Page 1

Advanced user Guide

Commander SX

IP66/Nema 4X

variable speed drive

Part Number :

3854 en - 03.2008 / b

Page 2

CONTROL TECHNIQUES

ADVANCED USER GUIDE

3854 en - 03.2008 / b

Commander SX

IP66/Nema 4X variable speed drive

NOTE

CONTROL TECHNIQUES reserves the right to modify the characteristics of its products at any time in order to incorporate the

latest technological developments. The information con tained in this document may therefore be changed without notice.

WARNING

For the user's own safety, this variable speed drive must be connected to an approved earth ( terminal).

If accidentally starting the installation is likely to cause a risk to personn el or the machines be ing driven, it is essential to supp ly

the equipment via a circuit-breaking device (power contactor) which can be controlled via an external safety system (emergency

stop, detection of errors on the installation).

The variable speed drive is fitted with safety devices which, in the event of a fault, control stopping and thus stop the motor.

The motor itself can become jammed for mechanical reasons. Voltage fluctuations, and in particular power cuts, may also cause

the motor to stop.

The removal of the causes of the shutdown can lead to restarting, which may be dangerous for certain machines or installations.

In such cases, it is essential that the user takes appropriate precautions against the motor restarting after an unscheduled st op.

The variable speed drive is designed to be able to supply a motor an d the driven machine above its rated speed.

If the motor or the machine are not mechanically designed to withstand such speeds, the user may be exposed to serious danger

resulting from their mechanical deterioration.

Before programming a high speed, it i s important that the user checks that the installation can withstan d it.

The variable speed drive which is the subject of this manual is designed to be integrated in an installation or an electrical

machine, and can under no circumstances be considered to be a safety device. It is therefore the responsibility of the machine

manufacturer, the designer of the installation or the user to take all necessary precautio ns to ensure that the system complies

with current standards, and to provide any devices required to ensure the safety of equipment and personnel.

Using the drive for hoisting: when using this application, it is essential to follow the special instructions in an application-specific

manual which is available on request. It is the responsibility of the user to obtain this manual from his usual CONTROL

TECHNIQUES contact.

CONTROL TECHNIQUES declines all responsibility in the event of the above recommendations not being observed.

........................................

Manual corresponding to software versions higher than or equal to 3.10

This generation of drives requires the use of a SX SOFT parameter-setting software version higher than or equal to

V3.00, or the KEYPAD-LCD console version higher than or equal to V3.10

2

Page 3

CONTROL TECHNIQUES

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

Safety Information

Warnings, Cautions and Notes

• A Warning contains information which is

essential for avoiding a safety hazard.

Caution :

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other

equipment.

Note : A Note contains information which helps to ensure

correct operation of the product.

Electrical safety - general warning

The voltages used in the drive can cause severe e lectrical

shock and/or burns, and could be lethal. Extreme care is

necessary at all times when working with or adjacent to the

drive.

Specific warnings are given at the relevant places in this User

Guide.

System design and safety of personnel

The drive is intended as a component for professional

incorporation into complete equipment or a system. If

installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level

of stored electrical energy, and is used to control equipment

which can cause injury.

Close attention is required to the electrical installation and the

system design to avoid hazards either in normal operation or

in the event of equipment malfunction. System design,

installation, commissioning and maintenance must be carried

out by personnel who have the necessary training and

experience. They must read this safety information and this

User Guide carefully.

The STOP and SECURE INPUT (Option) functions of the

drive do not isolate dangerous voltages from the output of the

drive or from any external option unit. The supply must be

disconnected by an approved electrical isolation device

before gaining access to the electrical connections.

With the sole exception of the SECURE INPUT (Option)

function, none of the drive functions must be used to

ensure safety of personn el, i.e. they m ust not be used for

safety-related functions.

Careful consideration must be given to the functions of the

drive which might result in a hazard, either through their

intended behaviour or through incorrect operation due to a

fault. In any application where a malfunction of the drive or its

control system could lead to or allow damage, loss or injury,

a risk analysis must be carried out, and where necessary,

further measures taken to reduce the risk - for example, an

over-speed protection device in case of failure of the speed

control, or a fail-safe mechanical brake in case of loss of

motor braking.

The SECURE INPUT (Option) function has been approved

as meeting the requirements of EN954-1 category 3 for the

prevention of unexpected starting of the drive. It may be used

in a safety-related application. The system designer is

responsible for ensuring that the complete system is

safe and designed correctly according to the relevant

safety standards.

Environmental limits

Instructions in this User Guide regarding transport, storage,

installation and use of the drive must be complied with,

including the specified environmental limits. Drives must not

be subjected to excessive physical force.

Compliance with regulations

The installer is responsible for complying with all relevant

regulations, such as national wiring regulations, accident

prevention regulations and electromagnetic compatibility

(EMC) regulations. Particular attention must be given to the

cross-sectional areas of conductors, the selection of fuses or

other protection, and protective earth (ground) connections.

This User Guide contains instruction for achieving

compliance with specific EMC standards.

Within the European Union, all machinery in which this

product is used must comply with the following directives:

98/37/EC: Safety of machinery.

89/336/EEC: Electromagnetic Compatibility.

Motor

Ensure the motor is installed in accordance with the

manufacturer’s recommendations. Ensure the motor shaft is

not exposed.

Standard squirrel cage induction motors are designed for

single speed operation. If it is intended to use the capability of

the drive to run a motor at speeds above its designed

maximum, it is strongly recommended that the manufacturer

is consulted first.

Low speeds may cause the motor to overheat because the

cooling fan becomes less effective. The motor should be fitted

with a protection thermistor. If necessary, an electric forced

vent fan should be used.

The values of the motor parameters set in the drive affect the

protection of the motor. The default values in the drive should

not be relied upon.

It is essential that the correct value is entered in parameter 06

motor rated current. This affects the thermal protection of the

motor.

Adjusting parameters

Some parameters have a profound effect on the operation of

the drive. They must not be altered without careful

consideration of the impact on the controlled system.

Measures must be taken to prevent unwanted changes due

to error or tampering.

1

1

Independent approval by CETIM has been given for sizes 1 to 3.

3

Page 4

CONTROL TECHNIQUES

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

FOREWORD

CAUTION

• This is the technical manual complementing installation and maintenance manual ref. 3840.

• Before setting the drive parameters, it is essential to have strictly observed all instructions

relating to installation, connection and commissioning of the drive contained in document ref. 3840

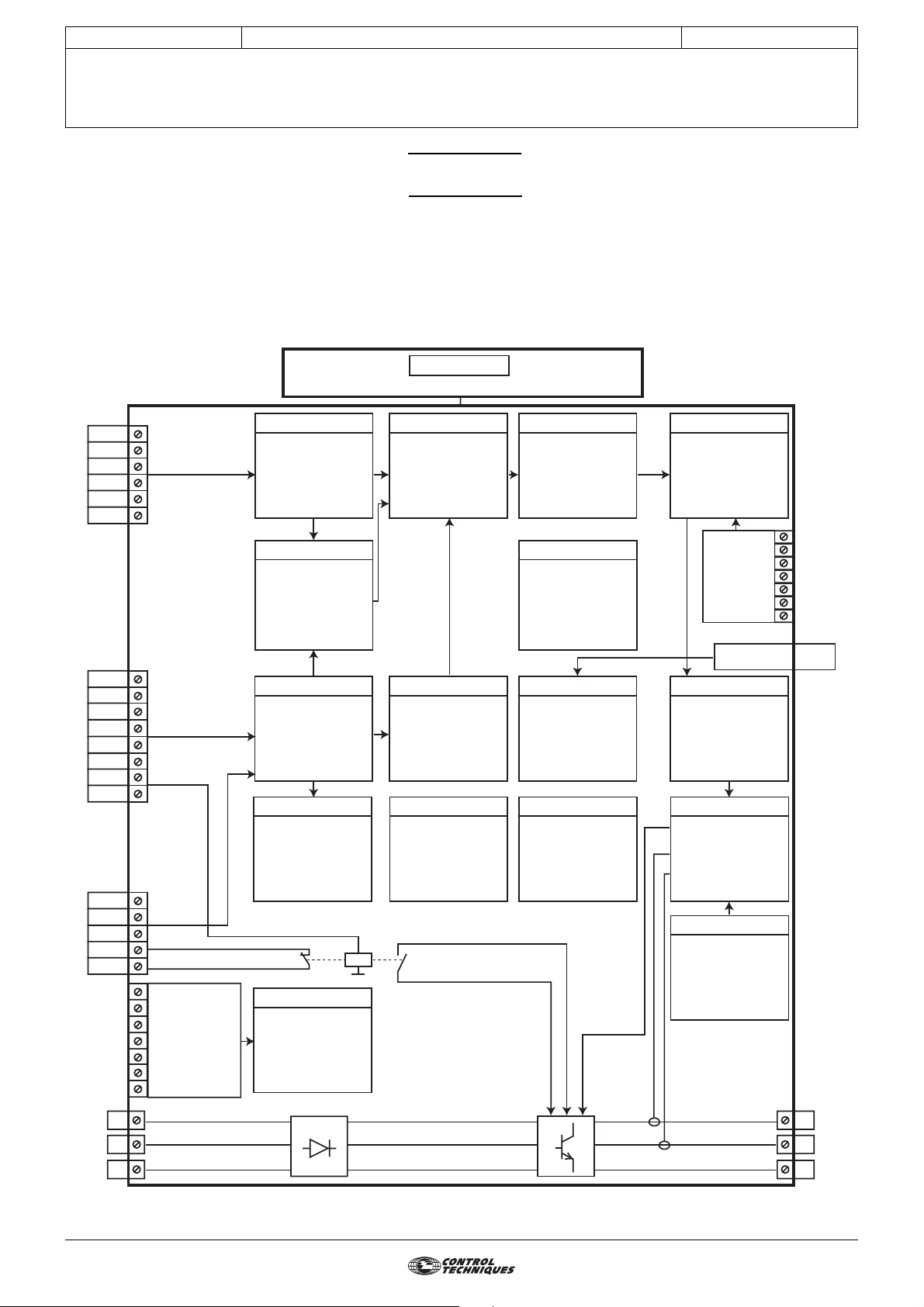

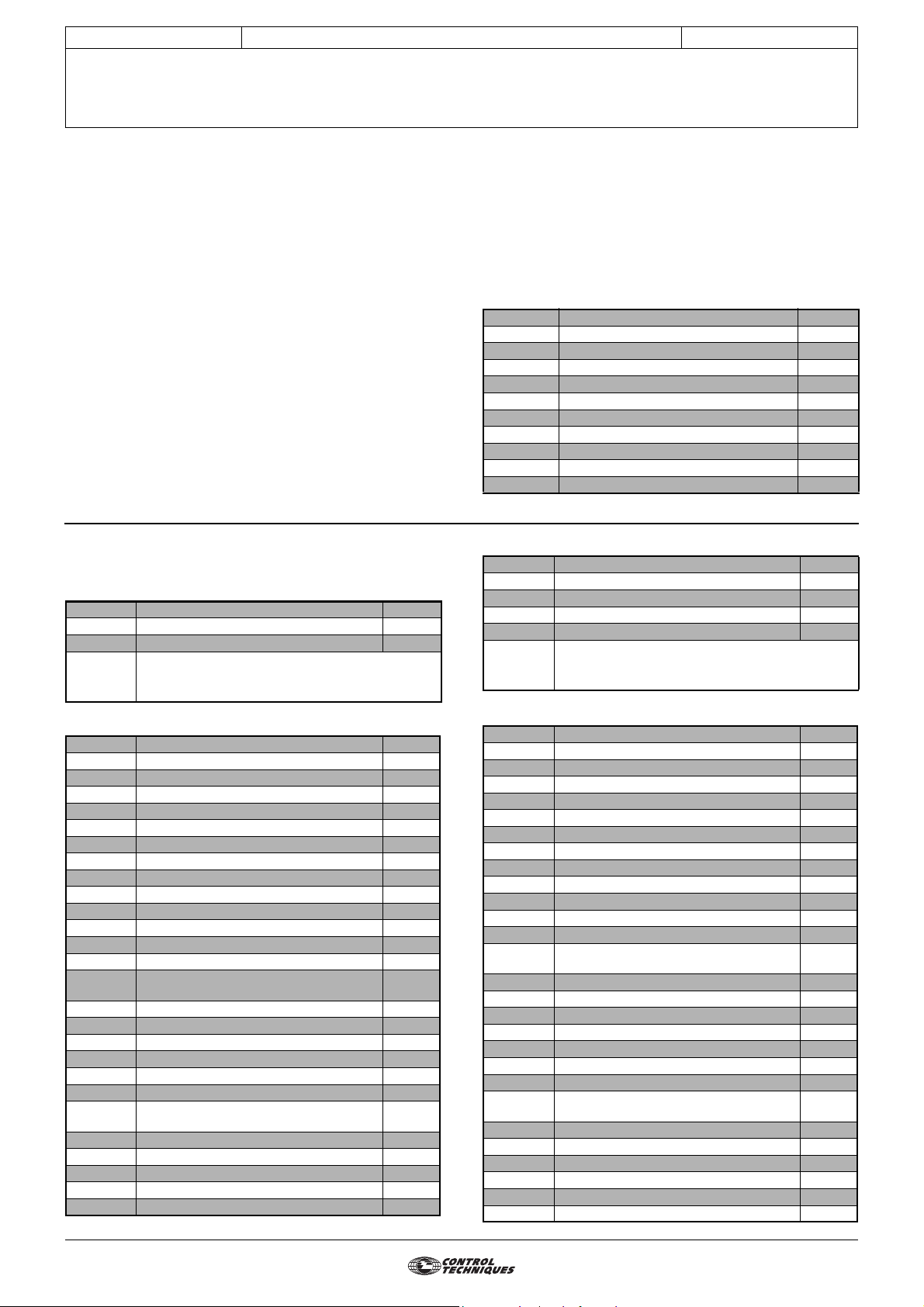

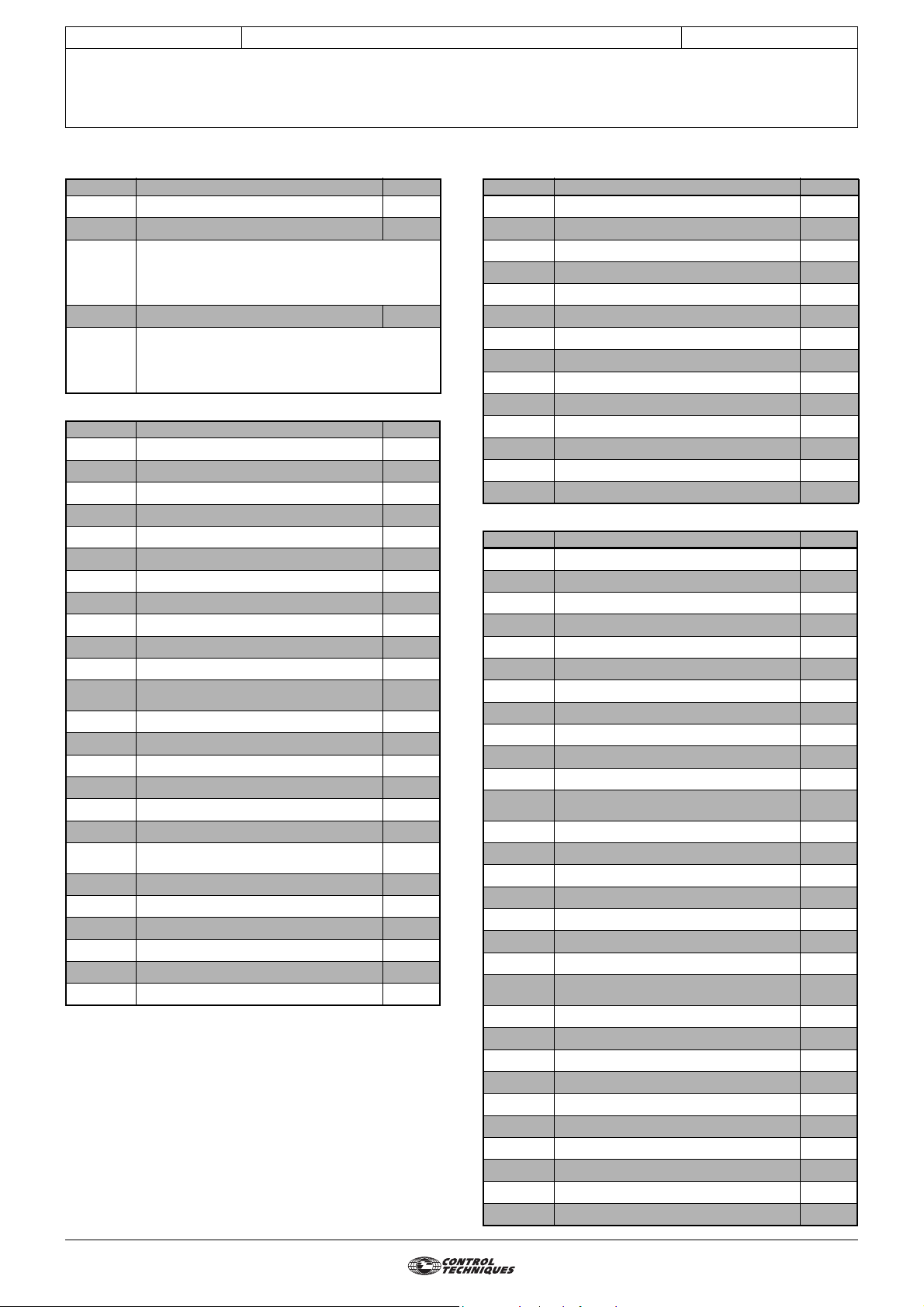

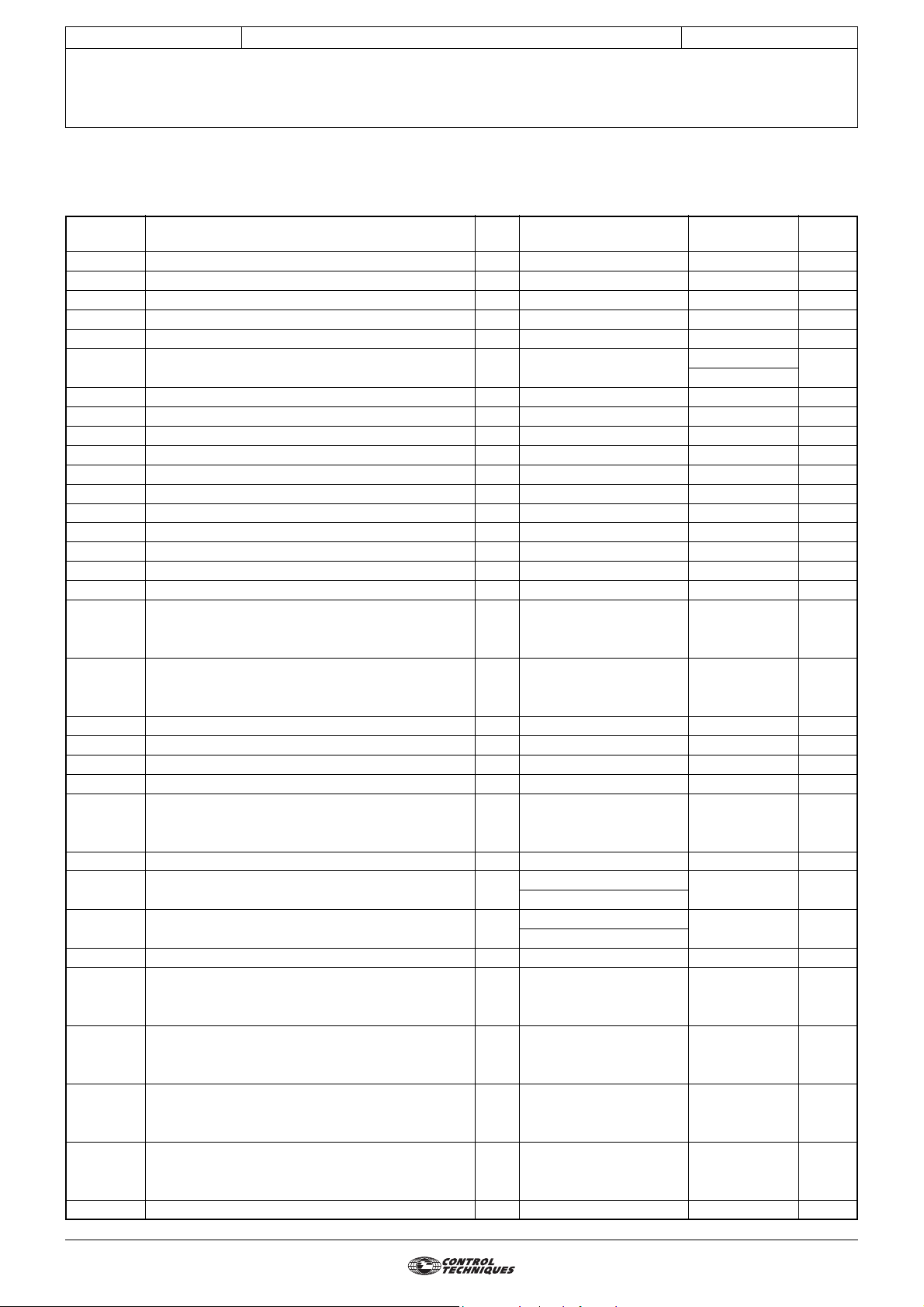

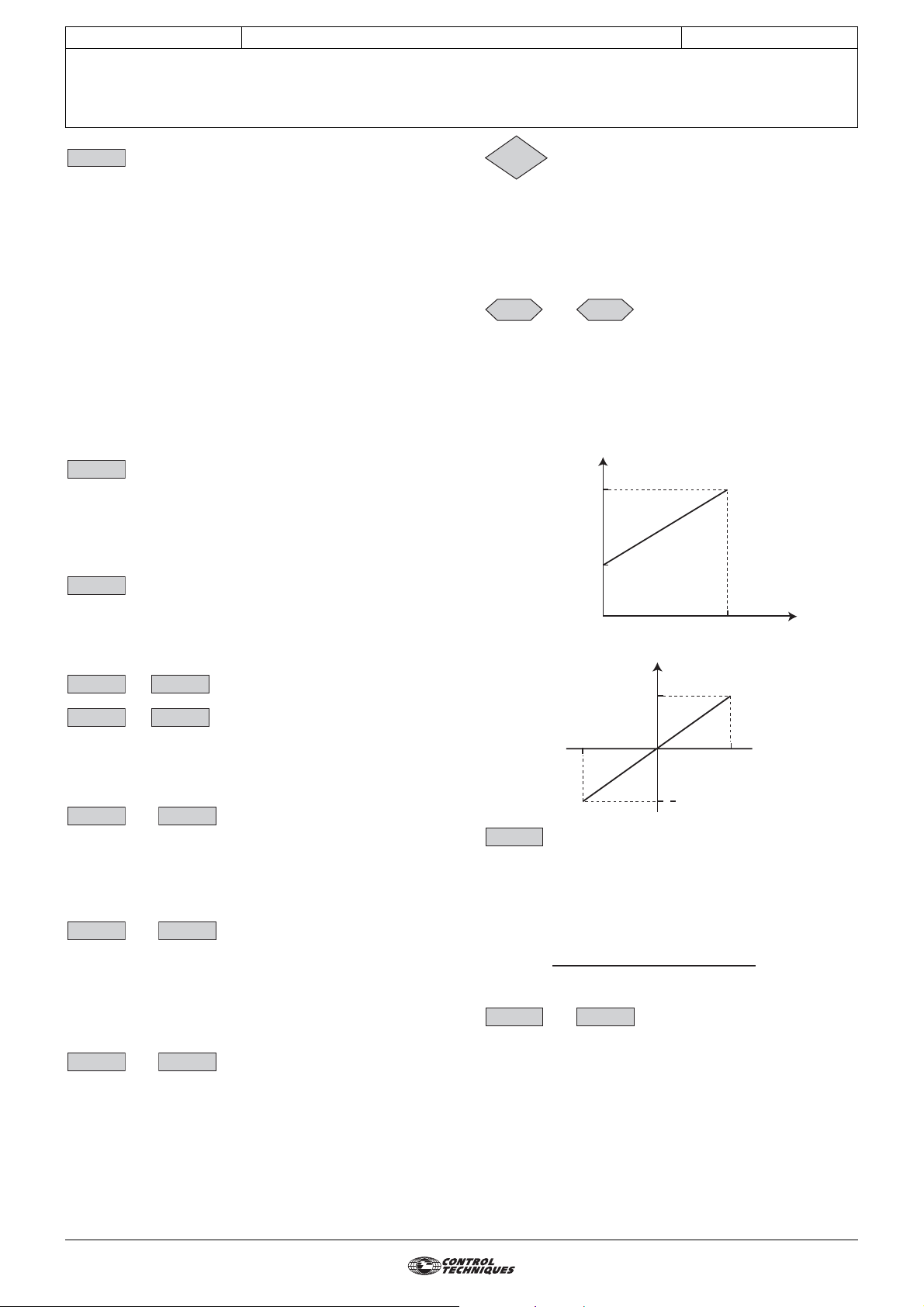

MENU ORGANISATION

MENU 0

See installation and maintenance manual Ref. 3840

3854 en - 03.2008 / b

10V

ADI1

0V

ADI2

0V

ADIO3

DIO1

24V

DI2

DI3

24V

DI4

SDI1

SDI2

COM

RL1C

RL1O

SDO1

SDO2

Additional

I/O, fieldbus

or Modbus RTU

option

MENU 7

Configuration

of

analog I/O

MENU 14

PID controller

MENU 8

Configuration

of

digital I/O

MENU 9

Logic functions

(And, Or,

Motorised pot,

binary sum)

MENU 15

Configuration of

additional I/O

or Modbus RTU/

fieldbus

configuration

MENU 1

Speed

reference

and

limiting

MENU 6 MENU 11 MENU 4

Programmable

logic, timers

MENU 12 MENU 16 MENU 5

Math functions,

threshold

detectors,

brake control

MENU 2

Ramps

MENU 10

Drive states

and

diagnostics

User menu,

serial link,

miscellaneous

PLC functions

(Timing, latching,

upcounting/

downcounting)

Alarms, speed

thresholds,

encoder option

and torque

Motor control

(mode, switching

frequency,

characteristics)

parameters

MENU 3

Encoder

option

serial link RJ45

Current

control

MENU 21

Second

motor

L1

L2

L3

4

U

V

W

Page 5

CONTROL TECHNIQUES

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

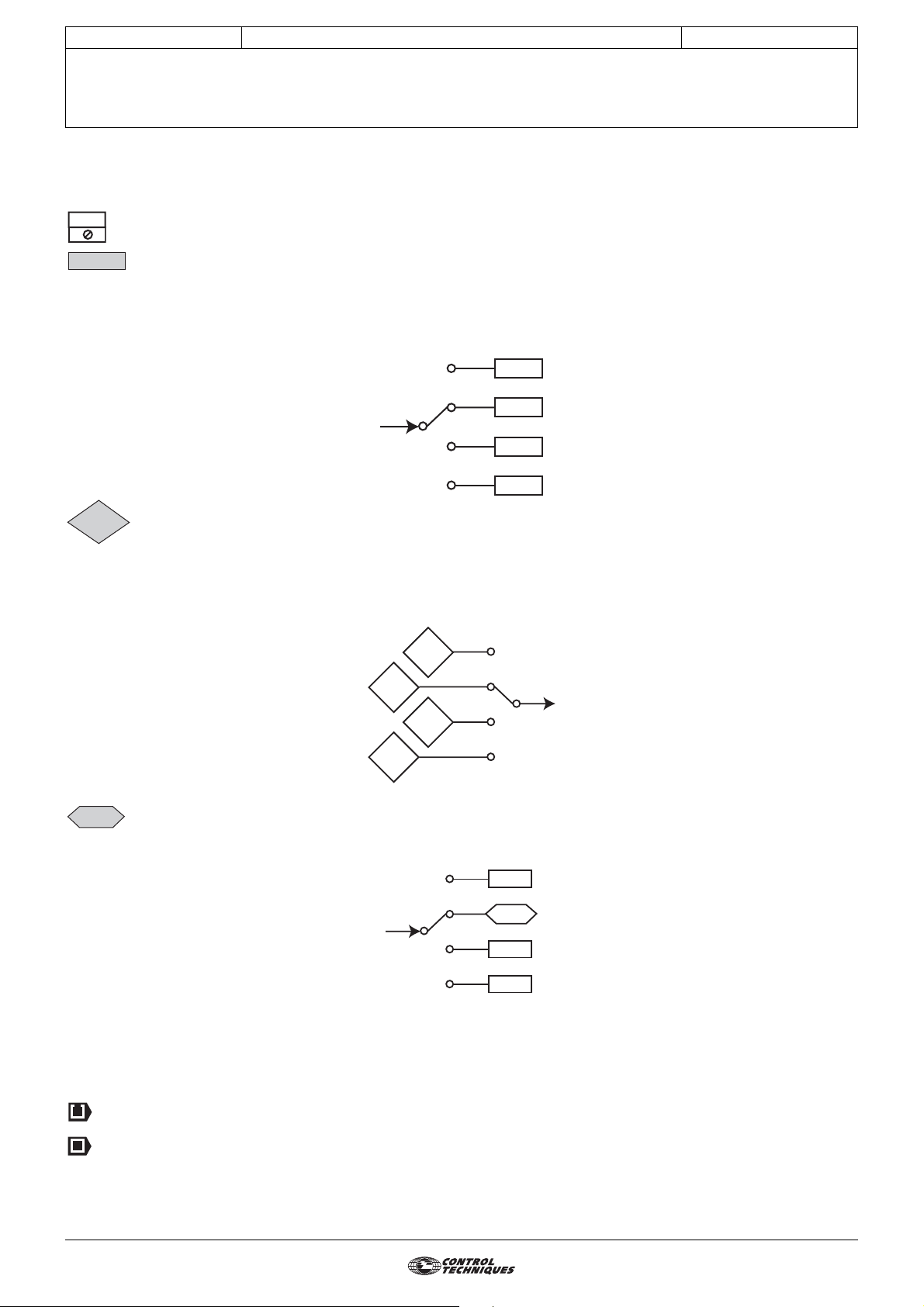

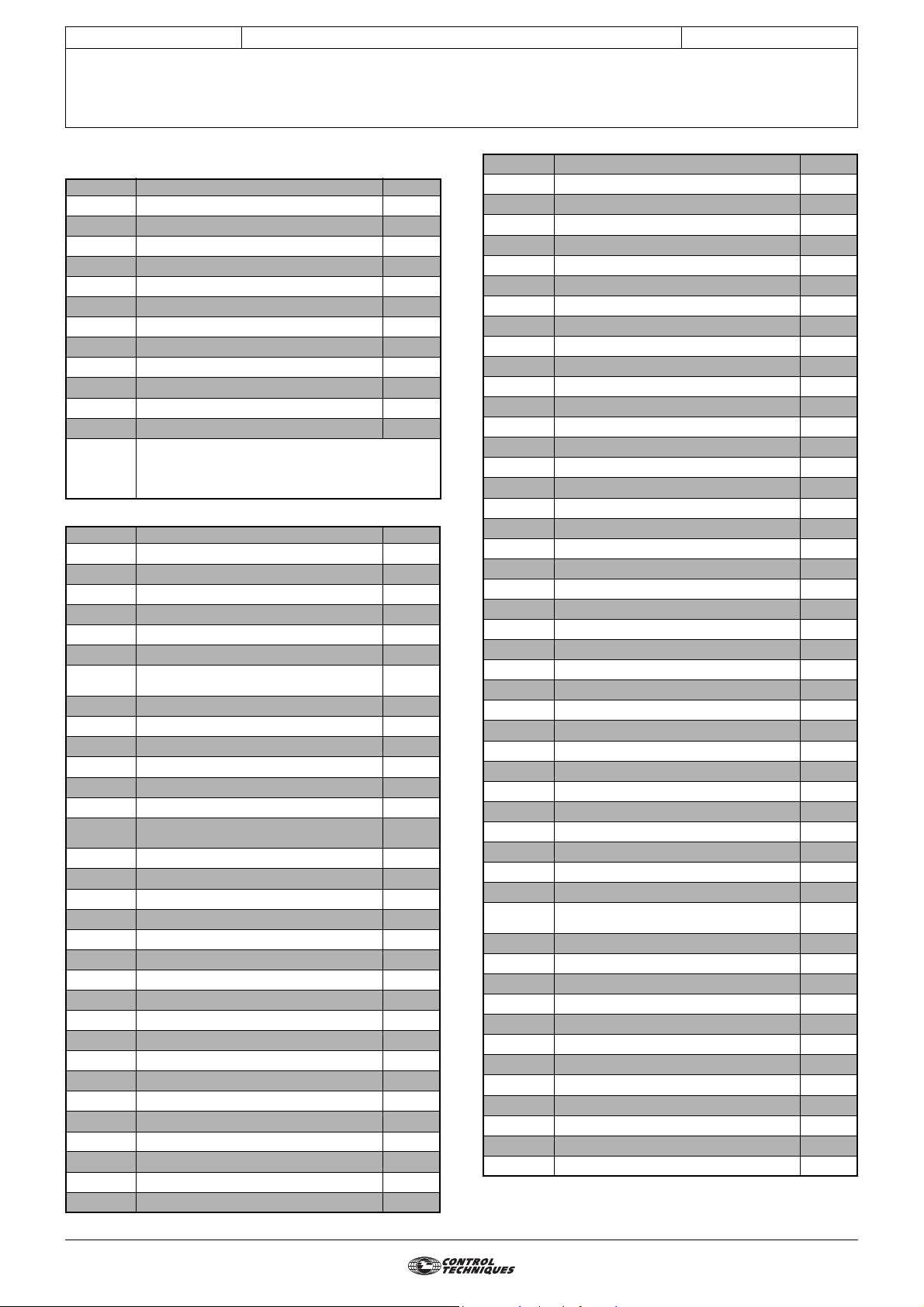

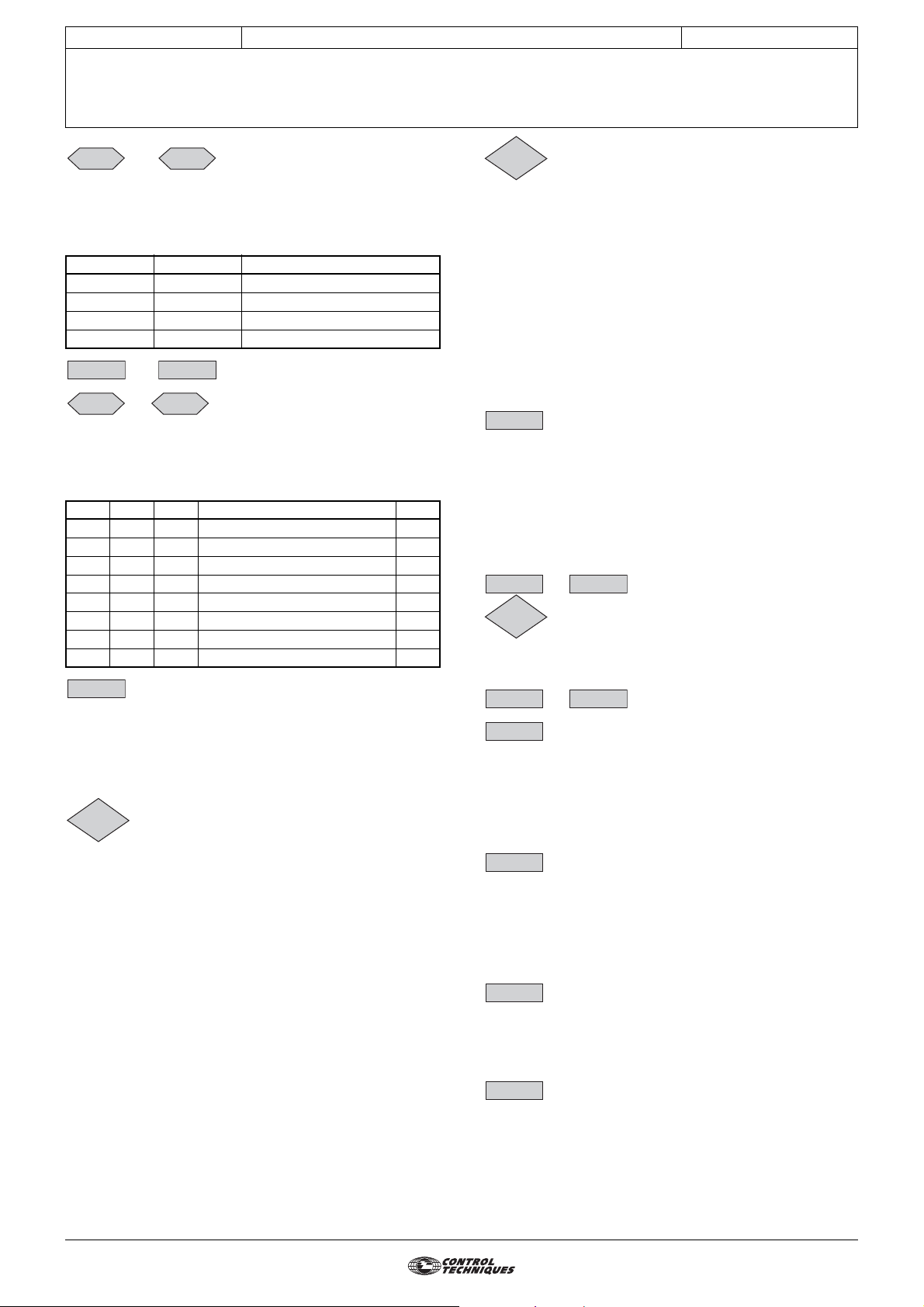

Explanation of symbols used in this document.

1.06 : A shadowed number in bold refers to a parameter.

ADI1

: Refers to a drive input or output terminal.

3854 en - 03.2008 / b

1.21

1.01

: Parameters which appear in a rectangle or identified R-W are parameters with Read and Write access.

They can be designated as an assignment destination for connection to:

- digital inputs for bit parameters

- analog inputs for non-bit parameters

- outputs of internal functions (comparators, logical or arithmetical operations, etc.)

Parameters identified R-W/P cannot be assigned.

: Parameters which appear in a diamond or identified RO/P are parameters with Read Only access which are

write-protected. They are used to provide information concerning operation of the drive and can be designated as an

assignment source for connection to:

- digital outputs for bit parameters

- analog outputs for non-bit parameters

- inputs of internal functions (comparators, logical or arithmetical operations, etc.)

1.36

0 (Disabled) (OFF): The values of "bit" parameters can correspond to a value 0, 1, 2, etc. via the serial link, to a

: Parameters which appear in a hexagon or identified by R-A are parameters which can only be assigned to:

- digital inputs for bit parameters

- analog inputs for non-bit parameters

mnemonic of up to 32 characters using the LCD console, or to a mnemonic of 4

characters maximum using the drive display. These values and labels are given for each

parameter concerned.

: Indicates a parameter used when the drive is configured in open loop Flux Vector Control mode or

U/F.

: Indicates a parameter used when the drive is configured in closed loop Flux Vector Control mode.

5

Page 6

CONTROL TECHNIQUES

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

Notes

3854 en - 03.2008 / b

6

Page 7

CONTROL TECHNIQUES

ADVANCED USER GUIDE

3854 en - 03.2008 / b

Commander SX

IP66/Nema 4X variable speed drive

CONTENTS

1 - PARAMETER SETTING USING THE LCD KEYPAD ....................................................................................................9

1.1 - Presentation ....................................................................................................................................................................9

1.2 - Connection to the drive....................................................................................................................................................9

1.3 - Architecture ...................................................................................................................................................................10

1.3.1 - Read mode............................................................ ................................. ...........................................................11

1.3.2 - Simplified parameter-setting mode (menu 0) ...................................................................................................12

1.3.3 - Advanced parameter setting mode (menus 1 to 21).........................................................................................12

1.4 - Commissioning using simplified parameter-setting mode..............................................................................................12

2 - MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING ............................................................13

2.1 - Parameters 01 to 10 ...................................................................................................................................................13

2.2 - Parameters 11 to 24: preset configurations .................................................................................................................13

2.2.1 - Configuration 0: 05 = A1.A2 ..................................... .................................. .................................. .. .................13

2.2.2 - Configuration 1: 05 = A1.Pr ................................................................................... .................................. ........13

2.2.3 - Configuration 2: 05 = A2.Pr ................................................................................... .................................. ........14

2.2.4 - Configuration 3: 05 = 4Pr ............................................................................................ ....................................14

2.2.5 - Configuration 4: 05 = 8Pr ............................................................................................ ....................................15

2.2.6 - Configuration 5: 05 = E.Pot ...................................... ... .................................. ................................. ... ..............15

2.2.7 - Configuration 6: 05 = TorQ .............................................................. .. .................................. ............................16

2.2.8 - Configuration 7: 05 = Pid ............................................................................................... ... ...............................16

2.2.9 - Configuration 8: 05 = Pump .................... .................................. .................................. ....................................17

2.2.10 - Configuration 9: 05 = A.CtP ..........................................................................................................................18

2.2.11 - Configuration 10: 05 = HoiS ..........................................................................................................................18

2.2.12 - Configuration 11: 05 = Pad ...........................................................................................................................19

2.2.13 - Configuration 12: 05 = HuAC ........................................................................................................................19

2.3 - Parameter 25 to 35 ......................................................................................................................................................20

2.4 - Parameters 36 to 80 ....................................................................................................................................................20

3 - MENU 1: SPEED REFERENCE: SELECTION, LIMITING AND FILTERS................................................................... 21

3.1 - List of parameters in Menu 1 .........................................................................................................................................21

3.2 - Menu 1 diagram ............................................................................................................................................................24

3.2.1 - Selection of reference (speed) .........................................................................................................................24

3.2.2 - Limiting and filters ....................................... .................................. ... .. ..............................................................25

3.3 - Explanation of parameters in Menu 1 ............................................................................................................................26

4 - MENU 2: RAMPS ..........................................................................................................................................................31

4.1 - List of parameters in Menu 2 .........................................................................................................................................31

4.2 - Menu 2 diagrams ...........................................................................................................................................................32

4.2.1 - Acceleration ramps ..........................................................................................................................................32

4.2.2 - Deceleration ramps ..........................................................................................................................................33

4.3 - Explanation of parameters in Menu 2 ............................................................................................................................34

5 - MENU 3: FREQUENCY THRESHOLDS - ENCODER OPTION ..................................................................................37

5.1 - List of parameters in Menu 3 .........................................................................................................................................37

5.2 - Menu 3 diagram ............................................................................................................................................................40

5.2.1 - Basic version ....................................................................................................................................................40

5.2.2 - With encoder option .........................................................................................................................................42

5.3 - Explanation of parameters in Menu 3 ............................................................................................................................44

6 - MENU 4: CURRENT AND TORQUE CONTROL..........................................................................................................47

6.1 - List of parameters in Menu 4 .........................................................................................................................................47

6.2 - Menu 4 diagram ............................................................................................................................................................48

6.2.1 - Basic version ....................................................................................................................................................48

6.2.2 - With encoder option .........................................................................................................................................49

6.3 - Explanation of parameters in Menu 4 ............................................................................................................................50

7 - MENU 5: MOTOR CONTROL .......................................................................................................................................53

7.1 - List of parameters in Menu 5 .........................................................................................................................................53

7.2 - Menu 5 diagram ............................................................................................................................................................55

7.3 - Explanation of parameters in Menu 5 ............................................................................................................................56

7.4 - Factory settings according to the rating .........................................................................................................................60

8 - MENU 6: PROGRAMMABLE LOGIC AND TIMERS....................................................................................................61

8.1 - List of parameters in Menu 6 .........................................................................................................................................61

8.2 - Menu 6 diagrams ...........................................................................................................................................................62

8.2.1 - Programmable logic .........................................................................................................................................62

8.2.2 - Timer, energy meter and alarms ......................................................................................................................63

8.2.3 - Downstream contact management ..................................................................................................................63

8.3 - Explanation of parameters in Menu 6 ............................................................................................................................64

9 - MENU 7: ASSIGNMENT OF ANALOG INPUTS AND OUTPUTS................................................................................69

9.1 - List of parameters in Menu 7 .........................................................................................................................................69

9.2 - Menu 7 diagram ............................................................................................................................................................70

9.2.1 - Assignment of analog I/O .................................................................................................................................70

9.2.2 - Scaling block ....................................................................................................................................................70

9.2.3 - Temperature indications ...................................................................................................................................70

9.3 - Explanation of parameters in Menu 7 ............................................................................................................................71

7

Page 8

CONTROL TECHNIQUES

ADVANCED USER GUIDE

3854 en - 03.2008 / b

Commander SX

IP66/Nema 4X variable speed drive

CONTENTS

10 - MENU 8: ASSIGNMENT OF DIGITAL INPUTS AND OUTPUTS...............................................................................75

10.1 - List of parameters in Menu 8 .......................................................................................................................................75

10.2 - Menu 8 diagrams .........................................................................................................................................................77

10.2.1 - Assignment of digital inputs and the relay output ...........................................................................................77

10.2.2 - Local controls .................................................................................................................................................78

10.3 - Explanation of parameters in Menu 8 ..........................................................................................................................79

11 - MENU 9: LOGIC FUNCTIONS, MOTORISED POT AND BINARY SUM ..................................................................83

11.1 - List of parameters in Menu 9 .......................................................................................................................................83

11.2 - Menu 9 diagrams .........................................................................................................................................................84

11.2.1 - Logic functions ...............................................................................................................................................84

11.2.2 - Motorised pot function ................................................................. ...................................................................84

11.2.3 - Binary sum function ........................................................................................................................................84

11.3 - Explanation of parameters in Menu 9 ..........................................................................................................................85

12 - MENU 10: DRIVE STATES AND DIAGNOSTICS ......................................................................................................87

12.1 - List of parameters in Menu 10 .....................................................................................................................................87

12.2 - Menu 10 diagrams .......................................................................................................................................................90

12.2.1 - Operating states ................................ .............................................................................................................90

12.2.2 - Braking resistor and trip management configuration ......................................................................................91

12.3 - Explanation of parameters in Menu 10 ........................................................................................................................92

13 - MENU 11: SERIAL LINK - DRIVE CHARACTERISTICS - MISCELLANEOUS.........................................................97

13.1 - List of parameters in Menu 11 .....................................................................................................................................97

13.2 - Menu 11 diagram ........................................................................................................................................................99

13.3 - Explanation of parameters in Menu 11 ......................................................................................................................100

14 - MENU 12: THRESHOLD DETECTORS, VARIABLE SELECTORS AND BRAKE CONTROL FUNCTION............105

14.1 - List of parameters in Menu 12 ...................................................................................................................................105

14.2 - Menu 12 diagrams .....................................................................................................................................................106

14.2.1 - Comparators ................................................................................................................................................106

14.2.2 - Variable selectors .........................................................................................................................................106

14.2.3 - Brake control in open loop mode .................................................................................................................107

14.2.4 - Brake control in closed loop mode ...............................................................................................................108

14.3 - Explanation of parameters in Menu 12 ......................................................................................................................109

15 - MENU 13: RESERVED .............................................................................................................................................113

16 - MENU 14: PID CONTROLLER .................................................................................................................................115

16.1 - List of parameters in Menu 14 ...................................................................................................................................115

16.2 - Menu 14 diagram ......................................................................................................................................................116

16.3 - Explanation of parameters in Menu 14 ......................................................................................................................117

17 - MENU 15: MODBUS RTU AND FIELDBUS CONNECTION OPTIONS, AND ADDITIONAL I/O ...........................119

18 - MENU 16: PLC FUNCTIONS ....................................................................................................................................121

18.1 - List of parameters in Menu 16 ...................................................................................................................................121

18.2 - Menu 16 diagrams .....................................................................................................................................................122

18.2.1 - Timer relays .................................................................................................................................................122

18.2.2 - Latching relays .............................................................................................................................................122

18.2.3 - Counter ........................................................................................................................................................123

18.3 - Explanation of parameters in Menu 16 ......................................................................................................................124

19 - MENUS 17 TO 20: RESERVED ...............................................................................................................................127

20 - MENU 21: OPERATING PARAMETERS FOR A SECOND MOTOR.......................................................................129

20.1 - List of parameters in Menu 21 ...................................................................................................................................129

20.2 - Explanation of parameters in Menu 21 ......................................................................................................................130

21 - OPERATION WITH MODBUS RTU .........................................................................................................................133

21.1 - Serial link ................................. .................................. ... ... ................................. .........................................................133

21.1.1 - Location and connection ..............................................................................................................................133

21.1.2 - Protocols ........................................ ... ...........................................................................................................133

21.1.3 - Parameter setting..........................................................................................................................................133

21.1.4 - Networking ...................................................................................................................................................133

21.2 - Parameter setting using the PC ................................ ... ................................. ... .........................................................133

21.3 - Control word and status word ....................................................................................................................................133

21.4 - MODBUS RTU ..........................................................................................................................................................134

21.4.1 - General information.......................................................................................................................................134

21.4.2 - Description of exchanges .............................................................................................................................134

21.4.3 - Parameter assignment .................................................................................................................................135

21.4.4 - Data encoding ..............................................................................................................................................135

21.4.5 - Function codes .............................................................................................................................................135

21.4.6 - Example ......................................... ..............................................................................................................137

21.4.7 - Wait time ......................................................................................................................................................137

21.4.8 - Exceptions ....................................................................................................................................................137

21.4.9 - CRC .............................................................................................................................................................137

8

Page 9

CONTROL TECHNIQUES

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

PARAMETER SETTING USING THE LCD KEYPAD

3854 en - 03.2008 / b

1 - PARAMETER SETTING USING THE LCD KEYPAD

1.1 - Presentation

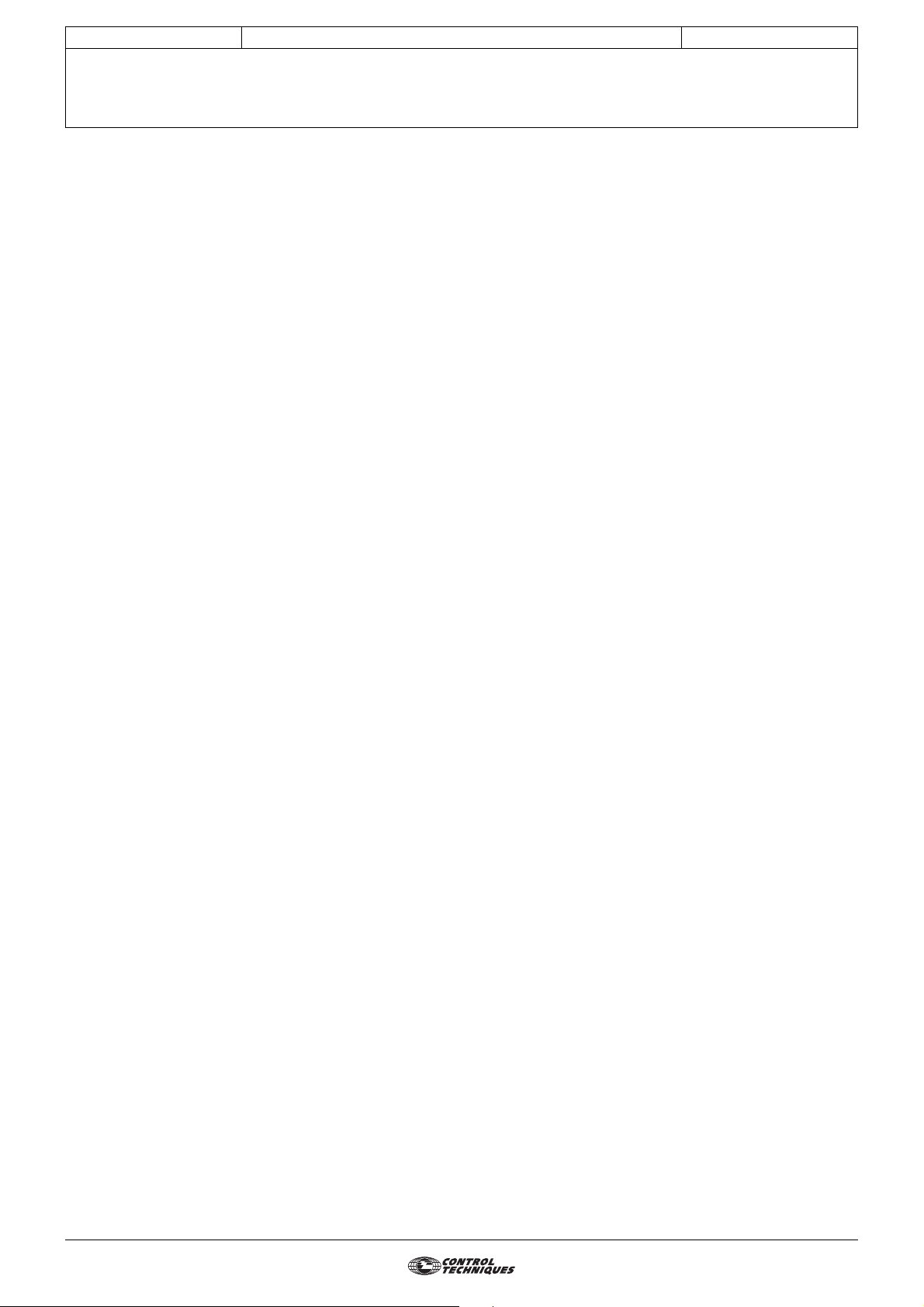

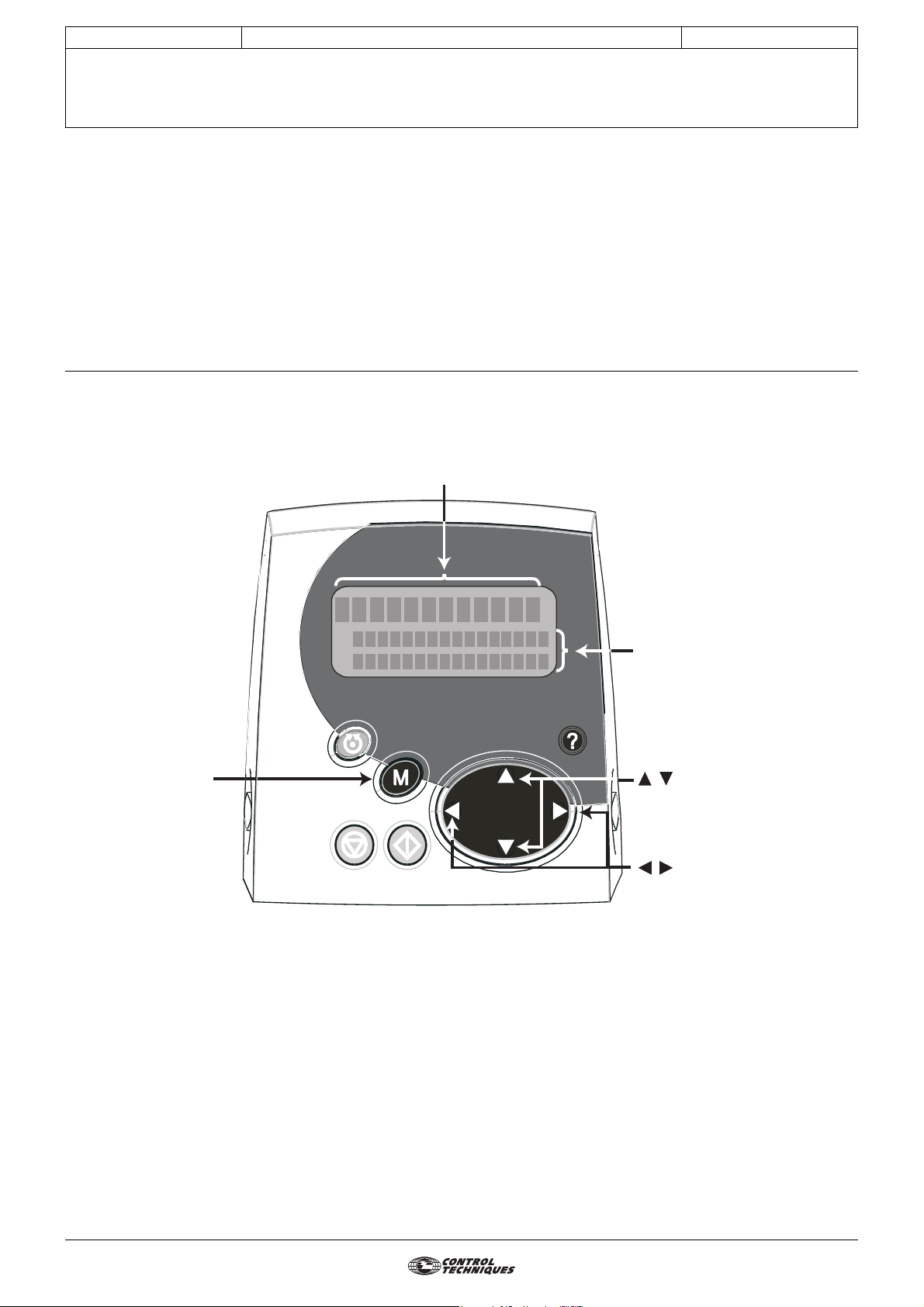

A

D

F

C

B

• The drives use an algorithm which is adjusted by

parameters. The performance levels obtained

depend on the parameter setting. Inappropriate settings

may have serious consequences for personnel and

machinery.

• The drive parameters must only be set by

appropriately qualified and experienced personnel.

• Before powering up the drive, check that the

power connections (mains supply and motor) are

correct, and that any moving parts are mechanically

protected.

• Before setting the drive parameters, all

instructions relating to installation and connection of the

drive contained in the installation document must have

been followed to the letter (see manual supplied with the

drive).

• Users of the drive should take particular care to

avoid starting it accidentally.

G

E

Ref. Function

Backlit LCD with a 3-line display for indicating:

- The drive operating status and its main data

- The main adjustment parameters via a

A

"simplified parameter setting" menu (menu 0)

- All drive parameters via 21 menus for

"advanced parameter setting" (access via a code)

Green key for run command if control via the

B

keypad is enabled (see 6.43).

Red button for drive reset (RESET) and stop

C

command.

Blue button for change of direction of rotation if

D

control via the keypad is enabled (see 6.43).

Navigation button ( , , , ) for

E

moving through the various menus and changing

the contents of parameters.

F

G

button for saving and changing the mode

(display, read, set parameters).

? button not used.

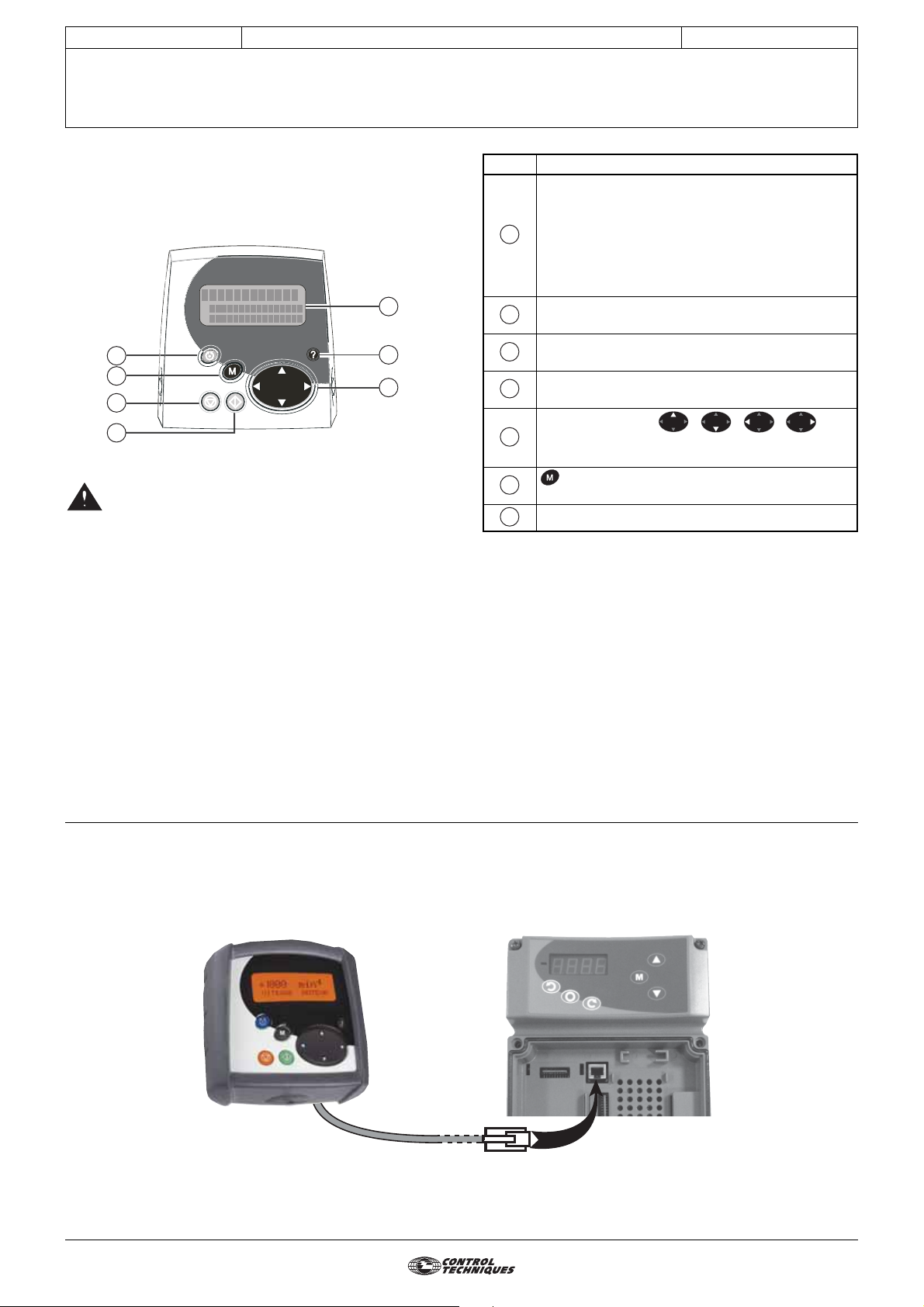

1.2 - Connection to the drive

The parameter-setting keypad connects to the Commander SX with a male/male RJ45 - RJ45 shielded cable.

The drive automatically detects the presence of the LCD keypad.

9

Page 10

CONTROL TECHNIQUES

ADVANCED USER GUIDE

3854 en - 03.2008 / b

Commander SX

IP66/Nema 4X variable speed drive

PARAMETER SETTING USING THE LCD KEYPAD

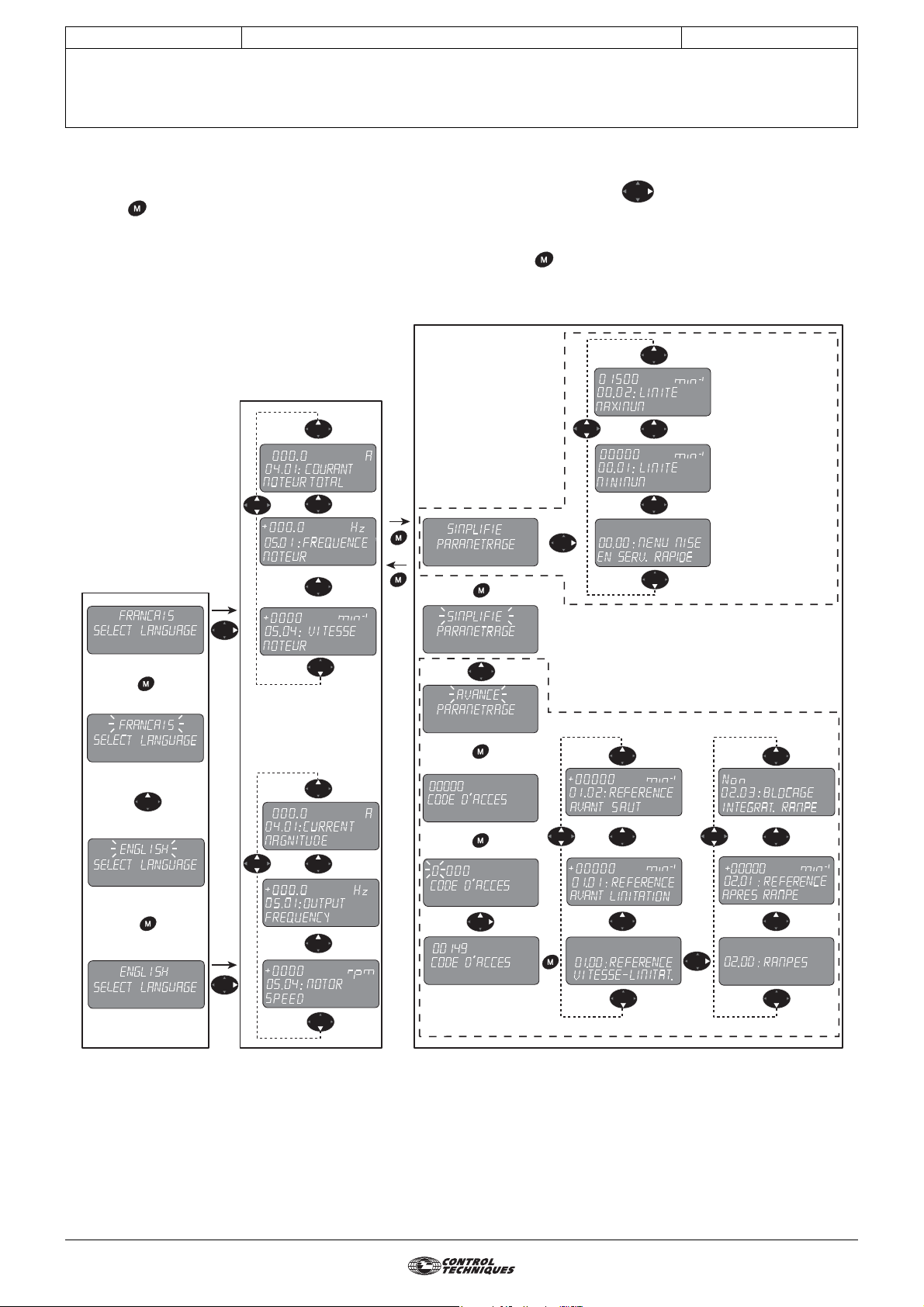

1.3 - Architecture

On power-up, the keypad offers a choice of languages (factory setting: French). Press the key to access read mode. Then

press the key to access parameter-setting mode; there are 2 parameter-setting levels:

- "Simplified" parameter setting (user menu, known as menu 0)

- "Advanced" parameter setting (menus 1 to 21), protected by an access code (factory setting = 149)

To return from parameter-setting mode to read mode, simply hold down the button for a few seconds.

Basic architecture

Parameter-setting mode

Simplied parameter

setting (menu 0)

Read mode

Language selection

5 sec

Advanced parameter setting (menus 1 --> 21)

10

Page 11

CONTROL TECHNIQUES

r

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

PARAMETER SETTING USING THE LCD KEYPAD

3854 en - 03.2008 / b

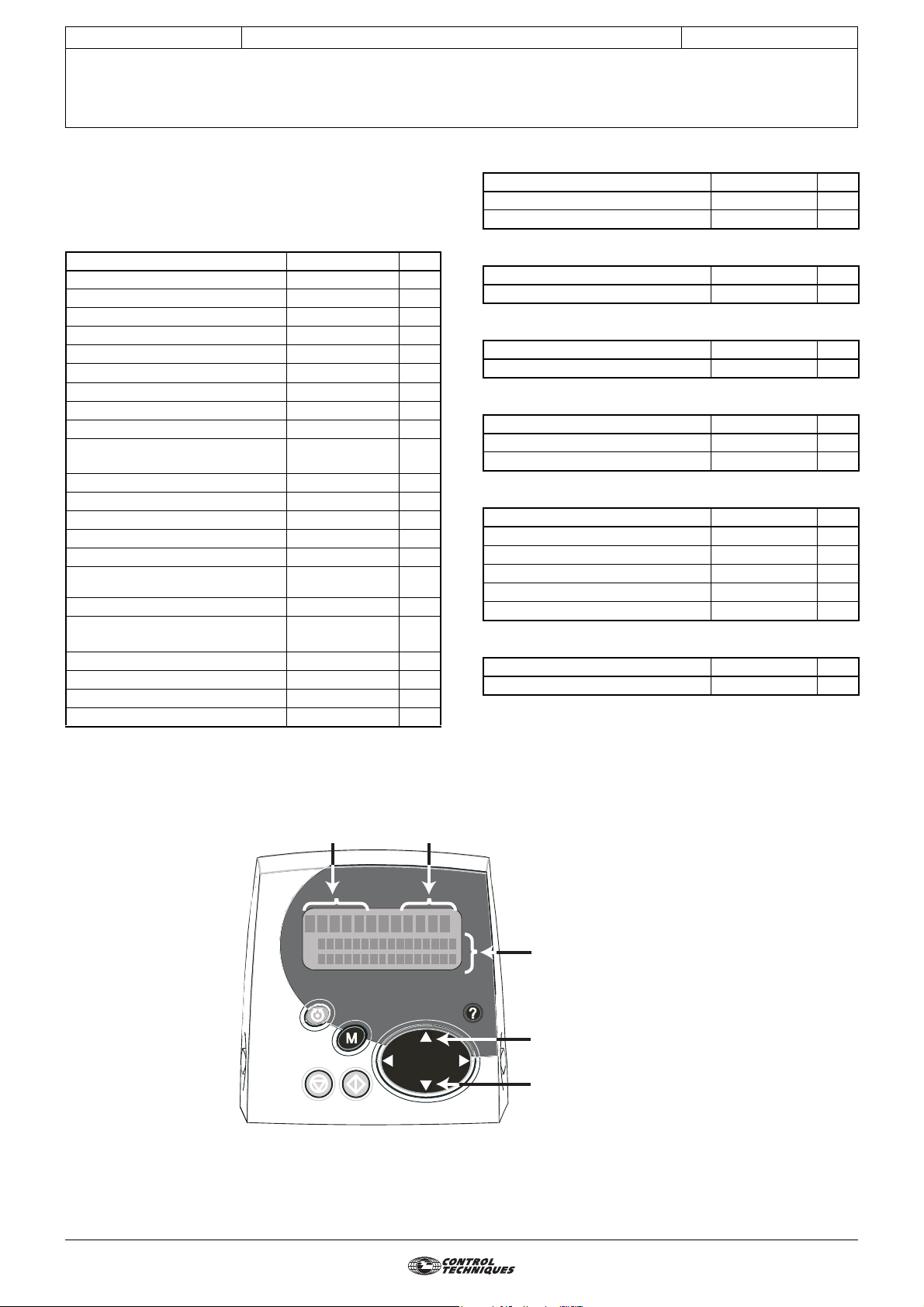

1.3.1 - Read mode

Read mode is used to display the status of the drive an d its

main measurement points when stopped or during operation.

1.3.1.1 - List of displayed parameters

Name Address Unit

MOTOR SPEED 5.04 rpm

MOTOR FREQUENCY 5.01 Hz

TOTAL MOTOR CURRENT 4.01 A

ACTIVE CURRENT 4.02 A

OUTPUT VOLTAGE 5.02 V

DC BUS VOLTAGE 5.05 V

ANALOG INPUT 1 7.01 %

ANALOG INPUT 2 7.02 %

ANALOG/DIG./PTC INPUT 3 7.03 %

DIGITAL IN/OUT 1 to 4 STATE

+ SDI

RELAY + BRAKE OUTPUT 8.07 and 12.40 -

SELECTED REFERENCE 1.49 -

SELECTED PRESET REFERENCE 1.50 -

SPEED REFERENCE SELECTED 1.01 rpm

POST-RAMP REFERENCE 2.01 rpm

RUN COUNTER: YEARS/DAYS,

Hr/Min

ENERGY METER: MWh, KWh 6.24 and 6.25 -

TRIP -2 to

TRIP -10

Drive SOFTWARE VERSION 11.29 -

LCD KEYPAD VERSION - MAX DRIVE CURRENT RATING 11.32 -

LAST PRESET CONFIG. 11.48 -

8.01 to 8.07 -

6.22 and 6.23 -

10.21 to

10.29

-

• Configuration of A1.A2:

Name Address Unit

ANALOG REFERENCE 2 1.37 rpm

ANALOG REFERENCE 1 1.36

• Configuration of A1.Pr and A2.Pr:

Name Address Unit

ANALOG REFERENCE 1 1.36

• Configuration of E.Pot:

Name Address Unit

MOTORISED POT. REFERENCE 9.03

• Configuration of Torq:

Name Address Unit

ANALOG REFERENCE 1 1.36 rpm

TORQUE REFERENCE 4.08

• Configuration of PID and PUMP:

Name Address Unit

PID REFERENCE 14.20 %

PID FEEDBACK 14.21 %

PID MAIN REFERENCE 14.19 %

PID ERROR 14.22 %

PID OUTPUT VALUE 14.01 %

• Configuration of PAD:

Name Address Unit

REFERENCE VIA KEYPAD 1.17

rpm

rpm

rpm

%

%

1.3.1.2 - Basic display

Signed value Unit

+1500

0

5.04:

SPEED

MO TOR

mpr

Parameter address and name

Display the next parameter

Display the previous paramete

11

Page 12

CONTROL TECHNIQUES

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

PARAMETER SETTING USING THE LCD KEYPAD

3854 en - 03.2008 / b

1.3.2 - Simplified parameter setting mode (menu 0)

A user menu, known as menu 0, contains the most useful

parameters. Each parameter in menu 0 is the image of a

parameter contained in another menu in advanced

parameter-setting mode.

The drive has 21 menus (menu 1 to menu 21).

A parameter is indicated by XX.YY, where the first two figures

(XX) refer to the menu and the next two figures (YY) refer to

the parameter number in the menu.

The change from simplified parameter setting mode to

advanced parameter setting mode is protected by an access

code (factory setting: 149).

1.3.3 - Advanced parameter setting mode (menus 1 to 21)

Advanced parameter setting mode provides access to all the

drive parameters. The parameters are arranged in menus.

1.4 - Commissioning using simplified parameter setting mode

Parameter value

Press once to change

the value of the selected

parameter.

The second press on

the button is used to

confirm the modification

and access the other

parameters.

1500

0

1.06:

REFEREN

rmp

AMXIMU

CLAMP

C

E

M

Parameter number and name

, are used to select the

menu 0 parameter to be modified

or to increment/decrement the

value of the parameter currently

being modified.

, are used to exit

parameter-setting mode or to move

the cursor when modifying a value.

12

Page 13

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2 - MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

This section describes the interactions between menu 0 (user

menu) and the advanced menus (menus 1 to 21).

On the one hand, each parameter in menu 0 (01 to 80) is in

fact the image (address) of a parameter in the advanced

menus (e.g. parameter 02 corresponds to parameter 1.06 in

menu 1).

On the other hand, when a preset configuration is selected by

parameter 05, the drive automatically assigns parameters 11

to 24 of menu 0 to adapt the drive to the application, and also

then internally sets a list of parameters (different depending

on the selected preset configuration).

It is therefore useful to know these internal settings in cases

where the user starts parameter setting via menu 0, and ends

with the advanced menus.

Refer to the installation and commissioning manual ref. 3840

for commissioning using menu 0.

2.2 - Parameters 11 to 24: preset configurations

2.2.1 - Configuration 0: 05 = A1.A2

Parameter Name Address

11 ADI1 mode 7.06

12 ADI2 mode 7.11

13

24

• Internal setting

Parameter Name Value

1.14 Reference selector 0

6.04 Start/stop logic select 0

7.06 ADI1 mode 6

7.08 ADI1 input scaling 1 0 0

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.36

7.11 ADI2 mode 4

7.12 ADI2 input scaling 1 0 0

7.13 ADI2 input invert 0

7.14 ADI2 input destination 1.37

7.15 ADIO3 mode 10

7.16 ADIO3 scaling 1 0 0

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 10.03

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 1.41

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

Not used

to

WARNING:

The purpose of the preset configurations in menu 0 is to

adapt the drive to the application as closely as possible.

However, if the user changes the structure of the

selected preset configuration by adding settings via the

advanced menus, the 05 parameter changes to "OPEn"

(unrestricted parameter setting).

2.1 - Parameters 01 to 10

Parameter Name Address

01

02 Maximum reference clamp 1.06

03 Acceleration rate 2.11

04 Deceleration rate 2.21

05 Preset configuration select 11.46

06 Motor rated current 5.07

07 Motor rated speed 5.08

08 Motor rated voltage 5.09

09 Rated power factor (cos ϕ) 5.10

10 Quick setup menu access 11.44

2.2.2 - Configuration 1: 05 = A1.Pr

Parameter Name Address

11 ADI1 mode 7.06

12 Preset reference 2 1.22

13 Preset reference 3 1.23

14 Preset reference 4 1.24

15

to

24

• Internal setting

Parameter Name Value

1.14 Reference selector 1

1.15 Preset selector 0

6.04 Start/stop logic select 0

6.43 Run/Stop source 0

7.06 ADI1 mode 6

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.36

7.11 ADI2 mode 7

7.13 ADI2 input invert 0

7.14 ADI2 input destination 1.46

7.15 ADIO3 mode 10

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

7.33 AIO3 feature 0

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 10.03

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 1.45

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

8.41 DIO1 feature 0

Minimum reference clamp

Not used

1.07

13

Page 14

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2.2.3 - Configuration 2: 05 = A2.Pr

Parameter Name Address

11 ADI1 mode 7.06

12 Preset reference 2 1.22

13 Preset reference 3 1.23

14 Preset reference 4 1.24

15

Not used

to

24

• Internal setting

Parameter Name Value

1.14 Reference selector 1

1.15 Preset selector 0

6.04 Start/stop logic select 0

6.43 Run/Stop source 0

7.06 ADI1 mode 4

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.36

7.11 ADI2 mode 7

7.13 ADI2 input invert 0

7.14 ADI2 input destination 1.46

7.15 ADIO3 mode 10

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

7.33 ADIO3 feature 0

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 1.45

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

8.41 DIO1 feature 0

DIO1 input destination/output source

10.03

2.2.4 - Configuration 3: 05 = 4Pr

Parameter Name Address

11 Preset reference 1 1.21

12 Preset reference 2 1.22

13 Preset reference 3 1.23

14

15

24

• Internal setting

Parameter Name Value

1.14 Reference selector 3

1.15 Preset selector 0

6.04 Start/stop logic select 0

6.43 Run/Stop source 0

7.06 ADI1 mode 7

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.46

7.11 ADI2 mode 8

7.13 ADI2 input invert 0

7.15 ADIO3 mode 10

7.17 ADIO3 input invert 0

7.18

7.33 ADIO3 feature 0

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 1.45

8.27 Output relay source 10.01

8.41 DIO1 feature 0

Preset reference 4 1.24

to

Not used

ADIO3 input destination/output source

DIO1 input destination/output source

5.04

10.03

14

Page 15

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2.2.5 - Configuration 4: 05 = 8Pr

Parameter Name Address

11

12 Preset reference 2 1.22

13 Preset reference 3 1.23

14 Preset reference 4 1.24

15 Preset reference 5 1.25

16 Preset reference 6 1.26

17 Preset reference 7 1.27

18 Preset reference 8 1.28

19

24

• Internal setting

Parameter Name Value

1.14 Reference selector 3

1.15 Preset selector 0

6.04 Start/stop logic select 0

6.43 Run/Stop source 0

7.06 ADI1 mode 7

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.46

7.11 ADI2 mode 7

7.13 ADI2 input invert 0

7.14 ADI2 input destination 1.47

7.15 ADIO3 mode 10

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

7.33 ADIO3 feature 0

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 10.03

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 1.45

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

8.41 DIO1 feature 0

Preset reference 1

Not used

to

1.21

2.2.6 - Configuration 5: 05 = E.Pot

Parameter Name Address

11

12

13

14

15

16

17

18

24

• Internal setting

Parameter Name Value

1.09 R ef er en ce o ff se t va l id at ion 1

1.14 Reference selector 1

6.04 S ta rt /s to p lo gic s el ec t 0

6.43 Run/Stop source 0

7.06 A DI 1 mo de 6

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.36

7.11 ADI2 mode 7

7.13 A DI 2 in pu t in vert 0

7.14 ADI2 input destination 9.26

7.15 A DI O3 m ode 10

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

7.33 ADIO3 feature 0

8.10 S ec ur e di sa bl e se l ec t 1

8.11 DIO1 input or output invert 0

8.12 D I2 i np ut i nv ert 0

8.13 DI3 input invert 0

8.14 D I4 i np ut i nv ert 0

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 10.03

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 9.27

8.27 Output relay source 10.01

8.31

8.41

9.25

ADI1 mode

Manual motorised pot reset

Automatic motorised pot reset

Motorised pot bipolar select

Motorised pot rate

Motorised pot scale factor

Motorised pot reference

Not usedto

DIO1 input or output select 1

DI O 1 fe at ur e 0

Motorised pot destination 1.04

7.06

9.28

9.21

9.22

9.23

9.24

9.03

15

Page 16

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2.2.7 - Configuration 6: 05 = TorQ

Parameter Name Address

11

12 ADI2 mode 7.11

13

18

19 ADI2 scaling 7.12

20

24

• Internal setting

Parameter Name Value

1.14 Reference selector 1

6.04 Start/stop logic select 0

6.43 Run/Stop source 0

7.06 ADI1 mode 6

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.36

7.11 ADI2 mode 6

7.13 ADI2 input invert 0

7.14 ADI2 input destination 4.08

7.15 ADIO3 mode 10

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

7.33 ADIO3 feature 0

8.10 Secure disable select 1

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 10.03

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 4.11

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

8.41 DIO1 feature 0

ADI1 mode 7.06

Not usedto

Not usedto

2.2.8 - Configuration 7: 05 = Pid

Parameter Name Address

11 ADI1 mode

12

13

14

15

16

17

18

19

20

21

22

23

24

• Internal setting

Parameter Name Value

1.14 R ef er en ce s el ec tor 1

6.04 Start/stop logic select 0

6.43 R un /S to p so ur ce 0

7.06 ADI1 mode 6

7.09 A DI 1 in pu t in vert 0

7.10 ADI1 input destination 1.27

7.11 A DI 2 mo de 2

7.13 ADI2 input invert 0

7.14 ADI2 input destination 1.28

7.15 ADIO3 mode 6

7.17 ADIO3 input invert 0

7.18

7.33 A DI O3 f ea tu re 4

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 D I3 i np ut i nv ert 0

8.14 DI4 input invert 0

8.17 O ut pu t re la y inve r t 0

8.21

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 14.08

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

8.41 DIO1 feature 2

14.02 PID main reference source 1.26

14.03 PID reference source 1.27

14.04 PID feedback source 1.28

14.16 PID output destination 1.36

ADI2 mode 7.11

PID proportional gain

PID integral gain

PID derivative gain

PID upper limit

PID lower limit

PID output scaling

ADI2 input scaling

ADIO3 input scaling

PID reference

PID feedback

PID main reference

PID output

ADIO3 input destination/output source

DIO1 input destination/output source

7.06

14.10

14.11

14.12

14.13

14.14

14.15

7.12

7.16

14.20

14.21

14.19

14.01

1.26

10.04

16

Page 17

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2.2.9 - Configuration 8: 05 = Pump

Parameter Name Address

11

12 ADI2 mode 7.11

13

14 PID integral gain 14.11

15 Stop on Vmin enable 14. 56

16

17 Draining time delay 16.05

18 Digital reference 14.51

19

20 Reference input in customer units 14.54

21 Sensor input in customer units 14.55

22

23

24

• Internal setting

Parameter Name Value

5.09 Motor rated voltage 40 0

7.06 ADI1 mode 6

7.10 ADI1 input destination 1.23

7.11 ADI2 mode 2

7.14 ADI2 input destination 1.24

7.15 ADIO3 mode 10

7.18 ADIO3 input destination/output source 10.90

7.33 ADIO3 feature 4

7.62 Block scaling 1 0 5

7.64 Scaling block destinati on 12.24

7.68 Scaling block source 12.12

8.11 DIO1 input or output invert 1

8.14 DI4 input invert 0

8.21 DIO1 input destination/output source 10.63

8.22 DI2 input destination 9.30

8.23 DI3 input destination 12.10

8.24 DI4 input destination 1.42

8.31 DIO1 input or output select 0

8.41 DIO1 feature 9

9.04 Logic function 1 source 1 12.01

9.06 Logic function 1 source 2 8.02

9.14 Logic function 2 source 1 9.01

9.16 Logic function 2 source 2 8.04

9.33 Binary sum destination 0

9.34 Binary sum output offset 0

9.64 Logic function 3 source 1 12.02

9.65 Logic function 3 source 1 invert 1

9.66 Logic function 3 source 2 14.56

9.74 Logic function 4 source 1 9.61

9.75 Logic function 4 source 1 invert 1

9.76 Logic function 4 source 2 14.56

9.78 Logic function 4 output invert 1

ADI1 mode 7.06

PID proportional gain

Draining threshold

Customer unit scaling coefficient

Motor speed

Not usedand

14.10

12.04

14.53

5.04

Parameter Name Value

11.01 Parameter 46 set-up 6.22

11.02 Parameter 47 set-up 6.23

11.03 Parameter 48 set-up 7.62

11.04 Parameter 49 set-up 10.20

11.05 Parameter 50 set-up 10.21

11.06 Parameter 51 set-up 10.22

11.07 Parameter 52 set-up 10.23

11.08 Parameter 53 set-up 10.24

11.09 Parameter 54 set-up 10.25

11.10 Parameter 55 set-up 10.26

11.11 Parameter 56 set-up 10.27

11.12 Parameter 57 set-up 10.28

11.13 Parameter 58 set-up 10.29

11.44 Quick setup menu access 1

12.03 Comparator 1 source 1.24

12.04 Comparator 1 threshold 200

12.05 Comparator 1 hysteresis 20

12.06 Comparator 1 output invert 1

12.08 Function 1 variable 1 source 1.23

12.09 Function 1 variable 2 source 1.22

12.11 Function 1 output destination 1.21

12.23 Comparator 2 source 1.24

12.25 Comparator 2 hysteresis 10

12.28 Function 2 variable 1 source 14.51

12.29 Function 2 variable 2 source 1.06

12.30 Function block 2 select 4

12.31 Function 2 output destination 1.22

12.33 Function 2 variable 1 scale 1 0

12.63 Comparator 3 source 9.32

12.64 Comparator 3 threshold 64

12.65 Comparator 3 hysteresis 0

12.67 Comparator 3 output destination 6.30

14.02 PID main reference source 1.21

14.03 PID reference source 1.21

14.04 PID feedback source 1.24

14.08 PID enable 1

14.09 PID option enable source 8.04

14.10 PID proportional gain 15000

14.11 PID integral gain 2000

14.16 PID output destination 1.36

14.53 Customer unit coefficient 1

14.56 Stop on V min enable 1

16.02 Timer relay 1 input source 9.02

16.05 Timer relay 1 value 1 0 0

16.09 Timer relay 1 output destination 10.61

16.12 Timer relay 2 input source 9.71

16.13 Ti m er r el ay 2 t yp e 1

16.15 Timer relay 2 value 100

16.19 Timer relay 2 output destination 9.29

17

Page 18

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2.2.10 - Configuration 9: 05 = A.CtP

Parameter Name Address

11

Not usedto

24

• Internal setting

Parameter Name Value

1.14 Reference selector 1

6.04 Start/stop logic select 0

6.43 Run/Stop source 0

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.36

7.11 ADI2 mode 8

7.13 ADI2 input invert 0

7.14 ADI2 input destination 0

7.15 ADIO3 mode 10

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

7.33 ADIO3 feature 4

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 1

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 10.03

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 9.30

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

8.41 DIO1 feature 9

9.33 Binary sum destination 7.06

9.34 Binary sum output offset 4

2.2.11 - Configuration 10: 05 = HoiS

Parameter Name Address

11

12 Preset reference 2 (PR2) 1.22

13

24

• Internal setting

Parameter Name Value

1.10 Bipolar reference select 1

1.14 Reference selector 1

2.51 Ramp hold condition 1

6.04 Start/stop logic select 0

6.43 Run/Stop source 0

7.06 ADI1 mode 6

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.36

7.11 ADI2 mode 8

7.13 ADI2 input invert 0

7.14 ADI2 input destination 0

7.15 ADIO3 mode 7

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 1.45

7.33 ADIO3 feature 4

8.10 Secure disable select 1

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 12.51

8.22 DI2 input destination 6.30

8.23 DI3 input destination 6.32

8.24 DI4 input destination 0

8.27 Output relay source 10.01

8.31 DIO1 input or output select 0

8.41 DIO1 feature 9

9.04 Logic functi on 1 source 1 8.04

9.05 Logic function 1 source 1 invert 1

9.06 Logic functi on 1 source 2 9.02

9.07 Logic function 1 source 2 invert 1

9.08 Logic function 1 output invert 0

9.10 Logic function 1 output destination 2.03

9.14 Logic functi on 2 source 1 1.45

9.16 Logic functi on 2 source 2 10.07

Not used

Not used

to

18

Page 19

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2.2.12 - Configuration 11: 05 = Pad

Parameter Name Address

11

12 Power-up keypad reference (Preset 1) 1.21

13

14

15

16

24

• Internal setting

Parameter Name Value

1.14 R ef er en ce s el ec tor 4

6.11 Enable local control FWD key 1

6.12 Enable local control Stop key 1

6.13 Enable keypad REV key 0

6.43 R un /S to p so ur ce 2

7.11 ADI2 mode 8

7.15 A DI O3 m ode 10

7.18 ADIO3 input destination/output source 5.04

7.33 A DI O3 f ea tu re 0

8.10 Secure disable select 0

8.17 O ut pu t re la y inve r t 0

8.22 DI2 input destination 0

8.23 DI3 input destination 6.39

8.24 DI4 input destination 6.13

8.27 Output relay source 10.01

8.81 DIRF input destination 0

8.83 D IR R in pu t de st in atio n 0

Power-up keypad reference

Enable FWD key 6.11

Enable Stop key 6.12

Enable REV key 6.13

Not usedto

1.51

2.2.13 - Configuration 12: 05 = HuAC

Parameter Name Address

11

12 ADI2 mode 7.11

13

24

• Internal setting

Parameter Name Value

1.14 Reference selector 0

6.04 Start/stop logic select 0

7.06 ADI1 mode 7

7.09 ADI1 input invert 0

7.10 ADI1 input destination 1.41

7.11 ADI2 mode 4

7.13 ADI2 input invert 0

7.14 ADI2 input destination 1.37

7.15 ADIO3 mode 10

7.17 ADIO3 input invert 0

7.18 ADIO3 input destination/output source 5.04

7.33 ADIO3 feature 4

8.10 Secure disable select 0

8.11 DIO1 input or output invert 0

8.12 DI2 input invert 0

8.13 DI3 input invert 0

8.14 DI4 input invert 0

8.17 Output relay invert 0

8.21 DIO1 input destination/output source 10.02

8.24 DI4 input destination 1.42

8.27 Output relay source 10.01

8.31 DIO1 input or output select 1

8.41 DIO1 feature 9

9.04 Logic functi on 1 source 1 8.04

9.06 Logic functi on 1 source 2 10.01

9.10 Logic function 1 output destination 9.30

9.33 Binary sum destination 6.43

9.34 Binary sum offset 0

9.64 Logic functi on 3 source 1 1.41

9.65 Logic function 3 source 1 invert 1

9.66 Logic functi on 3 source 2 8.04

9.67 Logic function 3 source 2 invert 1

9.68 Logic function 3 output invert 1

12.08 Function 1 variable 1 source 1.17

12.10 Function block 1 select 0

12.11 Function 1 output destination 1.21

12.13 Function 1 variable 1 scale 1000

12.15 Function 1 associated parameter 0

16.02 Timer relay 1 input source 9.61

16.03 Timer relay 1 type 0

16.04 Timer relay 1 unit of time 0

16.05 Timer relay 1 value 5

16.09 Timer relay 1 output destination 6.15

Not used

Not usedto

19

Page 20

CONTROL TECHNIQUES

MENU 0 CORRESPONDENCE AND AUTOMATIC PARAMETER SETTING

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

2.3 - Parameter 25 to 35

Parameter Name Address

25

• If 25 = OP.LP (0 or 1)

Parameter Name Address

26

• If 26 = r.run (0) or r.no (1) or r.FSt (3) or r.On (4)

or SqrE (5)

27

30

31

32

33

35

• If 26 = UtoF (2)

27

28

29

30

31

35

• If 25 = cL.LP (2) or SrvO (3)

Parameter Name Address

26 Encoder type 3.38

27

28

29

30

31

32

33

34

35

Operating mode

Open loop mode select 5.14

Not usedto

Current loop P gain 4.13

Current loop I gain 4.14

Not usedto

Not usedand

Boost

Dynamic V to F

Not usedto

Encoder lines per revolution

Drive encoder filter

Speed loop P gain Kp1

Speed loop I gain Ki1

Current loop P gain

Current loop I gain

Ramp bypass

Not usedand

11.31

5.15

5.13

3.34

3.42

3.10

3.11

4.13

4.14

2.02

2.4 - Parameters 36 to 80

Parameter Name Address

36

37

38

39

40

41 Brake apply/magnetisation delay 12.46

42

43

44

45

46 *

47 *

48 *

49 *

50 *

51 *

52 *

53 *

54 *

55 *

56 *

57 *

58 *

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

(*) For preset configuration 05 = Pump, the addresses for 46

to 58 are different.

See section 2.2.9 - Internal setting.

Brake controller enable

Upper current threshold

Lower current threshold

Brake release frequency

Brake apply frequency

Post-brake release delay

Brake apply delay

Not used

Not used

Start/stop logic select

Secure disable select

ADIO3 mode

ADIO3 feature

DIO1 feature

Jog reference

Bipolar reference enable

Skip (critical speed)

Skip reference band

Deceleration ramp mode select

S ramp enable

Stop mode

Mains loss mode

Catch a spinning motor

Maximum switching frequency

Motor rated frequency

Number of motor poles

Autotune

Parameter cloning

Factory setting

User security code

Parameter displayed at power-up

Selection of load display

Speed display unit

Parameter scaling

Last trip

Penultimate trip

ADI1 input level

ADI2 input level

ADIO3 input or output level

Pre-offset reference

Pre-ramp reference

Current magnitude

Motor speed

DC bus voltage

12.41

12.42

12.43

12.44

12.45

12.47

12.48

12.49

6.04

8.10

7.15

7.33

8.41

1.05

1.10

1.29

1.30

2.04

2.06

6.01

6.03

6.09

5.18

5.06

5.11

5.12

11.42

11.43

11.30

11.22

4.21

5.34

11.21

10.20

10.21

7.01

7.02

7.03

1.60

1.03

4.01

5.04

5.05

20

Page 21

CONTROL TECHNIQUES

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

MENU 1: SPEED REFERENCE: SELECTION, LIMITING AND FILTERS

3 - MENU 1: SPEED REFERENCE: Selection, limiting and filters

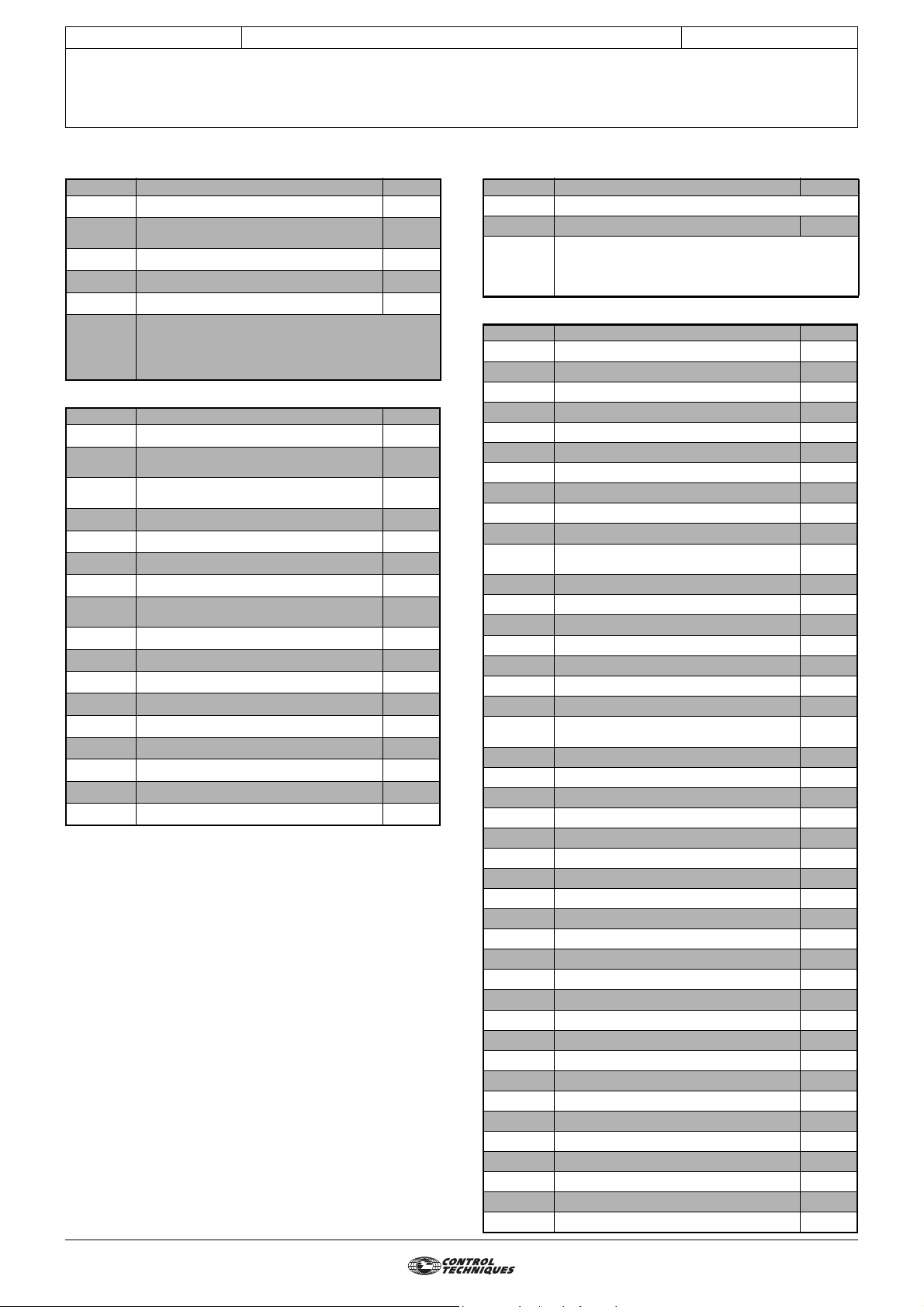

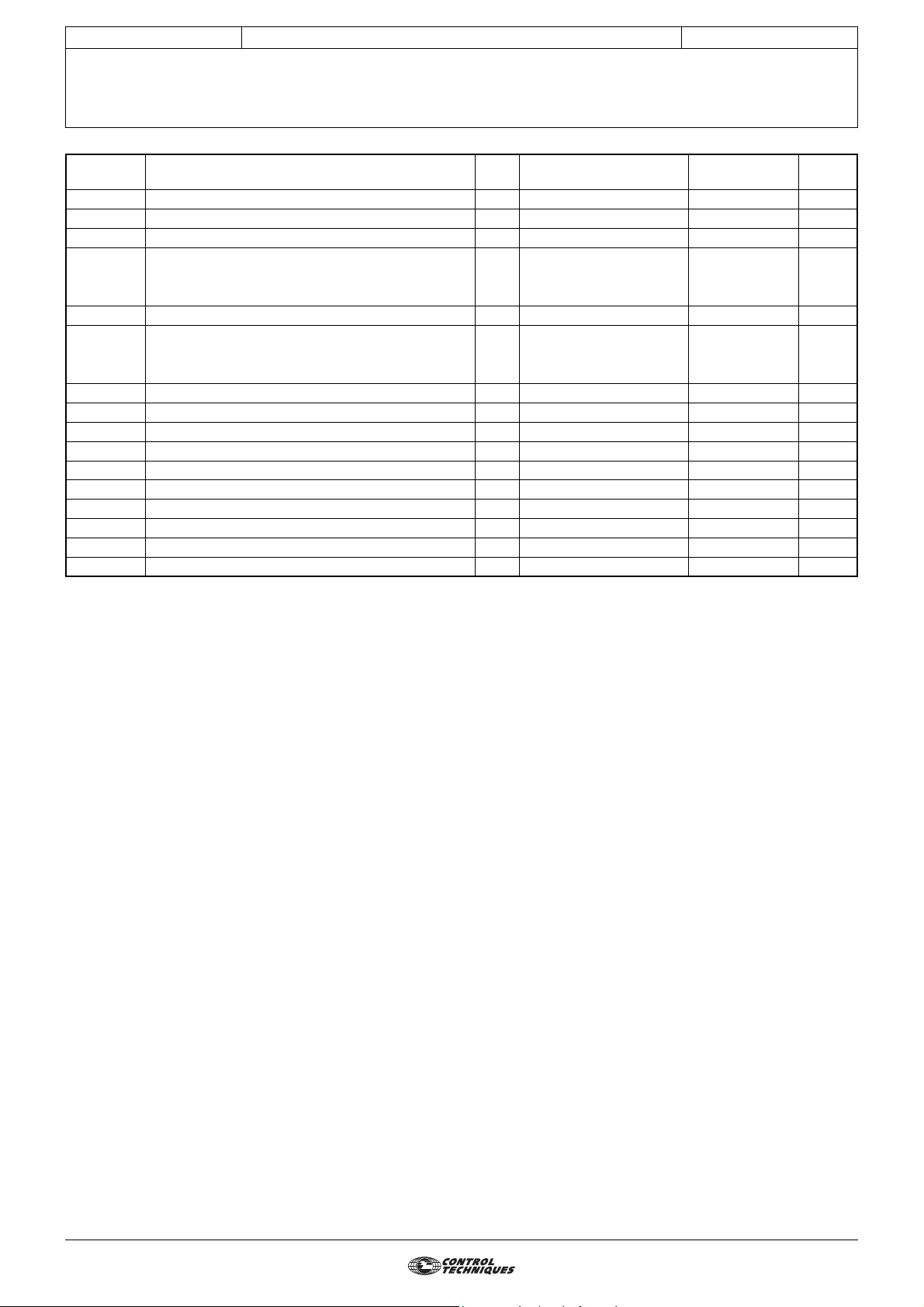

3.1 - List of parameters in Menu 1

3854 en - 03.2008 / b

Parameter Name Type Adjustment range Factory setting

1.01 Speed reference selected RO/P ± 1.06 --

1.02 Pre-skip filter reference RO/P ± 1.06 or 1.07 to 1.06 --

1.03 Pre-ramp reference RO/P ± 1.06 or 1.07 to 1.06 --

1.06

1.04 Reference of fse t R-W

1.05 Jog reference R-W

1.06 Maximum reference clamp R-W

1.07 Minimum reference clamp R-W 0 to 1.06 0

1.08 Not used

1.09 Reference offset validation R-W 0 or 1 0

1.10 Bipolar reference select R-W 0 or 1 0

1.11 Reference enable indicator RO/P 0 or 1 - -

1.12 Reverse select indicator RO/P 0 or 1 - -

1.13 Jog select indicator RO/P 0 or 1 - -

1.14 Reference selector R-W 0 to 4 0

1.15 Preset selector R-W 0 to 9 0

1.16 Preset reference timer R-W 0 to 9999 s 0

1.17 Keypad reference R-W 1.07 to 1.06 (1.10 = 0) 0 -

1.18

to

1.20

1.21 Preset 1

to

1.28 Preset 8

1.29 Skip reference 1 R-W

1.30 Skip reference band 1 R-W

1.31 Skip reference 2 R-W

1.32 Skip reference band 2 R-W

1.33

and

1.34

1.35 Reference in skip zone RO/P 0 or 1 - -

1.36 Analog reference 1 R-A

1.37 Analog reference 2 R-A

1.38 Percentage trim R-W ± 100.0% 0

1.39

and

1.40

1.41

and

1.42

1.43

and

1.44

1.45

to

1.47

1.48 Reference timer reset R-W 0 or 1 0

Not used

to

Not used

Not used

Reference selector R-A 0 or 1 - -

Not used

Preset reference select R-A 0 or 1 - -

R-W ± 1.06 0

1.07 to 1.06 (1.10 = 0)

1.07 to 1.06 (1.10 = 0)

±

0 to 1.06 rpm 45 rpm

0 to 32000 rpm

0 to 1.06 rpm

0 to 300 rpm 15 rpm

0 to 1.06 rpm

0 to 300 rpm 15 rpm

± 1.06 (1.10 = 1)

± 1.06 (1.10 = 1)

0

Eur: 1500 rpm

USA: 1800 rpm

0

0

--

--

User

setting

21

Page 22

CONTROL TECHNIQUES

MENU 1: SPEED REFERENCE: SELECTION, LIMITING AND FILTERS

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

Parameter Name Type Adjustment range Factory setting

1.49 Selected reference indicator RO/P 1 to 4 - -

1.50 Selected preset reference indicator RO/P 1 to 8 - -

1.51 Power-up keypad reference R-W 0 to 2 0

1.52

to

1.59

1.60 Pre-offset reference RO

1.61

to

1.68

1.69 Number of preset references timed R-W 1 to 8 8

1.70 Scan time selection R-W 0 or 1 0

1.71 Preset 1 time R-W 0 to 9999 s 0

1.72 Preset 2 time R-W 0 to 9999 s 0

1.73 Preset 3 time R-W 0 to 9999 s 0

1.74 Preset 4 time R-W 0 to 9999 s 0

1.75 Preset 5 time R-W 0 to 9999 s 0

1.76 Preset 6 time R-W 0 to 9999 s 0

1.77 Preset 7 time R-W 0 to 9999 s 0

1.78 Preset 8 time R-W 0 to 9999 s 0

Not used

Not used

± 1.06

--

User

setting

22

Page 23

CONTROL TECHNIQUES

MENU 1: SPEED REFERENCE: SELECTION, LIMITING AND FILTERS

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

Notes

3854 en - 03.2008 / b

23

Page 24

CONTROL TECHNIQUES

Commander SX

IP66/Nema 4X variable speed drive

MENU 1: SPEED REFERENCE: SELECTION, LIMITING AND FILTERS

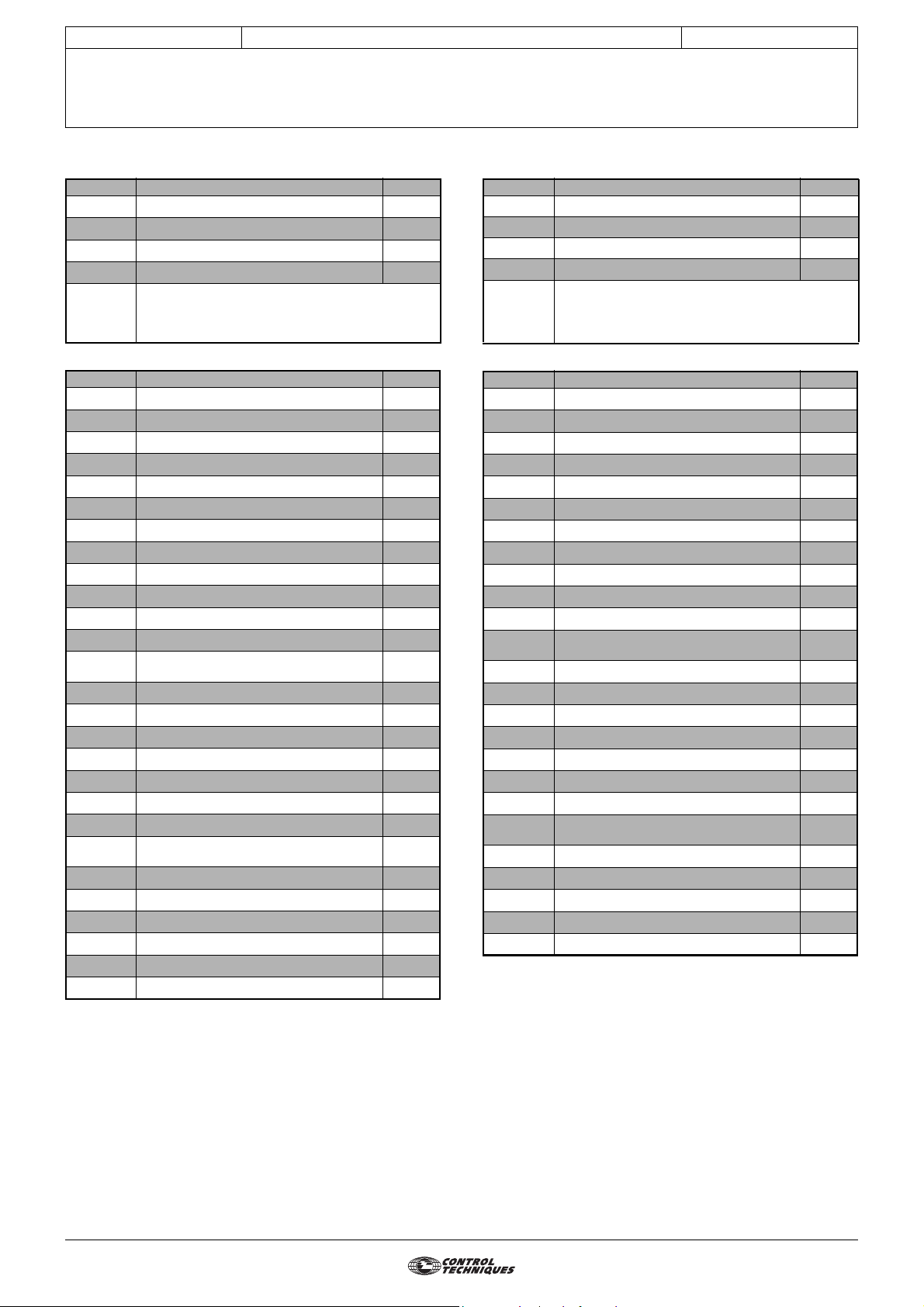

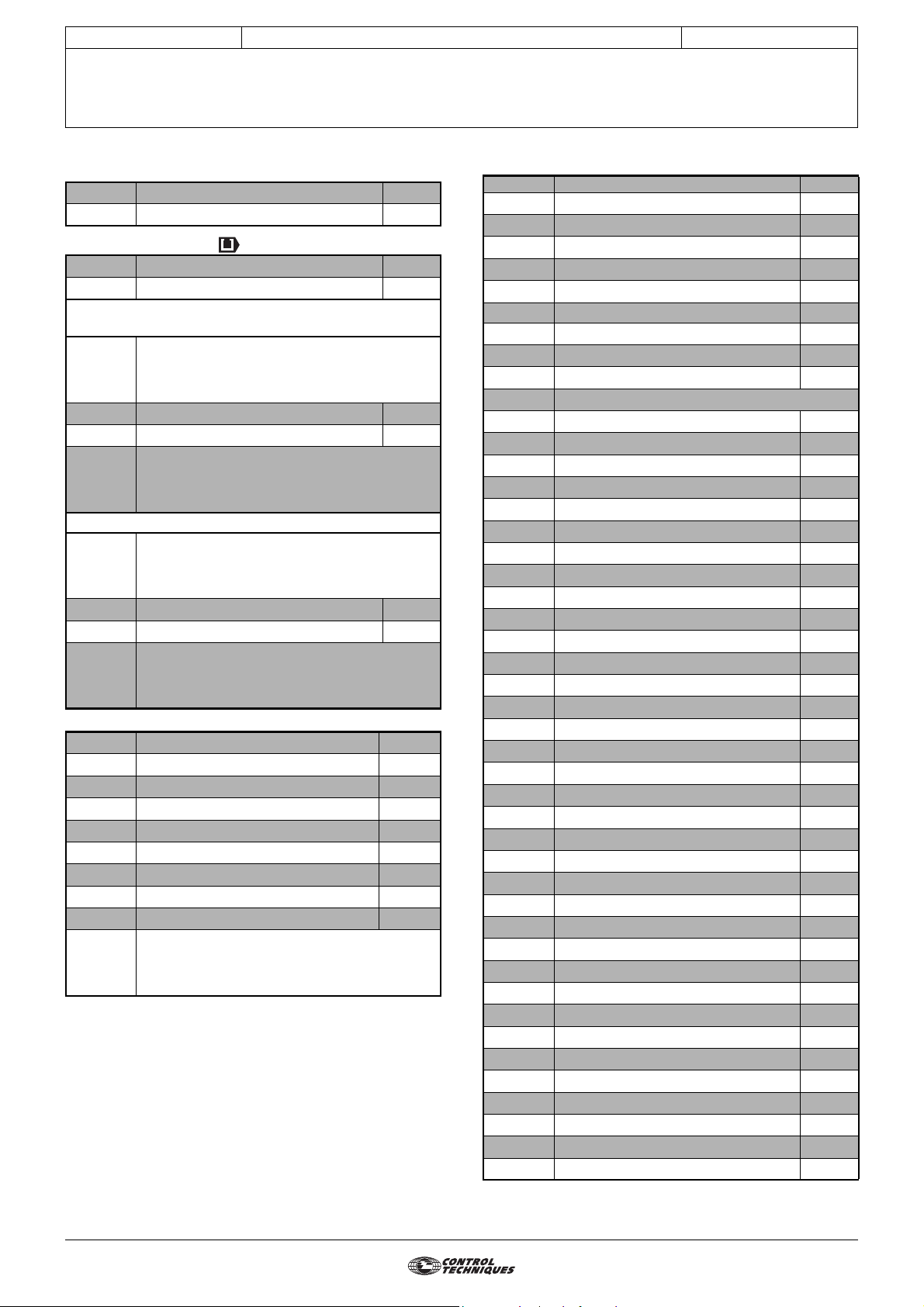

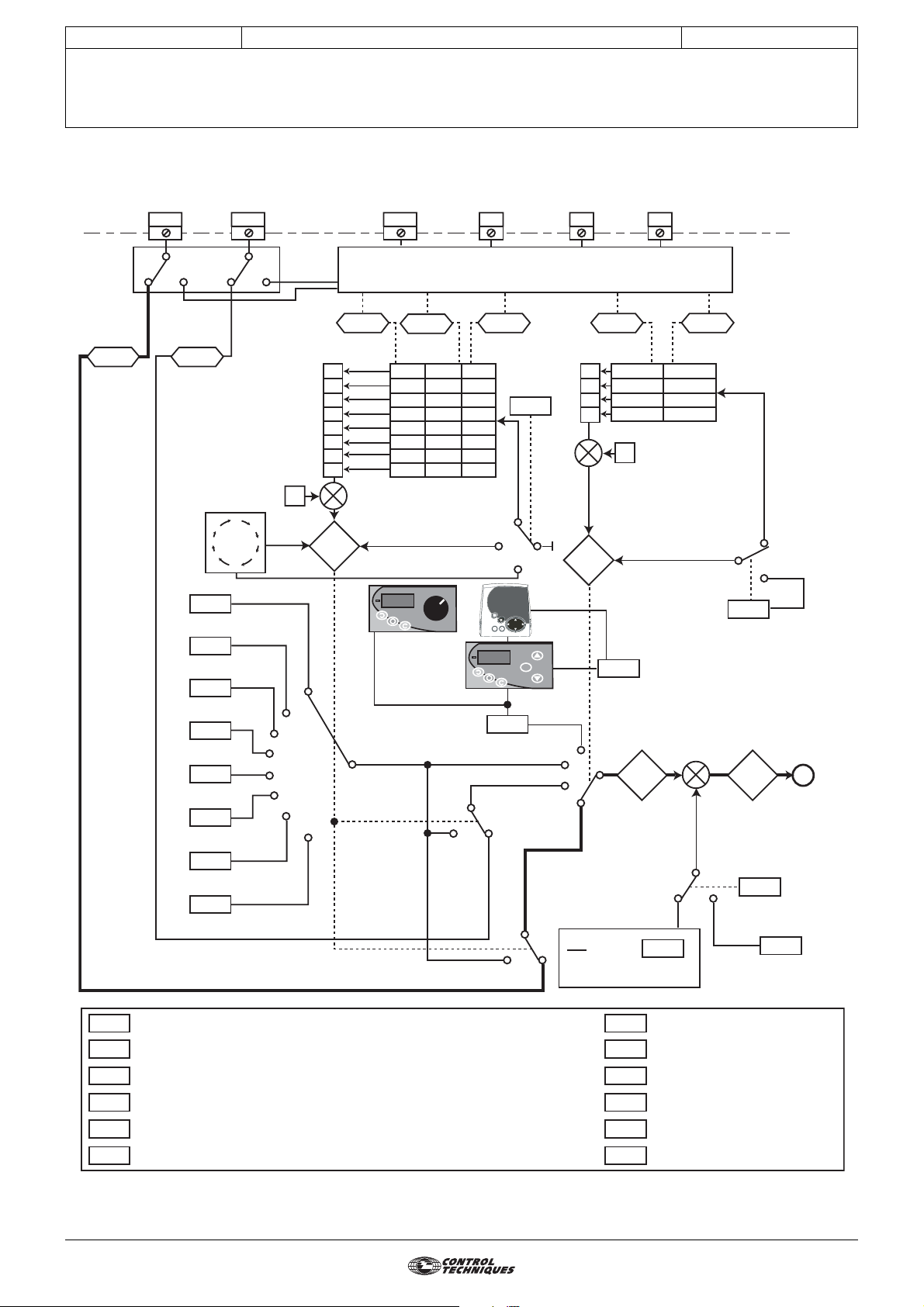

3.2 - Menu 1 diagram

3.2.1 - Selection of reference (speed)

ADI1 ADI2 DIO1 DI2 DI3 DI4

ADVANCED USER GUIDE

3854 en - 03.2008 / b

Menu 7

Analog

reference

1

1.36 1.37

Paramétrage cycleur

1.16

1.48

1.69

1.70

1.71

1.72

Analog

reference

2

Scan timer

7

Pr1

1.21

Pr2

1.22

Pr3

1.23

Pr4

1.24

Pr5

1.25

Pr6

1.26

Pr7

1.27

Pr8

1.28

Preset reference selector timer

Reference timer reset flag

Number of scanned references

Scan time selection

Preset 1 scan timer time

Preset 2 scan timer time

1

8 6 2

5

3

4

3

4

5

6

Preset

reference

select

1

1

2

7

8

+

0

1

2

3

4

5

6

7

1.50

1.47

Preset

reference

selected

indicator

1.46

0

0

0

0

1

0

1

0

0

1

0

1

1

1

1

1

1 to 8

Keypad control

mode reference

>1 and

1.15 = 0

>1 and

1.15 = 0

Menu 8

1.45 1.42 1.41

0

1

0

1

0

1

0

1

Preset

selector

0

9

1.17

1

1.15

M

0

1

2

3

1.49

4

3

2

1

Percentage trim

Ref

100

1

0

0

1

1

+

1

Reference

selected indicator

Power-up

keypad

control

mode

reference

1.51

Pre-offset

reference

1.60 1.01

x (100 + )

1.73

1.74

1.75

1.76

1.77

1.78

0

1

0

1

+

+

0

1.38

Preset 3 scan timer time

Preset 4 scan timer time

Preset 5 scan timer time

Preset 6 scan timer time

Preset 7 scan timer time

Preset 8 scan timer time

Reference

select

1.14

Reference

selector

Frequency/speed

reference selected

Reference

offset select

1.09

1

Reference

offset

0

1 to 4

A

1.04

24

Page 25

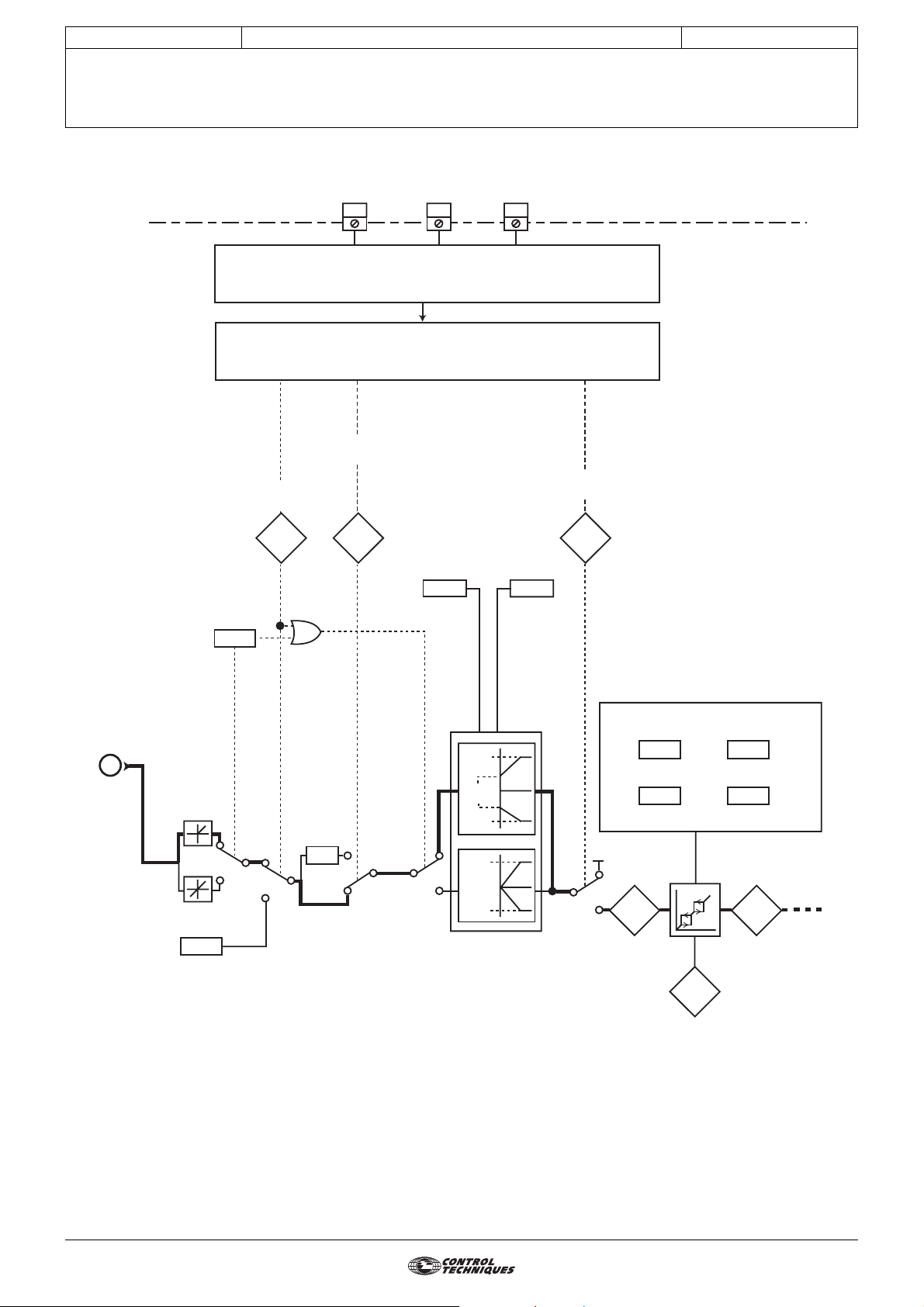

CONTROL TECHNIQUES

MENU 1: SPEED REFERENCE: SELECTION, LIMITING AND FILTERS

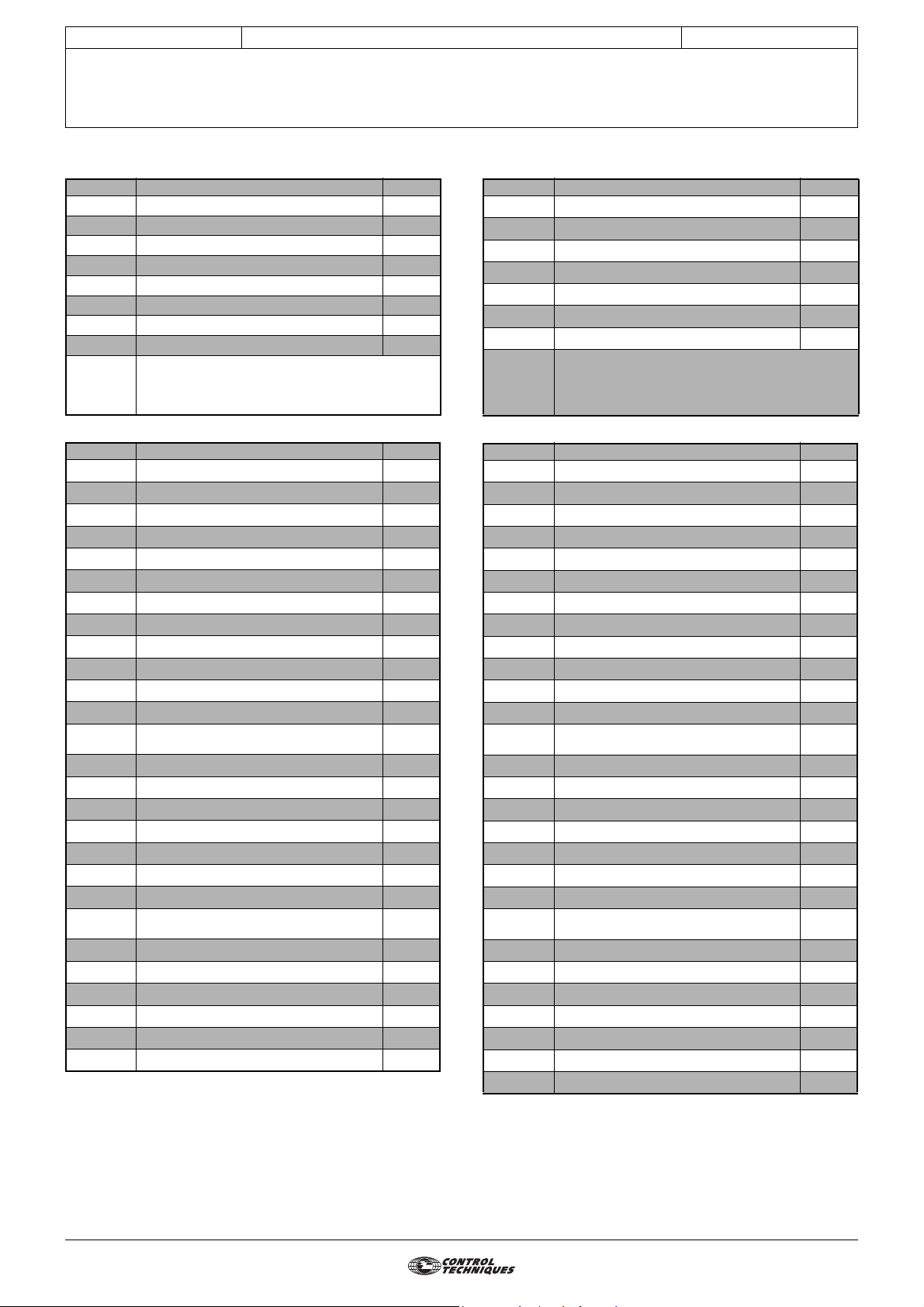

3.2.2 - Limiting and filters

Jog selected

indicator

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

DI1DI2DI3

MENU 8

MENU 6

Reverse

selected indicator

Reference

enabled indicator

3854 en - 03.2008 / b

1.13 1.12 1.11

Bipolar

reference

enable

A

Jog reference

1.10

0

1

1.05

OU

0

1

X(-1)

1

0

Maximum

reference

clamp

1.06 1.07

0

1

reference

1.06

1.07

1.06

1.06

1.06

Minimum

clamp

Skip references

12

1.29

1.30

Pre-skip

filter

0

reference

1

1.02 1.03

Reference in

rejection zone

1.35

1.31

1.32

Pre-ramp

reference

Skip

Band

Menu 2

25

Page 26

CONTROL TECHNIQUES

MENU 1: SPEED REFERENCE: SELECTION, LIMITING AND FILTERS

ADVANCED USER GUIDE

Commander SX

IP66/Nema 4X variable speed drive

3854 en - 03.2008 / b

3.3 - Explanation of parameters in menu 1

1.01

Adjustment range :± 1.06

Indicates the reference value.

1.02

Adjustment range :± 1.06 or 1.07 to 1.06

Reference after limiting but before the skips.

1.03

Adjustment range :± 1.06 or 1.07 to 1.06

Indicates the reference after the skips but before the

acceleration or deceleration ramps.

1.04

Adjustment range :± 1.06

Factory setting :0

This reference is added to (positive value) or subtracted from

(negative value) the selected reference if 1.09 equals 1

(OFFS). It can be used to correct the selected main reference

to obtain an accurate setting.

1.05

Adjustment range :0 to 1.06 rpm

Factory setting :45 rpm