Emerson Copeland EazyCool ZXDI Series, ZXDI050E, ZXDI060E, ZXDI040E, ZXDI075E Application Manuallines

Page 1

Application Guidelines

Copeland EazyCool

™

Indoor Condensing Units

ZXDI Range

Page 2

C6.1.10/0118-0318/E

About these guidelines ............................................................................................... 1

1 Safety instructions ........................................................................................... 1

1.1 Icon explanation ............................................................................................................... 1

1.2 Safety statements ............................................................................................................ 1

1.3 General instructions ......................................................................................................... 2

2 Product description ......................................................................................... 3

2.1 Common information about Copeland EazyCool™ ZXDI indoor condensing units ........ 3

2.2 EU Ecodesign Directive 2009/125/EC ............................................................................. 3

2.3 Product range .................................................................................................................. 3

2.4 Product nameplate ........................................................................................................... 3

2.5 Nomenclature ................................................................................................................... 3

2.6 Application range ............................................................................................................. 4

2.6.1 Qualified refrigerants and oils .............................................................................. 4

2.6.2 Application limits ................................................................................................... 4

2.7 Bill of material .................................................................................................................. 4

2.8 Main components description .......................................................................................... 4

2.8.1 Compressor .......................................................................................................... 4

2.8.2 Condenser fan(s) .................................................................................................. 5

2.8.3 Housing ................................................................................................................ 6

2.9 P&I diagram for ZXDI units .............................................................................................. 7

2.10 XCM25D Electronic controller – Features ....................................................................... 8

2.10.1 Description ........................................................................................................... 8

2.10.2 Functionality ......................................................................................................... 8

2.10.3 Main control & safety features .............................................................................. 9

2.10.4 Additional features for customization ................................................................. 10

2.11 XCM25D Electronic controller – Programming .............................................................. 12

2.11.1 Programming the local display ........................................................................... 12

2.11.2 Remote display CCM60 ..................................................................................... 13

2.11.3 Single commands ............................................................................................... 14

2.11.4 Double commands – Entering programming level 1 "Pr1" ................................. 14

2.11.5 How to program the parameters (Pr1 and Pr2) .................................................. 14

2.11.6 Entering programming level 2 "Pr2" ................................................................... 15

2.11.7 Fast access menu .............................................................................................. 15

2.12 Controller keyboard ........................................................................................................ 15

2.12.1 How to lock the keyboard ................................................................................... 15

2.12.2 How to unlock the keyboard ............................................................................... 16

2.13 Parameters level 1 – Required settings ......................................................................... 16

2.14 Digital operation ............................................................................................................. 16

2.15 Reset to factory settings – Emerson "Hot Key" ............................................................. 17

2.15.1 How to save factory settings or user settings .................................................... 17

Page 3

C6.1.10/0118-0318/E

2.15.2 Emerson "Hot Key" for ZXDI units with XCM25D controller .............................. 17

2.15.3 Location of the "Hot Key" plug connection on the XCM25D controller .............. 18

2.15.4 How to program a "Hot Key" from the controller (upload) .................................. 18

2.15.5 How to program a controller using an Emerson "Hot Key" (download) ............. 18

2.16 Troubleshooting – Alarm history .................................................................................... 19

2.17 Compressor motor protection ........................................................................................ 19

2.18 System pressure protection ........................................................................................... 19

2.18.1 High-pressure safety switch ............................................................................... 19

2.18.2 High pressure: pressure relief valve ................................................................... 20

2.18.3 Low-pressure safety switch – Optional .............................................................. 20

2.18.4 Ambient temperature sensor .............................................................................. 20

2.19 Alarm output (DO5) ........................................................................................................ 20

2.20 Fan speed control – Ziehl-Abegg PKE-6 controller ....................................................... 20

2.21 Dimensions in mm ......................................................................................................... 21

3 Installation ...................................................................................................... 22

3.1 Condensing unit handling .............................................................................................. 22

3.1.1 Transport and storage ........................................................................................ 22

3.1.2 Weights............................................................................................................... 22

3.2 Electrical connection ...................................................................................................... 23

3.2.1 Power supply connections.................................................................................. 23

3.2.2 Maximum operating currents for cable selection ............................................... 23

3.2.3 Electrical wiring .................................................................................................. 23

3.2.4 Electrical protection standard (protection class) ................................................ 23

3.2.5 Overload protection ............................................................................................ 23

3.3 Refrigeration piping connections ................................................................................... 24

3.3.1 Refrigeration piping installation .......................................................................... 24

3.3.2 Brazing recommendations.................................................................................. 25

3.3.3 Brazing procedure .............................................................................................. 25

3.4 Location & fixings ........................................................................................................... 26

3.5 Required distances ........................................................................................................ 26

3.6 Air ducts connection ....................................................................................................... 27

4 Starting up & operation.................................................................................. 28

4.1 Evacuation ..................................................................................................................... 28

4.2 Charging procedure ....................................................................................................... 28

4.2.1 Refrigerant charging procedure ......................................................................... 28

4.2.2 Oil charging procedure ....................................................................................... 29

4.2.3 Oil separator ....................................................................................................... 29

4.3 Rotation direction of Scroll compressors ....................................................................... 29

4.4 Maximum compressor cycle .......................................................................................... 29

4.5 Checks before starting & during operation .................................................................... 30

Page 4

C6.1.10/0118-0318/E

5 Maintenance & repair ..................................................................................... 31

5.1 Replacing a compressor ................................................................................................ 31

5.2 Condenser fins ............................................................................................................... 31

5.3 Electrical connections .................................................................................................... 31

5.4 Routine leak testing ....................................................................................................... 32

5.5 Condenser fans & motors .............................................................................................. 32

6 Certification & approval ................................................................................. 32

7 Dismantling & disposal .................................................................................. 32

DISCLAIMER .............................................................................................................. 33

Appendix 1: Overview of the ZXDI indoor unit components................................... 34

Appendix 2: Wiring diagram – ZXDI units (380-420V/3Ph/50 Hz) ............................ 35

Appendix 3: Parameter list level 1 (Pr1) ................................................................... 36

Appendix 4: Parameter list Level 1 & Level 2 (Pr1 & Pr2) ....................................... 37

Appendix 5: Alarm menu ........................................................................................... 55

Appendix 6: Additional features for customization ................................................. 60

Appendix 7: Temperature / resistance curve for B7 Sensor (customer option) .... 62

Appendix 8: List of tables and figures ..................................................................... 63

Page 5

Page 6

C6.1.10/0118-0318/E 1

About these guidelines

The purpose of these application guidelines is to provide guidance in the application of Copeland

EazyCool™ ZXDI indoor condensing units. They are intended to answer the questions raised while

designing, assembling and operating a system with these products.

Besides the support they provide, the instructions listed herein are also critical for the proper and

safe functioning of the condensing units. Emerson will not guarantee the performance and

reliability of the product if it is misused in regard of these guidelines.

These application guidelines cover stationary applications only. For mobile applications, contact

Application Engineering as other considerations may apply.

1 Safety instructions

Copeland EazyCool™ ZXDI indoor refrigeration condensing units are manufactured according to

the latest European and US Safety Standards. Particular emphasis has been placed on the user's

safety.

These condensing units are intended for installation in machines and systems according to the

Machinery directive MD 2006/42/EC. They may be put to service only if they have been installed

in these systems according to instructions and conform to the corresponding provisions of

legislation. For relevant standards please refer to the Manufacturer’s Declaration, available at

www.emersonclimate.eu.

These instructions should be retained throughout the lifetime of both the compressor and the

condensing unit.

You are strongly advised to follow these safety instructions.

1.1 Icon explanation

WARNING

This icon indicates instructions to

avoid personal injury and material

damage.

WARNING

This icon indicates operation with

possible personal injury due to

uncovered rotating parts.

High voltage

This icon indicates operations with a

danger of electric shock.

CAUTION

This icon indicates instructions to

avoid property damage and possible

personal injury.

Danger of burning or frost burn

This icon indicates operations with a

danger of burning or frost burn.

IMPORTANT

This icon indicates instructions to

avoid malfunction of the compressor.

Explosion hazard

This icon indicates operations with a

danger of explosion.

NOTE

This word indicates a

recommendation for easier operation.

1.2 Safety statements

▪ Refrigerant compressors must be used in accordance with their intended use.

▪ Only qualified and authorized HVAC or refrigeration personnel are permitted to

install, commission and maintain this equipment.

▪ Electrical connections must be made by qualified electrical personnel.

▪ All valid standards for connecting electrical and refrigeration equipment must be

observed.

▪ The national legislation and regulations regarding personnel protection must be

observed.

Use personal safety equipment. Safety goggles, gloves,

protective clothing, safety boots and hard hats should be worn

where necessary.

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantl

ing &

disposal

Page 7

2 C6.1.10/0118-0318/E

1.3 General instructions

WARNING

System breakdown! Personal injuries! Never install a system in the field

and leave it unattended when it has no charge, a holding charge, or with the

service valves closed without electrically locking out the system.

System breakdown! Personal injuries! Only approved refrigerants and

refrigeration oils must be used.

WARNING

High shell temperature! Burning! Do not touch the compressor until it has

cooled down. Ensure that other materials in the area of the compressor do not

get in touch with it. Lock and mark accessible sections.

WARNING

Uncovered rotating parts! No safety grids on the condenser fans!

Personal injuries! Never start the condensing unit or run the fans with no air

ducts connected or without protective end-grids on the air outlets.

CAUTION

Overheating! Bearing damage! Do not operate compressors without

refrigerant charge or without being connected to the system.

IMPORTANT

Transit damage! Compressor malfunction! Use original packaging. Avoid

collisions and tilting.

The contractor is responsible for the installation of the unit and should check the following points:

▪ Sufficient liquid sub-cooling in the line to the expansion valve(s) to avoid "flash-gas" in the

liquid line;

▪ Sufficient amount of oil in the compressor (in case of long piping additional oil must be

charged).

Page 8

C6.1.10/0118-0318/E 3

2 Product description

2.1 Common information about Copeland EazyCool™ ZXDI indoor condensing

units

Emerson has developed the Copeland EazyCool™ ZXDI indoor condensing unit to meet primarily

the demands of the food retail and food service sectors. It is a refrigeration air-cooled condensing

unit that uses the latest Copeland™ brand products patented Scroll technology as the main driver

and has electronic protection and diagnostics features built in the compact chassis. The

combination of large condensers and low speed fans allows for particularly quiet operation.

2.2 EU Ecodesign Directive 2009/125/EC

The European Directive 2009/125/EC with regard to Ecodesign requirements for professional

refrigerated storage cabinets, blast cabinets, condensing units and process chillers requires

manufacturers to decrease the energy consumption of their products by establishing minimum

energy efficiency standards. Copeland™ brand products condensing units are prepared and

optimized to meet the requirements of the Ecodesign Directive. The integrated variable speed fan

and condenser reduce the noise level and energy consumption significantly. This, combined with

Copeland scroll technology, allows for high-efficiency operation.

For the rated cooling capacity, rated power input and rated COP value please refer to Copeland™

brand products Select software at www.emersonclimate.eu.

These guidelines meet the requirements of Regulation 2015/1095, Annex V, section 2(a), with

regard to product information, namely:

▪ (v) See chapter 2.6

▪ (vi) See chapters 5.2 and 5.4

▪ (vii) See chapters 2.10.3 and 4.2

▪ (viii) See chapter 7

2.3 Product range

Copeland EazyCool ZXDI condensing units are released for multiple refrigerants. They are

available in one cabinet size and are equipped with two fans. They are designed for medium

temperature refrigeration applications.

2.4 Product nameplate

The condensing unit nameplate shows model designation and serial number, as well as locked

rotor amps, maximum operating current, safety pressures and weight.

The compressor has its own nameplate with all electrical characteristics.

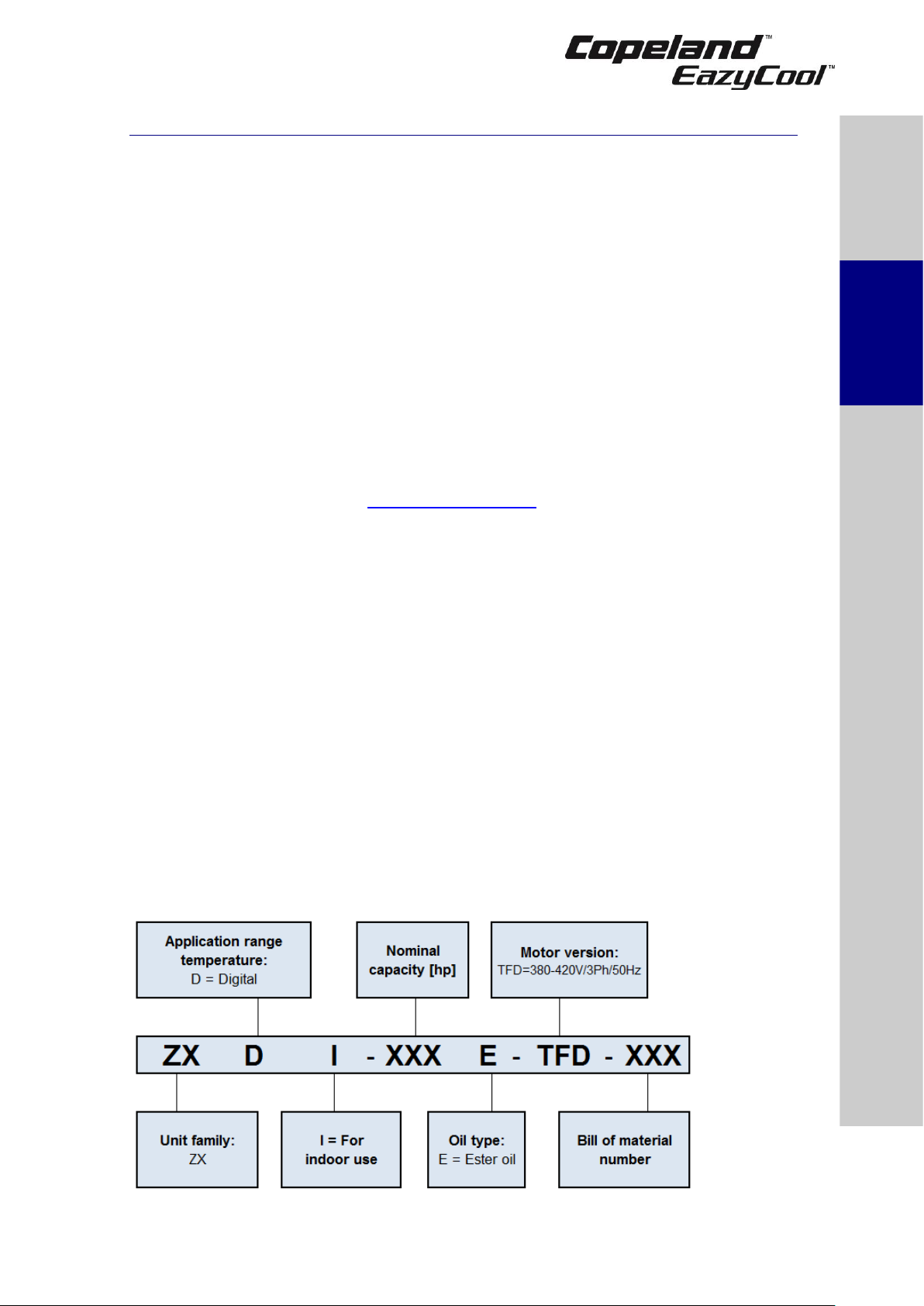

2.5 Nomenclature

The model designation contains the following technical information about the condensing unit:

Figure 1: Nomenclature ZXDI units

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 9

4 C6.1.10/0118-0318/E

2.6 Application range

2.6.1 Qualified refrigerants and oils

Qualified refrigerants

R404A, R407A, R407F, R448A, R449A

R134a, R450A, R513A

Qualified

servicing oils

Emkarate RL 32 3MAF

Mobil EAL Arctic 22CC

Condensing

unit

ZXDI040E

ZXDI050E

ZXDI060E

ZXDI075E

Oil charge in litres

1.36

1.89

Table 1: Qualified refrigerants and oils

WARNING

Use of R450A and R513A refrigerants! Risk of compressor damage!

Migration of R450A or R513A into the compressor crankcase could cause low

oil viscosity, which could lead to compressor damage. When using R450A or

R513A it is critical to meet the following requirements:

▪ maintain adequate superheat settings with a minimum superheat of 8-10K;

▪ no liquid refrigerant migration into the compressor at any time, especially

during standstill, during or after defrost, or after reverse mode for example

in heat pumps;

▪ pump-down is not recommended;

▪ the use of a crankcase heater is mandatory;

▪ retrofit to R450A and R513A is only allowed for compressors which are

approved for these refrigerants.

Contact your local Application Engineering representative for any further

information.

NOTE: The ZXDI units are equipped with an oil separator. This separator is pre-charged

with 0.5 liter of oil.

2.6.2 Application limits

For application envelopes, please refer to the compressor application envelopes which can be

found in Copeland™ brand products Select software, available at www.emersonclimate.eu.

ZXDI indoor condensing units can be used at an ambient temperature from -15°C to 45°C. For

lower ambient temperatures please contact your local Application Engineering representative.

2.7 Bill of material

BOM

Family

Introduction

date

Controller concept

Oil

separator

Suction

accumulator

554

ZXDI

Jan/2018

XCM25D (Emerson - Dixell)

Yes

No

Table 2: BOM

2.8 Main components description

2.8.1 Compressor

Condensing

unit

Compressor model

(Digital)

Compressor

LRA (A)

Compressor

MOC* (A)

Unit rated

current (A)

ZXDI040E

ZBD29KQE-TFD

48

7.9

11.3

ZXDI050E

ZBD38KQE-TFD

64

11.3

14.7

ZXDI060E

ZBD45KQE-TFD

74

11.4

14.8

ZXDI075E

ZBD48KQE-TFD

100

14

17.4

* MOC = Maximum Operating Current

Table 3: Cross reference table units/compressor models

Page 10

C6.1.10/0118-0318/E 5

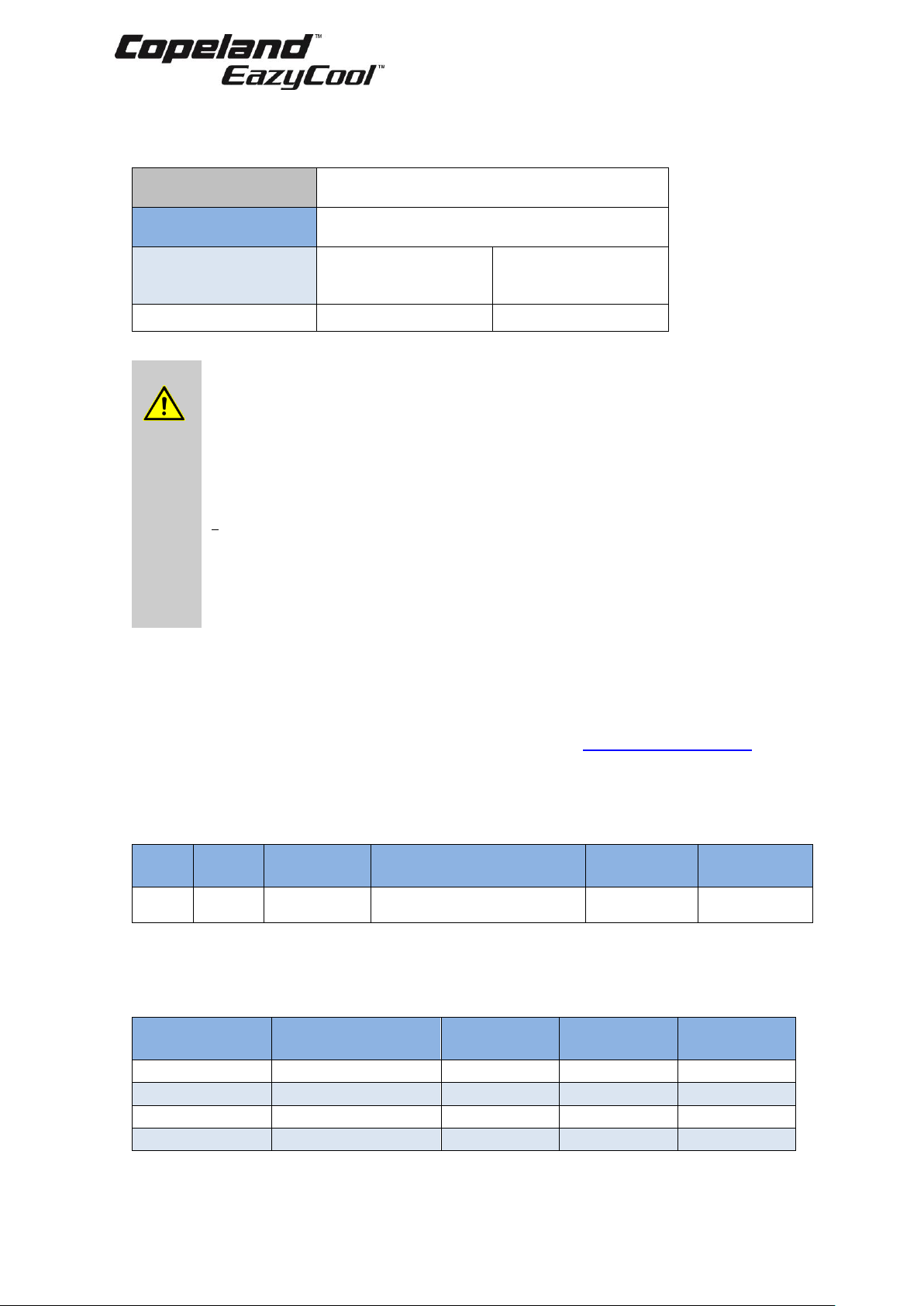

2.8.2 Condenser fan(s)

WARNING

Uncovered rotating parts! No safety grids on the condenser fans!

Personal injuries! Never start the condensing unit or run the fans with no air

ducts connected or without protective end-grids on the air outlets.

The condensers of the ZXDI condensing units are equipped with single-phase fans.

Condensing

unit

Nr. of fans

(pcs)

Fan blade

diameter

(mm)

Weight

per 1 fan

(kg)

Maximum

current @

100% per

1 fan (A)

Power

consumption

@ 100% per

1 fan (W)

ZXDI040E

2

450

~12

1.7

375

ZXDI050E

ZXDI060E

ZXDI075E

Table 4: Condenser fan technical data

Figure 2: Fan details and dimensions

Figure 3: Fan bracket details

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 11

6 C6.1.10/0118-0318/E

2.8.3 Housing

Copeland EazyCool ZXDI indoor condensing units have the following housing features:

▪ Controller-window in front of the cabinet door. The window is IP54 and shows the current

value of the electronic controller.

▪ The main power switch is installed on the cabinet door and allows to de-energize the unit

without opening the door. To open the door the main power switch must be in off position.

▪ The quick-locks allow for easy and quick opening of the cabinet door by means of the

cabinet key.

▪ The cabinet key is delivered with the unit. It is attached to one of the piping connections by

means of a cable strap.

Figure 4: ZXDI unit housing

Page 12

C6.1.10/0118-0318/E 7

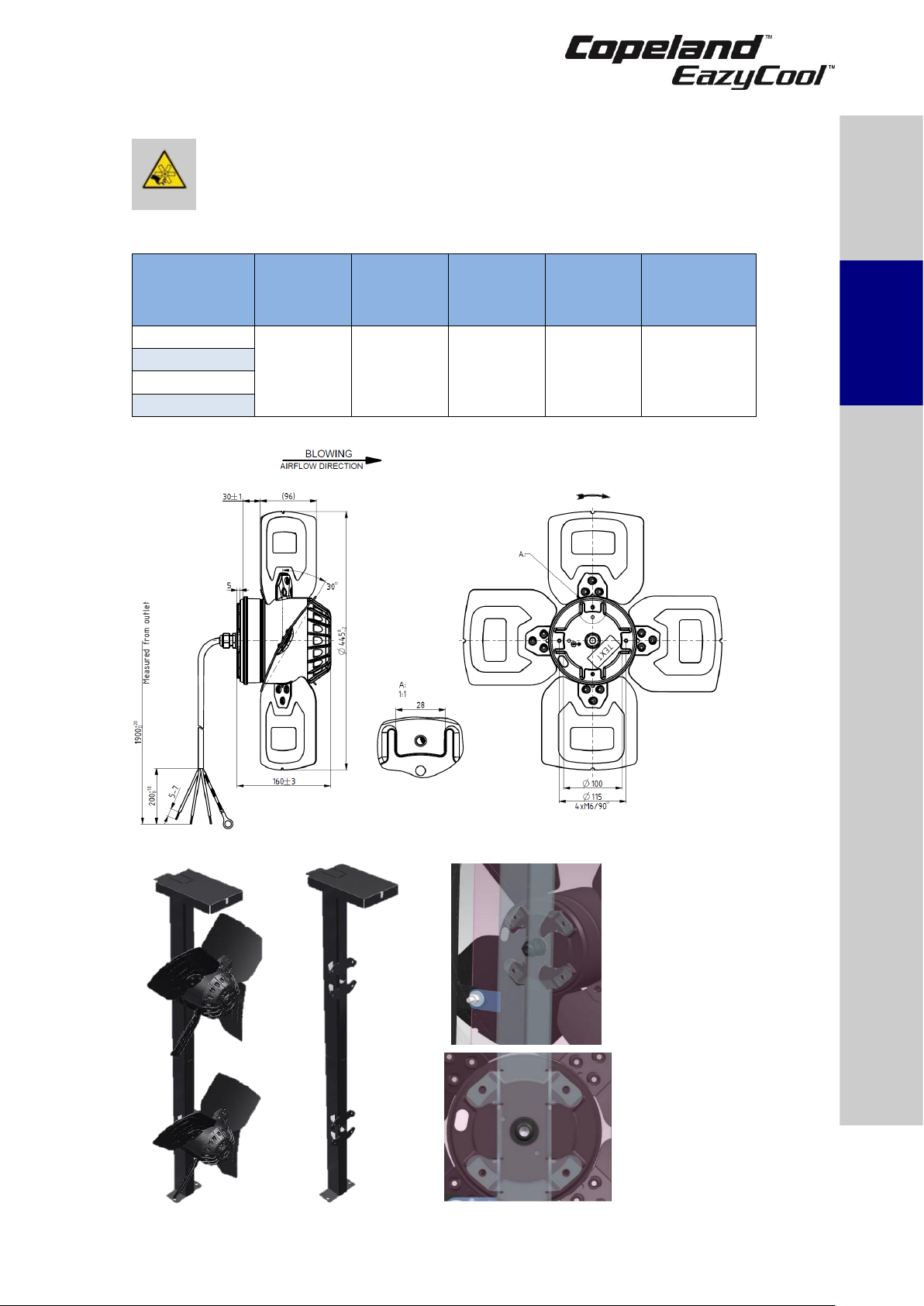

2.9 P&I diagram for ZXDI units

IMPORTANT

Check valve in front of liquid receiver! Risk of excessive internal

pressure caused by liquid expansion! Check required safety devices

according to EN 378.

Figure 5: P&I diagram for ZXDI units

Position

Description

Comments

Fast access

menu

1 (M1)

High efficient Copeland Scroll ZBD compressor

2

Oil separator

Pre-charged with 0.5 L

3 (M2)

Condenser with 2 fans

4

Liquid receiver with service valve

5

Filter drier / sight glass combination

6

Service valve, liquid line

7

Service valve, suction line

PSL (S2)

Adjustable low-pressure switch (not factory

mounted)

System safety

(option)

PSH (S1)

Non-adjustable high-pressure switch

System safety

PTL (B1)

Pressure sensor, low pressure

Compressor setpoint

P1P

PTH (B2)

Pressure sensor, high pressure

Fan speed control

P2P

TT1 (B3)

Discharge temperature sensor

Compressor safety

P3t

TT2 (B6)

Ambient temperature sensor

Additional functions

P6t

Table 5: Legend of the P&I diagram for ZXDI units

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 13

8 C6.1.10/0118-0318/E

2.10 XCM25D Electronic controller – Features

The XCM25D controller is designed to be a powerful, flexible controller for use in multiple

applications. It has been developed for ZXDI condensing units and allows the adjustment of all

relevant parameters by the user.

2.10.1 Description

WARNING

Electrical shock hazard! Serious personal injuries! There are unused fast-

on pins (C1 & DO2) on the XCM25D which could be under voltage. They are

covered by insulated fast-on flags in the factory. Handle carefully when

removing insulating flags during service on site.

The controller is designed for usage in an indoor refrigeration unit. It is rated to be used for the

following environment:

▪ Outdoor controller ambient temperature for operation: -40C to 60C

▪ Ambient temperature for storage: -40C to 80C

▪ Maximum humidity: 90% at 48C (non-condensing)

▪ Board power: 24V AC +15%/-20%

▪ Voltage sensing capabilities - Three phase: 200-240, 380-460, 575V AC ± 10%

The units of measure are selectable. The factory default unit is [bar] (always considered relative)

for pressure and [°C] for temperature.

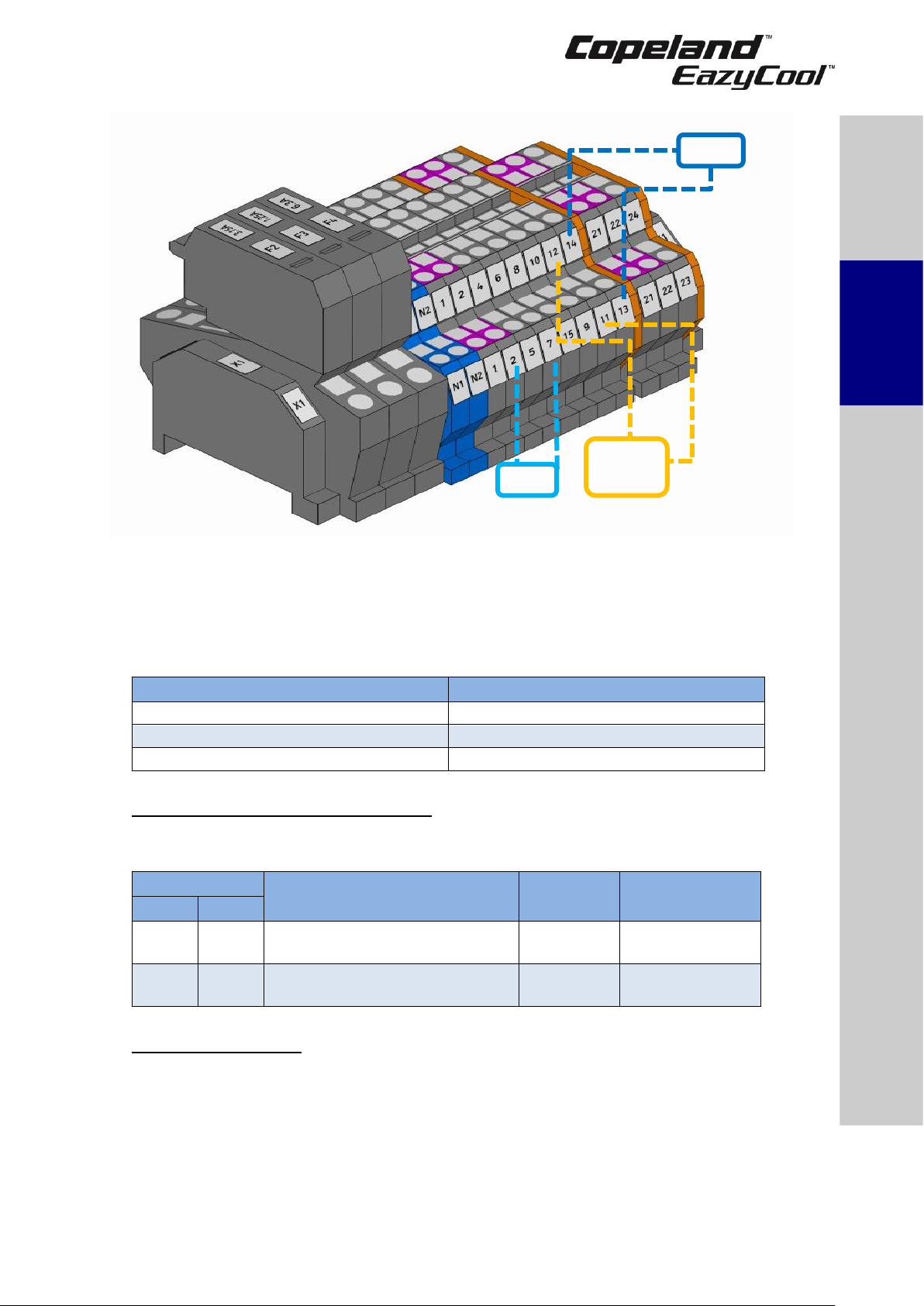

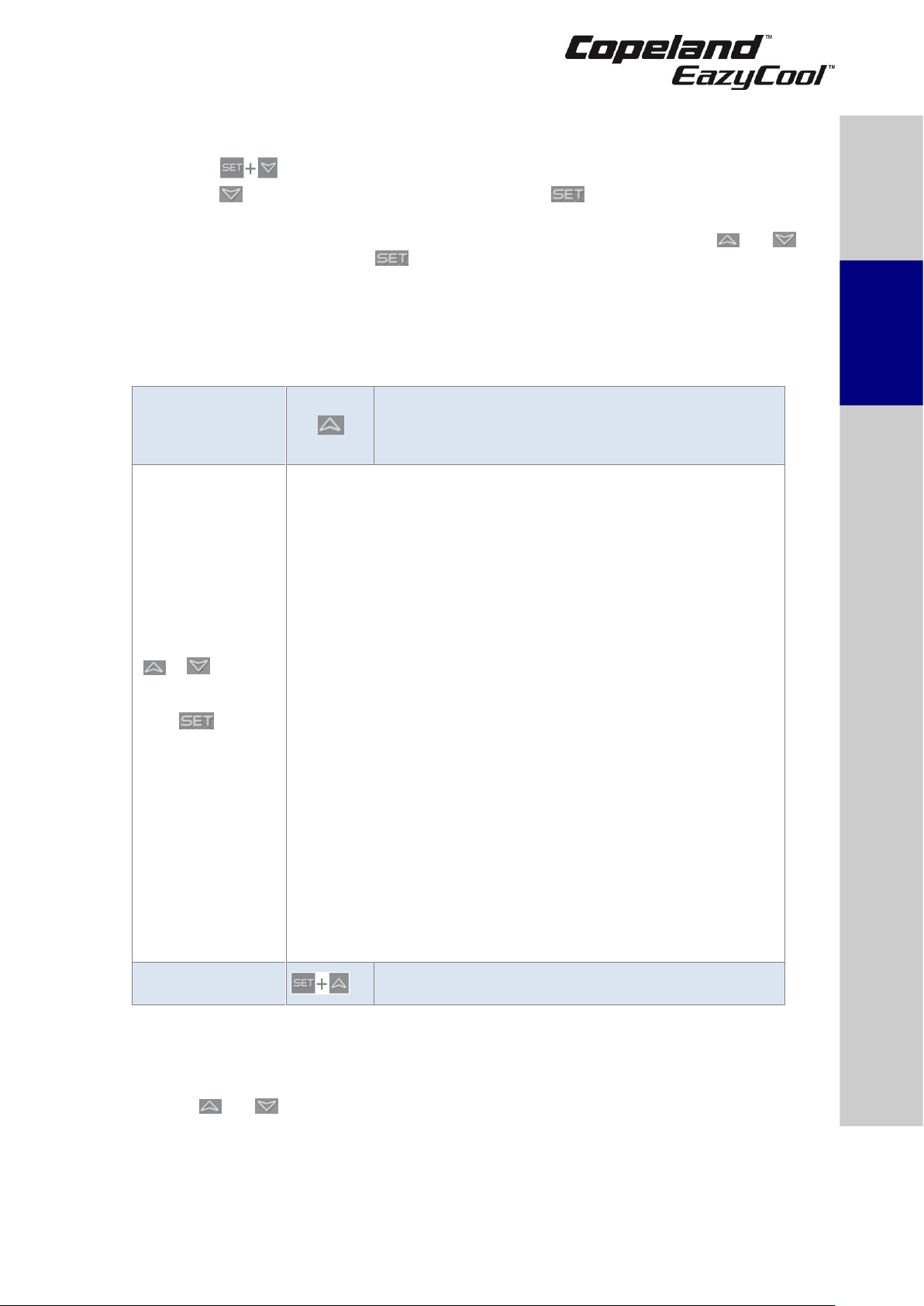

Figure 6: Electronic controller

2.10.2 Functionality

The controller allows for easy commissioning by the technician with the factory settings at the

highest program level. It also offers the possibility to make substantial changes to the system

optimization in further programming levels. Advanced functionality can also be activated.

The following functions are covered by the controller:

▪ Condensing unit control

▪ Condenser fan control

▪ Voltage and current sensing (compressor protection)

▪ Digital compressor control

NOTE: The XCM25D controller on ZXDI units includes all the functions necessary for unit

control. For additional functionalities please contact your local Application Engineering

representative.

Page 14

C6.1.10/0118-0318/E 9

Figure 7: XCM25D controller functionality overview

2.10.3 Main control & safety features

Suction pressure control: Each unit is equipped with a suction pressure transmitter. The

XCM25D controls the suction pressure by evaluating the input signal of the pressure transmitter.

When using a digital unit (ZXDI), the setpoint (C16/StC) and proportional band (C17/Pbd) need to

be adjusted. The signal of the suction pressure transmitter is also used for additional functionalities

and to keep the compressor running within the approved envelopes.

Condensing pressure control: Each unit is equipped with a high-pressure transmitter. The

XCM25D controls the condensing pressure by regulating the fan speed corresponding to the highpressure transmitter signal. The output signal of the unit controller to the fan speed controller is a

0-10V signal.

The unit controller can regulate the condensing pressure in two ways. The first approach is to keep

a constant condensing temperature. This mode is utilized by the factory settings. The pre-adjusted

setpoint is 27°C as a universal setting. If lower condensing pressure is required set up the

condenser setpoint (E39/FSP) to a lower value.

The second control way is fan modulation based on the compressor envelope. This mode of

setpoint control is only available if a suction pressure input is not used. The parameter (E38/FSM)

enables/disables the mode as needed. If this function is unused, the condensing temperature

setpoint will be set as a parameter (E39/FSP) value. The compressor is allowed to run at minimum

condensing temperatures based on the suction pressure of the compressor. This is the most

energy-efficient way to minimize the condensing temperature as much as possible.

NOTE: The fan speed controller is a Ziehl-Abegg PKE-6 controller. For more information

please refer to Chapter 2.20 "Fan speed control – Ziehl-Abegg PKE-6 controller" and to the

fan speed controller user’s guide – part of the unit standard delivery.

Maximal condenser fans pressure difference: To provide the condenser with appropriate air

flow the pressure drop for the fan must not exceed 60 Pa at 3500 m³/h per one fan. Additional

components such as mufflers, flaps, protection grids etc... must also be taken into account when

designing the air ducts route as they will cause additional pressure drop.

The following table shows pressure drops at 3500 m³/h for most commonly used ducting

components:

Spiral duct 500 mm

Ventilation bow 90°, 500 mm

1 Pa/m

10 Pa

Table 6

Example: If 8 meters spiral duct and 3 bows 90° are required on the installation, then

1 Pa × 8 + 10 Pa x 3 = 8 Pa + 30 Pa = 38 Pa, so 38 Pa < 60 Pa.

Compressor phase reversal: Ensures that the compressor keeps running in one direction only

(clockwise = right rotation) – necessary for a compliant Scroll compressor to compress and pump

refrigerant. Reset is automatic once the phase rotation is correct for the compressor.

Motor current overload protection: This feature eliminates the need for external current

protection for the compressor motor.

Condenser fan

control

Digital Scroll

control

Alarm

management

Electrical

protection

Monitoring of the discharge

line temperature

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 15

10 C6.1.10/0118-0318/E

Fixed high-pressure switches: This is a non-adjustable protection device designed to prevent

the compressor from operating outside of its safe high-pressure range. Reset is automatic for a

set number of trips (7) then the unit will lock out and require manual restart. This feature is

important to prevent the unit from cycling under these controls for a long period of time.

▪ Cut-out: 28.8 bar

▪ Cut-in: 24 bar

Adjustable high-pressure limitation: The unit controller provides the possibility to stop the unit

at a required discharge pressure which is lower than the cut-out value of the fixed high-pressure

switch. Detailed instructions can be found in chapter 2.10.4 "Additional features for customization"

hereunder.

Discharge temperature protection: Each unit is equipped with a discharge line sensor (NTC).

The XCM25D controller will stop the compressor if discharge temperatures reach unacceptable

levels.

Adjustable low-pressure alarm: The unit controller features an adjustable low-pressure alarm

managed by the suction pressure sensor. This alarm has been factory-set at 0.5 bar(rel), ie, the

lowest permitted pressure of the refrigerant with the lowest pressure-vapour properties. If needed

the user can modify this value according to the required application.

Option: Adjustable low-pressure switches PS1: This device protects the system against lowpressure operation. It must be adjusted depending on running conditions and potential special

requirements like pump-down. The compressor envelopes published in Select must be respected

at all times. In case of controller breakdown, the low-pressure switch could be used for emergency

operation (rewiring required).

A crankcase heater is directly connected to the controller. The crankcase heater will be energized

when the ambient sensor is below a given value (10°C) and the compressor has been off for a

period of time (5 minutes). The minimum off time does not apply at initial power-up.

In addition to the above, the ZXDI indoor condensing unit has the following features:

▪ Liquid line assembly (filter drier and sight glass/moisture indicator)

▪ Anti-corrosion treatment to the condenser fins

The electronic controller is also the base controller for the connection of many optional and

customer supplied functions such as:

▪ Main load controller

▪ Evaporator fan contactor

▪ Superheat controller for one electronic expansion device

2.10.4 Additional features for customization

A lot of additional features are provided by the XCM25D controller. In the European design of the

electrical panel a few of the additional functionalities are prearranged and can easily be installed

by connecting additional hardware to the electrical terminals. The tables in Appendix 6 show the

parameters that have to be changed in case a special feature of the controller should be activated.

The tables do not show the required settings which have to be done by the system operator, eg,

choosing correct setpoints for different components and different applications.

NOTE: After programming an additional function, the system will have to be restarted. To

engage system restart, switch off the main power supply, wait for 5 seconds and switch it

on again.

Component

Description

Prearranged terminals /

Wiring diagram

B12

Low-pressure switch, optional; can be

ordered factory-installed.

Terminals: X1.2 / X1.7

Alarm contact

Sensor for evaporator or room

Terminals: X1.11 / X1.12

Sensor B7

Sensor for evaporator or room

(NTC10kΩ)

Terminals: X1.13 / X1.14

Table 7: Prearranged additional connections

Page 16

C6.1.10/0118-0318/E 11

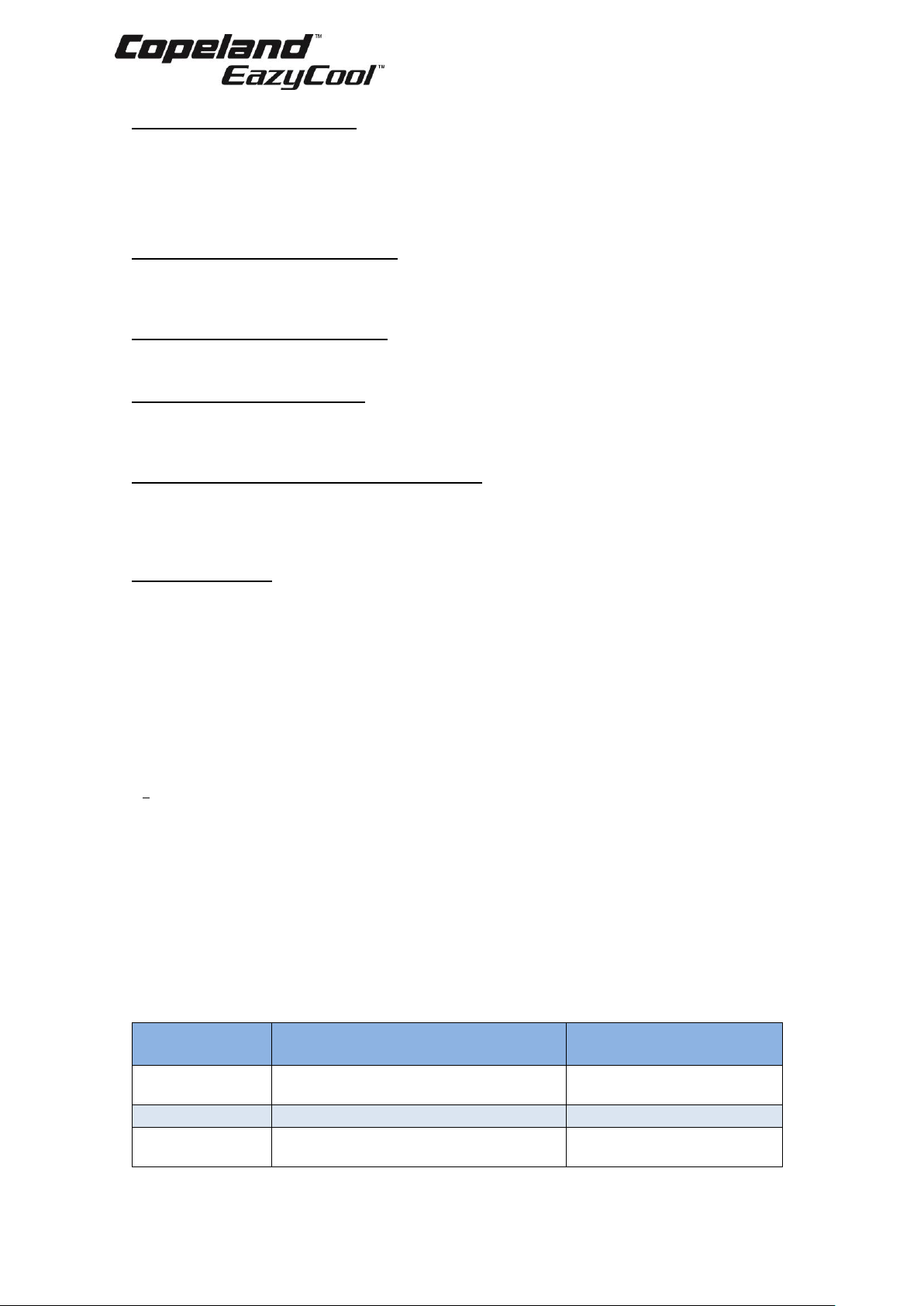

Figure 8: Prearranged additional connections

NOTE: Depending on the required functionalities additional components might be

necessary. Please contact your local Application Engineering representative.

NOTE: Check the current limitations given by the controller relays.

NOTE: The solenoid valve function is not available on ZXDI indoor units.

Digital output

Specifications

DO1, DO2 and DO3

Relay SPDT 16A, 250V AC

DO3

Relay SPST 8A, 250V AC

DO4 and DO5

Relay SPST 5A, 250V AC

Table 8: Digital output specifications

Adjustable discharge pressure limitation

The controller has dedicated parameters to provide the possibility of adjustable discharge pressure

cut-out.

Parameters

Description

Factory

settings

Recommended

settings

ZXDE

ZXDI

E58

AU2

Condenser temperature/pressure

threshold for high alarm

27

Required value

E61

AH2

Condenser temperature/pressure

threshold for alarm recovery

23

Required value

Table 9: Discharge pressure limitations

Low ambient operation

Very low ambient temperatures can result in malfunction of expansion devices because of

insufficient pressure difference. Therefore, pressure cut-out during system start-up can occur. For

proper operation of the expansion devices, the unit running time must allow to build up sufficient

condensing pressure.

At low ambient conditions, the compressor will need to run for a minimum period of time to allow

the system pressures to stabilize. If the unit operates below a defined ambient temperature

(ambient temp. < C12/LAO) or if the ambient sensor has failed, the compressor should run for a

set period of time (C14/LAS) when it is started based on a low suction reading.

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Alarm

contact

Page 17

12 C6.1.10/0118-0318/E

The unit will be turned on for the minimum run time when the low-pressure input is closed.

If the pressure drops below the cut-out value or the low-pressure input opens, the unit should

continue to run for the remaining minimum on time (C14/LAS) or until a satisfactory condenser

pressure is reached (C13/LAd).

If a suction pressure transducer is present and the suction pressure falls below a given value

(C15/LAT) during the minimum on time (C14/LAS), then disregard the timer and shut the

compressor off to protect against vacuum operation.

NOTE: For additional features please contact your local Application Engineering

representative.

2.11 XCM25D Electronic controller – Programming

CAUTION

Low refrigerant charge! Compressor damage! Never energize the

unit/controller without minimum refrigerant system charge. There is a risk of

malfunction of the controller in deep vacuum operation which can cause

compressor damage.

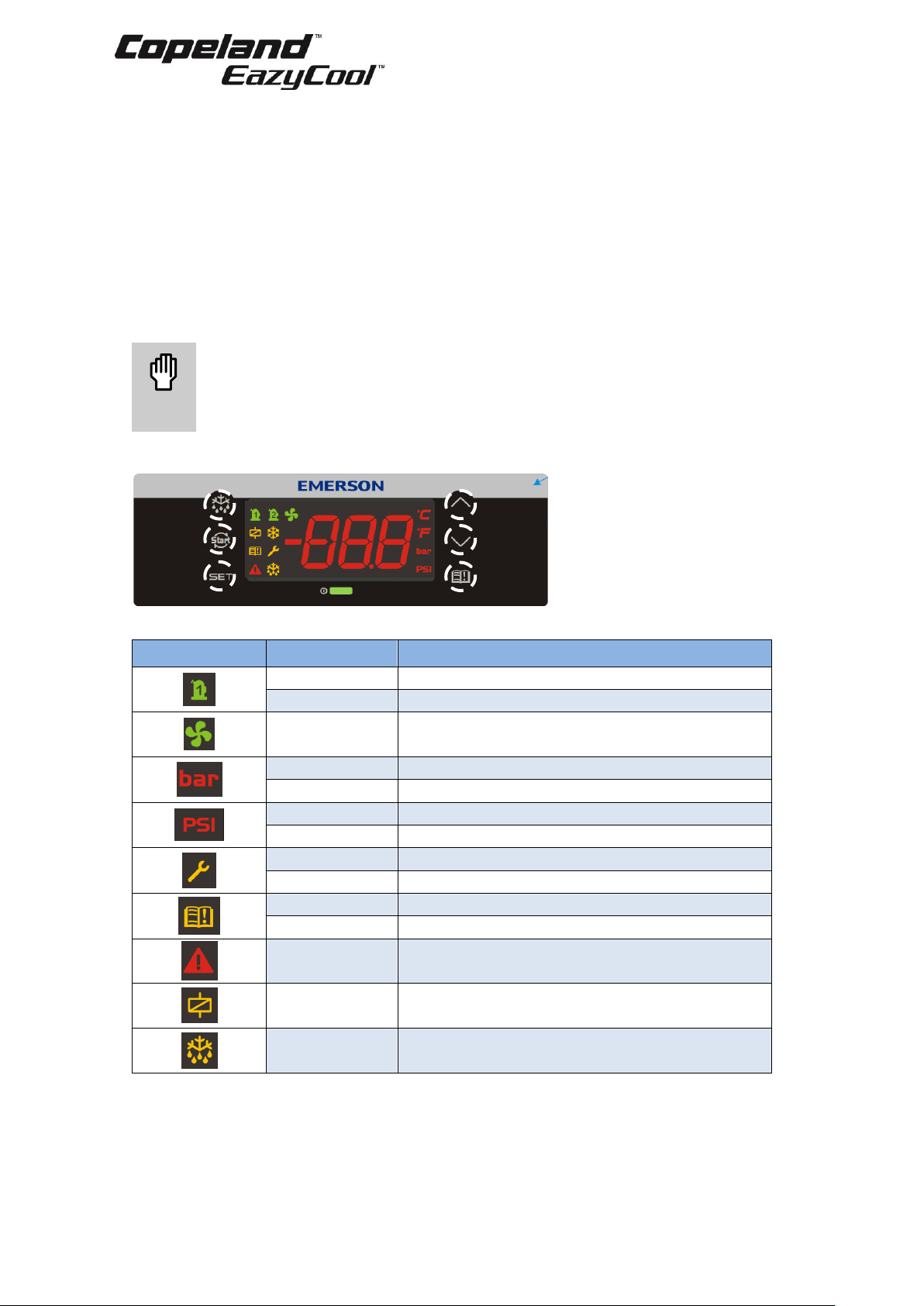

2.11.1 Programming the local display

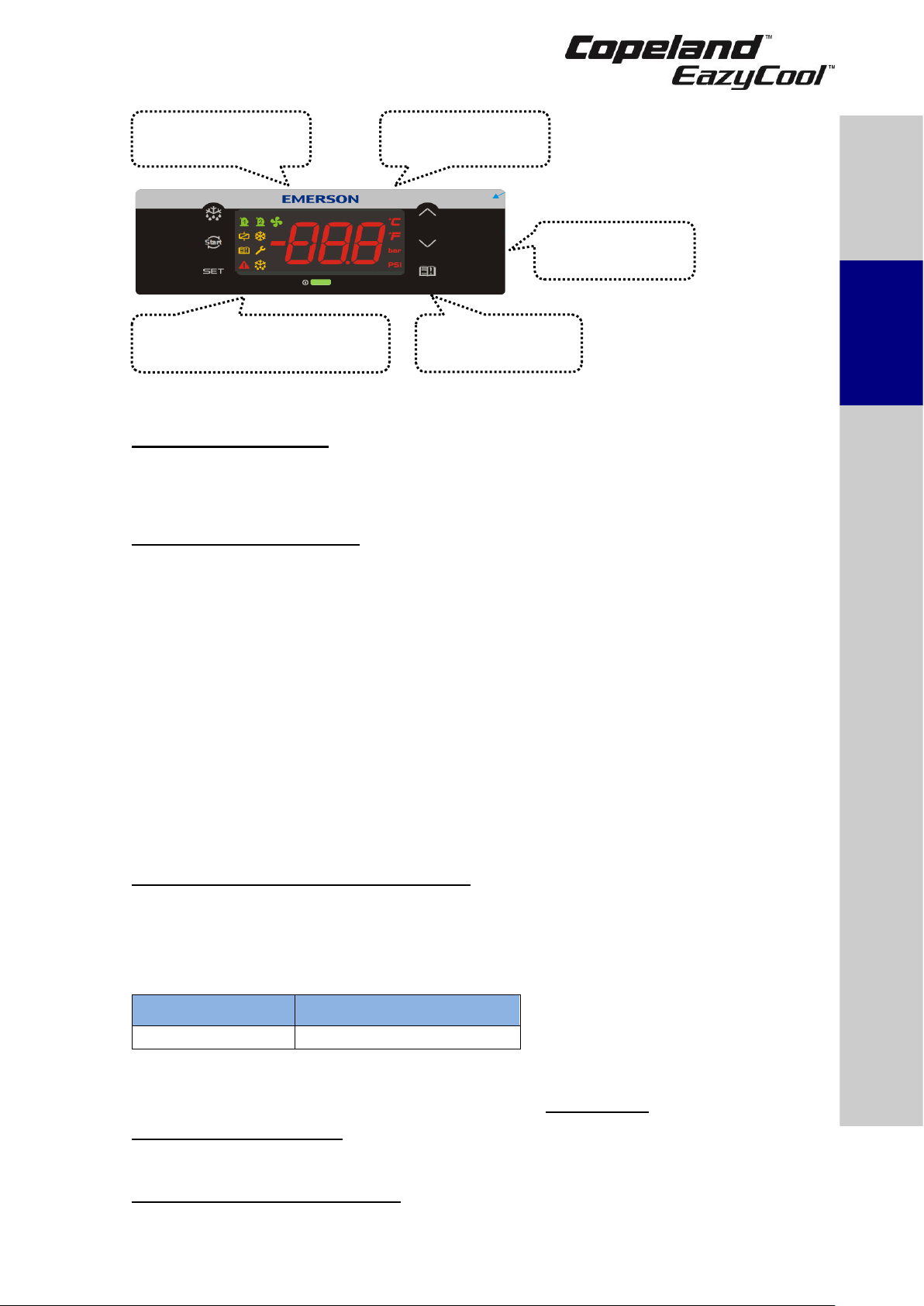

Figure 9: Local display

LED

Mode

Function

On

Compressor 1 enabled

Flashing

Anti-short cycle delay enabled

On

Condensing fans enabled

On

Bar display

Flashing

Programming mode

On

PSI display

Flashing

Programming mode

On

When browsing the service menu

Flashing

In fast access menu

On

When browsing the alarm menu

Flashing

A new alarm occurred

On

An alarm is occurring

On

Digital unloader solenoid On

On

In defrost

Table 10: LED functions description

NOTE: By default, the local display will show the value of the suction pressure during

operation. This can be changed by choosing another value for parameter B03/Lod (Remote

Display visualization).

Page 18

C6.1.10/0118-0318/E 13

Setting for

B03/Lod

Value shown on the display

Comments

0

P1 value = Suction pressure

1

P2 value = Mid-coil temperature (condenser)

2

P3 value = Discharge line temperature

3

P4 value = Vapour inlet EVI

Not applicable

4

P5 value = Vapour outlet EVI

Not applicable

5

P6 value = Ambient temperature

6

P7 value = Not used in factory setting

7

PEr value = Probe error

8

Aou value = Analog output

Table 11: Display visualisation

2.11.2 Remote display CCM60

The remote display CCM60 allows for remote monitoring and control of the XCM25D controller via

cable. This device has the same interface as the unit controller therefore the commands and

symbols are identical to those of the XCM25D controller. The remote display shall be mounted on

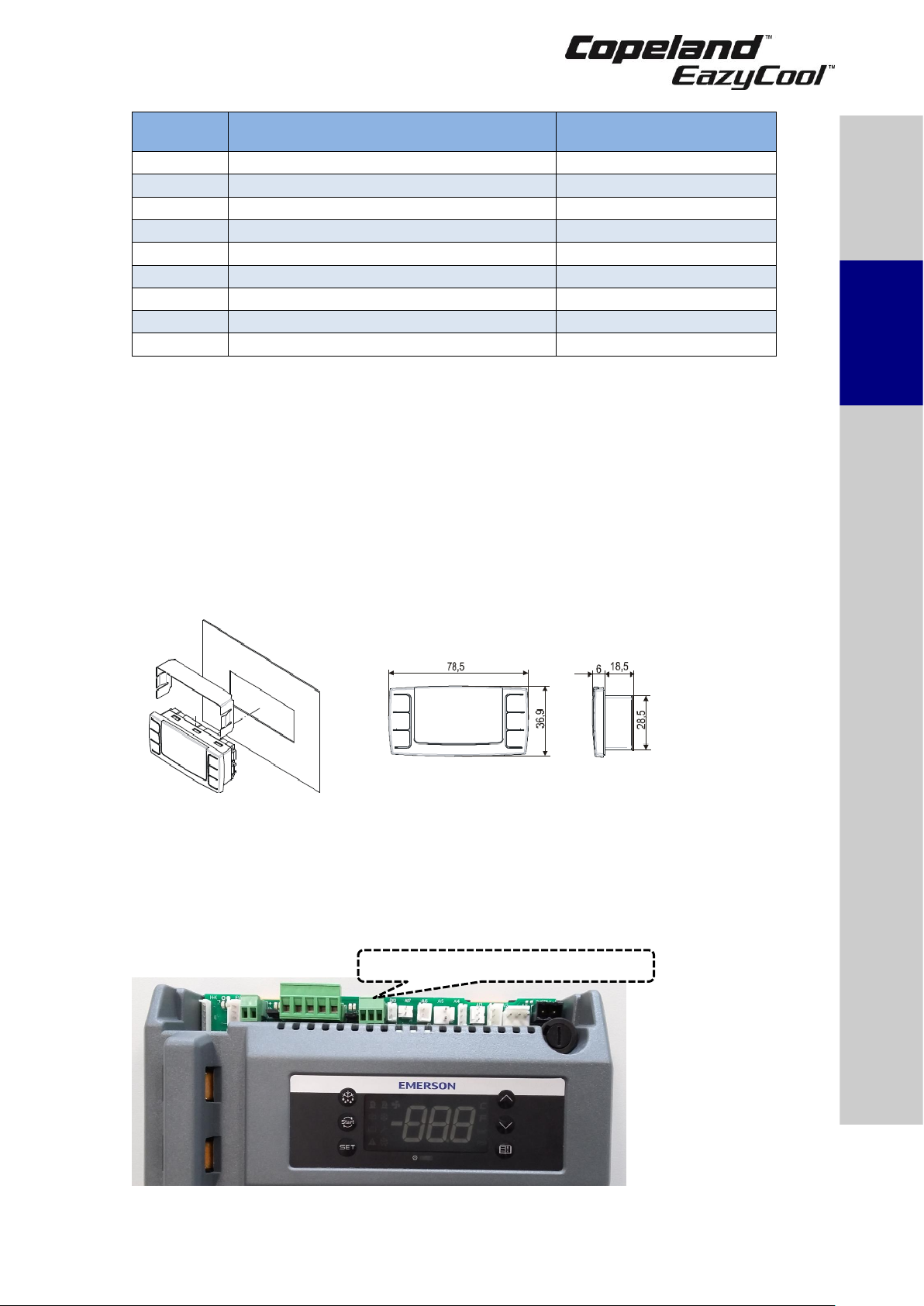

a vertical panel, in a 29 x 71 mm hole, and secured using the special bracket supplied (see

Figure 10).

The temperature range allowed for correct operation is 0°C to +60°C.

Avoid places subject to strong vibrations, corrosive gases, excessive dirt or humidity. Allow for air

to circulate through the cooling holes.

When front-mounted, the remote display is IP65 rated.

Figure 10: Remote display front panel mounting

The remote display is a proprietary bus of communication for Dixell HMI (x-rep, CCM60) interfaces.

There are two connection terminals on the back of the remote display (+ and -).

NOTE: Emerson recommends using a shielded cable twisted pair 2 x 0.5mm².

The device must be connected to the VNR-terminal on the unit controller according to the polarity.

Figure 11 shows the VNR terminal on the unit controller.

Figure 11: VNR connection for the remote display

VNR connection for remote display

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 19

14 C6.1.10/0118-0318/E

Before connecting cables make sure the power supply complies with the hardware requirements.

Separate the terminal cables from the power supply cables, the outputs and the power

connections.

2.11.3 Single commands

Press the SET button to display the target setpoint. In programming mode, this

allows to select a parameter or to confirm an operation.

Press the RESET button and hold for 5 seconds to reset any lockouts if the

current state of the controller allows for it to be reset.

(UP) To view the fast access menu. In programming mode, this browses the

parameter codes or increases the displayed value.

(DOWN) In programming mode, this browses the parameter codes or decreases

the displayed value.

(SERVICE) To enter the service and alarm menu.

Hold for 3 seconds to start a manual defrost or terminate an active defrost.

Table 12: Single commands

2.11.4 Double commands – Entering programming level 1 "Pr1"

Press simultaneously for about 3 seconds to lock (PoF) or unlock (Pon) the

keyboard.

Press simultaneously to leave the programming mode or menu. On submenus

rtC and EEV this combination allows to go back to the previous level.

Press simultaneously for about 3 seconds to access the first level of

programming mode.

Table 13: Double commands

The device provides 2 programming levels:

▪ Pr1 with direct access

▪ Pr2 protected with a password (intended for experts)

2.11.5 How to program the parameters (Pr1 and Pr2)

Access pre-

program level

Press simultaneously for about 3 seconds to access the preprogramming level. The message rtC (real-time clock) appears.

Access

program level

or

Press the Up or Down key until the message Par appears.

Access Pr1

Press the SET button to enter the program level. First parameter

appears.

Select item

or

Select the parameter or submenu using the arrows.

Show value

Press the SET button.

Modify

or

Use the arrows to modify the value.

Confirm and

store

Press the SET button: the value will blink for 3 seconds, then the

display will show the next parameter.

EXIT

Press simultaneously to exit the programming mode, or wait

for 30 seconds (MTO) without pressing any key.

Table 14: Programming level 1 parameters

When entering the programming level for the first time the display will show the rtC (real-time

clock) label.

▪ Press to access parameters N01/02/03/04/05 (Min/Hr/MdY/Mon/YEr) to adjust time &

date. For further details, see Chapter 2.13, "Parameters level 1 – Required settings".

▪ Press or to change from the rtC label to the Par label, in order to access

programming level 1.

▪ Press : the parameters of programming level 1 can be changed.

Page 20

C6.1.10/0118-0318/E 15

2.11.6 Entering programming level 2 "Pr2"

To enter the Pr2 programming menu:

▪ Press simultaneously for 3 seconds. The first parameter label will be displayed.

▪ Press till the T18 label is displayed, then press the key;

▪ The blinking PaS label will be displayed; wait for a few seconds;

▪ The display will show "0 - -" with blinking 0: insert the password [321] using the and

keys and confirming with the key.

2.11.7 Fast access menu

This menu contains the list of probes and some values that are automatically evaluated by the

board such as the superheat and the percentage of valve opening. nP or noP stands for "probe

not present" or "value not evaluated", Err means "value out of range", "probe damaged, not

connected or incorrectly configured".

Entering fast access

menu

Press and release the UP arrow. The duration of the

menu in case of inactivity is 3 minutes.

The values that will be displayed depend on the

configuration of the board.

Use the

or

arrow to select

an entry, then

press

to see the value

or to go on with

another value.

▪ P1P: Pressure value of the P1 probe (suction pressure)

▪ P2t: Temperature value of the P2 probe (not valid)

▪ P2P: Pressure value of the P2 probe (discharge pressure)

▪ P3t: Temperature value of the P3 probe (discharge line

temperature)

▪ P4t: Temperature value of the P4 probe (not applicable)

▪ P5t: Temperature value of the P5 probe (not applicable)

▪ P6t: Temperature value of the P6 probe (ambient temperature)

▪ P7t: Temperature value of the P7 probe (free)

▪ SH: Value of superheat. nA = not available

▪ oPP: Percentage of step valve opening.

▪ SEtd: Value of the dynamic setpoint (condenser fan SET). This

information is available only if the dynamic setpoint function is

enabled.

▪ AOO: Percentage of the analog output (0-10V or TRIAC PWM

Mod.). This information is available only if the 0-10V or TRIAC PWM

Mod. is enabled.

▪ dStO: Percentage of the PWM output driving the valve of the Digital

Scroll compressor.

▪ L°t: Minimum room temperature.

▪ H°t: Maximum room temperature.

▪ HM: Menu.

▪ tU1: Voltage reading V1 (not valid in standard configuration)

▪ tU2: Voltage reading V2 (not valid in standard configuration)

▪ tU3: Voltage reading V3 (not valid in standard configuration)

▪ tA1: Current reading I1

▪ tA2: Current reading I2

Exit

Press simultaneously or wait for the timeout of about

60 seconds

Table 15: Fast access menu

2.12 Controller keyboard

2.12.1 How to lock the keyboard

Keep the and keys pressed simultaneously for more than 3 seconds. The "PoF" message

will be displayed and the keyboard will be locked. At this point it is only possible to see the setpoint

or the maximum or minimum temperatures stored. If a key is pressed for more than 3 seconds,

the "PoF" message will be displayed.

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 21

16 C6.1.10/0118-0318/E

2.12.2 How to unlock the keyboard

Keep the and keys pressed simultaneously for more than 3 seconds, till the "Pon"

message is displayed.

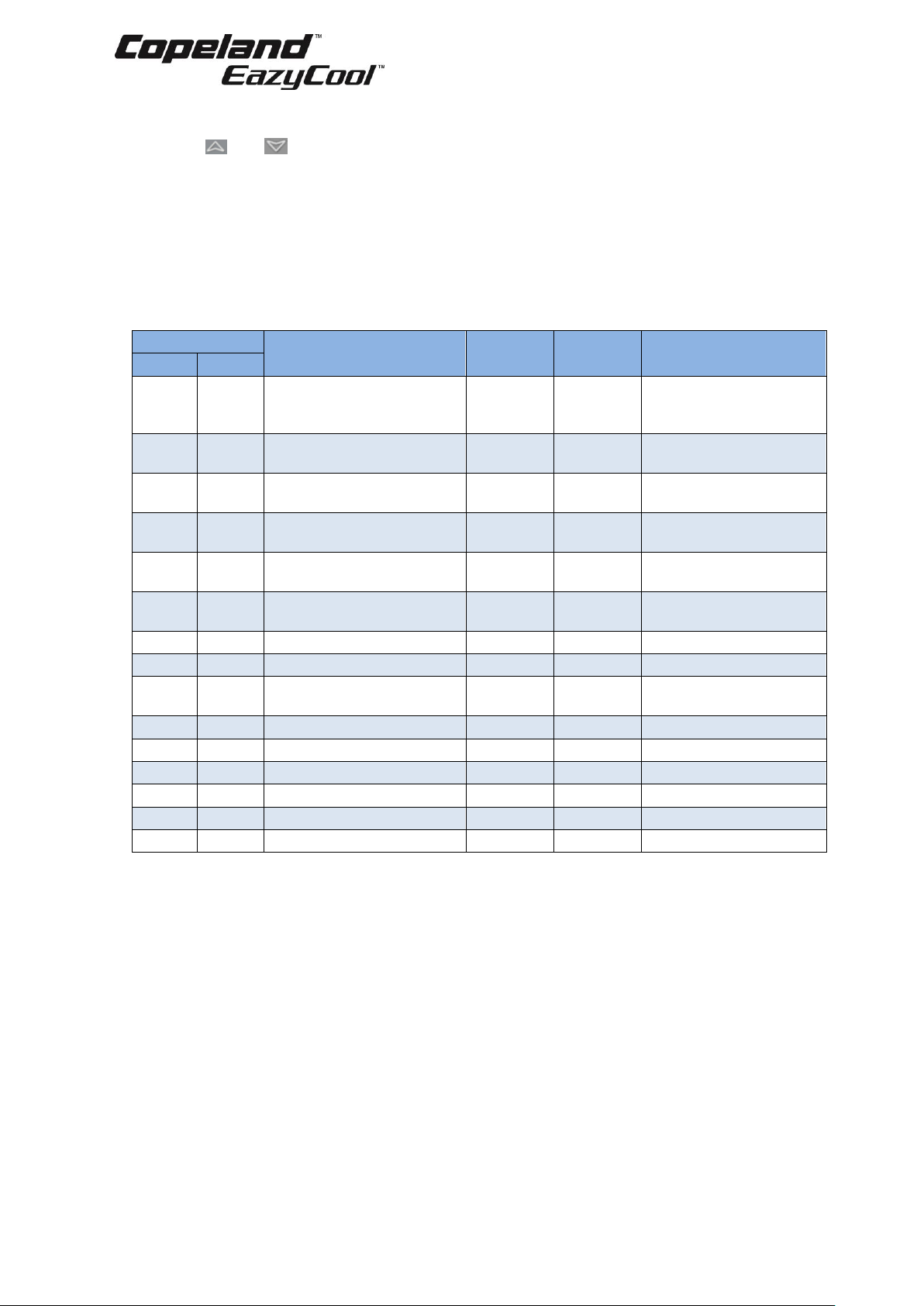

2.13 Parameters level 1 – Required settings

The XCM25D is preconfigured to reduce the required settings on job-site to a minimum. In most

cases it will not be necessary to enter programming level 2 "Pr2". Table 16 gives an overview of

the parameters available in programming level 1 "Pr1".

NOTE: When changing parameter C05 (LS) a reset of the controller (interruption of power

supply) is required.

Parameters

Description

Unit

Factory

setting

Comments

ZXDE

ZXDI

C07

rEF

Refrigerant selection for

regulation

[-]

R404A

R134a, R404A, R407A,

R407F, R448A, R449A,

R450A, R513A

C16

StC

Digital compressor

setpoint

[bar]

3.3

C17

Pbd

Proportional band for

compressor regulation

[bar]

2.0

C21

tdG

Cycle time for digital

compressor

[sec]

10

C24

PMi

Minimum capacity for

digital compressor

[%]

20

C25

PMA

Maximum capacity for

digital compressor

[%]

100

D29

LPA

Low-pressure alarm value

[bar]

0.5

E39

FSP

Condenser setpoint

[°C]

35.0

E46

Fbd

Regulation band of

variable fan

[°C]

10.0

N01

Min

Current minute

[-]

[-]

N02

Hr

Current hour

[-]

[-]

N03

MdY

Day of the month

[-]

[-]

N04

Mon

Month

[-]

[-]

N05

YEr

Year

[-]

[-]

T18

PAS

Access to Pr2 level

[-]

[-]

Password: 3 2 1

Table 16: Parameters in programming level Pr1

NOTE: The full list of parameters in programming level "Pr2" can be found in Appendix 4.

2.14 Digital operation

A Digital unit is able to operate in a part-load mode. Part-load operation is achieved by loading

and unloading of the Digital scroll compressor for certain periods of time (time cycles). The cycle

of time can be chosen between 10 and 30 seconds. Example: if the time cycle is 20 seconds at

50% of capacity request, the compressor will run for 10 seconds loaded and 10 seconds unloaded.

The regulation starts when the suction pressure (AI1) increases and reaches the value

(SP-PB/2+(PB*PMI)/100) or (StC-Pbd/2+(Pbd*PMi)/100). Within the adjustment range

(SP-PB/2~SP+PB/2) or (StC-Pbd/2 ~ StC+Pbd/2) the Digital scroll compressor is activated in

PWM mode in accordance with the value of the control variable.

When the pressure is higher than (SP+PB/2) or (StC+Pbd/2) then the TRIAC output is at

maximum capacity. When the pressure is lower than (SP+PB/2) or (StC+Pbd/2) but higher than

(SP-PB/2) the Digital Scroll compressor modulates the capacity according to the proportional

band. If the pressure is lower than (SP-PB/2)/ (StC-Pbd/2) the Digital Scroll compressor switches

off.

Page 22

C6.1.10/0118-0318/E 17

For proper commissioning of the Digital unit the following diagram must be considered:

Figure 12: Digital operation

NOTE: When the digital valve on the compressor is discharged, the compressor is loaded.

NOTE: At start-up, the valve is energized for C20/Sut start-up time, ie, interval time with the

digital valve energized before regulation starts. It ranges from 0 to 10 seconds.

2.15 Reset to factory settings – Emerson "Hot Key"

2.15.1 How to save factory settings or user settings

There is no way to reset the XCM25D controller to factory settings other than with additional

equipment. Emerson recommends using the Emerson "Hot Key" (not part of the standard delivery)

to save the factory settings at initial power up. The same hot key can also be used to save user

settings.

Thanks to a special programming software (Emerson Wizmate) and corresponding hardware

(Emerson Prog-Tool), the user can:

▪ preprogram hot keys

▪ copy hot keys

▪ change parameter levels

▪ compare parameter lists

For further information please visit our website at www.emersonclimate.eu or contact your local

Application Engineering representative.

2.15.2 Emerson "Hot Key" for ZXDI units with XCM25D controller

The Emerson "Hot Key" DK00000300 can be used for uploading and downloading of parameter

lists. Copeland ident number 3226456.

Figure 13: Emerson "Hot Key"

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 23

18 C6.1.10/0118-0318/E

2.15.3 Location of the "Hot Key" plug connection on the XCM25D controller

The "Hot Key" plug connection is located on the upper left corner of the XCM25D.

Figure 14: Location of "Hot Key" plug connection

2.15.4 How to program a "Hot Key" from the controller (upload)

▪ Program one controller with the front keypad.

▪ When the controller is on, insert the "Hot Key" and press the UP key; the "uPL" message

appears followed a by a flashing "End" label.

▪ Press the SET key and the "End" label will stop flashing.

▪ Turn the controller off, remove the "Hot Key" and then turn it on again.

NOTE: The "Err" message appears in case of a failed programming operation. In this case

push the key again if you want to restart the upload or remove the "Hot Key" to abort the

operation.

2.15.5 How to program a controller using an Emerson "Hot Key" (download)

▪ Turn the controller off.

▪ Insert a pre-programmed "Hot Key" into the 5-pin receptacle and turn the controller on.

▪ The parameter list of the hot key will be automatically downloaded into the controller

memory. The "doL" message will blink followed a by a flashing "End" label.

▪ After 10 seconds the controller will restart working with the new parameters.

▪ Remove the "Hot Key".

NOTE: The message "Err" is displayed in case of a failed programming operation. In this

case turn the unit off, then on again if you want to restart the download, or remove the "Hot

Key" to abort the operation.

Page 24

C6.1.10/0118-0318/E 19

2.16 Troubleshooting – Alarm history

The controller records the total number of alarm activations (max 50) in the alarm menu (see

Appendix 5).

Action

Key or display

Notes

Enter menu

Push and release the ALR key.

Waiting for action

SEC

The menu to change the section will be entered. The

alarm list section is active.

Enter section list

Press SET to confirm. The following list will be

available to select the proper network function.

Select active alarm

code from list

or

Scroll the list of active alarms by alarm number (letter

+ number, A01-A50).

Press to see the alarm name or code.

Press to see the next active alarm.

Select the alarm to

see the detailed rtC

information

Enter the sub menu with alarm time details.

Select detailed

information from

active alarm list

or

With the rtC activated:

The Hur (hour) parameter is displayed.

Press to see the alarm hour.

Press : Min is displayed.

Press to see the alarm minute.

Press : dAy is displayed.

Press to see the alarm day.

Press : MOn is displayed.

Press to see the alarm month.

Press : YEA is displayed.

Press to see the alarm year.

Note: The clock info indicates the START time of the

alarm.

Without the rtC activated:

The COn (hours) parameter is displayed.

Press to see the compressor working hours.

To exit: press or wait for 15 seconds without

pressing any key.

Exit menu

Press simultaneously or wait for about 10

seconds without pressing any key.

Table 17: How to check the alarm list

2.17 Compressor motor protection

The electronic controller protects the compressor motor against the following:

▪ over current

▪ phase loss

▪ incorrect phase rotation

▪ voltage imbalance

If the compressor motor current exceeds a predefined (non-adjustable) current limit, the electronic

controller shuts the unit down and generates an error signal. For this function two of the main

phase supply lines to the compressor (compressor via the contactor) are routed through the

current sensors.

2.18 System pressure protection

2.18.1 High-pressure safety switch

A high-pressure switch is registered by the electronic board. The sensing device is a nonadjustable, high-pressure switch that will open in the event of an abnormally high discharge

pressure (cut-out 28.8 bar).

Safety

instructions

Product

description

Installation

Starting up

&

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 25

20 C6.1.10/0118-0318/E

▪ The unit will stop then and restart automatically after a 5-minute delay and after unit

pressure has decreased to 24 bar.

▪ After 7 successive high-pressure cut-outs over 1 hour, the unit will lock out. In this case a

manual reset will be necessary.

2.18.2 High pressure: pressure relief valve

There is a connection port sideways on the top of the unit liquid receiver for a pressure relief valve.

A 3/8"-NPT connection is used. The pressure relief valve is not factory-assembled.

2.18.3 Low-pressure safety switch – Optional

In a way similar to the high-pressure sensor, the electronic controller registers the switching action

of the adjustable low-pressure switch, which will open in the event of an abnormally low suction

pressure:

▪ The unit will stop then restart automatically after a 3-minute delay and when the unit reaches

the cut-in pressure level.

The unit is always equipped with a suction pressure transmitter which also takes care for protection

against vacuum operation. The use of the optional low-pressure cut-out will provide the highest

protection level for the unit. In rare instances of controller breakdown, the optional low-pressure

switch would allow to run the unit in emergency mode.

2.18.4 Ambient temperature sensor

An ambient temperature sensor supplied by Emerson is connected to the electronic controller.

This temperature sensor has several functionalities like emergency mode control, lower fan speed

limitation and crankcase heater control. The sensor is located at the housing on the backside of

the compressor compartment.

2.19 Alarm output (DO5)

The digital output DO5 is pre-configured as an alarm contact. The relay (max. 5A, 250V AC) is

activated in case of alarms and lock-outs. Warnings will be shown only on the controller display.

2.20 Fan speed control – Ziehl-Abegg PKE-6 controller

The PKE-6 controller is used for continuous speed control adjustment on the variable voltage

motor of the fan. The electrical protection class of the controller is IP54.

The output signal of the unit controller XCM25D to the fan speed controller PKE-6 is a 0-10V digital

signal. It has two main functions: fan speed control and temperature/pressure control of the

condenser.

The fan speed factory setting is 100% rpm.

Depending on the characteristics of the connected air ducts, eg, presence of elbows, reductions,

grids, and the level of noise produced, the fan speed can be adjusted to an appropriate value

considering the expected unit performance and sound level.

A 10µF start capacitor is required for each fan.

Fan

speed

U

[V]

N

[rpm]

Pe

[W]

Airflow

[m3/h]

100%

230

1390

375

5352

98%

206

1360

373

5237

95%

190

1320

368

5083

87%

170

1210

361

4659

71%

150

985

332

3793

51%

130

709

257

2730

37%

110

514

178

1979

Table 18: Fan data based on changing frequency/fan speed

Page 26

C6.1.10/0118-0318/E 21

Figure 15: PKE-6 Fan speed controller details and dimensions

NOTE: For more information about the fan speed controller and possible adjustments,

please refer to the fan speed controller user’s guide – part of the unit standard delivery.

2.21 Dimensions in mm

The figures hereafter show the overall physical dimensions of the ZXDI indoor condensing units:

Figure 16: Dimensions of ZXDI condensing units (all models)

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 27

22 C6.1.10/0118-0318/E

3 Installation

WARNING

High pressure! Injury to skin and eyes possible! Be careful when opening

connections on a pressurized item.

Copeland EazyCool ZXDI indoor condensing units are delivered with a holding charge of neutral

gas.

The condensing unit should to be installed in a closed machine room. Soundproofing the machine

room is highly recommended because of a potentially high sound production. The room

characteristics must also be taken into account.

It is important to prevent any dirt, dust, plastic bags, leaves or papers from entering the air ducts

and covering or blocking the condenser and its fins. Proper protective end-grids should be used

for this purpose.

A clogged condenser will increase the condensing temperature, thus reducing the cooling

capacity, which could lead to a high-pressure switch tripping. Clean the condenser fins on a regular

basis.

The unit must be installed in such a way that the airflow through the connected air ducts is not

restricted. The incoming air flow must be sufficient to cover the entire air needs of the unit.

3.1 Condensing unit handling

3.1.1 Transport and storage

WARNING

Risk of collapse! Personal injuries! Move condensing unit only with

appropriate mechanical or handling equipment according to weight. Keep in

the upright position. Stack pallets on top of each other when not exceeding

300 kg. Do not stack single boxes on top of each other. Keep the packaging

dry at all times.

Figure 17: Transport and storage

3.1.2 Weights

Condensing

unit

Net weight*

(kg)

Gross weight**

(kg)

ZXDI040E

138

154

ZXDI050E

142

158

ZXDI060E

146

162

ZXDI075E

152

168

* Product without packaging

** Product including packaging

Table 19: Weights

Page 28

C6.1.10/0118-0318/E 23

3.2 Electrical connection

3.2.1 Power supply connections

Copeland EazyCool ZXDI indoor condensing units are designed for a 380-420V/3Ph/50 Hz power

supply. A voltage tolerance of ± 10% is acceptable.

The electrical connection of the condensing unit to the power supply must be made by qualified

technicians according to the valid electrical directives, for instance DIN EN 60204-1. The voltage

drop and the temperatures on line must also be considered for cable selection.

The circuit breaker must be switched off before opening the front door.

WARNING

Electrical shock hazard! Serious personal injuries! There are unused fast-

on pins (C1 & DO2) on the XCM25D which could be under voltage. They are

covered by insulated fast-on flags in the factory. Handle carefully when

removing insulating flags during service on site.

3.2.2 Maximum operating currents for cable selection

Condensing unit

Locked

rotor

Rated unit

current (A)*

ZXDI040E-TFD

48

11.3

ZXDI050E-TFD

64

14.7

ZXDI060E-TFD

74

14.8

ZXDI075E-TFD

100

17.4

* At nominal voltage of 400V

Table 20: Maximum operating currents for cable selection

3.2.3 Electrical wiring

Before commissioning, ensure that the neutral "N" and ground protection "PE" wires are connected

to the main switch.

3.2.4 Electrical protection standard (protection class)

▪ Units: IP class IPX4.

▪ Scroll compressors: IP21 according to IEC 34.

▪ Fan: IP44 according to IEC 34.

▪ Solenoid valve coils: IP65 according to DIN 43650.

3.2.5 Overload protection

WARNING

Isolating switch "On"! Danger of electric shock! Before any intervention on

the overload compressor protection, turn off the isolating switch to de-energize

the unit.

Figure 18

Safety

instruc

tions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 29

24 C6.1.10/0118-0318/E

Condensing unit

Overload setting

Compressor MOC*

(A)

Overload range

(A)

ZXDI-040E-TFD

7.9

6 - 10

ZXDI-050E-TFD

11.3

9 - 14

ZXDI-060E-TFD

11.4

9 – 14

ZXDI-075E-TFD

14

13 – 18

* MOC = Maximum Operating Current

Table 21: Overload protection details

3.3 Refrigeration piping connections

3.3.1 Refrigeration piping installation

WARNING

High pressure! Risk of personal injury! The units are pressurized with dry

air. Be careful when opening connections on a pressurized item.

WARNING

Low surface temperature! Danger of frostbite! The liquid line should be

insulated with 19 mm insulation thickness. Temperature could be as low as

–15°C.

IMPORTANT

Tubing quality! Installation contamination! All interconnecting piping

should be of refrigeration grade, clean, dehydrated and must remain capped

at both ends until installation. Even during installation, if the system is left for

any reasonable period of time (say 2 hours), pipes should be re-capped to

prevent moisture and contaminant from entering the system.

Connection sizes! Unsuitable refrigerant flow rate! Do not assume that the

service connection sizes on the unit (at the service valves) are in fact the

correct size to run your interconnecting refrigeration pipes. The service valve

sizes have been selected for convenience of installation and in some cases

(larger units) these may be considered too small. However, for the very short

pipe run within our units these service connection sizes are adequate. All

interconnecting piping should be sized to satisfy the duty required.

The pipe should be sized to ensure optimum performance and good oil return. The sizing must

also take into account the full capacity range through which this particular unit will need to operate.

Pipe runs should be kept as short as possible, using the minimum number of directional changes.

Use large radius bends and avoid trapping of oil and refrigerant. This is particularly important for

the suction line. The suction line should ideally slope gently towards the unit. Recommendation

slope is 1/200 to 1/250. Upper and lower oil traps, double risers and reduced pipe diameters may

be required for suction lines where long vertical risers cannot be avoided.

All pipes should be adequately supported to prevent sagging which can create oil traps. The

recommended pipe clamp support distance is shown in Table 22 below:

Tube size

Max distance

between 2 clamp

supports

12.7 mm (1/2 inch)

1.20 m

16.0 mm (5/8 inch

1.50 m

22.0 mm (7/8 inch)

1.85 m

28.5 mm (1 1/8 inch)

2.20 m

Table 22: Maximum distance between 2 clamp supports

Page 30

C6.1.10/0118-0318/E 25

3.3.2 Brazing recommendations

IMPORTANT

Blockage! Compressor breakdown! Maintain a flow of oxygen-free nitrogen

through the system at very low pressure during brazing. Nitrogen displaces

the air and prevents the formation of copper oxides in the system. If allowed

to form, the copper oxide material can later be swept through the system and

block screens such as those protecting capillary tubes, thermal expansion

valves, and accumulator oil return holes.

Contamination or moisture! Bearing failure! Do not remove the plugs until

the compressor is set into the unit. This minimises any entry of contaminants

and moisture.

▪ Remove the discharge connection cap.

▪ Remove the suction connection cap.

▪ Open both valves mid-way. Care should be taken to avoid the holding charge releasing too

quickly.

▪ Be sure tube fitting inner surface and tube outer surface are clean prior to assembly.

▪ Both tubes are extended from the condensing unit housing, therefore we recommend to

isolate the housing by using a wet cloth on the copper tubing.

▪ Recommended brazing materials: a copper/phosphorous or copper/phosphorous/silver

alloy rod should be used for joining copper to copper whereas to join dissimilar or ferric

metals a silver alloy rod either flux coated or with a separate flux would be used.

▪ Use a double-tipped torch.

Figure 19: Brazing – Sectional view

3.3.3 Brazing procedure

For brazing of the tubes, please refer to Figure 20 and procedure hereunder:

▪ Fit the copper tube into the unit tube.

▪ Heat area 1. As the tube approaches brazing

temperature,

▪ Heat area 2 until braze temperature is attained.

It is necessary to heat the tube evenly. Move the torch

up and down and rotating around the tube.

▪ Add braze material to the joint while moving the

torch around the joint to flow braze material around the

circumference.

▪ Then heat area 3. This will draw the brazing material down into the joint.

NOTE: The time spent heating area 3 should be minimal. As with any brazed joint,

overheating may be detrimental to the final result.

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certificatio

n &

approval

Dismantling &

disposal

Figure 20: Suction tube brazing areas

Page 31

26 C6.1.10/0118-0318/E

To disconnect:

▪ Heat joint areas 2 and 3 slowly and uniformly until solder softens and tube can be pulled out

of the fitting.

To reconnect:

▪ See procedure above.

3.4 Location & fixings

IMPORTANT

Dust and dirt contamination! Risk of unit lifetime reduction! The unit

should always be installed in a location that ensures clean air flow. External

fouling of the condenser fins also leads to high condensing temperatures, and

will reduce the lifetime of the unit.

It is recommended that a clearance of 300 mm from the wall of the room (or the next unit) be

maintained from the unit left and rear panels whereas a clearance of 500 mm must be maintained

from the unit right, top and front panels (seen facing the front of the unit). Both service access and

airflow through connected air ducts have been considered in making these recommendations.

Where multiple units are to be installed in the same room, the installer has to consider each

individual case carefully. There can be many variations of unit quantities and available space and

it is not the intention of this manual to go over these. However, in general terms, air by-pass around

each condenser and between the units should be avoided at all times.

Ideally, the unit should be mounted level on a solid concrete slab with anti-vibration pads between

unit feet and concrete. However, the ZXDI unit has also been designed for wall mounting on

suitable brackets. In this case, it is equally important that the dimensional guidelines given in

Chapter 3.5 "Required distances" are followed. Wall mounting brackets are not part of the standard

delivery.

Another factor to consider in finding a good installation site is the direction of the prevailing wind.

For example, if the air leaving the condenser through the air ducts faces the prevailing wind, the

air flow through the condenser can be impeded, causing high condensing temperatures and

ultimately resulting in reducing the lifetime of the unit.

3.5 Required distances

Figure 21: Fixing dimensions and distances

Page 32

C6.1.10/0118-0318/E 27

3.6 Air ducts connection

WARNING

Uncovered rotating parts! No safety grids on the condenser fans!

Personal injuries! Never start the condensing unit or run the fans with no air

ducts connected or without protective end-grids on the air outlets.

The connection of the air ducts to the condensing unit has to be made based on standard rules

for air distribution ducts. Duct connection dimensions are designed based on standard EN 15062007, which has to be taken into consideration for all air ducts dimensioning.

The foil must be removed from the condenser fan before connecting the air ducts.

The condensing units covered in these guidelines are prepared for connection to air ducts with a

diameter of 500 mm.

Before commissioning and starting the unit, check the ducts for air leaks. Look for sections that

should be joined but might be separated and for possible holes in the air channels.

Two values must be taken into consideration when designing a proper air duct route and selecting

component parts, ie, the total pressure drop and the airflow.

The length of the air duct has little impact on the total pressure drop and on the air-flow (pressure

drop ~ approx. 0.5-1 Pa/m). An air duct length of up to 5 meters has virtually no impact at all on

pressure drop.

Elbows and other components such as diameter reductions on the air duct route have a much

bigger influence on total pressure drop and air flow – see Table 23 below.

Air duct diameter Ø 500 mm (connection to condenser per fan)

Total straight length (m)

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

Number of

elbows

1

2

3

4

5

6

Table 23: Maximum acceptable air duct length depending on diameter and number of elbows

When taking into account all the fittings, the total linear length and additional components, the total

pressure drop should be limited to 60 Pa per fan at 3500 m³/h. Please also refer to Chapter 2.10.3

"Main control & safety features".

Safety

instructions

Product

description

Installation

Starting up &

operation

Maintenance &

repair

Certification &

approval

Dismantling &

disposal

Page 33

28 C6.1.10/0118-0318/E

4 Starting up & operation

WARNING

Uncovered rotating parts! No safety grids on the condenser fans!

Personal injuries! Never start the condensing unit or run the fans with no air

ducts connected or without protective end-grids on the air outlets.

Before commissioning, ensure that all valves on the condensing unit are fully opened.

4.1 Evacuation

CAUTION

System pressure below atmospheric pressure! Compressor damage!

Never energize the unit/controller without minimum refrigerant system charge.

There is a risk of malfunction of the controller in deep vacuum operation which

can cause compressor damage.

IMPORTANT

The evacuation procedure is based upon achieving an actual system vacuum

standard and is NOT TIME DEPENDENT! The installation has to be

evacuated with a vacuum pump before commissioning. Proper evacuation

reduces residual moisture to 50 ppm. The installation of adequately sized

access valves at the furthest point from the compressor in the suction and

liquid lines is advisable. The system must be evacuated down to less than

3 mbar. If required break the vacuum with dry nitrogen. Pressure must be

measured using a vacuum pressure gauge on the access valves and not on

the vacuum pump. This serves to avoid incorrect measurements resulting from

the pressure gradient along the connecting lines to the pump.

4.2 Charging procedure

4.2.1 Refrigerant charging procedure

IMPORTANT

Inadequate charge! Overheating! The Scroll compressor design requires

system charging as quickly as possible with liquid refrigerant into the liquid

line. This will avoid running the compressor under conditions whereby

insufficient suction gas is available to cool not only the motor but also the

scrolls. Temperature builds up very quickly in the scrolls if this is not done.

Service valve closed! Compressor damage! Do not charge the unit with

vapour (gas). The suction service valve must not be fully closed at any time

when the compressor is running. To do so would cause damage to the

compressor in the same manner as explained above. This valve is provided

for ease of connection and for the fitting of service gauges without removing