Page 1

AE4-1322

™

Copeland ScrewCopeland Screw

Copeland Screw

Copeland ScrewCopeland Screw

™

CompressorsCompressors

Compressors

CompressorsCompressors

April 2002

Semi-Hermetic Compact Semi-Hermetic Compact

Semi-Hermetic Compact

Semi-Hermetic Compact Semi-Hermetic Compact

SCH2 & SCA2SCH2 & SCA2

SCH2 & SCA2

SCH2 & SCA2SCH2 & SCA2

High Temp Compressors

35 – 140 Horsepower

1 General1 General

1 General

1 General1 General

2 Design and functions2 Design and functions

2 Design and functions

2 Design and functions2 Design and functions

2.1 Design features

2.2 Compression process Vi control

2.3 Capacity control and start unloading

2.4 Hydraulic control

2.5 Starting the compressor

2.6 Infinite capacity control

Oil circulation

Contents

5 Economizer operation5 Economizer operation

5 Economizer operation

5 Economizer operation5 Economizer operation

Application ManualApplication Manual

Application Manual

Application ManualApplication Manual

5.1 General

5.2 Operation principal

5.3 ECO operation with subcooling circuit

5.4 ECO operation with intermediate

pressure receiver

5.5 Layout and selection

recommendations

5.6 Additional components

5.7 Control

3 Lubricants3 Lubricants

3 Lubricants

3 Lubricants3 Lubricants

4 Integration into the refrigeration circuit4 Integration into the refrigeration circuit

4 Integration into the refrigeration circuit

4 Integration into the refrigeration circuit4 Integration into the refrigeration circuit

1.1 Mounting the compressor

1.2 System layout

1.3 Guide lines for special system

variations

1.4 Additional cooling by liquid injection

1.5 Additional cooling by external oil

cooler

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

6 Electrical connections6 Electrical connections

6 Electrical connections

6 Electrical connections6 Electrical connections

6.1 Motor design

6.2 Selection of electrical components

6.3 Compressor protection system

6.4 Schematic wiring diagrams

Page 2

Semi-hermetic compact screwsSemi-hermetic compact screws

Semi-hermetic compact screws

Semi-hermetic compact screwsSemi-hermetic compact screws

SCH2/SCA2 seriesSCH2/SCA2 series

SCH2/SCA2 series

SCH2/SCA2 seriesSCH2/SCA2 series

35 to 140 HP Nominal motor power35 to 140 HP Nominal motor power

35 to 140 HP Nominal motor power

35 to 140 HP Nominal motor power35 to 140 HP Nominal motor power

11

GeneralGeneral

1.

General

11

GeneralGeneral

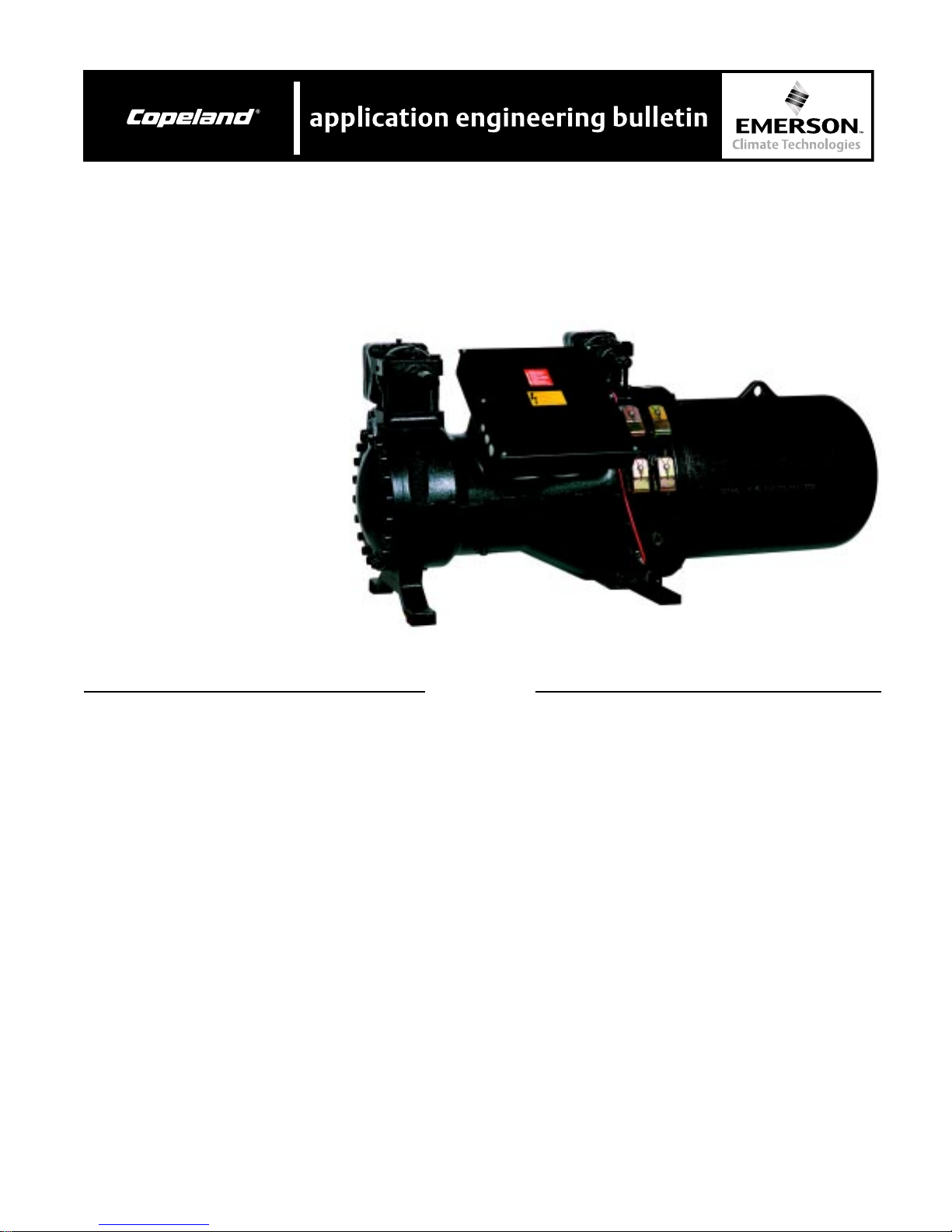

This new series represents the result of further development to provide a simplified and favorably priced screw

compressor for use in factory made systems.

Contrary to the semi-hermetic and open type, SHM/

SHL and SDM/SDL compressor models for commercial

and industrial installation, the compact screws are

designed with an integral oil separator. The effort

involved in installation is therefore comparable with that

for semi-hermetic reciprocating compressors.

In addition to this, the electrical control and the monitoring of the oil circuit has been simplified. The proven

basic construction and the ease of service have been

retained.

The most modern screw compressor technology is now

available in the middle capacity range for compact liquid

chillers and air conditioning equipment.

2. Design and function2. Design and function

2. Design and function

2. Design and function2. Design and function

2.1 Design features

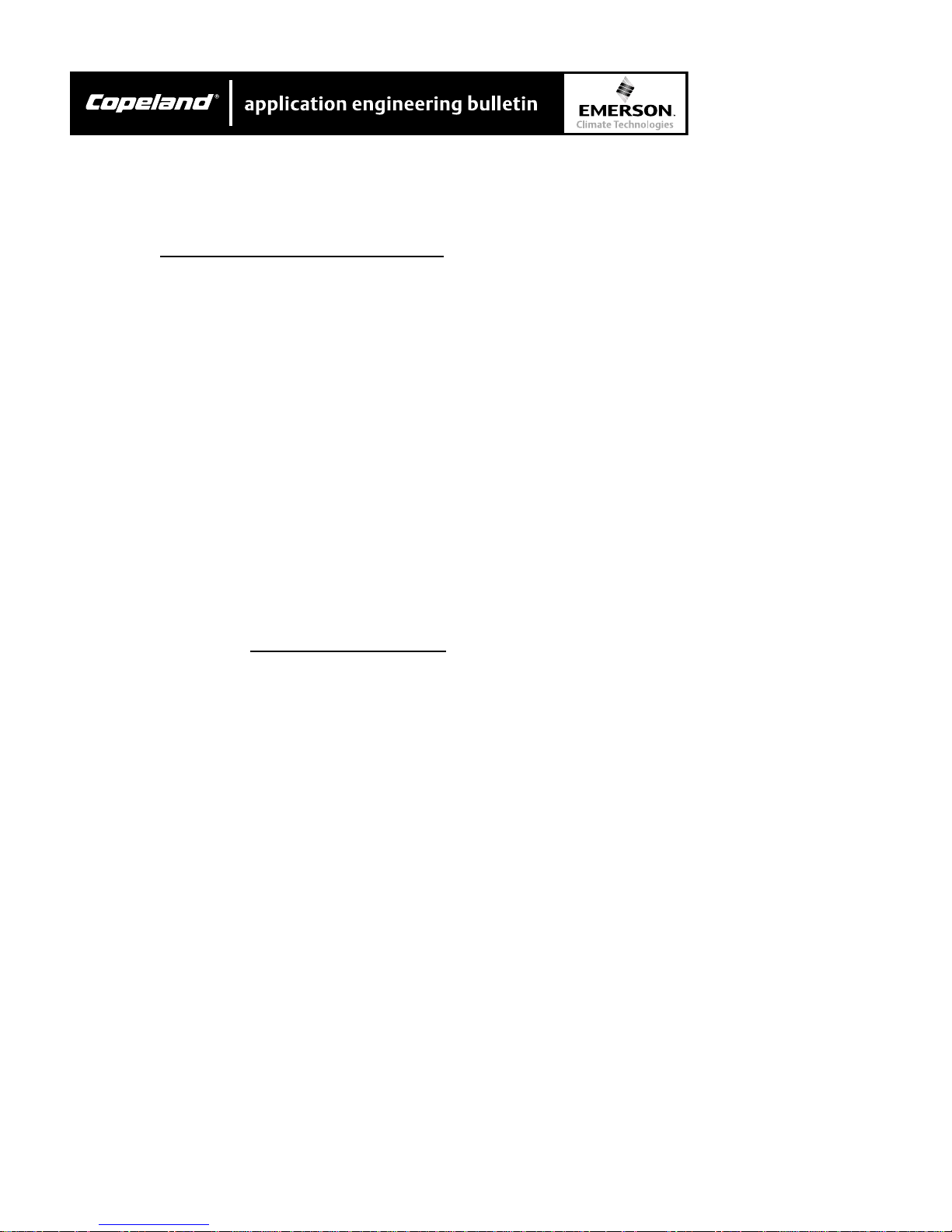

Copeland Compact screws are of the twin rotor design

with a newly-developed profile geometry (lobe ratio 5:6).

The main parts of these compressors are the two rotors

(male and female rotor), which are fitted into a closed

housing. The rotors are precisely located at both ends

in rolling contact bearings (radial and axial), which, in

conjunction with the generously sized oil supply

chambers, provides optimum emergency running

characteristics.

Owing to the specific design, this type of compressor

does not require any working valves. To protect against

reverse running when the compressor is switched off

(expansion operation) a check valve is incorporated in

the discharge chamber (this valve does not, however,

replace any check valves required by the system

design). An internal pressure relief valve is utilized for

over-pressure protection.

The compressor is driven by a three-phase asynchronous motor, which is built into the compressor housing.

The motor rotor is located on the shaft of the male

screw rotor. Cooling is achieved by cold refrigerant

AE4-1322

vapor, which mainly flows through bores in the motor

rotor.

The main technical features:

Balanced product rangeBalanced product range

Balanced product range

Balanced product rangeBalanced product range

• •

• 8 basic models

• •

• •

• Tight performance graduation

• •

Minimal space requirements and convenientMinimal space requirements and convenient

Minimal space requirements and convenient

Minimal space requirements and convenientMinimal space requirements and convenient

piping designpiping design

piping design

piping designpiping design

• Shortest installed length in its performance category

- shut-off valves / connections within compressor

dimensions

• Suction and discharge gas connections can be

rotated in 90° increments

• Terminal box accessible from top, wire access from

underneath

Universal applicationsUniversal applications

Universal applications

Universal applicationsUniversal applications

••

• R134a, R407C and R22

••

••

• R404A, R507A upon request

••

••

• With or without economizer

••

••

• Optimized R-134a version (SCA2)

••

New high-efficiency profileNew high-efficiency profile

New high-efficiency profile

New high-efficiency profileNew high-efficiency profile

• Further developed geometry

• High rigidity

• Patented manufacturing process for highest

precision

• High tip speed to minimize blow-by

Double-walled, pressure-compensated rotorDouble-walled, pressure-compensated rotor

Double-walled, pressure-compensated rotor

Double-walled, pressure-compensated rotorDouble-walled, pressure-compensated rotor

housinghousing

housing

housinghousing

••

• Extremely stable, therefore no expansion even at

••

high pressure levels

••

• Additional sound attenuation

••

Proven, long-life bearings with pressure unloadingProven, long-life bearings with pressure unloading

Proven, long-life bearings with pressure unloading

Proven, long-life bearings with pressure unloadingProven, long-life bearings with pressure unloading

• Robust axial bearings in tandem configuration

• Bearing chamber pressure isolated by seal rings

• Pressure unloading of axial bearings

Optimized oil managementOptimized oil management

Optimized oil management

Optimized oil managementOptimized oil management

• Three-stage oil separator

• Long-life oil filter 10 µ mesh size

• Pressure relieved bearing chamber ensuring minimum refrigerant dilution in the oil and thus higher

viscosity

Large volume motor for part winding or direct startLarge volume motor for part winding or direct start

Large volume motor for part winding or direct start

Large volume motor for part winding or direct startLarge volume motor for part winding or direct start

- optional star delta design- optional star delta design

- optional star delta design

- optional star delta design- optional star delta design

• Especially high efficiency

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

2

Page 3

• Integrated PTC sensors in each winding coil

• Slot keys for maximum operating safety

• Stator is slide fit (field replaceable)

Intelligent electronicsIntelligent electronics

Intelligent electronics

Intelligent electronicsIntelligent electronics

• Thermal motor temperature control by winding PTCs

• Phase sequence control for direction of rotation

• Manual reset lock-out

• Oil temperature protection by PTC sensor

Flexible with additional coolingFlexible with additional cooling

Flexible with additional cooling

Flexible with additional coolingFlexible with additional cooling

• Direct liquid injection

• External oil cooler for extended application and

highest efficiency

Dual capacity controlDual capacity control

Dual capacity control

Dual capacity controlDual capacity control

• Infinite or 4-step slide control with V

compensation.

i

Alternative operation modes by varying the control

sequence only - no need for compressor modification

• Simple control by solenoid coils

• Automatic start unloading

Economizer with sliding suction positionEconomizer with sliding suction position

Economizer with sliding suction position

Economizer with sliding suction positionEconomizer with sliding suction position

• Unique for compact screws

• Efficient economizer operation with part load as well

• Highest cooling capacity and energy efficiency at full

and part load conditions

Fully equippedFully equipped

Fully equipped

Fully equippedFully equipped

• Capacity control / start unloading

• Suction and Discharge shut-off valve

• Check valve in discharge gas outlet

• Oil sight glass

• Insertion type oil heater with sleeve

• Oil fill / drain service valve

• Suction gas filter with large surface are and fine mesh

• Electronic protection system

Proven optional accessoriesProven optional accessories

Proven optional accessories

Proven optional accessoriesProven optional accessories

• Oil level switch

• Shut-off valve / adapter for economizer operation and

liquid injection

• Adapter for external oil cooler

2.2 Compression process V2.2 Compression process V

2.2 Compression process V

2.2 Compression process V2.2 Compression process V

-control-control

-control

-control-control

ii

i

ii

With screw compressors, suction, compression and

discharge occur in one flow direction. With this process

the suction gas is pressed into the profile hollows by the

profile peaks. The volume is steadily reduced and it is

thereby compressed. The compressed gas is then

discharged through a discharge port whose size and

geometry determine the so called “internal volume ratio

AE4-1322

(Vi)”. This value must have a defined relationship to the

mass flow and the working pressure ratio, to avoid

losses in efficiency due to over- and under-compression.

The internal discharge ports of the SCH2/SCA2 screw

compressors are designed for a very wide application

range.

In view of high efficiency and operational safety a part of

the discharge channel is integrated into the control

slide, which enables a Vi control at part load conditions.

Due to this the internal volume ratio (Vi) virtually remains constant down to approximately 70% part load.

The economizer channel built into the control slide is

another outstanding feature (figure 3). It enables a fully

functional operation of the subcooler circuit independently from the compressor’s load conditions. This is a

design solution which is unique for screw compressors

of this size. This ensures highest possible capacity and

efficiency at both full and part load conditions. For

details regarding economizer operation see Section 5.

2.3 Capacity control and start unloading2.3 Capacity control and start unloading

2.3 Capacity control and start unloading

2.3 Capacity control and start unloading2.3 Capacity control and start unloading

SCH2/SCA2 models are provided as a standard with a

“Dual Capacity Control” (slide system). This allows for

infinite infinite

infinite or

infinite infinite

4-step capacity control4-step capacity control

4-step capacity control without compressor

4-step capacity control4-step capacity control

modifications. The different operating modes can be

achieved by changing the control sequences of the

solenoid valves.

The special geometry of the slide means that the

volume ratio Vi is adjusted to the operating conditions in

part-load operation. This provides particularly high

efficiency.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

3

Page 4

AE4-1322

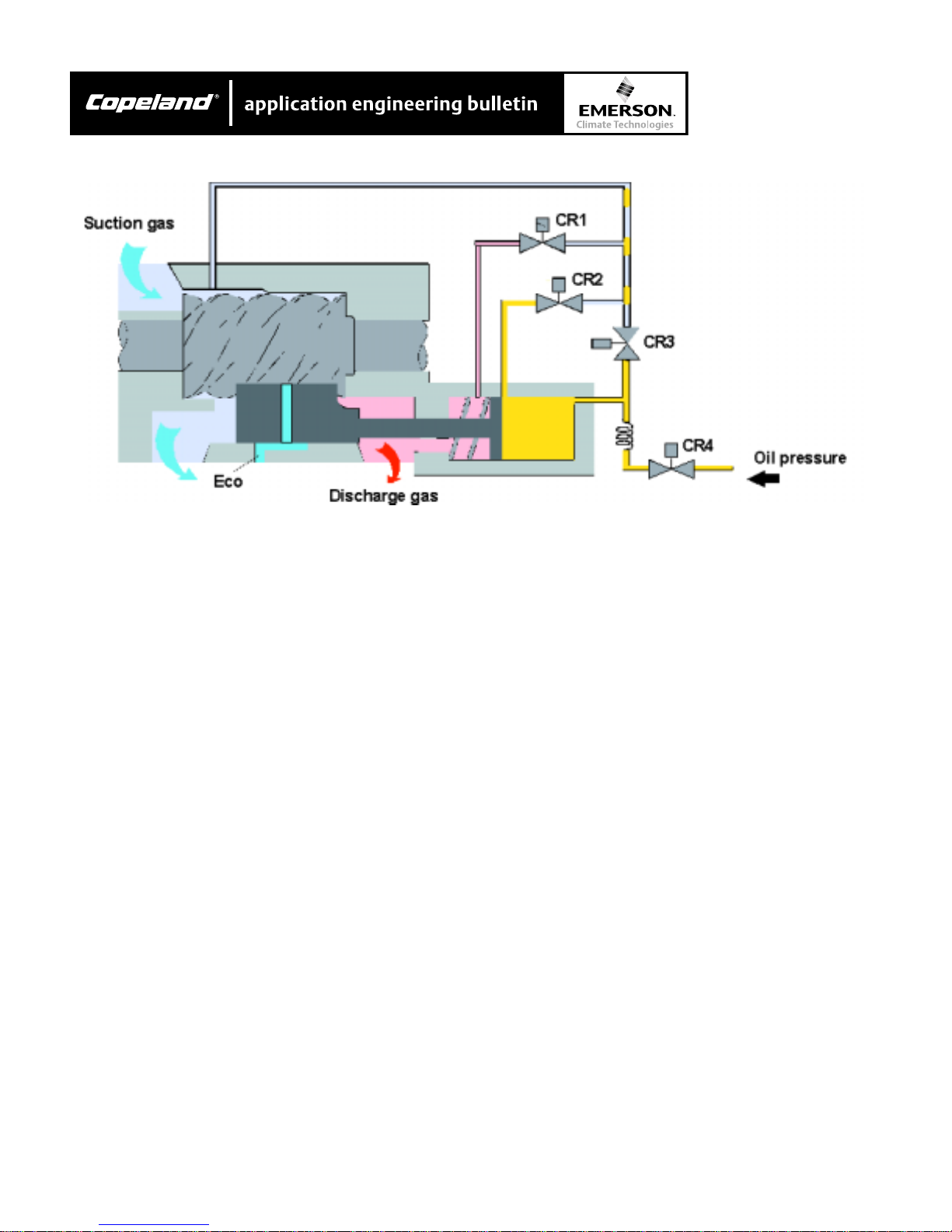

Oil Hydraulic Scheme

Another feature of this system is the automatic startunloading. It reduces starting torque and acceleration

times considerably. This not only puts lower stresses

on motor and mechanical parts but also reduces the

load on the power supply network.

Significant design features are the robust dimensioning

as well as the precise guidance of the slide elements

and the control piston. Capacity control is achieved by

means of solenoid valves that are flanged on to the

compressor. A “dual set point controller” or any similar

component is suitable as a control module.

2.4 Hydraulic control2.4 Hydraulic control

2.4 Hydraulic control

2.4 Hydraulic control2.4 Hydraulic control

Figure 3 shows the design principle of the hydraulic

scheme. By moving the slide the suction gas flow is

controlled.

If the slide is moved totally to the suction slide (in the

figure 3 to the left), the working space between the

profiles is filled with suction gas. The more the slide is

moved to the discharge slide, the smaller the resulting

profile volume becomes. Less refrigerant is taken in.

The mass flow is lower, and the cooling capacity

decreases.

Figure 3

chamber increases. The slide is moved to the suction

side. The cooling capacity increases.

If the valve CR1, CR2 or CR3 is opened, the pressure

on the hydraulic piston decreases. By means of the

discharge gas the slide is pressed to the discharge

side. The cooling capacity is reduced.

2.5 Starting the compressor2.5 Starting the compressor

2.5 Starting the compressor

2.5 Starting the compressor2.5 Starting the compressor

During the shut - down of the compressor the solenoid

valve CR3 is open. The pressure in the hydraulic

cylinder is then released. The spring (fig. 3) pushes the

slide to the discharge side end position.

When starting the compressor, it is unloaded. Valve

CR4 is energized on demand thus moving the slide

towards the suction side. The refrigerating capacity

increases to the set load condition by energizing the

valves CR1, CR2 or CR3.

2.6 Infinite capacity control2.6 Infinite capacity control

2.6 Infinite capacity control

2.6 Infinite capacity control2.6 Infinite capacity control

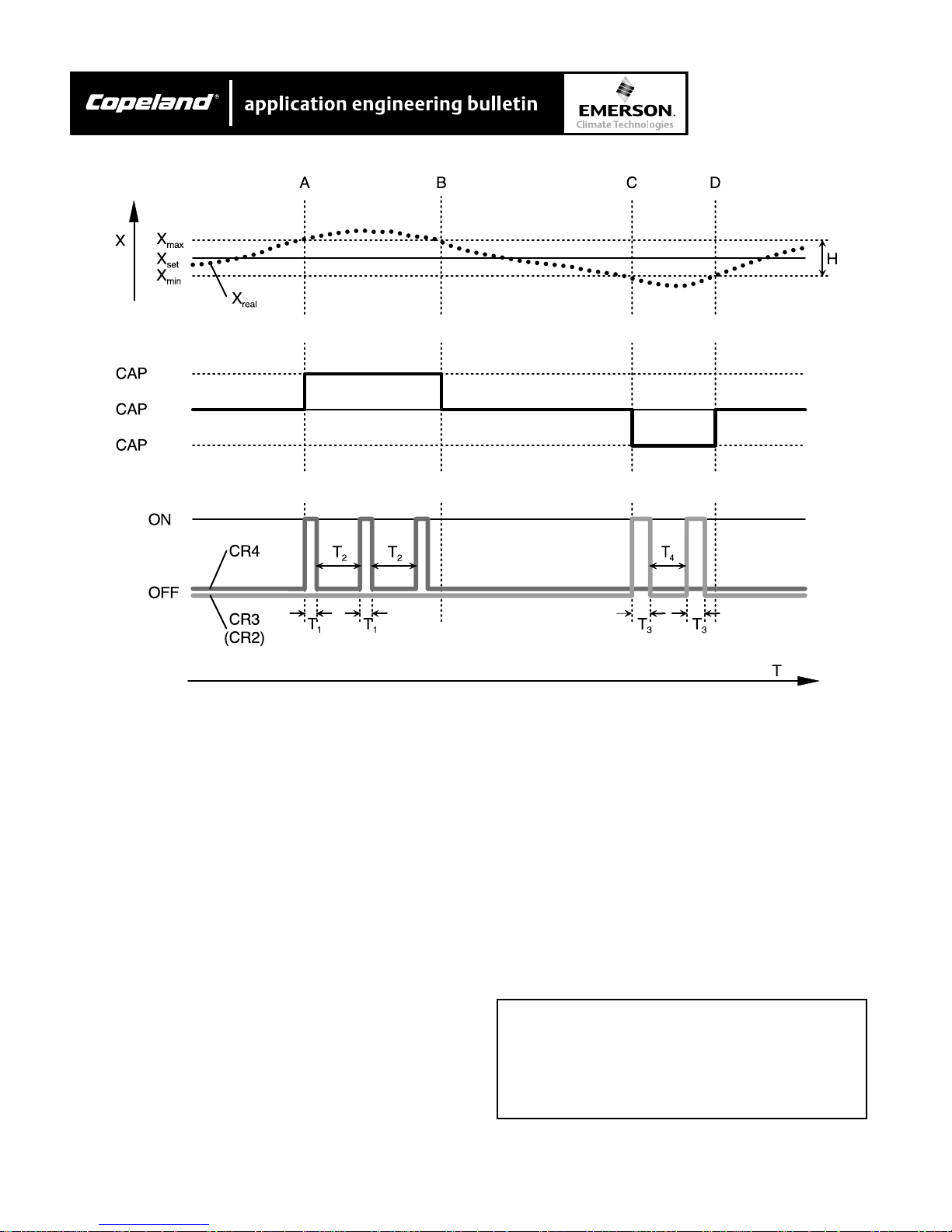

Infinite capacity control is recommended for systems

where high control accuracy is required. For control

principle see charts A, B, and C.

The slide is controlled by a hydraulic piston. If the valve

CR4 is opened, the oil pressure in the pressure

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

If the actual value is within the set control range H, the

cooling demand of the plant remains unchanged. Then

4

Page 5

AE4-1322

there is no need to move the slide. No solenoid valve

is energized.

The control input can be the air or water temperature at

the evaporator or the suction pressure.

Chart A

Control Sequence – Infinite Capacity ControlControl Sequence – Infinite Capacity Control

Control Sequence – Infinite Capacity Control

Control Sequence – Infinite Capacity ControlControl Sequence – Infinite Capacity Control

Minimum CapacityMinimum Capacity

Minimum Capacity

Minimum CapacityMinimum Capacity

mm

m

mm

CR 1 2 3 4

Start/Stop mmlm

⇑⇑

Cap

⇑ mmml

⇑⇑

⇓⇓

Cap

⇓ mmlm

⇓⇓

⇔⇔

Cap

⇔ mmmm

⇔⇔

Cap. 100% mmml

Cap. Min.W mmlm

Chart B

Control Sequence – Infinite Capacity ControlControl Sequence – Infinite Capacity Control

Control Sequence – Infinite Capacity Control

Control Sequence – Infinite Capacity ControlControl Sequence – Infinite Capacity Control

Minimum Capacity 50%Minimum Capacity 50%

Minimum Capacity 50%

Minimum Capacity 50%Minimum Capacity 50%

Cap

4 Cap.

⇑⇑

⇑

⇑⇑

mm

m

mm

mm

m

mm

mm

m

mm

ll

l

ll

ll

l

ll

mm

m

mm

mm

m

mm

Min.50%

Increased cooling demandIncreased cooling demand

Increased cooling demand

Increased cooling demandIncreased cooling demand

If the actual value exceeds the upper set point, the

cooling demand has increased (operating point A in fig.

4). The solenoid valve CR4 is opened for short intervals

till the actual value is within the set control range again

(operating point B). Now the compressor operates with

increased cooling capacity.

Chart C

Control Sequence – 4-Step Capacity ControlControl Sequence – 4-Step Capacity Control

Control Sequence – 4-Step Capacity Control

Control Sequence – 4-Step Capacity ControlControl Sequence – 4-Step Capacity Control

Decreased cooling demandDecreased cooling demand

Decreased cooling demand

Decreased cooling demandDecreased cooling demand

A decreased cooling demand falls below the lower set

point (operating point C). The solenoid valve CR3 now

opens for short intervals till the actual value is within

the set control range again (operating point D). The

compressor operates with decreased cooling capacity.

With the solenoid valves CR3 / CR4, capacity can be

controlled between 100% and nominally 25%. Alternatively valves CR2 / CR4 can be energized; in this case

control will be limited between 100% and nominally

50%.

The limitation to a minimum of approximately 50%

cooling capacity is recommended for the following

application conditions (control with valves CR2 / CR4):

• In case of operation at high-compression ratios /

condensing temperatures, the main concern is high

discharge temperature.

• For systems with multiple compressors either used

in split or singlecircuits. Under these conditions

capacity control between 100 and 50%, in combination with individual compressor on/off cycling,

guarantees highest possible efficiency – without

significant restrictions in the application range. Due

to the usually lowered condensing temperature at

part load conditions, the lead compressor can even

be operated very effectively down to nominal 25% of

cooling capacity (with valves CR3 / CR4)

2.7 4-step capacity control2.7 4-step capacity control

2.7 4-step capacity control

2.7 4-step capacity control2.7 4-step capacity control

This type of capacity control is particularly suited to

systems with high inertia – in connection with indirect

cooling, for example. Liquid chillers are typical applications. Chart C shows the control of the solenoid valves

or the individual capacity steps.

CR 1 2 3 4

Start/Stop mmlm

Cap 25% mmly

Cap 50% mlmy

Cap 75% lmmy

Cap. 100% mmmm

Solenoid Coil De-Energized Solenoid Coil De-Energized

m

Solenoid Coil De-Energized

Solenoid Coil De-Energized Solenoid Coil De-Energized

Solenoid Coil EnergizedSolenoid Coil Energized

l

Solenoid Coil Energized

Solenoid Coil EnergizedSolenoid Coil Energized

Solenoid Coil Pulsing (10 secs. on / 10 secs. off) Solenoid Coil Pulsing (10 secs. on / 10 secs. off)

y

Solenoid Coil Pulsing (10 secs. on / 10 secs. off)

Solenoid Coil Pulsing (10 secs. on / 10 secs. off) Solenoid Coil Pulsing (10 secs. on / 10 secs. off)

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

The cycle time of the intermitting valve, CR4, should be

adjusted to about 10 seconds before commissioning.

Even shorter intervals may be necessary, particularly

with systems with high pressure differences. Therefore,

in this case adjustable time relays should be used.

For this type of operation a restriction of minimum

refrigeration capacity to approximately 50% is also

recommended, as with the systems described in

Section 2.6. Control is then effected with the CR4 valve

(intermittent) and with CR1 (75%) and CR2 (50%).

5

Page 6

AE4-1322

2.8 Oil circulation2.8 Oil circulation

2.8 Oil circulation

2.8 Oil circulation2.8 Oil circulation

The lubrication circuit is designed as is typical for

screw compressors. This type of design, however, has

a vessel directly flanged-on to the compressor housing

at the high-pressure side. It contains the oil reservoir.

The vessel simultaneously serves as an oil separator.

The oil circulation results from the pressure difference

to the oil injection point, where the pressure level is

slightly above suction pressure. The oil flows through a

generously sized filter element to the throttle point and

subsequently to the bearing chambers and the profile

spaces of the rotors. The oil is then transported

together with the refrigerant vapor in the direction of

compression. In addition to lubrication it also provides

a dynamic seal between the rotors and between the

housing and the rotors. The oil then flows together with

the compressed vapor into the reservoir vessel. Here oil

and vapor are separated in a highly efficient process.

The oil collects in the lower part of the separator vessel

Figure 4

Infinite capcity control scheme

and flows back into the compressor either direct or via

an external oil cooler. Depending on the operating

conditions the circulating oil must be cooled with liquid

injection or an external oil cooler (see Section 4.4 and

4.5)

Monitor the oil circuitMonitor the oil circuit

Monitor the oil circuit

Monitor the oil circuitMonitor the oil circuit

• For short circuits

additional cooling and for small system volumes

and refrigerant charges: indirect monitoring by

means of oil temperature protection (standard)

without without

without refrigerant injection for

without without

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

Lack of oil leads to a dramaticLack of oil leads to a dramatic

Lack of oil leads to a dramatic

Lack of oil leads to a dramaticLack of oil leads to a dramatic

temperature increase.temperature increase.

temperature increase.

temperature increase.temperature increase.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

6

Page 7

AE4-1322

• For circuits

cooling and / or for greater system volumes:

Direct monitoring by means of an oil level monitor in

the oil separator(optional accessory) is recommended.

3 Lubricants3 Lubricants

3 Lubricants

3 Lubricants3 Lubricants

Apart from the lubrication it is also the task of the oil to

provide dynamic sealing of the rotors. Special demands

result from this with regard to viscosity, solubility and

foaming characteristics. Copeland approved oils may

therefore be used only.

Important instructionsImportant instructions

Important instructions

Important instructionsImportant instructions

• Observe the application limits of the compressors.

• The lower limit value of the discharge gas temperature (140°F) is a reference value only. It must be

ensured by sufficient suction super-heat that the

discharge gas temperature is at least 54°F (R134a,

R404A / R507A mi. 36°F) above the condensing

temperature.

• Ester oils Solest170 (for HFC refrigerants) and

CP4214-320 (for R22) are very hygroscopic. Special

care is therefore required when dehydrating the

system and when handling open oil containers.

withwith

with refrigerant injection for additional

withwith

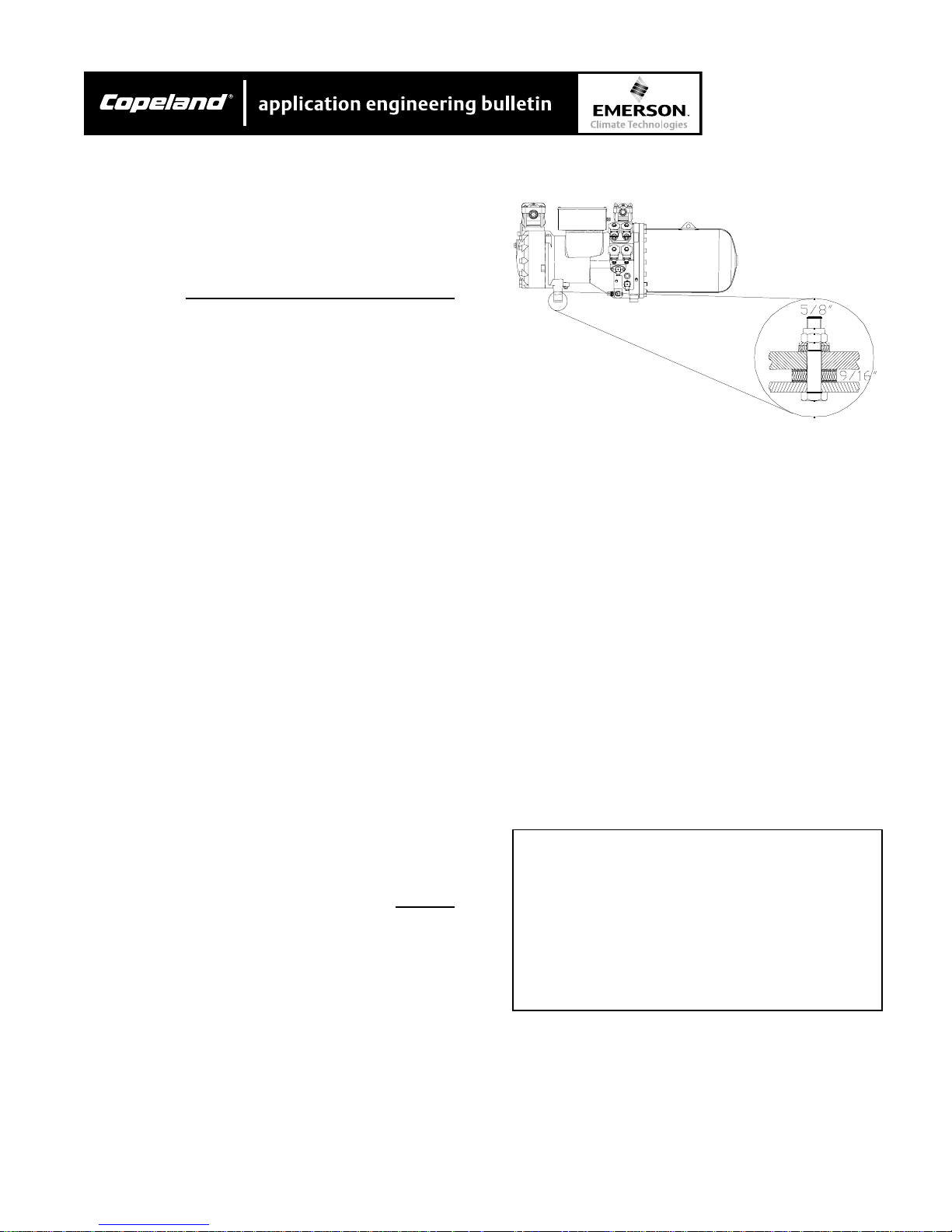

Figure 5

Mounting and installation

4.1 Mounting the compresso4.1 Mounting the compresso

4.1 Mounting the compressor

4.1 Mounting the compresso4.1 Mounting the compresso

With stationary systems the compressor has to be

installed horizontally.

In case of marine application, mounting in direction of

the longitudinal axis of the boat may be required.

Detailed layout recommendation can be provided upon

request.

Anti-vibration mountingsAnti-vibration mountings

Anti-vibration mountings

Anti-vibration mountingsAnti-vibration mountings

• A corrected design may be necessary for directexpansion evaporators with finned tubes on the

refrigerant side (consultation with manufacturer).

The above information corresponds to the present

status of our knowledge and is intended as a guide for

general applications. This information does not have

the purpose of confirming certain oil characteristics or

their suitability for a particular case.

4 Integration into the refrigeration circuit4 Integration into the refrigeration circuit

4 Integration into the refrigeration circuit

4 Integration into the refrigeration circuit4 Integration into the refrigeration circuit

Compact screw compressors are well suited for

integration in factory-assembled plants (liquid chillers

and air conditioning units). Their use in extended

systems is also possible, for example, with remotely

installed condenser.

Systems with multiple compressors should preferably

be designed with individual circuits. Parallel compound

is possible, but requires a special oil equalizing

system by means of oil level control.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

Rigid mounting of the compressor is possible. The use

of anti-vibration mountings especially matched to the

compressors is recommended, however, to reduce the

transmission of body radiated noise.

With direct mounting on water cooled condensers:

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

Do not mount the compressor directlyDo not mount the compressor directly

Do not mount the compressor directly

Do not mount the compressor directlyDo not mount the compressor directly

on the condenseron the condenser

on the condenser

on the condenseron the condenser

condenser structural mmember! condenser structural mmember!

condenser structural mmember!

condenser structural mmember! condenser structural mmember!

Damage of the condenser is possibleDamage of the condenser is possible

Damage of the condenser is possible

Damage of the condenser is possibleDamage of the condenser is possible

(fatigue fractures). Use anti-vibration (fatigue fractures). Use anti-vibration

(fatigue fractures). Use anti-vibration

(fatigue fractures). Use anti-vibration (fatigue fractures). Use anti-vibration

mountings!mountings!

mountings!

mountings!mountings!

The installation of the anti-vibration mountings is shown

in figure 5. The bolts should only be tightened until

slight deformation of the upper rubber disc is just

visible.

7

. Do not use the. Do not use the

. Do not use the

. Do not use the. Do not use the

Page 8

4.2 System layout4.2 System layout

4.2 System layout

4.2 System layout4.2 System layout

Oil heaterOil heater

Oil heater

Oil heaterOil heater

AE4-1322

The compressor is installed in the refrigerating circuit

similar to semi-hermetic reciprocating compressors.

Plant design and pipe layoutPlant design and pipe layout

Plant design and pipe layout

Plant design and pipe layoutPlant design and pipe layout

The pipelines and the system layout must be arranged

so that the compressor cannot be flooded with oil or

liquid refrigerant during shutdown.

Suitable measures are (also as a simple protection

against liquid slugging during start)

• either to raise the suction line after the evaporator

(goose neck)

• or to install the compressor above the evaporator.

Additional safety is provided by a solenoid valve

installed directly before the expansion valve. In addition

the discharge line should first be angled downwards

after the shut-off valve.

Due to the low level of vibration and discharge gas

pulsation the suction and discharge lines can be made

without the use of flexible elements or mufflers.

However, pipelines must be sufficiently flexible and

supported to not exert any strain on the compressor.

The most favorable pipe runs are designed parallel to

the compressor axis and the discharge line first

leading downwards. The distance to the axis should be

as short as possible and the parallel pipe section

should be at least half the compressor’s length.

Finally, long radius elbows should be used.

Due to gas pulsations there can be vibrations especially in discharge and economizer lines. Therefore

critical pipe lengths (+/- 15%) with their natural frequencies being in resonance with the compressor

pulsations must be avoided.

An oil heater is provided to prevent too high a concentration of refrigerant in the oil during shutdown. It is

mounted in a heater sleeve and can be replaced if

necessary without accessing the refrigerating circuit.

For electrical connection see section 6.4.

Figure 6

Typical system design

Additional insulation of the oil separatorAdditional insulation of the oil separator

Additional insulation of the oil separator

Additional insulation of the oil separatorAdditional insulation of the oil separator

Operation at low ambient temperatures or at high

temperatures on the discharge side during standstill

(such as heat pumps) requires additional insulation of

the oil separator.

Among other things the operating conditions and the

refrigerant (sonic speed) as well as the compressor’s

pulsation frequency must be considered in the calculation.

The base frequency of the compressor is approx.

250Hz (50Hz network) or 300 Hz (60 Hz network).

Frequencies of higher orders (500 / 1000 Hz or 600 /

1200 Hz) should also reviewed at in the final layout.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

Filter drierFilter drier

Filter drier

Filter drierFilter drier

Generously sized filter driers of suitable quality should

be used to ensure a high degree of dehydration and to

maintain the chemical stability of the system.

Suction side cleaning filterSuction side cleaning filter

Suction side cleaning filter

Suction side cleaning filterSuction side cleaning filter

The use of a suction side filter (filter mesh 25 m) will

protect the compressor from damage due to dirt from

the system and is strongly recommended for site built

systems.

8

Page 9

AE4-1322

Expansion valve and evaporatorExpansion valve and evaporator

Expansion valve and evaporator

Expansion valve and evaporatorExpansion valve and evaporator

Expansion valve and evaporator have to be adjusted

using utmost care. This is especially important for

those systems that cover a large control range, e.g.

100% to 25%. In each case, sufficient suction gas

superheat and stable operating conditions must be

assured in full load as well as part load modes.

Depending on the evaporator’s design and performance

range several circuits may be necessary each with

separate expansion and solenoid valves.

3.3 Guidelines for special system variations3.3 Guidelines for special system variations

3.3 Guidelines for special system variations

3.3 Guidelines for special system variations3.3 Guidelines for special system variations

Pump down circuitPump down circuit

Pump down circuit

Pump down circuitPump down circuit

If the evaporator and / or the suction line can become

warmer than the compressor during shutdown, a “pump

down” cycle must be incorporated in addition to the oil

heater.

Additional check valve in the discharge line andAdditional check valve in the discharge line and

Additional check valve in the discharge line and

Additional check valve in the discharge line andAdditional check valve in the discharge line and

automatic sequence controlautomatic sequence control

automatic sequence control

automatic sequence controlautomatic sequence control

For systems with multi-circuit condensers and / or

evaporators, an increased danger exists when individual circuits are shut off. During this period liquid

refrigerant can migrate into the evaporator (no temperature and pressure equalization possible). In these

cases an additional check valve must be installed in

the discharge line. In addition the compressors should

be operated with an automatic sequence control.

The same is also valid for individual systems without

temperature and pressure equalization during longer

shutdown. In extreme cases a suction accumulator or

“pump down” cycle can also become necessary.

Additional oil level controlAdditional oil level control

Additional oil level control

Additional oil level controlAdditional oil level control

accumulator is recommended to protect against liquid

slugging. To effectively avoid increased oil carry-over

(such as due to a rapid decrease of pressure in the oil

separator), the oil temperature must remain at least

54° F above the condensing temperature during charge

over. In addition, it may be necessary to install a

pressure regulator immediately after the oil separator

to limit pressure drop. Under certain conditions it is

also possible to turn off the compressor shortly before

the change over procedure and to restart after pressure

equalization. It must however be assured that the

compressor is operating with the required minimum

pressure differential no longer than 30 seconds (see

application ranges Section 9).

3.4 Additional cooling by means of direct liquid3.4 Additional cooling by means of direct liquid

3.4 Additional cooling by means of direct liquid

3.4 Additional cooling by means of direct liquid3.4 Additional cooling by means of direct liquid

injectioninjection

injection

injectioninjection

Additional cooling is required in areas of high condensing and / or low evaporating temperatures. A relatively

simple method is direct liquid inject at the economizer

connection.

The following criteria must be followed to ensure

reliable operation and to avoid excessive dilution of the

oil.

Liquid inject valveLiquid inject valve

Liquid inject valve

Liquid inject valveLiquid inject valve

Specially designed expansion valves are only suitable

for liquid injection. They must control the discharge

temperature to setting of 190°F (e.g. Danfoss TEAT20,

also series 935-101-B, Sporian Y1037).

The valve bulb must be mounted on the discharge line:

• Clean the tubes surface carefully to bright metal.

Distance from discharge shut-off valve approx. 8 to

10 inches.

The above guidelines also apply to systems with long

pipelines (suchas a remote evaporator and / or condenser). In addition the compressor must be equipped

with an oil level switch (accessory). For electrical

connection see Section 6.4.

Systems with reverse cycling and hot gas defrostSystems with reverse cycling and hot gas defrost

Systems with reverse cycling and hot gas defrost

Systems with reverse cycling and hot gas defrostSystems with reverse cycling and hot gas defrost

These system layouts require individually system

design review to protect the compressor against liquid

slugging and increased oil carry-over. A suction

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

• Apply heat transfer paste to the contact surface.

• Fix the bulb firmly with adequate pipe clips. Mind

heat expansion!

• Insulate the bulb and the section of discharge line

9

Page 10

AE4-1322

Pipe runsPipe runs

Pipe runs

Pipe runsPipe runs

To ensure a bubble free liquid supply to the liquid

injection valve, the connection must be made on the

bottom of a horizontal section of the liquid line.

Installation of the liquid inject valve at the com-Installation of the liquid inject valve at the com-

Installation of the liquid inject valve at the com-

Installation of the liquid inject valve at the com-Installation of the liquid inject valve at the compressorpressor

pressor

pressorpressor

• Min. 6 to 8 in. above liquid injection connection

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

VV

ibration fractures possible! install liquidibration fractures possible! install liquid

V

ibration fractures possible! install liquid

VV

ibration fractures possible! install liquidibration fractures possible! install liquid

injection and solenoid valves withinjection and solenoid valves with

injection and solenoid valves with

injection and solenoid valves withinjection and solenoid valves with

adequate supports!adequate supports!

adequate supports!

adequate supports!adequate supports!

Check for vibration during operation!Check for vibration during operation!

Check for vibration during operation!

Check for vibration during operation!Check for vibration during operation!

Calculating the cooling capacity of the liquidCalculating the cooling capacity of the liquid

Calculating the cooling capacity of the liquid

Calculating the cooling capacity of the liquidCalculating the cooling capacity of the liquid

injection valveinjection valve

injection valve

injection valveinjection valve

Figure 7

Liquid injection valve (system design)

• With the selection software

• Consider the most extreme conditions to be

expected during actual operation:

- min. evaporating temperature

- max. suction gas superheat and condensing

temperature

Further conditions for valve selectionFurther conditions for valve selection

Further conditions for valve selection

Further conditions for valve selectionFurther conditions for valve selection

• Pressure at the injection point:

- R134a approximately 30 to 45 psig above

suction pressure R407C, R22 approx. 40 to

50 psig above suction pressure

- Never size the valve too large danger of

refrigerant flooding!

Additional components in the liquid lineAdditional components in the liquid line

Additional components in the liquid line

Additional components in the liquid lineAdditional components in the liquid line

• Solenoid valve (energized parallel to compressor

contactor)

• Filter dryer (if required)

• Liquid sight glass

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

10

Page 11

3.5 Additional cooling by means of external oil3.5 Additional cooling by means of external oil

3.5 Additional cooling by means of external oil

3.5 Additional cooling by means of external oil3.5 Additional cooling by means of external oil

coolercooler

cooler

coolercooler

AE4-1322

• Oil coolers must be controlled by thermostats (see

table for temperature settings).

The application of an external oil cooler (air, water or

refrigerant cooled) instead of refrigerant inject provides

additional extension of the application envelopes and

even better efficiency.

When calculating an oil cooler, worst case operating

conditions must be used:

• Min. evaporating temperature

• Max. suction gas superheat

• Max. condensing temperature

• Operation mode (capacity control, ECO)

Oil cooler capacity can be calculated by using the

selection software.

Recommendations for external oil coolersRecommendations for external oil coolers

Recommendations for external oil coolers

Recommendations for external oil coolersRecommendations for external oil coolers

• Connections for external oil coolers are located on

the back side of the compressor below the discharge shut-off valve (oval or rectangular flange).

The flange is replaced by a tube adaptor (option):

• Install oil cooler as close as possible to the compressor.

• Piping design must avoid gas pockets and any

drainage of oil into the compressor during shutdowns (installation of the oil cooler preferably at

compressor level or below).

• For rapid heating of the oil circuit and minimizing

the pressure drop with cold oil an oil by-pass (or

even heating the cooler during shut down) is

required under the following conditions:

- the oil temperature in the cooler drops below

60°F during shut down,

- the oil volume of cooler plus oil piping exceeds

the compressor’s oil charge,

- The oil cooler is an integral part of the con-

denser coil

• The by-pass valve should have a temperature

responsive modulating control function. The use of a

solenoid valve for intermittent control would require

highly sensitive control thermostat and a minimal

switching differential (effective temperature variation

< 18°F).

• The oil side pressure drop during normal operation

should not exceed 7 psig.

• Due to the additional oil volume (cooler, piping) a

solenoid valve may be necessary in the oil line.

This is to avoid oil migration into the compressor

during shutdowns. The solenoid valve must be

installed close to the compressor’s oil inlet connection and its electric control should be parallel to the

contactor’s normally open contact. Recommended

additional components:

- Sight glass to check oil flow,

- Manual shut-off ball valves in both feed and

return lines for ease of service,

- Oil filter (max. 25 µ mesh size)

With an additional oil volume (cooler and piping) of

10% of the compressor’s standard oil charge and

assured cleanliness of components and pipes the

above mentioned measures can be omitted.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

Figure 8

External oil cooler connection

Water cooled oil coolerWater cooled oil cooler

Water cooled oil cooler

Water cooled oil coolerWater cooled oil cooler

Temperature control by thermostatic water regulator

(for set point see table, required sensor temperature

should be equal to or greater than 250°F).

11

Page 12

Figure 9

Water-cooled oil cooler

Air cooled oil coolerAir cooled oil cooler

Air cooled oil cooler

Air cooled oil coolerAir cooled oil cooler

Temperature control by thermostatic switching on and

off or stepless speed control of the cooler fan (see

table for set point, required sensor temperature should

be equal to or greater than 250°F).

AE4-1322

Thermosyphon oil cooling (cooling by refrigerant)Thermosyphon oil cooling (cooling by refrigerant)

Thermosyphon oil cooling (cooling by refrigerant)

Thermosyphon oil cooling (cooling by refrigerant)Thermosyphon oil cooling (cooling by refrigerant)

Temperature control either by thermostatic regulation

valve for refrigerant feed or by-pass valve (see table for

set point; admissible operating and sensor temperature

should be equal to or greater than 250°F).

As an example figure 11 shows a layout with a primary

receiver after the condenser. An alternative layout of the

thermosyphon circuit as well as refrigerant circulation

by means of a pump or an ejection is also possible

(information upon request).

If the oil coolers is integrated into the condenser the

by-pass valve controls the temperature (see table for

set point; admissible operating and / or sensor temperature should be equal to or greater than 250°F).

DL SL

Figure 10

Air cooled oil coolers

Figure 11

Thermosyphon oil cooling

4 Economizer operation

1.1 General1.1 General

1.1 General

1.1 General1.1 General

SCH2/SCA2 screw compressors are designed for

economizer operation “ECO”. With this operation mode

both cooling capacity and efficiency are improved by

means of a sub-cooling circuit or 2-stage refrigerant

expansion. There are capacity and efficiency advantages in ECO operation over the conventional application, particularly at high condensing temperatures.

A unique feature of the compact screws is the economizer channel integrated into the control slide (fig.12).

This enables to operate the sub-cooling circuit regardless of the compressor load condition. Screw compressors with a fixed ECO suction position have this

frequently located in the suction area of the rotors

during part load and then has no effect.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

12

Page 13

5.2 Operation principle5.2 Operation principle

5.2 Operation principle

5.2 Operation principle5.2 Operation principle

AE4-1322

5.3 Economizer operation with sub-cooling circuit5.3 Economizer operation with sub-cooling circuit

5.3 Economizer operation with sub-cooling circuit

5.3 Economizer operation with sub-cooling circuit5.3 Economizer operation with sub-cooling circuit

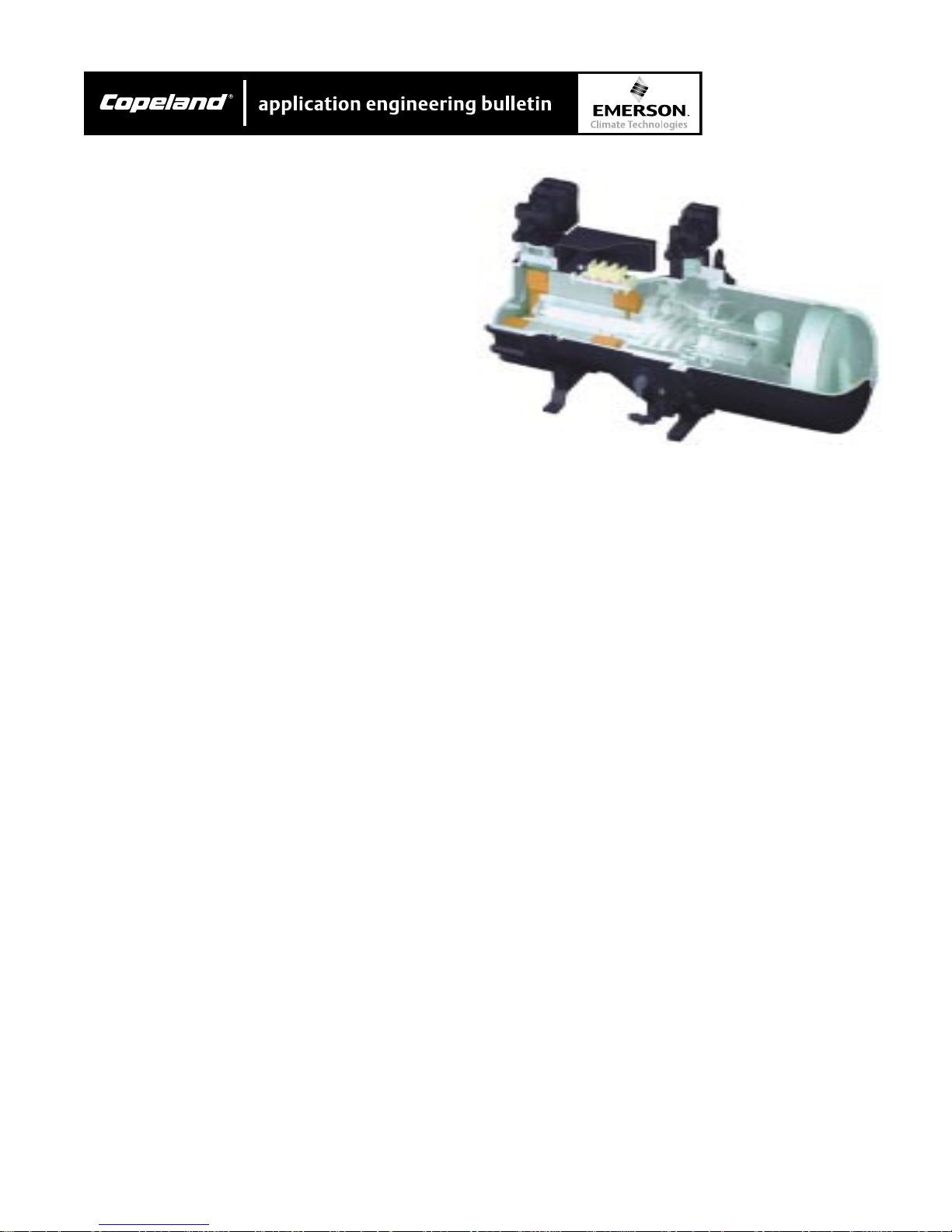

With screw compressors the compression process

occurs only in one flow direction (see Section 2.2).

This fact enables to locate an additional suction port at

the rotor housing. The position is selected so that the

suction process has already been completed and a

slight pressure increase has taken place. Via this

connection an additional mass flow can be taken in,

which has only a minimal effect on the flow from the

suction side.

The pressure level at the ECO suction point is similar

to the intermediate pressure with 2-stage compressors. This means that an additional sub-cooling circuit

or intermediate pressure receiver for 2-stage expansion

can be integrated into the system. This design

achieves a significantly higher cooling capacity through

additional liquid sub-cooling. At the same time, there is

a relatively low increase in the compressor’s power

input, as the total working process becomes more

efficient – due to the higher suction pressure, among

other things.

System with sub-cooling circuit

Figure 12

With this operation mode a heat exchanger is utilized

as a liquid sub-cooler. A part of the refrigerant mass

flow from the condenser enters the sub-cooler via an

expansion device, and evaporates upon absorbing heat

from the counter-flowing liquid refrigerant (sub-cooling).

The superheated vapor is taken in at the compressor’s

ECO connection, mixed with the mass flow from the

evaporator and compressed to a high pressure.

With this type of operation the sub-cooled liquid is

under condensing pressure. Therefore the piping to the

evaporator does not require any special features –

apart from insulation.The system can be applied

universally.

5.4 ECO operation with intermediate pressure5.4 ECO operation with intermediate pressure

5.4 ECO operation with intermediate pressure

5.4 ECO operation with intermediate pressure5.4 ECO operation with intermediate pressure

receiverreceiver

receiver

receiverreceiver

This layout version for 2-stage refrigerant pressure relief

is particularly advantageous in connection with flooded

evaporators and is therefore primarily used in plants

with large cooling capacity.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

13

Page 14

5.5 Layout and selection recommendations5.5 Layout and selection recommendations

5.5 Layout and selection recommendations

5.5 Layout and selection recommendations5.5 Layout and selection recommendations

Pipe layoutPipe layout

Pipe layout

Pipe layoutPipe layout

• Design the sub-cooler so that during shutdown,

neither liquid refrigerant nor oil can enter the compressor.

• Until operating conditions are established during

temporary operation without economizer and when

switching off the compressor, the compressor can

discharge a certain amount of oil through the ECO

connection. Oil transfer into the sub-cooler must

therefore be prevented by a pipe bending vertically

upwards with a check valve (see fig.13).

In order to avoid instability of the check valve when

the ECO circuit is switched off, a by-pass-line with a

solenoid valve towards the suction side must also be

included (1/4”). The solenoid valve is only open when

the ECO is not operating. This way it creates

sufficient closing pressure for the check valve.

AE4-1322

• Pipe vibrations:

Due to the pulsations emitting from the profile area

of the compressor, critical pipe lengths must be

avoided. See also Section 4.2.

5.6 Additional components5.6 Additional components

5.6 Additional components

5.6 Additional components5.6 Additional components

Refrigerant sub-coolerRefrigerant sub-cooler

Refrigerant sub-cooler

Refrigerant sub-coolerRefrigerant sub-cooler

Frost proof shell and tube, coaxial or plate heat

exchangers are suitable as sub-coolers. In the design

phase the relatively high temperature gradient on the

liquid side must be taken into consideration.

For capacity determination see output date in the

compressor software:

• Sub-cooler capacity

• ECO mass flow

• Saturated ECO temperature and

• Liquid temperature.

Layout parametersLayout parameters

Layout parameters

Layout parametersLayout parameters

• See Section 6 for electric control. Other layout

versions are also possible, but must be checked for

their suitability and operating safety in individual

tests.

• The ECO connection leads directly into the profile

area. For this reason a high degree of cleanliness

must be maintained for sub-cooler and pipes.

• Dimension of the ECO suction line:

In view of the usually short pipe lengths, the following

pipe diameters can be used:

SCH2 5000 to 9000 1 ¼” – 12 Rotolock

SCA2 3500 to 7000

SCH2 11H0 to 14H0 1 ½” – 12 Rotolock

SCA2 9000 to 11H0

Min 6 – 8” rise

• Intermediate temperature

- corresponds to the evaporating temperature in

the sub-cooler

- for layout design, take 18°F suction gas

superheat into consideration

• Liquid temperature (inlet)

As a nominal selection basis, liquid sub-cooling of

4°F is assumed

example:

tc = 90°F liquid temperature (inlet) = 86ºF.

• Liquid temperature (outlet) The software pre-set

date are based on 18°F above saturated ECO

temperature

Example:

tm = +68ºF liquid temperature (outlet) = 86ºF

Input of individual data is possible. Keep in mind,

however, that in practice a stable operating mode is

very difficult to achieve with differences between

liquid temperature (outlet) and saturated ECO

temperature of less than 18°F.

Figure 13

Liquid injection connections

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

14

Page 15

Thermostatic expansion valvesThermostatic expansion valves

Thermostatic expansion valves

Thermostatic expansion valvesThermostatic expansion valves

• Valve layout for liquid sub-cooler:

- Basis is the sub-cooling capacity

- Evaporating temperature corresponds to the

ECO intermediate temperature.

- Valves with a superheat adjustment of about 10

K should be used in order to avoid unstable

operation when switching on the sub-cooling

circuit and in connection with load fluctuations.

- If the sub-cooling circuit is also operated under

part-load conditions, this must be given due

consideration when designing the valves.

• Valve layout for evaporator:

Due to the high degree of liquid sub-cooling suction

mass flow is much lower than with systems with

similar capacity and no sub-cooler (see software

data). This requires a modified layout. In this

context the lower vapor content after expansion

must also be taken into consideration. For further

hints on the layout of expansion valves and evaporators see Section 4.2.

5.7 Control5.7 Control

5.7 Control

5.7 Control5.7 Control

Between that start and the stabilization of operating

conditions, the solenoid valve of the sub-cooling circuit

is switched on time delayed or depending on suction

pressure. For further hints and a schematic layout

diagram see Section 6.4.

AE4-1322

The compressors are supplied as standard with part

winding motors of connection (Part Winding “PW”).

Start delta motors are available as special design.

Part winding motorsPart winding motors

Part winding motors

Part winding motorsPart winding motors

Starting methods (connections according to figures 14

and 15):

• Part winding start to reduce the starting current

• Direct on line start (DOL)

Start delta motorsStart delta motors

Start delta motors

Start delta motorsStart delta motors

Starting methods (connections according to figures 16

and 17).

The start current value in star mode (1/3 ofThe start current value in star mode (1/3 of

The start current value in star mode (1/3 of

The start current value in star mode (1/3 ofThe start current value in star mode (1/3 of

the direct on line value) is generally statedthe direct on line value) is generally stated

the direct on line value) is generally stated

the direct on line value) is generally statedthe direct on line value) is generally stated

according to standard locked rotor condi-according to standard locked rotor condi-

according to standard locked rotor condi-

according to standard locked rotor condi-according to standard locked rotor conditions. In realitytions. In reality

tions. In reality

tions. In realitytions. In reality

obtained during the start. Moreoverobtained during the start. Moreover

obtained during the start. Moreover

obtained during the start. Moreoverobtained during the start. Moreover

switching from start to delta mode there is aswitching from start to delta mode there is a

switching from start to delta mode there is a

switching from start to delta mode there is aswitching from start to delta mode there is a

current peak as high as the direct start value.current peak as high as the direct start value.

current peak as high as the direct start value.

current peak as high as the direct start value.current peak as high as the direct start value.

This is caused by the voltage interruptionThis is caused by the voltage interruption

This is caused by the voltage interruption

This is caused by the voltage interruptionThis is caused by the voltage interruption

during switch-over of the contactors, whichduring switch-over of the contactors, which

during switch-over of the contactors, which

during switch-over of the contactors, whichduring switch-over of the contactors, which

results in a speed drop due to theresults in a speed drop due to the

results in a speed drop due to the

results in a speed drop due to theresults in a speed drop due to the

compressorcompressor

compressor

compressorcompressor

, however, however

, however

, however, however

’’

s small rotating masses.s small rotating masses.

’

s small rotating masses.

’’

s small rotating masses.s small rotating masses.

, approx. 50% are, approx. 50% are

, approx. 50% are

, approx. 50% are, approx. 50% are

, when, when

, when

, when, when

6 Electrical connection6 Electrical connection

6 Electrical connection

6 Electrical connection6 Electrical connection

6.1 Motor design6.1 Motor design

6.1 Motor design

6.1 Motor design6.1 Motor design

Figure 14

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

Figure 15

15

Figure 16

Figure 17

Page 16

Figure 18

Power factor correction on individual compressors

AE4-1322

6.2 Selection of electrical components6.2 Selection of electrical components

6.2 Selection of electrical components

6.2 Selection of electrical components6.2 Selection of electrical components

Cables, contractors and fusesCables, contractors and fuses

Cables, contractors and fuses

Cables, contractors and fusesCables, contractors and fuses

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Nominal power is not the same asNominal power is not the same as

Nominal power is not the same as

Nominal power is not the same asNominal power is not the same as

maximum motor power! When selectingmaximum motor power! When selecting

maximum motor power! When selecting

maximum motor power! When selectingmaximum motor power! When selecting

cables, contactors and fuses: cables, contactors and fuses:

cables, contactors and fuses:

cables, contactors and fuses: cables, contactors and fuses:

operating current / maximum motoroperating current / maximum motor

operating current / maximum motor

operating current / maximum motoroperating current / maximum motor

power must be considered. See chapter 8. power must be considered. See chapter 8.

power must be considered. See chapter 8.

power must be considered. See chapter 8. power must be considered. See chapter 8.

Contactor selection: according toContactor selection: according to

Contactor selection: according to

Contactor selection: according toContactor selection: according to

operational category operational category

operational category

operational category operational category

Part winding motorsPart winding motors

Part winding motors

Part winding motorsPart winding motors

The following current values appear in the part windings:

PW1 PW2

50% 50%

Both of the contactors should be selected for at least

60% of the maximum operating current.

Star delta motorsStar delta motors

Star delta motors

Star delta motorsStar delta motors

Calculate mains and delta contactor each to at least

60%, start contactor to 33% of the maximum operating

current.

MaximumMaximum

Maximum

MaximumMaximum

AC 3.AC 3.

AC 3.

AC 3.AC 3.

Power factor correctionPower factor correction

Power factor correction

Power factor correctionPower factor correction

For the reduction of the reactive current when using

inductive loads (motors, transformers), power factor

correction systems (capacitors) are increasingly being

used. However, apart from the undisputed power

supply advantages, experience shows that the layout

and execution of such systems is not a simple matter,

as insulation damage on motors and increased contact

arcing on contactors can occur.

With a view to a safe operating mode, the correction

system should be designed to effectively prevent “overcorrection” in all operating conditions and the uncontrolled discharge of the capacitors when starting and

shutting down the motors.

General design criteriaGeneral design criteria

General design criteria

General design criteriaGeneral design criteria

• Maximum power factor (P.F. 0.95 - taking into

consideration all load conditions.)

Individual correction (Fig. 21)Individual correction (Fig. 21)

Individual correction (Fig. 21)

Individual correction (Fig. 21)Individual correction (Fig. 21)

• With capacitors that are directly fitted to the motor

(without the possibility of switching off with

contactors), the capacitor capacity must never be

greater than 90% of the zero-load reactive capacity

of the motor (less than 25% of max. motor power).

With higher capacities there is the danger of selfexiting when shutting off, resulting in damage to the

motor.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

16

Page 17

AE4-1322

• For part winding start a separate capacitor should

be used for each half of the winding (50% each).

Only one capacitor is used for start delta motors

(parallel to contactor K1).

• In the case of extreme load fluctuations (large

capacity range) combined with high demands on a

low reactive capacity, capacitors that can be

switched on and off with contactors (in combination

with a discharge throttle) may be necessary.

Design is similar to central correction.

Central correction (Fig. 22)Central correction (Fig. 22)

Central correction (Fig. 22)

Central correction (Fig. 22)Central correction (Fig. 22)

• When the designing, connected loads and the

operating times of all inductive loads (including

fluorescent lamps if they do not have their own

correction) must be taken into consideration.

• The number of capacitor stages must be selected

so that the smallest unit does not have a larger

capacity than the lowest inductive load (with P.F.

0.95). Extreme part load conditions are particularly

critical, such as can occur during the night, at

weekends or while being put into operation. If loads

are too low the entire correction device should be

disconnected from the power supply.

• With central correction (as well as with individual

correction with contactor control) discharge throttle

must always be provided. Reconnection to the

power supply may only occur after complete

discharge and a subsequent time delay.

The layout of correction systems for motors with

direct starting is similar.

CAUTION!CAUTION!

CAUTION!

CAUTION!CAUTION!

It is essential to observe the generalIt is essential to observe the general

It is essential to observe the general

It is essential to observe the generalIt is essential to observe the general

design and layout instruction of thedesign and layout instruction of the

design and layout instruction of the

design and layout instruction of thedesign and layout instruction of the

correction system manufacturer correction system manufacturer

correction system manufacturer

correction system manufacturer correction system manufacturer

Frequency inverterFrequency inverter

Frequency inverter

Frequency inverterFrequency inverter

Operation with a frequency inverter is possible. However, layout and operating conditions must be individually approved by Copeland

3.3 Compressor protection system3.3 Compressor protection system

3.3 Compressor protection system

3.3 Compressor protection system3.3 Compressor protection system

The SCH2/SCA2 compressors are fitted with the

protection device INT69VSY-II.

Monitoring functionsMonitoring functions

Monitoring functions

Monitoring functionsMonitoring functions

• Winding temperature (PTC sensors in motor

winding)

- Interruption of the control current with excess

temperature

- Manual reset (after winding has cooled) by

interruption of supply voltage L/N for at least

2 seconds

• Oil temperature (sensor with PTC resistance in oil

sump)

- Function as above (winding temperature)

..

.

..

..

.

..

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

Figure 20

Power factor correction on central power system

17

Page 18

• Direction of rotation/phase sequence (direct measurement at compressor terminals)

- Immediate interruption of control current and

lock-out with wrong direction of rotation / phase

sequence (indication via signal contact 12)

- Reset (after correction of fault) by interruption of

the supply voltage L/N for at least 2 seconds.

The protection device is built into the terminal box.

The wiring to the motor and oil temperature PTC

sensors and also to be motor terminals is factory

mounted. The electrical connections to the device

should be made according to figure 21 or 22 and the

schematic wiring diagrams.

In principle the device could be also built into the

control panel. In the case it is essential to adhere to

the following recommendations:

Special attention must be given when fitting the

INT69VSY-II in the control panel:

AE4-1322

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Make sure that the rotation monitoring isMake sure that the rotation monitoring is

Make sure that the rotation monitoring is

Make sure that the rotation monitoring isMake sure that the rotation monitoring is

functioning! Tfunctioning! T

functioning! T

functioning! Tfunctioning! T

INT69VSYINT69VSY

INT69VSY

INT69VSYINT69VSY

according to the wiring diagram. according to the wiring diagram.

according to the wiring diagram.

according to the wiring diagram. according to the wiring diagram.

the jumper L/D1 at this time.the jumper L/D1 at this time.

the jumper L/D1 at this time.

the jumper L/D1 at this time.the jumper L/D1 at this time.

The following requirements must be ensured byThe following requirements must be ensured by

The following requirements must be ensured by

The following requirements must be ensured byThe following requirements must be ensured by

the control logic:the control logic:

the control logic:

the control logic:the control logic:

• Minimum time of standstill: 1 minute. Valid during

maintenance also!

Returning time of the control slide - CR3 (Y3)

energized

• Maximum cycling rate 6 to 8 starts per hour!

• Minimum running time desired 5 minutes!

• Switch-over time part winding 0.5 seconds start

delta 1 second

erminal D1 of theerminal D1 of the

erminal D1 of the

erminal D1 of theerminal D1 of the

-II must be connected-II must be connected

-II must be connected

-II must be connected-II must be connected

RemoveRemove

Remove

RemoveRemove

• The connecting cables to the motor terminals must

be wired in the sequence described (L1 to terminal

“1” etc.) Check with a direction of rotation indicator!

• Danger of induction!

Only use shielded cables or a twisted pair to

connect to the PTC motor sensors and oil temperature PTC sensors.

• Additional fuses (4 A) must be incorporated in the

connecting cables between “L1/L2/L3” of the

protection device and the motor terminals “1/2/3”.

• The terminals T1-T2 on the compressor and 1-2 on

protection device must not come into contact with

supply or control voltage.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

If the rotation direction is wrong: DangerIf the rotation direction is wrong: Danger

If the rotation direction is wrong: Danger

If the rotation direction is wrong: DangerIf the rotation direction is wrong: Danger

of severe compressor damage! of severe compressor damage!

of severe compressor damage!

of severe compressor damage! of severe compressor damage!

6.4 Schematic wiring diagrams6.4 Schematic wiring diagrams

6.4 Schematic wiring diagrams

6.4 Schematic wiring diagrams6.4 Schematic wiring diagrams

The following schematic wiring diagrams show examples of application for

start each with infinite and 4-step capacity con-start each with infinite and 4-step capacity con-

start each with infinite and 4-step capacity con-

start each with infinite and 4-step capacity con-start each with infinite and 4-step capacity control.trol.

trol. In addition optional control schemes for liquid

trol.trol.

injection, economizer operation and oil level controls

are included.

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

part winding and star deltapart winding and star delta

part winding and star delta

part winding and star deltapart winding and star delta

Instruction for start delay timer with economizerInstruction for start delay timer with economizer

Instruction for start delay timer with economizer

Instruction for start delay timer with economizerInstruction for start delay timer with economizer

operationoperation

operation

operationoperation

The switching-on device F7 must ensure that the

refrigerant flow to the liquid sub-cooler is not switched

on until operating conditions have sufficiently stabilized. This is achieved by using the solenoid valve Y6.

With frequent starting from high suction pressure, a

pressure switch should be sued. The set point should

be sufficiently above the nominal evaporating temperature in order to prevent the economizer solenoid valve

Y6 from short cycling.

For systems with relatively constant pull down cycles

(such as liquid chillers), an alternative is to use a time

relay. The delay time must then be checked individually for each individual systems.

LegendLegend

Legend

LegendLegend

B2 Control Unit

F1 Main fuse

F2 Compressor fuse

F3 Control circuit fuse

F4 Control circuit fuse

F5 High pressure cut out

F6 Low pressure cut out

F7 Start delay timer “Economizer”

F8 Oil level switch (option)

F13 Thermal overload “motor” PW1

18

Page 19

AE4-1322

F14 Thermal overload “motor” PW2

H1 Signal lamp “motor fault” (over temp / phase

failure)

H4 Signal lamp “oil level fault”

K1 Contactor “first PW” (for PW) “Mains contactor”

(Y/)

K2 Contactor “second PW” (PW) “Start contactor”

(Y)

K3 “Delta contactor” (Y))

K4 Auxiliary contactor (option)

K2T Time relay “pause time”

K3T Time relay “part winding: or “star delta”

K4T Time relay “oil level switch”

K5T Fixed pulse relay “CR4” flashing function on / off

10 seconds

M1 Compressor

Q1 Main switch

R1 Oil heater *

R2 Oil temperature sensor (PTC) *

R3-8 Motor PTC sensor *

S1 On-off switch

S2 Fault reset “motor & discharge temperature”

and/or “direction of rotation”

S4 Fault reset “oil level”

U Screening unit (if required, such as from Murr

Elektronik)

Y1 SV “capacity control” *

Y2 SV “capacity control” *

Y3 SV “capacity control” *

Y4 SV “capacity control” *

Y5 SV “liquid line”

Y6 SV “refrigerant injection” alternatively

“econimizer”

Y7 SV “economizer by-pass” INT69VSY-II

Control device for motor protection and dis

charge gas superheat protection *

SV Solenoid valve

* Parts are included with compressor

Capacity control

Y1 CR1, Y2 CR2

Y3 CR3, Y4 CR4

Figure 21

Part winding start wiring diagram

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

19

Page 20

AE4-1322

Figure 23

Part winding start options

Figure 22

Part winding start with 4-step capacity control

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

20

Page 21

Data for accessories and oil chargeData for accessories and oil charge

Data for accessories and oil charge

Data for accessories and oil chargeData for accessories and oil charge

Liquid sub-coolingLiquid sub-cooling

Liquid sub-cooling

Liquid sub-coolingLiquid sub-cooling

AE4-1322

• Oil heater: 115/230 VAC

SCH2 5000 to 9000 200W

SCA2 3500 to 7000

SCH2 11H0 to 14H0 300W

SCA2 9000 to 11H0

• Capacity control:

24/115/230 VAC 50/60 Hz

• Oil charge:

Solest170 for R134a, R407C, R404A and R507A

CP4214-320 for R 22

Oil heaterOil heater

Oil heater

Oil heaterOil heater

Ensures the lubricity of the oil even during long standstill periods. It prevents increased refrigerant dilution

into the oil and therefore reduction of viscosity.

The oil heater must be used during the shutdown for

• outdoor installation of the compressor (insulate the

oil separator additionally if necessary)

• long off cycles

• high refrigerant charge

• danger of refrigerant condensation into the

compressor

10 Performance data10 Performance data

10 Performance data

10 Performance data10 Performance data

For detailed compressor selection with the option of

individual data input our selection software is available

as CD-ROM or can be downloaded from our internet

web site. The resulting output data include all important performance parameters for compressors and

additional components, application ranges, technical

data and dimensional drawings. Moreover, specific data

sheets can be generated which may either be printed

out or transferred into other software programs, such

as Excel, for further use.

Basic parametersBasic parameters

Basic parameters

Basic parametersBasic parameters

Evaporating and condensing temperatures correspond

to “dew point” conditions (saturated vapor). With

zeotropic blends like R407C this leads to a change in

the basic parameters (pressure levels, liquid temperatures) compared with data according to “intermediate

temperatures” used so far. As a consequence this

results in a lower numerical value for cooling capacity

and efficiency (COP).

With standard conditions

nono

no liquid sub-cooling is

nono

considered. Therefore the rated cooling capacity and

efficiency (COP) show lower values in comparison to

data based on 9 or 15°F of sub-cooling.

Economizer operationEconomizer operation

Economizer operation

Economizer operationEconomizer operation

Data for economizer operation system inherently

include liquid sub-cooling. The liquid temperature is

defined as 18°F above saturated temperature (dew

point with R407C) at economizer inlet (t

= tms +

cu

18°F).

10.1 Compressor selection by software10.1 Compressor selection by software

10.1 Compressor selection by software

10.1 Compressor selection by software10.1 Compressor selection by software

• Select the menu

CSH Compact Screws.

• Type the desired Cooling Capacity.

• Select desired operating conditions:

-Refrigerant and for R407C

-Reference temperature

-Evaporating temperature

-Condensing temperature

-Without or with economizer

-Liquid Sub-cooling

-Suction Gas superheat or suction gas temp.

-Useful superheat

-Power supply

• Hit Calculate.

In the window Output Data the selected compressors with performance data are shown (fig. 24).

• Data output:

At this stage an input of individual text (Head line)

is possible.