Page 1

Controlinc Network Master

Model M250 Version 5.1

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

May 2020

Page 2

Notes

May 2020

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

This page intentionally left blank

Page 3

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

Table of Contents

Section 1: Introduction

1.1 Reference Documents ................................................................................... 1

1.2 System Configuration ................................................................................... 2

1.3 General System Specifications ....................................................................... 4

1.3.1 Environmental .................................................................................... 4

1.3.2 Electrical ............................................................................................ 4

1.3.3 LCD Touch Panel Specifications ...........................................................4

1.3.4 M250 PLC Port 2 Setup for Database Exchange Link (DxL) ................... 5

1.4 Parts List ....................................................................................................... 8

Section 2: Installation

2.1 Network Master Mounting ............................................................................ 9

2.1.1 Mounting of NEMA Enclosure ............................................................. 9

2.1.2 Mounting of Rack Mount Enclosure ..................................................11

2.2 Power Input ................................................................................................ 12

2.3 Field Network Wiring .................................................................................. 12

2.3.1 Network Grounding ......................................................................... 13

2.3.2 Network Termination ....................................................................... 14

Table of Contents

May 2020

Section 3: Conguring the System

3.1 System Protection and Software Versions ................................................... 15

3.1.1 Password Protection ......................................................................... 15

3.1.2 CoProcessor Software Protection ..................................................... 15

3.1.3 Software Version Identification ........................................................15

3.2 Selecting Diagnostic/Programming Mode ................................................... 16

3.3 Chassis Identification and Hot Standby ........................................................ 16

3.4 Configuring Modbus Host Port Interface(s) ................................................. 16

3.4.1 Configuring Ethernet Ports ............................................................... 16

3.5 Configuring the Field Network .................................................................... 17

3.5.1 Configuring the Number of Slaves .................................................... 17

3.5.2 Configuring Field Network Baud Rate ............................................... 17

3.5.3 Configuring Network Master Receiver Time-Out ............................... 17

3.5.4 Configuring Report-By-Exception (RBE) ............................................ 17

3.6 Configuring Network Address Sequence ..................................................... 17

3.7 Configuring Device Types ............................................................................ 18

Table of Contents

i

Page 4

Table of Contents

May 2020

Section 4: Modbus Register Maps

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

4.1 Valve Status and Command Registers per Modbus Function Code ............... 19

4.2 Valve Status Bit Data for Each Valve ............................................................. 20

4.2.1 Multiple Valve Status Locations Using Function Code 02 ...................21

4.2.2 Multiple Valve Status Data Using Modbus Function Code 03 ............. 22

4.2.3 Multiple Valve Status Data Using Modbus Function Code 04 ............. 22

4.3 Reading Valve Position and Setpoint ............................................................ 23

4.4 Writing Discrete Commands to Valve Actuators .......................................... 23

4.5 Writing Analog Valve Position Setpoint (Function Codes 06 and 16) ............ 24

4.6 Reading Auxiliary Analog Inputs Using Function Code 03 ............................ 24

4.6.1 Reading Torque Analog Input Using Function Code 03 ...................... 24

4.7 Reading and Writing Auxiliary Analog Outputs ............................................ 24

4.8 Reading User Discrete Inputs ....................................................................... 25

4.9 Writing User Relay Outputs (MRTU Support) ............................................... 25

4.10 System Status Word .................................................................................... 26

4.11 Combined System Alarms ........................................................................... 27

4.12 Network Fault Location ............................................................................... 27

4.13 M250 Global Database and Modbus Holding Register Map .......................... 27

Section 5: Theory of Operation

5.1 Valve Actuator Network Connections .......................................................... 31

5.2 Power-up Initialization .................................................................................31

5.3 Hot Standby Fail-Over .................................................................................32

5.3.1 Modbus Host Link and Fail-over ........................................................ 33

5.4 Network Fault Detection ............................................................................. 33

5.5 Polling Process ............................................................................................ 33

5.6 Report-by-Exception ...................................................................................34

5.7 Priority Scan ................................................................................................ 34

5.8 Writing Discrete Commands to Valve Actuators .......................................... 34

5.9 Writing Position Setpoint ............................................................................ 35

5.10 Writing Analog Outputs .............................................................................. 35

5.11 Writing User Relay Outputs ......................................................................... 35

5.12 Writing ESD Command ............................................................................... 35

Section 6: Software Source Code

6.1 Host Database Configuration Aid ................................................................ 36

ii

Table of Contents

Page 5

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

Section 7: LCD Touch Panel Backup Terminal Operation

7.1 Home Screen ..............................................................................................37

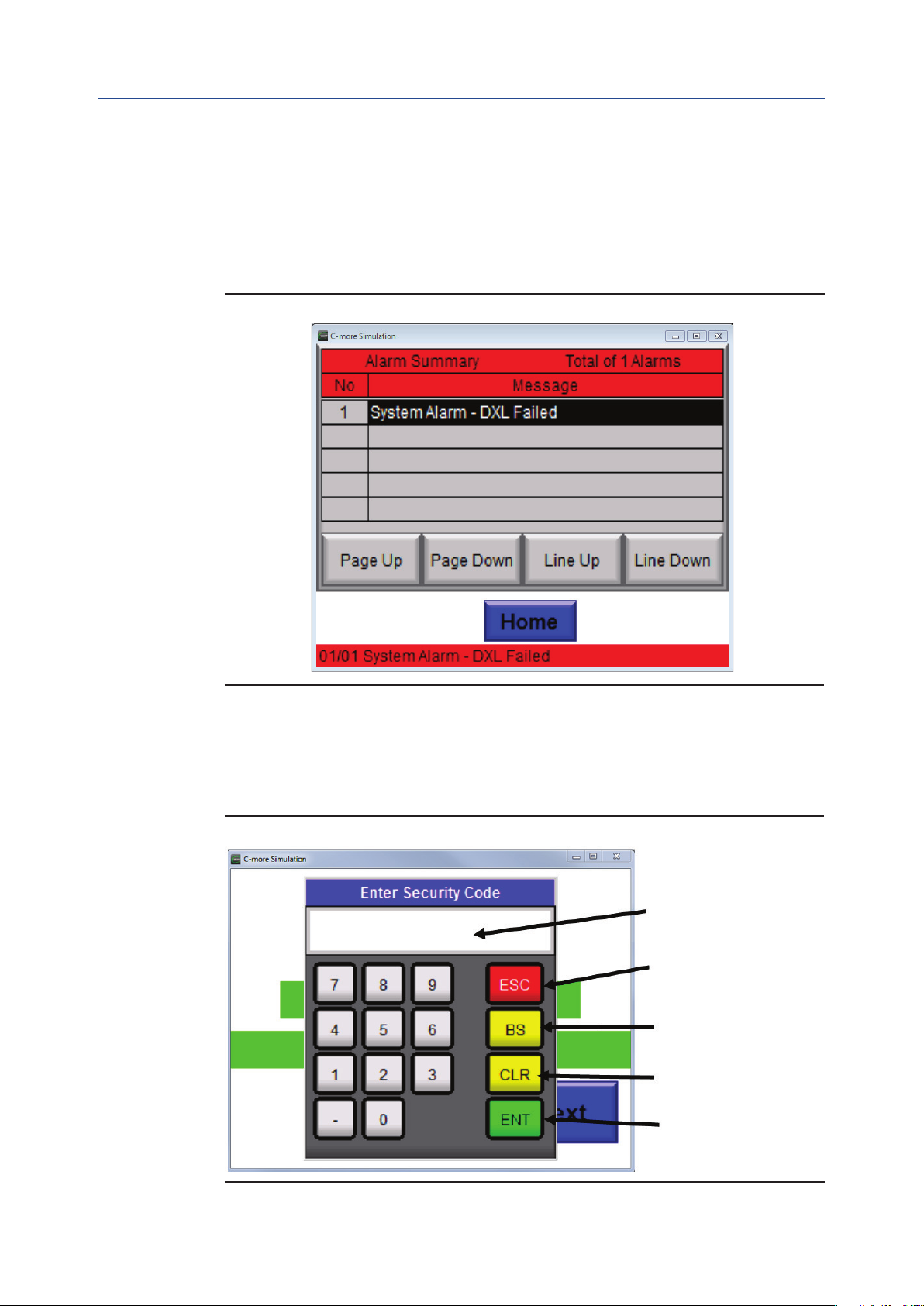

7.1.1 Alarm Display ................................................................................... 38

7.1.2 Security Codes Screen ...................................................................... 38

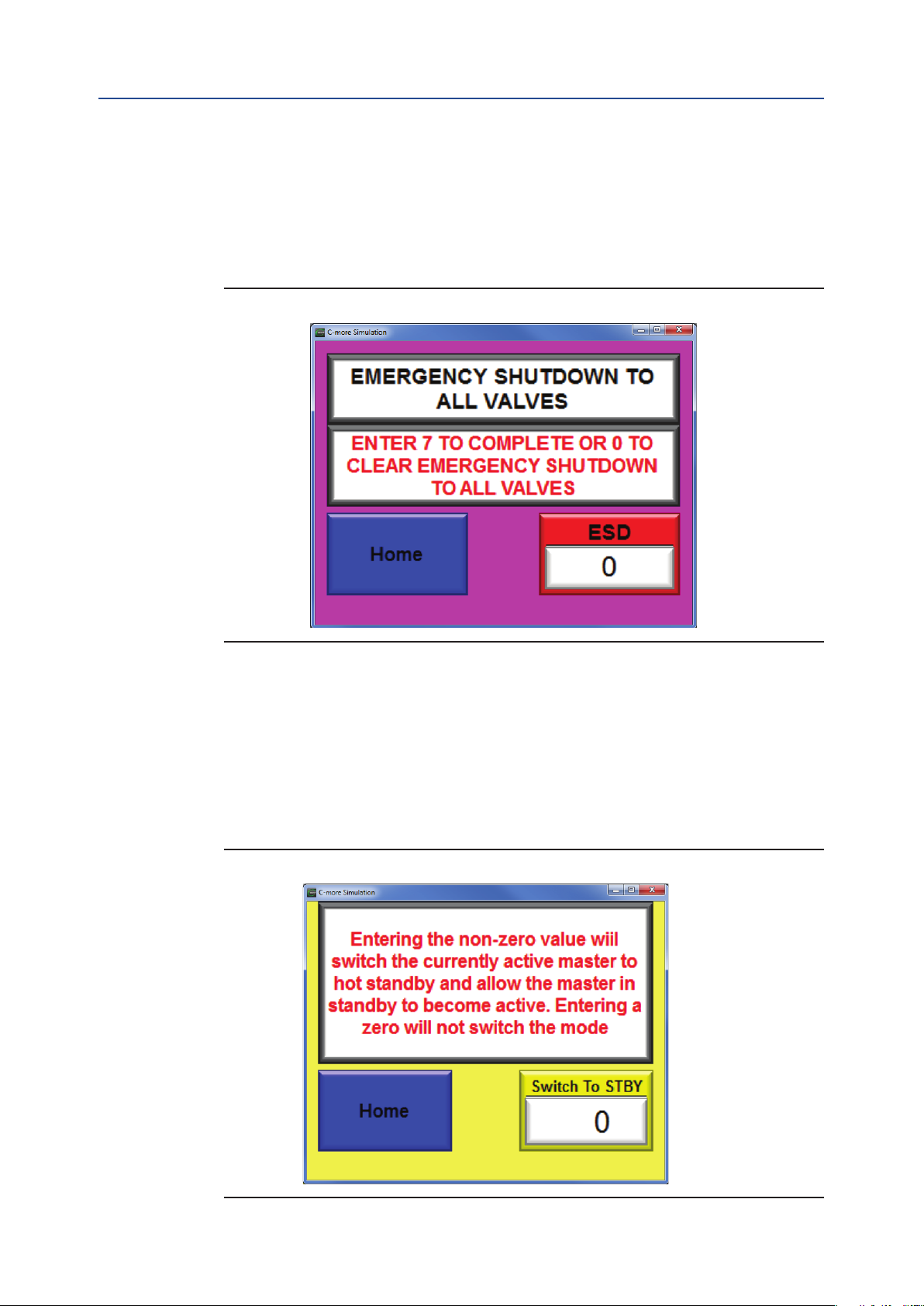

7.1.3 ESD Screen ....................................................................................... 39

7.1.4 Switch Active Master to Standby Screen ........................................... 39

7.2 Valve Control and Status Display ................................................................. 40

7.2.1 Valve Control .................................................................................... 40

7.3 Navigation Buttons ..................................................................................... 41

7.4 Network Diagrams ...................................................................................... 42

7.5 Network Fault Location ............................................................................... 42

7.6 Alarm Display .............................................................................................. 43

Section 8: System Setup and Conguration Using LCD

Touch Panel

8.1 Main Menu Screen ....................................................................................... 44

8.2 Security Codes ............................................................................................ 45

8.3 Data Entry ................................................................................................... 45

8.4 Host Port Configuration .............................................................................. 46

8.5 System Setup .............................................................................................. 47

8.6 Scan List ...................................................................................................... 48

8.7 Device Type ................................................................................................. 49

Table of Contents

May 2020

Section 9: Valve Network Topology

9.1 E>Net Ring Network on NEMA BOX or Rack Mount ...................................... 50

9.2 Redundant Parallel Bus Networks ................................................................ 51

Section 10: Multiple Masters to DCS

10.1 Master’s can be Distributed Throughout the Plant .......................................52

10.2 Using Ethernet Host Interface ..................................................................... 53

10.3 Using one RS485 and one Ethernet Modbus TCP/IP Host ............................. 54

Table of Contents

iii

Page 6

Notes

May 2020

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

This page intentionally left blank

Page 7

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 1: Introduction

Section 1: Introduction

Emerson Controlinc Network Masters are the master of Emerson Controlinc valve actuator networks

with Modbus RTU protocol. The system provides network management, data concentration, and

protocol conversion, off-loading the host system of these tasks. This enhances overall system

performance and minimizes software development and system conguration tasks by the system

integrator. The Network Master serves as the master of a master/slave network. It manages the

network by keeping an orderly cycle of data transfers to and from the slave devices (valve actuators).

It handles error detection, alarming, and network recovery. The Network Master serves as a data

concentrator for the host by providing a common database for all slave devices. The host is required

to communicate with only one slave device (network master) for all data transfers to and from the

eld. Data can be transferred between the network master and host in large blocks at a much higher

communications rate than would be possible if the host communicated with each slave device

(valve actuator) on the eld network. The Network Master acquires data from the valve actuators by

polling or scanning each device in a sequence of slave address from a table called a scan list. Polling

is a process of the Network Master sending to each slave address, a command to return its status

information, including alarms, discrete and analog inputs and outputs. When control commands

(valve open, stop, close, position setpoint, etc.) are generated by a host system up-line of the

Network Master, it then sends the appropriate commands over the network to the addressed slave

device. A more detailed functional description of operation is provided in the Theory of Operation

section of this manual.

1.1 Reference Documents

In addition to this Controlinc Network Master Operations Manual, the following references are

required for proper installation, conguration, and operation of the Network Master. All referenced

documents are supplied with the system. Paragraph numbers, as listed below, are used for reference

to these documents in this manual.

1. Emerson Controlinc 320B Quick Start Guide

2. FACTS Engineering 205 Basic CoProcessor User's Manual

3. FACTS Extended BASIC Reference Manual

4. Direct Logic DL205 User Manual

5. Bettis XTE3000 Electric Actuator IOM

All manuals and software are provided in electronic format with the system on CD.

Introduction

1

Page 8

Section 1: Introduction

May 2020

1.2 System Conguration

Controlinc Network Master Model M250N contains redundant valve actuator network masters in a

single enclosure. M250N supports one Controlinc E>Net ring network with up to 250 valve actuators.

Options for support of redundant bus networks and redundant E>Net rings are also available. The

supplied system uses standard RS485 and Modbus RTU protocol for the valve actuator networks.

Ethernet TCP/IP encapsulated Modbus protocol connections are provided for redundant host

computer networks. The Ethernet links are IEEE 802.3 with RJ45 connectors for 10/100Base-TX.

Protocol is Ethernet v2 encapsulation TCP/IP Version 4.

Redundant systems consist of two identical chassis with identical software. One is the primary

master and the other a hot stand-by master. The two chassis may switch roles of primary and hot

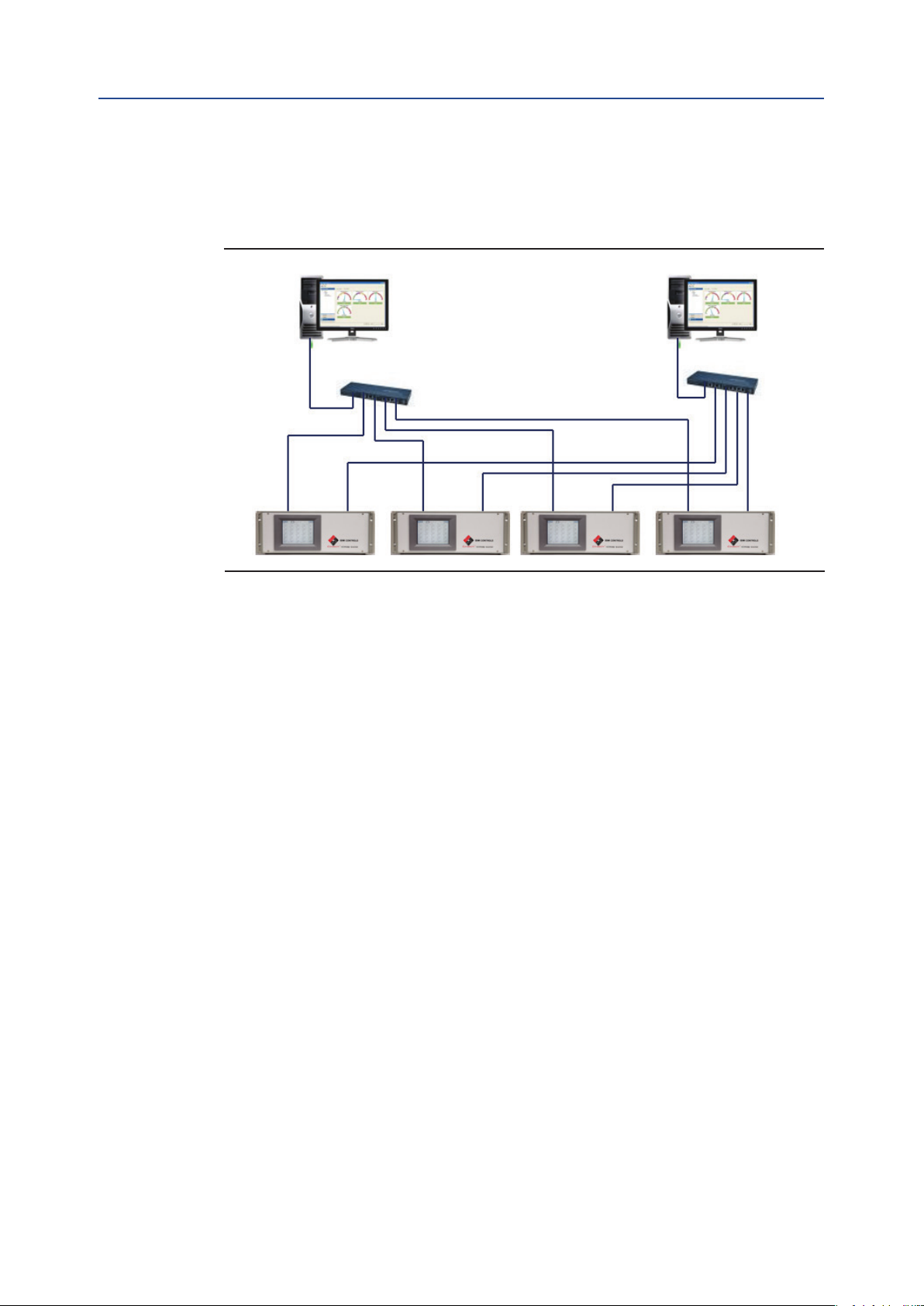

stand-by at any time. Figure 1 shows the specic system conguration of the supplied system.

The network masters communicate with Controlinc valve actuators that control both block valves

(Open, Stop, Close) and modulating or positioner type valves. The system consists of two six-slot

chassis with each chassis having a central processor located in Slot 0, which provides a global

database for the CoProcessors installed the chassis. The central processor also performs such

functions as watchdog timers and system alarm generation for the CoProcessors. It also provides

interrupt control for fast data transfers between processor modules. The main processor in each

chassis supports a “Data Exchange Link” (DxL) to share all data between redundant databases. See

Figures 2 and 3 for internal communication link connections.

Each chassis consists of two Modbus Slave modules located in Slots 3 and 4. These slave modules

communicate with redundant Modbus host systems up line. The CoProcessor installed in Slot 1 is

the Controlinc Network Master to a ring eld network. Two ports of the Network Master module are

connected to Network Interface Module (NIM) Model M124I with redundant, isolated ports. Each

NIM has connections to the redundant Network Master modules of the redundant chassis. Any one of

the four ports may acquire data from and control all actuators in the eld in either direction around

the network. Multiple M250N systems may be networked from a single host or redundant hosts to

automate any size system from a few valves to thousands of valves covering a large network area.

Ten (10) independent processors ensure full redundancy of all functions in a single unit. All

components except display are redundant with double-redundant host links to redundant hosts

and automatic processor hot swapping. Host equipment is not required to implement any fail-over

logic. Full-time redundant Modbus host links are standard. Plug-in modular construction and DIN-rail

mounting of components ensure minimum MTR, minimizing down time. LCD touch panel provides

valve actuator monitor and control of all valves in case redundant host links fail. All valve status and

alarms may be displayed by the LCD touch panel for maintenance purposes. The LCD touch panel

is a valuable troubleshooting tool during system commissioning. A more detailed description of

operation is provided in the Theory of Operation section of this manual.

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

2

Introduction

Page 9

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 1: Introduction

Figure 1 DCS System Diagram

Ethernet Links

10/100 BaseT

RS232 Modbus RTU

Links at 115.2K baud

NEMA Enclosure

with LCD Touch Panel

Introduction

3

Page 10

Section 1: Introduction

May 2020

Installation and Operations Manual

1.3 General System Specications

1.3.1 Environmental

Storage temperature: –20 °C to 70 °C

Ambient operating temperature: 0 to 55 °C

Ambient humidity: 5 to 95% (non-condensing)

Vibration resistance: MIL STD 810C, Method 514.2

Shock resistance: MIL STD 810C, Method 516.2

1.3.2 Electrical

Standard input voltage: 117 V AC at 50/60 Hz (100-240 V AC)

Total current at nominal voltage: 3.5 A (includes LCD panel)

Maximum inrush current: 60 A

Total power consumption: 35 VA nominal (includes LCD)

Isolation resistance: >10 MΩ at 500 V DC

Dielectric withstand voltage: 1500 V AC at 1 min.

MAN-01-09-91-0726-EN Rev. 1

1.3.3 LCD Touch Panel Specications

— Display type: 5.7 in. diagonal color TFT

— Enclosure: NEMA 4/4X (IP65)

— Input voltage: 12–24 V DC

— Power consumption: 16.0 W, 1.30 A at 12 V DC, 0.66 A at 24 V DC

— Operating temp: 0 to 50 °C

4

Introduction

Page 11

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 1: Introduction

1.3.4 M250 PLC Port 2 Setup for Database Exchange Link (DxL)

Primary Master Secondary Master

DirectNet DirectNet

Base Timeout x 1 Base Timeout x 1

RTS/CTS 0 mS, 0 mS RTS/CTS 0 mS, 0 mS

Station Address 2 Station Address 1

38400,1, Odd, Hex 38400, 1, Odd, Hex

PLC to PLC cable is RS232, 3-wire, rolled, with 15-pin D connectors

Primary Secondary

Pin/Wire Pin/Wire

2 Red 3 Red

3 Wht 2 Wht

7 Grn 7 Grn

8 Blk 8 Blk

Introduction

5

Page 12

Section 1: Introduction

May 2020

Figure 2 M250 NEMA TP Internal Wiring

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

6

Introduction

Page 13

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 1: Introduction

Figure 3

Introduction

7

Page 14

Section 1: Introduction

May 2020

1.4 Parts List

Figure 4 is a list of materials supplied within each Network Master enclosure. This may be used as a

spare parts list.

Figure 4

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

Item Qty Model

1 1 EA9-T6CL-R 2000802501 Color graphics LCD touch panel

2 1 2938730 2001803004 Power Supply, 24 V DC, 3 A

3 1 NIM124I 84713 -C Network Interface Module, Iso. RS485

4 2 D2-06B-1 2001805050 Base, 6-slot with 110/220 V AC P/S

5 2 D2-250-1 2001805052 CPU, DL205-250

6 6 37586-1 Cable, CoProcessor to NIM, 6x6, 11”

7 8 F2-CP128 2001805051 CoProcessor, Overdrive

8 1 NIM-TCP 87065 Network Interface Module, Ethernet

9 1 37587-1 Cable, CPU to CPU DxL

10 3 BK/MDA-1 7019900428 Fuse, 1 A, 250 V, Time Lag, CRM MDA

11 2 37586-4 Cable, CoProcessor to LCD, 6x6, 15”

12 2 37586-3 Cable, CoProcessor to NIM, 6x6, 13”

13 2 37586-2 (NEMA) Cable, CoProcessor to LCD, 6x6, 46”

14 1 37587 (NEMA) Cable, CPU to CPU DxL

8

Emerson Part

Number

Description

Introduction

Page 15

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 2: Installation

Section 2: Installation

2.1 Network Master Mounting

If the system is supplied from the factory in an NEMA enclosure, no internal wiring is required except

for connecting power and eld network wiring. The next three Sections (2.1, 2.2 and 2.3) discuss

mounting, power input and eld network wire connections to the NIM.

2.1.1 Mounting of NEMA Enclosure

The enclosure is rated for NAMA 4/12 and IP65/IP55. Dimensions of the enclosure are shown in

Figure 5. Mounting dimensions are shown in Figure 6. The enclosure may be bulkhead mounted

using the internal mounting holes. External mounting brackets may be used if desired.

When mounting using the internal mounting holes, caution must be used to ensure the holes are

sealed to maintain the NEMA/IP rating. The enclosure is supplied with ve 1/2" compression type

cable entry hubs. These may be tted with conduit type ttings if desired. If the system includes

backup LCD keypad terminal, some planning is required to allow for proper height above the oor to

view the display and properly operate the keypad.

Figure 5

Installation

(5) Cable entries are provided for:

(1) Power Cable

(2) Field RS-485 Network Cables

(2) Host RS-485 Network Cables

9

Page 16

Section 2: Installation

May 2020

NOTE

Allow 1 in. clearance on left side for ventilation and room for the door to swing open to left.

Figure 6 NEMA Box Mounting

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

10

Installation

Page 17

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 2: Installation

2.1.2 Mounting of Rack Mount Enclosure

The enclosure is designed for standard EIA 19" DIN rail rack mounting. Dimensions of the enclosure

are shown in Figure 7. The enclosure conforms to EIA RS-310, IEC 297-1, and DIN 41 494, Part 1

standards. The rack in which the enclosure(s) are mounted must allow a minimum of 20" (508 mm)

depth, allowing space for cable connections. If the system includes backup LCD keypad terminals,

some planning is required to allow for proper height above the oor to view the display and operate

the keypad properly.

Figure 7

Enclosure Depth = 15.0" (381 mm)

Allow a total depth of 20" (508 mm)

for rear panel cable connections.

Figure 8 Rear Panel View

Valve Network Ports

RJ45 Ethernet Ports

Installation

11

Page 18

Section 2: Installation

May 2020

2.2 Power Input

The system operates from 120 V AC or 220 V AC, 50/60 Hz single-phase power with internal

three wire power terminals. Ensure that a good safety ground is provided to the electrical supply to

which the power input is connected. The system contains three main fuses (6.3x32 mm, 1 A) in the

DIN-rail mounted fuse blocks. Each chassis and the LCD touch panel are independently fused. Each

NIM is powered from redundant 24 V DC power supplies from the two chassis power supplies. The

LCD touch panel is powered from an independent 24 V DC power supply. All other modules within the

unit are powered over the base back plane from the associated main chassis power supply.

2.3 Field Network Wiring

The eld network is wired in a ring conguration from Port A around a loop to Port B of the network

master. Beginning at Port A, the network is wired to Port A of the rst actuator and then from Port B of

the rst actuator to Port A of the second actuator and so on until the network returns from Port B of the

last actuator to Port B of the network master. Networks may have parallel wired (bus wired) actuators

between series wired actuators. Always wire parallel actuators to Port A and remove termination and

bias. Do not connect more than 15 actuators in parallel between any two series connected actuators.

Networks are polarized with (+) and (-) symbols on all drawings. Proper operation requires that polarity

be observed at all connections. Connect the eld networks to the Port A and B connectors on the NIM in

the network master as shown in Figure 9. The networks must be connected to Port A and Port B of the

valve actuators as shown in the wiring diagram of the Controlinc 320B Quick Start manual. Controlinc

supports many different network topologies. This manual supports only a single ring E>Net network

topology that allows a combination of parallel (bus) and series E>Net connections on the same network.

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

12

Installation

Page 19

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 2: Installation

Figure 9 Controlinc TEC2000 E > Net Ring Network Wiring (Typical)

2.3.1 Network Grounding

The shield or drain wire of the network must be earth grounded at only one point per network

segment. This single ground point may be at any location in the system where a good earth ground

can be obtained. This may be Port B of each actuator if desired. If the network shield is connected

to the internal ground or the chassis of the valve actuator, then the actuator housing must have

a good earth ground. The NIM connection is normally the building/vessel hull equipment ground

grid. A jumper may be installed between terminals 22 and 23 on the TBM of each actuator to carry

the ground throughout the loop. Do not connect the network cable shields to a power line ground

cable. Power lines can conduct lightning and other transients into the network. Do not connect both

ends of the network shield to earth ground at the network master. This can cause a ground loop,

making the transient protection system ineffective.

Installation

13

Page 20

Section 2: Installation

May 2020

2.3.2 Network Termination

The network requires termination and bias to be asserted at every network segment in

the E>Net ring. Parallel (bus) connected actuators must have termination and bias turned off.

Setting DIP switches S1 and S2 on the NIM to the ON position terminates the Network Master (NIM).

Figure 10 TEC2000 Controlinc E > Net Ring Network Wiring (Typical)

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

14

Installation

Page 21

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 3: Conguring the System

Section 3: Configuring the System

The system is shipped from the factory precongured per customer’s supplied data. This section

of the manual is provided only for conguration from a Modbus host port. The user should read

this entire section before attempting to congure the system. It may also be helpful to read Theory

of Operation Section 5 of this manual for a better understanding of the system before attempting

system conguration. Conguration data and associated Modbus registers are shown in Table 5-12

in Section 4 of this manual. The system is congured from any Modbus host capable of reading and

writing up to 540 conguration registers in the range of 42326 through 42866 shown in Table 5-12.

The system may be congured using the LCD touch panel. The system is congured at the factory per

the customer specications. If the user changes the total number of actuators on the eld network or

other operational parameters, then the system conguration must be changed. If the actuators are

not addressed in sequence around the loop, then the user must enter the actuator address sequence

in the Network Address Scan List. Other parameters such as Modbus port baud rate, network

master receiver time-out, and enabling/disabling diagnostic mode may be required during system

integration and start-up.

NOTICE

When conguration changes are made, the affected module will automatically reset and reinitialize

with the new conguration parameters. Caution must be used when conguring the Modbus

slave module to which the conguration computer is connected. The communication port of the

conguration computer must match the conguration written to the connected slave module. Both

primary and secondary chassis are congured at the same time regardless of which Module slave port is

used to congure the system.

3.1 System Protection and Software Versions

3.1.1 Password Protection

All software is protected by password available only to the programmer. The software development

package is not supplied with the system. Source code is supplied only for backup and must not be

modied by the user. Should a development software package be acquired, the software on the

system is password protected. This means the user may not edit the software without the password.

This does not limit the user’s ability to congure any part of the system via the Modbus host

communication ports.

3.1.2 CoProcessor Software Protection

Access to all application software in the CoProcessor modules is disabled unless each module is put

into diagnostic mode. The user must access the Modbus register containing the Diagnostic Mode

register by one of the Host communication links or the touch panel.

3.1.3 Software Version Identification

Software version number of each module may be obtained by reading the associated “Software

Version” Modbus register shown in Table 5-12. Software versions are reported as a three-digit

number with an implied decimal point between the rst and second most signicant digits.

Conguring the System

15

Page 22

Section 3: Conguring the System

May 2020

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

3.2 Selecting Diagnostic/Programming Mode

The chassis near the bottom or back of the enclosure is the Primary chassis. The chassis near the

top or front of the enclosure is the Secondary chassis. Each chassis identies itself by setting the

appropriate bit in the “System Status Word”, Modbus Register 40254 as shown in Table 10 in

Section 4.10 of this manual. If Bit 8 is set, then the chassis with which you are communicating is the

Primary Network Master. If Bit 9 is set, then the chassis with which you are communicating is the

Secondary Network Master. Either chassis may be in Hot Stand-by mode. Bits 4 and 5 of register

40254 identify the chassis that is in hot standby. The two chassis may be forced to swap roles of

active and hot standby mode by writing a non-zero value to Modbus Register 40255. This register will

be reset to zero after mode swap is executed.

3.3 Chassis Identication and Hot Standby

The chassis near the bottom or back of the enclosure is the Primary chassis. The chassis near the

top or front of the enclosure is the Secondary chassis. Each chassis identies itself by setting the

appropriate bit in the “System Status Word," Modbus Register 40254 as shown in Table 10 in

Section 4.10 of this manual. If Bit 8 is set, then the chassis with which you are communicating is the

Primary Network Master. If Bit 9 is set, then the chassis with which you are communicating is the

Secondary Network Master. Either chassis may be in Hot Stand-by mode. Bits 4 and 5 of register

40254 identify the chassis that is in hot standby. The two chassis may be forced to swap roles of

active and hot standby mode by writing a non-zero value to Modbus Register 40255. This register will

be reset to zero after mode swap is executed.

3.4 Conguring Modbus Host Port Interface(s)

The host port may be congured for RS232 full duplex or RS422/RS485 with either 4-wire or 2-wire

half duplex by writing to the Port Hardware Mode register as shown in Table 12. The module must

be congured for RS232 if a NIM is used for connecting the Host RS-485 networks. Modbus slave

address, baud rate, and parity may be congured by writing to the associated conguration register

shown in Table 12.

3.4.1 Configuring Ethernet Ports

If your system is equipped with Ethernet host ports, the two ports for Host#1 and Host#2 must be

congured independently. Each port may be congured using Telnet or the supplied Device Installer

software. All network master parameters may be congured using Emerson Master Conguration

software. Setting of all Modbus coprocessor ports and the NIM-TCP ports must match, else

communication link will be lost. If no IP address was assigned at time of order, the default IP address

(169.254.132.147) labeled at each port on the NIM-TCP module may be used to access the ports and

assign an IP address. Both ports may be assigned the same IP address only when connected to two

independent Ethernet links. Software is supplied on the CD with the system to congure the system,

set IP addresses and test the system via the Ethernet ports.

16

Conguring the System

Page 23

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 3: Conguring the System

3.5 Conguring the Field Network

Editing the values loaded to Modbus registers 42828 through 42833 as shown in Table 12

congure the eld network ports and network master functions. Each parameter is discussed in the

following paragraphs.

3.5.1 Configuring the Number of Slaves

The number of slaves (valve actuators) on the eld network is congured by editing the constant

loaded to “Number of Field Network Devices” in Modbus register 42830.

3.5.2 Configuring Field Network Baud Rate

Editing the constant written to Modbus register 42831 as shown in Table 5-12 change network baud

rate of the Network Master. If the number written to this register is not a valid baud rate, the system

will default to 9600 baud. The baud rate must match the baud rate of the valve actuators connected

to the network. The default baud of all devices and all ports of the Network Master is 9600.

3.5.3 Configuring Network Master Receiver Time-Out

Editing the constant loaded to Modbus register 42832 may change receiver time-out of the network

masters. Receiver time-out is the amount of time the network master will wait for a response from

a slave device before moving on to the next device. If this time is too short (less than 10 mS) it could

cause collisions on the network, degrading communications throughput. If this time is too long, it will

cause time to be wasted while the master is trying to put unconnected devices on the network. The

default setting is 50 mS.

3.5.4 Configuring Report-By-Exception (RBE)

Loading a zero to Modbus register 42833 will disable RBE. Writing a non-zero value to register 42833

enables RBE, the default setting.

3.6 Conguring Network Address Sequence

The network master must know the sequence of slave addresses around the network ring in order

to properly perform network fault location. Unless otherwise specied, all systems are shipped with

a scan list in contiguous sequence starting at address #1 at Port A and ending with the last address

at Port B. To change the sequence of addresses in the scan list, it is necessary to edit the scan list

located in Modbus registers 42326 through 42575 or the number of registers equal to the number

of actuators on the network. If the system reloads default settings, the contiguous sequence of 1 to

250 will be loaded to this list.

Conguring the System

17

Page 24

Section 3: Conguring the System

May 2020

3.7 Conguring Device Types

The network master must know the type of slave device connected to the network corresponding

to each network address in order to acquire the desired data. There are ve different device types

that may be selected for each unit connected to the network. All device types return valve status

(inputs 16-31). Remaining data acquired is listed below. For EHO extended status and alarms,

please use Device Type 4.

Device Data Acquired

Type 0 Valve position (0-100% in 1% increments)

Type 1 Valve position (0-100% in 1% increments)

Coils (0-15)

Inputs (0-15)

Type 2 Valve position (0-4095)

Position setpoint (0-4095)

Analog output (0-4095)

Type 3 Valve position (0-4095)

Position setpoint (0-4095)

Analog output (0-4095)

Coils (0-15)

Inputs (0-15)

Type 4 Valve position (0-4095)

Position setpoint (0-4095)

Analog output (0-4095)

Valve torque (0-4095)

User analog input #1 (0-4095)

User analog input #2 (0-4095)

Type 5 Valve position (0-4095)

Position setpoint (0-4095)

Analog output (0-4095)

Valve torque (0-4095)

User analog input #1 (0-4095)

User analog input #2 (0-4095)

Coils (0-15)

Inputs (0-15)

Type 7 XTE3000

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

18

Unless otherwise specied, all systems are shipped with all devices congured as Type 2. To change

the device type for any one or all devices, it is necessary to edit the device type list located in Modbus

registers 42576 through 42825 or the number of registers equal to the number of devices on the

network. The touch panel may be used to edit device types. If the system reloads default settings, all

devices will be set as Device Type 2.

Conguring the System

Page 25

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 4: Modbus Register Maps

Section 4: Modbus Register Maps

4.1 Valve Status and Command Registers per

Modbus Function Code

Controlinc Network Masters communicate with host computer equipment using Modbus RTU

protocol. Valve actuator status and alarms data may be acquired from the Network Master using any

one of four Modbus Function Codes (01 thru 04). Data is returned as either discrete (bit) type using

Function Code 01 and 02 or as 16-bit unsigned integers using Function Code 03 and 04. Command

outputs to the valves may be written to the Network Master using four Function Codes (05, 15, 06,

and 16). Table 5-12 is the address map for valve actuators up to a maximum of 250. Status of each

valve is stored as 16 discrete inputs and as 16 coils. Discrete commands to each valve consist of eight

bits (coils) per valve and are stored as coils in one 16-bit register per actuator. Position setpoint is an

analog word (0-4095) value written to the valve actuator using the 06 or 16 function codes.

All registers are unsigned 16-bit integers.

NOTE

Modbus addressing shown in the tables of this section is the normal conguration addressing method

used by most SCADA and DCS systems. If you are building Modbus messages at the communication

driver level, keep in mind that HEX-starting addresses in the Modbus message are offset by one. You

must subtract one from the address in the tables when building a Modbus message. For example, to

read the rst valve status bits as coils using Function Code 01, the starting address of 1025 shown in

Table 5-12 would be 400 Hex (1024 decimal) in the Modbus message. If valve status of the rst valve

is read using Function Code 02, the starting address of 10001 shown in Table 5-12 would be 00 Hex

in the Modbus message. If valve status of the rst valve is read using Function Code 03, the starting

address of 40001 shown in Table 5-12 would be 00 Hex in the Modbus message

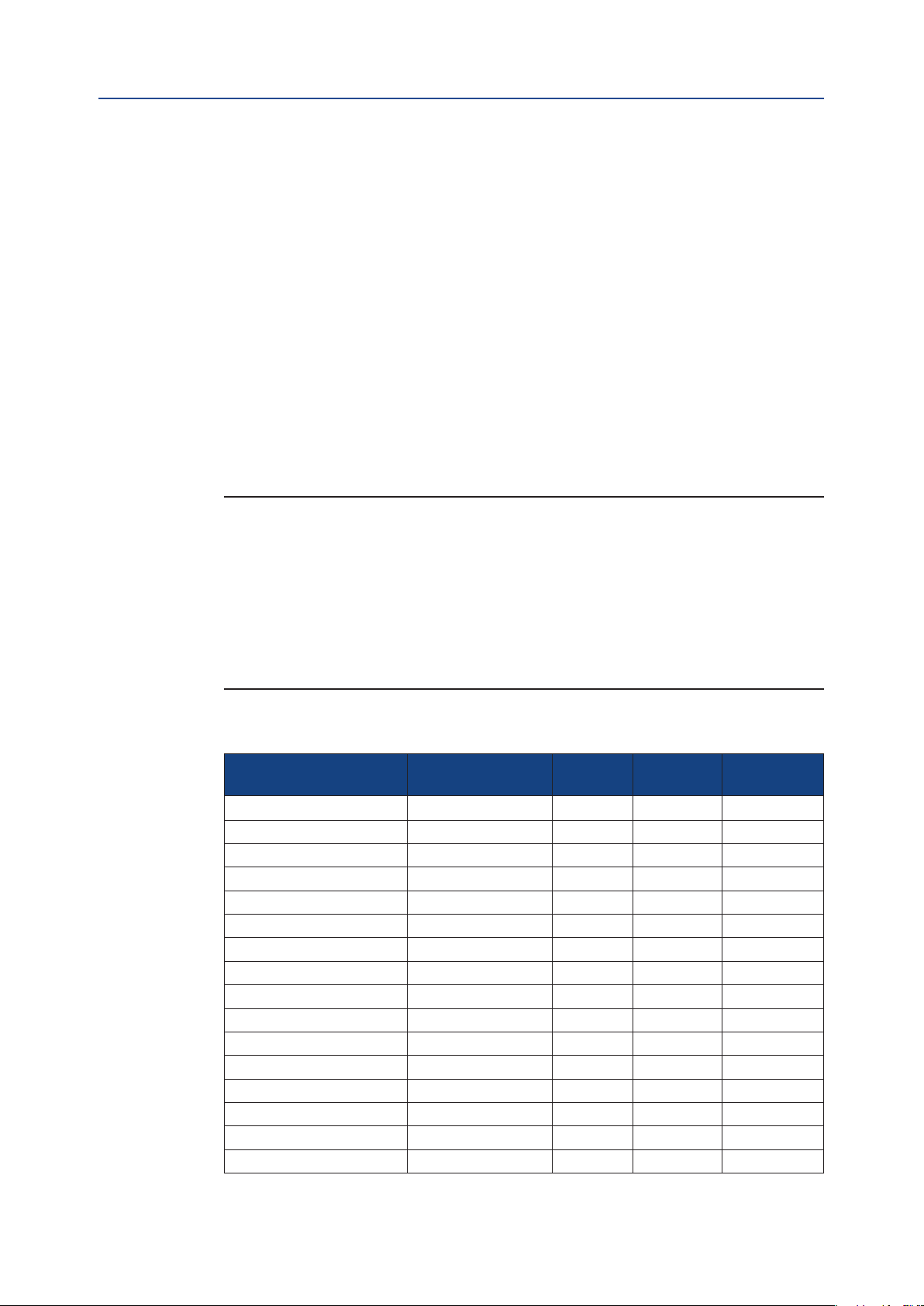

Table 1. Memory Map of Valve Data and Commands by Function Code

Function Code and

Valve data/Command

01 Discrete valve status Read Coils (discrete) 01025 05024 4000

01 Discrete Outputs (0-15) Read Coils (discrete) 05089 09088 4000

02 Discrete valve status Read Inputs (discrete) 10001 14000 4000

02 Discrete Inputs (raw 0-15) Read Inputs (discrete) 14065 18064 4000

03 Valve status word Read Holding Register 40001 40250 250

03 Valve position feedback Read Holding Register 40256 40505 250

03 Valve position setpoint Read Holding Register 40576 40825 250

03 Aux. analog input #1 Read Holding Register 40826 41075 250

03 Aux. Analog input #2 Read Holding Resister 41076 41325 250

03 Aux. Analog output Read Holding Register 41326 41575 250

03 Discrete Inputs (raw 0-15) Read Holding Register 41576 41825 250

03 Discrete Outputs (0-15) Read Holding Register 41826 42075 250

03 Raw torque analog input Read Holding Register 42076 42325 250

04 Valve status word Read Input Register 30001 30250 250

04 Discrete Inputs (raw 0-15) Read Input Register 30256 30505 250

05 Discrete valve commands Write Coils (discrete) 00001 01000 1000

Command Data Type Begin Reg Ending Reg Max Number

Modbus Register Maps

19

Page 26

Section 4: Modbus Register Maps

May 2020

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

Function Code and

Valve data/Command

05 Discrete Outputs (0-15) Write Coils (user relays) 05089 09088 4000

15 Discrete valve commands Write Multiple Coils 00001 01000 1000

15 Discrete Outputs (0-15) Write Multiple Coils 05089 09088 4000

06 Discrete valve commands Write Holding Register 40512 40575 64

06 Valve position setpoint Write Holding Register 40576 40825 250

06 Aux. analog output Write Holding Register 41326 41575 250

06 Discrete Outputs (0-15) Write Holding Register 41826 42075 250

16 Discrete valve commands Write Multiple Registers 40512 40575 250

16 Valve position setpoint Write Multiple Registers 40576 40825 250

16 Aux. Analog output Write Multiple Registers 41326 41575 250

16 Discrete Outputs (0-15) Write Multiple Registers 41826 42075 250

Command Data Type Begin Reg Ending Reg Max Number

4.2 Valve Status Bit Data for Each Valve

Valve status information is stored in contiguous registers in sequence with the valve actuator

network address. Table 2 shows the valve status for valve address #1 when using Modbus Function

Code 02.

Table 2. Valve Status Information for Valve at Network Address #1

Modbus Address Valve Status Description

10001 Open Limit Switch Valve Fully Open

10002 Close Limit Switch Valve Fully Closed

10003 Transition Opening Valve is Moving Open

10004 Transition Closing Valve is Moving Close

10005 Manual Mode Selector Swt in Local

10006 Auto Mode Selector Swt in Remote

10007 Open Torque Alarm Open Torque Swt Tripped

10008 Close Torque Alarm Close Torque Swt Tripped

10009 Valve Stall Alarm Valve is Not Moving

10010 Power Monitor Alarm Loss of Control Voltage

10011 Motor Overload Alarm Overload Relay Tripped

10012 Phase Monitor Alarm 3-Phase power reversed

10013 Local ESD Alarm Local ESD input activated

10014 Actuator Fail Alarm Failed self-diagnostics

10015 Com No-Response Alarm Com Failure on both lines

10016 Unit Alarm Set when any alarm bit set

Note: Unit alarm bit (10016) is set if any one or more alarm bits 7 through 13 are set.

20

Modbus Register Maps

Page 27

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 4: Modbus Register Maps

For EHO extended status and alarms, please refer to Table 3.

Table 3. Valve Status Information for Valve at Network Address #1

Modbus Address Valve Status Description

10001 Off Mode Not in Local or Remote

10002

10003 Low Oil Level Low Oil Level

10004 Partial Stroke Fail Partial Stroke Fail

10005 Electronic Fault Alarm Electronic Failed Alarm

10006 Hydraulic Power Unit Fault Alarm Hydraulic Power Unit Fault Alarm

10007 Over Pressure Alarm Over Pressure Alarm

10008

10009

10010

10011

10012

10013

10014

10015

10016

4.2.1 Multiple Valve Status Locations Using Function Code 02

Valve status information shown in Table 3 is repeated for each actuator on the network in sequence

of network address. Data for valve at network address number 2 is located at Modbus addresses

10017 through 10032. Data for valve at network address 3 is located at 10033 through 10048 and so

on for up to 250 valves on the network as shown in Table 4.

Table 4. Using Modbus Function Code 02

Valve Actuator Network Address Modbus Addresses for Valve Status

001 10001 thru 10016

002 10017 thru 10032

003 10033 thru 10048

004 10049 thru 10064

005 10065 thru 10080

thru thru

248 13953 thru 13968

249 13969 thru 13984

250 13985 thru 14000

Modbus Register Maps

21

Page 28

Section 4: Modbus Register Maps

May 2020

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

4.2.2 Multiple Valve Status Data Using Modbus Function Code 03

The same valve status data can be accessed by the Host using Function Code 03 by reading unsigned

16-bit integers from holding registers beginning at Modbus Address 40001 as shown in Table 5.

The 16 bits of valve status for each valve actuator is the same as that shown in Table 3.

Table 5. Using Modbus Function Code 03

Valve Actuator Network Address Modbus Addresses for Valve Status

001 40001

002 40002

003 40003

004 40004

005 40005

thru thru

248 40248

249 40249

250 40250

4.2.3 Multiple Valve Status Data Using Modbus Function Code 04

The same valve status data can be accessed by the Host using Function Code 04 by reading unsigned

16-bit integers from input registers beginning at Modbus Address 30001 as shown in Table 6. The 16

bits of valve status for each valve actuator is the same as that shown in Table 3.

Table 6. Using Modbus Function Code 04

Valve Actuator Network Address Modbus Addresses for Valve Status

001 30001

002 30002

003 30003

004 30004

005 30005

thru thru

248 30248

249 30249

250 30250

22

Modbus Register Maps

Page 29

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 4: Modbus Register Maps

4.3 Reading Valve Position and Setpoint

Valve position feedback is accessed by the Host using Modbus Function Code 03 to read holding

registers beginning at Modbus address 40256. Position setpoint of each valve may be read in

sequence with valve address starting at Modbus address 40576. Device types 0 and 1 return valve

position as 0-100% in 1% increments. All other device types return analog data representing analog

position and setpoint of each valve as unsigned 16-bit integer with a 12-bit value of 0 to 4095. Each

valve's analog position and setpoint are located in holding registers in sequence of network address

as shown in Table 7.

Table 7. Valve Position Feedback and Setpoint using Modbus Function Code 03

Valve Actuator Network Address

001 40256 40576

002 40257 40577

003 40258 40578

004 40259 40579

005 40260 40580

thru thru

248 40503 40823

249 40504 40824

250 40505 40825

Position Setpoint

Modbus Addresses

4.4 Writing Discrete Commands to Valve Actuators

Discrete commands are written to a single valve actuator as coils (bit) data using Modbus Function

Code 05 or Function Code 15. Commands may also be written to multiple valve actuators by writing

a single holding register using Function Code 06 or to multiple holding registers using Function

Code 16. Emergency Shut Down to all valve actuators (ESD) is accomplished by writing seven (7) to

Modbus Register 40575. This will cause ESD to be broadcast to all valve actuator addresses. Writing

a zero to register 40575 ends the ESD function. Each valve actuator will respond to four commands

as shown in Table 8. The four bits associated with each valve is in sequence with the valve actuator

network address. When writing to holding registers, data is written to four valve actuators. Writing

zeros to any location has no affect on operation. Each command is a positive one (set coil) and the

coil is automatically reset when the command is executed. Only one coil per valve may be written at

any one time. Writing multiple coils to a single valve will cause no action, i.e. it is treated as a no-op.

Modbus Register Maps

Table 8. Writing Commands to Valves using Function Code 05 or 15

Modbus Address Comman and Valve Network Address

0001 Open - Valve at address 001

0002 Stop - Valve at address 001

0003 Close - Valve at address 001

0004 ESD - Valve at address 001

0005 Open - Valve at address 002

0006 Stop - Valve at address 002

0007 Close - Valve at address 002

0008 ESD - Valve at address 002

0009 Open - Valve at address 003

00010 Stop - Valve at address 003

00011 Close - Valve at address 003

00012 ESD - Valve at address 003

00013 Open - Valve at address 004

00014 Stop - Valve at address 004

00015 Close - Valve at address 004

00016 ESD - Valve at address 004

23

Page 30

Section 4: Modbus Register Maps

May 2020

Discrete command holding registers contain four commands per valve for four valves per 16-bit

register. A single register may be written to command four valves by using the Modbus Function

Code 06. Multiple registers may be written using Function Code 16. Command holding registers

begin at Modbus address 40512. A total of 63 registers are used for the command coils. The last valve

network address in register 40574 is valve address 250. Each actuator is congured to respond to the

ESD command in either of three ways; go closed, go open, or stay put. Each actuator can also control

an ESD relay, which may be wired to control the actuator, external equipment or to override some

internal function. See Section 1.1 for instructions on setting ESD functions of the valve actuator.

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

4.5 Writing Analog Valve Position Setpoint

(Function Codes 06 and 16)

If the valve is a modulating or positioning unit (except device types 0 and 1), the position setpoint may be

written to the valve as an unsigned 16-bit integer from 0 to 4095 using Modbus Function Codes 06 or 16.

Setpoint of each valve is in sequence with network address. Any Emerson actuator with Controlinc, except

device types 0 and 1, may be a positioner or modulating unit. The actuator, depending on the command

issued by the master, automatically sets the operating mode.

4.6 Reading Auxiliary Analog Inputs Using

Function Code 03

Device types 4 and 5 have two auxiliary analog inputs for data acquisition of other equipment such

as pressure or temperature transducers. The two inputs for each actuator are identied as AIN2 and

AIN3. The analog data is returned as unscaled 12-bit unsigned integers with a value between 0 and

4095. The host is required to scale the values to engineering units for display to the Man Machine

Interface (MMI). The values are scaled by (real time value/4095*full scale engineering units). Data for

auxiliary analog inputs AIN2 is in sequence with network address starting at Modbus register 40826.

Up to 250 values may be acquired. The last register for the 250th unit is 42075. Data for auxiliary

analog inputs AIN3 is in sequence with network address starting at address 42076. Up to 250 values

may be acquired. The last register for the 250th unit is 42325.

4.6.1 Reading Torque Analog Input Using Function Code 03

Device types 4 and 5 may have an optional analog input for relative torque measurement. The torque

data is scaled as 0-4095 for 0-100% of the analog value read from register 15 labeled AIN#1. The user

must provide scaling at the host for conversion to actual torque based on the actuator model and

spring pack. Torque data range is provided on the data sheet supplied with each actuator. Torque

data may be used for detection of valve problems by measuring and storing an initial maximum

opening torque and then comparing the current reading to the stored initial maximum torque

reading. If the current reading exceeds the initial maximum torque reading by a predetermined

amount (limit), then a valve maintenance alarm or message may be generated. The analog torque

reading is in sequence with network address starting at Modbus register 42076. Up to 250 values

may be acquired. The last register for the 250th unit is 42325.

4.7 Reading and Writing Auxiliary Analog Outputs

All device types, except type 0 and 1, have an option to add one 4 - 20 mA analog output. The host

may write to the output by writing to a Modbus register in sequence with network address starting at

register 41326. Up to 250 analog outputs may be written. The last register for the 250th unit is 41575.

Data must be written to the actuators as 12-bit analog data with a range of 0 to 4095 corresponding

to 4 - 20 mA. The data is written to the actuators using Modbus Function Code 06 or 16. The analog

output may be read back from the actuator using Function Code 03

24

.

Modbus Register Maps

Page 31

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 4: Modbus Register Maps

4.8 Reading User Discrete Inputs

Each Controlinc equipped actuator has two isolated discrete inputs available to the User. These are

Inputs 13 (User Input #1) and 14 (User Input #2) in the discrete input memory map. Inputs 0-15 are

the raw hardware discrete inputs and are de-bounced by software. None of the inputs are software

generated. The Network Master reads all discrete inputs (0-15) of device types 1, 3, and 5 and places

these into contiguous data base locations corresponding to network address of the actuator. Inputs

of each actuator are shown in Table 8. The host, using Function Codes 02, 03, and 04, may access

these inputs. When using Function Code 02, the inputs are addressed from 14065 to 18064 with

16 inputs per actuator as shown in Table 5-9 for up to 250 actuators. When using Function Code 03,

the discrete inputs are addressed from register 41576 (valve #1) to 41825 (valve #250). When using

Function Code 04, the discrete inputs are addressed from register 30256 (valve #1) to 30505

(valve #250). Inputs (bits) of each valve actuator within the 40000 and 30000 registers are in the

same sequence as shown in Table 9

Table 9. Discrete Inputs for Valve at Network Address #1 Using Function Code 02

Modbus Address Valve Status Description

10001 Open Limit Switch Valve Fully Open

10002 Close Limit Switch Valve Fully Closed

10003 Auxiliary Open Contact Aux. contact of starter

10004 Auxiliary Close Contact Aux. contact of starter

10005 Manual Mode Selector Swt in Local

10006 Auto Mode Selector Swt in Remote

10007 Open Torque Alarm Open Torque Swt Tripped

10008 Close Torque Alarm Close Torque Swt Tripped

10009 Power Monitor Alarm Loss of Control Voltage

10010 Motor Overload Alarm Overload Relay Tripped

10011 Phase Monitor Alarm 3-Phase power reversed

10012 Local ESD Alarm Local ESD input activated

10013 VFC Fault Alarm VFC alarm input activated

10014 User Discrete Input #1 Isolated user wired input

10015 User Discrete Input #2 Isolated user wired input

10016 On-board execute button Used by 320A or B only

.

4.9 Writing User Relay Outputs (MRTU Support)

Device types 1, 3, and 5 have two User Relay Outputs, which may be controlled by the host. The

outputs are Coils 04 (User Relay #1) and 05 (User Relay #2) in the Controlinc Coil Map (0-15). The

Network Master may read and write all 16 coils but masks all coils except 00, 01, 04 and 05. If the user

attempts to write to any other coils, the command will be ignored. The user should not write to coils

00 (close) or 01 (open) if the device is a valve actuator. Write these coils only if the device is an MRTU.

The database of the Network Master is congured for 16 coils per actuator for 250 actuators in

sequence with valve address. The User Relays may be controlled using Function Codes 05, 15, 06,

or 16. If Function Codes 05 or 15 are used the coils are addressed from coil 05089 to 09088 with

16 coils per actuator. For example, writing to the relays of valve number one, write to coil 05093 for

User Relay #1 and 05094 for User Relay #2. User Relays of each consecutive valve are offset by 16.

For example, User Relay #1 of valve number two would be coil 05109 (5093+16). Coils 00 (close)

and 01 (open) are masked by the network master when the selector switch is in "Remote" mode.

This prevents the host from overwriting these coils in the valve actuator when under control by the

Controlinc card in the actuator.

Modbus Register Maps

25

Page 32

Section 4: Modbus Register Maps

May 2020

4.10 System Status Word

The system status word is the status of the Network Master. This word is located in Modbus register

40254. The system status word may be read using Modbus Function Code 02 or 03 in the same

manor as reading valve status. Bit locations for Function Code 02 are shown in Table 10. Only the rst

least signicant twelve bits are dened.

The four most signicant bits are reserved for future functions and are set to zeros. If Bit 8 is set (true)

then the chassis is the primary network master. If Bit 9 is set (true) then the chassis is the secondary

network master. Bit assignments are shown in Table 10.

Table 10. System Status Word Bit Map

Bit Status Denition Note CR FC02

0 Primary Watchdog Timer Alarm 20 14049

1 Secondary Watchdog Timer Alarm 21 14050

2 Primary Failed Write Command Alarm C(FW) 22 14051

3 Secondary Failed Write Command Alarm C(FW) 23 14052

4 Primary Master in Hot Standby Mode C(HM) 24 14053

5 Secondary Master in Hot Standby Mode C(HM) 25 14054

6 Primary Network Fault Alarm C(NF) 26 14055

7 Secondary Network Fault Alarm C(NF) 27 14056

8 Primary Network Master Active C(AM) 30 14057

9 Secondary Network Master Active C(AM) 31 14058

10 Primary Host Link Failed Alarm 32 14059

11 Secondary Host Link Failed Alarm 33 14060

12 DXL Grant primary master access to network 34 14061

13 DXL Grant secondary master access to network 35 14062

14 DXL Fail Alarm 36 14063

15 Switch Active Master to Hot Standby & Standby to Active 37 14064

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

Primary and Secondary Host Link Failed alarms shown in Table 5-10 are determined by queries

received from the Modbus host computer (DCS) using function codes 01, 02, 03, 04 or 08. If a query

is not received from the host in about ve to six seconds, then this alarm is set. Host link alarms are

exchanged between the primary and secondary network masters. These alarms are also used to help

determine which master takes control of the network.

The host communication status and associated network fail over is discussed in the Theory of

Operation Section of this manual. The host(s) must repeatedly transmit queries to both primary

and secondary masters within ve seconds between transmissions to prevent the masters from

detecting a faulty link from the host(s). The network master will not respond to any queries while in

hot standby.

26

Modbus Register Maps

Page 33

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 4: Modbus Register Maps

4.11 Combined System Alarms

In addition to the system alarms located in the system status word at Modbus register 40254, there

are four combined system alarms located at Modbus register 40251 as shown in Table 11. The system

is in alarm when this register is non-zero and the alarm is cleared when this register in zero. Bit 0 is

a combined alarm for bits 1-3 in register 40251, meaning this bit is set when any one of the other

system alarms is set. Bit 1 is set when any valve actuator on the loop is in alarm. This is a combination

of all actuator Unit alarms. Bit 2 is set when the Primary master is in alarm. This is a combination

of Bits 0, 2, 6 and 14 of the system status word shown in Table 5-10. This alarm is also set when

the Primary master is powered down. Bit 3 is set when the Secondary master is in alarm. This is a

combination of Bits 1, 3, 7 and 14 of the system status word shown in Table 5-10. This alarm is also

set when the Secondary master is powered down.

Table 11. Combined System Alarms (Modbus Register 40251)

Bit Alarm Denition

0 System Alarm (Combined system alarm, set when any one of Bits 1,2, or 3 is set)

1 Actuator Unit Alarm (Set when any valve actuator unit alarm is set)

2 Primary Master Alarm (Set when any primary master alarm is set)

3 Secondary Master Alarm (Set when any secondary master alarm is set)

4-15 Reserved for future enhancements

4.12 Network Fault Location

If the eld network is connected in a ring conguration, the Network Master automatically detects

and locates a single line fault. Location of the fault may be displayed by the LCD touch panel or the

MMI as two network addresses. The two network addresses between which the fault is located is

available in Modbus register 40252 (Network Fault Low Address) and register 40253

(Network Fault High Address).

By reading these two locations, the SCADA or DCS host may display to the MMI the location of the

fault when a Network Fault system alarm bit is set. It is important for the address scan list be properly

congured as described under system conguration, Section 3.6 of this manual in order for fault

location to function properly.

4.13 M250 Global Database and Modbus

Holding Register Map

Table 11 is supplied for the benet of the software engineer and is not required for system

conguration. The system automatically allocates memory for the database as shown. All

communication modules, masters and slaves, located in Slots 1-5 of the I/O rack share the

same database located in the memory of the main processor. Table 5-12 is supplied for system

conguration. For more detail on system conguration, see Section 3 of this manual. All

communication modules may be congured from any one of the Modbus slave ports normally

connected to a host. The LCD touch panel may be used to congure the network masters.

Refer to Table 12 for database location of Network Master conguration written by the LCD touch panel.

Modbus Register Maps

NOTE

Network Address Scan List defaults to addresses 1 to 250 in sequence.

Device Type List defaults to all type 2.

All communication ports default to RS232, 9600, N, 8, 1.

All modules default to Normal Run Mode.

27

Page 34

Section 4: Modbus Register Maps

May 2020

Table 12. M240N Global Database and Modus Register Assignments for Valve Data

(All Actuator Data is in Sequence with Valve Actuator Network Address)

Parameter Octal Decimal Hex Modbus

Valve Status and Alarms (240 words)

System Alarm Begin 1772 1018 3FA 40251 RO

Network Fault Low Address End 1773 1019 3FB 40252 RO

Network Fault High Address 1774 1020 3FC 40253 RO

System Status Word (1 word) 1775 1021 3FD 40254 RO

Swap Primary and Hot Standby 1776 1022 3FE 40255 R/W

Valve Position Feedback (250 words)

Net Fault Index Low 2371 1273 4F9 40506 RO

Net Fault Index High 2372 1274 4FA 40507 RO

Discrete Valve Commands (63 words)

ESD to all Valve Actuators 2476 1342 53E 40575 R/W

Valve Position Setpoint (250 words)

User Analog Input #1 (124 words)

User Analog Input #2 (124 words)

Analog Output (124 words)

User Discrete Inputs

(valve inputs 0-15) (124 words)

User Discrete Outputs

(valve outputs 0-15) (124 words)

Valve Torque (raw analog) (250 words)

EHO Extended Status and Alarms cont.

(250 words)

EHO Extended Status and Alarms cont.

(250 words)

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

Begin 1400 0768 300 40001

End 1771 1017 3F9 40250

1777 1023 3FF 40256

2370 1272 4F8 40505

Begin 2377 1279 4FF 40512

End 2475 1341 53D 40574

Begin 2477 1343 53F 40576

End 3070 1592 638 40825

Begin 3071 1593 639 40826

End 3462 1842 732 41075

Begin 3463 1843 733 41076

End 4054 2092 82C 41325

Begin 4055 2093 82D 41326

End 4446 2342 926 41575

Begin 4447 2343 927 41576

End 5040 2592 A20 41825

Begin 5041 2593 A21 C 5089

End 5432 2842 B20 C 9088

Begin 5433 2843 B21 42076

End 6024 3092 C14 42325

Begin 10000 4096 1000 43329

End 10371 4345 10F9 43578

Begin 10372 4346 10FA 43579

End 10763 4595 11F3 43828

RO

RO

R/W

R/W

RO

RO

R/W

RO

R/W

RO

RO

RO

28

WARNING

!

Writing 7 to Register 40575 will cause all actuators to execute ESD.

Writing zero to Register 40575 will disable (end) ESD.

Modbus Register Maps

Page 35

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 4: Modbus Register Maps

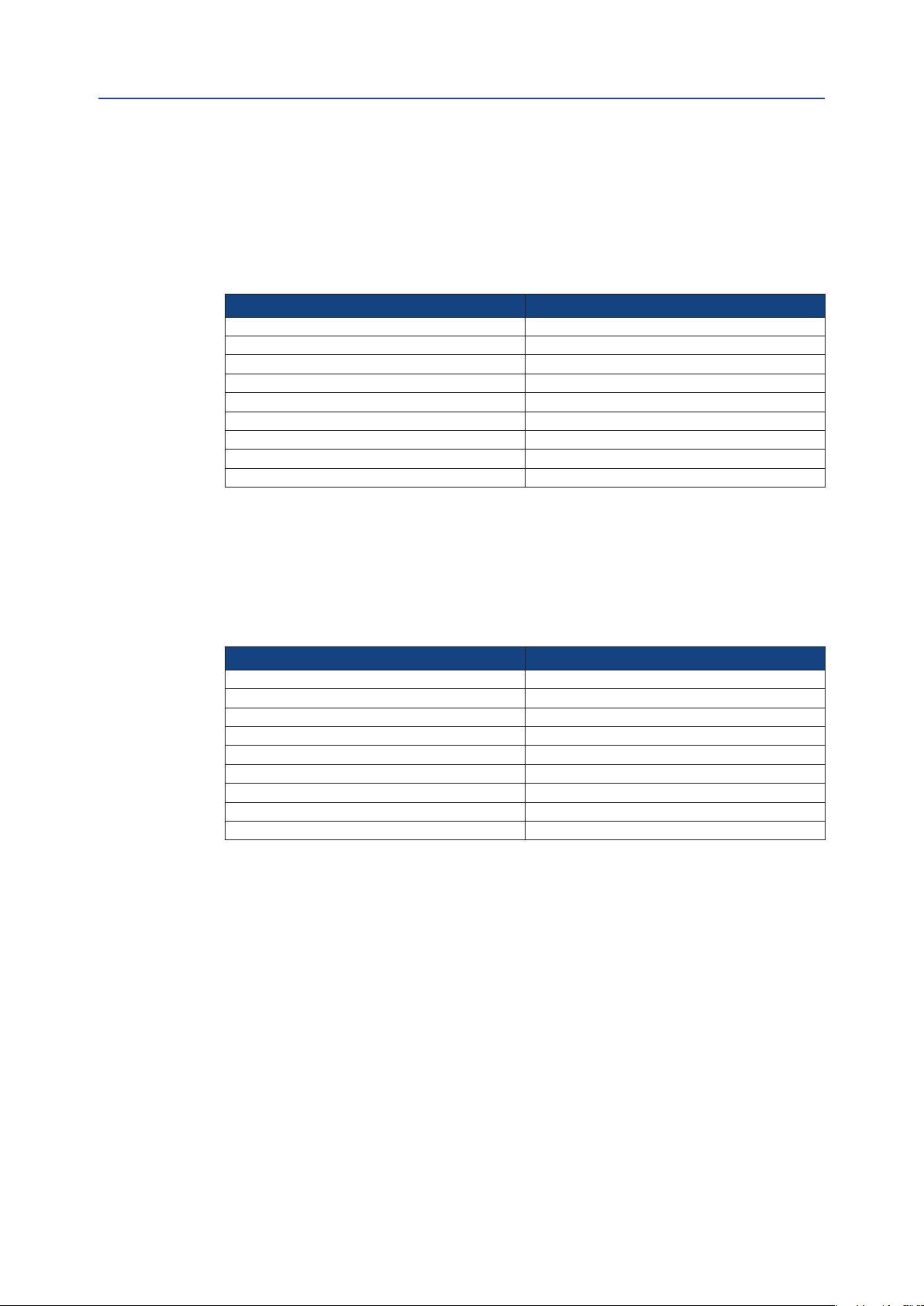

Table 13. M240N Network Master Conguration (Writing to RO Registers is

allowed but will be over-written by the controller)

(All Registers are 16-bit Unsigned Integers)

Conguration

Slot/Parameter

Network Address

Scan List

(250 words)

Device Type List

(124 words)

Main CPU

S/W Version

System Reset

Slot 1

(Net Master)

Software Version

Diagnostic Mode

Number of Field

Network Devices

Baud rate of Valve

Actuator Network

Receiver Time-Out Enter time in milliseconds (50 mS) 7017 E0F 42832 R/W

Enable/Disable

Report-By-Exception

Reserved Data written ignored. 7021 E11 42834 R/W

Reserved Data written ignored. 7022 E12 42835 R/W

Enable Program Mode

Reload Default Scan

List and Device Types

Conguration Options, Default

settings shown in [brackets]

Physical sequence of

Actuators on Network

Type of each Slave Device on Valve

Actuator Network

Software Version Number of RLL.

Data written to this register will

be over-written by the CPU on

powerup

Writing non-zero value will cause

the system to reset. This register

is zeroed after reset.

Valve Actuator Network Master

Module S/W Version Number

Written by Module in Slot 1

(0=Normal Run Mode)

Non-Zero=Diagnostic Mode

(250) Total number of slave devices connected to network

Enter whole number/100.

Example: 48, 96, 192, 384. (96)

0=Disable report by exception (RBE)

(Non-Zero=Enable RBE)

Writing a non-zero value to this register

allows the module to be programmed

from Port 1.

Writing zero to this register reloads

sequential scan list from 1 to 250 and all

device types as 2. Do not write a non-zero

value. The master writes 0x5A5A to this

register after defaults are loaded.

Begin 6025 C15 42326

End 6416 D0B 42575

Begin 6417 D0F 42576

End 7010 E08 42825

Begin 7011 E09 42826 RO

End 7012 E0A 42827 R/W

PLC

Octal

7013 E0B 42828 RO

7014 E0C 42829 R/W

7015 E0D 42830 R/W

7016 E0E 42831 R/W

7020 E10 42833 R/W

7023 E13 42836 R/W

7024 E14 42837 R/W

PLC

Hex

Modbus

Register

R/W

R/W

Modbus Register Maps

29

Page 36

Section 4: Modbus Register Maps

May 2020

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

Conguration

Slot/Parameter

Slot 2

(LCD Terminal)

Software Version

Diagnostic Mode

LCD Slave Address

LCD Baud rate

LCD Slave Parity (0=None), 1=Odd, 2=Even 7031 E19 42842 R/W

Port Hardware Mode (0=RS232), Non-Zero=RS422/485 7032 E1A 42843 R/W

Reserved for Future

Expansion

LCD Control Passcode

Slot 3

(Host Port 1)

Software Version

Diagnostic Mode

Modbus Slave Address

Modbus Slave Baud rate

Modbus Slave Parity (0=None), 1=Odd, 2=Even 7042 E22 42851 R/W

Port Hardware Mode (0=RS232), Non-Zero=RS422/485 7043 E23 42852 R/W

Reserved for Future

Expansion

Slot 4

(Host Port 2)

Software Version

Diagnostic Mode

Modbus Slave Address

Modbus Slave Baud rate

Modbus Slave Parity (0=None), 1=Odd, 2=Even 7054 E2C 42861 R/W

Port Hardware Mode (0=RS232), Non-Zero=RS422/485 7055 E2D 42862 R/W

Reserved for Future

Expansion

Conguration Options, Default

settings shown in [brackets]

LCD Panel and Control Passcode

Module S/W Version Number

Written by Module in Slot 2

(0=Normal Run Mode)

Non-Zero=Diagnostic Mode

Enter whole number from 1 to 254.

(Default=5)

Enter whole number/100. Example: 96,

192, 384, 1152 etc.

Data written to these registers are

ignored.

(0=Passcode Disabled).

Write integer between 0 and 998.

Modbus Slave Conguration

Module S/W Version Number

Written by Module in Slot 3

(0=Normal Run Mode)

Non-Zero=Diagnostic Mode

Enter whole number from 1 to 254.

(Default=5)

Enter whole number/100. Example: 96,

192, 384, 1152 etc.

Data written to these registers are

ignored.

Modbus Slave Conguration

Module S/W Version Number

Written by Module in Slot 4

(0=Normal Run Mode)

Non-Zero=Diagnostic Mode

Enter whole number from 1 to 254.

(Default=5)

Enter whole number/100. Example: 96,

192, 384, 1152 etc.

Data written to these registers are

ignored.

Begin 7033 E1B 42844

End 7034 E1C 42845

Begin 7044 E24 42853

End 7047 E27 42856

Begin 7056 E2E 42863

End 7061 E31 42866

PLC

Octal

7025 E15 42838 RO

7026 E16 42839 R/W

7027 E17 42840 R/W

7030 E18 42841 R/W

7035 E1D 42846 R/W

7036 E1E 42847 RO

7037 E1F 42848 R/W

7040 E20 42849 R/W

7041 E21 42850 R/W

7050 E28 42857 RO

7051 E29 42858 R/W

7052 E2A 42859 R/W

7053 E2B 42860 R/W

PLC

Hex

Modbus

Register

R/W

R/W

R/W

30

Modbus Register Maps

Page 37

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1 May 2020

Section 5: Theory of Operation

Section 5: Theory of Operation

This section describes systems with redundant network masters. If your system does not have

redundant masters, references to redundant chassis or modules do not apply. The system normally

has two Network Master chassis running identical software. System conguration and the Network

Master’s ability to access the eld network determine mode of operation of each chassis. Either of the

network masters may take control of the eld network. The following paragraphs explain how the

system functions from an application software point of view. This will provide a better understanding

of how the system functions. The Network Masters may be referred to as modules.

5.1 Valve Actuator Network Connections

In order to better understand how the Network Masters, operate, the user needs to understand what

goes on at the network and actuator level. Each Controlinc equipped valve actuator has a network

Port A and Port B connection. When a message is received on either port, it is conditioned by

hardware and transmitted at the other port. If a message is received on Port A, it is transmitted

at Port B. If a message is received at Port B, it is transmitted at Port A.

Messages on the network are conditioned and transmitted in both directions without intervention

of microprocessor software. As the message passes through the actuator, it is received by the

microprocessor of the valve actuator. If the message address matches the actuator address, the

command is processed and the valve actuator responds to the host command. When the actuator

responds, it transmits on both Ports A and B. Thus, both communication channels of the network

master receive messages returned from the eld. Both redundant Network Masters receive all

messages from the network from both ends of a ring.

5.2 Power-up Initialization

The M250N system supports one Network Master module per chassis but may support a variable

number of slave modules. At power up, the Network Master module congures itself based on

information read from the global database as written to the system via Modbus registers 41574

through 41584. Each communication module in the rack reads the number of slaves congured for

the network from memory location 0x927 (Modbus register 41577).

The master module uses the number of slaves to allocate memory and build a scan list obtained from

a master scan list starting at memory location 0x82B, Modbus register 41325. The module then

reads the device type list starting at memory location 0x8A7 (Modbus register 41449). The module

reads its network baud rate from memory location 0x928 (Modbus register 41578). This is the baud

rate for network Ports 1 and 2 of the module. The module reads its receiver time out from memory

location 0x929 (Modbus register 41579). This is the amount of time in milliseconds it will wait for

a response from a slave before agging the slave response as bad and going on to the next slave

address. The module reads the RBE enable from memory location 0x92A, Modbus register 41580.

If the value in this location is greater then zero, then the master will use Report-By-Exception (RBE)

in the polling process. If the value is zero, then RBE is disabled.The module reads its network baud

rate from memory location 0x928 (Modbus register 41578). This is the baud rate for network Ports 1

and 2 of the module. The module reads its receiver time out from memory location 0x929 (Modbus

register 41579). This is the amount of time in milliseconds it will wait for a response from a slave

before agging the slave response as bad and going on to the next slave address. The module reads

the RBE enable from memory location 0x92A, Modbus register 41580. If the value in this location is

greater then zero, then the master will use Report-By-Exception (RBE) in the polling process. If the

value is zero, then RBE is disabled.

Theory of Operation

31

Page 38

Section 5: Theory of Operation

May 2020

The module reads the Diagnostic Mode from memory location 0x926 (Modbus register 41576).

If the value in this register is greater than zero, the module transmits ASCII debug messages to Port

3 at 9600, N, 8, 1. Transmitting these debug messages signicantly slows down the normal process.

It is advisable to always write a zero to this register to enable normal run mode after diagnostics is

complete. While in diagnostic mode, the module will transmit to Port 3 selected Modbus messages

sent to and received from the network ports. It will also transmit other useful diagnostic messages to

Port 3, such as error messages. The module reads the Program Mode from memory location 0x92D

(Modbus register 41583). If the value in this register is greater than zero, the module will enable Port

1 as the programming port, disable "LOCKOUT," and enable entry of Control C at Port 1. This mode

allows the processor to be halted by entering Control C. The program may be edited on line or a new

program downloaded at Port 1.

One of the two redundant chassis is congured at the factory as the “primary” chassis and the other

is congured as the “secondary” chassis. The secondary chassis normally powers up in the Hot

Standby mode. The secondary master module/chassis delays two seconds after power-up to allow

the primary module/chassis to take control of the network. If the system is installed with a

Hot Standby system, this forces the Hot Standby unit (secondary module/chassis) to remain in the

Hot Standby mode so long as the primary master is communicating on the same network to which

it is connected.

5.3 Hot Standby Fail-Over

Installation and Operations Manual

MAN-01-09-91-0726-EN Rev. 1

After power up, both masters listen to the network to which they are connected for 500 mS. If no

activity is detected (quiet line), the module checks status of the host links to both chassis. If the

other chassis is not present, then the rst chassis will proceed to take control of its network if it has