Page 1

Instruction Manual

s

Document: CI-CW-GFC-ISTRAN

Part: D301647X012

November, 2009

ControlWave GFC IStran

ControlWave GFC IStran

Intrinsically Safe Communication Interface

Remote Automa ti on Solution

www.EmersonProcess.com/Remote

Page 2

Be sure that these instructions are carefully read and understood before any operation is

attempted. Improper use of this device in some applications may result in damage or injury. The

user is urged to keep this book filed in a convenient location for future reference.

These instructions may not cover all details or variations in equipment or cover every possible

situation to be met in connection with installation, operation or maintenance. Should problems arise

that are not covered sufficiently in the text, the purchaser is advised to contact Emerson Process

Management, Remote Automation Solutions division (RAS) for further information.

IMPORTANT! READ INSTRUCTIONS BEFORE STARTING!

EQUIPMENT APPLICATION WARNING

The customer should note that a failure of this instrument or system, for whatever reason, may

leave an operating process without protection. Depending upon the application, this could result in

possible damage to property or injury to persons. It is suggested that the purchaser review the

need for additional backup equipment or provide alternate means of protection such as alarm

devices, output limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches,

etc. If additional information is required, the purchaser is advised to contact RAS.

RETURNED EQUIPMENT WARNING

When returning any equipment to RAS for repairs or evaluation, please note the following: The

party sending such materials is responsible to ensure that the materials returned to RAS are clean

to safe levels, as such levels are defined and/or determined by applicable federal, state and/or

local law regulations or codes. Such party agrees to indemnify RAS and save RAS harmless from

any liability or damage which RAS may incur or suffer due to such party's failure to so act.

ELECTRICAL GROUNDING

Metal enclosures and exposed metal parts of electrical instruments must be gr ounded in

accordance with OSHA rules and regulations pertaining to "Design Safety Standards for Electrical

Systems," 29 CFR, Part 1910, Subpart S, dated: April 16, 1981 (OSHA rulings are in agreement

with the National Electrical Code).

The grounding requirement is also applicable to mechanical or pneumatic instruments that

include electrically operated devices such as lights, switches, relays, alarms, or chart drives.

EQUIPMENT DAMAGE FROM ELECTROSTATIC DISCHARGE VOLTAGE

This product contains sensitive electronic components that can be damaged by exposure to an

electrostatic discharge (ESD) voltage. Depending on the magnitude and duration of the ESD, this

can result in erratic operation or complete failure of the equipment. Read supplemental document

S14006 for proper care and handling of ESD-sensitive components.

Remote Automation Solutions

A Division of Emerson Process Management

1100 Buckingham Street, Watertown, CT 06795

Telephone (860) 945-2200

Page 3

Emerson Process Management

Training

GET THE MOST FROM YOUR EMERSON

INSTRUMENT OR SYSTEM

Avoid Delays and problems in getting your system on-line

Minimize installation, start-up and maintenance costs.

Make the most effective use of our hardware and software.

Know your system.

As you know, a well-trained staff is essential to your operation. Emerson offers a full

schedule of classes conducted by full-time, professional instructors. Classes are offered

throughout the year at various locations. By participating in our training, your personnel

can learn how to install, calibrate, configure, program and maintain your Emerson products

and realize the full potential of your system.

For information or to enroll in any class, go to http://www.EmersonProcess.com/Remote

click on “Training” or contact our training department in Watertown at (860) 945-2200.

and

Page 4

BLANK PAGE

Page 5

ControlWave GFC-IStran Instruction Manual

Contents

Chapter 1 – Introduction 1-1

1.1 Physical Description..................................................................................................................1-2

1.1.1 IStran PCB ....................................................................................................................1-3

Chapter 2 – Function and Electrical Characteristics 2-1

2.1 Hazardous and Non-Hazardous Characteristics.......................................................................2-1

2.1.1 Hazardous Interface......................................................................................................2-1

2.1.2 Non-Hazardous Interface..............................................................................................2-3

2.2 Switched & Unswitched Modes.................................................................................................2-5

2.2.1 Configuring the Hazardous Interface for Switched Mode.............................................2-6

2.2.2 Configuring the Hazardous Interface for Unswitched Mode.........................................2-6

2.2.3 Configuring the Non-Hazardous Interface for Switched Mode .....................................2-6

2.2.4 Configuring the Non-Hazardous Interface for Unswitched Mode.................................2-6

2.3 Non-Hazardous Power Output..................................................................................................2-6

Chapter 3 – System Wiring 3-1

3.1 Introduction to System Wiring...................................................................................................3-1

3.2 Grounding..................................................................................................................................3-1

3.3 Cable Length.............................................................................................................................3-2

3.4 Field Wiring Diagrams...............................................................................................................3-2

Chapter 4 – Installation 4-1

4.1 Installation Overview.................................................................................................................4-1

4.2 Installation Notes.......................................................................................................................4-1

Chapter 5 – Specifications 5-1

5.1 Environment..............................................................................................................................5-1

5.2 Operating Specifications...........................................................................................................5-1

Index I-1

Issued Nov-09 Contents v

Page 6

ControlWave GFC-IStran Instruction Manual

vi Contents Issued Nov-09

Page 7

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Chapter 1 – Introduction

The ControlWave GFC Intrinsically Safe IStran Communication

Interface (IStran) allows an intrinsically safe ControlWave Gas Flow

Computer / Corrector (CW-GFC-IS) to communicate with a device

located in a Division 2 or non-hazardous area.

Underwriter’s Laboratories (UL) approves the IStran interface with a

CW-GFC-IS unit when you use it with approved intrinsically safe

battery power/solar panel power, or when the CW-GFC-IS receives

external power through the IStran.

The IStran performs the following functions:

Replaces six intrinsic safety barriers for RS-232 signals (3 in, 3 out)

Provides 500V isolation between two devices

Operates at speeds up to 19,200bps

Allows the CW-GFC-IS to receive power from outside the Division

1 area

Allows the CW-GFC-IS to control power to a radio or modem

located outside the Division 1 area

You can also use the IStran for certain applications where intrinsic

safety is unnecessary, such as to provide isolation between two devices

or to allow multiple devices to share a single radio or modem.

Figure 1-1. IStran Front View

Issued Nov-09 Introduction 1-1

Page 8

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

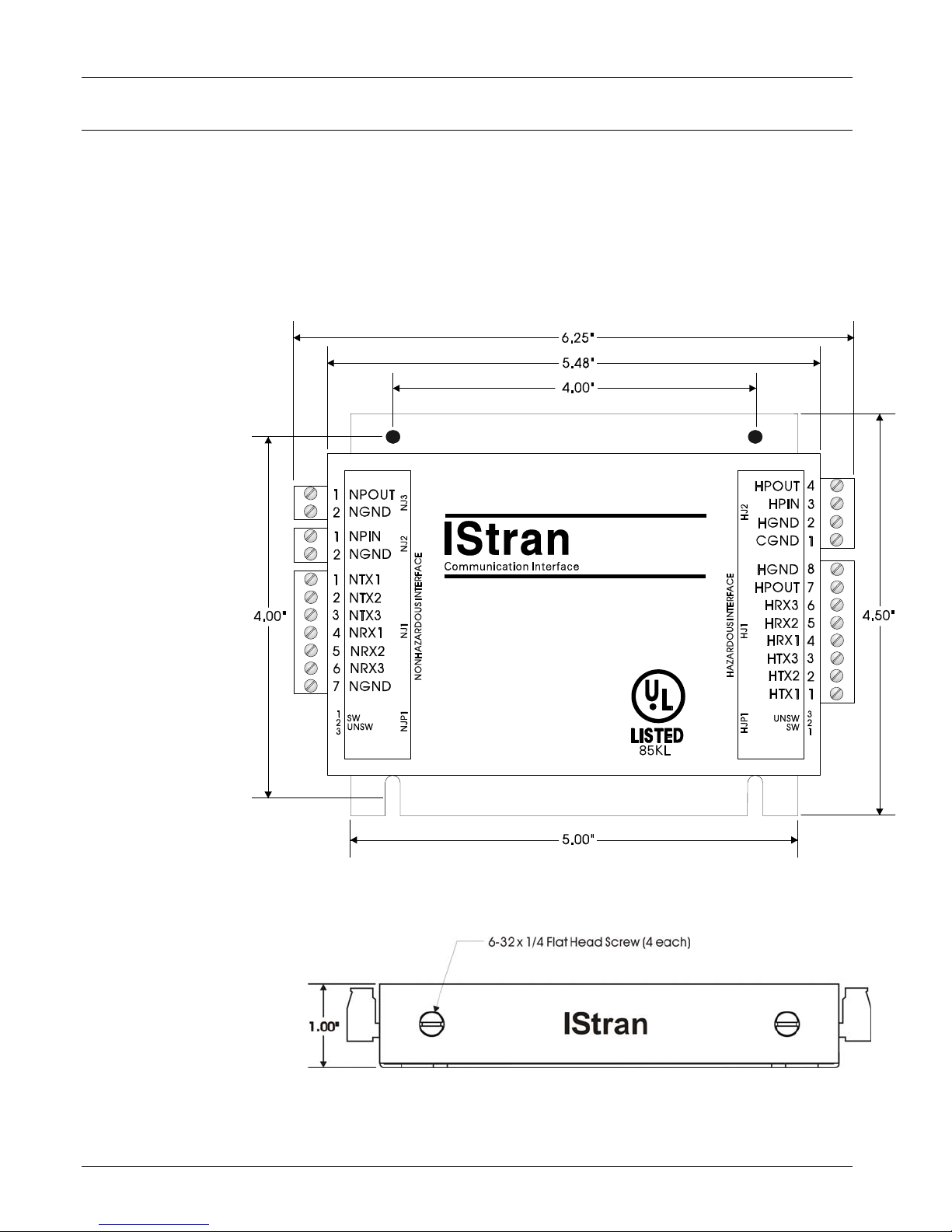

1.1 Physical Description

The IStran assembly measures 6.25 inches (length) by 4.50 inches

(width) by approximately 1 inch (depth). (See Figure 1-2, 1-3, and 1-4.)

The IStran assembly consists of the following major components:

One IStran printed circuit board (PCB) for the IStran assembly

Yellow alodined aluminum base plate (0.060 inch thick)

Black anodized cover (0.090 inch thick)

1-2 Introduction Issued Nov-09

Figure 1-2. Physical Dimensions – IStran – Front View

Figure 1-3. Physical Dimensions – IStran – Edge (Side) View

Page 9

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Figure 1-4. IStran PCB Mounted on Base Plate (Cover removed)

1.1.1 IStran PCB

Switched Mode

Unswitched Mode

The IStran PCB provides two interfaces designated hazardous and nonhazardous. You configure each interface independently to operate in

either switched or unswitched mode.

Switched mode sets the TX drivers into a high-impedance state to

reduce power consumption.

In unswitched mode, the TX drivers are always active and they always

follow the corresponding RX inputs. In cases where power consumption

is not a key factor, configure the IStran for unswitched mode.

Issued Nov-09 Introduction 1-3

Page 10

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

1-4 Introduction Issued Nov-09

Page 11

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Chapter 2 – Function and Electrical Characteristics

You can use the ControlWave GFC Intrinsically Safe IStran

Communication Interface (IStran) in both hazardous and nonhazardous environments.

2.1 Hazardous and Non-Hazardous Characteristics

Table 2-1 provides the characteristics common to both the hazardous

and non-hazardous IStran interfaces:

Table 2-1. Common Characteristics for Hazardous and Non-Hazardous Interfaces

Description Specification

Data Rate Maximum: 19.2 Kbps

Propagation Delay, any RX to

any TX

Output Enable Delay

(Switched Mode, enable to

TX valid)

RX Input High Level Minimum: 4.5 VDC

RX Input Low Level Minimum: -16 VDC

RX Input Load Resistance Typical: 3.01 Kohm

TX Output Load Resistance Minimum: 3 Kohm

Maximum: 10 uS

Typical: < 10 uS

Maximum: 50 uS

Maximum: 16 VDC

Maximum: 0.5 VDC

Quiescent Supply Current

(Both if in switched mode, all

TX off)

Idle Supply Current (Both if in

unswitched mode, all TX low)

Active Supply Current (Both if

active, worst case)

2.1.1 Hazardous Interface

You connect the hazardous interface to an intrinsically safe device.

Table 2-2, identifies each connector position, the corresponding signal

name, and briefly describes each input/output point on the hazardous

interface.

Table 2-2. Hazardous Interface Connector

Position Name Function

HJ2-4 HPOUT Hazardous Power Output - connect to HJ1-3

HJ2-3 HPIN Hazardous Power Input

HJ2-2 HGND Hazardous Interface Ground - connect to HJ2-

HJ2-1 CGND Enclosure Ground (Tied to NGND)

HJ1-8 HGND Hazardous Interface Ground - (Reference for

Maximum: 800 uA

Typical: 21 mA

Maximum: 43 mA

(HPIN) for single supply applications

1 (CGND) for single supply applications

Issued Nov-09 Function and Electrical Characteristics 2-1

Page 12

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Position Name Function

HPOUT and signals)

HJ1-7 HPOUT Hazardous Power

HJ1-6 HRX3 Signal Input

HJ1-5 HRX2 Signal Input

HJ1-4 HRX1 Signal Input

HJ1-3 HTX3 Signal Output (Follows NRX3)

HJ1-2 HTX2 Signal Output (Follows NRX2)

HJ1-1 HTX1 Signal Output (Follows NRX1)

HJP1-1 SW Jumper to COM for Switched Mode

HJP1-2 COM Mode Selection Common

HJP1-3 UNSW Jumper to COM for Unswitched Mode

Table 2-3 provides the characteristics of the hazardous interface.

Table 2-3. Hazardous Interface Characteristics

Description Specification

HPOUT Voltage Typical 6.3 VDC (No Load)

Minimum: 5.9 VDC (Max. Load)

Maximum: 6.4 VDC (No Load)

HPOUT Current Limit

Threshold

HPOUT Load Capacitance Maximum: 100 uF

HPIN Quiescent Supply

Current

(Switched Mode,

Transmitters Off)

HPIN Supply Current

(All TX Outputs High, 3 KW

Load

HTX Output High Level Minimum: 4.5 VDC, Maximum: 5.0

HTX Output Low Level Minimum: 0 VDC, Maximum: 0.1

HJP1 Jumper Operation If you don’t install a jumper, or if you install the

Minimum: 130 mA at 8 VDC

Maximum: 300 mA at 16 VDC

Maximum: 100 uA

Maximum: 6 mA

VDC

VDC

jumper between pins 1 and 2 (SW), the

hazardous interface operates in switched

mode. If you install the jumper between pins 2

and 3 (UNSW), the hazardous interface

operates in unswitched mode. Figure 2-1

shows the jumper in switched mode.

2-2 Function and Electrical Characteristics Issued Nov-09

Page 13

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Figure 2-1. Setting Jumper HJP1

2.1.2 Non-Hazardous Interface

Typically you connect the non-hazardous interface to a radio or modem

located with the IStran assembly in a non-hazardous or Division 2 rated

area. Table 2-4 identifies each connector position and the corresponding

signal name, and provides a brief description of each I/O point on the

non-hazardous interface.

Table 2-4. Non-Hazardous Interface Connector

Position Name Function

NJ3-1 NPOUT Switched Power Output

NJ3-2 NGND Local Ground reference

(Return for NPOUT)

NJ2-1 NPIN Power Supply Input

NJ2-2 NGND Local Ground

(Return for NPIN)

NJ1-1 NTX1 Signal Output (Follows HRX1)

NJ1-2 NTX2 Signal Output (Follows HRX2)

NJ1-3 NTX3 Signal Output (Follows HRX3)

NJ1-4 NRX1 Signal Input

NJ1-5 NRX2 Signal Input

NJ1-6 NRX3 Signal Input

NJ1-7 NGND Local Ground

NJP1-1 SW Jumper to COM for Switched Mode

NJP1-2 COM Mode Selection Common

NJP1-3 UNSW Jumper to COM for Unswitched Mode

Issued Nov-09 Function and Electrical Characteristics 2-3

Page 14

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Table 2-5 provides the characteristics of the non-hazardous interface.

Table 2-5. Non-Hazardous Interface Characteristics

Description Specification

NPIN Voltage (When

HPOUT is not used)

NPIN Voltage (When

HPOUT is used)

NPIN Supply Current

(Switched Mode,

Transmitters Off)

NPIN Supply Current (All

TX Outputs High, 3

KWLoads)

NPOUT Leakage Typical: < 1 uA Maximum: 100 uA

Minimum: 5.4 VDC

Maximum: 16 VDC

Minimum: 8 VDC

Maximum: 16 VDC

Typical: < 500 uA at 12 VDC, 77 F (25

C)

Maximum: 750 uA

Maximum: 37 mA

NPIN to NPOUT On-

Resistance (NPIN ³ 12 V)

NRX3 to NPOUT On Typical: < 10 uS

NPOUT Load Current Maximum: 1.8 A Continuous

NTX Output High Level Typical: 7.4 VDC into 3 Kohm Load

NTX Output Low Level Typical: -4.9 VDC into 3 Kohm Load

NJP1 Jumper Operation If you didn’t install a jumper, or if you installed

Typical: < 0.3 ohm

Maximum: 0.5 ohm

Maximum: 3.0 A Intermittent (Max 60

Seconds, 50% duty)

Minimum: 5.0 VDC

Maximum: 9.5 VDC

Minimum: -9.5 VDC

Maximum: -3.0 VDC

a jumper between pins 1 and 2 (SW), the nonhazardous interface operates in switched

mode. If you install a jumper between pins 2

and 3 (UNSW), the non-hazardous interface

operates in unswitched mode. (Figure 2-2

shows the jumper in switched mode.)

2-4 Function and Electrical Characteristics Issued Nov-09

Page 15

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Figure 2-2. Setting Jumper NJP1

2.2 Switched & Unswitched Modes

You can configure each IStran interface independently to operate in

switched or unswitched mode. In switched mode, the TX drivers can

enter a high-impedance state to reduce power consumption. The outputs

transition smoothly to and from the high-impedance state. Most modern

device inputs pull the high impedance IStran output to ground and

interpret it as a low, or mark state. Some devices may not properly

interpret the high-impedance signal, and in some systems it is

impractical for you to operate either or both interfaces in switched

mode. In these cases, or when power consumption is not a concern,

configure the interface(s) for unswitched mode. In unswitched mode,

the TX drivers are always active and they always follow the

corresponding RX inputs.

You enable or disable switched mode for the hazardous interface by

jumper position HJP1, and for the non-hazardous interface by jumper

position NJP1 (see Figures 2-1 and 2-2). When either interface is in

switched mode, the RX3 (NRX3 or HRX3) input of the opposite

interface turns it on or off.

Issued Nov-09 Function and Electrical Characteristics 2-5

Page 16

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

2.2.1 Configuring the Hazardous Interface for Switched Mode

To configure the hazardous interface for switched mode, place the

supplied shorting jumper in the HJP1 position marked SW (short HJP1

pins 1 and 2 as shown in Figure 2-1). If you don’t install a jumper at

HJP1 the hazardous interface defaults to switched mode. When you

configure the hazardous interface for switched mode, the HTX outputs

are in a high-impedance state when NRX3 is low (or negative), and the

HTX outputs follow the NRX inputs normally when NRX3 is high

(positive).

2.2.2 Configuring the Hazardous Interface for Unswitched

Mode

To configure the hazardous interface for unswitched mode, place the

supplied shorting jumper in the HJP1 position marked UNSW (short

HJP1 pins 2 and 3). This is the opposite jumper position of that shown

in Figure 2-1. In unswitched mode, the HTX outputs remain on and

they always follow the corresponding NRX inputs.

2.2.3 Configuring the Non-Hazardous Interface for Switched

Mode

To configure the non-hazardous interface for switched mode, place the

supplied shorting jumper in the NJP1 position marked SW (short NJP1

pins 1 and 2 as shown in Figure 2-2). The non-hazardous interface is

also in switched mode by default if you don’t install a jumper at NJP1.

When you configure the non-hazardous interface for switched mode, the

NTX outputs are in a high-impedance state when HRX3 is low (or

negative), and the NTX outputs follow the HRX inputs normally when

HRX3 is high (positive).

2.2.4 Configuring the Non-Hazardous Interface for Unswitched

Mode

To configure the non-hazardous interface for unswitched mode, place

the supplied shorting jumper in the position marked UNSW (short NJP1

pins 2 and 3). This is the opposite jumper position of that shown in

Figure 2-2. In unswitched mode, the NTX outputs are always turned on

and they always follow the corresponding HRX inputs.

2.3 Non-Hazardous Power Output

The non-hazardous power supply is routed through a FET (field effect

transistor) from the power input to an output terminal. The power

supply comes in on the NPIN terminal and switched power goes out on

the NPOUT terminal.

2-6 Function and Electrical Characteristics Issued Nov-09

Page 17

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

When hazardous interface signal input HRX3 is at a high (positive)

level, NPOUT turns on and can supply power to an external device.

When HRX3 is at a low (or negative) level, NPOUT turns off. You

determine the voltage drop between NPIN and NPOUT by multiplying

the NPOUT load current by the NPIN to NPOUT on-resistance. You

must also take into account the resistance of the associated field wiring

when you calculate the total drop between the power supply and the

load.

In order to minimize resistance between NPIN and NPOUT, the IStran

Caution

does not

over-current protection at the power source to prevent damage to the

IStran, power source, or load in case of a short circuit or other overcurrent condition.

provide over-current. You must install a fuse or other means of

Issued Nov-09 Function and Electrical Characteristics 2-7

Page 18

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

2-8 Function and Electrical Characteristics Issued Nov-09

Page 19

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Chapter 3 – System Wiring

This chapter includes details on grounding and wiring for the IStran.

3.1 Introduction to System Wiring

The IStran connects a radio, modem, or other communications device to

a ControlWave GFC-IS Flow Computer/Corrector. An IStran can also

provide an intrinsically safe interface between an external power supply

and RS-232 signals associated with a radio, modem or ControlWave

RTU (in a non-hazardous area) and a ControlWave GFC-IS in a Class I,

Division 1 area.

3.2 Grounding

The IStran provides up to 500V of isolation between the hazardous and

non-hazardous interfaces. When using the ground isolation capability of

the IStran, devices on either side require separate power sources, and

each source must power the corresponding IStran interface. Refer to the

field wiring diagrams in Section 3.4 for systems with independent power

sources.

When isolation is not required, a single power source supplies both

IStran interfaces and, optionally, both connected devices. To power both

IStran interfaces using a single power source, connect the power source

between NPIN and NGND. Use connector HJ2 (see Figure 1-4) as a

jumper position to wire HPOUT to HPIN and HGND to CGND. Note

that CGND and NGND are internally connected, and that CGND is

connected to the IStran case. Refer to the field wiring diagrams in

Section 3.4 for systems with a single power source.

When a ground connection already exists between the power source and

the ControlWave or communications device, do not wire the ground

terminal on the IStran communications connector (NJ1 or HJ1). The

ground reference established on the IStran power connector (NJ2 or

HJ2) serves as both power supply return and signal ground reference.

Wiring the communications connector ground terminal may introduce a

ground loop and degrade the performance of the IStran under these

circumstances. The wiring diagrams in Section 3.4 illustrate the

recommended practices.

For intrinsic safety applications, you must use redundant earth grounds.

Both grounds must measure less than one ohm to earth. The NGND

terminal provides one ground, and the case provides the other. If the

mounting panel does not provide a suitable ground path, connect a

12AWG or larger ground conductor to one of the IStran mounting

screws.

Issued Nov-09 System Wiring 3-1

Page 20

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

3.3 Cable Length

Underwriter’s Laboratories (UL) lists the IStran for use with cable

lengths up to 25 feet on either or both interfaces. Typically, you install

the IStran in close proximity to the communications device (connected

to the non-hazardous interface) and at some distance from the CWGFC-IS (connected to the hazardous interface). Because of cable

capacitance and inductance, 25 feet is the maximum cable length

allowable for use with a CW-GFC-IS located in a Division 1 area.

The cable length between a CW-GFC-IS operating in a Division 1 area

Warning

and the IStran must not exceed 25 feet.

3.4 Field Wiring Diagrams

Figure 3-1 illustrates a typical communication system. The power

source to the non-hazardous interface must not use or generate more

than 250V. If you install the IStran in a Division 2 area, you must make

power input and output connections using Division 2 wiring methods

described in Section 4.1.

In this example a single power source supplies both the communications

device and the CW-GFC-IS. The power supply input range for this

configuration is 8 to 16V. You connect the grounds of both devices

together through the IStran. The CW-GFC-IS power supply current

must be 120mA or less, and it must operate down to 5.9V. The IS

termination panel (part number 400135-01-9) contains the power and

communication connections.

Figure 3-1. Modem System with Single Power Source

3-2 System Wiring Issued Nov-09

Page 21

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Figure 3-2 is similar to Figure 3-1 except it uses an MDS radio instead

of a modem.

Figure 3-2. Radio System with Single Power Source

Figures 3-3 and 3-4 illustrate an externally powered CW-GFC-IS

(without a modem or radio). In this example, the external power source

to the non-hazardous interface must not generate more than 16Vdc and

must be able to supply at least 8Vdc. If you install the IStran in a

Division 2 area, you must connect the power inputs and outputs using

Division 2 wiring methods. (See Section 4.1.)

Note: If you only require a modem or radio, refer to Figure 3-1 and

Figure 3-2. The only difference is that you can replace the 12V

battery by an external 8 to 16 Vdc power supply.

Issued Nov-09 System Wiring 3-3

Figure 3-3. CW-GFC-IS with External Power Source

Page 22

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Figure 3-4. CW-GFC-IS with External Power Supply

3-4 System Wiring Issued Nov-09

Page 23

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Chapter 4 – Installation

4.1 Installation Overview

The IStran and the communications device reside in a non-hazardous or

Division 2 rated area, while the CW-GFC-IS resides in a Division 1,

Division 2, or non-hazardous area.

You must provide a suitable enclosure for the IStran. When you mount

the IStran in a Division 2 area, you must make the non-hazardous

interface connections in accordance with Article 501-4(b) of the

National Electrical Code NFPA 70.

When you connect the IStran to a CW-GFC-IS mounted in a Division 1

Caution

area, wire all circuits according to wiring methods specified in article 504

of the National Electrical Code NFPA 70. Contact your IStran supplier for

assistance.

Warning

4.2 Installation Notes

When you install the IStran in a Division 2 area, ensure that the area is

non-hazardous before you connect or disconnect the non-hazardous

interface.

Use four #6 screws with lock washers to secure the IStran to a grounded

metal panel. Illustrations in Chapter 1 show the physical dimensions of

the IStran units. The four mounting holes/slots are 0.156" in diameter.

Total height is approximately 1". The case material is 5052 aluminum

with a black anodize finish. The thickness of the base is 0.060", and the

top is 0.090". The case hardware is stainless steel.

The IStran accepts stranded wires up to 14AWG. When you must insert

two wires in a single position, 18AWG is the maximum recommended

size. The recommended strip length is 1/4 inch, and the insulation must

not extend into the connector clamp. For cables, use 26AWG or larger

conductors and do not configure them as twisted pairs. If you use a

shield, connect it only at one end, closest to the system ground

reference. For optimum performance over long distances, use lowcapacitance cables. In the multi-drop configuration, keep all IStran units

in close proximity.

Issued Nov-09 Installation 4-1

Secure all wiring before you apply power to the IStran or to the

associated devices. For intrinsic safety applications, use a single cable to

connect the IStran hazardous interface to the intrinsically safe device.

Maintain a minimum 2” separation between the intrinsically safe wiring

and all other wiring. Install the IStran hazardous interface near the point

where the intrinsically safe wiring exits the enclosure housing the

Page 24

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

IStran. Do not install any other wiring through the same hole or allow

other wires to share a cable or conduit with the intrinsically safe wiring.

Secure the intrinsically safe wiring and limit slack to ensure that, should

one of the intrinsically safe wires become dislodged from an IStran

terminal, it must still maintain a 2” separation with either the IStran

non-hazardous interface wiring or any other circuits except those on the

IStran hazardous interface.

Refer to Figures 3-1 through 3-4 in Chapter 3 when you connect wires

between an optional modem or radio and an IStran assembly.

Note: MDS and Freewave radios use different RXD/TXD naming

conventions. MDS uses RXD and TXD to mean “receive input”

and “transmit output” respectively, while Freewave uses RXD

for “transmit output” and TXD for “receive input.”

Refer to Chapter 3 when you connect wires between an externally

powered CW-GFC-IS and an IStran.

4-2 Installation Issued Nov-09

Page 25

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

Chapter 5 – Specifications

5.1 Environment

The IStran design supports operation inside a building or a weatherproof enclosure only.

5.2 Operating Specifications

Table 5-1 provides the operating specifications for the IStran:

Table 5-1. IStran Operating Specifications

Description Specification

Operating

Temperature Range

Operating Humidity

Range

Transient

Susceptibility

Vibration Effect

ESD Susceptibility

EMI Compatibility

Hazardous Locations

o

-40

C to +70oC (-40oF to +158oF)

15% to 95% RH (non-condensing)

Field connected circuits designed to meet

requirements of ANSI/IEEE C37.90.1-1989

(formerly IEEE 472) for surge withstand capability.

10 to 500 Hz at 1 g on any axis per SAMA PMC-31-

1 without damage or impairment.

Field connected circuits designed to meet the

requirements of IEC 801-2 for ESD withstand

capability up to 10KV.

Designed to meet the susceptibility requirements of

IEC 801-3 level 2(3V/M) from 500kHz to 500MHz.

Designed to meet FCC Rules Part J, Subpart 15,

Class A for radiated emissions.

Designed to meet NFPA and UL requirements for

installation in Class I, Division 2, Groups C and D

hazardous locations.

Designed to meet NFPA and UL requirements for

connection to intrinsically safe devices located in

Division 1 locations.

The intrinsically safe device must be designed

and/or approved for the intended connection.

Issued Nov-09 Specifications 5-1

Page 26

ControlWave GFC IS Communication Interface Manual (CI-CW-GFC-ISTRAN)

5-2 Specifications Issued Nov-09

Page 27

WARRANTY

A. Remote Automation Solutions (RAS) warrants that goods described herein and manufactured by RAS are

free from defects in material and workmanship for one year from the date of shipment unless otherwise

agreed to by RAS in writing.

B. RAS warrants that goods repaired by it pursuant to the warranty are free from defects in material and

workmanship for a period to the end of the original warranty or ninety (90) days from the date of delivery of

repaired goods, whichever is longer.

C. Warranties on goods sold by, but not manufactured by RAS are expressly limited to the terms of the

warranties given by the manufacturer of such goods.

D. All warranties are terminated in the event that the goods or systems or any part thereof are (i) misused,

abused or otherwise damaged, (ii) repaired, altered or modified without RAS consent, (iii) not installed,

maintained and operated in strict compliance with instructions furnished by RAS or (iv) worn, injured or

damaged from abnormal or abusive use in service time.

E. These warranties are expressly in lieu of all other warranties express or implied (including without limitation

warranties as to merchantability and fitness for a particular purpose), and no warranties, express or

implied, nor any representations, promises, or statements have been made by RAS unless endorsed

herein in writing. Further, there are no warranties which extend beyond the description of the face hereof.

F. No agent of RAS is authorized to assume any liability for it or to make any written or oral warranties beyond

those set forth herein.

REMEDIES

A. Buyer's sole remedy for breach of any warranty is limited exclusively to repair or replacement without cost

to Buyer of any goods or parts found by Seller to be defective if Buyer notifies RAS in writing of the alleged

defect within ten (10) days of discovery of the alleged defect and within the warranty period stated above,

and if the Buyer returns such goods to the RAS Watertown office, unless the RAS Watertown office

designates a different location, transportation prepaid, within thirty (30) days of the sending of such

notification and which upon examination by RAS proves to be defective in material and workmanship. RAS

is not responsible for any costs of removal, dismantling or reinstallation of allegedly defective or defective

goods. If a Buyer does not wish to ship the product back to RAS, the Buyer can arrange to have a RAS

service person come to the site. The Service person's transportation time and expenses will be for the

account of the Buyer. However, labor for warranty work during normal working hours is not chargeable.

B. Under no circumstances will RAS be liable for incidental or consequential damages resulting from breach

of any agreement relating to items included in this quotation from use of the information herein or from the

purchase or use by Buyer, its employees or other parties of goods sold under said agreement.

Page 28

How to return material for Repair or Exchange

Before a product can be returned to Remote Automation Solutions (RAS) for repair, upgrade, exchange, or to verify

proper operation, Form (GBU 13.01) must be completed in order to obtain a RA (Return Authorization) number and

thus ensure an optimal lead time. Completing the form is very important since the information permits the RAS

Watertown Repair Dept. to effectively and efficiently process the repair order.

You can easily obtain a RA number by:

A. FAX

Completing the form (GBU 13.01) and faxing it to (860) 945-2220. A RAS Repair Dept. representative will

return the call (or other requested method) with a RA number.

B. E-MAIL

Accessing the form (GBU 13.01) via the RAS Web site (www.emersonprocess.com/remote) and sending it

via E-Mail to CustServe.RAS@Emerson.com

. A RAS Repair Dept. representative will return E-Mail (or

other requested method) with a RA number.

C. Mail

Mail the form (GBU 13.01) to

Remote Automation Solutions

A Division of Emerson Process Management

Repair Dept.

1100 Buckingham Street

Watertown, CT 06795

A RAS Repair Dept. representative will return call (or other requested method) with a RA number.

D. Phone

Calling the RAS Repair Department at (860) 945-2442. A RAS Repair Department representative will

record a RA number on the form and complete Part I, send the form to the Customer via fax (or other

requested method) for Customer completion of Parts II & III.

A copy of the completed Repair Authorization Form with issued RA number should be included with the product

being returned. This will allow us to quickly track, repair, and return your product to you.

Page 29

Remote Automation Solutions

Repair Authorization Form

(

Providing this information will permit Remote Automation Solutions to effectively and efficiently process your return.

Completion is required to receive optimal lead time. Lack of information may result in increased lead times.)

Date ____________ RA # _________________ SH Line No. _________

Standard Repair Practice is as follows: Variations to

this is practice may be requested in the “Special

Requests” section.

• Evaluate / Test / Verify Discrepancy/Repair/Replace

The party sending in material is responsible to ensure that the materials returned are clean to safe levels,

defined and/or determined by applicable federal, state and /or local law regulations or codes. Such party agrees

to indemnify Remote Automation Solutions harmless to any liability or damage which Remote Automation Solutions

may incur or suffer due to such party’s failure to so act.

Part I Please complete the following information for single unit or multiple unit returns

Please be aware of the Non warranty standard

charge:

• There is a $100 minimum evaluation charge.

Address No. _____________ Address No. ____________

Bill to : _____________________________________

____________________________________________

____________________________________________

Ship to: ___________________________________

____________________________________________

____________________________________________

Purchase Order: _________________________ Contact Name: _____________________________

Phone: _____________________ Fax: ______________________ E-Mail: ______________________

Part II Please complete Parts II & III for each unit returned

Model No./Part No. _________________________ Description: __________________________________

Range/Calibration: _________________________ S/N: ___________________________________

Reason for return : Failure Upgrade Verify Operation Other __________________________

1. Describe the conditions of the failure (Frequency/Intermittent, Physical Damage, Environmental Conditions,

Communication, CPU watchdog, etc.) ___________________ (Attach a separate sheet if necessary)

2. Comm. interface used:

Other: ______________________________________

3. What is the Firmware revision?_______________ What is the Software & version? _______________

Standalone

RS-485

Ethernet Modem (PLM (2W or 4W) or SNW)

Part III If checking “replaced” for any question below, check an alternate option if replacement is not

available

A. If product is deemed not repairable would you like your product:

B. If Remote Automation Solutions is unable to verify the discrepancy, would you like the product:

replaced *see below?

* Continue investigating by contacting the customer to learn more about the problem experienced? The person to

contact that has the most knowledge of the problem is: __________________ phone _________________

If we are unable to contact this person the backup person is:________________ phone _________________

Special Requests:

__________________________________________________________________________________________

Ship prepaid to: Remote Automation Solutions, Repair Dept., 1100 Buckingham Street, Watertown, CT 06795

Form GBU 13.01 Rev. F 11/25/08

Phone: 860-945-2442 Fax: 860-945-2220

returned replaced scrapped?

returned

Page 30

BLANK PAGE

Page 31

ControlWave GFC-IStran Instruction Manual

Index

Non-Hazardous power output.............................2-6

F

Field wiring diagrams..........................................3-2

Figures

1-1. Istran Front View..................................... 1-1

1-2. Physical Dimensions - Istran Front View 1-2

1-3. Physical Dimensions – IStran Edge (Side)

View.............................................................. 1-2

1-4. Istran PCB Mounted on Base Plate........ 1-3

2-1. Setting Jumper HJP1.............................. 2-3

2-2. Setting Jumper NJP1.............................. 2-5

3-1. Modem System with Single Power Source3-

2

3-2. Radio System with Single Power Source 3-3

3-3. CW-GFC-IS with External Power Source3-3

3-4. CW-GFC-IS with external power supply. 3-4

G

S

Specifications......................................................5-1

Switched Mode ............................................1-3, 2-5

configuring the Hazardous interface for ......... 2-6

configuring the non-Hazardous interface for.. 2-6

T

Tables

2-1. Common Characteristics for Hazardous and

Non-Hazardous Interfaces ........................... 2-1

2-2. Hazardous Interface Connector..............2-1

2-3. Hazardous Interface Characteristics....... 2-2

2-4. Non-Hazardous Interface Connector ...... 2-3

2-5. Non-Hazardous Interface Characteristics2-4

5-1. IStran Operating Specifications............... 5-1

Grounding........................................................... 3-1

H

Hazardous characteristics .................................. 2-1

Hazardous interface

configuring for Switched Mode....................... 2-6

N

Non-Hazardous characteristics........................... 2-1

U

Un-Switched Mode.......................................1-3, 2-5

configuring the Hazardous interface for ......... 2-6

configuring the non-Hazardous interface for.. 2-6

W

Wiring..................................................................3-1

field wiring diagrams.......................................3-2

Issued Nov-09 Index I-1

Page 32

Customer Instruction Manual

CI-CW-GFC-ISTRAN

ControlWave GFC IStran

November, 2009

Emerson Process Management

Remote Automation Solutions

1100 Buckingham Street

Waterto

wn, CT 06795

Phone: +1 (860) 945-2262

Fax: +1 (860) 945-2525

www.EmersonProcess.com/Remote

Emerson Process Management

Remote Automation Solutions

6338 Viscount Rd.

Mississauga, Ont

Canada

Phone: 905-362-0880

Fax: 905-362-0882

www.EmersonProcess.com/Remote

Emerso

n Process Management SA de CV

Calle 10 #145

Col. San Pedro de los Pinos

01180 Mexico, D.F.

Mexico

T +52 (55) 5809-5300

F +52 (55) 2614-8663

www.EmersonProcess.com/Remote

Emerso

n Process Management, Ltd.

Remote Automation Solutions

Blackpole Road

W

orcester, WR3 8YB

United Kingdom

Phone: +44 1905 856950

Fax: +44 1905 856969

www.EmersonProcess.com/Remote

Emerso

n Process Management AP Pte Ltd.

Remote Automation Solutions Division

1 Pandan Crescent

Singapore 128461

Phone: +65-6770-8584

Fax: +65-6891-7841

www.EmersonProcess.com/Remote

. L4V 1H3

NOTICE

“Remote Automation Solutions (“RAS”), division of Emerson Process

Management shall not be liable for technical or editorial errors in this manual

or omissions from this manual. RAS MAKES NO WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH

RESPECT TO THIS MANUAL AND, IN NO EVENT SHALL RAS BE LIABLE

FOR ANY INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL

DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION,

LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS

INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND

POWER, AND CLAIMS OF THIRD PARTIES.

Bristol, Inc., Bristol Babcock Lt

Computer Division are wholly owned subsidiaries of Emerson Electric Co.

doing business as Remote Automation Solutions (“RAS”), a division of

Emerson Process Management. FloBoss, ROCLINK, Bristol, Bristol

Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS,

PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The

Emerson logo is a trademark and service mark of the Emerson Electric Co.

All other trademarks are property of their respective owners.

The contents of this publication are presented for informational purposes

only. While every effort has been made to ensure informational accuracy,

they are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. RAS reserves the right to modify or improve the designs or

specifications of such products at any time without notice. All sales are

governed by RAS’ terms and conditions which are available upon request.

© 2009 Remote Automation Solutions, division of Emerson Process

Management. All rights reserved.

d, Bristol Canada, BBI SA de CV and the Flow

Loading...

Loading...