Emerson Bettis Q series, Bettis Q100, Bettis Q150, Bettis Q200, Bettis Q350 Installation, Operation & Maintenance Manual

...Page 1

APPROVED

Bettis Q-Series Valve Actuator

Installation, Operation & Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

Page 2

Page 3

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

Table of Contents

October 2017

I

Table of Contents

Contents

A Before you start ������������������������������ 1

A1 Orientation (see fig. A1) ............................ 1

A2 Installation, operation and maintenance

reference documents ................................ 1

A3 Operating medium ................................... 1

A4 Product integrity ....................................... 1

A5 Hazardous areas ........................................ 2

A6 Warning ; Moving parts ............................ 2

A7 Prevent moisture entering the actuator .... 2

A8 Warehouse storage ................................... 2

A9 On site storage .......................................... 2

A10 Lifting instructions .................................... 2

1 Introduction ������������������������������������ 3

1.1 Orientation (see fig. 1.1) ........................... 3

2 Installation �������������������������������������� 4

2.1 Before you start......................................... 4

2.2 Failure modes ............................................ 4

2.3 Operating principle ................................... 5

2.4 Actuator assembly codes ......................... 9

2.5 Valve Installation ..................................... 11

2.6 Recommended tubing sizes .................... 12

2.7 Air consumption per stroke at

atmospheric pressure .............................12

3 Mechanical stroke adjustment ������� 13

3.1 Adjusting the “Open” position ................ 13

3.2 Adjusting the “Closed” position .............. 13

3.3 Adjusting the end position with no

electrical wiring connected ..................... 14

4 Removing and mounting of the

Bettis Q-Series Modules ����������������� 15

4.1 Removing the Bettis Q-Series modules ... 15

4.2 Mechanical alignment and mounting

of the control module .............................15

4.3 Tightning moments ................................ 15

4.4 Connecting air supply ............................. 15

5 Speed control option ��������������������� 16

5.1 Mounting Speed Control throttle(s): ...... 16

5.2 Adjusting Speed Control throttle(s): ....... 16

6 Manual Control option ������������������� 17

6.1 Mounting Manual Control ....................... 17

6.2 Manual Control operation ....................... 17

7 Trouble shooting Bettis Q-Series ���� 18

7.1 Mechanical problems .............................. 18

7.2 Pneumatic problems ............................... 18

7.3 Electrical problems .................................19

8 Maintenance ���������������������������������� 20

8.1 General....................................................20

8.2 Single acting / Spring Return actuators ...20

8.3 Bettis Q-Series recommended spare parts . 20

8.4 Position tracking device kits .................... 20

8.5 Conversion kits........................................ 20

8.6 High Temp and Low Temp Conversion kits .. 20

9 Disassembly ����������������������������������� 21

9.1 Before starting ....................................... 21

9.2 Removing end caps all types QD and

QS 40 to QS 350 ...................................... 22

9.3 Removing end caps type QS 600

to 1600 ...................................................23

9.4 Removing limit stop bolts, pistons and

pinion assembly ...................................... 24

10 Reassembly ������������������������������������ 26

10.1 Reassembly guide band and pinion

assembly ................................................. 26

10.2 Reassemble the pistons........................... 28

10.3 Reassembly end caps, all types QD and /

QS 40 to QS 350 ...................................... 29

10.4 Reassembly end caps single acting

actuators QS 600 to QS 1600 .................. 30

10.5 Mounting and setting of limit stops ........ 31

10.6 Final assembly and airtightness test .......32

11 Bettis Q-Series Parts ����������������������� 33

11.1 Exploded view Bettis Q-Series

(base actuator) ........................................33

11.2 Bill Of Material ......................................... 34

11.3 Exploded view Bettis Q-Series

(Control Module) ....................................35

Page 4

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

1

A2 Installation, operation and

maintenance reference documents

Before mounting, installing, commissioning or

(dis)assembling the actuator consult the following

documents:

- All chapters of this manual and

- Installation Guide of the supplied Control Module.

- For installation in hazardous area’s:

The applicable section of the Installation Guide, as

shipped with the Control Module.

- For Control Modules with bus communication

there may be an additional Reference Manual with

more detailed information.

(available from www.emerson.com/bettis).

A3 Operating medium

• Air or inert gasses:

- Filtered to 50 micron (5 micron for QC54).

- Check the Installation Guide as shipped with the

module for the applicable air quality.

• Maximum pressure, 8 bar g / 120 psig

• Dew point 10 K below operating temperature.

• For subzero applications take appropriate

measures.

A4 Product integrity

• Assembly or disassembly is only allowed for

replacing seals and guide bands (soft parts).

A Before you start

Fig A1 Orientation

• Bettis Q-Series actuators must be isolated both

pneumatically and electrically before (dis)

assembly.

• It is not permitted to connect a pressure vessel

with unreduced media to the Bettis Q-Series

pneumatic actuator.

• Bettis Q-Series actuators must not be connected

to an air supply greater than 8 bar g or 120 psig

• This manual does not provide instructions for

installations in hazardous areas.

• Installation, adjustment, putting into service, use,

assembly, disassembly and maintenance of the

pneumatic actuator must be done by qualified

personnel.

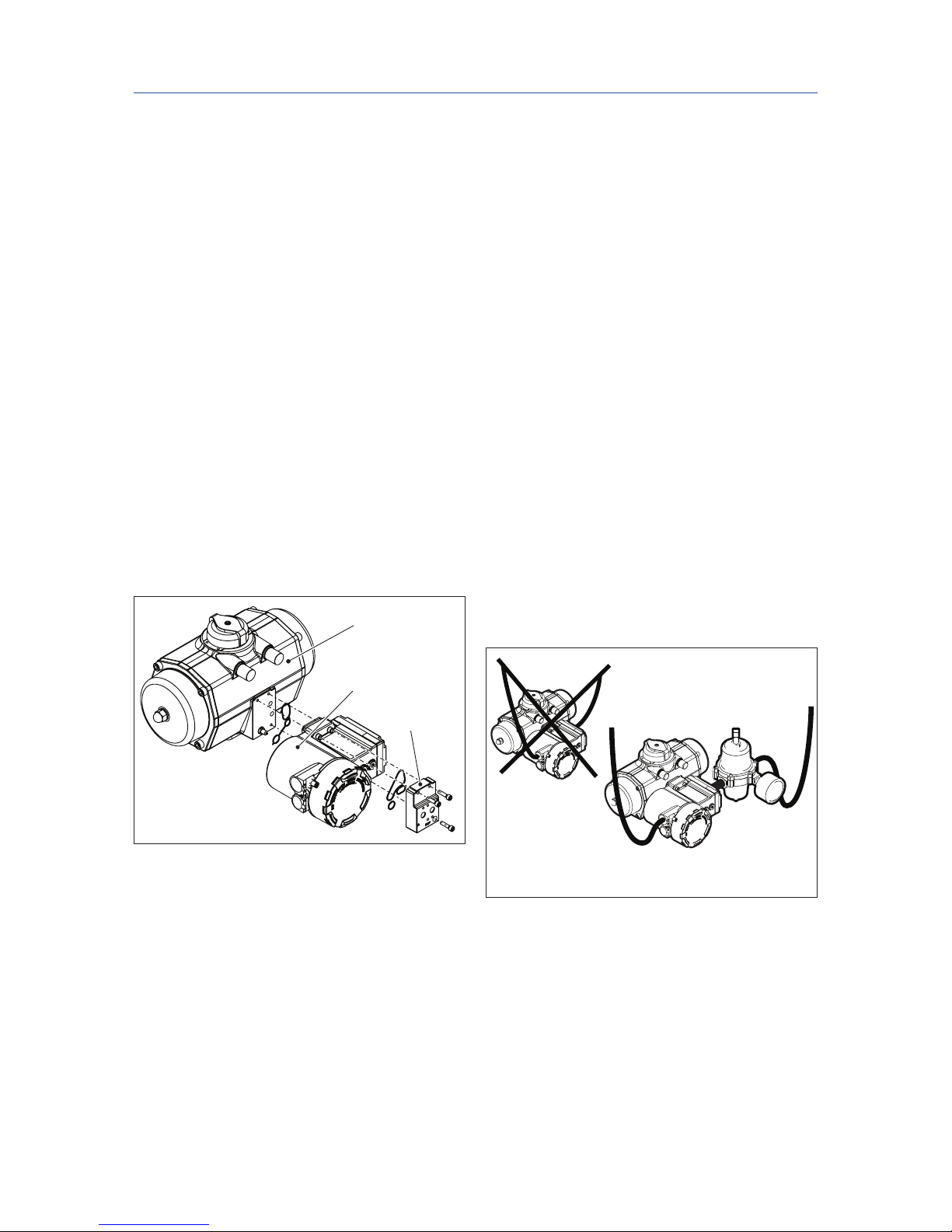

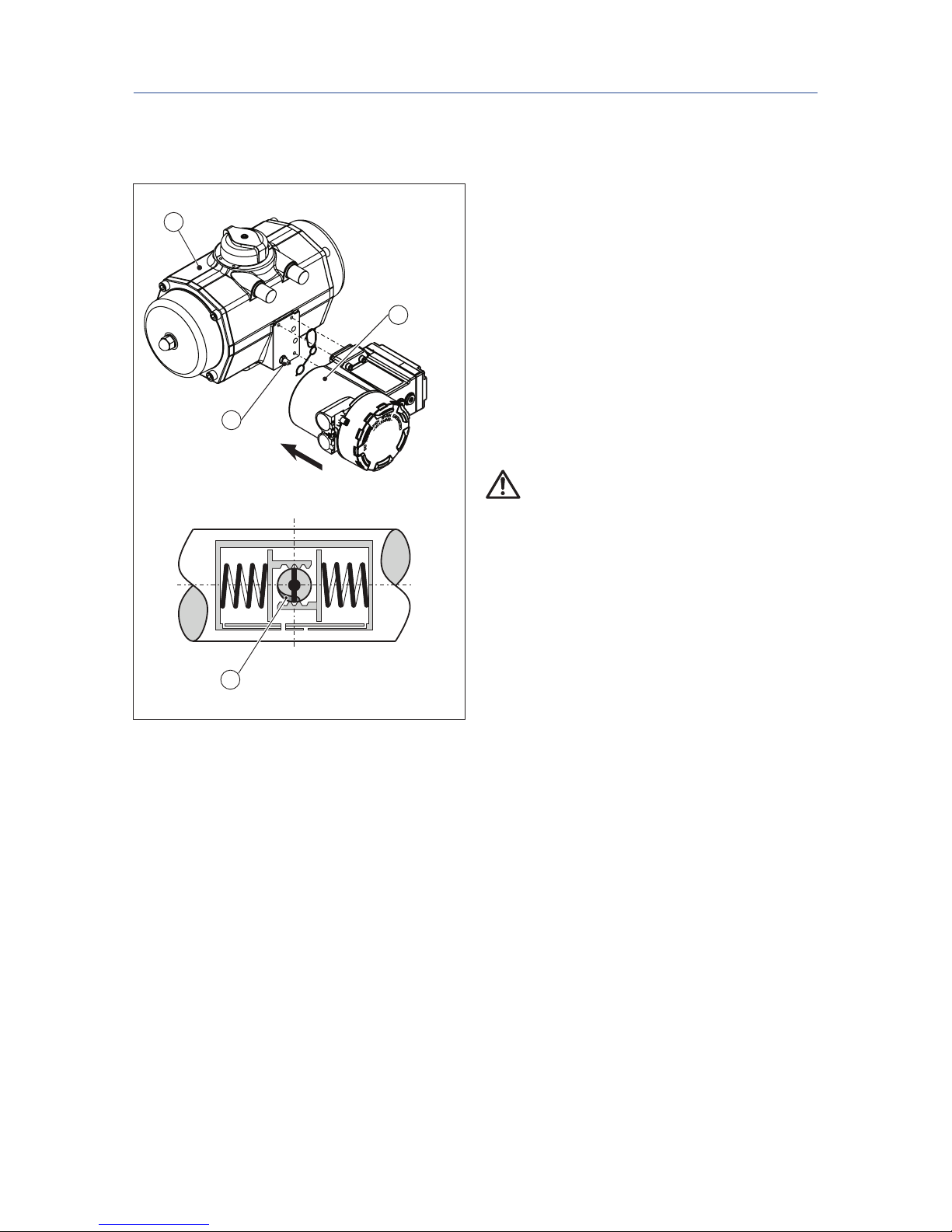

A1 Orientation(seeg.A1)

The Bettis Q-Series actuator is an integrated concept

for the automation of quarter turn valves, dampers

or other quarter turn applications. It can consists of

three basic parts:

1. Pneumatic actuator

2. Pneumatic Module or NAMUR Plate

3. Control Module

1

2

3

50µm

(QC54 = 5µm)

OK

Fig A2 When needed, use Filter/Regulators with correct filter

specification.

Page 5

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

2

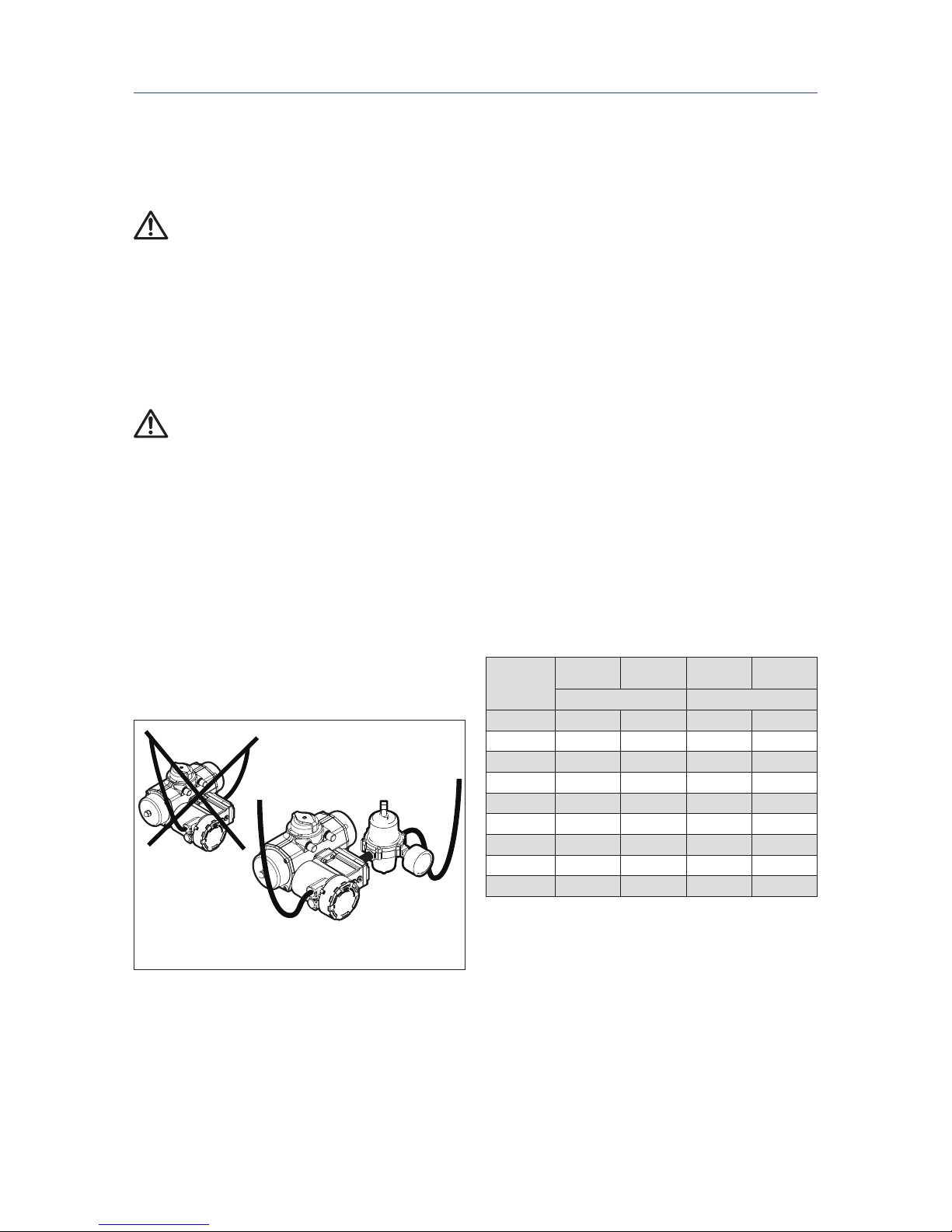

A5 Hazardous areas

Improper installation in a hazardous area can

cause an explosion.

• Assembly, disassembly and maintenance must be

done in safe area’s without a potential explosion

hazard.

• For information about installation in a hazardous

area, refer to the appropriate sections of the

Installation Guide, as shipped with the control

module.

A6 Warning ; Moving parts

Applying pressure to the actuator or

Applying a control signal to the Control

Module, may cause the actuator/valve

assembly to operate.

A7 Prevent moisture entering the

actuator

Condensation or moisture that enters the

actuator or the Control Module can damage these

components and can result in failures. Therefore:

• Try not to mount the actuator with the conduit

openings or the air entries, pointing upward.

• Ensure integrity of gaskets and o-rings.

• Install drip loops in conduit or cable. When

needed use Filter/Regulators with correct filter

specification.

• Seal all conduit openings whether used or not.

50µm

(QC54 = 5µm)

OK

Fig A3 Install drip loops and use Filter/Regulators with correct

filter specification.

A8 Warehouse storage

• Bettis Q-Series Actuators and Control Modules

should be stored in a clean, dry warehouse, free

from excessive vibration and rapid temperature

changes.

• Actuators should not be stored on any floor

surface.

A9 On site storage

• Bettis Q-Series Actuators and Control Modules

should be stored in a clean, dry warehouse, free

from excessive vibration and rapid temperature

changes.

• Ensure all actuator covers are in place and

securely fastened.

• Replace plastic conduit plugs with appropriate

pipe plugs.

Failure to follow proper storage guidelines will void

warranty.

A10 Lifting instructions

• Use lifting equipement as required by national or

local legislation.

Table A1 Weight of Actuators with

control modules

ACTUATOR

TYPE

Double

acting

Spring

Return

Double

acting

Spring

Return

in kg� in Ib

Q40 3.9 4.5 8.6 9.9

Q65 4.5 5.7 9.9 12.6

Q100 5.2 6.7 11.5 14.8

Q150 6.9 9 15.2 19.8

Q200 7.9 11.2 17.4 24.7

Q350 12.5 19 27.6 41.9

Q600 21.5 29.7 47.4 65.5

Q950 28.5 40.7 62.8 89.7

Q1600 44.8 67.9 98.8 149.7

• It is strongly recommended to use lifting straps to

lift the actuator/valve assembly.

• If an actuator/valve assembly should be lifted, it

is strongly recommended to connect the lifting

straps in such way that the actuator and valve is

supported.

Page 6

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

3

1 Introduction

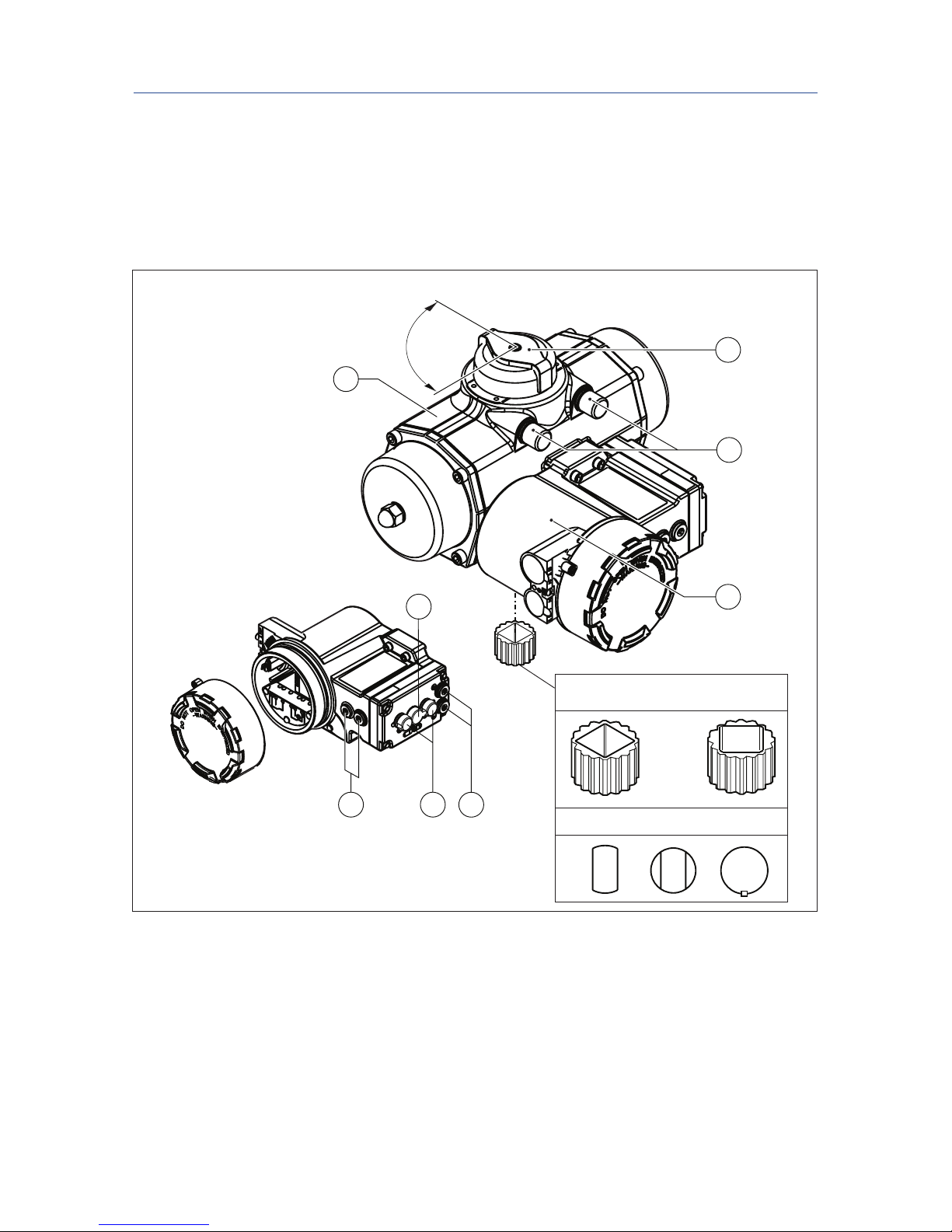

1.1 Orientation(seeg.1.1)

Fig 1.1 Introduction

5. Entries for optional manual control

6. Exhausts

7. Supply air entry

8. Entries for optional speed control

1. Pneumatic actuator

2. Visual Position Indication

3. Stroke adjustment bolts

4. Control Module

The Bettis Q-Series actuator is an integrated concept for the automation of quarter turn valves, dampers or

other quarter turn applications.

1

2

3

4

5

6

7

8

Factory setting:

Rotation 90°

±0.5°

Insert according

ISO 5211 or DIN 3337

Optional insert shapes

Page 7

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

4

2 Installation

2�1 Before you start

In case of an air or electrical failure, it is important to know the behavior of the actuator.

Before mounting the actuator on a valve consult the following paragraph’s.

2�2 Failure modes

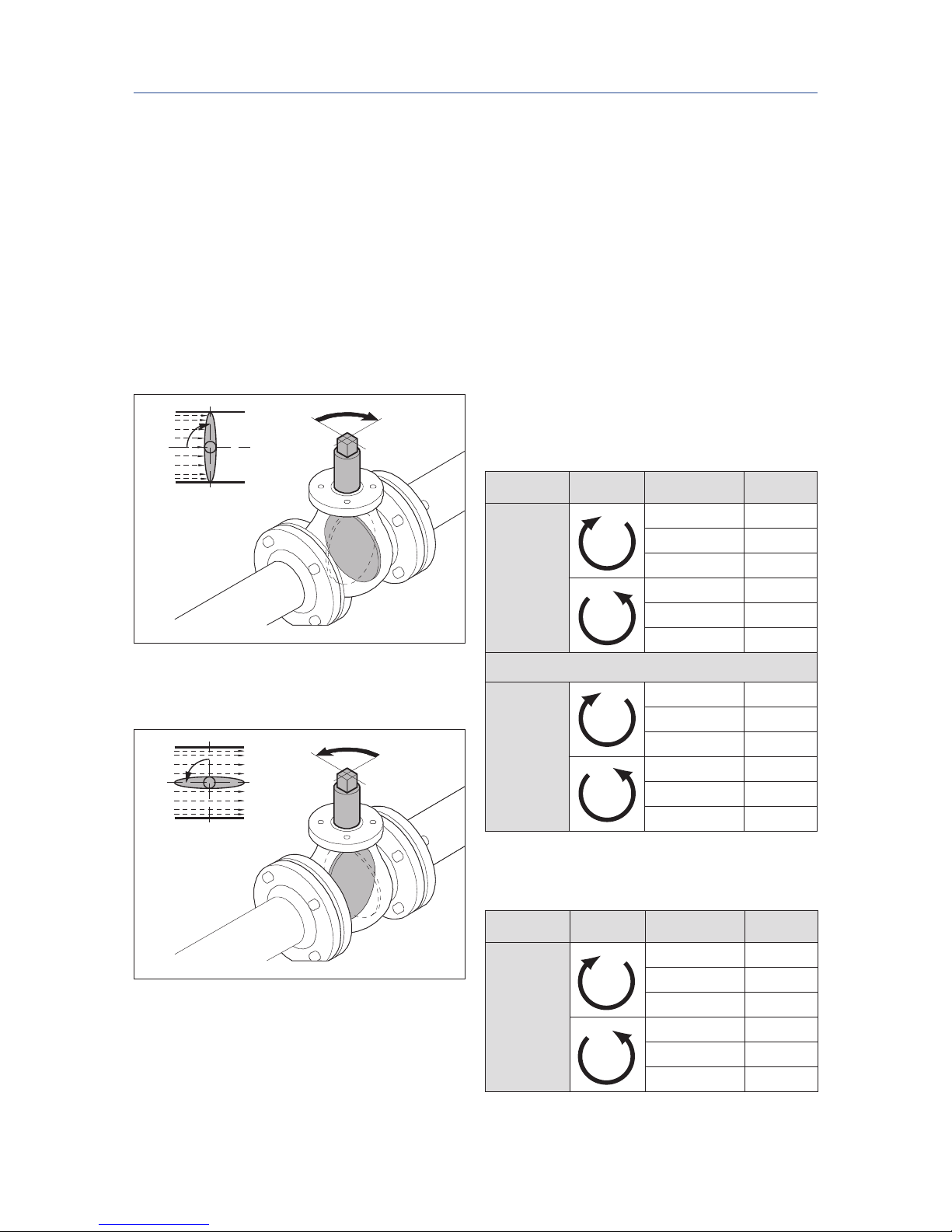

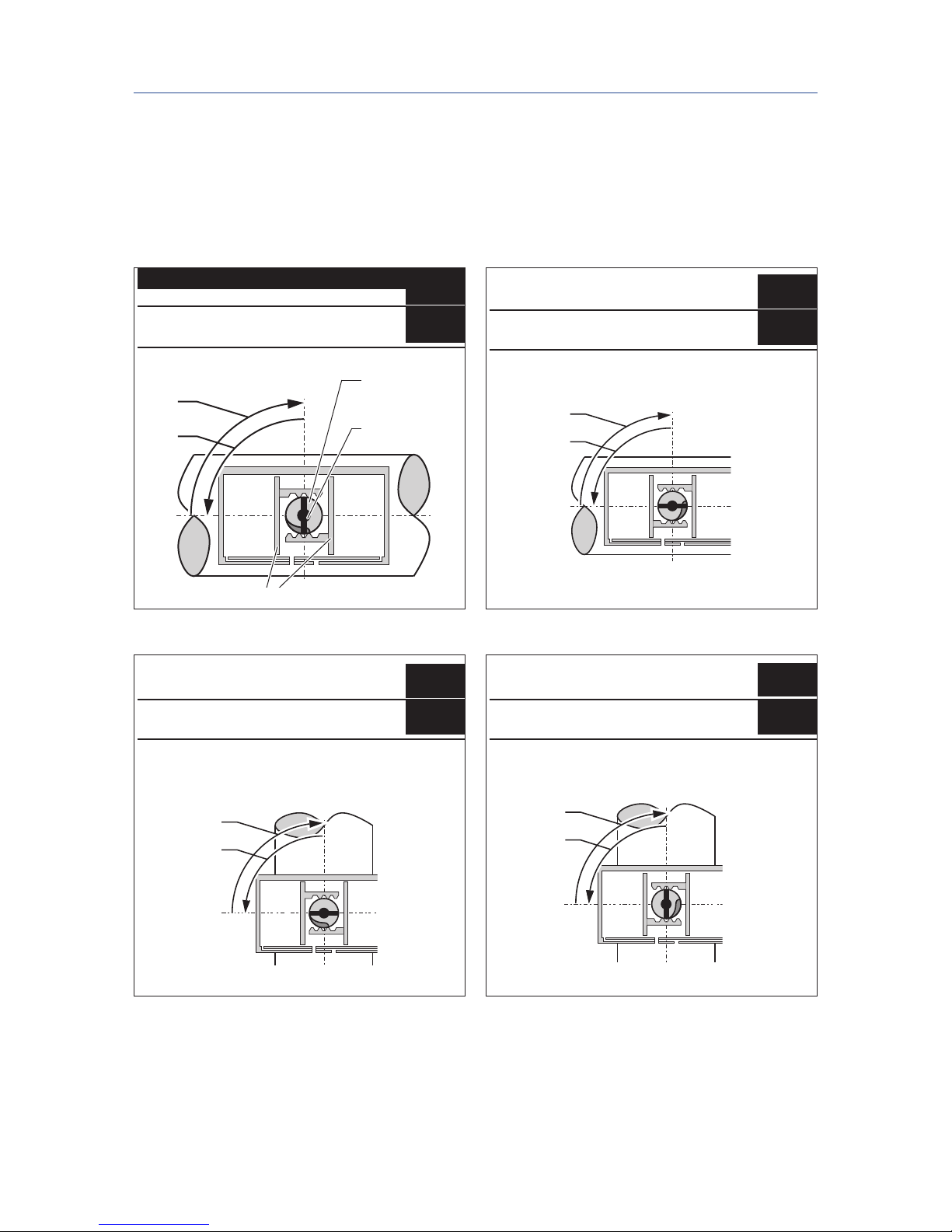

Fig. 2.2.2

Fig. 2.2.1

closed

open

- the valve is open after a counter clock wise

rotation (viewed from above).

2�2�2 Position after a failure

The position of the actuator after a failure depends on

the:

- Operating principles (see §2.3)

- Assembly code (see §2.4)

- Kind of failure

Table 2�1 Position after a failure

Principle of

operation

Assembly

code :

Kind of

failure :

Position :

Double

acting

actuator

CW

Pressure not defined

Signal Closed

Supply voltage Closed

CC

Pressure not defined

Signal Open

Supply voltage Open

Single

acting

actuator

(Spring

Return)

CW

Pressure Closed

Signal Closed

Supply voltage Closed

CC

Pressure Open

Signal Open

Supply voltage Open

Table 2�2 Position after a failure with a Double

acting module with Fail-In-LastPosition function

Principle of

operation

Assembly

code :

Kind of

failure :

Position :

Double

acting

actuator

CW

Pressure not defined

Signal not defined

Supply voltage Closed

CC

Pressure not defined

Signal not defined

Supply voltage Open

2�2�1 Valve rotation

Valves are normally manufactured so that:

- the valve is closed after a clock wise rotation

(viewed from above).

Page 8

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

5

B-port

A-port

Ps

Rb

5/2 Spool valve

Ra

Option: LMC

Option:

Throttle 1

Option:

Throttle 2

Pilot

valve 1

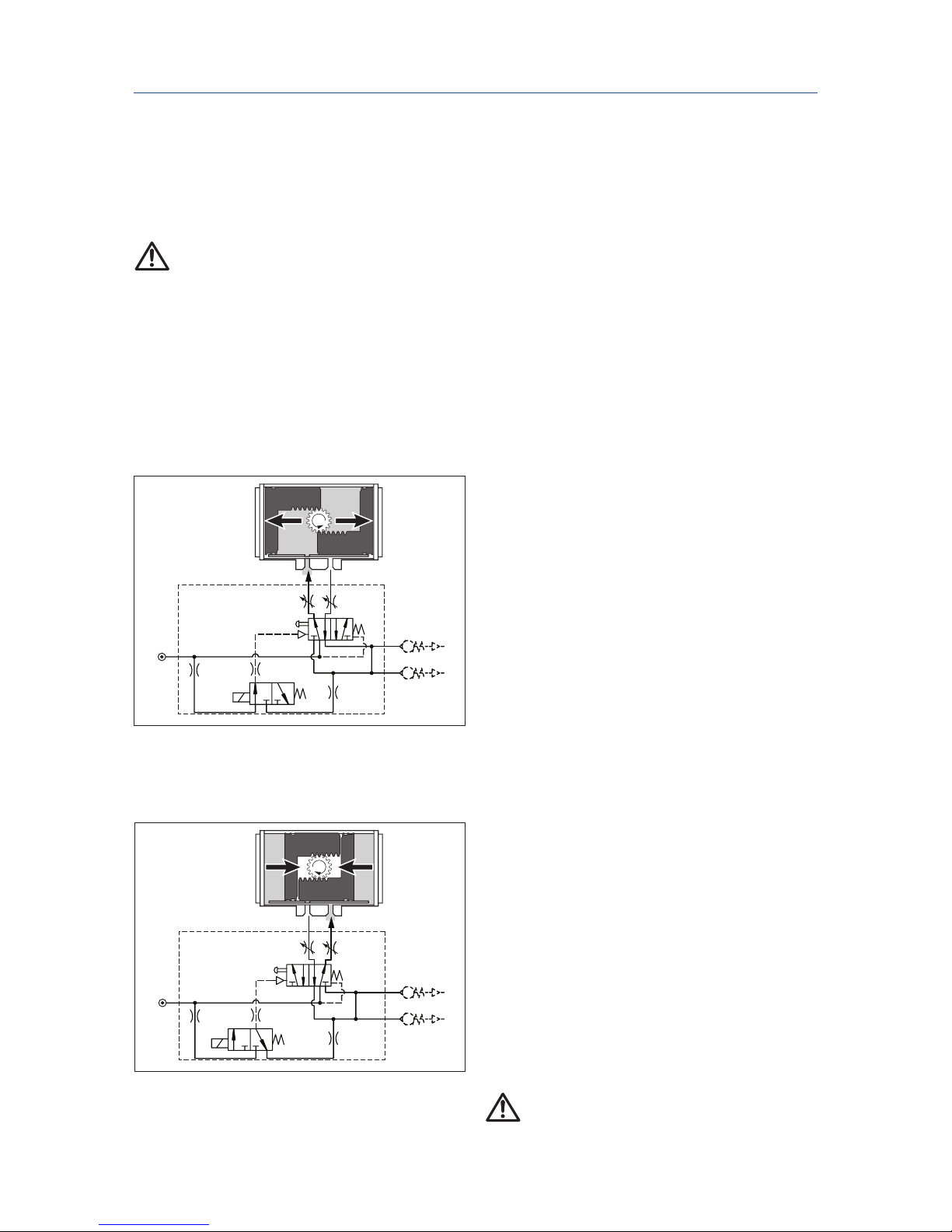

2�3 Operating principle

See paragraph 2.4 for more information about

actuator assembly codes

* Electric control signals can be connected in the

Control Module (QC; see documentation supplied

with the Control Module). The Control Module is

equipped with a pilot valve which controls a 5/2

spool valve.

* Connect air supply to air inlet (Ps).

Outward stroke

1 Send control signal “Open” to the Control

Module.

2 Pilot valve 1 will be activated and the 5/2 spool

valve will pressurize the central air chamber.

3 The piston will move outwards to the “Open”

position.

4 The Control Module indicates the “Open” position

and activates feedback signal “Open”.

Inward stroke

1 Send control signal “Close” to the Control

Module.

2 Pilot valve 1 will be deactivated and the 5/2 spool

valve will pressurize the end cap air chambers.

3 The piston will move inwards to the “Closed”

position.

4 The Control Module indicates the “Closed”

position and activates feedback signal “Closed”.

Optional controls:

LMC Local Manual Control

SC Speed Control throttles

IMPORTANT:

In case of an electric control signal failure, the

actuator will move to its “Closed” position.

2�3�1 Double acting actuators

IMPORTANT

The operating principle, as explained here, is

applicable for actuators with assembly code CW

(direct acting).

- The outward stroke will move the valve to the

“Open” position.

- The inward stroke will move the valve to the

“Closed” position.

For assembly codes CC the operating principle is

reversed (reverse acting):

B-port

A-port

Ps

Rb

Pilot

valve 1

5/2 Spool valve

Ra

Option: LMC

Option:

Throttle 1

Option:

Throttle 2

Fig. 2.3.1

Fig. 2.3.2

Page 9

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

6

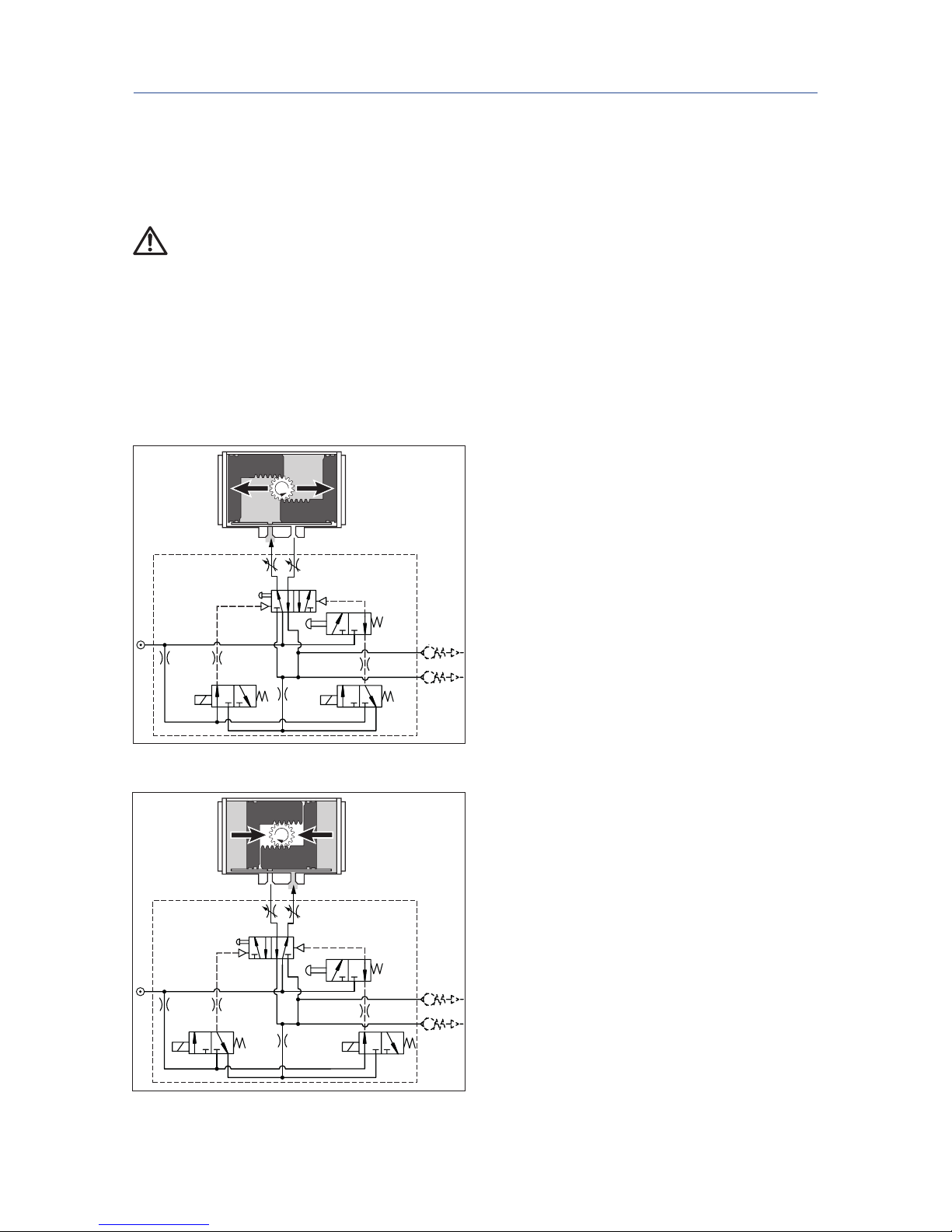

2�3�2 Double acting actuators with Fail In

Last Position function

IMPORTANT

The operating principle, as explained here, is

applicable for actuators with assembly code CW

(direct acting).

- The outward stroke will move the valve to the

“Open” position.

- The inward stroke will move the valve to the

“Closed” position.

For assembly codes CC the operating principle is

reversed (reverse acting):

See paragraph 2.4 for more information about

actuator assembly codes

* Electric control signals can be connected in the

Control Module (QC; see documentation supplied

with the Control Module). The Control Module is

equipped with a pilot valve which controls a 5/2

spool valve.

* Connect air supply to air inlet (Ps).

Outward stroke

1 Send control signal “Open” to the Control Module to

activate Pilot valve 1 and de-activate Pilot valve 2.

2 The 5/2 spool valve will pressurize the central air

chamber.

3 The piston will move outwards to the “Open”

position.

4 The Control Module indicates the “Open” position

and activates feedback signal “Open”.

Inward stroke

1 Send control signal “Close” to the Control Module

to activate Pilot valve 2 and

de-activate Pilot valve 1.

2 The 5/2 spool valve will pressurize the end cap air

chambers.

3 The piston will move inwards to the “Closed”

position.

4 The Control Module indicates the “Closed”

position and activates feedback signal “Closed”.

Optional controls:

LMC Local Manual Control

SC Speed Control throttles

B-port

A-port

Ps

Pilot valve 1

5/2 Spool valve

Pilot valve 2

Option: LMC 1

Option:

LMC 2

Option:

Throttle 1

Option:

Throttle 2

Rb

Ra

B-port

A-port

Ps

Pilot valve 1

5/2 Spool valve

Pilot valve 2

Option: LMC 1 Option: LMC 2

Option:

Throttle 1

Option:

Throttle 2

Rb

Ra

Fig. 2.3.3

Fig. 2.3.4

Page 10

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

7

A-port

B-port

Ps

Pilot

valve 1

3/2 Spool valve

Ra

Option: LMC

Option: Throttle 1

A-port

B-port

Ps

Pilot

valve 1

3/2 Spool valve

Ra

Option: LMC

Option: Throttle 1

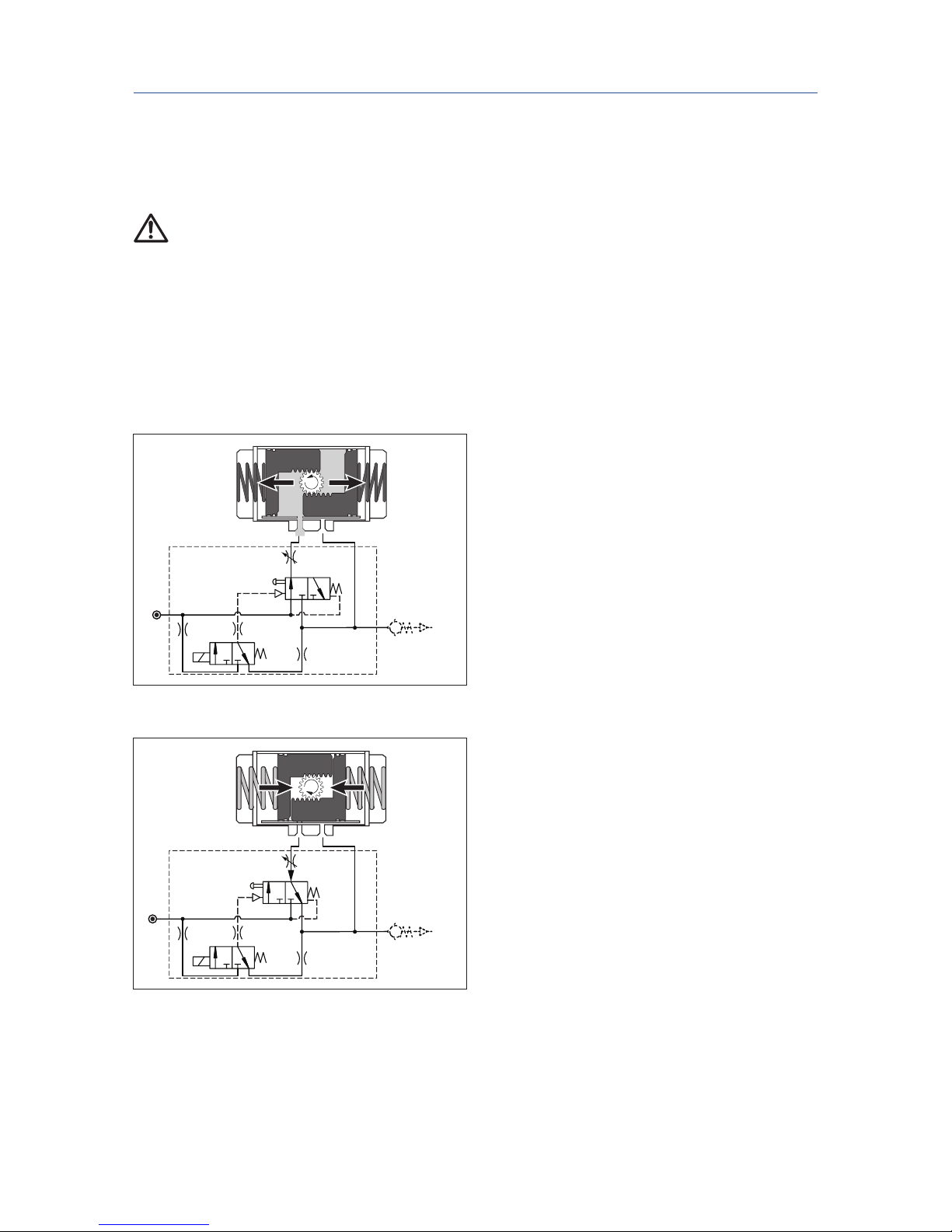

2.3.4 Singleacting(springreturn)actuators

See paragraph 2.4 for more information about

actuator assembly codes

* Electric control signals can be connected in the

Control Module (QC; see documentation supplied

with the Control Module). The Control Module is

equipped with a pilot valve controls a 3/2 spool

valve.

* Connect air supply to air inlet (Ps).

Outward stroke

1 Send control signal “Open” to the Control Module.

2 Pilot valve 1 will be activated and the 3/2 spool

valve will pressurize the central air chamber.

3 The piston will move outwards to the “Open”

position

4 The Control Module indicates the “Open” position

and activates feedback signal “Open”.

Inward stroke

1 Send control signal “Close” to the Control Module.

2 Pilot valve 1 will be deactivated and the 3/2 spool

valve will vent the central air chamber

3 The springs will move the pistons inwards to the

“Closed” position

4 The Control Module indicates the “Closed”

position and activates feedback signal “Closed”.

Optional controls:

LMC Local Manual Control

SC Speed Control throttles

Fig. 2.3.5

Fig. 2.3.6

IMPORTANT

The operating principle, as explained here, is

applicable for actuators with assembly code CW

(direct acting).

- The outward stroke will move the valve to the

“Open” position.

- The inward stroke will move the valve to the

“Closed” position.

For assembly code CC the operating principle is

reversed (reverse acting):

Page 11

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

8

3

1

2

4

2�3�5 Position feedback

Bettis Q-Series patented, position sensing system

The Bettis Q-Series actuator (1) has a patented,

contactless position sensing system. This system

consists of a position probe (2) which is rides on a

special curve (4) in the pinion bottom.

The curve is shaped in such a way that the position

probe moves linearly and proportionally to the

rotation of the actuator pinion.

The linear movement of the position probe is used,

inside the control module (3) to operated the limit

switches.

WARNING:

Do not put the Control module in direct contact

with magnetic material. This can cause damage or

malfunction of the position feedback.

Installation of the Bettis Q-Series modules

For installation instructions of the modules see

chapter 4.

Installation Guides - Control modules

Each Control Module is shipped with an Installation

Guide, which contains more information on the

pneumatic and electrical installation and operation

of the Module. Additionally, these Installation Guides

can be downloaded from www.emerson.com/bettis

Fig. 2.3.7

Page 12

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

9

2�4 Actuator assembly codes

2�4�1 Double acting assembly codes

2

1

2

2

1

2

B

A

A

B

2

1

2

A

B

2

1

2

2

1

2

1

2

2

1

2

2

B

A

A

B

B

A

A

B

2

1

2

1

2

2

A

B

A

B

CC

I

CW

C

CC

C

Standard assembly code:

(= Clock Wise Rotation)

Visual indicator mounted:

(= for In line position indication

Pinion

Position

indicator

Pistons

A = Pilot valve operated in Control Module - Central air chamber (1) pressurized

B = Pilot valve not operated in Control Module - End cap air chambers (2) pressurized

All views are from above. Pistons are shown in inner position

Optional assembly code:

(= Counter Clock Wise Rotation)

Visual indicator mounted:

(= for In line position indication

Optional assembly code:

(= Clock Wise Rotation)

Visual indicator mounted:

(= for Cross line position indication)

Optional assembly code:

(= Counter Clock Wise Rotation)

Visual indicator mounted:

(= for Cross line position indication)

CW

I

Page 13

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

10

2.4.2 Singleacting(SpringReturn)assemblycodes

B

A

2

1

2

B

A

2

1

2

B

A

2

1

2

B

A

2

1

2

B

A

2

1

2

B

A

2

1

2

B

A

2

1

2

B

A

2

1

2

B

A

2

1

2

Standard assembly code:

(= Clock Wise Rotation /

Spring to Close)

Visual indicator mounted:

(= for In line position indication

Pinion

Optional assembly code:

(= Clock Wise Rotation /

Spring to Close)

Visual indicator mounted:

(= for Cross line position indication

Position

indicator

Pistons

Optional assembly code:

(= Counter Clock Wise Rotation /

Spring to Open)

Visual indicator mounted:

(= for Cross line position indication

A = Pilot valve operated in Control Module - Central air chamber (1) pressurized

B = Pilot valve not operated in Control Module - Springstroke(2)

All views are from above. Pistons are shown in inner position

Optional assembly code:

(= Counter Clock Wise Rotation /

Spring to Open)

Visual indicator mounted:

(= for In line position indication

CC

C

CW

C

CC

I

CW

I

Page 14

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

11

1

2

ISO 5211 DIN 3337

90°

45°

Fig. 2.5.4

Fig. 2.5.5

2�5 Valve Installation

WARNING!

Actuator must be isolated both

pneumatically and electrically before (dis)

Fig. 2.5.1

Fig. 2.5.2

Fig. 2.5.3

CAUTION!

Be sure that the insert is mounted at 90° or 45°.

assembly. Before mounting or (dis)assembling the

actuator consult the relevant sections of this manual.

Remove handle nut, handle, lock washer, etc. from

valve if required.

It is possible to mount the insert turned 22.5°. This

way the valve will not open or close the right way.

CAUTION!

- Before mounting the actuator on the valve

be sure that both the actuator and the

valve have the same position.

- When mounting do not hit with hammer

on pinion top.

IMPORTANT!

- When mounting the actuator across the

pipeline, the NAMUR slot at the pinion

top is turned 90° and does not reflect the

position of the valve blade.

- When mounting NAMUR (VDI/VDE3845)

switch boxes or positioners take care that

these devices can be and will be set to

reflect the actual limit positions.

OK

OK

Page 15

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

12

2�6 Recommended tubing sizes

Actuator Model no� Runs up to 1�2 mtr / 4 ft� Runs over 1�2 mtr� / 4 ft�

Q-40, 65 6 mm / 1/4” 6 mm / 1/4”

Q-100, 150, 200, 350 6 mm / 1/4” 8 mm ~ 5/16”

600, 950, Q1600 8 mm / 1/4” 10 mm ~ 3/8”

2�7 Air consumption per stroke at atmospheric pressure

Air chamber

-at1atm(litres)

Model

Q40 Q65 Q100 Q150 Q200 Q350 Q600 Q950 Q1600

Central air chamber 0.16 0.33 0.35 0.84 0.8 1.8 2.9 4.7 7.3

End cap air chambers 0.22 0.36 0.49 0.78 1 1.9 3.1 4.9 8.0

- at 1 atm (cu./in.)

Central air chamber 10 20 21 51 49 110 177 287 445

End cap air chambers 13 22 30 48 61 116 189 299 488

Page 16

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

13

Fig. 3.3

Closed

-3°15°

Open

75°

90°

±0.5°

93°

3 Mechanical stroke adjustment

The factory setting of the stroke is 90°

±0.5°

If required the stroke can be adjusted by means of

two stroke adjustment bolts.

3�1 Adjusting the “Open” position

1. Connect supply pressure and control wiring

according the instructions shipped with the

Control Module.

2. Remove the nut caps (A).

3. Loosen nuts (B). See table 3.1.

Repeat next steps 4 to 8 until desired setting is

achieved:

4. Send the actuator/valve assembly to the “Open”

position (see instructions shipped with the

Control Module).

5. Check whether the position of the valve is correct.

The position indication knob (C) indicates the

valve position

If the position is not correct, proceed with the

following steps:

6. Send the actuator/valve assembly to the “Closed”

(opposite) position (see instructions shipped with

the Control Module).

7. Turn the limit stop bolts (see table 3.1):

Turning in reduces the stroke:

Turning out increase the stroke:

8. Send the actuator/valve assembly to the “Open”

position (see instructions shipped with the

Control Module).

9. Check whether the position of the valve is correct.

When the “Open” position is correct proceed with

adjusting the “Closed” Position.

3�2 Adjusting the “Closed” position

1. Execute steps 4 to 8 of §3.1 but now for the

“Closed” position.

2. Mount the nut caps (A).

Code CW and Code CC

Closed

position

Fig. 3.1

Fig. 3.2

ABC

Open

position

Page 17

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

14

OK

OK

Fig. 3.1.2

3�3 Adjusting the end position with no

electrical wiring connected�

If the Control Module is equipped with the optional

Pneumatic Manual Override (A), only supply

pressure needs to be connected to cycle the

actuator. For more information on how to use the

“Pneumatic Manual Override” see chapter 6.

REMARK:

In case of air leakage over the limit stop bolts, turn

the lock nut of the limit stop bolts tighter, until

leakage stops.

Table 3�1 Angular Displacment & Tools

Actuator Size

Angular

displacement

Tools

Nut Bolt

Q40 3.0 ° W10 mm SD1.2 mm

Q65 3.6 ° W13 mm SD1.2 mm

Q100 2.7 ° W13 mm SD1.2 mm

Q150 2.7 ° W17 mm SD1.5 mm

Q200 2.3 ° W17 mm SD1.5 mm

Q350 2.7 ° W19 mm SD1.5 mm

Q600 2.7 ° W24 mm W10 mm

Q950 2.5 ° W24 mm W10 mm

Q1600 2.7 ° W30 mm W10 mm

W = Wrench

SD = Screwdriver

Page 18

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

15

4 Removing and mounting of the Bettis Q-Series Modules

WARNING

Bettis Q-Series actuators must be isolated

both pneumatically and electrically before

(dis)assembly.

The Pneumatic Module (1) is placed between the

Control module (2), and the housing (3) of the

actuator. It controls the air going in and out the

actuator.The actuator can be equipped with a

NAMUR plate (6) for direct solenoid mounting.

Fig. 4.1

4x No. 2

3x No. 5

1

2

3

4

4

5

6

4�1 Removing the Bettis Q modules

1 To prevent warping of the modules and damage

the threads:

- First loosen the all screws 1/4 to 1/2 turns.

- The screws can now be removed completly.

2 Prevent damage to the position probe (5) to

guarantee accurate position feedback.

4�2 Mounting the Bettis Q modules

1 Take care that the following mating surfaces are

clean.

- Between the actuator housing and the

Pneumatic Module (or NAMUR plate).

- Between the Pneumatic Module and the Control

Module.

2 To align the position probe (5) properly to the

Control Module:

- First mount the Pneumatic Module.

- Then mount the Control Module.

3 Press the O-rings (8) and seals (4, 7 & 9) firmly

their mating grooves to keep them in place during

mounting.

4 Prevent damage to the position probe (5) to

guarantee accurate position feedback.

5 When fastening the module turn each screw two

to three turns at a time, in sequence, to assure an

air tight connection.

4�3 Tightning moments

The Control Module and Pneumatic module should

be fastened by using the allen keys as indicated and

applying the following tightning moments:

- Phillips head size 2, 1.8 to 2.2 Nm

(16 - 19.5 In.lbs)

- Allen Key No 5: 6.1 to 6.6 Nm

(54 - 58.4 In.lbs)

4�4 Connecting air supply

To connect air supply see the Installation Guide

shipped with the control module.

TIP

Grease the O-rings and seals before

mounting. This makes them sticky and

prevents that these O-rings and seals fall

away during mounting.

Alignmentedge

Alignmentedge

IPT

probe

Fig. 4.2

Page 19

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

16

5 Speed control option

WARNING

Bettis Q-Series actuators must be isolated

both pneumatically and electrically before

any (dis)assembly is begun.

The Bettis Q-Series can be supplied with a Speed

Control option. One throttle is required for Spring

Return actuators and up to two for Double Acting

actuators.

The speed control throttle controls the air flow

in and out of an air chamber and as such limits

the speed of the “Opening” and “Closing” stroke

simultaneously

5�1 Mounting Speed Control

throttle(s):

1 Remove the plug(s) at the side of the module and

turn in the throttle (1).

2 Spring Return actuators: Use the top entry only.

3 Double acting actuators: Use both bottom and

top entries.

- For standard actuators, the top entry will

throttle the closing stroke.

- For standard actuators, the bottom entry will

throttle the opening stroke.

- For reverse acting actuators, the opposite

strokes will be throttled.

5�2 Adjusting Speed Control

throttle(s):

1 Remove the nut cap (2).

2 Clockwise rotation of the adjustment screw

reduces the speed.

3 Counter clockwise rotation of the adjustment

screw increases the speed.

4 Replace the nut cap.

2

1

Figure 5.1 Speed Control option

Speed Control option

O-ring seal

Speed control

Nut cover

Spring Return:

Top entry only.

Double Acting:

Bottom and/or top entries.

Page 20

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

17

6 Manual Control option

WARNING

Bettis Q-Series actuators must be isolated

both pneumatically and electrically before

(dis)assembly.

For commissioning, emergency or maintenance

purposes, the Bettis Q-Series can be supplied with

one or two Manual Control options. These can

operate the pilot valve(s) inside the module and as

such operate the actuator, when there is air pressure

available, but no control signal or power supply.

6�1 Mounting Manual Control

1 To add a Manual Control, remove the plug(s)

in front of the module and turn in the Manual

Control.

- For normal operation the module should be

fitted with one Manual Control.

- For Double Acting with a Fail-in-Last-Position

function, two Manual Control can be fitted.

6�2 Manual Control operation

1 The Manual Control has a “Push & Lock” function:

- To operate the Manual Control, use a screw

driver, push to activate and release to

de-activate the pilot valves.

- If required turn it 45°, to lock it in position and

keep the actuator in its operated state.

2 In case of a Fail in Last Position configuration with

two manual controls:

- The manual control on the right side (default

location) will pressurize the central air chamber

and cause the actuator to rotate counter

clock wise. For reverse acting Bettis Q-Series

actuators (Assembly code CC) the actuator will

rotate clock wise.

- The manual control on the left side (Location for

2nd Manual Control) will pressurize the end cap

air chambers and cause the actuator to rotate

clock wise. For reverse acting Bettis Q-Series

actuators (Assembly code CC) the actuator will

rotate counter clock wise.

- In order to operate one of the manual control,

be sure the opposite manual control is

de-activated and unlocked.

3 It is possible to rotate the screw multiple cycles.

The unit will than toggle every 90° between

“locked” (1) and “unlocked” (0).

45°

Fig. 6. 1 Local Manual Control option

Manual Control option

O-ring seal

Manual control

Nut cover

Location for 2nd

Manual Control

Default location of

Manual Control

Lock

Unlock

On

Off

Page 21

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

18

7 Trouble shooting Bettis Q-Series

7�1 Mechanical problems

Problem Possible error Solution Wheretond

Feedback position and actual

position are not the same.

Actuator and valve are

mounted 90° rotated in

relation to each other.

Remove actuator from valve.

Check assembly code of

actuator. Put both valve and

actuator in “Closed” position.

Mount actuator on valve.

Chapter 1 and 2 of

DOC.IOM.BQ.E

Valve is in “Closed” position,

actuator is in “Open”

position and will not move

anymore.

Valve does not reach the

completely “Closed” or

“Open” position.

Limit stop screws are not

set correctly.

Readjust the limit stop screws Chapter 3 of DOC.IOM.BQ.E

Chapter 2, §2.5 of

DOC.IOM.BQ. E

Insert is not mounted

properly

Mount the insert in the right

position. Remark: Rotate insert

for one cam = 22.5°

Pressure to low Apply pressure as per sizing Data sheets DA =

BQ1.602.01.

SR = BQ1.602.02 or

BQ1.602.03

Sizing is wrong Check valve torque data with

actuator torque data

Actuator rotates, valve does

not.

No coupling between

actuator shaft and valve

spindle.

Install a coupling between

actuator shaft and valve

spindle.

Chapter 2 of DOC.IOM.BQ.E

7�2 Pneumatic problems

Problem Possible error Solution Wheretond

Actuator does not react to

electrical control signal.

There is no supply

pressure at the actuator.

Supply the right pressure to

the actuator.

See supplied

documentation of the

Control Module.

Supply pressure is

connected to one to the

exhausts.

Connect supply pressure to

port “Ps”.

See supplied

documentation of the

Control Module.

Actuator does not react good

to electrical control signal.

There is sufficient

supply air pressure but

insufficient supply air

capacity.

Take care the supply air tubing

has the right dimensions.

See chapter 2, §2.6 of

DOC.IOM.BQ.E

Control Module is not

mounted properly.

Mount the “Control Module”

in the right way to the

“Pneumatic Control Module”.

See chapter 4, of

DOC.IOM.BQ.E

Speed control (if present)

blocks air flow.

Turn the speed control more

open.

Select 1 size larger actuator

See chapter 5 of

DOC.IOM.BQ.E

Manual override

(if present) on the Control

Module is locke

Unlock manual override on the

Control Module.

See chapter 6 of

DOC.IOM.BQ.E

Double acting actuator

will only move to “open”

position.

Control module has

wrong pneumatic

cartridge.

Replace pneumatic cartridge

for version suitable for double

acting actuators.

See DOC.QC4.PNC.1

Page 22

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

19

Problem Possible error Solution Wheretond

Actuator does not react

to control signals

Control wiring, Power supply

wiring or feedback wiring are

not right connected.

Connect all wiring in the right

way.

See documentation

shipped with the Control

Module. (DOC.IG.BQCxx)

The power supply voltage is

not the same as the voltage

of the applicable Control

Module.

Connect the right power

supply voltage.

See documentation

shipped with the Control

Module. (DOC.IG.BQCxx)

Actuator does not react

consistent.

Initialization was not

completed in the right way.

Execute the initialization

procedure or set feedback

signal manuall

See documentation

shipped with the Control

Module. (DOC.IG.BQCxx)

Sizing is wrong Re size the actuator to the

valve

Data sheets

DA = BQ1.602.01.

SR = BQ1.602.02 or

BQ1.602.03

There are problems with

position feedback after

sending the actuator

to either the “Open” or

“Closed” position.

The wiring of the feedback

signals may be switched.

Connect the feedback wiring

in the right way.

See documentation

shipped with the Control

Module. (DOC.IG.BQCxx)

7�3 Electrical problems

Page 23

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

20

8 Maintenance

CAUTION:

Actuator must be isolated both pneumatically and electrically before any (dis)assembly is begun.

Before mounting or (dis)assembling the actuator consult the relevant sections of this manual.

IMPORTANT

Under the European Pressure Equipment Directive, conversion of actuators may only be performed

by companies or personnel, authorized by Emerson.

8�1 General

All Bettis Q-Series actuators are supplied with sufficient lubrication for their normal working life. If required,

recommended lubrication for all standard actuators is a Castrol High Temperature Grease or equivalent.

Periodic checks should be performed to make certain that all fasteners remain tight.

Depending upon the conditions under which the actuator must work such as extended duty, or abnormal

operating conditions, periodic replacement of internal seals is recommended. Repair kits containing all

necessary seals and instructions can be obtained through authorized Bettis Q-Series distributors.

NOTE:

This product is only intended for use in large-scale fixed installations excluded from the scope of Directive

2011/65/EU on the restriction of the use of certain hazardous substances in electrical and electronic

equipment (RoHS 2)

8�2 Single acting / Spring Return actuators

On spring return actuators, the springs can be replaced.

SPRINGS SHOULD ALWAYS BE REPLACED IN COMPLETE SETS.

Spring kits are available through authorized Bettis Q-Series distributors.

8�3 Bettis Q-Series recommended spare parts

All soft seals, bearings, and nonreusable parts are included in the Bettis Q-Series recommended spare parts

kit.

The spare parts kit is identical for both the double acting and the spring return models. For the spring return

models we recommend a set of spare springs for each different model in addition to the recommended spare

parts kit. Keep in mind that, when necessary, springs are to be replaced in complete sets.

The following spare parts kits are available:

1 Repair kit for Bettis Q-Series actuator and all modules, available per actuator size.

2 Module seals kit, suitable for all module variations.

8�4 Position tracking device kits

The position tracking device takes care of the mechanical part of the feedback signal. In case the position

tracking device malfunctions, spares are available. Position tracking device kits are available per actuators

size and contain all necessary seals and lubricants. They can be obtained through authorized Bettis Q-Series

distributors.

8�5 Conversion kits

When the action of an actuator needs to be changed from spring return to double acting or visa versa,

conversion kits can be utilized. Two kinds of conversion kits are available:

1 Single acting (spring return) Conversion kits, to make a spring return actuator.

2 Double acting Conversion kits, to make a double acting actuator.

8�6 High Temp and Low Temp Conversion kits

For the Bettis Q actuators with the NAMUR plate, special conversion kits are available to make the Bettis Q

suitable for High temperature or Low temperature applications. There are no “High temp” or “Low temp”

conversion kits available for Bettis Q actuators with modules.

Page 24

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

21

A

2

1

No. 5

sw = 10mm

1

2

9.1.1

9.1.2

9.1.3

9 Disassembly

9�1 Before starting

9.1.1

Caution! Never disassemble a valve that is

under pressure!

Caution! Ball valves and plug valves can

trap pressurized media in the cavity. Isolate

the piping system in which the actuator

valve assembly is mounted and relieve any

pressure on the valve.

9.1.1 / 9.1.2

Prevent damage to the position probe (A) to

guarantee accurate position feedback.

Page 25

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

22

1

2

QD

2

QS

A

B

AB

9.2.1

9.2.2

9.2.3

9�2 Removing end caps all types QD and QS 40 to QS 350

9.2.1

Be careful not to damage the endcap (A)

and B-port (B) O-rings.

9.2.2 / 9.2.3

Caution! If the actuator is a “spring return”

model, uniformly loosen all endcaps screws,

1/4 - 1/2 turns at a time, in sequence, to

relieve pre-load of the springs.

On all actuators with springs use caution

when removing endcaps.

Page 26

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

23

9.3.1

9.3.2

1 2

4

2 1

1 2

A

B

QS 600 / 950 / 1600

3

9.3.1

Be careful not to damage the endcap (A) and

B-port (B) O-rings.

Caution! If the actuator is a “spring return”

model, loosen endcap screws in sequence as

shown, 1/4 - 1/2 turns at a time, to relieve preload of the springs.

On all actuators with springs use caution

when removing endcaps.

9�3 Removing end caps type QS 600 to 1600

Page 27

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

24

2

2

1

9.4.1

9.4.3

9.4.2

9.4.1

Remove limit stop bolts.

1

2

9.4.2

Remove the two pistons by using an adaptor fitted

in a vice.

Place the actuator on top of the adaptor

(either the square end or the insert shape

end).

Turn the complete actuator and the pistons

will come out.

9.4.3

Before removing the pinion be sure the

position probe is removed (see chapter 1.1)

Remove spring clip from pinion top and

remove pinion.

For removing the circlip, circlip pliers are

required.

9�4 Removing limit stop bolts, pistons and pinion assembly�

Page 28

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

25

9.4.5

3

1

2

9.4.4

9.4.4

Remove spring clip form upper pinion part and

remove upper pinion part through bore of housing

For removing the circlip, circlip pliers are

required.

9.4.5

Removing the insert requires an extraction

tool. Please contact your local Bettis Q-Series

representative for more information about this

extraction tool.

Page 29

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

26

10.1.1

10 Reassembly

10�1 Reassembly guide band and pinion assembly

14

1

1

1

1

5

5

6

6

2

3

15

9

8

13

4

7

7

10

1

11

12

14

CASTROL High

Temperature grease

or equal

Before reassembly check the requested

assembly code (see chapter 2.7).

10.1.1

Apply grease to the parts as per table 10.1 and

figure 10.1.1

Table 10�1 Grease instructions

Part Section of part Amount of grease

O-rings

1 Completely Light film

Housing

2 Piston bore Light film

3 Top pinion bore Light film

4 Bottom pinion bore Light film

Pistons

5

O-ring & guideband

groove

Fully greased

6 Outer side of legs Light film

7 Gear teeth

Half the teeth depth

full with grease

Pinion

8 Bottom O-ring groove Fully greased

9 Top O-ring groove Light film

10 Gear teeth

Half the teeth depth

full with grease

Upper pinion part

11 Outer diameter Fully greased

12 Inner diameter Light film

Housing guideband

13 Inner diameter Light film

Piston Guidebands

14 Completely Light film

Important:

Do not grease the middle part of the piston

bore (15) and the outer diameter of the

housing guideband .

Take care that half the gear depth is full

with grease.

Check the product coding on the actuator’s

product labels to define which type of grease

to use.

- For standard actuators (-20°C to +80°C /

-4°F to +176°F): Castrol High Temperature

grease

- For low temperature operation (-40°C

to +80°C / -40°F to +176°F): Castrol

Tribol GR TT 1 PD (previously known as

Castrol OPTITEMP TT1) or LG2 grease (or

equivalent).

- For high temperature operation (-20°C

to +120°C / -4°F to +248°F): Castrol High

Temperature grease

Page 30

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

27

10.1.2

10.1.3

1

2

3

1

2

3

Code CW

Code CC

1

2

1

2

A

B

C

F

E

10.1.2

1. Mount the upper pinion part (A),

2. Mount the stroke adjustment cam (B) and

housing guide band (C).

Keep the stroke adjustment cam in position

while mounting the pinion.

The two circlips have one side with bevelled

edges (E) which must go DOWN onto the

thrust washer, the square edge side (F) must

face UPWARDS.

10.1.3

Mount the pinion.

For fastening the circlips, circlip pliers are

required.

Use limit stop screws (3) as a reference to

position limit stop cam (1) and pinion (2) as

shown. See indication dot in the Pinion top

slot. Views are from above.

The position of the pinion and the limit stop

cam, as shown, is the position where the

pistons are in the inward position (see next

paragraph).

Page 31

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

28

10.2.2

10.2.3

1

2

2

1

a

b

a = b

= Code CW

CASTROL LMX or

FINA CERAN WR2

(or equal)

a

a = b

b

= Code CC

CASTROL LMX or

FINA CERAN WR2

(or equal)

c

d

c=d

ok !

ok !

90°

10.2.1

10�2 Reassemble the pistons

10.2.1 / 10.2.2

1 Check required assembly code.

2 Apply a light film of grease to the bore of the

housing.

3 Ensure that O-rings (1) and guide bands (2) are

kept in place during assembly.

4 Align the pinion so that the teeth on the pinion

will “pickup” the pistons rack teeth when turning

the top of the pinion:

- clockwise (CW) for assembly code CW or

- counter clockwise (CCW) for assembly code CC

Turn the pinion gently to guide the guide

band into the housing, taking care not to

damage the guide band.

10.2.3

Ensure that smooth movement and 90

degree operation can occur without moving

the pistons out of the actuator body.

Ensure that the slot on the pinion top is:

- exactly perpendicular (code CW) or

- in line (code CC) with the actuators centre

line.

If not, turn the pistons outward until they

disengage from the pinion. Shift one tooth

of the pinion, reassemble and check again.

Check the product coding on the actuator’s

product labels to define which type of grease

to use.

- For standard actuators (-20°C to +80°C /

-4°F to +176°F): Castrol High Temperature

grease

- For low temperature operation (-40°C

to +80°C / -40°F to +176°F): Castrol

Tribol GR TT 1 PD (previously known as

Castrol OPTITEMP TT1) or LG2 grease (or

equivalent).

- For high temperature operation (-20°C

to +120°C / -4°F to +248°F): Castrol High

Temperature grease

Page 32

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

29

N-1 N-2

N-3 N-4

N-5 N-6

1

2

10.3.3

10.3.2

10.3.1

CASTROL LMX or

FINA CERAN WR2

(or equal)

10�3 Reassembly end caps, all types QD and QS 40 to QS 350

10.3.1

When replacing springs in a spring return actuator,

ensure that the springs are replaced in their identical

position in the spring pack from where they were

removed. Before assembling the springs and

endcaps, make sure that the pistons are inwards.

10.3.2

Put some grease on the endcap O-ring before

mounting.

10.3.3

Ensure that endcap O-rings (1) and airport O-rings

(2) are in place on both sides.

Put some grease on the air port O-rings (2),

so they and stay in place while mounting.

Check the product coding on the actuator’s

product labels to define which type of grease

to use.

- For standard actuators (-20°C to +80°C /

-4°F to +176°F): Castrol High Temperature

grease

- For low temperature operation (-40°C

to +80°C / -40°F to +176°F): Castrol

Tribol GR TT 1 PD (previously known as

Castrol OPTITEMP TT1) or LG2 grease (or

equivalent).

- For high temperature operation (-20°C

to +120°C / -4°F to +248°F): Castrol High

Temperature grease

Page 33

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

30

1

1

2

2 1

1 2

QS 600 / 950 / 1600

2

b

10.4.1

10.4.2

N-1 N-2

N-3 N-4

N-5 N-6

a

10.4.2

Ensure that endcap O-rings (a) and airport O-rings

(b) are in place on both sides.

Engage the bolts with the tapped holes in the

actuator body by forcing down slightly on the cap.

Tighten each bolt in small and equal turns.

Table 10�3 Tightening torque Bettis Q-Series

end-cap bolts

Actuator

Typ e

Cap Bolt

Size

Hexagon

Key size

Tightening Torque

Nm in�lb

max� min� max� min�

40 M5 4mm 1,7 1,3 15 11

65 M6 5 mm 3,2 2,7 28 24

100 M6 5mm 3,2 2,7 28 24

200 M8 6mm 7,1 5,2 63 46

350 M10 8mm 14 11,2 124 99

600 M12 10mm 44,2 25 391 222

950 M12 10mm 44,2 25,1 391 222

1600 M14 12mm 70,6 39,6 624 350

10�4 Reassembly end caps single acting actuators QS 600 to QS 1600

10.4.1

When replacing springs in a spring return actuator,

ensure that the springs are replaced in their identical

position in the endcap from where they were

removed.

Before assembling the springs and endcaps, make

sure that the pistons are inwards.

Page 34

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

31

2

A

B

10.5.1

10.5.2

10.5.3

10�5 Mounting and setting of limit stops

Setting of limit stops

Closed position

1 Move actuator to the “Closed” position(1.

2 Turn the “Closed” limit stop screw in until it

blocks.

3 Move actuator to the “Open” position(1.

4 Turn the “Closed” limit stop screw in as shown in

table 2.5.2

Open position

1 Repeat the steps 1 to 4 as described for the

“Closed” position but now for the “Open”

position.

(1

Apply pressure to port A or B

REMARK

This procedure does not apply for setting the exact

end positions of a “Bettis Q-Series mounted on a

valve”.

To set the end positions of a Bettis Q-Series mounted

on a valve, do as described above, check the valve

position and adjust where necessary.

Table 3�1 Angular Displacment & Tools

Actuator

Size

Angular

displacement

Tools

Nut Bolt

Q40 3.0 ° W10 mm SD1.2 mm

Q65 3.6 ° W13 mm SD1.2 mm

Q100 2.7 ° W13 mm SD1.2 mm

Q150 2.7 ° W17 mm SD1.5 mm

Q200 2.3 ° W17 mm SD1.5 mm

Q350 2.7 ° W19 mm SD1.5 mm

Q600 2.7 ° W24 mm W10 mm

Q950 2.5 ° W24 mm W10 mm

Q1600 2.7 ° W30 mm W10 mm

W = Wrench

SD = Screwdriver

Page 35

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

32

M12x1.5

1

2

3

Code CW

Code CC

10.6.2

10.6.3

10.6.1

10�6 Final assembly and airtightness test

10.6.1

Plug the IPT device hole (1) with a M12x1.5 plug.

Apply pressure (max. 8 barg / 116 PSI) to ports (2)

and (3). Use some soapsuds at the indicated points.

Applying pressure to the actuator will cause

the actuator/valve assembly to operate.

In case of leakage around :

1 The limit stop bolts (and/or the spring-package-

bolt at spring return models):

- Turn the lock nut of the bolts tighter, until

leakage stops.

2 The endcaps :

- Disassemble the endcaps, replace O-rings and

reassemble the endcaps.

3 The pinion top or bottom and A- or B-port:

- Disassemble the complete actuator, replace

O-rings and reassemble the actuator.

10.6.2

Take care that the position probe and the mounting

hole is clean. Apply Castrol CLS grease to the tip (1)

to ensure proper functioning.

sw = 10mm

1

CASTROL CLS

(or equal)

10.6.3

Check the position of the inner part of the position

indication knob. When mounted to the pinion top,

the projection of the inner part will fit in the groove

on the pinion top.

To disassemble the inner part, press as shown.

For assembly of the Control

modules see Chapter 4

Page 36

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

33

1

10

37

47

9

12

38

42

40

36

41

15

11

8

14

17

18

19

20

21

32

33

34

29

35

43

2

38

39

44

46

48

45

49

15

135020

19

18

17

13

10

11

12

51

52

39

7

6

5

4

3

2

11 Bettis Q-Series Parts

11.1 ExplodedviewBettisQ-Series(baseactuator)

11.1

Page 37

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

October 2017

34

11�2 Bill Of Material

Notes

1. Included in repair kits.

2. Options

Pos� Qt y� Description Note

1 1 Body

2 2 Washer 1

3 1 Circlip 1

4 1 Circlip 1

5 1 Indicator insert

6 1 Indicator knob

7 1 Indicator arrow

8 1 Screw

9 1 Guide band (housing) 1

10 2 Piston

11 2 O-ring 1

12 2 Guide band (piston) 1

13 8 End cap screws

14 2 End cap QD

15 2 O-ring 1

17 4 Nut cover

18 4 Nut

19 4 Washer 1

20 4 O-ring 1

21 2 Limit stop screw

23 1 O-ring 1

29 1 O-ring seal IPT port 1

Pos� Qt y� Description Note

32 3 Screw

33 1 NAMUR plate

34 1 O-ring

35 1 O-ring

36 1 O-ring

37 1 Pinion

38 2 Bearing ring 1

39 2 O-ring 1

40 1 Insert

41 2 O-ring 1

42 1 Limitstop cam

43 1 Upper pinion part

44 2 Springpack bolt (QS)

45 2 Washer

46 2 Spring retainer

47 2 Outer spring

48 2 Middle spring

49 2 Inner spring

50 2 End cap QS

51 2 O-ring 1

52 1 Center plate 2

Page 38

October 2017

Installation, Operation and Maintenance Manual

DOC.IOM.BQ.E Rev. 2

35

11.3 ExplodedviewBettisQ-Series(Controlmodule)

Pos� Qty� Description

1 1 Module Housing

2 1 Pilot valve Cartridge

3 1 Switch cartridge

4 1 Cover

5 1 Cover seal

6 1 Cover lock screw

7 1 Blind plug

8 1 Pneumatic compartment cover

9 1 Pneumatic compartment cover seal

10 1 Module to Actuator O-ring seal (1

11 1 Module to Actuator O-ring seal (1

12 3 Module fastening screws and washers

13 1 Pneumatic cartridge

14 1 Pneumatic cartridge seal

15 1 Shield switch adjustment screws

16 1 Manual control (option)

17 2 Manual control blind plug (default)

18 1/2 Silencer (1x SR, 2x DA)

19 0/1 Exhaust blind plug (0x DA, 1x SR)

20 2 Speed control blind plug

22 1 IPT device

23 1 O-ring seal IPT port (1

NOTES

1. Included in seal kit for the modules.

2. Items shown are for Modules QC41, QC42 and QC43.

3. Items 2 and 3 are different for QC40 (ASI) and QC54 (FF).

4. For further details on the control modules please check the

maintenance manuals as available for each control module from www.emerson.com/bettis.

1234 56 7

8

9

10

11

13

14

12

15

1617

20

1918

22 23

Page 39

Page 40

For complete list of sales and manufacturing sites, please visit

www.emerson.com/actuationtechnologieslocations or contact us at

info.actuationtechnologies@emerson.com

WorldAreaCongurationCenters(WACC)offersalessupport,service,

inventory and commissioning to our global customers�

ChoosetheWACCorsalesofcenearestyou:

NORTH & SOUTH AMERICA

19200 Northwest Freeway

Houston TX 77065

USA

T +1 281 477 4100

Av. Hollingsworth

325 Iporanga Sorocaba

SP 18087-105

Brazil

T +55 15 3413 8888

ASIA PACIFIC

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6777 8211

No. 1 Lai Yuan Road

Wuqing Development Area

Tianjin 301700

P. R. China

T +86 22 8212 3300

MIDDLE EAST & AFRICA

P. O. Box 17033

Jebel Ali Free Zone

Dubai

T +971 4 811 8100

P. O. Box 10305

Jubail 31961

Saudi Arabia

T +966 3 340 8650

24 Angus Crescent

Longmeadow Business Estate East

P.O. Box 6908 Greenstone

1616 Modderfontein Extension 5

South Africa

T +27 11 451 3700

EUROPE

Holland Fasor 6

Székesfehérvár 8000

Hungary

T +36 22 53 09 50

Strada Biffi 165

29017 Fiorenzuola d’Arda (PC)

Italy

T +39 0523 944 411

www.emerson.com/bettis

©2018 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Bettis

TM

is a mark of one of the Emerson family of companies.

All other marks are property of their respective owners.

The contents of this publication are presented for information purposes

only, and while every effort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which

are available on request. We reserve the right to modify or improve the

designs or specifications of our products at any time without notice.

Loading...

Loading...