Page 1

Copeland Scroll

™

Compressor

ZFKQ for Refrigeration Applications

Product catalogue

1

Page 2

Emerson developed the ZFKQ range of Copeland Scroll™ compressors to provide the best performance in low

temperatures. The series has a wide application envelope that can operate from -40°C to +7°C evaporating

temperature. Its optimized design perfectly fits frozen food application requirements while its scroll

compliance mechanism makes it highly tolerant of liquid slugging.

The range consists of:

• The ZF*KQE models that operate with liquid injection in order to control discharge temperature and

extend the operating envelope.

• The ZFI*KQE models that are optimized for vapor injection with the use of a subcooler. This boosts the

refrigeration system's cooling capacity and efficiency.

Features and benefits

High efficiency all year round

• The unique Copeland Compliant Scroll design patented by Emerson operates under continuous scroll flank

contact, maintained by centrifugal force. This minimizes gas leakage while maximizing efficiency.

• With its capability for condensing operation down to 4°C on low temperature applications, Copeland

Scroll technology provides the best seasonal efficiencies.

• Equipped with dynamic discharge valve that allows the discharge gas to reach desired pressure. This helps

reduce efficiency loss by preventing gas re-compression.

• The vapor injection technology allows ZFI*KQE compressors to perform higher efficiency than single-stage

compressors at low temperature operation condition. Thus makes ZFI*KQE the best in-class performance.

Compactness

• The small footprint of Copeland Scroll compressors enables compact system designs.

• Weight and dimensions for refrigeration equipment is reduced with increased capacity per compressor

weight.

Robustness and reliability

• The Copeland Compliant Scroll design is tolerant to stresses caused

by liquid slugging, flooded starts and debris commonly found in

refrigeration systems.

• Easy to service and maintain due to their compact size and lightweight,

simple design.

• Engineered for optimum performance with today’s chlorine-free

refrigerants.

• The Copeland Scroll compressor design has several inherent reliability

advantages:

- 70% fewer moving parts than reciprocating compressors

- Axial & radial scroll compliance provides improved liquid handling

capability

- Hermetic design reduces leak potential

• Redesigned suction gas flow results in lower oil circulation and better

motor cooling.

™

• EVI CoreSense

optimum system operation.

2

Control kits provide advanced features to ensure

Page 3

Compressor protection

• ZF*KQE and ZFI*KQE compressors are supplied with internal thermal protectors that prevent motor

overheating in case of loss of phase or low refrigerant charge.

• The ZF*KQE models that operate with liquid injection through DTC Valve in order to control the discharge

temperature.

• The ZFI*KQE models that can operate with Emerson EVI CoreSense

injection superheat as well as a safe discharge temperature.

™

control kits in order to control vapor

Smooth operation

• All Copeland Scroll compressors are designed with a discharge check valve that isolates the high pressure

discharge gas. This allows the compressor to start unloaded, resulting in low inrush currents.

• Smooth operations are made possible by the continuous compression process. This generates less vibration

than reciprocating technology.

Delivers unmatched energy efficiency: 5%–20% improvement

• Motor, scroll and bearing redesign minimize annual energy consumption.

• Precision machined scrolls provide the highest isentropic efficiency and wear-in for improved performance

over time.

• New valving technology adjusts the scroll compression ratio based on operating condition, significantly

improving low ambient performance.

• Using vapor injection improves system capacity by 50% and efficiency by 20% on average at the low

temperature rating condition.

One model for multiple refrigerants

• All ZF and ZFI compressors are qualified for R22, R404A, R507, R407A/C, R407F, R448A, and R449A.

Notes: This catalogue only provides performance tables for R22 and R404A. Please visit Select Software Asia for

more information.

3

Page 4

Table of contents

Features and benefits 02

Nomenclature 05

Bill of material 05

Operating envelopes 06

Product line-up 08

Performance data 09

Technical data 17

EVI CoreSense

™

Dimensional drawings 26

Schematic diagram 43

Available models list 44

Contact list 48

19

4

Page 5

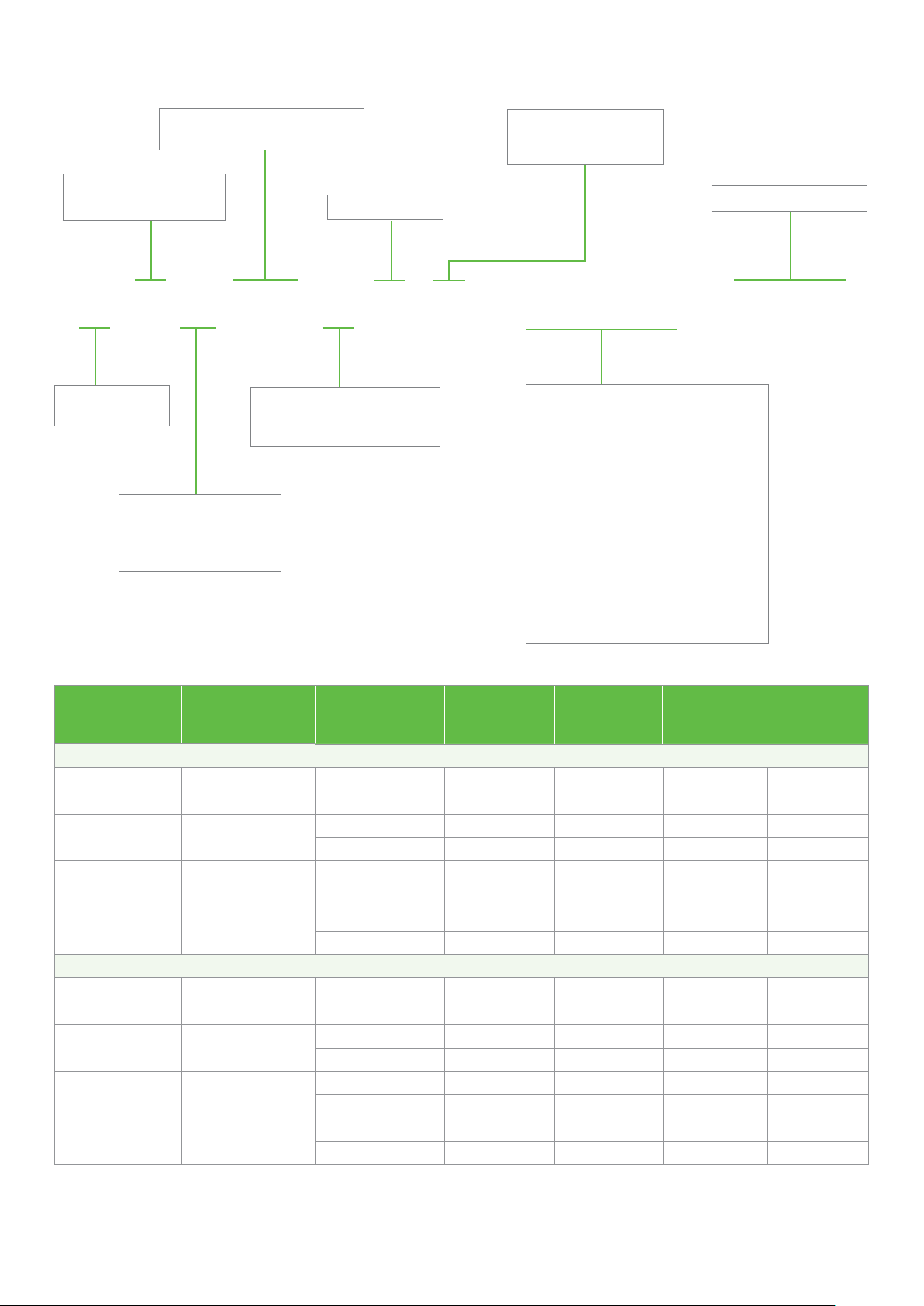

Nomenclature

Base capacity @ LT rating

Low temperature

refrigeration

(Btu/h) @ 60 Hz (ARI)

Generation

Lubricant

Blank Mineral oil

E POE oil

Bill of material

Z F I 20 K Q E - T F D - XXX

Scroll family

Technology

I Vapor injection

Blank Liquid injection

Bill of material

Base capacity multiplier

K 1,000

Motor type

TPThree-phase motor

Motor protection

W External electronic protection

E External enhanced protection

F Internal inherent protection

Electrical codes

7 – 380 V

C 200 V 208-230 V

5 220-220 V 200-230 V

V 200 V 208-230 V

D 380-420 V 460 V

Electrical

Single-phase motor

50 Hz 60 Hz

Compressor

model

ZF06-11KQE TFD, TF5, PFV

ZF13-28KQE TFD,TF7,TFC¹

ZF28KQE TFC

ZF34-54KQE TFD, TF7, TFC

ZFI20-39KQE TFD, TF7, TFC¹

ZFI39KQE TFC

ZFI50-81KQE TFD, TF7, TFC

ZFI122KQE TED, TE7, TEC

Remarks: See technical data sheet for the detailed connection size

ZF06-ZF54KQE only provide rotalock connection to liquid injection fitting for the installation of DTC valve

¹Except ZF28KQE-TFC and ZFI39KQE-TFC

²BOM 554/564 (Sight glass fitting with restriction) only work with Emerson OMB oil management device,

BOM567 (Standard sight glass fitting) works with Emerson OM3 in rack application.

Motor

code

BOM

number

550

551

550

551

580

591

554

564 / 567²

550

552

580

592

554

564 / 567²

522

523

Stub tube

connection

Liquid injection

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

Vapor injection

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

Rotalock

connection

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

Oil sight

glass

Schrader

valve

5

Page 6

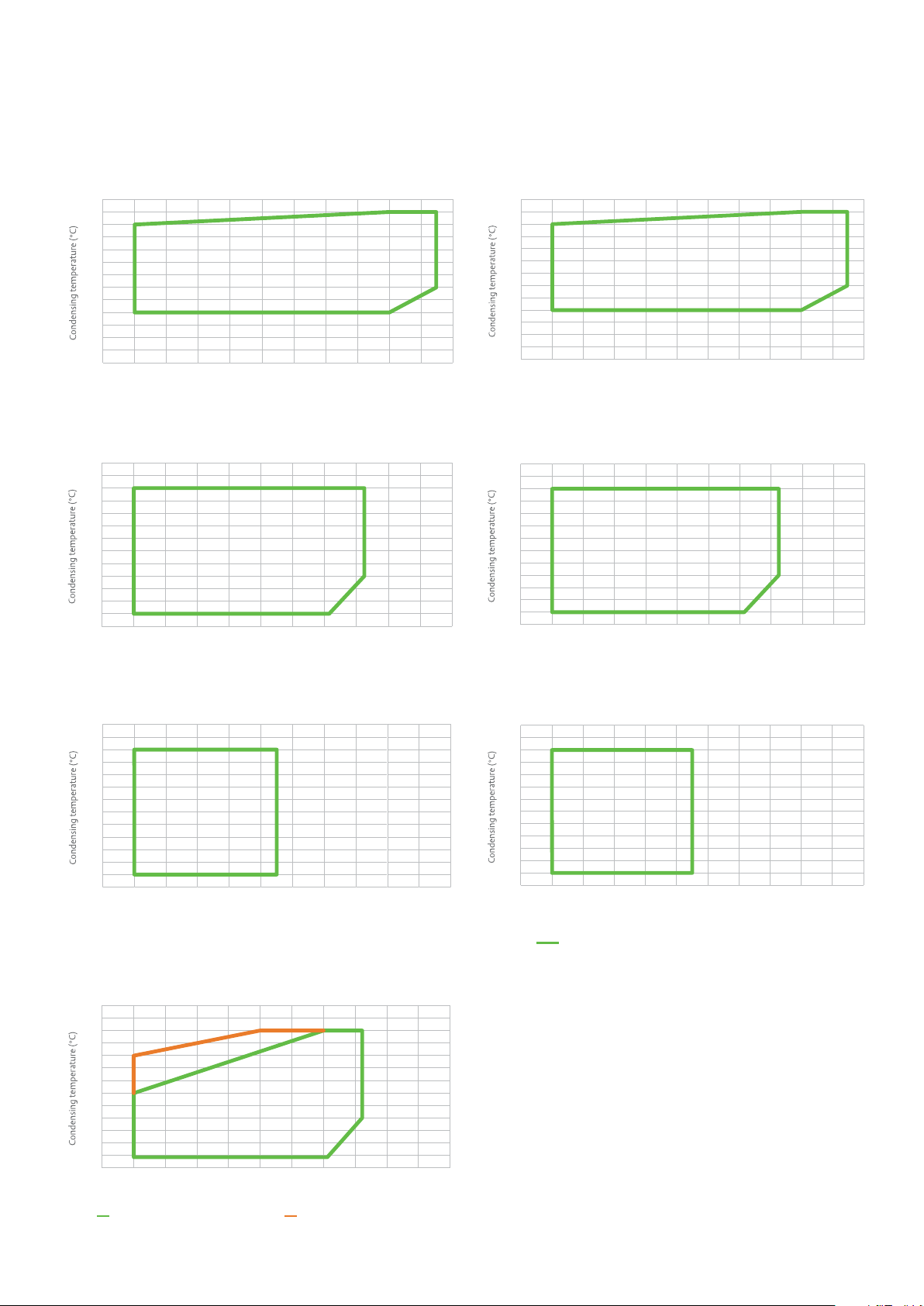

Operating envelopes

65

g

R22

Liquid injectionVapor injection

ZF06 - 18KQEZFI20-26KQE

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Evaporating temperature (°C)

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Evaporating temperature (°C)

-15 -10 -5 0510

-15 -10 -5 0510

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

ZF25-41KQEZFI36-59KQE

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Evaporating temperature (°C)

-15 -10 -5 0510

-15 -10 -5 0510

Evaporating temperature (°C)

ZFI122KQE

Note:

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

20°C Return

as + Vapor injection

Evaporating temperature (°C)

Evaporating temperature (°C)

-15 -10 -5 0510

-15 -10 -5 0510

20K Superheat + Vapor injection

ZF49-54KQEZFI68-81KQE

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Note:

20°C return gas + liquid injection

Evaporating temperature (°C)

-15 -10 -5 0510

6

Page 7

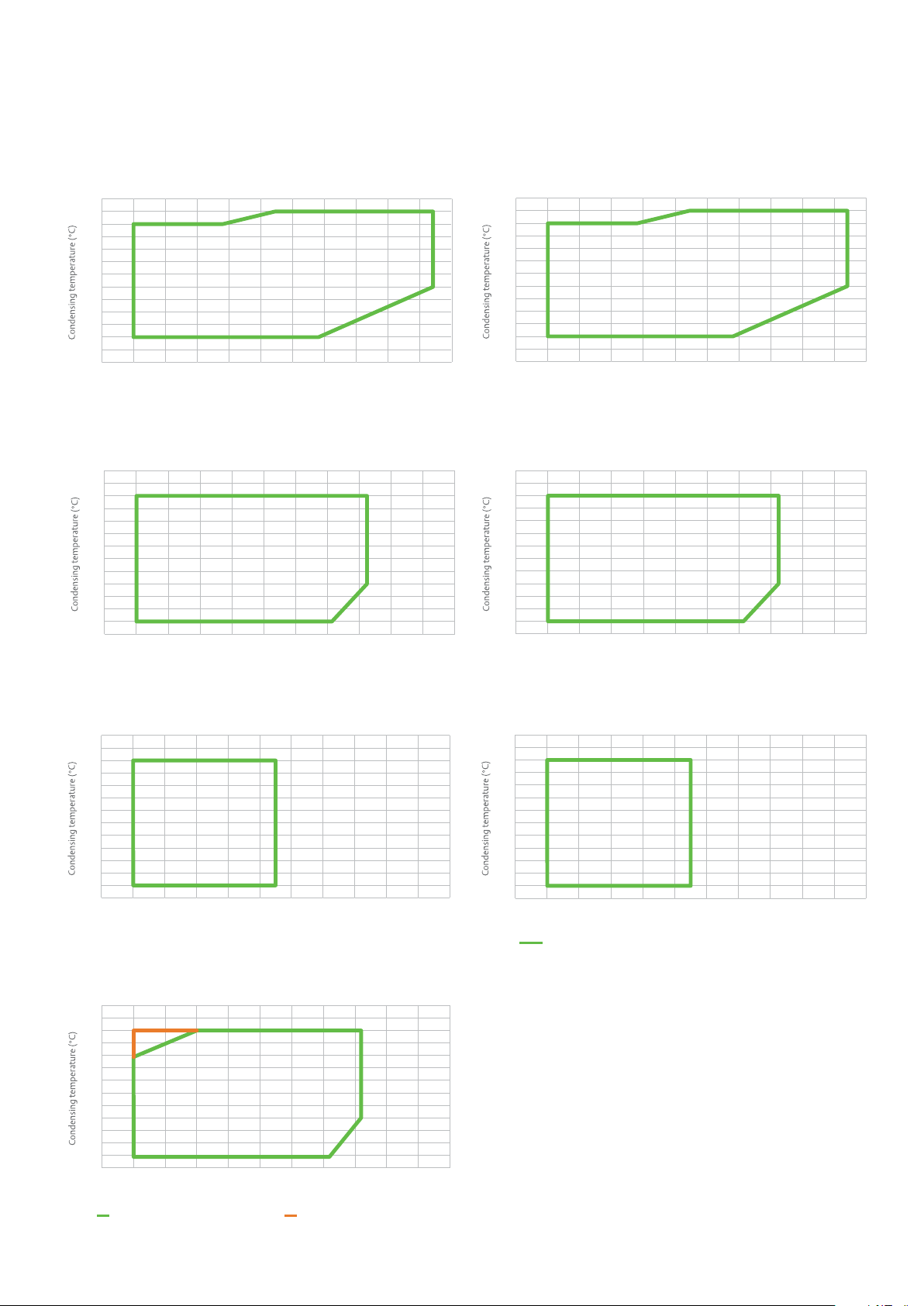

65

Evaporating temperature (°C)

65

60

55

45

35

50

40

30

20

25

15

10

0

-45 -40 -35 -30 -25 -20

Evaporating temperature (°C)

20°C Return

g

as + Vapor injection

-15 -10 -5 0510

5

20K Superheat + Vapor injection

Operating envelopes

R404A

Liquid injectionVapor injection

ZF06 - 18KQEZFI20 - 26KQE

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Evaporating temperature (°C)

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Evaporating temperature (°C)

-15 -10 -5 0510

-15 -10 -5 0510

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

ZF25 - 41KQEZFI36 - 59KQE

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Evaporating temperature (°C)

-15 -10 -5 0510

-15 -10 -5 0510

Evaporating temperature (°C)

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

ZFI122KQE

Note:

Evaporating temperature (°C)

-15 -10 -5 0510

ZF49-54KQEZFI68-81KQE

60

55

50

45

40

35

30

25

20

15

10

5

0

-45 -40 -35 -30 -25 -20

Note:

20°C return gas + liquid injection

-15 -10 -5 0510

7

Page 8

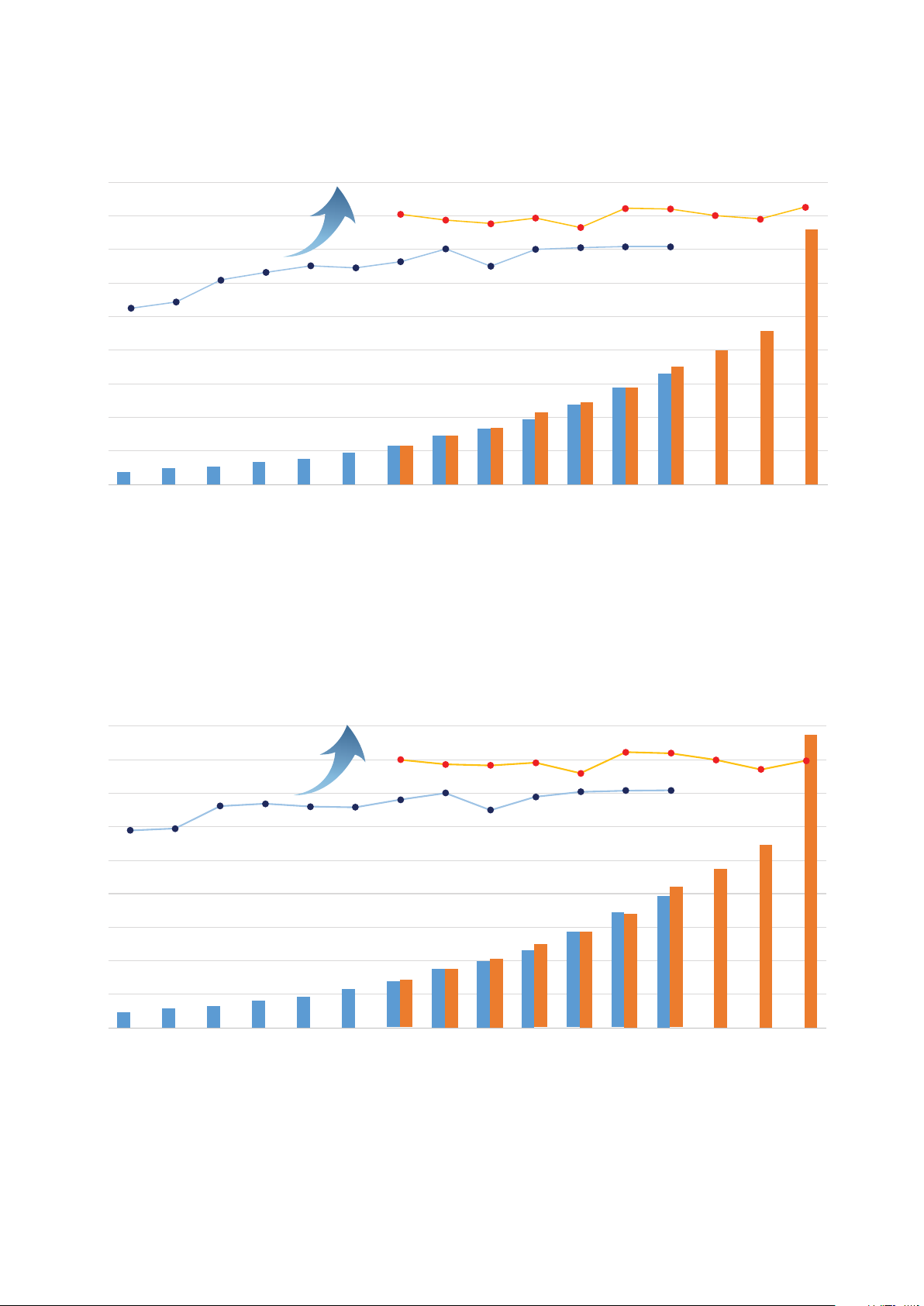

Product line-up

Ca

P

Ca

R404A - 50 Hz

pacity, kW

45

40

35

COP

20%

ZF Liquid injection

30

25

20

15

10

5

0

ZF06 ZF08 ZF09 ZF11 ZF13 ZF15 ZF18

ZFI Vapor injection

ZF25

ZFI20

ZFI23

ZF28

ZFI26

ZF34

ZFI36

ZF41

ZFI39

ZF49

ZFI50

CO

2.0

1.6

1.2

0.8

0.4

0.0

ZF54

ZFI59ZFI68 ZFI81ZFI122

pacity, kW

45

COP

40

35

30

ZF Liquid injection

25

20

15

10

5

0

ZF06 ZF08 ZF09 ZF11 ZF13 ZF15 ZF18

20%

R404A - 60 Hz

ZFI Vapor injection

ZF25

ZFI20

ZFI23

ZF28

ZFI26

ZF34

ZFI36

ZF41

ZFI39

ZF49

ZF54

ZFI50

ZFI59ZFI68 ZFI81ZFI122

COP

2.0

1.6

1.2

0.8

0.4

0.0

Notes: Based on low temperature cold room conditions: -25°C evaporating, 45°C condensing and 20°C return gas temperature.

8

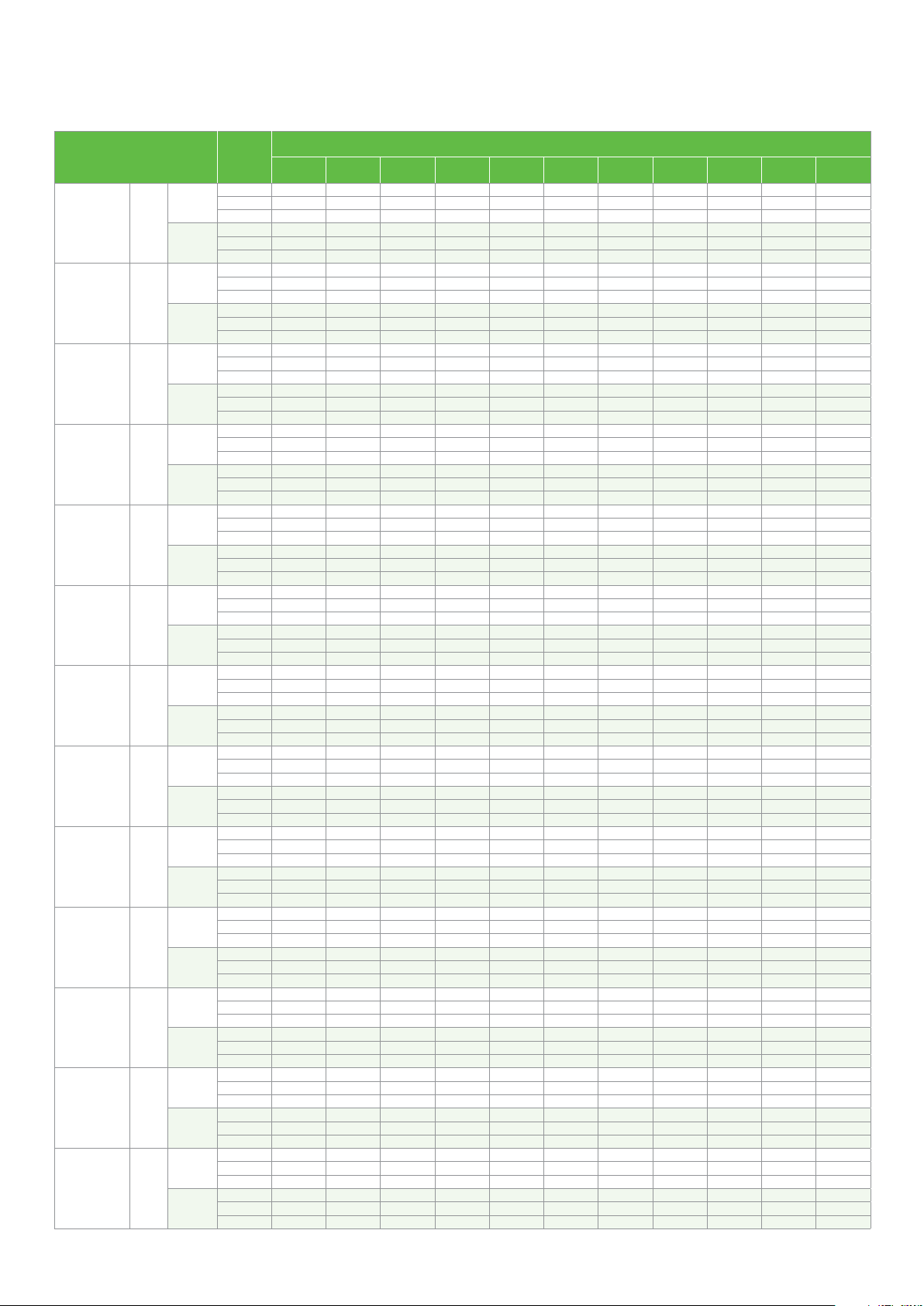

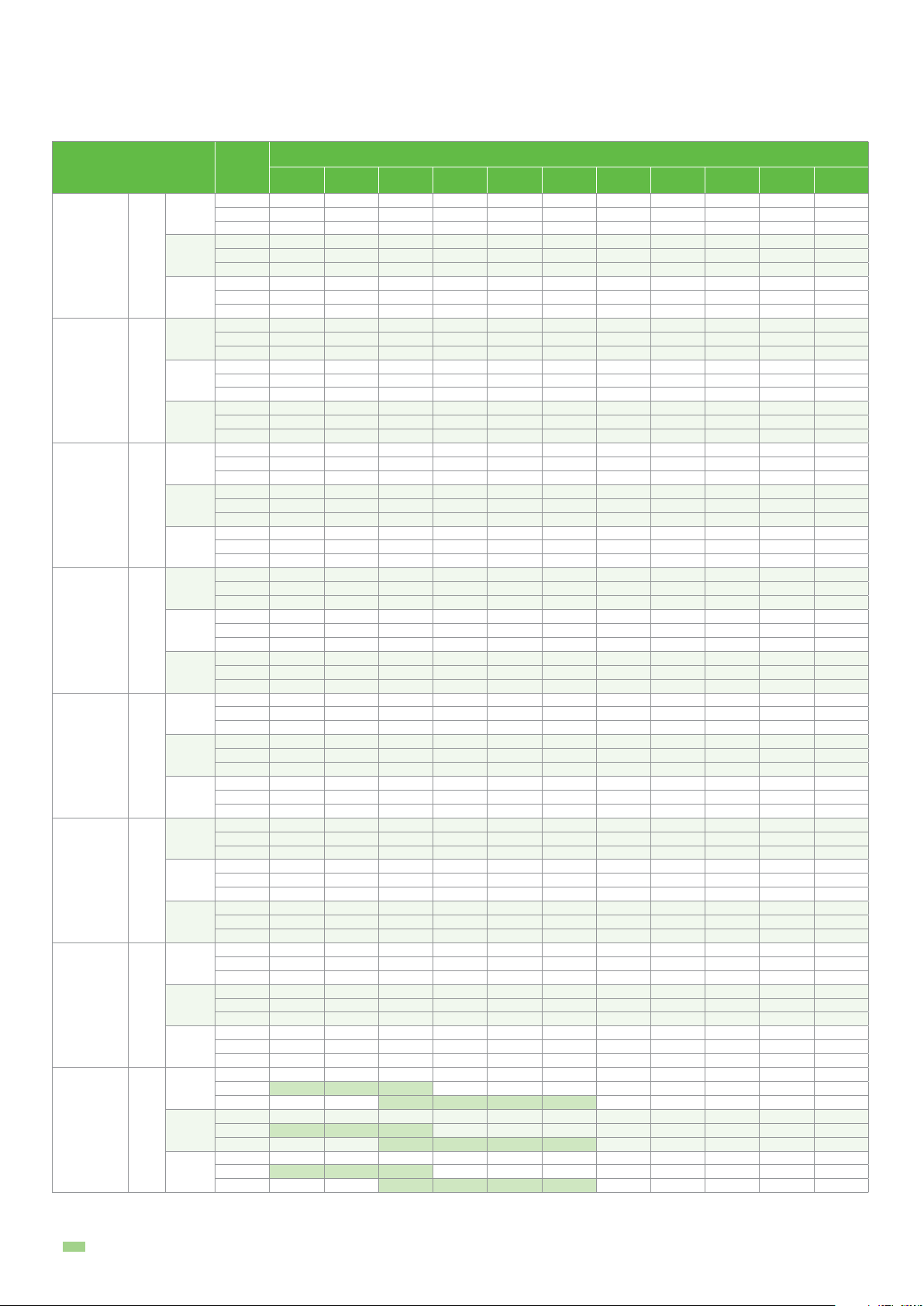

Page 9

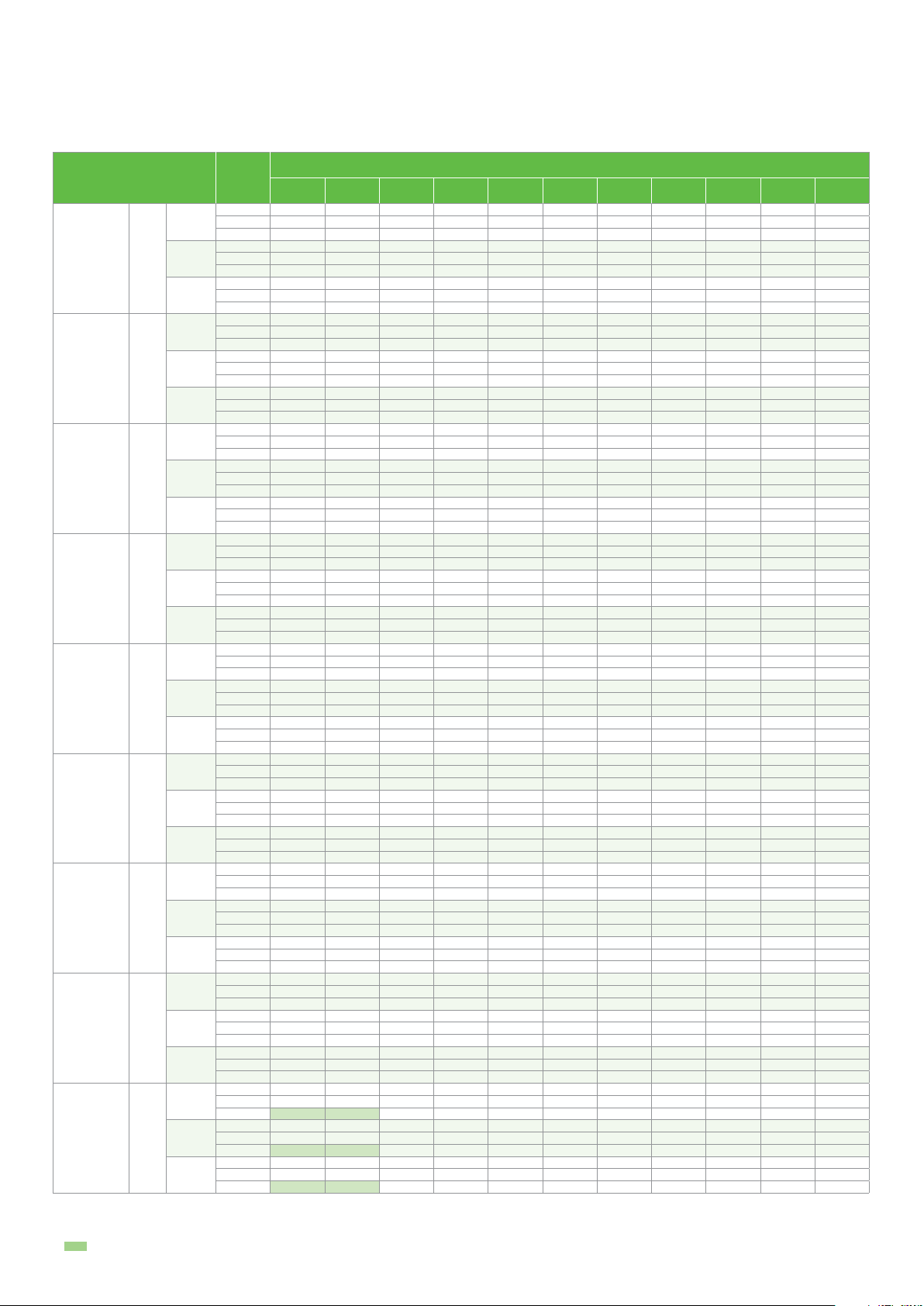

Performance data

TFC: 200 V ; 3-Phase, 50 Hz

TFD: 380-420 V ; 3-Phase, 50 Hz

Liquid injection

Model

ZF06KQE

ZF08KQE

ZF09KQE

ZF11KQE

ZF13KQE

ZF15KQE

ZF18KQE

ZF25KQE

ZF28KQE

ZF34KQE

ZF41KQE

ZF49KQE

ZF54KQE

Notes:

1. Q for capacity; P for power. Units in kW

2. All ZF*KQE values are rated at return gas temperature: 20°C and subcooling: 0 K

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

Cond.

temp.

o

Q

P

Q

P

Q

P

Q

Q

Q

P

Q

P

Q

P

Q

P

Q

Q

Q

P

Q

P

30 1.15 1.46 1.82 2.24 2.73 3.31 3.98 4.74 5.62 6.61 7.05

40 1.05 1.34 1.67 2.06 2.52 3.05 3.66 4.37 5.18 6.10 6.50

50 0.97 1.23 1.53 1.88 2.29 2.77 3.32 3.96 4.70 5.55 5.91

30 1.21 1.24 1.29 1.34 1.40 1.47 1.55 1.65 1.76 1.89 1.95

40 1.43 1.47 1.52 1.58 1.64 1.70 1.78 1.87 1.98 2.10 2.15

50 1.69 1.74 1.79 1.85 1.92 1.99 2.06 2.15 2.25 2.36 2.41

30 1.41 1.79 2.23 2.75 3.36 4.07 4.89 5.83 6.91 8.13 8.66

40 1.29 1.65 2.06 2.54 3.10 3.75 4.50 5.37 6.36 7.50 7.99

50 1.19 1.52 1.89 2.32 2.82 3.40 4.09 4.87 5.78 6.82 7.27

30 1.44 1.48 1.54 1.60 1.67 1.75 1.85 1.96 2.10 2.25 2.32

40 1.70 1.76 1.81 1.88 1.95 2.03 2.12 2.23 2.35 2.50 2.56

50 2.01 2.07 2.14 2.21 2.28 2.36 2.46 2.56 2.68 2.81 2.87

30 1.59 2.01 2.50 3.09 3.78 4.58 5.51 6.58 7.79 9.17 9.77

40 1.46 1.85 2.30 2.84 3.48 4.22 5.07 6.06 7.18 8.46 9.01

50 1.34 1.69 2.11 2.59 3.16 3.83 4.60 5.50 6.52 7.69 8.20

30 1.52 1.57 1.61 1.67 1.72 1.79 1.86 1.94 2.04 2.15 2.19

40 1.80 1.85 1.90 1.95 2.01 2.07 2.14 2.22 2.31 2.41 2.45

50 2.10 2.16 2.22 2.28 2.34 2.41 2.48 2.56 2.65 2.75 2.79

30 1.97 2.49 3.10 3.82 4.67 5.65 6.78 8.07 9.54 11.20 11.91

40 1.81 2.29 2.86 3.52 4.30 5.21 6.26 7.47 8.84 10.39 11.06

50 1.65 2.08 2.59 3.19 3.89 4.72 5.67 6.78 8.04 9.47 10.09

P

P

P

P

30 1.69 1.74 1.81 1.88 1.97 2.08 2.20 2.34 2.50 2.67 2.74

40 2.00 2.06 2.13 2.21 2.30 2.40 2.52 2.65 2.80 2.97 3.04

50 2.37 2.44 2.51 2.59 2.69 2.79 2.91 3.04 3.19 3.35 3.42

30 2.30 2.89 3.60 4.44 5.44 6.60 7.94 9.48 11.23 13.21 14.07

40 2.12 2.66 3.32 4.09 5.01 6.07 7.31 8.73 10.34 12.17 12.97

50 1.93 2.43 3.02 3.72 4.55 5.51 6.63 7.93 9.41 11.08 11.82

30 2.02 2.08 2.15 2.23 2.31 2.41 2.51 2.62 2.74 2.87 2.93

40 2.38 2.45 2.52 2.61 2.70 2.81 2.92 3.04 3.17 3.31 3.37

50 2.79 2.86 2.94 3.04 3.14 3.26 3.38

30 2.79 3.52 4.39 5.42 6.63 8.03 9.63 11.47 13.54 15.87 16.87

40 2.57 3.25 4.05 5.01 6.12 7.42 8.91 10.62 12.55 14.73 15.68

50 2.34 2.95 3.68 4.54 5.56 6.74 8.11 9.68 11.46 13.48 14.35

30 2.47 2.53 2.61 2.70 2.82 2.95 3.11 3.29 3.52 3.78 3.89

40 2.89 2.97 3.06 3.15 3.27 3.40 3.55 3.74 3.95 4.19 4.30

50 3.38 3.47 3.58 3.68 3.81 3.94 4.10 4.28 4.49 4.73 4.83

30 3.25 4.12 5.17 6.42 7.89 9.60 11.58 13.84 16.41 19.31 20.57

40 2.98 3.78 4.75 5.90 7.25 8.82 10.64 12.73 15.11 17.80 18.97

50 2.69 3.42 4.30 5.34 6.56 7.99 9.65 11.55 13.73 16.20 17.27

30 3.13 3.18 3.25 3.33 3.43 3.55 3.69 3.86 4.05 4.27 4.36

40 3.68 3.75 3.82 3.91 4.02 4.14 4.29 4.46 4.65 4.86 4.96

50 4.31 4.39 4.49 4.60 4.72 4.86 5.02 5.20 5.40 5.62 5.72

30 4.08 5.17 6.48 8.04 9.89 12.04 14.52 17.35

40 3.73 4.74 5.95 7.39 9.09 11.06 13.34 15.96

50 3.37 4.29 5.39 6.69 8.22 10.02 12.09 14.48

30 3.93 3.99 4.07 4.17 4.30 4.45 4.63 4.84

40 4.62 4.70 4.79 4.90 5.04 5.19 5.38 5.59

50 5.40 5.50 5.62 5.76 5.92 6.09 6.29 6.52

30 4.79 6.07 7.61 9.45 11.62 14.14 17.06 20.39

40 4.39 5.57 7.00 8.69 10.68 13.00 15.68 18.76

50 3.96 5.04 6.33 7.86 9.66 11.77 14.21 17.02

30 4.72 4.79 4.88 5.01 5.16 5.34 5.55 5.80

40 5.54 5.63 5.75 5.88 6.04 6.23 6.45 6.70

50 6.48 6.61 6.75 6.91 7.10 7.31 7.55 7.82

30 5.31 6.77 8.52 10.59 13.01 15.82 19.06 22.74

40 4.81 6.19 7.83 9.75 12.00 14.59 17.58 20.99

50 4.22 5.51 7.03 8.79 10.84 13.22 15.95 19.06

30 4.32 4.50 4.68 4.87 5.06 5.26 5.46 5.66

40 4.95 5.21 5.46 5.71 5.95 6.19 6.42 6.64

50 5.67 6.02 6.36 6.68 6.98 7.27 7.53 7.77

30 6.35 8.03 10.03 12.41 15.21 18.48 22.26 26.61

40 5.80 7.40 9.27 11.46 14.03 17.01 20.46 24.42

50 5.09 6.61 8.36 10.38 12.72 15.43 18.56 22.15

30 5.24 5.49 5.75 6.01 6.27 6.53 6.80 7.06

40 6.05 6.38 6.71 7.03 7.35 7.66 7.97 8.27

50 6.95 7.36 7.76 8.16 8.53 8.90 9.26 9.61

30 7.81

40 7.10 8.99 11.31 14.08 17.33

50 6.23 8.00 10.16 12.72 15.71

30 6.48 6.68 6.94 7.25 7.59

40 7.52 7.76 8.08 8.45 8.86

50 8.78 9.07 9.43 9.86 10.32

30 8.99 11.36 14.18 17.49 21.36

40 8.31 10.54 13.16 16.23 19.82

50 7.50 9.56 11.96 14.78 18.06

30 4.26 4.73 5.16 5.62 6.14

40 5.54 6.02 6.48 6.95 7.47

50 7.25 7.80 8.31 8.83 9.40

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

C

9.82 12.30 15.28 18.78

Evap. temp.

R22

o

C

3.51 3.65 3.80 3.87

9

Page 10

Performance data

TFC: 200 V ; 3-Phase, 50 Hz

TFD: 380-420 V ; 3-Phase, 50 Hz

Vapor injection

R22

Model

ZFI20KQE

ZFI26KQE

ZFI36KQE

ZFI39KQE

ZFI50KQE

ZFI59KQE

ZFI68KQE

ZFI122KQE

Notes:

1. Q for capacity, P for power. Units in kW; LO for liquid out temperature in °C

2. All ZF*KQE values are rated at return gas temperature: 20°C and max subcooling

3. 20K Superheat

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TEC

TED

temp.

o

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

30 2.56 3.22 4.01 4.94 6.00 7.18 8.47 9.87 11.37 12.97 13.64

40 2.55 3.21 3.99 4.90 5.93 7.06 8.30 9.63 11.06 12.56 13.18

50 2.32 2.99 3.78 4.68 5.68 6.78 7.97 9.24 10.59 12.01 12.60

30 2.14 2.18 2.27 2.39 2.55 2.72 2.91 3.09 3.28 3.45 3.51

40 2.39 2.50 2.63 2.76 2.90 3.02 3.13 3.22 3.26 3.27 3.26

50 2.98 3.13 3.27 3.39 3.48 3.53 3.53 3.48 3.37 3.18 3.09

30 -7.70 -6.20 -4.40 -1.80 1.30 4.90 8.80 12.80 16.70 20.60 22.00

40 -4.90 -3.60 -1.70 0.90 4.30 8.10 12.20 16.30 20.40 24.40 25.90

50 3.60 2.60 3.10 5.00 7.90 11.60 15.60 19.80 23.90 28.00 29.50

30 3.85 4.79 5.97 7.36 8.94 10.66 12.51 14.45 16.45 18.49 19.30

40 3.79 4.73 5.89 7.25 8.78 10.45 12.22 14.07 15.96 17.87 18.63

50 3.44 4.38 5.55 6.89 8.38 9.99 11.70 13.47 15.26 17.06 17.77

30 2.98 3.08 3.21 3.36 3.57 3.84 4.19 4.65 5.21 5.91 6.23

40 3.37 3.57 3.75 3.92 4.10 4.31 4.56 4.86 5.24 5.70 5.91

50 4.23 4.49 4.69 4.84 4.95 5.05 5.15 5.26 5.41 5.60 5.69

30 -5.40 -3.40 -1.70 0.50 3.50 7.20 11.50 16.20 21.10 26.10 28.10

40 -2.20 -0.40 1.20 3.50 6.60 10.50 15.00 19.80 24.80 29.90 32.00

50 6.20 5.90 6.20 7.70 10.40 14.10 18.50 23.30 28.40 33.60 35.60

30 5.37 6.66 8.04 9.62 11.52 13.85 16.72 20.25

40 5.00 6.28 7.63 9.17 11.02 13.29 16.09 19.54

50 4.41 5.65 6.96 8.44 10.22 12.42 15.13 18.49

30 3.08 3.38 3.73 4.11 4.51 4.90 5.29 5.64

40 4.00 4.27 4.57 4.90 5.24 5.57 5.88 6.16

50 5.64 5.82 6.03 6.27 6.51 6.73 6.93 7.09

30 -12.40 -11.80 -7.70 -3.60 -0.90 -0.30 -1.70 -5.00

40 -2.20 -3.10 0.10 3.60 5.80 6.10 4.40 0.90

50 5.20 3.80 6.80 10.30 12.40 12.60 10.80 7.20

30 6.15 7.66 9.25 11.06 13.23 15.92 19.27 23.43

40 5.74 7.22 8.77 10.54 12.66 15.28 18.55 22.62

50 5.07 6.51 8.00 9.70 11.74 14.28 17.46 21.42

30 3.50 3.78 4.16 4.60 5.06 5.47 5.80 6.01

40 4.50 4.75 5.10 5.49 5.87 6.22 6.46 6.57

50 6.32 6.49 6.74 7.02 7.30 7.51 7.62 7.58

30 -19.40 -14.90 -10.50 -6.90 -4.30

40 -6.70 -5.20 -2.40 0.40 2.50 3.50 3.40 2.30

50 2.00 2.10 4.50 7.20 9.20 10.20 10.10 9.00

30 7.46 9.11 10.98 13.16 15.76 18.89 22.65 27.14

40 6.89 8.55 10.40 12.54 15.08 18.12 21.77 26.12

50 6.04 7.67 9.48 11.55 14.00 16.92 20.43 24.63

30 4.09 4.41 4.87 5.39 5.92 6.40 6.77 6.99

40 5.26 5.55 5.96 6.42 6.88 7.27 7.55 7.65

50 7.39 7.59 7.88 8.22 8.54 8.78 8.90 8.82

30 -12.90 -11.40 -7.40 -3.50 -0.90 -0.10 -1.00 -3.50

40 -2.20 -2.40 0.40 3.60 5.70 6.20 5.10 2.60

50 5.30 4.40 7.10 10.20 12.30 12.80 11.70 9.10

30 8.79 10.88 13.11 15.67 18.75 22.54 27.23 32.99

40 8.19 10.25 12.43 14.93 17.94 21.63 26.19 31.81

50 7.19 9.20 11.32 13.74 16.64 20.21 24.63 30.10

30 5.07 5.37 5.91 6.57 7.23 7.76 8.05 7.97

40 6.45 6.73 7.23 7.83 8.40 8.83 8.98 8.74

50 9.02 9.20 9.58 10.03 10.43 10.66 10.60 10.12

30 -11.60 -9.20 -5.00 -1.20 1.30 2.20 1.40 -0.70

40 -0.50 -0.20 2.70 5.80 7.80 8.40 7.50 5.10

50 7.30 6.60 9.30 12.30 14.30 14.90 13.90 11.50

30 10.54 12.93 15.57 18.63 22.31

40 9.77 12.15 14.76 17.76 21.34

50 8.55 10.90 13.44 16.35 19.81

30 5.92 6.38 7.04 7.79 8.56

40 7.61 8.03 8.62 9.29 9.95

50 10.69 10.97 11.40 11.89 12.35

30 -9.50 -8.30 -4.20 -0.20 2.30

40 0.70 0.30 3.30 6.70 8.80

50 8.20 7.10 10.00 13.20 15.20

30 19.81 23.68 28.57 34.68 42.18 51.26 62.10 74.88

40 19.42 23.58 28.34 33.36 40.00 47.83 57.05 67.82

50 26.57 31.90 37.83 44.57 52.15 61.16

30 11.73 12.30 12.90 13.56 14.30 15.14 16.12 17.26

40 14.80 15.48 16.12 16.60 17.33 18.11 18.97 19.94

50 20.01 20.72 21.40 21.99 22.76 23.58

30 -20.50 -9.30 -1.90 2.60 4.90 5.50 5.10 3.70

40 -6.70 -3.50 1.70 7.00 11.60 15.10 17.50 18.90

50 9.50 13.50 18.80 24.10 28.60 32.10

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

C

Cond.

o

Evap. temp.

C

-3.00 -2.90 -3.80

10

Page 11

Performance data

TF7: 380 V ; 3-Phase, 60 Hz

TFC : 208-230 V ; 3-Phase, 60 Hz

TFD : 460 V ; 3-Phase, 60 Hz

Liquid injection

Model

ZF06KQE

ZF08KQE

ZF09KQE

ZF11KQE

ZF13KQE

ZF15KQE

ZF18KQE

ZF25KQE

ZF28KQE

ZF34KQE

ZF41KQE

ZF49KQE

ZF54KQE

Notes:

1. Q for capacity; P for power. Units in kW

2. All ZF*KQE values are rated at return gas temperature: 20°C and subcooling: 0 K

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

Cond.

temp.

o

C

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

30 1.32 1.66 2.08 2.59 3.18 3.87 4.66 5.54 6.54 7.64 8.11

40 1.23 1.55 1.94 2.42 2.97 3.61 4.35 5.17 6.10 7.13 7.57

50 1.15 1.44 1.80 2.23 2.73 3.32 3.99 4.75 5.59 6.54 6.94

30 1.31 1.35 1.39 1.44 1.49 1.56 1.65 1.75 1.88 2.05 2.12

40 1.57 1.60 1.64 1.67 1.71 1.77 1.85 1.95 2.07 2.23 2.30

50 1.90 1.92 1.94 1.96 2.00 2.05 2.12 2.21 2.33 2.48 2.55

30 1.68 2.11 2.64 3.29 4.04 4.92 5.92 7.05 8.31 9.71 10.31

40 1.57 1.97 2.47 3.07 3.78 4.60 5.53 6.58 7.76 9.06 9.62

50 1.46 1.83 2.29 2.83 3.47 4.22 5.07 6.03 7.11 8.31 8.83

30 1.63 1.68 1.73 1.79 1.86 1.94 2.05 2.18 2.34 2.55 2.64

40 1.96 2.00 2.03 2.08 2.13 2.20 2.30 2.42 2.58 2.77 2.86

50 2.36 2.39 2.41 2.44 2.49 2.55 2.63 2.75 2.89 3.08 3.17

30 1.92 2.43 3.03 3.74 4.56 5.52 6.64 7.92 9.38 11.04 11.77

40 1.76 2.24 2.80 3.45 4.20 5.09 6.11 7.29 8.65 10.19 10.86

50 1.62 2.06 2.56 3.14 3.83 4.62 5.55 6.62 7.85 9.26 9.87

30 1.64 1.69 1.75 1.82 1.91 2.00 2.11 2.25 2.40 2.58 2.66

40 1.95 2.01 2.07 2.15 2.23 2.32 2.43 2.55 2.69 2.86 2.93

50 2.30 2.37 2.44 2.52 2.61 2.70 2.81 2.93 3.07 3.22 3.29

30 2.38 3.01 3.75 4.62 5.63 6.81 8.16 9.70 11.46 13.44 14.30

40 2.18 2.76 3.45 4.25 5.19 6.28 7.54 8.99 10.63 12.50 13.31

50 1.98 2.51 3.12 3.84 4.69 5.68 6.83 8.16 9.68 11.40 12.16

30 1.82 1.89 1.98 2.09 2.22 2.37 2.54 2.75 2.97 3.23 3.34

40 2.16 2.24 2.33 2.44 2.57 2.72 2.89 3.08 3.29 3.53 3.63

50 2.57 2.66 2.77 2.88 3.01 3.16 3.32 3.51 3.71 3.94 4.04

30 2.75 3.46 4.33 5.35 6.56 7.96 9.57 11.41 13.49 15.83 16.84

40 2.54 3.20 3.99 4.94 6.04 7.33 8.81 10.51 12.43 14.60 15.54

50 2.30 2.90 3.62 4.48 5.48 6.65 8.00 9.55 11.31 13.31 14.17

30 2.17 2.29 2.41 2.53 2.64 2.75 2.85 2.95 3.04 3.12 3.14

40 2.55 2.67 2.80 2.94 3.08 3.22 3.37 3.53 3.68 3.83 3.90

50 2.97 3.08 3.21 3.36 3.52 3.70

30 3.38 4.27 5.32 6.57 8.02 9.70 11.63 13.82 16.29 19.06 20.25

40 3.12 3.94 4.92 6.07 7.41 8.97 10.76 12.80 15.11 17.70 18.82

50 2.83 3.57 4.46 5.50 6.73 8.15 9.79 11.67 13.80 16.20 17.24

30 2.75 2.84 2.95 3.08 3.25 3.45 3.68 3.96 4.28 4.64 4.80

40 3.21 3.32 3.44 3.58 3.74 3.94 4.16 4.42 4.73 5.07 5.22

50 3.75 3.87 4.01 4.16 4.33 4.53 4.76 5.01 5.30 5.63 5.77

30 3.96 5.02 6.28 7.79 9.56 11.63 14.01 16.75 19.86 23.37 24.89

40 3.65 4.62 5.79 7.17 8.79 10.68 12.87 15.39 18.26 21.50 22.91

50 3.31 4.20 5.26 6.51 7.97 9.69 11.68 13.97 16.59 19.57 20.86

30 3.38 3.43 3.52 3.66 3.83 4.03 4.23 4.44 4.63 4.81 4.88

40 3.94 4.01 4.12 4.29 4.48 4.70 4.94 5.18 5.41 5.62 5.70

50 4.57 4.66 4.80 4.98 5.21 5.46 5.73 6.00 6.27 6.53 6.62

30 4.97 6.29 7.88 9.76 11.99 14.58 17.57 21.00

40 4.57 5.80 7.26 8.99 11.02 13.39 16.14 19.30

50 4.15 5.27 6.59 8.16 10.00 12.15 14.64 17.52

30 4.24 4.30 4.42 4.59 4.81 5.05 5.30 5.56

40 4.95 5.02 5.17 5.37 5.62 5.90 6.19 6.49

50 5.74 5.84 6.01 6.25 6.53 6.85 7.18 7.52

30 5.84 7.39 9.26 11.47 14.08 17.13 20.64 24.67

40 5.37 6.81 8.52 10.56 12.95 15.74 18.97 22.67

50 4.87 6.19 7.74 9.58 11.75 14.28 17.21 20.58

30 5.09 5.15 5.30 5.51 5.77 6.06 6.37 6.68

40 5.93 6.03 6.20 6.45 6.74 7.08 7.43 7.79

50 6.88 7.01 7.22 7.50 7.84 8.21 8.62 9.03

30 6.40 8.16 10.27 12.76 15.68 19.06 22.96 27.40

40 5.79 7.46 9.43 11.75 14.45 17.58 21.18 25.28

50 5.08 6.64 8.47 10.59 13.07 15.92 19.21 22.96

30 5.21 5.42 5.64 5.86 6.10 6.33 6.58 6.82

40 5.96 6.27 6.58 6.88 7.17 7.46 7.73 8.00

50 6.83 7.25 7.66 8.04 8.41 8.75 9.07 9.37

30 7.65 9.67 12.09 14.95 18.32 22.26 26.82 32.06

40 6.99 8.91 11.16 13.81 16.90 20.49 24.65 29.43

50 6.13 7.97 10.07 12.51 15.33 18.59 22.36 26.69

30 6.31 6.62 6.93 7.24 7.55 7.87 8.19 8.51

40 7.29 7.69 8.08 8.47 8.85 9.23 9.60 9.96

50 8.38 8.87 9.35 9.83 10.28 10.73 11.16

30 9.41 11.83 14.82 18.41 22.63

40 8.56 10.84 13.63 16.97 20.88

50 7.50 9.64 12.24 15.32 18.93

30 7.81 8.04 8.36 8.73 9.14

40 9.06 9.35 9.74 10.18 10.67

50 10.58 10.92 11.36 11.88 12.44

30 10.79 13.63 17.01 20.99 25.64

40 9.98 12.65 15.79 19.48 23.79

50 9.00 11.47 14.35 17.73 21.68

30 7.93 8.49 9.01 9.56 10.19

40 9.46 10.05 10.59 11.16 11.79

50 11.51 12.18 12.79 13.41 14.09

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

Evap. temp.

R22

o

C

3.88 4.09 4.30 4.52 4.61

11.57

11

Page 12

Performance data

TF7: 380 V ; 3-Phase, 60 Hz

TFC : 208-230 V ; 3-Phase, 60 Hz

TFD : 460 V ; 3-Phase, 60 Hz

Vapor injection

Model

ZFI20KQE

ZFI26KQE

ZFI36KQE

ZFI39KQE

ZFI50KQE

ZFI59KQE

ZFI68KQE

ZFI122KQE

Notes:

1. Q for capacity, P for power. Units in kW; LO for liquid out temperature in °C

2. All ZF*KQE values are rated at return gas temperature: 20°C and max subcooling

3. 20K Superheat

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TE7

TEC

TED

12

Cond.

temp.

o

C

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

30 3.17 3.98 4.96 6.11 7.42 8.88 10.50 12.26 14.16 16.21 17.06

40 3.16 3.98 4.96 6.08 7.35 8.75 10.30 11.97 13.77 15.70 16.50

50 2.88 3.72 4.70 5.81 7.05 8.41 9.89 11.49 13.21 15.02 15.78

30 2.47 2.52 2.62 2.76 2.93 3.14 3.36 3.62 3.88 4.16 4.28

40 2.77 2.91 3.05 3.21 3.36 3.50 3.64 3.77 3.87 3.96 3.99

50 3.46 3.65 3.81 3.94 4.04 4.10 4.12 4.09 4.00 3.86 3.79

30 -6.90 -5.80 -4.00 -1.40 1.80 5.30 8.90 12.50 16.00 19.30 20.50

40 -5.00 -4.00 -2.00 0.90 4.40 8.10 12.00 15.90 19.60 23.10 24.40

50 3.50 2.00 2.60 4.70 7.80 11.40 15.30 19.20 23.00 26.60 28.00

30 4.70 5.84 7.28 8.97 10.89 12.99 15.24 17.60 20.04 22.51 23.50

40 4.63 5.78 7.19 8.85 10.71 12.74 14.89 17.13 19.43 21.75 22.67

50 4.20 5.36 6.77 8.41 10.23 12.20 14.27 16.42 18.60 20.78 21.64

30 3.51 3.64 3.79 3.98 4.23 4.56 4.99 5.54 6.24 7.10 7.50

40 3.95 4.20 4.42 4.63 4.85 5.10 5.41 5.79 6.27 6.86 7.14

50 4.98 5.29 5.52 5.70 5.84 5.96 6.09 6.25 6.45 6.72 6.85

30 -3.00 -1.60 0.00 2.30 5.30 8.80 12.70 16.90 21.30 25.60 27.40

40 -0.30 0.90 2.60 5.00 8.10 11.90 16.00 20.40 24.90 29.40 31.20

50 7.70 6.90 7.30 9.00 11.70 15.30 19.40 23.80 28.40 33.10 34.90

30 6.45 8.00 9.65 11.54 13.82 16.63 20.12 24.42

40 6.00 7.53 9.15 10.99 13.21 15.95 19.35 23.56

50 5.29 6.78 8.35 10.12 12.26 14.91 18.20 22.28

30 3.63 3.99 4.40 4.85 5.32 5.79 6.23 6.62

40 4.73 5.03 5.39 5.78 6.18 6.57 6.93 7.24

50 6.66 6.87 7.12 7.40 7.68 7.94 8.17 8.33

30 -10.70 -10.10 -5.90 -1.70 0.80 1.10 -0.80 -4.70

40 -0.40 -1.40 1.80 5.30 7.40 7.40 5.30 1.30

50 6.70 5.20 8.30 11.80 13.90 13.90 11.70 7.60

30 7.41 9.17 11.08 13.27 15.89 19.09 23.01 27.81

40 6.89 8.64 10.51 12.64 15.20 18.32 22.14 26.82

50 6.08 7.78 9.58 11.64 14.10 17.11 20.81 25.35

30 4.10 4.47 4.93 5.44 5.96 6.47 6.93 7.30

40 5.31 5.63 6.03 6.48 6.93 7.35 7.71 7.98

50 7.46 7.68 7.97 8.28 8.60 8.88 9.09 9.19

30 -17.90

40 -5.00 -3.20 -0.60 2.00 3.90 5.10 5.30 4.80

50 3.60 4.00 6.10 8.60 10.60 11.80 12.10 11.50

30 9.02 11.02 13.28 15.92 19.08 22.86 27.41 32.84

40 8.34 10.35 12.59 15.18 18.25 21.93 26.34 31.61

50 7.30 9.29 11.47 13.98 16.94 20.48 24.72 29.80

30 4.88 5.27 5.82 6.44 7.07 7.64 8.09 8.34

40 6.28 6.64 7.12 7.67 8.22 8.69 9.02 9.14

50 8.83 9.07 9.42 9.82 10.20 10.50 10.63 10.54

30 -12.80 -11.30 -7.40 -3.50 -0.90 -0.10 -0.90 -3.20

40 -2.10 -2.40 0.50 3.60 5.70 6.20 5.30 2.80

50 5.20 4.40 7.10 10.20 12.30 12.80 11.80 9.30

30 10.78 13.13 15.81 18.96 22.71 27.21 32.59 39.00

40 9.96 12.33 14.98 18.07 21.73 26.10 31.31 37.52

50 8.70 11.05 13.65 16.64 20.17 24.37 29.39 35.35

30 5.87 6.45 7.12 7.85 8.61 9.36 10.08 10.73

40 7.63 8.13 8.72 9.35 10.00 10.64 11.23 11.73

50 10.77 11.11 11.52 11.97 12.43 12.85 13.22 13.49

30 -11.50 -8.10 -4.30 -1.10 1.20 2.50 2.80 2.30

40 0.30 1.20 3.40 5.80 7.70 8.70 8.90 8.20

50 7.60 7.70 9.80 12.20 14.10 15.20 15.50 14.90

30 12.64 15.56 18.75 22.45 26.88

40 11.73 14.64 17.78 21.40 25.71

50 10.30 13.15 16.20 19.70 23.86

30 7.03 7.49 8.25 9.16 10.07

40 8.97 9.40 10.10 10.91 11.70

50 12.57 12.85 13.37 13.98 14.53

30 -8.50 -5.20 -1.30 2.10 4.50

40 2.80 3.70 6.30 8.90 10.80

50 10.50 10.40 12.60 15.20 17.10

30 23.12 27.63 33.35 40.48 49.23 59.83 72.48 87.40

40 22.59 27.44 32.99 38.94 46.69 55.83 66.58 79.16

50 30.92 37.15 44.07 51.94 60.87 71.39

30 14.17 14.86 15.58 16.38 17.27 18.30 19.48 20.86

40 17.80 18.63 19.41 20.05 20.93 21.88 22.92 24.09

50 24.10 24.98 25.81 26.57 27.50 28.49

30 -14.60 -3.80 3.30 7.50 9.70 10.40 9.90 8.60

40 -1.30 1.70 6.70 11.80 16.20 19.60 21.80 23.10

50 14.20 18.00 23.20 28.20 32.50 35.90

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

-13.00 -8.60 -5.20 -2.70 -1.30 -0.90 -1.40

Evap. temp.

R22

o

C

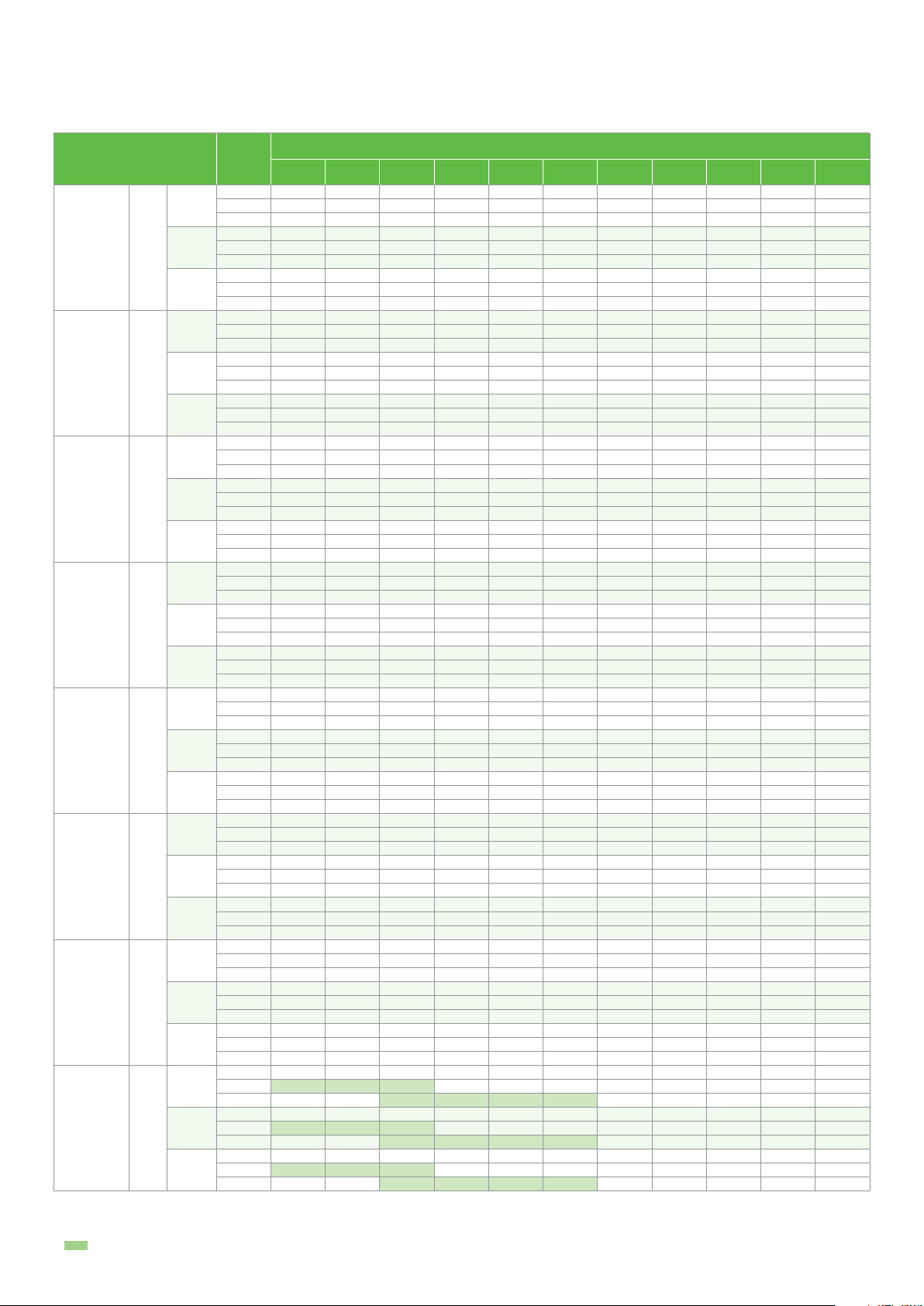

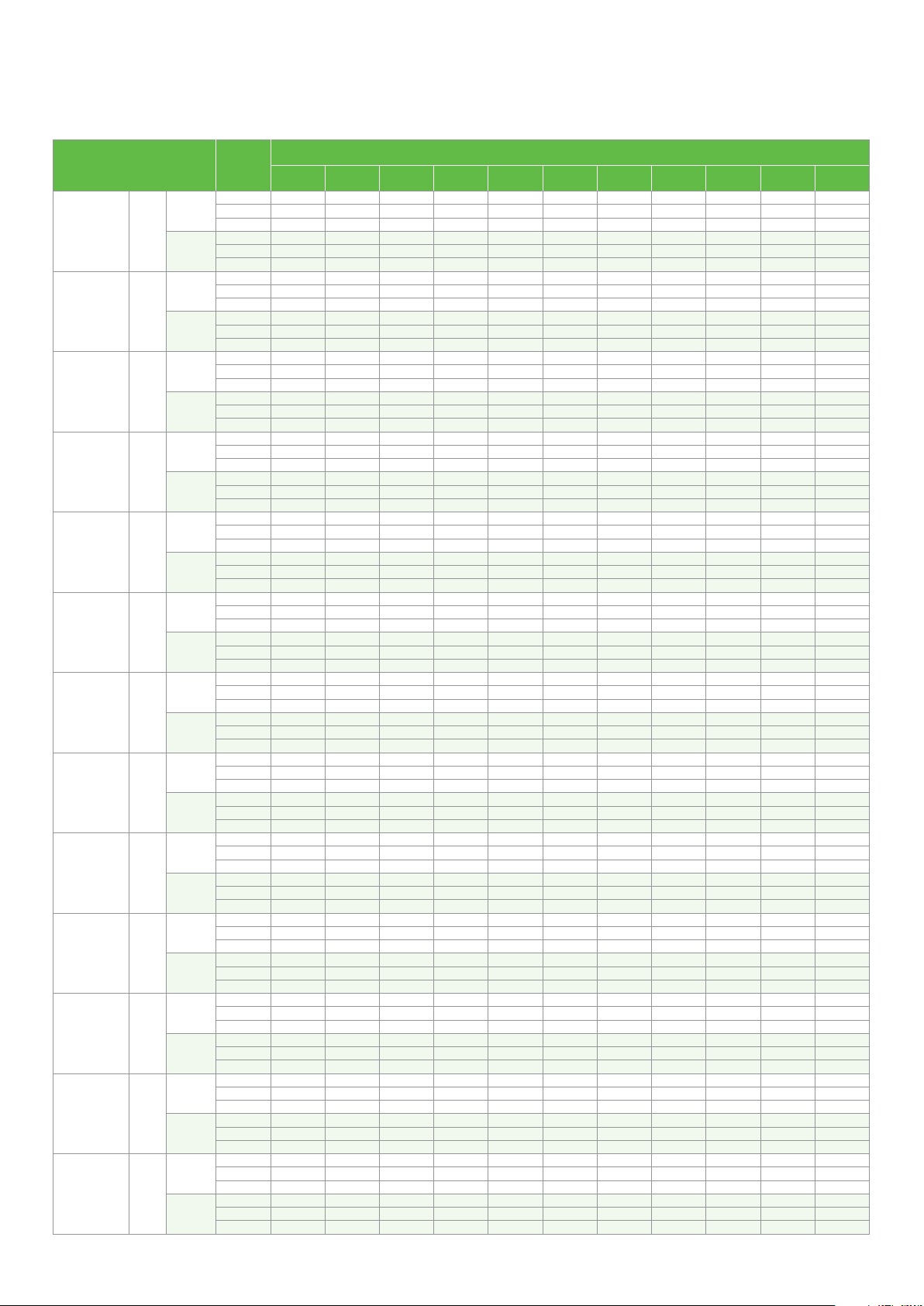

Page 13

Performance data

TFC: 200 V ; 3-Phase, 50 Hz

TFD: 380-420 V ; 3-Phase, 50 Hz

Liquid injection

R404A

Model

ZF06KQE

ZF08KQE

ZF09KQE

ZF11KQE

ZF13KQE

ZF15KQE

ZF18KQE

ZF25KQE

ZF28KQE

ZF34KQE

ZF41KQE

ZF49KQE

ZF54KQE

Notes:

1. Q for capacity; P for power. Units in kW

2. All ZF*KQE values are rated at return gas temperature: 20°C and subcooling: 0 K

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

Cond.

temp.

o

C

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

30 1.28 1.61 2.00 2.47 3.01 3.64 4.38 5.22 6.19 7.28 7.76

40 1.13 1.43 1.77 2.18 2.65 3.21 3.85 4.58 5.43 6.39 6.81

50 0.96 1.22 1.51 1.85 2.25 2.71 3.25 3.87 4.59 5.41 5.77

30 1.17 1.23 1.30 1.37 1.45 1.54 1.64 1.75 1.87 2.00 2.05

40 1.40 1.46 1.52 1.59 1.67 1.76 1.85 1.96 2.08 2.20 2.26

50 1.72 1.77 1.82 1.89 1.96 2.04 2.13 2.24 2.35 2.47 2.52

30 1.58 1.98 2.46 3.03 3.70 4.48 5.38 6.42 7.61 8.96 9.54

40 1.39 1.75 2.18 2.68 3.26 3.94 4.73 5.64 6.68 7.86 8.37

50 1.18 1.50 1.86 2.28 2.77 3.34 4.00 4.76 5.64 6.65 7.10

30 1.39 1.47 1.54 1.63 1.73 1.84 1.95 2.08 2.22 2.37 2.44

40 1.67 1.74 1.81 1.89 1.99 2.09 2.21 2.33 2.47 2.62 2.69

50 2.05 2.10 2.17 2.25 2.33 2.43 2.54 2.66 2.79 2.94 3.00

30 1.71 2.17 2.71 3.35 4.10 4.97 5.97 7.13 8.45 9.96 10.61

40 1.53 1.94 2.41 2.96 3.60 4.35 5.23 6.23 7.39 8.71 9.29

50 1.32 1.67 2.07 2.52 3.06 3.69 4.42 5.27 6.25 7.38 7.88

30 1.46 1.48 1.52 1.57 1.65 1.74 1.84 1.96 2.09 2.23 2.29

40 1.77 1.78 1.81 1.86 1.92 2.00 2.10 2.21 2.33 2.47 2.52

50 2.16 2.16 2.18 2.22 2.27 2.34 2.43 2.53 2.65 2.78 2.84

30 2.17 2.74 3.41 4.19 5.10 6.16 7.41 8.85 10.50 12.39 13.22

40 1.94 2.45 3.03 3.70 4.49 5.41 6.49 7.75 9.20 10.86 11.60

50 1.65 2.09 2.58 3.15 3.81 4.58 5.48 6.55 7.78 9.22 9.86

30 1.79 1.82 1.87 1.94 2.03 2.14 2.27 2.41 2.57 2.75 2.83

40 2.13 2.15 2.20 2.26 2.34 2.45 2.57 2.70 2.85 3.02 3.09

50 2.53 2.56 2.60 2.67 2.75 2.85 2.97 3.10 3.24 3.40 3.47

30 2.45 3.15 3.98 4.93 6.03 7.30 8.74 10.36 12.19 14.24 15.12

40 2.19 2.78 3.48 4.31 5.27 6.38 7.66 9.11 10.76 12.61 13.41

50 1.94 2.40 2.95 3.62 4.42 5.35 6.44 7.70 9.13 10.77 11.48

30 1.87 1.93 2.00 2.08 2.19 2.30 2.44 2.59 2.76 2.95 3.03

40 2.27 2.33 2.41 2.49 2.59 2.70 2.83 2.97 3.13 3.30 3.37

50 2.78 2.85 2.93 3.02 3.12 3.23 3.35

30 3.01 3.89 4.91 6.08 7.44 9.01 10.82 12.89 15.26 17.93 19.10

40 2.66 3.42 4.29 5.30 6.47 7.84 9.43 11.26 13.36 15.76 16.81

50 2.36 2.95 3.64 4.44 5.40 6.53 7.86 9.41 11.22 13.31 14.22

30 2.21 2.33 2.45 2.58 2.73 2.90 3.09 3.31 3.56 3.85 3.97

40 2.68 2.82 2.95 3.09 3.24 3.41 3.60 3.80 4.04 4.30 4.41

50 3.26 3.42 3.58 3.73 3.90 4.07 4.25 4.45 4.67 4.92 5.02

30 3.70 4.70 5.85 7.20 8.78 10.64 12.81 15.33 18.25 21.58 23.04

40 3.29 4.17 5.17 6.34 7.70 9.30 11.17 13.36 15.91 18.84 20.13

50 2.81 3.57 4.41 5.37 6.50 7.83 9.40 11.25 13.42 15.94 17.06

30 2.79 2.89 3.01 3.14 3.29 3.46 3.65 3.85 4.07 4.30 4.40

40 3.29 3.40 3.53 3.67 3.83 4.00 4.18 4.38 4.59 4.82 4.91

50 3.92 4.04 4.18 4.33 4.49 4.67 4.85 5.05 5.26 5.48 5.57

30 4.59 5.81 7.32 9.08 11.09 13.32 15.75 18.37

40 4.09 5.12 6.42 7.96 9.73 11.71 13.87 16.20

50 3.63 4.45 5.50 6.79 8.28 9.96 11.81 13.82

30 3.03 3.31 3.54 3.76 4.00 4.30 4.67 5.16

40 3.43 3.80 4.11 4.39 4.69 5.03 5.44 5.95

50 3.84 4.31 4.72 5.09 5.46 5.85 6.32 6.87

30 5.25 6.65 8.36 10.38 12.67 15.22 18.00 21.00

40 4.67 5.85 7.34 9.10 11.12 13.38 15.85 18.51

50 4.15 5.08 6.29 7.76 9.46 11.39 13.50 15.79

30 3.74 4.08 4.37 4.64 4.94 5.30 5.76 6.37

40 4.23 4.68 5.07 5.42 5.78 6.20 6.71 7.34

50 4.74 5.32 5.82 6.28 6.73 7.22 7.79 8.48

30 6.03 7.72 9.67 11.94 14.57 17.62 21.16 25.23

40 5.30 6.82 8.54 10.51 12.79 15.44 18.51 22.06

50 4.47 5.79 7.25 8.90 10.81 13.01 15.59 18.58

30 4.18 4.41 4.67 4.93 5.22 5.53 5.85 6.20

40 4.85 5.16 5.46 5.77 6.08 6.40 6.73 7.07

50 5.66 6.04 6.41 6.77 7.13 7.48 7.82 8.16

30 7.57 9.62 11.96 14.69 17.88 21.62 25.98 31.04

40 6.71 8.56 10.62 12.98 15.71 18.90 22.64 26.99

50 5.65 7.29 9.06 11.04 13.31 15.96 19.05 22.68

30 5.07 5.40 5.75 6.11 6.48 6.88 7.30 7.75

40 5.95 6.33 6.72 7.12 7.52 7.94 8.36 8.81

50 6.95 7.40 7.85 8.29 8.74 9.18 9.63 10.09

30 9.14

40 8.07 10.21 12.72 15.65 19.05

50 6.80 8.66 10.80 13.27 16.14

30 6.24 6.53 6.90 7.33 7.81

40 7.36 7.67 8.06 8.52 9.02

50 8.73 9.07 9.48 9.97 10.51

30 10.46 13.21 16.47 20.31 24.80

40 9.23 11.69 14.56 17.91 21.80

50 7.78 9.91 12.36 15.19 18.47

30 7.14 7.47 7.90 8.39 8.94

40 8.42 8.77 9.22 9.75 10.33

50 9.99 10.37 10.85 11.41 12.03

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

11.54 14.39 17.75 21.67

Evap. temp.

o

C

3.48 3.62 3.78 3.85

13

Page 14

Performance data

TFC: 200 V ; 3-Phase, 50 Hz

TFD: 380-420 V ; 3-Phase, 50 Hz

Vapor injection

R404A

Model

ZFI20KQE

ZFI26KQE

ZFI36KQE

ZFI39KQE

ZFI50KQE

ZFI59KQE

ZFI68KQE

ZFI81KQE

ZFI122KQE

Notes:

1. Q for capacity, P for power. Units in kW; LO for liquid out temperature in °C

2. All ZF*KQE values are rated at return gas temperature: 20°C and max subcooling

3. 20K Superheat

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TEC

TED

temp.

o

C

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

30 3.43 4.28 5.23 6.30 7.50 8.86 10.40 12.14 14.09 16.28 17.23

40 3.25 4.07 4.99 6.04 7.23 8.60 10.14 11.90 13.88 16.11 17.08

50 2.92 3.70 4.59 5.62 6.80 8.17 9.73 11.50 13.51 15.76 16.74

30 2.17 2.23 2.30 2.38 2.46 2.53 2.58 2.62 2.62 2.59 2.57

40 2.73 2.78 2.84 2.92 3.01 3.09 3.16 3.22 3.25 3.27 3.26

50 3.56 3.58 3.62 3.68 3.75 3.82 3.90 3.96 4.01 4.04 4.05

30 -13.50 -9.80 -6.10 -2.00 2.30 6.50 10.50 14.20 17.40 20.00 20.90

40 -6.70 -4.80 -2.20 1.00 4.60 8.30 12.00 15.40 18.20 20.60 21.40

50 6.00 4.80 5.10 6.50 8.90 11.60 14.50 17.20 19.70 21.80 22.50

30 5.14 6.29 7.61 9.14 10.90 12.91 15.20 17.79 20.72 24.02 25.44

40 5.09 6.12 7.33 8.74 10.39 12.30 14.49 17.01 19.86 23.06 24.45

50 5.08 5.97 7.03 8.32 9.84 11.62 13.70 16.10 18.83 21.94 23.30

30 3.22 3.38 3.54 3.70 3.84 3.98 4.11 4.24 4.37 4.50 4.55

40 3.85 4.07 4.28 4.47 4.65 4.81 4.97 5.12 5.26 5.39 5.44

50 4.74 5.01 5.26 5.50 5.70 5.90 6.07 6.24 6.38 6.52 6.57

30 -13.00 -8.10 -4.00 -0.10 3.70 7.20 10.50 13.60 16.10 18.10 18.80

40 -10.10 -5.20 -0.80 3.30 7.30 10.90 14.20 17.10 19.50 21.50 22.10

50 -7.30 -2.10 2.60 7.00 11.10 14.90 18.20 21.00 23.40 25.10 25.70

30 6.48 8.01 9.76 11.70 13.85 16.20 18.73 21.45

40 6.29 7.67 9.27 11.08 13.09 15.32 17.74 20.32

50 6.24 7.42 8.82 10.43 12.26 14.30 16.54 18.97

30 3.78 4.05 4.29 4.52 4.75 4.97 5.19 5.42

40 4.46 4.86 5.21 5.52 5.80 6.05 6.27 6.47

50 5.21 5.78 6.29 6.72 7.09 7.42 7.69 7.91

30 -13.80 -10.00 -5.40 -0.70 3.90 8.10 12.00 15.40

40 -10.80 -5.80 -0.50 4.50 9.10 13.20 16.90 20.20

50 -11.10 -3.70 3.00 9.00 14.20 18.50 22.30 25.40

30 7.44 9.19 11.19 13.43 15.89 18.58 21.49 24.61

40 7.22 8.80 10.63 12.71 15.04 17.58 20.35 23.34

50 7.16 8.51 10.12 11.97 14.06 16.41 18.97 21.76

30 4.49 4.81 5.10 5.38 5.64 5.91 6.17 6.45

40 5.30 5.78 6.19 6.56 6.90 7.19 7.46 7.70

50 6.19 6.87 7.47 7.99 8.43 8.82 9.14 9.40

30 -13.80 -10.00 -5.40 -0.70 3.90

40 -10.80 -5.80 -0.50 4.50 9.00 13.20 16.90 20.10

50 -11.10 -3.70 3.00 9.00 14.20 18.50 22.30 25.40

30 9.11 10.80 12.99 15.63 18.68 22.06 25.71 29.59

40 8.66 10.29 12.40 14.91 17.77 20.94 24.34 27.91

50 8.04 9.65 11.68 14.07 16.79 19.75 22.91 26.23

30 5.04 5.42 5.76 6.08 6.38 6.67 6.98 7.31

40 6.06 6.49 6.89 7.26 7.61 7.97 8.33 8.72

50 7.31 7.79 8.25 8.67 9.09 9.50 9.92 10.38

30 -18.10 -7.60 -2.60 0.50 3.40 6.70 10.50 14.80

40 -12.10 -2.70 1.90 5.00 8.10 11.70 15.70 20.20

50 -3.60 3.70 7.30 10.10 13.10 16.70 20.80 25.20

30 11.10 13.15 15.82 19.05 22.74 26.86 31.31 36.02

40 10.55 12.53 15.09 18.16 21.65 25.51 29.65 34.01

50 9.80 11.75 14.21 17.14 20.45 24.05 27.92 31.93

30 6.15 6.61 7.03 7.41 7.77 8.14 8.51 8.92

40 7.39 7.91 8.39 8.85 9.29 9.72 10.17 10.65

50 8.92 9.51 10.05 10.58 11.09 11.58 12.11 12.66

30 -15.40 -5.10 -0.30 2.70 5.60 8.80 12.60 16.70

40 -9.50 -0.30 4.20 7.20 10.20 13.60 17.50 21.80

50 -1.20 5.90 9.50 12.10 15.00 18.60 22.50 26.90

30 12.60 14.92 17.95 21.61 25.81

40 11.97 14.23 17.13 20.60 24.56

50 11.12 13.33 16.14 19.45 23.20

30 7.15 7.68 8.17 8.62 9.04

40 8.60 9.20 9.77 10.29 10.80

50 10.36 11.05 11.70 12.30 12.89

30 -15.40 -5.10 -0.30 2.70 5.50

40 -9.60 -0.40 4.10 7.20 10.20

50 -1.20 5.90 9.40 12.10 15.00

30 14.37 17.01 20.46 24.63 29.43

40 13.66 16.23 19.55 23.50 28.03

50 12.68 15.21 18.41 22.18 26.47

30 8.26 8.87 9.44 9.96 10.45

40 9.94 10.64 11.30 11.90 12.49

50 11.98 12.78 13.53 14.23 14.91

30 -10.00 -0.20 4.40 7.30 9.90

40 -4.50 4.20 8.50 11.40 14.20

50 3.50 10.20 13.60 16.10 18.80

30 23.14 27.67 33.39 40.53 49.30 59.91 72.57 87.50

40 21.96 26.81 32.42 38.99 46.75 55.91 66.68 79.27

50 18.04 23.62 30.52 36.81 43.84 51.83 60.98 71.51

30 13.14 13.77 14.45 15.18 16.01 16.96 18.06 19.33

40 16.21 17.02 17.80 18.59 19.40 20.28 21.24 22.32

50 20.57 21.72 22.09 22.95 23.78 24.62 25.48 26.39

30 -10.40 -2.80 2.10 5.00 6.40 6.60 5.90 4.60

40 -0.90 1.10 4.60 8.10 11.00 13.20 14.60 15.20

50 16.20 10.20 10.00 12.50 16.10

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

Cond.

o

Evap. temp.

C

8.10 12.00 15.40

19.50 22.40 24.40

14

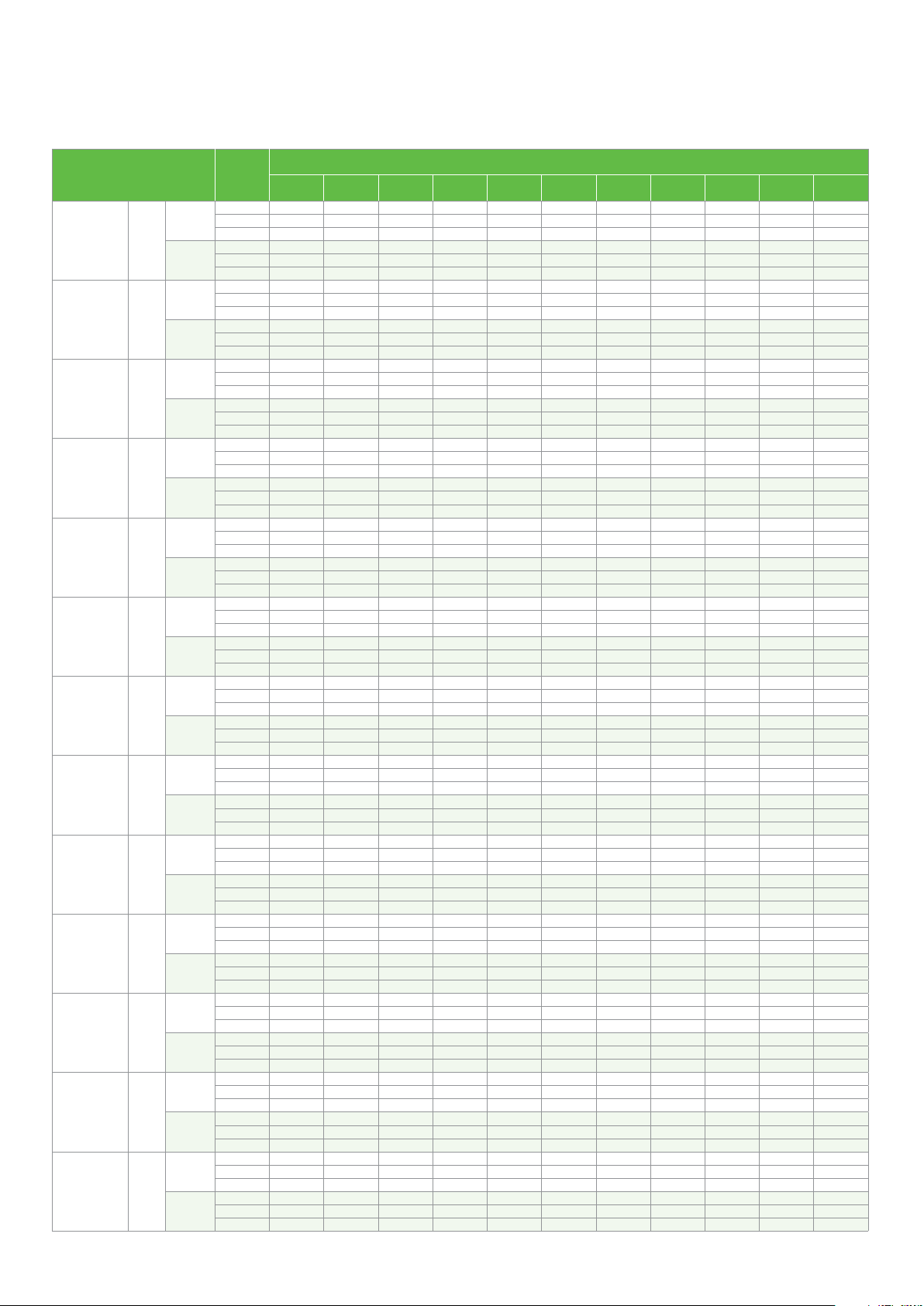

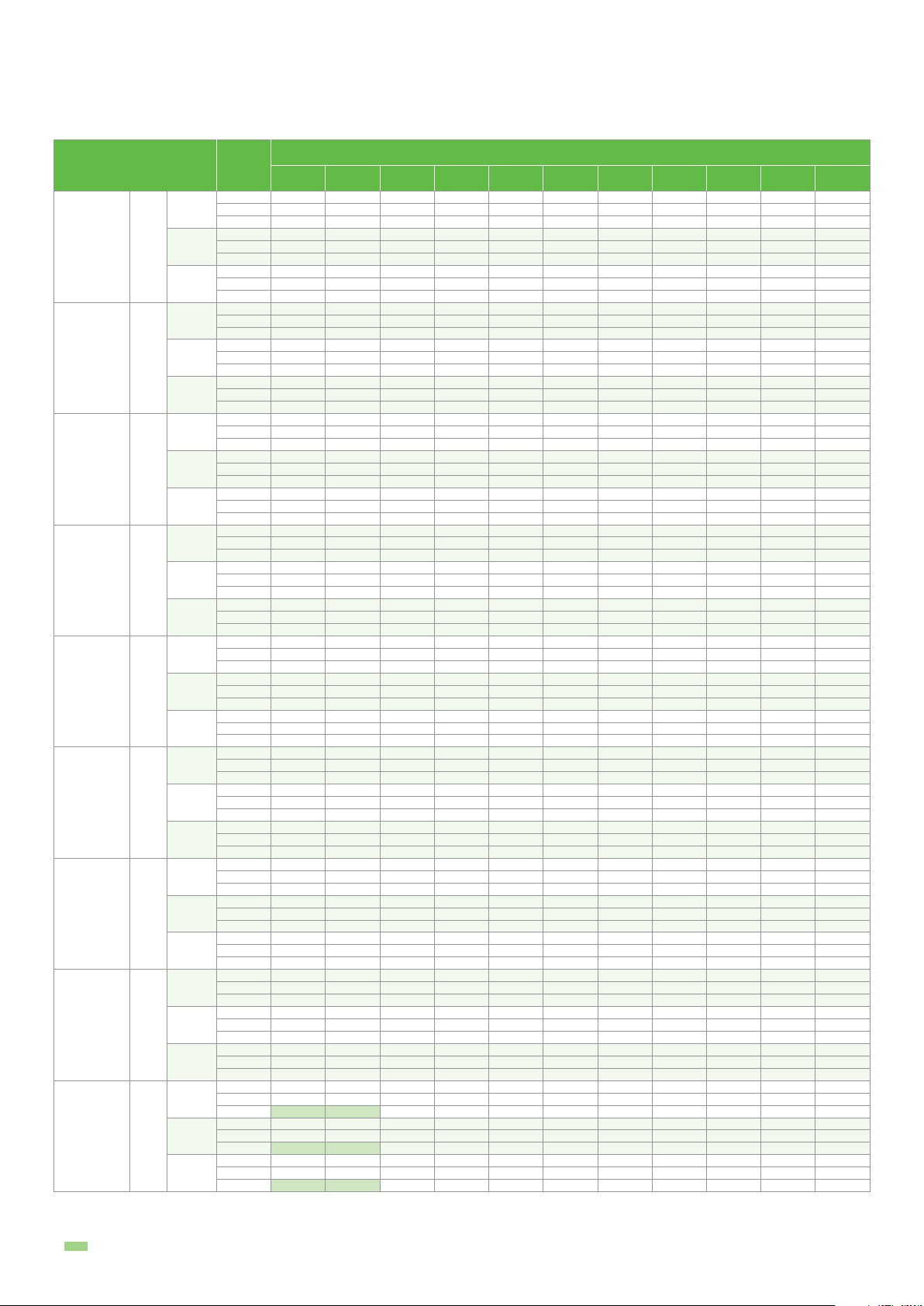

Page 15

Performance data

TF7: 380 V ; 3-Phase, 60 Hz

TFC : 208-230 V ; 3-Phase, 60 Hz

TFD : 460 V ; 3-Phase, 60 Hz

Liquid injection

R404A

Model

ZF06KQE

ZF08KQE

ZF09KQE

ZF11KQE

ZF13KQE

ZF15KQE

ZF18KQE

ZF25KQE

ZF28KQE

ZF34KQE

ZF41KQE

ZF49KQE

ZF54KQE

Notes:

1. Q for capacity; P for power. Units in kW

2. All ZF*KQE values are rated at return gas temperature: 20°C and subcooling: 0 K

TFC

TFD

TFC

TFD

TFC

TFD

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

Cond.

temp.

o

C

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

Q

P

30 1.49 1.90 2.36 2.90 3.53 4.26 5.12 6.12 7.27 8.59 9.17

40 1.30 1.67 2.09 2.56 3.10 3.74 4.48 5.34 6.34 7.49 7.99

50 1.11 1.45 1.80 2.20 2.65 3.17 3.78 4.49 5.32 6.29 6.72

30 1.27 1.29 1.34 1.43 1.52 1.63 1.74 1.84 1.93 1.99 2.00

40 1.57 1.57 1.60 1.67 1.77 1.88 2.00 2.12 2.22 2.32 2.34

50 1.94 1.90 1.92 1.97 2.06 2.17 2.30 2.43 2.56 2.68 2.72

30 1.90 2.39 2.98 3.66 4.47 5.42 6.51 7.76 9.20 10.83 11.53

40 1.68 2.12 2.64 3.24 3.95 4.77 5.72 6.81 8.07 9.50 10.12

50 1.42 1.81 2.25 2.76 3.35 4.03 4.83 5.76 6.82 8.04 8.58

30 1.57 1.63 1.71 1.80 1.92 2.04 2.17 2.32 2.46 2.61 2.66

40 1.91 1.95 2.01 2.09 2.20 2.32 2.45 2.60 2.75 2.91 2.98

50 2.40 2.40 2.44 2.50 2.59 2.69 2.82 2.96 3.11 3.27 3.34

30 2.11 2.67 3.32 4.08 4.98 6.02 7.23 8.62 10.23 12.05 12.85

40 1.87 2.37 2.94 3.60 4.37 5.27 6.32 7.53 8.93 10.54 11.24

50 1.60 2.03 2.51 3.06 3.71 4.46 5.34 6.36 7.56 8.94 9.55

30 1.58 1.63 1.69 1.78 1.88 2.01 2.15 2.31 2.49 2.68 2.76

40 1.92 1.95 2.01 2.09 2.18 2.30 2.44 2.59 2.76 2.95 3.03

50 2.34 2.37 2.41 2.48 2.56 2.67 2.80 2.95 3.12 3.30 3.38

30 2.60 3.30 4.11 5.07 6.19 7.49 8.99 10.72 12.68 14.90 15.87

40 2.33 2.94 3.65 4.48 5.46 6.59 7.90 9.41 11.13 13.10 13.95

50 1.99 2.52 3.11 3.81 4.62 5.57 6.68 7.96 9.44 11.14 11.88

30 1.90 1.97 2.06 2.18 2.33 2.50 2.70 2.92 3.17 3.45 3.57

40 2.30 2.37 2.46 2.57 2.71 2.86 3.05 3.25 3.48 3.74 3.85

50 2.79 2.86 2.95 3.06 3.19 3.35 3.52 3.71 3.93 4.17 4.27

30 2.95 3.80 4.79 5.93 7.24 8.73 10.40 12.29 14.40 16.74 17.74

40 2.60 3.32 4.16 5.15 6.31 7.63 9.14 10.85 12.77 14.92 15.85

50 2.28 2.83 3.50 4.31 5.27 6.39 7.70 9.20 10.91 12.84 13.68

30 2.24 2.30 2.39 2.50 2.65 2.82 3.03 3.28 3.56 3.89 4.03

40 2.70 2.76 2.85 2.95 3.09 3.25 3.44 3.67 3.92 4.22 4.35

50 3.30 3.37 3.45 3.55 3.68

30 3.74 4.72 5.88 7.25 8.86 10.73 12.90 15.40 18.26 21.50 22.91

40 3.30 4.16 5.17 6.35 7.74 9.36 11.24 13.41 15.91 18.76 20.00

50 2.81 3.54 4.38 5.36 6.51 7.85 9.43 11.27 13.39 15.83 16.90

30 2.70 2.79 2.92 3.07 3.26 3.49 3.78 4.13 4.54 5.02 5.24

40 3.19 3.34 3.49 3.66 3.85 4.07 4.32 4.62 4.96 5.36 5.54

50 3.77 3.98 4.19 4.40 4.62 4.84 5.08 5.36 5.66 6.01 6.16

30 4.46 5.67 7.07 8.70 10.61 12.84 15.43 18.42 21.87 25.81 27.53

40 3.98 5.05 6.26 7.66 9.29 11.21 13.44 16.04 19.05 22.51 24.03

50 3.47 4.37 5.37 6.53 7.87 9.46 11.32 13.51 16.06 19.03 20.34

30 3.27 3.37 3.52 3.72 3.96 4.24 4.55 4.88 5.23 5.59 5.73

40 3.88 3.98 4.13 4.34 4.59 4.87 5.19 5.53 5.88 6.24 6.39

50 4.57 4.68 4.85 5.07 5.33 5.63 5.96 6.31 6.68 7.05 7.20

30 5.52 7.01 8.78 10.86 13.27 16.05 19.21 22.79

40 4.93 6.19 7.72 9.53 11.67 14.15 17.01 20.27

50 4.44 5.42 6.65 8.15 9.96 12.10 14.60 17.48

30 3.63 3.96 4.28 4.60 4.90 5.21 5.53 5.87

40 4.06 4.50 4.91 5.30 5.68 6.04 6.41 6.78

50 4.46 5.03 5.56 6.06 6.52 6.97 7.40 7.82

30 6.31 8.01 10.03 12.41 15.16 18.33 21.94 26.03

40 5.63 7.07 8.82 10.89 13.33 16.17 19.43 23.15

50 5.07 6.19 7.59 9.31 11.38 13.82 16.67 19.97

30 4.47 4.89 5.29 5.67 6.05 6.43 6.83 7.25

40 5.00 5.55 6.06 6.54 7.00 7.45 7.90 8.36

50 5.50 6.21 6.86 7.47 8.05 8.59 9.12 9.64

30 7.22 9.25 11.58 14.29 17.44 21.10 25.33 30.21

40 6.34 8.16 10.22 12.59 15.32 18.49 22.16 26.41

50 5.35 6.93 8.68 10.66 12.94 15.58 18.66 22.24

30 5.08 5.37 5.68 6.01 6.36 6.73 7.13 7.55

40 5.91 6.28 6.65 7.02 7.40 7.79 8.19 8.60

50 6.89 7.35 7.80 8.25 8.68 9.10 9.52 9.93

30 9.12 11.59 14.41 17.70 21.55 26.05 31.30 37.40

40 8.09 10.31 12.80 15.64 18.93 22.78 27.27 32.51

50 6.81 8.79 10.92 13.30 16.04 19.22 22.96 27.33

30 6.11 6.51 6.92 7.36 7.81 8.29 8.80 9.34

40 7.17 7.63 8.10 8.57 9.06 9.56 10.08 10.61

50

30 11.01 13.90 17.34 21.38 26.11

40 9.72 12.31 15.33 18.85 22.95

50 8.19 10.44 13.01 15.99 19.44

30 7.52 7.87 8.31 8.83 9.41

40 8.86 9.24 9.71 10.26 10.87

50 10.52 10.92 11.43 12.01 12.67

30 12.55 15.85 19.76 24.38 29.76

40 11.08 14.03 17.47 21.49 26.17

50 9.33 11.90 14.83 18.23 22.16

30 8.57 8.97 9.48 10.07 10.73

40 10.10 10.53 11.07 11.70 12.39

50 11.99 12.45 13.02 13.69 14.44

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

8.37 8.92 9.45 9.99 10.52 11.06 11.60 12.15

o

Evap. temp.

C

3.83 4.01 4.21 4.45 4.71 4.83

15

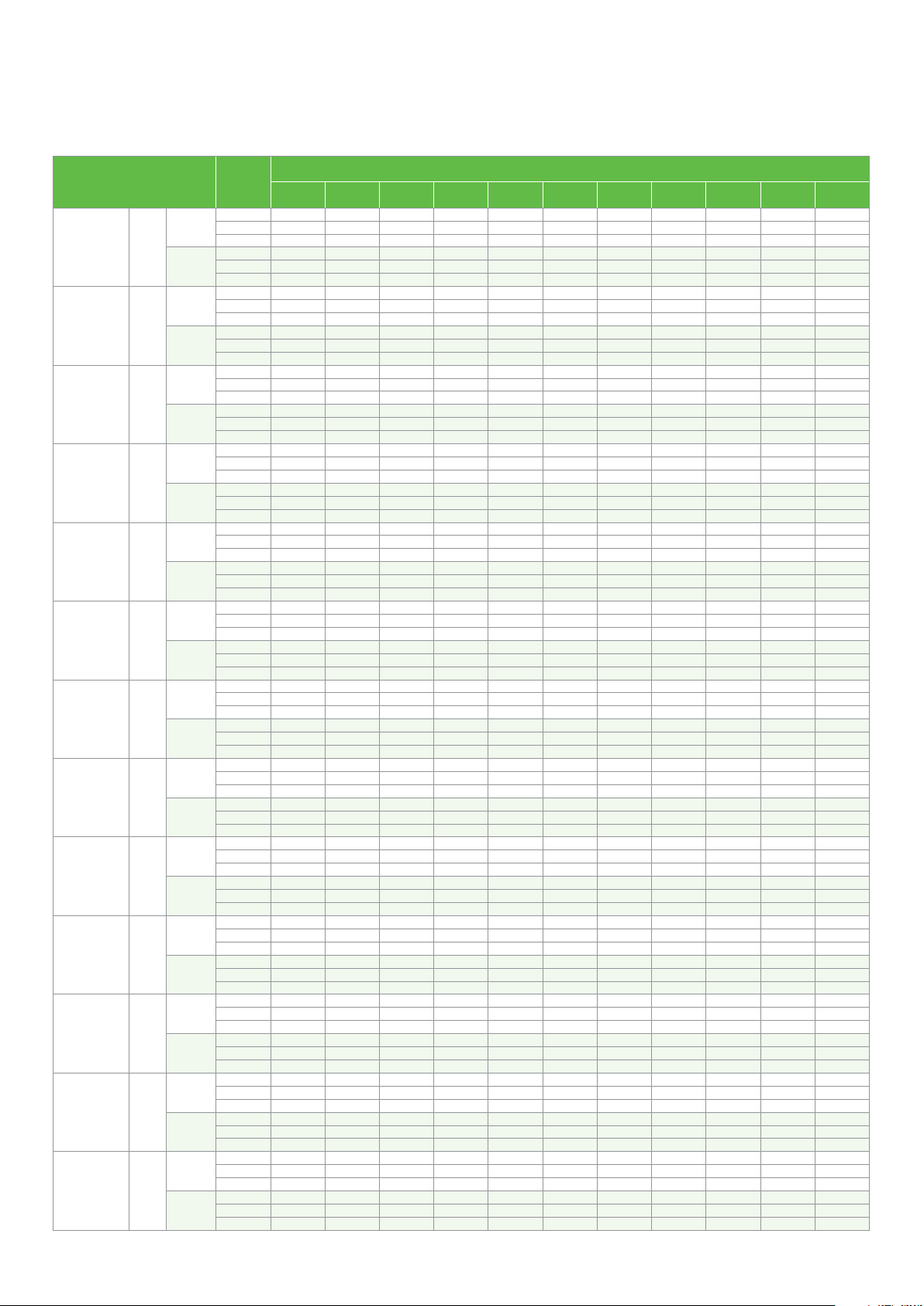

Page 16

Performance data

TF7: 380 V ; 3-Phase, 60 Hz

TFC : 208-230 V ; 3-Phase, 60 Hz

TFD : 460 V ; 3-Phase, 60 Hz

Vapor injection

Model

ZFI20KQE

ZFI26KQE

ZFI36KQE

ZFI39KQE

ZFI50KQE

ZFI59KQE

ZFI68KQE

ZFI81KQE

ZFI122KQE

Notes:

1. Q for capacity, P for power. Units in kW; LO for liquid out temperature in °C

2. All ZF*KQE values are rated at return gas temperature: 20°C and max subcooling

3. 20K Superheat

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TF7

TFC

TFD

TE7

TEC

TED

Cond.

temp.

o

C

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

Q

P

LO

30 4.27 5.27 6.40 7.69 9.15 10.81 12.68 14.80 17.16 19.82 20.96

40 4.21 5.16 6.25 7.48 8.89 10.50 12.32 14.38 16.71 19.30 20.43

50 4.01 4.91 5.95 7.13 8.49 10.05 11.82 13.84 16.11 18.67 19.78

30 2.65 2.79 2.93 3.05 3.16 3.26 3.35 3.43 3.49 3.55 3.57

40 3.24 3.41 3.57 3.72 3.86 3.99 4.10 4.21 4.31 4.39 4.42

50 4.00 4.19 4.38 4.55 4.71 4.87 5.01 5.15 5.28 5.40 5.45

30 -9.30 -6.50 -3.30 0.20 3.90 7.70 11.30 14.50 17.50 19.80 20.60

40 -9.40 -6.00 -2.40 1.60 5.70 9.80 13.50 16.90 19.80 22.20 22.90

50 -7.10 -3.50 0.40 4.70 8.90 13.00 16.80 20.10 22.90 25.10 25.80

30 6.30 7.81 9.47 11.34 13.43 15.81 18.50 21.55 24.98 28.86 30.55

40 6.03 7.47 9.04 10.79 12.76 14.98 17.49 20.35 23.58 27.23 28.81

50 5.64 6.99 8.46 10.08 11.89 13.94 16.27 18.91 21.90 25.29 26.77

30 3.80 4.05 4.30 4.55 4.80 5.07 5.34 5.64 5.97 6.33 6.49

40 4.50 4.83 5.15 5.46 5.75 6.04 6.34 6.64 6.95 7.29 7.43

50 5.46 5.89 6.28 6.64 6.98 7.30 7.61 7.92 8.22 8.54 8.67

30 -12.20 -8.00 -4.10 -0.10 3.90 7.80 11.30 14.40 17.20 19.20 19.90

40 -9.60 -4.70 -0.20 4.30 8.60 12.60 16.20 19.30 21.90 23.90 24.50

50 -5.80 -0.30 4.80 9.60 14.10 18.20 21.80 24.90 27.40 29.20 29.80

30 7.73 9.58 11.62 13.92 16.56 19.64 23.23 27.39

40 7.53 9.15 10.97 13.08 15.56 18.50 21.95 26.01

50 7.74 9.00 10.49 12.29 14.48 17.14 20.35 24.21

30 4.46 4.84 5.16 5.45 5.73 6.03 6.38 6.79

40 5.25 5.74 6.17 6.56 6.95 7.36 7.80 8.31

50 6.26 6.85 7.37 7.88 8.38 8.89 9.44 10.08

30 -12.60 -9.00 -4.10 0.60 4.70 7.70 9.80 11.00

40 -9.90 -3.90 2.10 7.10 10.80 13.40 14.90 15.50

50 -16.10 -3.90 5.40 12.10 16.70 19.50 20.90 21.00

30 8.89 11.02 13.36 16.01 19.06 22.59 26.72 31.51

40 8.66 10.53 12.62 15.05 17.90 21.28 25.25 29.93

50 8.91 10.35 12.06 14.14 16.65 19.72 23.41 27.86

30 5.35 5.80 6.18 6.53 6.87 7.23 7.65 8.14

40 6.29 6.88 7.39 7.87 8.33 8.82 9.35 9.96

50 7.51 8.21 8.84 9.45 10.04 10.66 11.32 12.08

30 -12.60

40 -9.90 -3.90 2.10 7.10 10.80 13.40 14.90 15.50

50 -16.10 -3.90 5.40 12.10 16.70 19.50 20.90 21.00

30 10.79 12.78 15.38 18.52 22.10 26.11 30.43 35.02

40 10.25 12.19 14.67 17.65 21.05 24.80 28.83 33.06

50 9.53 11.42 13.82 16.66 19.88 23.40 27.14 31.04

30 5.95 6.40 6.80 7.18 7.53 7.88 8.24 8.63

40 7.15 7.66 8.13 8.57 8.99 9.41 9.84 10.31

50 8.63 9.20 9.73 10.25 10.74 11.23 11.72 12.25

30 -15.40 -5.10 -0.30 2.70 5.60 8.80 12.60 16.70

40 -9.50 -0.40 4.20 7.20 10.20 13.60 17.50 21.80

50 -1.20 5.90 9.50 12.10 15.00 18.50 22.50 26.90

30 13.38 15.84 19.06 22.95 27.40 32.36 37.72 43.40

40 12.71 15.10 18.18 21.88 26.09 30.74 35.73 40.97

50 11.81 14.16 17.12 20.65 24.64 28.97 33.64 38.46

30 7.41 7.96 8.46 8.93 9.37 9.80 10.25 10.74

40 8.90 9.53 10.11 10.66 11.19 11.71 12.25 12.83

50 10.74 11.45 12.11 12.75 13.36 13.95 14.59 15.25

30 -15.40 -5.10 -0.30 2.70 5.60 8.80 12.60 16.70

40 -9.50 -0.30 4.20 7.20 10.20 13.60 17.50 21.80

50 -1.20 5.90 9.50 12.10 15.00 18.60 22.50 26.90

30 15.12 17.91 21.54 25.94 30.99

40 14.37 17.08 20.57 24.73 29.49

50 13.35 16.00 19.37 23.35 27.85

30 8.58 9.22 9.80 10.34 10.86

40 10.32 11.05 11.73 12.35 12.96

50 12.44 13.27 14.05 14.77 15.48

30 -15.40 -5.10 -0.30 2.70 5.50

40 -9.60 -0.40 4.10 7.20 10.20

50 -1.20 5.90 9.40 12.10 15.00

30 17.37 20.58 24.75 29.80 35.61

40 16.52 19.63 23.63 28.41 33.88

50 15.33 18.39 22.26 26.82 32.00

30 10.23 10.99 11.69 12.33 12.94

40 12.30 13.17 13.98 14.73 15.45

50 14.83 15.82 16.74 17.61 18.45

30 -15.40 -5.10 -0.30 2.70 5.50

40 -9.60 -0.40 4.10 7.20 10.20

50 -1.20 5.90 9.40 12.10 15.00

30 27.01 32.29 38.98 47.31 57.54 69.93 84.71 102.13

40 25.63 31.29 37.84 45.51 54.57 65.26 77.84 92.54

50 20.92 27.41 35.62 42.97 51.17 60.50 71.18 83.48

30 15.86 16.63 17.45 18.34 19.34 20.48 21.81 23.35

40 19.58 20.55 21.49 22.44 23.43 24.49 25.65 26.96

50 24.75 26.13 26.66 27.71 28.72 29.72 30.76 31.87

30 -6.40 0.90 5.70 8.40 9.70 9.90 9.30 8.00

40 2.80 4.70 8.00 11.40

50 19.30 13.50 13.20 15.70 19.10 22.30 25.10 27.00

-40 -35 -30 -25 -20 -15 -10 -5 0 5 7

-9.00 -4.10 0.60 4.70 7.70 9.80 11.00

o

Evap. temp.

14.20 16.30 17.60 18.20

C

R404A

16

Page 17

Technical data

Compressor model

Nominal horsepower hp 2 2.5 3 3.5 4 5 6 7.5 9 10 13 15 17

Displacement

Motor type

Locked rotor

current

(LRA)

Maximum

operating

current

(MOC)

Maximum

continuous

current

(MCC)

Rated load

current

(RLA=MCC/1.4)

Rated load

current

(RLA=MCC/1.56)

Winding resistance at

Connection size

Outline

dimension

Sight glass fitting thread in 1 1/4“-12UNF 1 1/4“-12UNF 1 1/4“-12UNF

Terminal box IP grade IP21 IP21 (Except ZF28KQE-TFC with IP54) IP54

Crankcase heater power W 70 70 90

Mounting parts

Installation size (hole size)

50 Hz

60 Hz 7.1 8.8 9.7 12.1 14.1 17.4 20.6 25.8 30.3 35.1 42.6 51.2 58.3

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

25˚C

Oil quantity L 1.3 1.5 1.5 1.5 1.9 1.9 1.9 1.9 1.9 3.4 3.4 3.4 3.4

Net weight kg 25 27 27 29 39 39 39 39 40 63 63 66 66

m

50 Hz

60 Hz

TFD

TFC 56.0 70.0 83.0 87.0 94.0 122.0 171.0 223.0 197.9 220.0 248.0 338.7 404.0

TFD

TFC 55.0 63.0 77.0 88.0 99.0 123.0 156.0 224.0 199.0 239.0 248.0 338.7 404.0

TF7 NA NA NA NA 57.0 64.0 70.0 119.6 106.6 145.0 145.0 220.0 220.0

TFD

TFC 10.0 12.0 13.0 14.5 16.0 22.0 25.0 28.8 38.7 51.4 57.7 67.9 31.0

TFD

TFC 10.0 12.0 13.0 14.5 16.0 22.0 25.0 28.8 38.7 51.4 57.7 67.9 31.0

TF7 NA NA NA NA 10.0 12.0 14.0 17.4 20.9 23.3 27.6 40.6 39.6

TFD

TFC 13.0 13.5 13.5 16.5 18.5 23.5 28.5 36.3 42.6 52.0 59.0 71.0 82.2

TFD

TFC 13.0 13.5 13.5 17.0 18.5 26.5 30.5 37.4 42.6 52.0 59.0 71.0 82.2

TF7 NA NA NA NA 11.5 15.9 17.7 19.9 23.8 28.6 30.4 40.5 44.4

TFD

TFC 9.3 9.6 9.6 11.8 13.2 16.8 20.4 25.9 30.4 37.1 42.1 50.7 58.7

TFD

TFC 9.3 9.6 9.6 12.1 13.2 18.9 21.8 26.7 30.4 37.1 42.1 50.7 58.7

TF7 NA NA NA NA 8.2 11.4 12.6 14.2 17.0 20.4 21.7 28.9 31.7

TFD

TFC 8.3 8.7 8.7 10.6 11.9 15.1 18.3 23.3 27.3 33.3 37.8 45.5 52.7

TFD

TFC 8.3 8.7 8.7 10.9 11.9 17.0 19.6 24.0 27.3 33.3 37.8 45.5 52.7

TF7 NA NA NA NA 7.4 10.2 11.3 12.8 15.3 18.3 19.5 26.0 28.5

TFD

TFC 1.79 1.46 1.23 1.00 0.91 0.69 0.56 0.39 0.37 0.31 0.28 0.22 0.18

TF7 NA NA NA NA 2.78 2.23 1.92 1.20 1.06 0.85 0.85 0.56 0.56

Suction

Discharge 1 1 1 1 1 1 1 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4

Injection 11/16 11/16 11/16 11/16 11/16 11/16 11/16 11/16 11/16 1 1 1 1

Suction

Discharge NA NA NA NA 1/2 1/2 1/2 3/4 3/4 7/8 7/8 7/8 7/8

Injection NA NA NA NA 1 1/16 ( Rotalock only) 1 (Rotalock only)

Length

Width 246 246 246 246 257 257 257 257 257 280 280 280 280

Height 369 391 391 405 442 442 442 442 451 534 534 552 552

ZF06KQE ZF08KQE ZF09KQE ZF11KQE ZF13KQE ZF15KQE ZF18KQE ZF25KQE ZF28KQE ZF34KQE ZF41KQE ZF49KQE ZF54KQE

3

/hr

Amps

Amps

Amps

Amps

Amps

Amps

Amps

Amps

Amps

Amps

5.9 7.3 8.0 10.0 11.7 14.4 17.1 21.4 25.1 29.1 35.3 42.4 48.3

TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD

TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC

TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD TFD

TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC TFC

NA NA NA NA TF7 TF7 TF7 TF7 TF7 TF7 TF7 TF7 TF7

26.0 32.0 40.0 46.0 51.5 64.0 74.0 102.0 121.4 100.0

27.0 31.0 39.0 44.0 49.5 75.0 75.0 99.0 121.4 100.0 125.0 139.0 185.0

5.0 6.0 6.0 7.1 8.0 10.0 12.5 13.7 16.8 25.0

5.0 6.0 6.0 7.1 8.0 10.0 12.5 13.7 16.8 25.0 29.0 30.0 31.0

6.0 7.0 6.5 8.0 10.0 12.0 12.5 16.6 20.1 25.0

6.0 7.0 7.0 9.0 10.0 12.5 12.5 16.6 20.1 25.0 27.0 28.3 40.0

4.3 5.0 4.6 5.7 7.1 8.6 8.9 11.9 14.4 17.9

4.3

3.8 4.5 4.2 5.1 6.4 7.7 8.0 10.6 12.9 16.0

3.8 4.5 4.5 5.8 6.4 8.0 8.0 10.6 12.9 16.0 17.3 18.1 25.6

7.15 5.94 4.83 4.03 3.64 2.75 2.27 1.74 1.63 1.24

Ohm

1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 3/4 1 3/4 1 3/4 1 3/4

in

NA NA NA NA 7/8 7/8 7/8 7/8 7/8 1 3/8 1 3/8 1 3/8 1 3/8

in

246 246 246 246 246 246 246 246 246 280 280 280 280

mm

mm 190 x 190 (Ø19)

5.0 5.0 6.4 7.1 8.9 8.9 11.9 14.4 17.9 19.3 20.2 28.6

Liquid injection

118.0 139.0

29.0 30.0

27.0 28.3

19.3 20.2

17.3 18.1

1.24 1.09

Rotalock connection

Brazing connection

168.0

31.0

40.0

28.6

25.6

0.78

17

Page 18

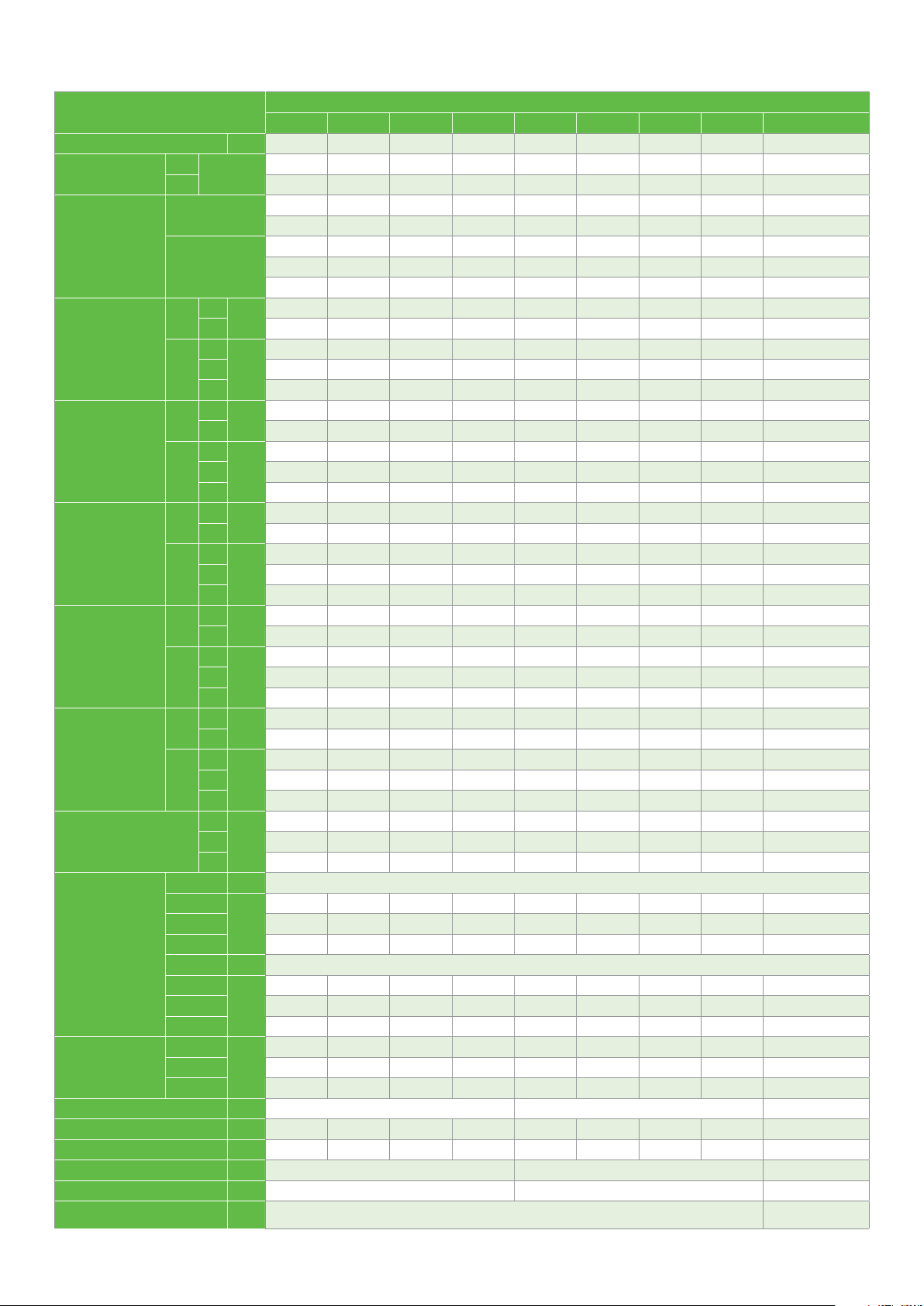

Technical data

Compressor model

Nominal horsepower hp 4 6 8 10 12 15 18 20 30

Displacement

Motor type

Locked rotor current

(LRA)

Maximum operating

current

(MOC)

Maximum continuous

current

(MCC)

Rated load current

(RLA=MCC/1.4)

Rated load current

(RLA=MCC/1.56)

Winding resistance at 25˚C

Connection size

Outline dimension

Sight glass fitting thread in 1 1/4“-12UNF 1 1/4“-12UNF 1-3/4” x 12 UNF

Oil quantity L 1.9 1.9 1.9 1.9 3.4 3.4 3.4 3.4

Net weight kg 39 39 39 40 63 63 66 66 179

Terminal box IP grade IP21 (Except ZFI39KQE-TFC with IP54) IP54 IP56

Crankcase heater power W 70 90 150

Mounting parts

Installation size (hole size)

50 Hz

60 Hz 14.1 20.6 25.8 30.3 35.1 42.6 51.2 58.3 93.3

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

50 Hz

60 Hz

m

50 Hz

60 Hz

TFD

TFC 135.0 172.0 223.0 197.9 220.0 248.0 338.7 404.0 599

TFD

TFC 123.0 156.0 224.0 199.0 239.0 248.0 338.7 404.0 599

TF7 64.0 70.0 119.6 106.6 145.0 145.0 220.0 220.0 358

TFD

TFC 18.0 26.0 36.7 37.2 51.4 57.7 67.9 31.0 101.6

TFD

TFC 18.0 26.0 36.7 37.2 51.4 57.7 67.9 31.0 101.6

TF7 12.2 16.3 18.9 20.5 23.3 27.6 40.6 39.6 61.2

TFD

TFC 24.0 28.5 35.3 42.6 52.0 59.0 71.0 82.2 119.7

TFD

TFC 24.0 30.5 38.2 42.6 52.0 59.0 71.0 82.2 140.0

TF7 14.0 17.5 20.3 24.3 28.6 30.4 40.5 44.4 94.9

TFD

TFC 17.1 20.4 25.2 30.4 37.1 42.1 50.7 58.7 85.5

TFD

TFC 17.1 21.8 27.3 30.4 37.1 42.1 50.7 58.7 100.0

TF7 10.0 12.5 14.5 17.4 20.4 21.7 28.9 31.7 67.8

TFD

TFC 15.4 18.3 22.6 27.3 33.3 37.8 45.5 52.7 76.7

TFD

TFC 15.4 19.6 24.5 27.3 33.3 37.8 45.5 52.7 89.7

TF7 9.0 11.2 13.0 15.6 18.3 19.5 26.0 28.5 60.8

TFD

TFC 0.69 0.56 0.39 0.37 0.31 0.28 0.22 0.18

TF7 2.23 1.92 1.20 1.06 0.85 0.85 0.56 0.56 0.25

Suction

Discharge 1 1 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4 1-3/4"x 12UN

Injection 1 1 1 1 1 1 1 1 1''-14

Suction

Discharge 1/2 1/2 3/4 3/4 7/8 7/8 7/8 7/8 1-3/8''

Injection 1/2 1/2 1/2 1/2 5/8 5/8 5/8 5/8 3/4"

Length

Width 257 257 257 257 297 297 297 297 409.3

Height 442 442 442 451 534 534 552 552 715

ZFI20KQE ZFI26KQE ZFI36KQE ZFI39KQE ZFI50KQE ZFI59KQE ZFI68KQE ZFI81KQE ZFI122KQE

3

/hr

Amps

Amps

Amps

Amps

Amps

Amps

Amps

Amps

Amps

Amps

Ohm

mm

mm 190 x 190 (Ø19) 266.7 x 266.7 (Ø22.6)

11.7 17.1 21.4 25.1 29.1 35.3 42.4 48.3 77.3

TFD TFD TFD TFD TFD TFD TFD TFD TED

TFC TFC TFC TFC TFC TFC TFC TFC TEC

TFD TFD TFD TFD TFD TFD TFD TFD TED

TFC TFC TFC TFC TFC TFC TFC TFC TEC

TF7 TF7 TF7 TF7 TF7 TF7 TF7 TF7 TE7

64.0 74.0 102.0 121.4 100.0 118.0 139.0 168.0 310

62.0 70.0 99.0 121.4 100.0 125.0 139.0 185.0 310

9.0 13.7 16.0 18.1 25.0 29.0 30.0 31.0 53.6

9.0 13.7 16.0 18.1 25.0 29.0 30.0 31.0 53.6

12.0 13.0 16.6 20.3 25.0 27.0 28.3 40.0 65.4

12.0 13.0 18.5 20.3 25.0 27.0 28.3 40.0 71.7

8.6 9.3 11.9 14.5 17.9 19.3 20.2 28.6 46.7

8.6 9.3 11.9 14.5 17.9 19.3 20.2 28.6 51.2

7.7 8.3 10.6 13.0 16.0 17.3 18.1 25.6 41.9

7.7 8.3 10.6 13.0 16.0 17.3 18.1 25.6 46.0

2.75 2.27 1.74 1.63 1.24 1.24 1.09 0.78 0.36

1 1/4 1 1/4 1 1/4 1 1/4 1 3/4 1 3/4 1 3/4 1 3/4 2-1/4" x 12UN

in

7/8 7/8 7/8 7/8 1 3/8 1 3/8 1 3/8 1 3/8 1-5/8"

in

246 246 246 246 328 328 328 328 448

Vapor injection

Rotalock connection

Brazing connection

0.09

6.0

18

Page 19

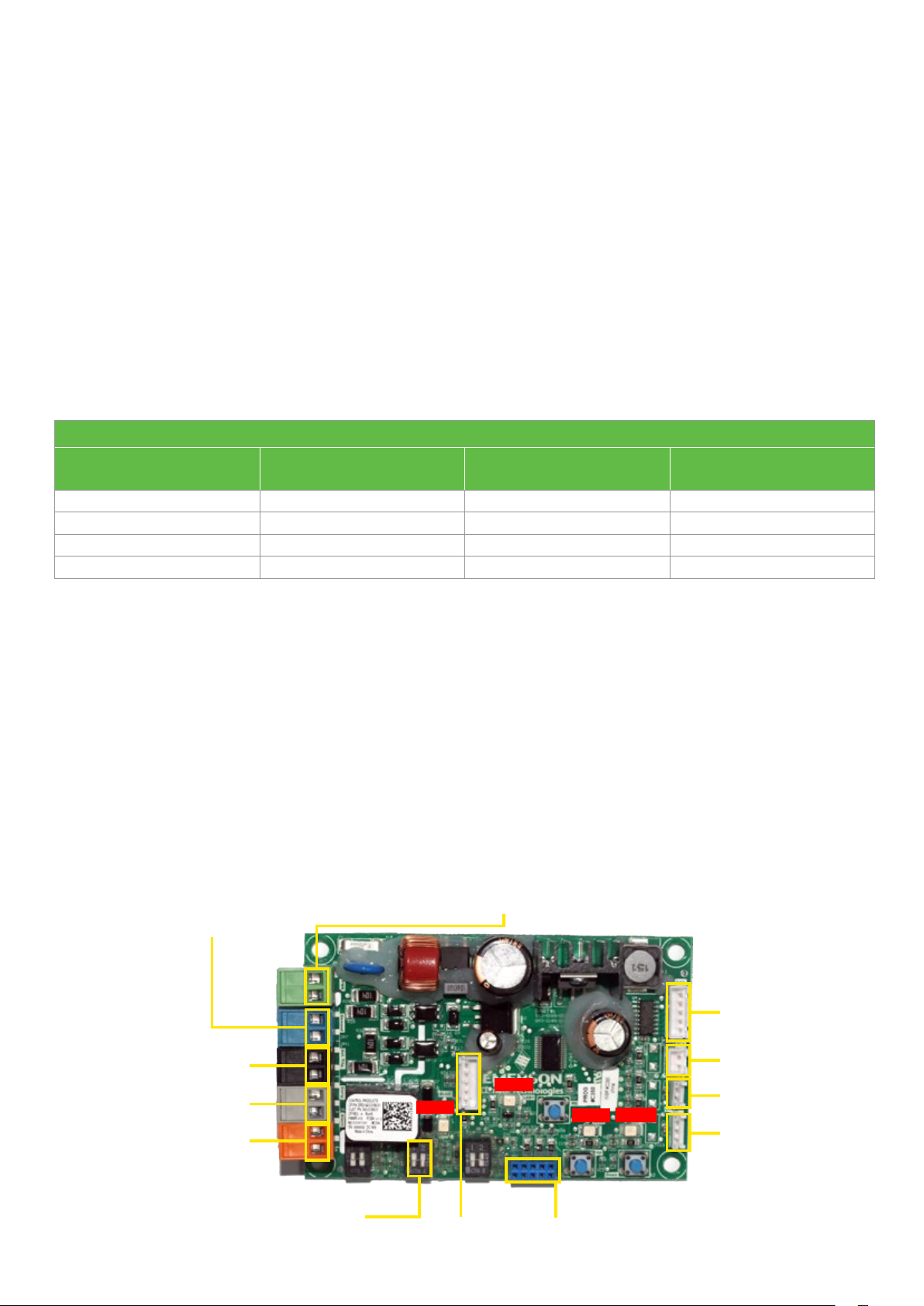

EVI CoreSense™ control kits and wiring diagram

EVI CoreSense control kits

Introduction

The EVI CoreSense control kit of ZFI compressor is intended to control vapor injection, maintain a safe discharge temperature,

and provide intelligent diagnosis and protection.

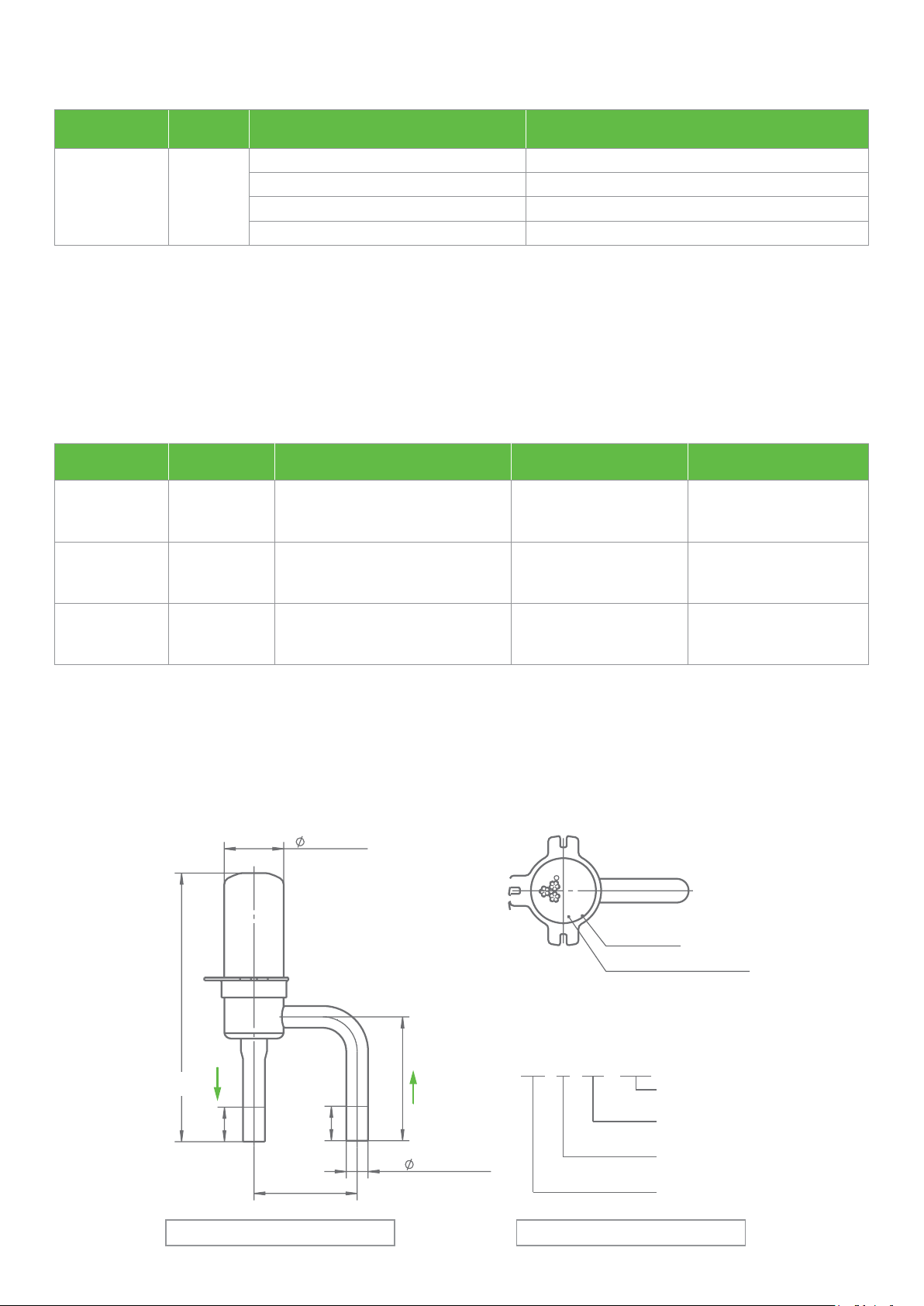

The kit includes a printed circuit board (PCB), an electronic expansion valve (EXV), and three sensors, as well as containing a

transformer and an EXV filter. All parts are common, except the EXV valve orifice size, which will be applied to different ZFI models.

In vapor injection application, the valve is driven by sensors mounted near the heat exchanger and attempts to maintain

the vapor outlet sensor 5K higher than the vapor inlet. The system will switch to discharge line temperature control if vapor

injection is insufficient to maintain a safe discharge temperature. If the discharge temperature becomes dangerously high, the

system will stop the compressor, turn on an LED alarm, and trigger a voltage free alarm relay contact. The compressor can autoreset, but not lockout.

Emerson provides customer EVI CoreSense control kits with and without CoreSense box.

EVI CoreSense control kits

Part number

without CoreSense box

562-0313-00 562-0291-01 ZFI20~ZFI26 Ø1.3mm (TS113C03)

562-0313-01 562-0291-02 ZFI36~ZFI59 Ø1.65mm (TS116C03)

562-0313-02 562-0291-03 ZFI68~ZFI81 Ø1.8mm (TS118C03)

562-0313-03 562-0291-06 ZFI122 Ø2.4mm (TS124C03)

Part number

with CoreSense box

Apply for ZFI models

EXV valve orifice size

(Identification code)

Printed circuit board

Wear a ground strap when working with the PCB to avoid the risk of damage from static discharges.

General PCB layout, input and output ports are shown in the image below, the ports to EXV, DLT, as well as the vapor in and

vapor out sensors are done with Poka-yoke connector design. Connect sensors, EXV, and system wiring as shown in wiring

diagram.

The PCB is supplied power through a transformer with a power input of 50/60 Hz, 220VAC, and an output of 12VAC to the PCB

board.

For EVI control kits with CoreSense box, the board and transformer are both mounted in the box, using 4 x Ø5mm holes at

61 x 101mm centers, fastened by screws. Spare part number is 543-0189-01 for field service.

For EVI control kits without CoreSense box, we provide individual parts for compact system design. The board is with 4 x Ø4mm

holes at 61 x 101mm centers, please use plastic stakes provided. Spare part number is 543-0219-01 for field service.

Compressor start/stop input signal

(from LP switch/cold room temp sensor)

(220 VAC)

Reserved

Compressor

contactor

Dry contact alarm output

terminal

SW1 SW2 SW3

Dip-switch

Board power supply input terminals

(from 12 VAC transformer)

LED 1

LED 4

Programming

ports

Communication ports

LED 2

LED 3

EXV driver

output ports

DLT sensor

input ports

Vapor in sensor

input ports

Vapor out sensor

input ports

19

Page 20

Dip-switch setting

The dip-switch default setting has been done in-factory, please do not change setting and ensure that the replacement board

is set correctly.

For the glide-refrigerants application like R407A, R407F, R407C, we would recommend 10K superheat. Please contact your

local Emerson sales and application engineer to reset the dip-switch.

Dip-switch default factory setting

SW1 SW2 SW3

BIT1 ON OFF OFF

BIT2 ON OFF ON

Dip-switch

Setting position

Function description of

default setting

1 2

O

N

1. Discharge Line Temperature (DLT) control target ≤110°C

2. Vapor out superheat target is 5K

3. Compressor will shut down If DLT above 125°C

4. Compressor can auto-reset and no lockout due to DLT overheat protection

5. Compressor minimum stop time is 0 minute

6. Vapor injection mode

O

N

1 2

O

N

LED functions

LED1 (yellow-green)

LED1 will light up during initialization after power on, after that, blinking lights will indicate the sensor status.

LED Color Compressor or sensor status LED1 behavior

Idle compressor waiting to start Blinks at 1 Hz

1 2

DLT overheat protection Blinks 2 times at 1 Hz, waiting 5s, then repeat…

LED1

LED2, LED3 (yellow-green)

LED2 and LED3 will blink once when entering or exiting EXV manual operation, and also indicate EXV opening and closing.

LED Color EXV status LED2, LED3 behavior

LED2

LED3

20

Yellow-

Green

Yellow-

Green

DLT failure Blinks 3 times at 1 Hz, waiting 5s, then repeat…

Vapor in sensor failure Blinks 4 times at 1 Hz, waiting 5s, then repeat…

Vapor out sensor failure Blinks 5 times at 1 Hz, waiting 5s, then repeat…

Opening LED2 is flashing at 1 Hz, LED3 off

Closing LED3 is flashing at 1 Hz, LED2 off

Fully open LED2 constant on, LED3 off

Fully closed LED3 constant on, LED2 off

Page 21

LED4 (red color) alarm

LED4 will turn on when alarm is triggered by the following items

LED Color Sensor status LED4 behavior

DLT overheat protection LED4 on, red color

LED4 Red

DLT sensor failure LED4 on, red color

Vapor in sensor failure LED4 on, red color

Vapor out sensor failure LED4 on, red color

Temperature sensors

The EVI kits include 3 temperature sensors. Please ensure all sensors are mounted in the correct locations, fastened, and

insulated properly.

The discharge temperature sensor should be installed approximately 178mm (7 inches) from discharge tube outlet. If a service

valve is installed at the discharge tube, the sensor should be located 127mm (5 inches) from the valve braze.

The vapor-in sensor is connected to the pipe between the EXV and PHE. The vapor-out sensor is connected to the pipe from

the PHE to the compressor vapor injection port. Don’t make the vapor-in and vapor-out sensor location reversed.

Sensor Wire length Resistance value vs. temperature Open Short

Discharge

temperature

sensor

Vapor-in

sensor

Vapor-out

sensor

930mm or

1800mm

1360mm or

1800mm

750mm or

1800mm

351.6 kΩ @0°C

100.0 kΩ @25°C

5.8 kΩ @100°C

28.1 kΩ @0°C

10.0 kΩ @25°C

0.9 kΩ @100°C

28.1 kΩ @0°C

10.0 kΩ @25°C

0.9 kΩ @100°C

>1000kΩ <400Ω

>500kΩ <500Ω

>500kΩ <500Ω

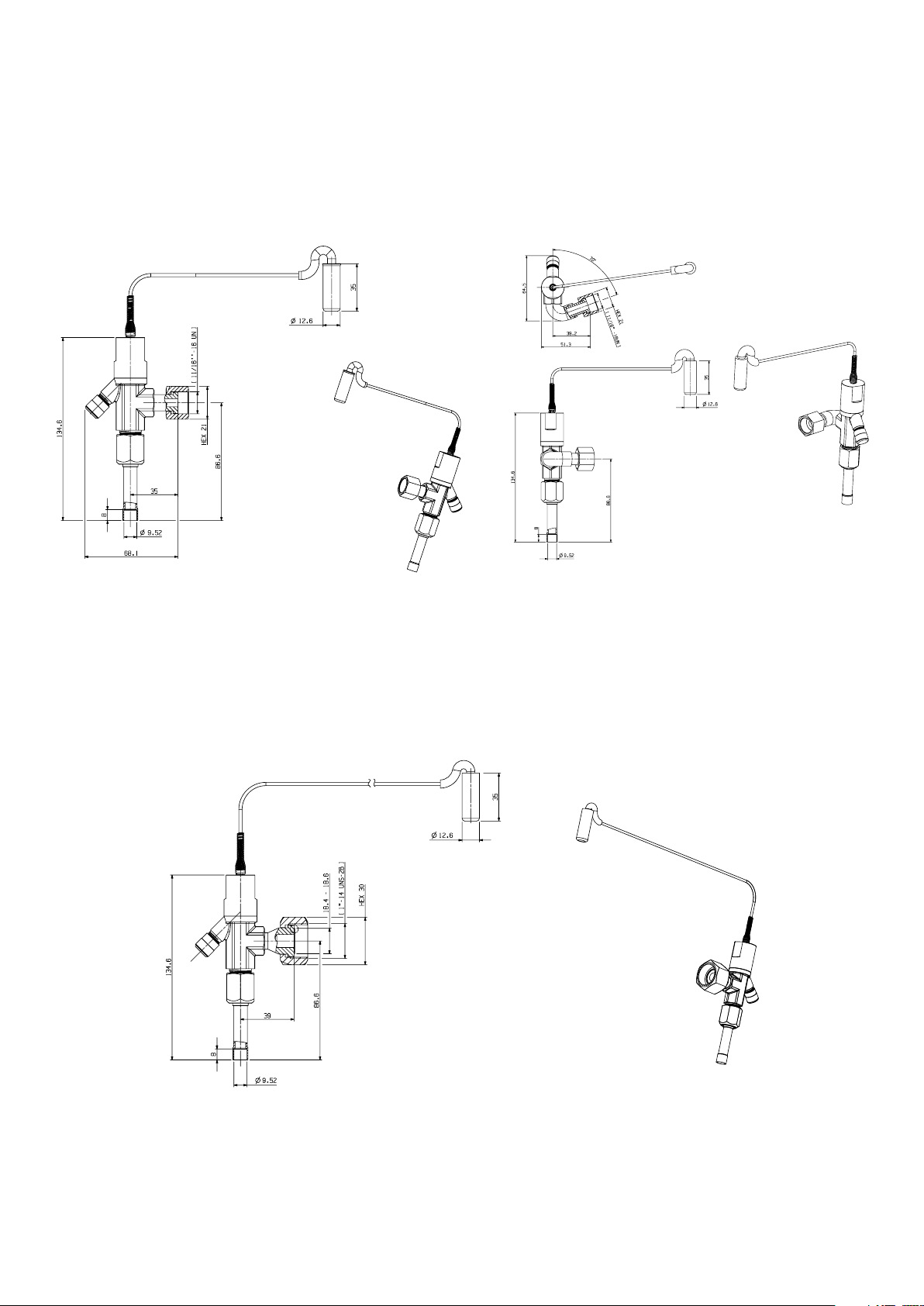

Electronic expansion valve (EXV)

The EXV contains an EXV-valve and EXV-coil, lead wire length for coil is 1796mm, the valve size includes Ø1.3mm, Ø1.65mm

and Ø1.8mm depending on system size, applied to different ZFI models.

The liquid refrigerant should pass from the bending tube and flow out from the straight tube. Please weld the filter before the

EXV provided along with the kits.

17.35max

13829001

10C311ST

R

Production lot

Product identification code

87 3±

Liquid out

EXV valve connection size, mm EXV valve identification code

Product identification code specific

10 C 31 1ST

Liquid in

63 3±

01

01

×2 53.6 1.0±

03 3±

Optional design

Refrigerant

Valve orifice

Product series

21

Page 22

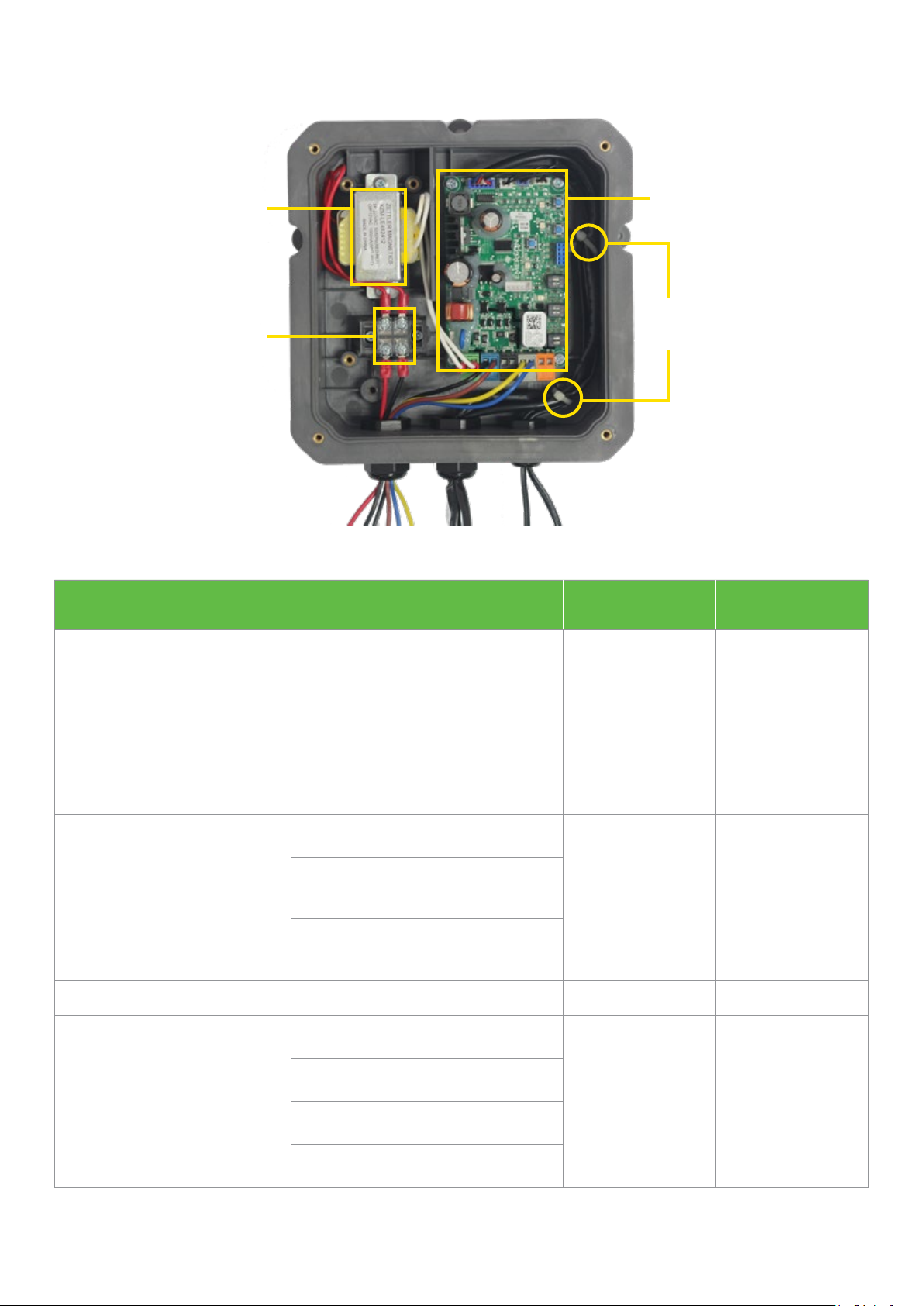

ZFI standard control box wiring example

Transformer

Terminal

Waterproof

gland no.

Wire function

Wire connection

1 2 3

A B C D E F

Gland 1 Gland 2 Gland 3

A (red) and B (black):

Controller power supply input

(220–240 VAC 50/60 Hz)

C (black) and D (brown):

Compressor start/stop input

(220–240 VAC 50/60 Hz)

E (blue) and F (yellow):

Compressors contactor coil

Control output

Wires A and B:

Connect to terminal

Wires C and D:

Connect to the blue connector on the

control board

Wires E and F:

Connect to the gray connector

on the control board

Control board

Cables fixed

by ribbon

EXV Coil

DLT Sensor

Connect to the

EXV, DLT sensor at

the top edge of the

control board

Vapor-in sensor

Vapor-out sensor

Connect to the

vapor-in/out port at

the top edge of the

control board

Gland internal diameter range 2–3 mm

Jacket line requirement

22

Internal wire size:

18 AWG

Rated voltage:

300 V/600 V

Rated temperature:

80/105 °C

Recommended:

UL105, UL1011, UL1007

Page 23

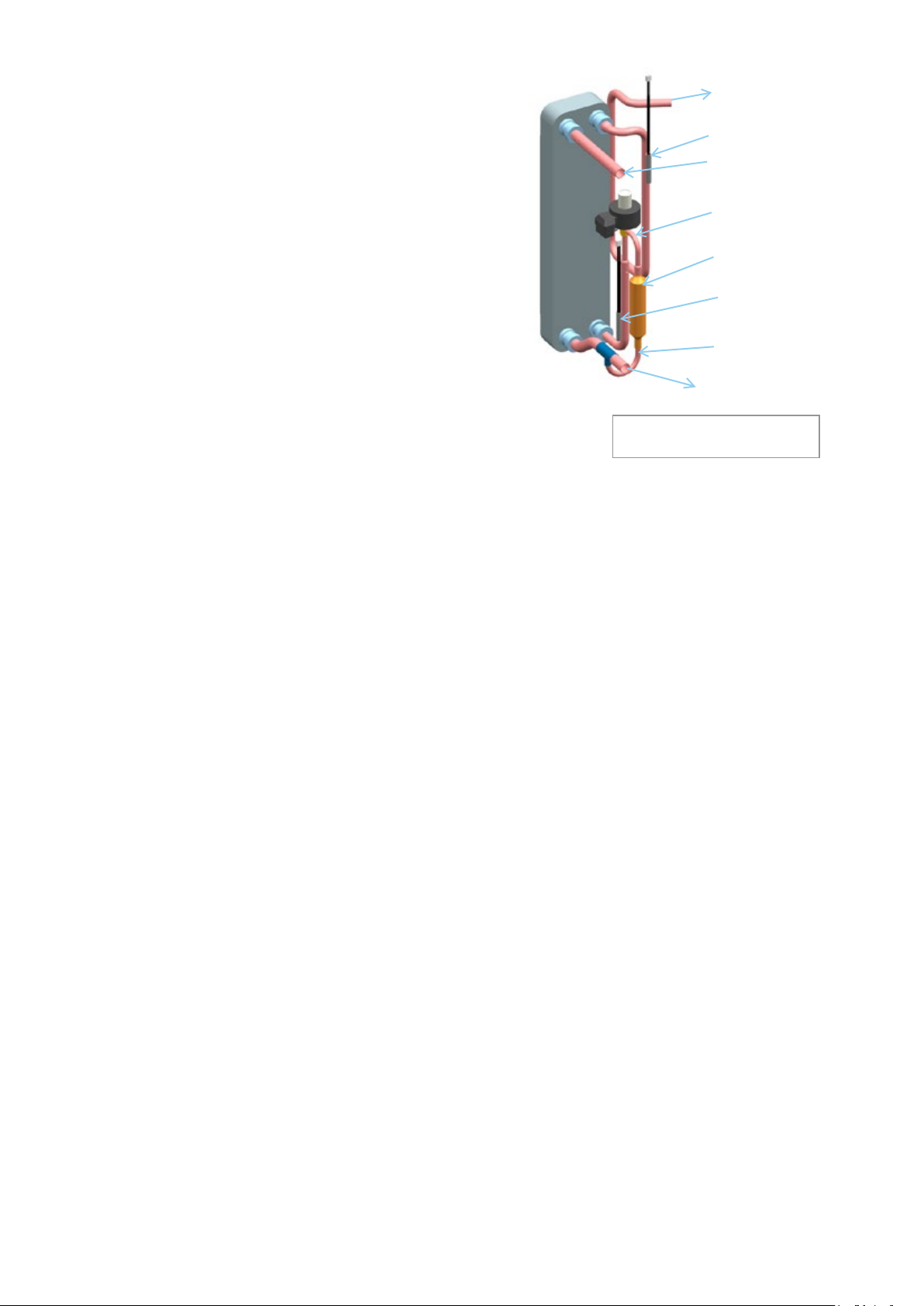

Plate heat exchanger (PHE) and

liquid line temperature

Vapor-out

to compressor

Mount plate heat exchanger in the vertical position and

oriented correctly. Ensure that sensors are located correctly

as well.

ZFI vapor injection compressors can deliver very cold liquid

with economizer cycle. The sub-cooling of liquid line calls for

these recommendations:

1. Liquid line pipe connecting the economizer to the

evaporator expansion valve should be well-insulated

separately.

2. The lower liquid line temperature can increase the

evaporator valve capacities. Please follow the valve

manufacturer's recommended liquid temperature

correction factors for proper selection of evaporator

expansion valve. Refer to product catalogue or select

software for liquid line temperature.

Vapor-out sensor

Liquid-in

Liquid-in

to EXV side

Filter

Vapor-in sensor

EXV liquid

supply

Liquid-out

Example of PHE assembly with

downstream liquid supply

23

Page 24

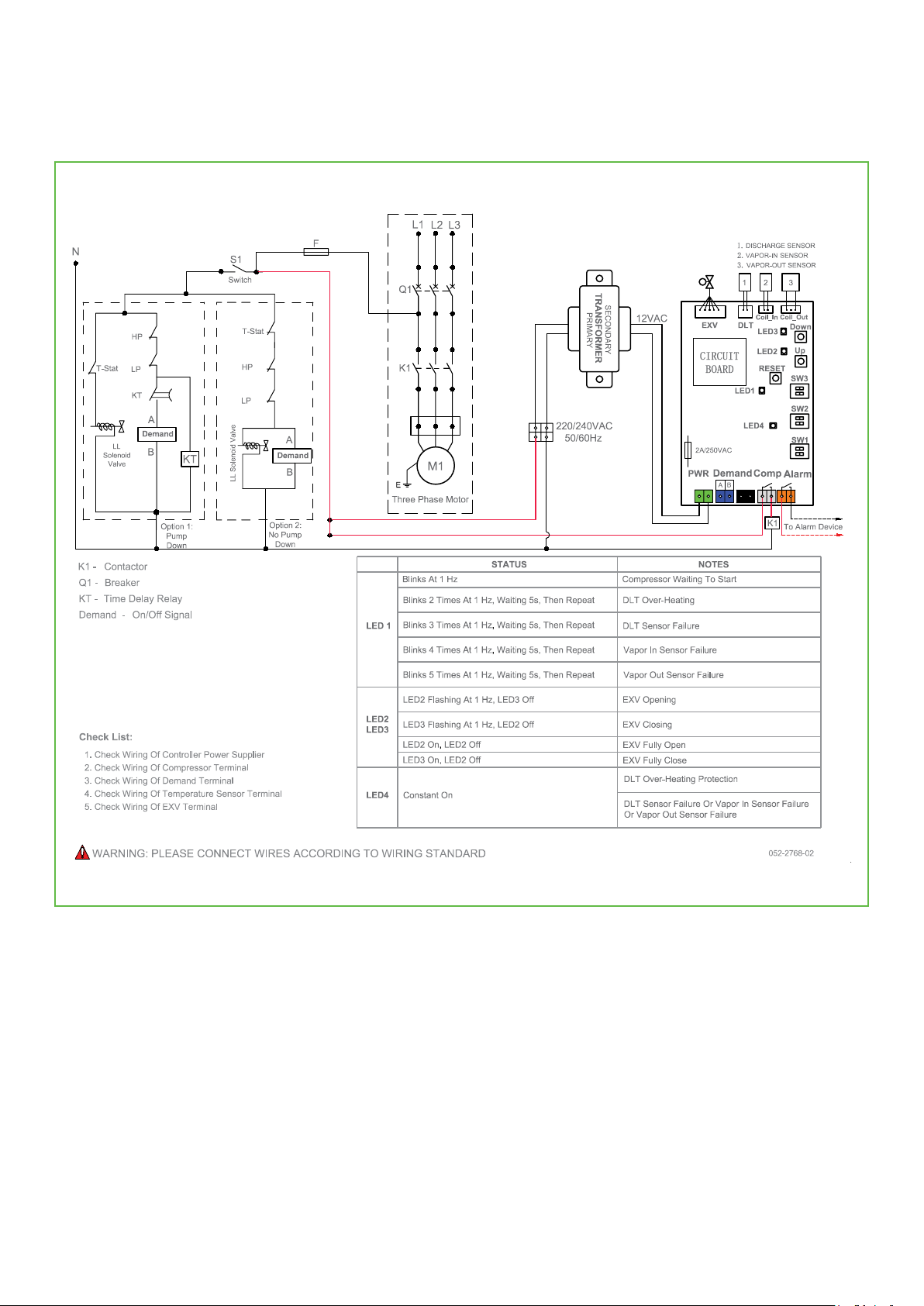

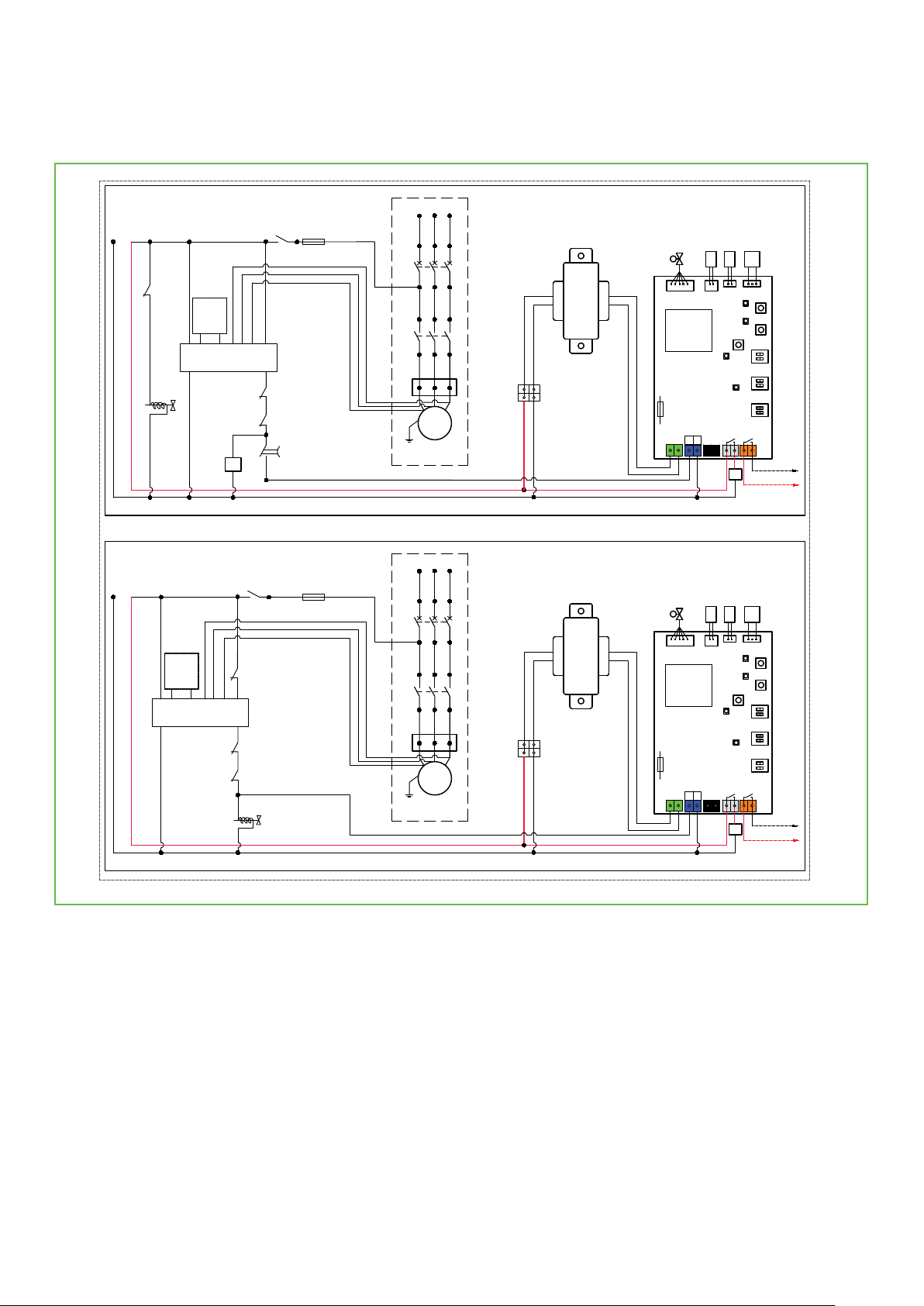

Wiring diagram

ZFI 20 - ZFI81

24

Page 25

ZFI 122

Wiring Diagram (Pump Down)

N

Wiring Diagram (No Pump Down)

N

T-Stat

To DPT

Sensor

T1

CoreSense Module P47

T2

LL

Solenoid

Valve

To DPT

Sensor

T1

T2

L3L2L1

CoreSense Module P47

Discharge Sensor

EXV

控制板

CIRCUIT

CIRCUIT

BOARD

2A/250VAC

EXV DLT

CIRCUIT

BOARD

2A/250VAC

PWR

1.

2.

3.

DLT

LED1

DemandPWR

A B

1.

2.

3.

LED1

Demand

B

A

Vapor-in Sensor

Vapor-out Sensor

1

2 3

Coil_In Coil_Out

LED3

LED2

RESET

LED4

Comp

K1

Discharge Sensor

Vapor-in Sensor

Vapor-out Sensor

1

2 3

Coil_In

LED3

LED2

RESET

LED4

Comp

K1

Down

Up

SW3

SW2

SW1

Alarm

To Alarm Device

Coil_Out

Down

Up

SW3

SW2

SW1

Alarm

To Alarm Device

L1

L2

L3

S1

F

L3L2L1

Switch

M1

Q1

K1

M2

HP

M1

E

Three Phase Motor

L1

L2

L3

Q1

K1

KT

T-Stat

M1

S1

Switch

LP

KT

F

M2

HP

LP

LL Solenoid Valve

M1

E

Three Phase Motor

220VAC

50/60Hz

220VAC

50/60Hz

TRANSFORMER

SECONDARY

PRIMARY

TRANSFORMER

SECONDARY

PRIMARY

12VAC

12VAC

25

Page 26

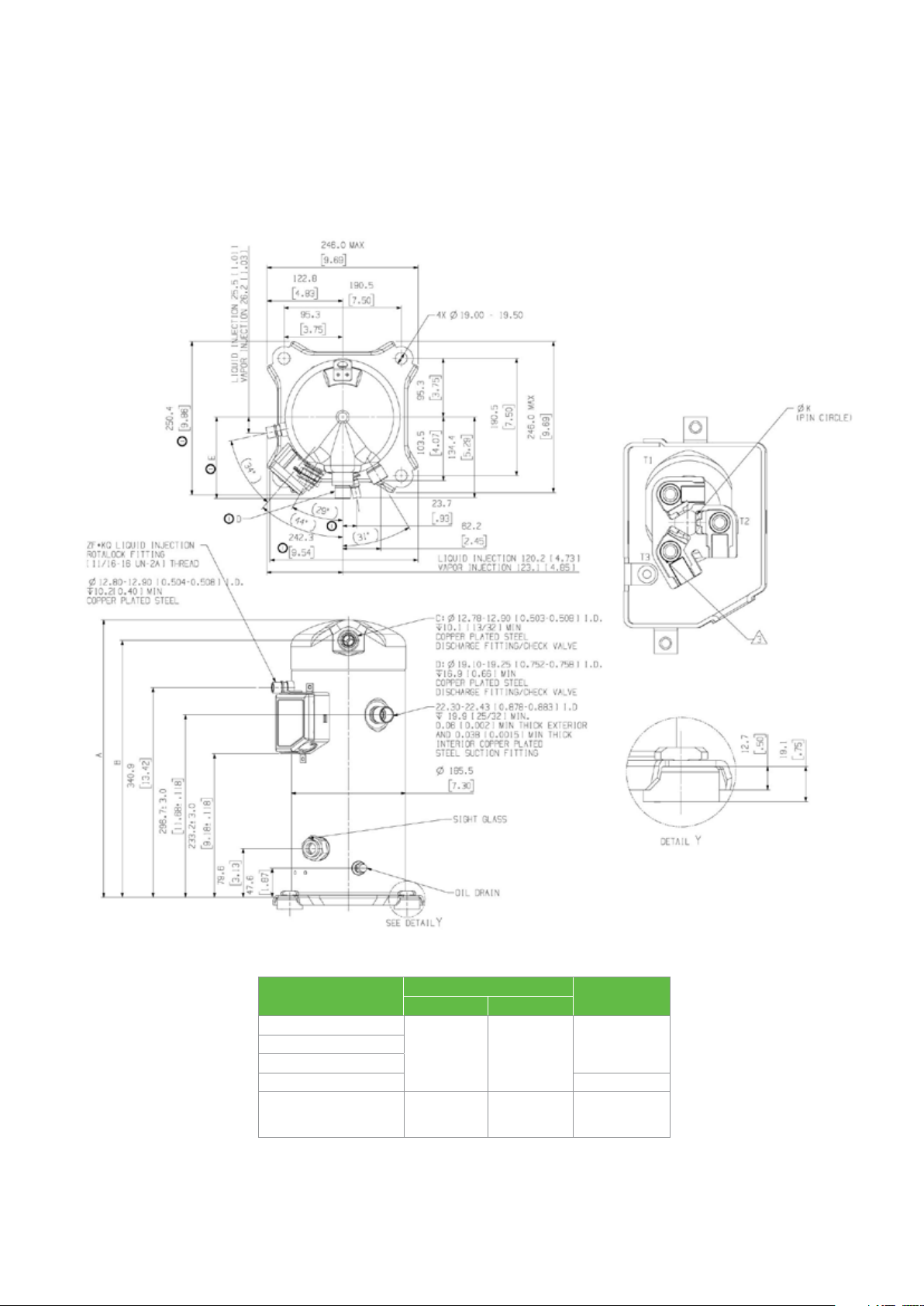

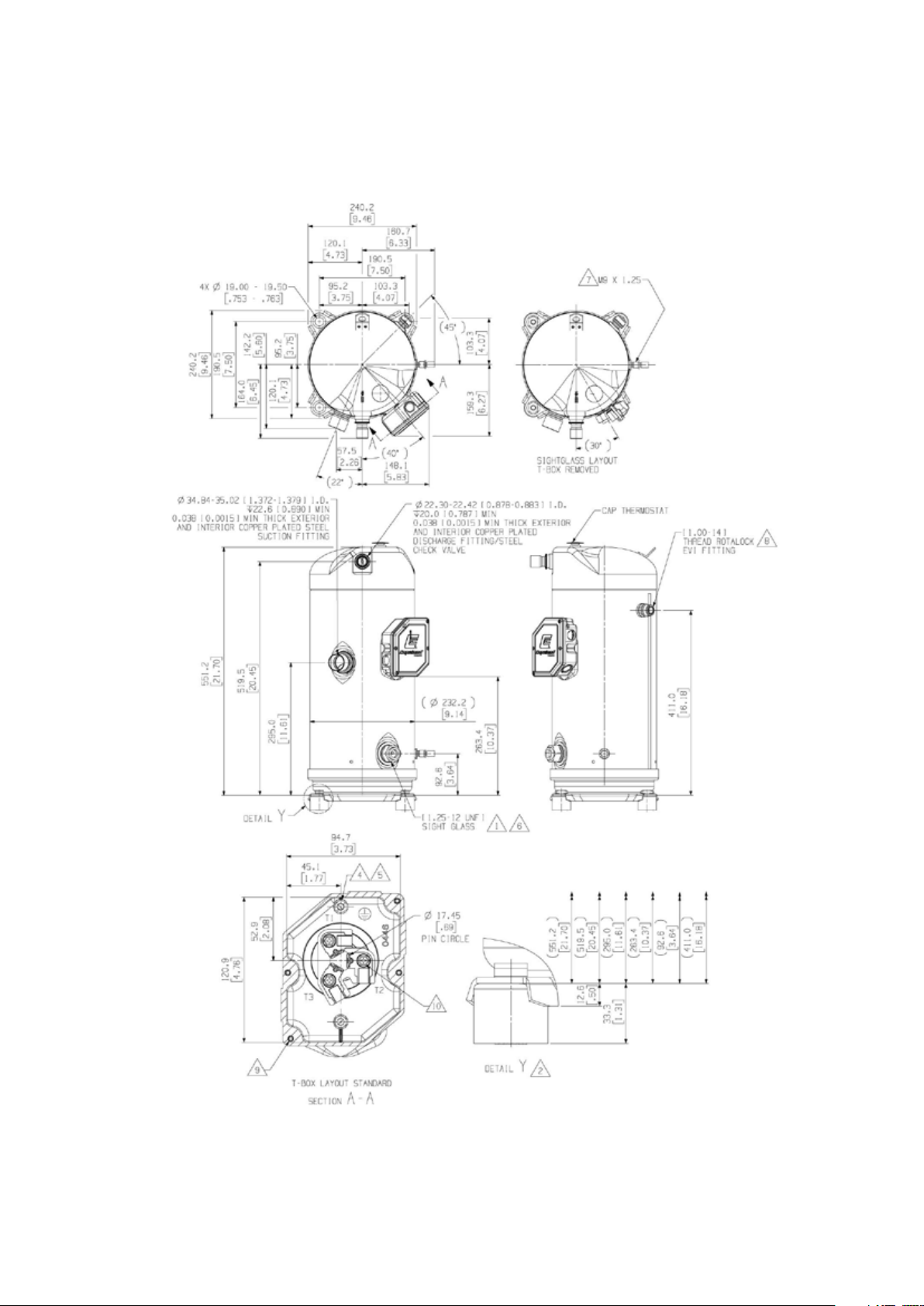

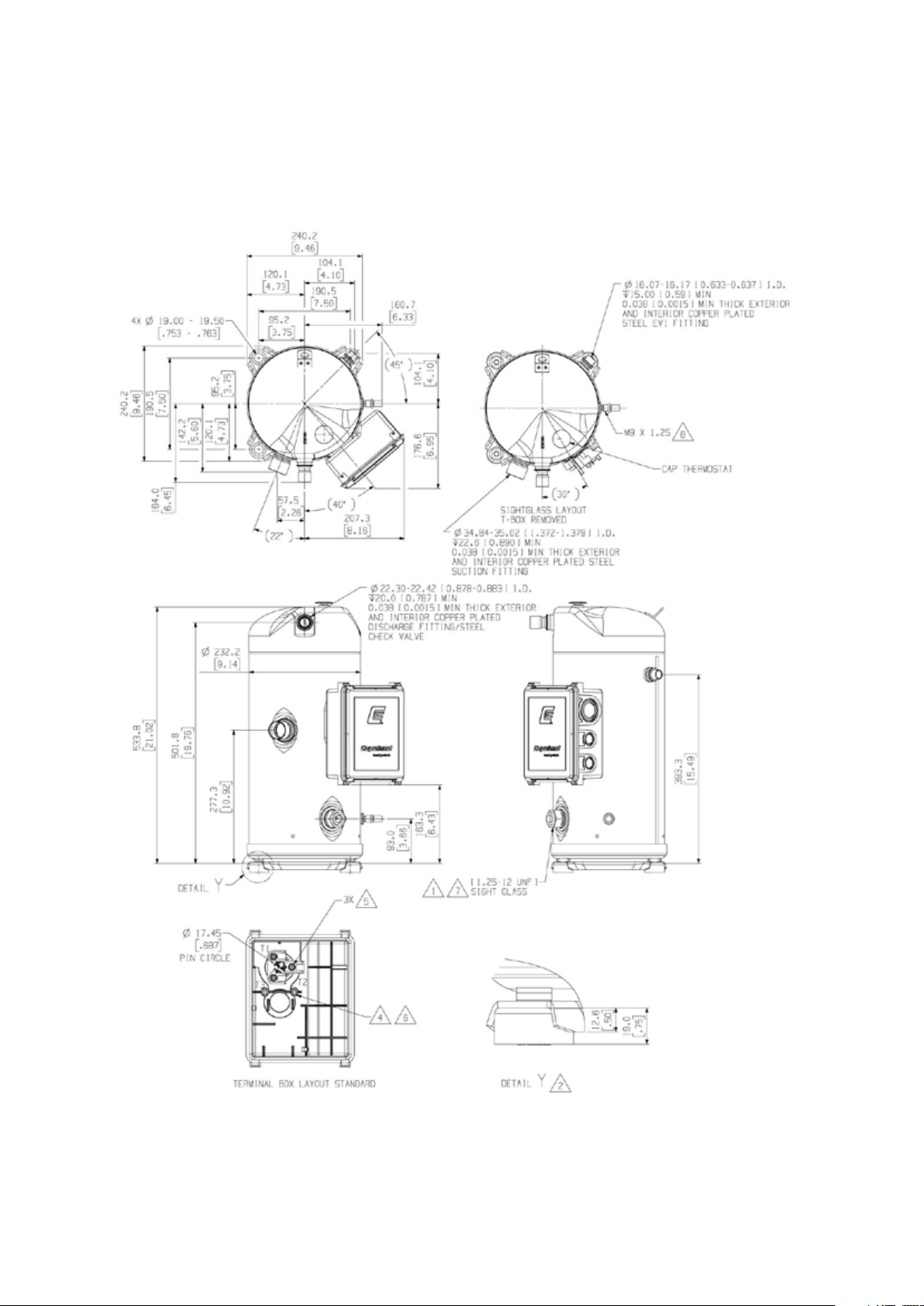

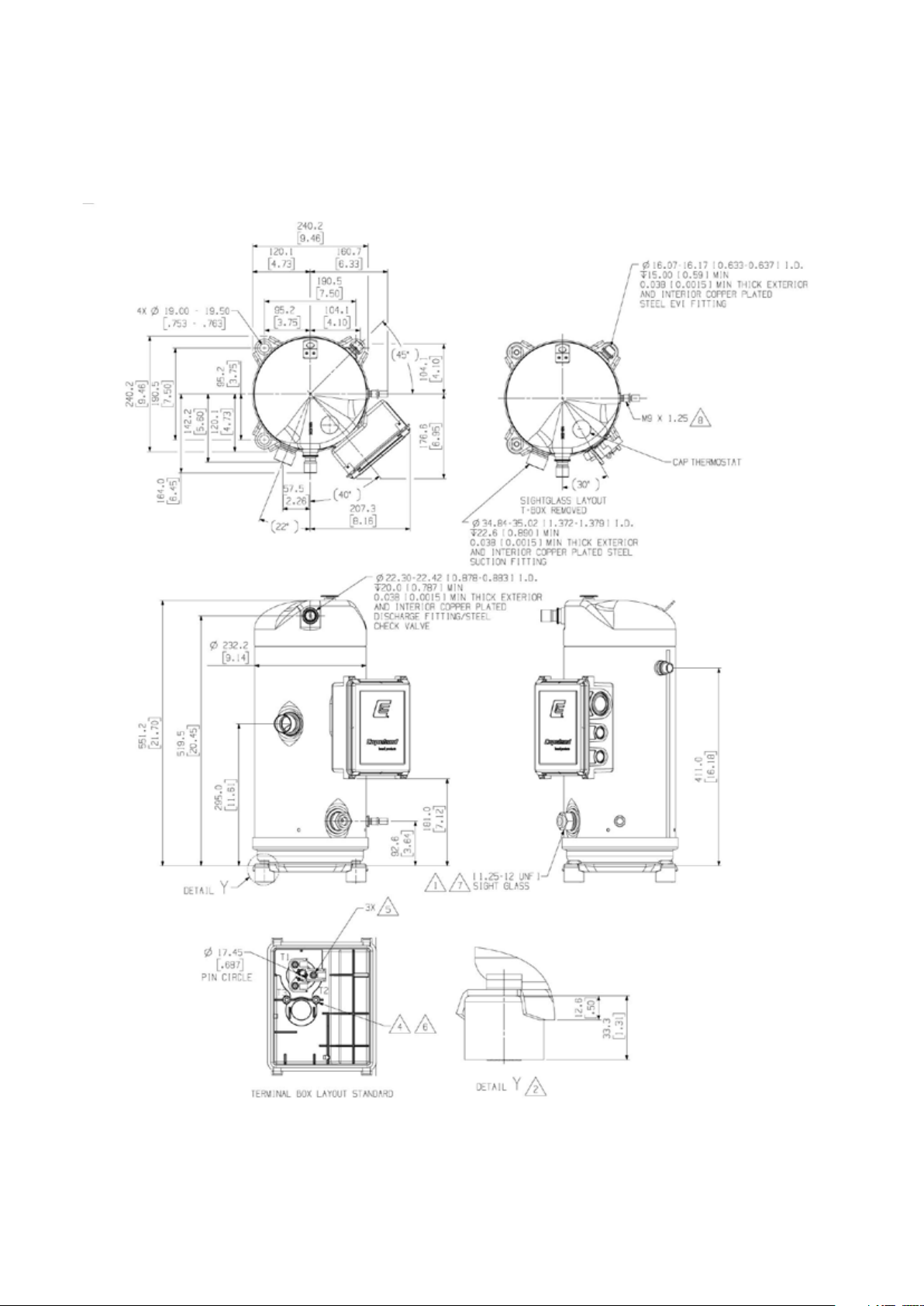

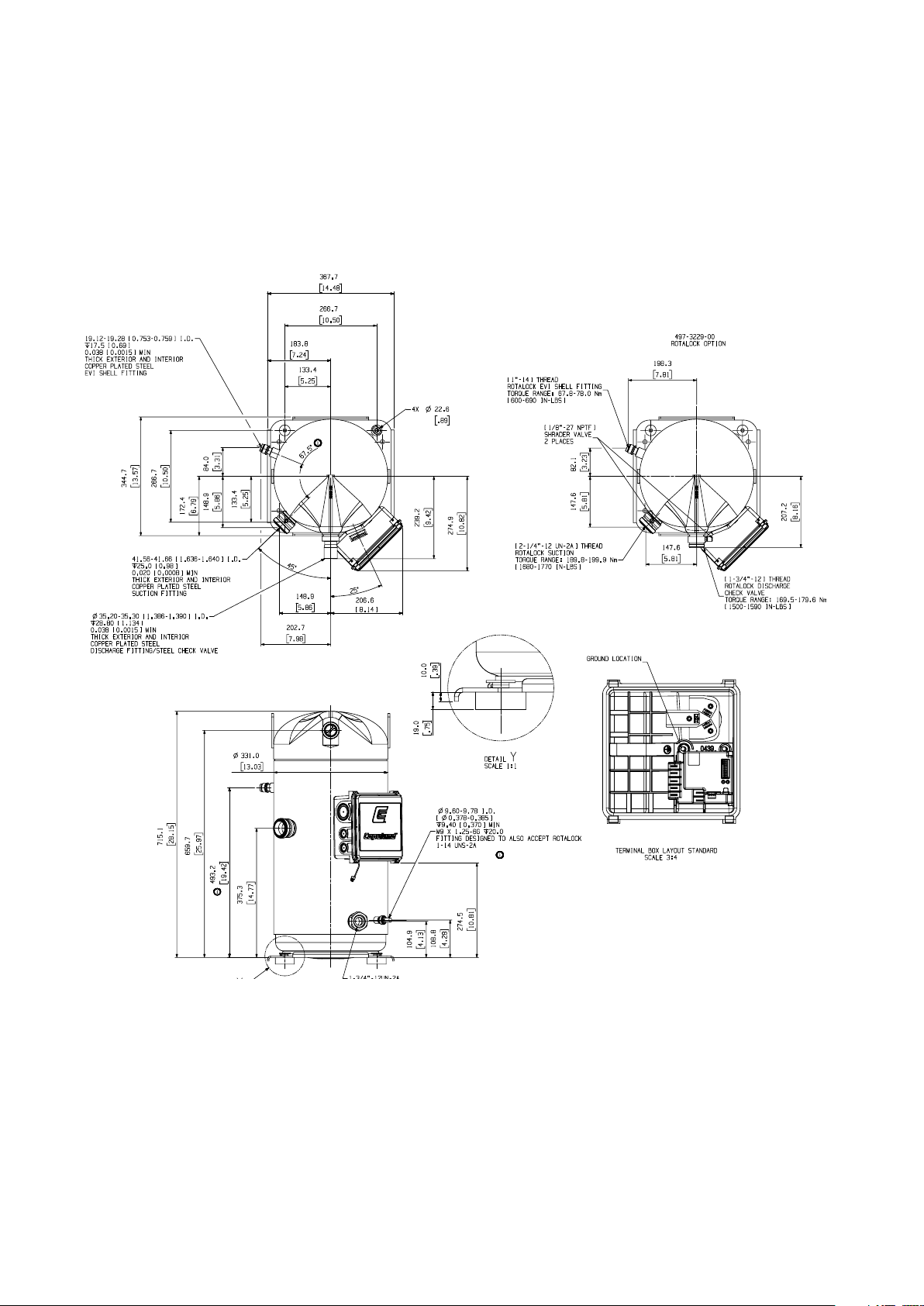

Dimensional drawings

ZF06KQE - ZF11KQE (BOM 551)

Rotalock connection

Model number

mm[in]

A±3.0 B C D±3.0 E F G

ZF06KQE

ZF08KQE

ZF09KQE

ZF11KQE

Notes:

(1) All tolerances ± 1.5mm [0.06in] unless otherwise specified

(2) Due to accumulated assembly tolerances, the listed components may vary from the mounting holes. All fittings: ± 3.0mm [0.12in]

(3) Tube ends must be plugged

(4) All units are in mm[inch]

368.7

[14.52]

391.3

[15.41]

391.3

[15.41]

405.0

[15.94]

343.1

[13.51]

365.7

[14.40]

365.7

[14.40]

379.4

[14.94]

243.8

[9.60]

263.7

[10.38]

263.7

[10.38]

276.4

[10.88]

202.2

[7.96]

222.1

[8.74]

222.1

[8.74]

234.8

[9.24]

279.4

[11.00]

302.0

[11.88]

302.0

[11.88]

315.7

[12.42]

[2.71]

[2.93]

[2.93]

[2.93]

26

68.9

74.6

74.6

74.6

43.4

[1.70]

49.1

[1.93]

49.1

[1.93]

49.1

[1.93]

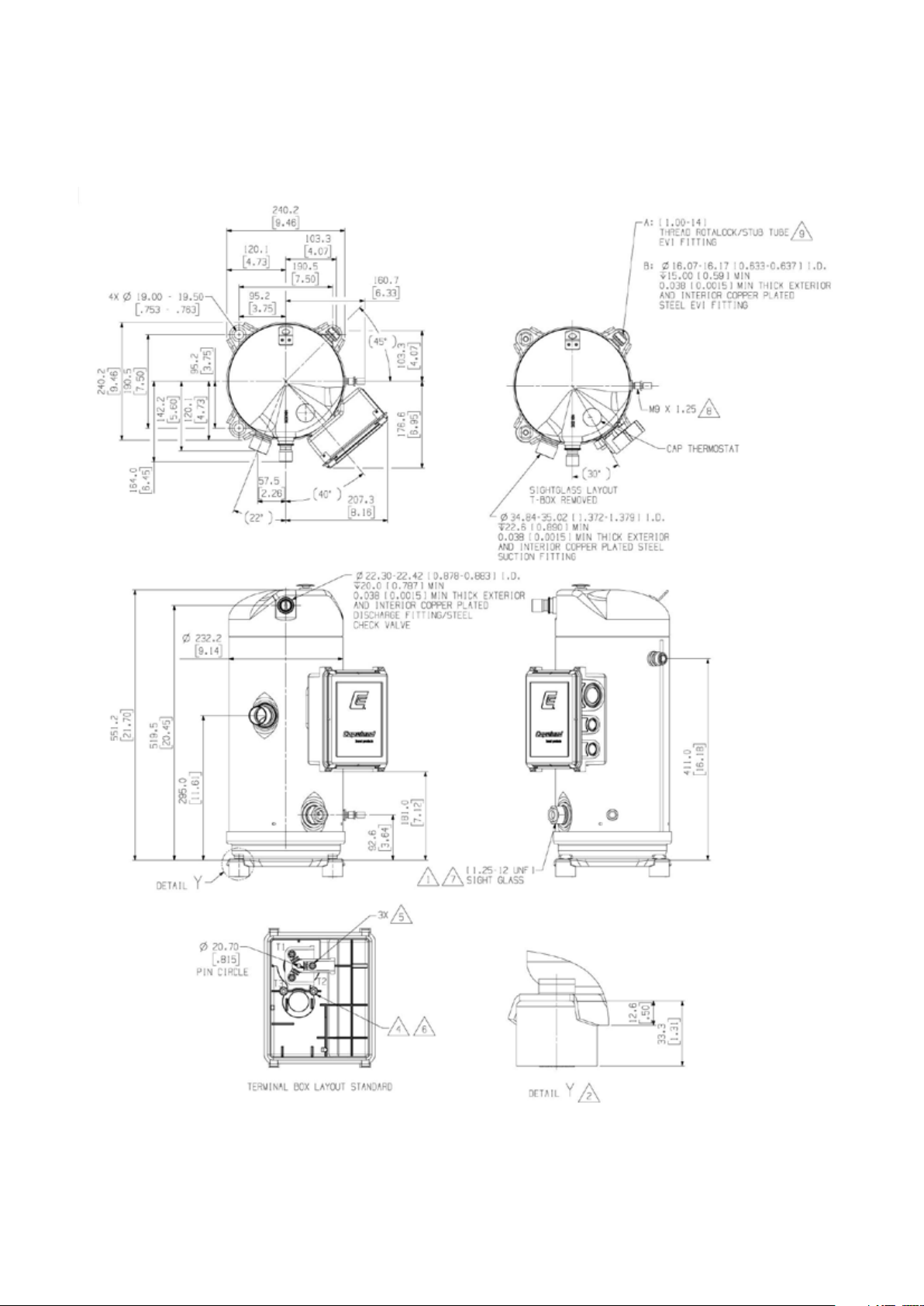

Page 27

Dimensional drawings

ZF13KQE - ZF28KQE (BOM 551)

Rotalock connection

Model number

mm[in]

A±3.0 B±3.0

ZF13KQE

442.0

ZF18KQE

ZF25KQE D

ZF28KQE

Notes:

(1) All tolerances ± 1.5mm [0.06in] unless otherwise specified

(2) Due to accumulated assembly tolerances, the listed components may vary from the mounting holes. All fittings: ± 3.0mm [0.12in]

(3) Tube ends must be plugged

(4) All units are in mm[inch]

[17.40]

451.0

[17.76]

409.6

[16.13]

418.6

[16.48]

Discharge

fitting

CZF15KQE

D

27

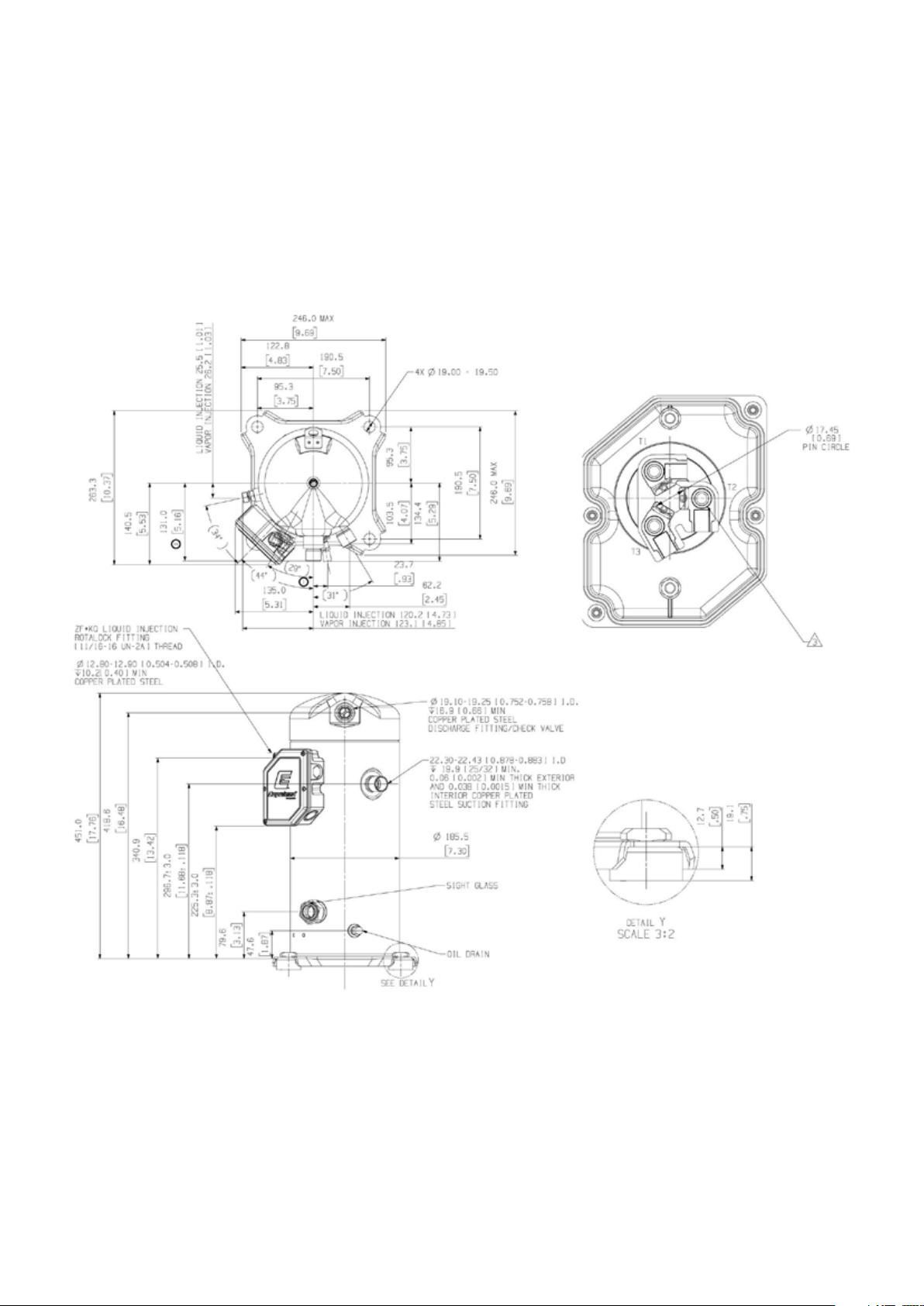

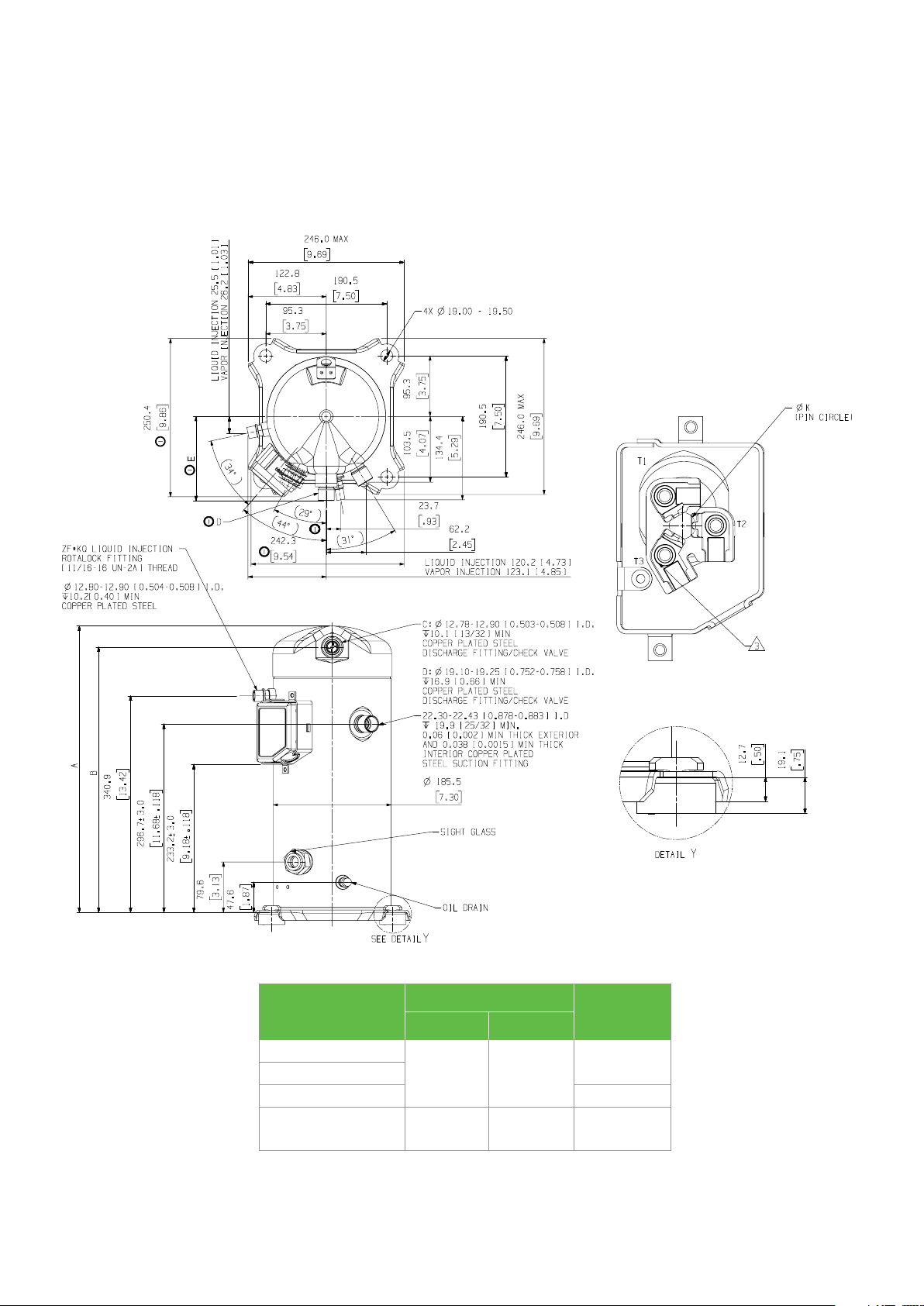

Page 28

Dimensional drawings

246.0 MAX

250.2

ZFI20KQE - ZFI39KQE (BOM 552)

Rotalock connection

[9.69]

122.8

[4.83]

123.1

[9.85]

B

(34º)

26.2

[1.03]

[4.85]

95.3

[3.75]

190.5

[7.50]

95.3

126.9

[3.75]

[5.00]

THERMOSTAT

TUBE

190.5

[7.50]

[9.69]

246.0 MAX

122.8

[4.80]

Ø K

(PIN CIRCLE)

47.6

[1.87]

241.2

[9.50]

(31º)

76.2

[3.00]

ØA THREAD ROTALOCK

SPUD DISCHARGE

31.75[1.25-12] THREAD

ROTALOCK SPUD

SUCTION

Ø 185.5

[7.30]

SIGHT GLASS

PER BOM

OIL DRAIN

12.7

[0.75]

[0.50]

(ROTALOCK)

DETAIL

19.1

VAPOR INJECTION FITTING

(BRAZED) [0.50 I.D.]

VAPOR INJECTION FITTING

[1.00-14 UNS-2A] THREADS

PER BILL OF MATERIAL

FOOT

OR

29º

(44º)