Emerson Bettis Q-Series, Bettis QC4124VDC, Bettis QC42115VAC, Bettis QC43230VAC Installation Manual

Installation Guide Bettis Q-Series

DOC.IG.BQC41.1 Rev. 3 August 2018

Bettis Integrated Control Modules

QC41 24VDC

QC42 115VAC

QC43 230VAC

Bettis Q-Series Installation Guide

August 2018 DOC.IG.BQC41.1 Rev. 3

1 Applicable Control modules:

QC41 - 24VDC - Weather Proof

- Explosion Proof / Flame proof

QC42 - 115VAC - Weather Proof

- Explosion Proof / Flame proof

QC43 - 230VAC - Weather Proof

- Explosion Proof / Flame proof

Note:

Both executions can be equipped with one or two

pilot valves:

* One pilot valve is default and suitable for normal

operation of double acting or spring return

actuators.

* Two pilot valves are required for Fail in Last

Position function on double acting actuators.

The enclosures of both Weather Proof and Explosion

Proof / Flame proof modules, have a IP66 or NEMA

4X, ingress protected rating.

2 Before starting

* Actuator must be isolated both pneumatically

and electrically before any (dis)assembly is

begun.

* Installation, adjustment, putting into service,

use, assembly, disassembly and maintenance of

the control module must be done by qualified

personnel.

* Be sure that the actuator is correctly mounted

before connecting air supply and electrical

wiring (see Installation & Operation Manual

Bettis Q-Series Valve Actuator, DOC.IOM.BQ.E)

* Check the module label for the right execution

(see figure 2.2)

* Check the type of actuator: single or double

acting (see figure 2.2).

* For mechanical installation of the module see

installation instruction leaflet DOC.QC4.MTI.1,

as shipped with the module.

2.1 Intended use

The Bettis Q-Series actuator is an integrated

concept for the automation of quarter turn valves,

dampers or other quarter turn applications. It

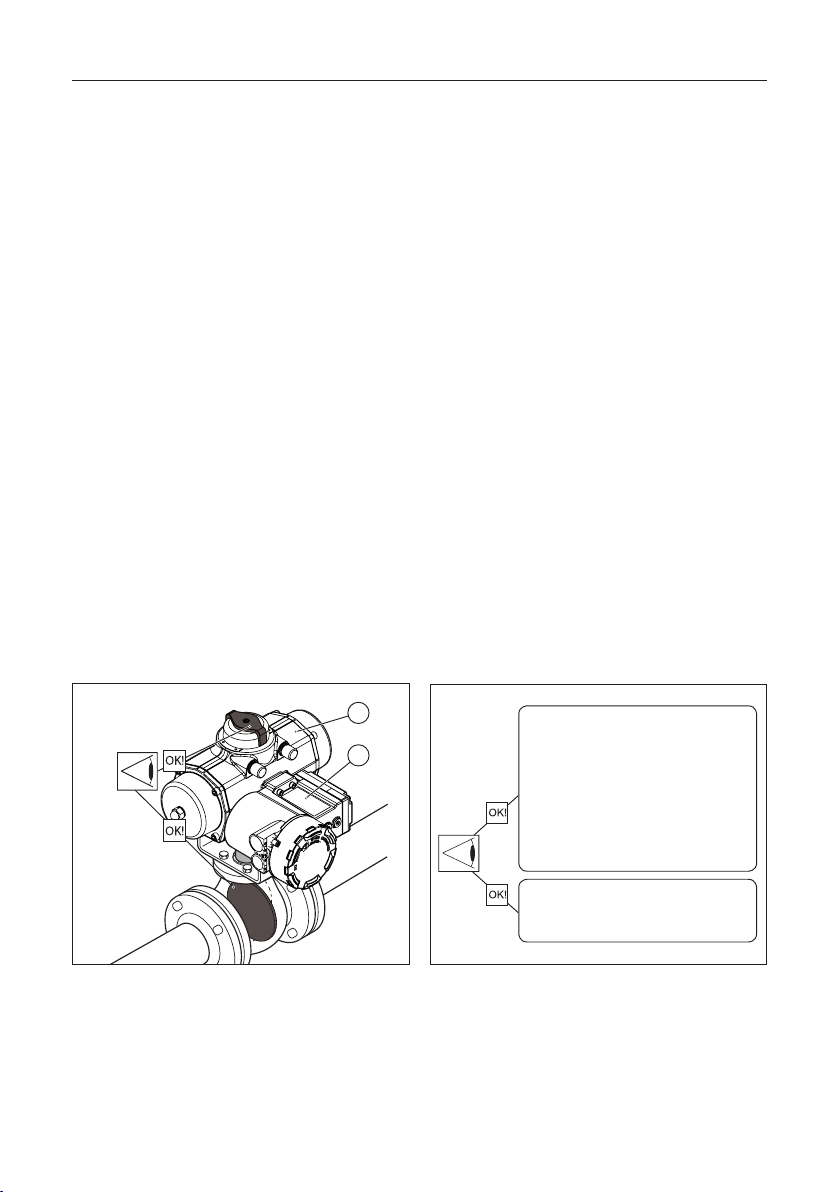

consists of two basic parts (see figure 2.1):

1. Pneumatic actuator

2. Control Module

The control module allows operation of the

actuator and supplies position feedback signals.

1

2

Fig. 2.1 Check proper mounting before connecting air

supply and electrical wiring.

2

Control Module Type Label =

24VDC

QC41..WP.. = Weather Proof

QC41..Px.. = Explosion-/Flame proof

115VAC

QC42..WP.. = Weather Proof

QC42..Px.. = Explosion-/Flame proof

230VAC

QC43..WP.. = Weather Proof

QC43..Px.. = Explosion-/Flame proof

Actuator Type Label =

QS xxxx = Single acting (Spring Return)

QD xxxx = Double acting

Fig. 2.2 Identification

Installation Guide Bettis Q-Series

DOC.IG.BQC41.1 Rev. 3 August 2018

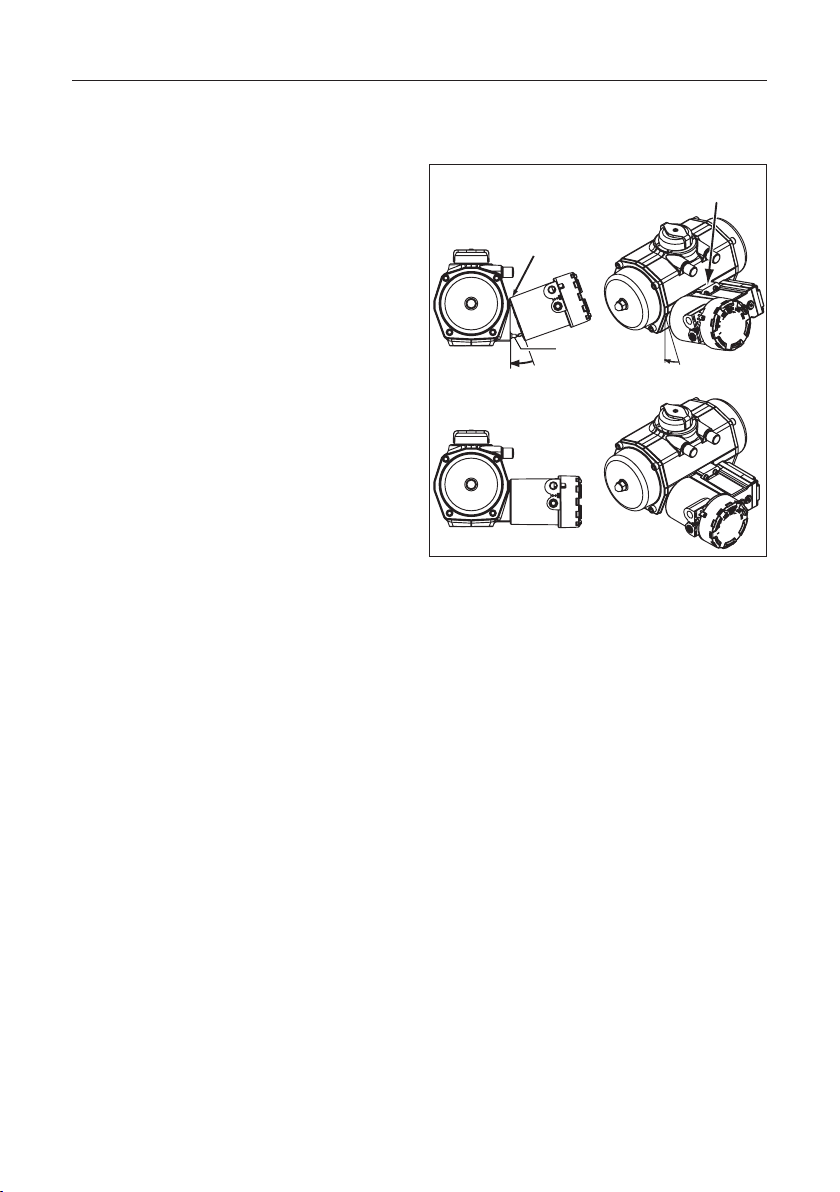

2.2 Mechanical alignment and mounting of

the control module

The control module is equipped with an alignmentedge on top of the module. This allows easy

alignment and mounting of the control module on

to the actuator housing.

Procedure: (see figure 2.3)

1. First take care that both mating faces from the

actuator and control module are clean and free

of dirt.

2. Check if the module has the required function

3. Remove the transparent film from the control

module.

4. Ensure seals are placed correctly.

5. Level the screws with the surface.

6. Place the alignment-edge (1) of the control

module at the top of the pneumatic interface.

7. Flip the module down taking care that the IPT

Probe (see fig 5; nr.2) on the actuator fits in the

mating hole on the control module and loosely

place the screws.

8. Tighten screws according force in sequence.

Tightening moments

The Control Module should be fastened by using

an Allen key and applying the following tightening

moments:

- Allen Key No 5: 6.1 to 6.6 Nm (54 - 58.4

In.lbs)

Alignment-edge

Alignment-edge

IPT probe

Fig. 2.3 Alignment and mounting of control

module to actuator

3

Bettis Q-Series Installation Guide

August 2018 DOC.IG.BQC41.1 Rev. 3

3 Pneumatic connections

IMPORTANT

1 The actuator/valve combination can move

after connecting the air supply.

2 Ensure that the QC4x control modules are

mounted properly to the actuator to achieve

good functioning and the required ingress

protection, before connecting the air supply.

3 Check that the maximum supply pressure

P

= 8bar/116Psi

max

4 Be sure that the minimum required supply

pressure for the application is available at the

actuator.

5 Take appropriate measures to prevent

condensation or moisture to entering the

actuator or the control module. Condensation

or moisture can damage these components

and can result in failures.

6 The exhaust ports Ra and Rb on the module

(see figure 3.1) are shipped from the factory

with transport protection.

* If ingress protection IP66 or NEMA 4X is

required, appropriate connections must be

used in exhaust ports Ra & Rb.

3.1 Operating media :

* Air or inert gasses.

* Air filtered at 50 micron.

* Dew point 10 K below operating temperature.

* For subzero applications take appropriate

measures.

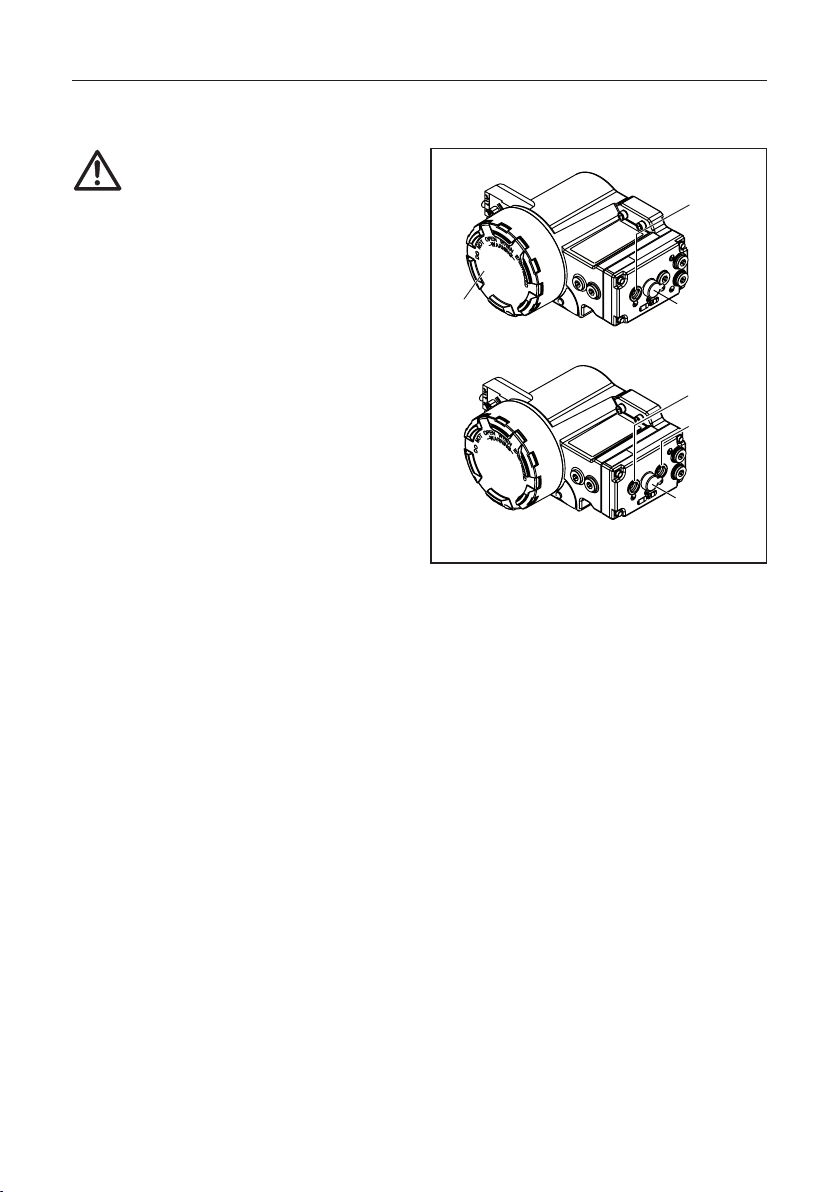

3.2 Single acting (spring return) or Double

acting actuator :

1 Remove the transport sticker from the air supply

(Ps).

2 Connect air supply to port (Ps).

Single acting

Control

Module cover

Double acting

Fig. 3.1 Pneumatic connections

Ra

Ps

1/4” BSP or

1/4” NPT

Ra

Rb

Ps

1/4” BSP or

1/4” NPT

4

Installation Guide Bettis Q-Series

DOC.IG.BQC41.1 Rev. 3 August 2018

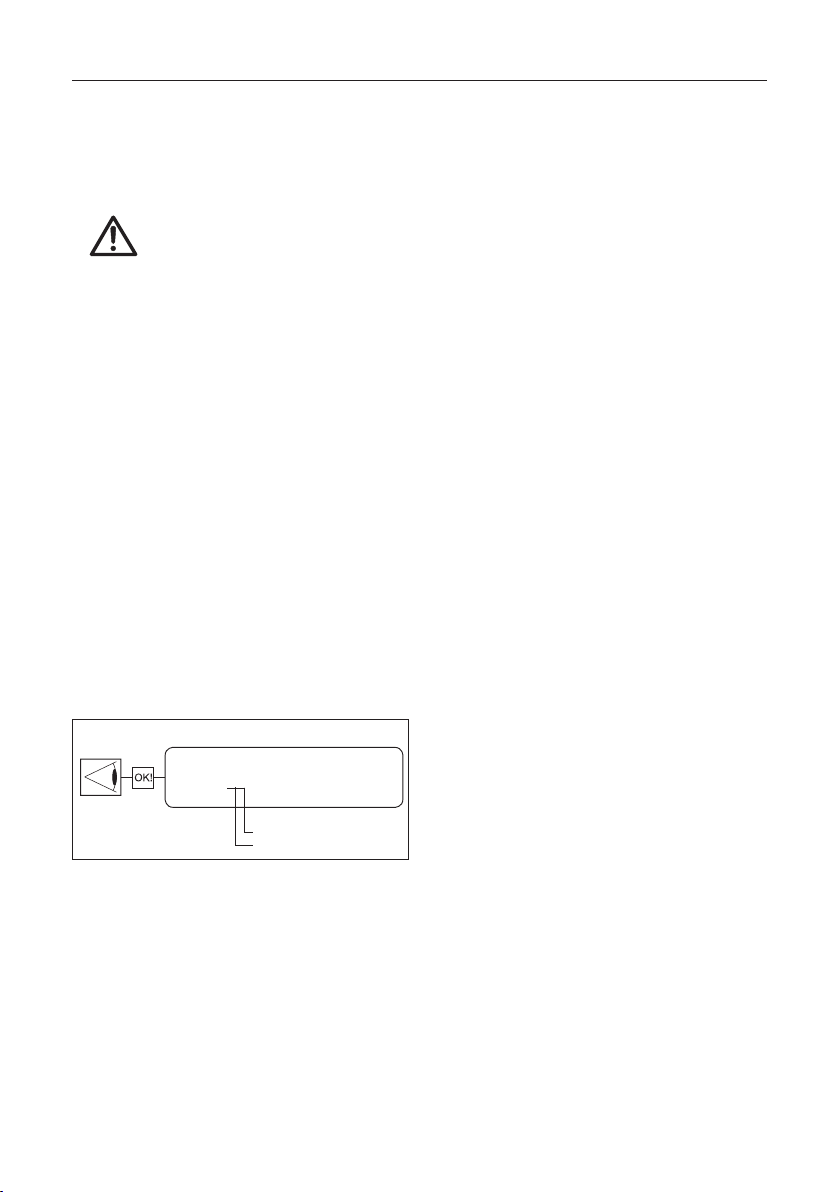

4 Electric Connections

The conventional Control Module contains a pilot

valve for controlling the actuator and switches for

position feedback.

WARNING:

* If the Control Module is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

* For electrical safety the marked protective

conductor terminal inside or outside the

Control Module housing shall be connected to

earth.

* If required, mount earth wire (1) between top

(2) and stainless steel washer (3) of earth wire

connection (see figure 4.2).

* To fulfill the electrical safety regulations

according IEC 61010-1, a switch and circuitbreaker shall be included in the building

installation. It is advised to indicate the

location of the circuit breaker by means of a

label on or nearby the installed

Bettis Q-Series modules. The disconnection

switch or circuit breaker shall disconnect all

current-carrying conductors.

* Heat resistant cable and cable glands shall be

used, suitable for temperatures of at least 80°C

* Use and mount cable glands as required by

national or local legislation.

* If IP66 or NEMA 4X ingress protection is

required, then the electrical entries must be

fitted with devices rated IP66 or NEMA 4X.

Electrical safety requirements:

Use In- and outdoor.

Altitude

Maximum relative humidity

Mains supply

fluctuation

Over voltage

category

Pollution degree 2 (3 when the cover remains closed)

Temperature see table 4.1

Operating full power available

up to 2000 meter (6000 feet).

80% for temperatures up to 31°C

(87.8°F) decreasing linearly to

50% relative humidity at 40°C

(104°F).

up to ±10% of nominal voltage

II

Caution! :

Risk of electric shock

* Installation, adjustment, putting into service,

use, assembly, disassembly and maintenance

of the control module is strictly reserved to

qualified personnel.

* Do not attempt to install or repair any electric

device without shutting off incoming power.

Terminals

Lockable

Module cover

Electrical entries:

3/4”NPT

or M25

1/2”NPT

or M20

Switch terminals

Control Module

Type Label

Pilot valve

terminals

Option: Manual

control

Option: Additional

manual control for

“Fail in Last Position”

Fig. 4.1 Terminal connections behind cover.

Fig. 4.2 Earth wire connection

5

Bettis Q-Series Installation Guide

August 2018 DOC.IG.BQC41.1 Rev. 3

4.1 Bettis Q-Series QC4x modules

Hazardous Area instructions

IMPORTANT

All installation, inspection, maintenance and

repair of the equipment should be performed

by suitably trained personnel.

The Control Modules must not be used in

atmospheres that contains acetone, ethyl

acetate or acetic acid vapors.

4.1.1 ATEX/IECEx Intended use

The Control Modules QC4x..P5.. of the

Bettis Q-Series pneumatic actuator is a Group II

category 2 (ATEX) equipment with protection level

Gb, Db (IECEx) and intended for use in areas in

which explosive atmospheres caused by mixtures of

air and gases, vapors, mists or by air/dusts are likely

to occur.

The pneumatic actuator part, together with the

pneumatic module part of the Bettis Q-Series

pneumatic actuators is a Group II category 2

equipment and intended for use in areas in which

explosive atmospheres caused by mixtures of air

and gases, vapors, mists or by air/dusts are likely to

occur.

Therefore it may be used in hazardous area

classified Zones 1, 2 (Gasses) and/or 21, 22 (Dust).

Control Module Type Label =

QC41·MP5MSA1·0040UQP000

Pneumatic action

Switch cartridge

Fig. 4.4 Switch cartridge and pneumatic action

identification

4.1.2 Hazardous area Special safety instructions

for safe use

1. For ATEX, all installation, inspection,

maintenance and repair must be done by

suitably trained personnel. For information refer

to EN60079-14, EN60079-17, EN60079-19.

2. Substitution of component may impair

suitability for Zone 2 Increased Safety.

3. Do not open cover of terminal compartment

when an explosive atmosphere is present.

4. Cleaning this housing by rubbing should be done

in a non-hazardous area,

5. Potential electrostatic charging hazard, clean

only with a damp cloth - danger of propagating

discharge.

6. The apparatus shall be installed in such a way

that the risk from electrostatic discharges and

propagating brush discharges caused by rapid

flow of dust is avoided.

7. All grounding and bonding installation

requirements must be addressed.

8. The cable entry device and the closing elements

of unused apertures must be of a certified

flameproof type, suitable for the conditions of

use and correctly installed.

9 Blind plugs or cable gland shall be engaged

into the cable entries minimal 5.5 threads for

M20x1.5 entries and minimal 5 threads for NPT

entries.

10. Certified Ex t cable glands shall be use in a dust

environment.

11. Heat resistant cable and cable glands shall be

used, suitable for temperatures of at least 80°C

12. The maximum temperature of the supply

air must stay below the maximum ambient

temperature as marked on the control module

(see table 4.1).

13. The maximum temperature of the base actuator

must stay below the maximum ambient

temperature as marked on the control module

(see table 4.1).

14. Contact your local Emerson representative for

information on the dimensions of the flame

proof joints.

15.Precaution shall be taken to avoid danger of

ignition due to electrostatic charges on the

marking plate of the enclosure.

4.1.3 FM Special safety instructions

1. Metric entries are not allowed. Metric entries are

for IECEx or ATEX installations only.

2. Wiring must be done according NEC 500.

Note:

This product is only intended for use in large-scale

fixed installations excluded from the scope of

Directive 2011/65/EU on the restriction of the use

of certain hazardous substances in electrical and

electronic equipment (RoHS 2).

6

Loading...

Loading...