Page 1

026-1724 Rev 0 12-MAY-2008

Copeland®

PerformanceAlert™

Gateway System

Installation and

Operation Manual

Page 2

Page 3

1640 Airport Road, Suite 104

Kennesaw, GA 30144

Phone: (770) 425-2724

Fax: (770) 425-9319

ALL RIGHTS RESERVED.

The information contained in this manual has been carefully checked and is believed to be accurate. However, Computer Process Controls, Inc. assumes no responsibility for any inaccuracies that may be contained herein. In no event will

Computer Process Controls, Inc. be liable for any direct, indirect, special, incidental, or consequential damages resulting

from any defect or omission in this manual, even if advised of the possibility of such damages. In the interest of continued

product development, Computer Process Controls, Inc. reserves the right to make improvements to this manual, and the

products described herein, at any time without notice or obligation.

Page 4

Page 5

Table of Contents

1 OVERVIEW ................................................................................................................................................................... 1

1.1. T

HE PERFORMANCEALERT™ GATEWAY SYSTEM ....................................................................................................... 1

1.2. T

HE PERFORMANCEALERT™ GATEWAY BOARD......................................................................................................... 1

1.3. T

HE PERFORMANCEALERT™

D

IAGNOSTIC MODULE ........................................................................................................................................................... 1

1.4. H

AND-HELD TERMINAL ............................................................................................................................................... 2

2 GATEWAY BOARD MOUNTING ............................................................................................................................. 3

3 GATEWAY POWER

WIRING............................................................................................................................................................................... 4

4 NETWORKING............................................................................................................................................................. 5

4.1. C

ONNECTING THE PERFORMANCEALERT™ MODULES TO THE GATEWAY BOARD..................................................... 5

4.1.1. PerformanceAlert™ Module MODBUS Wiring ................................................................................................... 5

4.1.2. PerformanceAlert™ Module MODBUS Addressing ............................................................................................ 6

4.1.3. Gateway MODBUS Wiring................................................................................................................................... 6

4.1.4. MODBUS Termination ......................................................................................................................................... 6

4.2. C

ONNECTING THE GATEWAY TO THE RS485 I/O NETWORK ....................................................................................... 6

4.2.1. Gateway Board Numbering .................................................................................................................................. 7

4.2.1.1. Setting the Gateway Address Switch .................................................................................................................................. 7

4.2.2. Setting the Baud Rate Dip Switches ...................................................................................................................... 7

4.2.3. Gateway Board RS485 I/O Termination............................................................................................................... 8

5 GATEWAY SOFTWARE SETUP............................................................................................................................... 9

6 PERFORMANCEALERT™

I/O SUMMARY................................................................................................................................................................. 10

6.1. E2 I/O B

6.2. I/O S

OARD SETUP ................................................................................................................................................. 10

ETUP FOR CONDENSED MODE ............................................................................................................................ 10

6.2.1. Condensed Mode Point Setup ............................................................................................................................. 10

6.3. I/O S

ETUP FOR EXPANDED MODE .............................................................................................................................. 11

6.3.1. Expanded Mode Point Setup ............................................................................................................................... 11

7 OPERATION ............................................................................................................................................................... 14

7.1. P

ERFORMANCEALERT™ STAT SUMMARY ................................................................................................................. 14

7.1.1. Screen 1: Comm Status ....................................................................................................................................... 14

7.1.2. Screen 2: PF Alert Alarm Status......................................................................................................................... 14

7.1.3. Screens 3 through 6: Firmware Versions ........................................................................................................... 15

7.2. I

NDIVIDUAL PERFORMANCEALERT™ MODULE STATUS............................................................................................ 15

7.2.1. Individual Module Status .................................................................................................................................... 15

7.2.1.1. Screen 1............................................................................................................................................................................. 15

7.2.1.2. Screen 2............................................................................................................................................................................. 16

7.2.1.3. Screen 3............................................................................................................................................................................. 16

7.2.1.4. Screen 4............................................................................................................................................................................. 16

7.2.1.5. Screen 5............................................................................................................................................................................. 16

7.2.2. Individual Module History .................................................................................................................................. 16

7.2.2.1. Screens 1 and 2 ................................................................................................................................................................. 16

7.2.2.2. Screens 3 through 11......................................................................................................................................................... 16

7.2.2.3. Screens 12 and 13 ............................................................................................................................................................. 17

7.2.2.4. Screen 14........................................................................................................................................................................... 17

026-1724 Rev 0 12-MAY-2008 Table of Contents • v

Page 6

7.2.2.5. Screens 15 through 17....................................................................................................................................................... 17

7.2.2.6. Screen 18 and 19............................................................................................................................................................... 17

7.2.3. Individual Module Configuration........................................................................................................................ 17

7.2.3.1. Screen 1: Rack # and Install Date ..................................................................................................................................... 17

7.2.3.2. Screen 2: Date of Installation............................................................................................................................................ 18

7.2.3.3. Screen 3: Customer Code ................................................................................................................................................. 18

7.2.3.4. Screen 4: Compressor Model............................................................................................................................................ 18

7.2.3.5. Screen 5: Serial Number ................................................................................................................................................... 18

7.2.3.6. Screen 5: Setpoints............................................................................................................................................................ 18

7.2.3.7. Screens 6 through 8: Lockout Setpoints ........................................................................................................................... 18

7.2.4. Communication Statistics.................................................................................................................................... 19

7.2.5. Resets................................................................................................................................................................... 19

7.2.5.1. Clear History Log ............................................................................................................................................................. 19

7.2.5.2. Reset PerformanceAlert™ Module................................................................................................................................... 19

8 E2 APPLICATIONS .................................................................................................................................................... 20

8.1. P

ASSING PERFORMANCEALERT™ ALARM DATA TO THE E2 ADVISORY LOG........................................................... 20

8.1.1. Generic Alarming Setup...................................................................................................................................... 20

8.1.2. Alarm Parameter Settings ................................................................................................................................... 20

8.1.2.1. Digital Alarms................................................................................................................................................................... 20

8.1.2.2. Analog Alarms .................................................................................................................................................................. 21

8.1.3. Advisory Values and Priorities ........................................................................................................................... 22

8.1.4. How the Alarm Appears in the E2 Advisory Log ................................................................................................ 22

8.2. U

SING PERFORMANCEALERT™ CURRENT TRANSDUCER VALUES AS COMPRESSOR PROOFS................................... 22

8.2.1. Creating Analog Sensor Control Applications.................................................................................................... 22

8.2.2. Programming Analog Sensor Control Applications ........................................................................................... 22

8.2.2.1. General.............................................................................................................................................................................. 23

8.2.2.2. Inputs ................................................................................................................................................................................ 23

8.2.2.3. Setpoints............................................................................................................................................................................ 23

8.2.3. Setting Up Proofing in Suction Group Applications........................................................................................... 23

vi • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 7

1 Overview

1.2. The PerformanceAlert™

The PerformanceAlert™ Gateway is designed to allow

the Emerson Climate Technologies Retails Solutions family of site controllers (E2, Einstein, and REFLECS) to in-

terface directly with up to 14 Copeland

®

PerformanceAlert™ Diagnostic Modules.

The Gateway uses two network ports: one, a MODBUS

port used to connect the Gateway with the PerformanceAlert™ modules, and the second an I/O network port

that connects the Gateway to the I/O network of an E2 or

Einstein control system (or COM A/D of a REFLECS network).

The Gateway mimics the behavior of a MultiFlex 16 input board, passing along data from the PerformanceAlert™

modules about compressor behavior to the site controller in

the form of virtual board/point addresses. The Gateway’s

board/point addresses may be used by the site controller for

I/O control, logging, and alarming.

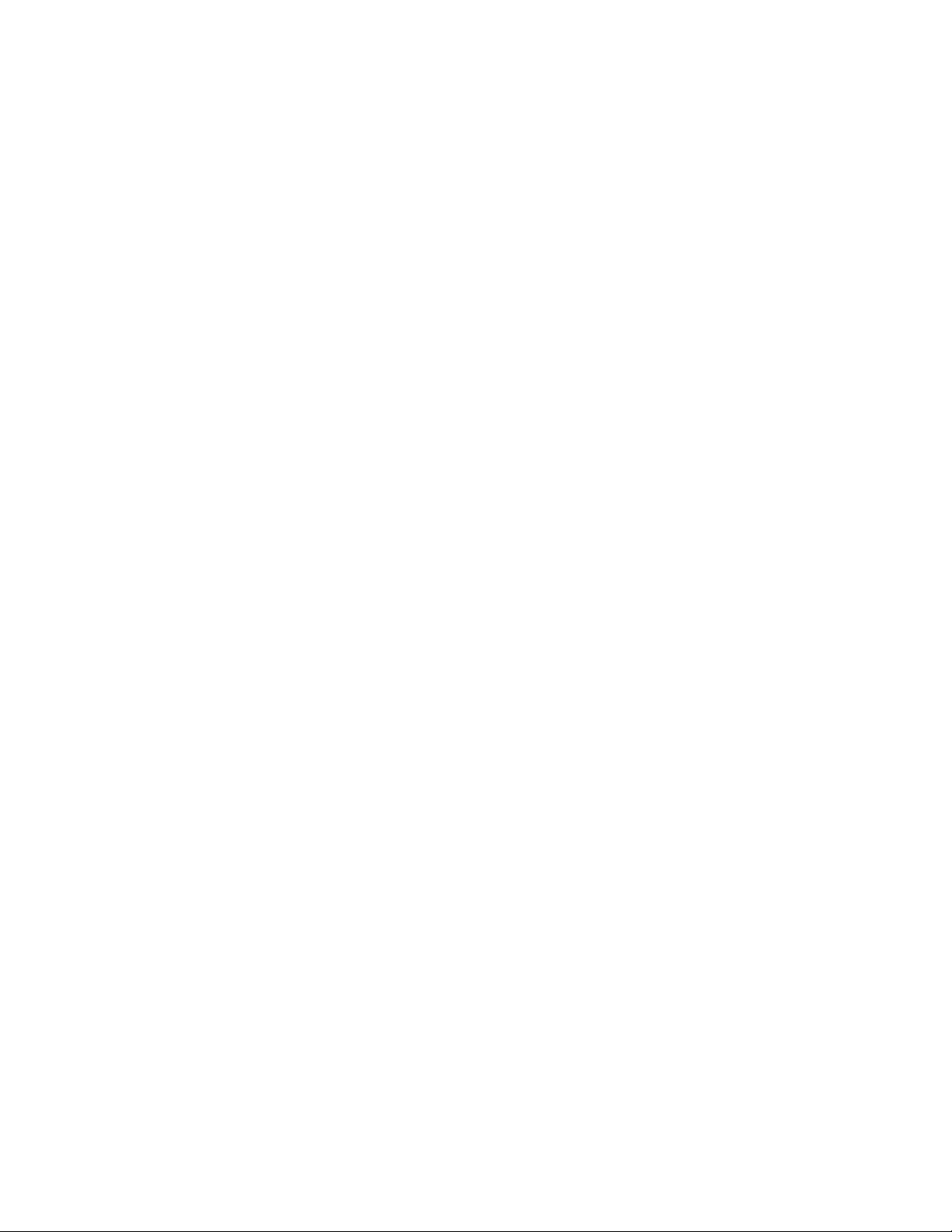

1.1. The PerformanceAlert™

Gateway System

Gateway Board

5

9

7

1

Hand-Held Terminal Jack

2

RS485 I/O Network

3

RS485 Receiver Bus Net

I/O Net Term Jumpers

4

5

Receiver Bus Term Jumpers

6

General Status LED

LEGEND

7

Alarm Status LED

Dip Switch

8

Power Connector

9

I/O Net Status LED

10

Receiver Bus Status LED

11

Figure 1-2 - Gateway Board

The PerformanceAlert™ Gateway (Figure 1-2) allows

you to connect up to fourteen (14) PerformanceAlert™ Diagnostic Modules. On the I/O network, the Gateway board

mimics the behavior of one or more 16AI boards, which

use virtual 16AI board/point addresses to pass along information from the modules to the E2.

The PerformanceAlert™ Gateway is capable of operating in one of two different modes: a Condensed Mode,

which maps a single 16AI point to the alarm status of each

PerformanceAlert™ module, and an Expanded Mode,

which maps sixteen 16AI points for each module, including alarm status for all alarm types, current transducer values, and discharge line temperature.

4

11

3

10

2

1

68

26502044

In Condensed Mode, the PerformanceAlert™ Gateway

mimics the equivalent of one 16AI board. In Expanded

Mode, the PerformanceAlert™ Gateway mimics the equiv-

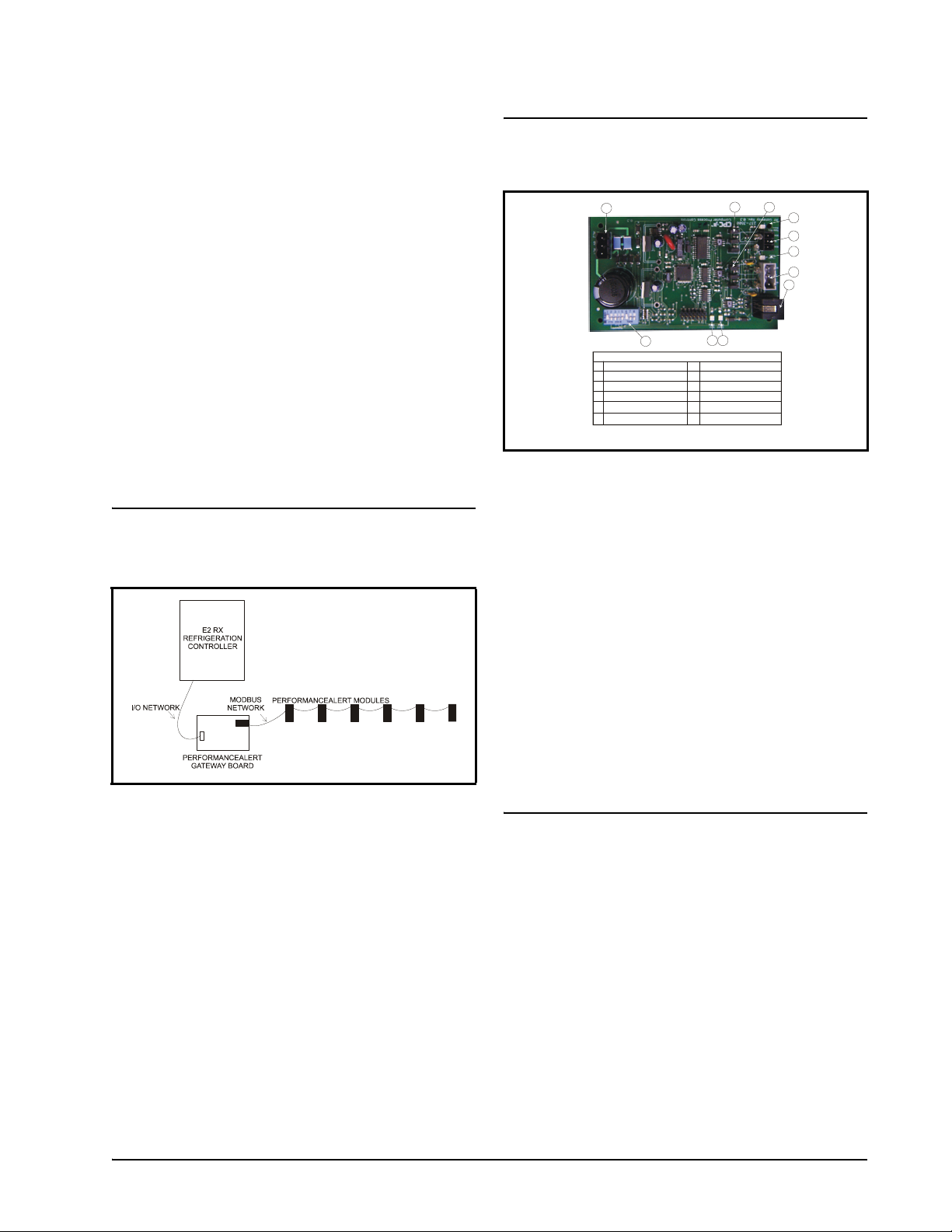

Figure 1-1 - Typical Layout of PerformanceAlert™ Modules and Gateway Board

A typical layout of a CPC-controlled Perfor-

manceAlert™ network configuration is shown in Figure 1-

alent of up to fourteen 16AI boards.

1.3. The PerformanceAlert™

Diagnostic Module

1. Each compressor in each rack is equipped with one PerformanceAlert™ Diagnostic Module. All modules are

wired together in a single MODBUS daisy-chain and connected to the PerformanceAlert™ Gateway board. The

Gateway Board is also connected to the E2 via the I/O network, where it mimics the behavior of a MultiFlex input

board (16AI) and sends values from the modules to the E2

as virtual board/point addresses.

The Copeland® PerformanceAlert™ Diagnostic Module is a breakthrough innovation for troubleshooting refrigeration system faults. The module can be installed in the

electrical box of the condensing unit near the compressor

contactor or in the electrical panel of a refrigeration rack

system. By monitoring and analyzing data from the Cope-

®

land

brand compressors, the module can accurately detect

the cause of electrical and system related issues.

The PerformanceAlert™ Gateway System Overview • 1

Page 8

The PerformanceAlert™ Gateway is compatible with

the following PerformanceAlert™ module part numbers:

P/N

®

Application

®

Perfor-

Copeland

943-0059-00 1-phase Scroll

943-0057-00 3-phase Scroll

943-0053-00 1-phase Reciprocating

943-0055-00 3-phase Reciprocating

Table 1-1 - Copeland® PerformanceAlert™ Module Part Numbers

Installation and operation of the Copeland

manceAlert™ Diagnostic Module is documented and supported by Copeland

®

, and is beyond the scope of this

document. For more information, visit www.EmersonClimate.com or contact Emerson Climate Technologies, Inc.

at 1-888-EMR-9950.

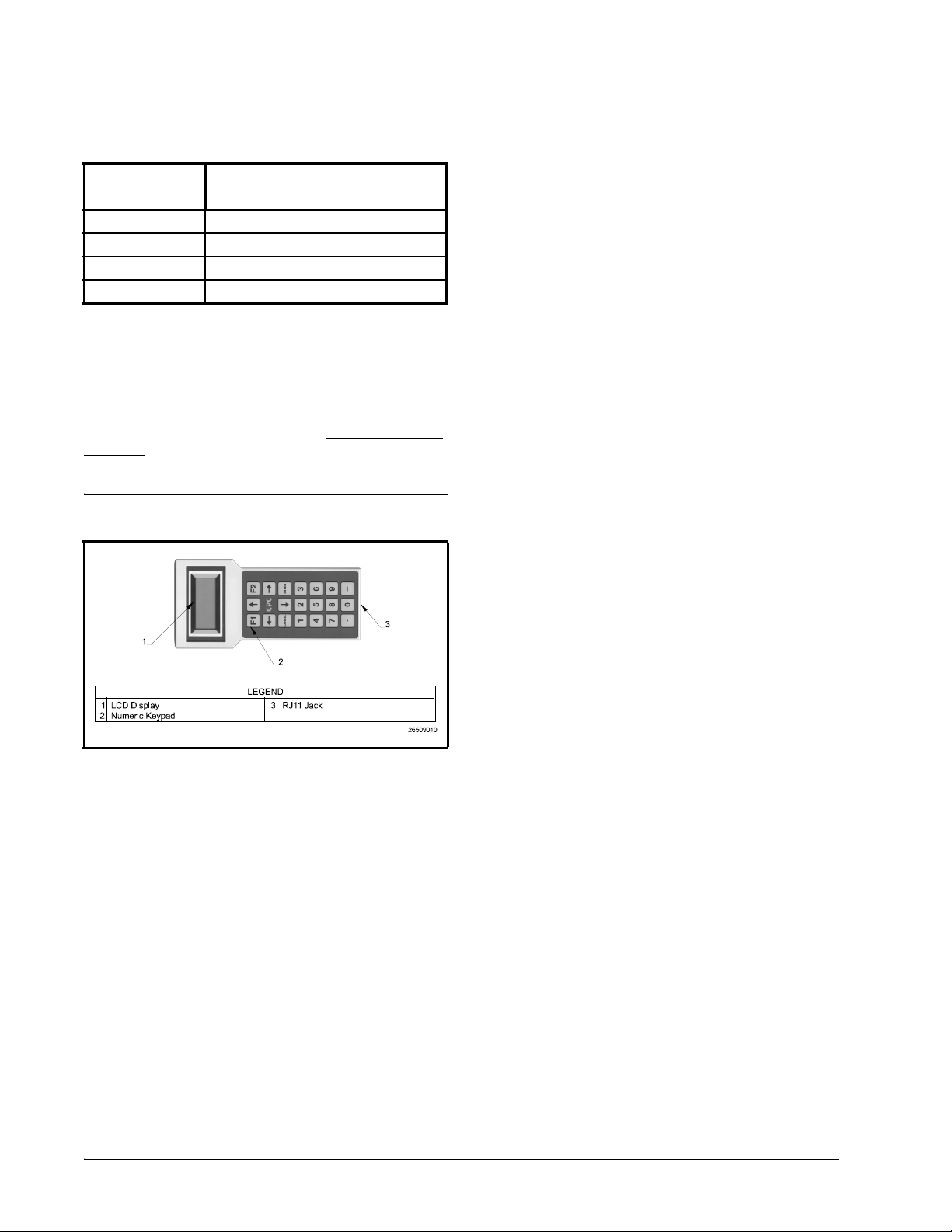

1.4. Hand-Held Terminal

Figure 1-3 - Hand-Held Terminal (HHT)

The Hand-Held Terminal (HHT) (P/N 811-3110),

shown in Figure 1-3, connects directly to the RJ11 jack on

the Gateway and is used to configure and view status for

the Gateway and its associated modules.

2 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 9

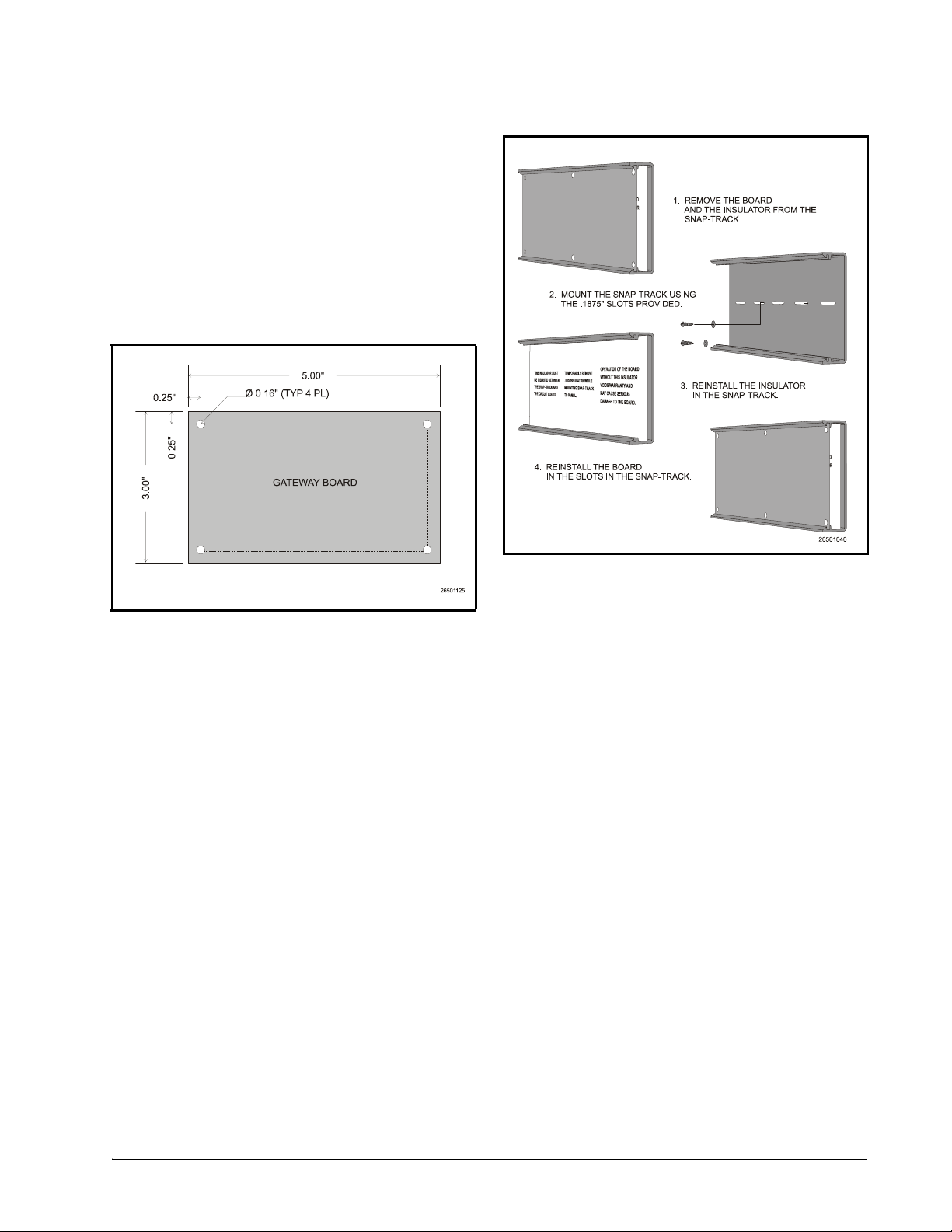

2 Gateway Board

Mounting

The Gateway is typically mounted in the same area as

the site controller, near the controller’s 16AI, 8RO, and

other RS485 Network peripherals. The Gateway is designed to fit into a standard 3" snap track (supplied with the

board) or may be mounted in a panel or on stand-offs. Follow the dimensions in Figure 2-1 for panel mounting.

Figure 2-2 - Snap-Track Installation

Figure 2-1 - Gateway Board Mounting Dimensions

The Gateway should be mounted in an environment

with ambient temperature between -40°F and 150°F, with a

non-condensing relative humidity between 5% and 95%.

Gateway boards are not supplied with an enclosure but

come with a snap-track for easy installation. The insulation

sheet and I/O board must be removed from the track before

the track is mounted. The snap-track is mounted using the

0.1875” mounting slots. Figure 2-2 shows this installation

procedure.

Hand-Held Terminal Gateway Board Mounting • 3

Page 10

3 Gateway Power

Wiring

Input Voltage

Power

Table 3-1 - Gateway Power Requirements

The Gateway requires 24VAC power from a Class 2

center-tapped transformer.

Emerson Climate Technologies Retail Solutions supplies several sizes of center-tapped transformers for powering multiple 16AIs, 8ROs, and other RS485 peripheral

boards of the E2, Einstein, and REFLECS systems.

Refer to your controller’s user manual for information

on how to use the center-tapped transformers listed in Ta-

ble 3-1 to power multiple RS485 I/O devices for the US and

Canada.

Figure 3-1 shows how to connect the 56VA and 80VA

transformers to the Gateway power connector.

P/N

Power Rating

Table 3-1-US and Canada Power Ratings for CPC Transformers

24VAC, Class 2, 50/60Hz

5VA

Three-Board Six-Board

640-0056 640-0080

5 6 VA 8 0 VA

Figure 3-1 - Pinout for the 56VA (640-0056) and 80VA (640-

0080) Transformers

4 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 11

4 Networking

Networking the PerformanceAlert™ Gateway System

requires interconnecting the Gateway with all PerformanceAlert™ modules on the MODBUS network, as well

as connecting the Gateway to the E2 via the RS485 I/O network port.

Cable Type

Emerson Climate Technologies Retail Solutions specifies all RS485 I/O and MODBUS wiring used by the E2

must be Belden 8641 (24AWG, 300V, CPC P/N 135-

8641); Belden 8761 (22 AWG, 300V not stocked by CPC);

or a 600V-shielded 22AWG equivalent stocked by CPC (P/

N 135-0600). These are two-connector shielded twisted

pair cable that support a maximum daisy chain cable distance of 4000 feet (1219 m) between the E2 and the end device on the network.

4.1. Connecting the Perfor-

manceAlert™ Modules To

the Gateway Board

MODBUS network devices must be installed using a

daisy-chain network structure. A daisy-chain connects the

Gateway and all associated PerformanceAlert™ modules

in a single unbranched network segment, with termination

resistance applied to the network at the two end devices.

Figure 4-1 shows two diagrams of valid daisy-chain network structures, one with the Gateway at the beginning of

the network segment, and one with the Gateway in the middle of a network segment.

4.1.1. PerformanceAlert™ Module MODBUS Wiring

Figure 4-2 - PerformanceAlert™ MODBUS Wire Connection

The MODBUS connector for the PerformanceAlert™

module is located as shown in Figure 4-2. Connect the

MODBUS network cable segment(s) so that the BLACK

wire connects to all positive (+) terminals and the WHITE

wire connects to all negative (-) terminals. Connect the

SHIELD wire to the GND terminal of the connector.

The GND terminal of each module must also be connected to a separate solid earth ground, using a 14AWG

wire no more than six (6) inches in length.

The best earth ground sources to use are listed below, in

priority order:

• A large metal panel or plate that is connected to a

good electrical ground. A panel or plate that is at

least 3 feet by 3 feet (0.9 m by 0.9 m) is desirable.

• Earth grounded steel rack.

• Water pipes (metal, assuming there are no plastic

sections).

• Electrical system earth ground.

Note: If grounding against a metal plate or

panel that is coated or painted, scrape away

the coating to expose the bare metal before

making the ground attachment.

Figure 4-1 - MODBUS Daisy Chain Structures

Connecting the PerformanceAlert™ Modules To the Gateway Board Networking • 5

Page 12

4.1.2. PerformanceAlert™ Module MODBUS Addressing

Figure 4-3 - PerformanceAlert™ MODBUS Addressing

Jumpers AD1 through AD4 on the PerformanceAlert™

module set the MODBUS device address. Modules should

be uniquely numbered in sequence starting with 1 and continuing in numerical order up to 14. Refer to Figure 4-3 for

jumper settings for each address number.

4.1.3. Gateway MODBUS Wiring

4.1.4. MODBUS Termination

Figure 4-4 - Gateway Board MODBUS Wiring

Connect the Gateway to the MODBUS network as

shown in Figure 4-4. Connect the BLACK wire to

RS485+, the WHITE wire to RS485-. Connect the

SHIELD wire to the middle (0v) terminal.

For convenience, when the Gateway is not the end of

the daisy-chain, the MODBUS connector has a second set

of terminals.

Figure 4-5 - MODBUS Termination

To minimize network interference on the MODBUS

network, the daisy chain must be terminated at both endpoints, with all devices in between left unterminated. Refer

to the diagram in Figure 4-1 for diagrams showing the daisy chain endpoints.

The PerformanceAlert™ module is terminated by placing a jumper across the TRMNTR pins. The Gateway

board is terminated by setting the three jumpers next to the

MODBUS connector to the TERMINATION setting as

shown in Figure 4-5.

4.2. Connecting the Gateway to

the RS485 I/O Network

Connect the RS485 I/O Network wire to the three-terminal connector on the Gateway board as shown in Figure

4-6. For further information about how RS485 networks

are configured, refer to your site controller’s user manual.

6 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 13

Figure 4-6 - Connecting the Gateway to the RS485 Network

4.2.1. Gateway Board Numbering

The E2, Einstein, or REFLECS controller interprets the

PerformanceAlert™ Gateway board as one or more 16AI

Analog Input boards. The number of virtual "boards" is dependent on two things: the setting of the board’s address

DIP switch, and whether the PerformaceAlert Gateway

will operate in "Condensed" or "Expanded" data mode.

In Condensed mode, the Gateway behaves in the same

manner as one 16AI board whose address is equal to the

address set by the DIP switches (see Figure 4-7 on page 7).

In Expanded mode, the Gateway assigns each PerformanceAlert™ module a 16AI address equal to its MODBUS address. For example, when modules 1 through 8 are

enabled through the Gateway in Expanded mode, the Gateway behaves as eight 16AI boards numbered 1 through 8.

The address DIP switches have no function when the Gateway is set to Expanded mode.

4.2.1.1. Setting the Gateway Address Switch

MODBUS

BAUD

RATE

Figure 4-7 - Gateway Dip Switch Numbering

If using the PerformanceAlert™ Gateway in Condensed Mode, set the address DIP switches to the virtual

16AI board address you wish the Gateway to use (Figure

4-7). The Gateway in Condensed mode behaves in the

same manner as one 16AI board whose address is equal to

the address set by the DIP switches.

4.2.2. Setting the Baud Rate Dip Switch-

es

Dip switches 6 and 7 (Figure 4-8) control the baud rate

at which the Gateway communicates with the site controller on the RS485 Network. These switches must be set to

the same baud rate setting as the E2, Einstein, or REFLECS

(usually 9600 baud).

Dip switch 8 controls the baud rate on the MODBUS

network. Since the PerformanceAlert™ module communicates at 9600 baud only, set this switch to the DOWN position to select 9600 baud (see Figure 4-8).

Connecting the Gateway to the RS485 I/O Network Networking • 7

Page 14

G

ATEWAY

S

DIP SWITCH

I/O NETWORK OR

COM A AND D

BAUD RATE

2345678

1

I/O NET BAUD RATE SETTINGS

9600 19200

MODBUS BAUD RATE SETTINGS

Figure 4-8 - Dip Switch Setting for Numbering Gateway

MODBU

BAUD

RATE

9600

4.2.3. Gateway Board RS485 I/O Termination

Figure 4-9 - Gateway RS485 I/O Network Termination

If the Gateway board will be an end device on the

RS485 I/O network daisy chain, set the three jumpers next

to the I/O Network connector to the TERMINATION position as shown in Figure 4-9.

8 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 15

5 Gateway Software

Setup

When the Gateway and all PerformanceAlert™ modules are correctly powered up and networked, the Gateway

firmware must be configured with a Hand-Held Terminal

(HHT) to set the Gateway’s data mode, enable used PerformanceAlert™ MODBUS addresses, and disable unused

MODBUS addresses.

1. Plug the HHT into the HHT jack. The Opening Screen will be shown.

PF ALERT GATEWAY

810-3730

VER: 1.10B07 02

(PRESS )

2. From the opening screen, press the DOWN

ARROW key to display the Main Menu

screen.

SELECT: 1

1=INDIVIDUAL

2=STAT SUMMARY

3=GW SETUP

repeat until all are set correctly.

PF ALERT-1 : ENB

PF ALERT-2 : ENB

PF ALERT-3 : ENB

PF ALERT-4 : ENB

IMPORTANT: Always set unused addresses to "DIS." In Expanded Mode, this

will allow the 16AI board number to be

used by other I/O network devices (see

Section 6.3., I/O Setup for Expanded Mode).

5. To move to the next screen, press DOWN

ARROW until the cursor moves off the bottom of the HHT screen, then press DOWN

ARROW one more time. The next screen,

showing PF ALERT-5 through 8, will be

shown.

6. Repeat steps 4 and 5 until all PF ALERT

fields are set. From the fourth and last PF

ALERT field screen, press the DOWN ARROW key to scroll to the next config screen,

the Data Mode screen.

PF ALERT DATA:

CONDENSED

3. Press RIGHT ARROW to move the cursor to

the SELECT field, then press 3 to choose GW

SETUP. Press the DOWN ARROW key

twice to enter your selection and view the PF

Alert Enable screens.

PF ALERT-1 : UNK

PF ALERT-2 : UNK

PF ALERT-3 : UNK

PF ALERT-4 : UNK

The four PF Alert Enable screens have a total of fourteen fields numbered PF ALERT-1 through PF ALERT-14.

These fields correspond to the addresses of the connected

PerformanceAlert™ modules. The field values represent

whether the module at that address is enabled (ENB), disabled (DIS), or unknown (UNK) meaning no module with

that address is currently communicating with the gateway.

For each address, if a module is connected and is using that

address, the PF ALERT field corresponding to that number

must be set to ENB (enable). All others must be set to DIS

or left in the UNK state.

4. Press the RIGHT ARROW key to move the

cursor to the PF ALERT 1 field at the top of

the screen. Use the MINUS (-) key to change

the field’s value from DIS (if no module is

connected that uses this address) or ENB (if a

module will use this address). Use the UP

ARROW and DOWN ARROW keys to move

the cursor to other fields on the screen, and

7. Press RIGHT ARROW to move the cursor to

the Data Mode field. Use the MINUS (-) key

to toggle between CONDENSED and EXPANDED mode. Refer to Section 6.2., I/O

Setup for Condensed Mode, and Section 6.3.,

I/O Setup for Expanded Mode, for a complete

description of both modes. When finished,

press DOWN ARROW twice to save changes

and move to the next screen.

8. The final screen under the GW SETUP menu

option is a read-only status screen showing

the configuration of the I/O and MODBUS

networks. The first two lines, IONET ADDRESS and IONET BAUD, show the board

number and baud rate as set by the Gateway

board’s DIP switches. The last two lines,

MOD BAUD and MOD PARITY, will always read 9600 and NONE respectively,

since the Gateway’s MODBUS port needs to

be set to 9600 baud with no parity. If MOD

BAUD reads 19200, the Gateway dip switch

is set wrong and must be switched to the

DOWN position (see Figure 4-8 on page 8)

IONET ADDR:1

IONET BAUD:9600

MOD BAUD :9600

MOD PARITY:NONE

Connecting the Gateway to the RS485 I/O Network Gateway Software Setup • 9

Page 16

6 PerformanceAlert™

I/O Summary

6.2. I/O Setup for Condensed Mode

During operation, the PerformanceAlert™ Gateway

serves two main functions:

• Communicating with, and collecting information

from, the PerformanceAlert™ modules, and

• Passing along information from the modules to the

site controller in the form of virtual 16AI point values.

This section will show how to map data points from the

Gateway to I/O points in the site controller for both data

modes (Condensed and Expanded).

6.1. E2 I/O Board Setup

The E2 must be configured to communicate with the

Gateway by adding the board(s) to the system configuration.

Log in to the E2 with an access level high enough to

change configuration, and press

Connected I/O Boards and Controllers screen.

I to open the

Note: If you will be using the PerformanceAlert™ Gateway in Expanded Mode,

skip this section and follow the instructions in

Section 6.3., I/O Setup for Expanded Mode.

In Condensed Mode, the Gateway behaves as a single

16AI board address whose address is set by the board’s address DIP switches (see Section 4.2.1.1., Setting the Gate-

way Address Switch).

Points 1 through 14 of this virtual board correspond to the overall alarm status of PerformanceAlert™ modules #1 through #14. The point will be ON as long as one or more of the following failure conditions are active:

1. The PerformanceAlert™ module is not communicating with the Gateway, OR

2. Alert code 4, 5, 6, 7, 8, and/or 10 are active,

OR

3. The compressor is in lockout

6.2.1. Condensed Mode Point Setup

To set up the Gateway’s virtual 16AI points for use in

logging, alarming, and I/O control, press

PUT DEFINITIONS) to access the Input Status screen.

Sixteen rows in the Input Status table will have the

same number in the Brd field as the virtual 16AI address of

the Gateway board. These rows correspond to "points" 1

through 16 on the Gateway. Since 15 and 16 are invalid

PerformanceAlert™ module addresses, these points will be

unused and will always be OFF.

I (IN-

To make a point ready for use by the E2, you must set

the input name and type from this screen:

4. Use the arrow keys until the cursor highlights

the Application field in the row corresponding to the point you wish to set up.

Figure 6-1 - Connected I/O Boards Screen

Add as many 16AIs as are necessary to cover the board

number(s) used by the PerformanceAlert™ Gateway. The

E2 will add the specified number of 16AI boards, numbered 1 through the number you entered, to the network

configuration. Press

After adding the board(s), press

LINE STATUS) to view the current status of the network.

Verify that the address(es) used by the PerformanceAlert™

Gateway are shown in this list and read "Online."

10 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Jto save and exit.

I (ON-

5. Press

6. When prompted to select the data type, select

A - SETUP

- Digital. The Digital Input setup screen

will be displayed.

7. In the Point Name field, enter a unique name

that will help you & others easily know the

function of this point. For example, if setting

up point 1, which will be the alarm status of

PerformanceAlert™ module #1, an appropriate name would be PF ALERT CMP1.

8. Press

J to save the name and return to

Page 17

the Input Status screen. The point will now

display a "D" (for digital) in the Type column, and will also display the current value

of the point in the Value field (ON or OFF).

9. Repeat steps 1 through 5 until all points are

defined.

When finished, the points are ready for use in E2 applications. If you wish to set up the Condensed Mode points

so that alarms from PerformanceAlert™ are written to the

E2 Advisory Log, refer to Section 8.1.1., Generic Alarm-

ing Setup.

You may wish to use the Gateway points as inputs for

Digital Sensor control applications, where you may set up

output control. Refer to the E2 User’s Guide (P/N 026-

1610) for Digital Sensor Control setup instructions.

6.3. I/O Setup for Expanded

Mode

If you will be using the PerformanceAlert™

Gateway in Condensed Mode, skip this section

and follow the instructions in Section 6.2., I/O

Setup for Condensed Mode.

NOTE: Expanded Mode may not be used if

networking the Gateway to an RMCC. The

RMCC will only support Condensed Mode.

and functions are fixed and are the same for each module.

Table 6-1 lists the point numbers and their data types and

functions.

Point # Type Function

1 Digital High DLT Warning

2 Digital System Component Trip

3 Digital Compressor Short Cycle

4 Digital Compressor Locked Rotor

5 Digital Open Circuit

6 Digital Missing Phase

7 Digital 3 Phase Circuit Failure

8 Digital Welded Contactor

9 Digital Low Voltage Notice

10 Digital Communication Failure

11 Digital DLT Open/Short Failure

12 Digital Relay State

13 Analog T1 Current (0-655 Amps)

14 Analog T3 Current (0-655 Amps)

15 Analog Discharge Line Temperature

(-58°F—266°F)

16 Digital Digital Summary (same as alarm

summary output in Condensed

mode (Section 6.2.) )

Table 6-1 - PerformanceAlert™ Gateway Expanded Mode Input Map

In Expanded mode, for every PerformanceAlert™

module address set to "enable" (ENB) in the Gateway (see

step 4 of the Gateway Setup instructions in Section 5), the

Gateway board will emulate a 16AI board whose board

number is the same number as the PerformanceAlert™

module. When a PerformanceAlert™ module is set to "disable" (DIS) in the Gateway, the Gateway board does not

use this board number, meaning it may be used by other

MultiFlex input boards.

Each virtual 16AI board address shares sixteen data

points corresponding to alarm states and sensor values

from the PerformanceAlert™ module. The point numbers

Points 1 through 11 are alarm states. They will be ON

whenever the corresponding alarm type is active on the

PerformanceAlert™ module, and OFF when the alarm type

is not active.

Point 12 represents the digital state of the PerformanceAlert™’s compressor relay (ON when the compressor relay is ON, and OFF when the compressor is OFF).

Points 13 and 14 are the measured currents through T1

and T3 respectively.

Point 15 is the measured temperature read from the discharge line temperature sensor.

Point 16 has the same function as the alarm state point

in Condensed Mode. It is ON whenever any alarm is active

on the PerformanceAlert™ module. Consequently, whenever any of the points from 1 through 11 are ON, point 16

will be ON as well.

6.3.1. Expanded Mode Point Setup

To set up the Gateway’s virtual 16AI points for use in

logging, alarming, and I/O control, press

PUT DEFINITIONS) to access the Input Status screen.

I (IN-

I/O Setup for Expanded Mode PerformanceAlert™ I/O Summary • 11

Page 18

For every board number used by the PerformanceAlert™ Gateway, there will be sixteen rows in the

Input Status table corresponding to "points" 1 through 16

on the Gateway. To make a point ready for use by the E2,

you must set the input name and type from this screen.

Setup for Digital Points (1-12, 16)

1. Use the arrow keys until the cursor highlights

the Application field in the row corresponding to the point you wish to set up.

2. Press

3. When prompted to select the data type, select

A - SETUP

- Digital. The Digital Input setup screen

will be displayed.

4. In the Point Name field, enter a unique name

that will help you & others easily know the

function of this point. For example, if setting

up point 1 on board #3, which will be the

High DLT warning for PerformanceAlert™

module #3, an appropriate name would be

HIGH DLT CMP3.

5. Press

6. Repeat steps 1 through 5 until all digital

Setup for Points 13 and 14 (Current Transducers)

1. Use the arrow keys until the cursor highlights

2. Press

3. When prompted to select the data type, select

J to save the name and return to

the Input Status screen. The point will now

display a "D" (for digital) in the Type column, and will also display the current value

of the point in the Value field (ON or OFF).

points are defined.

the Application field in the row corresponding to the point you wish to set up.

A - SETUP

- Analog. The Analog Input setup screen

will be displayed.

4. In the Point Name field, enter a unique name

that will help you & others easily know the

function of this point. For example, if setting

up point 13 on board #3, which will be the T1

current for PerformanceAlert™ module #3,

an appropriate name would be T1 AMPS

CMP3.

5. In the Sensor Type field, press F4 to access

the Look-Up table. Highlight "Linear" as the

sensor type, and press

6. In the Select Eng. Units field, press F4 to access the Look-UP table. Highlight "A" as the

unit type, and press

7. The Low Eng Units and High Eng Units

> to select.

> to select.

fields near the bottom of the screen must be

set to 0 and 655.5 respectively. The Low Eng

Units by default should read 0 and will not require modification. Move the cursor to the

High Eng Units field and enter 655.5 as the

new value.

8. Press

9. Repeat steps 1 through 8 until all current

Setup for Point 15 (Discharge Line Temp)

1. Use the arrow keys until the cursor highlights

2. Press

3. When prompted to select the data type, select

J to save the name and return to

the Input Status screen. The point will now

display a "A" (for digital) in the Type column, and will also display the current value

of the point in the Value field (ON or OFF).

transducer points have been defined.

the Application field in the row corresponding to the point you wish to set up.

A - SETUP

- Analog. The Analog Input setup screen

will be displayed.

4. In the Point Name field, enter a unique name

that will help you & others easily know the

function of this point. For example, if setting

up point 15 on board #1, an appropriate name

would be DLT CMP1.

5. In the Sensor Type field, press F4 to access

the Look-Up table. Highlight "Linear" as the

sensor type, and press

6. In the Select Eng. Units field, press F4 to access the Look-UP table. Highlight "DF" (if

using °F on this E2) or "DC" (if using °C on

this E2) as the unit type, and press

lect.

7. Set the Low Eng Units and High Eng Units.

• If using °C (DC) as the unit, enter -50 as

the Low Eng Unit and 130 as the High Eng

Unit.

• If using °F (DF) as the unit, enter -58 as the

Low Eng Unit and 266 as the High Eng

Unit.

8. Press

When finished, the points are ready for use in E2 applications. You may wish to use the Gateway points as inputs

for Analog and Digital Sensor control applications, where

J to save the name and return to

the Input Status screen. The point will now

display a "D" (for digital) in the Type column, and will also display the current value

of the point in the Value field (ON or OFF).

> to select.

> to se-

12 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 19

you may set up logging, alarming, and (if desired) output

control. Refer to the E2 User’s Guide (P/N 026-1610) for

Analog and Digital Sensor Control setup instructions.

I/O Setup for Expanded Mode PerformanceAlert™ I/O Summary • 13

Page 20

7 Operation

During normal operation the operating status of the PerformanceAlert™ modules can be viewed in either of three

ways:

• Through E2 appliction status screens,

• Through PerformanceAlert™ Software loaded on a

laptop computer, and

• Through the Hand-Held Terminal interface on the

Gateway board.

The means for checking status on the E2 will depend on

how you have configured the Gateway board points. If you

created Sensor Control applications for each point, you

may view the PerformanceAlert™ status using the Sensor

Control status and summary screens. Refer to the E2 User’s

Guide (P/N 026-1610) for more details.

The PerformanceAlert™ Software is a utility which

connects the PerformanceAlert™ module to an RS232 or

USB port on the computer and allows direct viewing of a

module’s diagnostics information and setpoints. This tool

is documented and supported by Copeland

the scope of this document. For more information, visit

www.EmersonClimate.com

Technologies, Inc. at 1-888-EMR-9950.

The Hand-Held Terminal can be used to look at the

overall online and alarm summary of all modules (Section

7.1.) as well as the status of an individual PerformanceAlert™ module (Section 7.2.).

or contact Emerson Climate

7.1. PerformanceAlert™ Stat

Summary

1. Plug the HHT into the Gateway board’s HHT

jack.

2. Press the DOWN ARROW key to move to

the Main Menu.

SELECT: 2

1=INDIVIDUAL

2=STAT SUMMARY

3=GW SETUP

®

, and is beyond

7.1.1. Screen 1: Comm Status

COMM STATUS:

12345678901234

111111XXXXXXXX

E2: ACTIVE

Comm Status. The list of characters on Line 3 of the

HHT display, which are numbered 1 through 14 by the

numbers above them on Line 2, represent the online status

of modules 1 through 14. For each module, this character

will display one of the following states:

• 1 - PerformanceAlert™ module is communicating

with the Gateway.

• 0 - PerformanceAlert™ module is not communicating with the Gateway

• X - This address is set to “disable” (DIS) and thus

not communicating (see step 4 of Section 5).

E2 Status. The bottom line of the HHT display shows

the current state of communication between the Gateway

and the E2. This field will read ACTIVE when the Gateway

and E2 are communicating, or NO COMM when they are

not communicating.

7.1.2. Screen 2: PF Alert Alarm Status

PF ALERT ALARM

STATUS:

1234567901234

000000XXXXXXX

The list of characters on Line 4, numbered 1 through 14

by the numbers above them on Line 3, show the current

alarm active status of the PerformanceAlert™ modules.

For each module, this character will display one of the following states:

• 1 - Active alarm, following the same criteria as the

alarm status outputs (see Section 6.2. for ON criteria)

• 0 - No alarms are active on the PerformanceAlert™

module

• X - This address is set to “disable” (DIS) and thus

not communicating (see step 4 of Section 5).

3. Press RIGHT ARROW and then 2 to select

"STAT SUMMARY." Press the DOWN ARROW key two times to navigate to the first

stat summary screen.

The six screens under the Stat Summary heading will

show you online status, alarm status, and firmware version

for the PerformanceAlert™ modules.

14 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 21

7.1.3. Screens 3 through 6: Firmware Versions

1 ON [2.00B02]

2 ON [2.00B02]

3 ON [2.00B02]

4 ON [2.00B02]

5 ON [2.00B02]

6 ON [2.00B02]

7 OFF [ ]

8 OFF [ ]

9 OFF [ ]

10 OFF [ ]

11 OFF [ ]

12 OFF [ ]

13 OFF [ ]

14 OFF [ ]

field, enter the number of the PerformanceAlert™ module you wish to view.

Press DOWN ARROW twice.

PF ALERT 1-14

SELECT: 1

You may only select a PerformanceAlert™ address for

a module that is set to ENABLE and is communicating

with the Gateway. If a module is not enabled or is not communicating, an error message will be given.

If the address selected is on-line, the Individual Module

Menu will be shown.

7.2.1. Individual Module Status

SELECT: 1

1=STATUS 4=STATS

2=HISTORY5=RESET

3=CONFIG

These screens show the enable/disable status of all 14

PerformanceAlert™ module addresses, and the firmware

versions of the connected PerformanceAlert™ modules.

Addresses set to enable will be shown as ON or OFF in

these screens, while disabled module addresses will be

shown as DIS.

Any time a module is enabled and communicated with

a PerformanceAlert™ Gateway, its firmware revision

number is recorded by the Gateway and displayed in this

screen. In most cases, this means enabled modules will be

shown with firmware revision numbers, and disabled ones

will be shown without revision numbers between the

brackets. If a module is later removed or disabled, however, its revision number will remain in its address slot.

7.2. Individual Perfor-

manceAlert™ Module Status

1. Plug the HHT into the Gateway board’s HHT

jack.

2. Press the DOWN ARROW key to move to

the Main Menu.

SELECT: 1

1=INDIVIDUAL

2=STAT SUMMARY

3=GW SETUP

To view the status screens, press RIGHT ARROW to move the cursor to the Select field. Press 1 and then DOWN ARROW twice.

7.2.1.1. Screen 1

PF ALERT: 1

ONLINE

ALARM: NONE

This screen shows the on-line status and alarm status of

the module.

The on-line status will read ONLINE, OFFLINE, or

DISABLE.

The alarm status will read NONE when no alarm is active. It will read ACTIVE when one or more of the following conditions are true:

• The module is offline,

• The PerformanceAlert™ module has shut down the

compressor (see Copeland

Application Engineering Bulletin and Section

7.2.3.7., or

• Alert codes 4 (Locked Rotor Alarm), 5 (Open Circuit Detected), 6 (Missing Phase Alarm), 7 (Open

Circuit/Reverse Phase), 8 (Welded Contactor

Alarm), and/or 10 (Lost Communication) are active.

®

PerformanceAlert™

3. Press RIGHT ARROW and then 1 to select

“INDIVIDUAL.” Press the DOWN ARROW

key two times.

4. Press the RIGHT ARROW key. In the Select

Individual PerformanceAlert™ Module Status Operation • 15

Page 22

7.2.1.2. Screen 2

IN ST: 00000000

OUT ST: 00000000

SYS ST:0 0000

FLAGS : 00000000

7.2.2.1. Screens 1 and 2

LAST 10 ALARMS:

A1 -MOST RECENT

A10-PAST 24H

A1: 10 A2: 4

This status screen shows the input, output, system, and

warning flag status displayed as bits.

7.2.1.3. Screen 3

POWER V : 0.00

CT1 (A) : 1.04

CT2 (A) : 0.96

LRA PEAK: 0.00

This status screen shows the module’s input power (in

volts), the value of CT1 and CT2 (in amps), and the LRA

Peak (in amps).

7.2.1.4. Screen 4

PK RMS A : 1.0

LINE TEMP: 78.00

NOW ALERT: 0

This status screen shows the peak RMS current (in

amps), the current discharge line temperature (in degrees

Farrenheit), and the alarm code of the current alert being

displayed. If any alert is being displayed, its alert description will be shown in Line 4 of the display; otherwise, Line

4 will be blank.

7.2.1.5. Screen 5

PAST ALERT: 10

NO COMMUNICATION

This status screen shows the code number and description of the last alert that occurred in the module (not the one

currently active, if an alert is currently active).

7.2.2. Individual Module History

SELECT: 2

1=STATUS 4=STATS

2=HISTORY5=RESET

3=CONFIG

To view the status screens, press RIGHT ARROW to move the cursor to the Select field. Press 2 and then DOWN ARROW twice.

A3:6 A4 :4

A5:6 A6 :4

A7:6 A8 :8

A9:10 A10:1

Screens 1 and 2 show the last 10 alert condition codes

that have occured on this module in the past 24 hours

(counting back from the current time). The alarm codes are

shown from most recent (A1) to least recent (A10).

7.2.2.2. Screens 3 through 11

HIGH DISCHARGE

DAYS: C1234567

NNNNYNNN

COUNT: 3

Screens 3 through 11 show the 7-day history of each of

the alarm codes from 1 through 9, showing which days they

have occurred. The current "day," which represents the period of time between the current time and 24 hours ago, is

displayed under the "C." The remaining seven fields represent alarm occurrences from 1 to 7 days previous to the current time.

If one or more alarms have occurred during any of the

days displayed on this screen, a Y will appear under the day

the alarm or alarms occurred. Otherwise, an N will be

shown, meaning no alarms of that type occurred on that

day.

The Count field at the bottom of each screen shows the

cumulative total of alarms that have occurred on this module in its entire time of operation.

Table 7-1 shows the order of the screens for each alarm

code type.

Screen # Alarm Code

3 HIGH DISCHARGE (Code 1)

4 COMPONENT TRIP (Code 2)

5 SHORT CYCLING (Code 3)

6 LOCKED ROTOR (Code 4)

7 OPEN CKT COMPR (Code 5)

8 MISSING PHASE (Code 6)

9 REVERSE PHASE (Code 7)

10 WELDED CONTACTS (Code 8)

11 LOW VOLTAGE (Code 9)

Table 7-1 - Alarm Status Screen Order (By Code)

16 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 23

7.2.2.3. Screens 12 and 13

WF0 HI DLT OFF

WF1 LCK ROT OFF

WF2 OPEN CIR OFF

WF3 LOW V OFF

7.2.2.6. Screen 18 and 19

TRIP HISTORY:

DAYS: C1234567

NNNNNNNN

COUNT : 0

WF4 MMC OFF

WF5 DLT OPEN OFF

WF6 DLT SHOR OFF

WF7 OFF

Screens 6 and 7 shows the current state of the warning

flags 0 through 7.

7.2.2.4. Screen 14

NOW ALERT : 0

LAST ALERT: 10

Screen 8 shows the current alert code active in the module (NOW ALERT), and the alert code that was active previous to the current one (LAST ALERT).

7.2.2.5. Screens 15 through 17

CMPR: START RUN

DAY1: 0 0

DAY2: 0 0

DAY3: 0 0

CMPR: START RUN

DAY4: 0 0

DAY5: 0 0

DAY6: 0 0

CMPR: START RUN

DAY7: 0 0

STARTS: 0

RUN : 0

The Day1 through Day7 fields show the number of

times the compressor has started and the runtime (in minutes) for the current day (Day1) and the previous 6 days

(Day2 through Day7).

BYPASS HISTORY:

DAYS: C1234567

NNNNNNNN

COUNT : 0

Screens 18 and 19 show the 7-day history of trip conditions and bypass conditions, showing which days they have

occurred. Screen 18 shows the history of trip conditions,

while screen 19 shows the history of bypass conditions.

The current "day," which represents the period of time

between the current time and 24 hours ago, is displayed under the "C." The remaining seven fields represent alarm occurrences from 1 to 7 days previous to the current time.

If one or more trips or bypasses have occurred during

any of the days displayed on this screen, a Y will appear under the day the trip(s) or bypass(es) occurred. Otherwise, an

N will be shown, meaning no trips or bypasses occurred on

that day.

The Count field at the bottom of each screen shows the

cumulative total of trips or bypasses that have occurred on

this module in its entire time of operation.

7.2.3. Individual Module Configuration

SELECT: 3

1=STATUS 4=STATS

2=HISTORY5=RESET

3=CONFIG

To view the status screens, press RIGHT ARROW to move the cursor to the Select field. Press 3 and then DOWN ARROW twice.

7.2.3.1. Screen 1: Rack # and Install Date

PF ALERT: 1

RACK : 2

The Starts and Run fields on Screen 17 show the total

number of compressor starts and the total runtime (in minutes) since the last time statistics were cleared in the module.

Individual PerformanceAlert™ Module Status Operation • 17

On this screen, you may enter a rack number . This

number is stored in the module memory for reference purposes.

Page 24

7.2.3.2. Screen 2: Date of Installation

DATE OF

INSTALLATION:

DATE: 08-15-0

7.2.3.6. Screen 5: Setpoints

DLT TTP : 230.0

SEVERE ALERT

OFF TIME : 20

LO V SP: 217.0

On this screen, you may enter the date the compressor

was installed. This date is stored in the module memory for

reference purposes.

7.2.3.3. Screen 3: Customer Code

CUSTOMER CODE

CODE: 000

On this screen, you may enter a three-character customer code number. This code is stored in the module memory

for reference purposes.

7.2.3.4. Screen 4: Compressor Model

COMPRESSOR MODEL

This screen enables you to enter a description of the

compressor model the PerformanceAlert™ module is attached to. Press the RIGHT ARROW key to make the cursor appear in Line 3 of the display. To enter text on this

line, for each character use the POINT "." and MINUS "-"

keys to scroll through the alphanumeric characters until the

desired character is shown. Press RIGHT ARROW to

move to the next character. When finished, press DOWN

ARROW to enter the name, and DOWN ARROW again to

save changes and exit to Screen 4.

7.2.3.5. Screen 5: Serial Number

COMPRESSOR S/N

S/N: 1234567890

On this screen, you may enter a ten-character string of

text. This code is stored in the module memory for reference purposes.

The DLT TTP is the high temperature setpoint for tripping on high discharge line temperature. When the discharge line temperature is above the DLT TTP setpoint (in

degrees Farrenheit), a HIGH DISCHARGE alert will occur.

The Severe Alert OFF Time is the minimum number of

minutes the compressor will remain OFF when a trip occurs as a result of an alarm code 1, 4, 6, or 7. When one of

these alarm codes occurs, the compressor will not reset until the Severe Alert OFF Time delay has elapsed.

The LO V STP is the setpoint for low voltage trip. An

voltage below this value will cause a LOW VOLTAGE

alert to occur. This setpoint is a fixed value and may not

be altered.

7.2.3.7. Screens 6 through 8: Lockout Setpoints

DISABLED = 255

C1 LOUT CNT: 2

C2 LOUT CNT: 2

C3 LOUT CNT: 2

DISABLED = 255

C4 LOUT CNT: 2

C6 LOUT CNT: 1

C7 LOUT CNT: 1

OPEN CDT : 90

MIN ON TM : 0.10

MIN OFF TM: 0.10

CAUTION! Setting an Cx LOUT CNT field

to any number other than 255 will allow the

PerformanceAlert™ to shut down the compressor under severe conditions.

NOTE - For lockout to be enabled, the PerformanceAlert™ module’s Lockout Jumper must

be properly set. See the Copeland

manceAlert™ Application Engineering Bulletin for more information about this jumper and

how to set it.

®

Perfor-

For alert codes 1,2,3,4,6, and 7, the LOUT CNT field

with the number corresponding to the alert code number

sets the maximum number of times per day the alert must

occur before a lockout will occur. For example, C1 LOUT

18 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 25

CNT will be the number of times a HIGH DISCHARGE

PROTECTION alert must occur in a single 24-hour period

to cause a lockout.

If you wish to set a lockout setpoint for an alert code,

enter the desired maximum number of daily occurrences in

the field. If you do not wish to lockout for an alert code, set

the field value to 255. Table 7-2 shows the minimum and

maximum values for each field.

Property Min # of

Occurrences

C1 LOUT CNT 2 6

C2 LOUT CNT 2 10

C3 LOUT CNT 2 240

C4 LOUT CNT 2 10

C6 LOUT CNT 1 10

C7 LOUT CNT 1 10

Table 7-2 - Min/Max Field Values for LOUT CNT Parameters

The Open CDT field sets the delay time (in minutes) of

the lockout that will occur when an open circuit condition

is present. Enter a desired lockout time between 60 and 180

minutes.

The Minimum ON Time and Minimum OFF Time

fields set the minimum ON and OFF times of the compressor (in minutes or tenths of a minute). Specify the desired

minimum times from 0.1 to 15.0 minutes.

Max # of

Occurrences

7.2.4. Communication Statistics

SELECT: 4

1=STATUS 4=STATS

2=HISTORY5=RESET

3=CONFIG

The Communication Statistics screen is designed to

help troubleshoot potential network problems between the

Gateway and a PerformanceAlert™ module. From the Individual Menu, select 4 to view the Communication Statis-

tics screen.

MSG SNT: 45520

NO RESP: 2

BAD CRC: 0

INVALID:0 MX:1

MSG SNT: The total number of messages sent.

NO RESP: The number of messages that resulted in no

response.

BAD CRC: The number of messages received that had

a bad CRC.

INVALID: The number of messages that resulted in an

unexpected response (such as a MODBUS exception)

MX: The maximum number of consecutive times an er-

ror condition was detected in responses.

To clear all counts on this screen, press the CANCEL

key. The MSG SNT, NO RESP, BAD CRC, INVALID,

and MX counts will all reset to zero.

7.2.5. Resets

SELECT: 5

1=STATUS 4=STATS

2=HISTORY5=RESET

3=CONFIG

From the "Reset" menu option, you may clear a PerformanceAlert™ module’s history log or reset the module itself. From the Individual Menu, select 5 to view the Reset

Menu.

7.2.5.1. Clear History Log

SELECT: 1

1=CLEAR HISTORY

2=RESET PF ALERT

Performing a "Clear History" operation will erase all

history statistics for the selected PerformanceAlert™ module (see Section 7.2.2.). Select 1 from the Reset menu to

clear history.

THIS WILL CLEAR

THE HISTORY LOG.

CLR HISTORY: NO

Press RIGHT ARROW to move the cursor to the Clr

History field, and press the MINUS "-" key to toggle the

field from "NO" to "YES." Press RIGHT ARROW and UP

ARROW to execute the change and return to the Reset

menu. The history will be erased.

7.2.5.2. Reset PerformanceAlert™ Module

SELECT: 2

1=CLEAR HISTORY

2=RESET PF ALERT

By selecting "Reset PF Alert" you may force a reset of

the PerformanceAlert™ module. Select 2 from the Reset

menu to reset the module.

THIS RESTARTS

THE PF ALERT.

RESET UNIT : NO

Press RIGHT ARROW to move the cursor to the Reset

Unit field, and press the MINUS "-" key to toggle the field

from "NO" to "YES." Press RIGHT ARROW and UP ARROW to execute the change and return to the Reset menu.

The module will reset.

Individual PerformanceAlert™ Module Status Operation • 19

Page 26

8 E2 Applications

The PerformanceAlert™ Gateway provides a means

for E2 to use data from the PerformanceAlert™ modules

for general logging, alarming, and control purposes. For

convenience, this section will cover some of the most common and useful applications of PerformanceAlert™ data in

E2 applications.

8.1. Passing Perfor-

manceAlert™ Alarm Data to

the E2 Advisory Log

The E2 features many advanced alarm control capabilities, all of which are centered around the collection of

alarms kept in the E2 Advisory Log. Though the PerformanceAlert™ Gateway passes alarm information from

PerformanceAlert™ modules to the E2, it only does so as

I/O point data, not as alarms written to the E2 Advisory

Log.

In order to write PerformanceAlert™ alarm data to the

E2 Advisory Log, you must set up Generic Alarming parameters on the Gateway’s virtual I/O points.

points set up:

Figure 8-1 - Input Status Screen (Condensed Mode Shown)

3. Highlight the point you want to set up. Press

A: SETUP. The Digital Input or Analog

Input screen will be displayed.

4. Press

A: SET ALARMS. The Digital

Alarm Setup or Analog Alarm Setup screen

will appear.

8.1.1. Generic Alarming Setup

Setting up Generic Alarming for PerformanceAlert™

Gateway I/O points is done from the E2 Input Status

Screen.

1. Log in to the E2 and press

Definitions).

2. If you have not yet done point setup for the

Gateway’s virtual I/O points, follow the steps

outlined in Section 6.2.1., Condensed Mode

Point Setup or Section 6.3.1., Expanded

Mode Point Setup. When point setup is com-

plete for all PerformanceAlert™ Gateway

virtual I/O points, you should see the letter

"D" next to each PerformanceAlert™ input

point. In the example (Figure 8-1), the Gateway is operating in Condensed Mode designated as 16AI board #1, with all fourteen I/O

I (Input

Figure 8-2 - Digital Alarm Setup Screen

After completing Step 4, complete generic alarm setup

by following the instructions appropriate for the input type

(Digital or Analog).

8.1.2. Alarm Parameter Settings

8.1.2.1. Digital Alarms

For all Condensed Mode data points, and for all Expanded Mode data points except 13, 14, and 15, digital

alarming may be set up so that an alarm will be generated

when the point transitions to the ON state.

Continuing from step 4 of Section 8.1.1., Generic

Alarming Setup:

5. Set the Advisory Method field to "Select

Methods."

6. In the "Alarm On an" field, set this field to

"Yes" and press

the right of the cursor where you may choose

which digital state will trigger the alarm. Set

this field to ON.

>. A field will appear to

20 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Page 27

7. In the Report Delay and Report Priority

Fields, you must decide three things: whether

you want a PerformanceAlert™ advisory to

be an ALARM or NOTICE in the E2 Advisory log; what report priority you want the

alarm to be; and how long the PerformanceAlert™ alarm must be active before

the alarm will be generated.

Of these analog points, it is not necessary to set up generic alarming on points 13 and 14. On point 15, the discharge line temperature, alarming already occurs with high

discharge causes a trip condition to occur (in Expanded

Mode, Generic Alarming should be set up for this condition

on point 1). If desired, you may use Generic Alarming to

generate a warning when discharge line temperature runs

too close to the trip setpoint.

In the example shown in Figure 8-3, the advisoryis configured to be an ALARM generated after a ten minute delay with a report

priority of 20. You will generally want to set

up critical alarms such as Locked Rotor or

Phase Fail as ALARM advisories with a priority of 20 or above. To keep a point from

generating notices, the Report Priority under

the Notice column is set to 0

To make an advisory appear as a low-priority

notice, enter a 99 in the Report Priority "Notice Levels" column and a 0 in the Report Priority "Alarm Levels" column.

Figure 8-3 - Digital Alarm Settings

8. Press

J to save changes and return to the

Digital Input Setup screen. Note the OUTPUT fields at the bottom of the screen now

has the additional letter "A" at the end. This

signifies that this point has active generic

alarming parameters.

Continuing from step 4 of Section 8.1.1., Generic

Alarming Setup:

5. Set the Advisory Method field to "Absolute

Levels."

6. Set the Advisory Use field to "Instantaneous."

7. In the "Notice Levels" column, highlight the

"Occupied Hi" field, and enter the desired

warning temperature threshold. This value

should not be higher than the programmed

DLT trip setpoint in the PerformanceAlert™.

8. In the "Notice Levels" column, set the Report

Delay to the desired amount of time (in

HH:MM) the discharge line temperature

must remain at or above the Occupied Hi

field value to cause the advisory to occur.

9. In the "Notice Levels" column, set the Report

Priority to 99 (the lowest possible priority

level).

10. In the "Notice Levels" column, highlight the

Return to Normal Delta field, and enter the

number of degrees the discharge line temperature must fall below the value in the Occupied Hi field to set the advisory status to

"return-to-normal."

11. In the "Alarm Levels" column, highlight the

Report Priority field and change its value to

zero to disable generation of ALARM advisories.

9. Press

8.1.2.2. Analog Alarms

The only analog values on the PerformanceAlert™

Gateway are points 13, 14, and 15 of each virtual 16AI

board that represents a PerformanceAlert™ module when

the Gateway is operating in Expanded Mode. Points 13 and

14 are current values; point 15 is the discharge line temperature.

Passing PerformanceAlert™ Alarm Data to the E2 Advisory Log E2 Applications • 21

J to return to the Input Status

screen. Repeat steps 1 through 8 for the remaining digital PerformanceAlert™ Gateway points until all digital points are set up

for alarming.

Page 28

When finished, the Analog Alarm Setup screen should

appear similar to Figure 8-4. Press

and exit to the Input Status screen.

Figure 8-4 - Analog Alarm Setup Parameters

J to save changes

8.1.3. Advisory Values and Priorities

When setting up Generic Alarming, you will want to

choose advisory types and advisory priorities that are appropriate to the overall alarm filtering and reporting settings for the E2. When alarm dial-outs or annunciation

devices are being used, the E2 will generally be set up to

filter out low-priority alarms and notices. Refer to the E2

User’s Guide for more information about alarm reporting

and dial-out settings.

8.1.4. How the Alarm Appears in the E2

Advisory Log

Because Generic Alarming is not designed specific to

PerformanceAlert™ Gateway, the alarm message generated when a PerformanceAlert™ alarm occurs will not specifically say anything about PerformanceAlert™. Digital

alarm messages will read "State Switched ’ON’", and analog alarm messages will read "Occupied Hi Limit Exceeded." The only indicator of which PerformanceAlert™

module generated the alarm will be from the point name

you entered during point setup, which will be shown in the

alarm’s "Property or Board/Point" column in the alarm log

(Figure 8-5).

In the example in Figure 8-5, since point #1 of the PerformanceAlert™ gateway was named "PF COMP 1" when

the point was set up in Section 6.2.1., the origin of the

alarm can be seen in the application name.

8.2. Using PerformanceAlert™

Current Transducer Values

as Compressor Proofs

When the PerformanceAlert™ Gateway is used in Expanded Mode, the T1 and T3 compressor current values

passed in points 13 and 14 of each virtual 16AI board can

be used to verify a compressor is running when commanded to run and OFF when commanded to be OFF.

For each compressor with a PerformanceAlert™ module installed, one Sensor Control application must be created and programmed to read the current values from the

PerformanceAlert™ Gateway and turn an output ON or

OFF depending on whether the current values signify the

compressor is ON or OFF. This Sensor Control output will

be used as the compressor proof and tied to the appropriate

Suction Group compressor proof input.

8.2.1. Creating Analog Sensor Control

Applications

1. Log in to the E2 and press I (Add

Application).

2. In the "Type" field, select "Analog Sensor

Control." In the "How many?" field, enter the

number of compressor proofs you will be creating.

3. Press

4. Press

8.2.2. Programming Analog Sensor Control Applications

>. The applications will be created.

Press

* when E2 asks if you want to edit

new applications.

H to return to the home screen.

5. Press I (Configured Applications).

6. Press

7. From the Sensor Control summary screen,

8. Press

Figure 8-5 - Example of Advisory Log with "State switched On" Advisory

22 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

to select "Sensor Controls" from the

Configured Applications menu.

highlight the name of the analog sensor control you wish to edit, and press

Sensor Control’s Status Screen will be

shown.

>. The

E (Setup) to begin editing.

Page 29

8.2.2.1. General

8.2.2.3. Setpoints

Figure 8-6 - Analog Sensor Control Compressor Proofing General Screen

In the Name field, enter "CMP x PRF" (where x is the

address of the PerformanceAlert™ module whose current

transducer values will be using for proofing by this application). Set all other values in this screen as shown in Fig-

ure 8-6:

Num Inputs: 2

Eng Units: A

Comb Method: MIN

Show Advanced: No

8.2.2.2. Inputs

Figure 8-7 - Analog Sensor Control Compressor Proofing Inputs Screen

In the Inputs tab, enter the board and point address of

the T1 and T3 currents from the PerformanceAlert™ Gateway in the Input1 and Input2 fields. The board number

should correspond to the address number of the PerformanceAlert™ module. T1 will always be point #13 and T3

will always be point #14.

Figure 8-8 - Analog Sensor Control Compressor Proofing Setpoints Screen

In the Setpoints tab, enter 3.0 in the CUTIN field and

2.5 in the CUTOUT field. These setpoints will result in the

sensor control output being ON when the current is above

3 amps and OFF whenever it falls below 2.5 amps. Leave

the Cut In Delay and Cut Out Delay fields set to 0:00:00.

8.2.3. Setting Up Proofing in Suction Group Applications

After entering the CUTIN and CUTOUT setpoints in

the Setpoints tab (Section 8.2.2.3.), press ) to save changes

and exit. You are now ready to configure the compressor in

the suction group to use the output of the sensor control application as its proof.

The instructions below assume the compressor rack is

already set up in a pre-existing Enhanced Suction group application. Refer to the E2 User’s Guide for information on

setting up a suction group.

1. Press

2. Press

3. If more than one Suction Group application is

4. From the suction group’s Status Screen, press

I (Configured Applications).

to select "Suction Groups" from the

Configured Applications menu.

present, highlight the suction group the compressor belongs to, and press

>.

Using PerformanceAlert™ Current Transducer Values as Compressor Proofs E2 Applications • 23

Page 30

E: SETUP.

Figure 8-9 - Analog Sensor Control Compressor Proofing Inputs Screen

APPLICATION: Choose the name

(CMPR x PROOF) you entered for the Analog Sensor Control application

OUTPUT: Choose COMMAND OUT

5. Press

6. Locate the compressor stage for which you

7. Press

Figure 8-10 - Analog Sensor Control Compressor Proofing Setpoints Screen

8. The Proof tab should have a blank Board/

9. For each field in the Controller/Application/

4+ to navigate to the Stage Setup

tab (Figure 8-9).

wish to set up proofing. For this stage, change

the value of the Proof field from "No" to

"Yes."

4+ to bring up the Additional Tabs

menu. Press

Point definition named COMP PROOF with

a number next to the name equal to the number of the compressor stage. Move the cursor

to highlight the Board field of this COMP

PROOF definition, and press

change the definition type from a Board/

Point to a Controller/Application/Output type

definition.

Output, use the Look-Up Table (

point the COMP PROOF input to the output

of the Analog Sensor Control application.

CONTROLLER: Name of this E2

) to select the "Proof" tab.

C to

D) to

Figure 8-11 - Defined Compressor Proof Output

If defined correctly, the proof should look similar to

Figure 8-11. Press

Repeat the process outlined in this section to create all

necessary compressor proofs.

J to save changes and exit.

24 • PerformanceAlert Gateway I&O Manual 026-1724 Rev 0 12-MAY-2008

Loading...

Loading...