Page 1

Controller Output % Flow %

Control Valve Dynamic Specification

(Summary - Version 3.0, 11/98)

Competitive Marketplace

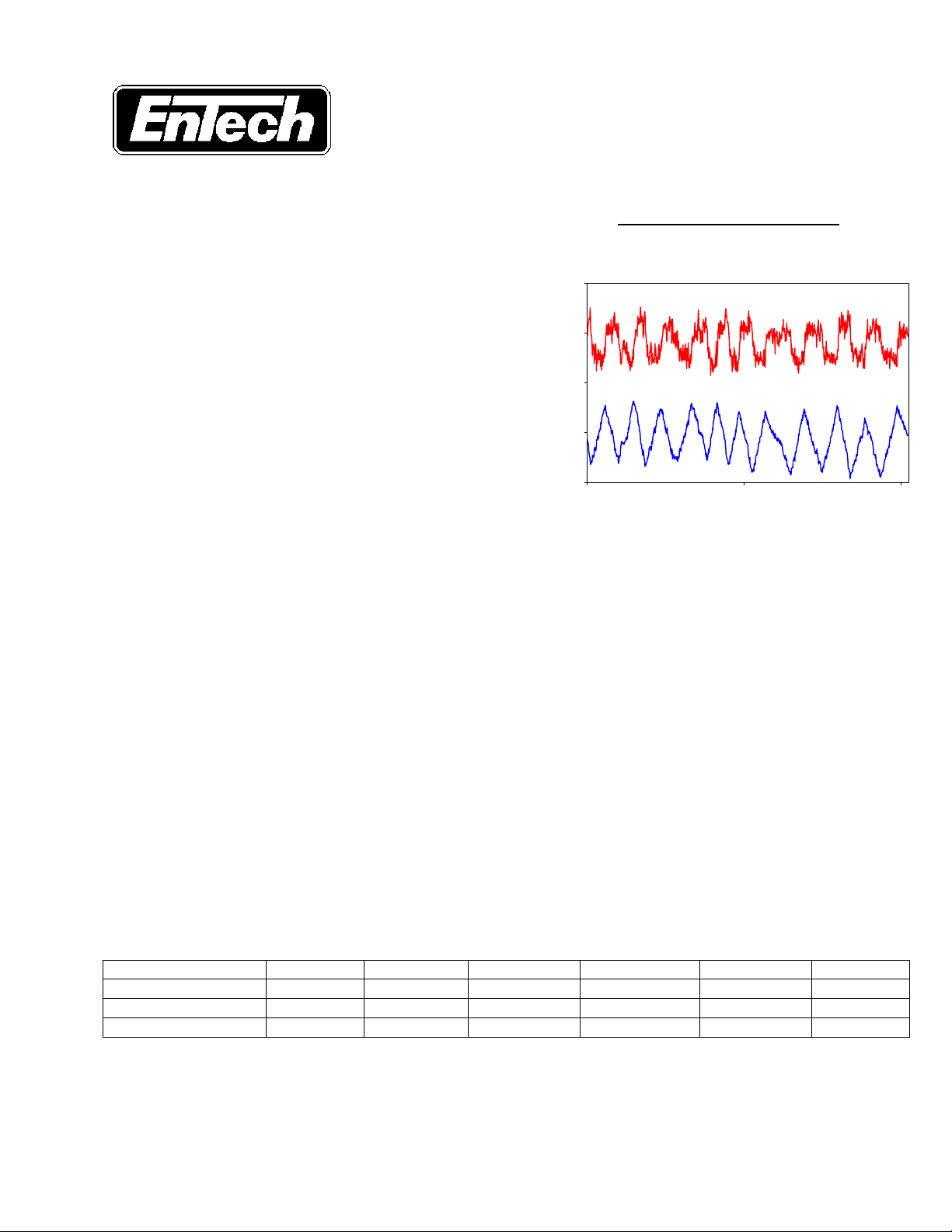

The global market’s continuing demand for quality and uniformity in

manufactured products means there is even greater focus being given

to process control equipment and its performance. EnTech Control

Engineering Inc. has specialized in the optimization of process

performance, particularly in pulp and paper manufacturing where

product uniformity specifications are now approaching 1%. Plant

process variability audits frequently find that product variability is

increased by individual control loops that limit cycle because their

control valves are unable to track their controller output signals closely

enough (Figure 1). This undesirable behaviour of control valves is

the biggest single contributor to poor control loop performance

and the destabilization of process operation.

Purpose: to define the degree to which control valves can be

nonlinear and still allow acceptable process control performance.

About Version 3.0: The original EnTech Control Valve Dynamic Specification was issued in 1992. Version 3.0 replaces all

previous versions. It uses ISA terminology, considers end user needs, defines a valve step response performance index, and is

applicable to all process industries. All words in italics are defined in the definitions section: see full text of the specification.

55

53

51

49

47

0 500 1000

Time seconds

Figure 1 – Typical Control Valve Induced Limit Cycle

Control Valve System: The Specification considers the control valve as a dynamic system, from input signal through to

the flow coefficient that determines the fluid flow in the pipe. The key is that a measured change in a process variable is

expected in response to small input step-changes (1% and less). Valve stem movement is not an adequate indication, but is

considered to be a good measure of the speed of response of the valve system.

SPECIFICATION

There are three sections: Nonlinear, Dynamic Step Response and Valve Sizing. Each has a number of recommendations, a

default value, and an extra space for a user-specified selection. If no control loop application knowledge is available, the

default values should be used. The performance of a control valve system shipped as a package should be

documented in a specification sheet, including the parameters called out in this specification.

1. NONLINEAR SPECIFICATION

The nonlinear specification sets the maximum allowed dead band, step resolution and total hysteresis. The total hysteresis

influences the potential minimum step size, which in turn determines the amplitude of the potential controller output limit cycle.

The minimum step size together with the flow gain determines the amplitude of the potential PV limit cycle. Three classes are

given: nominal, fine and very fine. Default values are provided for both rotary valves and sliding stem valves.

Valve Tracking Nonlinearities (% input signal) DEFAULT DEFAULT

Class Nominal - 1% Fine - 0.5% V Fine – 0.1% Rotary Valves Sliding Stem User

Dead Band (%)

Step Resolution (%)

Total Hysteresis (%)

0.6 0.3 0.06

0.4 0.2 0.04

1.0 0.5 0.1

2. DYNAMIC STEP RESPONSE SPECIFICATION - STEP SIZE RANGE – REGION C

The dynamic response specification sets the ranges over which consistent dynamics are to be achieved (Region C). The step

size range is set from minimum to maximum. Minimum step size depends on the total hysteresis, as well as the magnitude of

Region B. It is valve design dependent and is likely to be about double the total hysteresis. Values are given for nominal, fine,

and very fine. The finer, the more capable the valve design. Default values are given for rotary and sliding stem valves.

0.6 0.3

0.4 0.2

1.0 0.5

Copyright EnTech 1998 – All Rights Reserved

Page 2

Minimum Step Size (%) DEFAULT DEFAULT

Nominal Fine Very Fine Rotary Valves Sliding Stem User

2.0 1.0 0.2

2.0 1.0

The Maximum step size determines the upper range over which the valve is nearly linear and depends on the size of Region D.

Values are given for nominal, wide and very wide. The wider, the more capable the valve design.

Maximum Step Size (%)

Nominal Wide Very Wide DEFAULT User

10 50 100

10

STEP RESPONSE - REGION C – Consistent Dynamics

The step response specification sets T86, % Overshoot, Travel Gain, Tss. Each class is based on the fastest control loop

speed of response (λ) available, given the valve T86 and Tss as specified. The four classes include: Very Fast (1 second),

Fast (5 seconds), Nominal (10 seconds), Slow (1 minute). The default is set for 5 sec.

T86 Step Response Time (seconds) by Fastest Loop Speed of Response Class (Function of Td / T86 Ratio)

Class 1 second 5 seconds 10 seconds 1 minute DEFAULT User

Td / T86 < 0.5

Td / T86 > 0.5

0.4 2 4 24

0.25 1.25 2.5 15

2

1.25

Tss Steady State Time (seconds) by Fastest Loop Speed of Response Class (Function of Td / T86 Ratio)

Class 1 second 5 seconds 10 seconds 1 minute DEFAULT User

Td / T86 < 0.5

Td / T86 > 0.5

1 5 10 60

0.63 3.1 6.3 38

5

3.2

Travel gain %Overshoot (% of step change)

Nominal DEFAULT User Nominal DEFAULT User

0.8 to 1.2

0.8 to 1.2

20

20

Valve Performance Index W - Weighting Factor - (Based on Equations 1 and 2) 0=perfect, 100=poor

W(T86) Equation 1 = W(Lambda) Equation 2 =

3. VALVE SIZING SPECIFICATION

Flow Characteristic Nonlinearities:

This section of the specification is intended as a guideline for control valve sizing calculations. The flow limit cycle amplitude

can be predicted as one half of the minimum step size times the flow gain. It can best be expressed as potential process

variability on a percentage basis, by calculating the limit cycle amplitude as a percentage of the nominal flow. The flow gain %

is the flow gain in flow units / valve travel %, divided by the flow at the operating point and expressed as a percent. The

designer should consider the worst case in the process design (highest or lowest flow).

Maximum Allowed Flow Limit Cycle Amplitude (% of Nominal Flow) DEFAULT DEFAULT

Nominal Fine Very Fine Rotary Valves Sliding Stem User

Minimum Step Size (%)

Flow Gain %

Flow Limit Cycle (%)

2.0 1 0.2

1.0 1.0 1.0

1.0 0. 5 0.1

2.0 1

1.0 1.0

1.0 0. 5

The control loop process gain is a function of the flow gain, the relationship of the flow in the pipe to the measured process

variable, and the span of the transmitter used to make the process measurement. Ideally, the process gain should be

approximately equal to unity (% PV / % valve travel) for good design. The amount by which the process gain varies over the

operating range of the process, determines the degree to which the control loop will be difficult to tune. Poor tuning leads to

control loop cycling and higher process variability. Ideally the process gain range should be limited to plus and minus a factor

of two.

Variation in Process Gain (Kp), DEFAULT DEFAULT

Nominal High Low High Low User

Nominal Kp (%/%)

1.0 2.0 0.5

2.0 0.5

A full copy of the specification is available via the EnTech home page at: http://www.entechcontrol.com/, or by calling EnTech.

2

Copyright EnTech 1998 – All Rights Reserved

Page 3

For more information:

For more information on Variability Management please visit our website

www.EmersonProcess.com/solutions/VariabilityManagement , or

Contact us at:

AAT@emersonprocess.com

email:

phone: +1 512-832-3575

Emerson Process Management

12301 Research Blvd.

Research Park Plaza, Building III

Austin, Texas 78759 USA

Loading...

Loading...