Emerson Copeland EazyCool OME-4MTL-05X, Copeland EazyCool OME-4MTL-07X, Copeland EazyCool OME-4MTL-09X Application Manuallines

Page 1

Application Guidelines

Copeland Eazycool

™

CO2 Refrigeration Units

Page 2

C6.1.11/0718-0619/E

About these guidelines .............................................................................................. 1

1 Safety instructions .......................................................................................... 1

1.1 Icon explanation ............................................................................................................... 1

1.2 Safety statements ............................................................................................................ 1

1.3 General instructions ......................................................................................................... 2

2 Product description ........................................................................................ 3

2.1 General information about Copeland EazyCool™ CO2 refrigeration unit ........................ 3

2.2 EU Ecodesign Directive 2009/125/EC ............................................................................. 3

2.3 Main product features ...................................................................................................... 4

2.4 Product nameplate ........................................................................................................... 5

2.5 Nomenclature ................................................................................................................... 5

2.6 Application range ............................................................................................................. 6

2.6.1 Qualified refrigerant and oil .................................................................................. 6

2.6.2 Application limits ................................................................................................... 6

2.6.3 Recommendations for minimum suction superheat – Lubrication conditions ...... 6

2.6.4 Pressure levels of CO2 vs. other refrigerants ....................................................... 7

2.7 Main components description .......................................................................................... 8

2.7.1 Compressor .......................................................................................................... 8

2.7.2 Electrical cabinet .................................................................................................. 8

2.7.3 Liquid receiver ...................................................................................................... 9

2.7.4 Fan ....................................................................................................................... 9

2.7.5 Condenser / gas cooler regulation valve (HPV) ................................................... 9

2.7.6 Flashgas bypass valve (BPV) .............................................................................. 9

2.7.7 Housing .............................................................................................................. 10

2.7.8 Exploded view of the CO2 unit ............................................................................ 11

2.7.9 P&I diagram for CO2 units .................................................................................. 12

2.7.10 Design pressures ............................................................................................... 12

2.8 CO2 Unit control – General ............................................................................................ 13

2.8.1 iPro IPR215D controller description ................................................................... 14

2.8.2 Visograph display description ............................................................................ 14

2.9 How to use the iPro IPR215D controller ........................................................................ 15

2.9.1 How to change parameters ................................................................................ 15

2.9.2 Parameter grouping ............................................................................................ 16

2.9.3 "Service" menu ................................................................................................... 17

2.9.4 How to enter the "Service" menu ....................................................................... 17

2.9.5 How to check the values of analog outputs........................................................ 18

2.9.6 How to check the status of the relays / loads ..................................................... 18

2.9.7 How to perform a maintenance using the "Compressors service" sub-menus .. 19

2.9.8 How to check the values of digital inputs ........................................................... 20

2.9.9 How to check the values of the probes .............................................................. 21

Page 3

C6.1.11/0718-0619/E

2.9.10 How to set the date and time ............................................................................. 21

2.9.11 How to check the operating values of the frequency inverter M200 .................. 22

2.9.12 Controller setting ................................................................................................ 22

2.9.13 Manual compressor run ...................................................................................... 22

2.9.14 How to reset the controller to factory settings .................................................... 23

2.9.15 How to save user’s settings................................................................................ 23

2.9.16 Data logging ....................................................................................................... 23

2.9.17 Active alarm(s) log menu.................................................................................... 24

2.10 iPro IPR215D controller – Functionality ......................................................................... 25

2.10.1 Suction pressure control..................................................................................... 25

2.10.2 Pumpdown mode ............................................................................................... 26

2.10.3 Fan speed / gas cooler control ........................................................................... 26

2.10.4 Alarms ................................................................................................................ 27

2.11 iPro IPR215D controller – Peripheral devices ............................................................... 29

2.11.1 XEV20D Stepper valve actuator ........................................................................ 29

2.11.2 Variable frequency drive M200 .......................................................................... 29

2.11.3 Main contactor and circuit breakers ................................................................... 29

2.12 Compressor safety ......................................................................................................... 30

2.12.1 Compressor motor protection ............................................................................. 30

2.12.2 High-pressure safety (type-approved pressure limiter) ...................................... 30

2.12.3 High-pressure safety control .............................................................................. 30

2.12.4 Pressure relief valve – High-pressure side ........................................................ 31

2.12.5 Pressure relief valve – Liquid receiver ............................................................... 31

2.12.6 Low-pressure safety control ............................................................................... 32

2.13 Oil level monitoring device OW5 TraxOil ....................................................................... 33

3 Installation ..................................................................................................... 34

3.1 CO2 Refrigeration unit handling ..................................................................................... 34

3.1.1 Transport and storage ........................................................................................ 34

3.1.2 Weights............................................................................................................... 34

3.1.3 Lifting .................................................................................................................. 35

3.2 Refrigeration piping connections ................................................................................... 36

3.2.1 Refrigeration piping installation and connections ............................................... 36

3.2.2 Brazing recommendations.................................................................................. 37

3.3 Electrical connection ...................................................................................................... 38

3.3.1 Power supply connections.................................................................................. 38

3.3.2 Electrical wiring .................................................................................................. 39

3.3.3 Electrical protection standard (protection class) ................................................ 39

3.4 Location & fixings ........................................................................................................... 39

4 Start-up & operation ...................................................................................... 41

4.1 Evacuation ..................................................................................................................... 41

Page 4

C6.1.11/0718-0619/E

4.2 Charging procedure ....................................................................................................... 43

4.2.1 Refrigerant charging procedure ......................................................................... 43

4.2.2 Oil charging procedure ....................................................................................... 43

4.3 Maximum compressor cycle .......................................................................................... 43

4.4 Checks before starting & during operation .................................................................... 44

5 Maintenance & repair .................................................................................... 45

5.1 Opening the unit housing ............................................................................................... 45

5.1.1 To open the electrical cabinet ............................................................................ 45

5.1.2 To open the compressor chamber ..................................................................... 46

5.1.3 To remove the fan safety grid ............................................................................ 46

5.1.4 To access the inner parts of the condenser / gas cooler ................................... 46

5.2 Replacing a compressor ................................................................................................ 47

5.3 Condenser fins ............................................................................................................... 47

5.4 Electrical connections .................................................................................................... 48

5.5 Routine leak testing ....................................................................................................... 48

5.6 Condenser fan & motor .................................................................................................. 48

6 Certification & approval ................................................................................ 48

7 Dismantling & disposal ................................................................................. 48

DISCLAIMER ............................................................................................................. 49

Appendix 1: Alarm menu iPro IPR215D controller ................................................. 50

Appendix 2: Temperature / resistance curve for NTC ............................................ 58

Appendix 3: Temperature / resistance curve for PTC ................................ ............ 60

Appendix 4: Ecodesign overview tables according to Regulation 2015/1095/EU 62

Appendix 5: List of tables and figures .................................................................... 64

Page 5

Page 6

C6.1.11/0718-0619/E 1

About these guidelines

The purpose of these application guidelines is to provide guidance in the application of Copeland

EazyCool™ refrigeration units for natural refrigerant CO2. They are intended to answer the questions

raised while designing, assembling and operating a system with these products.

Besides the support they provide, the instructions listed herein are also critical for the proper and

safe functioning of the refrigeration units. Emerson will not guarantee the performance and reliability

of the product if it is misused in regard of these guidelines.

These application guidelines cover stationary applications only. For mobile applications, contact

Application Engineering as other considerations may apply.

1 Safety instructions

Copeland EazyCool™ CO2 refrigeration units are manufactured according to the latest European

Safety Standards. Particular emphasis has been placed on the user's safety.

These refrigeration units are intended for installation in machines and systems according to the

Machinery directive MD 2006/42/EC. They may be put to service only if they have been installed in

these systems according to instructions and conform to the corresponding provisions of legislation.

For relevant standards please refer to the Manufacturer’s Declaration, available at

www.climate.emerson.com/en-gb.

These instructions should be retained throughout the lifetime of both the compressor and the

refrigeration unit.

You are strongly advised to follow these safety instructions.

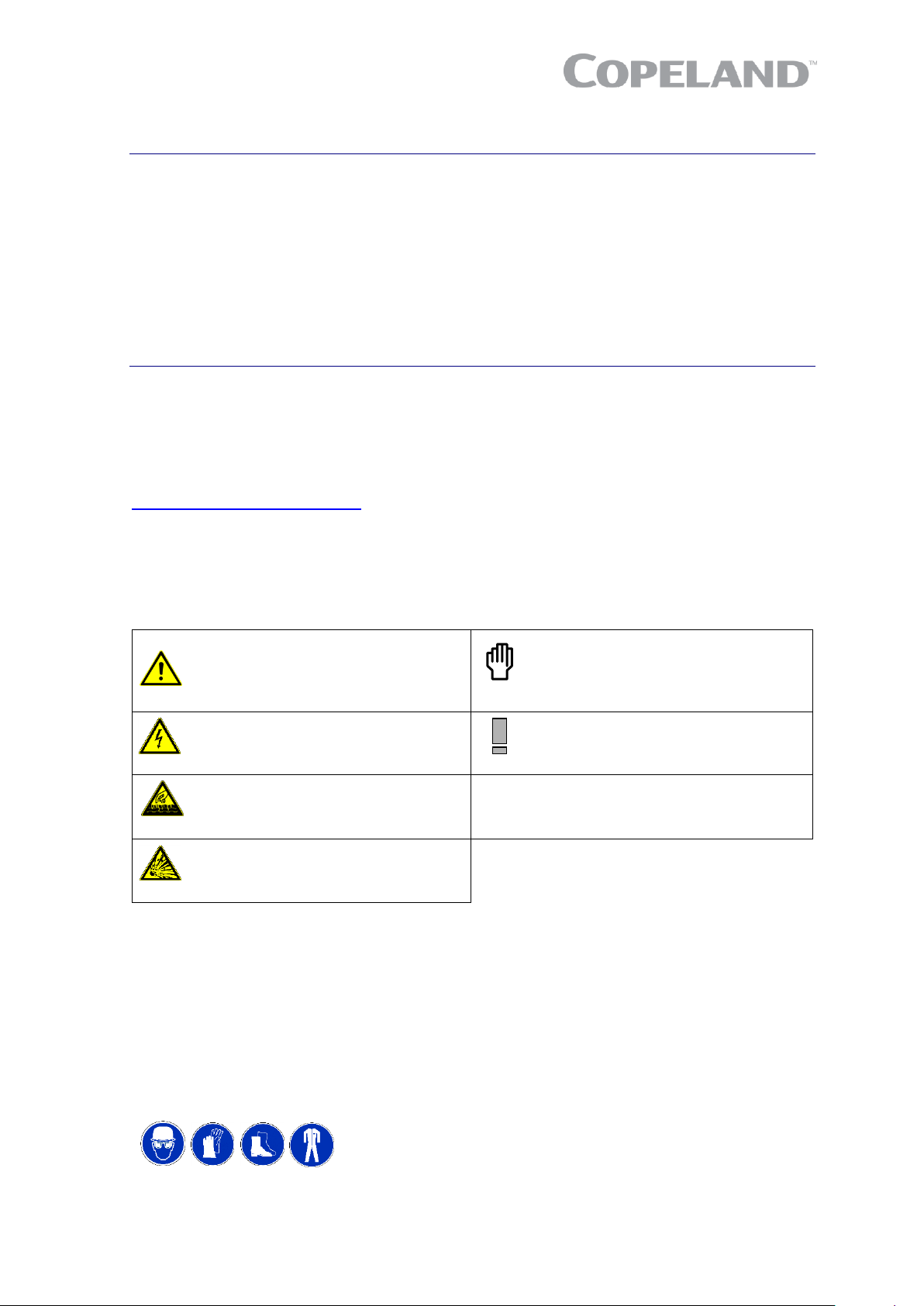

1.1 Icon explanation

WARNING

This icon indicates instructions to

avoid personal injury and material

damage.

CAUTION

This icon indicates instructions to avoid

property damage and possible

personal injury.

High voltage

This icon indicates operations with a

danger of electric shock.

IMPORTANT

This icon indicates instructions to avoid

malfunction of the compressor.

Danger of burning or frost burn

This icon indicates operations with a

danger of burning or frost burn.

NOTE

This word indicates a recommendation

for easier operation.

Explosion hazard

This icon indicates operations with a

danger of explosion.

1.2 Safety statements

▪ Refrigerant compressors and units must be used in accordance with their intended use.

▪ Only qualified and authorized HVAC or refrigeration personnel are permitted to install,

commission and maintain this equipment.

▪ Electrical connections must be made by qualified electrical personnel.

▪ All valid standards for connecting electrical and refrigeration equipment must be

observed.

▪ The national legislation and regulations regarding personnel protection must be

observed.

Use personal safety equipment. Safety goggles, gloves,

protective clothing, safety boots and hard hats should be worn where

necessary.

Page 7

2 C6.1.11/0718-0619/E

1.3 General instructions

WARNING

System breakdown! Personal injuries! Never install a system in the field

and leave it unattended when it has no charge, a holding charge, or with the

service valves closed without electrically locking out the system.

System breakdown! Personal injuries! Only CO2 and approved refrigeration

oils must be used.

WARNING

CO2 refrigerant! Danger of suffocation! Never release significant volumes

of CO2 or the entire contents of the system into closed rooms. In case of closed

room, if possible, keep the room well ventilated and/or install a CO2 detection

device. CO2 is odourless and colourless, so it cannot be perceived directly in

case of emission.

WARNING

Earth leakage current! Danger of electric shock! This product can cause

both AC and DC earth leakage current. To protect against both kinds of leakage

current it is recommended to use an AC/DC sensitive RCD type B or B+ on

the power supply side.

WARNING

High surface temperature! Burning! Do not touch the compressor or piping

until they have cooled down. Ensure that other materials in the area of the

compressor do not come into contact with it. Mark and secure accessible

sections.

CAUTION

Overheating! Bearing damage! Do not operate compressors without

refrigerant charge or without being connected to the system.

CAUTION

Contact with POE! Material damage! POE lubricant must be handled

carefully and the proper protective equipment (gloves, eye protection, etc.)

must be used at all times. POE must not come into contact with any surface

or material that it might damage, including without limitation, certain polymers,

eg, PVC/CPVC and polycarbonate.

IMPORTANT

Transit damage! Compressor and/or unit malfunction! Use original

packaging. Avoid collisions and tilting.

The contractor is responsible for the installation of the unit and should check the following points:

▪ Sufficient liquid sub-cooling in the line to the expansion valve(s) to avoid "flash-gas" in the liquid

line;

▪ Sufficient amount of oil in the compressor (in case of long piping additional oil must be charged).

Page 8

C6.1.11/0718-0619/E 3

2 Product description

2.1 General information about Copeland EazyCool™ CO2 refrigeration unit

Emerson has developed the Copeland™ EazyCool CO2 refrigeration unit to meet primarily the

demands of the food retail and food service sectors. It is an air-cooled refrigeration unit that uses the

latest Copeland™ brand products transcritical Stream compressors with inverter. All electronic

protection and diagnostics features are built in the chassis, as well as the controls for the refrigeration

unit.

Figure 1: Front view CO2 unit

2.2 EU Ecodesign Directive 2009/125/EC

The European Directive 2009/125/EC with regard to Ecodesign requirements for professional

refrigerated storage cabinets, blast cabinets, condensing units and process chillers requires

manufacturers to decrease the energy consumption of their products by establishing minimum

energy efficiency standards. Copeland brand products condensing units are prepared and optimized

to meet the requirements of the Ecodesign Directive. The integrated variable speed fan and

condenser reduce the noise level and energy consumption significantly. This, combined with

Copeland Stream CO2 compressor technology, allows for high-efficiency operation.

These guidelines meet the requirements of Regulation 2015/1095, Annex V, section 2(a), with regard

to product information, namely:

▪ (v) ➔ See chapter 2.6 "Application range"

▪ (vi) ➔ See chapters 5.3 "Condenser fins" and 5.5 "Routine leak testing"

▪ (vii) ➔ See chapter 4.2 "Charging procedure"

▪ (viii) ➔ See chapter 7 "Dismantling & disposal"

The Ecodesign overview tables according to Annex V of Regulation 2015/1095/EU for all Copeland

EazyCool CO2 units can be found in Appendix 4.

Page 9

4 C6.1.11/0718-0619/E

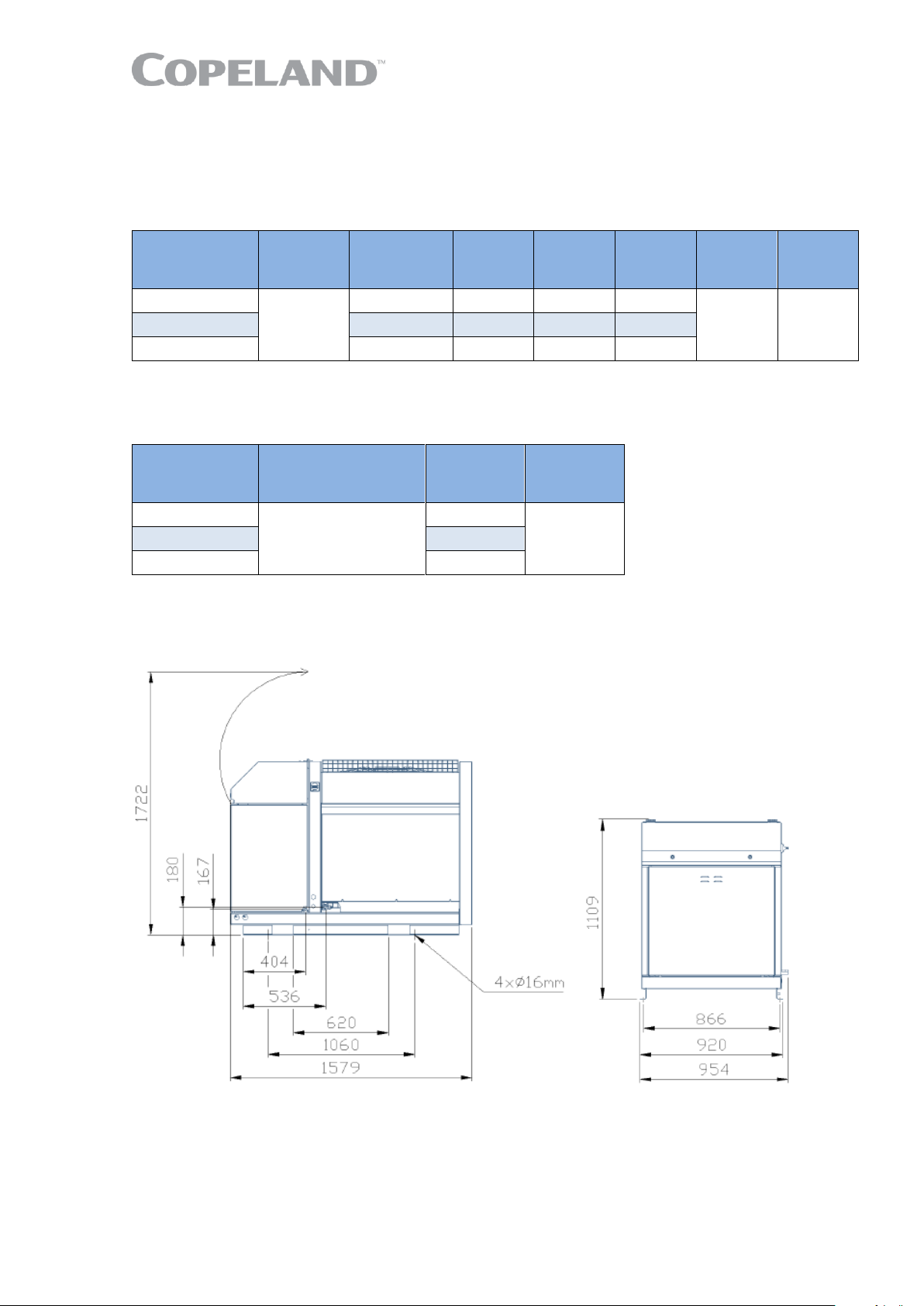

2.3 Main product features

Copeland EazyCool refrigeration units are released for CO2 (R744) refrigerant only. They are

available in one cabinet size and are always equipped with one fan.

The units are designed for medium temperature applications only. The inverter is calculated to drive

the compressor in subcritical and transcritical applications.

Refrigeration unit

Refrigerant

type

Displacement

@ 50 Hz [m3/h]

Cooling

capacity*

[kW]

Nominal

power

[kW]

Max.

current

[A]

Ps

high side

[bar]

Ps

low side

[bar]

OME-4MTL-05X

R744

4.6

8.72

11

19

120/90

90

OME-4MTL-07X

6.2

11.81

14

22

OME-4MTL-09X

7.4

14.65

16

27

* Cooling capacity declared at ambient temperature 32°C, evaporating temperature -10°C, suction temperature

0°C and compressor frequency 50 Hz

Table 1: CO2 unit technical data

Refrigeration unit

Outer dimensions

length/width/height with

closed cover [mm]

Weight

[kg]

Liquid

receiver size

[litres]

OME-4MTL-05X

1579 / 954 / 1109

440

24.9

OME-4MTL-07X

450

OME-4MTL-09X

462

Table 2: CO2 unit features

The figures hereafter show the overall physical dimensions of the CO2 refrigeration units in

millimetres.

Figure 2: Dimensions of models OME-4MTL-05X, OME-4MTL-07X & OME-4MTL-09X

NOTE: When the electrical cabinet cover is open the total height is 1722 mm. This must be

taken into consideration when deciding on the unit location, to ensure easy access to the

electrical cabinet.

Page 10

C6.1.11/0718-0619/E 5

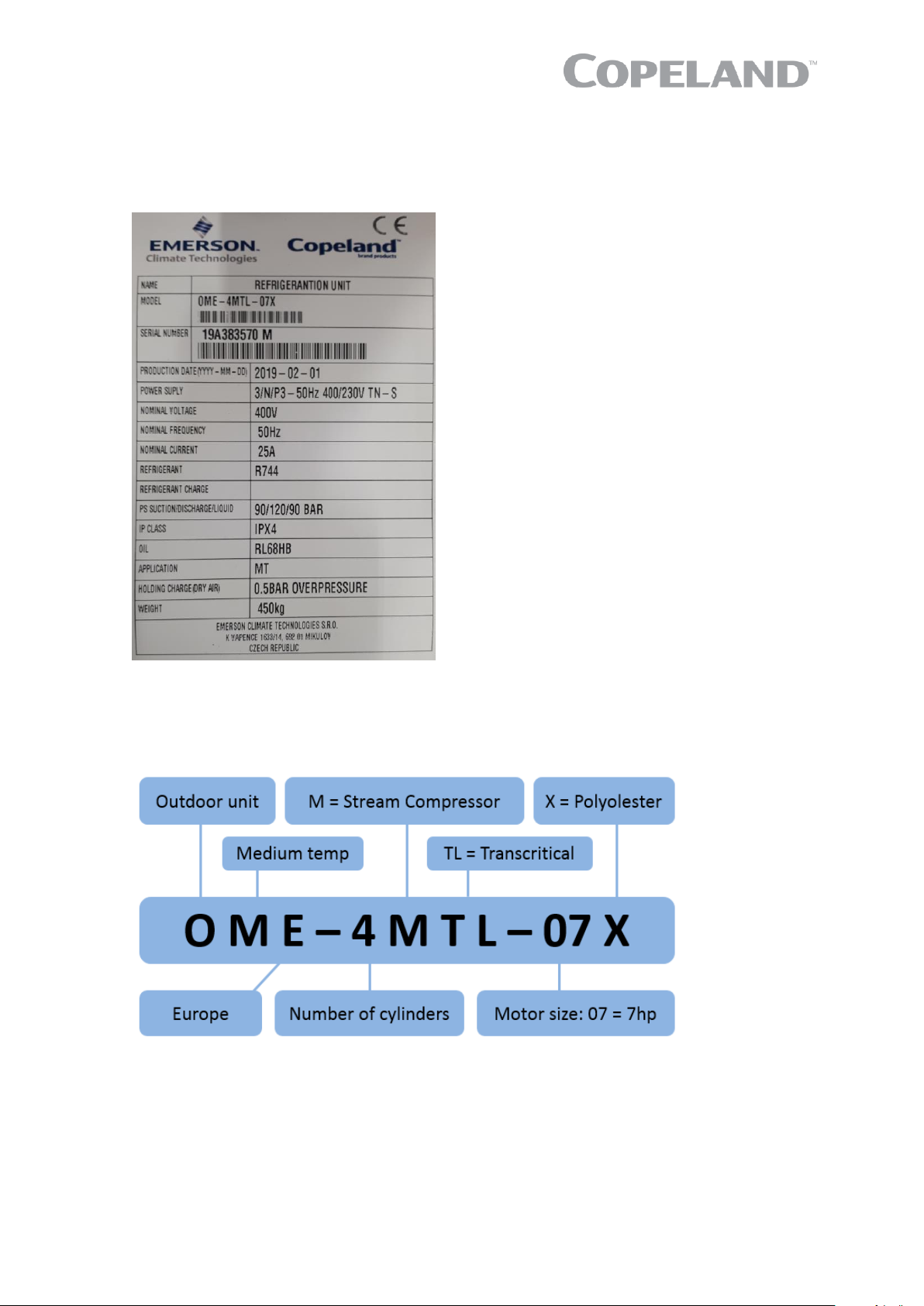

2.4 Product nameplate

The refrigeration unit nameplate shows model designation and serial number, as well as nominal

power and safety pressures.

The compressor has its own nameplate with all electrical characteristics.

Figure 3: Nameplate of CO2 units

2.5 Nomenclature

The model designation contains the following technical information about Copeland EazyCool CO2

refrigeration units:

Figure 4: Nomenclature of CO2 units

Page 11

6 C6.1.11/0718-0619/E

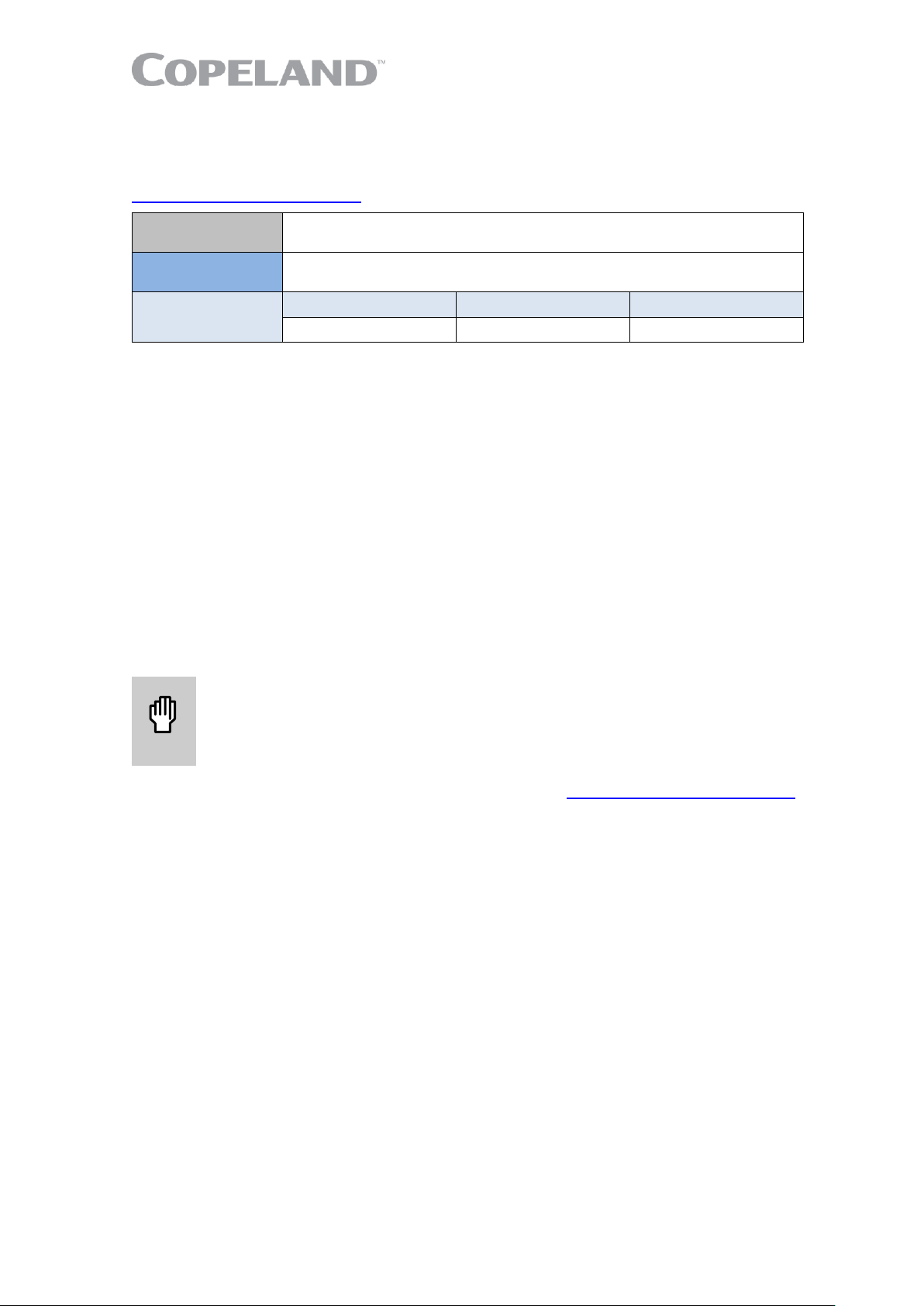

2.6 Application range

2.6.1 Qualified refrigerant and oil

Oil recharge values can be taken from Copeland brand products Select software available at

www.climate.emerson.com/en-gb.

Qualified

refrigerant

R744 (CO2)

Qualified

servicing oil

Polyolester Emkarate RL 68 HB

Oil charge

in litres

OME-4MTL-05X

OME-4MTL-07X

OME-4MTL-09X

1.5

1.5

1.5

Table 3: Qualified refrigerant and oil

NOTE: Use only lubricants that are qualified for the product. The use of non-approved

lubricants can damage the product and will result in loss of warranty!

NOTE: The polyolester oil is very hygroscopic. Never keep the system open to the ambient. If

for any reason there is no refrigerant in the system, it is recommended to charge the system

with a protective gas, eg, inert gas N2.

The recommended quality for carbon dioxide purity class is 4.0 [(≥ 99.99%) H2O ≤ 10 ppm,

O

2

≤ 10 ppm, N

2

≤ 50 ppm] or higher.

The characterization of R744 (CO2) according to EN 378-1 is safety class A1, not flammable,

ODP = 0 and GWP = 1. High concentrations of CO2 are dangerous. This refrigerant is odourless and

colourless. Therefore the use of CO2 detectors is required.

CO2 is heavier than air. As a result, local concentrations (especially at floor level or in deeper slots =

CO2 pockets) can be higher than average values in the machine room. The ventilation system must

take this into account.

2.6.2 Application limits

WARNING

Oil dilution due to low superheat! Compressor breakdown! Low suction

superheat leads to oil dilution. Always operate the system with adequate

superheat to avoid oil viscosity decrease. Additional measures in system

design might help to avoid unacceptable lubrication conditions.

For the application envelope, please refer to Select software at www.climate.emerson.com/en-gb.

2.6.3 Recommendations for minimum suction superheat – Lubrication conditions

The operation of CO2 compressors / units at conditions where the viscosity of the oil is low might

become very harmful with regard to compressor lifetime expectancy. Indicators like oil temperature

and discharge temperature must be observed to judge about the lubrication conditions. Depending

on the application (low temp, medium temp, parallel compression, etc.…) different minimum suction

superheat values should be respected to secure maximum protection of the compressor. In general,

higher superheat on the suction inlet of a compressor provides higher safety, but the limits for the

maximum allowable discharge temperature should be considered as well (superheat has a direct

impact on discharge temperature). For medium temperature applications, an absolute minimum of

10K is recommended.

Particular attention should be paid to the following points:

▪ Measuring the suction superheat becomes more critical with larger diameters on the suction

tube. Ensure proper positioning of sensor. Sensor sleeves must be used with large diameters.

▪ The oil temperature is measured by the dedicated unit sensor and can be read out from the

Visograph display in the service menu.

▪ The discharge temperature is observed by the unit controller. The temperature on the discharge

line should never exceed 135°C (measured directly after the compressor shut-off valve). The

temperature of the discharge gas on the outlet of the valve plate is 10-15K higher than the

temperature on the discharge line.

Page 12

C6.1.11/0718-0619/E 7

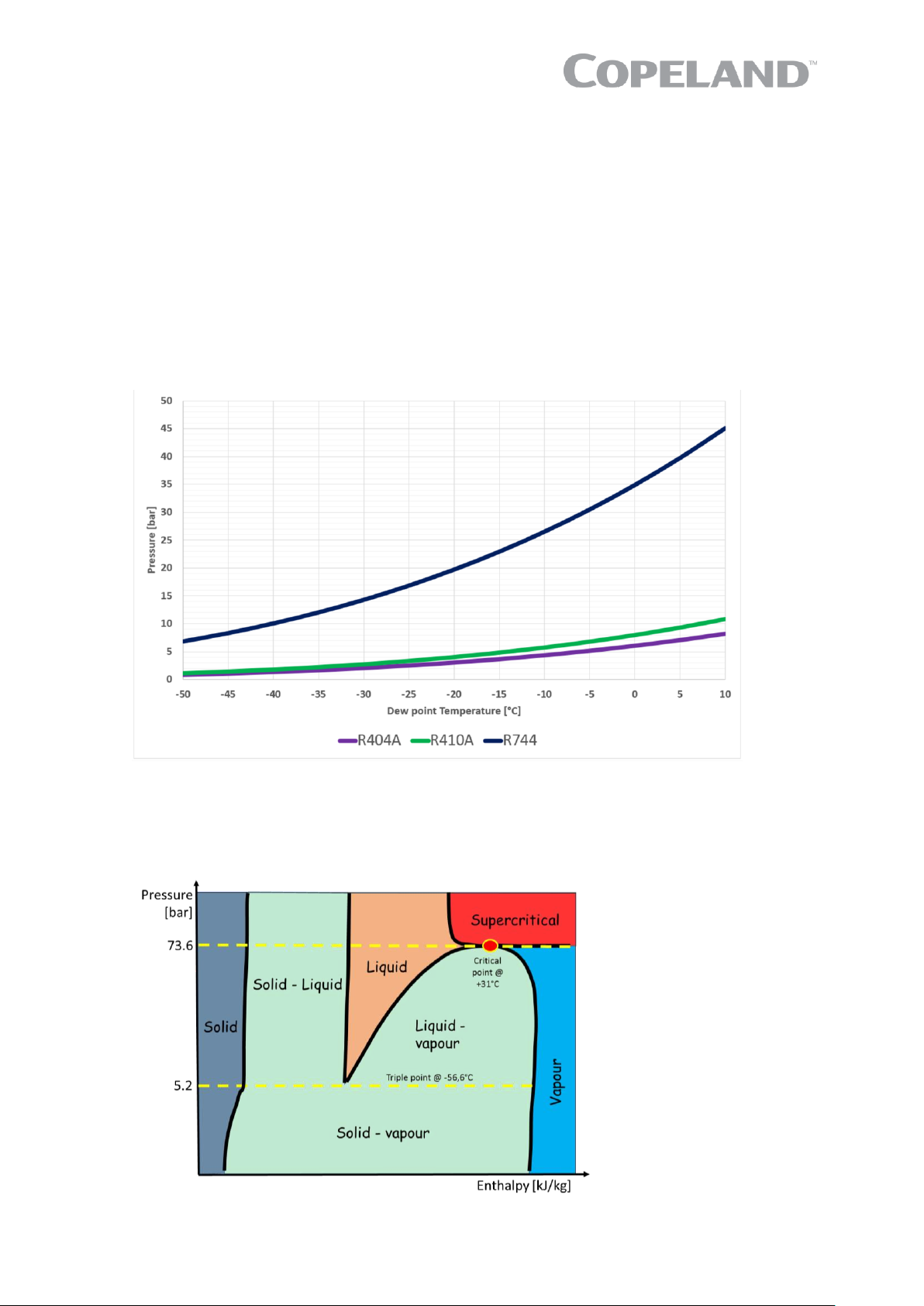

2.6.4 Pressure levels of CO2 vs. other refrigerants

Figure 5 below compares the evaporating pressures of R744 to those encountered with R410A and

R404A. It can be observed that R744 systems will require to operate at much higher pressures than

conventional systems.

Note that below a pressure of 5.2 bar, solid and gaseous R744 phases may co-exist at low

temperature. This behaviour is totally different from that observed with traditional refrigerants, and

will have important consequences on the operation, servicing and maintenance of a system working

with R744.

Gaseous R744 is 1.5 times heavier than air. Therefore, when released to the air it will concentrate

at low elevations.

R744 will form "dry ice" at -56.6°C. One kg of dry ice has the cooling capacity of 2 kg of ordinary ice.

Gaseous or liquid R744 stored under pressure will form dry ice through an auto-refrigeration process

if rapidly depressurized.

Figure 5: Pressure levels of CO

2

Figure 6 shows the thermodynamic properties (p-h-diagram) of R744. Compared to other fluids

traditionally used as refrigerants, its critical point at 31°C is very low and its critical pressure at about

73.6 bar is high.

Figure 6: Pressure/enthalpy diagram CO2

Page 13

8 C6.1.11/0718-0619/E

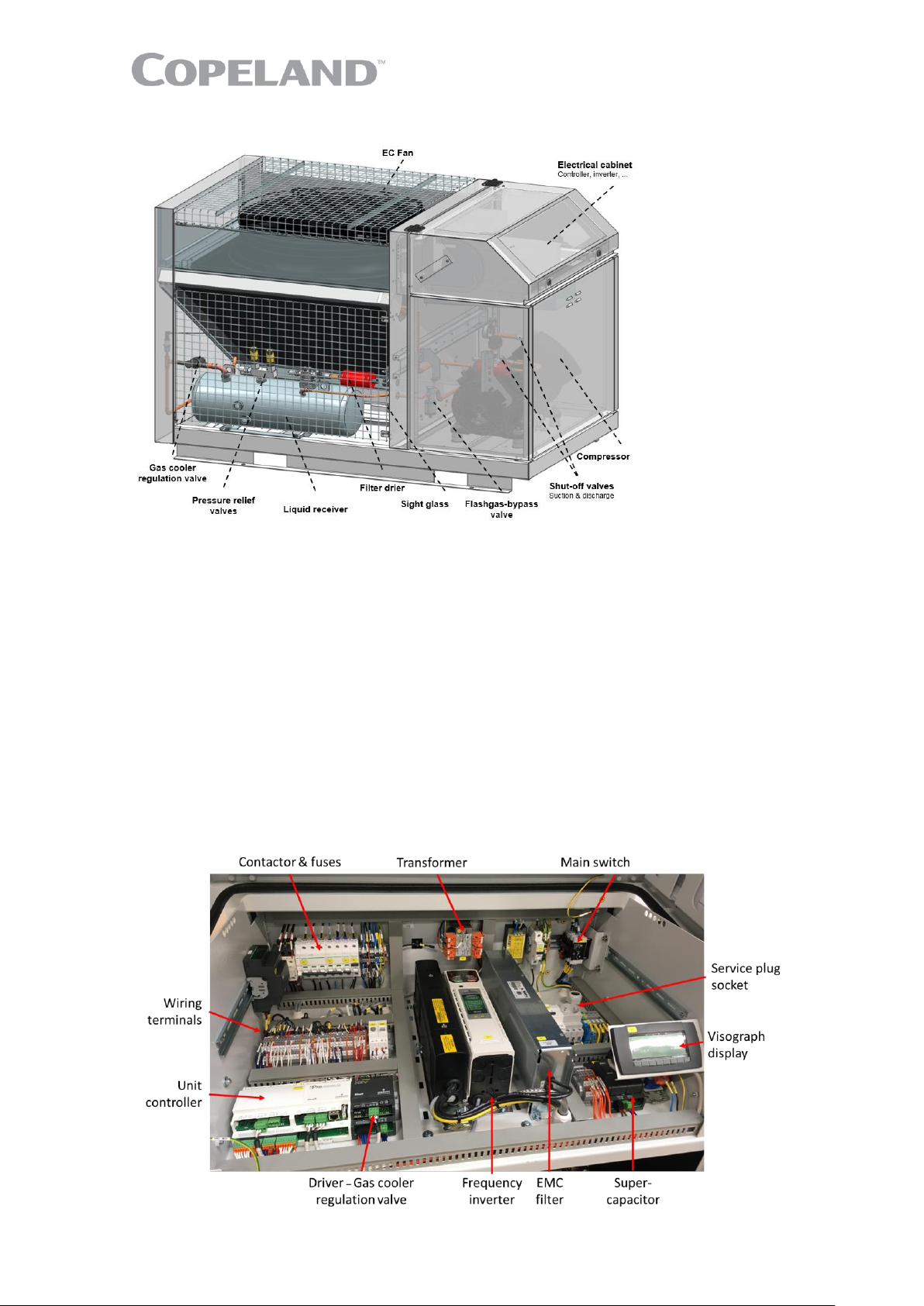

2.7 Main components description

Figure 7: Main components of CO2 unit

2.7.1 Compressor

The compressor is installed in the chamber below the electrical cabinet. The standard delivery is with

shut-off valve on discharge, CoreSense Protection module, oil watch system connected to one of the

sight glass connections. One additional sight glass on the opposite side of the compressor allows for

a visual check of the oil level. A third sight glass located in the crankcase cover will give an indication

that there is oil on the inlet of the oil splasher.

All electrical wiring is pre-assembled in the factory. A pressure relief valve (135 bar) is installed

directly on the compressor. A pressure cut-out device is installed on the discharge side of the

compressor in compliance with EN 378 requirements.

2.7.2 Electrical cabinet

The electrical cabinet is located on the edge above the compressor chamber beside the fan. All

electrical components like main unit controller, inverter, contactors, transformers, wiring terminals

and fuses are installed in this area. The electrical cabinet is covered by a hinged upper shell which

can be fixed in two opening angles.

Figure 8: Electrical cabinet

Page 14

C6.1.11/0718-0619/E 9

2.7.3 Liquid receiver

The liquid receiver (24.9 litres for the whole range of units) is installed below the condenser / gas

cooler. It is equipped with a shut-off valve on the outlet and a safety group (2 pressure relief valves

90 bar, connected to a switch-over valve).

There are 2 sight glasses in the shell of the liquid receiver to check the refrigerant level.

2.7.4 Fan

The condenser of the Copeland EazyCool CO2 refrigeration unit is equipped with an EC fan.

Figure 9: Fan design

Fan

Power

input

[W]

Maximal

current

[A]

Air flow

[m³/h]

Unit

Description

OME-4MTL-05X

FN071-6IQ.BD.V7P3

280

1.4 - 1.0

7100

OME-4MTL-07X

FN071-ZIQ.DG.V7P3

660

3.4 - 2.4

11950

OME-4MTL-09X

FN071-ZIQ.DG.V7P3

660

3.4 - 2.4

11950

Table 4: Fan specifications

Technical data

Supply frequency

[Hz]

50/60 Hz

Supply voltage

[V]

200-277

Min to max ambient temperature

[°C]

-35 to +60

ErP 2015

[-]

Yes

IP class

[-]

IP54

Fan motor type

[-]

EC

Fan blades

[-]

Plastic

Table 5: Fan technical data

2.7.5 Condenser / gas cooler regulation valve (HPV)

The high-pressure regulation valve is installed between the condenser / gas cooler and the liquid

receiver. It regulates the high pressure for optimum COP in transcritical operation.

The driver for the stepper motor valve is installed in the electrical cabinet.

The driver for the HPV is an XEV20D. It gets a signal from the iPro unit controller – see chapter 2.8

"CO2 Unit control – General".

2.7.6 Flashgas bypass valve (BPV)

The flashgas bypass valve is installed between the flashtank and the suction line to the compressor.

Without the flashgas bypass valve there is a risk of unacceptably high pressure in the flashtank in

case the ambient temperature exceeds 35°C. The flashgas bypass valve is aimed at keeping the

flashtank pressure below a set level defined by parameter GC20 (factory-set at 35 bar) at all times.

Page 15

10 C6.1.11/0718-0619/E

If a system does not require cooling capacity and the ambient temperature around the unit is high,

the pressure in the flashtank section will increase. When reaching a critical pressure limit defined by

parameter GC78 (factory-set at 40 bar) inside the flashtank during compressor stop, the compressor

will start and perform a short pumpdown cycle to reduce the pressure level in the flashtank area.

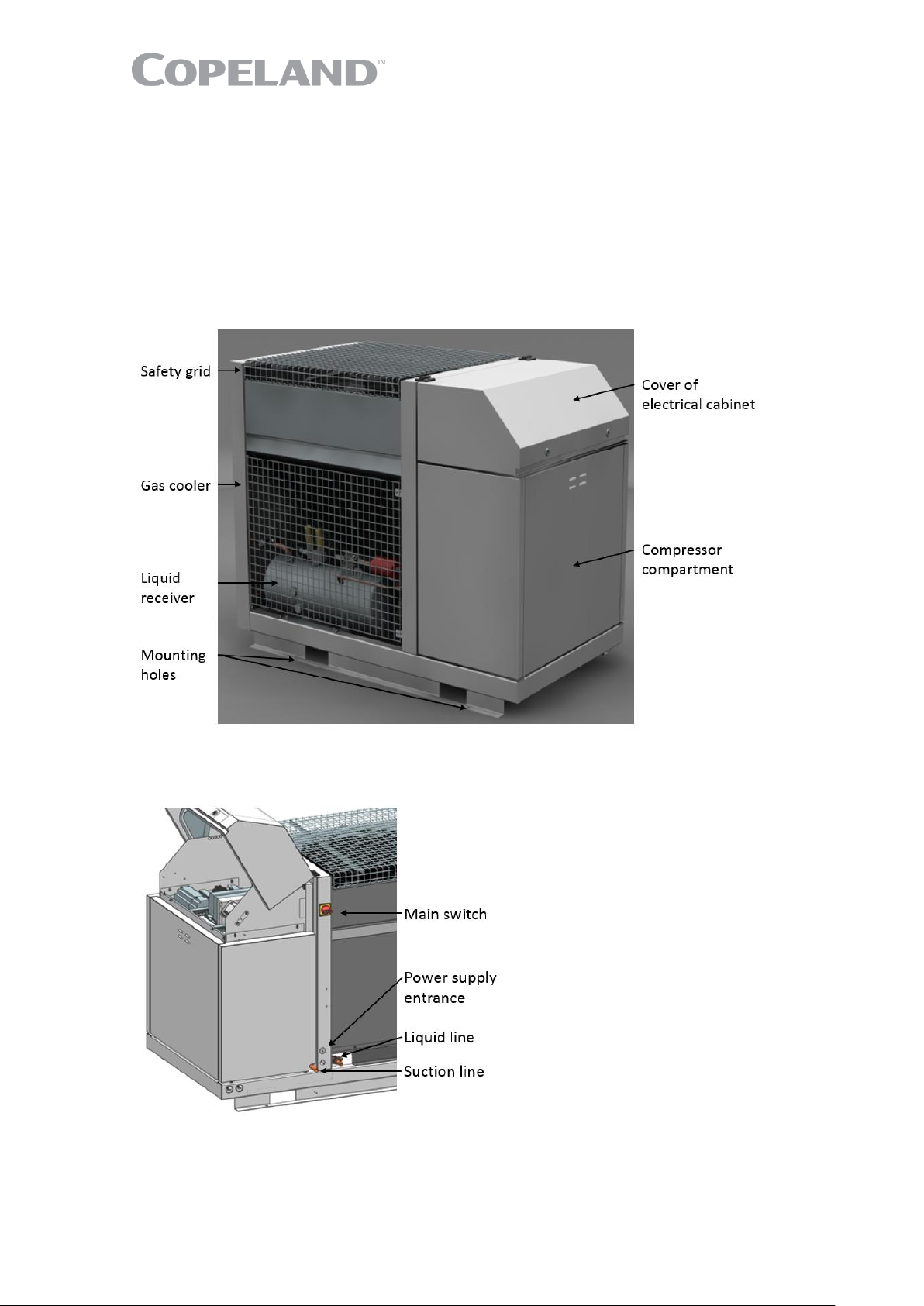

2.7.7 Housing

Copeland EazyCool CO2 refrigeration units have a new, unique design. They are equipped with an

electrical cabinet located above the compressor chamber with a hinged cover for easy and servicefriendly access. The electrical cabinet and the compressor area are accessible independently. The

fan has vertical air flow and is protected by a safety grid. The gas cooler, liquid receiver and

connected parts are freely accessible by the service technician.

Figure 10: Overview of the unit housing

Figure 11: Position of the connections

Page 16

C6.1.11/0718-0619/E 11

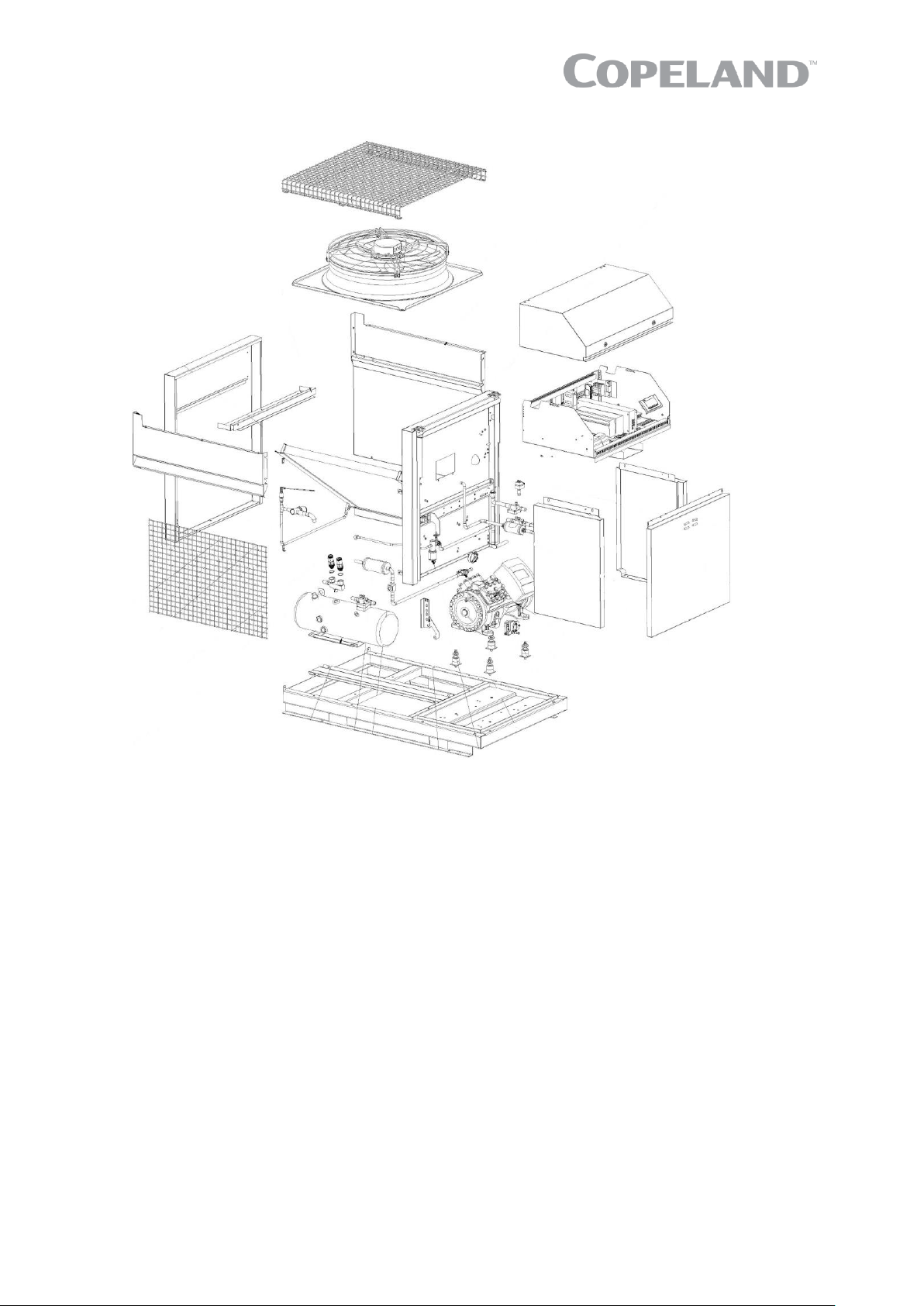

2.7.8 Exploded view of the CO2 unit

Figure 12: Exploded view of the unit

Page 17

12 C6.1.11/0718-0619/E

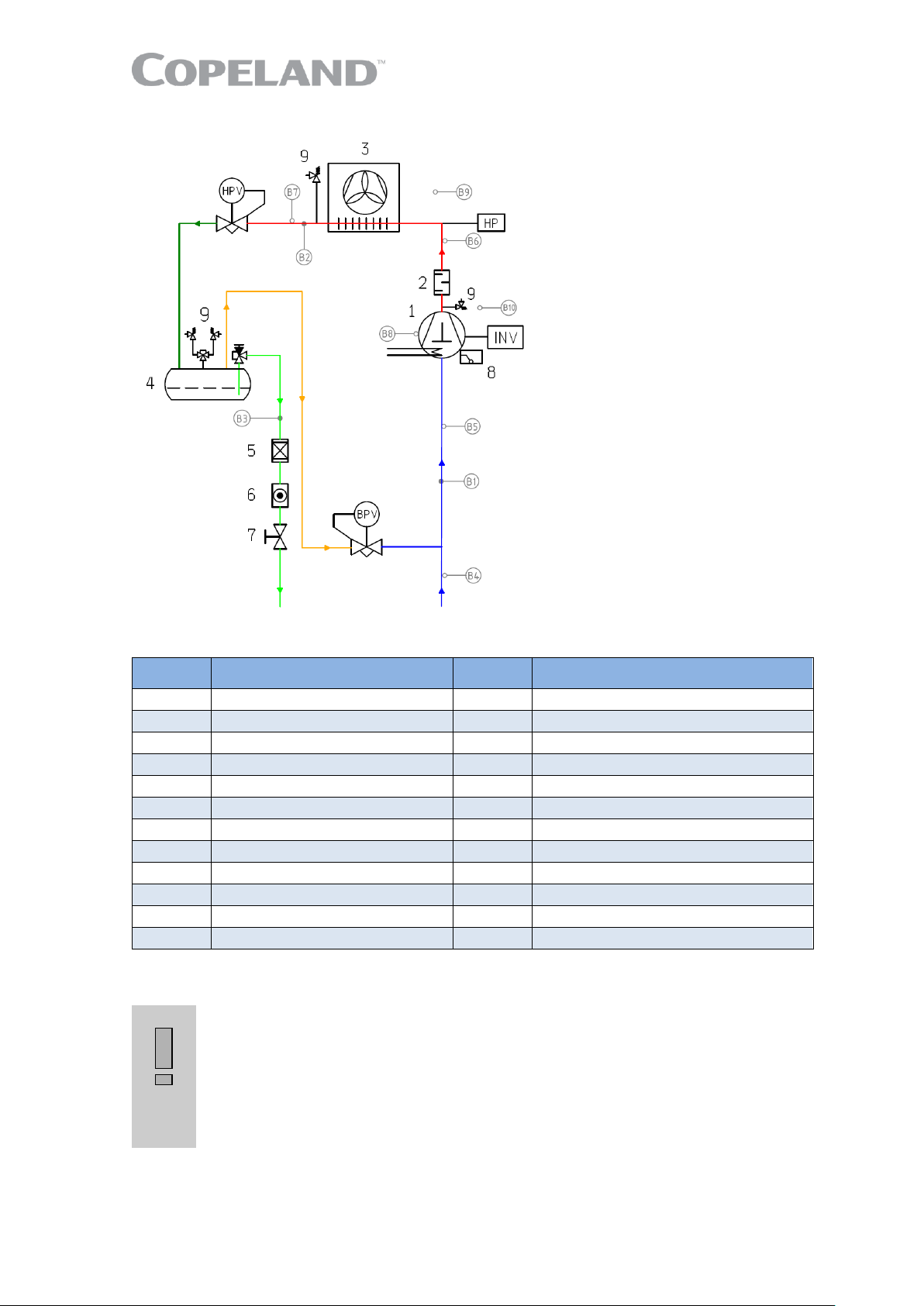

2.7.9 P&I diagram for CO2 units

Figure 13: P&I diagram for CO2 units

Position

Description

Position

Description

1

Copeland Stream compressor

INV

Compressor inverter

2

Discharge mufler

B1

Suction pressure

3

Gas cooler/condenser

B2

Discharge pressure

4

Flash tank

B3

Liquid receiver pressure

5

Filter-dryer

B4

Suction gas temperature unit

6

Sight glass

B5

Suction gas temperature compressor

7

Ball valve

B6

Discharge line temperature

8

OW5 oil watch

B7

Gas cooler temperature

9

Pressure relief valve

B8

Oil temperature

HPV

High pressure valve

B9

Ambient temperature

BPV

Bypass valve

B10

Cabinet temperature

HP

High pressure limiter

Table 6: Legend of the P&I diagram for CO2 units

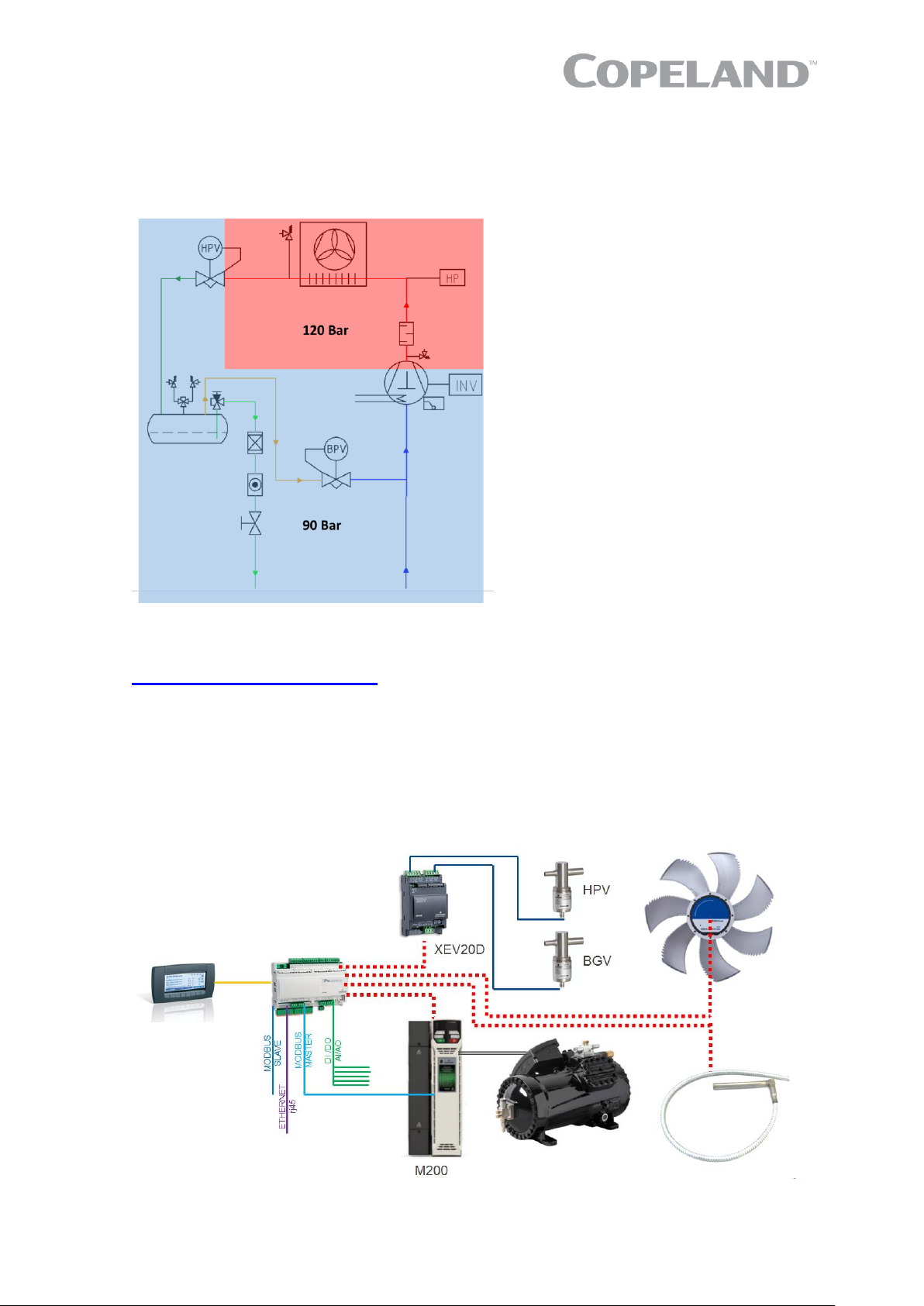

2.7.10 Design pressures

IMPORTANT

Piping design pressure! Risk of CO2 blow-off! The CO2 unit liquid and

suction line piping is designed for a design pressure (Ps) of 90 bar as

pressures around 85 bar can occur during normal operation. The installer must

always consider the system liquid and suction lines in terms of maximum

operating pressure. If the system piping design pressure is lower than 90 bar,

additional safety devices are required. The CO2 unit can control different

receiver pressures depending on the application (parameter GC20).

The unit has 2 different pressure areas:

▪ The design on suction side is made for a maximum allowable absolute pressure of 90 bar at

standstill. The section after the high-pressure valve (liquid line, liquid receiver, filter drier, sight

Page 18

C6.1.11/0718-0619/E 13

glass) to the liquid line outlet of the unit is approved for an absolute pressure of 90 bar at

standstill too.

▪ A ½" fitting is pre-installed in the suction line for an additional pressure relief valve.

▪ The area with discharge pipe, condenser/gas cooler and high-pressure regulation valve is

approved for a maximum allowable absolute pressure of 120 bar.

Figure 14: Design pressures of CO2 unit

NOTE: The design pressure Ps is a safety-related value. The restrictions for reliable operation

of the unit are defined by the application envelope which can be found in Select software at

www.climate.emerson.com/en-gb.

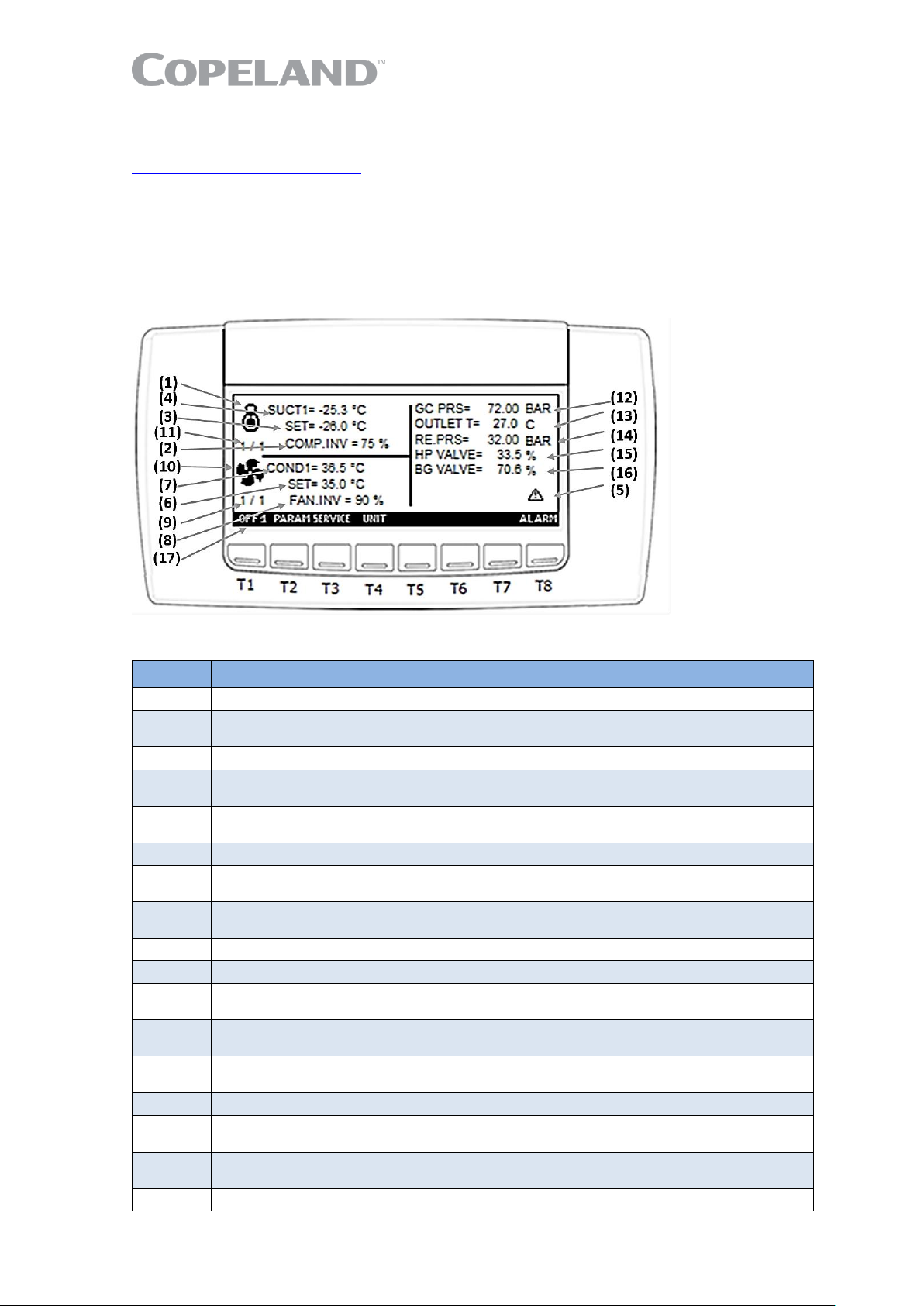

2.8 CO2 Unit control – General

Copeland EazyCool CO2 refrigeration units are equipped with an iPro controller (IPR215D) and a

Visograph display. The iPro controller manages the compressor variable frequency drive through 010V and a digital signal. It also handles the high-pressure regulation which is done by a stepper

motor valve, driven by a standard driver device, controlled by iPro through CAN BUS. The stepper

motor valve driver can operate two valves simultaneously. The controller can handle gas cooler

pressure and liquid receiver pressure in parallel.

Figure 15: CO2 unit controller schematics

IPR215D

Visograph

Page 19

14 C6.1.11/0718-0619/E

2.8.1 iPro IPR215D controller description

The iPro controller is a standard IPR215D Dixell controller. A detailed manual can be found at

www.climate.emerson.com/en-gb.

The controller is factory-set for -10°C evaporating temperature. To achieve the required

temperatures, Emerson recommends to change only the evaporating temperature as the rest of the

parameters are already pre-set.

NOTE: The other factory settings can be found in Technical Information CC7.8.11 "Copeland

EazyCool™ CO2 Refrigeration Units – iPro IPR215D Controller Parameter List".

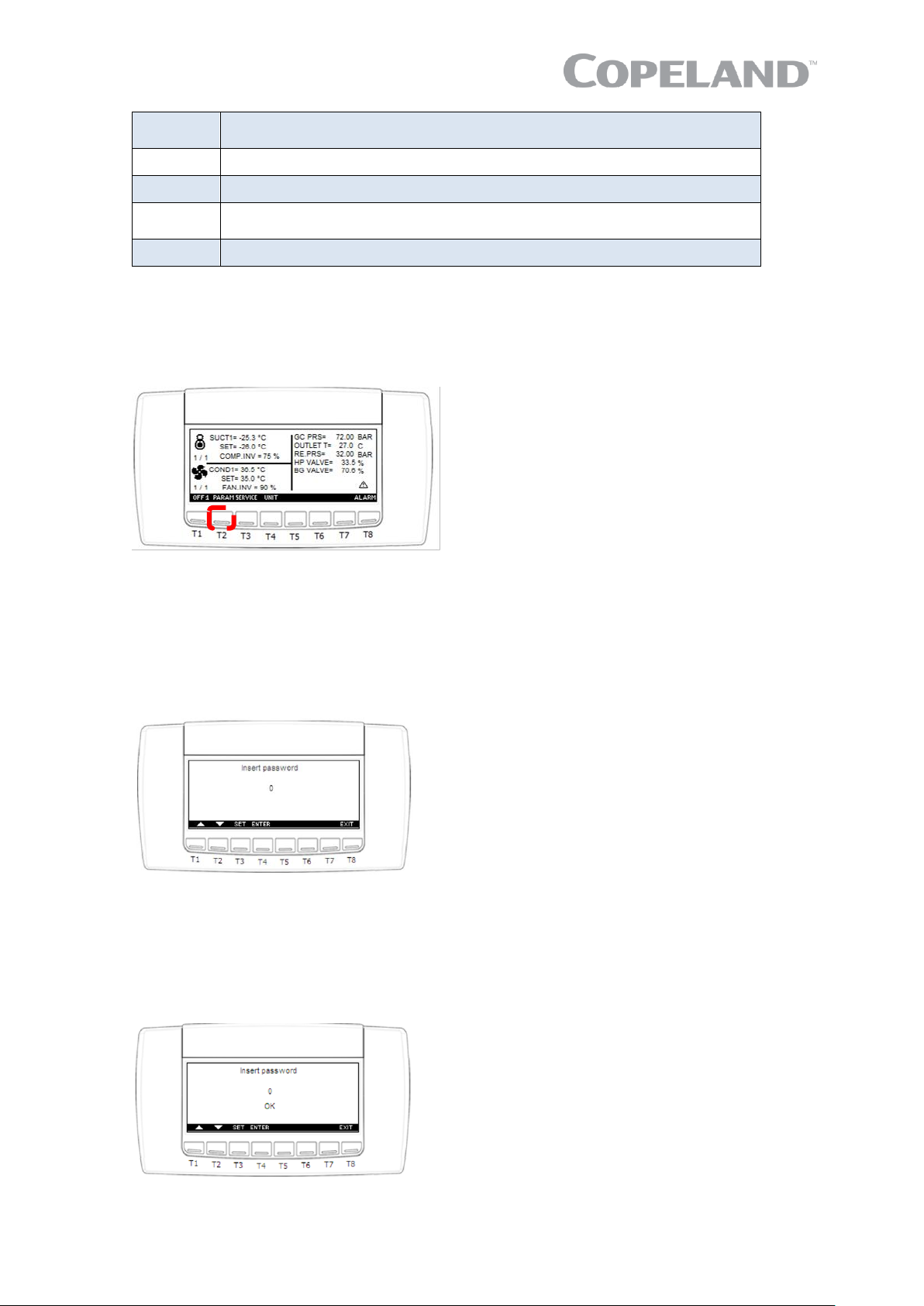

2.8.2 Visograph display description

Figure 16: Visograph display

Position

Description

Comments

1

Compressor symbol

2

Percentage of analog output

for frequency compressor

For frequency compressor. Displays the percentage

of the analog output driving the inverter.

3

Suction pressure setpoint

4

Current value of suction

pressure

5 Alarm

Displayed when an alarm occurs in suction or gas

cooler/condenser section

6

Condensing pressure setpoint

7

Current value of condensing/

gas cooler pressure

8

Percentage of analog output

for EC fan

For fan inverter. Displays the percentage of the

analog output driving the inverter.

9

Number of activated fans

10

Fan symbol

11

Number of activated

compressors and steps

12

Gas cooler pressure

The same value is displayed in "Stage Gas Cooler

Info"

13

Outlet temperature

The same value is displayed in "Stage Gas Cooler

Info"

14

Receiver pressure

15

Gas cooler regulation valve

(HPV) % opening

16

Flash gas regulation valve

(BGV) % opening

17

Operating mode

Table 7: Display description – Legend

Page 20

C6.1.11/0718-0619/E 15

OFF1

To switch the controller off. Press for 10 seconds to switch the controller off

(enabled only if parameter OT5 = yes)

PARAM

To enter the parameter programming menu

SERVICE

To enter the service menu

UNIT

Measurement unit: to switch the probe visualization and setpoint from

pressure to temperature and vice versa

ALARM

To enter the alarm menu

Table 8: Key functions

2.9 How to use the iPro IPR215D controller

2.9.1 How to change parameters

Press the PARAM key to access the programming menu.

Figure 17: iPro Parameter key

The device provides 2 programming levels:

▪ Pr1 with direct access – press Pr1 to enter this menu;

▪ Pr2 protected with a password – password set to 12 by factory.

If the password function is enabled, the following interface will be displayed when pressing the Pr2

key:

Figure 18: Password setting

To enter password:

1) Press the SET key

2) Use the UP and DOWN keys to enter password 12

3) Press the SET key to confirm password. The following interface will be displayed:

Figure 19: Password confirmation

4) Press ENTER to access the Pr2 menu

Page 21

16 C6.1.11/0718-0619/E

2.9.2 Parameter grouping

The parameters are grouped in sub-menus.

No.

Parameter grouping

No.

Parameter grouping

1

Setpoint (SETC1, SETF1)

28

Analog outputs 4 (AO4_1- AO4_26)

2

Compressor rack setup (CF1, CF16)

29

Analog outputs 5 (AO5_1- AO5_26)

3

Regulation (CF18, CF20-CF22, CF24)

30

Analog outputs 6 (AO6_1- AO6_26)

4

Display (CF26-CF27)

31

Auxiliary outputs (AR1-AR18)

5

Analog inputs (AI1-AI31)

33

Superheat alarms (ASH1- ASH16)

6

Safety digital inputs (SDI1-SDI3)

34

Gas leak detector (GLD1-GLD20)

7

Digital inputs (CDI1, CDI3)

35

Other (OT1 – OT6)

8

Compressor function

(RC1-RC4, RC35-RC38, RC45)

36

DI configuration (DIC1- DIC20)

9

Compressor safety (SL1-SL11, SL14-SL15)

37

DO configuration (DOC1- DOC15)

10

Fan function (RC9-RC33, RC43, RC47-RC55)

38

AO configuration (AOC1- AOC6)

11

Fan safety (SL12, SL13, SL16)

41

AI configuration (AIC1- AIC10)

12

Fan setting for max COP (RC56-RC61)

42

CoreSense configuration

(CO1-CO2, CO16-CO17)

13

Fan regulation band optimization with

frequency compressor (RC62-RC69)

43

ECM (ECM01-ECM9)

14

Operating mode scheduling (OMS1-OMS21)

44

XEV02 (XEV1-XEV4)

15

Alarms configuration (AC1-AC2)

45

M200 (VFD1-VFD33)

16

Compressor alarms (AL1-AL21)

46

M200 (INV1-INV33)

17

Fan alarms (AL24-AL43)

47

HTR (HTR1-HTR4)

23

Dynamic setpoint suction (DSP1- DSP4)

48

EPM (EPM1-EPM18)

24

Dynamic setpoint condenser (DSP9-DSP11)

49

Gas cooler heat reclaim (HTRC1-HTRC13)

25

Analog outputs 1 (AO1_1- AO1_26)

50

Gas cooler (GC1-GC64)

26

Analog outputs 2 (AO2_1- AO2_26)

51

Manual pumpdown (SPF1, SPF2)

27

Analog outputs 3 (AO3_1- AO3_26)

52

Unit protection (DLT1-DLT24)

Table 9: Parameter grouping

NOTE: The parameter sub-menu will be visible only if at least one parameter in the group is

visible in Pr1 or Pr2.

Press the SET key to access a menu. The parameters and their respective values will be displayed

(see Figure 20 below).

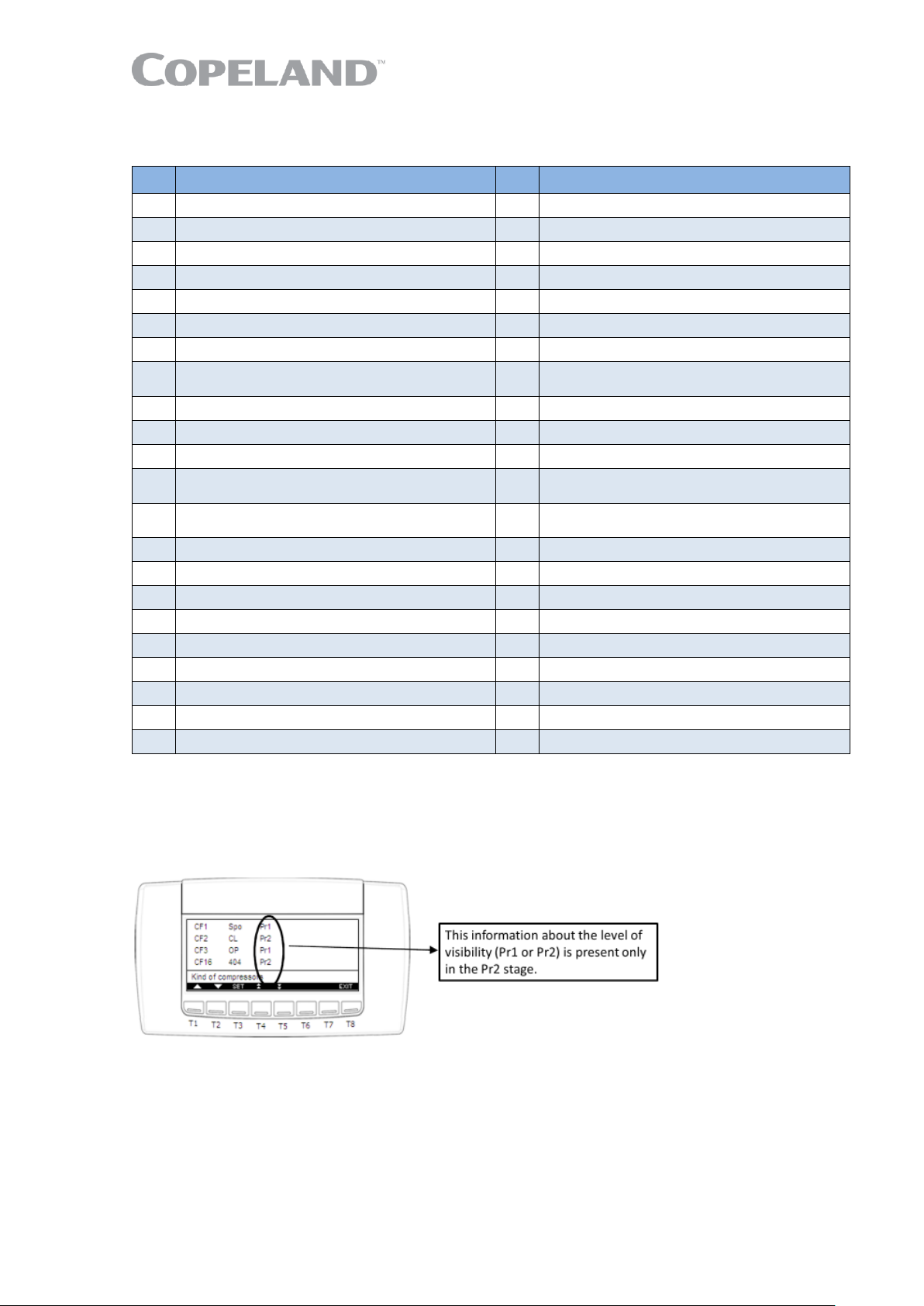

Figure 20: Parameter level information

▪ Press the SET key and use the UP and DOWN keys to modify a value

▪ Press the SET key again to store the new value

▪ Use the UP and DOWN keys to move to the next parameter

NOTE: The Pr2 or Pr1 message is present only in the Pr2 menu. It is possible to modify the

level of each parameter by changing Pr2 to Pr1 and vice versa.

NOTE: After pressing the EXIT key, the previous screen will be displayed again.

Page 22

C6.1.11/0718-0619/E 17

2.9.3 "Service" menu

The main functions of the controller are available from the "Service" menu and are listed below:

▪ check the values of analog outputs;

▪ check the status of compressor relays;

▪ operate a maintenance session;

▪ check the status of safety and configurable digital outputs;

▪ check the values of the probes;

▪ set the real-time clock;

▪ start a pumpdown;

▪ set the password and enable it for a defined menu;

▪ set the language;

▪ check the values of superheat probes;

▪ configure IP/Modbus address;

▪ manage / configure files;

▪ check the parameters of XEV20, XEV02, ECM, M200 and energy meter if these devices have

been configured;

▪ manage the log files;

▪ execute evacuation

▪ etc…

The following sub-menus are also available:

Probes

CoreSense setup

File management configuration

Analog outputs

CoreSense information

ip/mdb address configuration

Output (om)

Log file management

Real-time clock

Loads status

Update Visograph

Language

Digital inputs

M200 status

Password

Superheat (inactive)

Energy meter status

Gas cooler information

Pumpdown

XEV02 status

Compressor service circuit 1

Controller online/offline

Table 10: Sub-menu overview

2.9.4 How to enter the "Service" menu

Press the SERVICE key to enter the "Service" menu.

Figure 21: iPro "Service" key

The following interface will be displayed:

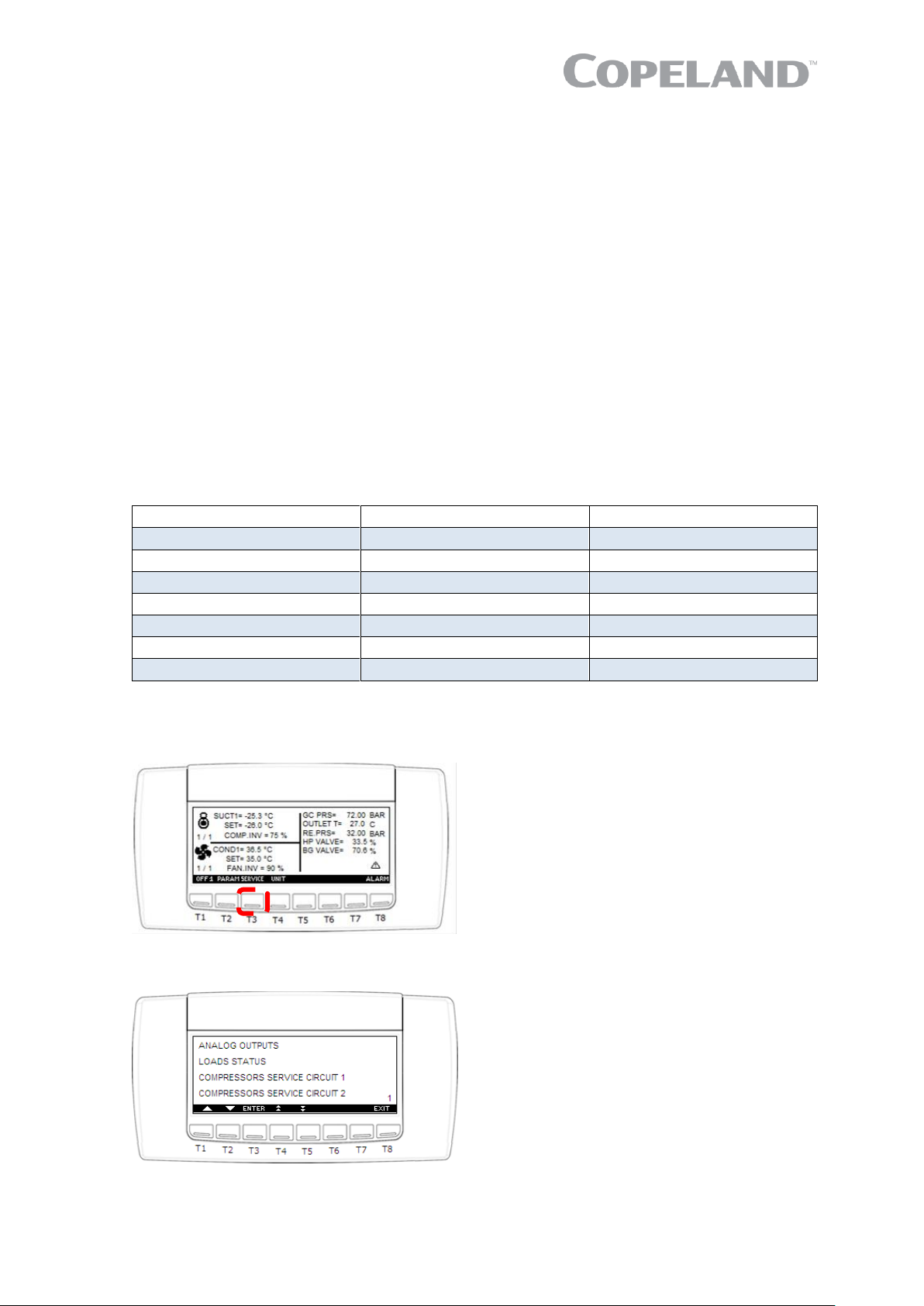

Figure 22: iPro "Service" menu

Page 23

18 C6.1.11/0718-0619/E

2.9.5 How to check the values of analog outputs

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Analog outputs" sub-menu

3) Press ENTER

Figure 23: iPro "Analog outputs" screen

Analog

output

Factory setting

Description

Wiring

diagram

Function

AOC1

2 - 0-10V output inverter 1 suction – Circuit 1

VF Drive M200

X1: 25 / 21

OUT1

AOC2

5 - 0-10V output inverter condenser – Circuit 1

Fan speed

X1: 25 / 22

OUT2

AOC3

0 - Not used

Reserved

X1: 25 / 23

OUT3

AOC4

0 - Not used

AOC5

0 - Not used

AOC6

0 - Not used

Table 11: Analog outputs overview

2.9.6 How to check the status of the relays / loads

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Loads status" sub-menu

3) Press ENTER. The "Loads status" sub-menu displays the status of the of the relays in the

following format:

Figure 24: iPro "Loads status" screen

Digital

output

Factory setting

Description

Wiring

diagram

Function

DOC1

C1 - Inverter 1

suction - Circuit 1

Compressor (VF drive) on – Signal "Run"

X1: 71 / 70

RL1

OA1

DOC2

0 - Not used

X1: 71 / 72

RL2

OA2

DOC3

0 - Not used

X1: 71 / 73

RL3

OA3

DOC4

46 - Alarm

ALR1 – Alarm / Level 1

X1: 80 / 76

RL4

OA4

DOC5

0 - Not used

ALR2 – Alarm / Level 2

X1: 80 / 77

RL5

OA5

DOC6

0 - Not used

ALR – General alarm / Active if ALR1 or ALR2

X1: 80 / 78

RL6

OA6

DOC7

0 - Not used

X1: 80 / 79

RL7

OA7

DOC8

0 - Not used

X1: 80 / 81

RL8

OA8

DOC9

C58 - Inverter

free - Circuit 1

For fan DI – Delay adjustable

X1: 86 / 84

RL9

OA9

DOC10

0 - Not used

X1: 86 / 85

RL10

OA10

DOC11

C49 - Auxiliary

output 1

Compressor heater

X1: 90 / 87

RL11

OA11

DOC12

0 - Not used

Reserved (heat recovery, solenoid control)

X1: 90 / 88

RL12

OA12

DOC13

0 - Not used

Reserved (heat recovery, solenoid control)

X1: 90 / 89

RL13

OA13

DOC14

0 - Not used

Reserved (heat recovery, solenoid control)

X1: 90 / 91

RL14

OA14

DOC15

0 - Not used

X1: 90 / 92

RL15

OA15

Table 12: Digital outputs

Page 24

C6.1.11/0718-0619/E 19

2.9.7 How to perform a maintenance using the "Compressors service" sub-menus

The "Compressors service" sub-menus allow to perform a maintenance session consisting of:

▪ disabling an output;

▪ checking and (possibly) erasing the running hour of a load.

NOTE: Disabling an output will exclude it from the regulation.

NOTE: The "Compressors service" sub-menu can be protected by a password.

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Compressors service circuit 1" or "Compressors

service circuit 2" sub-menu

3) Press ENTER

Figure 25: "Compressor 1 service" menu

To disable an output during a maintenance session:

1) Enter the "Compressor service circuit 1" sub-menu

2) Use the UP and DOWN keys to select the "Load status" sub-menu

3) Press the SET key

To enable or disable a load for regulation: Press one of the following keys as per Figure 25:

▪ ENB to enable the load for regulation

▪ DISB to disable the load for regulation

Regulation with some outputs disabled: If some of the outputs are disabled, they will be excluded

from the regulation, and regulation will be performed with the other outputs.

To display the running hours of a load: The controller memorises the running hours of each load.

To see how long a load has been working:

1) Enter the "Compressor service circuit 1" sub-menu

2) Use the UP and DOWN keys to select the "Load status" sub-menu and refer to Figure 25 for

screen layout.

To erase the running hours of a load: After a maintenance session, it is usually useful to erase

the running hours of a load. Follow the steps below:

1) Enter the "Compressor service circuit 1" sub-menu

2) Use the UP and DOWN keys to select the "Load status" sub-menu

3) Press the SET key

4) Press the RST key to erase the running hours

To exit: Press the EXIT key to get back to the "Service" menu.

Page 25

20 C6.1.11/0718-0619/E

2.9.8 How to check the values of digital inputs

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Digital inputs" sub-menu

3) Press ENTER

Figure 26: iPro "Digital inputs" screen

Digital

input

Factory setting

Description

Wiring

diagram

Function

DIC1

o63 - Inverter suction

1 safety

VF drive failure

NO >> Normally open, closed if failure

X1: 40

DI1

DIC2

0 - Not used

HP switch

NC >> Normally closed, open if high

pressure

X1: 41

DI2

DIC3

0 - Not used

Oil alarm

NC >> Normally closed, open if oil alarm

X1: 42

DI3

DIC4

0 - Not used

Motor winding temperature alarm (KRIWAN)

NC >> Normally closed, open if motor

temperature alarm

X1: 43

DI4

DIC5

0 - Not used

VF drive under power

NC >> Normally closed, open if drive is not

powered

X1: 44

DI5

DIC6

0 - Not used

Fan alarm

Closed after power on, open if fan alarm

X1:

DI6

DIC7

0 - Not used

Fan alarm 2nd input

Closed after power on, open if fan alarm

X1: 46

DI7

DIC8

0 - Not used

Operation mode

Potential free contact controlled by user

X1: 47

DI8

DIC9

0 - Not used

X1: 48

DI9

DIC10

0 - Not used

X1: 49

DI10

DIC11

0 - Not used

DI11

DIC12

o60 - Safety inverter

condenser - Circuit 1

DI12

DIC13

0 - Not used

DI13

DIC14

0 - Not used

DI14

DIC15

o57 - Oil frequency

compressor suction Circuit 1

DI15

DIC16

0 - Not used

DI16

DIC17

o58 - Safety

frequency compressor

suction - Circuit 1

DI17

DIC18

o59 - Thermal safety

of frequency

compressor

DI18

DIC19

o74 - External alarm 1

DI19

DIC20

C95 - Operating mode

2

DI20

Table 13: Digital inputs overview

Page 26

C6.1.11/0718-0619/E 21

2.9.9 How to check the values of the probes

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Probes" sub-menu

3) Press ENTER. The "Probes" sub-menu displays the probe values in the following format:

Figure 27: iPro "Probes" menu

NOTE: To change the measurement unit for probes PB1, PB2, PB3 and PB4, press the UNIT

key as per Figure 27.

Analog

input

Name in

wiring

diagram

Description

Signal

Wiring

diagram

Probe type

AIC1

B1

Suction pressure

4-20mA

X1: 16 / 2

PT5-150

AIC2

B2

Gas cooler pressure

4-20mA

X1: 16 / 3

PT5-150

AIC3

B3

Liquid receiver pressure

4-20mA

X1: 16 / 4

PT5-150

AIC4

B4

Unit suction line temperature

NTC

X1: 7 / 5

NT6-55

AIC5

B5

Compressor suction line

temperature

NTC

X1: 7 / 6

NT6-55

AIC6

B6

Discharge line temperature

PTC

X1: 7 / 10

S6H

AIC7

B7

Gas cooler outlet temperature

NTC

X1: 7 / 11

NT6-55

AIC8

B8

Oil temperature

NTC

X1: 7 / 12

NT6-55

AIC9

B9

Ambient temperature

NTC

X1: 7 / 13

NG6

AIC10

B10

Cabinet temperature

NTC

X1: 7 / 14

NG6

Table 14: Probes overview

NOTE: The temperature/resistance tables for NTC & PTC sensors are available in Appendices

2 & 3.

2.9.10 How to set the date and time

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Real-time clock" sub-menu

3) Press ENTER

4) Use the UP and DOWN keys to set the day

5) Press SET to confirm and move to the time setting

6) Follow the same procedure to set the date and time

7) Press SET to confirm

Figure 28: iPro "Real-time clock" display

Page 27

22 C6.1.11/0718-0619/E

2.9.11 How to check the operating values of the frequency inverter M200

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "M200 status" sub-menu

3) Press ENTER

2.9.12 Controller setting

IMPORTANT

Never adjust the suction pressure to a value that is outside of the envelope

approved by Emerson.

To change the suction pressure:

1) Press the PARAM key to access the programming menu

2) Use the UP and DOWN keys to select the Pr1 menu

3) Press Pr1 to enter this menu

4) Select setpoint (SETC1)

5) Use the UP and DOWN keys to adjust SETC1 to the desired suction pressure

NOTE: No change to the iPro HPV (gas cooler high-pressure valve) setting is required before

starting the unit.

2.9.13 Manual compressor run

IMPORTANT

Manual compressor runs are intended for maintenance purposes only!

Only qualified personnel and certified companies are allowed to perform a

manual compressor run as it can force the compressor to operate outside of

the approved envelope. In any case special care shall be taken when

performing one. In particular, never run the compressor for more than

2 minutes.

During a manual compressor run, all the safety features remain active: the controller run signal is

bypassed. Besides, during manual operation the HPV and BGV valves are closed, unless this was

manually overwritten.

To manually run the compressor, check first that the SB2 switch is switched to "I" then switch on the

SB1 switch. The compressor will immediately start at minimal speed.

Figure 29: Manual compressor operation

SB2

SB1

Page 28

C6.1.11/0718-0619/E 23

2.9.14 How to reset the controller to factory settings

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Conf file management" sub-menu

3) Press the SET key. The parameter map will be transferred from "Backup.conf" file to

"default_10D.conf" file.

Figure 30: Reset to factory settings

The controller will reboot, and the parameters will be reloaded from the "Param_model.conf" file.

2.9.15 How to save user’s settings

NOTE: Saving the user’s settings will overwrite the factory settings!

To update the back-up file with the current parameter map:

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Conf file management" sub-menu

3) Press the SET key

4) Use the UP and DOWN keys to select the "Send parameters to Backup.conf file" sub-menu

5) Press the SET key

To load the parameters from the "Backup.conf" file to the iPro rack:

1) Enter the "Load parameters from Backup.conf file" sub-menu

2) Press the SET key. The parameters will be loaded from the "Backup.conf" file.

The iPro rack will reboot and the parameters will be reloaded to the "Conf file management" file.

2.9.16 Data logging

The controller will continuously store all the alarms in an endless loop – maximum log file size 1MB.

There are 4 log files, of which only 3 can be exported:

▪ AccessLog

▪ AlarmLog

▪ ParamLog

▪ ParamAlarmLog

The ParamLog and ParamAlarmLog files contain the same variables, but:

▪ the ParamLog file has a fixed sampling rate (5 minutes);

▪ the ParamAlarmLog file stamps the info every time an alarm starts or stops.

Page 29

24 C6.1.11/0718-0619/E

No

Variable

Description

1

Suction pressure [bar]

SuctPrss_BAR

2

Condensing pressure [bar]

Cond/GCPrss_BAR

3

Liquid receiver pressure [bar]

LiqRecPrss_BAR

4

Suction temperature unit [°C]

Aux2Temp_C

5

Suction temperature compressor [°C]

SuctTemp_C

6

Discharge line temperature [°C]

DLT_C

7

Gas cooler outlet temperature [°C]

GCoutletTemp_C

8

Oil temperature [°C]

Aux3Temp_C

9

Ambient temperature [°C]

DynCondTemp_C

10

Cabinet temperature [°C]

ThermTemp_C

11

Inverter output voltage

Comp_PCT

12

Fan output voltage

Fan_PCT

13

HPV valve opening

HPV_PCT

14

BGV valve opening

BGV_PCT

15

Inverter M200 output power

M200power_kW

16

Inverter M200 output frequency

M200freq_Hz

Table 15: Data logging parameters (in addition to the date and hour)

2.9.17 Active alarm(s) log menu

NOTE: This function is not available from the Visograph screen.

The iPro rack can store up to 1 MB of alarm data in a log file, including the start and end dates of

each alarm. This file can be exported through the Dixell website integrated on a memory card or via

the USB port using the "Log file management" sub-menu.

To save the alarm log file into a USB key:

1) Enter the "Service" menu

2) Use the UP and DOWN keys to select the "Log file management" sub-menu

3) Press ENTER

4) The following interface will be displayed: "Send alarm log to usb" (see Figure 31)

Figure 31

5) Use the UP and DOWN keys to select the function

6) Press ENTER. If the USB key is not ready the following message will be displayed:

▪ "Warning! USB not ready".

7) To save the log file, follow the steps as described on the display. At the end of the process,

one of the following messages will be displayed:

▪ "Send completed successfully!" ➔ Saving was successful.

▪ "Send error!" ➔ Saving failed.

Page 30

C6.1.11/0718-0619/E 25

2.10 iPro IPR215D controller – Functionality

The iPro IPR215D controls the complete refrigeration unit. It provides a lot of customization features

like alarms and special operating modes. Thanks to the high degree of flexibility, the user can either

use the factory-set alarms or set up his own alarms according to the application requirements.

The following functionalities are pre-programmed:

▪ suction pressure control

▪ fan speed / gas cooler control

▪ alarms

The refrigeration unit is able to operate in both subcritical and transcritical modes. The setpoint for

switching from subcritical to transcritical operation is adjustable (GC1). The factory setting for this

trigger point is 27°C, measured over gas cooler outlet sensor B7 (AIC7). The (adjustable) hysteresis

(GC2) for the (GC1) setpoint is 1K.

Figure 32: Switching from transcritical to subcritical mode

NOTE: A system control very close to the critical point may result in a loss of capacity and

unstable system behaviour. This can be overcome by setting GC3 to a higher value (76-80 bar)

or by dynamic offset using parameters GC16 and GC17.

2.10.1 Suction pressure control

2.10.1.1 Standard suction pressure control

The setpoint for suction pressure control is parameter SETC1, the factory setting is -10°C.

SETC1 Compressor Circuit 1 setpoint

Range: -15°C to -5°C

Unit: [°C]

Depending on the number of evaporators, ie, on the suction side internal volume, a rapid decrease

of the suction pressure during compressor start might occur. This can result in low-pressure cut-out

before reaching stable regulation conditions. The acceleration of the compressor speed can be

adjusted by decreasing the value of SETC1.

2.10.1.2 Automatic pumpdown

If parameter SPF4 is set to "yes" a pumpdown will be performed before stopping the compressor. If

it is set to "no", only the manual pumpdown and the automatic pumpdown during the bypass

optimization function will be performed.

SPF1 Compressor setpoint during pumpdown

Range: -70°C to -10°C

Unit: [°C]

Page 31

26 C6.1.11/0718-0619/E

Parameter

Description

Level

Min value

Max value

Factory

setting

SPF1

Differential to be subtracted from

the compressor setpoint

Pr1

0K

20K

8K

SPF2

Compressor frequency during

pumpdown

Pr1

0%

(min speed

25 Hz)

100%

(max speed

60 Hz)

0%

SPF3

Pumpdown maximum time

Pr1

0 min

25 min

3 min

SPF4

Automatic pumpdown

Pr1

yes

SPF5

Pumpdown offset

Pr2

0°C

40°C

20°C

Table 16: Pumpdown parameters

2.10.2 Pumpdown mode

The pumpdown function of the CO2 refrigeration unit does not work in the same way as in units using

standard refrigerants. Based on the ambient temperature and the compressor setpoint, the controller

calculates two different pumpdown setpoints:

▪ setpoint based on ambient temperature = T

Amb

– SPF5

▪ setpoint based on compressor setpoint = SETC1 – SPF1

The lowest pumpdown setpoint will always be applied. The following diagram illustrates the controller

logic:

Figure 33: Controller logic for the pumpdown function

NOTE: The pumpdown setpoint will never be lower than what parameter RC02 allows.

2.10.3 Fan speed / gas cooler control

2.10.3.1 Subcritical operation

For gas cooler outlet temperatures typically below 27°C (AIC7 < GC1 - GC2), the system operates

in subcritical mode.

▪ The CO2 refrigerant condenses inside the gas cooler (condenser).

▪ The condenser outlet temperature is read by the probe AIC7, which defines the fan speed.

▪ The gas cooler valve HPV will keep a certain sub-cooling of the refrigerant (about 2-3K) in order

to create pressure differential between the gas cooler and the flash tank.

▪ The fan speed setpoint is +5°C with a proportional band of +5K, ie, down to 7.5°C, the fan will

always run at full speed, unless the ambient temperature goes down below 12°C. In this case

the fan speed will be reduced. At an ambient temperature of -15°C the maximal fan speed is

reduced down to 50%.

SETF1 Condenser Circuit 1 setpoint

Range: +5°C to +25°C

Unit: [°C]

-18°C < 0°C

Controller will perform

pumpdown down to -18°C

Ambient condition:

T

Amb

= 20°C

SPF5 = 20K

Compressor setpoint:

SETC1 = -10°C

SPF1 = 8K

Pumpdown setpoint based

on ambient temperature:

T

Amb

– SPF5 = 0°C

Pumpdown setpoint based on

compressor setpoint:

SETC1 – SPF1 = -18°C

Page 32

C6.1.11/0718-0619/E 27

Figure 34: Sensoring in subcritical mode

2.10.3.2 Transcritical operation

For temperatures typically above 27°C (AIC7 > GC1), the system operates in transcritical mode.

▪ According to the gas cooler outlet temperature detected by the AIC7 probe, the high-pressure

valve modulates to maintain a pressure that maximizes the COP (Coefficient of Performance).

▪ The fan speed setpoint is +5°C with a proportional band of +5K.

2.10.3.3 Transcritical operation with flashgas bypass

In transcritical operation mode in CO2 systems, the liquid receiver becomes a flashtank, in which the

liquid phase is separated from the gas phase. In high ambient conditions, the amount of gas will

increase due to the thermodynamic properties of CO2. Flashgas ratios of 50% or more are not

unusual. Typically, the flashgas is removed to the compressor suction side to keep the pressures in

the flashtank at acceptable levels.

Bypassing flashgas will reduce the mass flow coming from the cold rooms/cabinets. This necessary

process will however reduce the total system efficiency. The flashgas-bypass valve limits the

maximum pressure in the flashtank to 43 bar (adjustable with parameter GC20 according to

application and piping design).

▪ The fan speed setpoint is +5°C with a proportional band of +5K.

2.10.4 Alarms

In the event of an alarm, the alarm symbol will be flashing on the main display.

Figure 35: iPro Alarm flashing symbol

Page 33

28 C6.1.11/0718-0619/E

Press the ALARM key to enter the "Alarm" menu:

Figure 36: iPro "Alarm" key

The header of the corresponding menu will be flashing. Four alarm menus are available from the

display:

▪ Compressor alarms Circuit 1

▪ Fan alarms Circuit 1

▪ Alarms Circuit 1

▪ Generic alarms

An additional alarm menu is available from the iPro internal webpage.

1) Use the UP and DOWN keys to select the desired alarm section

2) Press ENTER to confirm and access the alarm sub-menu

Figure 37: Active alarms screen

The alarm menu will display the active alarm in the following format:

▪ Column 1: Alarm code

▪ Column 2: Alarm description

Several alarms are pre-programmed in the unit. The configuration can easily be adjusted to the user’s

needs. The factory settings only consider a general compressor alarm (Parameter AL09 "Relay for

temperature/pressure compressors alarms"), and a general fan alarm, both connected to "ALR".

Alarm

Factory setting

Description

Wiring

diagram

Function

ALR1

ALR1

X4: 80 / 76

ALR1

R4

ALR2

ALR2

X4: 80 / 77

ALR2

R5

ALR3

ALR

X4: 80 / 78

ALR

R6

ALR4

Reserved

X4: 80 / 79

ALR4

R7

ALR5

Reserved

X4: 80 / 81

ALR5

R8

PFC

Potential free contact (source 24VAC (69))

Operation mode

X4: 69 / 47

PFC

Potential free contact (source 24VAC (69))

Not used

X4: 69 / 48

PFC

Potential free contact (source 24VAC (69))

Not used

X4: 69 / 49

Table 17: Alarm overview

Compressor alarm: The activation of the relay for temperature/pressure compressor alarms can be

set in the "Compressor alarms" menu.

Parameter AL10 allows for an additional alarm for "Running hours for compressor maintenance"

(factory setting >> 0 = not used). To activate the maintenance alarm change AL10 from "nu - not

used" to ALR1 or ALR2.

Page 34

C6.1.11/0718-0619/E 29

Fan alarm: The activation of the relay for temperature/pressure fan alarms can be set in the "Fan

alarms" menu.

NOTE: The OME-4MTL-05X will not trigger any fan alarm because there is no alarm contact in

the fan in this model.

Alarm for faulty probe: Another alarm is connected to "ALR" in case a probe is faulty. Parameter

AL11 "Alarm relay for faulty probe" is set to ALR.

2.11 iPro IPR215D controller – Peripheral devices

The iPro unit controller interacts with several devices inside the electrical cabinet. These guidelines

only provide general information about and short descriptions of the peripheral devices. Dedicated

technical documentation (manuals, operating instructions) for those devices is available at

www.climate.emerson.com/en-gb.

2.11.1 XEV20D Stepper valve actuator

The XEV20D stepper valve actuator communicates with the unit controller via CAN Bus. It is intended

either for bipolar stepper valves or unipolar stepper valves. Both the gas cooler regulation valve and

the flashgas-bypass regulation valve are driven by the XEV20D.

Figure 38: XEV20D stepper valve actuator

2.11.2 Variable frequency drive M200

The Emerson variable frequency drive M200 has been designed for applications that require flexible

integration with systems via industrial Ethernet protocols and fieldbuses, together with advanced

RFC-A open-loop motor control. Connection to RS485 networks using Modbus RTU allows for

communication with the iPro unit controller.

The M200 frequency inverter uses the 0…10V input signal of the iPro controller to adjust the

compressor speed to the requirements. For more details see the M200 Inverter Handbook.

NOTE: The variable frequency drive should not be used to change the system settings. All

required changes and adjustments can be made directly on the system controller via the

Visograph display.

2.11.3 Main contactor and circuit breakers

The components of the electrical main load circuit are located in the left back area of the electrical

cabinet. Before commissioning some electrical components need power supply to enable heating up

the compressor oil sump and to manually open the gas cooler (HPV) and the flashtank valve (BPV)

on demand, eg, tightness test and evacuation procedure.

NOTE: For safety reasons never switch the F1 (compressor) or F3 (fans) circuit breaker on

without a minimum refrigerant charge inside the system.

NOTE: The unit main switch must always be switched on to provide power to the control chain

and dedicated electrical components.

Page 35

30 C6.1.11/0718-0619/E

Figure 39: Main contactor and circuit breakers

2.12 Compressor safety

2.12.1 Compressor motor protection

Copeland EazyCool CO2 units are equipped with a Stream 4MTL compressor including CoreSense

Protection technology.

All relevant electrical protection features are covered by the Emerson M200 variable frequency drive.

For more details see the M200 Inverter Handbook.

The discharge line temperature is monitored and controlled by the iPro controller.

The different areas of the system are limited by different design pressures (Ps) – see chapter 2.7.10

"Design pressures" for details. There are different levels of protection and control to keep the

pressures within the approved envelope at all times.

2.12.2 High-pressure safety (type-approved pressure limiter)

A type-approved pressure limiter (according to EN 12263) with automatic reset is installed on the

compressor. It is an Alco normally-closed switch.

The pressure cut-out is set to 114 bar and the cut-in is set to 107 bar.

Figure 40: High-pressure cut-out device

2.12.3 High-pressure safety control

There are 3 pressure transmitters assembled in the unit. These transmitters are used for system

control purposes as well as for safety. They are located on the suction side (B1 = AIC1), between

the gas cooler and the high-pressure regulation valve (B2 = AIC2), and on the liquid receiver outlet

(B3 = AIC3).

The factory setting of the high pressure is slightly below the activation setpoint of the high-pressure

safety switch.

The transmitter on the liquid receiver is also used to limit the liquid receiver pressure during operation

by means of the flashgas-bypass.

Page 36

C6.1.11/0718-0619/E 31

Figure 41: Pressure transmitters in the CO2 unit

2.12.4 Pressure relief valve – High-pressure side

A 120-bar pressure relief valve is installed in the gas cooler outlet. This valve protects the highpressure side including the gas cooler. In case of blocked HPV the high-pressure cut-out will switch

the compressor off before the pressure relief valve opens.

The pressure relief valve will reach 100% of blow-off capacity when the maximum allowable pressure

Ps of the compressor is exceeded by 10% (opening at 1.0 x Ps, max capacity at 1.1 x Ps).

Figure 42: Pressure relief valve on high-pressure side

2.12.5 Pressure relief valve – Liquid receiver

There are two pressure relief valves (90 bar) on the liquid receiver, connected on a changeover

valve. In case of refrigerant blow-off, this allows for easy replacement of the relief device without

interruption of unit operation by using the second valve.

Typically, after a blow-off event, the relief devices are not 100% tight anymore. Therefore component

exchange after activation is recommended. The thread connections on the changeover valve and

pressure relief valve are M24x1.5.

Page 37

32 C6.1.11/0718-0619/E

Figure 43: Liquid receiver with safety group

Figure 44: Pressure relief valves with changeover valve

2.12.6 Low-pressure safety control

As on discharge and liquid sides, a suction pressure transmitter (B1 = AIC1) provides information

about suction pressure to the system controller. This value is used to evaluate the load requirement

and to protect the unit / system against low pressure on suction side.

Figure 45: Low side pressure transmitter

Page 38

C6.1.11/0718-0619/E 33

2.13 Oil level monitoring device OW5 TraxOil

The compressor in the Copeland EazyCool CO2 refrigeration unit is equipped with an OW5 TraxOil

oil level monitoring system. This device is intended to prevent the compressor from operating with

insufficient oil. The OW5 uses a hall sensor to measure the oil level. Unaffected by foaming oil or

light, a magnetic float changes its position according to the oil level. The hall sensor converts the

magnetic field changes into an equivalent signal, which is used by the integrated electronic controller

to monitor and display the actual oil level with LEDs.

In case of low oil level and after a delay time of 120 seconds the OW5 will generate an alarm which

will make the unit controller stop the compressor immediately.

This alarm can be displayed on the Visograph like any other alarm of the unit.

Figure 46 below depicts the sight glass level control zones. Table 18 describes the LED code legend.

Figure 47 shows the OW5 TraxOil mounted on the compressor.

Figure 46: Sight glass level control zones

LED’s

Status

Function

Alarm

•

Oil level in green zone (60 - 40%)

OK

• •

Oil level in green zone (60 - 40%)

OK

•

Oil level in yellow zone (40 - 25%)

Warning

•

Oil level in red zone (25 - 0%)

Alarm

Yes, delay

20 to 120 sec

Table 18: LED code legend

Figure 47: OW5 TraxOil mounted on the compressor

Page 39

34 C6.1.11/0718-0619/E

3 Installation

WARNING

High pressure! Injury to skin and eyes possible! Be careful when opening

connections on a pressurized item. Never install the unit at such a height that

if the pressure relief valve opens, the gas flow can reach an individual’s head.

IMPORTANT

Always install the unit in such a way that all installation, commissioning and

servicing works can be carried out safely and easily.

Copeland EazyCool CO2 refrigeration units are delivered with a holding charge of neutral gas.

The refrigeration unit should be located in such a place to prevent any dirt, dust, plastic bag, leaves

or papers from covering the condenser / gas cooler and its fins.

A clogged condenser / gas cooler will increase the refrigeration temperature and/or the gas cooler

outlet temperature which could lead to a high-pressure switch tripping. Clean the condenser fins on

a regular basis.

The unit must be installed without restricting the airflow. Harmful environmental conditions like very

low or high temperatures should also be avoided.

The place of installation has to be level and horizontal. The unit must be secured to the ground to

avoid any movement of the base frame. The ground needs to be designed for the weight of the unit.

It might be necessary to install additional vibration absorbers between the unit and the ground to

avoid the transmission of vibration to the rest of the building.

The place of installation should be sufficiently lit and should allow easy access for service and

maintenance work.

In case of installation in a machine room, standard EN 378-3 and all additional national regulations

shall be observed.

A risk assessment of the place of installation has to be conducted before actual system installation.

It should be documented for local authorities and should contain safety-related measures to avoid

risks. The risk assessment of the unit itself has been performed by the manufacturer.

3.1 CO2 Refrigeration unit handling

3.1.1 Transport and storage

WARNING

Risk of collapse! Personal injuries! Move units only with appropriate

mechanical or handling equipment according to weight. Keep in the upright

position. Respect stacking loads according to Figure 48. Do not stack

anything on top of the unit packaging. Keep the packaging dry at all times.

Respect the maximum number of identical packages which may be stacked on one

another, where "n" is the limiting number:

▪ Transport: n = 0

▪ Storage: n = 0

Figure 48: Maximum stacking loads for transport and storage

3.1.2 Weights

Unit

Net weight [kg]

OME-4MTL-05X

440

OME-4MTL-07X

450

OME-4MTL-09X

462

Table 19: Weights

Page 40

C6.1.11/0718-0619/E 35

3.1.3 Lifting

Always lift the unit by points marked with red arrows on pictures below.

Figure 49: Lifting points for CO2 units

When lifting the unit with slings, always use the spreader bar mounted above the unit to avoid

squeezing the unit.

Figure 50: Lifting unit with slings and centre of gravity

Page 41

36 C6.1.11/0718-0619/E

3.2 Refrigeration piping connections

3.2.1 Refrigeration piping installation and connections

WARNING

High pressure! Risk of personal injury! The units are pressurized with dry

air. Be careful when opening connections on a pressurized item.