Emerson CP200 Instruction Manual

Instruction Manual

Form 5834

December 2013

CP200 Series

CP200 Series Commercial / Industrial PressureLoaded Pressure Reducing Regulator

P1180

Figure 1. Typical CP200 Pressure Loaded Pressure Reducing Regulator

Table of Contents

Introduction ............................................................................1

Specifications ........................................................................3

Principle of Operation ............................................................4

Installation and Overpressure Protection ..............................6

Startup ...................................................................................7

Adjustment.............................................................................7

Shutdown...............................................................................7

Maintenance ..........................................................................8

Parts Ordering .......................................................................9

Parts List................................................................................9

www.fisherregulators.com

Introduction

Scope of the Manual

This manual provides instructions for the installation,

maintenance, and parts ordering information for CP200 Series

pressure loaded pressure reducing regulators.

D103121X012

CP200 Series

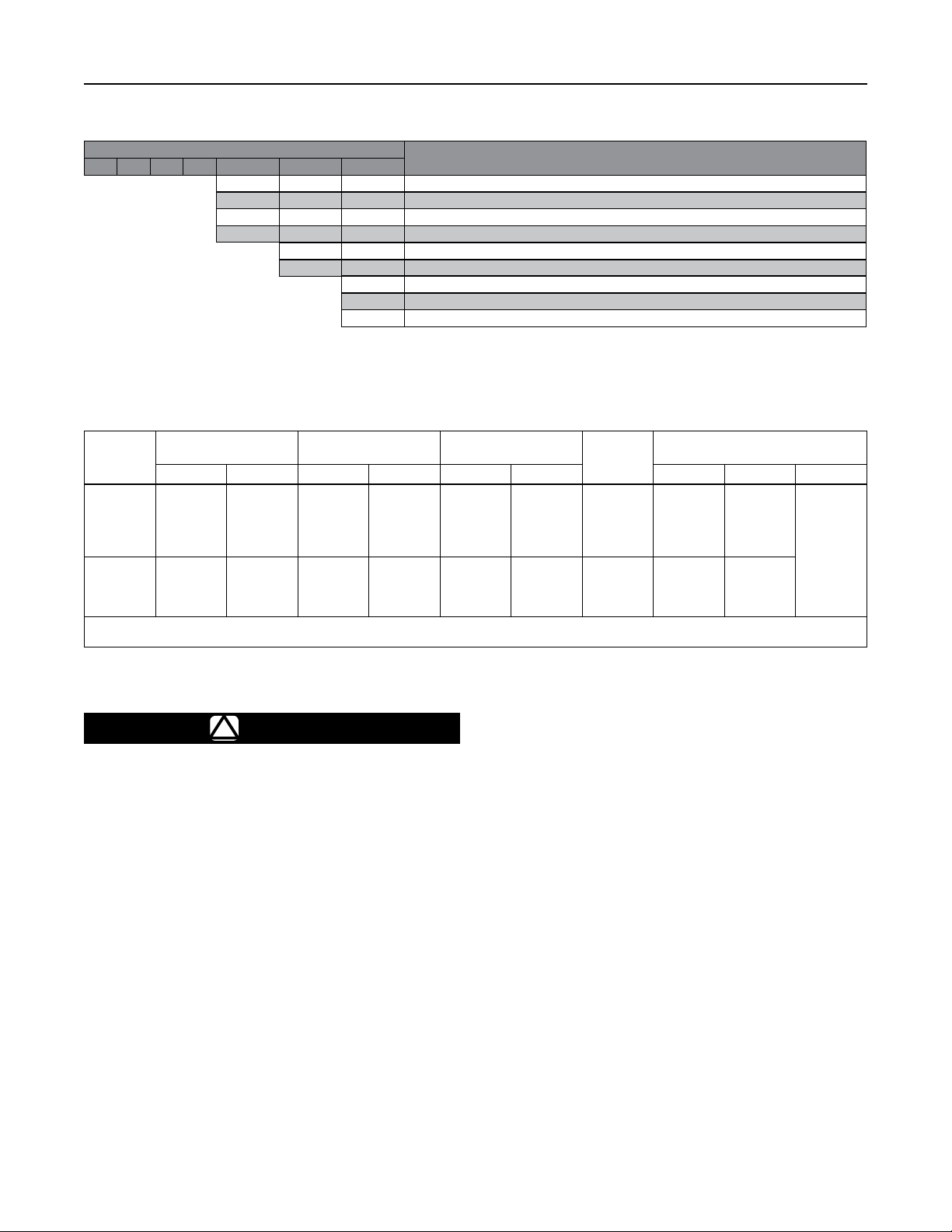

Table 1. Available Congurations

TYPE NUMBER

C P 2 0

OVERPRESSURE PROTECTION MODULE

0 Without Overpressure Protection Module

5 With Secondary Seat™ Protection

6 With Secondary Seat Protection with bleed to indicate Secondary Seat is functioning

PRESSURE REGISTRATION

I Internal Registration

RELIEF

N Non Relief

T Internal Token Relief

OPTIONS

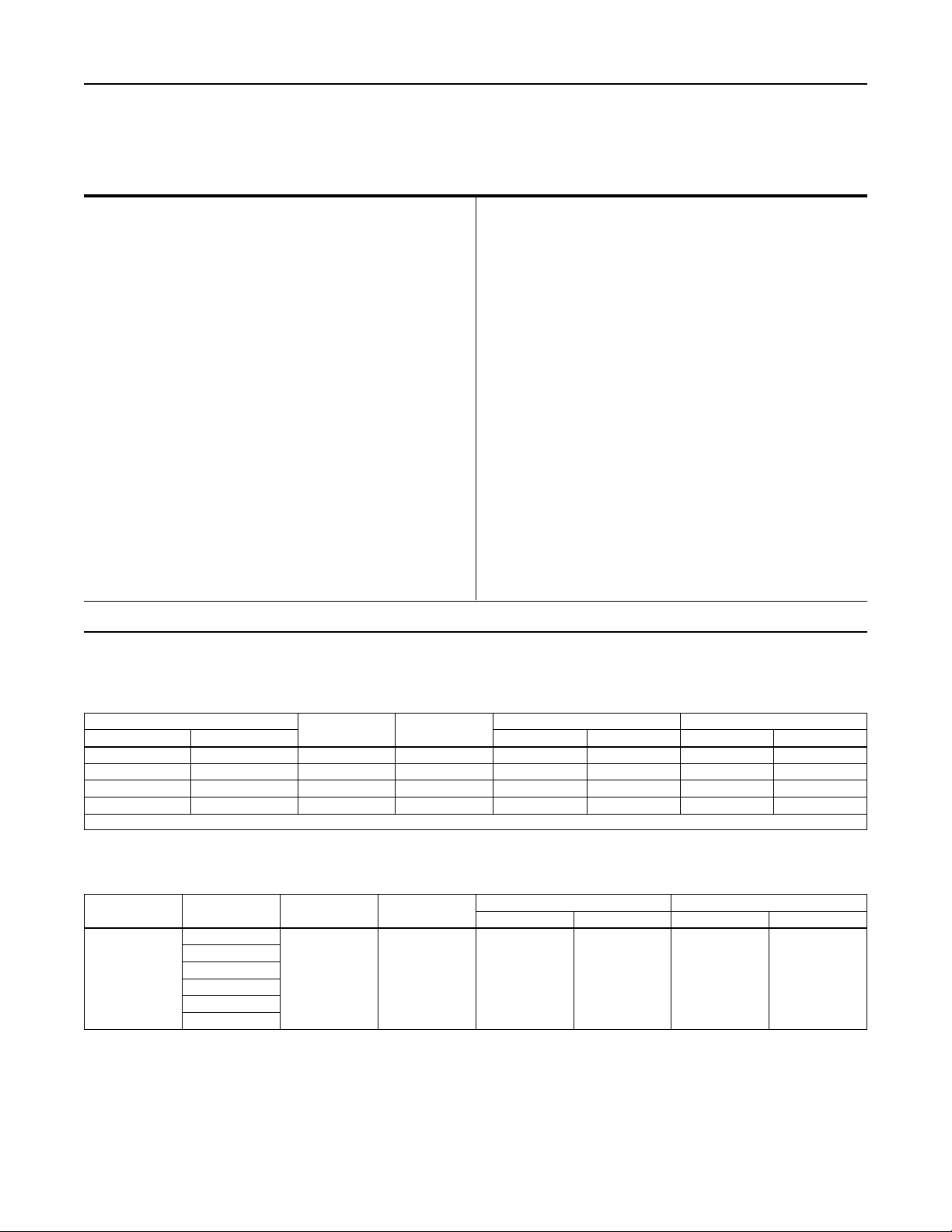

Table 2. Inlet Pressure Ratings and Flow and Sizing Coefcients

SERIES

CP200

CP205 and

CP206

1. Inlet pressures based on lock-up performance. For maximum inlet pressure values with optimum regulating performance refer to the applicable Flow Capacity table in the bulletin.

2. To comply with ANSI B109.4 relief requirements, the maximum inlet pressure may need to be reduced.

ORIFICE SIZE

Inch mm psig bar C

1/8

3/16

1/4

3/8

1/2

1/8

3/16

1/4

5/16

3.2

4.8

6.4

9.5

13

3.2

4.8

6.4

7.9

MAXIMUM OPERATING

INLET PRESSURE

125

125

125

60

40

125

125

125

100

8.6

8.6

8.6

4.1

2.8

8.6

8.6

8.6

6.9

FLOW COEFFICIENTS

(1)(2)

102

172

(WIDE-OPEN)

g

12

24

44

12

24

44

70

C

0.40

0.80

1.52

3.30

4.40

0.4

0.8

1.5

2.7

C

1

v

30

30

29

31

39

30

30

29

30

IEC SIZING COEFFICIENTS

X

0.53

0.58

0.53

0.60

0.97

0.53

0.58

0.53

0.53

T

F

0.87

0.82

0.85

0.83

0.72

0.87

0.82

0.85

0.85

D

F

0.89

L

WARNING

!

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion and/or re causing

property damage and personal injury or death.

Fisher® regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes, rules

and regulations, and Emerson Process

Management Regulator Technologies, Inc.

(Regulator Technologies) instructions.

If the regulator vents gas or a leak develops in

the system, service to the unit may be required.

Failure to correct trouble could result in a

hazardous condition.

Call a gas service person to service the

unit. Only a qualied person must install or

service the regulator.

Product Description

The CP200 Series pressure loaded regulators are intended

for general pressure reduction for commercial and industrial

applications using pressure factor measurement, also

referred to as xed factor billing.

2

CP200 Series

Specications

The Specications section lists the specications for the regulator. The following information are stamped on the regulator at the

factory: Type, date of manufacture, spring range, orice size, maximum inlet pressure, maximum operating outlet pressure, and

maximum outlet casing pressure.

Available Congurations

Type CP200IN - Regulator with internal registration

Type CP200IT - Regulator with internal registration and

token relief

Type CP205IN - Type CP200IN with

Secondary Seat™ Protection

Type CP205IT - Type CP200IT with

Secondary Seat Protection

Type CP206IT - Type CP200IT with Secondary Seat

Protection with bleed to indicate Secondary Seat

is functioning

See Table 1

Body Sizes, End Connection Style, and

Pressure Rating

(1)

See Table 4

Inlet Pressure Ratings

(1)

See Table 2

Maximum Outlet Pressure

(1)

Emergency Casing: 25 psig / 1.7 bar

Operating: 20 psig / 1.4 bar

Outlet Pressure Ranges

See Table 3

Pressure Loading Regulator Spring Case Connection

1/4 NPT

Orice Sizes and Flow and IEC Sizing Coefcients

See Table 2

Temperature Capabilities

-20 to 150°F / -29 to 66°C

Pressure Registration

Internal

Factory Setpoint Inlet Pressures for Various

Orice Sizes

1/8-inch / 3.2 mm: 80 psig / 5.5 bar

3/16-inch / 4.8 mm: 60 psig / 4.1 bar

1/4-inch / 6.4 mm: 40 psig / 2.8 bar

5/16-inch / 7.9 mm: 30 psig / 2.1 bar

3/8-inch / 9.5 mm: 25 psig / 1.7 bar

1/2-inch / 13 mm: 25 psig / 1.7 bar

Approximate Weight

10 pounds / 4 kg

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Product has passed Regulator Technologies testing for lockup, relief start-to-discharge and reseal down to -40°.

(1)(2)

Table 3. Outlet Pressure Ranges

OUTLET PRESSURE RANGES

psig bar Inch mm Inch mm

1 to 2 69 mbar to 0.14 bar GE30199X012 Yellow Stripe 0.078 1.98 1.35 34.3

2 to 5 0.14 to 0.34 GE27213X012 Orange Stripe 0.100 2.54 1.47 37.4

5 to 10 0.34 to 0.69 GE39890X012 Black Stripe 0.114 2.90 1.47 37.4

10 to 20 0.69 to 1.4 GE30200X012 Purple Stripe 0.137 3.48 1.42 36.2

1. Outlet pressure range is controlled by 67CP Series pressure loading regulator spring.

(1)

PART NUMBER SPRING COLOR

SPRING WIRE DIAMETER SPRING FREE LENGTH

Table 4. Body Sizes, Material, End Connection, and Pressure Rating

TYPE BODY SIZE, NPS

3/4 x 1

CP200, CP205,

and CP206

3/4 x 1-1/4

1 x 1-1/4

3/4

1

1-1/4

END

CONNECTION

NPT Gray Cast Iron 4 102 175 12.1

BODY MATERIAL

FACE-TO-FACE DIMENSION PRESSURE RATING

Inch mm psig bar

3

CP200 Series

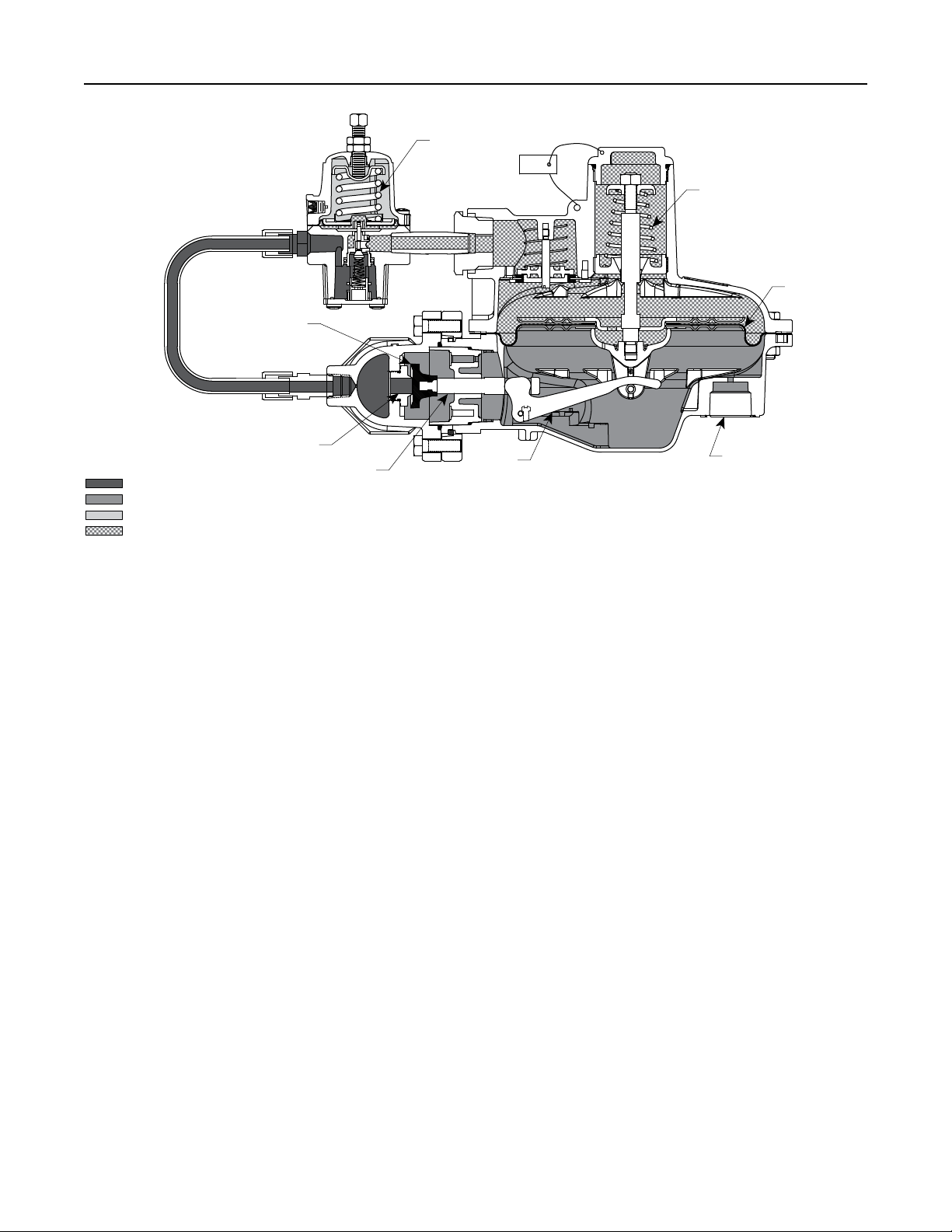

TYPE 67CP PRESSURE

LOADING REGULATOR

VALVE DISK

CONTROL SPRING

CLOSING SPRING

DIAPHRAGM

ORIFICE

M1129

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

Figure 2. Type CP200IN Pressure Loaded Pressure Reducing Regulator with Internal Registration Operational Schematic

VALVE STEM

Principle of Operation

Refer to Figure 2. The CP200 Series has spring-to-close

construction and uses 67CP Series pressure loading regulator

to supply loading pressure to the top of the main diaphragm.

Since the loading pressure regulator controls the main

regulator, adjustment to the downstream pressure is made

using the loading pressure regulator. The load pressure

supplied by the loading regulator is constant and equal to the

desired downstream pressure plus the pressure required to

overcome the light closing spring.

LEVER

MAIN REGULATOR

Zero Downstream Demand (Lockup)

As downstream demand decreases further, the outlet

pressure registering under the main diaphragm together

with the closing spring act to close the main disk against the

orice seating surface. At this point the loading regulator will

continue to supply a small amount of gas downstream that is

equal to the capacity of the bleed restriction in the diaphragm

assembly. As downstream demand decreases to zero ow

outlet pressure rises to meet the lock-up pressure of the

loading regulator. This causes the loading regulator to lock up

PRESSURE RETAINING

PLUG (DO NOT REMOVE)

to stop all ow downstream.

Type CP200 Base Regulator

Type CP205 with Secondary Seat™ Protection

Increasing Downstream Demand

As downstream demand increases the outlet pressure

registering on the underside of the main diaphragm decreases

and the constant loading pressure above the main diaphragm

forces the diaphragm downward. This downward diaphragm

motion is transferred through the lever causing the main

disk to move away from the orice seating surface to supply

additional ow downstream to the required demand.

Decreasing Downstream Demand

As downstream demand decreases the outlet pressure

registering on the underside of the main diaphragm

increases forcing the main diaphragm upward. This upward

motion is transferred through the lever causing the main disk

to move toward the orice seating surface to reduce ow to

meet the required demand.

Refer to Figure 3. The Type CP205 provides

Secondary Seat Protection. As downstream demand

decreases and downstream pressure rises to the regulator

pressure lock-up value, the regulator will lock up. If,

however, damage has occurred to the primary disk, to the

primary orice’s seating surface, or debris has become

lodged between the primary disk and primary orice, the

outlet pressure will continue to rise. This additional pressure

causes the primary disk to apply additional force to the

orice seating surface, which causes the secondary seating

surface to move toward the secondary disk or sealing

surface. If downstream demand decreases to zero, then the

secondary seating surface will contact the sealing surface to

provide lockup.

4

Loading...

Loading...