Page 1

Technical Information

Date of last update: Oct-11 Ref: D7.8.4/1011/E

Application Engineering Europe

C

C

OORRE

E

S

S

EENNSSE

E

™

™

D

D

IIAAGGNNOOSSTTIICCSS FFOORR

S

S

TTRREEAAMM

R

R

EEFFRRIIGGEERRAATTIIOONN

C

C

OOMMPPRREESSSSOORRS

S

CoreSense™ Diagnostics for Stream Refrigeration Compressors ............................................................................... 1

1 Introduction .......................................................................................................................................................... 3

2 Specifications ........................................................................................................................................................ 3

3 Emerson CoreSense™ Diagnostics – Features ..................................................................................................... 3

3.1 “Jog” feature ................................................................................................................................................. 4

3.2 Crankcase heater (CCH) control.................................................................................................................... 4

3.3 Insufficient oil pressure protection .............................................................................................................. 5

3.4 Motor overheat protection .......................................................................................................................... 5

3.5 High discharge temperature protection ....................................................................................................... 5

3.6 Locked rotor protection ................................................................................................................................ 5

3.7 Missing phase protection ............................................................................................................................. 5

3.8 Low voltage protection ................................................................................................................................. 5

3.9 Voltage imbalance protection ...................................................................................................................... 6

3.10 Flash memory information ........................................................................................................................... 6

3.10.1 The following asset information will be saved in the flash memory (EEPROM); ................................. 6

3.10.2 Compressor running status information will be saved in the flash memory (EEPROM): ..................... 6

3.10.3 Compressor Operating Parameters ...................................................................................................... 6

3.11 Modbus® communication ............................................................................................................................. 6

3.12 Local and remote reset ................................................................................................................................. 6

3.13 Alarm history and running conditions .......................................................................................................... 7

3.14 Compressor status codes .............................................................................................................................. 7

3.15 LEDs on the module to display the failure alarms ........................................................................................ 7

4 Electrical connections ........................................................................................................................................... 9

4.1 System wiring diagram ................................................................................................................................. 9

4.2 Terminal box and current sensing transformer connections ..................................................................... 10

4.2.1 Installation of current sensing module ............................................................................................... 10

4.2.2 CoreSense™ Diagnostics with Υ/Δ motors ........................................................................................ 11

1/17

Page 2

Technical Information

D7.21.2/1011/E

4.2.3 CoreSense™ Diagnostics with part winding ...................................................................................... 11

5 CoreSense™ Diagnostics jumper settings .......................................................................................................... 13

6 CoreSense™ Diagnostics DIP-Switch setting ..................................................................................................... 13

7 Troubleshooting.................................................................................................................................................. 15

2/17

Page 3

Technical Information

D7.21.2/1011/E

Operating temperature

-32°C to 66°C

Steady load current for relay

3A

Voltage requirements

120 VAC or 240 VAC

Power rating for the module

3VA

Inrush current for relay

19A

Storage temperature

-40°C to 85°C

Voltage sensor module

24 VAC

Protection class

IP54

Nr

Feature

Nr

Feature

1

Motor Overheat Protection

8

Alarm History and Compressor Operating Conditions

2

Oil Pressure Protection

9

Crankcase Heater Control

3

Discharge Temperature Protection

10

Local and Remote Reset Capability

4

Locked Rotor Protection

11

Modbus® Communication

5

Single Phase/Missing Phase Protection

12

Power Consumption Monitoring (Voltage, Current,

Power Factor)

6

Voltage Imbalance Protection

13

Crankcase Heater Control

7

Low Voltage Protection

14

Compressor Run Status (Proofing)

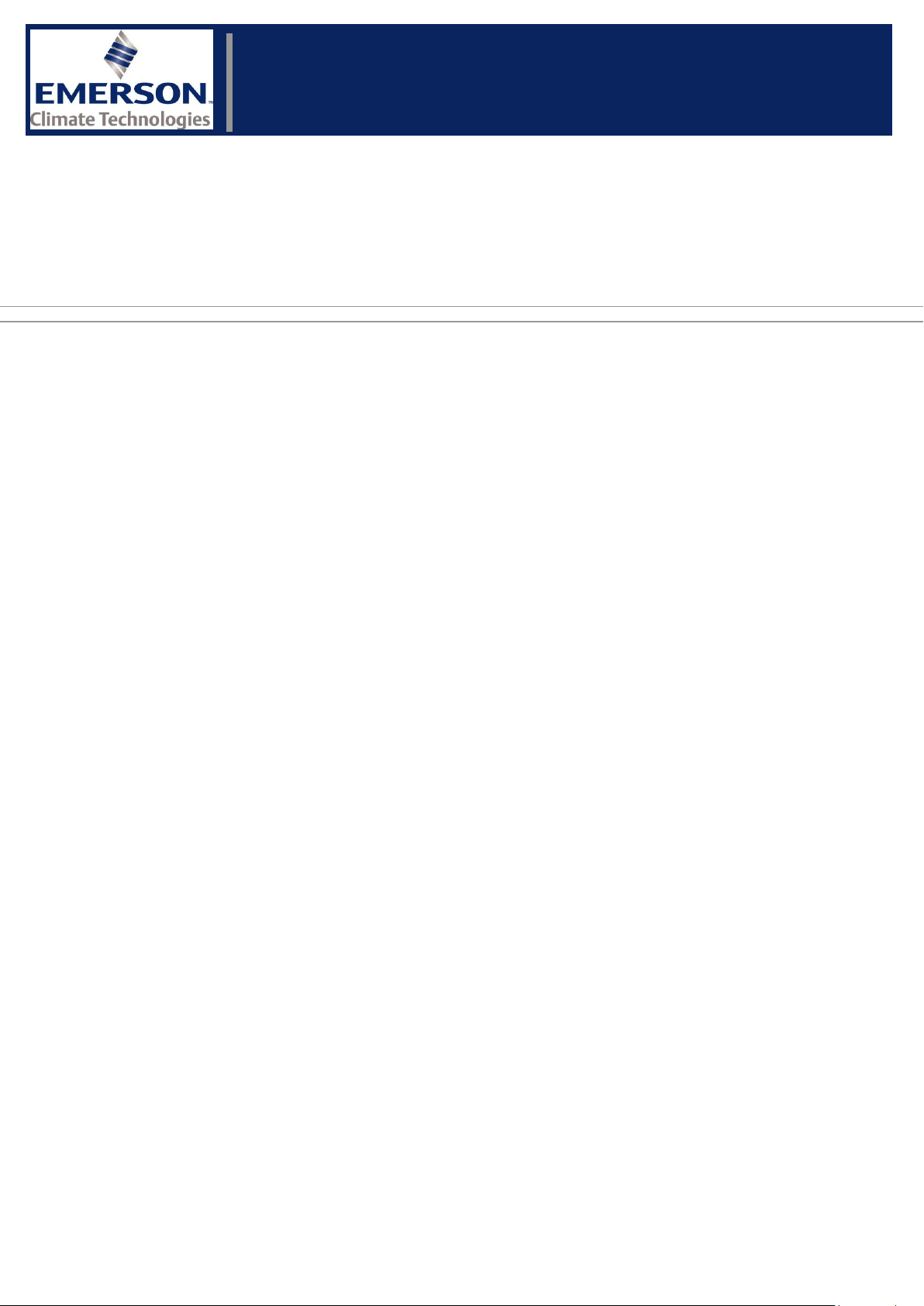

1 Introduction

CoreSense™ is an ingredient brand name for compressor electronics associated with Emerson‟s Copeland® brand

products. CoreSense™ technology uses compressor as a sensor to unlock information from within the compressor

providing value added features such as advanced motor protection, diagnostics, communication.

With active protection, advanced algorithms, and features like fault history and LED indicators, CoreSense™

Diagnostics for Copeland compressors enable technicians to diagnose the past and recent state of the system,

allowing for quicker, more accurate diagnostics and less down time. The CoreSense™ Diagnostics is initially

available as standard with the 4- and 6-cylinder Stream compressors.

Figure 1: Stream compressor with CoreSense™ Diagnostic

2 Specifications

Power supply for control module (in front of the compressor) is 120VAC or 240VAC.

Table 1

3 Emerson CoreSense™ Diagnostics – Features

Table 2

3/17

Page 4

Technical Information

D7.21.2/1011/E

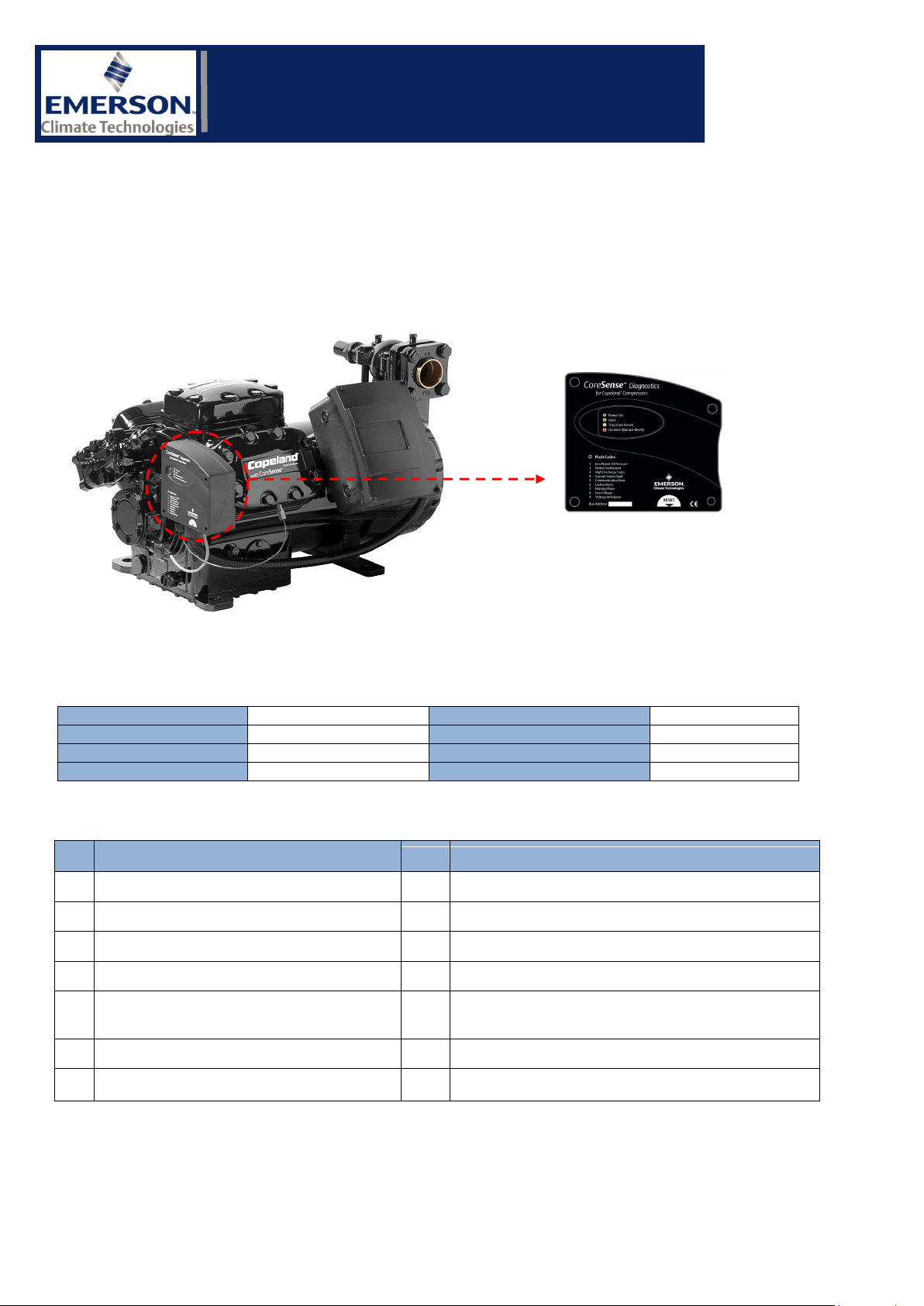

Figure 2

3.1 “Jog” feature

The reset button below the control module may be used as an emergency shutdown,

such as for clearing liquid during a start-up. After the module re-boots (approximately

3 seconds) the compressor will run again. The reset button may be pushed as necessary

to stop the compressor.

Reset button

Figure 3

3.2 Crankcase heater (CCH) control

The sensor module contains an on-board CCH control relay. An auxiliary contactor is no longer required to turn the

heater on when the compressor turns off.

The appropriate voltage supply to the CCH power input terminals (115V/230V) is required.

4/17

Page 5

Technical Information

D7.21.2/1011/E

3.3 Insufficient oil pressure protection

The CoreSense™ Diagnostics module replaces the mechanical oil pressure switch. Furthermore, it provides the

added value of communication for insufficient oil pressure warning and lockouts via LED flash codes and/or a

supervisory pack controller. Total insufficient oil pressure time for the compressor is stored and accumulated in the

module memory.

CoreSense™ Diagnostics will issue a warning when oil pressure differential falls below 0.48-0.62 bar for

4 seconds.

Once the oil pressure differential falls below 0.48-0.62 bar for 2 minutes (120 sec), the module will shut the

compressor off and a “low oil pressure lockout“ will be reported. Before using the reset button, troubleshooting

needs to be done to understand the failure. The compressor will switch back on once the reset has been activated

either manually or remotely through the communication network, or when power has been cycled to the

CoreSense™ module. This feature is not applicable to Copeland compressor models 4MTL (Stream CO2

compressors) as these have no positive oil pump fitted and are “splash” lubricated.

3.4 Motor overheat protection

Using Positive Temperature Coefficient (PTC) sensors on 4M* and 6M* Stream compressor models, the

CoreSense™ Diagnostics module provides motor overheating protection. The CoreSense™ Diagnostic module

replaces the Kriwan module INT69TM.

Alarm condition:

Trip condition: PTC Resistance > 4.5 kΩ;

Reset condition: PTC Resistance < 2.5 kΩ; 5 min time delay.

3.5 High discharge temperature protection

Discharge temperature protection is provided using a NTC sensor in the compressor cylinder head. The sensor is

pre-installed at the factory and connected to the module. CoreSense™ will protect the compressor from high

discharge temperature conditions. If the temperature sensor detects a discharge temperature higher than 154°C,

the CoreSense™ will shut off the compressor until the temperature cools down to an acceptable level (about

130°C).

Either trip or lockout alarm can be selected by user. Default is trip alarm.

Trip/lockout value ≥ 154°C for 2 sec.

Trip alarm: Automatic reset after 2 minutes; discharge temp < 130ºC.

Lockout alarm: Manual reset is necessary.

3.6 Locked rotor protection

Appears when the rotor is mechanically seized. Locked rotor current is expected to decrease within 4 seconds after

the motor comes up to speed.

3.7 Missing phase protection

If any one of the 3 power phases is missing immediately after the compressor contactor is energized, a singlephasing condition exists.

The maximum response time shall be 1.2 seconds from the time of contactor energization.

Alarm condition: If any phase voltage < 84% of max of 3 input voltages for a period of 1 second.

Trip time: 5 minutes with automatic reset.

Lockout condition: Appears after the 10 consecutive trip alarms. Manual reset (using reset button below

the module or using remote reset by pack controller).

In the case of a part winding motor this feature is detectable for primary winding only. Missing phase, voltage

imbalance and low voltage are not detectable for the secondary winding. A missing phase can be detected during

start-up, but not while the motor is running.

3.8 Low voltage protection

Appears when there is a low supply voltage.

5/17

Page 6

Technical Information

D7.21.2/1011/E

Alarm condition: Motor compressor voltage < low voltage setting at compressor running state. The default low

voltage setting is 75% of the nominal line voltage stored in the module for 2 sec.

Trip Time: 5 minutes.

The module determines the operating frequency of the compressor. The compressor low voltage setting shall be

lowered by the same percentage as the operating frequency if less than the nominal frequency. For example if a

60 Hz nominal frequency compressor is running at 57 Hz (5% less), then the low voltage setting shall be reduced

by 5%.

3.9 Voltage imbalance protection

The purpose of this protection feature is to protect the compressor against a voltage imbalance condition that leads

to motor overheating.

A configurable setting (default = 5%) for voltage imbalance is used to determine the operating limit of the

compressor.

Alarm condition:

Trip: When the voltage imbalance > 5% (configurable).

Reset: Automatic reset after 5 min; voltage imbalance < 5%.

3.10 Flash memory information

Emerson Climate Technologies can provide a software to access EEPROM information.

3.10.1 The following asset information will be saved in the flash memory (EEPROM);

Compressor model number

Compressor serial number

Compressor model number modified

Compressor serial number modified

Sensor module firmware revision

3.10.2 Compressor running status information will be saved in the flash memory (EEPROM):

Number of compressor running hours

Number of compressor starts

Number of resets and type of reset

Accumulated runtime without good oil pressure

Number of relay cycles

3.10.3 Compressor Operating Parameters

Current

Voltage

Power factor

Power consumption

Discharge temperature values

3.11 Modbus® communication

CoreSense™ Diagnostics has communication capability via a Modbus® network connection. With communication

enabled, CoreSense™ warnings, trips and lockouts can be displayed and recorded in a pack controller such as the

iPro Rack Controller from Dixell.

The CoreSense™ Diagnostics module is compatible with any other pack controller that has Modbus® protocol.

3.12 Local and remote reset

The CoreSense™ Diagnostics module is equipped with a reset button placed below the control module. The reset

button may be pushed as necessary to stop the compressor.

The CoreSense™ Diagnostics module is equipped with a remote reset capability, such that if a compressor is off in

a lockout condition, the user can remotely restart the compressor through their rack controller or compatible remote

access software.

NOTE: Service contractor and end user policies need to be considered when deciding whether or not to

use the remote reset feature in the pack controller.

6/17

Page 7

Technical Information

D7.21.2/1011/E

Operating information

Alarm history

Number of compressor running hours -

8 days alarm history

Accumulated running time without good oil

pressure

Most recent 10 alarms

Number of switching cycles

Total number of alarms since the compressor first

operation

Compressor power consumption*

Current, voltage, power factor*

Alert alarms

Compressor will not turn off.

Trip alarms

Compressor turns off for some

time with automatic reset.

Lockout alarms

Compressor turns off.

Manual reset necessary.

3.13 Alarm history and running conditions

*This data is not stored in CoreSense™ EEPROM memory. These values can be stored in a laptop using CoreSense™ PC

Interface Software or Modbus® communication.

Table 3

3.14 Compressor status codes

Steady green: An indication of normal operation. There are no faults or issues with the compressor.

Flashing green: An indication that there is an alert (warning) condition. The compressor can still be

running.

Flashing orange: An indication that the compressor has tripped with auto reset.

Flashing red: An indication that the compressor is in lockout state.

Solid red: An indication that the control module has failed.

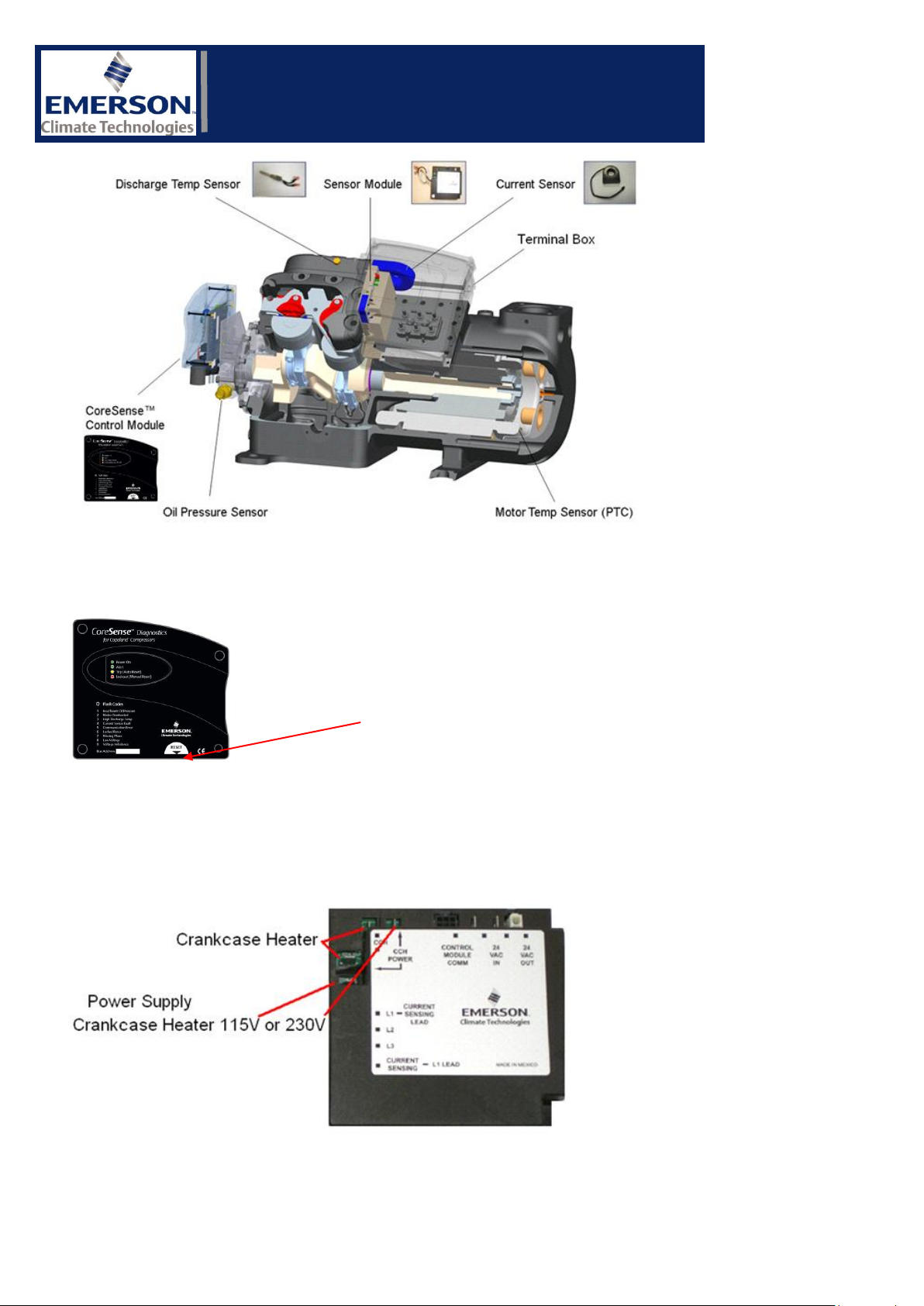

3.15 LEDs on the module to display the failure alarms

For warning/alert (green), trip and lockout (red), the flash count is defined as 0.1 second „on‟ and 0.4 second „off‟

with a 2-second pause before the flash count repeats (timings are +/- 50 ms).

Definitions:

Trip: The module has shut off the compressor due to a fault condition. The compressor will be available to

run when the fault condition no longer exists, and the minimum off time has been satisfied.

Lockout: The module has shut off the compressor due to a fault condition. The compressor will be

available to run again when the fault condition has been cleared and manual or remote reset is done.

Figure 4

7/17

Page 8

Technical Information

D7.21.2/1011/E

LED

flashes

count

Status LED description

Auto

reset

time

Lockout

condition

Status LED troubleshooting information

1

Low Oil

Pressure

NA

Low Oil

Pressure

N/A

Without

sufficient oil

pressure for 2

minutes

If flashing green, compressor has been

without sufficient oil pressure for 4 seconds.

If flashing red, compressor has been

without sufficient oil pressure for 2 minutes.

2

NA

Motor

Protection

Trip

NA

2 min

NA

If flashing orange, compressor is turned

off because motor temperature has

exceeded set point. (3 series PTCs; 1 input)

(Trips at 4.5K Ohms, and will reset when

below 2.75K Ohms.)

3

Discharge

Temp.

Discharge

Temp.

Discharge

Temp.

2 min

Exceeds max

set point

(configured in

EEPROM from

iPRO)

If flashing green, the discharge

temperature probe is open or disconnected.

If flashing orange, discharge temperature

has exceeded set point; compressor is

turned off for 2 minutes before resetting.

If flashing red, discharge temperature has

exceeded set point and the compressor is

locked out.

(The customer has configured the module

to lock out when the DLT temperature

exceeds the maximum set point.) DLT

probe is FACTORY INSTALLED

4

Current

Sensor

Fault

NA

NA

NA

NA

If flashing green, current sensor is

disconnected from the module. Compressor

run state is not known by module.

5

Communica

tion Error

NA

NA

NA

NA

Communication between Control module

and iPro (/System) Controller has been lost.

Communication between Control module

and Sensor module has been lost.

Configuration miss-match between SW

configuration from iPro and HW (network

mode)

6

NA

Locked

Rotor

Locked

Rotor

5 min

10 consecutive

events

If flashing orange, compressor failed to

start, and excessive current may be present

in the compressor. The compressor is

turned off and will remain off for 5 minutes.

If flashing red, compressor failed to start,

and excessive current may be present in

the compressor. The compressor is locked

out after 10 consecutive events.

7

NA

Missing

Phase

Missing

Phase

5 min

10 consecutive

events

If flashing orange, compressor is turned

off due to missing phase.

If flashing red, the compressor is locked out

after 10 consecutive missing phase alarms.

8

N/A

Low Voltage

Low

Voltage

5 min

10 consecutive

events

If flashing orange, compressor is turned

off due to low compressor voltage.

If flashing red, the compressor is locked

out after 10 consecutive low voltage alarms.

9

N/A

Voltage

Imbalance

Voltage

Imbalance

5 min

10 consecutive

events

If flashing orange, compressor is turned

off due to voltage imbalance.

If flashing red, the compressor is locked

out after 10 consecutive voltage imbalance.

Table 4

8/17

Page 9

Technical Information

D7.21.2/1011/E

4 Electrical connections

4.1 System wiring diagram

Fuses and wire cable sizing must be done in accordance with all applicable electrical code standards. Figure 5

below shows the recommended basic system wiring for a compressor with CoreSense™.

Figure 5: Wiring diagram

Figure 6: CoreSense™ wiring terminals description

9/17

Page 10

Technical Information

D7.21.2/1011/E

Figure 7: CoreSense™ module with current sensor

4.2 Terminal box and current sensing transformer connections

For space reasons inside the compressor terminal box wires L1 and L2 connected to the sensor module need to be

exchanged in such a way that the black wire is connected to terminal 2 (V) and the white wire goes to terminal 1

(U) on the terminal plate as shown on the drawing. This results in that the current of L2 is sensed instead of L1.

4.2.1 Installation of current sensing module

One of the motor power leads passes through the “toroid” (current

sensing module). Information from the current sensing module is

used to determine running amps, power consumption and locked

rotor conditions. There are 3 voltage sensing leads attached to the

motor terminals and connected to the sensor module. Two of the

leads are white, and one is black. For proper calculation of power

factor and motor power it is necessary for the black voltage sensing

lead and the power lead through the current sensing module to be

connected to the same motor terminal.

Class II transformers have a maximum VA (Volt-Ampere) rating of

less than 100 and a maximum secondary output of 30 VAC.

Figure 8: Current sensing module and T-Box wiring

10/17

Page 11

Technical Information

4.2.2 CoreSense™ Diagnostics with Υ/Δ motors

Terminal box and the current sensing “toroid” connections are

factory-installed. One of the motor power leads must be routed

through Current Sensing Transformer (see Figures 9 & 10 below).

Figure 9: Current sensing transformer

D7.21.2/1011/E

Figure 10: Wiring sensor module and leads routed through the current sensor

One motor lead must be routed through the centre opening of the current sensing transformer.

4.2.3 CoreSense™ Diagnostics with part winding

If using the CoreSense™ Diagnostics module with a part-winding start motor, one power lead of each of the

windings should be passed through the current sensing transformer in the same direction (see Figures 10 and 11)

to provide accurate compressor proofing. If the leads (L2 and L8 in picture below) are not routed in the same

direction, the running current may indicate close to zero.

11/17

Page 12

Technical Information

D7.21.2/1011/E

Figure 11: Wiring part winding

Figure 12: Wiring Sensor module and leads routed through the current sensor

12/17

Page 13

Technical Information

D7.21.2/1011/E

5 CoreSense™ Diagnostics jumper settings

The last compressor in the daisy-chain must be “terminated” by moving the jumper from JP5 to JP3. For all other

compressors the jumper should remain in the default JP5 position.

JP4 should be set “1-2” if connected to an iPro rack controller. Set JP4 to “2-3” for other pack controllers.

Do not remove JP1. This is reserved for future use.

Figure 13

6 CoreSense™ Diagnostics DIP-Switch setting

Figure 14: CoreSense™ Diagnostics DIP-Switch setting

13/17

Page 14

Technical Information

D7.21.2/1011/E

Assign a unique node address to each CoreSense™ diagnostics module using switches 1 through 5.

a. Set the communications baud rate for the module using switch 7. “Off” = 19200 baud, “On” = 9600 baud.

The baud rate for each module should be set to match the rack controller.

b. Set switch 8 to “Off” for no parity, to “On” for even parity.

c. Set switch 9 to “Off” for stand-alone mode, to “On” for network mode. Network mode will generate a

communications error if the rack controller fails to communicate with the device. For stand-alone mode, no

communications are expected so the communication error is blocked.

d. Factory default setting is “On” for dip-switch 10, ie, discharge temperature protection. If you want to

disconnect the discharge temperature sensor, turn off dip-switch 10.

Push the reset button after changing the switch settings.

Ensure that the dip-switch settings on each module match the settings for the selected controller communication

port.

Information in this document is subject to change without notification.

14/17

Page 15

Technical Information

Flash

code

Alarm conditions

Possible failure reasons

Troubleshooting measures

1

Insufficient oil

pressure

Warning: Appears when the

differential oil pressure is less than

0.48 – 0.62 bar for 4 seconds.

Lockout: Appears when the

differential oil pressure is less than

0.48 – 0.62 bar for 2 minutes

continuous, or intermittent but

determined to be unsafe.

Loose wiring connections between

CoreSense™ module and oil

sensor.

Faulty oil sensor (missing O-ring

or clogged sensor screen).

Faulty oil pump.

Clogged strainer screen or worn

bearings.

Verify the oil level present in the sight glass. If the oil is not present, resolve reservoir

oil supply problem or oil level control setting issues.

Verify that the harness is fully engaged to the sensor.

Measure oil pump differential pressure. If less than 7 to 9 psi, inspect for clogged oil

screen, faulty oil pump, liquid floodback or worn bearings.

If good oil pressure exists, measure resistance across the oil sensor while the

compressor runs. If the sensor resistance is "open" inspect for clogged sensor screen

or missing O-ring.

If sensor resistance is "closed", temporarily jumper across the harness connector pins

(do not damage the pins!) while the compressor runs. If the oil warning does not go

away, verify harness connector engagement at the module circuit board.

2

Motor overheat

Trip: Appears when the PTC

Thermistor resistance is > 4.5 kΩ.

Lockout: Appears when 10

consecutive motor overheat trip

alarms occur.

Motor rotor is mechanically

seized.

Open circuit in harness.

Connector pin not engaging at

connector on control module

Faulty CoreSense™ module.

In case of trip alarm, allow the motor to cool down for a minimum of 2 minutes (it may

take longer) and the compressor will start automatically.

In case of lockout alarm or multiple trips, check PTC resistance when the motor is cold

(off for at least an hour). If resistance is high, inspect for faulty sensor or loose

connection under terminal plate.

If resistance is low, inspect for loose terminal strip connections, harness connection

failure at circuit board, open harness circuit or high motor temp due to return gas

temperature, motor voltage or load condition.

3

Discharge temp

protection

Warning: When the discharge

temperature sensor is defective or

disconnected.

Trip/Lockout: When the discharge

temperature is > 154°C for 2

seconds.

Open discharge probe (faulty).

The probe connection has not

been made to the harness

connector.

The connector is not plugged into

the CoreSense™ circuit board.

The Discharge temperature has

exceeded the maximum limit

154°C.

Blocked condenser.

Possible loss of refrigerant.

If there is a warning, verify proper probe connection to the harness and proper

harness connection into the circuit board.

If there is a warning, unplug the discharge temp probe and verify if the resistance of

the probe is as specified vs its approximate ambient temperature.

If the probe resistance is correct inspect the harness connector receptacle for damage

and apply NyoGel 760G connector lubricant.

Trip or Lockout: resolve system issues (high superheat, high head pressure), inspect

for mechanical damage that can lead to high temps (valve plate gasket, suction or

discharge valve failure).

7 Troubleshooting

D7.21.2/1011/E

15/17

Page 16

Technical Information

D7.21.2/1011/E

Flash

code

Alarm conditions

Possible failure reasons

Troubleshooting measures

4

Connection lost

CT to sensor

Warning: Appears when the signal

from current sensor is not

communicated to the sensor module.

The current sensor is not

connected to the sensor module.

Faulty current sensor.

Faulty sensor module.

Verify if the CT connector is connected to the sensor module. If not connect the 4-pin

current sensor connector into the sensor module.

Verify if there is continuity between pin 3 & 4 (closest to the latch) of the current

sensing connector. The resistance should be less than 1 Ω. If the resistance is

greater than 1 Ω, replace the current sensing module. Be certain that the receptacles

are fully engaged in the connector block.

Verify if the Amp and Volts values are correctly displayed. If not, inspect the wire

harness connector to ensure that the pins are fully engaged.

If the above-mentioned trouble shooting measures didn't give the positive results, the

reason is faulty sensor module or mis-installed connector. Replace the faulty sensor

module with new one.

5

Communication

Error

Warning: Appears when there is no

communication between control

module and sensor module or rack

controller

Communication between

CoreSense™ control module and

rack controller has been lost.

Communication between the

CoreSense™ control module and

the sensor module has been lost.

Is there a communication network? If not, set the network dip-switch to "stand-alone"

and press reset.

Is there a communication network? If not, verify that the communication harness is

engaged at both the CoreSense™ module and the sensor module.

If the LED on the top edge of the sensor module is dark, verify 24VAC power to the

sensor module, or replace the sensor module.

If communication network amber light is continuously on, reverse the communication

wire polarity. If voltage between centre pin and the right or left pin isn't 2.3-2.6VDC,

inspect for communication wire failure or wire strands that are "shorting" between the

wires or to ground.

6

Locked rotor

Trip: Appears when the excessive

current is present in the compressor.

Refer AE bulletin for more details.

Lockout: Appears when 10

consecutive locked rotor trip alarms

occur.

Motor rotor is mechanically seized.

Excessive current present in the

compressor.

Damaged valve plates in cylinder

head.

Verify that motor voltage is adequate (+/- 10% of nominal rated voltage), especially

during the starting event.

Start compressor with no load. If it does start with no load, inspect the valve plate(s)

for damage or look for other causes of leak-back.

7

Missing phase

Trip: Appears when there is a missing

phase / single phasing.

Lockout: Appears when 10

consecutive missing phase trip

alarms occur.

Loose wiring connections at the

terminals inside compressor T-Box.

Worn out contactors.

Line break in one of the phases.

Verify voltage supply from the main power buss.

Verify voltage into and out of contactor (Repair or replace contactor if necessary).

Verify that motor electrical connections are tight at the compressor motor terminals.

16/17

Page 17

Technical Information

D7.21.2/1011/E

Flash

code

Alarm conditions

Possible failure reasons

Troubleshooting measures

8

Low voltage

Trip: Appears when there is a low

compressor voltage.

Supply voltage is not in the

specified range.

Loose wiring connections at the

terminal plate.

Worn out contactors.

Faults with other peripheral

electrical loads.

Verify voltage supply from the main buss.

Verify voltage into and out of contactor (repair or replace contactor if necessary).

Measure voltage at the compressor terminal (refer to AE10-1244, Recommended

Contactor Selection for 3-Phase Motor Control – Power Supply Problems).

Verify that motor electrical connections are tight at the compressor.

Verify that there are not any faults with other peripheral electrical loads (for example

fan motors).

9

Voltage

imbalance

Trip: Appears when the voltage

imbalance value exceeds the set

value (default 5%).

Loose wiring connections at the

compressor terminal plate inside TBox.

Worn out contactors.

Faults with other peripheral

electrical loads.

Single phasing conditions.

Verify voltage supply from the main buss.

Verify voltage into and out of contactor (repair or replace contactor if necessary).

Measure voltage at the compressor terminal (refer to AE10-1244, Recommended

Contactor Selection for 3-Phase Motor Control– Power Supply Problems).

Verify that motor electrical connections are tight at the compressor.

Verify that there are not any faults with other peripheral electrical loads (for example

fan motors).

17/17

Loading...

Loading...