Emerson Copeland EV2 Series, Copeland EV2080M-L1, Copeland EV2080M-L2 Application Engineering Bulletin

Page 1

© 2018 Emerson Climate Technologies, Inc.

1

TABLE OF CONTENTS

Safety

Safety Instructions ................................................... 2

Safety Icon Explanation ........................................... 2

Instructions Pertaining to Risk of

Electrical Shock, Fire, or Injury to Persons ............. 3

Safety Statements ................................................... 4

Introduction

Product Description ................................................. 5

Theory of Drive Operation ....................................... 5

Agency Recognition ................................................. 5

Nomenclature .......................................................... 5

Installation

Drive Handling ......................................................... 5

Mounting .................................................................. 5

Drive Dimensions..................................................... 5

Wiring Diagram ........................................................ 5

Operation & Function

............................................... 5

Hi-pot Procedure / Set-up ...................................... 5

Temperature & Humidity ......................................... 6

Pre-operation Checks ............................................. 6

Power On/Off ......................................................... 6

Communication Setting ......................................... 6

Input Voltage and Input Current ............................. 6

Dynamic DC Bus Voltage Control by Buck ............ 6

Speed Control ......................................................... 6

Start-up ................................................................... 6

Shutdown ................................................................ 6

Fault Clearing ......................................................... 6

Lockout Faults ........................................................ 6

Stator Heat Control ................................................ 6

Status Indication ..................................................... 7

4 States of RGB LED (DS1-LED) ....................... 7

Rolling LED ......................................................... 7

Power Interrupt ....................................................... 7

Drive Configuration ................................................ 7

High Pressure Cut Out ........................................... 7

Drive Cooling .......................................................... 7

Drive Over Temperature Protection ....................... 7

Air Cooled Heat Exchanger ................................... 8

Cold Plate Heat Exchanger .................................... 8

Foldback ................................................................. 8

Troubleshooting ..................................................... 8

EMC Guidelines ..................................................... 8

Figures

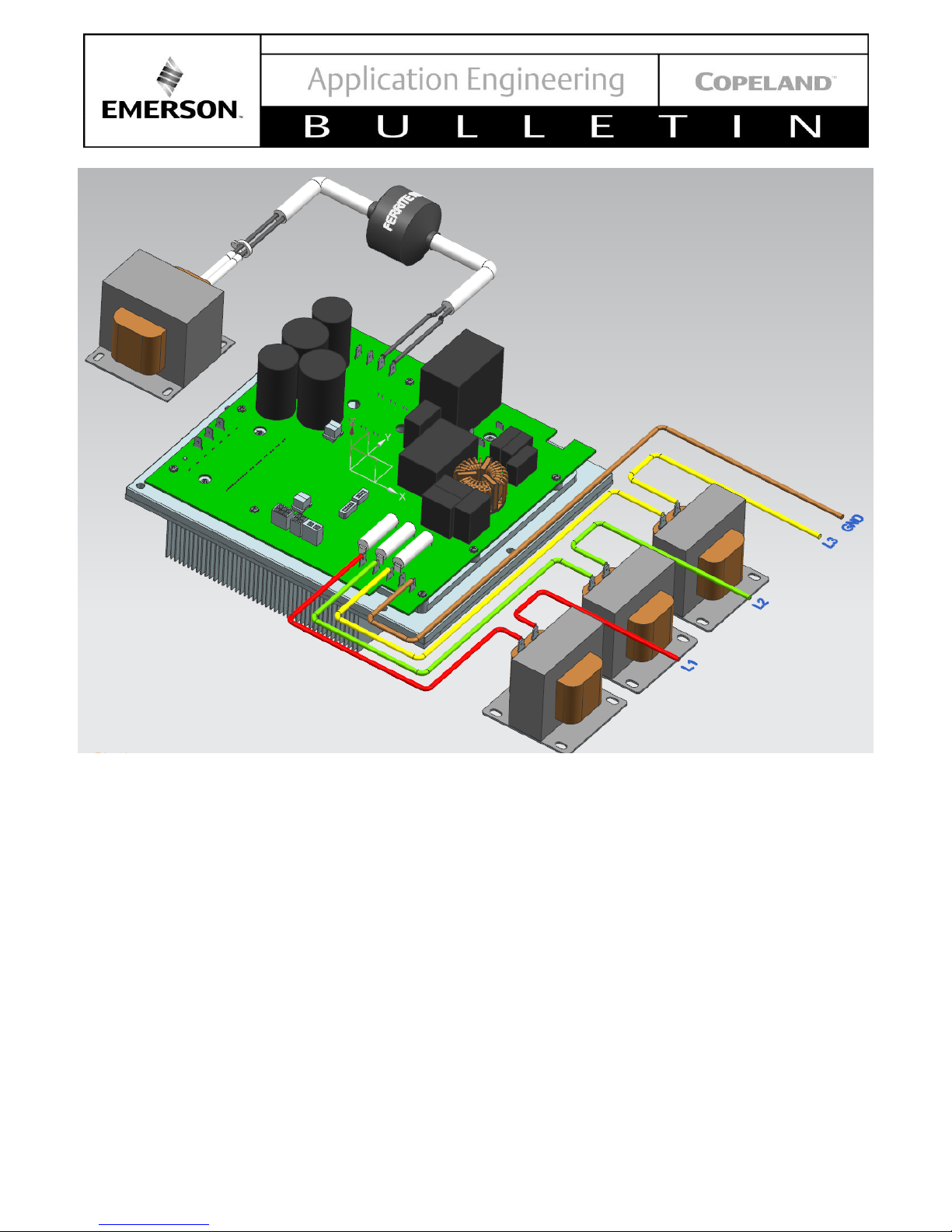

Drive Assembly 3D Wiring Diagram ....................... 9

Drive Assembly 2D Wiring Diagram ..................... 10

Tables

Communication Connector Pin Definition ............ 11

Sensor Connector Pin Definition .......................... 11

Addendum

AE8-1429 R1

January 2018

EV2 Three Phase Series Variable Speed Drives

517-625V, 8.0 kW

These commodities, technology or software, are subject to the U.S. Export Administration Regulations (EAR).

Diversion contrary to U.S. law is prohibited. ECCN: EAR99

Page 2

© 2017 Emerson Climate Technologies, Inc.

2

AE8-1429

Safety Instructions

Copeland Scroll™ variable speed drives are manufactured according to the latest U.S. and

European Safety Standards. Particular emphasis has been placed on the user's safety. Safety icons

are explained below and safety instructions applicable to the products in this bulletin are grouped on

Page 3. These instructions should be retained throughout the lifetime of the compressor. You are

strongly advised to follow these safety instructions.

Safety Icon Explanation

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation

which, if not avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

CAUTION, without the safety alert symbol, is used to address practices not related

to personal injury.

FLAMMABLE

DANGER

WARNING

CAUTION

NOTICE

CAUTION

Page 3

© 2017 Emerson Climate Technologies, Inc.

3

AE8-1429

Instructions Pertaining to Risk of Electrical Shock, Fire, or Injury to Persons

WARNING

ELECTRICAL SHOCK HAZARD

• Disconnect and lock out power before servicing.

• Discharge all capacitors for a minimum of two minutes before servicing.

• Use compressor with grounded system only.

• Molded electrical plug must be used when required.

• Refer to original equipment wiring diagrams.

• Electrical connections must be made by qualified electrical personnel.

• Failure to follow these warnings could result in serious personal injury.

WARNING

PRESSURIZED SYSTEM HAZARD

• System contains refrigerant and oil under pressure.

• Remove refrigerant from both the high and low compressor side before

removing compressor.

• Never install a system and leave it unattended when it has no charge,

a holding charge, or with the service valves closed without electrically

locking out the system.

• Use only approved refrigerants and refrigeration oils.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal injury.

WARNING

FIRE HARD

• Open flames and smoking are strictly forbidden.

• Continuously check if the ambient atmosphere is nonexplosive.

• During service make sure that:

o The area is well ventilated.

o The materials and equipment used are suitable for use under

explosive conditions.

o Only non-sparking tools are used.

o Anti-static gloves and clothes are used.

o A build-up of electrostatic charges is avoided.

• In the case of explosive atmosphere:

o Immediately stop the compressor and de-energize the power

supply of the compressor and any other electrical component/

equipment such as crankcase heater.

o No unshielded flame is allowed.

• Before opening the refrigeration, system or working on it with an unshielded

flame:

o Continuously check if the ambient atmosphere is non-explosive

and ensure proper ventilation of the room before creating any

naked flame. No naked flame is allowed in an explosive

atmosphere.

• When atmosphere reaches a dangerous concentration of flammable gas:

o Avoid any ignition source and ventilate the room further.

• Closed all valves tightly if any parts of the refrigeration systems are charged

with flammable refrigerants.

Page 4

© 2017 Emerson Climate Technologies, Inc.

4

AE8-1429

WARNING

BURN HAZARD

• Do not touch the compressor until it has cooled down.

• Ensure that materials and wiring do not touch high temperature areas of

the compressor.

• Use caution when brazing system components.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in serious personal injury or

property damage.

R290 MIXTURE IN POTENTIALLY EXPLOSIVE ATMOSPHERE

• R290 mixed with air can create an explosive atmosphere.

• Immediately stop the compressor and ventilate the room if an explosive

atmosphere is detected.

• No open flame is allowed.

CAUTION

COMPRESSOR HANDLING

• Use the appropriate lifting devices to move compressors.

• Personal safety equipment must be used.

• Failure to follow these warnings could result in personal injury or

property damage.

Safety Statements

• Refrigerant compressors must be employed only for their intended use.

• Only qualified and authorized HVAC or refrigeration personnel are permitted to install commission and

maintain this equipment.

• Electrical connections must be made by qualified electrical personnel.

• All valid standards and codes for installing, servicing, and maintaining electrical and

refrigeration equipment must be observed.

Page 5

© 2018 Emerson Climate Technologies, Inc.

5

INTRODUCTION

Product Description

The inverter drive has been developed specifically for

the variable speed compressor. The drive will power

the compressor, control the compressor running

speed, provide compressor and drive protection and

communicate with the master controller. The drive

requires cooling and is typically installed in a system

near the compressor.

Theory of Drive Operation

The primary purpose of the drive is to convert the

50/60 Hz AC input voltage into a variable frequency,

variable voltage output to power the variable speed

scroll compressor. The drive conditions the AC input

Voltage through a series of conditioning processes to

arrive at the desired output. The drive first converts the

AC input voltage into a DC bus. The DC voltage is then

pulse-width modulated to replicate a sinusoidal current

at the desired frequency and voltage.

Agency Recognition

UL 60730-1

Nomenclature

The model number of the drive includes the power

rating and nominal voltage input to the drive. Contact

Application Engineering

for all the alpha and numeric

characters in the drive model number.

INSTALLATION

Drive Handling

Caution must be used when lifting and installing

the drive. Failure to use caution may result in

bodily injury.

The drive is designed to meet creepage and

clearance requirements for a maximum altitude of

2000 meters.

•

Correct handling and storage of the drive is

essential in preventing mechanical damage.

•

Box and the protection bag inside the box need to

be carefully opened. Do not use any sharp material

to open the protection bag, which may damage the

drive.

•

Never cut across the drive with any sharp

materials.

•

Do not hold by the components on the drive or

drive accessories, this can damage them.

•

Once opened do not stack the drives on each other.

•

When handling the drive, the only correct way is to

hold it by the edges of the heatsink.

•

Do not drop any mechanical tools on the drive or

drive accessories.

•

It is always recommended to use ESD control

wristbands while touching any part of the drive.

Personnel handling the drives in a manufacturing plant

environment should guard against static electricity by

using the appropriate equipment – antistatic wrist

straps and mats.

Mounting

The drive should be located within 5 feet of the

compressor since the wiring between the drive, and the

compressor is unshielded.

Air-cooled drives are supported inside the HVAC

system by an extended heatsink plate. The plate

mounts through an opening in the cabinet sheet metal

to expose the heat exchanger to the condenser fan air

stream. The flange contains a gasket surface to

prevent water from entering the electronics side of the

control box.

The flat plate option accommodates installation to

systems using the mating gas or liquid cooled cold

plate heat exchanger. The mating cold coupling plate is

designed by OEM to accommodate the system design.

There are holes in the drive mounting flange for

mounting purposes. These holes will accommodate a

M5 sized screw for mounting.

Drive Accessories and Dimensions

Contact

Application Engineering

for all the drawings

and detailed dimensions with tolerances.

Wiring Diagram

Refer to

Figures 1-2

for a detailed description of the

drive wiring diagrams. Refer to

Tables 1-2

for a

detailed description of the connector pins definition.

OPERATION & FUNCTION

Hi-pot Procedure / Set-up

Refer to

Addendum

for hi-pot procedure and setup.

Please call your Application Engineer for additional

details.

Page 6

© 2017 Emerson Climate Technologies, Inc.

6

AE8-1429

Temperature & Humidity

Drive operating temperature range: -20°C to 55°C

Drive storage temperature range: -40°C to 85°C

Humidity: Maximum Relative Humidity 95%

Pre-operation Checks

Check the drive carefully before use it. Make sure

that all the wires are correctly and tightly

connected. Improper operation may cause fire or

injury to persons.

Power On/Off

The drive should use rated AC power supply: 50/60Hz,

517-625V on EV20XXM-LX-XXX models.

Use of incorrect power supply may damage the drive.

The user should make sure that the correct

combination of a power supply, drive, and accessories

are used.

When powering off the drive, make sure to wait for at

least 60 seconds to ensure that the drive is completely

turned off.

Communication Setting

The drive is designed to be used in a master-slave

configuration where the master is a system controller.

Standard Modbus protocol RTU is available.

Users can also change the slave ID, baud rate, parity

and stop bit method. Detailed parameters and default

values are in the Modbus Map (refer to

Addendum

).

Modbus uses a three-layer protocol – physical, data

link, and application. Refer to

Addendum

for additional

details.

Input Voltage and Input Current

The drives are designed for rated AC power supply:

50/60Hz, 517-625V on EV20XXM-LX-XXX drive

models. Published performance of the drive and

compressor combination will have a performance

tolerance specified on the compressor performance

data sheet when the Drive input voltage is in the

specified range as above.

Drive

Max AC Input Current

EV2080L 11A RMS

Dynamic DC Bus Voltage Control by Buck

The drive has dynamic DC bus voltage control function,

which is capable of improving efficiency.

Speed Control

The frequency range of EV2 is from 15Hz to 120Hz. If

the frequency set by system controller is less than

15Hz but not zero, then the compressor will work at

15Hz. Similarly, if the frequency set by system

controller is greater than 120Hz, then the compressor

will work at 120Hz.

Start-up

Refer to

Addendum

for start-up procedures and

requirements.

Shutdown

Refer to

Addendum

for shutdown procedures and

requirements.

Fault Clearing

In the Modbus relationship, the drive is considered a

slave, and the system controller is the master. Faults

will not clear unless they are commanded to.

To clear faults, use the following method:

1. The compressor has been shut down for at least

35 seconds.

2. The fault condition no longer exists (registers 78-

85).

3. The drive has received a zero speed command

(register 101 = 0).

4. The drive has been disabled (register 100 = 0).

5. Write '1' to register 103.

Faults will not clear unless all items above are true.

Lockout Faults

There are specific faults that will cause the drive to

'lockout' after 10 consecutive occurrences. These

faults are noted in the

Addendum

. These faults will not

clear unless the power to the drive is fully cycled.

Stator Heat Control

In actual use, the system controller may decide

whether to preheat or not according to the

environment. When preheating is needed, the system

controller sends register 100 a compressor enable

command and register 102 a stator heating power

value. The drive transmits up to 50W DC power to

warm-up the compressor.

The stator heating is ON if the followings are true:

1. There are no active errors.

Page 7

© 2017 Emerson Climate Technologies, Inc.

7

AE8-1429

2. Compressor enabled.

3. Compressor speed is set zero.

4. Stator heater power setting is from 10~50.

If the system sends a speed demand to the drive while

the stator is heating, the drive should stop stator

heating and start the compressor. While running, if the

system sends a zero-speed command, the drive

should shut down the compressor automatically, and

then resume the stator heating to the value saved in

Stator Heater Power Memory Register (a value or zero

= off).

Status Indication

There is one control chip on the drive board. And drive

board has both RGB LED (DS1), and Rolling 7segment LED for drive status display.

4 states of RGB LED (DS1-LED)

1. PURPLE: When the drive is in programming

mode via bootloader.

2. GREEN Solid: When the drive is in normal state

(no faults) in standby mode and the compressor

is not running. The LED will be solid GREEN.

3. GREEN Blinking: When the compressor is

running, LED will blink at 1Hz in GREEN.

4. RED: When the drive has any active faults or

protections.

Rolling LED

There is also a Rolling LED for drive status display.

For further information, refer to Tables 7 & 8 for

detailed functionality and display status modes.

Power Interrupt

Power interrupts can result in a drive trip that won't

harm the drive. The drive can withstand interrupts of a

short duration (<=10 ms) but will trip on anything

longer.

Drive Configuration

Another feature available on the drive is the option to

change communication parameters, configure the drive

to use different types of compressors and sensors.

Modbus registers 200 - 207 and 210 -213 serve this

function (refer to

Modbus Map

within the

Addendum

for details).

These options are password protected. Register 200

must have the correct password written before any

parameters can be changed. All register functions and

default values are located in the

Modbus Map

.

•

Registers 201-204 are for communication

parameters.

•

Registers 203 and 204 are automatically

configured by the drive, based on baud rate and

parity information from the system controller.

•

Register 205 is for compressor model type.

•

Registers 206 & 207 are for sensor type

configurations.

•

Register 210 is controlled shutdown rate

configuration.

•

Register 211 and 212 are configured for speed

ramp-up and ramp-down rate configuration.

•

Register 213 is configured for ramp-up speed

during compressor start-up.

Once configured only changes to registers 201-204 will

require power cycle for the changes to be

implemented.

Refer to

Addendum

for configuration process flow and

communication settings process flow.

High Pressure Cut Out

CN5 on EV2080X-LX-XXX is a 2-port connector on

drive model. The output is a 3.3VDC signal. The highpressure cutout switch must be normally closed. If the

switch is open, the drive will not operate. The output

current for the high-pressure contact will range from

300uA to 400uA. To ensure correct functionality of the

high-pressure switch for the system’s lifetime, typically

gold-plated contacts are recommended. Refer Table-2

for detailed pinout.

This port is hardware Protected Electronic Circuit (PEC),

and software is Class-B according to UL60730-1.

Drive Cooling

Because of the power electronics used in the drive and

the associated heat generation, drive cooling is

required to keep the drive components in their design

temperature range. The allowable temperature range

of the drive (The ambient air surrounding the drive) is 4°F to 131°F. Drive temperature should be monitored

during system development at system extreme

conditions to ensure that the maximum allowable drive

temperature isn’t exceeded. The highest drive

temperature will typically occur during high load

conditions or during high drive ambient.

Drive Over Temperature Protection

The drive is self-protected against high internal

temperatures. There are different modes of protection;

temperature high and foldback. For temperature high

refer to

Troubleshooting Table

within

Addendum

.

For foldback protection refer to Section 2 in the

Addendum

for more information.

Page 8

© 2017 Emerson Climate Technologies, Inc.

8

AE8-1429

Air Cooled Heat Exchanger

Drives cooled by the aluminum air-cooled heat

exchanger are designed to be in the air flow stream of

the condenser. The air-cooled heat exchanger must be

installed so that the heat exchanger fins are parallel to

the cooling air flow. The airflow must be a minimum of

3 meters/sec measured at the outlet of the heatsink in

the direction of airflow.

Cold Plate Heat Exchanger

The cold plate design can be used when another

cooling source is available – suction gas from the

evaporator coil, subcooled liquid refrigerant, glycol

solution from a geothermal loop, water from a cooling

tower, etc. When the refrigerant is used for drive

cooling, the heat given up by the drive is transferred

into the refrigeration system. This can be a net gain for

heating applications and a net loss for cooling

applications.

There must be thermal grease between flat plate cold

plate. There is no standard for the thickness

requirement of thermal grease; normally, it's between

0.2mm-0.4mm. The entire surface of the flat plate must

be covered. Dow Corning TC-5022 silicone heat sink

compound or a similar product is recommended.

Contact

Application Engineering

for cold plate

details.

The soldering/brazing that is required to connect the

cooling source to the cold plate should be performed

before the cold plate is attached to the drive, to prevent

overheating drive components with the torch.

Foldback

To protect the drive components or the compressor,

the compressor speed will 'foldback' or slow down to

help reduce risk to components. The foldback event(s)

will be flagged in the drive's Modbus registers. This will

allow the operating system to respond and mitigate the

conditions causing foldback.

For further information refer to Section 2 in the

Addendum.

TROUBLESHOOTING

The drive may indicate fault or protection for various

reasons. If fault or protection occurs, users should

power down the drive, check the drive, and check the

drive running condition carefully. For the description,

check and handling of these faults or protections,

please refer to the

Troubleshooting – Fault and

Protection

within

Addendum

EMC Guidelines:

•

Install the star earth (ground) connection as close

as possible to the drive. A non-coating screw is

recommended for installation on the service panel

to maintain a good ground connection. The star

connection includes:

– System Input ground

– Drive ground

•

The usage of additional ferrites and numbers of

turns in the input power supply cables, compressor

cables, sensor cables are optional but preferred

based on system application and noise level.

•

Any of the input power supply cables, sensor

cables, compressor cables and communication

cables should not cross or touch each other to

avoid noise coupling.

•

Usage of shielded cable is optional depending on

system application, but if used it’s mandatory to

have correct connections on both sides of the cable.

Page 9

© 2018 Emerson Climate Technologies, Inc.

9

Figure 1 – Drive Assembly 3D Wiring Diagram

Page 10

© 2017 Emerson Climate Technologies, Inc.

10

AE8-1429

Figure 2 – Drive Assembly 2D Wiring diagram

Page 11

© 2017 Emerson Climate Technologies, Inc.

11

AE8-1429

Table 1 – Communication Connector Pin Definition

Pin

Number

Description

Figure

1

RS485 (+)

2

Not Used

3

Not Used

4

RS485 (-)

5

Common

6

EMI Drain Wire

Description

Part Number

6-Pin Connector Housing

Molex 0039012065

or Equivalent

Connector Pins

Molex 0039000038

or Equivalent

Table 2 – Sensor Connector Pin Definition

Pin

Number

Description Figure

1

Sensor Pin-1

2

Sensor Pin-2

3

Not Used

4

Not Used

A1

High Pressure Signal

A2

3.3VDC

(DLT Sensor) Connector (Pin -1 to 4) P/N Information

Description

Part Number

4-Pin Connector Housing

Molex 39-01-2045 or Equivalent

Connector Pins

Molex 39-00-0428 or Equivalent

(HPS) Connector (A1/A2) P/N Information

Description

Part Number

2-Pin Connector Housing

JST Sales America XLP-02V or

Equivalent

Connector Pins

JST Sales America SXF-41T-P0.7

or Equivalent

The contents of this publication are presented for informational purposes only and are not to be construed as warranties or guarantees, express or implied, regarding

the products or services described herein or their use or applicability. Emerson Climate Technologies, Inc. and/or its affiliates (collectively "Emerson"), as applicable,

reserve the right to modify the design or specifications of such products at any time without notice. Emerson does not assume responsibility for the selection, use or

maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson product remains solely with the purchaser or end user.

Page 12

TABLE OF CONTENTS

1 Start-up and Shutdown Sequence of The Compressor ............................................................... 2

2 Drive Foldback Information ............................................................................................................... 3

3 Modbus Map ....................................................................................................................................... 5

4 Drive Configuration Flow Charts .................................................................................................... 11

5 Drive Status Display – Rolling Led ................................................................................................ 12

6 Troubleshooting Guide .................................................................................................................... 13

7 Hi-pot Testing .................................................................................................................................... 15

8 Accessories ....................................................................................................................................... 16

ADDENDUM to AE8-1429 10/31/2017

Page 13

1 START-UP AND SHUTDOWN SEQUENCE OF THE COMPRESSOR

Table 1 - Start-up Sequence

Stage

Description

Target Speed (rpm)

Ramp Up Rate (rpm/s)

Duration (s)

I

Compressor continues to ramp up

1500 (configurable)

375

4

II

Compressor remains at the

platform speed

1500

-

10

III

Compressor reaches commanded

speed

Commanded

Default = 60

-

Table 2 - Shutdown Sequence

Stage

Description

Target Frequency

(rpm)

Ramp Down Rate

(rpm/s)

I

Compressor Shutdown requested

- -

II

Compressor gets to minimum

speed

900

Default = 150

III

Compressor Stop

- -

Figure 1 – Start-up Sequence

Speed

Time

1500-3500 RPM

(Reg.213)

Customer configured

4S

14

S

10S

375RPM/S

60-360RPM/S (Reg.211)

60-360RPM/S (Reg.212)

Ramp Up/Down rate is

Customer configured

Page 14

Figure 2 – Shutdown Sequence

2 DRIVE FOLDBACK INFORMATION

Table 3 – Input Current Foldback

Condition

Action taken by the Drive

1

Input Current >= Foldback Current

Will reduce the speed at the rate of 120 rpm/s

2

Recovering Current <= Input Current < Foldback

Current

Will remain in the current speed

3

Input Current < Recovering Current

Speed will be recovered to commanded speed

4

If the compressor load is not recovered and continue to

exceed the foldback limit in one of the conditions below:

• After compressor running speed has reached to

Envelope min foldback speed and then stay

Envelope min foldback speed for >= 30sec.

OR

• If the original running speed was already <

Envelope min foldback speed for >= 30sec

Compressor will be tripped

Stop

Shutdown Initiated

60-360RPM/S (Reg.210)

900RPM (Minimum Speed)

Shutdown Down rate is

Customer configured

Page 15

Table 4 – Output Torque Foldback

Condition

Action taken by the Drive

1

Output Torque >= Foldback Limit of operating speed

range

Will reduce the speed at the rate of 60 rpm/s

2

Recovering Torque <= Output Torque < Foldback Limit

of operating speed range

Will remain in the current speed

3

Output Current < Recovering Current

Speed will be recovered to commanded speed

4

If the compressor load is not recovered and continue to

exceed the foldback limit in one of the conditions below:

• After compressor running speed has reached to

Envelope min foldback speed and then stay at

Envelope min foldback speed for >= 30sec.

OR

• If the original running speed was already <

Envelope min foldback speed for >= 30sec

Compressor will be tripped

Table 5 – IGBT Temperature Foldback

Condition

Action taken by the Drive

1

IGBTTemperature >= Foldback Temperature

Will reduce the speed at the rate of 180 rpm/s

2

Recovering Temperature <= IGBT Temperature <

Foldback Temperature

Will remain in the current speed

3

IGBT Temperature < Recovering Temperature

Speed will be recovered to commanded speed

4

If the compressor load is not recovered and continue to

exceed the foldback limit in one of the conditions below:

• After compressor running speed has reached to

Envelope min foldback speed and then stay at

Envelope min foldback speed for >= 30sec.

OR

• If the original running speed was already <

Envelope min foldback speed for >= 30sec

Compressor will be tripped

Table 6 – Inverter Temperature Foldback

Condition

Action taken by the Drive

1

Inverter Temperature >= Foldback Temperature

Will reduce the speed at the rate of 180 rpm/s

2

Recovering Temperature <= Inverter Temperature <

Foldback Temperature

Will remain in the current speed

3

Inverter Temperature < Recovering Temperature

Speed will be recovered to commanded speed

4

If the compressor load is not recovered and continue to

exceed the foldback limit in one of the conditions below:

• After compressor running speed has reached to

Envelope min foldback speed and then stay at

Envelope min foldback speed for >= 30sec.

OR

• If the original running speed was already <

Envelope min foldback speed for >= 30sec

Compressor will be tripped

Page 16

3 MODBUS MAP

Modbus

Register

Register Type

Description

Fault

Shutdown

Units

Bytes

Data Format

0

Serial and

Model Numbers

(Read)

Drive Model Number

N/A

N/A

32

bytes

ASCII

charact

er

string

EV20XXM-C1-19X/89X

0XX:power Ex. 055 = 5.5kW max

capacity

1

Drive Serial Number

N/A

N/A

32

bytes

ASCII

charact

er

string

ADXXXXXXX

Ex. AD13K0001

AD: Production Code

13:2013,production year.

K: Month Code, A=Jan,

B=Feb,…,L=Dec.

0001: Product Serial Number.

3

Software

Version (Read)

Allowed maximum

Speed (for speed limit

protection)

N/A

Hz

2 Bytes

Value: 0~120 = 0~120Hz

Ex. : If value = 100, then maximum

allowed running speed = 100Hz

4 Allowed minimum

Speed (for speed limit

protection)

N/A

Hz

2 Bytes

Value: 0~120 = 0~120Hz

Ex. : If value = 100, then minimum

allowed running speed = 100Hz

12

DSP Boot Version (High

Word)

N/A

N/A

2 Bytes

16.8.8

Ex. 4.20.0: 4=Internal ver; 20=Major ver;

0=Minor ver

16.8.8

Ex. 4.20.0: 4=Internal ver; 20=Major ver;

0=Minor ver

13

DSP Boot Version (Low

Word)

N/A

N/A

2 Bytes

14

DSP Main Version (High

Word)

N/A

N/A

2 Bytes

15

DSP Main Version (Low

Word)

N/A

N/A

2 Bytes 16

Trip Limits

(Read)

Compressor Phase Over

Current

N/A

Amps (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

17

AC Input Over Current

N/A

Amps (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

18

DC Bus Over Voltage

N/A

Volts (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

19

DC Bus Under Voltage

N/A

Volts (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

20

AC Input Over Voltage

N/A

Volts (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

21

AC Input Under Voltage

N/A

Volts (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

22

Power Module Over Temp

N/A

Celsius

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

23

IGBT Over Temp

N/A

Celsius

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

32

DC Bus Voltage Low

N/A

Volts (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

34

Board Temp High

N/A

Celsius

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

35

Power Module Temp High

N/A

Celsius

2 Bytes

11.5

Page 17

Ex. If Value = 512, then Conversion =

512/(2^5)

36

IGBT Temp High

N/A

Celsius

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

38

Sensor 2 (Thermistor, DLT)

High Temp Limit

N/A

Celsius

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

48

Drive

Status/Readings

(Read)

Torque Fold Back Status

N/A

N/A

2 Bytes

0 = No ; 1 = Yes

49

Power Module & IGBT Temp

Fold Back Status

N/A

N/A

2 Bytes

0 = No ; 1 = Yes

50

AC Input Current Fold Back

Status

N/A

N/A

2 Bytes

0 = No ; 1 = Yes

53

Compressor Phase_U

Current

N/A

Amps (RMS)

2 Bytes

8.8

Ex. If Value = 512, then Conversion =

512/(2^8)

54

Compressor Phase_V

Current

N/A

Amps (RMS)

2 Bytes

8.8

Ex. If Value = 512, then Conversion =

512/(2^8)

55

Compressor Phase_W

Current

N/A

Amps (RMS)

2 Bytes

8.8

Ex. If Value = 512, then Conversion =

512/(2^8)

56

Buck IGBT Current

N/A

Amps (Avg)

2 Bytes

8.8

Ex. If Value = 512, then Conversion =

512/(2^8)

57

DC Bridge Voltage for 575V

drive

N/A

Volts (DC)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

58

Sensor 1 (HP transducer

only) Reading

N/A

N/A

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

59

Power-Up Status

N/A

N/A

2 Bytes

0 = Not Ready

1 = Power-Up Complete

60

Compressor running speed

N/A

RPM

2 Bytes

15.1

Ex. If Value = 512, then Conversion =

512/(2^1)

61

Torque

N/A

Nm

2 Bytes

7.9

Ex. If Value = 512, then Conversion =

512/(2^9)

62

Torque Limit

N/A

Nm

2 Bytes

7.9

Ex. If Value = 512, then Conversion =

512/(2^9)

64

DC Bus Voltage

N/A

Volts (DC)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

65

AC Input Voltage

N/A

Volts (RMS)

2 Bytes

12.4

Ex. If Value = 512, then Conversion =

512/(2^4)

66

AC Input Current

N/A

Amps (RMS)

2 Bytes

8.8

Ex. If Value = 512, then Conversion =

512/(2^8)

67

AC Input Power

N/A

Watts

2 Bytes

16.0

Ex. If Value = 512, then Conversion =

512/(2^0)

68

Compressor Phase Current

N/A

Amps (RMS)

2 Bytes

8.8

Ex. If Value = 512, then Conversion =

512/(2^8)

70

Power Module Temp

N/A

Celsius

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

77

Sensor 2 (Thermistor, DLT)

Reading

N/A

Celsius

2 Bytes

11.5

Ex. If Value = 512, then Conversion =

512/(2^5)

Compressor Phase Over

Current

Immediate

Shutdown

N/A

Bit 0

0 = No ; 1 = Yes

Lockout (After 10 fault occurrences*)

Page 18

78

1st Fault

Occurred

(Read)

AC Input Over Current

Immediate

Shutdown

N/A

Bit 1

0 = No ; 1 = Yes

DC Bus Over Voltage

Immediate

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

DC Bus Under Voltage

Immediate

Shutdown

N/A

Bit 3

0 = No ; 1 = Yes

AC Input Over Voltage

Immediate

Shutdown

N/A

Bit 4

0 = No ; 1 = Yes

AC Input Under Voltage

Immediate

Shutdown

N/A

Bit 5

0 = No ; 1 = Yes

Sensor 1 (High Pressure

Switch Open)

Immediate

Shutdown

N/A

Bit 8

0 = No ; 1 = Yes

Power Module Over Temp

Immediate

Shutdown

N/A

Bit 11

0 = No ; 1 = Yes

IGBT Over Temp

Immediate

Shutdown

N/A

Bit 12

0 = No ; 1 = Yes

Lost Rotor Position

Immediate

Shutdown

N/A

Bit 13

0 = No ; 1 = Yes

Lockout (After 10 fault occurrences*)

Pre-charge Relay Open

N/A

N/A

Bit 15

0 = No ; 1 = Yes

79

1st Fault

Occurred

(Read)

DC Bus Voltage Low

N/A

N/A

Bit 0

0 = No ; 1 = Yes

Torque Limit Fold Back

Timeout

Controlled

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

Power Module Temp. Fold

Back Timeout

Controlled

Shutdown

N/A

Bit 3

0 = No ; 1 = Yes

AC Input Current Fold Back

Timeout

Controlled

Shutdown

N/A

Bit 4

0 = No ; 1 = Yes

Auto Config Communication

Timeout

N/A

N/A

Bit 6

0 = No ; 1 = Yes

Modbus Communication Lost

Controlled

Shutdown

N/A

Bit 7

0 = No ; 1 = Yes

Sensor 2 (Thermistor, DLT)

High Temp

Controlled

Shutdown

N/A

Bit 8

0 = No ; 1 = Yes

Board Temp High

Controlled

Shutdown

N/A

Bit 10

0 = No ; 1 = Yes

Power Module Temp High

Controlled

Shutdown

N/A

Bit 11

0 = No ; 1 = Yes

IGBT Temp High

Controlled

Shutdown

N/A

Bit 12

0 = No ; 1 = Yes

80

Multiple Faults

Occurred

(Read)

Compressor Phase Over

Current

Immediate

Shutdown

N/A

Bit 0

0 = No ; 1 = Yes

Lockout (After 10 fault occurrences*)

AC Input Over Current

Immediate

Shutdown

N/A

Bit 1

0 = No ; 1 = Yes

DC Bus Over Voltage

Immediate

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

DC Bus Under Voltage

Immediate

Shutdown

N/A

Bit 3

0 = No ; 1 = Yes

AC Input Over Voltage

Immediate

Shutdown

N/A

Bit 4

0 = No ; 1 = Yes

AC Input Under Voltage

Immediate

Shutdown

N/A

Bit 5

0 = No ; 1 = Yes

Sensor 1 (High Pressure

Switch Open)

Immediate

Shutdown

N/A

Bit 8

0 = No ; 1 = Yes

Power Module Over Temp

Immediate

Shutdown

N/A

Bit 11

0 = No ; 1 = Yes

IGBT Over Temp

Immediate

Shutdown

N/A

Bit 12

0 = No ; 1 = Yes

Lost Rotor Position

Immediate

Shutdown

N/A

Bit 13

0 = No ; 1 = Yes

Lockout (After 10 fault occurrences*)

Pre-charge Relay Open

N/A

N/A

Bit 15

0 = No ; 1 = Yes

DC Bus Voltage Low

N/A N/A

Bit 0

0 = No ; 1 = Yes

Torque Limit Fold Back

Timeout

Controlled

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

Page 19

81

Multiple Faults

Occurred

(Read)

Power Module Temp. Fold

Back Timeout

Controlled

Shutdown

N/A

Bit 3

0 = No ; 1 = Yes

AC Input Current Fold Back

Timeout

Controlled

Shutdown

N/A

Bit 4

0 = No ; 1 = Yes

Auto Config Communication

Timeout

N/A

N/A

Bit 6

0 = No ; 1 = Yes

Modbus Communication Lost

Controlled

Shutdown

N/A

Bit 7

0 = No ; 1 = Yes

Sensor 2 (Thermistor, DLT)

High Temp

Controlled

Shutdown

N/A

Bit 8

0 = No ; 1 = Yes

Board Temp High

Controlled

Shutdown

N/A

Bit 10

0 = No ; 1 = Yes

Power Module Temp High

Controlled

Shutdown

N/A

Bit 11

0 = No ; 1 = Yes

IGBT Temp High

Controlled

Shutdown

N/A

Bit 12

0 = No ; 1 = Yes

82

1st Fault

Occurred

(Read)

Compressor Phase Current

Imbalance

Immediate

Shutdown

N/A

Bit 0

0 = No ; 1 = Yes

Micro Electronic Fault or

Drive EEPROM Fault

Immediate

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

Lockout (After 10 fault occurrences*)

Motor Over Speed

Immediate

Shutdown

N/A

Bit 3

0 = No ; 1 = Yes

Sensor 1 (HP Transducer)

fault – High Pressure

Sensing Low

Immediate

Shutdown

N/A

Bit 5

0 = No ; 1 = Yes

Compressor Model

Configuration Error

Immediate

Shutdown

N/A

Bit 6

0 = No ; 1 = Yes

High Pressure Sensor Type

Configuration Error

Immediate

Shutdown

N/A

Bit 7

0 = No ; 1 = Yes

83

1st Fault

Occurred

(Read)

Sensor 2 (Thermistor, DLT)

Low Temp or Open

Controlled

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

Power Module Temp Low or

Sensor Open fault

Controlled

Shutdown

N/A

Bit 5

0 = No ; 1 = Yes

Fault Limit Lockout

N/A

N/A

Bit 15

Lockout Status

0 = No ; 1 = Yes

84

Multiple Faults

Occurred

(Read)

Compressor Phase Current

Imbalance

Immediate

Shutdown

N/A

Bit 0

0 = No ; 1 = Yes

Micro Electronic Fault or

Drive EEPROM Fault

Immediate

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

Lockout (After 10 fault occurrences*)

Motor Over Speed

Immediate

Shutdown

N/A

Bit 3

0 = No ; 1 = Yes

Sensor 1 (HP Transducer)

fault – High Pressure

Sensing Low

Immediate

Shutdown

N/A

Bit 5

0 = No ; 1 = Yes

Compressor Model

Configuration Error

Immediate

Shutdown

N/A

Bit 6

0 = No ; 1 = Yes

High Pressure Sensor Type

Configuration Error

Immediate

Shutdown

N/A

Bit 7

0 = No ; 1 = Yes

85

Multiple Faults

Occurred

(Read)

Sensor 2 (Thermistor, DLT)

Low Temp or Open

Controlled

Shutdown

N/A

Bit 2

0 = No ; 1 = Yes

Power Module Temp Low or

Sensor Open fault

Controlled

Shutdown

N/A

Bit 5

0 = No ; 1 = Yes

Fault Limit Lockout

N/A

N/A

Bit 15

Lockout Status

0 = No ; 1 = Yes

Page 20

Modbus

Register

Register Type

Description

Bytes

Data Format

Default

Values

Additional Notes

100

Standard

Commands

(Read/Write)

Compressor

Enable

2 Bytes

0 = Disable 1 = Enable

0

101

Compressor

Speed Demand

2 Bytes

16.0

Ex. If Value = 512, then

Conversion = 512/(2^0)

1RPM/bit

0

102

Stator Heater

Demand

2 Bytes

16.0 0 = Disable

Ex. If Value = 512, then

Conversion = 512/(2^0)

1Watt/bit

0

103

Faults Clear

Command

2 Bytes

1=Fault Clear , non-1= No

Action

0

200

Customer

Configuration

Parameter

(Read/Write)

Map access

Password

2 Bytes

Password = 0x2345

Customer access to 201~213

N/A

201

Modbus Format

2 Bytes

2 = RTU

2

The drive has a feature to detect the

baud rate and parity of the system

controller and automatically configure to

those values.

Example: If controller is running at

19200bps and Even parity, 1 stop bit.

Then registers are automatically

configured to Reg.203 = 19200 &

Reg.204 = 1

202

ModBUS Slave ID

Address

2 Bytes

1-247

45

203

ModBUS Baud

Rate

2 Bytes

1200 = 1200BPS

2400 = 2400BPS

4800 = 4800BPS

9600 = 9600 BPS

19200 = 19200 BPS

38400 = 38400 BPS

19200

204

ModBUS Parity

2 Bytes

1=Even parity, 1 stop bit;

2=Odd parity, 1 stop bit;

3=No Parity, 2 stop bits:

4=Even parity, 2 stop bits:

5=Odd parity, 2 stop bits;

6=No parity, 1 stop bit

1

205

Compressor

Model Number

2 Bytes

0 = Not Configured

301 = ZPV0212E-2E9 (900 7200RPM)

311 = ZPV0212E-2E9 Rev1

(900 - 7200RPM)

410 = ZPV0282E-2E9 (900 7200RPM)

411 = ZPV0282E-2E9 Rev1

(900 - 7200RPM)

501 = ZPV0382E-2E9 (900 7200RPM)

511 = ZPV0382E-2E9 Rev1

(900 - 7200RPM)

502 = ZPV0342E-2E9 (900 7200RPM)

512 = ZPV0342E-2E9 Rev1

(900 - 7200RPM)

555 = ZPV0412E-2E9 (900 –

7200RPM)

0

206

Sensor 1 (HP

Switch)

2 Bytes

0 = Not Configured

100 = HP Switch N/C

(normally closed)

0

207

Sensor 2 (Scroll

Thermistor, DLT)

2 Bytes

0 = N/A

100 = 10Kohm resistor (to

simulate 25oC DLT temp)

200 = DLT 1 (Sensor)

0

When configured to “100”, the DLT limit

at Reg.38 is not applicable, it is only for

lab usage.

210

Controlled

Shutdown Rate

Config Option

2 Bytes

16.0

0 = Not Configured

Can be configured in

increments of "20" (20 to 120).

Decimal value of 20 =

60rpm/sec

50

Page 21

Ex. If Value = 50, then it's

150rpm/sec

These values need to be re-configured

only if different shutdown, ramp up &

ramp down rates are required.

211

Speed Ramp-up

Rate Config

Option

2 Bytes

16.0

0 = Not Configured

Can be configured in

increments of "20" (20 to 120).

Decimal value of 20 =

60rpm/sec

Ex. If Value = 20, then it's

60rpm/sec

20

212

Speed Ramp-

down Rate Config

Option

2 Bytes

16.0

0 = Not Configured

Can be configured in

increments of "20" (20 to 120).

Decimal value of 20 =

60rpm/sec

Ex. If Value = 20, then it's

60rpm/sec

20

213

Ramp-up Speed

Level Config

Option during

Start-up

2 Bytes

16.0

100RPM/bit

0 = Default Ramp-up profile at

start-up

Ex. 15 = 1500RPM

Range: 1500RPM to

3500RPM in 100RPM

increments

0

Range: 1500RPM to 3500RPM in

100RPM increments. Drive cannot be

configured outside this band.

*Note: After 10 occurrences of a particular lockout related fault within 10hours time period, the drive will go into hard

lockout and need to be power cycled to clear the fault.

Page 22

4 DRIVE CONFIGURATION FLOW CHARTS

Apply Power to Drive

Write Password “0x2345”

to Register 200.

Read Registers 201 to 213

(201 & 202 are

default,203 & 204 are

autoconfigured by the

drive)

Do values match

spec?

Faults?Query fault status

Write values according to

Modbus Map to Registers

205 to 213

Operate drive

Troubleshoot according to

the fault

YES

YES

NO

NO

Page 23

5 DRIVE STATUS DISPLAY – ROLLING LED

Table 7 - Rolling LED Display Status Information

Item

Major Fault

Long Fault Code

1

Compressor Phase Over Current

INVERTER OVER CURRENT

2

AC Input Over Current

AC OVER CURRENT

3

DC Bus Over Voltage

DC OVER VOLTAGE

4

DC Bus Under Voltage

DC UNDER VOLTAGE

5

AC Input Over Voltage

AC OVER VOLTAGE

6

AC Input Under Voltage

AC UNDER VOLTAGE

7

AC Voltage Imbalance

AC IMBALANCE

8

Sensor 1 (High Pressure Switch Open)

HP SWITCH OPEN

9

Power Module Over Temp

INVERTER OVER TEMP

10

PFC-IGBT Over Temp

IGBT OVER TEMP

11

Lost Rotor Position

LOST ROTOR

12

Compressor Phase Current Imbalance

INVERTER CURRENT IMBALANCE

13

Micro Electronic Fault or Drive EEPROM Fault

MICRO FAULT

14

Motor Overspeed

MOTOR OVERSPEED

15

Compressor Model Configuration Error

COMPRESSOR CONFIG ERROR

16

High Pressure Sensor Type Configuration Error

HP SENSOR CONFIG ERROR

Table 8 - Rolling LED Display Status Information

Item

Minor Fault

Long Fault Code

1

DC Voltage Low

DC VOLTAGE LOW

2

Compressor Phase Current Foldback Timeout

ENVELOP FOLDBACK TIMEOUT

3

Power Module Temp. Fold Back Timeout

OVER TEMP FOLDBACK TIMEOUT

4

AC Input Current Fold Back Timeout

INPUT OC FOLDBACK TIMEOUT

5

Auto Config Communication Timeout

AUTO CONFIG TIMEOUT

6

Modbus Communication Lost

MODBUS COMMS LOST

7

Sensor 2 (Thermistor, DLT) High Temp

DLT TEMP HIGH

8

Board Temp High

MICRO TEMP HIGH

9

Power Module Temp High

INVERTER TEMP HIGH

10

PFC-IGBT Temp High

IGBT TEMP HIGH

11

Sensor 2 (Thermistor, DLT) Low Temp or Open

SENSOR 2 LOW TEMP OR OPEN

12

Fault Limit Lockout

FAULT LIMIT LOCK OUT

Page 24

6 TROUBLESHOOTING GUIDE

Item

Fault/Protection

Check and Handling

Registers

Bit

Rolling LED

Code

1

Compressor Phase

Over Current

1. Check the U/V/W connections on drive side

2. Check the compressor motor windings

3. Check the compressor is operating with in

specified limits

78 80 0

INVERTER

OVER

CURRENT

2

Torque Limit Fold

Back Timeout

1. Compressor Torque ≥ foldback protection

value (for 30 seconds).

2. Check if the compressor is operating outside

the specified speed range.

79 81 2 ENVELOPE

FOLDNACK

TIMEOUT

3

AC Input Over

Current

1. Check the line voltage is too low.

2. Check the line voltage for noise.

3. Check the compressor is operating with in

specified limits.

4. If the problem still persists, then it's possibly

a drive component issue. Replace the drive

78

80

1

AC OVER

CURRENT

4 DC Bus Over

Voltage

1. Check the DC bus voltage if it is > 850VDC

2. Check AC Power Supply

3. Check the compressor is operating with in

specified limits.

4. Restart the drive

78 80 2 DC OVER

VOLTAGE

5 DC Bus Under

Voltage

1. Check the DC bus voltage if it is < 350VDC

2. Check the compressor is operating with in

specified limits.

3. Restart the drive

78 80 3 DC UNDER

VOLTAGE

6

AC Input Over

Voltage

Check the line voltage if it is > 645VAC

78

80 4 AC OVER

VOLTAGE

7 AC Input Under

Voltage

1. Check the line voltage if it is < 500VAC

2. Check the compressor is operating with in

specified limits.

78 80 5 AC UNDER

VOLTAGE

8

AC Voltage

Imbalance

Check if all input cables are connected or any line is

missing. Checking if the voltage is below 500VAC. If

the problem persists, replace the drive

78

80 6 AC

IMBALANCE

9

Power Module Over

Temp

Verify proper airflow over the heat-sink of the drive.

Remove any obstructions. Check that the compressor

is operating within specified limits. Check the

mounting screws on the drive, make sure they are

tight. If the problem, still persists replace the drive.

78

80

11

INVERTER

OVER TEMP

10

IGBT Over Temp

Verify proper airflow over the heat-sink of the drive.

Remove any obstructions. Check that the compressor

is operating within specified limits. Check the

mounting screws on the drive, make sure they are

tight. If the problem, still persists replace the drive.

78

80

12

IGBT OVER

TEMP

11 Lost Rotor Position

1. Check the U/V/W connections on drive side &

compressor side.

2. Check the compressor motor windings

3. Check system charge levels, if too high this

problem can occur.

78 80 13 LOST ROTOR

12

Compressor Phase

Current Imbalance

82

84 0 INVERTER

CURRENT

IMBALANCE

13

Microelectronic Fault

82 84 2

Page 25

EEPROM fault

1. DSP self-check error, restart the drive and fault

should go away.

2. If problem persists, replace the drive.

MICRO

FAULT

14

DC Bus Voltage Low

DC Bus Voltage is below 380V. Check the AC power

supply and if the right voltage is supplied according to

the drive model.

The drive running condition is not stable. Check the

compressor load and makes sure it is OK. Restart the

drive again. If problem persist, replace the drive.

79

81

0

DC VOLTAGE

LOW

15 AC Input Current

Fold Back Timeout.

1. Check the line voltage if it is < 500VAC.

2. Check the compressor is operating with in

specified limits.

3. If problem persists, replace the drive.

79 81 4 INPUT OC

FOLDBACK

TIMEOUT

16

Modbus

Communication Lost

1. Check mod-bus communication cable connections.

2. Check the communication parameters are set right.

3. Power cycle the drive.

4. If problem persists, replace the drive.

79

81

7

MODBUS

COMMS

LOST

17

Sensor 2

(Thermistor, DLT)

High Temp

1. Check the DLT/Scroll Thermistor connection.

2. Check the compressor is operating with in

specified limits.

79 81 8 DLT TEMP

HIGH

18

Power Module Temp

High

Verify proper airflow over the heat-sink of the drive.

Remove any obstructions. Check that the compressor

is operating within specified limits. Check the

mounting screws on the drive, make sure they are

tight. If the problem, still persists replace the drive.

79

81

11

INVERTER

TEMP HIGH

19

IGBT Temp High

Verify proper airflow over the heat-sink of the drive.

Remove any obstructions. Check that the compressor

is operating within specified limits. Check the

mounting screws on the drive, make sure they are

tight. If the problem, still persists replace the drive.

79

81

12

IGBT TEMP

HIGH

20

Power Module

Temp. Fold Back

Timeout

Verify proper airflow over the heat-sink of the drive.

Remove any obstructions. Check that the compressor

is operating within specified limits. Check the

mounting screws on the drive, make sure they are

tight. If the problem, still persists replace the drive.

79

81

3

OVER TEMP

FOLDBACK

TIMEOUT

21

Sensor 1 (High

Pressure Switch

Open)

Condensing Pressure beyond limit, system issue.

78 80 8 HP SWITCH

OPEN

22

Compressor Model

Configuration Error

Compressor model and configuration code do not

match

82

84 6 COMPRESSO

R CONFIG

ERROR

23

High Pressure

Sensor Type

Configuration Error

Pressure sensor and configuration code do not match

82

84 7 HP SENSOR

CONFIG

ERROR

24

Sensor 2

(Thermistor, DLT)

Low Temp or Open

1. Check the DLT/Scroll Thermistor connection.

2. Check the resistance of the sensor to ensure

values are with in specified limits.

83

85 2 SENSOR 2

LOW TEMP

OR OPEN

25

Fault Limit Lockout

Certain faults have a trip limit, see modbus map for

details

82

84

15

FAULT LIMIT

LOCK OUT

26

Auto Config

Communication

Fault Timeout

Baud rate or Parity of the system controller not

matching with drive. Check whether system controller

is working, then Power Cycle the drive.

79

81 6 AUTO

CONFIG

TIMEOUT

27

Motor Over Speed

Check if the compressor is operating within specified

limits. Check if the cables are not shorted. Shutdown

and restart the drive.

82 84 3 MOTOR

OVERSPEED

Page 26

28

Board Temp High

Processor over-heating. Verify proper airflow over the

heat-sink of the drive. Remove any obstructions. If

the problem, still persists replace the drive.

79 81 10 MICRO TEMP

HIGH

7 HI-POT TESTING

There many different types of dielectric testers available. When selecting one to use ensure it

has the following features:

• Can test to voltages up to 4000VDC or higher.

• Can read leakage currents less than 10µA.

• Has Arc Detection available.

Recommended test settings:

• APPLIED VOLTAGE: 3650 VDC

• MAXIMUM LEAKAGE CURRENT: Contact Applications Engineer

• RAMP UP TIME: 8 Seconds

• DWELL TIME: 5 Seconds

• RAMP DOWN: 8 Seconds

Test Procedure:

• Setup test on a clean and dry non-conductive surface.

• Ensure samples are handled properly and using ESD precautions.

• Verify the dielectric tester is configured per “Recommended test settings”.

• Contact Application Engineer for more details on connections and wiring setup.

• Execute Test.

• Note and record the maximum leakage current during the dwell period.

• Once test is complete, safely disconnect the component and store it properly.

Page 27

8 ACCESSORIES

Accessory

Assembly P/N

Drive Models

Compressor Models

Compressor Molded Plug

Cable, Spade Terminal

529-0372-00

EV2080M-L1

EV2080M-L2

All Compressors

Cable, Line Power to AC

Choke

529-0373-00

EV2080M-L1

EV2080M-L2

All Compressors

Cable, AC Choke to Drive

529-0374-00

EV2080M-L1

EV2080M-L2

All Compressors

Cable, Modbus

Communication

529-0249-00

EV2080M-L1

EV2080M-L2

All Compressors

Loading...

Loading...