Emerson Copeland 71, Copeland 611, Copeland 121, Copeland 271, Copeland 65 Technical Information

...

Technical Information

Date of last update: Jul-05

Ref: CC7.5.1/0705/E

Application Engineering Europe

F

F

AANNSS FFOORR

C

C

OONNDDEENNSSIINNGG

U

U

NNIITTS

S

1 Introduction

Condensing units manufactured by Copeland are equipped with fan(s).

Various fan models are and were used.

That is to say that today, it is possible to meet various fan(s) on the after-sales market.

2 General information

Condensing units can be equipped with 1, 2 or 4 fans.

The complete fan consists of an external rotor motor with the fan blades permanently fixed to the rotor and the fan

guard. The grid has 4 feet to mount it on the condenser.

Fan motors are protected by a thermostatic switch. A single-pole bimetallic-element switch protects the motor

against damage from:

Motor overload

Over-voltage and under-voltage

Electrical and mechanical blockages

Inadequate cooling.

The fans protection is IP 54 and its insulation class is "F".

Most fans can be equipped with a speed controller connected to the condensing pressure.

3 Fans for Copeland Scroll and DWM Copeland semi-hermetic condensing units

The fan is positioned in order to blow the air from the condenser to the compressor, so the compressor additional

fan is not necessary any more.

NOTE: After connecting the condensing unit electrically, check the rotational direction. The fan must blow from

the condenser to the compressor.

NOTE: All fans presently used on condensing units are single-phase fans.

3.1 Single-phase fans

Single-phase fans are used since January 2003.

3.1.1 Technical data

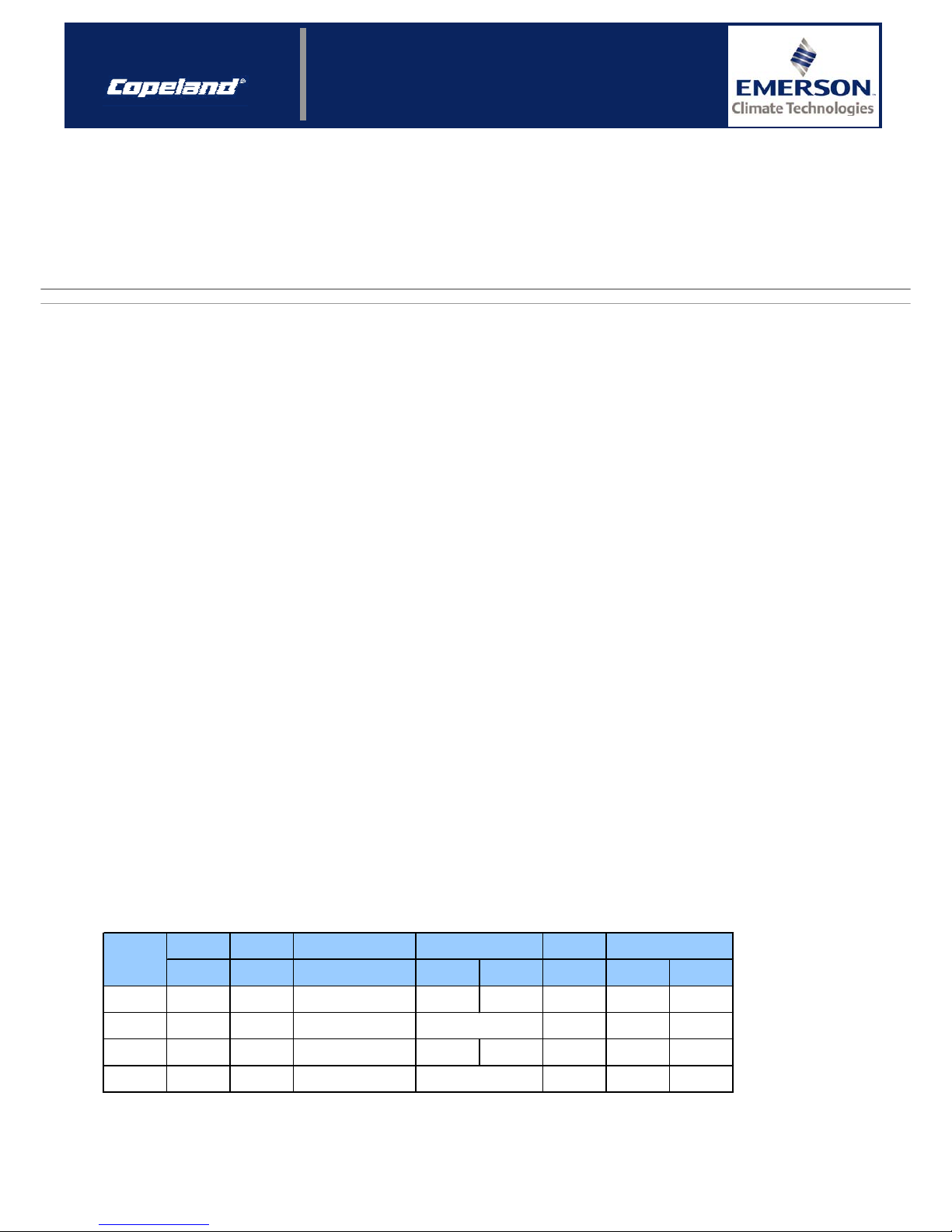

As described in table 1, various fan models are used.

Blade

diamete

r

Power input Voltage

Motor

current

mm W V (±10%) / Ph / Hz EBM Rotomatika A Main Auxilary

71 300 95 220 - 240 / 1 / 50 3 / 400 2.5 / 400 0.44 115 129

121 350 117 220 - 240 / 1 / 50 0.54 72 108

271 420 300 220 - 240 / 1 / 50 5 / 400 6.3 / 400 1.35 25 88

611 500 570 220 - 240 / 1 / 50 2.4 8.5 20.5

10 / 400

Winding resistance

Ω

(±10%), 25°C

Run capacitor

µF / V

4 / 400

Fan model

Table 1: Technical data – single-phase fans

1/4

CC7.5.1/0705/E

Technical Information

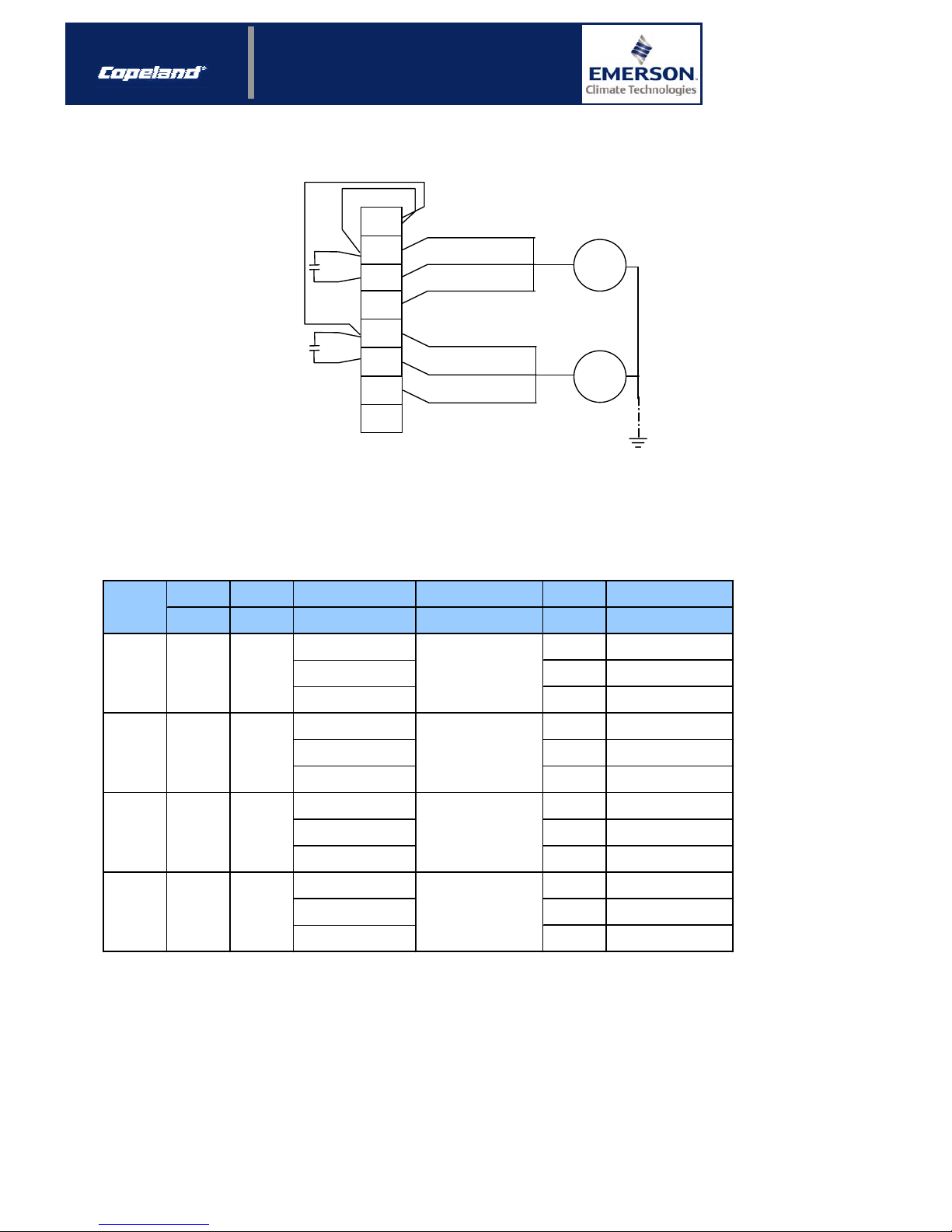

3.1.2 Single-phase fan wiring diagram

Z1 Black

U2 Blue

U1 Brown

M

1 ~

Z1 Black

U2 Blue

U1 Brown

M

1 ~

14

N

16

X1

15

13

L

9

10

11

L

C1

C1

12

Figure 1: Single-phase wiring diagram (230V ±15% / 1 ~ / 50-60 Hz)

3.2 Three-phase fans

Before January 2003, three-phase fans were used.

3.2.1 Technical data

Blade

diamete

r

Power input Voltage

Motor

current

mm W V (±10%) / Ph / Hz A

220 - 240 / 1 / 50 0.36

220-240 ∆ / 380-420 Y /

3 / 50

0.33 / 0.19

500 - 550 / 3 / 50 0.15

220 - 240 / 1 / 50 0.63

220-240 ∆ / 380-420 Y /

3 / 50

0.55 / 0.32

500 - 550 / 3 / 50 0.25

220 - 240 / 1 / 50 1.3

220-240 ∆ / 380-420 Y /

3 / 50

1.10 / 0.65

500 - 550 / 3 / 50 0.52

220 - 240 / 1 / 50 3.6

220-240 ∆ / 380-420 Y /

3 / 50

2.95 / 1.70

500 - 550 / 3 / 50 1.1

9.3

Winding resistance

5 / 400

8 / 400

16 / 400

25 / 400

20 / 60

51

6.2

6.2 / 18.6

54.7

57 ± 3 / 172 ± 10

325 ± 24

20

Ω (±10%), 25°C

102

104 ± 3 / 218 ± 6

574 ± 37

270 420 280

610 500 630

Fan model

75 300 80

Run capacitor

µF / V

120 350 135

Table 2: Technical data – three-phase fans

“Old” units were delivered with three-phase fans as a standard, but it is possible to convert these fans into singlephase motor by the mean of a capacitor. The characteristics of this run capacitor are given in table 2.

“New” single-phase kits can be used for retrofitting on units equipped with three-phase fans.

fan 75 is replaced by 71

fan 120 is replaced by 121

fan 210 is replaced by 211

fan 610 is replaced by 611

2/4

Loading...

Loading...