Page 1

Controlinc Quick Startup Guide

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

September 2020

Page 2

Notes

September 2020

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

This page intentionally left blank

Page 3

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Table of Contents

Section 1: Quick Start Guide

1.1 Setup Instructions ................................................................................................ 9

1.2 Entering Setup Mode ...........................................................................................9

1.3 Changing Setup Parameters ................................................................................. 9

1.4 Exiting Setup Mode ..............................................................................................9

1.5 Direct Command Mode ......................................................................................10

1.6 Valve Control Mode ...........................................................................................10

1.7 Valve Travel Limits ..............................................................................................11

1.8 ESD Function ......................................................................................................11

1.9 ESD/Monitor Relay Function ............................................................................... 12

1.10 ESD Trigger Sources ...........................................................................................12

1.11 ESD Delay Time ..................................................................................................13

1.12 Position Control Bandwidth ................................................................................14

1.13 Speed Control Bandwidth ..................................................................................14

1.14 Motor Starter Type .............................................................................................15

1.15 Analog Output Control .......................................................................................15

1.16 Modulation Delay Time ......................................................................................15

1.17 Network Response Delay Time ...........................................................................16

1.18 Torque Retry (Log-Jam) Control ..........................................................................16

1.19 Network Baud Rate ............................................................................................17

1.20 Network Parity ................................................................................................... 18

1.21 Calibrate Analog I/O ...........................................................................................18

1.22 Calibrate Analog Inputs ......................................................................................19

1.23 Calibrate Analog Output ....................................................................................19

1.24 Load Factory Default Calibrate Values ................................................................20

1.25 User Relay #1 Application ...................................................................................20

1.26 User Relay #2 Application ...................................................................................21

1.27 LSA Position Setpoint .........................................................................................22

1.28 LSB Position Setpoint .........................................................................................22

1.29 Anti-water Hammer ...........................................................................................23

1.30 Opening Duty Cycle ON Timer ............................................................................23

1.31 Opening Duty Cycle OFF Timer ...........................................................................24

1.32 Closing Duty Cycle ON Timer .............................................................................. 24

1.33 Closing Duty Cycle OFF Timer ............................................................................. 25

1.34 Write Protect .....................................................................................................26

1.35 Setpoint Tracking ...............................................................................................26

Table of Contents

September 2020

Table of Contents

i

Page 4

Table of Contents

September 2020

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 2: Modbus Memory Map Reference

2.1 Modbus Function Codes .....................................................................................27

2.2 Input Register Map .............................................................................................27

2.3 Input Register 03 (DCM320B only) .....................................................................28

2.4 Discrete Input Map .............................................................................................28

2.5 Coil Map .............................................................................................................29

2.6 Holding Register Map .........................................................................................30

Section 3: Network Installation Guide

Network Installation Guide ..........................................................................................31

Section 4: System Startup Guide

System Startup Guide ..................................................................................................33

Section 5: Optional Phase Monitor

Optional Phase Monitor ...............................................................................................35

Section 6: Alarm Denitions and Troubleshooting Guide

Alarm Denitions and Troubleshooting Guide ..............................................................37

Section 7: Diagnostic Features of 320B Controlinc M2CP

7.1 High Water Mark Torque Data (Max Torque Prole) ............................................38

7.2 Full Stroke Test (FST) ..........................................................................................39

7.3 Partial Stroke Test (PST) .....................................................................................43

ii

Table of Contents

Page 5

Preface

DCM320B is an upgrade of DCM320A. It is a t, form, and function replacement for the DCM320A. The DCM320B may be used

as a direct replacement of the DCM320A in existing installations. The primary difference is the DIP switch conguration method.

The DCM320B provides more range and resolution of most conguration parameters. This handy reference is a guide to help you

get your system up and running quickly. Refer to the wiring diagram supplied with the actuator for detailed wiring information.

The rst section of this guide will help you get your Controlinc actuators hooked-up and set-up correctly. If you need to change

conguration of the unit, we recommend using our Windows based DCMLink rather than setting conguration DIP switches

shown in this guide. Setting network station address DIP switches is required. The second section of this manual is the Modbus

memory map reference to help congure your host database. If you are using the Controlinc Network Master, then refer to the

manual supplied with that unit for memory maps. Section three of this manual is a brief system startup guide to help you do

things in the proper order to achieve a successful system startup. This last section also covers optional phase monitor module.

This document covers Revision F and later revision boards.

!WARNING

Failure to follow instructions for proper electrical wiring, storage, setup, and maintenance may cause serious injury, damage

equipment, or void the warranty. Refer to Manual E796 for instructions on storage, electrical hook-up, and maintenance.

Page 6

Notes

September 2020

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

This page intentionally left blank

Page 7

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 1: Quick Start Guide

Step 1: Identify network topology

Identify network topology from Figures 2 and 3, and note the ports being used (Ports A,B,C,D).

Refer to page 23 for guidance on network planning and installation.

Step 2: Set network jumpers and switches

If network topology is parallel bus, then remove network termination and bias by turning

OFF S1 and S2 of SW4 on the DCM 320B card. Remove jumpers JP1 and JP2 on the CAM05,

if installed. Terminations must be left in the most distant unit on the network. If E>Net is

selected, all ports must be terminated. Baudrate range selection is not required on DCM 320B

but is required on CAM05. Refer to Figure 5 for jumper and DIP switch locations.

Step 3: Connect network wiring (Refer to page 23 for guidance)

Wire network ports selected in Step 1. Refer to Figure 4 when wiring Ports A and B on TBM

320A module. Refer to Figure 5 when wiring Ports C and D on the CAM05 module.

Step 4: Connect auxiliary I/O wiring

Section 1: Quick Start Guide

September 2020

Refer to Figure 4 when connecting discrete auxiliary I/O wiring. Note that some functions must

be jumpered between screw terminals if not wired to external contacts. Analog I/O wiring is

connected to the DCM 320B module as shown in Figure 5.

Step 5: Set network station address

Each node (valve actuator) on the network must have a unique station address. Locate DIP

switch SW1 on the DCM 320B card shown in Figure 5. Locate the desired station address on

pages 7 and 8. Set the DIP switches of SW1 to the corresponding pattern shown beside the

selected address. Press execute button to store address.

NOTE:

We highly recommend using the windows based DCMLink to congure the actuators. DCMLink

is available at www.emerson.com or your local Actuation Technologies distributor. If using

DCMLink, you may skip step 6 below.

Quick Start Guide

1

Page 8

Section 1: Quick Start Guide

September 2020

Figure 1 DCMLink Homescreen

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Step 6: Select conguration parameters

The actuator may be congured using the 5 DIP switches of SW2 and 8 DIP switches of SW1.

This is a back-up means of conguring the unit if DCMLink is not available. The actuator

is normally shipped with factory default settings. These settings may be changed by the

following procedure. Locate DIP switches SW1, SW2, and Setup Execute Button on the

DCM 320B module shown in Figure 5. Place the Selector Switch in the "OFF" position. Select

the feature or conguration parameter from the conguration tables in this manual. Set

the DIP switches per the corresponding switch pattern and then press the execute button.

If the conguration parameter is valid, the green (setup data good) LED will ash. If error

data is entered, the red (setup data error) LED will light until the error is corrected. Repeat

this procedure for each parameter to be revised. Return all 5 DIP switches of SW2 to the

OFF position and return the 8 DIP switches of SW1 to the network station address when

conguration is complete. With all SW2 switches OFF and the address switches set, press the

execute button to store the network address to nonvolatile conguration memory.

2

Quick Start Guide

Page 9

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Figure 2 Controlinc Model 320B RS485 Network Topology Options

Single

Multidrop

Bus

Redundant

Multidrop

Bus

Single

E>Net

Redundant

E>Net

E>Net

Ring

Section 1: Quick Start Guide

September 2020

Redundant

E>Net Ring

Limits:

32 units

4,000 ft

total

Turn OFF

S1 abd S2

of SW4 on

320B card

(except last

actuator)

Limits based on EIA standard for

RS485 bus networks

Limits:

32 units

4,000 ft

total

Requires

CAM05

module

Turn OFF S1 and S2 of

SW4 on DCM320B and

remove JP1 and JP2 on

CAM05 card

Limits:

254 units

5,000 ft

between

units or

200 miles

total

Limits:

254 units

5,000 ft

between

units or

200 miles

total

Requires

CAM05

module

Limits:

254 units

5,000 ft

between

units or

200 miles

total

EIM Network Master required

for ring network topology

E>Net requires network terminations and

bias to be asserted at all ports of all series

connected E>Net actuators. Networks may

be a combination of parallel bus and series

E>Net connections. Limit number of parallel

connected units to 15 between series

connected E>Net units.

Limits:

254 units

5,000 ft

between

units or

200 miles

total

Requires

CAM05

module

Quick Start Guide

3

Page 10

Section 1: Quick Start Guide

September 2020

Figure 3

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Shield

Shield

Bus Network

Jumpers common shield through the network

E>Net

Shield

Shield

4

Quick Start Guide

Page 11

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Figure 4 TBM 320A Hook-up Diagram

Section 1: Quick Start Guide

September 2020

NOTE:

TBM320A is used with both DCM320A and DCM320B.

Quick Start Guide

5

Page 12

Section 1: Quick Start Guide

September 2020

Figure 5

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

6

Quick Start Guide

Page 13

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Figure 6 Conguration Data and Network Station Address (SW1)

Section 1: Quick Start Guide

September 2020

Quick Start Guide

Figure 6 Conguration Data and Network Station Address (SW1) continued.....

7

Page 14

Section 1: Quick Start Guide

September 2020

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

To store network station

address to nonvolatile

conguration memory,

set all SW2 switches to

OFF, set SW1 switches

to the desired address,

place selector switch in

OFF position and then

press execute button.

Addresses 0 and 255 are

reserved for broadcast.

Addresses 254 is reserved

on secondary port.

8

Quick Start Guide

Page 15

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.1 Setup Instructions

The DCM 320B is factory congured as specied by the customer purchase order. If eld setup

changes are required, follow setup instructions below. If unsure about setup of a module,

known factory default settings may be reloaded as shown under "Direct Command Mode".

When executed, the module loads known parameters from program memory to EEPROM

conguration memory. Default parameters are highlighted in this manual by a box around the

default or the value is listed.

1.2 Entering Setup Mode

Locate DIP switches SW1, SW2, Setup Execute Button and LED indicators on the DCM 320B

(See Figure 5). SW2 switches select mode and SW1 switches select setup parameters and

network station address.

1) Record network station address of SW1. These switches must be returned to the same

setting before exiting setup.

2) Place selector switch in the OFF position.

3) Select desired setup mode by setting SW2 as indicated on this and following pages.

4) Verify the DCM320B has entered setup mode by a rapid ashing CPU GOOD light.

Section 1: Quick Start Guide

September 2020

1.3 Changing Setup Parameters

The ve switches (S1 - S5) of SW2 select the parameter/mode to be congured. The eight

switches of SW1 (S1 - SB) are used to select desired setup data.

1) Locate the desired setup parameter to be revised on pages 10 through 26.

2) Set the ve switches of SW2 per the switch pattern shown for desired mode.

3) Set SW1 switches as shown or refer to the switches on Figure 6 for desired value.

Selected values are multiples of the stated resolution for each parameter.

4) When both SW2 and SW1 switches are set, press the execute button to store the setup

parameter to nonvolatile memory.

5) Verify the green LED (setup data good) light ashes. If an invalid enter is made, the red

LED (setup data error) light will turn on until the error is corrected.

1.4 Exiting Setup Mode

1) Tum off all ve SW2 switches.

2) Place selector switch in the OFF position.

3) Return SW1 switches to the Network Station Address recorded in Step 1 under

"Entering Setup Mode" above.

4) Press the Execute Button.

5) Verify the DCM320B has returned to the normal run mode by a slow ashing CPU

GOOD light.

Quick Start Guide

9

Page 16

Section 1: Quick Start Guide

September 2020

1.5 Direct Command Mode

SW2

All SW2 switches OFF. Normal run mode.

Return all SW2 switches to this position after setup.

SW2

S1 ON = Direct Command Mode. Select the desired

command by setting SW1 switches as follows.

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

SW1

SW1

SW1

S1 ON = Reload Factory Defaults. Loads default settings as

listed or designated by rectangle around description under

each setup mode parameter in this manual.

S2 ON = Reset passcode protection.

S1, S2 ON = Archive Torque Prole. Stores torque prole to

EEPROM for later retrieval by host computer.

1.6 Valve Control Mode

(Setpoint Source)

SW2

S2 ON = Valve Control Modes. Select the desired

control mode by setting SW1 switches as follows.

SW1

All SW1 switches OFF = Remote Host Control.

Host may write Setpoint or Open, Stop, Close.

Required by F.Fieldbus for modulating control.

SW1

SW1

S1 ON = Control from AIN1 (Torque Analog Input).

Position control with Potentionmeter or 0 - 5 V

signal connected to P3.

S2 ON = Control from AIN2 (User Analog Input #1).

Position control with 4 - 20 mA signal connected to P4-2.

SW1

S1, S2 ON = Control from AIN3 (User Analog Input #2).

Position control with 4 - 20 mA signal connected to P4-4.

SW1

S3 ON = Block Valve Control Mode. Required by Foundation

Fieldbus for discrete control mode.

SW1

S1, S3 ON = Pulse Input Control Mode. 24 V DC discrete control

wired to User Input #1 (OPEN) and User Input #2 (CLOSE).

10

Quick Start Guide

Page 17

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.7 Valve Travel Limits

SW2

S1, S2 ON = Valve Travel Limits Mode.

SW1

All switches OFF = Open and Close Position

Limits. Open to LSO and Close to LSC.

SW1

S1 ON = Enable close valve torque seat.

Open to LSO and Close to TSC.

SW1

S2 ON = Enable torque backseat.

Open to TSO and Close to LSC.

SW1

S1, S2 ON = Enable close torque seat and torque backseat.

Open to TSO and Close to TSC.

Section 1: Quick Start Guide

September 2020

1.8 ESD Function

SW2

S4 ON, Select ESD Function setup mode.

SW1

SW1

SW1

SW1

SW1

SW1

All SW1 switches OFF. Stay-Put (Stop) and do

not operate ESD relay. Factory default.

S1 ON, Go closed on ESD and do not

operate ESD relay.

S2 ON, Go open on ESD and do not

operate ESD relay.

S1, S2 ON, Go closed on ESD and operate ESD relay.

S3 ON, Go open on ESD and operate ESD relay.

S1, S3 ON, Stay-Put and operate ESD relay.

Do not operate close or open outputs.

Quick Start Guide

11

Page 18

Section 1: Quick Start Guide

September 2020

1.9 ESD/Monitor Relay Function

SW2

S2, S3 ON, Select ESD/Monitor Relay Function.

SW1

All SW1 switches OFF. Deactivate relay when

an alarm is detected.

SW1

S1 ON, Activate relay when software

based ESD is detected.

SW1

S2 ON, Activate relay on command from

remote network host. Factory default.

1.10 ESD Trigger Sources

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

NOTE:

At least one source must be selected, or ESD is disabled.

S1, S4 ON, Select ESD Trigger setup mode.

SW1

All SW1 switches OFF. Disable ESD.

SW1

S1 ON, Enable ESD on command

from network host. Factory default.

SW1

S2 ON, Enable ESD Relay control on local

ESD discrete input.

SW1

S1, S2 ON, Enable ESD on command from host and Enable ESD Relay control on local ESD discrete input.

SW1

S3 ON, Enable ESD on loss of communications

from host.

SW1

SW1

SW1

S1, S3 ON, Enable ESD on loss of command

from network host and Enable ESD on loss of

communications from host.

S2, S3 ON, Enable ESD Relay control on local

ESD discrete input and Enable ESD on loss of

communications from network host.

S1, S2, S3 ON, Enable ESD on command from network

host. Enable ESD Relay control on local ESD input and

Enable ESD on loss of communications from the host.

12

Quick Start Guide

Page 19

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.11 ESD Delay Time

SW2

S1, S2, S4 ON, Select ESD delay setup mode.

Select delay time by setting SW1 switches as shown

on Figure 6.

Range = 0 to 60 seconds

Resolution = 1 second

Default = 0

Example: Set ESD delay time to 30 seconds.

SW1

Locate the DIP switch pattern for 30 on Figure 6.

NOTE:

ESD Delay Time applies only to software generated ESD and not to the hardwired local ESD input.

Section 1: Quick Start Guide

September 2020

Notes on hardwired Local Inhibit/ESD:

1) Local ESD is a hardwired closed loop circuit wired to TBM tenninals 27 (+) and 28 (-)

using either an external 24 V DC power supply or the internal 24 V DC power available

at tenninals 26 (+) and 29 (-). See Figure 4.

2) Local ESD will inhibit control from the DCM320B module, local push buttons and

selector switch. To force valve closed on local ESD, insert jumper between terminals

9 and 10. To force valve open on local ESD, insert jumper between terminals 8 and 9.

Actuator will Stop (Stay-Put) if no jumpers are inserted between terminals 8-9 or 9-10.

3) To override motor thermal contacts during local ESD, insert jumper between terminals

XO and 53.

WARNING:

!

Do not override thermals in a hazardous area.

4) Software activated ESD can activate Local ESD by wiring N.C. contacts of ESD/Monitor

relay (terminals 32 and 33) in series with Local lnhibit/ESD inputs at terminals 27 and 28.

Quick Start Guide

13

Page 20

Section 1: Quick Start Guide

September 2020

1.12 Position Control Bandwidth

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

SW2

Example: Set control bandwidth to 2.5%.

S3, S4 ON, Select position control bandwidth

(Deadband) setup mode.

Select bandwidth by setting SW1 switches as shown

on Figure 6. (see example below).

Range = 0.1% to 5.0% (0 - 50)

Resolution = 0.1%

Default = 1.0%

SW1

Locate the DIP switch pattern for 25 on Figure 6,

i.e. 2.5 x 0.1% resolution = 2.5%.

1.13 Speed Control Bandwidth

SW2

S1, S3, S4 ON, Select speed control bandwidth

setup mode.

Select bandwidth by setting SW1 switches as

shown on Figure 6. (see example below).

Range = 0.3% to 10.0% (3 - 100)

Resolution = 0.1%

Default = 3.0%

Example: Set speed control bandwidth to 5%.

SW1

Locate the DIP switch pattern for 50 on Figure 6,

i.e. 50 x 0.1% resolution = 5.0%.

NOTE:

Speed control bandwidth is meaningful only when a VFD motor starter is used. Speed control

bandwidth must be greater than position control bandwidth.

14

Quick Start Guide

Page 21

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.14 Motor Starter Type

SW2

S1, S2, S3 ON, Select type of motor starter installed.

Select motor started type by setting SW1 switches.

SW1

All SW1 switches OFF. Enable Electro-mechanical

motor starter. Factory Default.

SW1

S1 ON, Enable Solid-State Relay (SSR)

motor starter type.

SW1

S2 ON, Enable Variable Frequency Drive (VDF)

motor starter type.

1.15 Analog Output Control

Section 1: Quick Start Guide

September 2020

SW2

S3 ON, Select source for analog output.

Select AO#1 source by setting SW1 switches.

SW1

SW1

All SW1 switches OFF. Enable Network Host

control of analog output AO#1. Factory default.

S1 ON, Enable Position Feedback

control of analog output AO#1.

1.16 Modulation Delay Time

SW2

S2, S3, S4 ON = Modulation Delay Timer Mode.

Select delay time by setting SW1 switches as

shown on Figure 6. (see example below).

Range = 0 to 25.5 seconds (0 - 255)

Resolution = 0.1 second

Default = 0.1 second

Example: Set modulation delay time to 6 seconds.

Quick Start Guide

SW1

Locate the DIP switch pattern for 60 on Figure 6,

i.e. 60 x 0.1 second resolution = 6.0 seconds

15

Page 22

Section 1: Quick Start Guide

September 2020

1.17 Network Response Delay Time

1.17.1 Primary Network Ports A and B

SW2

S1, S2, S3, S4 ON, Select Ports A and B response

delay mode.

Select delay time by setting SW1 switches as

shown on Figure 6. (see example below).

Range = 8 to 60 mS (8 - 60)

Resolution = 1 mS

Default = 8 mS

Example: Set response delay to 15 mS.

SW1

Locate the DIP switch pattern for 15 on Figure 6.

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.17.2 Secondary Network Ports C and D

SW2

S5 ON, Select Ports C and D response delay mode.

Select delay time by setting SW1 switches as shown

on Figure 6. (see example below).

Range = 8 to 60 mS (8 - 60)

Resolution = 1 mS

Default = 8 mS

1.18 Torque Retry (Log-Jam) Control

SW2

S1, S3 ON, Select Close Torque (Log-Jam) function.

SW1

All SW1 switches OFF. Disable close torque retry

(Log-Jam) funstion. Factory default.

SW1

S1 ON. Enable close torque retry (Log-Jam) function.

16

Quick Start Guide

Page 23

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.19 Network Baud Rate

1.19.1 Primary Network Ports A and B

Section 1: Quick Start Guide

September 2020

SW2

S1, S5 ON. Select baud rate for primary network ports A and B.

Select baud rate by setting SW1 switches as shown below.

Default = 9600.

1.19.2 Secondary Network Ports C and D

SW2

SW1 SW1

SW1 SW1

SW1 SW1

S2, S5 ON. Select baud rate for secondary network ports C and D.

Select baud rate by setting SW1 switches as shown below. Default = 19200.

All OFF = 1200

S1 = 2400

S2 = 4800 S1, 3 = 38400

S1, 2 = 9600

S3 = 1900

Quick Start Guide

17

Page 24

Section 1: Quick Start Guide

September 2020

1.20 Network Parity

1.20.1 Primary Network Ports A and B

SW2

S1, 2, 5 ON. Select parity for primary network.

Select parity by setting SW1 switches as shown below.

1.20.2 Secondary Network Ports C and D

SW2

S1, 2, 5 ON. Select parity for secondary network.

Select parity by setting SW1 switches as shown below.

SW1

SW1

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

All SW1 switches OFF = No parity

S1 = Even parity

SW1

S2 = Odd parity

1.21 Calibrate Analog I/O

SW2

S1, 3, 5 ON. Select analog input and ouput calibration mode.

Set SW1 to select the desired analog input or output calibration,

apply calibration current to input or connect 4 - 20 mA meter to

output and then press execute button.

18

Quick Start Guide

Page 25

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.22 Calibrate Analog Inputs

SW1

S2 ON, Set Torque analog input Zero.

Input zero offset resistance/voltage.

SW1

S1, 2 ON, Set Torque analog input Span.

Input full scale resistance/voltage.

SW1

S2, 3 ON, Set User #1 analog input Zero.

Input 4 mA offset current.

SW1

S1, 2, 3 ON, Set User #1 analog input Span.

Input 20 mA full scale current.

SW1

S2, 4 ON, Set User #2 analog input Zero.

Input 4 mA offset current.

SW1

S1, 2, 4 ON, Set User #2 analog input Span.

Input 20 mA full scale current.

Section 1: Quick Start Guide

September 2020

1.23 Calibrate Analog Output

SW1

S2, 3, 4 ON, Increase zero analog output at AO#1

while the Execute button is pressed.

SW1

S1, 2, 3, 4 ON, Decrease zero analog output at AO#1

while the Execute button is pressed.

SW1

S5 ON, Increase full scale analog output at AO#1

while the Execute button is pressed.

SW1

S1, 5 ON, Decrease full scale analog output at AO#1

while the Execute button is pressed.

Quick Start Guide

19

Page 26

Section 1: Quick Start Guide

September 2020

1.24 Load Factory Default Calibrate Values

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

SW1

All OFF. Torque

input Zero.

SW1

S3 ON, User

AIN#1 Zero.

SW1

S4 ON, User

AIN#2 Zero.

SW1

S3, 4 ON, Analog

Out Zero.

SW1

S2, 5 ON, Load factory default calibration values for all

analog inputs and outputs for both Zero and Span.

SW1

SW1

SW1

SW1

S1 ON, Tprque

input Span.

S1, 3 ON, User

AIN#1 Span.

S1, 4 ON, User

AIN#1 Span.

S1, 3, 4 ON,

Analog Out

Span.

1.25 User Relay #1 Application

SW2

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

S2, S3, S5 ON, Select User Relay#1 setup mode.

Select user relay#1 function by setting SW1

switches as shown below.

All SW1 switches OFF, Direct control of N.O

relay from network master. Factory default.

S1 ON, Activate normally open (N.O) relay

when Selector Switch in Remote position.

S2 ON, Activate normally open (N.O) relay

when Selector Switch in Local position.

S1, S2 ON, Activate normally open (N.O) relay at

LSA limit setpoint, if LSA position congured.

S3 ON, Activate normally open (N.O)

relay when any ESD is active.

S1, S3 ON, Direct control of normally closed (N.C)

contact from network master.

S2, S3 ON, Activate normally closed (N.C) relay

when Selector switch in Remote position.

S1, S2, S3 ON, Activate normally closed (N.C) relay

when Selector switch in Local position.

S4 ON, Activate normally closed (N.C) relay at

LSA limit setpoint, if LSA position congured.

S3 ON, Activate normally closed (N.C) relay

when any ESD is active.

20

Quick Start Guide

Page 27

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.26 User Relay #2 Application

Section 1: Quick Start Guide

September 2020

SW2

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

SW1

S1, S2, S3, S5 ON, Select User Relay#2 setup mode.

Select user relay#1 function by setting SW1 switches as

shown below.

All SW1 switches OFF, Direct control of N.O

relay from network master. Factory default.

S1 ON, Activate normally open (N.O) relay

when Selector Switch in Remote position.

S2 ON, Activate normally open (N.O) relay

when Selector Switch in Local position.

S1, S2 ON, Activate normally open (N.O) relay at

LSB limit setpoint, if LSB position congured.

S3 ON, Activate normally open (N.O)

relay when any ESD is active.

S1, S3 ON, Direct control of normally closed (N.C)

contact from network master.

S2, S3 ON, Activate normally closed (N.C) relay

when Selector switch in Remote position.

S1, S2, S3 ON, Activate normally closed (N.C) relay

when Selector switch in Local position.

S4 ON, Activate normally closed (N.C) relay at

LSB limit setpoint, if LSB position congured.

S3 ON, Activate normally closed (N.C) relay

when any ESD is active.

Quick Start Guide

NOTE:

User Relay #1 and User Relay #2 are non-latching SPST type. When power to the actuator is lost,

both relays are de-energized and the contacts will open. Do not apply these relays to critical

control applications where closed contacts are required during loss of power.

21

Page 28

Section 1: Quick Start Guide

September 2020

1.27 LSA Position Setpoint

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

SW2

Example: Set LSA position to 30%.

SW1

S4, 5 ON, Select LSA position setup mode.

Select LSA by setting SW1 switches as shown on

Figure 6. (see example below).

Range = 0 to 100%

Resolution = 1%

Default = 0 (LSA disabled)

Locate the DIP switch pattern for 30 on Figure 6.

1.28 LSB Position Setpoint

SW2

Example: Set LSB position to 60%.

S2, 4, 5 ON, Select LSB position setup mode.

Select LSB by setting SW1 switches as shown on Figure 6.

(see example below).

Range = 0 to 100%

Resolution = 1%

Default = 0 (LSB disabled)

SW1

Locate the DIP switch pattern for 60 on Figure 6.

22

Quick Start Guide

Page 29

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.29 Anti-water Hammer

SW2

S2, 4, 5 ON, Select anti-water hammer setup mode.

Select anti-water hammer position by setting SW1 switches as

shown on Figure 6. (see example below). This is the position that

anti-water hammer is activated while the valve is closing.

Range = 0 to 100%

Resolution = 1%

Default = 0 (anti-water hammer disabled)

Example: Set Anti-water hammer position to 10%.

SW1

Locate the DIP switch pattern for 10 on Figure 6.

1.30 Opening Duty Cycle ON Timer

Section 1: Quick Start Guide

September 2020

SW2

Example: Set Anti-water hammer position to 10%.

SW1

S1, 3, 4, 5 ON, Select opening duty cycle ON timer.

Select opening ON time by setting SW1 switches as shown on Figure 6.

(see example below).

Range = 0 to 65 seconds

Resolution = 1 second

Default = 0 (Timer disabled)

Locate the DIP switch pattern for 6 on Figure 6.

Quick Start Guide

23

Page 30

Section 1: Quick Start Guide

September 2020

1.31 Opening Duty Cycle OFF Timer

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

SW2

Example: Set opening OFF timer to 9 seconds.

SW1

S2, 3, 4, 5 ON, Select opening duty cycle OFF timer.

Select opening OFF time by setting SW1 switches as shown on Figure 6.

(see example below).

Range = 0 to 65 seconds

Resolution = 1 second

Default = 0 (Timer disabled)

Locate the DIP switch pattern for 9 on Figure 6.

1.32 Closing Duty Cycle ON Timer

SW2

Example: Set closing ON timer to 6 seconds.

SW1

S1, 2, 4, 5 ON, Select closing duty cycle ON timer.

Select closing ON time by setting SW1 switches as shown on Figure 6.

(see example below).

Range = 0 to 65 seconds

Resolution = 1 second

Default = 0 (Timer disabled)

Locate the DIP switch pattern for 9 on Figure 6.

24

Quick Start Guide

Page 31

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

1.33 Closing Duty Cycle OFF Timer

Section 1: Quick Start Guide

September 2020

SW2

Example: Set closing OFF timer to 9 seconds.

S3, 4, 5 ON, Select closing duty cycle OFF timer.

Select closing OFF time by setting SW1 switches as shown on Figure 6.

(see example below).

Range = 0 to 65 seconds

Resolution = 1 second

Default = 0 (Timer disabled)

SW1

Locate the DIP switch pattern for 9 on Figure 6.

NOTE:

Duty cycle timers are active only when selector switch is in REMOTE position. Opening and

closing speed of the valve may be adjusted (slowed) by enabling the opening or closing duty

cycle timers. Duty cycle timers are available only with a solid-state or VFD starter. Anti-water

hammer duty cycle is is xed at 50% duty with one second ON time and one second OFF

time for SSR and VFD starters and two seconds ON time and two seconds OFF time for

electro-mechanical starter. When activated, the Anti-water hammer function overrides the

closing duty cycle timer. If duty cycle or Anti-water hammer functions are used in any Anti

water hammer scheme, ElM must be advised of system parameters and conditions.

Quick Start Guide

25

Page 32

Section 1: Quick Start Guide

September 2020

1.34 Write Protect

Prevent conguration changes through network CAM connection when write protect is

enabled. Requirement for Foundation Fieldbus and Hart. Modbus communication will not be

affected. Register 12 Bit 5 is to be dened as Write Protect.

To Enable Select Write Protect:

SW2

S2, 4 ON

SW1

Locate the DIP switch pattern for 10 in Figure 6

To Disable Write Protect:

SW2

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

S2, 4 ON

SW1

Locate the DIP switch pattern for 37 in Figure 6

1.35 Setpoint Tracking

To Enable Setpoint Tracking:

SW2

S2, 4 ON

SW1

Locate the DIP switch pattern for 26 in Figure 6

To Disable Setpoint Tracking:

SW2

S2, 4 ON

SW1

Locate the DIP switch pattern for 53 in Figure 6

26

Quick Start Guide

Page 33

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 2: Modbus Memory Map Reference

September 2020

Section 2: Modbus Memory Map Reference

2.1 Modbus Function Codes

Host

beginning

register

01 Read Coil Status 00001

02 Read Input Status 10001

03 Read Holding Register 40001

04 Read Input Register 30001

05 Force Single Coil 00001

06 Preset Single Register 40001

07 Read Exception Status

08 Loopback Diagnostic Test

15 Force Multiple Coils 00001

16 Preset Multiple Registers 40001

17 Report Slave I.D.

NOTE:

All registers are zero based. Add one to inputs, coils or holding registers when conguring host

database. See host beginning registers above.

2.2 Input Register Map

(Use function code 04)

00 Inputs 0-15 (Live discrete inputs)

01 Inputs 16-31 (Standard valve status)

02 Inputs 32-47 (DCM320 valve status)

03 Inputs 48-63 (Specic to DCM320B)

Modbus Memory Map Reference

27

Page 34

Section 2: Modbus Memory Map Reference

September 2020

2.2 Input Register 03 (DCM320B only)

48 DCM is in Setup Mode

49 AIN1 Signal fault

50 AIN2 Signal fault

51 AIN3 Signal fault

52 Software triggered ESD active

53-63 Reserved inputs (always zero)

2.4 Discrete Input Map

(Inputs 0 through 15 are hardware inputs)

(use function code 02)

00 Open limit switch (LSO) 27 Phase monitor alarm

01 Close limit switch (LSC) 28 Local ESD alarm

02 Contactor Aux. open contact 29 Actuator fail alarm

03 Contactor Aux. close contact 30 No input (always zero)

04 Selector switch Local/Manual 31 Unit alarm (above alarms OR'ed)

05 Selector switch Remote/Auto 32 Open limit switch (LSO)

06 Open torque switch (TSO) 33 Close limit switch (LSC)

07 Close torque switch (TSC) 34 Stopped (valve stopped in mid travel)

08 Power monitor alarm 35 Opening (valve moving open)

09 Motor thermal overload 36 Closing (valve moving close)

10 Phase monitor 37 Valve stall alarm (valve not moving)

11 Local ESD alarm 38 Selector switch in Local/Manual

12 Aux. alarm input (VFD fault) 39 Unit alarm (alarms OR'ed)

13 User discrete input #1 40 Motor thermal overload alarm

14 User discrete input #2 41 Power monitor alarm

15 Reserved 42 Primary network alarm

16 Open limit switch (LSO) 43 Secondary network alarm

17 Close limit switch (LSC) 44 Open torque alarm (TSO)

18

Opening (valve moving open)

19

Closing (valve moving close)

20

Selector switch Local/Manual

21

Selector switch Remote/Auto

22

Open torque switch (TSO)

23

Close torque switch (TSC)

24

Valve stall alarm (valve not moving)

25 Power monitor alarm 52 ESD active alarm

26 Motor thermal overload alarm 53 EEPROM active cong

45 Close torque alarm (TSC)

46 Local ESD input alarm

47 Phase monitor alarm

48 RESERVED

49 Torque out of range

50 AIN1 out of range

51 AIN2 out of range

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

28

Modbus Memory Map Reference

Page 35

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

2.5 Coil Map

(Coils 0 through 7 are hardware outputs)

(use function code 01, 05 and 15)

00 Close motor starter output 43 Enable Stop on ESD with ESD relay

01 Open motor starter output 44 Enable ESD trigger from host

02 Solid-state relay NFC speed control 45 Enable ESD trigger on local ESD input

03 ESD/Monitor relay output 46 Enable ESD trigger from loss of com.

04 User relay #I/Override relay 47 Conguration conict error detected

05 User relay #2 48 Select AIN1 as setpoint source

06 Primary network channel 1 enable 49 Select AIN2 as setpoint source

07 Secondary network channel 2 enable 50 Select AIN3 as setpoint source

08 Host OPEN valve command 51 Move to Default on AIN1 fault

09 Host STOP command 52 Move to Default on AIN2 fault

10 Host CLOSE valve command 53 Move to Default on AIN3 fault

11 Host ESD command 54 reserved

12 Enable normal modulating mode 55 Enable setpoint tracking

13 reserved 56 reserved

14 Enable VFD starter control mode 57 Select N.C. contacts for Relay #1

15 Enable pulse control mode 58 Enable Relay #1 as Override on ESD

16 Open limit switch status (LSO) 59 Activate Relay #1 in Remote/Auto

17 Close limit switch status (LSC) 60 Activate Relay #1 in Local/Manual

18 Opening status (valve moving open) 61 Activate Relay #1 at LSA setpoint

19 Closing status (valve moving close) 62 Select N.C. contacts for Relay #2

20 Selector switch Local/Manual 63 Enable Relay #2 as Override on ESD

21 Selector switch Remote/Auto 64 Activate Relay #2 in Remote/Auto

22 Open torque alarm (TSO) 65 Activate Relay #2 in Local/Manual

23 Close torque alarm (TSC) 66 Activate Relay #2 at LSB setpoint

24 Valve stall alarm (valve not moving) 67 Set primary network to odd parity

25 Power monitor alarm 68 Set primary network to even parity

26 Motor overload alarm (Motor thermal) 69 Set secondary net to odd parity

27 Phase monitor alarm 70 Set secondary net to even parity

28 Local ESD alarm 71 Enable primary network alarm

29 Actuator fail alarm 72 Enable secondary network alarm

30 reserved for host (always zero) 73 reserved

31 Unit alarm (all alarms OR'ed) 74 reserved

32 Enable torque seat mode 75 Enable MRTU operating mode

33 Enable logjam retry mode 76 Enable torque backseat

34 Enable 4-20mA feedback at A0#1 77 Save torque prole to EEPROM

35 Enable monitor relay, else ESD relay 78 CPU has reset

36 Enable passcode protection 79 Load factory default conguration

37 Enable solid-state starter contol mode 80 Write protect

38 reserved 81 Setup mode

39 Enable Close on ESD w/o ESD relay 100 Host OPEN valve command

40 Enable Open on ESD w/o ESD relay 101 Host CLOSE valve command

41 Enable Close on ESD with ESD relay 102 Host STOP command

42 Enable Open on ESD with ESD relay 103 Host ESD command

Section 2: Modbus Memory Map Reference

September 2020

Modbus Memory Map Reference

29

Page 36

Section 2: Modbus Memory Map Reference

September 2020

2.6 Holding Register Map

(RO = Read Only RW = Read/Write)

(Use function 03, 06 and 16)

00 RW Coils 0-15 42 RW Passcode char 1(LSB) and 2(MSB)

01 RO Coils 16-31 43 RW Passcode char 3(LSB) and 4(MSB)

02 RW Coils 32-47 44 RO Firmware version

03 RW Coils 48-63 45 RO Compatibility number

04 RW Coils 64-79 46 reserved

05 RO Inputs 0-15 47 reserved

06 RO Inputs 16-31 48 RO Torque@ 10% valve position

07 RO Valve Position 1.0% increments 49 RO Torque@ 20% valve position

08 RO Valve Status inputs 32-47 50 RO Torque@ 30% valve position

09 RO Valve Status inputs 16-31 51 RO Torque@ 40% valve position

10 RW Analog Output (0-4095) 52 RO Torque@ 50% valve position

11 RW Valve Position Setpoint (0-4095) 53 RO Torque@ 60% valve position

12 RO Inputs 48-63 54 RO Torque@ 70% valve position

13 RO Valve Position (0.1% increments) 55 RO Torque@ 80% valve position

14 RO Position Analog Input (0-4095) 56 RO Torque@ 90% valve position

15 RO Torque Analog Input (0-4095) 57 RO Torque prole @ 10%

16 RO User Analog Input #1 (0-4095) 58 RO Torque prole @ 20%

17 RO User Analog Input #2 (0-4095 59 RO Torque prole @ 30%

18 RW Water Hammer setpoint (1-20%) 60 RO Torque prole @ 40%

19 RW Modulation delay (0.1-25.5 sec) 61 RO Torque prole @ 50%

20 RW ESD Delay timer (0-65.5 sec) 62 RO Torque prole @ 60%

21 RW Position Bandwidth (0.1-5.0%) 63 RO Torque prole @ 70%

22 RW Speed Bandwidth (0.5-10%) 64 RO Torque prole @ 80%

23 RW Default Position Setpoint (0-4095) 65 RO Torque prole @ 90%

24 RW Torque AIN Zero offset, raw cnts 66 RW Accumulator #1 (User Input #1)

25 RW Torque AIN Span, raw AID counts 67 RW Accumulator #1 (User Input #2)

26 RW User AIN1 Zero offset, raw counts 68 RW Lost COM ESD delay (mS)

27 RW User AIN1 Span, raw AID counts 69 RW Stall time delay (mS)

28 RW User AIN2 Zero offset, raw counts 70 RW RW Valve Travel Time/1% (mS)

29 RW User AIN2 Span, raw AID counts 100 RO RO Unit I.D.

30 RW A0#1 Zero offset, raw counts

31 RW A0#1 Span, raw D/A counts

32 RW LSA Setpoint (0-4095)

33 RW LSB Setpoint (0-4095)

34 RW Close ON duty cycle (0-65.5 sec)

35 RW Close OFF duty cycle (0-65.5 sec)

36 RW Open ON duty cycle (0-65.5 sec)

37 RW Open OFF duty cycle (0-65.5 sec)

38 RW Primary network baudrate

39 RW Primary network response delay

40 RW Secondary network baudrate

41 RW Secondary network response dela

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

NOTE:

1) Unless otherwise specied, analog I/O is

unsigned integer in range of 0-4095.

2) All time parameters are in mS.

3) Torque readings are raw AID counts.

4 ) T o r q u e p r o l e v a l u e s a r e r e a d f r o m E E P R O M .

5) Do not write to reserved registers.

30

Modbus Memory Map Reference

Page 37

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 3: Network Installation Guide

Section 3: Network Installation Guide

Step 1: Plan the network topology

Before connecting actuators, the entire network layout should be planned. Select desired

network topology from Figures 2 and 3. Topologies may be bus or E>Net or a combination of

bus and E>Net. All networks may be redundant or ring or redundant rings. Limit the number

of parallel connected bus units to 15 between E>Net units. Network planning should include

node addressing, wire routing, terminations, and grounding.

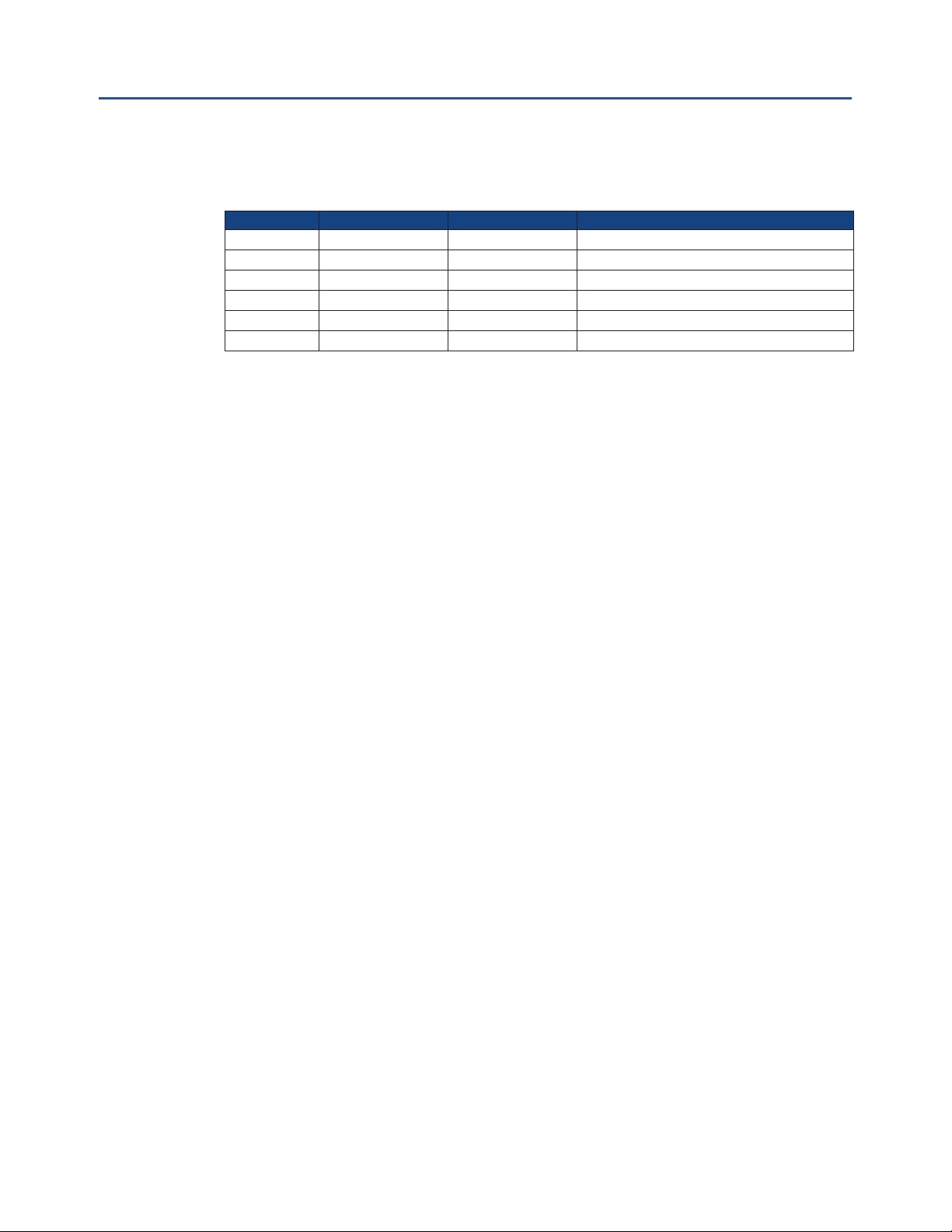

Step 2: Select network cable

Ensure correct cable is being used. Networks require twisted pair and shielded cable with a

characteristic impedance between 50 and 120 Ohms. Capacitance between conductors must

be less than 30 pF/ft (98 pF/m); 10-15 pF/ft is ideal. Shielding may be aluminum foil with drain

wire. Only cables with stranded conductors are recommended. Insulating and outer jacket

materials must be selected for the application environment. Following are acceptable Belden

or equivalent cables for most network applications.

September 2020

24AWG

9841, 12.8 pF/ft

22AWG

8761, 24 pF/ft

20AWG

8762, 27 pF/ft

18AWG

8760, 24 pF/ft

16AWG

8719, 23 pF/ft

14AWG

8720, 24 pF/ft

8162, 9729, and 9842 are 24AWG, 2-pair cables with <13 pF/ft

Step 3: Route cable away from electrical interference

Network cables should enter the electrical enclosure at the bottom or lowest point near the

transformer end. Route cable around the transformer end, normally in a counter clockwise

direction to the top side of the TBM. Never install network cable in the same conduit with

power conductors. Never route network cable through the high voltage contactor area. The

cable should never lie across the TBM or hinder the protective cover of the TBM. Always use

the shortest distance and keep excess cable to a minimum; 6" typical.

Network Installation Guide

31

Page 38

Section 3: Network Installation Guide

September 2020

Step 4: Observe polarity and network grounding

Each network connection is polarized + and - on wiring diagrams. Always use consistency

in wiring and the use of wire colors to track polarity. The cable shield or drain wire must be

connected to the designated (SH) terminal at each port of each actuator. The shield must be

connected to earth ground at only one point. Some networks may require a jumper between

shield connections (Terminals 22 and 23) of each actuator to carry the shield through the

network. The shield connection of each actuator is isolated from earth. Do not allow the shield

to touch circuits on the TBM or the metal enclosure. Use plastic electrical tape or heat shrink

tubing to isolate the shield or drain wire.

Step 5: Wire preparation and connections

Screw terminals of the TBM have wire clamps that accept wires without terminals but may be

applied if desired. Strip insulation back 3/8" when connecting directly to the TBM screw terminals.

Do not allow wire clippings to fall on the TBM or into the actuator enclosure. Protect conductors

and the shield or drain wire to prevent contact with the TBM. Use plastic electrical tape or heat

shrink tubing to prevent bare conductors from contacting other circuits or earth ground.

Step 6: Wire preparation and connections

Use DCMLink or Controlinc Pocket Technician to test the network prior to connecting to a host

or network master. The DCMLink is a Windows application that will run on a laptop using an

RS232 to RS485 adapter or the Network Interface Unit (NIU) for connecting to the network.

After all actuators are veried to operate in Local mode, test each actuator to verify all network

connections and each actuator operates via the network in Remote mode.

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

32

Network Installation Guide

Page 39

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 4: System Startup Guide

Step 1: Set position and torque limit switches

Set open and close position and torque switches while operating valve full open and close with

local push buttons. Refer to Manual E796 for limit switch setting instructions.

Step 2: Set DIP switches

Set address DIP switches to unique address as shown in the rst section of this guide. Refer to

Figure 5 for location of DIP switches. Refer to network station address switch settings on Figure 6.

Also remember to check baud rate of each actuator to ensure it matches the host system.

Step 3: Check network wiring

Check polarity of each network connection per wiring connections shown in Figure 3 of this

guide. Ensure shield is connected at each actuator and is earth grounded at only one point.

Refer to page 26 for additional instructions on network installation.

Step 4: Check network terminations

Bus networks require termination resistance and bias at each end of the network. Remove

termination and bias on all modules except the last, most distant unit at the end of the

network. Always leave termination and bias on every unit when using E>Net. See Figure 4 for

location of DIP switches and jumpers for termination and bias selection. Verify quiescent line

bias is 250mV minimum during no communication activity.

Section 4: System Startup Guide

September 2020

Step 5: Test network

Use DCMLink software to test each actuator. Ensure each station address is tested and verify

received data. View communication signals with oscilloscope to ensure good signal strength

and clean waveforms. Repeat test for each actuator on redundant network if installed.

System Startup Guide

33

Page 40

Section 4: System Startup Guide

September 2020

Step 6: Verify network master conguration

If using the Controlinc Network Master, refer to the User Manual supplied with the system

for setup details. If direct connecting to your DCS, SCADA, or PLC system, refer to the

manufacturer's supplied documentation. Verify network baud rate and parity match the

settings of the actuators. Verify the master is congured for the total number of actuators

and database matches network address assignments per actuator location on network. Take

system out of test or diagnostic mode when nished.

Step 7: Test host interface

If using the Controlinc Network Master, use Modbus host test software supplied with the

system to test slave port(s) of the network master. If direct connect to other host equipment,

use software supplied with that equipment to test actuators. Verify database for each node

and I/O point by tag name and mapping of each point to operator's screen. Operate each valve

open and close or to setpoint. Test each auxilliary I/O point.

Tools:

1) Speed handle or 3/8" battery drill with 1/2" thin wall socket

2) Common screwdriver

3) Multimeter (VOM)

4) Portable oscilloscope (optional)

5) Laptop computer with Windows

6) DCMLink w/ RS485 adapter

7) Other system test software supplied with host system

8) Programming cables

9) 4-20mA calibrator for analog I/O

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

34

System Startup Guide

Page 41

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 5: Optional Phase Monitor

Section 5: Optional Phase Monitor

If your actuator contains the optional phase monitor, then this section applies.

The phase monitor module shown in Figure 7 is mounted on the back side of the DCM 320B

module facing the motor starter.

Figure 7

Correct phase and voltage

Phase are out of sequence

Loss of phase or low voltage on

one phase

YEL

GRN

RED

September 2020

P/N 84137

Optional Phase Monitor

35

Page 42

Section 5: Optional Phase Monitor

September 2020

NOTE:

We advise using phase sentry mode rather than phase correction.

Phase sentry mode will cause the actuator to shut down if phases are out of sequence for

proper electric motor rotation or a loss of phase is detected. Phase correction mode will

cause the actuator to correct the phase sequence and continue to operate when phases are

out of sequence. Either mode will cause the actuator to shut down if a loss of phase

(single-phasing) is detected.

To select modes, do the following:

1) Remove TBM 320A termination panel.

2) Locate 3-pin jumper P9 on bottom of board marked PC and PS.

— PC means Phase Correction.

— PS means Phase Sentry.

3) Move the shorting strap to the desired mode selection (PC or PS).

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

36

Optional Phase Monitor

Page 43

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 6: Alarm Denitions and Troubleshooting Guide

Section 6: Alarm Denitions and

Troubleshooting Guide

Table 1.

Alarm Denition / explanation Actions to be taken

Open Torque Alarm

Close Torque Alarm

Valve Stall Alarm

Power Monitor Alarm

Motor Thermal Overload

Phase Monitor Alarm

Hardwired - ESD Alarm

Actuator Fail Alarm

Com No-Response

Alarm

Unit Alarm

Actuator exceeded open torque

limit setting

Actuator exceeded close torque

imit setting

No actuator movement or

position feedback after 8 seconds

upon a commanded movement

Indicates lost control voltage,

or lost power, or lost phas

(if supplied with a Phase

Sentry Module)

Protects motor windings from

increased internal temperature rise

when under increased load or duty

cycle.

Indicates the condition of the

three-phase primary power supply.

Can detect lost phase or incorrect phase.

External hardwired circuit is

activated on an open circuit. Local ESD

overrides other commands based on

conguration to Open, Close or Stay

Put when there is Emergency Shut

Down (ESD) trigger or loose/missing

ESD Inhibit Jumpers on the Terminal

Board Terminals.

Indicates Conguration Error or

control circuit connection is when a

conguration parameter out of range

Indicates there is no communication

from the actuator to the host via

Modbus RS485 Network.

Universal Alarm indicating actuator

has experienced an event; or any of

the control or conguration alarms

noted above except Lost

Communications.

Check torque switch dial setting for open torque

limit and proper orientation of Torque Switch Rotor

Assembly Cams

Check torque switch dial setting for close torque

limit and proper orientation of Torque Switch Rotor

Assembly Cams

• Check wire leads for potentiometer

connection to P2 of DCM 320B module.

• RED Lead to Bottom (Pin 3)

• Check for proper potentiometer movement

• Check for complete control circuit for

commanded action

• Check for correct Selector Switch position

• Verify DCM320B is not in conguration mode

• Check motor thermals

• Check primary and secondary fuses

• Verify primary power is present

Check for open circuit between terminals 1 and X0

if motor thermal leads are connected

• Check incoming primary power source.

• Check transformer

• Check Contactor to see the right power

source are present

Check if TBM jumpers on terminal 26 to 27 and 28

to 29 are present. If connected, check external ESD

trigger circuit for closed connection.

Check actuator conguration parameter and make

they are correct to their specications.

• Check network connection, polarity, parity,

baud rate, and modbus address

• Check for active DCM320B (LEDs D1-D5)

• Check that DCM320B Conguration

Dipswitches are in the Run Mode

• Check for other alarm conditions and resolve

as necessary.

September 2020

Alarm Denitions and Troubleshooting Guide

37

Page 44

Section 7: Diagnostic Features of 320B Controlinc M2CP

September 2020

QSG-01-10-93-0014-EN Rev. 1

Section 7: Diagnostic Features of 320B

Controlinc M2CP

7.1 High Water Mark Torque Data

(Max Torque Prole)

Design Notes for the High-Water Mark Torque Data (HWMTD) on the 320B Controlinc

Electronics for M2CP actuators.

7.1.1 Test Conditions

• Firmware will update HWMTD continuously and not only after PST or FST.

• Firmware will update HWMTD when actuator is in Remote or Local and is travelling in

open or close direction.

7.1.2 Test Description

1) Firmware will have a unique register block in RAM for open direction HWMTD from 0%

to 100% in 1% increments.

2) Firmware will have a unique register block in RAM for close direction HWMTD from

100% to 0% in 1% decrements.

3) 51 RAM Cell locations for open and another 51 RAM Cell locations for close direction.

4) Additional cells will be assigned for Time Stamp.

5) Enable/Disable HWMTD coil 1138, Reg 1230 bit 10. This bit is Enable High logic.

6) At power-up all open and close HWMTD RAM cell locations will all be 0x0000.

7) Each cell in HWMTD will contain the largest torque value for the respective actuator

stroke and direction.

7.1.3 Command to Enable HWMTD

• Host will set coil 1138 as single coil command. R1230.10

• Actuator will only do HWMTD if this bit is Enable High logic.

7.1.4 Command to Clear HWMTD Open

• When coil 1136 is set, rmware will clear all cells of HWMTD Open direction.

• Host will set coil 1136 as single coil command. R1230.8

• Time Stamp will be assigned when this command was given.

• Microcontroller Firmware will clear the coil.

7.1.5 Command to Clear HWMTD Close

• When coil 1137 is set, rmware will clear all cells of HWMTD Close direction.

• Host will set coil 1137 as single coil command. R1230.9

• Time Stamp will be assigned when this command was given.

• Microcontroller Firmware will clear the coil.

Quick Startup Guide

38

Diagnostic Features of 320B Controlinc M2CP

Page 45

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 7: Diagnostic Features of 320B Controlinc M2CP

7.2 Full Stroke Test (FST)

Design Notes for the Full Stroke Test implementation on the 320B Controlinc Electronics for

M2CP actuators.

Table 2. Parameter values and registers

Parameter Value/Range Default Register

Start Position 100% or 0% 100% R1227.L

Travel Range Always 100%

Pause Time 1 - 30 seconds 5 Seconds R1228.L

Initiated By 1 1, Network R1228.H

Status Data See Status Section R1221.H

7.2.1 Test Conditions

• Actuator must be in Remote for FST to start.

• Actuator must not be in alarm for FST to start.

• Actuator must not have any inhibits in effect for FST to start.

• Actuator will stop and FST will fail if any alarm or inhibit occurs during the test.

• Issuing a start FST command will not clear a valve stall alarm or any other alarms.

• Anti-water conguration to be ignored during FST.

7.2.2 Test Description

1) Actuator runs to 50% rst if it is not between 49% and 51% at startup.

2) The actuator pauses for the user congured Pause Time, 5 seconds is default time.

3) Actuator runs to the Congured Start Position (100% or 0%).

4) The actuator pauses for the user congured Pause Time, 5 seconds is default time.

5) Actuator runs to the opposite end from the Start Position (0% or 100%).

6) The actuator pauses for the user congured Pause Time, 5 seconds is default time.

7) Actuator runs to the original Start Position (100% or 0%).

8) Test status is reported in register map.

September 2020

NOTE:

If setpoint tracking is enabled in the actuator, the actuator will now run to the congured

setpoint.

Diagnostic Features of 320B Controlinc M2CP

39

Page 46

Section 7: Diagnostic Features of 320B Controlinc M2CP

September 2020

7.2.3 FST Status and Failure Codes

Table 3. FST Status Codes R (1221).H (lower nibble)

Status Code Value

Test Initialization 0

Test Passed 1

Test Failed 2

Test in Progress 3

User Abort 4

Table 4. FST Failure Codes R (1221).H (upper nibble)

Failure Codes Value

Test Passed or is in progress 0

Actuator Alarm 1

ESD Occurred 2

Change of Mode 3

User Abort 4

Not in Remote 5

Not at Correct Starting Position 6

Invalid Stroke Test Travel Range 7

Invalid Pause Time 8

Invalid Start Position 9

Interlock Condition 10, N/A for M2CP

Test in First Stroke 11, Test Description 5)

Test in Mid Stroke Delay 12, Test Description 6)

Test in Second Stroke 13, Test Description 7)

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

7.2.4 Event Log

Event #99 is the Full Stroke Test Event indication.

7.2.5 Command to Enable FST

• Host will set coil 1116 as single coil command. R1229.4

• Actuator will only do FST if this bit is enabled.

• While performing FST if this bit is disable, actuator will complete FST.

7.2.6 Command to Initiate FST

• Host will set coil 1022 as single coil command. R1005.6

• Microcontroller Firmware will clear the coil.

7.2.7 Command to Abort FST

• Host will set coil 1023 as single coil command. R1005.7

• Microcontroller Firmware will clear the coil.

40

Diagnostic Features of 320B Controlinc M2CP

Page 47

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

7.2.8 Command to Clear FST Prole Values

• Host will set coil 1125 as single coil command. R1229.13

• Microcontroller Firmware will clear the coil.

• R7336 to 7438 will now all be 0x0000.

7.2.9 Command to Delete Archive FST Values

• Host will set coil 1119 as single coil command. R1229.7

• Microcontroller Firmware will clear the coil.

• R7226 to 7328 will now all be 0x0000.

7.2.10 Command to Archive FST Prole

• Host will set coil 1117 as single coil command. R1229.5

• Microcontroller Firmware will clear the coil.

• Firmware will save FST Open/Close prole value to ash.

• FST prole value will now be written to R7226 to 7328 as archive values.

• Look at register assignment below.

7.2.11 FST Header Prole

Section 7: Diagnostic Features of 320B Controlinc M2CP

September 2020

Table 5. FST Header Prole

Register # High Byte Low Byte Description

7330 Range Start Position 100%, 0 or 100%

7331 Initiated By Pause Time Initiate = 1, Host. Pause Time: 1 - 30 seconds

7332 N/A N/A

7333 N/A N/A

7334 Time Byte 0 Time Byte 1 Currently Time is N/A

7335 Time Byte 2 Time Byte 3 Currently Time is N/A

7.2.12 Closing (100 - 0%) FST Prole, Registry

Torque at Actuator Position:

• R7336 UB LB – Torque at 1% – Torque at 0%

• R7337 UB LB – Torque at 3% – Torque at 2%

• ...

• R7385 UB LB – Torque at 99% – Torque at 98%

• R7386 UB LB – N/A – Torque at 100%

7.2.13 Opening (0 - 100%) FST Prole, Registry

Torque at Actuator Position:

• R7388 UB LB – Torque at 1% – Torque at 0%

• R7389 UB LB – Torque at 3% – Torque at 2%

• ...

• R7437 UB LB – Torque at 99% – Torque at 98%

• R7438 UB LB – N/A – Torque at 100%

Diagnostic Features of 320B Controlinc M2CP

41

Page 48

Section 7: Diagnostic Features of 320B Controlinc M2CP

September 2020

7.2.14 FST Header Archive

Table 6. FST Header Archive

Register # High Byte Low Byte Description

7220 Range Start Position 100%, 0 or 100%

7221 Initiated By Pause Time Initiate = 1, Host. Pause Time: 1 - 30 seconds

7222 N/A N/A

7223 N/A N/A

7224 Time Byte 0 Time Byte 1 Currently Time is N/A

7225 Time Byte 2 Time Byte 3 Currently Time is N/A

7.2.15 Closing (100 - 0%) FST Archive, Registry

Torque at Actuator Position:

• R7226 UB LB – Torque at 1% – Torque at 0%

• R7227 UB LB – Torque at 3% – Torque at 2%

• ...

• R7275 UB LB – Torque at 99% – Torque at 98%

• R7276 UB LB – N/A – Torque at 100%

7.2.16 Opening (0 - 100%) FST Prole, Registry

Torque at Actuator Position:

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

• R7278 UB LB – Torque at 1% – Torque at 0%

• R7279 UB LB – Torque at 3% – Torque at 2%

• ...

• R7327 UB LB – Torque at 99% – Torque at 98%

• R7328 UB LB – N/A – Torque at 100%

7.2.17 Situations that cause FST to Abort

1) Change in control from Remote to OFF or Local.

2) ESD.

3) Lost Comm.

4) Abort Command from User.

7.2.18 Situations that cause FST to Fail

1) Motor Overload.

2) Over Torque.

3) Valve Stall Alarm.

4) Loss of Power.

5) Wrong Direction.

6) Loss Comm.

7) Other Alarm Condition.

42

Diagnostic Features of 320B Controlinc M2CP

Page 49

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

Section 7: Diagnostic Features of 320B Controlinc M2CP

7.3 Partial Stroke Test (PST)

Design Notes for the Partial Stroke Test implementation on the 320B Controlinc Electronics for

M2CP actuators.

Table 7. Parameter values and registers

Parameter Value/Range Default Register

Start Position 100% or 0% 100% R1225.L

Stop Position 30% 70% if at 100%

30% if at 0% 5 seconds R1228.L

Travel Range 1% to 30% in increment of 1% 30% R1225.H

Pause Time 1 - 30 seconds 5 seconds R1226.L

Initiated By 1 1, Network R1226.H

Status Data See Status Section R1221.L

7.3.1 Test Conditions

• Actuator must be in Remote for PST to start.

• Actuator must not be in alarm for PST to start.

• Actuator must not have any inhibits in effect for PST to start.

• Actuator will stop and PST will fail if any alarm or inhibit occurs during the test.

• Issuing a start PST command will not clear a valve stall alarm or any other alarms.

• Anti-water conguration to be ignored during PST.

7.3.2 Test Description

1) Actuator runs to the Congured Start Position (100% or 0%)

2) Actuator pauses for the user congured Pause Time, 5 seconds is default time.

3) If congured start position is 100%, actuator will run to 70%, close PST.

4) Actuator pauses for the user congured Pause Time, 5 seconds is default time.

5) Actuator will run to 0%.

6) Actuator pauses for the user congured Pause Time, 5 seconds is default time.

7) Actuator will run to 30%, open PST.

8) Actuator pauses for the user congured Pause Time, 5 seconds is default time.

9) If congured start position is 0%, actuator will run to 30%, open PST.

10) Actuator pauses for the user congured Pause Time, 5 seconds is default time.

11) Actuator will run to 100%.

12) Actuator pauses for the user congured Pause Time, 5 seconds is default time.

13) Actuator will run to 70%, close PST.

14) Actuator pauses for the user congured Pause Time, 5 seconds is default time.

15) Either items 3-8 or 9-14 will be executed.

16) Test status is reported in register map.

September 2020

Diagnostic Features of 320B Controlinc M2CP

43

Page 50

Section 7: Diagnostic Features of 320B Controlinc M2CP

September 2020

NOTE:

If setpoint tracking is enabled in the actuator, the actuator will now run to the congured

setpoint.

7.3.3 PST Status and Failure Codes

Table 8. PST Status Code R1221.L (lower nibble)

Status Code Value

Test Initialization 0

Test Passed 1

Test Failed 2

Test in Progress 3

User Abort 4

Table 9. PST Failure Codes R1221.L (upper nibble)

Failure Codes Value

Test Passed or is in progress 0

Actuator Alarm 1

ESD Occurred 2

Change of Mode 3

User Abort 4

Not in Remote 5

Not at Correct Starting Position 6

Invalid Stroke Test Travel Range 7

Invalid Pause Time 8

Invalid Start Position 9

Interlock Condition 10, N/A for M2CP

Test in First Stroke 11, start position to 30% or 70%

Test in Mid Stroke Delay 12

Test in Second Stroke 13, opposite direction to 70% or 30%

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

7.3.4 Event Log

Event #xx is the Partial Stroke Test Event indication.

7.3.5 Command to Enable PST

• Host will set coil 1112 as single coil command. R1229.0

• Actuator will only do PST if this bit is enabled.

• While performing PST if this bit is disabled, actuator will complete PST.

7.3.6 Command to Initiate PST

• Host will set coil 1020 as single coil command. R1005.4

• Microcontroller Firmware will clear the coil.

7.3.7 Command to Abort PST

• Host will set coil 1021 as single coil command. R1005.5

• Microcontroller Firmware will clear the coil.

44

Diagnostic Features of 320B Controlinc M2CP

Page 51

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

7.3.8 Command to Clear PST Prole Values

• Host will set coil 1124 as single coil command. R1229.12

• Microcontroller Firmware will clear the coil.

• R7116 to 7219 will now all be 0x0000.

7.3.9 Command to Delete Archive PST Values

• Host will set coil 1115 as single coil command. R1229.3

• Microcontroller Firmware will clear the coil.

• R7006 to 7109 will now all be 0x0000.

7.3.10 Command to Archive PST Prole

• Host will set coil 1113 as single coil command. R1229.1

• Microcontroller Firmware will clear the coil.

• Firmware will save PST Open/Close prole value to ash.

• PST prole value will now be written to R7006 to 7109 as archive values.

• Look at register assignment below.

7.3.11 PST Header Prole

Section 7: Diagnostic Features of 320B Controlinc M2CP

September 2020

Table 10. PST Header Prole

Register # High Byte Low Byte Description

7110 Range Start Position 30%, 0 or 100%

7111 Initiated By Pause Time Initiate = 1, Host. Pause Time 1 - 30 seconds

7112 N/A N/A

7113 N/A N/A

7114 Time Byte 0 Time Byte 1 Currently Time is N/A

7115 Time Byte 2 Time Byte 3 Currently Time is N/A

7.3.12 Closing (100 - 70%) PST Prole, Registry

Torque at Actuator Position:

• R7116 UB LB – Torque at 1% – Torque at 0%

• R7117 UB LB – Torque at 3% – Torque at 2%

• ...

• R7166 UB LB – Torque at 99% – Torque at 98%

• R7167 UB LB – N/A – Torque at 100%

7.3.13 Opening (0 - 30%) PST Prole, Registry

Torque at Actuator Position:

• R7168 UB LB – Torque at 1% – Torque at 0%

• R7169 UB LB – Torque at 3% – Torque at 2%

• ...

• R7218 UB LB – Torque at 99% – Torque at 98%

• R7219 UB LB – N/A – Torque at 100%

Diagnostic Features of 320B Controlinc M2CP

45

Page 52

Section 7: Diagnostic Features of 320B Controlinc M2CP

September 2020

7.3.14 PST Header Archive

Table 11. PST Header Archive

Register # High Byte Low Byte Description

7000 Range Start Position 30%, 0 or 100%

7001 Initiated By Pause Time Initiate = 1, Host. Pause Time 1 - 30 seconds

7002 N/A N/A

7003 N/A N/A

7004 Time Byte 0 Time Byte 1 Currently Time is N/A

7005 Time Byte 2 Time Byte 3 Currently Time is N/A

7.3.15 Closing (100 - 70%) PST Archive, Registry

Torque at Actuator Position:

• R7006 UB LB – Torque at 1% – Torque at 0%

• R7007 UB LB – Torque at 3% – Torque at 2%

• ...

• R7056 UB LB – Torque at 99% – Torque at 98%

• R7057 UB LB – N/A – Torque at 100%

7.3.16 Opening (0 - 30%) PST Archive, Registry

Torque at Actuator Position:

Quick Startup Guide

QSG-01-10-93-0014-EN Rev. 1

• R7058 UB LB – Torque at 1% – Torque at 0%

• R7059 UB LB – Torque at 3% – Torque at 2%

• ...

• R7108 UB LB – Torque at 99% – Torque at 98%

• R7109 UB LB – N/A – Torque at 100%

7.3.17 Situations that cause PST to Abort

1) Change in control from Remote to OFF or Local.

2) ESD.

3) Lost Comm.

4) Abort Command from User.

7.3.18 Situations that cause PST to Fail

1) Motor Overload.

2) Over Torque.

3) Valve Stall Alarm.

4) Loss of Power.

5) Wrong Direction.

6) Loss Comm.

7) Other Alarm Condition.

46