Page 1

CROSBY SERIES BP OMNI-TRIM® PRESSURE RELIEF VALVES

InstallatIon, maIntenance and adjustment InstructIons

Before installation these instructions must be read fully and understood

1 GENERAL

Crosby valves have been tested and adjusted

at the factory. As service conditions differ it

may be necessary to make slight adjustments.

These adjustments are made easily if the

instructions below are followed carefully.

WARNING

To have trouble free performance be sure to clean

the inlets and outlets of valves thoroughly before

installing.

2 STORAGE AND HANDLING

Often, valves are on hand at the job site months

before they are installed. Unless stored and

protected properly, valve performance may be

affected adversely.

Rough handling and dirt may damage or

cause misalignment of the valve parts. It is

recommended that the valves be left in their

original shipping containers and that they be

stored in a warehouse or, as a minimum, on a

dry surface with a protective covering until they

are used.

Pressure relieving valves must be handled

carefully and never subjected to sharp impact

loads. They should not be struck, bumped or

dropped. Rough handling may alter the pressure

setting, deform valve parts and affect seat

tightness and valve performance adversely.

NOTE

Where valves have levers as in TypesD and E top

construction, DO NOT LIFT OR CARRY VALVES BY THE

LEVERS.

Inlet and outlet protectors should remain in

place until the valve is ready to be installed on

the system.

3 INSTALLATION

3.1 Inlet piping

The valve should be mounted vertically in an

upright position either directly on a nozzle from

the pressure vessel or on a short connection

fitting that provides a direct, unobstructed

flow between the vessel and the valve.

Installing a pressure relief valve in other than

this recommended position might affect its

operation adversely. A valve should never be

installed on a fitting having a smaller inside

diameter than the inlet connection of the valve.

Compliance with the above recommendations

will assure clean, positive valve operation.

Many valves are damaged when first placed

in service because of failure to clean the

connections properly when installed.

Both the valve inlet and the vessel and/or line

on which the valve is mounted must be cleaned

thoroughly of all dirt and foreign material.

3.2 Outlet piping

Discharge piping should be simple and direct.

A broken connection near the valve outlet is

preferred. The weight of the discharge piping

should be carried by a separate support and be

braced firmly against swaying or vibrations.

Fittings or pipe having a smaller inside

diameter than the valve outlet connections

must not be used. The flow from the valve must

discharge to a safe disposal area.

The safety of lives and property often depends

on the proper operation of the pressure relief

valves. The valves must be maintained according

to appropriate instructions and must be tested

periodically and reconditioned to ensure that they

function correctly.

Crosby pressure relief valves described in this

instruction are manufactured in accordance

with the requirements of ASME Boiler and

Pressure Vessel Code, Section VIII. Capacities

are certified by the National Board of Boiler

and Pressure Vessel Inspectors.

Engineering Doc. #IS-V3117A

© 2017 Emerson. All rights reserved.Emerson.com/FinalControl

VCIOM-06202-EN 18/03

Page 2

CROSBY SERIES BP OMNI-TRIM® PRESSURE RELIEF VALVES

InstallatIon, maIntenance and adjustment InstructIons

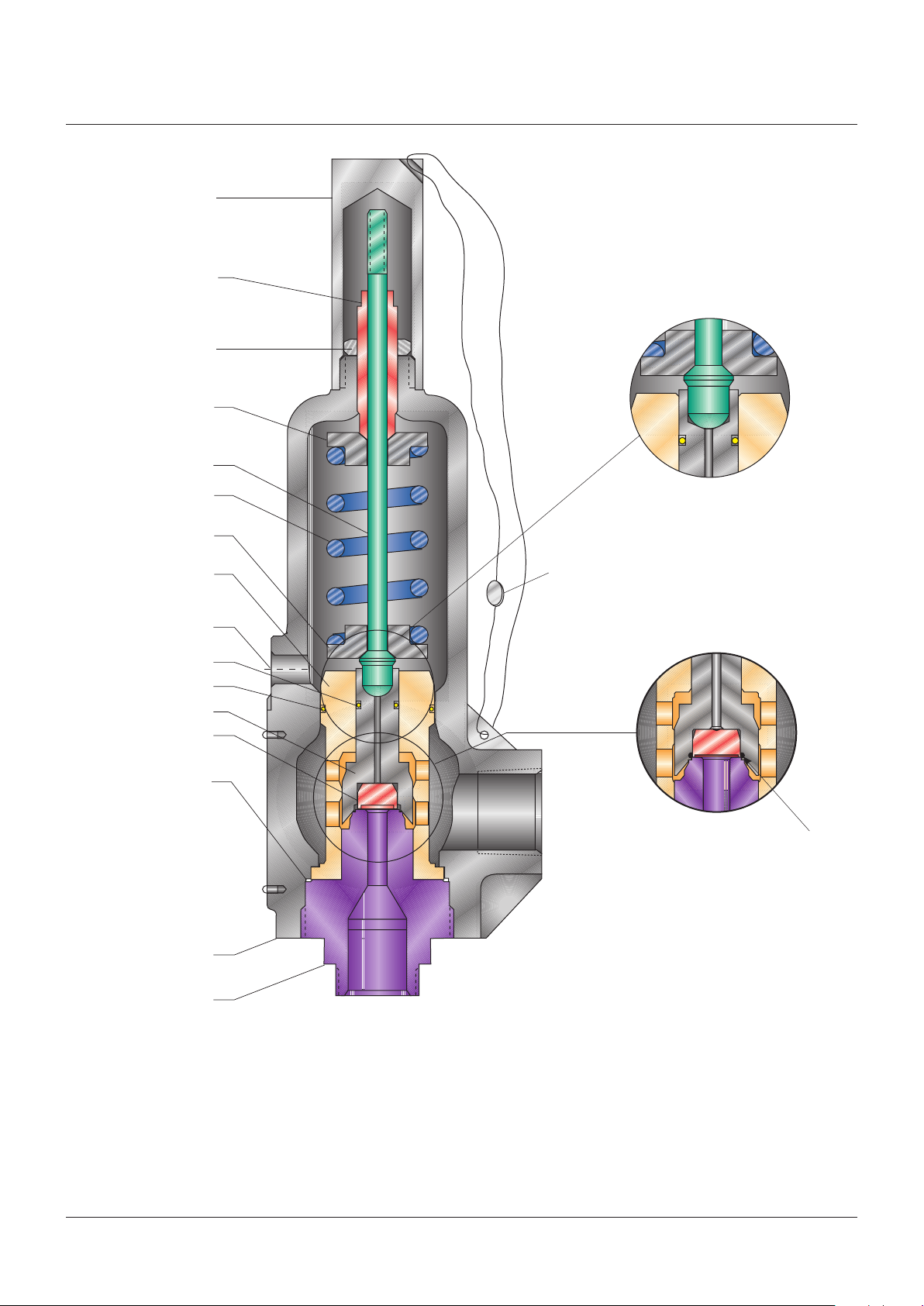

Cap

Adjusting bolt

Adjusting bolt nut

Spring washer (top)

Spindle

Spring

Spring washer (bottom)

Guide

* Cylinder vent hole

Piston O-ring

Guide O-ring

Disc holder

Disc insert

Cylinder O-ring

Cylinder

Seal and wire

Seat O-ring

Base

* This vent must remain open

Threaded connection

Series BP

2

Page 3

CROSBY SERIES BP OMNI-TRIM® PRESSURE RELIEF VALVES

InstallatIon, maIntenance and adjustment InstructIons

4 TESTING

Testing should be performed by trained

personnel using the applicable test procedure.

Follow these guidelines for performance of the

set pressure test:

4.1 Test fluids - set pressure test

The test fluid should be air or nitrogen for

valves used on gas and vapor service and water

for valves used on liquid service.

4.2 Temperature correction

When a valve is set on air or water at room

temperature and then used at a higher service

temperature, the cold differential set pressure

shall be corrected to exceed the set pressure

using the following temperature correction:

Operating temperature % Pressure

increaseºF ºC

0 to +150 -18 to +66 +151 to 400 +66 to +204 1%

4.3 Valve operation

Valves intended for compressible fluid service

and tested on air or nitrogen will open with a

sharp, clear popping action at the set point.

Valves for liquid service tested with water

are considered open at the first continuous

unbroken stream of liquid flowing through the

valve. Sometimes it is helpful to install a short

piece of pipe in the valve outlet to determine the

opening on water.

5 SET PRESSURE CHANGES

Set pressure changes beyond the specified

spring range will necessitate a change in the

valve spring assembly consisting of the spring

and two washers.

The new spring and washers must be

obtained from Emerson and the valve must

be reset and the nameplate restamped by an

authorized repair facility.

6 SET PRESSURE ADJUSTMENT

Before making any adjustments, reduce the

pressure under the valve seat to at least 25%

below the stamped opening pressure. This

will prevent seat damage due to turning of the

disc insert on the nozzle seat and minimize the

chance of an inadvertent opening.

7 MAINTENANCE

7.1 Dismantling

1. Remove the cap.

2. Before removing the adjusting bolt, take a

measurement from the top of the adjusting

bolt to the top of the cylinder as a reference

for resetting the valve later.

3. Loosen the adjusting bolt nut and turn the

adjusting bolt counterclockwise to remove

the load on the spring completely. Unless

this is done, unnecessary damage to the

seat or misalignment of the trim parts may

occur when the valve is reassembled.

4. Loosen the base from the cylinder but do

not remove.

5. Place the valve, upside down, in a vise and

remove the base.

6. Remove the guide and disc assembly as a

unit. A screwdriver or other suitable tool

can be inserted into the cylinder vent hole to

facilitate removal of the guide.

7. Remove the disc holder from the guide.

8. Remove the cylinder from the vise and

remove the spindle, spring and spring

washers.

9. Remove the disc insert by inserting a drive

pin or similar tool into the hole in the

disc holder and press out the disc insert.

Remove the O-ring with a suitable tool.

Becareful not to damage the O-ring groove.

10. Remove the guide O-ring, piston O-ring and

cylinder O-ring.

Cleaning

The following instructions are general

guidelines. Certain applications may require the

use of special cleaning procedures.

1. After the valve has been dismantled

completely, the seats on both the nozzle

and the disc insert should be examined to

determine how badly they are damaged,

if at all. Any severe damage may make it

advisable to replace the parts.

2. External parts, such as the cylinder and cap,

can be cleaned by immersion in a bath such

as a hot oakite solution or equivalent.

3. Internal parts, except O-rings, can be

cleaned using acetone, denatured alcohol

or any other suitable solvent. Mechanical

cleaning of internal parts, except seats,

can be performed using fine sandpaper or

emery cloth.

3

Page 4

CROSBY SERIES BP OMNI-TRIM® PRESSURE RELIEF VALVES

InstallatIon, maIntenance and adjustment InstructIons

7.2 Assembly

1. Prior to assembly the following surfaces are

to be coated with pure nickel “Never-Seez”:

(see Figure 1)

- Base to cylinder threads

- Spring washer bevels

- Adjusting bolt threads

- Cap threads

- Cap to cylinder sealing surfaces

2. Prior to assembly the guide surface of

the guide is to be lightly coated with

DowCorning 3451 grease.

3. All O-rings except the piston O-ring

and TFEO-rings are to be coated with

DowCorning 3451.

4. The piston O-ring is to be coated with

DowCorning 3451.

5.

Place the spring and washers onto the spindle.

6. Place the spindle/washer/spring assembly

into the cylinder. With the spindle protruding

through the top of the cylinder while

inverting the cylinder, place the inverted

cylinder into a vise.

7. Coat the entire guide O-ring with Dow

Corning 3451 and install on the guide.

8. Coat the entire seat O-ring (except TFE seat)

with Dow Corning 3451. Insert the O-ring

into the groove in the disc holder. Push the

disc insert into the disc holder. Installing

the disc insert with a TFE O-ring or a high

durometer elastomer may require a small

press.

9. Coat the entire piston O-ring with a small

amount of Dow Corning 3451 and install

onto the disc holder.

10. Install the disc holder into the guide.

11. Install the guide/disc holder assembly into

the cylinder.

12. Coat the cylinder O-ring with Dow Corning

3451 and install into the cylinder.

13. Screw the base into the cylinder until tight

(locked).

14. Screw the adjusting bolt nut onto the

adjusting bolt and install into the cylinder.

15. Screw the cap onto the cylinder with a

suitable wrench until tight.

8 ASSEMBLY OF CAPS AND LIFTING LEVER

DEVICES

Type A (screwed cap)

Apply pure nickel Never-Seez or equivalent to

the cap sealing surface and screw the cap onto

the top of the cylinder. Tighten the cap with a

suitable wrench.

Type B (screwed cap with test rod)

Apply pure nickel Never-Seez to the cap sealing

surface and screw the cap onto the top of

the cylinder. Tighten the cap with a suitable

wrench. Install the cap plug O-ring and screw

the cap plug into the cap. The test rod is

installed only during system hydrostatic testing.

Never install the test rod unless performing

system hydrostatic testing.

Type D (packed lifting lever)

1. Apply Loctite 242 or equivalent to the

spindle threads. Screw the spindle nut onto

the spindle. Screw the cap hand tight.

2. Apply Dow Corning 3451 or equivalent to the

cam O-ring and install onto the cam. Insert

the cam into the sleeve. Install the lever

onto the cam and secure with the lever pin.

3. Screw the lever assembly into the cap. If the

cam interferes with spindle nut, remove the

spindle assembly and raise the spindle nut.

Repeat until the spindle nut is approximately

1

/

16” above the cam.

4. Once the spindle nut is in position, remove

the cap and screw the locknut on the

spindle and, while securing the spindle

nut firmly with locking pliers, tighten the

locknut.

5. Apply pure nickel Never-Seez or equivalent

to the cap threads and to the cap sealing

surface. Screw the cap onto the top of the

cylinder. Tighten the cap with a suitable

wrench.

6. Apply Dow Corning 3451 or equivalent to the

cam sleeve O-ring and install the O-ring.

Install the lever assembly.

Type E (packed lifting lever with test rod)

Assembly of the Type E lifting lever is identical

to the Type D with the addition of the cap

plug O-ring and the cap plug. The test rod is

installed only during system hydrostatic testing.

Never install the test rod unless performing

system hydrostatic testing.

4

Page 5

CROSBY SERIES BP OMNI-TRIM® PRESSURE RELIEF VALVES

InstallatIon, maIntenance and adjustment InstructIons

FIGURE 1

Cap threads

(Never-Seez)

Cap to cylinder

sealing surface

(Never-Seez)

Spring washer bevels

(Never-Seez)

This vent must

remain open

Adjusting bolt threads

(Never-Seez)

Piston O-ring

(Dow Corning 3451)

Guide Surface

(Dow Corning 3451)

Guide O-ring

(Dow Corning 3451)

Seat O-ring

(Dow Corning 3451)

Cylinder O-ring

(Dow Corning 3451)

Cap

Base to cylinder threads

(Never-Seez)

Type A

Test rod

Cap plug

Cap plug O-ring

Cap

Type B

Spindle nut

Locknut

Cam

Cam

Cap plug

Locknut

Spindle nut

Cam

Cap

Cap plug O-ring

Cam sleeve O-ring

Cam sleeve

Lever pin

Cam O-ring

Lever

Type E

Cam sleeve O-ring

Cam sleeve

Lever pin

Cam O-ring

View showing valve gagged

with test rod

Lever

Type D

5

Page 6

CROSBY SERIES BP OMNI-TRIM® PRESSURE RELIEF VALVES

InstallatIon, maIntenance and adjustment InstructIons

9 REPLACEMENT SPARE PARTS

9.1 Ordering information

Emerson recommends that a sufficient

inventory of spare parts be maintained to

support process requirements. Always be

sure to use genuine Emerson parts to ensure

continued product performance and warranty.

9.2 Parts

To order parts, the following information always

should be included:

1. Quantity

2. Part name, i.e. (disc insert)

3. Size, style, type and valve number

4. Shop and/or serial number

5. Original purchase order number

(ifthenameplate has been destroyed)

NOTE

The size, style, shop number, set pressure and serial

number can always be found on the valve nameplate.

9.3 Springs with washers

To order springs with washers, the required

valve set pressure must also be specified in

addition to the other parts information. Should

back pressure (fixed or variable) or elevated

temperature exist during operation, also specify

these conditions. Emerson provides special

'fast response' delivery service of spare parts

to satisfy unplanned parts requirements. Fast

response delivery service can be initiated by

contacting your local Emerson representative.

Emerson.com/FinalControl

For additional information about

SeriesBPOMNI-TRIM pressure relief valves,

seeVCTDS-00594.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Crosby is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

andthe Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

6

Loading...

Loading...