Page 1

100-214-294 - REV. 05

Bransonic

Ultrasonic Bath

Instruction Manual

Branson Ultrasonics Corporation

41 Eagle Road

Danbury, CT 06813-1961 USA

(203) 796-0400

http://www.bransonultrasonics.com

Page 2

Manual Change Information

At Branson, we strive to maintain our position as the leader in ultrasonics plastics joining,

metal welding, cleaning and related technologies by continually improving our circuits and

components in our equipment. These improvements are incorporated as soon as they are

developed and thoroughly tested.

Information concerning any improvements will be added to the appropriate technical

documentation at its next revision and printing. Therefore, when requesting service

assistance for specific units, note the Revision information found on the cover of this

document, and refer to the printing date which appears at the bottom of this page.

Copyright and Trademark Notice

Copyright © 2017 Branson Ultrasonics Corporation. All rights reserved. Contents of this publication may not be

reproduced in any form without the written permission of Branson Ultrasonics Corporation.

Mylar is a registered trademark of DuPont Teijin Films.

Loctite is a registered trademark of Loctite Corporation.

WD-40 is a registered trademark of WD-40 Company.

Windows 7, Windows Vista, and Windows XP are registered trademarks of Microsoft Corporation

Other trademarks and service marks mentioned herein are held by their respective

owners.

ii 100-214-294 REV. 05

Page 3

Foreword

Congratulations on your choice of a Branson Ultrasonics Corporation system!

The Branson Ultrasonic Bath system is process equipment for the cleaning of parts using

ultrasonic energy. It is the newest generation of product using this sophisticated

technology for a variety of customer applications. This Instruction Manual is part of the

documentation set for this system, and should be kept with the equipment.

Thank you for choosing Branson!

Introduction

This manual is arranged into several structured chapters which will help you find the

information you may need to know to safely handle, install, set up, program, operate,

and/or maintain this product. Please refer to the Table of Contents and/or the Index of

this manual to find the information you may be looking for. In the event you require

additional assistance or information, please contact our Product Support department (see

1.3 Limited Warranty for information on how to contact them) or your local Branson

representative.

100-214-294 REV. 05 iii

Page 4

iv 100-214-294 REV. 05

Page 5

Table of Contents

Chapter 1:Safety and Support

1.1 Safety Requirements and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Limited Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2:Introduction

2.1 How Ultrasonics Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Ultrasonic Baths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3:Delivery and Handling

3.1 Unpacking Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Chapter 4:Technical Specifications

4.1 Model Name Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Equipment Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.4 Cleaning Solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.5 Solution Effect on Metals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Chapter 5:Installation and Setup

5.1 Installing Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Chapter 6:Operation

6.1 Operating Your Ultrasonic Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.2 M Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.3 MH Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.4 CPX Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.5 CPXH Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.6 Cleaning Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Chapter 7:Maintenance

7.1 Optimizing Your Ultrasonic Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

7.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

7.3 Glass Slide Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

7.4 Service Centers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

7.5 Information for Users on Disposal of Equipment . . . . . . . . . . . . . . . . . . . . . . . . . .71

100-214-294 REV. 05 v

Page 6

vi 100-214-294 REV. 05

Page 7

List of Figures

Chapter 1:Safety and Support

Chapter 2:Introduction

Chapter 3:Delivery and Handling

Chapter 4:Technical Specifications

Chapter 5:Installation and Setup

Chapter 6:Operation

Figure 6.1 M Series Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 6.2 MH Series Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 6.3 CPX Series Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Figure 6.4 CPXH Series Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 6.5 Draining of Units 1800 and 2800. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

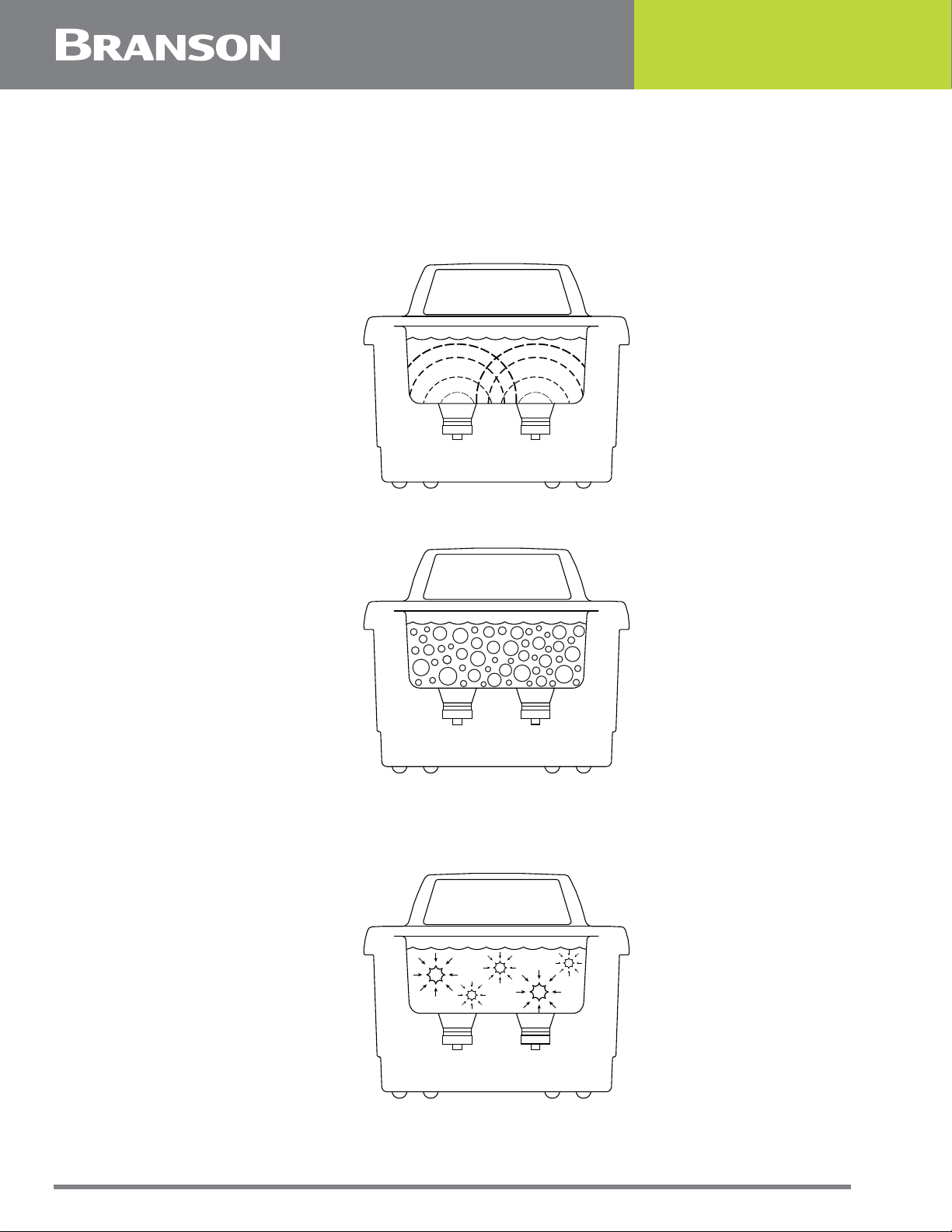

Figure 6.6 Direct Cleaning Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Figure 6.7 Indirect Cleaning Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Figure 6.8 Non Cleaning Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Chapter 7:Maintenance

100-214-294 REV. 05 vii

Page 8

viii 100-214-294 REV. 05

Page 9

List of Tables

Chapter 1:Safety and Support

Chapter 2:Introduction

Table 2.1 Ultrasonic Baths Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3:Delivery and Handling

Chapter 4:Technical Specifications

Table 4.1 Model Name Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 4.2 Equipment Specifications for North America Models. . . . . . . . . . . . . . . . . . . . . . . .15

Table 4.3 Equipment Specifications for Europe Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 4.4 Equipment Specifications for Japan Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table 4.5 Equipment Specifications for China Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Table 4.6 Fuse Table for North America and Japan Models . . . . . . . . . . . . . . . . . . . . . . . . . .19

Table 4.7 Fuse Table for Europe and China Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Table 4.8 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Table 4.9 Alkaline Solution Strength and Uses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Table 4.10 Chemicals Harmful to Your Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Table 4.11 Solution Effects on Metals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Chapter 5:Installation and Setup

Chapter 6:Operation

Table 6.1 Before you Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 6.2 M Series Explanation of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 6.3 For initial cleaning solution degassing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 6.4 Treating Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 6.5 Before you Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 6.6 MH Series Explanation of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 6.7 For initial cleaning solution degassing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 6.8 Treating Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 6.9 Before you begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 6.10 CPX Series explanation of controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Table 6.11 CPX Series LCD description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Table 6.12 Degassing your CPX Series unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Table 6.13 Treating Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Table 6.14 Before you begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Table 6.15 CPXH Series explanation of controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Table 6.16 LCD Description for CPXH Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Table 6.17 Degassing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 6.18 Ultrasonic Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Table 6.19 Treating samples in Timed Sonics Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Table 6.20 Treating Samples in Constant Sonics Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Table 6.21 Treating Samples in Auto Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Table 6.22 CPXH temperature calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Table 6.23 Draining your ultrasonic bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Table 6.24 Measuring the Solution Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Table 6.25 Solution Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

100-214-294 REV. 05 ix

Page 10

Chapter 7:Maintenance

Table 7.1 Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 7.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 7.3 Authorized Service Centers (North America) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 7.4 Technical Support (North America) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 7.5 Authorized Service Center/Technical Support (Europe) . . . . . . . . . . . . . . . . . . . . . 69

Table 7.6 Authorized Service Center/Technical Support (Asia) . . . . . . . . . . . . . . . . . . . . . . . 69

x 100-214-294 REV. 05

Page 11

Chapter 1: Safety and Support

1.1 Safety Requirements and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

100-214-294 REV. 05 1

Page 12

1.1 Safety Requirements and Warnings

This chapter contains an explanation of the different Safety Notice symbols and icons

found both in this manual and on the product itself and provides additional safety

information for ultrasonic welding. This chapter also describes how to contact Branson for

assistance.

2 100-214-294 REV. 05

Page 13

1.2 Safety Precautions

Before using your Ultrasonic Bath, please read and thoroughly understand these safety

precautions. Failure to follow them may result in serious personal injury or property

damage.

1.2.1 To avoid electrical shock:

• Do unplug from power source before filling or emptying the tank

• Do plug the unit into an appropriate grounded power socket

• Do connect the unit to a power supply using a properly sized overcurrent protection device. See

label on the back of unit for information on current rating

• Do keep the control panel and the area around the unit clean and dry—wipe up solution which

spills over the tank brim. Water and high voltage can cause electrical shock

• Do not operate the unit without proper grounding

• Do not remove the grounding prong on the line cord plug

• Do not disassemble your unit—high voltage inside the unit is dangerous

• Do not immerse the unit in water

1.2.2 To prevent personal and/or property damage:

• Do use water-based solutions

• Do not ever use alcohol, gasoline or flammable solutions. Doing so could cause a fire or explosion

and will void your warranty. Use only water-based solutions

• Do not ever use mineral acids. These could damage the tank

• Do not touch the stainless steel tank or cleaning solution—they may be hot

• Do not allow fluid temperature to exceed 70° C (158° F)

• Do not place your fingers or hands into the tank while the unit is operating. Doing so may cause

discomfort and possible skin irritation. Avoid contact with solutions and provide adequate

ventilation

• Do not use solutions containing chlorine bleach

1.2.3 To prevent damage to the unit:

• Do change your solution regularly

• Do not cover vents on the cover

• Do not operate the unit dry

• Do not place parts or containers directly on the bottom of the tank; use a tray or wire to suspend

items. Failure to comply may cause transducer damage and will void your warranty

• Do not allow the solution to drop more than 3/8 inch (1 cm) below the operating level line with

heat or ultrasonics on. Failure to comply may cause transducer and/or heater damage and will

void your warranty

• Turn off AC and heater switch before plugging/unplugging the line cord

1.2.4 Sound level and energy savings

• Do not operate the unit without a cover when possible

• The sound pressure released by the unit depends on the size of the bath and the application, but

is less than 80 dBA when used with a cover

• To reduce the sound pressure it is recommended to use a cover while ultrasonics are activated

and to switch the ultrasonics on with the bath loaded when possible

1.2.5 Insulation resistance test

Branson has taken all applicable measures to assure that manufactured units comply with

insulation resistance requirements, as outlined by IEC 61010-1:2010 (Third edition). As

100-214-294 REV. 05 3

Page 14

per the Portable Appliance Testing (PAT) requirements, testing should be carried out by

the user.

Before doing the insulation testing, however, please read the following pertinent

information:

All of Branson's 220 V "C" and 230 V "E" units are equipped with Metal Oxide Varistors

(MOVs) as the primary components to absorb overvoltages in the power line. MOVs

disperse the over-voltage to the ground line and thus away from the equipment. Per their

mode of operation, these MOVs will cause the insulation resistance test to fail when it is

carried out at 500 V DC. As such, Branson recommends performing the test at a reduced

voltage (250 V DC), as allowed by the Code of Practice for In-service Inspection and

Testing of Electrical Equipment published by the IET (The Institution of Engineering and

Technology), as this will prevent the MOVs from triggering and failing the test.

4 100-214-294 REV. 05

Page 15

1.3 Limited Warranty

Subject to the limitations outlined below, Branson warrants that the Ultrasonic Baths will

be free from defects in material and workmanship under normal use and regular service

and maintenance for a period of twenty four (24) months from the date of

shipment. Branson does not warrant that the operation of the software shall be

uninterrupted or error free. THIS IS THE SOLE AND EXCLUSIVE WARRANTY GIVEN WITH

RESPECT TO THE ULTRASONIC BATHS AND IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, ARISING BY OPERATION OF LAW OR OTHERWISE,

INCLUDING WITHOUT LIMITATION, MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE WHETHER OR NOT THE PURPOSE OR USE HAS BEEN DISCLOSED TO BRANSON.

This warranty does not extend to any losses or damages due to misuse, accident, abuse,

neglect, normal wear and tear, negligence (other than Branson's), unauthorized

modification or alteration, use beyond rated capacity, unsuitable power sources or

environmental conditions, improper installation, repair, handling, maintenance or

application or any other cause not the fault of Branson. If within thirty (30) days after

discovery of any warranty defects within the warranty period, the Customer notifies

Branson thereof in writing, Branson shall, at its option and as the Customer's exclusive

remedy, repair, correct or replace, or refund the purchase price for, that portion of the

product found by Branson to be defective. Failure by the Customer to give such written

notice within the applicable time period shall be deemed an absolute and unconditional

waiver of the Customer's claim for such defects. The Customer must return the product to

one of the Branson service centers, whose addresses are provided on 7.4 Service Centers

of this manual. The Customer will be responsible for freight sending the unit to the service

center. The service center will send the unit back to the Customer with freight prepaid.

Branson’s liability, whether based on warranty, negligence, tort or strict liability, or other

cause, arising out of and/or incidental to sale, use or operation of the transducer

elements, or any part thereof, shall not in any case exceed the cost of repair or

replacement of the defective equipment, and such repair or replacement shall be the

exclusive remedy of the purchaser, and in no case shall Branson be responsible for any

and/or all consequential punitive or incidental damages including without limitation, and/

or any consequential damages arising out of commercial losses.

WARNING General Warning

• Do not place parts or containers directly on the bottom of the tank; use a

tray or wire to suspend items. Direct placement can cause the units to fail

• Do not allow the solution to drop more than 3/8 inch (1 cm) below the

operating level line

• Do not ever use alcohol, gasoline or flammable solutions. Doing so could

cause a fire or explosion. Use only water-based solutions

• Do not use mineral acids. These could damage the tank

First time cleaning - First experiment with one piece, then proceed with the remainder.

100-214-294 REV. 05 5

Page 16

CAUTION General Warning

Never clean novelty or inexpensive jewelry in the ultrasonic bath. The

combination of heat and vibration may loosen a cement-held setting.

Never clean gemstones such as emerald, amethyst, pearl, opal, coral,

turquoise, peridot or lapis lazuli in the ultrasonic bath.

Solution level - Be sure to maintain solution level within 1/2 inch (1.3 cm) of the tank’s

“operating level” line. Surface activity can vary with liquid level.

Load size - It is faster and more efficient to run several small loads rather than a few big

loads.

Placing items - Never allow items to sit on the bottom of the tank. Always place them in

a tray or beaker or suspend in the solution.

Rinsing items - After cleaning, use a clean water bath to rinse away chemicals adhering

to items.

Lubricating items - When necessary, re-lubricate items immediately after cleaning.

Drying items - Air drying at room temperature works for some items. Place parts

requiring faster drying time under hot air blowers or in ovens.

Please call your local distributor if you have application questions.

6 100-214-294 REV. 05

Page 17

Chapter 2: Introduction

2.1 How Ultrasonics Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Ultrasonic Baths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

100-214-294 REV. 05 7

Page 18

2.1 How Ultrasonics Works

Ultrasonic sound is sound transmitted at frequencies generally beyond the r ange of human

hearing. In your ultrasonic bath, ultrasonic sound (sonics) can be used for cleaning

materials and parts, and for dissolving, homogenizing and degassing liquids. This is how it

works:

• As the sound waves from the transducer radiate through the solution in the tank, they cause

alternating high and low pressures in the solution

• During the low pressure stage, millions of microscopic bubbles form and grow. This process is

called CAVITATION, meaning “formation of cavities”

• During the high pressure stage, the bubbles collapse, or “implode” releasing enormous amounts

of energy

• For ultrasonic cleaning applications, these implosions act like an army of tiny scrub brushes. They

work in all directions, attacking every surface and invading all recesses and openings

• This same energy can be used for other applications, such as liquid dissolving, homogenizations,

and degassing

8 100-214-294 REV. 05

Page 19

2.2 Ultrasonic Baths

This line of ultrasonic baths include five sizes:

Table 2.1 Ultrasonic Baths Available

Model Number Tank Capacity

1800 1/2 gal. (1.91 l)

2800 3/4 gal. (2.81 l)

3800 1-1/2 gal. (5.71 l)

5800 2-1/2 gal. (9.51 l)

8800 5-1/2 gal. (20.81 l)

Each model is constructed using durable industrial style 40 kHz transducers. These

provide increased ultrasonic power along with built in sweep frequency to ensure uniform

ultrasonic activity throughout the bath. Models 1800 and 2800 have a molded dip in the

left side of their rims to facilitate emptying of solution from the tank. Models 3800, 5800

and 8800 have built in drains and are supplied with tank drain kits. Each model can be

purchased in four different configurations:

• With a Mechanical Timer (M);

• With a Mechanical Timer plus Heat (MH);

• With Digital Control and Timer (CPX);

• With Digital Control, plus Heat and Timer (CPXH).

When you first fill your unit, or refill it with fresh solution, use warm water for the solution.

Turn on the heater (if available), turn on the ultrasonics (press the Sonics key or rotate

the Timer), add the cover and the solution will heat quickly to temperature.

100-214-294 REV. 05 9

Page 20

2.2.1 Accessories For Your Unit

As parts cannot be placed on the tank bottom, accessories include beaker positioning

covers, solid and perforated insert trays, mesh baskets, beakers, and support racks.

NOTICE

Tank covers are included with every unit.

10 100-214-294 REV. 05

Page 21

Chapter 3: Delivery and Handling

3.1 Unpacking Your Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

100-214-294 REV. 05 11

Page 22

3.1 Unpacking Your Unit

Please check your unit and its carton carefully for any external or internal damage. If you

find damage, contact your shipping carrier immediately, before contacting your distributor .

Please retain your packaging for future use.

12 100-214-294 REV. 05

Page 23

Chapter 4: Technical Specifications

4.1 Model Name Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Equipment Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Cleaning Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Solution Effect on Metals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

100-214-294 REV. 05 13

Page 24

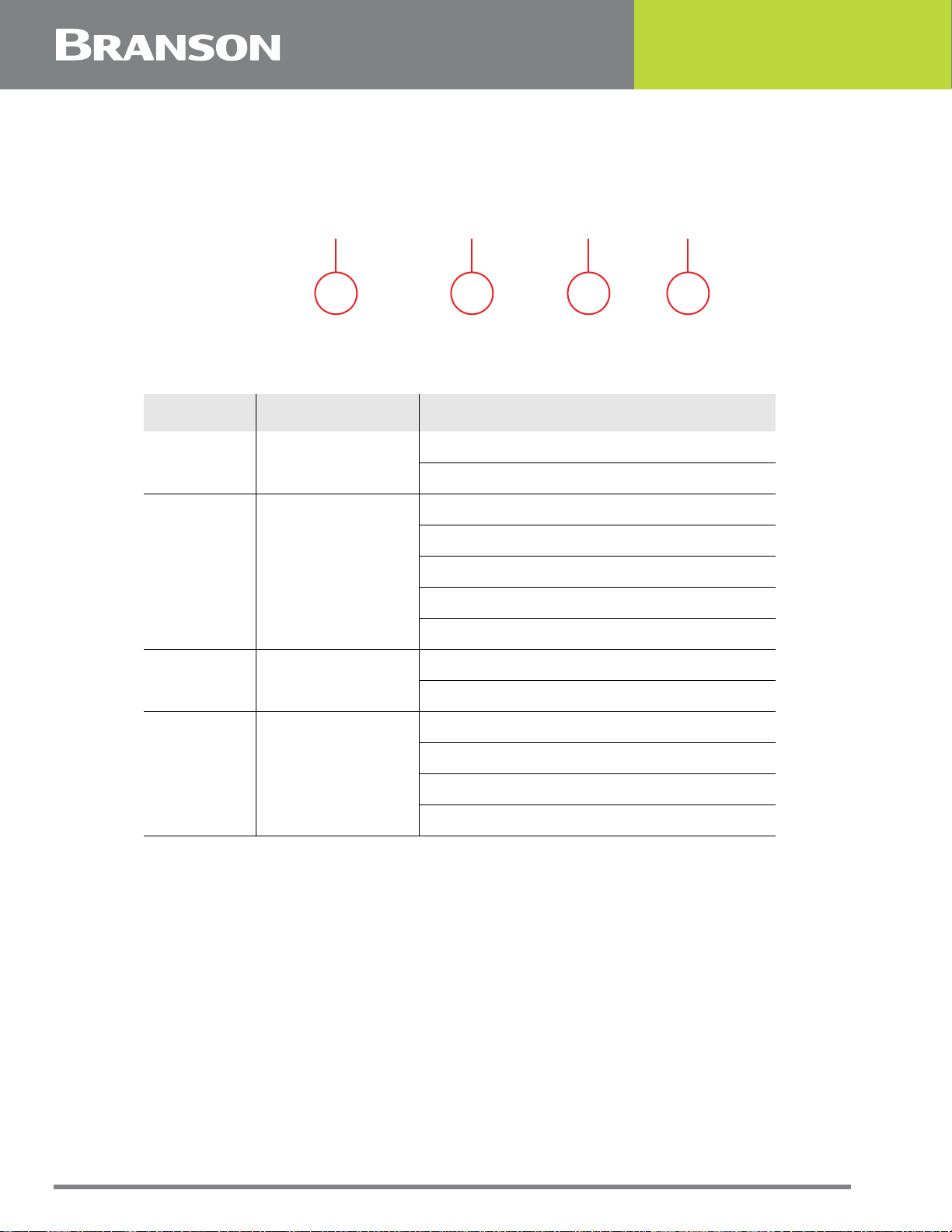

4.1 Model Name Definition

The name of the models determine the specifications of each unit. For example the

CPX1800H-E:

CPX 1800 H - E

1 2 3 4

Table 4.1 Model Name Definition

Item Stands For Availability

CPX: Digital

1 Model

M: Mechanical

1800: 1/2 gal (1.91 l)

2800: 3/4 gal (2.81 l)

2 Tank Capacity

3 Heater

4 Region/voltage

• All models have a frequency of 40 kHz

• In CPXH models, the temperature readout accuracy is ± 3° C (± 5.4° F)

• Models available for 120 V ± 10%, 50/60 Hz and 220 V ± 10%, 50/60 Hz operation

• All 120 V units have CSA/UL or equivalent approval and comply with FCC regulations

• All 220-230 V units meet CE standards

• All units have a ground leakage current less than .50 ma

• Operating ambient temperature is from 5° C to 40° C (41° F to 104° F)

3800: 1-1/2 gal (5.71 l)

5800: 2-1/2 gal (9.51 l)

8800: 5-1/2 gal (20.81 l)

Blank: No heater

H: Heater

Blank: North America (120 VAC)

E: Europe (230 VAC)

J: Japan (100 VAC)

C: China (220 VAC)

14 100-214-294 REV. 05

Page 25

4.2 Equipment Specifications

Table 4.2 Equipment Specifications for North America Models

Model

Name

M1800

M1800H 70 60 150

CPX1800H 70 60 150

CPX1800 70 0 90

M2800

M2800H 110 90 250

CPX2800H 110 90 250

CPX2800 110 0 250

M3800

M3800H 110 180 350

CPX3800H 110 180 350

CPX3800 110 0 130

Tank

Capacity

1/2 gal.

(1.91 l)

3/4 gal

(2.81 l)

1-1/2 gal

(5.71 l)

Tank

Size

(Inches)

L: 9.9

W: 5.5

H:4

L: 9.5

W: 5.5

H: 4

L: 11.5

W: 6

H:6

Overall

Size

(inches)

L: 9.9

W: 12

H: 11.9

L: 13.3

W: 12

H: 11.9

L: 15.6

W: 12.5

H: 14.8

Weight

9 lb

(4 kg)

10 lb

(4.5 kg)

14 lb

(6.4 kg)

Max

Sonics

Power

70 0 90

110 0 130

110 0 130

Heater

Power

Max.

Draw

Power

Req.

M5800

M5800H 160 280 490

CPX5800H 160 280 490

CPX5800 160 0 180

M8800

M8800H 280 560 930

CPX8800H 280 560 930

CPX8800 280 0 320

2-1/2 gal

(9.51 l)

5-1/2 gal

(20.81 l)

L: 11.5

W: 9.5

H: 6

L: 19.5

W: 11.5

H: 15.4

L: 15.6

W: 15.8

H: 14.9

L: 23.5

W: 18.3

H: 15.4

16 lb

(7.3 kg)

28 lb

(12.7 kg)

160 0 180

280 0 320

100-214-294 REV. 05 15

Page 26

Table 4.3 Equipment Specifications for Europe Models

Model

Name

Tank

Capacity

Tank

Size

(mm)

M1800-E

L: 150

M1800H-E 70 60 150

1.91 l

W: 140

CPX1800H-E 70 60 150

(1/2 gal)

H: 100

Overall

Size

(mm)

L:251

W: 305

H: 302

Weight

5.4 kg

(12 lb)

Max

Sonics

Power

Heater

Power

70 0 90

Max.

Draw

Power

Req.

CPX1800-E 70 0 90

M2800-E

M2800H-E 110 110 250

2.81 l

W: 140

L: 240

CPX2800H-E 110 110 250

(3/4 gal)

H: 100

L: 338

W: 305

H: 302

6.8 kg

(15 lb)

110 0 130

CPX2800-E 110 0 250

M3800-E

M3800H-E 110 215 350

5.71 l

W: 150

L: 290

CPX3800H-E 110 215 350

(1-1/2 gal)

H: 150

L: 396

8.2 kg

W: 318

(18 lb)

H: 302

110 0 130

CPX3800-E 110 0 350

M5800-E

M5800H-E 160 300 490

9.51 l

W: 240

L: 290

CPX5800H-E 160 300 490

(2-1/2 gal)

H: 150

L: 396

W: 401

H: 378

9.5 kg

(21 lb)

160 0 180

CPX5800-E 160 0 180

M8800-E

M8800H-E 280 600 930

20.81 l

W: 290

L: 495

CPX8800H-E 280 600 930

(5-1/2 gal)

H: 150

L: 597

W: 465

H: 391

16.3 kg

(36 lb)

280 0 320

CPX8800-E 280 0 320

16 100-214-294 REV. 05

Page 27

Table 4.4 Equipment Specifications for Japan Models

Model

Name

Tank

Capacity

Tank

Size

(inches)

M1800-J

L: 150

M1800H-J 70 45 135

1.91 l

W: 140

CPX1800H-J 70 45 140

(1/2 gal)

H: 100

Overall

Size

(inches)

L: 251

W: 305

H: 302

Weight

4 kg

(9 lb)

Max

Sonics

Power

Heater

Power

70 0 90

Max.

Draw

Power

Req.

CPX1800-J 70 0 90

M2800-J

M2800H-J 110 65 205

2.81 l

W: 140

L: 240

CPX2800H-J 110 65 205

(3/4 gal)

H: 100

L: 338

4.5 kg

W: 305

(10 lb)

H: 302

110 0 130

CPX2800-J 10 0 130

M3800-J

M3800H-J 110 130 275

5.71 l

W: 150

L: 290

CPX3800H-J 110 130 280

(1-1/2 gal)

H: 150

L: 396

6.4 kg

W: 318

(14 lb)

H: 376

110 0 130

CPX3800-J 110 0 130

M5800-J

M5800H-J 160 200 405

9.5 l

W: 240

L: 290

CPX5800H-J 160 200 410

(2-1/2 gal)

H: 150

L: 396

7.3 kg

W: 401

(16 lb)

H: 378

160 0 180

CPX5800-J 160 0 180

M8800-J

M8800H-J 280 400 755

20.81 l

W: 290

L: 495

CPX8800H-J 280 400 760

(5-1/2 gal)

H: 150

L: 597

12.7 kg

W: 465

(28 lb)

H: 391

280 0 320

CPX8800-J 280 0 320

100-214-294 REV. 05 17

Page 28

Table 4.5 Equipment Specifications for China Models

Model

Name

M1800-C

M1800H-C

CPX1800H-C

CPX1800-C

M2800-C

M2800H-C

CPX2800H-C

CPX2800-C

M3800-C

M3800H-C

CPX3800H-C

CPX3800-C

Tank

Capacity

1.91 l

(1/2 gal)

2.81 l

(3/4 gal)

5.71 l

(1-1/2 gal)

Tank

Size

(inches)

L: 150

W: 140

H: 100

L: 240

W: 140

H: 100

L: 290

W: 150

H: 150

Overall

Size

(inches)

L: 251

W: 305

H: 302

L: 338

W: 305

H: 302

L: 396

W: 318

H: 376

Weight

5.4 kg

(12 lb)

6.8 kg

(15 lb)

8.2 kg

(18 lb)

Max

Sonics

Power

Heater

Power

Max.

Draw

Power

Req.

70 0 90

70 55 145

70 55 145

70 0 90

110 0 130

110 105 250

110 105 250

110 0 130

110 0 130

110 205 350

110 205 350

110 0 130

M5800-C

M5800H-C

CPX5800H-C

CPX5800-C

M8800-C

M8800H-C

CPX8800H-C

CPX8800-C

9.5 l

(2-1/2 gal)

20.81 l

(5-1/2 gal)

L: 290

W: 240

H: 150

L: 495

W: 290

H: 150

L: 396

W: 401

H: 378

L: 597

W: 465

H: 391

9.5 kg

(21 lb)

16.3 kg

(36 lb)

160 0 180

160 285 490

160 285 490

160 0 180

280 0 320

280 560 930

280 560 930

280 0 320

18 100-214-294 REV. 05

Page 29

Table 4.6 Fuse Table for North America and Japan Models

Model Name Fuse 1 Fuse 2 Fuse 3

M1800 / M1800-J

M1800H / M1800H-J

250 V, 2A

CPX1800H / CPX1800H-J

CPX1800 / CPX1800-J 250 V, 1.6A

M2800 / M2800-J

250 V, 2.5AM2800H / M2800H-J

250 V, 1.6A

CPX2800H / CPX2800H-J

CPX2800 / CPX2800-J 250 V, 1.6A

M3800 / M3800-J

250 V, 2.5AM3800H / M3800H-J

CPX3800H / CPX3800H-J

CPX3800 / CPX3800-J 250 V, 1.6A

M5800 / M5800-J

250 V, 5A 250 V, 2AM5800H / M5800H-J

CPX5800H / CPX5800H-J

CPX5800 / CPX5800-J 250 V, 2.5A 250 V, 2.5A

250 V, 1A

M8800 / M8800-J

M8800H / M8800H-J

250 V, 10A

CPX8800H / CPX8800H-J

CPX8800 / CPX8800-J 250 V, 5A

250 V, 3.15A

100-214-294 REV. 05 19

Page 30

Table 4.7 Fuse Table for Europe and China Models

Model Name Fuse 1 Fuse 2 Fuse 3

M1800-E / M1800-C

M1800H-E / M1800H-C

250 V, 1.6A

CPX1800H-E / CPX1800H-C

CPX1800-E / CPX1800-C

M2800-E / M2800-C

250 V, 2.5AM2800-E / M2800H-C

CPX2800H-E / CPX2800H-C

CPX2800-E / CPX2800-C 250 V, 1.6A

M3800-E / M3800-C

250 V, 2.5AM3800H-E / M3800H-C

CPX3800H / CPX3800H-C

CPX3800-E / CPX3800-C 250 V, 1.6A

M5800-E / M5800-C

250 V, 1.6A

250 V, 1A

250 V, 5A 250 V, 2AM5800H-E / M5800H-C

CPX5800H-E / CPX5800H-C

CPX5800-E / CPX5800-C 250 V, 1.6A 250 V, 1.6A

M8800-E / M8800-C

M8800H-E / M8800H-C

250 V, 5A

250 V, 2A

CPX8800H-E / CPX8800H-C

CPX8800-E / CPX8800-C 250 V, 2.5A

20 100-214-294 REV. 05

Page 31

4.3 Temperature

Table 4.8 Temperature

Item

Heater

Solution

Over

Temperature

Protection

(CPXH only)

The heater may cause some discoloration of the tank. This is normal

and will not affect the performance of the unit.

The fastest method to heat your ultrasonic bath is to fill with warm

solution, use heat, ultrasonics (which also adds heat), and a cover.

If Max Temperature of 75° C is reached, Ultrasonics will pause for a

period of time until the temperature in the bath falls back down to 69° C

(the max set point). Once the temperature falls back down to 69° C,

Ultrasonics will resume. This will apply for both continuous/infinity

mode, as well as timed mode. In timed mode, the timer will pause while

Ultrasonics is off, and will resume once Ultrasonics resumes.

100-214-294 REV. 05 21

Page 32

4.4 Cleaning Solutions

CAUTION General Warning

Do not use alcohol, gasoline, bleach, mineral acids, solutions with a

flash point, semi-aqueous or combustible liquids in ultrasonic tanks,

or you will void the warranty. Only use non-flammable solutions and

water-based solutions.

4.4.1 Solution Types

Water-based solutions can be either slightly acidic or alkaline. They include detergents,

soaps and industrial cleaners designed to remove specific soils.

Acidic water-based solutions: remove rust, tarnish or scale. They range from mild

solutions that remove tarnish, to concentrated, inhibited acidic solutions that remove

investment plaster, milk-stone, zinc oxide and rust from steel and cast iron as well as

smut and heat-treat scale from hardened steel.

Alkaline water-based solutions: include carbonates, silicates and caustics. These

cause emulsifying action, which keeps soil from redepositing on the cleaned surface, and

improves cleaning action in hard water.

Table 4.9 Alkaline Solution Strength and Uses

Alkaline Strength Removes

Mild Light oils and greases, cutting oils and coolant compounds.

Mild to Strong

Heavy-duty Mill scale, heat-treat scale, corrosion or oxides.

Change the cleaning solution periodically. Cleaning solutions can become contaminated

with suspended soil particles which coat the tank bottom. This coating dampens the

ultrasonic action and reduces cleaning efficiency. Certain solutions will cavitate better than

others. Contact your local distributor for further information.

Heat and cavitation increase the chemical activity of cleaning solutions. Some materials

may be damaged by this stronger chemical action. When in doubt, test run samples of

items to be cleaned.

Caustic solutions: used to remove rust from steels, metal alloy corrosion and a variety

of tenacious soils.

4.4.2 Solution Amounts

Solution amounts may vary. The amount you use depends on the detergent and the type

of soil to be removed. Follow instructions on the solution container and refer to the table

below for the effects of solutions on metals.

Heavy grease and oils, waxes, vegetable oils, inks, wax or fatbase buffing and polishing compounds, milk residues and

carbohydrates.

22 100-214-294 REV. 05

Page 33

4.4.3 Chemicals Harmful to Your Tank

The following chemicals will harm your ultrasonic tank and the action of ultrasonics and

higher operating temperatures will increase their chemical activity. Do not use these or

similar chemicals directly or in dilution in your ultrasonic tank or you will void your

warranty.

Table 4.10 Chemicals Harmful to Your Tank

Harmful Chemicals

Acetophenone Chloracetic Acid Hydrocyanic Acid

Aluminum Chloride Chloric Acid Hydrofluoric Acid

Aluminum Flouride Chlorine, Anhydrous Hydroflousilicic Acid

Aluminum Sulphate Chromic Acid Iodoform

Ammonium Bifluoride Copper Chloride Mercuric Chloride

Ammonium Chloride Copper Fluoborate Muriatic Acid

Ammonium Hydroxide Ethyl Chloride Phosphoric (crude)

Amyl Chloride Ferric Chloride Sodium Hypochlorite

Antimony Trichloride Ferrous Chloride Potassium Chloride

Aqua Regia Ferris Sulfate Stannic Chloride

Bromine Fluoboric Acid Stannous Chloride

Calcium Bisulfate Fluorine Sulfur Chloride

Calcium Bisulfite Hydrobromic Acid Sulfuric Acid

Calcium Hypochloride Hydrochloric Acid Zinc Chloride

100-214-294 REV. 05 23

Page 34

4.5 Solution Effect on Metals

Table 4.11 Solution Effects on Metals

Cleaning

Agent

Steel Brass

Aluminum

Magnesium

Zinc

S.

Steel

Copper

Tin

Optical (1) none none none none** none** none none**

Jewelry (1)

Buffing (1)

Compound

Oxide (2)

remover

Electronic

cleaner (1)

General (1)

purpose

Industrial

strength (1)

Metal (1)

cleaner 1

Metal (1)

cleaner 2

none none none none none none none

none

slight

etch

none none

none none

none none

slight

stain

none

none none attacks none none

slight

attack

slight

attack

slight

attack

slight

attack

attacks attacks none none

none none none none

none none none none

none none none none

none none none none none none none

none none

slight

attack

none none none none

Metal (1)

cleaner 3

Liquid rust

(3) stripper

GP (1)

Powder

none none none none none none none

none none

attacks*** attacks***

attacks none

none none none none none none none

* Contact distributor for cleaning agent availability outside the US.

** No effect if solution temperature is less than 60° C (140° F).

(1) = Alkaline; (2) = Acidic; and (3) = Caustic.

WARNING General Warning

*** Free hydrogen may be released if solution comes in contact with

reactive metals.

slight

attack

24 100-214-294 REV. 05

Page 35

Chapter 5: Installation and Setup

5.1 Installing Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

100-214-294 REV. 05 27

Page 36

5.1 Installing Your Unit

Check the plate on the back of the unit for correct power requirements. Position your unit

within easy reach of a standard grounded electrical outlet. Do not place the unit on a

circuit which could become overloaded. If your unit does not operate correctly, first refer

to 7.2 Troubleshooting for possible causes, or contact an authorized service center listed

at the end of this manual for additional information.

28 100-214-294 REV. 05

Page 37

Chapter 6: Operation

6.1 Operating Your Ultrasonic Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 M Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 MH Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4 CPX Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.5 CPXH Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.6 Cleaning Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

100-214-294 REV. 05 29

Page 38

6.1 Operating Your Ultrasonic Bath

If this is the first time you are using the ultrasonic bath, please read this whole section

before operating your unit.

30 100-214-294 REV. 05

Page 39

6.2 M Series

CAUTION General Warning

Table 6.1 Before you Begin

Step Action

1 Select your cleaning solution (refer to 4.5 Solution Effect on Metals).

2

• Do not place parts or containers directly on the bottom of the tanks; use a

tray or wire to suspend items. Direct placement can cause the units to fail

• Do not allow the solution to drop more than 3/8 inch (1 cm) below the

operating level line with ultrasonics on

• Do not ever use alcohol, gasoline or flammable solutions. Doing so could

cause a fire or explosion. Use only water-based solutions

• Do not ever use mineral acids. These could damage the tank

Failure to comply with these cautions will void your warranty.

Allowing for the volume of the parts you will be cleaning and leaving room

for cleaning solution, fill the tank with warm tap water to the operating

level line.

3 Add cleaning solution to the tank water.

4 Plug the unit into a grounded outlet.

5

For maximum efficiency, refer to 7.1 Optimizing Your Ultrasonic Bath”,

before proceeding.

NOTICE

If this is the first time you are running the unit, or if you have

changed cleaning solution, you must degas the solution. If not, skip

to 6.2.3 Cleaning Items (Treating Samples).”

100-214-294 REV. 05 31

Page 40

6.2.1 M Series Explanation of Controls

Figure 6.1 M Series Controls

Table 6.2 M Series Explanation of Controls

Control Function

This switch is located on the back of the unit, next to the power

cord receptacle.

• Press the on side to power on the unit

Main Power Switch

• Press the off side to power off the unit

Timer Knob

6.2.2 Degassing

For initial cleaning solution degassing.

Table 6.3 For initial cleaning solution degassing.

Step Action

1 Turn Main Power switch on.

2

When operating the unit, normally leave the Main Power switch

in the on position, and use the Timer Knob to activate

ultrasonics.

Activates ultrasonics and sets time.

• Turn clockwise for timed operation (0–60 minutes)

• Turn counterclockwise to the HOLD position for continuous

operation

• Turn to the zero position to turn unit Off

Turn the Timer Knob clockwise to 5–10 and let the unit run to allow the

solution to “degas”.

NOTICE

Refer to 6.5.11 Solution for information on degassing.

32 100-214-294 REV. 05

Page 41

6.2.3 Cleaning Items (Treating Samples)

NOTICE

To stop ultrasonics at any time, turn the Timer Knob to the zero

position.

Table 6.4 Treating Samples

Step Action

1 Turn Main Power switch on.

Turn the Timer Knob clockwise to set the amount of time (0 - 60 minutes)

2

you wish the items to be cleaned. Turn the Timer Knob counterclockwise to

the Hold position for continuous operation.

3

4

5

6 When items are clean, slowly remove them from the tank.

7 Rinse the clean items with clean water and dry them, if necessary.

Place the items into a basket, perforated tray, or beakers in a positioning

cover.

If using beakers or a solid tray, add cleaning solution to beakers or tray to

cover the items.

Slowly lower the tray or beakers into the tank. Do not allow items to

contact the tank bottom.

100-214-294 REV. 05 33

Page 42

6.3 MH Series

CAUTION General Warning

Table 6.5 Before you Begin

Step Action

1 Select your cleaning solution (refer to 4.5 Solution Effect on Metals).

Allowing for the volume of the parts you will be cleaning and leaving room

2

for cleaning solution, fill the tank with warm tap water to the operating

level line.

• Do not place parts or containers directly on the bottom of the tanks; use a

tray or wire to suspend items. Direct placement can cause the units to fail

• Do not allow the solution to drop more than 3/8 inch (1 cm) below the

operating level line with heat or ultrasonics on

• Do not ever use alcohol, gasoline or flammable solutions. Doing so could

cause a fire or explosion. Use only water-based solutions

• Do not ever use mineral acids. These could damage the tank

Failure to comply with these cautions will void your warranty.

3 Add cleaning solution to the tank water.

4 Plug the unit into a grounded outlet.

5

For maximum efficiency, refer to 7.1 Optimizing Your Ultrasonic Bath,

before proceeding.

NOTICE

If this is the first time you are running the unit, or if you have

changed cleaning solution, you must degas the solution. If not, skip

to 6.3.3 Cleaning Items (Treating Samples).”

34 100-214-294 REV. 05

Page 43

6.3.1 MH Series Explanation of Controls

Figure 6.2 MH Series Controls

Table 6.6 MH Series Explanation of Controls

Control Function

This switch is located on the back of the unit, next to the power

cord receptacle.

Main Power

Switch

Heat Switch

Timer Knob

6.3.2 Degassing

Table 6.7 For initial cleaning solution degassing.

Step Action

1 Turn Main Power switch on.

• Press the on side to power on the unit

• Press the off side to power off the unit

When operating the unit, normally leave the Main Power switch in

the (on) position, and use the Timer Knob to activate ultrasonics.

Activates heat to 60° C (140° F) maximum.

NOTICE

Refer to 4.3 Temperature for further information on temperature.

Activates ultrasonics and sets time.

• Turn clockwise for timed operation (0–60 minutes)

• Turn counterclockwise to the HOLD position for continuous operation

Turn to the zero position to turn unit Off.

2 Turn Heat switch on.

Turn the Timer Knob clockwise to 5–10 and let the unit run to allow the

solution to “degas”.

3

NOTICE

Refer to 6.5.11 Solution for information on degassing.

100-214-294 REV. 05 35

Page 44

6.3.3 Cleaning Items (Treating Samples)

NOTICE

To stop ultrasonics at any time, turn the Timer Knob to the zero

position.

Table 6.8 Treating Samples

Step Action

1 Turn Main Power switch on.

Turn the Timer Knob clockwise to set the amount of time (0–60 minutes)

2

you wish the items to be cleaned. Turn the Timer Knob counterclockwise

to the HOLD position for continuous operation.

3

4

5

6 When items are clean, slowly remove them from the tank.

7 Rinse the clean items with clean water and dry them, if necessary.

Place the items into a basket, perforated tray, or beakers in a positioning

cover.

If using beakers or a solid tray, add cleaning solution to beakers or tray

to cover the items.

Slowly lower the tray or beakers into the tank. Do not allow items to

contact the tank bottom.

36 100-214-294 REV. 05

Page 45

6.4 CPX Series

CAUTION General Warning

Table 6.9 Before you begin

Step Action

1 Select your cleaning solution (refer to 4.5 Solution Effect on Metals).

Allowing for the volume of the parts you will be cleaning and leaving

2

room for cleaning solution, fill the tank with warm tap water to the

operating level line.

• Do not place parts or containers directly on the bottom of the tanks; use a

tray or wire to suspend items. Direct placement can cause the units to fail

• Do not allow the solution to drop more than 3/8 inch (1 cm) below the

operating level line with ultrasonics on

• Do not ever use alcohol, gasoline or flammable solutions. Doing so could

cause a fire or explosion. Use only water-based solutions

• Do not ever use mineral acids. These could damage the tank

Failure to comply with these cautions will void your warranty.

3 Add cleaning solution to the tank water.

4 Plug the unit into a grounded outlet.

5

For maximum efficiency, refer to 7.1 Optimizing Your Ultrasonic Bath,

before proceeding.

NOTICE

If this is the first time you are running the unit, or if you have

changed cleaning solution, you must degas the solution. If not, skip

to 6.4.4 Cleaning Items (Treating Samples).”

100-214-294 REV. 05 37

Page 46

6.4.1 CPX Explanation of Controls

Figure 6.3 CPX Series Controls

Table 6.10 CPX Series explanation of controls

Control Function

This switch is located on the back of the unit, next to the power cord

receptacle.

Main Power

Switch

• Press the on side to power on the unit

• Press the off side to power off the unit

When operating the unit, normally leave the Main Power switch in the on

position, and use the On/Standby key to switch between the operating

state and standby state.

On/Standby

When the Main Power switch on the rear panel is in the on position, press

to power on/off the unit.

Up/Down Keys

Press to increase/decrease ultrasonic or degassing cycle time (hold for

quick increments/decrements).

Time values are circular, pressing Up from 99 minutes takes you to

Constant Sonics Mode (Constant Sonics icon and “- -” display on the

LCD) and then to 1 minutes. Pressing Down from 1 minutes takes you to

Constant Sonics Mode and then to 99 minutes.

During power-up, use to select high or low ultrasonic power output.

38 100-214-294 REV. 05

Page 47

Table 6.10 CPX Series explanation of controls

Control Function

Sonics

Press to activate ultrasonics. If running in Timed Mode, a timer will begin

to count down and ultrasonics will stop at 0 minutes. In Constant Sonics

Mode (Constant sonics icon and “- -” on the display), timer has no

function.

Press sonics key again to deactivate ultrasonics.

If running in Timed Mode, press Up and Down keys to adjust the

ultrasonic cycle time (adjustable from 1 to 99 minutes).

Degas

Press to degas the solution or to run a degas application. A default timer

of 5 minutes will begin to count down and degassing will stop at 0

minutes.

Press Degas key again to stop degassing the solution.

During a degas cycle, press Up and Down keys to adjust the degas cycle

time (adjustable from 1 to 99 minutes).

NOTICE

Refer to 6.5.11 Solution for information on degassing.

6.4.2 CPX Series LCD Description

Table 6.11 CPX Series LCD description.

Reference Function

Power Level

Displayed for 15 s only during power-up, shows the current ultrasonic

output power selection.

Press the Sonics or Degas key to go into normal operating mode.

Press Up or Down keys to change between high (HI) and low (LO)

power ultrasonics.

Sonics/Degas Timer

Displays the duration of a timed ultrasonic or degas cycle.

Press Up and Down keys to adjust ultrasonic or degassing cycle time

(adjustable from 1 to 99 minutes).

In Constant Sonics Mode, “- -” is displayed.

Constant Sonics

Indicates the unit is operating in Constant Sonics Mode.

In Constant Sonics Mode, sonics will remain on until the Sonics key is

pressed or the unit is turned off.

100-214-294 REV. 05 39

Page 48

Table 6.11 CPX Series LCD description.

Reference Function

Sonics On

Indicates sonics are active.

If running in Timed Mode, ultrasonics will remain on until the timer

reaches 0 minutes.

In Constant Sonics Mode, ultrasonics will remain on until the Sonics

key is pressed or the unit is turned off.

Degas On

Indicates the unit is in Degas Mode.

In Degas Mode, degassing will continue until the timer reaches 0

minutes.

NOTICE

Refer to 6.5.11 Solution for information on degassing.

Alarm

Alarm Bell icon flashes when the unit encounters an abnormal

operating condition.

6.4.3 Degassing

For initial cleaning solution degassing.

NOTICE

Table 6.12 Degassing your CPX Series unit

Step Action

1 Turn Main Power switch on.

2 Press the On/Standby key to turn on the unit.

NOTICE

Refer to 7.2 Troubleshooting for information on troubleshooting.

To stop degassing at any time, press the Degas key.

Press Degas key once to start the degas process.

Default degas time is 5 minutes.

3

If necessary, use Up/Down keys to alter degas time during a degas cycle.

NOTICE

Refer to 6.5.11 Solution for information on degassing.

40 100-214-294 REV. 05

Page 49

Table 6.12 Degassing your CPX Series unit

Step Action

4

After completing the degas time, you are ready to set operating

parameters.

6.4.4 Cleaning Items (Treating Samples)

NOTICE

To stop ultrasonics at any time, press the Sonics key.

Table 6.13 Treating Samples

Step Action

1 Turn Main Power switch on.

2 Press the On/Standby key to turn on the unit.

Set the amount of time you wish the items to be cleaned, or select

Constant Sonics Mode:

3

• Use Up/Down keys to increase/decrease cycle time (hold for quick increments/

decrements)

• Pressing Up key from 99 minutes or Down key from 1 minutes takes you to

Constant Sonics Mode (Constant Sonics icon and “- -” display on the LCD

screen)

4 Press the Sonics key to activate ultrasonics.

5

6

7

Place the items into a basket, perforated tray, or beakers in a positioning

cover.

If using beakers or a solid tray, add cleaning solutions to beakers or tray

to cover the items.

Slowly lower the tray or beakers into the tank. Do not allow items to

contact the tank bottom.

8 When items are clean, slowly remove them from the tank.

9 Rinse clean items with clean, warm water and dry, if necessary.

100-214-294 REV. 05 41

Page 50

6.5 CPXH Series

CAUTION General Warning

Table 6.14 Before you begin.

Step Action

1 Select your cleaning solution (refer to 4.5 Solution Effect on Metals).

Allowing for the volume of the parts you will be cleaning and leaving

2

room for cleaning solution, fill the tank with warm tap water to the

operating level line.

• Do not place parts or containers directly on the bottom of the tanks; use a

tray or wire to suspend items. Direct placement can cause the units to fail

• Do not allow the solution to drop more than 3/8 inch (1 cm) below the

operating level line with heat or ultrasonics on

• Do not ever use alcohol, gasoline or flammable solutions. Doing so could

cause a fire or explosion. Use only water-based solutions

• Do not ever use mineral acids. These could damage the tank

Failure to comply with these cautions will void your warranty.

3 Add cleaning solution to the tank water.

4 Plug the unit into a grounded outlet.

5

For maximum efficiency, refer to 7.1 Optimizing Your Ultrasonic Bath”,

before proceeding.

NOTICE

If this is the first time you are running the unit, or if you have

changed cleaning solution, you must degas the solution. If not, skip

to 6.5.5 Cleaning Items (Treating Samples) in Timed Sonics Mode.”

42 100-214-294 REV. 05

Page 51

6.5.1 CPXH Series Explanation of Controls

Figure 6.4 CPXH Series Controls

Table 6.15 CPXH Series explanation of controls.

Control Function

This switch is located on the back of the unit, next to the power cord

Main

Power

Switch

receptacle.

• Press the on side to power on the unit

• Press the off side to power off the unit. When operating the unit, normally leave

the Main Power switch in the on position, and use the On/Standby key to switch

between the operating state and standby state

On/Standby

When the Main Power switch on the rear panel is in the on position, press

to power on/off the unit.

Up/Down Keys

Press to increase/decrease ultrasonic or degassing cycle time (hold for

quick increments/decrements).

Time values are circular, pressing Up key from 99 minutes takes you to 1

minutes. Pressing Down key from 1 minutes takes you to 99 minutes.

If the Fn key was pressed, use the Up/Down keys to adjust function

settings.

Heat

Press to turn heater on/off.

Heater will shut off when set temperature is attained.

100-214-294 REV. 05 43

Page 52

Table 6.15 CPXH Series explanation of controls.

Control Function

Sonics

Press to activate ultrasonics. If running in Timed Mode, a timer will begin to

count down and ultrasonics will stop at 0 minutes. In Constant Sonics Mode

(Constant Sonics icon and “- - -” on the display), timer has no function.

Press Sonics key again to deactivate ultrasonics.

If running in Timed Mode, press Up and Down keys to adjust the ultrasonic

cycle time (adjustable from 1 to 99 minutes).

Degas

Press to degas the solution or to run a degas application. The degas timer

will begin to count down from its current setting and degassing will stop at

0 minutes.

Press Degas key again to stop degassing the solution.

During a degas cycle, press Up and Down keys to adjust degas time

(adjustable from 1 to 99 minutes).

NOTICE

Refer to 6.5.11 Solution for information on degassing.

Auto

Press to begin an auto cycle. In Auto Mode, the following actions are

carried out automatically by the controller:

• Heater is turned on to bring bath to set temperature

• When set temperature is reached, ultrasonics are activated. The unit will abort

the auto cycle and flash the AUTO icon if set temperature is not reached within a

120-minute period

• When ultrasonics timer reaches 0 minutes, the auto cycle is finished

If at any point during an auto cycle the degas key is pressed, a degas cycle

will begin. If ultrasonics has already started, the ultrasonics timer will

restart after the degas period.

44 100-214-294 REV. 05

Page 53

Table 6.15 CPXH Series explanation of controls.

Control Function

Press the Fn key to access less-frequently used function.

• Press 1x to Set Target Temp

• Press 2x to Set Constant Sonics

• Press 3x to Set Power Level

• Press 4x Sel. Temp Units

• Press 5x to Set Degas Time

• Press 6x Ready State (Set Sonics Time)

The appropriate icon will flash to indicate which option is selected.

If no key is pressed after 15 seconds the unit will save any changes and

return to the Ready state.

Press the Fn key again after making any changes to scroll through the rest

of the options and return to the Ready state.

The following options are available:

• Set Temperature (Fn 1x): Press Up and Down keys to increase/decrease the

bath set temperature

Fn

(1x)

Indicates

Blinking

• Timed/Constant Sonics (Fn 2x): Press Up key to select Constant Sonics Mode

(Constant Sonics icon and “- - -” on the display)

Press down key to select Timed Sonics Mode

Fn

(2x)

Indicates

Blinking

100-214-294 REV. 05 45

Page 54

Table 6.15 CPXH Series explanation of controls.

Control Function

• Full/Low Power (Fn 3x): Press up key to select full power ultrasonic output.

Press down key to select low power ultrasonic output

Fn

• Temperature Units (Fn 4x): Press key to select Fahrenheit (°F). Press Down

key to select Celsius (°C)

Fn

(3x)

(4x)

Indicates

Blinking

Indicates

Blinking

• Degas Time (Fn 5x): Press Up/Down keys to increase/decrease degas time

(hold for quick increments/decrements). Time values are circular, pressing Up

from 99 minutes takes you to 1 minute. Pressing Down from 1 minute takes you

to 99 minutes

Fn

46 100-214-294 REV. 05

(5x)

Indicates

Blinking

Page 55

6.5.2 CPXH Series LCD Description

Table 6.16 LCD Description for CPXH Series.

Item Function

Sonics/Degas Set Time

Displays the set time for a timed ultrasonic or degas cycle.

• Press Up and Down keys to adjust ultrasonic or degassing cycle time

(adjustable from 1 to 99 minutes). In Constant Sonics Mode, “- - -” is

displayed

Set Temperature

Displays the target temperature.

Temperature units are indicated by the °F (for Fahrenheit) or °C (for

Celsius) right of the Current Temperature icon.

Current Temperature

Displays the current tank temperature as measured by the unit.

Temperature units are indicated right of the icon as either °F (For

Fahrenheit) or °C (for Celsius). Units can be switched using the Fn key.

See Fn key description on Table 6.15.

Sonics/Degas Timer

Displays the remaining time of a running timed ultrasonic or degas

cycle.

Press up and down keys to adjust ultrasonic or degassing cycle time

(adjustable from 1 to 99 minutes).

Auto

Indicates the unit is in Auto Mode. In Auto Mode, the following actions

are carried out automatically by the controller:

• Heater is turned on to bring bath to set temperature

• When set temperature is reached, ultrasonics are activated. The unit will

abort the auto cycle and flash the icon if set temperature is not reached

within a 120-minute period

• When ultrasonics timer reaches 0 minutes, the auto cycle is finished

If at any point during an auto cycle the degas key is pressed, a degas

cycle will begin. If ultrasonics has already started, the ultrasonics timer

will restart after the degas period.

Constant Sonics

Indicates the unit is operating in Constant Sonics Mode. In Constant

Sonics Mode, ultrasonics will remain on until the Sonics key is pressed

or the unit is turned off.

100-214-294 REV. 05 47

Page 56

Table 6.16 LCD Description for CPXH Series.

Item Function

Heat

Indicates the heater is on. Heater will shut off when set temperature is

attained.

Sonics On

Indicates sonics are active.

If running in Timed Mode, ultrasonics will remain on until the timer

reaches 0 minutes.

In Constant Sonics Mode, ultrasonics will remain on until the Sonics

key is pressed or the unit is turned off.

Degas On

Indicates the unit is in Degas Mode.

In Degas Mode, degassing will continue until the timer reaches 0

minutes.

6.5.3 Degassing

For initial cleaning solution degassing.

NOTICE

NOTICE

Refer to 6.5.11 Solution for information on degassing.

Power Level

Indicates the ultrasonic power output selection:

• Four bars indicate high power ultrasonics

• Two bars indicate low power ultrasonics

Alarm

Alarm Bell icon flashes when the unit encounters an abnormal

operating condition.

NOTICE

Refer to 7.2 Troubleshooting for information on troubleshooting.

To stop degassing at any time, press the Degas key.

48 100-214-294 REV. 05

Page 57

Table 6.17 Degassing

Step Action

1 Turn Main Power switch on.

2 Press the On/Standby key to turn on the unit.

Default degas time is 5 minutes.

3

To change the degas time, press the Fn key until the Degas icon appears

and the Set Time icon flashes. Then press the Up/Down keys to change

the degas time.

Press Degas key once to start the degas process.

4

If necessary, use up/down keys to alter degas time during a degas cycle.

NOTICE

Refer to 6.5.11 Solution for information on degassing.

5

After completing the degas time, you are ready to set operating

parameters.

6.5.4 Ultrasonics Operating Modes

Table 6.18 Ultrasonic Operating Modes

Mode Action

In Timed Sonics Mode, a timer will begin to count down and ultrasonics

Timed

Sonics

will remain on until the timer reaches 0 minutes.

For instructions, see 6.5.5 Cleaning Items (Treating Samples) in Timed

Sonics Mode.

In Constant Sonics Mode ultrasonics will remain on until the Sonics key is

Constant

Sonics

pressed or power is turned off to the unit.

For instructions, see 6.5.6 Cleaning Items (Treating Samples) in

Constant Sonics Mode.

In Auto mode ultrasonics will start once set temperature is attained.

Ultrasonics will remain on until the timer reaches 0 minutes.

Auto

For instructions, see 6.5.7 Cleaning Items (Treating Samples) in Auto

Mode.

100-214-294 REV. 05 49

Page 58

6.5.5 Cleaning Items (Treating Samples) in Timed Sonics Mode

NOTICE

To stop ultrasonics at any time, press the Sonics key.

Table 6.19 Treating samples in Timed Sonics Mode

Step Action

1 Turn Main Power on.

2 Press the On/Standby key to turn on the unit.

3 If necessary, degas the liquid. See 6.5.3 Degassing for instructions.

Set the amount of time you wish the items to be cleaned:

4

Use up/down keys to increase/decrease cycle time (hold for quick

increments/decrements).

Set the tank temperature:

• Press the Fn key until the Set Temperature icon flashes

• Press the Up/Down keys to alter the setting to the tank temperature you wish

5

to reach

• Press the Heat key once to activate heat. The Heat icon appears

NOTICE

Units can be switched between °F or °C using the Fn key. See Fn key

description on 6.5.1 CPXH Series Explanation of Controls.

Set the ultrasonic power level:

6

• Press the Fn key until the Power Level icon flashes

• Press the Up key to select high power ultrasonics or press the Down key to

select low power ultrasonics

7 Press the Sonics key to activate ultrasonics.

8

9

10

Place the items into a basket, perforated tray, or beakers in a positioning

cover.

If using beakers or a solid tray, add cleaning solution to beakers or tray

to cover the items.

Slowly lower the tray or beakers into the tank. Do not allow items to

contact the tank bottom.

11 When items are clean, slowly remove them from the tank.

12 Rinse clean items with clean, warm water and dry, if necessary.

50 100-214-294 REV. 05

Page 59

6.5.6 Cleaning Items (Treating Samples) in Constant Sonics Mode

NOTICE

To stop ultrasonics at any time, press the Sonics key.

Table 6.20 Treating Samples in Constant Sonics Mode

Step Action

1 Turn Main Power switch on.

2 Press the On/Standby key to turn on the unit.

3 If necessary, degas the liquid. See 6.5.3 Degassing for instructions.

Change sonics mode:

4

• Press the Fn key until the Constant Sonics icon and the Set Time icon flash

• Press the Up key to select Constant Sonics Mode

Set the tank temperature:

• Press the Fn key until the Set Temperature icon flashes

• Press the Up/Down keys to alter the setting to the tank temperature you wish

5

to reach

• Press the Heat key once to activate heat. The Heat icon appears

NOTICE

Units can be switched between °F or °C using the Fn key. See Fn key

description on Table 6.15.

Set the ultrasonic power level:

6

• Press the Fn key until the Power Level icon flashes

• Press the Up key to select high power ultrasonics or press the Down key to

select low power ultrasonics

7 Press the Sonics key to activate ultrasonics.

8

9

10

Place the items into a basket, perforated tray, or beakers in a positioning

cover.

If using beakers or a solid tray, add cleaning solution to beakers or tray

to cover the items.

Slowly lower the tray or beakers into the tank. Do not allow items to

contact the tank bottom.

11 When items are clean, slowly remove them from the tank.

12 Rinse clean items with clean, warm water and dry, if necessary.

100-214-294 REV. 05 51

Page 60

6.5.7 Cleaning Items (Treating Samples) in Auto Mode

NOTICE

To stop ultrasonics at any time, press the Sonics key.

Table 6.21 Treating Samples in Auto Mode

Step Action

1 Turn Main Power switch on.

2 Press the On/Standby key to turn on the unit.

3 If necessary, degas the liquid. See 6.5.3 Degassing for instructions.

Set the amount of time you wish the items to be cleaned:

4

• Use Up/Down keys to increase/decrease cycle time (hold for quick

increments/decrements)

5

6

7

8

9

10

Set the tank temperature:

• Press the Fn key until the Set Temperature icon flashes

• Press the Up/Down keys to alter the setting to the tank temperature you wish

to reach

• Press the Heat key once to activate heat. The Heat icon appears

• Units can be switched between °F or °C using the Fn key. See Fn key

description on

6.5.1 CPXH Series Explanation of Controls

Set the ultrasonic power level:

• Press the Fn key until the Power Level icon flashes

• Press the Up key to select high power ultrasonics or press the Down key to

select low power ultrasonics

Press the Auto key to begin Auto Cycle. Heater will turn on and sonics will

start once set temperature is attained.

Place the items into a basket, perforated tray, or beakers in a positioning

cover.

If using beakers or a solid tray, add cleaning solution to beakers or tray

to cover the items.

Slowly lower the tray or beakers into the tank. Do not allow items to

contact the tank bottom.

11 When items are clean, slowly remove them from the tank.

12 Rinse clean items with clean, warm water and dry, if necessary.

52 100-214-294 REV. 05

Page 61

6.5.8 CPXH Temperature Calibration

The CPXH unit temperature measurement is factory calibrated. Use the following

instructions to perform periodic calibrations:

Table 6.22 CPXH temperature calibration

Step Action

1

2

3 Press the On/Standby key to turn off the unit.

4

5 Stir the solution for 15 seconds to ensure thermal uniformity.

6

7

8 Press the On/Standby key to end calibration.

The ultrasonic bath liquid may be at room temperature or may be

heated-up to a desired operating temperature (e.g. 40° C).

Press the Fn key 4 times until the Current Temperature icon starts

blinking. Press the Up key to select °F. Press the Fn key 2 more times to

return to the Ready State.

Simultaneously, press both the On/Standby and the Fn key. Only the

bottom left digits and the Current Temperature icon should turn on.

Wait 2 minutes after turning the unit on before taking measurements.

This allows for the display to be properly updated.

Use the Up/Down keys to change the display temperature to match the

actual tank temperature.

6.5.9 Draining Your Unit

WARNING General Warning

Do not immerse the unit in water. Unplug the unit from the power

source.

Models 1800 and 2800 do not have a drain. To empty, use the indented side of the rim to

pour the used solution into a waste disposal unit, rinse the tank thoroughly and refill with

new solution.

100-214-294 REV. 05 53

Page 62

Figure 6.5 Draining of Units 1800 and 2800

Models 3800, 5800, and 8800 include a drain and valve kit.

Table 6.23 Draining your ultrasonic bath

Step Action

1 Place the unit to allow easy reach of the drain tube into a waste disposal unit.

2

Remove the thread protecting cap from the end of the unit’s drain pipe. This

will expose the white teflon sealing tape on the drain pipe’s threads.

54 100-214-294 REV. 05

Page 63

Table 6.23 Draining your ultrasonic bath

Step Action

Hand tighten the drain valve onto the dr ain pipe over the white teflon sealing

tape. Finish tightening the valve in place using an adjustable or a 21mm

wrench. Tighten the valve no more than one full turn when using the wrench

until the handle is on top.

3

CAUTION

Over tightening of the valve can cause damage to the ultrasonic tank. Alw ays

use teflon sealing tape or a sealing paste designed for use with stainless steel

if retightening or refitting of the drain valve is required.

Hand tighten the hose adaptor into the end of the drain valve. Slide the dr ain

tube over the barbed hose adaptor end.

4

Close the drain valve by turning the handle perpendicular to the valve body

5

and the unit is ready to fill with solution. To open the valve and drain the

tank, turn the handle so that it is in line with the valve body.

100-214-294 REV. 05 55

Page 64

6.5.10 Solution Temperature Measurement

The following instructions provide an accurate method to obtain consistent thermal

measurements using a calibrated temperature measurement instrument. These readings

can be used for cleaning process control or to verify the accuracy of the CPXH temperature

readings.

Table 6.24 Measuring the Solution Temperature

Step Action

1 Ensure that sonics and heaters are off.

2 Stir the solutions for 15 seconds to ensure thermal uniformity.

3

4

6.5.11 Solution

Table 6.25 Solution Usage

Item Definition

Solution

Activity

Degassing 1

Degassing 2

For CPXH models, wait 2 minutes after turning the unit on before taking

measurements. This allows for the display to be properly updated.

Suspend a thermocouple in the bath without allowing the probe to touch the

tank walls.

The amount of visible activity is not necessarily related to optimum

cavitation for cleaning.

Fresh solutions contain many dissolved gases (usually air), which

reduce effective ultrasonic action. Although solutions will naturally

degas over time, using Degas Mode speeds up the degassing process.