Page 1

Copeland Scroll™ Compressor

ZBKQ for Refrigeration Applications

Product Catalogue

1

Page 2

Table of contents

Features and benefits

Nomenclature 05

Bill of material 05

Operating envelopes 06

Product line-up 08

Performance data 09

Technical data 46

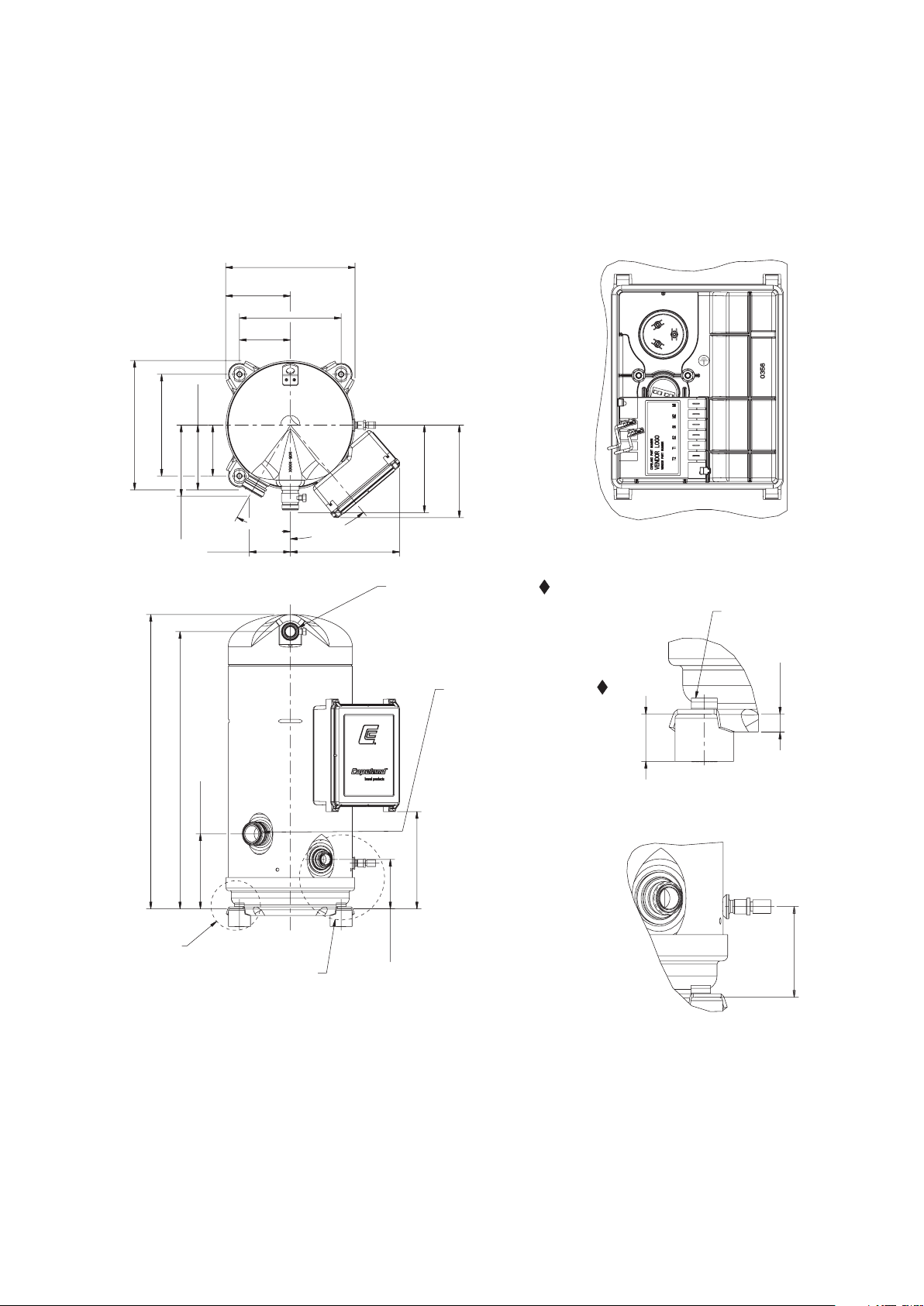

Dimensional drawings 49

Electrical wiring diagram 64

Quick application guide 66

03

Available models list 76

Contact list 80

2

Page 3

Emerson is the world’s leading compressor manufacturer

Axial compliance

Radial compliance

Fix

Discharge

and is committed to maximizing system efficiency and

protecting the environment. We offer a wide range of

solutions for commercial refrigeration applications. The

Copeland Scroll™ ZB Compressor is widely recognized in

the refrigeration market for its reliability and low running

cost in high and medium temperature applications. The

newly released ZB large refrigeration scroll compressor

expands the current ZB product line to 30 HP and is

optimized for medium temperature applications for

best-in-class seasonal energy efficiency. ZB refrigeration

scrolls offer customers an excellent solution to replacing

traditional semi-hermetic compressors and lead the

transition to scroll technology.

Dual compliance

Compliance means sealing between the orbiting and

fixed scroll involutes. Dual compliance means the

sealing is on both the axial and radial directions. This

prevents refrigerant leak back across successive scroll

pressure pockets. Compliance design also allows the

scroll involutes to separate in both the radial and axial

directions. This allows debris or liquid refrigerant to

pass through the scroll involutes without damaging the

compressor. Benefits of Dual Compliance are:

• Increased efficiency

• Better liquid handling capability

• Better handling of debris

Features and benefits

Robust and reliable

Copeland Scroll compressors have 70% fewer moving

parts than reciprocating compressors and feature a scroll

Compliance mechanism which makes them particularly

robust and reliable under severe conditions including

liquid slugging.

ed scroll

Suction

Orbiting

scroll

3

Page 4

Scroll wear in

Compactness

The scroll involutes of Copeland scroll compressor wear

in, rather than wear out. So unlike in other compressor

technologies among similar categories, there is no

constant degradation of performance with time due

to wear out.

Lower sound, vibration and pulsation

The compression process in a scroll set is symmetrical and

continuous. This inherently reduces the sound, vibration

and pulsation. This eliminates the need for use of

vibration absorbers and suction or discharge mufflers in

most of the applications. In further, ZB scroll compressors

are engineered to produce smooth sound spectrum

which improves the quality of sound.

Unloaded start

The scroll sets separate at the instant of compressor

shutdown. This allows the scroll set internal pressures

to equalize on compressor stops. In addition to this, the

scroll sets are not engaged at the instant of starting.

Scroll sets engage only after few milliseconds of startup.

This allows easier startup of ZB scroll compressors. Due

to this design feature, typically a start assist kit is not

required even on single phase compressors.

Copeland Scroll have the advantage of light weight and

compactness with small footprint, making them ideal

for the usage in condensing units, compact refrigeration

systems or special process units. Weight and dimensions

for refrigeration equipment is reduced accordingly.

High efficiency all year round

Copeland ZB Scroll is designed for medium-high

temperature refrigeration and process cooling

applications. Motor, scroll and bearing are optimized for

high seasonal efficiency, which helps end user reduce life

cycle cost all year round.

Multiple refrigerants

ZB compressors are approved for R404A, R507, R22,

R134a, R407F, R448A and R449A refrigerants.

DU bearings

A space age bearing material comprising of porous

bronze with PTFE-lead overlay. These bearings are used

in ZB scroll compressors in the scroll drive and main

bearings. DU bearings work with exceptionally low

friction between the load bearing surfaces. In addition,

DU bearings can operate safely for a short time with

loss of lubrication. This situations could happen on

compressor applications due to oil pump out during a

flooded start or heavy oil dilution after a defrost cycle.

2

Crankshaft

1

4

Page 5

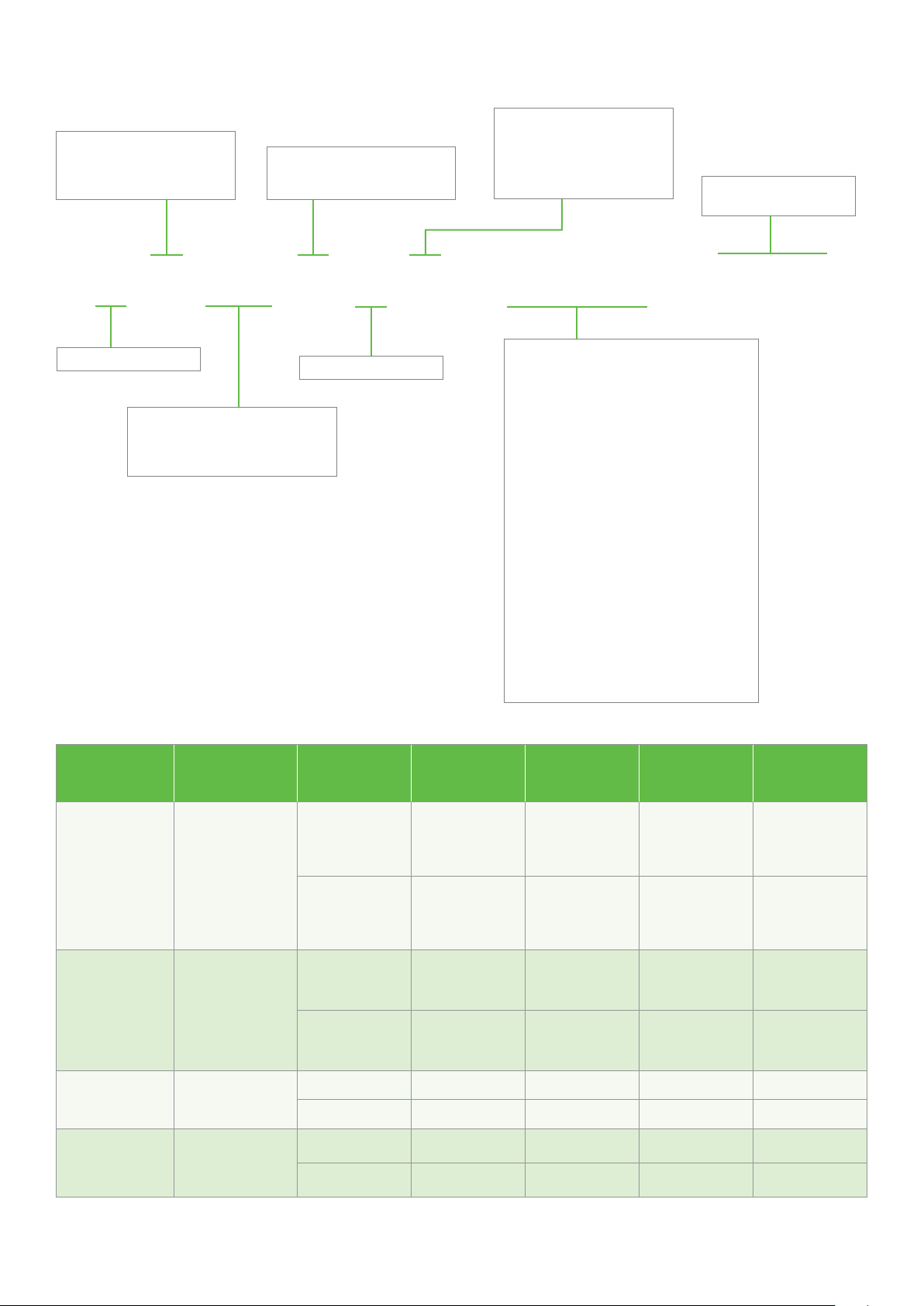

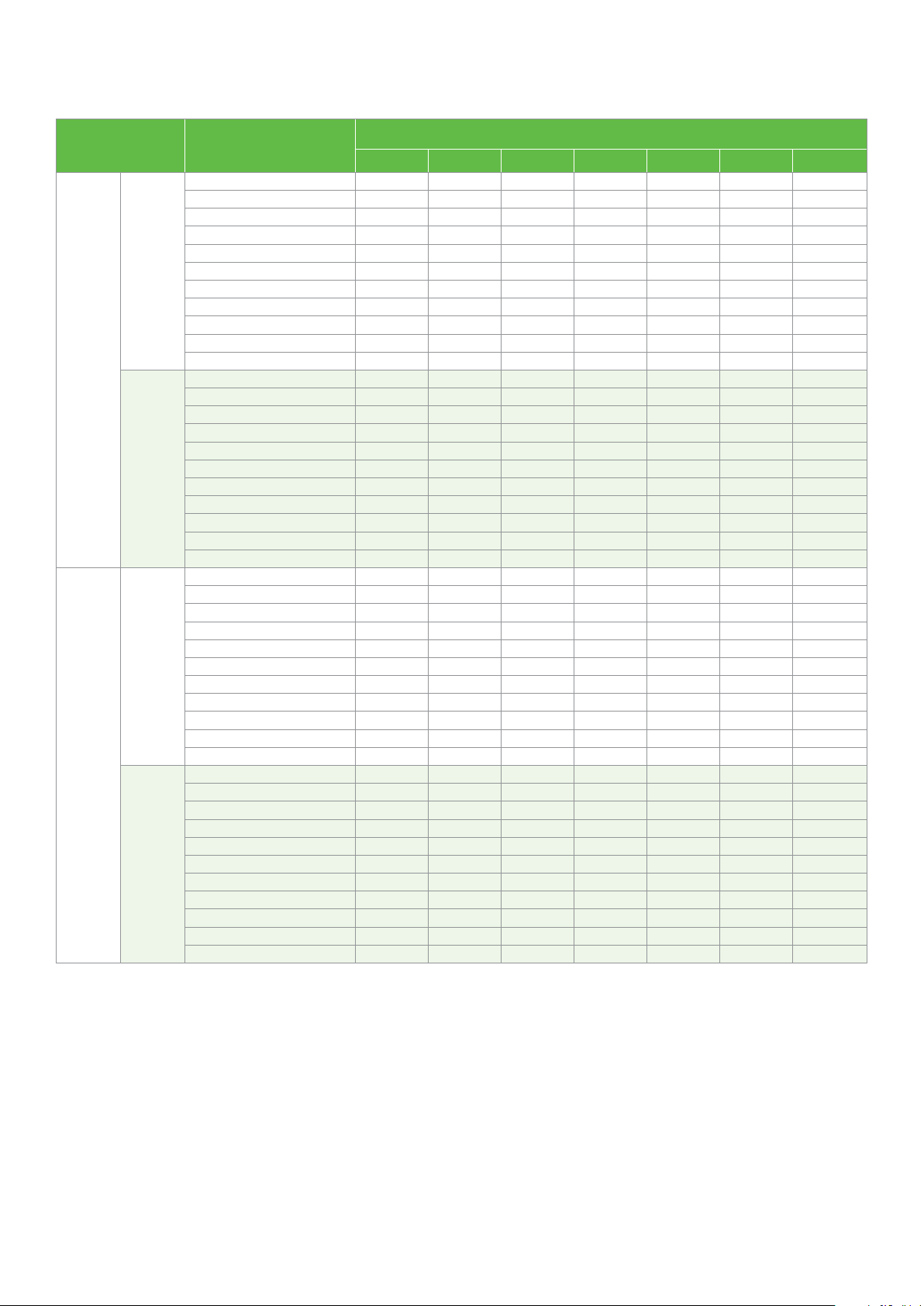

Nomenclature

Lubricant

Medium temperature

refrigeration

Base capacity multiplier

K 1000

Blank Mineral oil

E POE oil

Bill of materials

Z B 76 K Q E - T F D - XXX

Scroll family

Base capacity @ MT rating

(Btu/hr)@60 Hz (ARI)

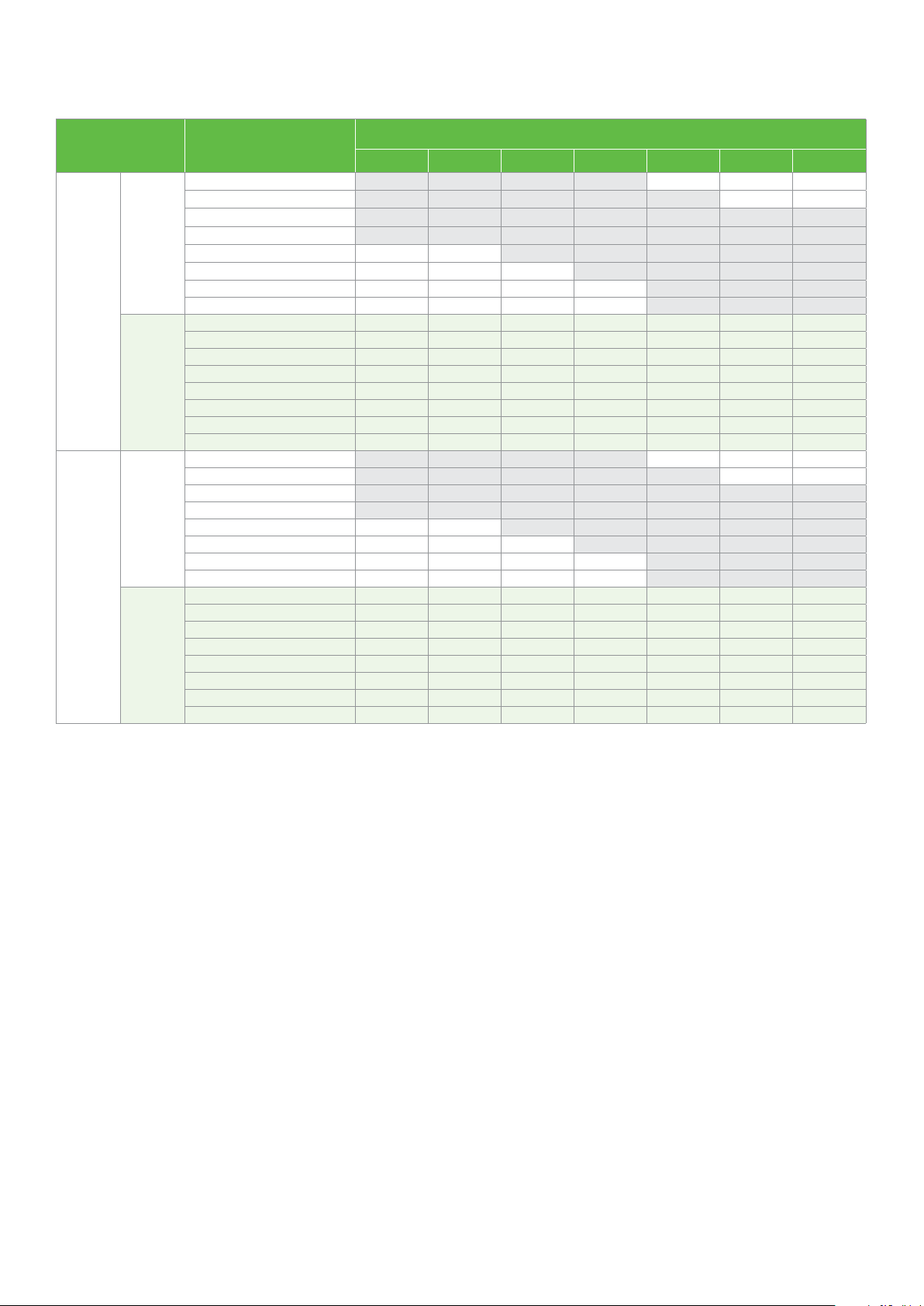

Bill of material

Compressor

model

Motor

code

Generation

BOM

number

Stub tube

connection

Motor voltages

Three-phase motor

T

P Single phase motor

Motor protection

F Internal inherent protection

W External electronic protection

E External enhanced

Electrical codes

50 Hz 60 Hz

J 220-240V 265V

V 200V 208-230V

D 380-420V 460V

7 - 380V

5 200-220V 200-230V

C 200V 208-230V

Rotalock

connection

Oil sight

glass

Schrader

valve

ZB15KQ/E

ZB19KQ/E

ZB21KQ/E

ZB29KQ/E

ZB38KQ/E

ZB45KQ/E

ZB48KQ/E

ZB58KQ/E

ZB66KQ/E

ZB76KQ/E

ZB88KQ

ZB95KQ/E

ZB114KQ/E

ZB130KQ/E TED, TE7, TEC

ZB150KQ/E

ZB190KQ/E

ZB220KQ/E

(1) PFJ is available for ZB15-ZB29 only

(2) PFV is available for ZB15-ZB38 only

TFD, TF5, TF7,

PFV, PFJ

TFD, TF5, TF7

(TW5/7 for

ZB95/114)

TWD,TW7,TWC

558

559

550

551

550

551

522

523

✓ ✓

✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

5

Page 6

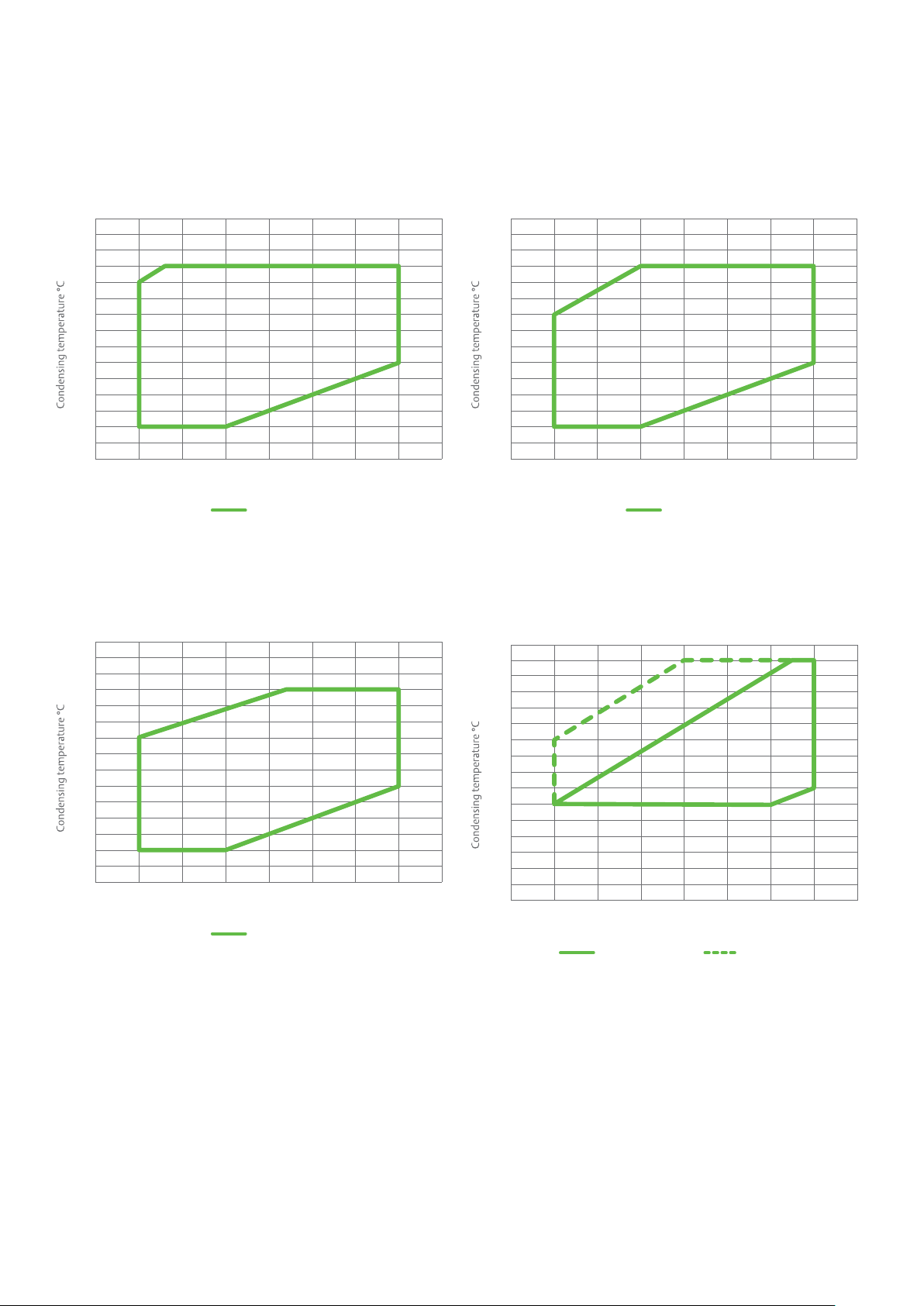

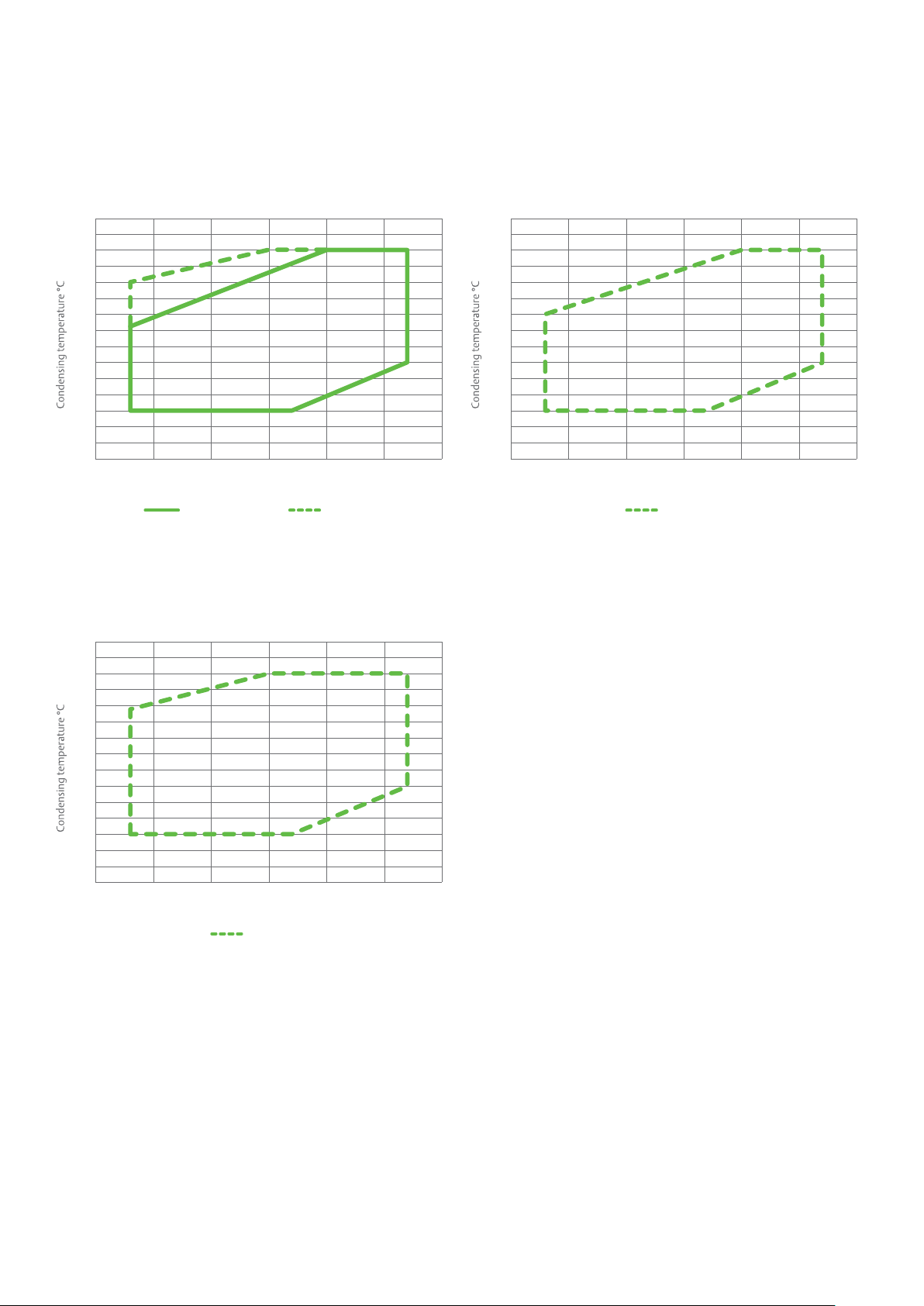

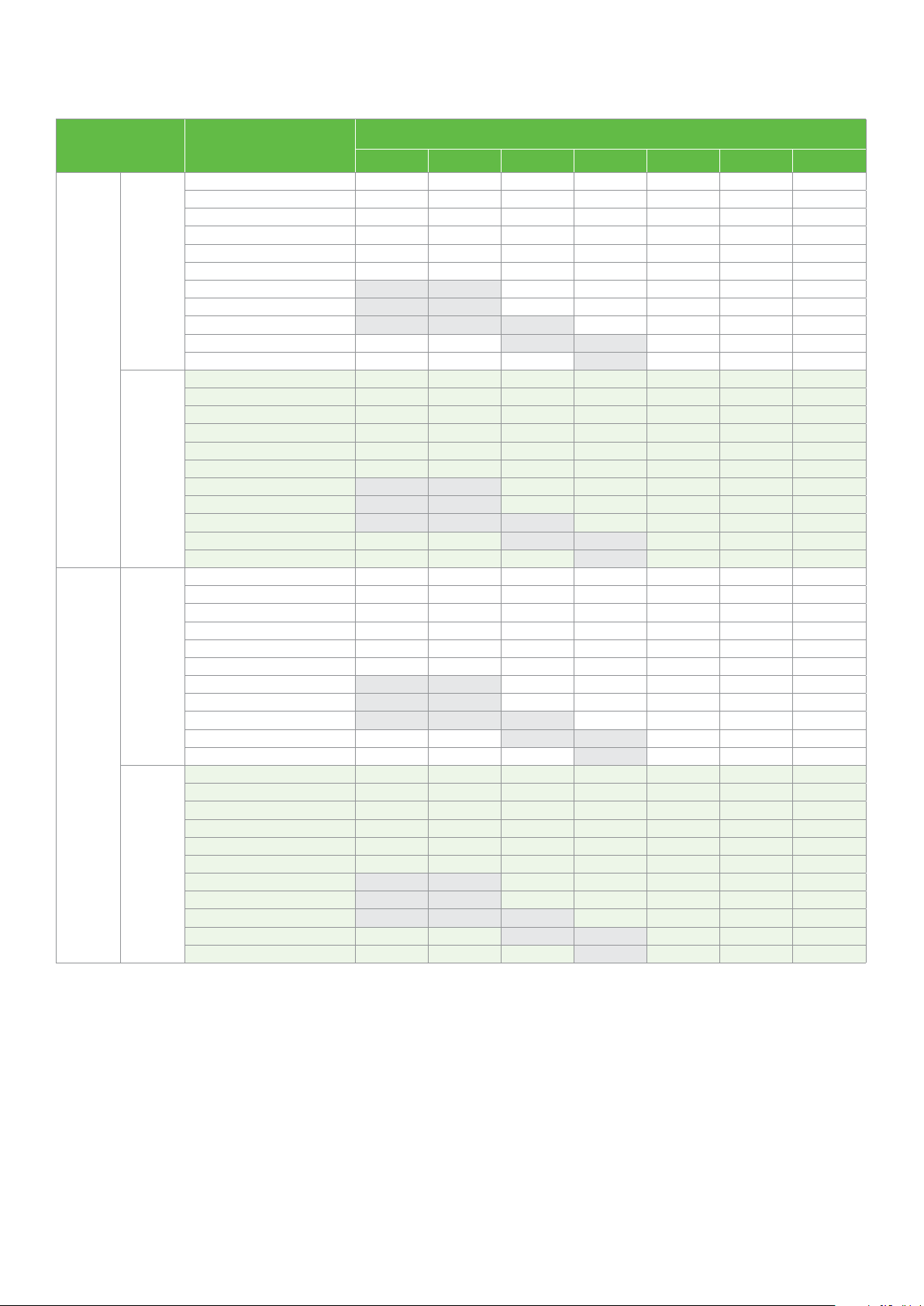

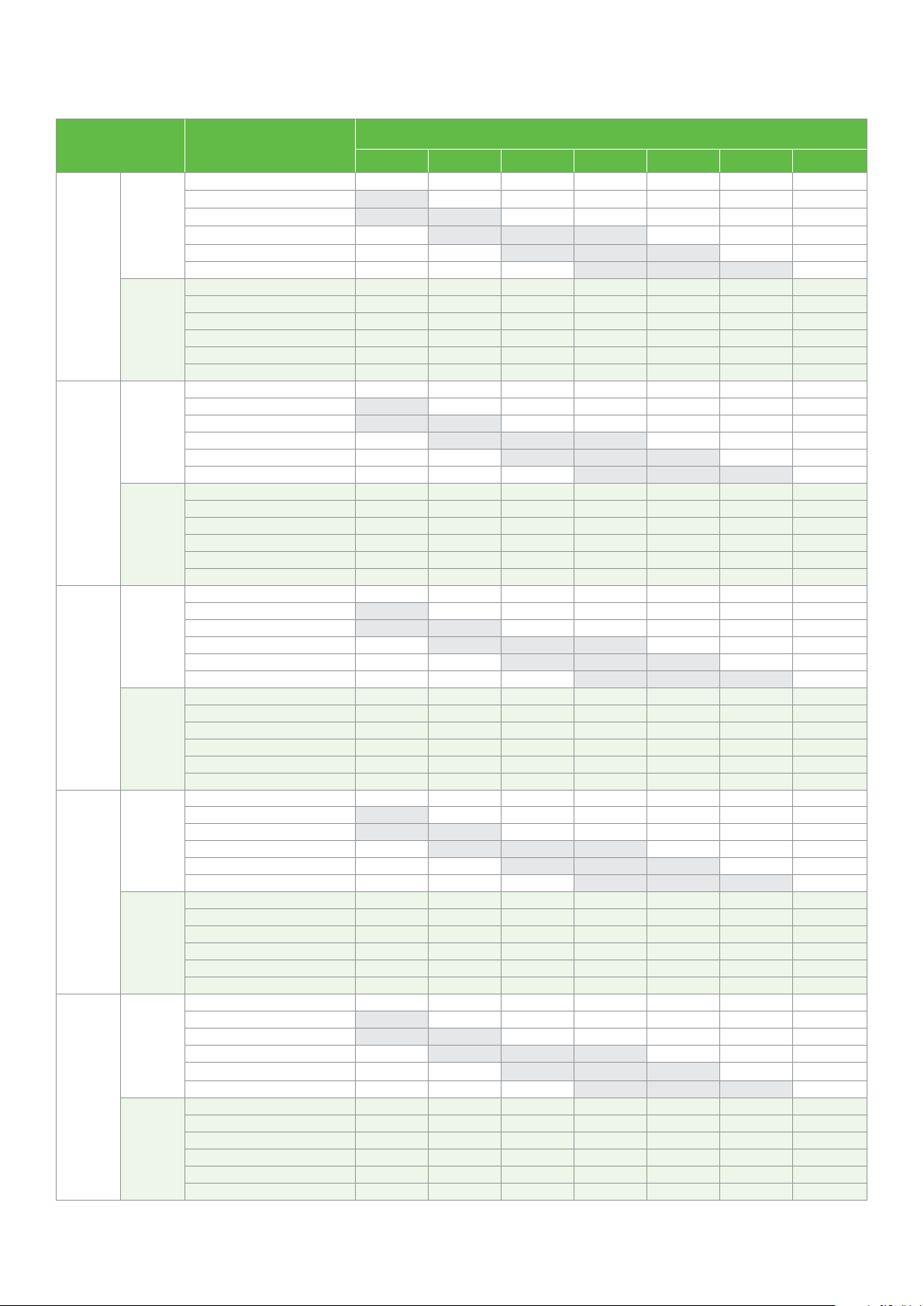

Operating envelopes

0101

R404AZB15KQE~ZB76KQE

20°C Return gas

0101

R404AZB190KQE~ZB220KQE

20°C Return gas

0101

R404AZB95KQE~ZB114KQE, ZB130KQE

20°C Return gas

5152

R134a ZB15KQE~ZB76KQE, ZB130KQE-ZB220KQE

20°C Return gas 11K Superheat

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-25

-20 -15 -10 -5 5

Evaporating temperature °C

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-25

-20 -15 -10 -5 5

Evaporating temperature °C

5

5

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-25

-20 -15 -10 -5 5

Evaporating temperature °C

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-20 -15 -10 -5 010

Evaporating temperature °C

5

0

6

Page 7

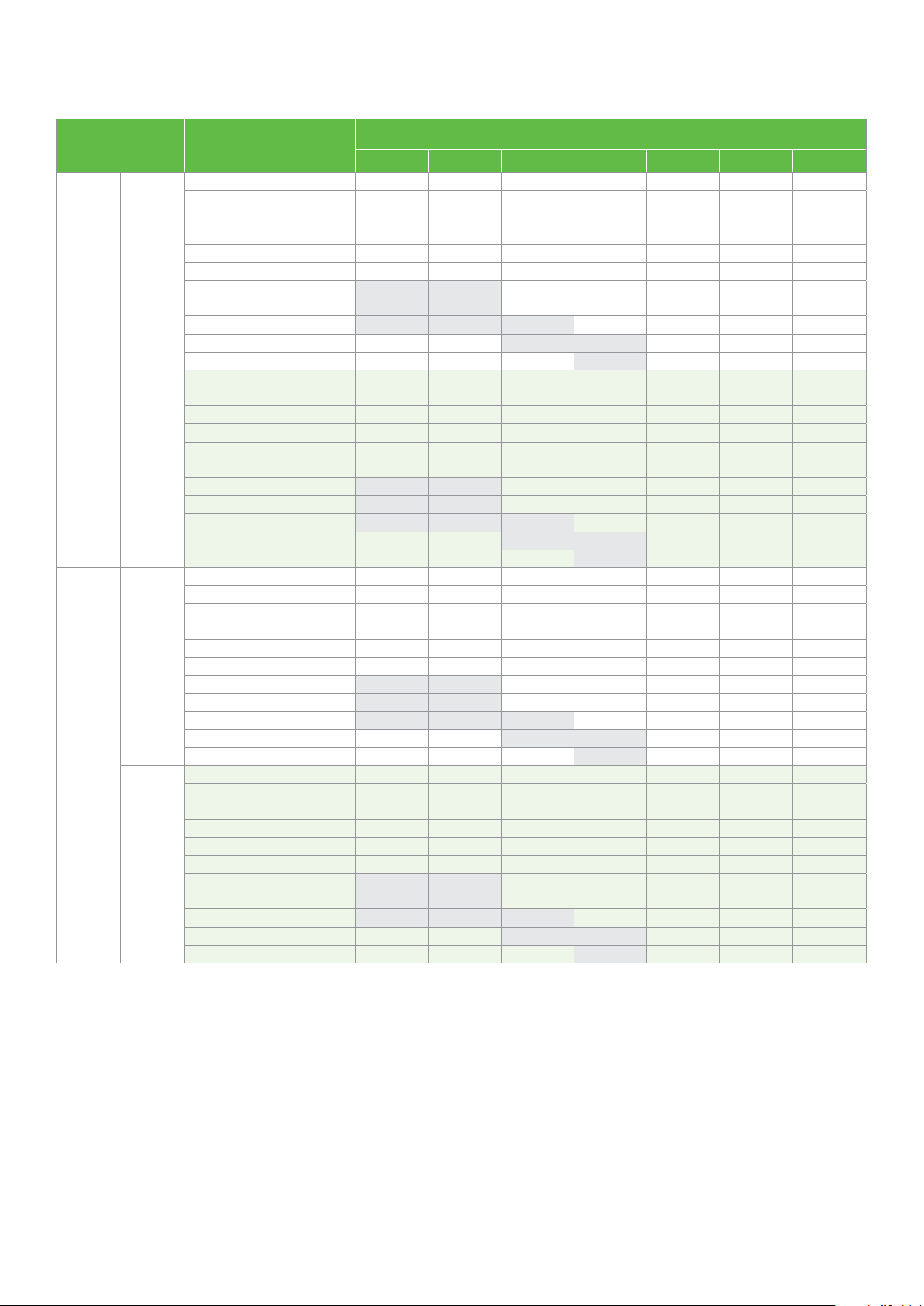

Operating envelopes

0101

R22ZB15KQ~ZB88KQ, ZB130KQ-ZB220KQ

20°C Return gas 11K Superheat

R22ZB95KQ~ZB114KQ (TFD only)

11K Superheat

R22ZB95KQ~ZB114KQ (TW7/TW5)

11K Superheat

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-15

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-15

-10 -5 5

Evaporating temperature °C

-10 -5 0510 15

Evaporating temperature °C

5

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-15

-10 -5 0510 15

Evaporating temperature °C

7

Page 8

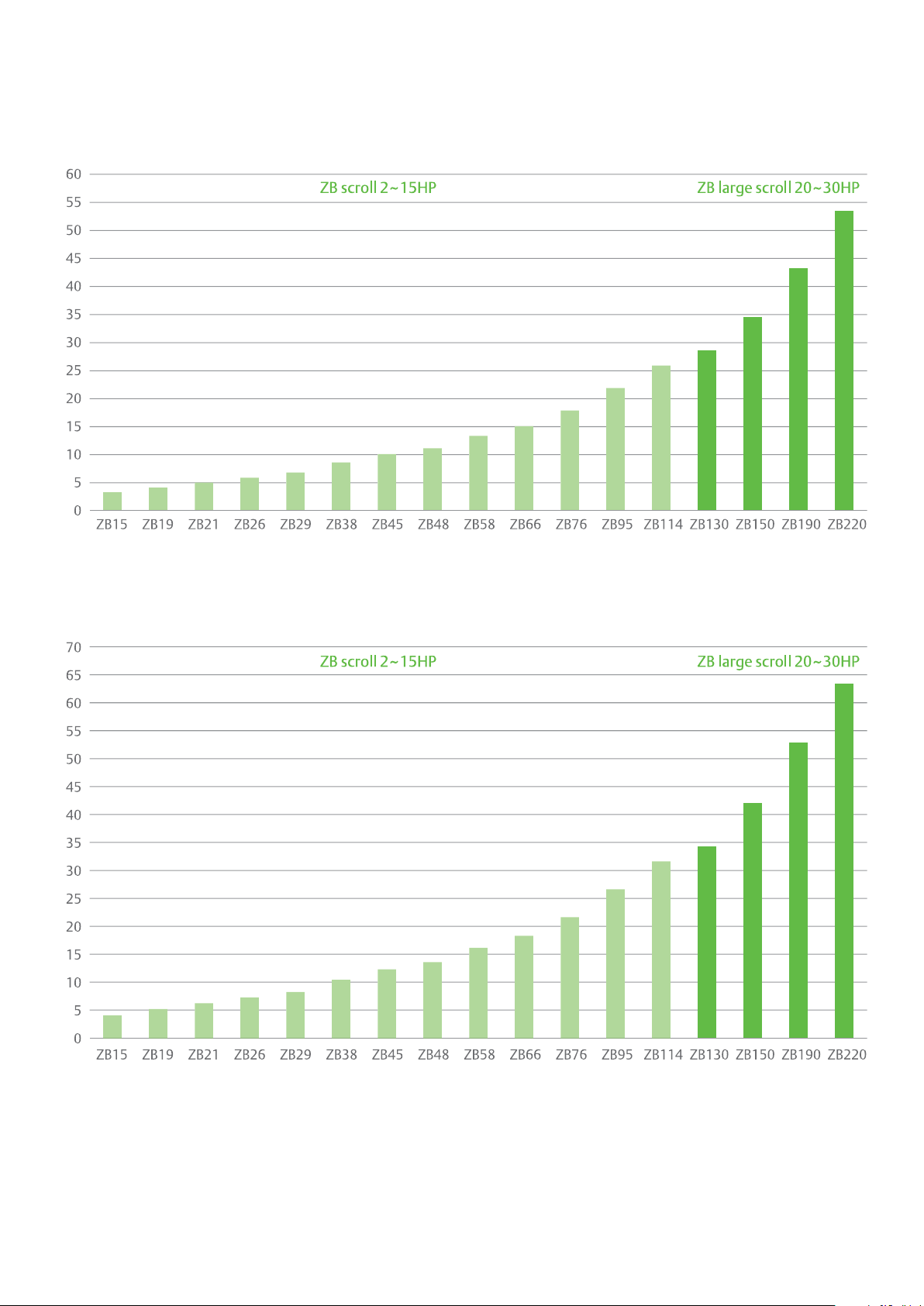

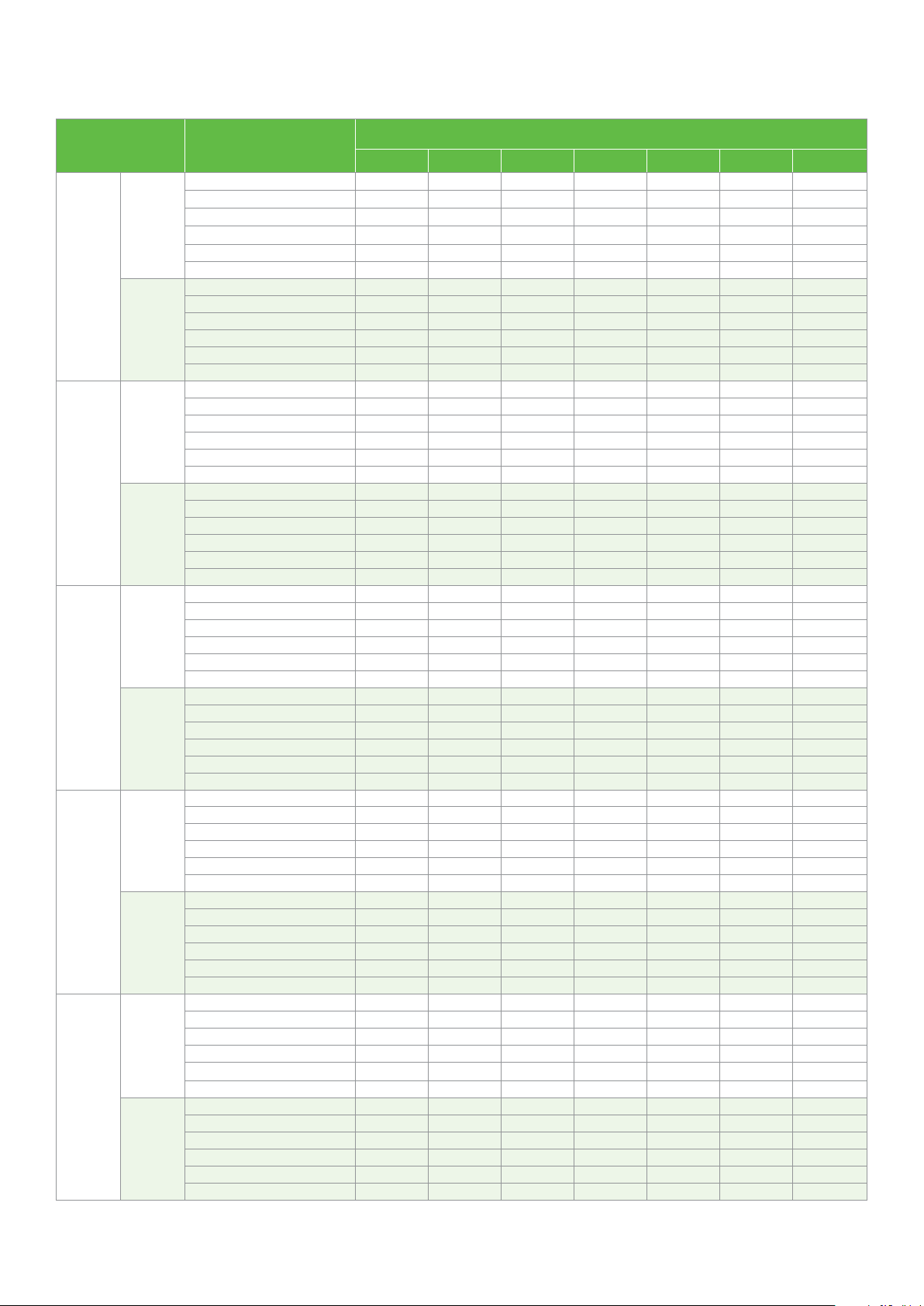

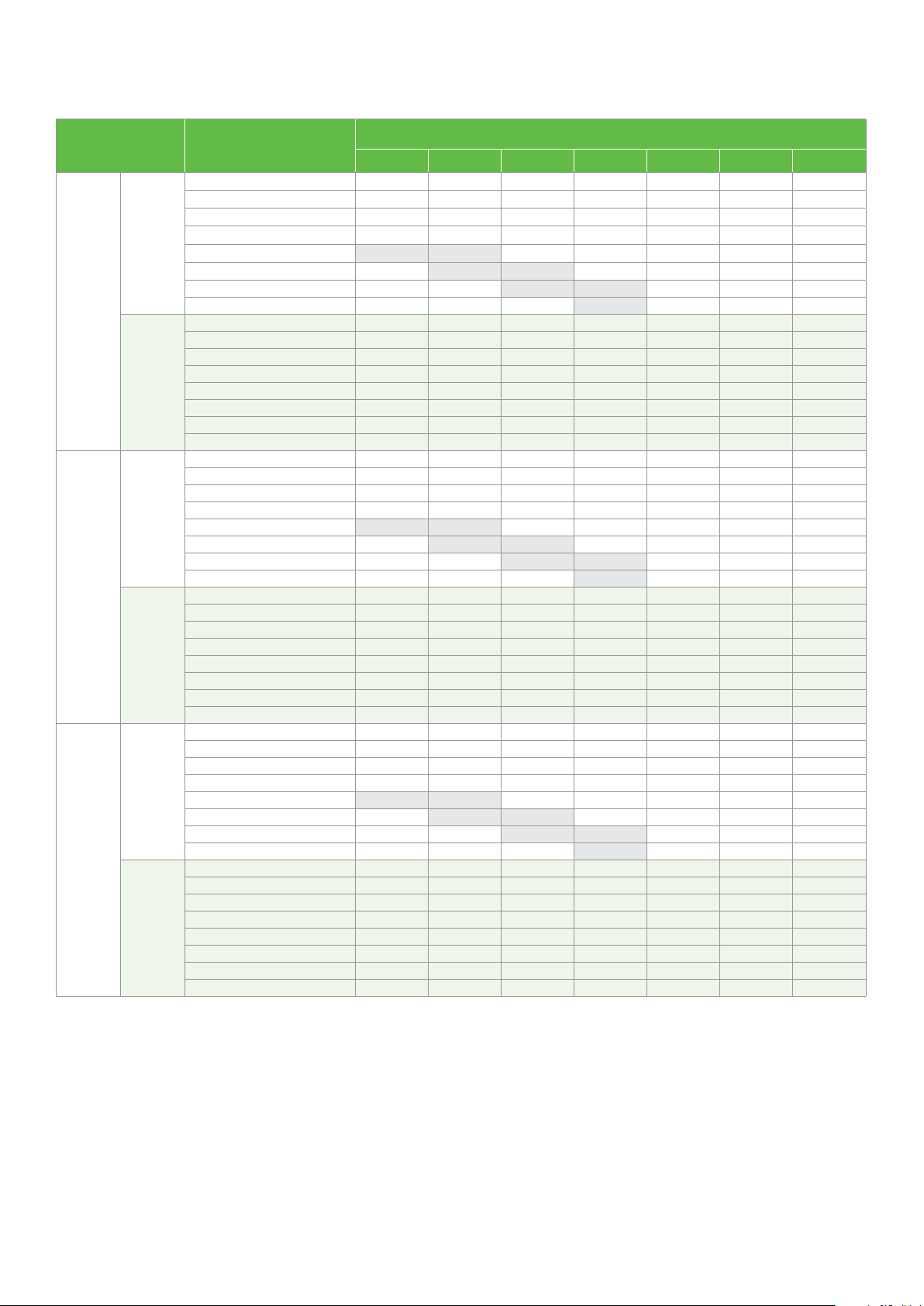

Product line-up

R404A - 50 HzCapacity, kW

Ca

pacity, kW R404A - 60 Hz

Notes: Based on medium temperature cold room conditions: -10°C evaporating, 45°C condensing, 20°C return gas, 0K sub-cooling

8

Page 9

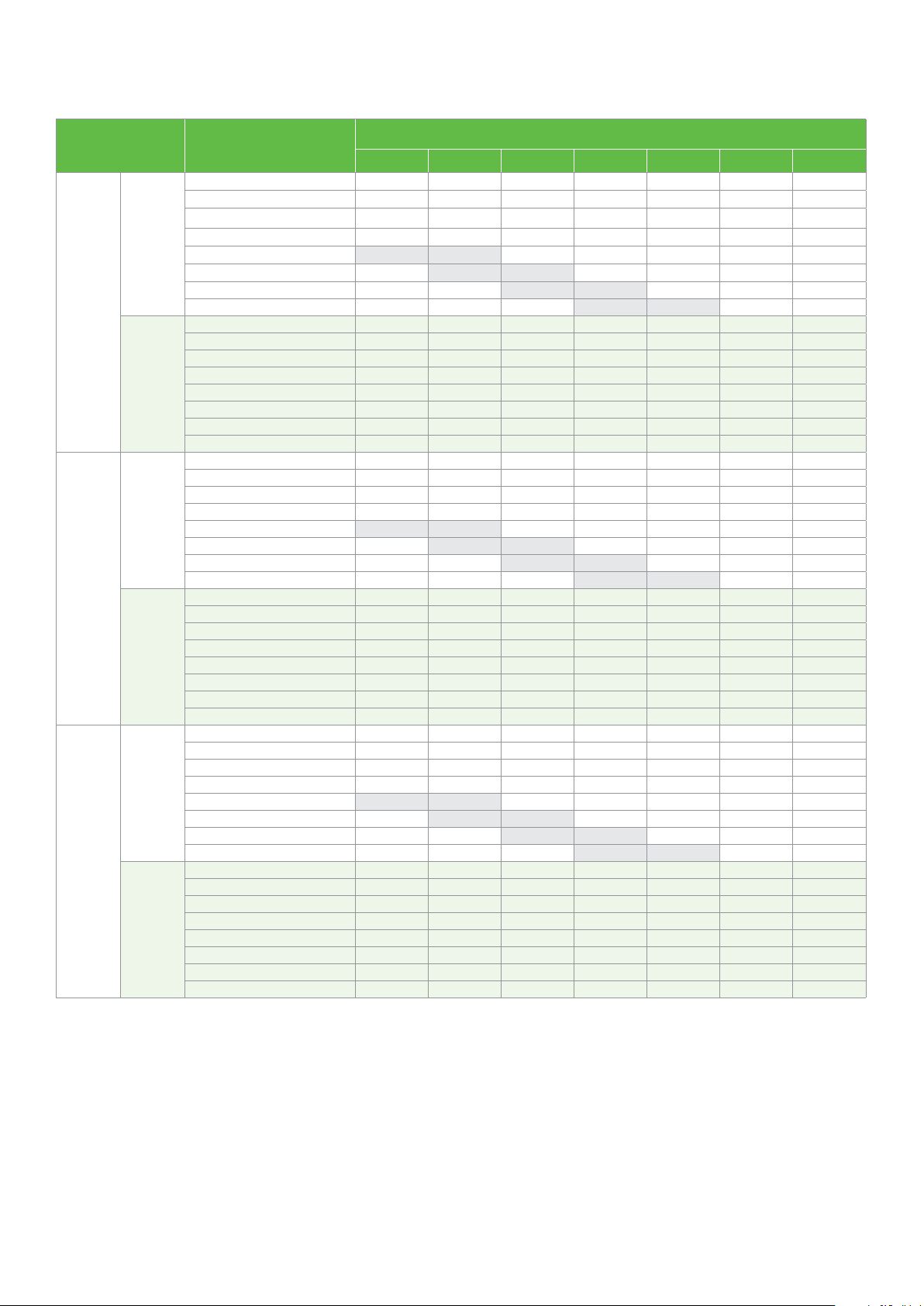

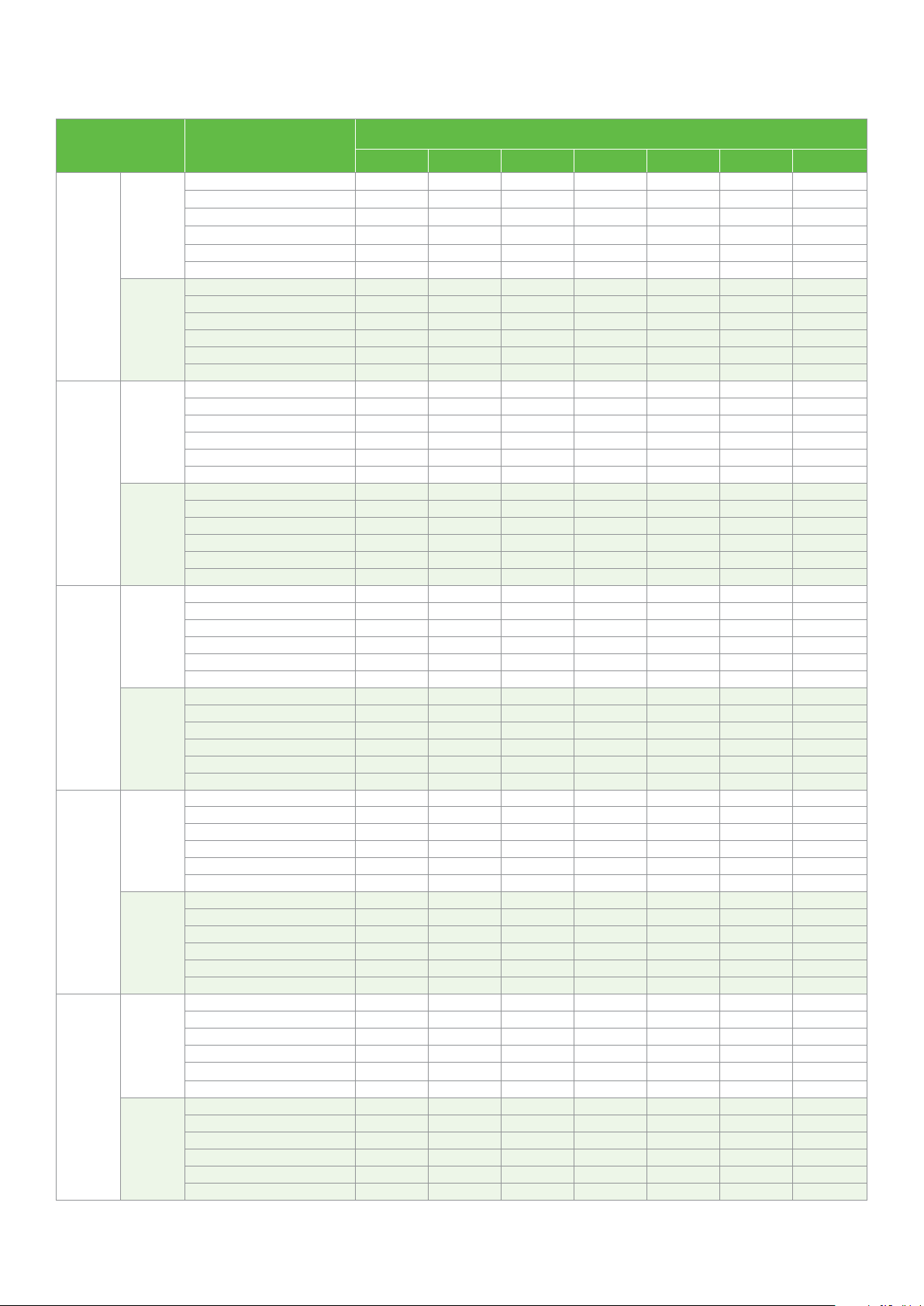

Performance data R22

Q=Capacity (kW) P=Power input (kW) 1-Phase

50 Hz

Model

Q

ZB15KQ

P

Q

ZB19KQ

P

Q

ZB21KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 4.0 4.4 5.3 6.3

20 3.9 4.2 5.1 6.1 7.2

30 3.6 3.9 4.7 5.6 6.7 7.9 8.6

40 3.3 3.5 4.3 5.2 6.1 7.3 7.9

50 2.7 2.9 3.9 4.6 5.5 6.6 7.2

55 2.7 3.4 4.4 5.2 6.2 6.8

60 3.2 3.9 4.9 5.8 6.4

65 3.6 4.5 5.4 5.9

15 0.9 0.9 0.9 0.9

20 1.0 1.0 1.0 1.0 1.0

30 1.2 1.2 1.2 1.2 1.2 1.2 1.2

40 1.4 1.4 1.4 1.4 1.4 1.4 1.4

50 1.7 1.7 1.7 1.7 1.7 1.7 1.7

55 1.9 1.9 1.9 1.9 1.9 1.9

60 2.1 2.1 2.1 2.1 2.1

65 2.4 2.3 2.3 2.3

15 4.7 5.0 6.1 7.3

20 4.5 4.8 5.9 7.0 8.3

30 4.1 4.5 5.4 6.5 7.7 9.1 9.9

40 3.7 4.1 4.9 5.9 7.1 8.4 9.1

50 3.1 3.4 4.4 5.3 6.4 7.6 8.3

55 3.1 3.9 5.0 6.0 7.2 7.8

60 3.6 4.5 5.6 6.7 7.4

65 4.2 5.2 6.3 6.8

15 1.0 1.0 1.0 1.0

20 1.1 1.1 1.1 1.1 1.1

30 1.3 1.3 1.3 1.3 1.3 1.3 1.3

40 1.6 1.6 1.6 1.6 1.6 1.6 1.6

50 1.9 1.9 1.9 1.9 1.9 1.9 1.9

55 2.2 2.1 2.1 2.1 2.1 2.1

60 2.4 2.4 2.4 2.4 2.3

65 2.7 2.6 2.6 2.6

15 5.9 6.3 7.7 9.1

20 5.6 6.1 7.4 8.8 10.5

30 5.2 5.6 6.8 8.2 9.7 11.5 12.5

40 4.7 5.1 6.2 7.5 8.9 10.6 11.5

50 3.9 4.2 5.6 6.7 8.0 9.6 10.4

55 4.0 4.9 6.3 7.6 9.0 9.9

60 4.6 5.7 7.1 8.5 9.3

65 5.2 6.6 7.9 8.6

15 1.4 1.4 1.4 1.4

20 1.5 1.5 1.5 1.5 1.6

30 1.8 1.8 1.8 1.8 1.8 1.9 1.9

40 2.2 2.2 2.2 2.2 2.2 2.2 2.2

50 2.7 2.7 2.7 2.7 2.7 2.7 2.7

55 3.0 3.0 3.0 3.0 3.0 2.9

60 3.3 3.3 3.3 3.3 3.3

65 3.7 3.7 3.6 3.6

9

Page 10

Performance data R22

Q=Capacity (kW) P=Power input (kW) 1-Phase

50 Hz

Model

Q

ZB26KQ

P

Q

ZB29KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 6.8 7.3 8.8 10.5

20 6.5 7.0 8.5 10.2 12.1

30 6.0 6.5 7.9 9.4 11.2 13.3 14.5

40 5.4 5.9 7.2 8.6 10.3 12.2 13.3

50 4.4 4.9 6.4 7.8 9.3 11.0 12.1

55 4.6 5.7 7.3 8.7 10.4 11.4

60 5.3 6.6 8.2 9.8 10.7

65 6.0 7.6 9.1 10.0

15 1.5 1.5 1.5 1.5

20 1.6 1.6 1.6 1.6 1.7

30 1.9 1.9 1.9 2.0 2.0 2.0 2.0

40 2.4 2.4 2.3 2.4 2.4 2.4 2.4

50 2.9 2.9 2.9 2.9 2.9 2.9 2.9

55 3.2 3.2 3.2 3.2 3.2 3.2

60 3.6 3.6 3.5 3.5 3.5

65 4.0 3.9 3.9 3.9

15 7.9 8.6 10.3 12.1

20 7.6 8.3 10.0 11.8 13.8

30 7.0 7.7 9.3 11.1 13.1 15.4 16.7

40 6.4 7.0 8.5 10.2 12.1 14.3 15.6

50 5.4 5.9 7.7 9.2 10.9 13.0 14.3

55 5.7 6.9 8.6 10.3 12.3 13.5

60 6.5 7.8 9.6 11.5 12.7

65 7.4 9.0 10.8 11.8

15 1.6 1.7 1.7 1.8

20 1.8 1.8 1.9 1.9 1.9

30 2.1 2.1 2.2 2.2 2.3 2.3 2.3

40 2.5 2.5 2.6 2.6 2.7 2.7 2.7

50 3.0 3.1 3.1 3.1 3.2 3.2 3.2

55 3.3 3.4 3.4 3.5 3.5 3.5

60 3.7 3.8 3.8 3.8 3.9

65 4.2 4.2 4.2 4.2

10

Page 11

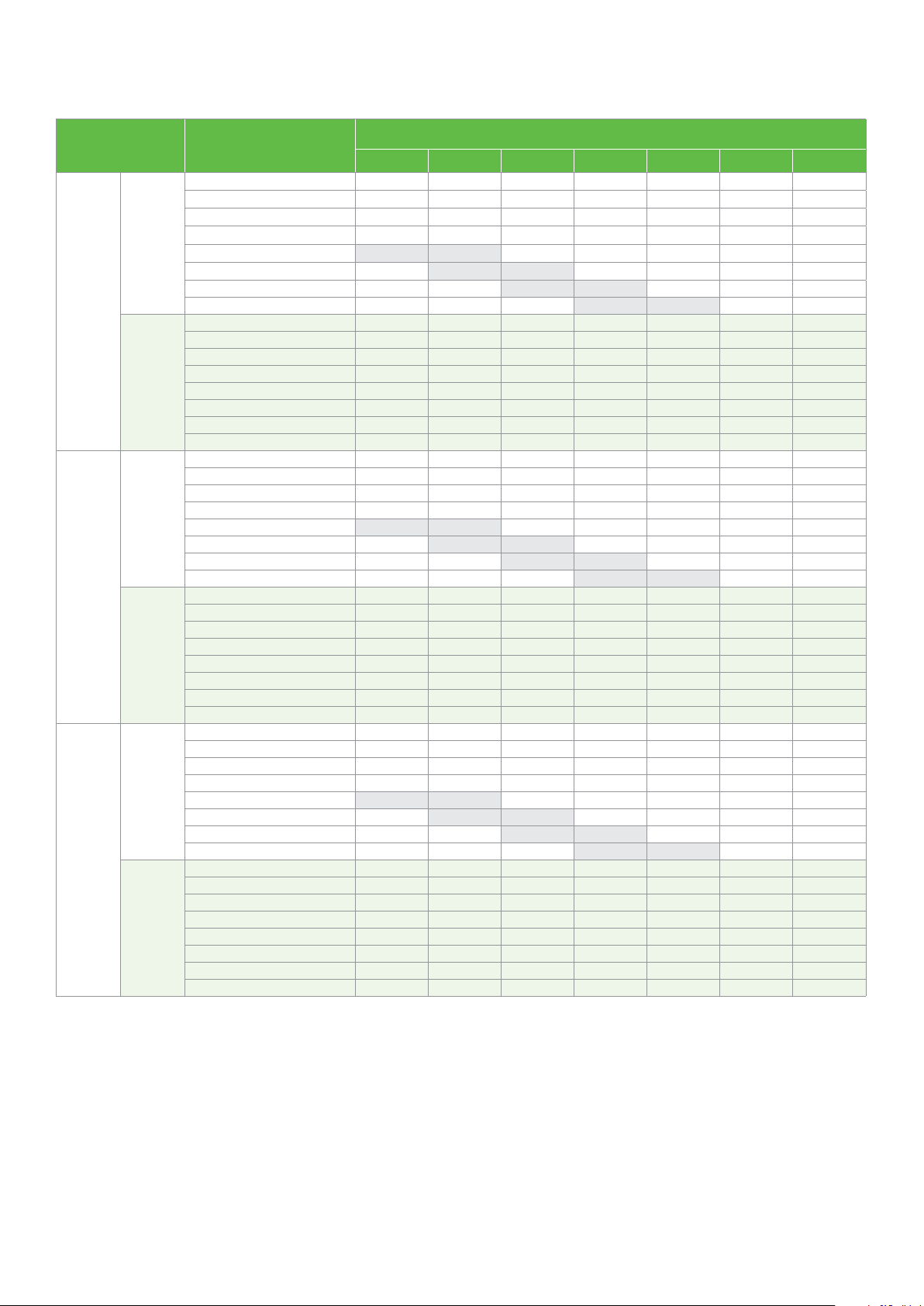

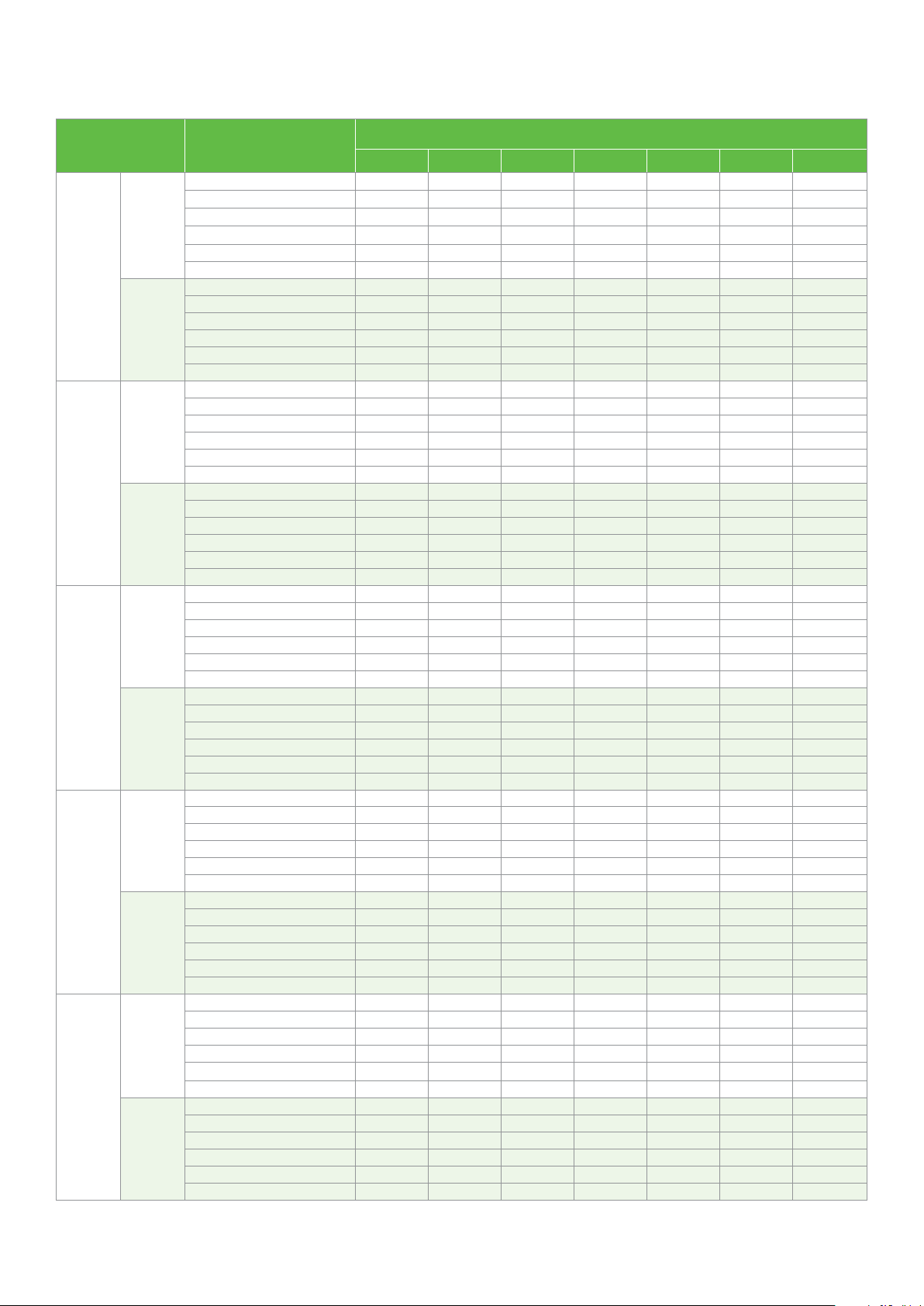

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB15KQ

P

Q

ZB19KQ

P

Q

ZB21KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 4.1 4.4 5.3 6.2

20 3.9 4.3 5.1 6.1 7.2

30 3.6 3.9 4.7 5.7 6.7 7.9 8.5

40 3.2 3.5 4.3 5.2 6.1 7.3 7.9

50 2.7 2.9 3.8 4.6 5.5 6.5 7.1

55 2.7 3.4 4.3 5.1 6.1 6.7

60 3.1 3.9 4.8 5.7 6.2

65 3.6 4.4 5.3 5.8

15 0.8 0.8 0.8 0.8

20 0.9 0.9 0.9 0.9 1.0

30 1.1 1.1 1.1 1.1 1.2 1.2 1.2

40 1.4 1.4 1.4 1.4 1.4 1.4 1.4

50 1.7 1.7 1.7 1.7 1.7 1.8 1.7

55 1.9 1.9 1.9 1.9 1.9 1.9

60 2.1 2.1 2.2 2.2 2.2

65 2.4 2.4 2.4 2.4

15 4.7 5.1 6.1 7.2

20 4.5 4.9 5.9 7.0 8.2

30 4.1 4.5 5.5 6.5 7.7 9.1 9.8

40 3.7 4.1 4.9 5.9 7.1 8.4 9.1

50 3.1 3.3 4.4 5.3 6.3 7.5 8.2

55 3.1 3.9 5.0 5.9 7.1 7.7

60 3.6 4.4 5.5 6.6 7.2

65 4.1 5.1 6.1 6.7

15 0.9 0.9 0.9 0.9

20 1.0 1.0 1.0 1.0 1.1

30 1.2 1.2 1.3 1.3 1.3 1.3 1.3

40 1.5 1.5 1.6 1.6 1.6 1.6 1.6

50 1.9 1.9 1.9 2.0 2.0 2.0 2.0

55 2.1 2.2 2.2 2.2 2.2 2.2

60 2.4 2.4 2.5 2.5 2.5

65 2.7 2.7 2.7 2.7

15 5.9 6.4 7.7 9.1

20 5.7 6.2 7.4 8.8 10.4

30 5.2 5.7 6.9 8.2 9.7 11.5 12.4

40 4.7 5.1 6.2 7.5 8.9 10.5 11.5

50 3.8 4.2 5.5 6.7 8.0 9.5 10.3

55 3.9 4.9 6.2 7.5 8.9 9.7

60 4.6 5.6 6.9 8.3 9.1

65 5.2 6.4 7.7 8.4

15 1.2 1.2 1.2 1.2

20 1.3 1.3 1.3 1.4 1.4

30 1.6 1.6 1.6 1.7 1.7 1.7 1.7

40 2.0 2.0 2.0 2.0 2.1 2.1 2.1

50 2.5 2.5 2.5 2.5 2.6 2.6 2.6

55 2.8 2.8 2.8 2.9 2.9 2.9

60 3.1 3.2 3.2 3.2 3.2

65 3.5 3.6 3.6 3.5

11

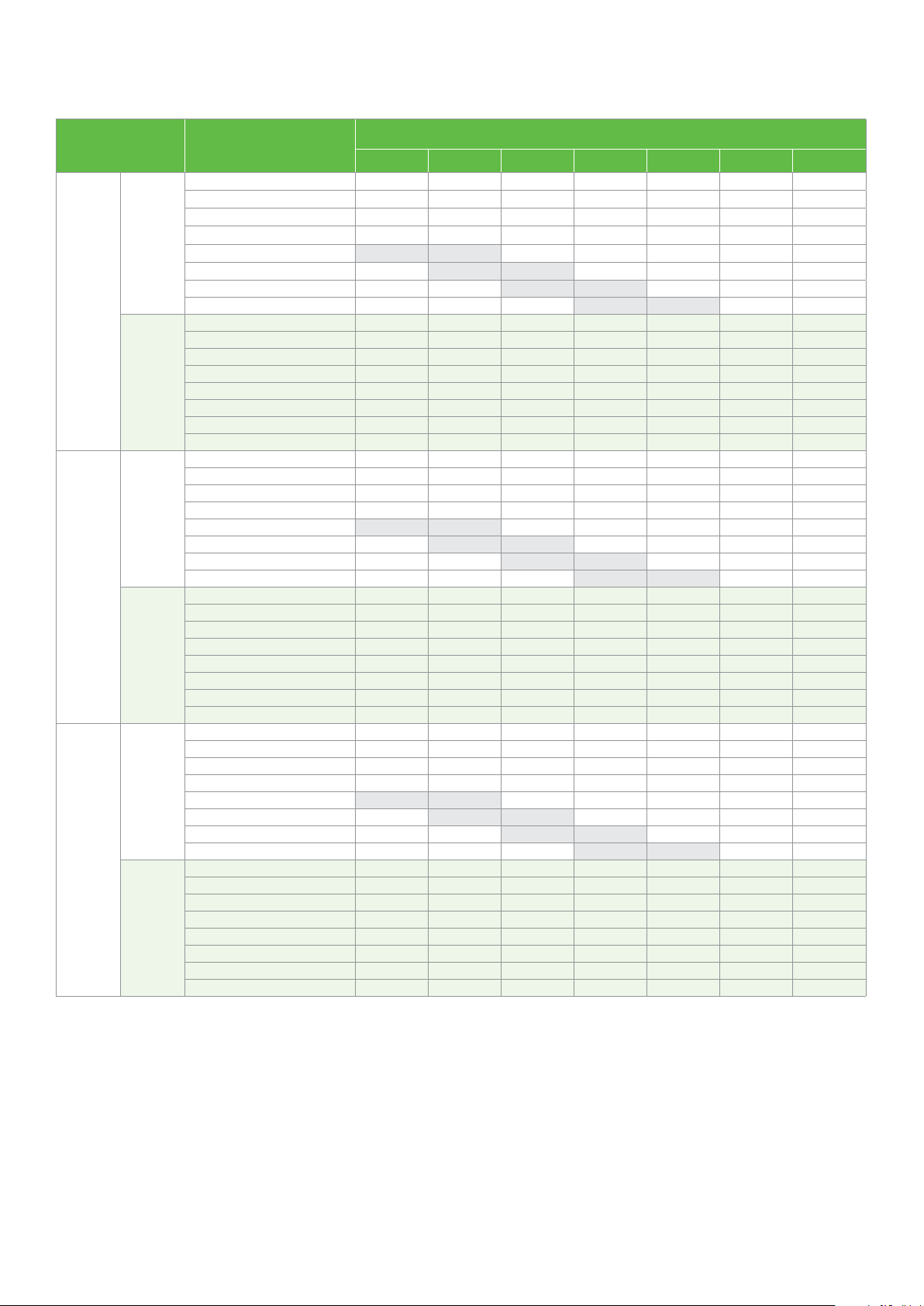

Page 12

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB26KQ

P

Q

ZB29KQ

P

Q

ZB38KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 6.9 7.5 9.0 10.7

20 6.7 7.2 8.7 10.4 12.4

30 6.1 6.7 8.1 9.7 11.6 13.9 15.2

40 5.6 6.1 7.4 8.8 10.6 12.7 14.0

50 4.6 5.1 6.6 7.9 9.5 11.4 12.6

55 4.8 5.9 7.4 8.9 10.7 11.8

60 5.5 6.7 8.3 10.0 11.0

65 6.2 7.7 9.2 10.2

15 1.2 1.2 1.2 1.2

20 1.4 1.4 1.4 1.4 1.4

30 1.7 1.7 1.7 1.7 1.8 1.8 1.7

40 2.2 2.2 2.2 2.2 2.2 2.2 2.2

50 2.8 2.8 2.8 2.8 2.8 2.8 2.7

55 3.2 3.1 3.1 3.1 3.1 3.1

60 3.6 3.6 3.5 3.5 3.4

65 4.0 4.0 3.9 3.9

15 7.9 8.6 10.3 12.2

20 7.6 8.3 9.9 11.8 13.9

30 7.0 7.6 9.2 11.0 13.0 15.4 16.6

40 6.3 6.8 8.3 10.0 11.9 14.1 15.4

50 5.1 5.6 7.4 8.9 10.7 12.7 13.8

55 5.3 6.5 8.4 10.0 11.9 13.0

60 6.1 7.5 9.3 11.1 12.1

65 6.9 8.6 10.3 11.2

15 1.5 1.5 1.5 1.6

20 1.6 1.6 1.7 1.7 1.8

30 2.1 2.0 2.1 2.1 2.2 2.2 2.2

40 2.5 2.5 2.6 2.6 2.6 2.7 2.7

50 3.2 3.2 3.2 3.2 3.3 3.3 3.3

55 3.5 3.6 3.6 3.6 3.7 3.6

60 4.0 4.0 4.1 4.1 4.1

65 4.5 4.5 4.5 4.5

15 9.8 10.6 12.7 15.1

20 9.5 10.2 12.4 14.7 17.3

30 8.7 9.4 11.4 13.7 16.2 19.1 20.7

40 7.8 8.5 10.3 12.4 14.8 17.6 19.1

50 6.4 7.0 9.2 11.1 13.3 15.8 17.2

55 6.5 8.1 10.4 12.4 14.8 16.2

60 7.6 9.3 11.5 13.8 15.1

65 8.6 10.7 12.8 14.0

15 1.9 1.9 1.9 2.0

20 2.1 2.1 2.1 2.2 2.3

30 2.6 2.6 2.6 2.7 2.7 2.8 2.8

40 3.2 3.2 3.2 3.3 3.3 3.4 3.4

50 4.0 4.0 4.0 4.1 4.1 4.1 4.1

55 4.5 4.5 4.5 4.6 4.6 4.6

60 5.0 5.1 5.1 5.1 5.1

65 5.7 5.7 5.7 5.7

12

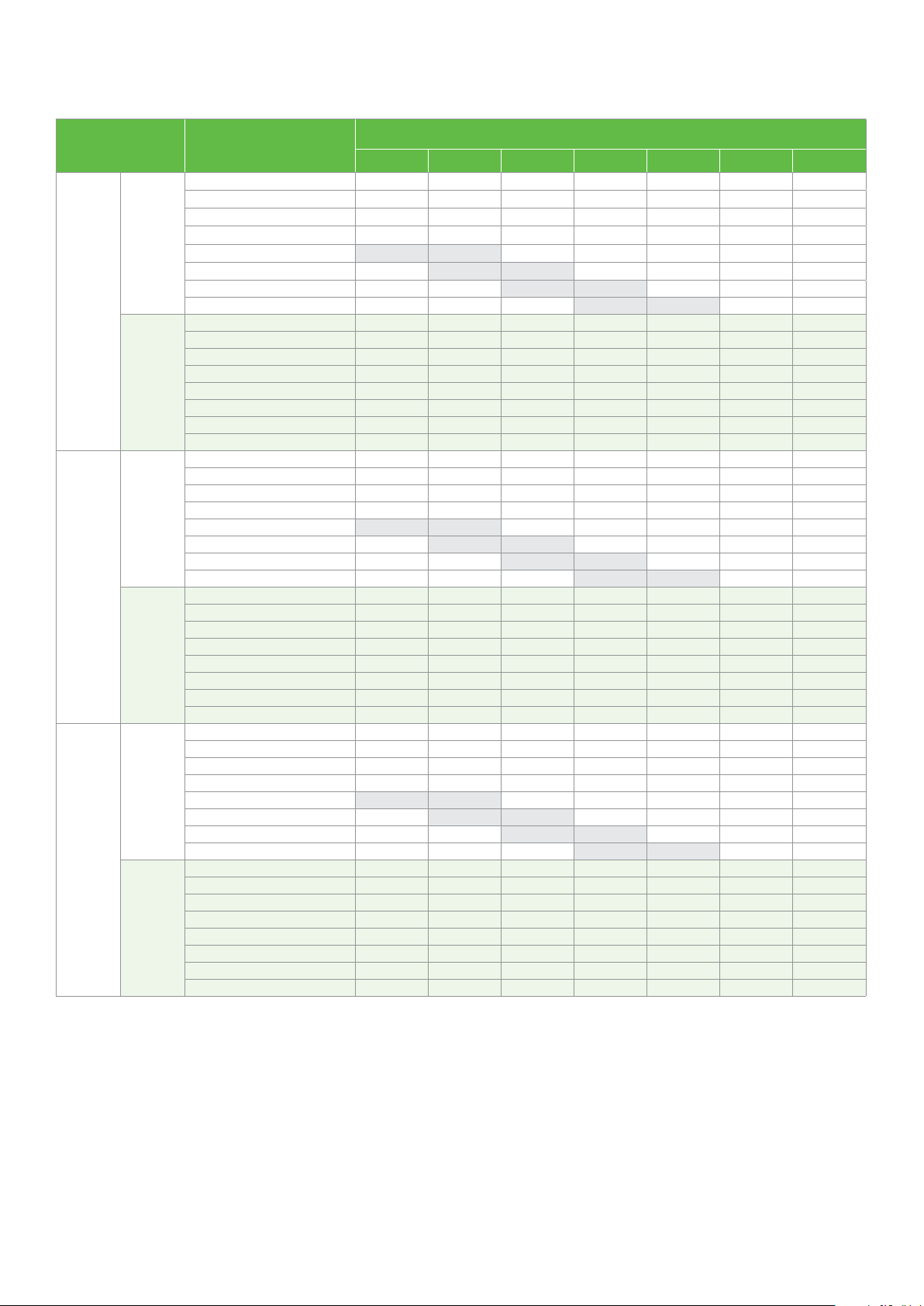

Page 13

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB45KQ

P

Q

ZB48KQ

P

Q

ZB58KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 11.8 12.8 15.4 18.4

20 11.4 12.3 14.8 17.7 21.1

30 10.5 11.4 13.7 16.4 19.5 23.1 25.1

40 9.5 10.3 12.5 15.0 17.8 21.1 23.0

50 7.7 8.4 11.1 13.4 16.0 19.0 20.7

55 7.8 9.8 12.5 15.0 17.9 19.4

60 9.0 11.2 14.0 16.7 18.2

65 10.2 12.8 15.4 16.8

15 2.1 2.1 2.2 2.2

20 2.3 2.4 2.4 2.5 2.6

30 3.0 3.0 3.0 3.1 3.1 3.2 3.2

40 3.7 3.7 3.8 3.8 3.8 3.9 3.9

50 4.7 4.7 4.7 4.7 4.7 4.8 4.8

55 5.2 5.3 5.3 5.3 5.3 5.3

60 5.9 5.9 5.9 5.9 5.9

65 6.6 6.6 6.6 6.6

15 13.0 14.0 16.9 20.2

20 12.5 13.5 16.3 19.5 23.2

30 11.5 12.5 15.1 18.1 21.5 25.4 27.6

40 10.4 11.3 13.7 16.5 19.6 23.2 25.3

50 8.4 9.3 12.2 14.7 17.6 20.9 22.7

55 8.6 10.8 13.8 16.5 19.6 21.4

60 9.9 12.3 15.4 18.3 20.0

65 11.2 14.1 16.9 18.5

15 2.3 2.3 2.4 2.5

20 2.6 2.6 2.7 2.7 2.8

30 3.3 3.3 3.3 3.4 3.4 3.5 3.6

40 4.1 4.1 4.1 4.2 4.2 4.2 4.3

50 5.1 5.1 5.2 5.2 5.2 5.2 5.2

55 5.8 5.8 5.8 5.8 5.8 5.8

60 6.5 6.5 6.5 6.5 6.5

65 7.3 7.2 7.2 7.2

15 15.4 16.7 20.2 24.2

20 14.7 15.9 19.4 23.3 27.8

30 13.3 14.5 17.8 21.5 25.7 30.5 33.2

40 11.9 13.0 16.1 19.6 23.6 28.1 30.5

50 9.3 10.4 14.2 17.5 21.2 25.3 27.6

55 9.3 12.3 16.2 19.8 23.8 26.0

60 11.0 14.3 18.3 22.2 24.3

65 12.8 16.6 20.3 22.4

15 2.7 2.8 2.8 2.9

20 3.1 3.1 3.2 3.2 3.3

30 3.9 3.9 3.9 4.0 4.1 4.2 4.3

40 4.9 4.9 4.9 4.9 5.0 5.1 5.1

50 6.1 6.1 6.1 6.1 6.1 6.2 6.2

55 6.9 6.9 6.8 6.8 6.9 6.9

60 7.7 7.7 7.6 7.7 7.7

65 8.6 8.6 8.5 8.6

13

Page 14

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB66KQ

P

Q

ZB76KQ

P

Q

ZB88KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 17.2 18.7 22.6 27.2

20 16.6 18.0 21.8 26.2 31.2

30 15.3 16.6 20.1 24.2 28.9 34.2 37.1

40 14.0 15.2 18.5 22.2 26.5 31.4 34.1

50 11.4 12.5 16.6 20.1 24.0 28.4 30.9

55 11.6 14.7 18.8 22.6 26.8 29.2

60 13.5 16.9 21.1 25.1 27.3

65 15.5 19.5 23.3 25.4

15 2.8 2.9 2.9 3.0

20 3.3 3.4 3.4 3.5 3.6

30 4.3 4.3 4.4 4.4 4.5 4.7 4.8

40 5.3 5.4 5.4 5.5 5.6 5.7 5.8

50 6.7 6.7 6.7 6.8 6.8 6.9 7.0

55 7.6 7.6 7.6 7.6 7.7 7.7

60 8.5 8.5 8.5 8.5 8.6

65 9.6 9.6 9.6 9.6

15 20.3 22.0 26.8 32.3

20 19.5 21.2 25.7 31.0 36.9

30 18.0 19.5 23.7 28.6 34.0 40.2 43.5

40 16.4 17.9 21.8 26.2 31.2 36.9 39.9

50 13.4 14.7 19.5 23.6 28.2 33.4 36.2

55 13.6 17.2 22.2 26.6 31.5 34.2

60 15.8 19.9 24.9 29.6 32.1

65 18.2 23.0 27.5 29.9

15 3.0 3.0 3.1 3.1

20 3.7 3.7 3.8 3.8 4.0

30 5.0 5.0 5.0 5.1 5.2 5.5 5.6

40 6.3 6.3 6.4 6.4 6.5 6.7 6.8

50 7.9 8.0 8.0 8.0 8.1 8.2 8.3

55 9.0 9.0 9.0 9.1 9.2 9.2

60 10.2 10.2 10.2 10.2 10.3

65 11.6 11.6 11.5 11.6

15 23.6 25.4 30.5 36.2

20 22.7 24.6 29.6 35.2 41.3

30 20.9 22.6 27.5 32.9 38.9 45.4 48.8

40 18.8 20.4 25.0 30.1 35.8 42.0 45.3

50 15.1 16.6 22.1 26.8 32.1 38.0 41.1

55 15.3 19.3 25.0 30.0 35.7 38.7

60 17.7 22.2 27.8 33.2 36.1

65 20.1 25.4 30.5 33.2

15 3.9 4.0 4.1 4.4

20 4.5 4.5 4.6 4.8 5.1

30 5.7 5.7 5.8 5.9 6.1 6.4 6.6

40 7.1 7.2 7.2 7.3 7.4 7.6 7.8

50 8.9 9.0 9.0 9.1 9.2 9.3 9.4

55 10.0 10.1 10.2 10.2 10.3 10.4

60 11.3 11.4 11.4 11.5 11.5

65 12.7 12.7 12.8 12.8

14

Page 15

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB95KQ

P

Q

ZB114KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 25.4 27.4 33.2 40.0

20 24.4 26.4 31.8 38.2 45.6

30 22.4 24.2 29.4 35.2 41.8 49.4 53.6

40 19.6 21.5 26.5 32.1 38.3 45.2 49.0

50 22.5 28.1 34.1 40.7 44.3

55 25.4 31.5 38.0 41.5

60 28.4 34.9 38.4

65 24.6 31.3 34.8

15 4.7 4.7 5.0 5.3

20 5.2 5.2 5.4 5.7 6.0

30 6.5 6.5 6.6 6.7 6.9 7.2 7.4

40 8.0 8.1 8.2 8.3 8.4 8.5 8.6

50 10.1 10.2 10.3 10.4 10.4

55 11.4 11.5 11.5 11.5

60 12.7 12.8 12.8

65 14.0 14.1 14.2

15 30.5 33.0 39.7 47.3

20 29.4 31.8 38.4 45.9 54.3

30 26.8 29.1 35.4 42.5 50.5 59.4 64.2

40 23.2 25.6 31.7 38.6 46.1 54.5 59.1

50 27.1 33.7 41.0 49.0 53.3

55 30.9 38.1 45.9 50.1

60 34.9 42.5 46.6

65 31.4 38.9 42.9

15 5.7 5.8 6.0 6.3

20 6.3 6.4 6.6 6.8 7.1

30 7.8 7.8 7.9 8.1 8.3 8.6 8.8

40 9.6 9.6 9.7 9.8 10.0 10.2 10.4

50 12.0 12.1 12.2 12.3 12.4

55 13.5 13.5 13.6 13.7

60 15.0 15.1 15.2

65 16.7 16.8 16.8

15

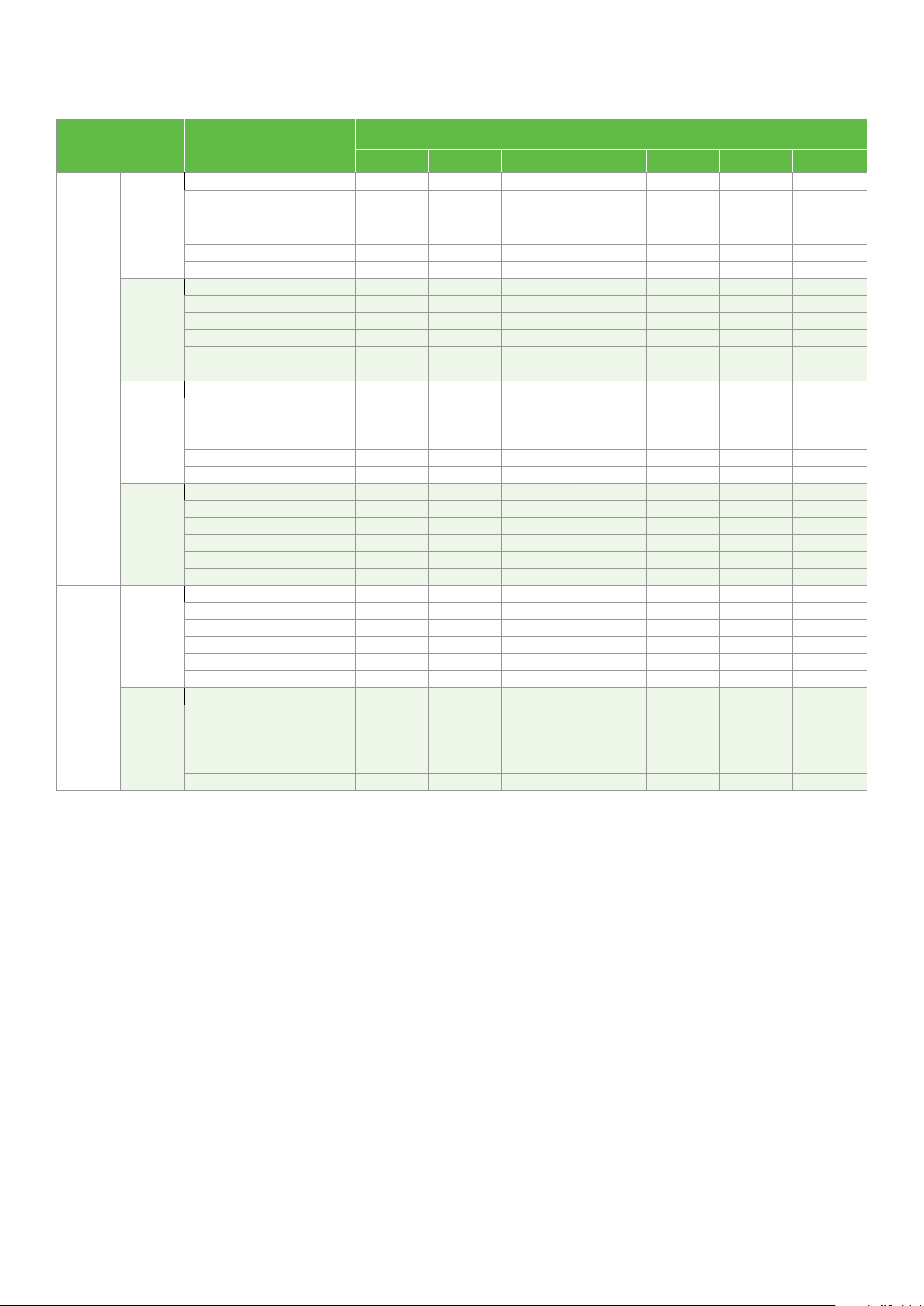

Page 16

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB130KQ

P

Q

ZB150KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12

15 33.7 36.4 43.9 52.5

20 32.2 34.8 42.1 50.4 60.0

25 30.7 33.3 40.4 48.5 57.7

30 29.2 31.8 38.7 46.6 55.5 65.5 69.9

35 27.7 30.2 37.0 44.7 53.3 62.9 67.0

40 26.1 28.5 35.2 42.7 51.0 60.2 64.1

45 24.1 26.6 33.3 40.5 48.5 57.4 61.1

50 21.9 24.4 31.1 38.2 45.9 54.3 58.0

55 19.3 21.8 28.4 35.5 43.0 51.1 54.5

60 25.4 32.3 39.7 47.5 50.8

65 28.7 36.0 43.5 46.6

15 5.8 5.8 5.9 6.1

20 6.6 6.6 6.8 6.9 7.1

25 7.4 7.4 7.6 7.8 8.0

30 8.2 8.3 8.4 8.6 8.8 9.0 9.1

35 9.2 9.2 9.4 9.5 9.7 9.9 10.0

40 10.1 10.2 10.3 10.5 10.7 10.9 11.0

45 11.2 11.3 11.4 11.6 11.8 12.0 12.0

50 12.4 12.5 12.6 12.8 13.0 13.1 13.2

55 13.7 13.8 14.0 14.1 14.3 14.5 14.5

60 15.5 15.6 15.8 16.0 16.0

65 17.3 17.5 17.7 17.7

15 40.1 43.3 52.4 63.3

20 38.1 41.1 49.7 59.9 72.0

25 36.4 39.3 47.4 57.0 68.3

30 34.8 37.6 45.4 54.5 65.1 77.6 83.2

35 33.2 36.0 43.5 52.1 62.2 74.0 79.3

40 31.5 34.2 41.6 49.9 59.5 70.6 75.6

45 29.3 32.1 39.5 47.6 56.8 67.4 72.1

50 26.8 29.6 37.2 45.1 53.9 64.1 68.6

55 23.7 26.6 34.1 42.3 50.9 60.7 65.0

60 30.7 38.7 47.5 57.0 61.1

65 34.7 43.6 52.9 56.9

15 7.2 7.3 7.5 7.7

20 8.2 8.3 8.5 8.8 9.0

25 9.3 9.4 9.5 9.8 10.0

30 10.4 10.4 10.6 10.8 11.0 11.3 11.4

35 11.5 11.6 11.7 11.9 12.1 12.3 12.4

40 12.7 12.8 12.9 13.1 13.3 13.5 13.5

45 14.1 14.2 14.3 14.5 14.6 14.8 14.8

50 15.7 15.8 15.9 16.0 16.1 16.3 16.3

55 17.5 17.6 17.7 17.8 17.9 18.0 18.1

60 19.8 19.9 19.9 20.0 20.1

65 22.2 22.3 22.4 22.4

16

Page 17

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB190KQ

P

Q

ZB220KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12

15 47.4 51.1 61.6 73.8

20 45.9 49.7 60.0 72.0 85.8

25 44.3 48.0 58.2 69.9 83.4

30 42.5 46.1 56.0 67.5 80.7 95.8 102.4

35 40.5 44.0 53.7 64.9 77.7 92.4 98.8

40 38.3 41.7 51.1 62.0 74.4 88.7 94.9

45 35.8 39.1 48.4 58.8 70.8 84.6 90.7

50 33.2 36.4 45.4 55.4 67.0 80.3 86.1

55 30.5 33.5 41.9 51.9 62.9 75.7 81.3

60 38.5 47.7 58.6 70.8 76.1

65 43.7 54.1 65.6 70.7

15 8.9 9.0 9.4 10.0

20 10.0 10.1 10.4 10.8 11.5

25 11.2 11.2 11.5 11.8 12.4

30 12.6 12.6 12.7 13.0 13.5 14.2 14.6

35 14.1 14.1 14.2 14.4 14.8 15.4 15.7

40 15.9 15.8 15.9 16.0 16.3 16.9 17.1

45 17.8 17.8 17.7 17.8 18.1 18.5 18.8

50 20.0 19.9 19.9 19.9 20.1 20.4 20.6

55 22.4 22.3 22.2 22.2 22.3 22.6 22.8

60 24.8 24.8 24.9 25.1 25.2

65 27.6 27.7 27.8 28.0

15 58.9 63.4 75.9 90.5

20 57.5 61.9 74.1 88.2 104.6

25 55.8 60.1 72.0 85.7 101.6

30 53.8 58.1 69.7 83.0 98.3 115.8 123.5

35 51.5 55.8 67.2 80.1 94.9 111.7 119.1

40 48.9 53.1 64.4 77.0 91.2 107.4 114.5

45 45.7 49.9 61.2 73.5 87.3 102.9 109.7

50 42.1 46.3 57.7 69.7 83.1 98.1 104.6

55 37.9 42.2 53.3 65.6 78.5 93.0 99.2

60 48.8 60.6 73.6 87.5 93.5

65 55.4 68.3 81.7 87.5

15 11.2 11.4 11.9 12.6

20 12.5 12.6 13.0 13.6 14.4

25 13.9 14.0 14.3 14.8 15.5

30 15.4 15.5 15.8 16.2 16.8 17.5 17.9

35 17.1 17.2 17.5 17.8 18.3 19.0 19.3

40 19.0 19.1 19.4 19.7 20.1 20.7 20.9

45 24.1 26.6 33.3 40.5 22.2 22.7 22.9

50 21.9 24.4 31.1 38.2 24.5 24.9 25.2

55 19.3 21.8 28.4 35.5 27.0 27.5 27.7

60 25.4 32.3 29.8 30.3 30.5

65 28.7 32.9 33.5 33.7

17

Page 18

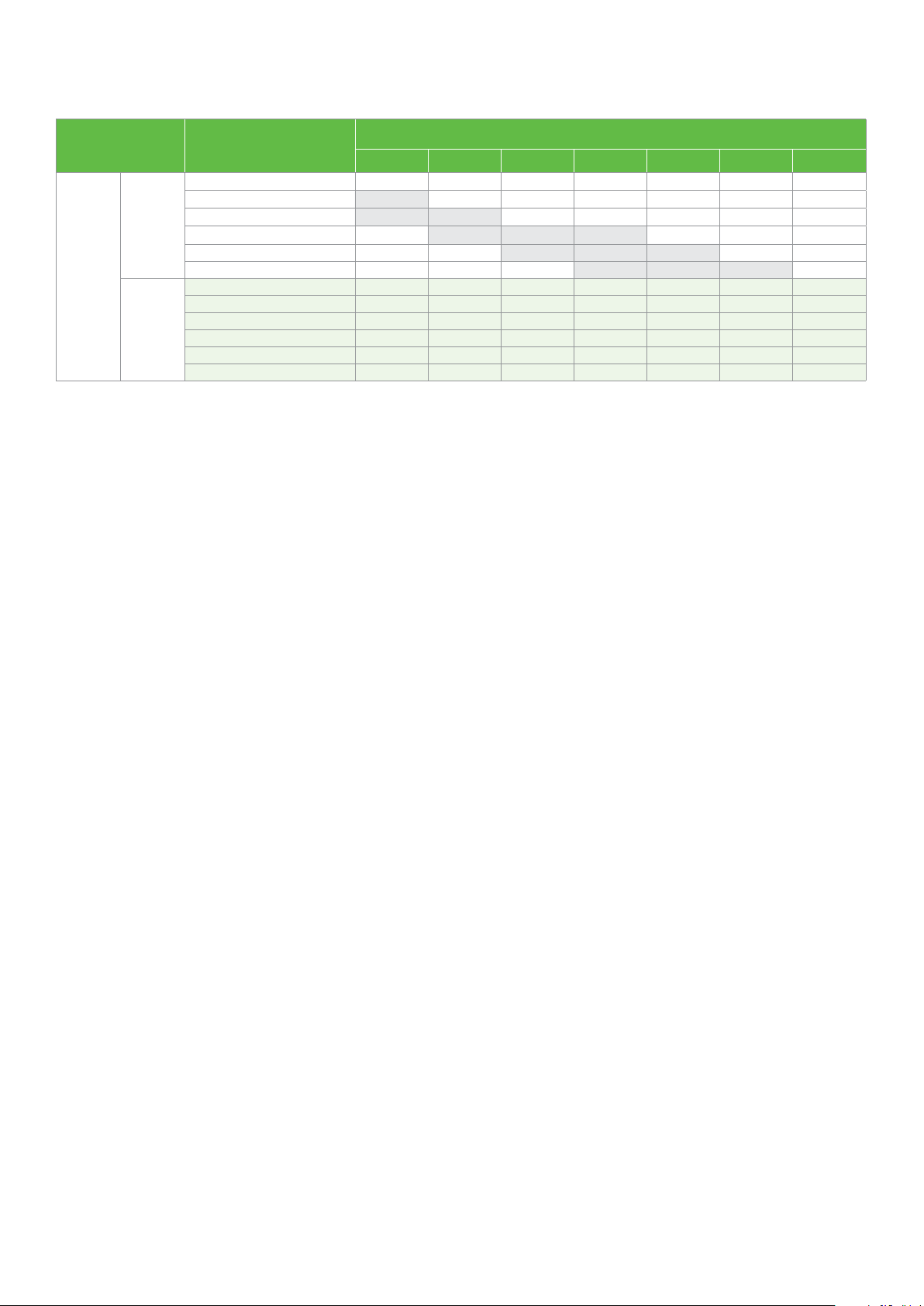

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 1-Phase

50 Hz

Model

Q

ZB15KQE

P

Q

ZB19KQE

P

Q

ZB21KQE

P

Q

ZB26KQE

P

Q

ZB29KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

18

Condensing

temperature oC

10 3.7 4.5 5.5

20 3.4 4.1 4.9 5.9 7.0

30 3.0 3.6 4.4 5.3 6.2 7.3 8.6

40 2.6 3.2 3.8 4.6 5.4 6.4 7.5

50 2.2 2.6 3.2 3.8 4.5 5.4 6.3

60 2.1 2.5 3.0 3.6 4.3 5.1

10 0.7 0.7 0.7

20 0.9 0.9 0.9 0.9 0.9

30 1.2 1.2 1.2 1.2 1.2 1.2 1.1

40 1.4 1.5 1.5 1.5 1.5 1.5 1.4

50 1.8 1.8 1.8 1.8 1.8 1.8 1.8

60 2.3 2.3 2.3 2.3 2.3 2.2

10 4.2 5.1 6.2

20 3.9 4.7 5.7 6.8 8.2

30 3.5 4.2 5.1 6.1 7.3 8.6 10.1

40 3.0 3.7 4.4 5.3 6.3 7.5 8.8

50 2.5 3.0 3.7 4.4 5.3 6.2 7.3

60 2.4 2.9 3.4 4.1 4.9 5.8

10 0.9 0.9 0.9

20 1.1 1.1 1.1 1.1 1.1

30 1.4 1.4 1.4 1.4 1.4 1.4 1.4

40 1.8 1.8 1.8 1.8 1.8 1.8 1.8

50 2.3 2.3 2.3 2.3 2.3 2.2 2.2

60 2.9 2.9 2.9 2.9 2.8 2.8

10 5.4 6.6 8.0

20 4.9 6.0 7.3 8.7 10.4

30 4.4 5.4 6.5 7.8 9.3 11.0 12.9

40 3.8 4.7 5.6 6.8 8.1 9.5 11.2

50 3.2 3.9 4.7 5.6 6.7 8.0 9.4

60 3.0 3.6 4.4 5.3 6.3 7.4

10 1.2 1.2 1.2

20 1.5 1.5 1.5 1.5 1.5

30 1.8 1.8 1.8 1.8 1.8 1.8 1.8

40 2.3 2.3 2.3 2.3 2.3 2.3 2.2

50 2.9 2.9 2.9 2.9 2.9 2.9 2.8

60 3.7 3.7 3.7 3.6 3.6 3.6

10 6.0 7.3 8.9

20 5.4 6.6 8.1 9.8 11.8

30 4.7 5.8 7.1 8.7 10.4 12.5 14.8

40 4.0 4.9 6.1 7.4 9.0 10.8 12.9

50 3.1 3.9 4.9 6.0 7.4 8.9 10.8

60 2.8 3.6 4.5 5.7 7.0 8.5

10 1.5 1.5 1.4

20 1.9 1.9 1.8 1.8 1.7

30 2.4 2.3 2.3 2.2 2.2 2.1 2.0

40 3.0 3.0 2.9 2.8 2.7 2.6 2.5

50 3.8 3.7 3.6 3.6 3.4 3.3 3.2

60 4.7 4.6 4.5 4.4 4.2 4.0

10 7.1 8.7 10.6

20 6.5 7.9 9.6 11.6 13.8

30 5.7 7.1 8.6 10.3 12.3 14.5 17.0

40 4.9 6.1 7.4 8.9 10.7 12.6 14.8

50 4.0 5.0 6.2 7.4 8.9 10.5 12.4

60 3.8 4.8 5.8 7.0 8.3 9.8

10 1.6 1.7 1.7

20 1.9 2.0 2.0 2.0 2.1

30 2.3 2.4 2.4 2.4 2.4 2.5 2.5

40 2.8 2.9 2.9 2.9 2.9 3.0 3.0

50 3.4 3.5 3.5 3.5 3.5 3.6 3.6

60 4.2 4.2 4.3 4.3 4.3 4.3

-20 -15 -10 -5 0 5 10

Evaporating temperature (

o

C)

Page 19

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB15KQE

P

Q

ZB19KQE

P

Q

ZB21KQE

P

Q

ZB26KQE

P

Q

ZB29KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 3.7 4.5 5.5

20 3.3 4.1 5.0 6.0 7.2

30 2.9 3.6 4.4 5.3 6.3 7.5 8.8

40 2.4 3.0 3.7 4.5 5.4 6.4 7.5

50 1.9 2.4 3.0 3.6 4.3 5.2 6.1

60 1.7 2.2 2.7 3.3 3.9 4.6

10 0.8 0.8 0.7

20 1.0 1.0 1.0 0.9 0.9

30 1.3 1.3 1.2 1.2 1.2 1.2 1.2

40 1.7 1.6 1.6 1.6 1.5 1.5 1.5

50 2.3 2.2 2.1 2.0 2.0 1.9 1.9

60 3.0 2.8 2.7 2.6 2.5 2.5

10 4.4 5.4 6.5

20 4.0 4.9 5.9 7.1 8.5

30 3.6 4.4 5.3 6.4 7.6 9.0 10.5

40 3.1 3.8 4.6 5.5 6.6 7.8 9.2

50 2.6 3.2 3.8 4.6 5.5 6.5 7.7

60 2.5 3.0 3.6 4.3 5.1 6.1

10 0.9 0.9 0.9

20 1.2 1.2 1.2 1.2 1.2

30 1.5 1.5 1.5 1.5 1.5 1.5 1.5

40 1.9 1.9 1.9 1.9 1.8 1.8 1.8

50 2.4 2.4 2.4 2.4 2.3 2.3 2.3

60 3.0 3.0 3.0 2.9 2.9 2.9

10 5.3 6.4 7.8

20 4.8 5.9 7.1 8.6 10.2

30 4.3 5.3 6.4 7.6 9.1 10.8 12.6

40 3.7 4.6 5.5 6.6 7.9 9.3 11.0

50 3.1 3.8 4.6 5.5 6.6 7.8 9.2

60 2.9 3.6 4.3 5.2 6.1 7.3

10 1.1 1.1 1.1

20 1.4 1.4 1.4 1.4 1.4

30 1.8 1.8 1.8 1.8 1.8 1.8 1.7

40 2.2 2.2 2.2 2.2 2.2 2.2 2.2

50 2.8 2.8 2.8 2.8 2.8 2.8 2.7

60 3.6 3.6 3.6 3.5 3.5 3.5

10 6.1 7.5 9.1

20 5.6 6.9 8.3 10.0 11.9

30 5.0 6.1 7.4 8.9 10.6 12.6 14.8

40 4.4 5.3 6.4 7.7 9.2 10.9 12.8

50 3.6 4.4 5.4 6.4 7.7 9.1 10.7

60 3.4 4.2 5.0 6.0 7.2 8.5

10 1.3 1.3 1.3

20 1.6 1.6 1.6 1.6 1.6

30 2.1 2.1 2.1 2.1 2.1 2.0 2.0

40 2.6 2.6 2.6 2.6 2.6 2.6 2.5

50 3.3 3.3 3.3 3.3 3.3 3.2 3.2

60 4.2 4.2 4.2 4.1 4.1 4.0

10 7.1 8.7 10.6

20 6.5 8.0 9.6 11.6 13.8

30 5.8 7.1 8.6 10.3 12.3 14.6 17.1

40 5.1 6.2 7.5 9.0 10.7 12.6 14.9

50 4.2 5.1 6.2 7.5 8.9 10.6 12.4

60 4.0 4.8 5.8 7.0 8.3 9.8

10 1.5 1.5 1.5

20 1.9 1.9 1.9 1.9 1.9

30 2.3 2.4 2.3 2.3 2.3 2.3 2.3

40 3.0 3.0 3.0 3.0 2.9 2.9 2.9

50 3.8 3.8 3.7 3.7 3.7 3.7 3.6

60 4.8 4.7 4.7 4.7 4.6 4.6

19

Page 20

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB38KQE

P

Q

ZB45KQE

P

Q

ZB48KQE

P

Q

ZB58KQE

P

Q

ZB66KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

20

Condensing

temperature oC

10 9.0 11.0 13.3

20 8.2 10.0 12.2 14.6 17.4

30 7.4 9.0 10.9 13.0 15.5 18.4 21.6

40 6.4 7.8 9.4 11.3 13.5 15.9 18.7

50 5.3 6.5 7.8 9.4 11.2 13.3 15.7

60 5.0 6.1 7.3 8.8 10.5 12.4

10 1.9 1.9 1.9

20 2.4 2.4 2.4 2.4 2.4

30 3.0 3.0 3.0 3.0 2.9 2.9 2.9

40 3.7 3.7 3.7 3.7 3.7 3.7 3.6

50 4.7 4.7 4.7 4.7 4.7 4.6 4.6

60 6.0 6.0 5.9 5.9 5.9 5.8

10 10.5 12.8 15.6

20 9.6 11.8 14.2 17.1 20.4

30 8.6 10.5 12.7 15.3 18.2 21.5 25.3

40 7.5 9.1 11.0 13.2 15.8 18.7 21.9

50 6.2 7.6 9.2 11.0 13.1 15.6 18.4

60 5.8 7.1 8.6 10.3 12.2 14.5

10 2.1 2.1 2.1

20 2.7 2.7 2.7 2.7 2.7

30 3.4 3.4 3.4 3.3 3.3 3.3 3.3

40 4.2 4.2 4.2 4.2 4.2 4.2 4.1

50 5.4 5.4 5.4 5.3 5.3 5.2 5.2

60 6.8 6.8 6.7 6.7 6.6 6.6

10 11.5 14.1 17.1

20 10.6 12.9 15.7 18.8 22.4

30 9.5 11.6 14.0 16.8 20.0 23.7 27.8

40 8.2 10.0 12.1 14.5 17.3 20.5 24.1

50 6.8 8.3 10.1 12.1 14.4 17.1 20.2

60 6.4 7.8 9.4 11.3 13.5 16.0

10 2.3 2.3 2.3

20 2.9 2.9 2.9 2.9 2.9

30 3.7 3.7 3.7 3.7 3.7 3.6 3.6

40 4.7 4.7 4.7 4.6 4.6 4.6 4.5

50 5.9 5.9 5.9 5.9 5.8 5.8 5.7

60 7.5 7.4 7.4 7.4 7.3 7.2

10 13.8 16.8 20.3

20 12.5 15.3 18.5 22.3 26.6

30 11.1 13.7 16.6 20.0 23.8 28.2 33.2

40 9.5 11.9 14.5 17.5 20.8 24.6 28.9

50 7.4 9.7 12.0 14.6 17.5 20.7 24.4

60 6.9 9.0 11.3 13.7 16.4 19.3

10 3.0 3.1 3.1

20 3.6 3.7 3.8 3.9 3.9

30 4.5 4.5 4.6 4.7 4.7 4.7 4.6

40 5.6 5.6 5.7 5.7 5.8 5.8 5.7

50 7.2 7.1 7.1 7.1 7.1 7.1 7.1

60 9.1 9.0 8.9 8.9 8.8 8.7

10 15.7 19.2 23.4

20 14.3 17.5 21.2 25.5 30.4

30 12.8 15.6 18.8 22.6 26.9 31.9 37.6

40 11.1 13.5 16.4 19.6 23.3 27.5 32.4

50 9.1 11.3 13.7 16.4 19.5 23.0 27.0

60 8.7 10.7 12.9 15.4 18.2 21.4

10 3.4 3.5 3.6

20 4.1 4.2 4.3 4.4 4.5

30 5.0 5.1 5.2 5.3 5.4 5.5 5.6

40 6.2 6.3 6.3 6.4 6.5 6.5 6.6

50 7.8 7.9 7.9 7.9 7.9 8.0 8.0

60 9.9 9.9 9.9 9.8 9.8 9.8

-20 -15 -10 -5 0 5 10

Evaporating temperature (

o

C)

Page 21

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB76KQE

P

Q

ZB95KQE

P

Q

ZB114KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 18.4 22.4 27.2

20 16.7 20.4 24.7 29.7 35.5

30 14.9 18.3 22.2 26.6 31.7 37.5 44.0

40 12.9 15.9 19.4 23.3 27.7 32.7 38.3

50 10.6 13.3 16.2 19.5 23.3 27.5 32.2

60 10.1 12.6 15.3 18.3 21.8 25.6

10 3.9 4.0 4.1

20 4.8 4.9 5.0 5.1 5.1

30 5.8 5.9 6.0 6.1 6.2 6.3 6.3

40 7.2 7.3 7.4 7.5 7.6 7.6 7.7

50 9.1 9.1 9.2 9.2 9.3 9.3 9.3

60 11.5 11.4 11.4 11.4 11.4 11.4

10 22.8 27.7 33.7

20 20.8 25.3 30.5 36.7 43.9

30 18.6 22.7 27.4 32.8 39.0 46.2 54.5

40 15.6 19.6 23.9 28.6 33.9 40.0 47.1

50 15.5 19.5 23.8 28.4 33.6 39.4

60 14.0 17.9 21.9 26.3 31.2

10 4.9 5.1 5.2

20 6.0 6.1 6.3 6.5 6.6

30 7.4 7.5 7.7 7.8 7.9 8.0 8.1

40 9.4 9.4 9.5 9.6 9.7 9.8 9.8

50 11.9 11.9 11.9 12.0 12.0 12.0

60 15.1 15.0 15.0 14.9 14.9

10 27.4 33.3 40.3

20 24.9 30.4 36.7 44.1 52.5

30 21.9 27.0 32.8 39.4 46.8 55.4 65.1

40 18.3 23.1 28.3 34.1 40.7 48.2 56.7

50 18.3 23.0 28.2 34.0 40.5 47.8

60 16.8 21.4 26.4 31.9 38.1

10 5.9 6.1 6.2

20 7.2 7.4 7.5 7.7 7.9

30 8.9 9.1 9.2 9.3 9.5 9.6 9.8

40 11.2 11.3 11.3 11.4 11.5 11.6 11.7

50 14.2 14.2 14.1 14.1 14.1 14.2

60 17.9 17.7 17.6 17.5 17.4

21

Page 22

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB130KQE

P

Q

ZB150KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 30.4 36.4 43.6

15 28.5 34.3 41.2 49.4

20 26.8 32.4 39.0 46.8 55.9

25 25.2 30.6 36.9 44.3 52.9 62.8

30 23.7 28.9 34.9 41.9 50.0 59.2 69.8

35 22.2 27.2 32.9 39.5 47.0 55.6 65.5

40 20.6 25.4 30.8 37.0 44.0 52.0 61.1

45 19.0 23.6 28.7 34.4 40.9 48.2 56.6

50 21.6 26.3 31.6 37.6 44.3 51.9

55 23.8 28.6 34.0 40.1 47.0

60 20.9 25.3 30.2 35.6 41.7

10 5.5 5.6 5.7

15 6.4 6.5 6.6 6.7

20 7.3 7.4 7.5 7.6 7.8

25 8.2 8.3 8.4 8.6 8.7 8.8

30 9.1 9.2 9.4 9.5 9.7 9.8 9.8

35 10.1 10.3 10.4 10.6 10.7 10.8 10.9

40 11.2 11.4 11.5 11.7 11.8 11.9 12.0

45 12.5 12.6 12.7 12.9 13.0 13.1 13.2

50 14.0 14.1 14.2 14.4 14.5 14.5

55 15.7 15.8 15.9 16.0 16.0

60 17.5 17.6 17.6 17.7 17.7

10 35.8 43.6 52.7

15 34.2 41.7 50.3 60.3

20 32.5 39.7 47.9 57.4 68.2

25 30.8 37.6 45.4 54.4 64.6 76.3

30 29.1 35.4 42.8 51.3 61.0 72.0 84.4

35 27.3 33.2 40.1 48.1 57.2 67.5 79.3

40 25.5 31.0 37.4 44.8 53.3 63.0 74.0

45 23.7 28.7 34.6 41.4 49.3 58.3 68.6

50 31.8 38.0 45.2 53.5 63.0

55 34.5 41.0 48.6 57.3

60 36.8 43.6 51.5

10 7.8 8.2 8.8

15 8.6 8.9 9.4 10.1

20 9.5 9.7 10.1 10.6 11.4

25 10.6 10.7 10.9 11.3 12.0 12.9

30 11.7 11.8 12.0 12.3 12.7 13.5 14.5

35 13.0 13.1 13.2 13.4 13.8 14.3 15.1

40 14.4 14.5 14.7 14.8 15.1 15.5 16.1

45 15.9 16.1 16.3 16.4 16.6 16.9 17.4

50 18.1 18.2 18.4 18.6 19.0

55 20.3 20.4 20.6 20.9

60 22.7 22.9 23.1

22

Page 23

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

50 Hz

Model

Q

ZB190KQE

P

Q

ZB220KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 44.9 54.6 66.0

15 42.8 52.2 63.0 75.5

20 40.7 49.6 60.0 71.8 85.4

25 38.6 47.0 56.8 68.1 80.9 95.5

30 36.4 44.3 53.6 64.2 76.3 90.1 105.7

35 34.2 41.6 50.2 60.2 71.6 84.6 99.3

40 32.0 38.8 46.8 56.1 66.7 78.9 92.6

45 29.7 36.0 43.3 51.9 61.7 73.0 85.9

50 39.8 47.6 56.6 67.0 78.9

55 43.2 51.4 60.9 71.8

60 46.1 54.6 64.5

10 9.8 10.3 11.1

15 10.9 11.2 11.8 12.7

20 12.0 12.2 12.7 13.3 14.4

25 13.3 13.5 13.8 14.3 15.0 16.2

30 14.7 14.9 15.1 15.4 16.0 16.9 18.2

35 16.3 16.5 16.6 16.9 17.3 18.0 19.0

40 18.1 18.3 18.4 18.6 18.9 19.4 20.2

45 20.0 20.3 20.5 20.6 20.9 21.2 21.8

50 22.7 22.9 23.1 23.4 23.8

55 25.5 25.7 25.9 26.3

60 28.6 28.8 29.1

10 55.4 67.4 81.4

15 52.9 64.4 77.8 93.2

20 50.3 61.3 74.0 88.7 105.4

25 47.6 58.1 70.1 84.0 99.9 117.9

30 45.0 54.7 66.1 79.2 94.2 111.3 130.5

35 42.2 51.4 62.0 74.3 88.4 104.4 122.5

40 39.4 47.9 57.8 69.2 82.3 97.3 114.4

45 36.6 44.4 53.5 64.0 76.2 90.1 106.0

50 49.1 58.7 69.9 82.7 97.4

55 53.3 63.4 75.1 88.6

60 56.9 67.4 79.7

10 11.9 12.4 13.4

15 13.1 13.5 14.2 15.3

20 14.5 14.7 15.2 16.1 17.3

25 16.0 16.2 16.6 17.2 18.1 19.5

30 17.8 17.9 18.2 18.6 19.3 20.4 21.9

35 19.7 19.9 20.0 20.4 20.9 21.7 22.9

40 21.8 22.0 22.2 22.4 22.8 23.4 24.4

45 24.0 24.4 24.6 24.9 25.1 25.6 26.3

50 27.4 27.6 27.9 28.2 28.7

55 30.7 30.9 31.2 31.6

60 34.4 34.7 35.0

23

Page 24

Performance data R134a

Q=Capacity (kW) P=Power input (kW) 1&3-Phase

50 Hz

Model

Q

ZB15KQE

P

Q

ZB19KQE

P

Q

ZB21KQE

P

Q

ZB26KQE

P

Q

ZB29KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

24

Condensing

temperature oC

30 1.9 2.4 3.0 3.7 4.5 5.4

35 1.8 2.3 2.9 3.5 4.3 5.2

45 1.6 2.0 2.6 3.2 3.9 4.7 5.6

55 1.7 2.2 2.7 3.4 4.1 4.9

65 1.8 2.3 2.9 3.5 4.2

75 1.9 2.4 3.0 3.5

30 0.8 0.8 0.8 0.8 0.8 0.8

35 0.8 0.8 0.8 0.9 0.9 0.9

45 1.0 1.0 1.0 1.1 1.1 1.1 1.1

55 1.3 1.3 1.3 1.3 1.3 1.3

65 1.6 1.6 1.6 1.6 1.6

75 2.0 2.0 2.0 2.0

30 2.2 2.8 3.5 4.3 5.2 6.3

35 2.0 2.7 3.3 4.1 5.0 6.0

45 1.8 2.3 3.0 3.7 4.5 5.4 6.4

55 2.0 2.5 3.1 3.9 4.7 5.7

65 2.1 2.7 3.3 4.1 4.9

75 2.2 2.7 3.4 4.0

30 0.9 0.9 0.9 0.9 0.9 0.9

35 1.0 1.0 1.0 1.0 1.0 1.0

45 1.2 1.2 1.2 1.2 1.2 1.2 1.2

55 1.5 1.5 1.5 1.5 1.5 1.5

65 1.8 1.8 1.9 1.9 1.9

75 2.3 2.3 2.3 2.3

30 2.8 3.5 4.4 5.4 6.5 7.9

35 2.7 3.3 4.2 5.1 6.2 7.5

45 2.3 2.9 3.7 4.6 5.6 6.8 8.1

55 2.5 3.2 4.0 4.9 6.0 7.2

65 2.7 3.4 4.2 5.1 6.2

75 2.7 3.5 4.3 5.1

30 1.1 1.1 1.1 1.1 1.1 1.1

35 1.2 1.2 1.2 1.2 1.2 1.2

45 1.5 1.5 1.5 1.5 1.5 1.5 1.5

55 1.8 1.8 1.8 1.9 1.9 1.9

65 2.2 2.3 2.3 2.3 2.3

75 2.8 2.8 2.8 2.9

30 3.2 4.1 5.1 6.2 7.6 9.1

35 3.0 3.9 4.8 5.9 7.2 8.7

45 2.6 3.3 4.3 5.3 6.5 7.8 9.4

55 2.9 3.7 4.6 5.7 6.9 8.3

65 3.1 3.9 4.9 5.9 7.1

75 3.2 4.0 5.0 5.9

30 1.2 1.2 1.2 1.2 1.2 1.3

35 1.3 1.3 1.4 1.4 1.4 1.4

45 1.7 1.7 1.7 1.7 1.7 1.7 1.7

55 2.1 2.1 2.1 2.1 2.1 2.1

65 2.6 2.6 2.6 2.6 2.6

75 3.2 3.2 3.2 3.3

30 3.9 4.8 5.9 7.2 8.8 10.5

35 3.5 4.5 5.6 6.9 8.3 10.1

45 3.1 3.9 5.0 6.1 7.5 9.0 10.1

55 3.3 4.2 5.3 6.6 8.0 9.0

65 4.0 4.5 5.6 6.8 7.7

75 3.6 4.6 5.6 6.3

30 1.4 1.4 1.4 1.4 1.4 1.4

35

45 1.9 1.9 2.0 2.0 2.0 2.0 2.0

55 2.4 2.4 2.4 2.4 2.5 2.5

65 3.0 3.0 3.0 3.0 3.1

75 3.8 3.8 3.8 3.8

-15 -10 -5 0 5 10 15

1.5 1.6 1.6 1.6 1.6 1.6

Evaporating temperature (

o

C)

Page 25

Performance data R134a

Q=Capacity (kW) P=Power input (kW) 1&3-Phase

50 Hz

Model

Q

ZB38KQE

P

Q

ZB45KQE

P

Q

ZB48KQE

P

Q

ZB58KQE

P

Q

ZB66KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-15 -10 -5 0 5 10 15

30 4.7 5.9 7.4 9.1 11.1 13.3

35 4.3 5.6 7.0 8.6 10.5 12.7

45 3.8 4.9 6.3 7.8 9.4 11.4 13.7

55 4.2 5.4 6.7 8.3 10.1 12.1

65 4.6 5.7 7.1 8.7 10.4

75 4.6 5.8 7.2 8.9

30 1.7 1.7 1.7 1.8 1.8 1.8

35 1.9 1.9 1.9 2.0 2.0 2.0

45 2.3 2.4 2.4 2.4 2.4 2.5 2.5

55 3.0 3.0 3.0 3.0 3.0 3.1

65 3.7 3.7 3.7 3.8 3.8

75 4.7 4.7 4.7 4.7

30 5.7 7.1 8.9 10.9 13.3 15.9

35 5.2 6.8 8.5 10.4 12.7 15.2

45 4.5 5.8 7.5 9.3 11.4 13.7 16.3

55 5.0 6.3 8.0 10.0 12.1 14.4

65 5.3 6.7 8.4 10.3 12.3

75 5.4 6.8 8.5 10.1

30 2.0 2.0 2.0 2.0 2.0 2.0

35 2.2 2.2 2.2 2.2 2.3 2.3

45 2.7 2.7 2.8 2.8 2.8 2.8 2.8

55 3.4 3.4 3.5 3.5 3.5 3.5

65 4.3 4.3 4.3 4.4 4.4

75 5.4 5.4 5.4 5.4

30 6.4 8.1 9.9 12.2 14.7 17.6

35 5.9 7.7 9.5 11.6 14.0 16.9

45 5.2 6.6 8.5 10.4 12.6 15.1 17.3

55 5.7 7.2 9.0 11.1 13.4 15.3

65 6.1 7.6 9.5 11.5 13.1

75 6.2 7.8 9.6 10.9

30 2.3 2.3 2.3 2.3 2.3 2.4

35 2.5 2.6 2.6 2.6 2.6 2.7

45 3.2 3.2 3.2 3.2 3.3 3.3 3.4

55 4.0 4.0 4.0 4.0 4.1 4.2

65 5.0 5.0 5.0 5.1 5.1

75 6.3 6.3 6.3 6.3

30 7.5 9.2 11.2 13.4 15.9 18.6

35 6.3 8.7 10.6 12.7 15.1 17.7

45 5.4 6.9 9.4 11.3 13.5 15.8 18.3

55 5.9 7.5 9.3 11.7 13.8 16.0

65 6.2 7.8 9.7 11.6 13.5

75 6.1 7.7 9.6 10.9

30 2.7 2.7 2.8 2.8 2.9 2.9

35 3.0 3.0 3.1 3.1 3.2 3.2

45 3.7 3.8 3.8 3.9 3.9 3.9 3.8

55 4.6 4.7 4.7 4.8 4.8 4.7

65 5.6 5.7 5.8 5.8 5.7

75 6.9 7.0 7.0 6.9

30 8.6 10.5 12.8 15.3 18.2 21.2

35 7.2 10.0 12.1 14.6 17.3 20.2

45 6.2 7.9 10.7 12.9 15.5 18.1 20.9

55 6.7 8.5 10.6 13.4 15.7 18.3

65 7.0 8.9 11.0 13.3 15.4

75 7.0 8.8 11.0 12.5

30 3.0 3.0 3.1 3.2 3.2 3.3

35

45 4.2 4.2 4.3 4.3 4.3 4.3 4.3

55 2.4 5.2 5.3 5.3 5.3 5.2

65 6.3 6.4 6.5 6.5 6.4

75 7.7 7.8 7.8 7.8

3.4 3.4 3.4 3.5 3.5 3.6

25

Page 26

Performance data R134a

Q=Capacity (kW) P=Power input (kW) 1&3-Phase

50 Hz

Model

Q

ZB76KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-15 -10 -5 0 5 10 15

30 9.8 12.1 14.7 17.6 20.9 24.4

35 8.2 11.4 13.9 16.7 19.8 23.2

45 7.1 9.0 12.3 14.8 17.7 20.7 24.0

55 7.7 9.7 12.2 15.3 18.0 20.9

65 8.1 10.1 12.6 15.2 17.7

75 8.0 10.1 12.5 14.3

30 3.5 3.6 3.6 3.7 3.8 3.8

35 3.9 4.0 4.0 4.1 4.2 4.2

45 4.9 4.9 5.0 5.0 5.1 5.1 5.0

55 6.0 6.1 6.2 6.2 6.2 6.1

65 7.4 7.5 7.5 7.5 7.4

75 9.0 9.1 9.1 9.0

26

Page 27

Performance data R22

Q=Capacity (kW) P=Power input (kW) 1-Phase

60 Hz

Model

Q

ZB15KQ

P

Q

ZB19KQ

P

Q

ZB21KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 5.8 6.3 7.5 8.9

20 5.5 5.9 7.1 8.4 9.9

30 4.3 4.7 5.7 6.8 8.1 9.6 10.4

40 3.9 4.3 5.2 6.2 7.4 8.8 9.6

50 3.2 3.5 4.6 5.6 6.7 8.0 8.7

55 3.2 3.9 4.9 5.8 6.8 7.4

60 3.4 4.2 5.1 6.1 6.6

65 3.6 4.5 5.3 5.7

15 1.1 1.1 1.1 1.1

20 1.2 1.2 1.2 1.2 1.2

30 1.4 1.4 1.4 1.4 1.4 1.4 1.4

40 1.7 1.7 1.7 1.7 1.7 1.7 1.7

50 2.1 2.0 2.0 2.0 2.0 2.0 2.0

55 2.6 2.6 2.6 2.6 2.6 2.6

60 2.9 2.9 2.9 2.9 2.9

65 3.2 3.2 3.2 3.2

15 5.6 6.1 7.3 8.7

20 5.4 5.8 7.1 8.4 10.0

30 5.0 5.4 6.5 7.8 9.3 11.0 12.0

40 4.5 4.9 6.0 7.1 8.5 10.1 11.0

50 3.7 4.1 5.3 6.4 7.7 9.2 10.0

55 3.8 4.7 6.0 7.2 8.6 9.4

60 4.4 5.4 6.8 8.1 8.9

65 5.0 6.3 7.5 8.3

15 1.3 1.3 1.3 1.3

20 1.4 1.4 1.4 1.4 1.4

30 1.7 1.7 1.7 1.7 1.7 1.7 1.7

40 2.0 2.0 2.0 2.0 2.0 2.0 2.0

50 2.5 2.5 2.5 2.5 2.5 2.5 2.4

55 2.8 2.7 2.7 2.7 2.7 2.7

60 3.1 3.0 3.0 3.0 3.0

65 3.4 3.4 3.3 3.3

15 7.1 7.6 9.2 11.0

20 6.8 7.4 8.9 10.6 12.6

30 6.2 6.8 8.2 9.8 11.7 13.9 15.1

40 5.7 6.2 7.5 9.0 10.7 12.8 13.9

50 4.6 5.1 6.7 8.1 9.7 11.5 12.6

55 4.8 6.0 7.6 9.1 10.9 11.9

60 5.5 6.8 8.5 10.2 11.2

65 6.3 7.9 9.5 10.4

15 1.6 1.6 1.6 1.6

20 1.8 1.7 1.8 1.8 1.8

30 2.1 2.1 2.1 2.1 2.1 2.2 2.2

40 2.6 2.6 2.6 2.6 2.6 2.6 2.6

50 3.2 3.2 3.1 3.1 3.1 3.1 3.1

55 3.5 3.5 3.5 3.5 3.5 3.4

60 3.9 3.9 3.9 3.8 3.8

65 4.3 4.3 4.3 4.2

27

Page 28

Performance data R22

Q=Capacity (kW) P=Power input (kW) 1-Phase

60 Hz

Model

Q

ZB26KQ

P

Q

ZB29KQ

P

Q

ZB38KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 8.1 8.8 10.6 12.7

20 7.8 8.5 10.3 12.3 14.6

30 7.2 7.8 9.5 11.4 13.5 16.0 17.5

40 6.5 7.1 8.7 10.4 12.4 14.7 16.1

50 5.4 5.9 7.8 9.4 11.2 13.3 14.5

55 5.5 6.9 8.8 10.5 12.6 13.7

60 6.4 7.9 9.8 11.8 12.9

65 7.3 9.1 11.0 12.0

15 1.8 1.8 1.8 1.9

20 2.0 2.0 2.0 2.0 2.1

30 2.4 2.4 2.4 2.4 2.5 2.5 2.5

40 2.9 2.9 2.9 2.9 2.9 2.9 2.9

50 3.6 3.6 3.6 3.6 3.6 3.6 3.5

55 4.0 4.0 4.0 4.0 3.9 3.9

60 4.4 4.4 4.4 4.4 4.4

65 4.9 4.9 4.9 4.8

15 9.5 10.3 12.4 14.6

20 9.2 10.0 12.1 14.3 16.7

30 8.5 9.3 11.3 13.4 15.8 18.6 20.2

40 7.7 8.4 10.3 12.3 14.6 17.3 18.9

50 6.5 7.1 9.3 11.1 13.2 15.7 17.2

55 6.8 8.3 10.4 12.4 14.8 16.3

60 7.9 9.5 11.6 13.9 15.3

65 8.9 10.9 13.0 14.3

15 2.1 2.1 2.2 2.3

20 2.3 2.3 2.4 2.4 2.5

30 2.7 2.7 2.8 2.8 2.9 2.9 2.9

40 3.2 3.2 3.3 3.3 3.4 3.4 3.4

50 3.9 3.9 3.9 4.0 4.0 4.1 4.1

55 4.3 4.3 4.4 4.4 4.5 4.5

60 4.7 4.8 4.9 4.9 4.9

65 5.3 5.4 5.4 5.4

15 12.0 12.7 15.2 18.1

20 11.4 12.1 14.5 17.4 20.4

30 10.4 11.0 13.2 16.1 19.1 21.9 23.0

40 9.5 10.0 12.0 14.8 17.8 20.6 21.8

50 7.7 8.2 10.6 13.2 16.1 19.0 20.2

55 7.5 9.2 12.3 15.1 18.0 19.2

60 8.3 10.8 14.0 16.8 18.0

65 9.6 12.7 15.4 16.7

15 2.5 2.5 2.7 2.8

20 2.7 2.8 2.9 3.0 3.1

30 3.3 3.3 3.4 3.5 3.5 3.6 3.5

40 4.0 4.0 4.0 4.1 4.2 4.2 4.2

50 4.8 4.8 4.9 5.0 5.0 5.1 5.1

55 5.3 5.4 5.5 5.5 5.6 5.6

60 5.9 6.0 6.1 6.2 6.2

65 6.6 6.7 6.8 6.8

28

Page 29

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB15KQ

P

Q

ZB19KQ

P

Q

ZB21KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 5.0 5.4 6.4 7.6

20 4.8 5.2 6.2 7.4 8.8

30 4.3 4.7 5.7 6.8 8.0 9.5 10.2

40 3.9 4.2 5.1 6.2 7.4 8.7 9.5

50 3.2 3.5 4.6 5.5 6.6 7.8 8.5

55 3.4 4.2 5.4 6.4 7.6 8.3

60 3.9 4.9 6.0 7.1 7.8

65 4.5 5.6 6.7 7.2

15 0.9 0.9 1.0 1.1

20 1.0 1.1 1.1 1.1 1.2

30 1.3 1.3 1.3 1.4 1.4 1.4 1.4

40 1.6 1.6 1.6 1.7 1.7 1.7 1.7

50 2.0 2.0 2.0 2.1 2.1 2.1 2.1

55 2.2 2.2 2.2 2.2 2.3 2.3

60 2.4 2.5 2.5 2.5 2.5

65 2.7 2.7 2.8 2.8

15 5.6 6.1 7.3 8.7

20 5.4 5.8 7.0 8.4 10.0

30 4.9 5.4 6.5 7.8 9.3 11.0 11.9

40 4.5 4.9 5.9 7.1 8.5 10.1 11.0

50 3.7 4.0 5.3 6.4 7.7 9.1 9.9

55 3.7 4.7 6.0 7.2 8.6 9.4

60 4.3 5.4 6.7 8.0 8.8

65 4.9 6.2 7.4 8.1

15 1.2 1.2 1.2 1.2

20 1.3 1.3 1.3 1.4 1.4

30 1.6 1.6 1.7 1.7 1.7 1.7 1.7

40 2.0 2.0 2.0 2.0 2.0 2.1 2.1

50 2.5 2.5 2.5 2.5 2.5 2.5 2.5

55 2.8 2.8 2.8 2.8 2.7 2.7

60 3.2 3.1 3.1 3.0 3.0

65 3.5 3.5 3.4 3.4

15 7.2 7.8 9.3 11.1

20 6.9 7.5 9.1 10.8 12.7

30 6.4 6.9 8.4 10.1 11.9 14.0 15.1

40 5.8 6.3 7.7 9.2 11.0 12.9 14.0

50 4.8 5.2 6.9 8.3 9.9 11.7 12.7

55 4.9 6.1 7.8 9.3 11.0 12.0

60 5.7 7.0 8.7 10.4 11.3

65 6.5 8.1 9.7 10.5

15 1.4 1.4 1.4 1.5

20 1.5 1.5 1.6 1.6 1.7

30 1.9 1.9 1.9 2.0 2.0 2.1 2.2

40 2.3 2.3 2.3 2.4 2.4 2.5 2.5

50 2.8 2.8 2.9 2.9 2.9 3.0 3.0

55 3.1 3.2 3.2 3.3 3.3 3.3

60 3.5 3.6 3.6 3.6 3.6

65 3.9 4.0 4.0 4.0

29

Page 30

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB26KQ

P

Q

ZB29KQ

P

Q

ZB38KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 8.4 9.1 11.0 13.1

20 8.1 8.7 10.5 12.6 15.0

30 7.4 8.0 9.7 11.6 13.8 16.3 17.7

40 6.7 7.3 8.9 10.6 12.7 15.0 16.2

50 5.5 6.0 8.0 9.6 11.4 13.5 14.7

55 5.6 7.1 9.0 10.8 12.7 13.9

60 6.5 8.1 10.1 11.9 13.0

65 7.5 9.3 11.1 12.1

15 1.5 1.5 1.5 1.6

20 1.7 1.7 1.7 1.8 1.8

30 2.1 2.1 2.1 2.2 2.3 2.3 2.3

40 2.7 2.7 2.7 2.7 2.8 2.8 2.8

50 3.4 3.4 3.4 3.4 3.5 3.5 3.4

55 3.8 3.8 3.8 3.9 3.9 3.8

60 4.3 4.3 4.3 4.3 4.3

65 4.8 4.8 4.8 4.8

15 9.9 10.7 12.8 15.2

20 9.5 10.3 12.4 14.8 17.4

30 8.7 9.5 11.5 13.7 16.3 19.2 20.8

40 7.8 8.5 10.4 12.5 14.9 17.6 19.2

50 6.4 7.0 9.2 11.1 13.3 15.8 17.3

55 6.6 8.2 10.4 12.5 14.9 16.2

60 7.6 9.3 11.6 13.9 15.2

65 8.6 10.7 12.8 14.0

15 1.8 1.8 1.8 1.9

20 2.0 2.0 2.0 2.1 2.2

30 2.5 2.5 2.5 2.5 2.6 2.7 2.7

40 3.1 3.1 3.1 3.1 3.2 3.2 3.2

50 3.8 3.8 3.8 3.9 3.9 4.0 4.0

55 4.2 4.3 4.3 4.4 4.4 4.4

60 4.8 4.8 4.9 4.9 4.9

65 5.4 5.4 5.5 5.4

15 12.0 12.9 15.5 18.5

20 11.6 12.5 15.1 18.0 21.2

30 10.7 11.6 14.0 16.8 19.9 23.3 25.2

40 9.7 10.5 12.8 15.4 18.3 21.5 23.3

50 7.9 8.7 11.5 13.8 16.5 19.5 21.1

55 8.2 10.2 13.0 15.5 18.4 20.0

60 9.5 11.7 14.6 17.3 18.8

65 10.9 13.6 16.1 17.5

15 2.3 2.3 2.4 2.5

20 2.5 2.6 2.6 2.8 2.9

30 3.1 3.2 3.2 3.3 3.4 3.5 3.6

40 3.9 3.9 3.9 4.0 4.1 4.2 4.2

50 4.7 4.8 4.8 4.9 4.9 5.0 5.0

55 5.3 5.3 5.4 5.5 5.5 5.5

60 5.9 6.0 6.0 6.1 6.1

65 6.6 6.7 6.7 6.7

30

Page 31

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB45KQ

P

Q

ZB48KQ

P

Q

ZB58KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 14.5 15.6 18.7 22.2

20 13.9 15.0 18.1 21.5 25.4

30 12.8 13.9 16.7 20.0 23.8 27.9 30.1

40 11.6 12.6 15.3 18.4 21.9 25.7 27.8

50 9.5 10.3 13.6 16.5 19.7 23.3 25.3

55 9.6 12.0 15.4 18.5 22.0 23.8

60 11.1 13.8 17.3 20.6 22.3

65 12.7 15.9 19.1 20.8

15 2.6 2.6 2.7 2.8

20 2.9 2.9 3.0 3.1 3.3

30 3.6 3.6 3.7 3.8 3.9 4.0 4.1

40 4.5 4.5 4.5 4.6 4.7 4.8 4.8

50 5.5 5.5 5.6 5.6 5.7 5.8 5.8

55 6.1 6.2 6.3 6.3 6.4 6.4

60 6.8 6.9 7.0 7.1 7.1

65 7.7 7.8 7.8 7.8

15 15.9 17.1 20.5 24.4

20 15.3 16.5 19.9 23.7 28.0

30 14.1 15.3 18.4 22.0 26.1 30.7 33.1

40 12.8 13.8 16.8 20.2 24.0 28.3 30.6

50 10.4 11.4 15.0 18.1 21.6 25.6 27.8

55 10.5 13.2 17.0 20.3 24.2 26.2

60 12.2 15.2 19.0 22.6 24.6

65 13.9 17.5 21.0 22.8

15 2.8 2.8 2.9 3.1

20 3.2 3.2 3.3 3.4 3.6

30 4.0 4.0 4.0 4.1 4.3 4.4 4.5

40 4.9 4.9 5.0 5.1 5.1 5.2 5.3

50 6.0 6.0 6.1 6.2 6.3 6.3 6.4

55 6.7 6.8 6.9 7.0 7.0 7.0

60 7.5 7.6 7.7 7.8 7.8

65 8.5 8.6 8.6 8.6

15 18.6 20.1 24.2 28.8

20 17.9 19.3 23.3 27.9 33.2

30 16.3 17.7 21.6 26.0 31.0 36.6

40 14.7 16.0 19.6 23.8 28.5 33.8 36.7

50 11.7 12.9 17.4 21.3 25.6 30.6 33.3

55 11.8 15.2 19.8 24.0 28.8 31.4

60 13.9 17.7 22.3 26.9 29.4

65 16.0 20.5 24.8 27.2

15 3.5 3.6 3.7 3.9

20 3.9 4.0 4.1 4.2 4.4

30 4.9 4.9 5.0 5.1 5.2 5.4 5.5

40 6.0 6.0 6.1 6.1 6.2 6.3 6.3

50 7.4 7.4 7.4 7.5 7.5 7.5 7.6

55 8.2 8.3 8.3 8.3 8.3 8.3

60 9.2 9.2 9.2 9.2 9.2

65 10.2 10.2 10.2 10.2

31

Page 32

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB66KQ

P

Q

ZB76KQ

P

Q

ZB88KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 20.5 22.2 26.9 32.3

20 19.8 21.5 26.0 31.3 37.4

30 18.4 20.0 24.2 29.2 34.8 41.2 44.7

40 16.9 18.3 22.3 26.8 32.0 37.9 41.1

50 13.8 15.2 20.1 24.2 29.0 34.3 37.3

55 14.2 17.8 22.9 27.3 32.4 35.2

60 16.6 20.6 25.7 30.5 33.1

65 19.1 23.9 28.4 30.9

15 3.9 3.9 4.1 4.3

20 4.4 4.4 4.5 4.7 4.9

30 5.4 5.4 5.5 5.7 5.8 6.0 6.1

40 6.6 6.6 6.7 6.8 7.0 7.1 7.2

50 8.1 8.1 8.2 8.3 8.4 8.5 8.6

55 9.0 9.1 9.2 9.3 9.3 9.4

60 10.1 10.2 10.2 10.3 10.3

65 11.2 11.3 11.4 11.4

15 24.5 26.6 32.2 38.7

20 23.8 25.7 31.2 37.4 44.4

30 22.2 24.0 29.0 34.7 41.1 48.4 52.3

40 20.3 21.9 26.6 31.8 37.7 44.3 47.9

50 16.5 18.1 23.9 28.7 34.1 40.2 43.4

55 16.8 21.1 27.0 32.2 38.0 41.1

60 19.5 24.3 30.2 35.7 38.7

65 22.5 28.1 33.4 36.2

15 4.8 4.9 5.0 5.3

20 5.3 5.3 5.5 5.6 5.9

30 6.4 6.4 6.5 6.7 6.9 7.1 7.2

40 7.8 7.9 8.0 8.1 8.2 8.4 8.5

50 9.7 9.7 9.8 9.9 10.0 10.1 10.2

55 10.8 10.9 10.9 11.0 11.1 11.2

60 12.1 12.1 12.2 12.3 12.4

65 13.4 13.5 13.6 13.6

15 33.4 36.3 43.7 51.2

20 30.2 32.9 40.1 47.4 54.7

30 25.4 27.8 34.4 41.4 48.5 55.3 58.5

40 22.2 24.2 30.1 36.6 43.4 50.3 53.5

50 18.0 19.7 26.4 32.3 38.8 45.5 48.8

55 18.4 23.1 30.1 36.4 43.0 46.3

60 21.2 26.8 33.9 40.3 43.6

65 24.2 31.0 37.3 40.6

15 5.4 5.5 5.7 6.0

20 5.9 6.0 6.2 6.5 6.8

30 7.2 7.3 7.4 7.6 7.9 8.2 8.4

40 8.8 8.9 9.0 9.1 9.3 9.6 9.7

50 10.8 10.8 11.0 11.1 11.2 11.4 11.5

55 12.0 12.2 12.3 12.4 12.5 12.6

60 13.5 13.6 13.7 13.8 13.9

65 15.1 15.2 15.3 15.3

32

Page 33

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB95KQ

P

Q

ZB114KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12.5

15 30.7 33.2 40.0 47.9

20 29.6 32.0 38.7 46.3 54.9

30 27.0 29.3 35.7 42.8 50.8 59.8 64.6

40 23.9 26.1 32.1 38.9 46.4 54.7 59.2

50 28.1 34.4 41.5 49.3 53.4

55 32.0 38.8 46.3 50.3

60 36.0 43.3 47.1

65 33.0 40.0 43.8

15 5.9 6.1 6.4 6.8

20 6.5 6.6 6.9 7.2 7.7

30 8.0 8.1 8.2 8.5 8.8 9.2 9.4

40 10.0 10.0 10.2 10.3 10.5 10.7 10.9

50 12.6 12.7 12.9 13.0 13.1

55 14.1 14.3 14.4 14.5

60 15.8 16.0 16.0

65 17.5 17.6 17.7

15 36.6 39.8 49.1 60.3

20 35.1 38.1 46.6 56.9 69.2

30 32.2 34.9 42.4 51.1 61.5 73.8 80.7

40 28.8 31.5 38.4 46.2 55.2 65.6 71.5

50 33.9 41.3 49.4 58.5 63.5

55 38.5 46.4 55.1 59.8

60 43.2 51.6 56.0

65 39.7 47.9 52.2

15 7.3 7.4 7.7 8.2

20 8.0 8.1 8.4 8.8 9.4

30 9.7 9.8 10.0 10.3 10.7 11.3 11.6

40 11.9 11.9 12.1 12.3 12.6 13.0 13.2

50 14.8 14.9 15.1 15.4 15.6

55 16.5 16.7 16.9 17.0

60 18.4 18.6 18.7

65 20.4 20.5 20.6

33

Page 34

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB130KQ

P

Q

ZB150KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12

15 40.5 43.7 52.7 63.1

20 38.6 41.8 50.5 60.6 72.1

25 36.8 39.9 48.5 58.2 69.3

30 35.1 38.1 46.5 55.9 66.6 78.7 83.9

35 33.3 36.3 44.5 53.7 64.0 75.5 80.5

40 31.3 34.3 42.3 51.3 61.2 72.3 77.0

45 28.4 31.5 40.0 48.7 58.3 68.9 73.4

50 25.7 28.8 37.4 45.8 55.1 65.3 69.6

55 22.6 25.7 33.7 42.7 51.6 61.3 65.5

60 30.1 38.5 47.7 57.0 61.0

65 34.2 43.3 52.2 56.0

15 6.9 7.0 7.1 7.3

20 7.9 7.9 8.1 8.3 8.6

25 8.9 8.9 9.1 9.3 9.6

30 9.9 10.0 10.1 10.3 10.6 10.8 11.0

35 11.0 11.0 11.2 11.4 11.7 11.9 12.0

40 12.2 12.2 12.4 12.60. 12.8 13.1 13.2

45 13.4 13.5 13.7 13.9 14.1 14.3 14.4

50 14.9 15.0 15.1 15.4 15.6 15.8 15.9

55 16.5 16.5 16.8 17.0 17.2 17.4 17.5

60 18.6 18.8 19.0 19.2 19.2

65 20.8 21.0 21.2 21.3

15 47.8 51.4 61.7 74.2

20 45.9 49.5 59.4 71.4 85.6

25 44.1 47.5 57.2 68.7 82.3

30 42.3 45.6 55.0 66.0 79.0 94.4 101.3

35 40.4 43.7 52.8 63.4 75.8 90.5 97.0

40 38.4 41.6 50.5 60.7 72.6 86.6 92.8

45 36.0 39.2 48.1 57.9 69.3 82.6 88.5

50 33.5 36.7 45.5 55.0 65.9 78.6 84.2

55 30.7 33.9 42.4 51.9 62.4 74.4 79.8

60 39.2 48.3 58.7 70.1 75.2

65 44.6 54.7 65.6 70.4

15 8.2 8.4 8.8 9.2

20 9.8 10.0 10.4 10.8 11.0

25 11.3 11.5 11.8 12.2 12.5

30 12.8 12.9 13.2 13.6 13.9 14.1 14.1

35 14.3 14.3 14.6 14.9 15.3 15.5 15.6

40 15.9 15.9 16.0 16.3 16.7 17.0 17.1

45 17.6 17.5 17.6 17.8 18.2 18.5 18.7

50 19.6 19.4 19.4 19.6 19.9 20.2 20.4

55 21.8 21.6 21.4 21.5 21.8 22.2 22.3

60 23.8 23.8 24.0 24.4 24.5

65 26.5 26.6 26.9 27.1

34

Page 35

Performance data R22

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB190KQ

P

Q

ZB220KQ

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-12 -10 -5 0 5 10 12

15 59.0 63.4 76.3 92.0

20 55.5 59.8 72.3 87.4 105.0

25 52.7 57.0 69.2 83.8 100.6

30 50.4 54.6 66.6 80.8 97.0 115.2 123.1

35 48.2 52.4 64.3 78.1 93.8 111.2 118.7

40 45.7 50.0 61.8 75.4 90.6 107.4 114.5

45 41.2 45.7 58.9 72.3 87.1 103.3 110.2

50 36.8 41.5 55.1 68.5 83.0 98.7 105.3

55 31.0 35.9 48.9 63.6 78.0 93.3 99.7

60 42.1 56.3 71.6 86.6 92.8

65 48.0 63.6 78.4 84.4

15 12.2 12.5 13.4 14.7

20 13.0 13.2 13.9 14.9 16.1

25 14.2 14.3 14.8 15.5 16.5

30 15.6 15.7 16.0 16.6 17.4 18.4 18.9

35 17.4 17.5 17.6 18.0 18.6 19.5 19.9

40 19.5 19.5 19.5 19.8 20.3 21.0 21.3

45 21.7 21.7 21.7 21.9 22.3 22.8 23.1

50 24.1 24.1 24.1 24.3 24.6 25.1 25.3

55 26.7 26.7 26.8 26.9 27.2 27.6 27.9

60 29.5 29.7 30.1 30.5 30.7

65 32.7 33.1 33.6 33.8

15 73.8 79.4 94.7 112.6

20 71.0 76.4 91.2 108.4 128.8

25 68.1 73.5 87.9 104.4 123.9

30 65.2 70.5 84.6 100.6 119.2 141.2 151.2

35 62.1 67.4 81.2 96.7 114.5 135.6 145.1

40 58.6 63.9 77.7 92.7 109.9 130.0 139.0

45 53.3 58.9 73.9 88.6 105.2 124.4 133.0

50 48.6 54.3 69.6 84.2 100.2 118.7 126.9

55 43.2 49.1 63.5 79.3 95.0 112.7 120.6

60 57.9 72.8 89.3 106.4 114.0

65 66.6 83.0 99.7 107.0

15 12.6 12.8 13.4 13.7

20 14.8 15.0 15.7 16.2 16.0

25 16.9 17.1 17.8 18.5 18.6

30 19.1 19.2 19.8 20.6 21.0 20.3 19.7

35 21.3 21.3 21.8 22.6 23.2 22.9 22.5

40 23.8 23.7 24.0 24.7 25.4 25.4 25.1

45 26.7 26.4 26.4 27.0 27.7 27.9 27.8

50 30.1 29.6 29.1 29.6 30.2 30.6 30.5

55 34.0 33.3 32.4 32.5 33.0 33.4 33.4

60 36.2 36.0 36.3 36.6 36.7

65 40.1 40.1 40.3 40.3

35

Page 36

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 1-Phase

60 Hz

Model

Q

ZB15KQE

P

Q

ZB19KQE

P

Q

ZB21KQE

P

Q

ZB26KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 4.4 5.4 6.6

20 4.0 4.9 5.9 7.1 8.4

30 3.6 4.4 5.3 6.3 7.5 8.8 10.3

40 3.1 3.8 4.6 5.5 6.5 7.6 8.9

50 2.6 3.2 3.8 4.6 5.4 6.4 7.5

60 2.5 3.8 3.6 4.3 5.1 6.1

10 0.9 1.0 1.0

20 1.2 1.2 1.2 1.2 1.2

30 1.5 1.5 1.5 1.5 1.5 1.5 1.5

40 1.8 1.9 1.9 1.9 1.9 1.9 1.8

50 2.3 2.3 2.3 2.3 2.3 2.3 2.3

60 2.9 2.3 2.9 2.9 2.9 2.9

10 5.5 6.8 8.2

20 5.0 6.1 7.4 8.9 10.5

30 4.5 5.4 6.6 7.9 9.3 11.0 12.8

40 3.9 4.7 5.7 6.8 8.1 9.5 11.2

50 3.2 3.9 4.8 5.7 6.8 8.0 9.4

60 3.1 3.7 4.5 5.4 6.4 7.6

10 1.2 1.2 1.2

20 1.5 1.5 1.5 1.5 1.5

30 1.8 1.9 1.9 1.9 1.9 1.9 1.8

40 2.3 2.3 2.3 2.3 2.3 2.3 2.3

50 2.9 2.9 2.9 2.9 2.9 2.9 2.9

60 3.6 3.6 3.6 3.6 3.6 3.6

10 6.6 8.1 9.8

20 6.0 7.3 8.8 10.6 12.6

30 5.3 6.5 7.8 9.4 11.1 13.1 15.4

40 4.6 5.6 6.8 8.1 9.7 11.2 13.3

50 3.8 4.7 5.7 6.8 8.1 9.6 11.2

60 3.7 4.5 5.4 6.4 7.7 9.0

10 1.4 1.4 1.4

20 1.8 1.8 1.8 1.8 1.8

30 2.2 2.2 2.2 2.2 2.2 2.2 2.2

40 2.8 2.8 2.8 2.8 2.8 2.9 2.8

50 3.5 3.5 3.5 3.5 3.5 3.5 3.5

60 4.3 4.3 4.3 4.3 4.3 4.3

10 7.7 9.4 11.4

20 7.0 8.5 10.3 12.4 14.7

30 6.2 7.6 9.2 11.0 13.0 15.3 17.9

40 5.4 6.6 7.9 9.5 11.3 13.3 15.6

50 4.5 5.5 6.6 8.0 9.5 11.2 13.1

60 4.3 5.2 6.3 7.5 8.9 10.5

10 1.6 1.7 1.7

20 2.1 2.1 2.1 2.1 2.1

30 2.6 2.6 2.6 2.6 2.6 2.6 2.6

40 3.2 3.2 3.3 3.3 3.3 3.2 3.2

50 4.0 4.1 4.1 4.1 4.1 4.1 4.0

60 5.1 5.1 5.1 5.1 5.0 5.0

36

Page 37

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 1-Phase

60 Hz

Model

Q

ZB29KQE

P

Q

ZB38KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 8.6 10.6 12.8

20 7.8 9.6 11.6 14.0 16.7

30 6.9 8.5 10.4 12.5 14.8 17.5 20.5

40 5.9 7.4 9.0 10.8 12.9 15.2 17.8

50 4.8 6.1 7.4 9.0 10.7 12.7 14.9

60 4.6 5.8 7.0 8.5 10.1 11.9

10 2.1 2.1 2.2

20 2.5 2.5 2.5 2.6 2.6

30 3.0 3.0 3.0 3.1 3.1 3.2 3.2

40 3.6 3.6 3.7 3.7 3.7 3.8 3.8

50 4.4 4.4 4.4 4.5 4.5 4.5 4.6

60 5.4 5.4 5.4 5.5 5.5 5.5

10 10.9 13.2 15.8

20 9.9 12.1 14.6 17.4 20.5

30 8.7 10.8 13.1 15.7 18.5 21.7 25.1

40 7.4 9.2 11.3 13.6 16.2 19.0 22.2

50 6.0 7.5 9.3 11.2 13.5 16.0 18.8

60 5.8 7.2 8.8 10.6 12.6 15.0

10 2.6 2.6 2.8

20 3.0 3.1 3.2 3.3 3.4

30 3.7 3.7 3.8 3.8 4.0 4.1 4.3

40 4.5 4.5 4.6 4.6 4.7 4.8 4.9

50 5.4 5.5 5.6 5.6 5.7 5.7 5.8

60 6.7 6.7 6.8 6.9 6.9 7.0

37

Page 38

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB15KQE

P

Q

ZB19KQE

P

Q

ZB21KQE

P

Q

ZB26KQE

P

Q

ZB29KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

38

Condensing

temperature oC

10 4.4 5.4 6.6

20 4.0 4.9 5.9 7.1 8.6

30 3.5 4.3 5.3 6.3 7.6 9.0 10.6

40 3.0 3.7 4.5 5.4 6.5 7.7 9.1

50 2.4 3.0 3.7 4.5 5.4 6.4 7.6

60 2.2 2.8 3.5 4.2 5.0 5.9

10 1.0 0.9 0.9

20 1.2 1.2 1.2 1.2 1.1

30 1.5 1.5 1.5 1.5 1.5 1.4 1.4

40 2.0 1.9 1.9 1.9 1.9 1.9 1.8

50 2.5 2.5 2.5 2.4 2.4 2.4 2.3

60 3.1 3.1 3.1 3.0 3.0 3.0

10 5.5 6.7 8.1

20 5.0 6.1 7.3 8.8 10.4

30 4.4 5.4 6.5 7.8 9.3 10.9 12.7

40 3.8 4.7 5.7 6.8 8.0 9.5 11.1

50 3.2 3.9 4.7 5.7 6.7 8.0 9.3

60 3.0 3.7 4.5 5.4 6.4 7.5

10 1.1 1.1 1.1

20 1.4 1.4 1.4 1.4 1.4

30 1.8 1.8 1.8 1.8 1.8 1.8 1.8

40 2.2 2.2 2.2 2.2 2.2 2.2 2.2

50 2.8 2.8 2.8 2.8 2.8 2.8 2.8

60 3.5 3.5 3.5 3.5 3.5 3.4

10 6.6 8.1 9.8

20 6.0 7.3 8.8 10.5 12.5

30 5.3 6.5 7.8 9.4 11.1 13.1 15.3

40 4.6 5.6 6.8 8.1 9.6 11.4 13.3

50 3.8 4.7 5.7 6.8 8.1 9.5 11.2

60 3.6 4.4 5.4 6.4 7.6 9.0

10 1.4 1.4 1.4

20 1.7 1.7 1.7 1.7 1.7

30 2.1 2.1 2.1 2.2 2.1 2.1 2.1

40 2.7 2.7 2.7 2.7 2.7 2.7 2.7

50 3.3 3.3 3.3 3.4 3.3 3.3 3.3

60 4.2 4.2 4.2 4.2 4.2 4.1

10 7.7 9.4 11.4

20 6.9 8.5 10.2 12.3 14.6

30 6.2 7.5 9.1 10.9 12.9 15.2 17.8

40 5.4 6.5 7.9 9.4 11.2 13.2 15.5

50 4.4 5.4 6.6 7.9 9.4 11.1 13.0

60 4.2 5.2 6.2 7.5 8.9 10.5

10 1.6 1.6 1.6

20 2.0 2.0 2.0 2.0 2.0

30 2.5 2.5 2.5 2.5 2.5 2.5 2.5

40 3.1 3.1 3.1 3.1 3.1 3.1 3.1

50 3.9 3.9 3.9 3.9 3.9 3.9 3.9

60 4.9 4.9 4.9 4.9 4.9 4.8

10 8.7 10.6 12.9

20 7.9 9.6 11.6 13.9 16.6

30 7.0 8.5 10.3 12.4 14.7 17.3 20.2

40 6.1 7.4 9.0 10.7 12.7 15.0 17.6

50 5.0 6.2 7.5 9.0 10.7 12.6 14.8

60 4.8 5.9 7.1 8.5 10.1 11.9

10 1.8 1.8 1.8

20 2.2 2.2 2.2 2.2 2.2

30 2.8 2.8 2.8 2.8 2.8 2.8 2.8

40 3.5 3.5 3.5 3.5 3.5 3.5 3.5

50 4.3 4.3 4.4 4.4 4.4 4.3 4.3

60 5.4 5.4 5.4 5.4 5.4 5.4

-20 -15 -10 -5 0 5 10

Evaporating temperature (

o

C)

Page 39

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB38KQE

P

Q

ZB45KQE

P

Q

ZB48KQE

P

Q

ZB58KQE

P

Q

ZB66KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 11.0 13.4 16.2

20 9.9 12.1 14.6 17.6 20.9

30 8.8 10.8 13.0 15.6 18.5 21.8 25.5

40 7.6 9.3 11.3 13.5 16.0 18.9 22.1

50 6.3 7.8 9.4 11.3 13.4 15.9 18.6

60 6.0 7.4 8.9 10.7 12.7 15.0

10 2.2 2.2 2.3

20 2.8 2.8 2.8 2.8 2.8

30 3.5 3.5 3.5 3.5 3.5 3.5 3.5

40 4.4 4.4 4.4 4.4 4.4 4.4 4.4

50 5.5 5.5 5.5 5.5 5.5 5.5 5.5

60 6.8 6.8 6.8 6.8 6.8 6.8

10 13.0 15.9 19.3

20 11.8 14.4 17.4 20.8 24.8

30 10.5 12.8 15.4 18.5 21.9 25.9 30.3

40 9.1 11.1 13.4 16.0 19.0 22.4 26.3

50 7.5 9.2 11.2 13.4 16.0 18.9 22.1

60 7.2 8.8 10.6 12.7 15.1 17.8

10 2.6 2.6 2.6

20 3.2 3.3 3.3 3.3 3.3

30 4.1 4.1 4.1 4.1 4.1 4.1 4.1

40 5.1 5.1 5.1 5.2 5.1 5.1 5.1

50 6.4 6.4 6.4 6.4 6.4 6.4 6.4

60 8.0 8.0 8.0 8.0 8.0 7.9

10 14.3 17.5 21.2

20 12.9 15.8 19.1 22.9 27.2

30 11.5 14.0 17.0 20.3 24.1 28.4 33.3

40 10.0 12.2 14.7 17.6 20.9 24.7 28.9

50 8.3 10.1 12.3 14.7 17.5 20.7 24.3

60 7.9 9.6 11.6 13.9 16.6 19.5

10 2.9 2.9 2.9

20 3.6 3.6 3.6 3.6 3.6

30 4.5 4.5 4.5 4.5 4.5 4.5 4.5

40 5.6 5.6 5.7 5.7 5.7 5.6 5.6

50 7.0 7.0 7.1 7.1 7.1 7.0 7.0

60 8.8 8.8 8.8 8.8 8.8 8.7

10 16.5 20.1 24.4

20 15.1 18.4 22.2 26.7 32.0

30 13.6 16.6 20.0 23.9 28.5 33.9 40.1

40 11.6 14.4 17.5 21.0 24.9 29.5 34.9

50 9.1 11.8 14.6 17.6 21.0 25.0 29.5

60 8.4 11.0 13.7 16.6 19.9 23.7

10 3.7 3.8 3.9

20 4.5 4.6 4.7 4.8 4.8

30 5.5 5.6 5.7 5.8 5.8 5.9 5.8

40 6.8 6.9 6.9 7.0 7.1 7.1 7.1

50 8.5 8.5 8.5 8.6 8.6 8.7 8.7

60 10.5 10.5 10.6 10.6 10.6 10.6

10 19.0 23.2 28.2

20 17.3 21.1 25.6 30.8 36.8

30 15.4 18.8 22.8 27.3 32.5 38.5 45.3

40 13.4 16.4 19.8 23.7 28.2 33.3 39.1

50 11.2 13.7 16.6 19.9 23.6 27.8 32.6

60 10.7 13.1 15.7 18.7 22.0 25.9

10 4.1 4.3 4.4

20 5.0 5.2 5.3 5.5 5.7

30 6.1 6.3 6.4 6.6 6.7 6.8 7.0

40 7.5 7.6 7.8 7.9 8.0 8.1 8.2

50 9.2 9.4 9.5 9.6 9.7 9.7 9.8

60 11.4 11.5 11.6 11.7 11.7 11.7

39

Page 40

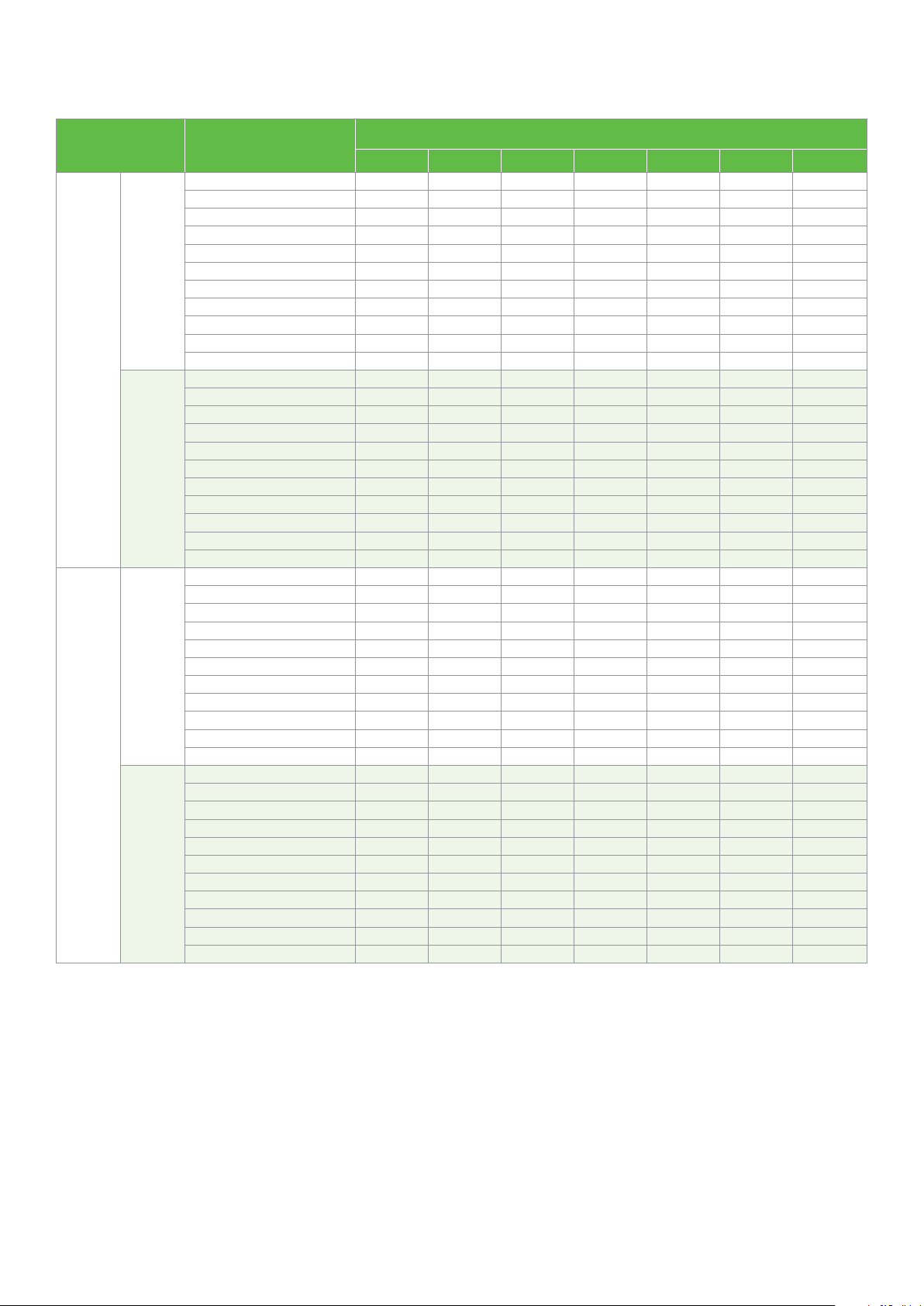

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB76KQE

P

Q

ZB95KQE

P

Q

ZB114KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 22.3 27.1 32.8

20 20.2 24.7 29.9 35.9 42.8

30 18.1 22.1 26.7 32.0 38.2 45.2 53.1

40 15.9 19.3 23.3 27.9 33.2 39.3 46.2

50 13.6 16.5 19.8 23.6 28.0 33.0 38.9

60 13.5 16.0 19.0 22.5 26.5 31.2

10 4.8 5.0 5.2

20 5.9 6.0 6.1 6.3 6.5

30 7.2 7.3 7.5 7.6 7.7 7.8 7.9

40 8.7 8.9 9.1 9.2 9.3 9.4 9.5

50 10.5 10.8 11.0 11.2 11.3 11.4 11.5

60 12.8 13.2 13.5 13.7 13.8 13.9

10 27.4 33.4 40.5

20 25.0 30.5 36.9 44.3 52.8

30 22.3 27.3 33.0 39.6 47.1 55.7 65.6

40 19.2 23.7 28.8 34.5 41.0 48.4 56.9

50 19.5 24.0 28.9 34.4 40.6 47.7

60 18.4 22.5 27.1 32.1 37.9

10 6.2 6.4 6.8

20 7.5 7.7 8.0 8.3 8.6

30 9.2 9.4 9.6 9.8 10.1 10.4 10.6

40 11.5 11.6 11.8 11.9 12.1 12.3 12.5

50 14.4 14.5 14.6 14.7 14.8 15.0

60 18.0 18.0 18.1 18.1 18.2

10 32.8 40.2 48.8

20 29.8 36.5 44.2 53.1 63.3

30 26.5 32.6 39.5 47.4 56.4 66.6 78.1

40 22.8 28.2 34.3 41.2 49.0 57.9 67.9

50 23.2 28.5 34.5 41.2 48.7 57.2

60 22.0 27.0 32.6 38.8 45.8

10 7.5 7.7 8.0

20 9.1 9.3 9.6 9.9 10.1

30 11.1 11.3 11.6 11.8 12.0 12.3 12.4

40 13.6 13.8 14.0 14.2 14.4 14.6 14.8

50 16.9 17.1 17.3 17.5 17.6 17.7

60 21.0 21.1 21.2 21.3 21.3

40

Page 41

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB130KQE

P

Q

ZB150KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 36.7 44.0 52.7

15 34.3 41.3 49.7 59.5

20 32.2 38.9 46.9 56.3 67.2

25 30.2 36.7 44.4 53.3 63.6 75.4

30 28.4 34.7 41.9 50.3 60.0 71.1 83.8

35 26.6 32.6 39.5 47.4 56.5 66.8 78.6

40 24.8 30.6 37.1 44.4 52.8 62.4 73.4

45 22.8 28.4 34.5 41.3 49.1 57.9 68.0

50 25.9 31.7 38.0 45.1 53.2 62.4

55 28.6 34.4 40.9 48.2 56.4

60 25.1 30.4 36.3 42.8 50.1

10 8.0 8.1 8.3

15 8.4 8.5 8.7 8.9

20 9.0 9.2 9.3 9.5 9.7

25 9.8 10.0 10.2 10.4 10.6 10.8

30 10.9 11.1 11.3 11.4 11.6 11.7 12.0

35 12.1 12.3 12.5 12.7 12.8 12.9 13.1

40 13.5 13.7 13.9 14.1 14.2 14.3 14.4

45 15.0 15.3 15.5 15.6 15.7 15.8 15.9

50 17.0 17.2 17.3 17.4 17.5 17.5

55 19.0 19.2 19.3 19.3 19.3

60 21.0 21.1 21.2 21.2 21.1

10 42.6 51.3 61.4

15 40.9 49.6 59.6 71.0

20 38.9 47.4 57.3 68.4 81.1

25 36.7 45.0 54.5 65.4 77.7 91.6

30 34.6 42.5 51.5 61.9 73.7 87.1 102.1

35 32.6 39.9 48.4 58.2 69.3 82.1 96.4

40 30.9 37.5 45.3 54.3 64.7 76.7 90.2

45 29.5 35.3 42.3 50.4 60.0 71.0 83.6

50 39.5 46.7 55.2 65.2 76.8

55 43.3 50.6 59.5 69.8

60 46.3 53.9 62.9

10 10.7 11.4 12.6

15 11.2 11.5 12.2 13.4

20 12.2 12.3 12.5 13.2 14.7

25 13.5 13.5 13.5 13.8 14.7 16.5

30 15.0 15.1 15.0 15.0 15.4 16.7 19.0

35 16.4 16.7 16.7 16.6 16.8 17.6 19.3

40 17.5 18.3 18.5 18.5 18.5 19.1 20.3

45 18.3 19.6 20.2 20.4 20.5 20.9 21.9

50 21.7 22.2 22.6 23.0 23.8

55 23.8 24.5 25.1 26.0

60 26.1 27.1 28.1

41

Page 42

Performance data R404A

Q=Capacity (kW) P=Power input (kW) 3-Phase

60 Hz

Model

Q

ZB190KQE

P

Q

ZB220KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-20 -15 -10 -5 0 5 10

10 59.8 64.2 73.9

15 59.3 63.6 72.8 86.5

20 58.1 62.1 70.9 83.9 100.4

25 56.3 59.9 68.3 80.6 96.3 114.6

30 53.9 57.2 65.1 76.7 91.5 108.7 127.8

35 51.1 54.1 61.4 72.3 86.1 102.3 120.1

40 48.1 50.7 57.4 67.6 80.5 95.4 111.9

45 44.9 47.2 53.3 62.6 74.5 88.3 103.4

50 49.1 57.6 68.5 81.1 94.7

55 52.6 62.5 73.8 86.0

60 56.6 66.7 77.4

10 14.5 10.8 5.6

15 15.7 13.4 9.5 4.9

20 16.8 15.7 13.0 9.6 6.0

25 17.7 17.7 16.1 13.8 11.3 9.4

30 18.6 19.6 18.9 17.5 15.9 14.9 15.2

35 19.5 21.2 21.4 20.7 19.9 19.6 20.7

40 20.4 22.7 23.5 23.4 23.2 23.6 25.2

45 21.3 24.1 25.4 25.8 26.0 26.9 28.9

50 27.0 27.7 28.3 29.4 31.8

55 29.2 30.0 31.3 33.8

60 31.2 32.5 35.1

10 73.5 86.5 101.4

15 68.3 81.5 96.7 113.8

20 63.0 76.1 91.4 108.6 127.6

25 58.0 70.7 85.6 102.5 121.4 142.0

30 53.5 65.4 79.7 96.0 114.4 134.6 156.5

35 49.9 60.7 73.9 89.3 106.9 126.4 147.7

40 47.3 56.7 68.5 82.7 99.1 117.6 138.0

45 46.2 53.7 63.9 76.5 91.4 108.5 127.6

50 60.3 71.0 84.1 99.5 116.9

55 66.4 77.3 90.7 106.2

60 71.5 82.5 95.7

10 10.3 12.4 15.1

15 13.2 14.5 16.2 18.7

20 16.3 17.0 18.0 19.5 21.8

25 19.4 19.7 20.2 21.0 22.4 24.7

30 22.3 22.5 22.7 23.0 23.8 25.3 27.7

35 24.8 25.2 25.3 25.4 25.8 26.7 28.3

40 26.7 27.5 27.9 28.0 28.2 28.8 29.9

45 28.0 29.4 30.2 30.6 30.9 31.4 32.3

50 32.1 33.1 33.7 34.3 35.2

55 35.2 36.4 37.4 38.5

60 38.9 40.5 42.0

42

Page 43

Performance data R134a

Q=Capacity (kW) P=Power input (kW) 1 & 3-Phase

60 Hz

Model

Q

ZB15KQE

P

Q

ZB19KQE

P

Q

ZB21KQE

P

Q

ZB26KQE

P

Q

ZB29KQE

P

*20°C Return gas temperature in non-shaded region

*11K Suction superheat in shaded region

*0K Subcooling

Condensing

temperature oC

Evaporating temperature (

o

C)

-15 -10 -5 0 5 10 15

30 2.3 2.9 3.6 4.5 5.4 6.5

35 2.2 2.8 3.5 4.2 5.2 6.3

45 2.0 2.4 3.2 3.9 4.7 5.7 6.8

55 2.1 2.7 3.3 4.1 5.0 5.9

65 2.2 2.8 3.5 4.2 5.1

75 2.3 2.9 3.6 4.2

30 1.0 1.0 1.0 1.0 1.0 1.0

35 1.0 1.0 1.0 1.1 1.1 1.1

45 1.2 1.2 1.2 1.3 1.3 1.3 1.3

55 1.6 1.6 1.6 1.6 1.6 1.6

65 1.9 1.9 1.9 1.9 1.9

75 2.4 2.4 2.4 2.4

30 2.7 3.4 4.2 5.2 6.3 7.6

35 2.4 3.3 4.0 5.0 6.0 7.2

45 2.2 2.8 3.6 4.5 5.4 6.5 7.7