Page 1

Control Link ACC Anti-Condensate Controller System

Installation and Operation Manual

026-4704 Rev 6

Page 2

Page 3

Emerson

1065 Big Shanty Road NW, Suite 100

Kennesaw, GA 30144 USA

Phone 770-425-2724

Fax 770-425-9319

Page 4

Page 5

Contents

1 OVERVIEW ................................................................................................................................................................... 1

2 COMPONENTS ............................................................................................................................................................. 1

2.1. C

ONTROL LINK ACC (P/NS 815-6100 AND 815-6105) ............................................................................................... 1

2.2. D

EWPOINT SENSOR (P/N 814-6115) ........................................................................................................................... 2

2.3. D

OOR FRAME TEMPERATURE SENSOR (P/N 281-0002) .............................................................................................. 2

3 MOUNTING THE CONTROL LINK ACC ............................................................................................................... 3

4 CALCULATING MAXIMUM AMBIENT TEMPERATURE ................................................................................. 4

5 WIRING THE CONTROL LINK ACC ...................................................................................................................... 6

5.1. P

OWER AND HEATER ELEMENT WIRING ..................................................................................................................... 6

5.2. R

ATINGS AND CURRENT PROTECTION.......................................................................................................................... 6

6 MOUNTING AND WIRING THE SENSORS ........................................................................................................... 7

6.1. T

HE DEWPOINT SENSOR ............................................................................................................................................... 7

6.1.1. Placement.............................................................................................................................................................. 7

6.1.2. Note About Using RTV Sealants ........................................................................................................................... 7

6.1.3. Dewpoint Sensor Mounting Dimensions............................................................................................................... 8

6.1.4. Dewpoint Sensor Wiring ....................................................................................................................................... 8

6.1.5. Dewpoint Sensor Storage...................................................................................................................................... 9

6.2. T

HE DOOR FRAME TEMPERATURE SENSOR ............................................................................................................... 10

6.2.1. Placement............................................................................................................................................................ 10

7 NETWORK WIRING AND CONFIGURATION.................................................................................................... 11

7.1. N

ETWORK CONNECTION TO E2 ................................................................................................................................. 11

7.2. E2 S

ETUP OF CONTROL LINK ACC DEVICES ............................................................................................................. 11

7.2.1. Setup Network Ports............................................................................................................................................ 11

7.2.2. Add and Connect Control Link ACCs - E2 Firmware Revision Prior to 2.8...................................................... 12

7.2.3. Add and Connect Control Link ACCs - E2 Firmware Version 2.8 and above ................................................... 13

7.3. W

7.4. MODBUS N

IRING TYPES............................................................................................................................................................ 15

ETWORK AND DAISY-CHAINING ............................................................................................................ 16

7.4.1. Step 1: Disconnect Power to the Control Link ACC and Open the ACC Enclosure .......................................... 16

7.4.2. Step 2: Connect the MODBUS Network Cable................................................................................................... 16

7.4.3. Step 3: Set the Network Address ......................................................................................................................... 16

7.4.4. Step 4: Set the Network Baud Rate and MODBUS Parity ................................................................................. 17

7.4.5. Step 5 - Terminate the End Devices ................................................................................................................... 18

7.4.5.1. Termination Block Network ............................................................................................................................................. 18

7.4.6. Step 6 - Connect a Dewpoint Sensor to Control Link ACC(s) on the Network................................................... 18

7.4.7. Step 7 - Set the Setpoint Temperature Offset ..................................................................................................... 19

7.4.8. Step 8 - Network Configuration Is Complete - Restore Power to the ACC ........................................................ 19

8 THE ACC HAND-HELD TERMINAL INTERFACE............................................................................................. 21

8.1. HHT H

8.2. K

8.3. H

8.4. C

ARDWARE OVERVIEW..................................................................................................................................... 21

EYS AND FUNCTIONS .............................................................................................................................................. 21

AND HELD TERMINAL EXPANSION BOARD ............................................................................................................ 22

ONNECTING THE HHT ADAPTER BOARD ................................................................................................................. 22

8.4.1. HHT Home Screen ............................................................................................................................................. 22

8.5. HHT I

NTERFACE NAVIGATION ................................................................................................................................... 23

Table of Contents • v

Page 6

8.5.1. ACC HHT Network Setup.................................................................................................................................... 23

8.5.1.1. Modes of ACC Addressing ............................................................................................................................................... 23

8.5.2. The ACC HHT Interface...................................................................................................................................... 23

8.5.2.1. ACC Start Screens ............................................................................................................................................................ 23

8.5.3. ACC Status Screens............................................................................................................................................ 24

8.5.3.1. Input Status Screen .......................................................................................................................................................... 24

8.5.3.2. Output Status Screen......................................................................................................................................................... 24

8.5.4. ACC Configuration Screens................................................................................................................................ 24

8.5.4.1. HHT Changes When ACC is Connected to E2 ................................................................................................................ 24

8.5.4.2. HHT Changes When ACC is Stand-Alone ....................................................................................................................... 24

8.5.4.3. The Main Selection Screen .............................................................................................................................................. 24

8.5.5. Upgrading ACC Using HHT............................................................................................................................... 26

8.5.6. Changing ACC Address Using HHT................................................................................................................... 26

8.5.7. Exit HHT Mode ................................................................................................................................................... 26

9 OPERATION................................................................................................................................................................ 27

9.1. C

ONTROL LINK ACC STATUS LEDS .......................................................................................................................... 27

9.1.1. Heater Status LED .............................................................................................................................................. 27

9.1.2. General Status LED ............................................................................................................................................ 27

9.1.3. TX and RX Status LEDs ...................................................................................................................................... 28

10 ERROR MODES........................................................................................................................................................ 29

10.1. P

10.2. P

10.3. P

10.4. P

10.5. P

RIORITY 1: FAIL: OVER TEMP ............................................................................................................................ 29

RIORITY 2: FAIL: TEMP SENS ............................................................................................................................. 29

RIORITY 3: FAIL: DEWPT SNS ............................................................................................................................ 29

RIORITY 4: FAIL: FLASH/CLK............................................................................................................................. 29

RIORITY 5: FAIL: CONFIGURE............................................................................................................................ 29

11 TROUBLESHOOTING CONTROL LINK ACCS AND THE ECT MODBUS NETWORK ........................... 30

11.1. I

F CONTROL LINK ACC IS OFFLINE ......................................................................................................................... 30

12 SPECIFICATIONS ................................................................................................................................................... 31

13 PART NUMBERS AND DESCRIPTIONS ............................................................................................................. 32

vi • Control Link ACC I&O Manual 026-4704 Rev 6

Page 7

1Overview

The Control Link ACC Anti-Condensate

Controller System is a controller for anti-sweat

heaters inside glass door cases and can be used either

as a stand-alone device or networked with the E2

controller over the MODBUS network. There are two

available models of the Control Link ACC:

• UL Listed version 7A/10A (P/N 815-6100)

• UL Recognized version 18A/26A/30A

(P/N 815-6105) - requires an additional heat sink

The Control Link ACC varies the anti-sweat

heaters based on the temperature of the door frame

and surrounding dewpoint, providing the most

efficient control possible in order to maximize energy

savings.

2 Components

2.1. Control Link ACC

(P/Ns 815-6100 and

815-6105)

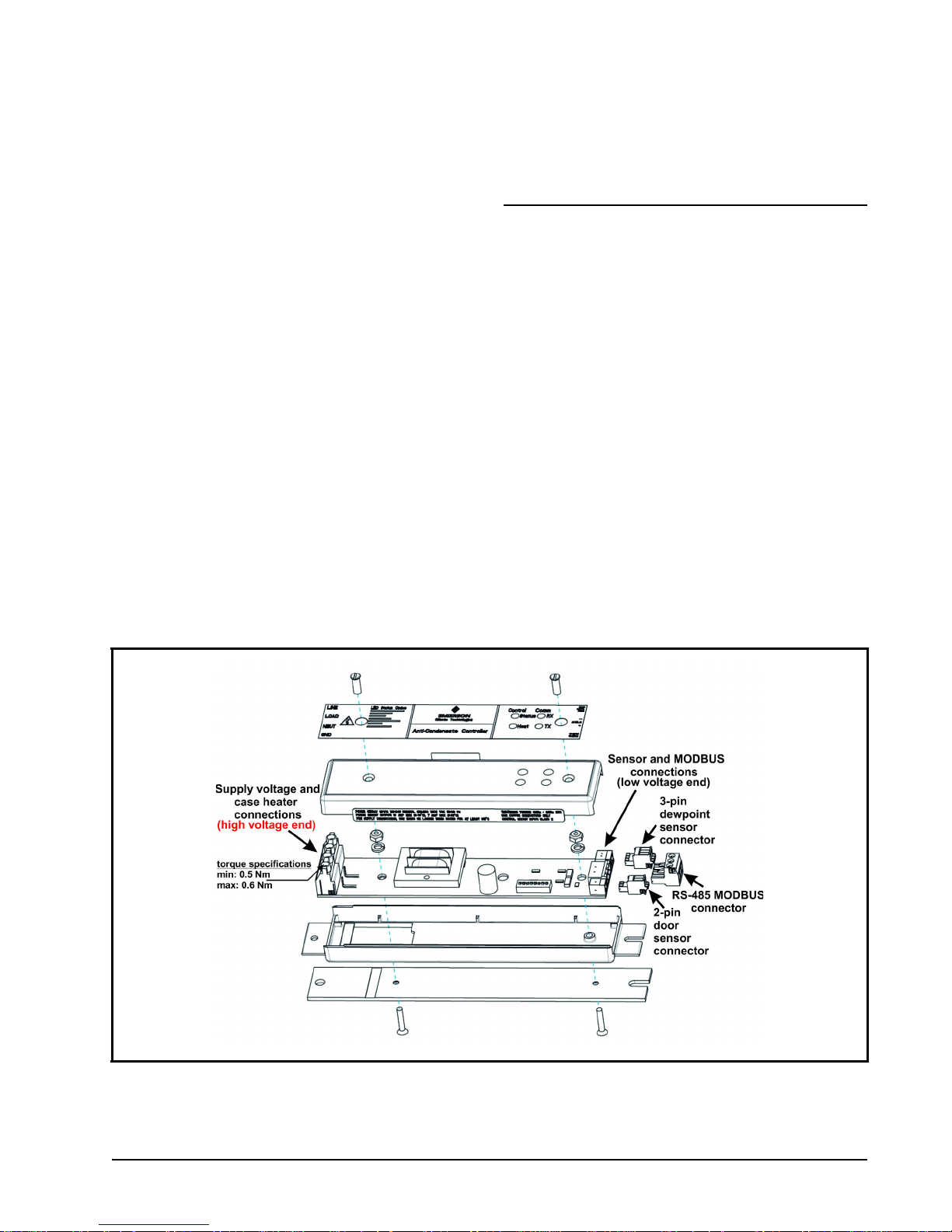

The Control Link ACC (Figure 2-1) handles all

aspects of anti-sweat heater control and uses solidstate switching to control the heaters. The on-board

processor calculates the required heater ON time

based on the dewpoint and door frame temperature

readings, and controls an on-board Triac to activate

and deactivate the heaters.

The controller is designed to mount in the mullion

between glass doors or in any other suitable electrical

enclosure, such as a raceway or on the top of the case.

The door frame temperature sensor and dewpoint

sensor are mounted remotely and connect to this

controller with cable harnesses.

Four LEDs can be viewed on the front of the

plastic enclosure. They indicate the general status,

heater ON, MODBUS network transmit (TX), and

MODBUS network receive (RX).

Figure 2-1 - Control Link ACC - Exploded View

Control Link ACC (P/Ns 815-6100 and 815-6105) Overview • 1

Page 8

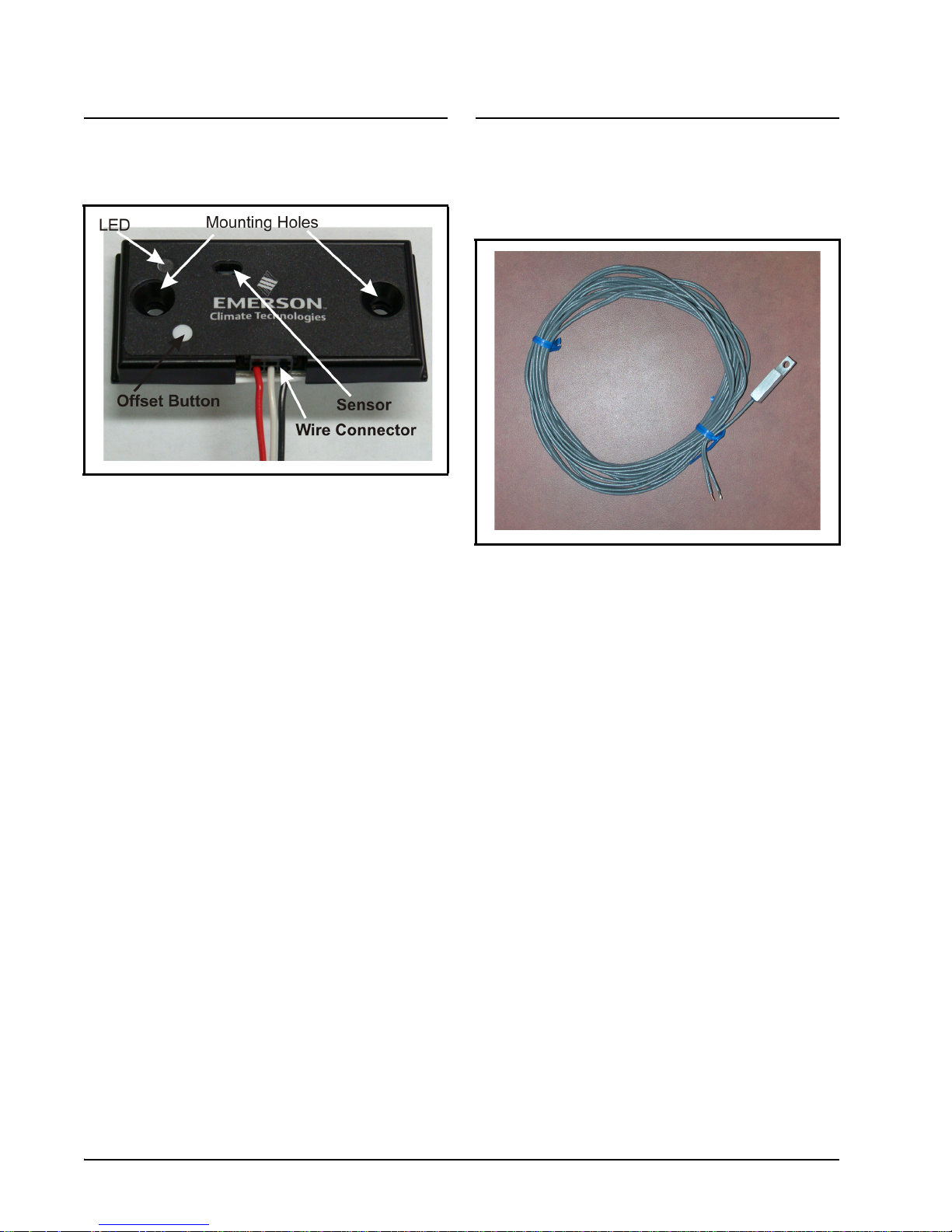

2.2. Dewpoint Sensor

2.3. Door Frame

(P/N 814-6115)

Figure 2-2 - Dewpoint Sensor (814-6115)

The Control Link ACC uses an external dewpoint

sensor (Figure 2-2) to measure the dewpoint of the

outside air next to the case doors. This sensor is

typically mounted directly above or to the side of the

case doors.

The dewpoint sensor is supplied in a mountable

enclosure with a 3-pin connector that attaches the

Control Link ACC to the dewpoint sensor (use a

3-wire 22AWG cable harness - Belden# 8771

P/N 135-8771 not supplied). The push button will

increase the offset in 1-degree (Celsius) (1.8°F)

increments indicated by the LED.

When Control Link ACC controllers are networked together via MODBUS, a single dewpoint

sensor connected to one Control Link ACC may be

shared by multiple Control Link ACC controllers.

Temperature Sensor

(P/N 281-0002)

Figure 2-3 - Door Frame Temp Sensor (281-0002)

In addition to the indoor air dewpoint, the Control

Link ACC also factors in the value of the temperature

of the case door frame using a mounted temperature

sensor (Figure 2-3). The door frame temperature

sensor should be mounted to the coldest surface of the

door frame. The door frame temperature sensor is

supplied with a 16-foot (4.88-meter) two-wire cable,

which plugs into the matching 2-pin connector on the

bottom, low voltage end of the Control Link ACC

(side closest to the LEDs).

2 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 9

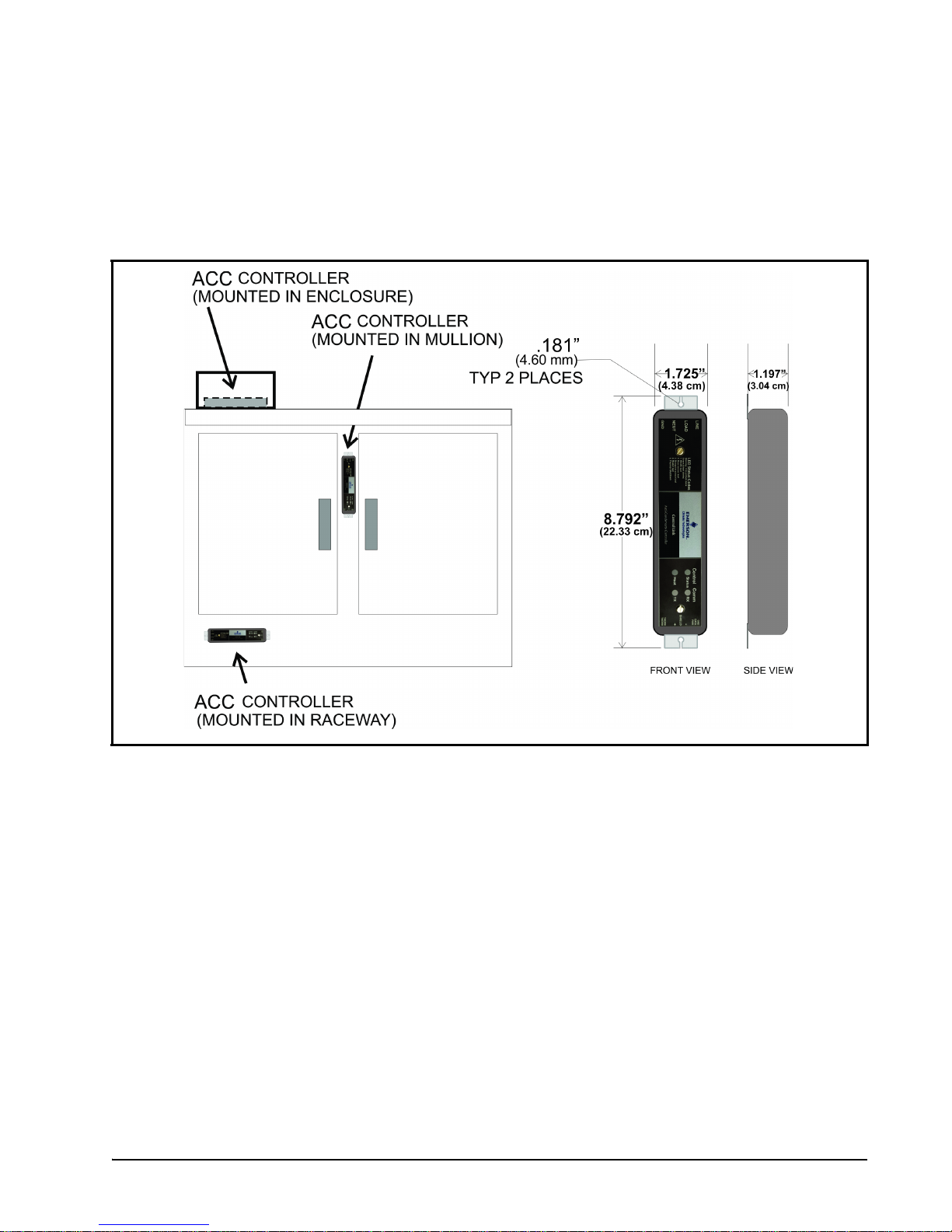

3 Mounting the Control Link ACC

The Control Link ACC is designed to be mounted in a case mullion, but may also be mounted in the raceway

or in a metal electrical enclosure on the top of the case. Figure 3-1 shows examples of where the Control Link

ACC may be mounted.

Figure 3-1 - Control Link ACC Mounting

Use the two mounting tabs at the top and bottom of the enclosure to screw the enclosure to the case wall,

raceway, or enclosure.

Use 9/64” (3.57 mm) drill pilot holes for mounting, and secure the Control Link ACC to the metal surface

using #8-32 thread forming screws. Mounting screws are not included with the Control Link ACC.

For heater current greater than 10A, the Control Link ACC UL Recognized version with external heat sink

must be used (P/N 815-6105). The heat sink of the Control Link ACC must be securely mounted against a

large heat-conductive surface. Using thermal grease, the Control Link ACC has a metal back which acts as a

heat sink, dissipating heat from the Triac that controls the heater.

The metal must be mounted against a conductive metal surface so heat can be conducted out of the

controller. Failure to secure against the case mullion or other metal surface may cause controller overheating

and shutdown.

Door Frame Temperature Sensor (P/N 281-0002) Mounting the Control Link ACC • 3

Page 10

4 Calculating Maximum Ambient

Temperature

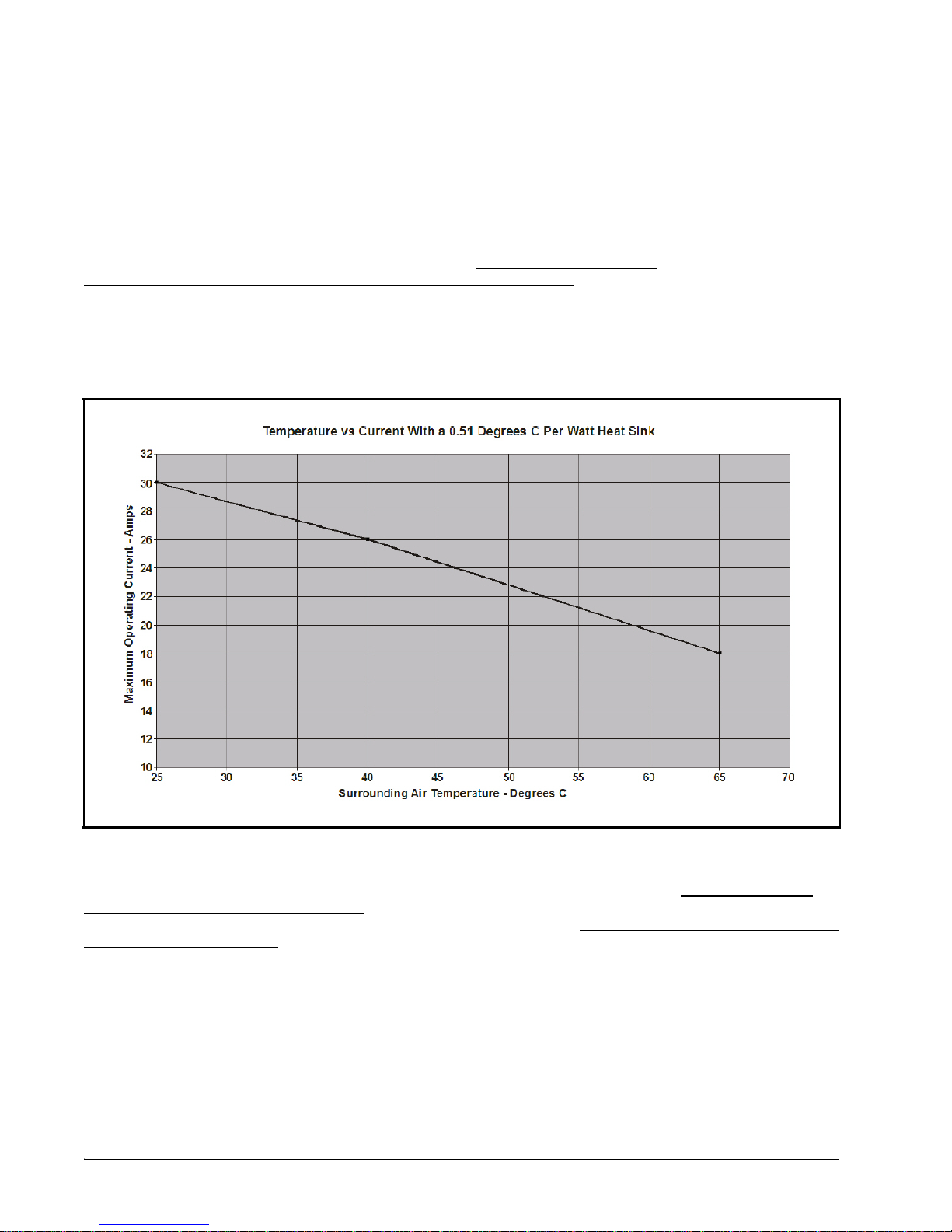

Figure 4-1 shows the effects of adding an external heat sink with a 0.51°C/Watt (0.92°F/Watt) rating (using

thermal grease to ensure optimum thermal conductivity). Note that the 0.51°C/Watt

(0.92°F/Watt) heat sink rating is characteristic of typical case mullions.

An external heat sink is required for heater currents (greater than) > 10Amps.

To calculate the maximum ambient temperature at which the ACC should run with an additional external

heat sink, choose a current-amperage rating that will be operating for the case (y-axis) and plot the maximum

allowed operating temperature (x-axis) on the graph. For example, with an external heat sink at 26Amps, the

maximum ambient temperature would be 40°C (149°F).

Figure 4-1 - Ambient Temperature Calculation - additional heat sink

For heater current greater than 10A, the heat sink of the Control Link ACC must be securely mounted

against a large heat-conductive surface. Using thermal grease, the Control Link ACC has a metal back which

acts as a heat sink, dissipating heat from the Triac that controls the heater. The metal must be mounted against

a conductive metal surface so heat can be conducted out of the controller. Failure to secure against the case

mullion or other metal surface may cause controller overheating and shutdown.

4 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 11

Figure 4-2 - Ambient Temperature Calculation - no external heat sink

Door Frame Temperature Sensor (P/N 281-0002) Calculating Maximum Ambient Temperature • 5

Page 12

5 Wiring the

Control Link ACC

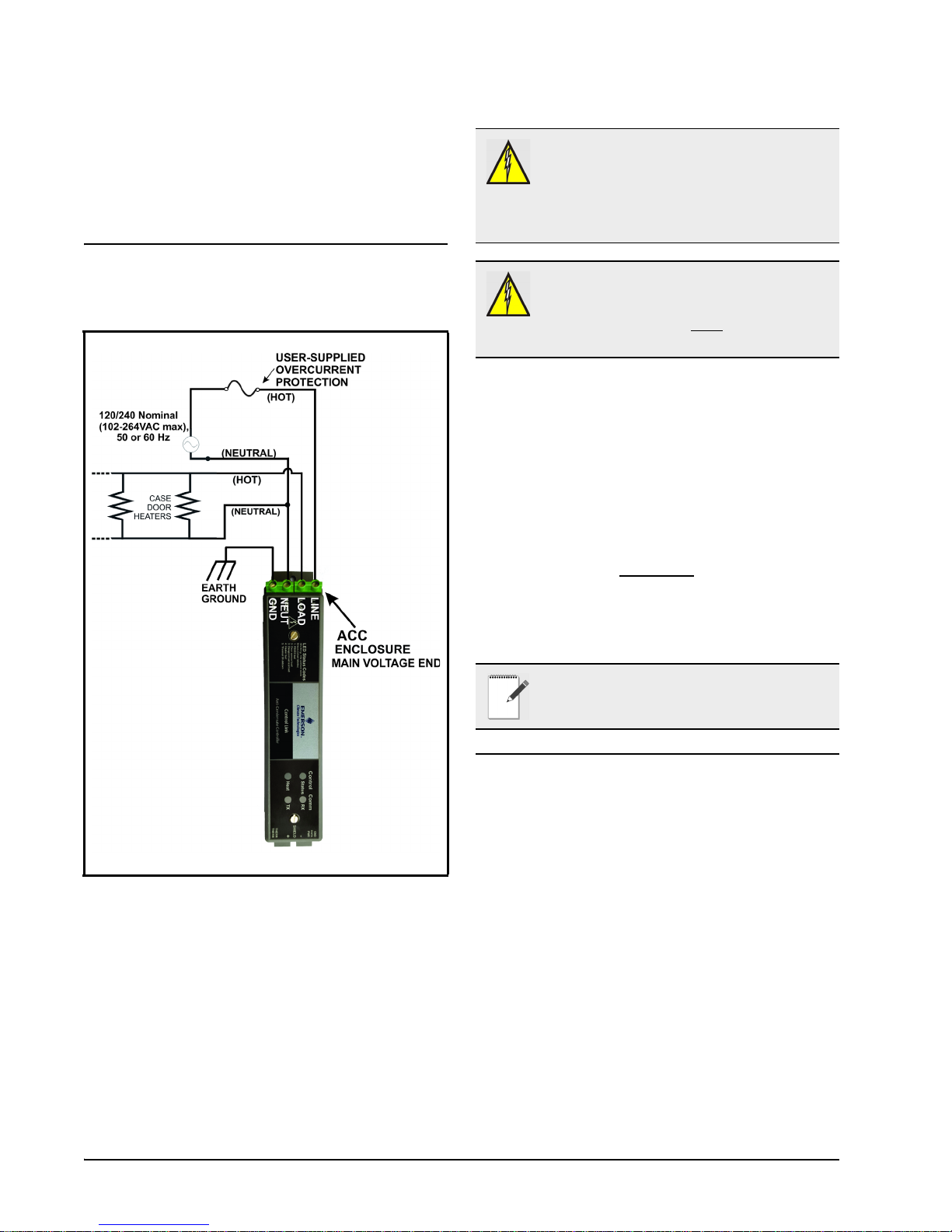

WARNING! CONNECT THE LINE

VOLTAGE ONLY TO THE HIGH VOLTAGE

END OF THE ACC, WHICH CONTAINS A

NON-REMOVABLE 4-TERMINAL BLOCK.

OTHERWISE, DAMAGE TO THE BOARD MAY

RESULT.

5.1. Power and Heater

Element Wiring

WARNING! OVER-CURRENT

PROTECTION OF THE LOAD MUST BE

DONE OUTSIDE OF THE CONTROL LINK

ACC. THE ACC DOES NOT

INTERNAL FUSING.

Connect the NEUT terminal to the NEUTRAL

side, and the LINE terminal to the HOT side of 120/

240 Nominal (102VAC to 264VAC), 50/60Hz line

voltage.

The LOAD terminal carries supply voltage when

the door heater Triac relay is ON (closed). Connect

the LOAD terminal and NEUTRAL side of the line

voltage to the case door heater elements. All heater

elements in the door frame and all doors of that frame

should be connected in parallel

ACC.

Connect the GND terminal on the controller to

Ground.

NOTE: For supply connectors, use 16AWG or

larger wires rated for at least 105 °C.

HAVE

to the Control Link

Figure 5-1 - Power/Heater Wiring

The screw connectors on the main voltage end of

the Control Link ACC enclosure are where the

connections to supply voltage and the case door

heater element(s) are made.

6 • Control Link ACC I&O Manual 026-4704 Rev 6

5.2. Ratings and Current

Protection

The Control Link ACC (P/N 815-6100) is UL

Listed for up to 10A max (40°C) and 7A max (65°C).

The Control Link ACC (P/N 815-6105) is UL

Recognized, with external heat sink, for up to 30A

max (25°C), up to 26A max (40°C), and up to 18A

max (65°C).

Page 13

6 Mounting and Wiring the Sensors

6.1. The Dewpoint Sensor

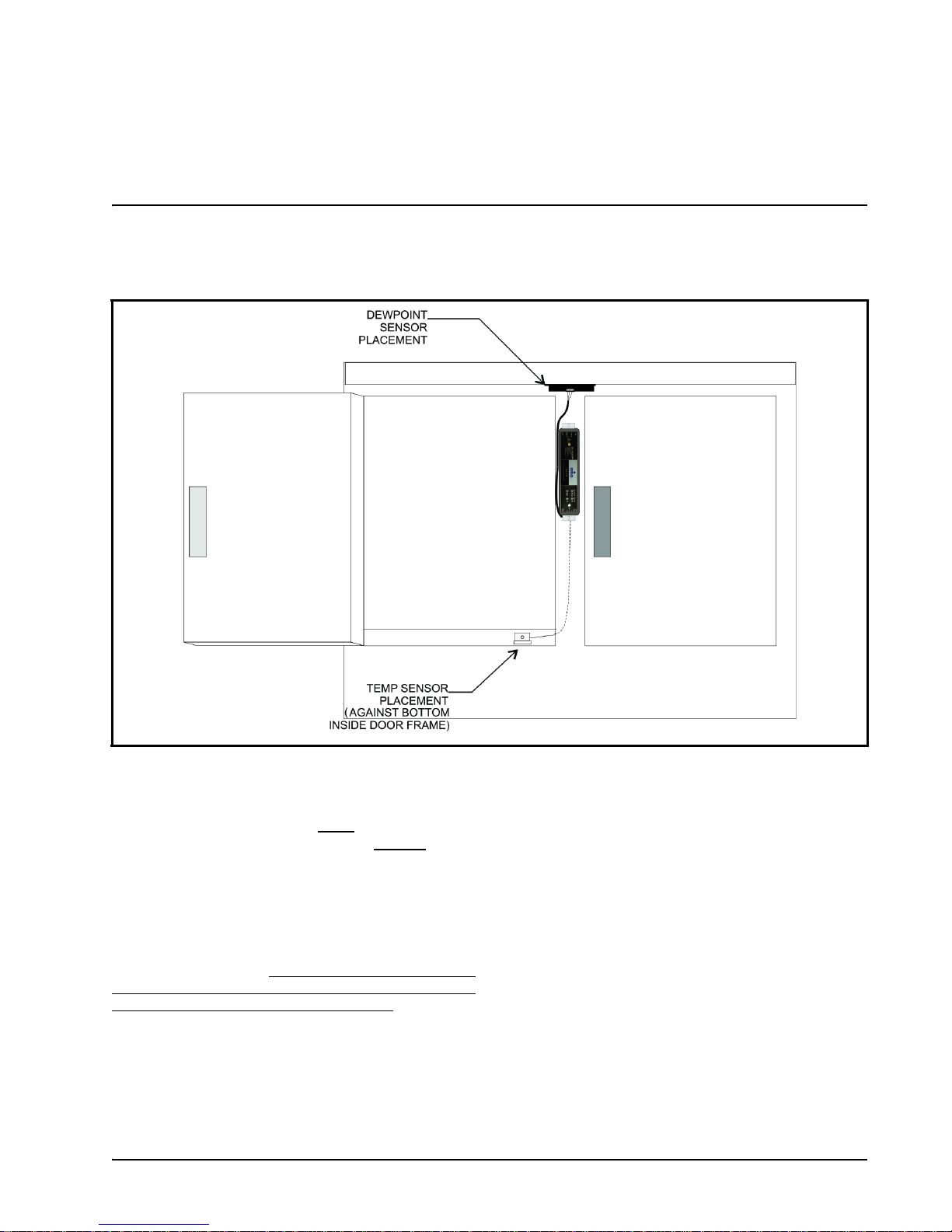

6.1.1. Placement

Figure 6-1 - Sensor Placement

In order for the Control Link ACC to function

properly, the dewpoint sensor must

it can measure the dewpoint of the air outside

case. Mount the sensor underneath the top side of the

case in the area just above the top of the doors

(Figure 6-1).

A 0.25” x 0.25” (6.35 mm x 6.35 mm) notch in the

edge of the metal frame behind the sensor may be requi re d f or the wi re s conn ec ting the dewpoint sensor to

the Control Link ACC. DO NOT let any RTV sealants

touch the sensor element and keep the sensor element

as far as possible from RTV-sealed areas.

Do NOT mount the dewpoint sensor near the

bottom of the case or any place where cold air from

the case can affect the sensor reading. Avoid

mounting the sensor in an area with excessive water

spray or moisture, extremely dirty environments, near

The Dewpoint Sensor Mounting and Wiring the Sensors • 7

be placed where

the

heat sources, or in the direct path of HVAC returns.

Secure the sensor to the mounting location with the

two included screws (P/N 031-6005) as shown in

Figure 6-2. Emerson recommends using pilot holes

for the screws. Tighten the screws just enough to

secure the sensor without warping the sensor housing.

Page 14

6.1.2. Note About Using RTV

Sealants

6.1.3. Dewpoint Sensor Mounting

Dimensions

Placing the dewpoint sensor in either of these

locations may require a hole to be drilled in the case

to run the wire from the sensor to the Control Link

ACC. Use caution when sealing this hole with RTV

sealants — the sensor element is sensitive to high

concentrations of RTV. Do not let any RTV sealants

touch the sensor element, and keep the sensor element

as far as possible from where the hole is sealed.

The dewpoint sensor’s mounting holes have 2.35”

(5.97 cm) spacing. Choose a location as close to the

case doors as possible, preferably directly over the

doors or (if necessary) on top of the case. Secure the

sensor to the mounting location with the two screws

provided. Note that the enclosure allows clearance for

a nut driver on the screw head. Figure 6-2 shows the

mounting dimensions.

Figure 6-2 - Dewpoint Sensor Dimensions

It may be necessary to cut a 0.25” x 0.25”(6.35 mm x 6.35 mm) notch in the edge of the metal frame behind

the sensor for the wires to pass through.

6.1.4. Dewpoint Sensor Wiring

The dewpoint sensor cable can be 20-24 AWG range. Emerson recommends Belden# 8771 (P/N 135-8771)

22AWG cable or equivalent (not supplied). To install or remove wires from the dewpoint sensor connector,

insert a small screwdriver, such as a Phoenix Contact (P/N 011-6993) PTSM Screwdriver (not supplied), into

the top rectangular slots on the connector (above the wire terminals) until it stops; insert or remove wires as

shown in Figure 6-4. Insert the three wires on the other end of the cable to the matching 3-pin connector of the

low voltage end of Control Link ACC by pressing in the orange tabs above the terminals using the small

screwdriver. Ensure the wire colors match for the Power, Data and Ground terminals on Dewpoint Sensor and

the Control Link ACC.

8 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 15

Figure 6-3 - Dewpoint Sensor Wiring

ACC

LOW VOLTAGE END

3-pin connector

2-pin

connector

TEMP

SENSOR

CABLE

BLACK

RED

WHITE

GND

PWR

DATA

THERM

THERM

Figure 6-4 - Dewpoint Sensor Connector - ACC View

The Dewpoint Sensor Mounting and Wiring the Sensors • 9

Page 16

6.1.5. Dewpoint Sensor Storage

Prior to installation, dewpoint sensors should be

stored separately from the cables. Do not store cables

and sensors together for a long period of time in a

closed box or bag. The sensor should be separated

from the cables when a shipment is received and

stored apart, preferably exposed to room air. The

sensors can become contaminated by outgassing from

the cable insulation if kept in a closed up box or bag

with the cable. Contamination can be reversed with

exposure to room air over a period of weeks or in a

temperature/humidity chamber over a period of three

days.

NOTE: If replacing the dewpoint sensor,

replace the entire assembly (keep the existing

cable).

6.2. The Door Frame

Temperature Sensor

6.2.1. Placement

The door frame temperature sensor should be

placed in an area where it can measure the

temperature of the door frame in the location on the

door frame that stays the coldest. The coldest spot on

a door frame is usually the bottom horizontal section

of the stationary frame, under the center door (for

cases with even-numbered doors), or near the center

mullion (for cases with odd-numbered doors). Cooler

doors may also be coldest at the top center of the

frame. Figure 6-1 on page 7 shows an example of

placement in a case with even-numbered doors — the

sensor is placed under the door just to the left of the

center mullion where the Control Link ACC is

installed. Do not mount the sensor outside the case

mullion - mount the sensor inside the case mullion.

Mount the case door frame temperature sensor

along the door frame inside the frame. Secure the

sensor in place by screwing it to the door frame using

the mounting hole.

The sensor is supplied with a 16-foot (4.88-meter)

cable. Connect the sensor into the 2-pin connector

(labeled THERM) at the bottom (closest to the

LEDs), low-voltage end of the Control Link ACC.

10 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 17

7 Network Wiring and Configuration

E2 PIB COM PORT ASSOCIATIONS

COM1

COM4

COM6

COM2

Serial Device

RS485 COM Port

(2 Connectors)

RS485 COM Card

(2 Connectors)

Serial Device

RS232 Port

POWER INTERFACE BOARD

(PIB)

E2 Modem/Expansion

COM Card Mounted

Above PIB

Plug-In

Modem

Card

COM3

E2 Enclosure (Right Side)

RS485

RS232

If each Control Link ACC will be configured with

its own dewpoint sensor, it is not necessary to network

the Control Link ACC together. However, when

networked, multiple Control Link ACC controllers

may use a single dewpoint sensor. Furthermore,

because the Control Link ACC is a MODBUScompliant device, a site controller can be

programmed to communicate with the Control Link

ACC controllers via MODBUS, supporting remote

configuration and data acquisition.

The E2 controller supports networking of up to 63

Control Link ACC controllers.

7.1. Network Connection to

E2

COM4 and COM6, which are optional ports requiring

expansion cards). COM ports can only be used for one

function; in other words, if COM2 is set up as the I/O

network, you cannot connect MODBUS devices to

COM2. Ensure your E2 is equipped with an RS485

COM Card (P/N 637-4890) and configured in E2

General Services (

, Serial tab) to

enable COM4 or an E2 Expansion COM Card

(P/N 637-4871) to enable COM6.

Connect the MODBUS network cable to the threeterminal connector on the COM port you wish to

assign as MODBUS. Like other Control Link

connections, wire RS485+ to RS485+, RS485- to

RS485-, and the shield cable to the middle term inal. If

the E2 will be the first device in the daisy-chain, set

the port’s termination jumpers to the TERMINATED

& BIASED position (all three jumpers UP);

otherwise, set all jumpers DOWN if not the first

device.

7.2. E2 Setup of Control Link

ACC Devices

Figure 7-1 - Location of E2 COM Ports

requires the E2 to be version 2.71 or above. Contact

Emerson for upgrade information if the controller is a

version before 2.71.

assigned for MODBUS communication (COM2, an

RS485 port on the E2 power interface board, and

Connecting a Control Link ACC to an E2 unit

An E2 has up to three COM ports that can be

7.2.1. Setup Network Ports

Before setting up a Control Link ACC, the port on

the E2 that has the MODBUS cable connected must

be set up as a MODBUS port.

1. Log in to the E2 with Level 4 access.

2. Press

3. Press

followed by - General

Controller Info.

+ to open the Serial tab of the General

Network Connection to E2 Network Wiring and Configuration • 11

Page 18

Controller Info setup screens:

and Controllers.

Figure 7-2 - Serial Communications Manager Screen

4. This screen will have a “Connection” field for all

COM ports on the E2. Highlight the COM port

connection field that will be used for Control Link,

and press - LOOK UP. From the list of

network types, select MODBUS.

5. Four fields will become visible underneath the

COM port connection field, which pertain to the

way the device communicates:

• Baud - Default setting is 19.2k. The baud rate

setting should be set to match the baud rate dip

switch settings of all Control Link devices. (All

devices connected to the same COM port should be

set to the same baud rate.)

• Data Size - Leave this field at the default value (8).

• Parity - Leave this field at the default value (None).

• Stop Bits - Leave this field at the default value (1).

6. Press

to save changes and exit.

7.2.2. Add and Connect Control Link

ACCs - E2 Firmware Revision

Prior to 2.8

Figure 7-3 - Connected I/O Screen

3. In the Connected I/O screen, in a section labeled

ECT Devices. Enter the number of ACC devices in

the CtrlLink ACC number field.

4. Press

5. Locate the CtrlLink ACC units you added to the

to return to the Network Setup menu,

then select

network list (press

list). The default name for a Control Link ACC

begins with a two-letter designator of the model

type (AC for anti-condensate). If desired, enter a

new name for each device in the Name field.

- Controller Setup.

and to scroll through the

To enable communications between E2 and the

Control Link units, the devices must be added and

addressed in E2.

1. Log in to the E2 with Level 4 access.

2. Press

12 • Control Link ACC I&O Manual 026-4704 Rev 6

- Connected I/O Boards

Figure 7-4 - Controller Setup Screen

6. By default, each CtrlLink ACC in the network list

has a board number of 0. To set the address and

begin communication, press

Select Address. In the list of MODBUS devices,

choose the address number corresponding to the

and select -

Page 19

Control Link ACC’s dip switch/jumper setting, and

to select it. If a network ID has already

press

been selected, its name will be shown next to the

network ID in this list. If the network ID you are

trying to assign has already been used, you must set

the network ID dip switch/jumper on this device to

a different number that is not being used.

the Control Link ACC having a firmware version

older than the minimum revision required by E2 for

communication. Replace the Control Link ACC

with a new controller that has the latest version of

firmware on it.

Figure 7-6 - Online Status Screen

Figure 7-5 - List of MODBUS Devices

7. Repeat Steps 5 and 6 until each Control Link ACC

device has a name and address.

8. When finished, press

Setup menu, then press

7-6). Locate the Control Link ACCs you set up, and

look at each device’s status in the Status field. You

will see one of the following messages:

• Online - The Control Link ACC is communicating

normally.

• Offline - The Control Link ACC is not

communicating, has not been commissioned, is not

functional, or is not powered up. Verify the Control

Link ACC is powered up, wired correctly, and has

the proper network address, baud rate, and parity

(see Section 11, Troubleshooting Control Link

ACCs and the ECT MODBUS Network).

• Unknown - The Control Link ACC is not

communicating or has not been commissioned.

Verify the Control Link ACC is powered up, wired

correctly, and has the proper network address, baud

rate, and parity (see Section 11, Troubleshooting

Control Link ACCs and the ECT MODBUS

Network).

• No Port - No port is set up in the E2 Serial

Configuration Manager to be a MODBUS port.

Follow the instructions in Section 7.2.1., Setup

Network Ports on page 11).

• Wrong FW Rev - This message is likely caused by

t o return to the Network

- Online Status (Figure

7.2.3. Add and Connect Control Link

ACCs - E2 Firmware Version

2.8 and above

To enable communications between E2 and the

Control Link units, the devices must be added and

addressed in E2.

1. Log in to the E2 with Level 4 access.

2. Press

Figure 7-7 - Connected I/O Screen

3. In the Connected I/O screen, under the ECT tab,

- Connected I/O Boards

and Controllers.

E2 Setup of Control Link ACC Devices Network Wiring and Configuration • 13

Page 20

Enter the number of ACC devices in the CtrlLink

ACC number field.

4. Press

5. Locate the CtrlLink ACC units you added to the

Figure 7-8 - Network Summary Screen

6. By default, each CtrlLink ACC’s board number in

to return to the Network Setup menu,

then select

network list (press

list). The default name for a Control Link ACC

begins with a two-letter designator of the model

type (CL for ControlLink) and a three-letter

designator for ACC (anti-condensate controller).

the network list is indicated by a - (dash). To set the

address and begin communication, press

Commission. (If you have more than one MODBUS

network, specify which network you want the

device to belong to.) A screen will open that will

allow you set the address:

- Network Summary.

and to scroll through the

to

Figure 7-9 - Set the Address of the ACC

7. In the list of MODBUS devices, choose the address

number corresponding to the Control Link ACC’s

dip switch/jumper setting, and press

it. If a network ID has already been selected, its

name will be shown next to the network ID in this

list. If the network ID you are trying to assign has

already been used, you must set the network ID dip

switch/jumper on this device to a different number

that is not being used.

to select

14 • Control Link ACC I&O Manual 026-4704 Rev 6

Figure 7-10 -

8. Repeat Steps 5 and 6 until each Control Link ACC

9. When finished, press

List of MODBUS Devices

device has been commissioned.

t o return to the Network

Setup menu, then press

(Figure 7-8). Locate the Control Link ACCs you set

up, and look at each device’s status in the Status

- Network Summary

Page 21

field. You will see one of the following messages:

• Online - The Control Link ACC is communicating

normally.

• Offline - The Control Link ACC is not

communicating, has not been commissioned, is not

functional, or is not powered up. Verify the Control

Link ACC is powered up, wired correctly, and has

the proper network address, baud rate, and parity

(see Section 11, Troubleshooting Control Link

ACCs and the ECT MODBUS Network).

• Unknown - The Control Link ACC is not

communicating or has not been commissioned.

Verify the Control Link ACC is powered up, wired

correctly, and has the proper network address, baud

rate, and parity (see Section 11, Troubleshooting

Control Link ACCs and the ECT MODBUS

Network).

• No Port - No port is set up in the E2 Serial

Configuration Manager to be a MODBUS port.

Follow the instructions in Section 7.2.1., Setup

Network Ports on page 11).

• Wrong FW Rev - This message is likely caused by

the Control Link ACC having a firmware version

older than the minimum revision required by E2 for

communication. Replace the Control Link ACC

with a new controller that has the latest version of

firmware on it.

7.3. Wiring Types

Emerson specifies Belden #8761 shielded twisted

pair cables for use as MODBUS wiring (or Belden

#82761 and Belden #88761 for plenum installations).

If the recommended cable is not available in your

area, be sure the wiring meets or exceeds the

following specs:

Shielded? Yes

Conductor Type Twisted Pair

Gauge 18 - 24 AWG

Capacitance

between signal

wires

Capacitance between signal and

shield

Maximum Length 4000 ft/18 to 22 AWG

Nominal

Impedance

31 pF/ft or less

(9.45 m) or less

59 pF/ft or less

(17.98 m) or less

(1219.2 m)

2500 ft/24 AWG

(762 m)

12050

Figure 7-11 - Network Summary Screen

Wiring Types Network Wiring and Configuration • 15

Page 22

ACC

Te rm i n at i o n

Block

ACC

(bare wires) to 0V or

SHIELD terminal

S

H

I

E

L

D

+

Tie SHIELD to Earth Ground

at each node. Keep additional

wire length < (less than)

6” (15.24 cm)

7.4.2. Step 2: Connect the MODBUS

7.4. MODBUS Network and

Network Cable

Daisy-Chaining

Figure 7-13 - Control Link ACC Network Connection

MODBUS network cable has two conductors plus

Figure 7-12 - Control Link ACC Daisy Chain

Control Link ACC must be networked in a single

open communications loop, or daisy chain. A daisy

chain connects all the Control Link ACCs together in

a single unbranched series, and requires termination

jumpers to be set on the controllers at either end of the

chain. No branching or “star configurations” are

allowed.

7.4.1. Step 1: Disconnect Power to

the Control Link ACC and Open

the ACC Enclosure

WARNING! DISCONNECT THE SUPPLY

POWER FROM THE CONTROL LINK ACC

BEFORE OPENING THE ENCLOSURE.

OPENING THE ENCLOSURE WHILE THE

CONTROL LINK ACC IS POWERED MAY RESULT

IN ELECTROCUTION.

Connecting a Control Link ACC to a MODBUS

network requires you to remove the top cover from

the Control Link ACC enclosure. Press down the tab

at the main voltage end of the enclosure, and remove

front cover of the Control Link ACC. If the Control

Link ACC is already mounted in the case mullion,

you may have difficulty removing the front cover; if

so, loosen the top mounting screw before pressing the

tab.

16 • Control Link ACC I&O Manual 026-4704 Rev 6

a shield. For each Control Link ACC, connect the two

conductors to the 485 terminals of the MODBUS

connector labeled + and - (at the bottom, low voltage

end of the enclosure), making sure to use the same

wire colors for each Control Link ACC connection.

For example, if the conductor wire colors are BLACK

and WHITE, use BLACK for all 485+ terminals and

WHITE for all 485- terminals (or vice-versa).

Connect the bare (SHIELD) wire to the center Shield

terminal (0V terminal on the E2).

7.4.3. Step 3: Set the Network

Address

NOTE: If you are networking Control Link

ACC only for purposes of sharing a dewpoint

sensor, you do not need to set a network

address. Set all network address dip switches or

jumpers to the DOWN (OFF) position. This will allow

the Control Link ACC to share a dewpoint sensor as

long as the network is physically present and terminated

correctly. The network address is only necessary for

assigning a network ID for MODBUS applications.

Depending on the hardware revision, the Control

Link ACC board has either eight dip switches or eight

three-pin jumpers, located in between the controller

and network status LEDs. Switches or jumpers 1-6 set

the network ID for the controller. Switches 7 and 8 set

the network baud rate and parity.

Page 23

Each Control Link ACC that will use the MODBUS network must have a unique network ID. Number each

controller in sequence, starting with 1. Refer to Figure 7-14 for dip switch and jumper settings

Figure 7-14 - Control Link ACC Network ID Dip Switch/Jumper Settings

7.4.4. Step 4: Set the Network Baud Rate and MODBUS Parity

Figure 7-15 - Control Link ACC Network Baud Rate/Parity Dip Switch/Jumper

NOTE: If you are networking Control Link ACC only for purposes of sharing a dewpoint sensor, you do not

need to set a baud rate or parity. Set all dip switches or jumpers to the DOWN (OFF) position.

the Control Link ACC to share a dewpoint sensor as long as the network is physically present and terminated

correctly. The dip switches or jumpers are only necessary for assigning a network ID for MODBUS applica-

tions.

This will allow

MODBUS Network and Daisy-Chaining Network Wiring and Configuration • 17

Page 24

In order for the Control Link ACC to communi-

TB

END

OF

DAI

SY CHAI

N

FROM LAST

DEVICE

AT END OF

DAISY-CHAIN

SHIELD

WIRE

(CONNECT

TO EARTH

GROUND)

cate with each other on the MODBUS network, they

must all be set to communicate at the same baud rate

and parity.

Switch/jumper 7 determines the baud rate at which

the controllers communicate. When switch/jumper 7

is ON, the Control Link ACC will operate at 9600

baud. If switch/jumper 7 is OFF (default), the Control

Link ACC will operate at 19200 baud. Switch/jumper

8 determines the MODBUS network parity. Some

MODBUS-enabled site controllers require even

network parity; to enable even parity, set switch/

jumper 8 to the ON position. For site controllers that

require no parity, set switch/jumper 8 to the OFF

(default) position.

7.4.5. Step 5: Terminate the End

Devices

wired to the end of the cable segment using the threepin connector. Wire the two signal wires to the outside

terminals, and connect the shield to Earth Ground:

Figure 7-17 - MODBUS Termination Block

7.4.6. Step 6 - Connect a Dewpoint

Sensor to Control Link ACC(s)

on the Network

Figure 7-16 - Control Link ACC Network Termination

Once all Control Link ACCs are networked, you

must terminate the end devices on the network.

7.4.5.1. Termination Block Network

Because the Control Link ACC has no on-board

means of termination, use the MODBUS termination

block (P/N 535-2711) for termination that can be

Once the Control Link ACCs are networked and

properly terminated, the only step remaining to allow

the Control Link ACCs to share a dewpoint sensor is

to connect at least one dewpoint sensor to one Control

Link ACC on the network. Any Control Link ACC on

the network can be configured with the dewpoint

sensor.

Each Control Link ACC first looks for a dewpoint

sensor connected to itself. If a dewpoint sensor is

directly connected to a Control Link ACC, it will use

that sensor for its dewpoint value and broadcast the

sensor’s value on the MODBUS network. If no sensor

is directly connected to a Control Link ACC, it will

au tomatically look on the MODBUS network and use

the sensor value broadcast by another Control Link

ACC that has a sensor.

For fail-safe purposes, you may have multiple

dewpoint sensors connected to different Control Link

ACCs on the network. The Control Link ACCs

automatically select a primary sensor to use, and will

switch to another dewpoint sensor on the network if

the primary sensor fails or is disconnected.

For dewpoint sensor wiring instructions, refer to

Figure 6-3 and Figure 6-4.

18 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 25

7.4.7. Step 7: Set the Setpoint

Temperature Offset

Figure 7-18 - Dewpoint Sensor Offset Button

The Control Link ACC seeks to maintain a

constant minimum difference between the dewpoint

of the outside air and the temperature of the door

frame. You may specify how big this difference will

be by pressing the temperature offset button on the

dewpoint sensor.

The offset button on the dewpoint sensor is located

on the lower left side of the sensor enclosure

(see Figure 7-18), and the offset value is indicated by

the LED in the upper left corner of the dewpoint

enclosure. The LED will normally flash once every 4

seconds.

1. Step 1: Push and hold the offset button for 5

seconds to enter the configuration mode. (The LED

will illuminate solid for 5 seconds prior to entering

configuration mode. After 5 seconds it will turn off

to indicate the dewpoint sensor has entered

configuration mode.)

2. Step 2: Release the offset button and the LED will

flash from 1 to 8 times depending on the current

offset configuration. Each LED flash represents a 1degree Celsius (1.8°F) incremental temperature

offset. If the button is not pushed any further, after

10 seconds the unit will exit the configuration mode

and will resume its normal operation and flash the

LED once every 4 seconds. (Repeat Step 1 to reenter the configuration mode.)

3. Step 3: If the button is pushed within 10 seconds

after the current setting is flashed, the offset value

will increment by 1 degree Celsius (1.8°F) and the

LED will flash the new offset value as one flash per

degree Celsius of offset. For example, if the offset

is set at 8°C (14.4°F), and the button is pushed to

increment the value, the value will start over at the

1-degree Celsius offset (1.8°F).

NOTE: If the offset button is pressed for more

than 15 seconds, the LED will remain ON solid

to indicate an offset button stuck condition, but

the offset value will not be changed.

The offset button determines the number of

degrees (in Celsius) that will be added to the value of

the dewpoint sensor to determine the target

temperature of the door frame. For example, if the

current dewpoint is 5°C (41°F) and the button is set to

a medium offset of 2°C (3.6°F), the Control Link

ACC will control the heaters to achieve a door frame

temperature of 7°C (44.6°F). As the dewpoint rises

and falls, the door frame temperature setpoint will

also rise and fall, so that the door frame temperature

will always stay slightly above the current dewpoint.

The Control Link ACC uses the offset button on

the dewpoint sensor to determine the value of the

temperature offset. The Control Link ACC prioritizes

them in the following ways:

1. If E2 is connected, the offset is configured at the E2.

2. If sharing a dewpoint sensor, the remote offset is

provided even if the Control Link ACC has its own

dewpoint sensor.

3. The local dewpoint sensor’s offset is used.

This priority structure is designed to make it easier

for temperature offsets to be changed in the field (by

simply changing it on the dewpoint sensor), and it

also allows multiple cases to use the same sensor

while using different temperature offsets.

TIP: Experiment with offsets to find the

lowest possible setting that still offers good

performance. In many cases, depending on

the placement of the door frame temperature

sensor, a LOW offset will still provide good anticondensate performance. The lower the offset being

used, the higher the energy savings.

7.4.8. Step 8 - Network

Configuration Is Complete Restore Power to the ACC

Restore power to the ACC and check the status of

the network by observing the LEDs on the front of

each Control Link ACC enclosure:

• If network communication is active, you should see

the RX LED blinking at least once every 15

seconds. If you see no activity or a regular blinking

pattern, there may be a problem with the MODBUS

MODBUS Network and Daisy-Chaining Network Wiring and Configuration • 19

Page 26

network wiring or configuration.

• For Control Link ACCs equipped with dewpoint

sensors, you should see the TX LED blink to

indicate transmission. If not, there may be a problem

with MODBUS or dewpoint sensor wiring.

• For Control Link ACCs that do not have dewpoint

sensors directly connected to them, verify the Status

LED is blinking once every 2 seconds to indicate

status is OK. If this LED blinks in a repeating

pattern of three short blinks, it means the Control

Link ACC is not receiving a dewpoint sensor value

broadcast over the network. There may be a problem

with the MODBUS or dewpoint sensor wiring.

20 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 27

8 The ACC Hand-

1

4

3

2

5

6

7

8

10

9

11

12

13

14

LEGEND

Up Arrow

1

3

4

11

7

8

9

10

2

Power Switch

RS-485 Connector

Enter Key

LCD

Numeric keypad

Function Key F1

External Power Connector (9-12 VDC)

Period and Minus Keys

5

6

13

Function Key F2

Right Arrow

Down Arrow

Cancel Key

12

14

Left Arrow

Held Terminal

Interface

The RS-485 port supports the following:

• Standard dumb terminal mode protocol

• PL-430 version of I/O net

•I/O Net

•MODBUS

8.2. Keys and Functions

8.1. HHT Hardware

Overview

Key Functions

F1 Key Returns you to the Home Screen.

F2 Key Takes you to the Main Menu

Enter Saves your settings into the memory

Cancel Clears/Erases texts in the editable

field; cancels overrides

Left Arrow Selects the first editable field from

top of screen, and the next editable

field from top to bottom

Right Arrow Selects the last editable field starting

from the bottom of the screen; and

the previous editable field from

bottom to top

Down Arrow Moves to the next screen, editable

field, end of screen, or advances

Up Arrow Go back to previous screen, editable

field, or top of screen

Period Key Scroll list selections and scroll

Minus Key

Number Keys

(numbered 0-9)

through ASCII characters if in a text

field

Choose a menu option or enter a

value

Figure 8-1 - Hand-Held Terminal

The power switch determines the power mode of

the device, whether if self-powered (BATT), external

powered (EXT), or powered by a target device

(HOST).

The LCD screen can display up to 4 lines of

characters (each line can hold 16 characters). It

displays the home screen and the different menu

screens of the HHT. The LCD serves also as a visual

indicator that the HHT is functioning.

HHT Hardware Overview The ACC Hand-Held Terminal Interface • 21

Table 8-1 - HHT Keys and Functions

Page 28

8.3. Hand Held Terminal

ECT HHT: <S/W>

814 - 3112

(PRESS )

VER: 1.00F01-01

8.4. Connecting the HHT

Expansion Board

Figure 8-2 - Hand Held Terminal Expansion Board

With the 814-3112 Hand-Held Terminal and the

536-3120 Adapter Board, you can access the ACC via

its MODBUS communication port without having to

use the site controller. The Hand-Held Terminal

interface allows you to perform these general

functions:

• View failure messages that relate to the ACC

• View the status of inputs

• View the output percentage ON

• Override the outputs to a fixed percentage

• Make temporary or permanent changes to set points.

If also connected to a site controller, any changes

will be overwritten

An ACC HHT will also have these specific

functions:

• It can issue a command to switch the MODBUS port

into a dumb HHT port to view and set ACC

information like a standard HHT

• It can be used to update firmware for the attached

ACC

Adapter Board

The HHT Adapter Board is connected on the low

voltage end of the ACC using a standard Belden 8761

cable (shown in Figure 8-3). The Hand-Held

Terminal plugs into the RJ11 jack on the HHT

Adapter Board. Press the Hand-Held Terminal

connector into the jack until it snaps into place. When

the connector is correctly seated, and the HHT is

powered up in Battery or External Power Position the

user will see the Home screen of the HHT.

8.4.1. HHT Home Screen

If the ACC is connected to an E2 network, the

network connection needs to be removed.

22 • Control Link ACC I&O Manual 026-4704 Rev 6

Figure 8-3 - HHT Adaptor Board Connection to the ACC

Page 29

8.5. HHT Interface

CONTROL LINK ACC

815 - 6100

(PRESS )

VER: 1.00F01-01

SELECT

1= SLAVE TERMINAL

3= UPGRADE ACC FW

2= ACC HHT MODE

ACC SETUP

BAUD : 19200

ADDR : 1

PARITY : NONE

WAITING CONNECT

TO MASTER CNTRL

Navigation

The Hand-Held Terminal interface consists of a

simple series of screens and menus.

8.5.1. Scrolling Through The HandHeld Screens

The up arrow and down arrow keys are used to

scroll through the screens. Some of these screens are

read-only, others are either menus that require you to

enter a selection or are configuration screens that have

one or more editable fields. The right arrow and left

arrow are used to select editable fields.

8.5.2. Shortcut Keys (F1 and F2)

At any time, you may press the F1 key on the

Hand-Held Terminal to return to the Home Screen, or

F2 to view the first status screen.

8.5.3. ACC HHT Network Setup

When the ACC is connected to the HHT for the

first time using the HHT protocol, the Network Setup

menu will be displayed.

HHT ONE-ON-ONE connection type (no other

nodes connected to the network). See Section 8.5.8.

for details.

If setting the address via the dip switches, set the

address to match the dip switch numbering in the

HHT Network Setup Screen (ADDR: 1).

Selecting option 2 (ACC HHT MODE) will lead

you to the Network Setup screen.

The network screen will display the baud rate, address, and parity selection. A baud rate of 19200 is

recommended, set the parity to NONE, and choose

the address of the ACC unit you need to access. A

message will then appear:

SLAVE TERMINAL: Returns the HHT into a mode

controlled by the host.

ACC HHT MODE: Enter the mode where the

MODBUS port runs the standard HHT dumb terminal

protocol.

UPGRADE ACC FW: Upgrade the firmware of an

ACC to the version loaded on the HHT.

NOTE: Press F1 for approximately 6 seconds

to return to this screen at any time.

8.5.3.1. Modes of ACC Addressing

The ACC can be addressed in two different ways,

via the dip switch on the unit or by using the HHT to

set the address over MODBUS. If you are setting the

address with the HHT, all the dip switches must be set

to 0 or OF F, a nd you must be d irectly conne cted to t he

Once you are in the ACC HHT mode, it will

display the ACC home screen (see Section 8.5.4.).

To leave ACC HHT mode to access another ACC,

press F1 for approximately 6 seconds. You will see

the Home Screen for the HHT shown at the start of

Section 8.4.

8.5.4. The ACC HHT Interface

8.5.4.1. ACC Start Screens

After finishing the initial setup, the HHT display

will show the model type, the part number, and the

firmware revision.

The fourth line of the home screen will flash and

display failure information if the HHT detects an

internal or communication problem after its powerup. If more than one failure exists, information will be

displayed according to the following priority order:

• FAIL: FLASH/CLK: The flash memory on the

HHT Interface Navigation The ACC Hand-Held Terminal Interface • 23

Page 30

micro is corrupted, and/or the crystal clock is not

DOOR TMP: 12.6

DOOR STPT: 13.0

TMP: 75 RH: 50

ROOM DP: 32.0

DUTY CYCLE%: 34

OVR: NO %: 00

SAVINGS%: 62

OVR SRC: HHT

functioning properly

• FAIL: DEWPT SNS: The ACC does not have a

valid dewpoint sensor reading.

• FAIL: TEMP SNS: The door frame temp sensor is

not functioning properly.

• FAIL: OVER TEMP: The output heater is turned

off because the driver is overheating.

OVR SRC: Source of the current override (HHT or

REMOTE).

NOTE: The HHT will be able to override an

override that was initiated remotely. The user

will be able to override the heater output to a

fixed percentage. Once the HHT is removed,

the override will end.

8.5.5. ACC Status Screens

The two ACC Status Screens show the current

readings of all ACC inputs, the Relative Humidity, the

Ambient Temperature, the Dewpoint and the Door

Temperature, and other operating information.

8.5.5.1. Input Status Screen

DOOR TMP: The current value from the door frame

temperature sensor. The statuses OPEN or SHORT

mean the sensor is not functioning properly.

DOOR STPT: The current value of the door frame

temperature setpoint.

ROOM DP: The current value of the room dewpoint

sensor. NONE means the ACC has not received a

valid dewpoint reading.

TMP: The current value of the ambient temperature.

NONE means the ACC has not received an ambient

temperature reading. The ACC bases control on the

dewpoint sensor so this is not critical.

RH: The relative humidity. NONE means the ACC

has not received a relative humidity reading. The

ACC bases control on the dewpoint sensor so this is

not critical.

SAVINGS%: The percentage of time the heater has

been off. This field may be reset by selecting it and

pressing cancel.

8.5.6. ACC Configuration Screens

All of the configuration of the ACC may be

changed using the HHT. HHT users may change

setpoints and overrides.

8.5.6.1. HHT Changes When ACC is

Connected to E2

All changes to setpoints made by the HHT are

temporary if the ACC is connected to a parent E2.

Changes made in the HHT do not change the

configuration stored in the E2. When the HHT is

unplugged from the ACC, all changes made by the

HHT are overwritten by the E2, including output

overrides. If you wish to make permanent changes to

the ACC’s configuration, you must make them

through the E2 (or through a remote communication

program connected to the E2, such as UltraSite32).

8.5.6.2. HHT Changes When ACC is

Stand-Alone

If the ACC is operating standalone with no

connection to an E2, the HHT is the only method that

may be used to change configuration. When the HHT

is unplugged from the ACC, all changes to

configuration will be saved. Overrides made with the

HHT, however, will be canceled when the HHT is

unplugged.

8.5.5.2. Output Status Screen

DUTY CYCLE%: The current output condition.

OVR and %: Active heater output override (YES or

NO) and percentage.

24 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 31

8.5.6.3. The Main Selection Screen

SELECT:___1

1: NETWORK

3: CTRL OPTIONS

2: TEMP OFFSET

ACC SETUP

BAUD : 19200

ADDR : 1

PARITY : NONE

DEW POINT SENSOR

STATE: ONLINE

VER: 1.00FO1

CONTROL LOOP:

MODE: CLOSED

BoardTemp: 77.3

OFFSET SRC: REM

ACT OFFSET: 1.0

CYCLE TIME: 0

PRG OFFSET: 2.0

100%DewPT: 65

0%DewPT: 25

CYCLE TIME: 10

Press down arrow past the Status Screen to access

the Main Selection screen. To select, press the right

arrow key, enter the number of the sub-menu you

wish to access, then press down arrow key twice to

access the sub-menu’s first screen.

• Network - General info about the ACC network and

dewpoint sensor attached.

• Temperature Offset - Setpoints that determine the

operation of the ACC.

• Ctrl Options - Where PID parameters are selected

8.5.6.3.1. Network

The network screen will display the baud rate,

address, and parity selection.

Board temperature will shutdown the output

heater if greater than 212°F (100°C)

Two modes can be selected for the temperature

offset, Closed Loop, and Open Loop.

Closed Loop

Closed Loop is the default that uses the Door

Temperature feedback.

OFFSET SRC: Specifies the source of the set point

offset:

• REM - Remote means it takes the offset reported

over ModBus network.

• PRG - Program means it uses the offset configured

as part of the user configuration.

• LOC - Local means it uses the offset set for the local

dew point sensor.

ACT OFFSET: Active temperature offset.

PRG OFFSET: Programmed temperature offset.

CYCLE TIME: Set from 0 to 30 seconds

(recommended setting). If the Cycle Time is 0 then

the controller will work in an instantaneous mode

where the output is updated every 0.1 seconds. Leave

the value to 0 for the greatest energy savings.

If the dewpoint sensor is connected, a screen will

display the state (ONLINE or OFFLINE) and the

firmware version of the sensor.

8.5.6.3.2. Temperature Offset Screen

The source of the set point offset can be selected

on the temperature offset screen. The set point offset

is added to the dew point to determine the setpoint for

door temperature.

HHT Interface Navigation The ACC Hand-Held Terminal Interface • 25

Open Loop

100%DewPT: Temperature offset at 100%.

0%DewPT: Temperature offset at 0%.

CYCLE TIME: Set from 0 to 30 seconds. For an

Open Loop operation, 10 seconds is recommended.

Page 32

8.5.6.3.3. Control Options Screen

PI PARAMETERS

P: 2.0

TEMP: FAHRENHEIT

I: 0.10

SELECT

1= SLAVE TERMINAL

3= UPGRADE ACC FW

2= ACC HHT MODE

CONTROLLINK ACC

VER: 3.10B006

UPGRADE: NO

SLOT: 1 CNT: 0

ACC SETUP:

BAUD: 19200

ADDR: 1

PARITY: NONE

UPGRADE RESULT:

FIRMWARE UPDATED

ACC SETUP:

BAUD: 19200

ADDR: 1

PARITY: NONE

ONE-ON-ONE?

NEED TO SET NODE

PROCEED?: NO

BAUD AND PARITY.

If the upgrade was successful this screen will

display:

The PID Parameters have been set to default

values 2.00 and 0.10. These values should not need to

be changed.

TEMP: Used to set the HHT display option. All

temperatures are in degrees Celsius internally, but

when TEMP is set to Fahrenheit (default) they are

displayed as Fahrenheit.

8.5.7. Upgrading ACC Using HHT

Return to the main HHT screen by pressing F1 for

approximately 6 seconds (if you are talking to an

ACC and in the ACC mode)

Select 3 for upgrade firmware and a new screen

will appear:

Press the down arrow to go to the Menu screen.

8.5.8. Changing ACC Address Using

HHT

If you are setting the address of the ACC with the

HHT, you must be connected directly to one and only

one ACC. From the Home screen, choose 2 (ACC

HHT mode), choose the address, and press down

arrow. (The user can also set the baud and parity,

19200 and no parity is recommended)

Pressing the down arrow may show you the next

screen if the HHT doesn't find an ACC at that selected

address.

Use the right/left arrow to see the arrow appear

next to NO (default). Press the – (dash) button to

toggle to YES.

Select the address of the ACC to upgrade.

Press the down arrow to start the upgrade. The

Block number will update as blocks are sent to the

ACC.

26 • Control Link ACC I&O Manual 026-4704 Rev 6

The HHT will ask if you are connected to the ACC

that you wish to communicate with directly; the user

has to be connected directly to set the address of an

ACC. Press the left or right arrow keys to display the

arrow next to the NO (default). Press the - (dash) key

to toggle it to YES.

Once the address (and/or baud and parity) is

changed, you will be connected in ACC HHT mode

and you will see the ACC Home Screen. See Section

8.5.4. for more details.

NOTE: If the address is already pre-set on the

ACC using the dip switches, the address cannot

be changed with the HHT. The pre-set dip

switches on the ACC will always take priority.

Page 33

8.5.9. Exit HHT Mode

To exit a current mode on the HHT, unplug and

reconnect (cycle power) or press down the F1 key for

6 seconds. This will return you to the HHT home

screen where you can access the ACC-HHT Mode

option. Select the address of the ACC you wish to

access.

HHT Interface Navigation The ACC Hand-Held Terminal Interface • 27

Page 34

9 Operation

The Control Link ACC uses two algorithms for

modes of operation. For the standard mode of

operation, the Control Link ACC prevents moisture

accumulation by maintaining door frame temperature

based on the dewpoint and setpoint offset. The

alternate PMAC mode of operation can be configured

from the E2 and is also used under failure conditions

if no door frame temperature sensor is available.

Using the PMAC algorithm, the Control Link ACC

will calculate the heater ON time based on the

dewpoint temperature. The configuration has two

parameters: the first sets the lower dewpoint

temperature at which the heater will be OFF. The

second sets the upper dewpoint temperature at which

the heater will be 100% ON. A linear calculation is

made between those limits:

Heater ON% = 100%*(Current _Dewpt - DewptOFF)

(DewptON - DewptOFF)

The ACC monitors a board temperature near the

heater output driver to ensure that the heater driver

does not exceed its maximum temperature rating.

There is a back-off algorithm that will become active

once the monitored board temperature says the heater

driver is within 6°C (10.8°F) of the maximum

temperature rating. At 6°C (10.8°F) below the

maximum rating, the ACC will not let the heater

driver be ON more than 95% of the time. If the

temperature continues to rise and is within 3°C

(5.4°F) of the maximum rating of the heater driver,

the algorithm will not let the heater driver be ON

more then 90% of the time. The final step is triggered

if the heater driver is more than 2°C above its

maximum rating at which time the heater will be

turned OFF. This is the OVER TEMP failure

condition (see Section 10, Error Modes). Once the

heat driver temperature drops 5°C (9°F) it will be

allowed to come back ON.

This back-off strategy will only come into affect if

the heater has to be ON 100%, you are running at the

maximum rated current, you are at maximum rated

ambient for the ACC.

9.1. Control Link ACC Status

LEDs

Figure 9-1 - LED Locations

The Control Link ACC has four status LEDs that

indicate what the controller is doing. They are: the red

Heater Status LED (HEAT), the green General Status

LED (Status) and the two Network Status LEDs (red

transmit TX and yellow receive RX).

9.1.1. Heater Status LED

The Heater Status LED (Heat) glows red any time

the door heaters are ON, and is OFF when the heaters

are OFF.

Under normal operation, this LED should pulse

ON and OFF when no door sweat is visible, indicating

it is pulsing the heaters to maintain the necessary

amount of heat to prevent door sweating (given the

current dewpoint and case temperature). When a case

door is opened, the LED will remain ON for longer

periods of time (and may even remain ON without

pulsing) to compensate for the change in case door

frame temperature.

Note that it is possible for this LED to remain OFF

for long periods of time if the dewpoint is very low

(e.g., during dry winter days).

9.1.2. General Status LED

The General Status LED blinks green to indicate

the controller is powered up and functioning

normally, and whether or not there are any alarm

conditions.

If the controller is functioning normally, the

Status LED will blink once per second. If there is an

error condition, it will blink at different rates to

indicate the active error condition (see Section 10,

Error Modes).

28 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 35

9.1.3. TX and RX Status LEDs

If the Control Link ACC is being networked with

other Control Link ACCs via its MODBUS network

connection, the TX and RX LEDs blink to indicate

transmission and receipt of network messages. On a

properly networked Control Link ACC, the RX LED

should blink about once every 15 seconds. If a

Control Link ACC has a dewpoint sensor, you should

also see the TX LED blink. If these LEDs do not

blink, there may be a problem with the MODBUS

network connection.

Control Link ACC Status LEDs Operation • 29

Page 36

10 Error Modes

The Control Link ACC has several error modes it

will enter when failures occur. The controller has a

General Status LED that blinks at a 0.5 Hz (1 blink

per second) rate if the microprocessor is running. If

any of the error modes below occur, the green Status

LED will blink at a rate specific to the error condition.

The controller has a Heat LED that illuminates when

the heater is on. In the case of an error condition, the

heater will go into the indicated mode. For each error

mode, note the priority level — if more than one error

mode is active, the LED blink rate will only show the

error condition with the highest priority (priority #1 is

the highest, and priority #5 is the lowest). Note that a

higher priority will mask a lower priority error until

the higher priority is fixed.

10.1.Priority 1: FAIL: OVER

TEMP

The board temperature sensor has determined that

the heater driver is exceeding its maximum

temperature rating. If this condition is detected, the

heater output will be turned OFF. Once the

temperature has fallen at least 5°C (9°F), the heater

will be allowed to come back ON. General Status

LED blinks 5 times: pause - 5 times - pause, and then

repeats.

10.3.Priority 3: FAIL: DEWPT

SNS

Cannot communicate with the dewpoint sensor,

and there is no dewpoint data being broadcast. The

ACC will attempt for a duration of 100 seconds to

communicate with a local dewpoint Sensor before

flagging this failure. Once past the first 100 seconds,

the remote timeout is 46 seconds before this error will

occur. If there is no dewpoint sensor, the heater will be

on 95% of the time. The General Status LED blinks 3

times: pause - 3 times - pause, and then repeats.

10.4.Priority 4: FAIL: FLASH/

CLK

Either the Flash executable code has changed or

the hardware clock is not functioning properly. The

General Status LED blinks: short - long - pause, and

then repeats.

10.5.Priority 5: FAIL:

CONFIGURE

The user configuration has an error in the version

stored in flash. The General Status LED blinks: long

- short -pause, and then repeats.

10.2.Priority 2: FAIL: TEMP

SENS

If the PMAC Algorithm mode is NOT enabled, a

door frame temperature sensor that is open or shorted

is considered to be a failure. The General Status LED

blinks 2 times: pause - 2 times - pause, and then

repeats. If the PMAC Algorithm is enabled, the

General Status LED will continue to blink normally

even if the door frame temperature sensor is not

present. If the door frame temperature sensor is not

present, the Control Link ACC will revert to PMAC

mode for operation.

30 • Control Link ACC I&O Manual 026-4704 Rev 6

Page 37

11 Troubleshooting

Control Link ACCs

and the ECT

MODBUS

Network

11.1.If Control Link ACC is

Offline

1. Check wiring - Verify the Control Link ACC is

properly connected to the MODBUS cable. Verify

the network polarity is correct (+ to +, - to -, 0V to

0V) and there are no loose wires. If none of the

Control Link ACCs are online, check wiring

connections on the E2. Check the cable jackets to

make sure all network cable is Belden #8761 or

equivalent.

6. Check network termination - The two devices on

either end of the MODBUS network should be

terminated, with all other devices in the daisy chain

unterminated. Check termination settings for all

devices on the network.

2. Verify MODBUS Port Setup - Press

E2 front panel. Verify COM2, COM4, or COM6 is

set up as a MODBUS port. If so, verify that the

MODBUS cable is connected to the proper

connectors (refer to Figure 7-1 on page 11). Verify

the COM port fields are properly set for ECT

MODBUS (19.2k baud, data size=8 bits,

Parity=NONE, stop bits=1).

3. Make sure Control Link ACCs were commissioned

- Press

followed by o n the E2 fron t

panel and verify the offline Control Link module

has a non-zero number in its Node/Board# field. If

the number in the Node/Board# field is zero (0),

highlight the controller name and select - SET

ADDRESS followed by

select the network ID that matches the setting on the

network address DIP switch/jumper.

4. Check Control Link ACC network card DIP

switch/jumper settings - make sure switches/

jumpers 1-6 on the Control Link ACC network card

match the network ID number of the offline Control

Link ACC.

5. Verify switches/jumpers 7 and 8 are in the DOWN

position - Switches/jumpers 7 and 8 in the DOWN

position specify 19.2k baud and no parity. If either

of these switches/jumpers are not in the DOWN

position, set them DOWN.

- Select Address. Then

+ on the

If Control Link ACC is Offline Troubleshooting Control Link ACCs and the ECT MODBUS Network • 31

Page 38

12 Specifications

Temperature Range Storage Temp: -40°C to 65°C (-40°F to 149°F)

Ambient Operating Temperatures

(UL Listed)

P/N 815-6100

Ambient Operating

Temperatures

(UL Recognized)

P/N 815-6105

Input Voltage 120/240 Nominal (102VAC to 264VAC) 50/60 Hz

Humidity 5% to 95% non-condensing

Door Frame Temp Sensor +/- 0.4°C of 0 to 80°C (+/- .72°F of 32°F to 176°F)

Dewpoint Sensor +/- 1°C (+/- 1.8°F) over RH of 40 to 95% RH

Agency Approvals UL916 Open Energy Management Equipment, File E118489, FCC Part 15

-40°C to +40°C (-40°F to 104°F)

up to 10A (indoor, freestanding with no additional heat sink)

-40°C to +65°C (-40°F to 149°F)

up to 7A (indoor, freestanding with no additional heat sink)

-40°C to +25°C (-40°F to 77°F) up to 30A (with additional heat sink with max

thermal resistance of 0.51°C/Watt (0.92°F/Watt)

-40°C to +40°C (-40°F to 104°F) up to 26A (with additional heat sink with

max thermal resistance of 0.51°C/Watt (0.92°F/Watt)

-40°C to +65°C (-40°F to 149°F) up to 18A (with additional heat sink with max

thermal resistance of 0.51°C/Watt (0.92°F/Watt)

up to +/- 0.6°C at -40°C and 120°C (+/- 1.08°F at -40°F and 248°F)

+/- 4°C (+/- 7.2°F) over RH of 10 to 40% RH

Class A (non-intentional radiators), CE, RoHS