Page 1

Application Guidelines

Copeland Scroll Digital

Receiver Units HLR

™

Page 2

C6.1.7/1110-0519/E

About these guidelines ................................................................................................ 1

1 Safety instructions ............................................................................................ 1

1.1 Icon explanation ................................................................................................................. 1

1.2 Safety statements .............................................................................................................. 1

1.3 General instructions ........................................................................................................... 2

2 Product description .......................................................................................... 3

2.1 Common information about Copeland Scroll Digital™ Receiver units HLR ...................... 3

2.2 Product range .................................................................................................................... 3

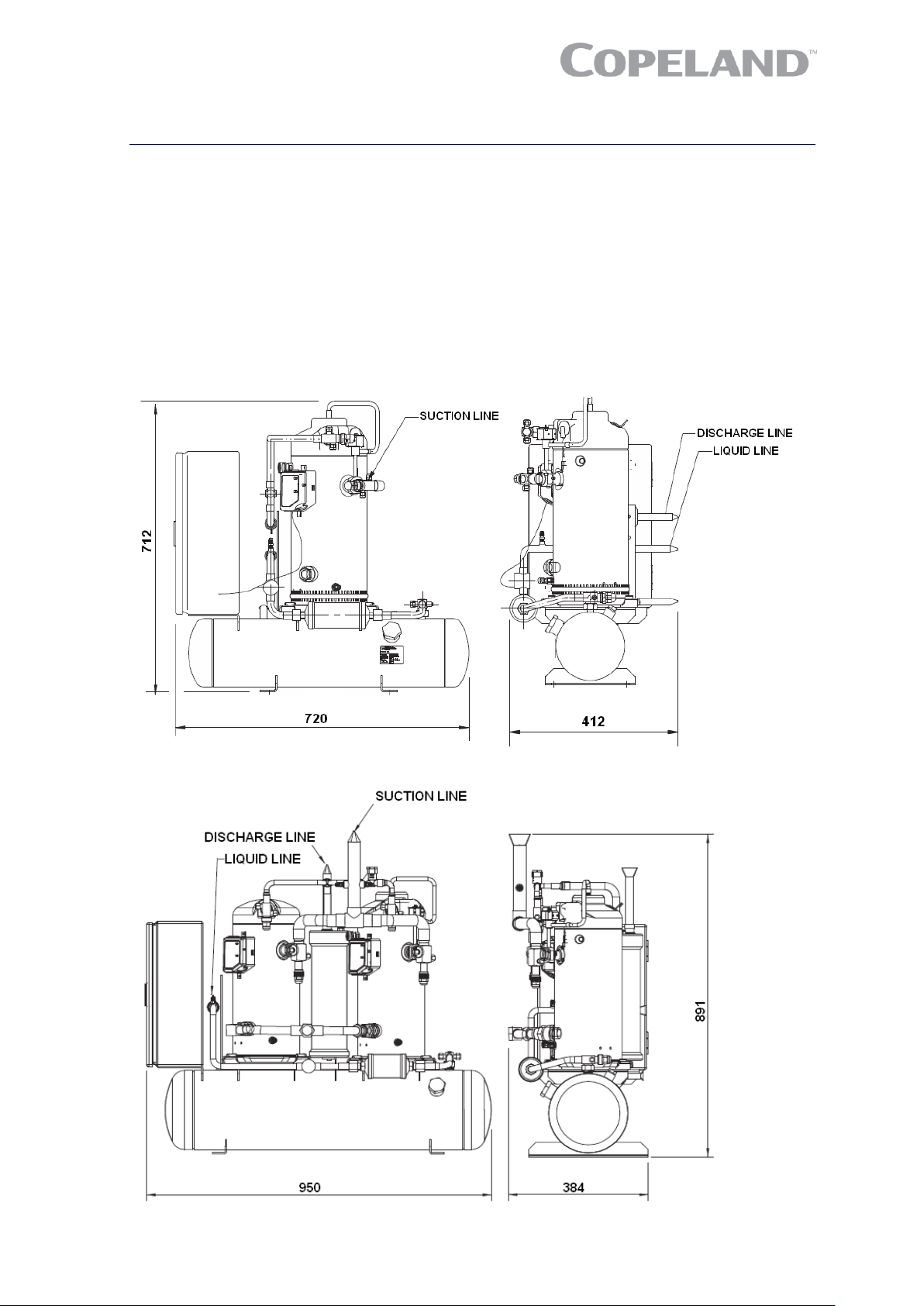

2.3 Dimensions in mm ............................................................................................................. 3

2.4 Product nameplate ............................................................................................................. 4

2.5 Nomenclature ..................................................................................................................... 4

2.6 Application range ............................................................................................................... 4

2.6.1 Qualified refrigerants and oils ................................................................................ 4

2.6.2 Application limits ..................................................................................................... 4

2.7 Main components description ............................................................................................ 5

2.7.1 Compressor ............................................................................................................ 5

2.7.2 Liquid receiver ........................................................................................................ 5

2.7.3 Electrical box components ..................................................................................... 5

2.7.4 Pressure switch ...................................................................................................... 5

2.7.5 Liquid line equipment ............................................................................................. 6

2.7.6 Solenoid valve for Copeland Scroll Digital compressor ......................................... 7

2.7.7 Oil separator: Alco Controls OSH .......................................................................... 7

2.8 Electronic controller EC2-552 ............................................................................................ 7

2.8.1 Select parameter configuration .............................................................................. 7

2.8.2 Parameter modification .......................................................................................... 8

2.8.3 Main parameters on EC2-552 ................................................................................ 8

3 Installation ....................................................................................................... 10

3.1 Receiver unit handling ..................................................................................................... 10

3.1.1 Transport and storage .......................................................................................... 10

3.1.2 Weights................................................................................................................. 10

3.2 Connection access ........................................................................................................... 11

3.2.1 Access to refrigeration components ..................................................................... 11

3.2.2 Access door to electrical box ............................................................................... 11

3.3 Refrigeration connections ................................................................................................ 12

3.3.1 Brazing recommendations.................................................................................... 12

3.3.2 Brazing procedure ................................................................................................ 12

3.4 Electrical connections ...................................................................................................... 13

3.4.1 Power supply connections.................................................................................... 13

3.4.2 Pre-wired electrical components .......................................................................... 13

3.4.3 Discharge temperature protection ........................................................................ 14

Page 3

C6.1.7/1110-0519/E

3.4.4 Electrical protection standard (protection class) .................................................. 14

3.4.5 HLR Receiver unit electrical data ......................................................................... 14

4 Starting up & operation................................................................................... 15

4.1 Charging procedure ......................................................................................................... 15

4.1.1 Refrigerant charging procedure ........................................................................... 15

4.1.2 Oil charging procedure ......................................................................................... 15

4.2 Rotation direction of scroll compressors .......................................................................... 15

4.3 Maximum compressor cycle ............................................................................................ 15

4.4 Checks before starting up and during operation .............................................................. 16

5 Maintenance & repair ...................................................................................... 16

6 Certification & approval .................................................................................. 16

7 Dismantling & disposal ................................................................................... 16

DISCLAIMER ............................................................................................................... 16

Page 4

C6.1.7/1110-0519/E 1

About these guidelines

The purpose of these application guidelines is to provide guidance in the application of Copeland

Scroll Digital™ Receiver Units HLR. They are intended to answer the questions raised while

designing, assembling and operating a system with these products.

Besides the support they provide, the instructions listed herein are also critical for the proper and

safe functioning of the receiver units. Emerson will not guarantee the performance and reliability of

the product if it is misused in regard of these guidelines.

These application guidelines cover stationary applications only. For mobile applications, contact

Application Engineering as other considerations may apply.

1 Safety instructions

Copeland Scroll Digital Receiver Units HLR are manufactured according to the latest European and

US safety standards. Particular emphasis has been placed on the user's safety.

HLR Digital Receiver Units are intended for installation in machines and systems according to the

Machinery directive MD 2006/42/EC. They may be put to service only if they have been installed in

these systems according to instructions and conform to the corresponding provisions of legislation.

For relevant standards please refer to the Manufacturer’s Declaration and other declarations

available at www.climate.emerson.com/en-gb.

These instructions should be retained throughout the lifetime of both the compressor and the unit.

You are strongly advised to follow these safety instructions.

1.1 Icon explanation

WARNING

This icon indicates instructions to avoid

personal injury and material damage.

CAUTION

This icon indicates instructions to avoid

property damage and possible personal

injury.

High voltage

This icon indicates operations with a

danger of electric shock.

IMPORTANT

This icon indicates instructions to avoid

malfunction of the compressor.

Danger of burning or frostbite

This icon indicates operations with a

danger of burning or frostbite.

NOTE

This word indicates a recommendation

for easier operation.

Explosion hazard

This icon indicates operations with a

danger of explosion.

1.2 Safety statements

▪ Refrigerant compressors must be employed only for their intended use.

▪ Only qualified and authorized HVAC or refrigeration personnel are permitted to install,

commission and maintain this equipment.

▪ Electrical connections must be made by qualified electrical personnel.

▪ All valid standards for connecting electrical and refrigeration equipment must be

observed.

▪ The national legislation and regulations regarding personnel protection must be

observed.

Use personal safety equipment. Safety goggles, gloves,

protective clothing, safety boots and hard hats should be worn

where necessary.

Page 5

2 C6.1.7/1110-0519/E

1.3 General instructions

WARNING

System breakdown! Personal injuries! Never install a system in the field

and leave it unattended when it has no charge, a holding charge, or with the

service valves closed without electrically locking out the system.

System breakdown! Personal injuries! Only approved refrigerants and

refrigeration oils must be used.

WARNING

High shell temperature! Burning! Do not touch the compressor until it has

cooled down. Ensure that other materials in the area of the compressor do

not come into contact with it. Lock and mark accessible sections.

CAUTION

Overheating! Bearing damage! Do not operate compressors without

refrigerant charge or without being connected to the system.

CAUTION

Contact with POE! Material damage! POE lubricant must be handled

carefully and the proper protective equipment (gloves, eye protection, etc.)

must be used at all times. POE must not come into contact with any surface

or material that it might damage, including without limitation, certain

polymers, eg, PVC/CPVC and polycarbonate.

IMPORTANT

Transit damage! Compressor and/or unit malfunction! Use original

packaging. Avoid collisions and tilting.

The contractor is responsible for the installation of the unit and should ensure that there is sufficient

liquid sub-cooling in the line to the expansion valve(s) to avoid "flash-gas" in the liquid line.

It is of vital importance that the discharge stop valve has been fully opened before the compressor

is started. If the discharge stop valve is closed or partly closed an unacceptable pressure with

accordingly high temperatures may develop on the discharge outlet in the compressor. When

operating with air the so-called diesel effect may occur, ie, the air sucked in is mixed with oil gas

and can explode due to the high temperature, and thereby destroy the compressor.

Page 6

C6.1.7/1110-0519/E 3

2 Product description

2.1 Common information about Copeland Scroll Digital™ Receiver units HLR

Emerson has developed the Copeland Scroll Digital™ Receiver Units HLR to meet refrigeration

demands for compact solutions at highest efficiency levels. These units allow continuous capacity

modulation from 10% to 100% and can be combined with various condenser concepts.

2.2 Product range

The range features ZB Scroll Digital™ compressors for medium temperature applications. It

consists of four models: two models including one compressor, and two models including two

compressors.

2.3 Dimensions in mm

Figure 1: HLR 13-ZBD30KCE, HLR13-ZBD45KCE, HLR 13-ZBD58KCE and HLR13-ZBD76KCE

Figure 2: HLR31-ZBDT60KCE, HLR31-ZBDT90KCE, HLR31-ZBDT116KCE and HLR31-ZBDT152KCE

Page 7

4 C6.1.7/1110-0519/E

2.4 Product nameplate

The Digital Receiver Unit nameplate shows model designation and serial number.

The compressor has its own nameplate with all electrical characteristics.

2.5 Nomenclature

The model designation contains the following technical information about the compressor:

Standard motor version available: TFD: 380-420V / 3 Ph / 50 Hz

2.6 Application range

2.6.1 Qualified refrigerants and oils

IMPORTANT

It is essential that the glide of refrigerant blends is carefully considered when

adjusting pressure and superheat controls.

Oil recharge values can be taken from Copeland Scroll™ compressors brochures or Copeland

brand products Select software available at www.climate.emerson.com/en-gb.

Qualified refrigerants

R404A, R407A, R407F, R448A, R449A, R450A,

R513A, R134a,

Qualified oil

Emkarate RL 32 3MAF

Qualified servicing

oils

Emkarate RL 32 3MAF / MOBIL EAL Arctic 22 CC

Table 1: Qualified refrigerants and oils

2.6.2 Application limits

For application envelopes, please refer to Select software at www.climate.emerson.com/en-gb.

Medium temperature range:

Evaporating temperature from -25°C up to 10°C, condensing temperature range depending on

evaporating temperature. See Select software or literature for further information.

HLR Digital Receiver Unit

H L R 31 ZB D T 90KCE TFD

Motor

version

Compressor size

T = Tandem

D = Digital

ZB = Scroll Medium temperature

Receiver size

Receiver

Liquid

Horizontal

Page 8

C6.1.7/1110-0519/E 5

2.7 Main components description

2.7.1 Compressor

Single-compressor unit

Tandem-compressor unit

Unit model

Compressor model

Unit model

Compressor models

HLR13-ZBD30KCE

ZBD30KCE

HLR31-ZBDT60KCE

ZBD30KCE + ZB30KCE

HLR13-ZBD45KCE

ZBD45KCE

HLR31-ZBDT90KCE

ZBD45KCE + ZB45KCE

HLR13-ZBD58KCE

ZBD58KCE

HLR31-ZBDT116KCE

ZBD58KCE + ZB58KCE

HLR13-ZBD58KCE

ZBD76KCE

HLR31-ZBDT152KCE

ZBD76KCE + ZB76KCE

Table 2: Compressors used in HLR Digital Receiver unit

2.7.2 Liquid receiver

The HLR Digital Receiver units are equipped with a liquid receiver with:

▪ Rotalock service valve on top of the receiver for liquid outlet line;

▪ 3/8"–14 NPTF connection for relief valve.

Fitting a pressure relief device according to standard EN 378-2 is the responsibility of the installer.

Unit model

Receiver volume

[Litres]

HLR13-ZBD30KCE, HLR13-ZBD45KCE,

HLR13-ZBD58KCE, HLR13-ZBD760KCE

13

HLR31-ZBDT60KCE, HLR31-ZBDT90KCE,

HLR31-ZBDT116KCE, HLR31-ZBDT152KCE

31

Table 3: Receiver volume

It is recommended to charge the system with refrigerant via the Rotalock service valves.

2.7.3 Electrical box components

All electrical components are pre-wired into the panel. The panel contains:

▪ compressor contactor(s)

▪ fuse(s)

▪ terminal blocks

▪ DIN rail-mounted terminals

▪ alarm relays

▪ electronic controller

NOTE: For further information, please refer to Application Guidelines C6.1.3 "Condensing

Unit Controller for Copeland EazyCool™ Outdoor Condensing Units" available on

www.climate.emerson.com/en-gb.

2.7.4 Pressure switch

Single-compressor units are equipped with:

▪ Dual pressure switch with automatic reset Alco Controls PS2-W7A

▪ Electronic unit controller EC2-552 with HP and LP pressure transmitters

Tandem-compressor units are equipped with:

▪ Single low-pressure switch with automatic reset Alco Controls PS1-W3A

▪ Two high-pressure switches with automatic reset Alco Controls PS3-W4S

▪ Electronic unit controller EC2-552 with HP and LP pressure transmitters

1) Alco Controls PS2-W7A (Dual pressure switch with automatic reset for singlecompressor unit)

The switch is equipped with display scale and pointers to

indicate the approximate settings. The display scales are

printed in relative pressure units "bar" and "psi".

Page 9

6 C6.1.7/1110-0519/E

For precise setting of the control, external gauges must be used.

The PS2-W7A has the following characteristics:

▪ Adjustable dual pressure switch

Set point adjustment range: LP (left) = -0.5 to 7 bar and HP (right) = 6 to 31 bar

Differential adjustment range: LP = 0.5 to 5 bar, HP = 4 bar

Factory setting: LP = 3.5 / 4.5 bar, HP = 20 bar

NOTE: The HP value should be set at maximum 26.2 bar (according to EN 12263).

2) Alco Controls PS1-W3A (Single low-pressure switch with automatic reset)

The control is equipped with display scale and pointers to

indicate the approximate settings. The display scales are

printed in relative pressure units "bar" and "psi".

For precise setting of the control, external gauges must be

used.

The PS1-W3A has the following characteristics:

▪ Adjustable single pressure switch

Set point adjustment range: = -0.5 to 7 bar

Differential adjustment range: = 0.5 to 5 bar

Factory setting: = 3.5 / 4.5 bar

3) Alco Controls PS3-W4S (High-pressure switch with automatic reset)

▪ Fixed switch point settings

Cut-out point: 26.2 bar

Cut-in point: 22 bar

4) Alco Controls PT5 Pressure

Transmitter

Digital Receiver units are equipped with HP and LP pressure transmitters, connected to the

EC2-552 electronic unit controller – see chapter 2.8 "Electronic

controller EC2-552".

An Alco PT5-30M pressure transmitter is used at the high-pressure

part of the system. An Alco PT5-07M pressure controller is used at

the low-pressure part of the system. The PT5 pressure transmitter

converts a pressure into a linear electrical 4-20 mA current output

signal. The heart of the transmitter is a piezoresistive chip enclosed

in an oil capsule.

2.7.5 Liquid line equipment

1) Filter drier Alco Controls ADK-plus

ADK-165 liquid line filter drier is for new installation or

after service. Optimum blend of molecular sieve and

activated alumina.

2) Liquid sight glass Alco Controls AMI 1SS*

The AMI series of moisture indicator is designed to monitor

the moisture content within the liquid line of a refrigeration

system. When the line is empty of liquid, circles may be

seen in the glass. However, when the liquid refrigerant

touches the glass, the circles disappear indicating the

system is fully charged.

Page 10

C6.1.7/1110-0519/E 7

2.7.6 Solenoid valve for Copeland Scroll Digital compressor

Copeland Scroll Digital compressors in HLR Digital Receiver units are equipped with a 24-volt AC

solenoid valve. The electronic controller operates the solenoid valve used for digital compressor

modulation based on the suction pressure.

2.7.7 Oil separator: Alco Controls OSH

The Alco Controls OSH-407 oil separator is fitted as standard on tandem-compressor Digital

Receiver units. The oil separator has the following characteristics:

▪ Hermetic construction

▪ Complies with UL standard and HP German pressurised vessel regulations (CE standard

effective Nov. 1999)

▪ PED category I

NOTE: The oil separator is not charged with oil. The installer has to charge the system

during the first hours in operation. Please refer to section 4.1 "Charging procedure".

2.8 Electronic controller EC2-552

The EC2-552 electronic condensing unit controller is mounted as standard in all HLR Digital

Receiver units, whether with one or two compressors.

The electronic controller enables:

▪ compressor modulation and/or staging based on suction pressure;

▪ TCP/IP Ethernet connection with web server functionality, to allow monitoring and configuration

of controllers through a standard web browser;

▪ alarm messaging by email;

▪ fan speed control if an Alco Controls FSP150 fan speed controller is installed.

Figure 3: Electronic controller EC2-552

The controller has been pre-programmed with a number of parameter values that are most likely

correct. Individual installation requirements however may make it necessary to alter parameter

settings.

The control target of the compressor controller (1) is to maintain the suction pressure at a defined

value by varying the available compressor capacity.

The control target of the condenser controller (2) is to maintain the condensing pressure at a

defined value. This is done by varying the fan speed, if fan speed control is installed.

2.8.1 Select parameter configuration

The configuration parameters can be protected by a numerical password. A value of "0" disables

this protection (default password: 12).

To select the parameter configuration:

➔ Press the Prg button for more than 5 seconds.

Controller 2: Fan

Value to be displayed:

LED ON: pressure

LED OFF: temperature

Active alarm

Compressor 1: On

Fan: On

Compressor 2: On

IR service LED

Controller 1: Compressor

Page 11

8 C6.1.7/1110-0519/E

In case of password value equal to "0": the first modifiable parameter code is displayed (/1).

➔ To modify parameters see chapter 2.8.2 "Parameter modification" below.

In case of password value NOT equal to "0": a flashing 0 is displayed.

1) Press or until the password value is displayed

2) Press SEL to confirm password

3) The first modifiable parameter code is displayed (/1)

4) To modify parameters see chapter 2.8.2 "Parameter modification" below

/1 Value to show on display

0 = Compressors and fans states (controller 1 = Compressor(s), and controller 2 = Fan(s))

1 = Suction pressure (bar(g))

2 = Saturation temperature from suction pressure (°C)

3 = Condensing pressure (bar(g))

4 = Saturation temperature from condensing pressure (°C)

5 = Digital Scroll compressor capacity (%)

6 = Fan speed (%)

7 = Digital Scroll compressor discharge temperature (°C)

2.8.2 Parameter modification

1) Press or to show the code of the parameter that has to be changed

2) Press SEL to display the selected parameter value

3) Press or to increase or decrease the value

4) Press SEL to temporarily confirm the new value and display its code

Repeat the procedure from step 1) "press or to show..." to modify other parameters.

To exit and confirm parameters with the new values:

➔ Press PRG to confirm the new values and exit the parameter modification procedure

To exit without modifying any parameter:

➔ Do not press any button for at least 60 seconds (TIME OUT)

2.8.3 Main parameters on EC2-552

The EC2-552 parameters must be configured according to unit model.

Parameter

EC2-552

c

Application parameters

Min

Max

Unit

Default

setting

c1

Number of compressors

1 2 -

2

c4

Compressor 1 control mode

0 2 flag

2

c5

Compressor switch logic

0 1 flag

1

c6

Number of compressors to switch in

case of sensor failure

0 2 -

0

Table 4: Main parameters for operation of HLR Digital Receiver units with Digital Scroll compressor

c1 Number of compressors

This default parameter is set to 2 for two-compressor units.

For single-compressor receiver units with Digital Scroll, c1 should be changed to 1.

c4 Compressor 1 control mode

0 = compressor 1 in standard control loop

1 = compressor 1 acts as base load compressor

2 = compressor 1 acts as modulating (PWM control for Digital Scroll compressor only)

NOTE: For a digital unit c4 should only be set to "2".

Page 12

C6.1.7/1110-0519/E 9

Parameter

EC2-552

F

Modulating parameters

Min

Max

Unit

Def

F2

Minimum output value

10

100 % 20

F3

Maximum output value

10

100 % 100

Table 5: Minimum and maximum output values

Minimum and maximum output values can be adjusted. In case of a single-compressor unit with a

Digital Scroll compressor; the maximum output could be set below 100% if the system requests

less than the maximum capacity. In that case F3 > F2.

NOTE: For further information, please refer to Application Guidelines C6.1.3 "Condensing

Unit Controller for Copeland EazyCool™ Outdoor Condensing Units" available on

www.climate.emerson.com/en-gb.

Page 13

10 C6.1.7/1110-0519/E

3 Installation

WARNING

High pressure! Injury to skin and eyes possible! Be careful when opening

connections on a pressurized item.

HLR Digital Receiver units are delivered with a holding charge of neutral gas.

Since these units are used with remote condensers, they should be located in such a place to

prevent any dirt, plastic bag, leaves or papers from covering the condenser and its fins.

A clogged condenser will increase the condensing temperature, thus reducing the cooling capacity,

which could lead to a high-pressure switch tripping. Clean the condenser fins on a regular basis.

3.1 Receiver unit handling

3.1.1 Transport and storage

WARNING

Risk of collapse! Personal injuries! Move units only with appropriate

mechanical or handling equipment according to weight. Keep in the upright

position. Respect stacking loads according to Figure 4. Do not stack

anything on top of the unit packaging. Keep the packaging dry at all times.

Respect the maximum number of identical packages which may be stacked on one

another, where "n" is the limiting number:

▪ Transport: n = 3

▪ Storage: n = 3

Figure 4: Maximum stacking loads for transport and storage

The unit without packaging must be handled by a forklift truck, while always taking into account the

centre of gravity of the unit.

3.1.2 Weights

Single-compressor unit

Tandem-compressor unit

Unit model

Weight [kg]

Unit model

Weight [kg]

Net*

Gross*

Net*

Gross*

HLR13-ZBD30KCE

68.3

88

HLR31-ZBDT60KCE

122.8

149

HLR13-ZBD45KCE

70.3

90

HLR31-ZBDT90KCE

125.8

152

HLR13-ZBD58KCE

95.3

115

HLR31-ZBDT116KCE

171.8

237

HLR13-ZBD76KCE

93.3

113

HLR31-ZBDT152KCE

180.3

315

Table 6: Weights

* Net weight = Receiver unit

Gross weight = Receiver unit and packaging

Page 14

C6.1.7/1110-0519/E 11

3.2 Connection access

3.2.1 Access to refrigeration components

Figure 5: HLR 13-ZBD30KCE, HLR13-ZBD45KCE, HLR 13-ZBD58KCE and HLR13-ZBD76KCE

Figure 6: HLR31-ZBDT60KCE, HLR31-ZBDT90KCE, HLR31-ZBDT116KCE and HLR31-ZBDT152KCE

3.2.2 Access door to electrical box

Use supplied key to open and close the electrical box door.

Figure 7

Discharge line

Liquid line

Suction line

Suction line

Discharge line

Liquid line

Suction line

Page 15

12 C6.1.7/1110-0519/E

3.3 Refrigeration connections

IMPORTANT

Blockage! Compressor breakdown! Maintain a flow of oxygen-free

nitrogen through the system at very low pressure during brazing. Nitrogen

displaces the air and prevents the formation of copper oxides in the system.

If allowed to form, the copper oxide material can later be swept through the

system and block screens such as those protecting capillary tubes, thermal

expansion valves, and accumulator oil return holes.

3.3.1 Brazing recommendations

▪ Remove the fishtails (= compressed tube ends) by cutting them off in the following sequence:

1) remove the discharge connection fishtail;

2) then remove the suction connection fishtail.

Removing the plugs in this sequence prevents oil mist from coating the suction tube, which

would make brazing difficult.

▪ Be sure tube fitting inner diameter and tube outer diameter are clean prior to assembly.

▪ Recommended brazing materials: a copper/phosphorous or copper/phosphorous/silver alloy rod

should be used for joining copper to copper whereas to join dissimilar or ferric metals a silver

alloy rod either flux coated or with a separate flux would be used.

▪ Use a double-tipped torch.

3.3.2 Brazing procedure

Please refer to Figure 8 and procedure below for the brazing of the tubes:

1) Fit the copper tube into the compressor tube.

2) Heat area 1. As the tube approaches brazing temperature:

3) heat area 2 until braze temperature is attained. It is necessary

to heat the tube evenly. Move the torch up and down and

rotating around the tube.

4) Add braze material to the joint while moving the torch around

the joint to flow braze material around the circumference.

5) Then heat area 3. This will draw the brazing material down into

the joint.

NOTE: The time spent heating area 3 should be minimal. As with any brazed joint,

overheating may be detrimental to the final result.

To disconnect:

▪ Heat joint areas 2 and 3 slowly and uniformly until solder softens and tube can be pulled out of

the fitting.

To reconnect:

▪ See procedure above.

Figure 8: Suction tube

brazing areas

Page 16

C6.1.7/1110-0519/E 13

3.4 Electrical connections

3.4.1 Power supply connections

The electrical connection of the HLR Digital Receiver unit to the power supply must be made by

qualified technicians; the electrical diagrams are located inside the electrical connection box.

Figure 9: Electrical connection box

3.4.2 Pre-wired electrical components

Electrical connections should be made with great care to avoid reverse rotation.

Pre-wired electrical

components

Single compressor units

HLR13-ZBD30KCE

HLR13-ZBD45KCE

HLR13-ZBD58KCE

HLR13-ZBD76KCE

Compressor contactor

18 A

18 A

25 A

25 A

Overload protector

6 to 10 A

9 to 14 A

13 to 18 A

17 to 23 A

Fuses 2 2 2 2

Electronic controller

EC2-552

EC2-552

EC2-552

EC2-552

Crankcase heater

1 1 1

1

HP/LP Pressure switch PS2

1 1 1

1

HP Pressure switch PS3

– – –

–

LP Pressure switch PS1

– – –

–

Digital 24V solenoid valve

1 1 1

1

Table 7: Electrical connections – Single compressor units

Pre-wired electrical

components

Tandem-compressor units

HLR13-ZBDT60KCE

HLR13-ZBDT90KCE

HLR31-ZBDT116KCE

HLR31-ZBDT152KCE

Compressor contactor

2 x 25 A

2 x 25 A

2 x 25 A

2 x 25 A

Overload protector

2 x (9 to 14 A)

2 x (9 to 14 A)

2x (13 to 18 A)

2x (17 to 23 A)

Fuses 2 2 2 2

Electronic controller

EC2-552

EC2-552

EC2-552

EC2-552

Crankcase heater

2 2 2

2

HP/LP Pressure switch PS2

– – –

–

HP Pressure switch PS3

2 2 2

2

LP Pressure switch PS1

1 1 1

1

Digital 24V solenoid valve

1 1 1

1

Table 8: Electrical connections – Tandem-compressor units

Contactor K1

Circuit breaker

Auxiliary relay K10

Fuses F1, F2

Transformer T1

Page 17

14 C6.1.7/1110-0519/E

3.4.3 Discharge temperature protection

Under extreme operating conditions internal discharge temperatures can reach very high levels.

The HLR Receiver units are equipped with digital gas temperature control on the compressor top

cap, connected directly to the EC2-552 controller.

3.4.4 Electrical protection standard (protection class)

▪ Compressors: IP21 according to IEC 34.

▪ HP-LP and LP safety pressure switches (Alco PS2 and PS1): IP44 according to EN 60529/IEC

529.

▪ HP safety pressure switch PS3 with cable assy: IP65 according to EN 175301-803/IEC 529.

▪ EC2-552 controller: IP65 (frontal protection with gasket).

3.4.5 HLR Receiver unit electrical data

Unit

Maximum operating

current (MOC)t

Locked rotor current

HLR13-ZBD30KCE-TFD

7.5 Amp

51.5 Amp

HLR13-ZBD45KCE-TFD

11.4 Amp

74 Amp

HLR13-ZBD58KCE-TFD

16.4 Amp

95 Amp

HLR13-ZBD76KCE-TFD

20.4 Amp

118 Amp

HLR31-ZBDT60KCE-TFD

18.2 Amp

2 x 51.5 Amp

HLR31-ZBDT90KCE-TFD

24.5 Amp

2 x 74 Amp

HLR31-ZBDT116KCE-TFD

31.8 Amp

2 x 95 Amp

HLR31-ZBDT152KCE-TFD

40.8 Amp

2 x 118 Amp

Table 9: Electrical data

TFD: 380-420 V / 3 Ph / 50 Hz

Page 18

C6.1.7/1110-0519/E 15

4 Starting up & operation

Before commissioning, ensure that all Rotalock valves and other valves on the unit are fully

opened.

4.1 Charging procedure

4.1.1 Refrigerant charging procedure

It is recommended to charge the unit with refrigerant into the receiver, via the Rotalock service

valve.

Alternatively, it could also be done by charging gas through the suction valve of the compressor.

The charging procedure should follow the rules of art of refrigeration.

Recommendation is to break vacuum in the system with partial charge of refrigerant, then start the

system.

For charge adjustment it is recommended to check the liquid sight glass just before the expansion

valve.

4.1.2 Oil charging procedure

HLR Digital Receiver units are supplied only with a compressor oil charge. After commissioning,

the oil level should be checked and topped up if necessary.

NOTE: The oil level should be approximately halfway up the sight glass.

Emerson recommends charging the unit with one of the following oil types:

▪ Emkarate RL 32 3MAF

▪ Mobil EAL Artic 22 CC

Charging is done through the Schräder valve located on the suction Rotalock valve.

Two-compressor Digital Receiver units equipped with an oil separator are delivered with a small oil

can to add oil, if necessary.

4.2 Rotation direction of scroll compressors

Scroll compressors, like several other types of compressors, will only compress in one rotational

direction. The rotation direction is not an issue with single-phase compressors since they will

always start and run in the proper direction. Three-phase compressors will rotate in either direction

depending upon the power phasing. Since there is a 50-50 chance of connecting power in such a

way as to cause rotation in the reverse direction, it is important to include notices and

instructions in appropriate locations on the equipment to ensure proper rotation direction

when the system is installed and operated.

Observing that suction pressure drops and discharge pressure rises when the compressor is

energized allows verification of proper rotation direction. There is no negative impact on durability

caused by operating three-phase Scroll compressors in the reversed direction for a short period of

time (under one hour) but oil may be lost. After several minutes of operation in reverse, the

compressor's protection system will trip due to high motor temperature. However, if allowed to

repeatedly restart and run in reverse without correcting the situation, the compressor will be

permanently damaged.

All three-phase Scroll compressors are identically wired internally. Therefore, once the correct

phasing is determined for a specific system or installation, connecting properly phased power leads

to the identified compressor terminals in the electrical panel will ensure proper rotation direction.

4.3 Maximum compressor cycle

Maximum permitted starts per hour: 10.

It can be controlled via the EC2-552 controller (parameter t3, t4 and/or t5).

Page 19

16 C6.1.7/1110-0519/E

4.4 Checks before starting up and during operation

▪ Please check that all Rotalock valves are fully opened.

▪ Check that the electrical panel is closed.

▪ After starting up and operation conditions are stabilised, Emerson recommends to check the oil

level in compressor(s) and if needed to add oil to ensure a sufficient oil level (halfway up the

sight glass).

5 Maintenance & repair

▪ De-energize the unit before any intervention.

▪ Close the Rotalock valves to isolate the compressor from the system and unscrew the flare

Rotalock connector from the compressor.

▪ Release the compressor mounting parts then lift the compressor to replace it with a new one.

For more detailed instructions, please refer to the compressor application guidelines.

6 Certification & approval

▪ Copeland Scroll Digital™ Receiver Units HLR comply with the Low Voltage Directive

LVD 2014/35/EU. The applied harmonised standard is EN 60335 (Household and similar

electrical appliances – Safety, Part 1: General Requirements and Part 2-89: Particular

requirements for commercial refrigerating appliances with an incorporated or remote refrigerant

condensing unit or compressor).

▪ The units and their piping comply with the Pressure Equipment Directive PED 2014/68/EU

(Art.3 §3 - Sound Engineering Practice).

▪ The units and their components as far as required are CE marked and thereby establish

conformity with the relevant directives.

▪ Conformity Declarations for components are available as far as required.

▪ The Manufacturer's Declaration of Incorporation has to be respected when incorporating these

products into a machine.

7 Dismantling & disposal

Removing oil and refrigerant:

▪ Do not disperse in the environment.

▪ Use the correct equipment and method of removal.

▪ Dispose of oil and refrigerant in compliance with national legislation

and regulations.

Dispose of compressor and/or unit in compliance with national legislation

and regulations.

DISCLAIMER

1. The contents of this publication are presented for informational purposes only and are not to be

construed as warranties or guarantees, express or implied, regarding the products or services

described herein or their use or applicability.

2. Emerson Climate Technologies GmbH and/or its affiliates (collectively "Emerson"), as

applicable, reserve the right to modify the design or specifications of such products at any time

without notice.

3. Emerson does not assume responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use and maintenance of any Emerson product remains

solely with the purchaser or end user.

4. Emerson does not assume responsibility for possible typographic errors contained in this

publication.

Page 20

BENELUX

Josephinastraat 19

NL-6462 EL Kerkrade

Tel: +31 45 535 06 73

Fax: +31 45 535 06 71

benelux.sales@emerson.com

UK & IRELAND

Unit 17, Theale Lakes Business Park

Reading, Berkshire RG7 4GB

Tel: +44 1189 83 80 00

Fax: +44 1189 83 80 01

uk.sales@emerson.com

GERMANY, AUSTRIA & SWITZERLAND

Theo-Mack-Str. 3

DE-63477 Maintal

Tel: +49 6109 605 90

Fax: +49 6109 60 59 40

ECTGermany.sales@emerson.com

FRANCE, GREECE & MAGHREB

8, Allée du Moulin Berger

FR-69134 Ecully Cédex, Technoparc - CS 90220

Tel: +33 4 78 66 85 70

Fax: +33 4 78 66 85 71

mediterranean.sales@emerson.com

ITALY

Via Ramazzotti, 26

IT-21047 Saronno (VA)

Tel: +39 02 96 17 81

Fax: +39 02 96 17 88 88

italy.sales@emerson.com

SPAIN & PORTUGAL

C/ Pujades, 51-55 Box 53

ES-08005 Barcelona

Tel: +34 93 412 37 52

iberica.sales@emerson.com

CZECH REPUBLIC

Hajkova 22

CZ - 133 00 Prague

Tel: +420 733 161 651

Fax: +420 271 035 655

Pavel.Sudek@emerson.com

SWEDEN, DENMARK, NORWAY & FINLAND

Pascalstr. 65

DE-52076 Aachen

Tel: +49 2408 929 0

Fax: +49 2408 929 525

nordic.sales@emerson.com

EASTERN EUROPE & TURKEY

Pascalstr. 65

DE-52076 Aachen

Tel: +49 2408 929 0

Fax: +49 2408 929 525

easterneurope.sales@emerson.com

POLAND

Szturmowa 2

PL-02678 Warsaw

Tel. +48 22 458 92 05

Fax +48 22 458 92 55

poland.sales@emerson.com

RUSSIA & CIS

Dubininskaya 53, bld. 5

RU-115054, Moscow

Tel: +7 - 495 - 995 95 59

Fax: +7 - 495 - 424 88 50

ECT.Holod@emerson.com

BALKAN

Selska cesta 93

HR-10 000 Zagreb

Tel: +385 1 560 38 75

Fax: +385 1 560 38 79

ROMANIA & BULGARIA

Parcul Industrial Tetarom 2

Emerson Nr. 4 400641 Cluj-Napoca

Tel: +40 374 13 23 50

Fax: +40 374 13 28 11

ro-bg.sales@emerson.com

MIDDLE EAST & AFRICA

PO Box 26382

Jebel Ali Free Zone - South, Dubai - UAE

Tel: +971 4 811 81 00

Fax: +971 4 886 54 65

mea.sales@emerson.com

ASIA PACIFIC

Suite 2503-8, 25/F., Exchange Tower

33 Wang Chiu Road, Kowloon Bay

Kowloon , Hong Kong

Tel: +852 2866 3108

Fax: +852 2520 6227

For more details, see www.climate.emerson.com/en-gb

Connect with us: facebook.com/EmersonCommercialResidentialSolutions

C6.1.7/1110-0519/E

Emerson Commercial & Residential Solutions

Emerson Climate Technologies GmbH - Pascalstrasse 65 - 52076 Aachen, Germany

Tel. +49 (0) 2408 929 0 - Fax: +49 (0) 2408 929 570 - Internet: www.climate.emerson.com/en-gb

The Emerson logo is a trademark and service mark of Emerson Electric Co. Emerson Climate Technologies Inc. is a subsidiary of Emerson Electric Co.

Copeland is a registered trademark and Copeland Scroll is a trademark of Emerson Climate Technologies Inc.. All other trademarks are property of their respective owners.

Emerson Climate Technologies GmbH shall not be liable for errors in the stated capacities, dimensions, etc., as well as typographic errors. Products, specications, designs and

technical data contained in this document are subject to modication by us without prior notice. Illustrations are not binding.

© 2019 Emerson Climate Technologies, Inc.

Loading...

Loading...