Page 1

CROSBY STYLE JCE SAFETY VALVE

InstallatIon, MaIntenance and adjustMent InstructIons

1 INSTALLATION

The valve must be installed with its main axis

perpendicular either on pipework or directly on

to the pressure vessel. The branch leading to

the valve shall be of sufficient size to prevent

a pressure drop in excess of 3% of the set

pressure when the valve is discharging its rated

capacity.

1.1 Drainage

If liquid can collect on the discharge side of the

valve, the drain plug (42) should be removed

and drain pipework connected so that the liquid

can be discharged at a point where it will not

cause injury to anyone.

1.2 Discharge pipework

In no case shall the nominal bore of the

discharge pipework be less than the nominal

bore of the valve outlet.

Except for balanced bellows valves, pipework

should be as short as possible, and of sufficient

size to limit the pressure drop through the

pipework to 10% of the set pressure.

The pipework should be suitably supported

so as not to impose an excessive load on the

valve, and consideration should be given to the

reaction due to the valve discharging its rated

capacity.

1.3 Preparing for installation

Remove all packing material. Check that the

set pressure and other details on the valve

nameplate are correct. Fit an inlet gasket and

ensure that it is properly located so that it does

not impede the flow to the valve. Connect up the

discharge piping, ensuring that an outlet gasket

is properly located.

Note: Fluid discharged from the bonnet vent

hole in the event of bellows failure on Balanced

Bellows valves is usually discharged to

atmosphere. If this fluid is toxic or inflammable,

it must be piped away to a safe place, however

atmospheric pressure within the casing must

be maintained.

Note: Pipework leading to the valve should

be thoroughly cleaned to remove any foreign

matter, as this would cause the valve to leak if

trapped between the seat (4) and disc (5).

2 PRESSURE ADJUSTMENT

The valve has been factory set, but if it is found

necessary to make pressure alterations, it

is desirable to remove the valve from the

installation and use a suitable test rig. If this

cannot be done, the pressure may be altered

in situ by removing the cap (3), retaining the

compression screw in position by means of the

flats provided and slackening off the locknut

(13). The set pressure of the valve may be

increased by turning the compression screw

(12) in a clockwise direction, or decreased by

turning the screw in anti-clockwise direction.

Note: On valves with packed or marine caps the

cap may be removed by following the procedure

in4.4 or 4.5.

The set pressure should be checked by bringing

the pressure within the vessel or pipework

up to the required level gradually. A pressure

gauge must be installed so that the pressure

may be checked.

3 MAINTENANCE

Before any maintenance work is carried out, all

pressure should be exhausted from the system.

If the work cannot be carried out in a satisfactory

manner by competent personnel, the valve

should be returned to the factory for service.

It is not always possible to carry out

maintenance work at the site, and we suggest

that the valve should be removed from the plant

and taken to a workshop.

4 DISMANTLING

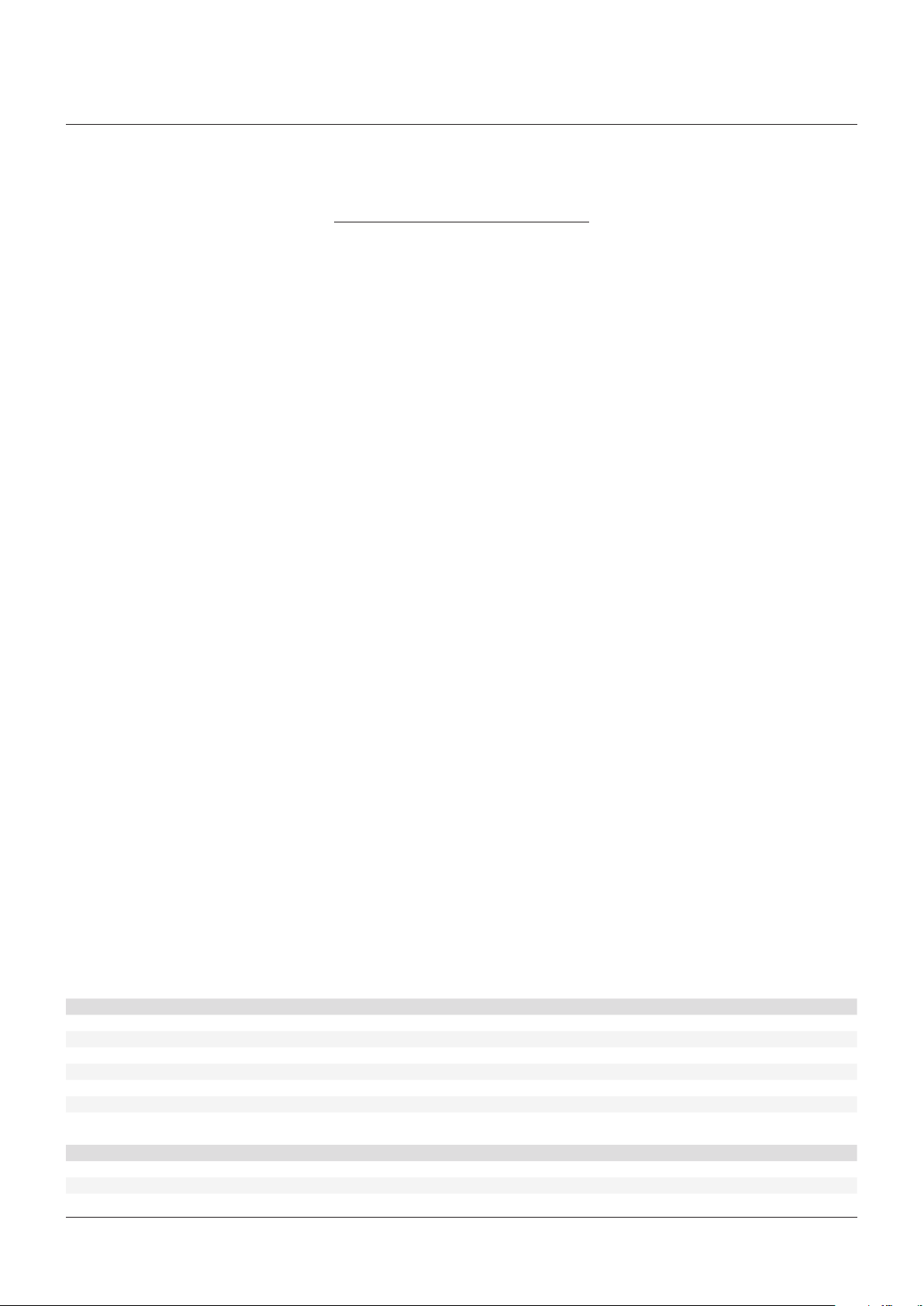

4.1 All valve types - Refer to figure 1

Unscrew the cap (3), if a packed or marine type

cap is fitted refer to sections 4.4 and 4.5. Slacken

the locknut (13) and remove all compression

from the spring (22) by turning the adjusting

screw (12) anti-clockwise. It is recommended

that the adjusting screw (12) is marked before

removal so that the valve can be approximately

reset to the correct pressure on reassembly.

Slacken the body nuts (19) and remove

the cover(2). Remove the spindle (10)

from the guide plate (9), complete with the

lower spring plate(11) as an assembly.

Thelowerspringplate(11) may then be lifted off

its split collar (69) and removed from the spindle

(10). Care should be taken not to lose the split

collar (69). If the valve is an 80mm or 100mm

high pressure model the 4 nuts (21) holding

the cover spacer (68) to the body (1) should be

removed and the cover spacer (68) lifted away

from the guide plate (9). The guide plate (9)

may now be removed from the body (1). It is not

recommended to release the guide plate (9) by

inserting a tool in the seat bore (4) as damage to

the disc (5) and seat (4) will result.

Note: Care must be taken when removing the

guide plate (9) not to damage the bellows unit

(23) on balanced bellows valves.

4.2 Conventional valve - Refer to figure 1

4.2.1 Remove the disc assembly from the

seat(4), being careful not to lose the

ball (31). Examine the disc (5), re-lap as

necessary. If the valve is a resilient seated

model refer to next section.

4.2.2 Resilient seated valve - Refer to figure 4.

The resilient seat (53) may be replaced,

if necessary, by removing the circlip (65)

from the disc assembly along with the

retaining plate (66).

Emerson.com/FinalControl VCIOM-01087-EN 17/11

© 2017 Emerson. All Rights Reserved.

Page 2

CROSBY STYLE JCE SAFETY VALVE

InstallatIon, MaIntenance and adjustMent InstructIons

4.3 Bellows valve - Refer to figure 1

4.3.1

Remove the bellows unit (23) complete

with disc assembly from the seat (4), being

careful not to lose the lift stop (81) and ball

(31). If the valve is a resilient seated model

follow the procedure outlined in4.2.2. to

remove the resilient seal; this must be done

before the bellows unit (23) is removed.

4.3.2 If the bellows unit (23) requires replacing,

this will be supplied welded to the disc.

The disc will be supplied fully lapped in

protective wrapping. Only use factory

supplied bellows units.

4.4 Marine cap - Refer to figure 2

To remove the marine cap (3) first remove

the fulcrum pin (56) from the lever (73) using

a suitable tool as a drift. The lever (73) may

now be withdrawn from the cap (3). Slacken

the grub screw (75) and unscrew the marine

cap (3). It is recommended that the spindle

nut (61) should be marked prior to removal so

that the correct position can be attained upon

reassembly. Remove the spindle nut (61) and

the spindle washer (83).

Further dismantling of the valve is achieved by

following the procedure outlined in4.1.

4.5. Packed cap - Refer to figure 3

To remove the packed cap (3) first undo the

gland (57). It may be necessary to ease the

eccentric shaft (70) outwards during this

operation to ensure that the gland (57) can

be withdrawn from the cap (3). The lever

assembly may now be withdrawn from

the cap complete with gland packing (58).

Thetensionpin(35)should be released from

the lever (73) by using a suitable tool as a drift.

The lever (73), gland (57) and gland packing(58)

may now be removed from the eccentric

shaft(70).

Note: It will be necessary to fit new gland

packing (58) on reassembly.

The cap (3) may now be unscrewed from the

bonnet (2). It is recommended that the lock

nut (82) should be marked prior to removal so

that the correct position can be attained upon

reassembly. Unscrew the locknut (82) and the

spindle nut (61).

Further dismantling of the valve is achieved by

following the procedure outlined in4.1.

5 EXAMINATION AND RECONDITIONING

5.1 Disc

Examination of the disc (5) will reveal whether it

requires re-lapping. The disc may be re-lapped,

using a flat cast iron lapping plate. Using a

fine lapping paste, without applying excessive

pressure, lap the disc until all imperfections

have been removed from the seating face. If

the disc is too badly damaged to relap fit a new

disc.

5.2 Seat

Examination of the seat (4) will reveal whether it

requires relapping. The seat (4) may be lapped

in situ in the body (1) using the same lapping

plate as for the disc (5) and following the same

procedure. If the seat face is too badly damaged

to re-lap it must be remachined. The maximum

amount of metal it is allowable to remove is

3mm. If this is exceeded, the valve must be

returned to the factory for a new seat fitting.

Having been machined the seat (4) should be

re-lapped as previously described.

Note: Ensure all lapping paste is removed from

the seat (4) and the disc (5) before reassembly.

5.2.1 Seat replacement

In the event of complete seat

replacement being required, the existing

seat must be machined out, and an

oversize seat obtained from the factory.

Donotomitremoval and replacement of

the seat security pin.

Machine out seat recess diameter to

give interference at ambient conditions

according to the following table.

5.2.2 Procedure for fitting new seat

Remove existing seloc pin. Remove /

machine seat from body. Re-machine

body to dimensions in table above. Coat

body recess with ‘Boss White sealant’.

Insert seat into liquid nitrogen and leave

until temperature has been reduced to

minus 196°C. Remove seat from liquid

nitrogen and insert into body recess,

using tools provided Hammer the seat

into body ensuring that the seat properly

‘bottoms’ in the recess. Allow assembly

to reach room temperature.

5.2.3 Seat change procedure

Drill into seat ‘B’ depth as shown below

through existing hole in body, and fit new

‘Seloc’ pin. Cut and dress pin flush with

body. (Note that body will be received

drilled)

Valve size Body dimensions (inch) Seat dimensions (inch) Interference (inch)

1” 1.3008 / 1.2992 1.3039 / 1.3029 0.0037 / 0.0021

1¼” 1.5764 / 1.5748 1.5795 / 1.5785 0.0047 / 0.0021

1½” 1.9701 / 1.9685 1.9739 / 1.9729 0.0054 / 0.0028

2” 2.3642 / 2.3622 2.3690 / 2.3678 0.0068 / 0.0036

2½” 3.1516 / 3.1496 3.1576 / 3.1564 0.0080 / 0.0048

3” 3.7425 / 3.7401 3.7499 / 3.7485 0.0098 / 0.0060

4” 4.7268 / 4.7244 4.7358 /4.7344 0.0114 / 0.0076

DN 25 32 40 50 65 80 100

‘A’ pin dia x length prior to cut off ø3 x 18 ø3 x 24 ø3 x 28 ø3 x 36 ø3 x 36 ø3 x 40 ø3 x 45

‘B’ pin/drill depth 1 1.5 2.5 2.5 2.5 2 2.5

2

Page 3

CROSBY STYLE JCE SAFETY VALVE

InstallatIon, MaIntenance and adjustMent InstructIons

5.3 General examination

Ensure that the bore of the guide plate (9) is

in good condition, and that the spindle (10)

where it passes through the guide (9) and the

adjusting screw bush (77) is free from any

surface defects. Ensure that the adjusting

screw bush (77) is not worn. Examine the ball

location points in the disc (5) and the spindle

(10) and ensure that they are of a clean smooth

finish. Examine the ball (31) for surface

imperfections and replace if damaged. If the

spring is corroded it should be replaced.

5.4 Resilient seal

If the resilient O-ring (53) is damaged it should

be replaced. The seal is removed from the disc

(5) by following the procedure outlined in4.2.3.

5.5 Bellows

If the bellows unit is damaged, distorted or

corroded in any way it should be replaced.

6 REASSEMBLY

6.1 Conventional metal seated valves

6.1.1 Apply grease to both ball and adjusting

screw. Place the ball (31) in position on

the disc (5) and position the disc assembly

onto the seat (4). Place new gasket (27)

onto the guide recess in the body.

6.1.2 Fit the spindle (10) on to the ball (31) and

slide the guide plate (9) into position in

the body recess. Ensure that the spindle

(10) is free to move. Fit the split collar (69)

onto the spindle (10) and slide the lower

spring plate (11) into position. Ensure that

the spring plate (11) is fully located on the

split collar. Place a new gasket (27) onto

the guide plate (9).

If the valve is an 80mm or 100mm high

pressure model the cover spacer (68)

should be positioned onto the guide plate

(9) and the 4 nuts (21) tightened. A new

gasket should be positioned on top of the

spacing piece.

Place the spring (22) onto the lower

spring plate (11) and fit the upper spring

plate (11) onto the spring (22). Lower the

bonnet (2) over the spindle (10) and onto

the guide plate (9). Tighten down fully the

4 nuts (19). Slide the adjusting screw (12)

over the spindle (10) and screw it into the

bonnet (2). Set the adjusting screw (12) to

its original position and secure with the

locknut (13).

6.2 Bellows metal seated valves

6.2.1 Place the ball (31) in position on the disc

(5) and the lift stop (81).

6.2.2 Place a new gasket (27) onto the body

recess and position the spacing piece

(47) onto the body (1). Position the disc/

bellows assembly onto the seat (4) and

ensure that the bellows flange locates

squarely into the spacing piece recess.

Follow the procedure outlined in6.1.2

to further assembly the valve. It is

very important that an effective seal is

achieved between the bellows flange and

the guide plate.

6.3 Resilient valves

Place the 0-ring (53) into position on the disc (5)

along with the retaining plate (65). Secure the

assembly with the circlip (66) ensuring that the

retaining plate (65) is centrally located on the

0-ring (65).

Follow the relevant procedure outlined in6.1.1

or 6.2.1 to further re-assemble the valve

6.4 Pressure Setting

The set pressure on gas/vapor is defined where

audible discharge occurs. On liquid valves

this is defined where the first steady stream

of liquid occurs. In both cases, the pressure

gauge measuring inlet pressure will stop rising

when set pressure is reached.

Ensure that the internal surfaces of the valve

inlet and test rig are clean and mount the

valve securely on the test rig. Set the valve to

the required pressure using air or nitrogen

for valves intended for gas or vapor service.

Inhibited water should be used for valves

intended for liquid duty. Adjust the adjusting

screw (12) until the required set pressure is

achieved and pull up the locknut (13). Finally

check that the set pressure has not altered.

Refit the cap (3) using a new gasket (28) if

applicable. To reassemble the packed and

marine caps reverse the procedure described

in4.4 or 4.5.

7 SUPPLEMENTARY NOTES

7.1 Danger can emanate from the incorrect

installation, maintenance and adjustment

of this product. For this reason only

qualified persons are permitted to work

on the product within the guidelines

supplied by the manufacturer.

7.2 Failure to adhere to these instructions

will invalidate any CE marking.

3

Page 4

CROSBY STYLE JCE SAFETY VALVE

InstallatIon, MaIntenance and adjustMent InstructIons

PARTS LIST

Item nr. Part name

1 Body

2 Bonnet

3 Cap

4 Seat

5 Disc

9 Guide plate

10 Spindle

11 Spring plate

12 Adjusting screw

13 Locknut

18 Body stud

19 Body nut

(H)

20

(H)

21

22 Spring

(B)

23

27 Body/bonnet gasket

28 Cap gasket

31 Ball

33 Nameplate

34 Nameplate pin

41 Warranty seal

42 Drain plug

(B)

47

62 Seat pin

(H)

68

69 Split collar

77 Adjusting screw bush

(B)

81

Cover stud

Cover nut

Bellows unit

Spacing piece

Cover spacer

Lift stop

FIGURE 1

Standard screwed cap

C1 Conventional

C2 Bellows type

Minimum withdrawal

allowance

Bellows type

B.S.P.

atmospheric

vent

N.P.T.

Body drain (remove

plug and pipe away

if required)

NOTE

B = denotes only used on bellows type valves

H = denotes only used on high pressure type valve

Dimensions (mm) unless otherwise stated

25 x 40 32 x 50 40 x 65 50 x 80 65 x 100 80 x 125 100 x 150

A 100 110 115 120 140 160 180

B 105 115 140 150 170 195 220

C1 410 455 570 615 725 825/925 H 925/1030 H

C2 445 490 605 665 785 865/965 H 955/1060 H

D 85 85 125 125 155 155 180

E ⅜” ⅜” ½” ½” ¾” ¾” ¾”

F ¼” ¼” ¼” ¼” ¼” ⅜” ⅜”

WT 8-5 14-0 20-0 30-0 42-5 64-5 86-0

NOTE

Weights (kg) given are approximate for cast iron valves.

H = denotes high pressure valve longer bonnet, spring and spindle.

Conventional

4

Page 5

CROSBY STYLE JCE SAFETY VALVE

InstallatIon, MaIntenance and adjustMent InstructIons

OPEN TYPE EASING GEAR

Valves which are used for steam or compressed

air are normally fitted with open type easing

gear.

This type of easing gear can also be used on

other fluids where a small escape of the fluid

to atmosphere, when the valve is discharging,

is not objectionable. It is normally fitted on

conventional type valves only. The purpose of

the easing gear is to check that the valve can

operate freely.

PACKED EASING GEAR

Alternatively packed easing gear can be

supplied. This is used when the fluid can not

be allowed to escape to atmosphere except

through the outlet connection, but where it

is necessary to check that the valve is free to

operate.

PARTS LIST

Item number Part name

3 Open type bonnet

56 Fulcrum pin

61 Spindle nut

73 Marine easing lever

75 Grub screw

83 Spindle washer

PARTS LIST

Item number Part name

3 Packed type bonnet

28 Cap gasket

35 Tension pin

57 Gland

58 Gland packing

61 Spindle nut

70 Eccentric shaft

73 Packed easing lever

82 Spindle lock nut

FIGURE 2

Open (marine) easing gear

FIGURE 3

Packed easing gear

RESILIENT SEAT

The standard construction using metal-tometal seats lapped to IMI Bailey Birkett’s high

standard is suitable for most applications.

Elastomeric seals are supplied as conditions

PARTS LIST

Item number Part name

5 Resilient disc

53 O-ring seal

65 Circlip

66 Retaining plate

FIGURE 4

Resilient disc

dictate.

O-ring material Temp. range

A. Viton -30 to 200°C

B. Nitrile -40 to 100°C

Other materials may be available upon request

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Crosby is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

5

Loading...

Loading...