, the valve should

be inspected, tested and new seals installed

before use.

Inlet piping

Safety valves should be mounted in a vertical

position, directly on the pressure vessel; the

nozzle should have a well-rounded approach

that provides smooth, unobstructed flow

between the vessel and the valve. A safety valve

should never be installed on a fitting having

an inside diameter smaller than the inlet

connection of the valve as restricted flow can

cause faulty valve operation.

Inlet piping (nozzles) must be designed to

withstand the total resultant forces due to the

valve discharging at the maximum accumulated

pressure and the expected piping loads.

The precise nature of the loading and

the resulting stresses will depend on the

configuration of the valve and the discharge

piping. This must be taken into consideration

by those responsible for the installation of the

safety valve and associated vessel or piping.

Determination of outlet reaction forces is the

responsibility of the designer of the vessel and/

or piping.

Many valves are damaged when first placed

into service because of failure to clean the

connections properly when installed. It is

essential that the valve inlet, the vessel and the

line on which the valve is mounted be cleaned

thoroughly of all foreign material. The inlet

connection bolts or studs should be tightened

uniformly to avoid straining or distorting the

valve body.

Outlet piping

Discharge piping should be simple and direct.

Where possible, a short vertical pipe connected

through a long radius elbow discharging

directly into the atmosphere is recommended.

Discharge piping should be designed so as not

to impose any loading on the valve. Excessive

discharge piping may cause seat leakage or

faulty valve operation. The inside diameter of

the discharge pipe must never be less than that

of the valve outlet.

Valve effluent must discharge to a safe disposal

area.

Valve bodies are provided with pipe thread

openings for drains. These should be connected

to prevent any accumulation of fluid in the

valve body. In addition, it is recommended that

discharge piping also be drained to prevent any

accumulation of fluid. Care must be observed

to ensure that the drains are directed or piped

to a safe disposal area.

4

Loading...

Loading...